Page 1

r

User’s Manual

LG Programmable Logic Controlle

MASTER-K 120S series

LG Industrial Systems

- When using LGIS equipment, thoroughly read this datasheet and associated

manuals introduced in this datasheet. Also pay careful attention to safety and

handle the module properly.

- Keep this datasheet within easy reach for quick reference

Page 2

y

y

y

g

SAFETY INSTRUCTIONS

To Prevent injury and property damage, follow these instructions.

Incorrect operation due to ignoring instructions will cause harm or

damage, the seriousness of which is indicated by the following symbols

WARNING

CAUTION

This symbol indicates the possibility of

death or serious injury

This s

mbol indicates the possibility of

injury or damage to property.

■ The meaning of each symbol in this manual and on your equipment is

as follows

This is the safety alert symbol.

Read and follow instructions carefull

situation.

.

to avoid dangerous

.

This s

mbol alerts the user to the presence of “dangerous

voltage” inside the product that mi

ht cause harm or electric

shock.

Page 3

r

r

g

SAFETY INSTRUCTIONS

Design Precautions

Install a safety circuit external to the PLC that keeps the entire system

safe even when there are problems with the external power supply o

the PLC module. Otherwise, serious trouble could result from

erroneous output or erroneous operation.

- Outside the PLC, construct mechanical damage preventing interlock

circuits such as emergency stop, protective circuits, positioning uppe

and lower limits switches and interlocking forward/reverse operation.

When the PLC detects the following problems, it will stop calculation and

turn off all output in the case of watchdog timer error, module interface

error, or other hardware errors.

However, one or more outputs could be turned on when there are

problems that the PLC CPU cannot detect, such as malfunction of output

device (relay, transistor, etc.) itself or I/O controller. Build a fail safe

circuit exterior to the PLC that will make sure the equipment operates

Warnin

safely at such times. Also, build an external monitoring circuit that will

monitor any single outputs that could cause serious trouble.

Make sure all external load connected to output does NOT exceed the

rating of output module.

Overcurrent exceeding the rating of output module could cause fire, damage

or erroneous operation.

Build a circuit that turns on the external power supply when the PLC

main module power is turned on.

If the external power supply is turned on first, it could result in erroneous

output or erroneous operation.

Page 4

SAFETY INSTRUCTIONS

Design Precautions

Do not bunch the control wires or communication cables with the main

circuit or power wires, or install them close to each other. They should

be installed 100mm (3.94inch) or more from each other.

Not doing so could result in noise that would cause erroneous operation.

Caution

Installation Precautions

Caution

Use the PLC in an environment that meets the general specification

contained in this manual or datasheet.

Using the PLC in an environment outside the range of the general

specifications could result in electric shock, fire, erroneous operation, and

damage to or deterioration of the product.

Completely turn off the power supply before loading or unloading the

module.

Not doing so could result in electric shock or damage to the product.

Make sure all modules are loaded correctly and securely.

Not doing so could cause a malfunction, failure or drop.

Make sure I/O and extension connector are installed correctly.

Poor connection could cause an input or output failure.

When install the PLC in environment of much vibration, be sure to

insulate the PLC from direct vibration.

Not doing so could cause electric shock, fire, and erroneous operation.

Be sure to there are no foreign substances such as conductive debris

inside the module.

Conductive debris could cause fires, damage, or erroneous operation.

Page 5

r

r

g

SAFETY INSTRUCTIONS

Wiring Precautions

Completely turn off the external power supply when installing o

placing wiring.

Not doing so could cause electric shock or damage to the product.

Make sure that all terminal covers are correctly attached.

Not attaching the terminal cover could result in electric shock.

Warnin

Caution

Be sure that wiring is done correctly be checking the product’s rated

voltage and the terminal layout.

Incorrect wiring could result in fire, damage, or erroneous operation.

Tighten the terminal screws with the specified torque.

If the terminal screws are loose, it could result in short circuits, fire, o

erroneous operation.

Be sure to ground the FG or LG terminal to the protective ground

conductor.

Not doing so could result in erroneous operation.

Be sure there are no foreign substances such as sawdust or wiring

debris inside the module.

Such debris could cause fire, damage, or erroneous operation.

Page 6

r

r

g

SAFETY INSTRUCTIONS

Startup and Maintenance Precautions

Do not touch the terminals while power is on.

Doing so could cause electric shock or erroneous operation.

Switch all phases of the external power supply off when cleaning the

module or retightening the terminal or module mounting screws.

Not doing so could result in electric shock or erroneous operation.

Do not charge, disassemble, heat, place in fire, short circuit, or solde

the battery.

Mishandling of battery can cause overheating or cracks which could result in

injury and fires.

Do not disassemble or modify the modules.

Doing so could cause trouble, erroneous operation, injury, or fire.

Switch all phases of the external power supply off before mounting o

removing the module.

Not doing so could cause failure or malfunction of the module.

Use a cellular phone or walky-talky more than 30cm (11.81 inch) away

from the PLC

Not doing so can cause a malfunction.

Warnin

Caution

Disposal Precaution

When disposing of this product, treat it as industrial waste.

Not doing so could cause poisonous pollution or explosion.

Caution

Page 7

Revision History

Date Code Revision history

2002.7. 10310000380 First edition is published

2003.5. 10310000380 A revised edition is published

– Main unit and expansion modules are added

– Built-in function are upgraded

2003.9 10310000380 A revised edition is published.

- Main units are added

- Built-in functions are upgraded.

Page 8

◎ Contents ◎

Chapter 1. General

1.1 Guide to Use This Manual ················· 1 - 1

1.2 Features ······················· 1 - 2

1.3 Terminology ······················ 1 - 3

Chapter 2. System Configuration

2.1 Overall Configuration ··················· 2 - 1

2.1.1 Basic System································································································2 - 1

2.1.2 Cnet I/F System·····························································································2 - 2

2.2 Product Functional Model ················· 2 - 4

2.2.1 Product Functional Block················································································· 2 - 4

2.2.2 MASTER-K120S Series System Equipment Product ·············································2 - 5

Chapter 3. General Specifications

3.1 General Specifications ·················· 3 - 1

Chapter 4. Names of Parts

4.1 Main Unit ······················· 4 - 1

4.1.1 60 Points Main Unit (Standard)·········································································4 - 2

4.1.2 40 Points Main Unit (Standard)··········································································4 -3

4.1.3 30 Points Main Unit (Standard)·········································································4 - 4

4.1.4 20 Points Main Unit (Standard)·········································································4 - 5

4.1.5 30 Points Main Unit (Economic)········································································4 - 6

4.1.6 20 Points Main Unit (Economic)·········································································4 -7

4.1.7 14 Points Main Unit (Economic)········································································ 4 - 7

4.1.8 10 Points Main Unit (Economic)········································································ 4 - 7

4.2 Expansion I/O Module··················· 4 - 8

4.2.1 20 Point I/O Module························································································4 - 8

4.2.2 10 Point I/O Module························································································4 - 8

4.2.3 8 Point I/O Module························································································· 4 - 9

4.3 Special Module ···················· 4 - 10

4.3.1 A/D·D/A Combination Module········································································4 - 10

4.3.2 D/A Conversion Module··················································································4 - 11

4.3.3 A/D Conversion Module··················································································4 - 11

4.3.4 Analog Timer Module·····················································································4 - 12

4.3.5 RTD Input Module·························································································4 - 12

Page 9

4.4 Communication I/F Module ················· 4 - 13

4.4.1 Cnet I/F Module····························································································4 - 13

4.4.2 Fnet I/F Module····························································································4 - 13

4.4.3 Pnet I/F Module····························································································4 - 14

4.4.4 DeviceNet I/F Module···················································································· 4 - 14

4.5 Option Module ····················· 4 - 14

Chapter 5. Power Supply / CPU

5.1 Power Supply Specifications ················ 5 - 1

5.1.1 Standard Type·······························································································5 - 1

5.3.2 Economic Type······························································································5 - 1

5.2 CPU Specifications···················· 5 - 2

5.2.1 Standard Type·······························································································5 - 2

5.2.2 Economic Type······························································································5 - 4

5.3 Operation Processing ··················· 5 -6

5.3.1 Operation Processing Method···········································································5 - 6

5.3.2 Operation Processing at Momentary Power Failure Occurrence······························· 5 - 7

5.3.3 Scan Time···································································································· 5 - 8

5.3.4 Scan Watchdog Timer·····················································································5 - 8

5.3.5 Timer Processing ·························································································5 - 9

5.3.6 Counter Processing·······················································································5 - 12

5.4 Program························································································5 - 14

5.4.1Classifications of Program ·············································································5 - 14

5.4.2 Program Execution Procedure·········································································5 - 14

5.4.3 Interrupt Programs························································································5 - 15

5.4.4 Error Handling······························································································5 - 17

5.5 Operation Modes ···················· 5 - 19

5.5.1 RUN Mode··································································································5 - 19

5.5.2 STOP Mode·································································································5 - 20

5.5.3 PAUSE Mode·······························································································5 - 20

5.5.4 DEBUG Mode(Standard Type Only)··································································5 - 20

5.5.5 Operation Mode Change················································································5 - 21

5.6 Function························ 5 - 23

5.6.1 Self-diagnosis······························································································5 - 23

5.6.2 I/O Force On/Off function ··············································································5 - 24

5.6.3 Direct I/O Operation function···········································································5 - 27

5.6.4 System error history······················································································5 - 27

5.7 Memory Configuration··················· 5 - 28

5.8 I/O Address Allocation··················· 5 - 29

5.9 Built-in Cnet Selection switch ···························································5 - 30

5.9.1 Structure·····································································································5 - 30

Page 10

5.9.2 Usage········································································································5 - 30

5.10 External Memory Module ················· 5 - 32

5.10.1 Structure···································································································5 - 32

5.10.2 Usage·······································································································5 - 32

5.11 RTC Module······················ 5 - 34

5.11.1 Structure···································································································5 - 34

5.11.2 Usage······································································································5 – 34

Chapter 6. Input and Output Modules

6.1 Input / Output Specifications ················ 6 - 1

6.2 Digital Input Specifications ················· 6 - 2

6.2.1 Main Unit ·····································································································6 - 2

6.2.2 Expansion Module ·························································································6 - 5

6.3 Digital Output Specification ················· 6 - 6

6.3.1 Main Unit (Relay Output)·················································································6 - 6

6.3.2 Main Unit (Tr Output :DRT/DT Type Only) ···························································6 - 9

6.3.3 Expansion Module ························································································ 6 - 11

Chapter 7. Usage of Various Functions

7.1 Built-in Functions ···················· 7 - 1

7.1.1 High Speed Counter Function··········································································· 7 - 1

7.1.2 Pulse Catch Function·····················································································7 - 14

7.1.3 Input Filter Function·······················································································7 - 16

7.1.4 External Interrupt Function··············································································7 - 17

7.1.5 PID Control Function(Standard Type Only)·························································7 - 19

7.2 Special Module ····················· 7 - 39

7.2.1 A/D·D/A Combination Module········································································7 - 40

7.2.2 A/D Conversion Module··················································································7 - 49

7.2.3 D/A Conversion Module··················································································7 - 55

7.2.4 Analogue Timer ··························································································7 - 61

7.2.5 RTD input Module ·······················································································7 - 63

7.3 Positioning Function(DRT /DTtype only) ············ 7 - 69

7.3.1 Specification································································································7 - 69

7.3.2 Positioning Function······················································································7 - 72

7.3.3 Positioning parameter and Operation Data·························································7 - 85

7.3.4 Instructions ································································································7 - 91

7.3.5 Flag list and Error code ··············································································7 - 100

7.3.6 Wiring with servo and stepping motor driver······················································7 - 104

Page 11

Chapter 8. Communication Function

8.1 Dedicated Protocol Communication ·············· 8 - 1

8.1.1 Introduction ··································································································8 - 1

8.1.2 System configuration method ···········································································8 - 2

8.1.3 Frame Structure ····························································································8 - 5

8.1.4 Lists of Commands ························································································8 - 7

8.1.5 Data Type····································································································8 - 8

8.1.6 Execution of Commands ·················································································8 - 9

8.1.7 1:1, 1:n Built-in Communication between MASTER-K120S’s ································8 - 28

8.1.8 Error Codes·································································································8 - 38

8.2 User Defined Protocol Communication ············· 8 - 39

8.2.1 Introduction ·································································································8 - 39

8.2.2 Parameter Setting·························································································8 - 39

8.2.3 Instruction ·································································································8 - 47

8.2.4 Example of usage ·······················································································8 - 48

8.3 Modbus Protocol Communication··············· 8 - 57

8.3.1 Introduction ·································································································8 - 57

8.3.2 Basic Specifications ······················································································8 - 57

8.3.3 Parameter Setting·························································································8 - 60

8.3.4 Instruction and examples ··············································································8 - 62

8.4 No Protocol Communication ················ 8 - 67

8.4.1 Introduction ·································································································8 - 67

8.4.2 Parameter Setting·························································································8 - 68

8.4.3 Instructions··································································································8 - 69

8.4.4 Examples ··································································································8 - 71

8.5 Remote Connection and Communication I/F module ········ 8 - 73

8.5.1 Remote Connection·······················································································8 - 73

8.5.2 Communication I/F Module ·············································································8 - 76

Chapter 9. Installation and Wiring

9.1 Installation ······················· 9 - 1

9.1.1 Installation Environment·················································································· 9 - 1

9.1.2 Handling Instructions······················································································9 - 3

9.1.3 Connection of Expansion Module······································································9 - 6

9.2 Wiring ························ 9 - 7

9.2.1 Power Supply Wiring······················································································ 9 - 7

9.2.2 Input and Output Devices Wiring·······································································9 - 8

9.2.3 Grounding···································································································· 9 - 9

9.2.4 Cable Specifications for wiring··········································································9 - 9

Page 12

Chapter 10. Maintenance

10.1 Maintenance and Inspection ················ 10 - 1

10.2 Daily Inspection ···················· 10 - 1

10.3 Periodic Inspection ··················· 10 - 2

Chapter 11. Troubleshooting

11.1 Basic Procedure of Troubleshooting ············· 11 - 1

1 1.2 Troubleshooting ············································································ 11 - 1

11.2.1 Troubleshooting flowchart used when the power LED turns off ·····························11 - 2

11.2.2 Troubleshooting flowchart used when the error LED is flickering····························11 - 3

11.2.3 Troubleshooting flowchart used when the RUN LED turns off································11 - 4

11.2.4 Troubleshooting flowchart used when the I/O devices doesn’t operate normally ········11 - 5

11.2.5 Troubleshooting flowchart used when a program can’t be written to the CPU············11 - 7

1 1.3 Troubleshooting Questionnaire························································· 11 - 8

1 1.4 Troubleshooting Examples······························································· 11 - 9

11.4.1 Input circuit troubles and corrective actions·······················································11 - 9

11.4.2 Output circuit troubles and corrective actions···················································11 - 10

11.5 Error code list ··············································································11 - 12

Appendix··················································································································

Appendix 1 System Definitions·······························································App1-1

Appendix 2 Flag Lists···········································································

App2-1

Appendix 3 Dimensions········································································App3-1

Page 13

Chapter 1 General

Chapter 1. General

1.1 Guide to Use This Manual

This manual includes specifications, functions and handling instructions for the MASTER-K120S series PLC.

This manual is divided up into chapters as follows:

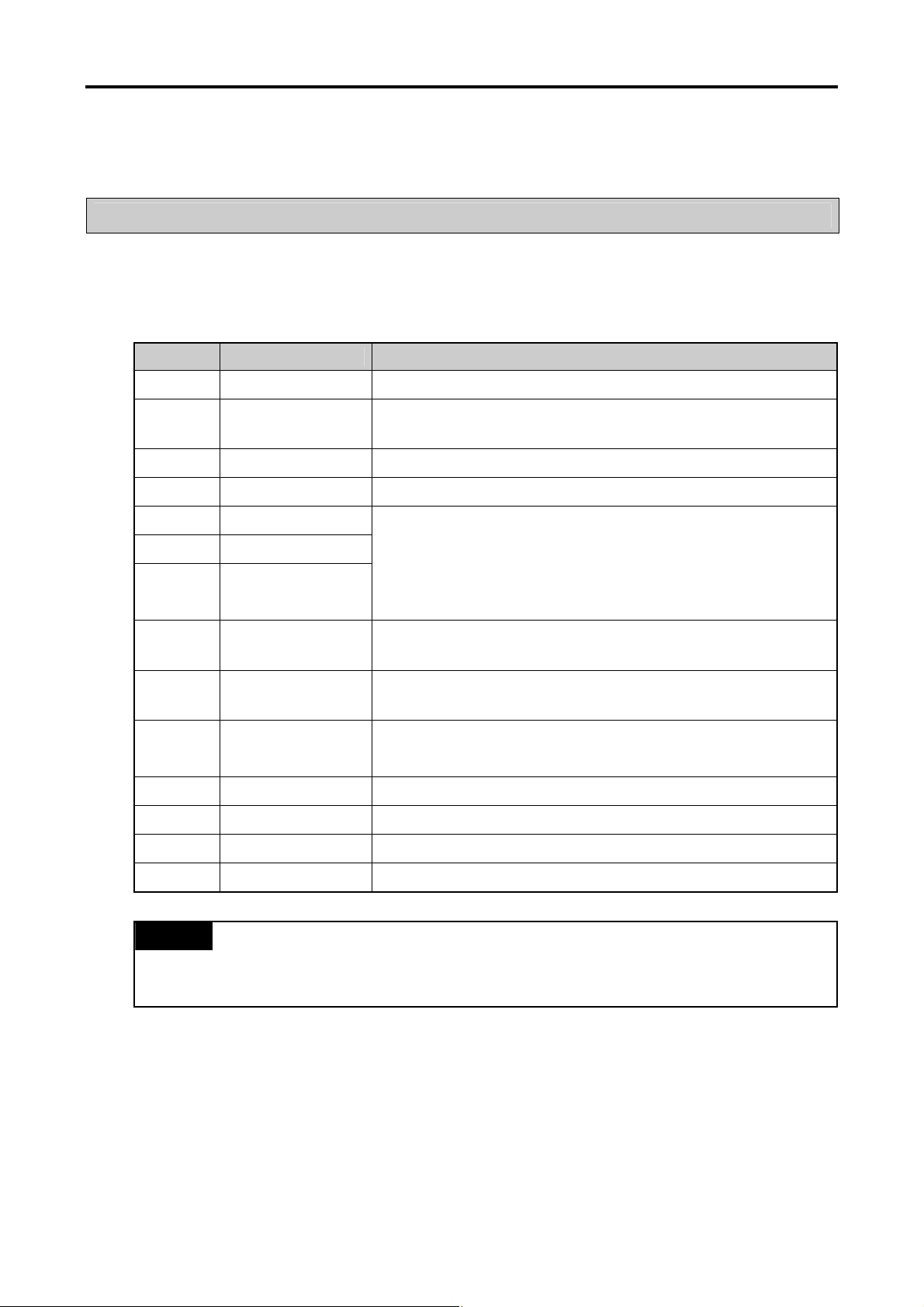

No. Title Contents

Chapter 1 General Describes configuration of this manual, unit's features and terminology.

Chapter 2 System configuration Describes available units and system configurations in the MASTER-K120S series.

Chapter 3 General Specification Describes general specifications of units used in the MASTER-K120S series.

Chapter 4 Names of Parts Describes each kind of manufacturing goods, titles, and main functions

Chapter 5 Power Supply / CPU

Chapter 6 Input and Output

Chapter 7

Chapter 8 Communication Function Describes built-in communication functions

Chapter 9 Installation and Wiring Describes installation, wiring and handling instructions for reliability of the PLC system

Chapter 10 Maintenance

Chapter 11 Troubleshooting Describes various operation errors and corrective actions.

Appendix 1 System Definitions Describes parameter setting for basic I/O and communications module

Appendix 2 Flag List Describes the types and contents of various flags.

Appendix 3 Dimensions Shows dimensions of the main units and expansion modules

REMARK

Usage of Various

Functions

Describes each kind of manufactured goods' usage

Describes the check items and method for long-term normal operation of the PLC

system.

-. This manual does not describes the programming method. For their own functions, refer to the related user's

manuals.

1-1

Page 14

Chapter 1 General

1.2. Features

1) MASTER-K120S series is extremely compact, to fit a wide range of applications and have following features.

(1) High speed processing

High speed processing of 0.1~0.9µs/step with an general purpose processor included .

(2) Various built-in functions

The main unit can perform many functions without using separate modules. Therefore, It is possible to construct various

systems just using the main unit.

• Fast Processing Applications

- Pulse catch: Allows the main unit to read a pulse which has width as small as 10 ㎲.

- High speed counter(Economic): Support high-speed counting up to 100(10)kHz for 1 phase, 50(5)kHz for 2 phase.

- External interrupts : Using in applications that have a high-priority event which requires immediate responses.

• The input filter function help reduce the possibility of false input conditions from external noise, such as signal

chattering. The filter time can be programmed from 0 to 1000ms.

• Using RS-232C and RS-485 built-in port, MASTER-K120S can connects with external devices, such as personal

computers or monitoring devices and communicate 1:N with MASTER-K120S system.

• Using built-in PID control function, PID control system can be constructed without using separate PID module.

• Using built-in Positioning function, position control system can be constructed without using separate position control

module.(only DRT/DT type has built-in positioning function)

(3) Battery-less

The user’s program can be saved permanently, because it is stored to EEPROM.

(4) When program is edited during processing, it is stored to EEPROM automatically

(5) Open network by use of communication protocols in compliance with international standard specifications.

(6) Various special modules that enlarge the range of application of the PLC

(7) It can easily do On/Off of the system, using RUN/STOP switch.

(8) It can easily save the user program in EEPROM by simple manipulation in KGLWIN without using external memory.

(9) Strong self-diagnostic functions

It can detect the cause of errors with more detailed error codes.

(10) It can prevent unintentional reading and writing, using password.

(11)

Debugging function(Standard type)

On-line debugging is available when the PLC Operation mode is set to debug mode.

y executed by one command.

y executed by break-point settings.

y executed by the condition of the device

y executed by the specified scan time.

(12) Various program execution function

External and internal interrupt program as well as scan program can be executed by setting the execution condition.

Therefore, user can set variously program execution mode.

1-2

Page 15

Chapter 1 General

1.3 Terminology

The following table gives definition of terms used in this manual.

Terms Definition Remarks

A standard element that has a specified function which configures the

Module

Unit

PLC system

KGLWIN

KLD-150S

I/O Image Area Internal memory area of the CPU module which used to hold I/O statuses.

Watch Dog Timer

system. Devices such as I/O board, which inserted onto the mother board

or base unit.

A single module or group of modules that perform an independent

Operation as a part of PLC system.

A system which consists of the PLC and peripheral devices. A user program

can control the system.

A program and debugging tool for the MASTER-K series. It executes

program creation, edit, compile and debugging(A computer software).

A hand-held loader used for program creation, edit, compile and debugging

for MASTER-K series.

Supervisors the pre-set execution times of programs and warns if a

program is not completed within the pre-set time.

Example)

CPU module

Power Supply module

I/O module

Example)

Main unit

FAM

Fnet Fieldbus network

Cnet Computer network(RS-232C, RS-422/485)

RTC

Abbreviation of the word ‘Factory Automation Monitoring S/W’. It is used to

call S/W packages for process supervision.

Abbreviation of ‘Real Time Clock’. It is used to call general IC that

contains clock function.

1-3

Page 16

Chapter 1 General

Terms Definition Remarks

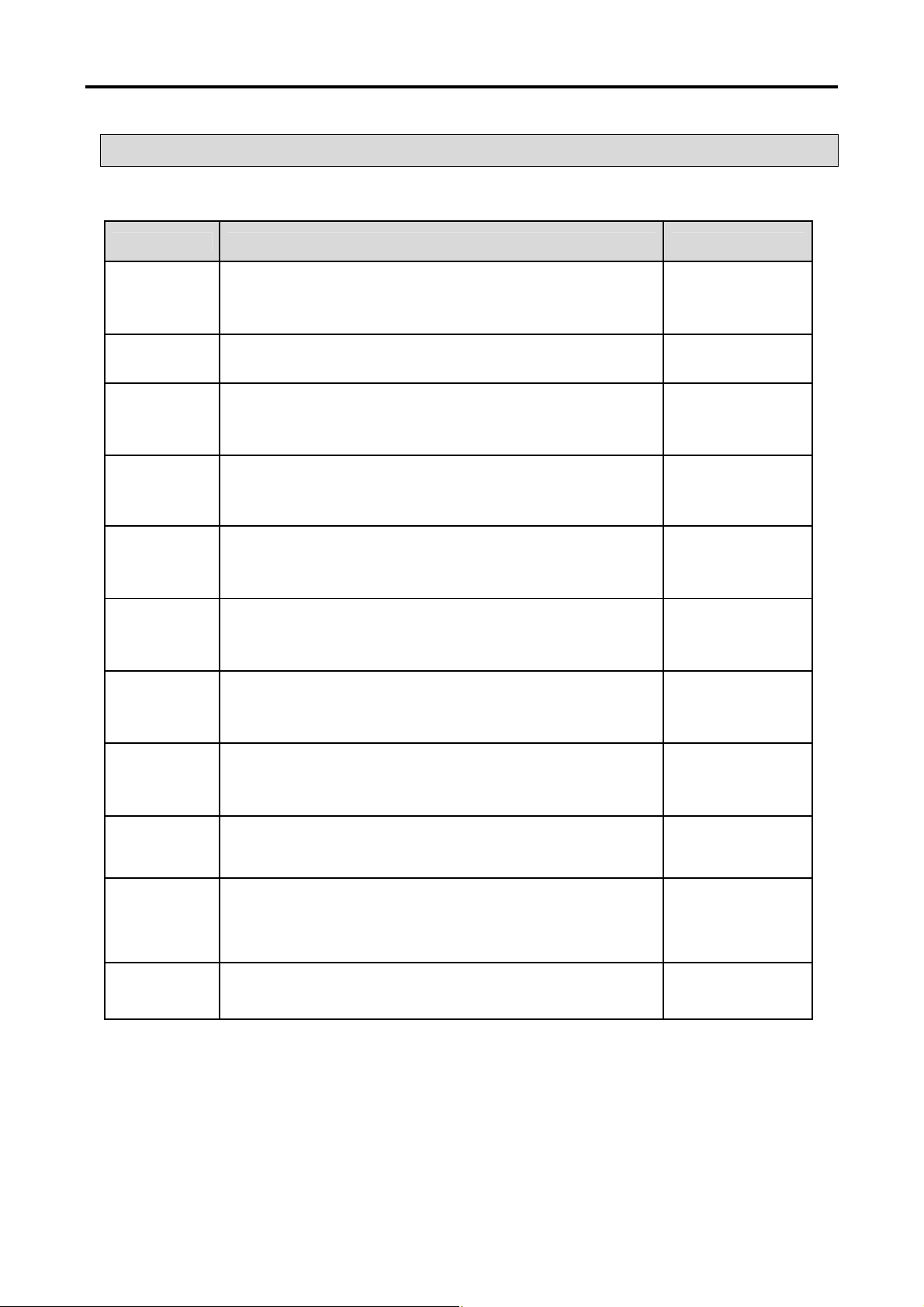

Sink Input

Source

Input

Current flows from the switch to the PLC input terminal if a input signal turns on.

Current flows from the PLC input terminal to the switch after a input signal turns

on.

Current flows from the load to the output terminal and the PLC output turn on.

Sink Output

Source

Output

Output

Contact

Current flows from the output terminal to the load and the PLC output turn on.

Output Contact

1-4

Page 17

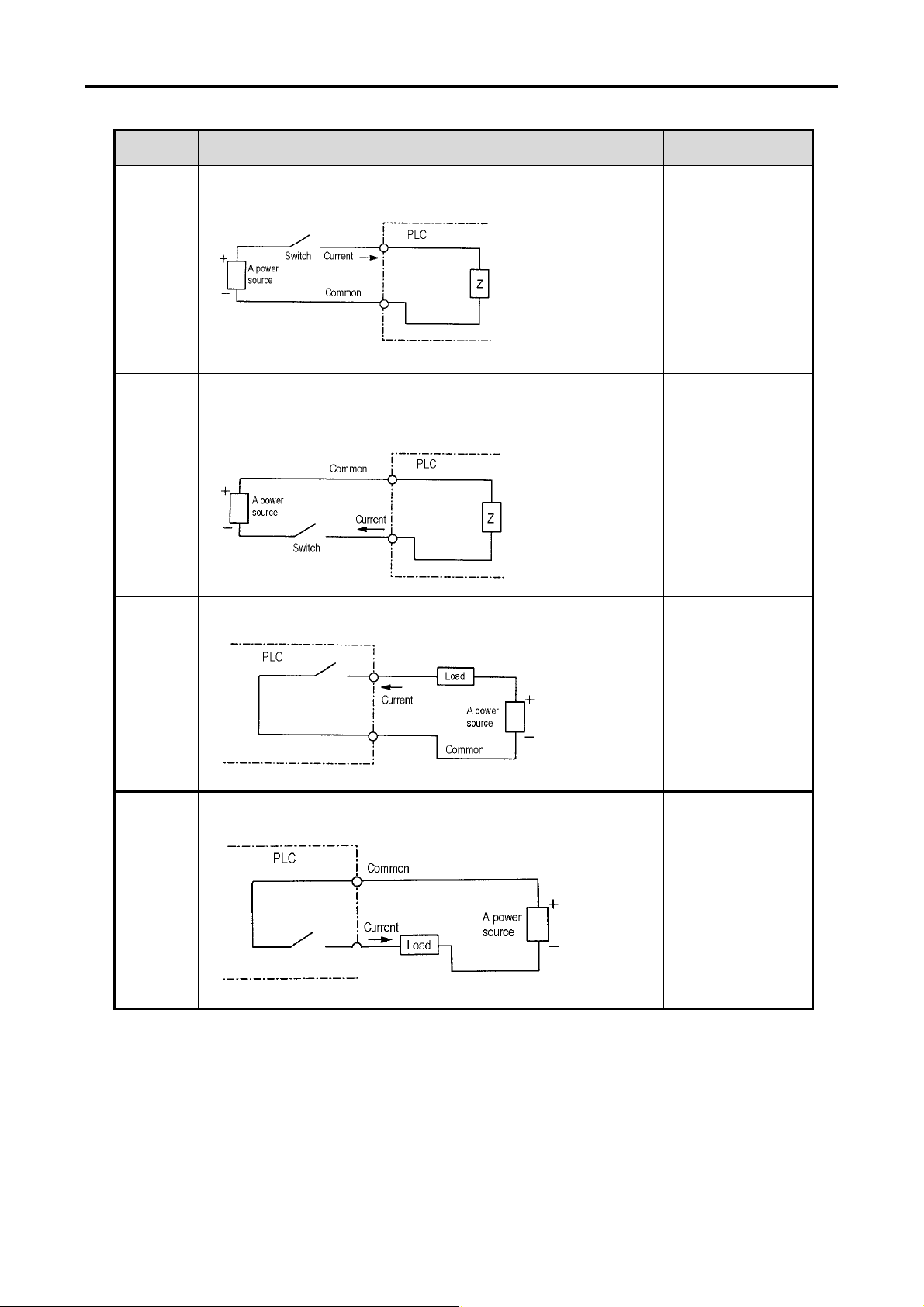

Chapter 2 System Configuration

Chapter 2. System Configuration

The MASTER-K120S series has suitable to configuration of the basic, computer link and network systems.

This chapter describes the configuration and features of each system.

2.1 Overall Configuration

2.1.1 Basic system

Main unit

expansion

cable

expansion

module

Total I/O points

Maximum number

of expansion

modules

Main unit

Expansion

module

Items

Communic

ation I/F

module

Digital I/O module

A/D-D/A module

Analog timer

Cnet I/F module

Economic

Standard

Digital I/O module

Analog I/O module

Analog timer

Resistance Temperature Detactor

Cnet I/F modules

DeviceNet I/F module

FieldBus I/F module

Profibus I/F Module

• 10-120 points

Standard Economic

• 3 modules • 2 modules

• 3 modules • 2 modules

• 3 modules • 2 modules

• 1 module • 1 modules

• K7M-DR10/14/20/30UE

• K7M-DR//DRT/DT20/30/40/60U

•

G7E-DR10A, G7E-DR20A, G7E-TR10A, G7E-DC08A, G7E-RY08A

• G7F-ADHA, G7F-ADHB, G7F-AD2A, G7F-DA2I, G7F-DA2V

• G7F-AT2A

• G7F-RD2A

• G7L-CUEB, G7L-CUEC

• G7L-DBEA

• G7L-FUEA

• G7L-PBEA

Option

module

RTC

Memory

• G7E-RTCA

• G7M-M256B

2-1

Page 18

Chapter 2 System Configuration

2.1.2 Cnet I/F system

Cnet I/F System is used for communication between the main unit and external devices using RS-232C/RS-422 Interface.

The MK120S has a built-in RS-232C port, RS-485 port and has also G7L-CUEB for RS-232C, G7L-CUEC for RS-422. It is

possible to construct communication systems on demand.

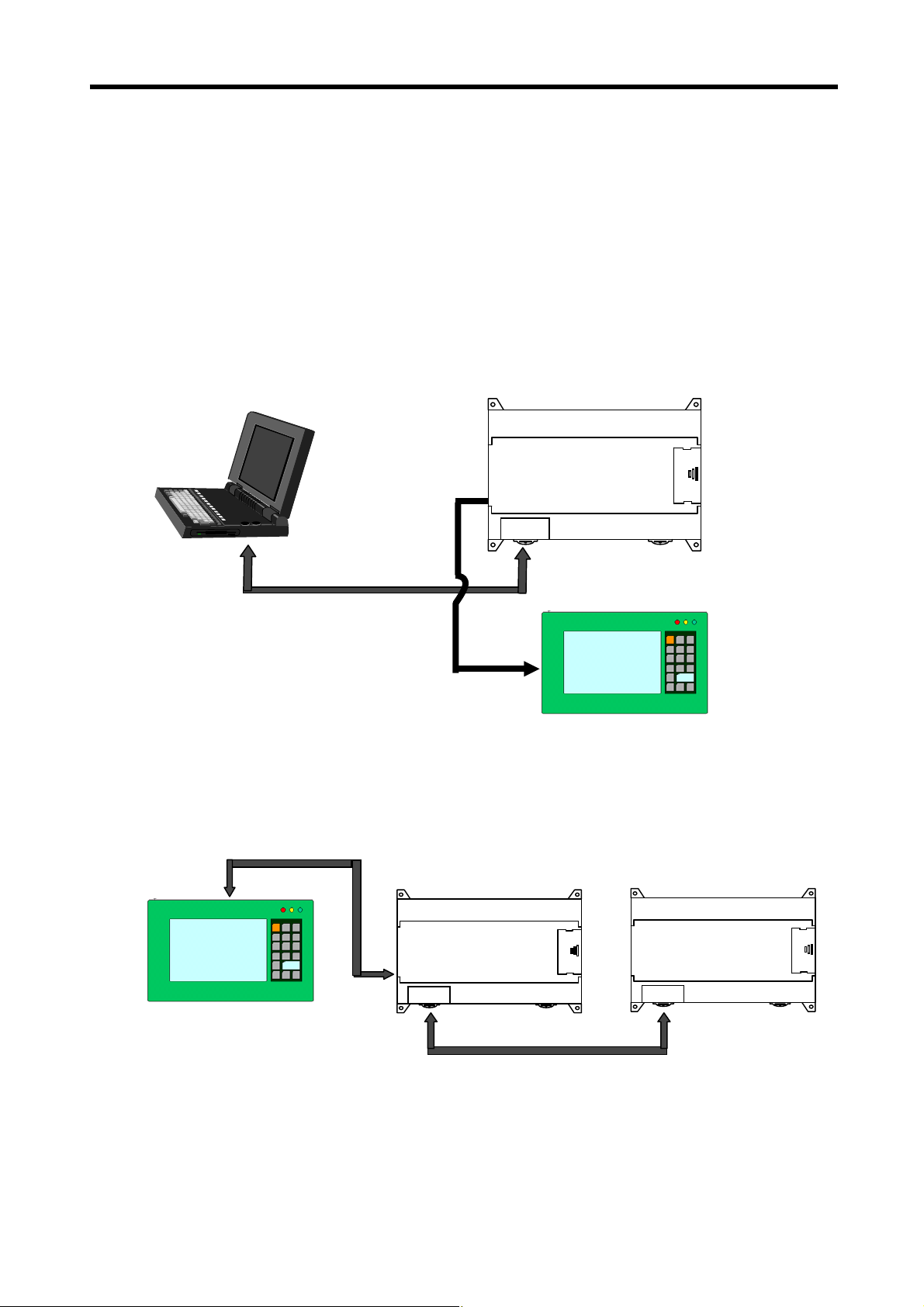

1) 1:1 Communications system

(1) 1:1 ratio of an external device (computer) to main unit using a built-in port

MASTER-K120S

RS-232C

Monitoring Device

RS-485

(2) 1:1 ratio of an external device (monitoring unit) to main unit using a built-in RS-485 port

RS-485

MASTER-K120S

MASTER-K120S

Monitoring Device

RS-232C

2-2

Page 19

Chapter 2 System Configuration

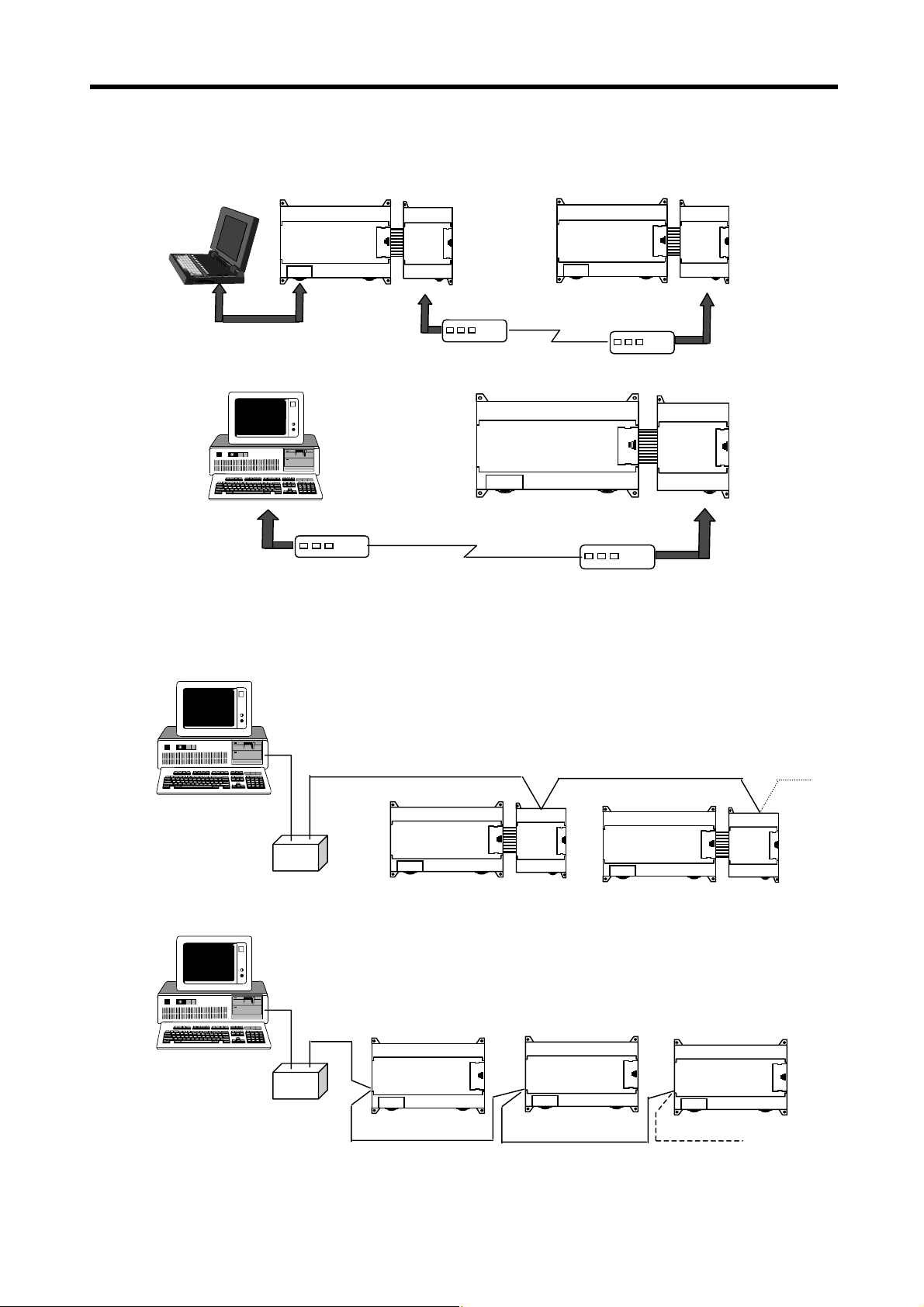

(3) RS-232C Communication over a long distance via modem by Cnet I/F modules

MASTER-K120S

Modem

2) 1:n Communications system

G7L-CUEB

Modem

MASTER-K120S

MASTER-K120S

G7L-CUEB

Modem

G7L-CUEB

Modem

This method can connect between one computer and multiple main units for up to 32 stations

RS-232C ⇔ RS-422 Converter

MASTER-K120S

G7L-CUEC

MASTER-K120S

G7L-CUEC

MASTER-K120S

RS-232C ⇔ RS-485

Converter

Built-in RS-485 Built-in RS-485

* Refer to ‘chapter 8. communication function’ for details.

2-3

Built-in RS-485

Page 20

Chapter 2 System Configuration

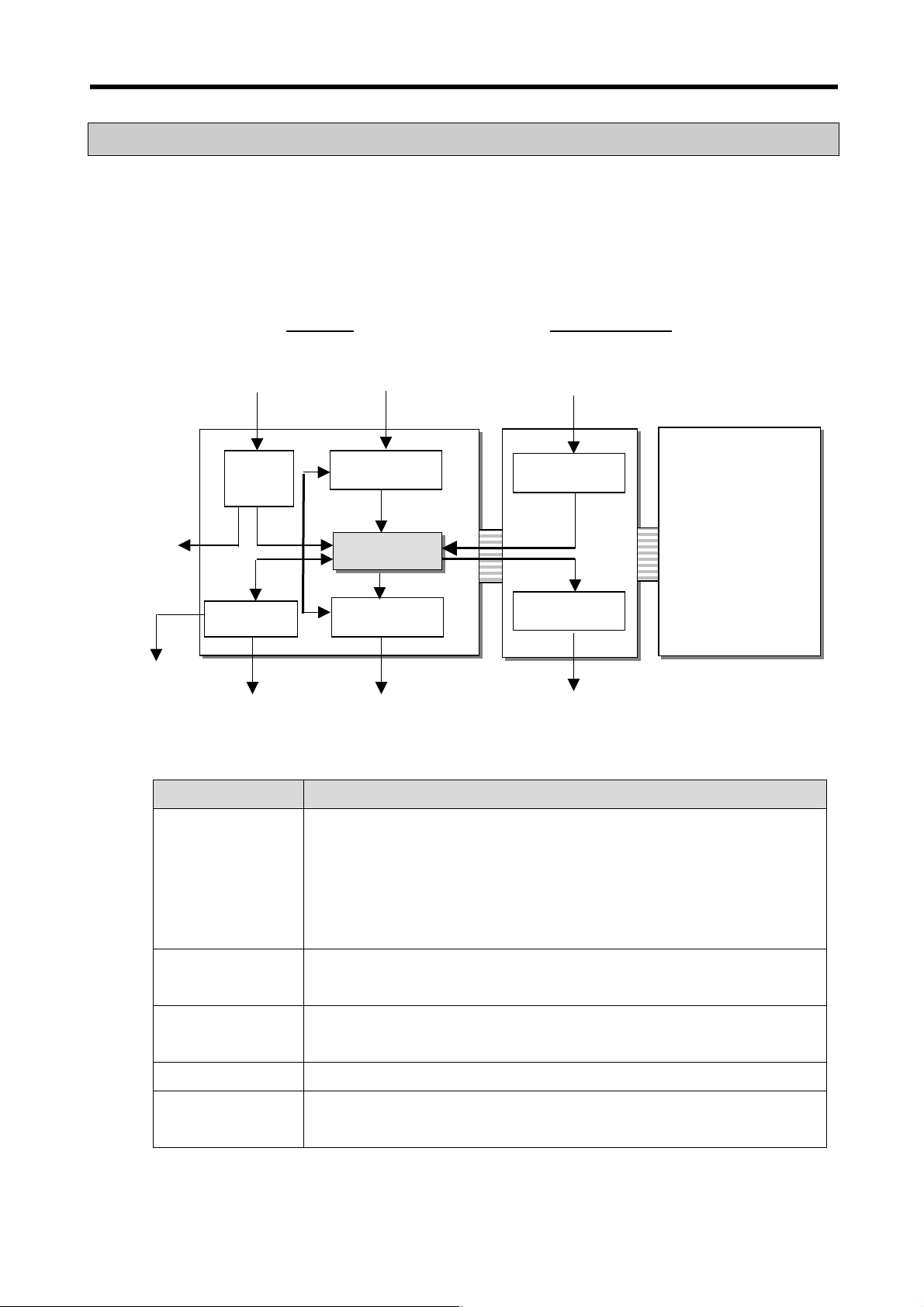

2.2 Product Functional Model

The following describes functional model of the MASTER-K120Sseries.

2.2.1 Product Functional Block

Product function block for the K120S series is as follows.

Power supply Input signal Input signal

DC24V

Power

supply

Built-in

RS-485

Built-in RS-232C I/F Output signal Output signal

Power

supply

Comm. I/F

Main Unit Expansion Modules

•

Input

CPU

Output

Input

Output

Special/communication

modules

Sub-system Description

CPU

Input

Output

Power Supply

Communication

Interface

• Signal processing function

-. Operating system function

-. Application program storage / memory function

-. Data storage / memory function

-. Application program execution function

• The input signals obtained from the machine/process to appropriate signal levels for

processing

• The output signals obtained from the signal processing function to appropriate signal

levels to drive actuators and/or displays

• Provides for conversion and isolation of the PLC system power from the main supply

• Provides the data exchange with other systems or PADT, such as KGLWIN, personal

computers

2-4

Page 21

Chapter 2 System Configuration

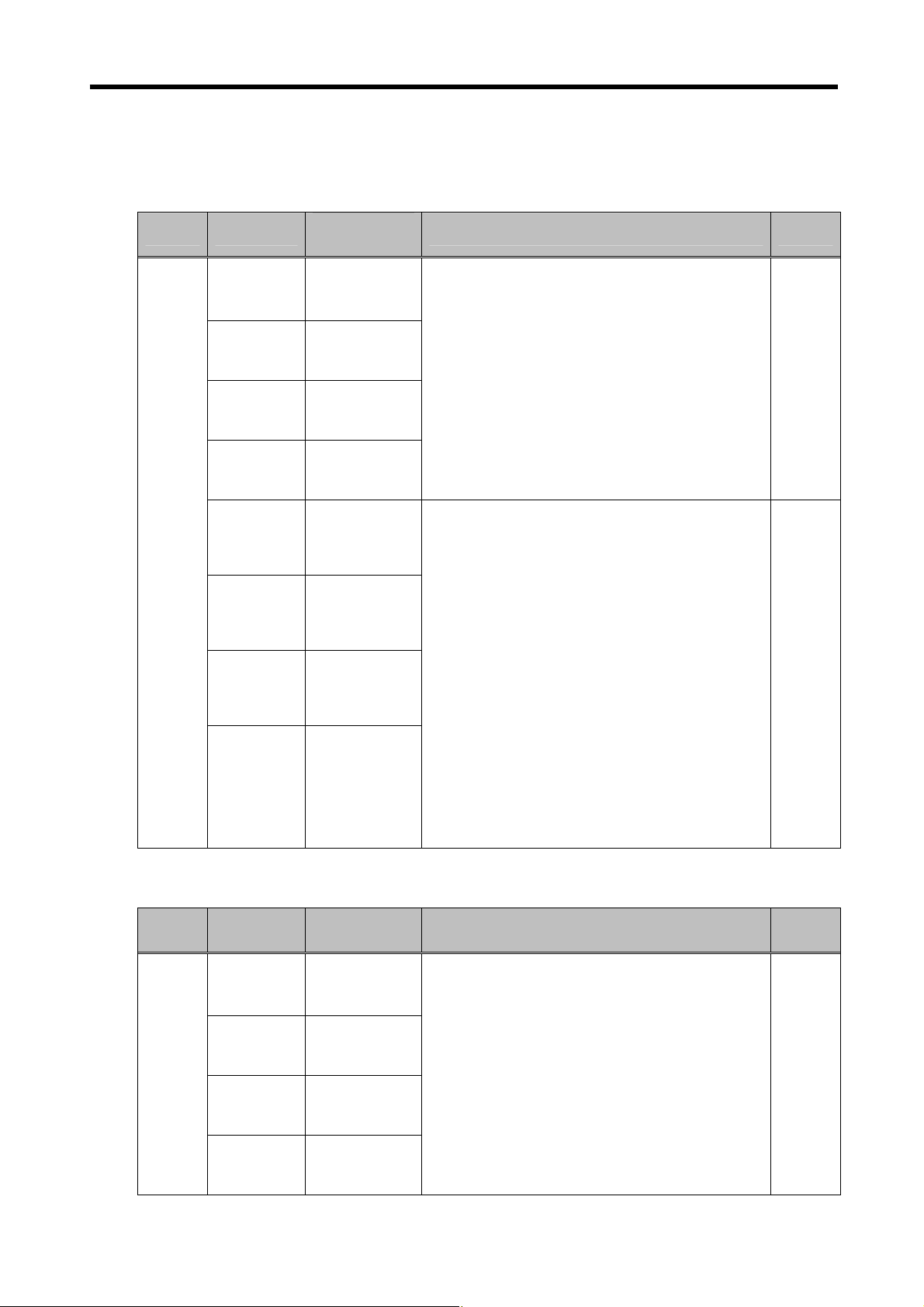

2.2.2 K120S Series System Equipment Product

1) Main Unit – Standard type

Items Models

K7M-DR20U

K7M-DR30U

K7M-DR40U

K7M-DR60U

K7M-

Main Unit

DRT/DT20U

K7M-

DRT/DT30U

K7M-

DRT/DT40U

K7M-

DRT/DT60U

2) Main Unit – Economic type

Items Models

K7M-DR10UE

K7M-DR14UE

Main Unit

K7M-DR20UE

K7M-DR30UE

I/O Point &

Power Supply

12 DC inputs(24VDC)

8 relay outputs

85~264 VAC

18 DC inputs(24VDC)

12 relay outputs

85~264 VAC

24 DC inputs(24VDC)

16 relay outputs

85~264 VAC

36 DC inputs(24VDC)

24 relay outputs

85~264 VAC

12 DC inputs(24VDC)

4/0 relay outputs

4/8 TR outputs

85~264 VAC

18 DC inputs(24VDC)

8/0 relay outputs

4/12 TR outputs

85~264 VAC

24 DC inputs(24VDC)

12/0 relay outputs

4/16 TR outputs

85~264 VAC

36 DC inputs(24VDC)

20/0 relay outputs

4/24 TR outputs

85~264 VAC

I/O Point &

Power Supply

6 DC inputs(24VDC)

4 relay outputs

85~264 VAC

8 DC inputs(24VDC)

6 relay outputs

85~264 VAC

12 DC inputs(24VDC)

8 relay outputs

85~264 VAC

18 DC inputs(24VDC)

12 relay outputs

85~264 VAC

Built-in Function Remark

• Program capacity : 10 k steps

• Max. expansion : 3 modules

• High-speed counter :

- 1 Phase : 100 kHz 1channel, 20 kHz 2channel.

- 2 Phase : 50 kHz 1channel, 10 kHz 1channel.

• Pulse catch : pulse width 10 ㎲ 2 points, 50 ㎲ 6 points,

• External interrupt: : 10 ㎲ 2 points, 50 ㎲ 6 points

• Input filter: 0 ~ 1000ms (can be designated with groups)

• PID control function

• RS-232C communication, RS-485 communication

• Program capacity : 10 k steps

• Max. expansion : 3 modules

• High-speed counter :

- 1 Phase : 100 kHz 1channel, 20 kHz 2channel.

- 2 Phase : 50 kHz 1channel, 10 kHz 1channel.

• Pulse catch : pulse width 10 ㎲- 2 points, 50 ㎲- 6 points,

• External interrupt: : 10 ㎲- 2 points, 50 ㎲- 6 points

• Input filter: 0 ~ 1000ms (can be designated with groups)

• PID control function

• RS-232C communication, RS-485 communication

• Positioning function

- 2axes 100 kpps

- Absolute / Incremental positioning method

- Single / Repeat operation method

- End / Keep / Continuous mode

- Return to origin, JOG, PWM, velocity control

Built-in Function Remark

• Program capacity : 2 k steps

• Max. expansion : 2 modules

• Pulse catch : pulse width 50 ㎲ 4 points,

• High-speed counter :

- 1 Phase : 10 kHz 2channel.

- 2 Phase : 5 kHz 1channel.

• External interrupt: : 50 ㎲ 4 points

• Input filter: 0 ~ 1000ms (can be designated with groups)

• RS-232C communication

• RS-485 communication(K7M-DR10/14UE only)

• Built-in analog timer(K7M-DR10/14UE only)

2-5

Page 22

Chapter 2 System Configuration

3) Expansion Modules

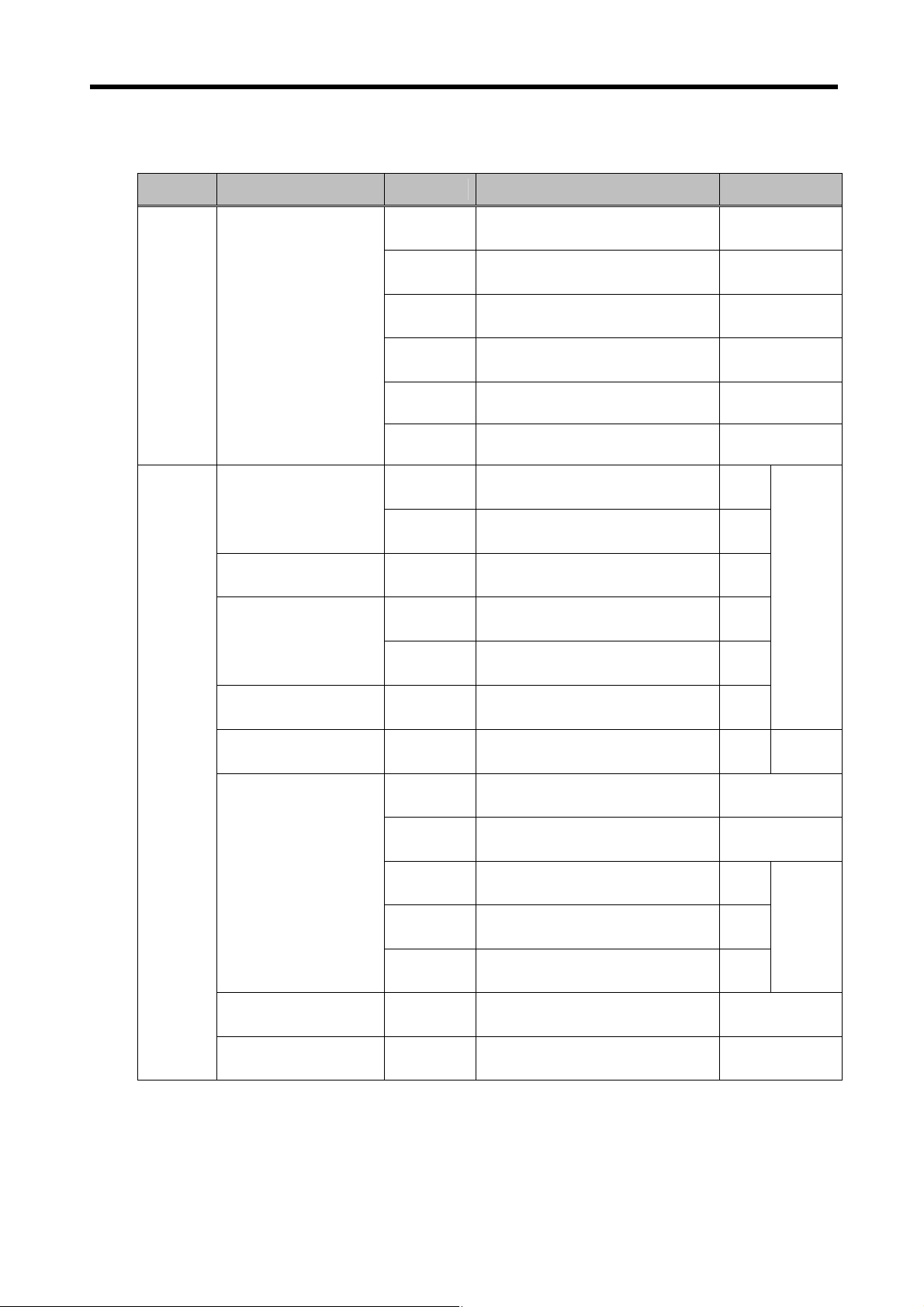

Section Items Models Description Remark

Expansion

module

Special

module

G7E-DR10A

G7E-DR20A

G7E-DC08A

Digital I/O module

G7E-TR10A

G7E-RY08A

G7E-DR08A

A/D-D/A

Combination module

A/D conversion module G7F-AD2A

D/A conversion module

Analog timermodule G7F-AT2A

RTD module G7F-RD2A

G7F-ADHA

G7F-ADHB

G7F-DA2I

G7F-DA2V

G7L-CUEB

• 6 DC inputs / 4 relay outputs

• 12 DC inputs / 8 relay outputs

• 8 DC inputs

• 10 Transistor outputs

• 8 relay outputs

• 4 DC Input, 4 Relay output

• A/D : 2 channel , D/A : 1 channel

• A/D : 2 channel , D/A : 2 channel

• A/D : 4 channel

• D/A : 4 channel(current output)

• D/A : 4 channel(voltage output)

• Points : 4points

• Digital output range : 0~200

• Resistance temperature detactor

- 4 channel(Pt100, JPt100)

• RS-232C : 1 channel

Slim Type

Slim Type

Slim

Type

Slim

Type

Slim

Type

Standard

type only

G7L-CUEC

Communication I/F module

RTC module G7E-RTCA

External Memory G7M-M256B

* External memory G7M-M256 isn’t supported in K120S series. Only G7M-M256B is available for K120S series.

G7L-DBEA

G7L-FUEA

G7L-PBEA

• RS-422 : 1 channel

• DeviceNet I/F module (Slave)

• FieldBus I/F module

• Profibus I/F module (Slave)

• Real Time Clock module

• External Memory module

2-6

Standard

type only

Page 23

Chapter 3 General Specifications

p

Chapter 3. General Specifications

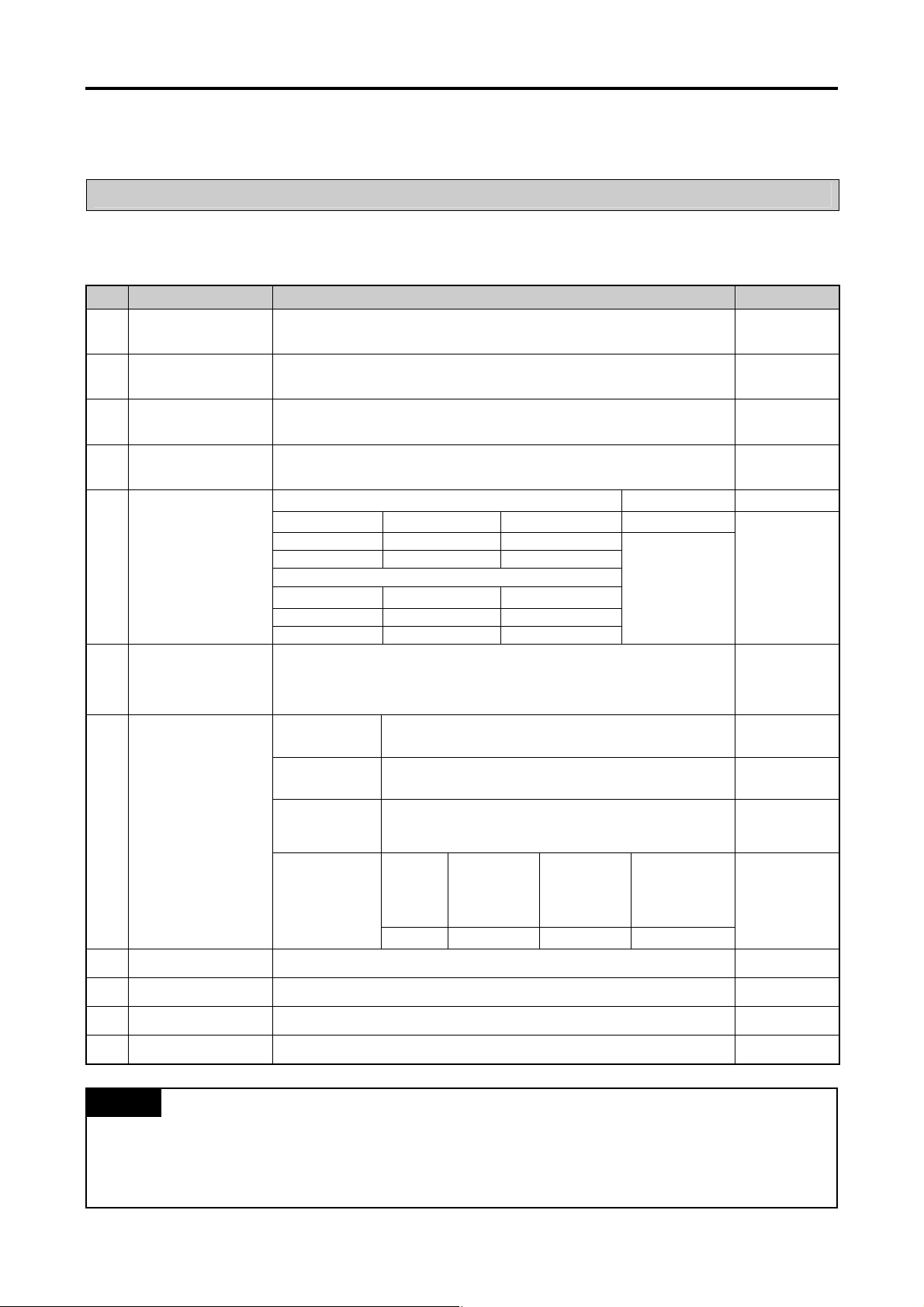

3.1 General Specifications

The following table shows the general specifications of the MASTER-K120S series.

No. Item Specifications References

1

2

3

4

5 Vibrations

6 Shocks

Operating ambient

Temperature

Storage ambient

Temperature

Operating ambient

Humidity

Storage ambient

Humidity

0 ~ 55 °C

−25 ~ +70 °C

5 ~ 95%RH, non-condensing

5 ~ 95%RH, non-condensing

Occasional vibration -

Frequency Acceleration Amplitude Sweep count

10 ≤ f < 57Hz

57 ≤ f ≤ 150Hz

Frequency Acceleration Amplitude

10 ≤ f < 57Hz

57 ≤ f ≤ 150Hz

• Maximum shock acceleration: 147 m/s

• Duration time: 11ms

• Pulse wave: half sine pulse ( 3 shocks per axis, on X, Y, Z axis )

−

2

{1G}

9.8m/s

Continuous vibration

−

2

{0.5G}

4.9m/s

2

{15G}

0.075mm

−

10 times for each

X, Y, Z axis

0.035mm

−

IEC 61131-2

IEC 61131-2

7 Noise Immunity

8

9

10

11

Atmosphere Free of corrosive gases and excessive dust

Altitude

Pollution degree

Cooling method

Square wave

Impulse noise

Electronic

discharge

Radiated

electromagnetic

field noise

Fast transient &

burst noise

Up to 2,000m

2

Air-cooling

± 1,500 V

Voltage: 4 kV ( Discharge by contact )

27 ~ 500 MHz, 10 V/m

Item Power supply

Voltage

2kV 1kV 0.25kV

Digital I/O

(24V and up)

Digital I/O

(less than24V)

Analog I/O

Interface

LGIS’ Internal

Standard

IEC 61131-2,

IEC 1000-4-2

IEC 61131-2,

IEC 1000-4-3

IEC 61131-2

IEC 1000-4-4

REMARK

1)

IEC (International Electrotechnical Commission): A n international civi lian institute who establishes internatio nal standards i n area of elec tric

and electronics.

2) Pollution degree: An indicator, which indicates pollution degree, which determine insulation performance of equipment.

* Pollution degree 2 : Normally, only non-conductive pollution occurs. Occasionally, however, a temporary conductivity caused by

condensation shall be ex

ected.

3-1

Page 24

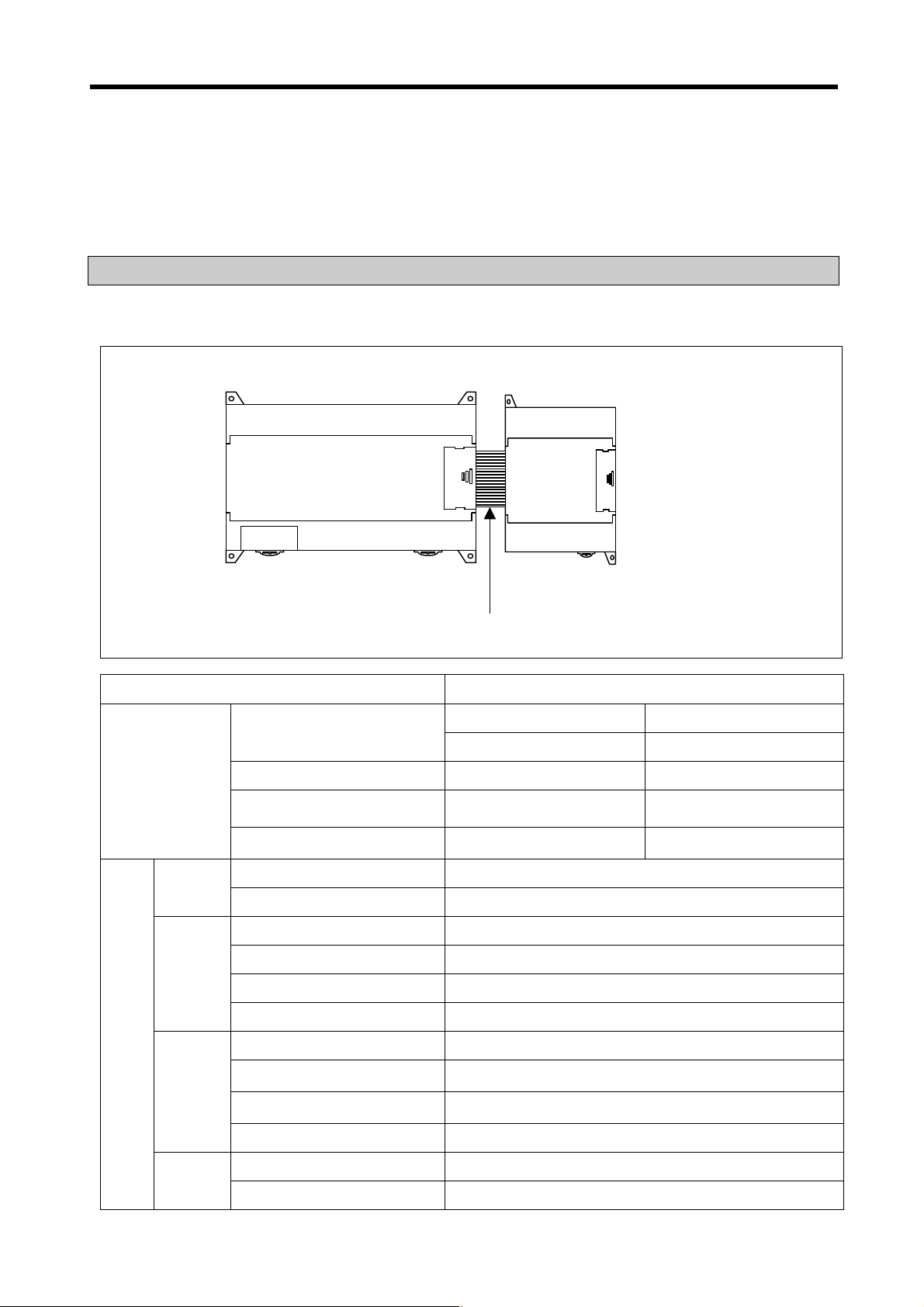

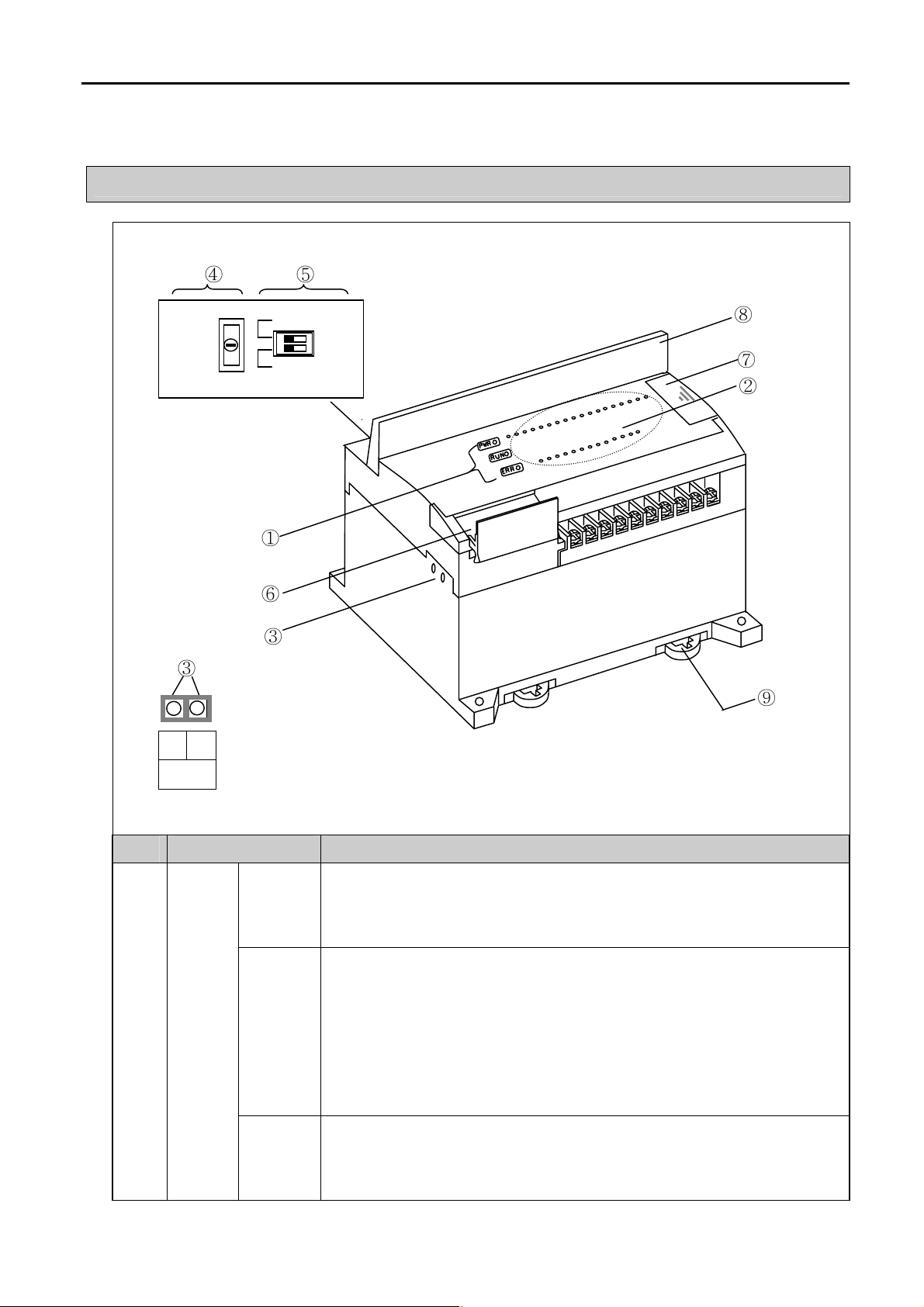

Chapter 4 Names of Parts

Chapter 4. Names of Parts

4.1 Main Unit

③

④

⑤

①

⑥

③

⑧

⑦

②

⑨

- +

RS-485

No. Name Description

Indicates status of power supply to the system

CPU

Condition

LED

PWR LED

RUN LED

ERR LED

y On : When the supplied power is normal

y Off : When the supplied power is abnormal

Indicates operating status of main unit

y On : Indicates local key switch or remote running mode

y Off : with the followings, LED turns off

- When the supplied power to the main unit is abnormal.

- While key switch is on stop mode

- Detecting an error which makes operation stop

Indicates operating status of CPU

y Flickering : self-inspected error

y Off: CPU is working normal.

4 -1

Page 25

Chapter 4 Names of Parts

No Name Description

I/O LED Indicates operating status of I/O

Built-in RS-485 connector

(Except K7M-DR10/14UE)

2-pin connector for built-in RS-485 communications.

Designates main unit’s operation mode

y RUN : Run program operation

Key switch for mode creation

.(Except economic type)

Dip-switch for Cnet I/F

RS-232C connector

Expansion connector cover Connector cover to connect with expansion unit

Terminal block cover

Private hook DIN rail

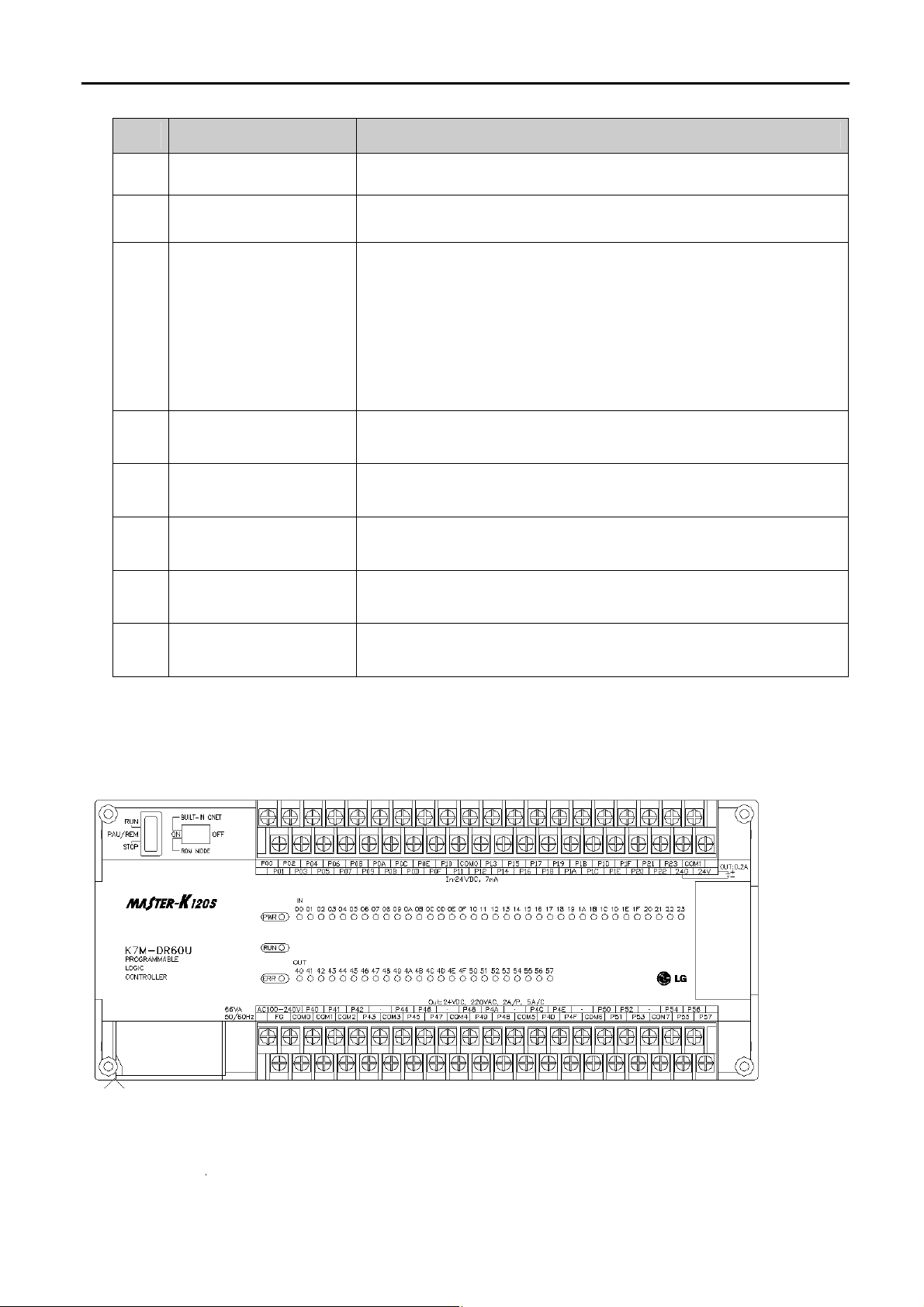

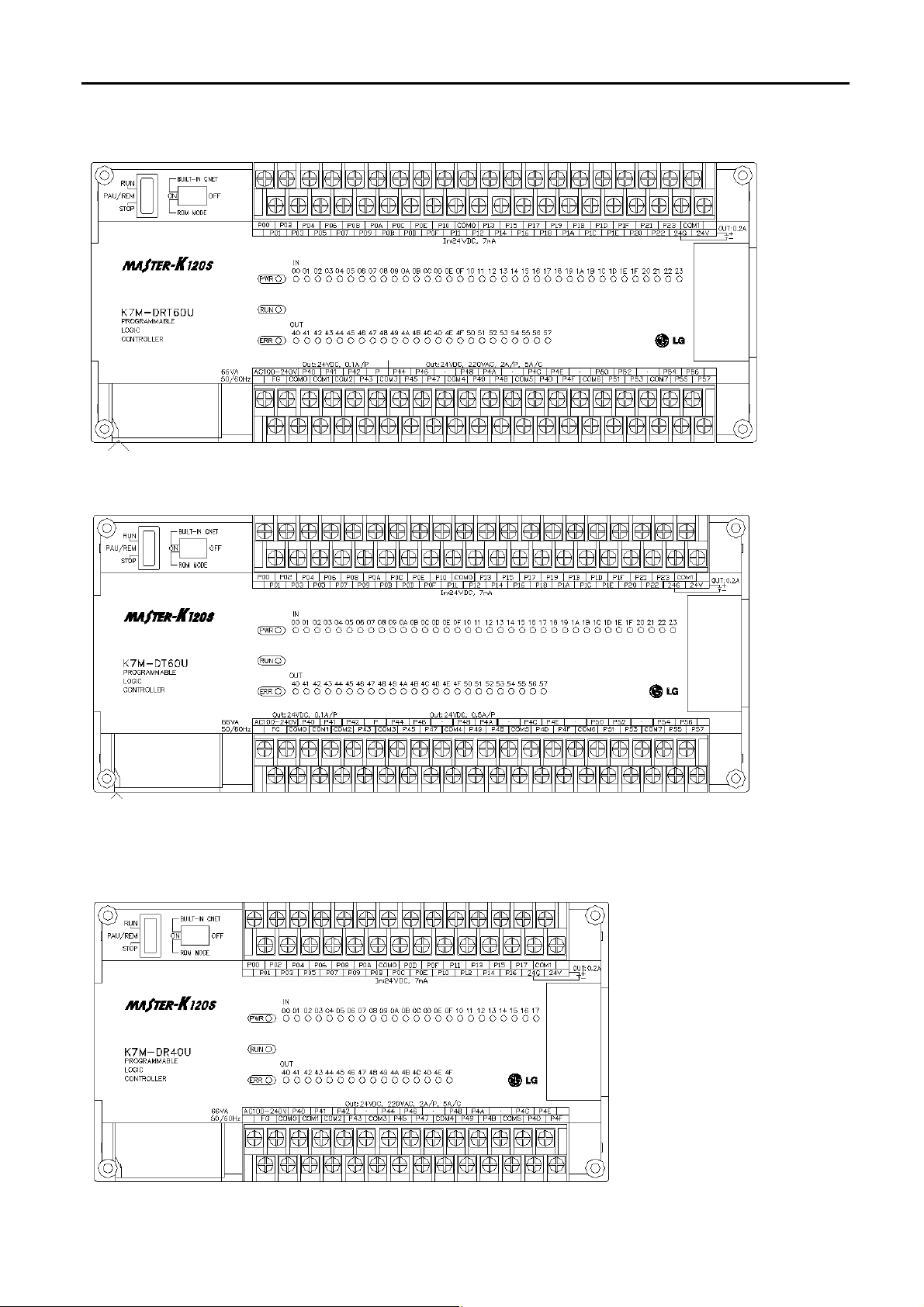

4.1.1 60-points main unit (Standard)

1) K7M-DR60U

y STO P : Stop program operation

y P AU / REM: usage of each modules are as follows:

- P A U S E : temporary stopping program operation

- REMOTE : designates remote driving

See Chapter 5.

9-pin DIN connector to connect with external devices like KGLWIN

Protection cover for wiring of terminal block

Private part hook for DIN rail

4 -2

Page 26

Chapter 4 Names of Parts

2) K7M-DRT60U

3) K7M-DT60U

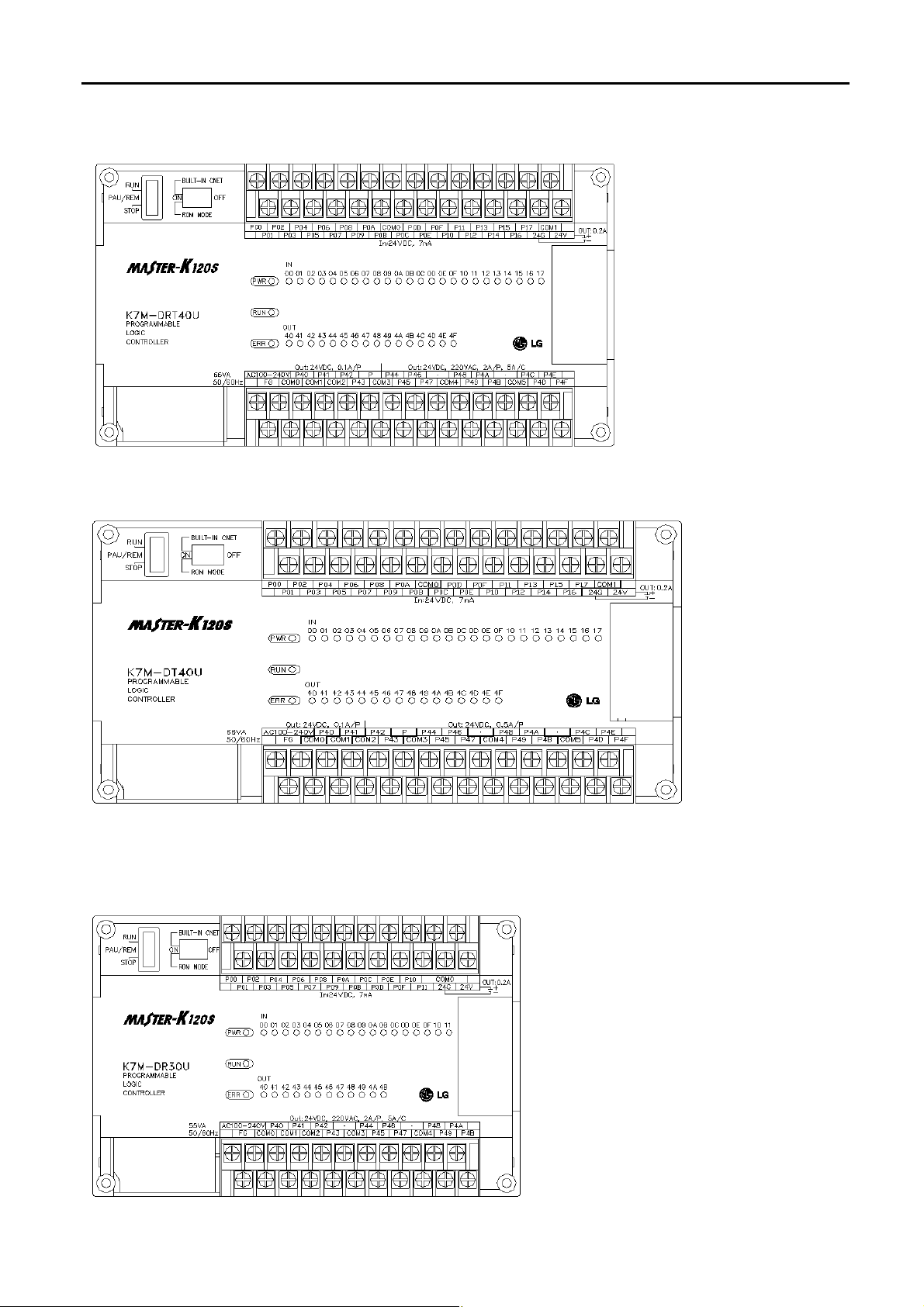

4.1.2 40-points main unit (Standard)

1) K7M-DR40U

4 -3

Page 27

Chapter 4 Names of Parts

2) K7M-DRT40U

3) K7M-DT40U

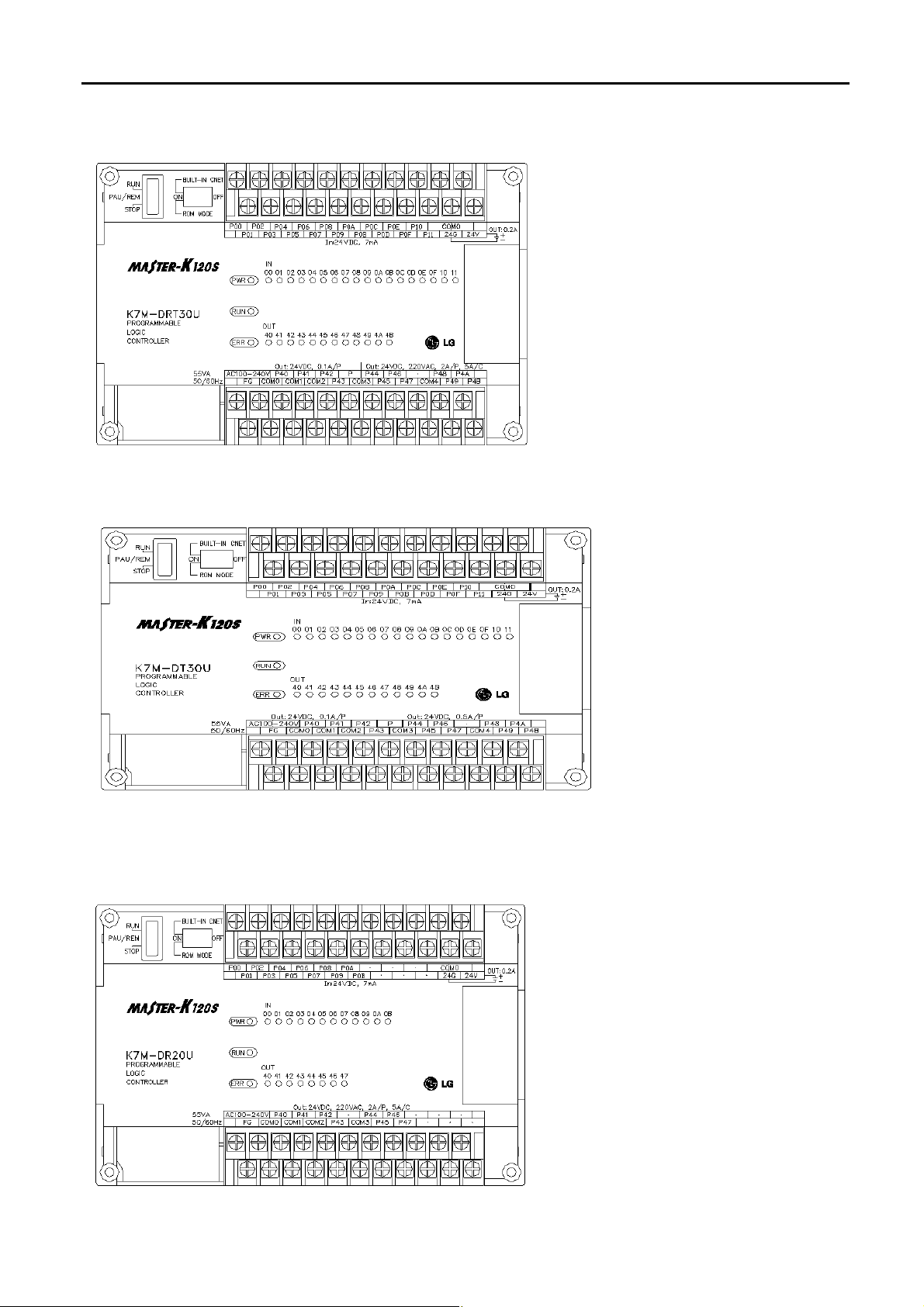

4.1.3 30-points main unit (Standard)

1) K7M-DR30U

4 -4

Page 28

Chapter 4 Names of Parts

2) K7M-DRT30U

3) K7M-DT30U

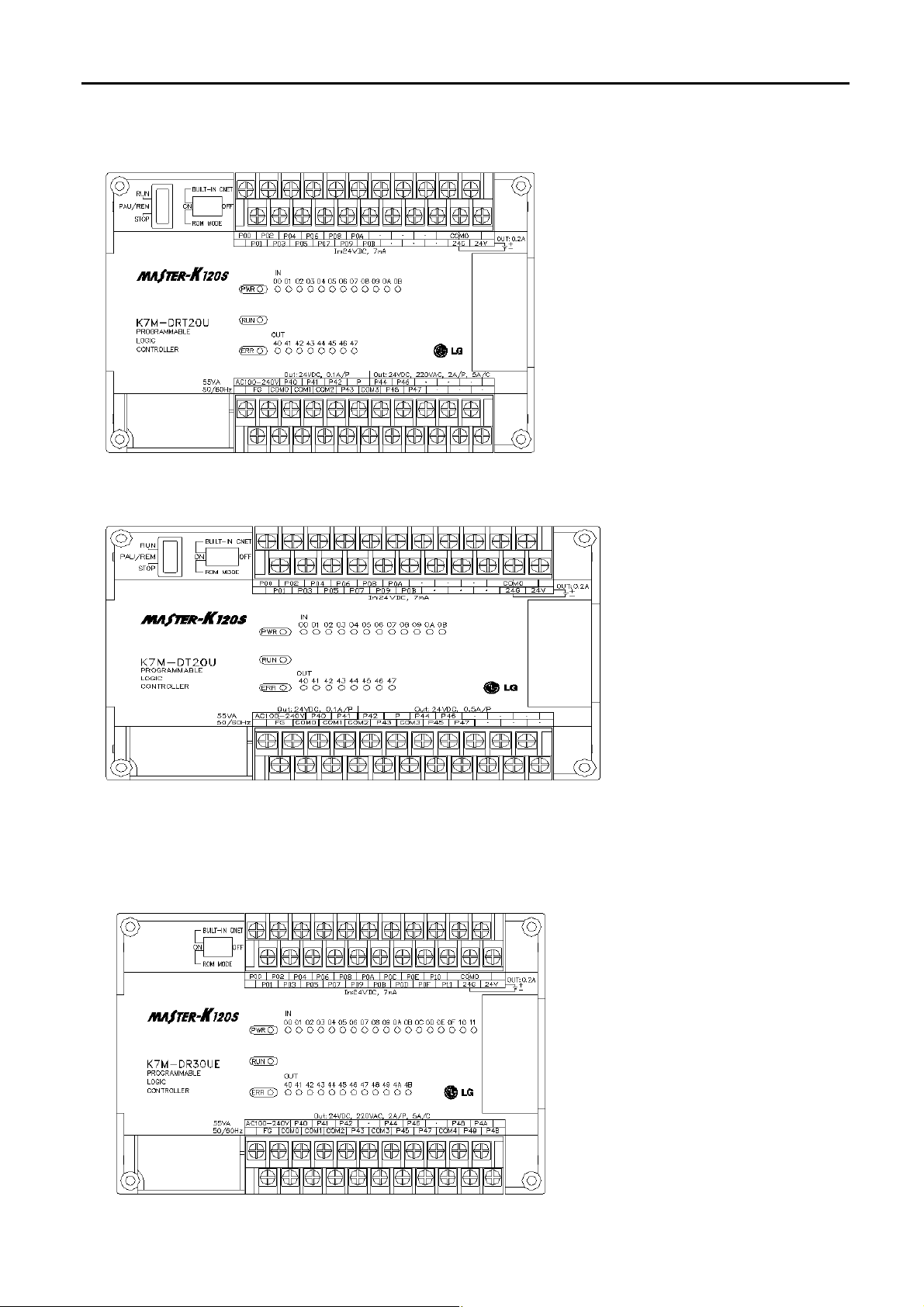

4.1.4 20-points main unit (Standard)

1) K7M-DR20U

4 -5

Page 29

Chapter 4 Names of Parts

2) K7M-DRT20U

3) K7M-DT20U

4.1.5 30-points main unit (Economic)

1) K7M-DR30UE

4 -6

Page 30

Chapter 4 Names of Parts

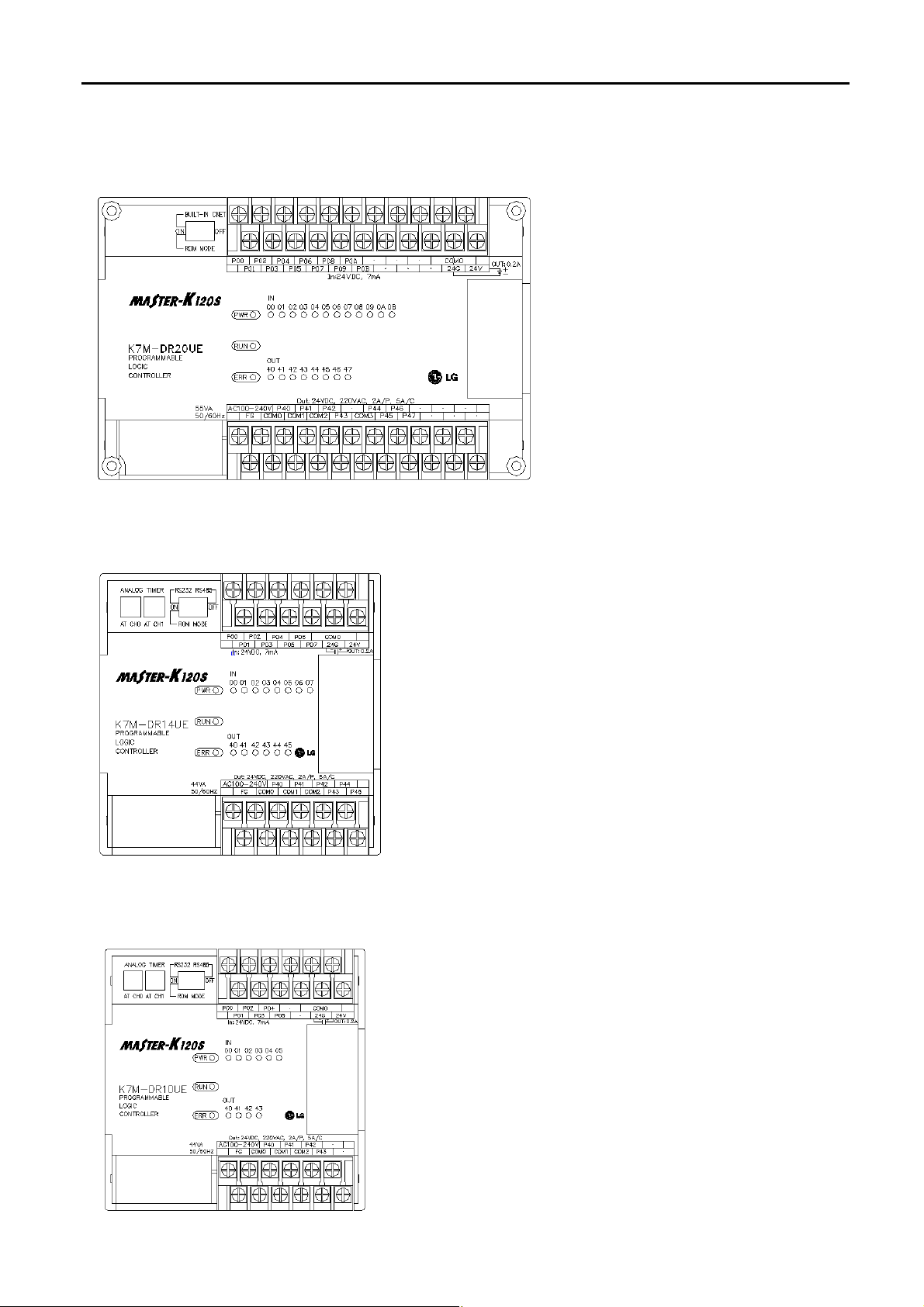

4.1.6 20-points main unit (Economic)

1) K7M-DR20UE

4.1.7 14-points main unit (Economic)

1) K7M-DR14UE

4.1.8 10-points main unit (Economic)

1) K7M-DR10UE

4 -7

Page 31

Chapter 4 Names of Parts

②

⑤③④

⑥

⑦

⑤

⑥⑧③④⑦

⑧

⑤⑤⑤⑥⑥

⑥

③④⑤

⑥

4.2 Expansion I/O Module

4.2.1 20points I/O Module

1) G7E-DR20A

4.2.2 10points I/O Module

1) G7E-DR10A

1) G7E-TR10A

②

①

①

No. Names

①

① Input LED

② Output LED

③ Input contact

④ Input common terminal

⑤ Output contact

⑥ Output common terminal

⑦ Expansion cable

⑧ Expansion Cable Connecting Terminal

No. Names

① Input LED

② Output LED

③ Input contact

④ Input common terminal

⑤ Output contact

②

⑥ Output common terminal

⑦ Expansion cable

⑧ Expansion Cable Connecting Terminal

No. Names

① Output LED

② Output contact

③ Output common terminal

④ External Power Supply Terminal (DC24V)

⑤ Expansion cable

⑥ Expansion Cable Connecting Terminal

4 -8

Page 32

Chapter 4 Names of Parts

③②③⑤④

③②③⑤④

4.2.3 8points I/O Module

1) G7E-DC08A

2) G7E-RY08A

②

No. Names

①

① Input LED

② Input contact

③ Input common terminal

④ Expansion cable

⑤ Expansion Cable Connecting Terminal

②

No. Names

①

① Output LED

② Output contact

③ Output common terminal

④ Expansion cable

⑤ Expansion Cable Connecting Terminal

4 -9

Page 33

Chapter 4 Names of Parts

⑦①②③④⑤⑥

4.3 Special Module

4.3.1 A/D·D/A Combination Module

1) G7F-ADHA

2) G7F-ADHB

③

No.

①

②

③

④

⑤

⑥

⑦

Names

RUN LED

Analog Output Terminal

Analog Input (Voltage/current) selecting jumper pin

Analog Input Terminal

External Power Supply Terminal (DC24V)

Expansion Cable

Expansion Cable Connecting Terminal

No.

Names

RUN LED

⑤

④

②

⑥

①

External Power Supply Terminal (DC24V)

Expansion Cable Connecting Terminal

Analog Input Terminal

Analog Output Terminal

Expansion Cable

4 -10

Page 34

Chapter 4 Names of Parts

①②③④⑤

①②③

④⑤⑥⑤③①④

②

4.3.2 D/A Conversion Module

1) G7F-DA2I

No.

Names

2) G7F-DA2V

①

②

③

④

RUN LED

Analog Output Terminal

Expansion Cable

Expansion Cable Connecting Terminal

External Power Supply Terminal (DC24V)

No.

Names

RUN LED

Analog Output Terminal

4.3.3 A/D Conversion Module

24V 24G

Input

Input

Select

CH0

V0 COM

I0

·

CH1 CH2 CH3

V1 COM

V2

I1

·

CH3

CH2

CH1

CH0

Expansion Cable

Expansion Cable Connecting Terminal

External Power Supply Terminal (DC24V)

COM

V3 COM

I2

I3

·

·

RUN LED

Analog Input Terminal

Analog Input (Voltage/current) selecting jumper

pin

External Power Supply Terminal (DC24V)

Expansion Cable

Expansion Cable Connecting Terminal

4 -11

Page 35

Chapter 4 Names of Parts

①②③④③①④②⑤

②

4.3.4 Analog timer Module

4.3.5 RTD Input Module

No.

①

②

③

④

Names

RUN LED

Analog Timer Volume Control Resistor

Expansion Cable

Expansion Cable Connecting Terminal

No.

①

②

Names

RUN LED

Analog Timer Volume Control Resistor

③

④

Expansion Cable

Expansion Cable Connecting Terminal

4 -12

Page 36

Chapter 4 Names of Parts

4.4 Communication I/F Module

4.4.1 Cnet I/F Module

1) G7L-CUEB

No. Names

① RS-232C connector

② Communication status LED

③ Expansion cable

④ Expansion cable connecting terminal

⑤ TM/TC selecting dip switch

2) G7L-CUEC

4.4.2 Fnet I/F Module

1) G7L-FUEA

No. Names

① RS-422/485 connector

② Power supply/Communication status LED

③ Expansion cable

④ Expansion cable connecting terminal

No. Names

① Station No. selecting switch

② Fnet cable connector 1 and 2

③ Expansion cable

④ Expansion cable connecting terminal

⑤ Communication status LED

4 -13

Page 37

Chapter 4 Names of Parts

4.4.3 Pnet I/F Module

1) G7L-PBEA

4.4.4 DeviceNet I/F Module

1) G7L-DBEA

No. Names

① Station No. selecting switch

② Pnet cable connector

③ Expansion cable

④ Expansion cable connecting terminal

⑤ Communication status LED

No. Names

① Station No. selecting switch(NA)

② DeviceNet cable connector

③ Expansion cable

④ Expansion cable connecting terminal

⑤ Baud rate selecting switch

⑥ Power supply/Communication status LED

4.5 Option Module

Option modules are attached the expansion slot of main unit or expansion unit, and supplies optional functions such as

memory expansion or real time clock. MASTER-K120S series have two option modules – External memory module and RTC

module.

No.

Names

①

Option module

②

4 -14

Connector

Page 38

Chapter 5 Power Supply / CPU

Chapter 5. Power Supply / CPU

5.1 Power Supply Specifications

5.1.1. Standard Type

Rated voltage

Rated frequency

Rated current

Input

Inrush current

Efficiency

Input fuse

Permitted Momentary

power failure

Output voltage

Output(1)

Output current

Output voltage

Output(2)

Output current

Power supply status indication

5.1.2. Economic Type

Items

DR/DRT/DT20U

K7M –

85 ~ 264 VAC

50 / 60 Hz (47 ~ 63 Hz)

0.5A(110VAC)/0.25A(220VAC) 0.6A(110VAC)/0.3A(220VAC)

Up to 30A Up to 60A

65% min.(rated input/maximum load)

2A/AC250V (Time Lag Type)

10 ms

DC 5V

1.2A 2A

DC 24V

0.2A

PWR LED On when power supply is normal

K7M –

DR/DRT/DT30U

K7M –

DR/DRT/DT40U

K7M –

DR/DRT/DT60U

Items K7M – DR10UE K7M – DR14UE K7M – DR20UE K7M – DR30UE

Rated voltage

Rated frequency

Rated current

Input

Inrush current

Efficiency

Input fuse

Permitted Momentary

power failure

Output voltage

Output(1)

Output current

Output voltage

Output(2)

Output current

Power supply status indication

85 ~ 264 VAC

50 / 60 Hz (47 ~ 63 Hz)

0.3A(110VAC) / 0.15A(220VAC) 0.5A(110VAC) / 0.25A(220VAC)

Up to 30A

65% min.(rated input/maximum load)

2A/AC250V (Time Lag Type)

10 ms

DC 5V

0.5A 1.2A

DC 24V

0.2A

PWR LED On when power supply is normal

5-1

Page 39

Chapter 5 Power Supply / CPU

5.2 CPU Specifications

The following table shows the general specifications of the MASTER-K120S series

5.2.1. Standard Type

Specifications

Items

K7M-DR/DRT/DT20U K7M-DR/DRT/DT30U K7M-DR/DRT/DT40U K7M-DR/DR`T/DT60U

Program control method Cyclic execution of stored program, Time-driven interrupt, Process-driven interrupt

I/O control method Indirect mode(Refresh method), Direct by program command

Program language Instruction list, Ladder diagram

Numbers of instructions Basic : 30, Application : 277

Remarks

Processing speed

Program capacity 10ksteps

I/O points 20 30 40 60

P P000 ~ P63F I/O relay,TR.

M M000 ~ M191F Auxiliary relay

K K000 ~ K31F Keep relay

L L000 ~ L63F Link relay

F F000 ~ F63F Special relay

Memory

device

T

0.1µs/step

100msec : T000 ~ T191 (192 points)

10msec : T192 ~ T250 (59 points)

1msec : T251 ~ T255 (5 points)

-. Adjustable by parameter setting

Timer

C C000 ~ C255 Counter

S S00.00 ~ S99.99

D D0000 ~ D4999 Data register

Operation modes RUN, STOP, PAUSE, DEBUG

Self-diagnosis functions Detects errors of scan time, memory, I/O and power supply

Data back-up method Latch area back-up

Up to 3 level

Max. expansion level

(External memory or RTC module can be connected as 4th expansion module)

5-2

Step controller

Page 40

Chapter 5 Power Supply / CPU

(continued)

Items

K7M-DR/DRT/DT20U K7M-DR/DRT/DT30U K7M-DR/DRT/DT40U K7M-DR/DRT/DT60U

Specifications

Remarks

Built-in

Function

PID control function

Cnet I/F Function

Capacity

High-

Counter function

speed

counter

Additional

function

Controlled by commands, Relay and PRC auto tuning,

PWM output, manual output, adjustable operation scan time,

Anti-windup, SV-Ramp, Delta MV, Position and Velocity algorithm

Dedicated protocol support

MODBUS protocol support RS-232C - 1port

User defined protocol support RS-485 - 1 port

No protocol support

1 phase : 100 kHz-2 channel, 20 kHz-2 channel

2 phase : 50 kHz-1 channel, 10 kHz-1 channel

4 different counter modes as following;

-. 1 phase operation mode.

-. 2 phase CW/CCW mode.

-. 2 phase Pulse + Direction mode.

-. 2 phase Multiplication mode(MUL4)

Internal/External preset function

Latch Counter function

RPM function

Comparison Output function

N0. of control axis : 2 Axis

Operation

Specification

Position-

Positioning

ing

Return to Origin

JOG Setting range : 5~100,000 ( High / Low speed)

Pulse catch

External interrupt

Input filter 0~1000ms(Adjustable)

Control method : Point-to-Point, Speed Control

Control unit : Pulse

Positioning data : 20 data / axis(Operation step N0. 1 ~ 20)

Positioning method : Absolute / Incremental

Operation method : Single / Repeat

Operation mode : End / Keep / Continuous

Address range : -2,147,483,648 ~ 2,147,483,647

Speed : Max. 100kpps(setting range 5 ~ 100,000)

Acceleration / Deceleration method : trapezoidal method

Origin detection when approximate origin turns off

Origin detection after deceleration when approximate origin turns on.

Origin detection by approximate origin.

Minimum pulse width : 10 ㎲( 2 points) and 50 ㎲(6 points)

10 ㎲(2 points) and 50 ㎲(6 points)

DRT / DT

Type Only

Weight (g) 520 540 660 850

5-3

Page 41

Chapter 5 Power Supply / CPU

5.2.2. Economic Type

Specifications

Items

K7M-DR10UE K7M-DR14UE K7M-DR20UE K7M-DR30UE

Program control method Cyclic execution of stored program, Time-driven interrupt, Process-driven interrupt

I/O control method Indirect mode(Refresh method), Direct by program command

Program language Instruction list, Ladder diagram

Numbers of instructions Basic : 30, Application : 269

Remarks

Processing speed

Program capacity 2ksteps

I/O points 10 14 20 30

P P000 ~ P63F I/O relay

M M000 ~ M191F Auxiliary relay

K K000 ~ K31F Keep relay

L L000 ~ L63F Link relay

F F000 ~ F63F Special relay

Memory

device

T

0.4µs/step

100msec : T000 ~ T191 (192 points)

10msec : T192 ~ T250 (59 points)

1msec : T251 ~ T255 (5 points)

-. Adjustable by parameter setting

Timer

C C000 ~ C255 Counter

S S00.00 ~ S99.99 Step controller

D D0000 ~ D4999 Data register

Operation modes RUN, STOP, PAUSE

Self-diagnosis functions Detects errors of scan time, memory, I/O and power supply

Data back-up method Latch area back-up

Up to 2 level

Max. expansion level

(External memory or RTC module can be connected as 3th expansion module)

5-4

Page 42

Chapter 5 Power Supply / CPU

(continued)

Items

Specifications

Remarks

K7M-DR10UE K7M-DR14UE K7M-DR20UE K7M-DR30UE

Built-in

Function

Cnet I/F Function

High-speed

counter

Pulse catch

External interrupt

Capacity

Counter

function

Additional

function

Dedicated protocol support

MODBUS protocol support RS-232C - 1port

User defined protocol support RS-485 - 1 port

No protocol support

1 phase : 10 kHz-2 channel

2 phase : 5 kHz-1 channel

4 different counter modes as following;

-. 1 phase operation mode.

-. 2 phase CW/CCW mode.

-. 1 phase Pulse + Direction mode.

-. 2 phase Multiplication mode(MUL4)

Internal/External preset function

Latch Counter function

RPM function

Comparison Output function

Minimum pulse width : 50 ㎲(4 points)

50 ㎲(4 points)

RS-485 is available

on K7M-DR10/14UE

only

Input filter 0 ~ 1000ms(Adjustable)

Weight (g) 360 370 500 510

5-5

Page 43

Chapter 5 Power Supply / CPU

A

5.3 Operation Processing

5.3.1 Operation Processing Method

1) Cyclic operation

A PLC program is sequentially executed from the first step to the last step, which is called scan. This sequential

processing is called cyclic operation. Cyclic operation of the PLC continues as long as conditions do not change

for interrupt processing during program execution. This processing is classified into the following stages:

Stages Processing

Operation Start

-

Initialization

Stage for the start of a scan processing. it is executed only one

time when the power is applied or reset is executed. It executes

the following processing..

▶ I/O reset

▶ Execution of self-diagnosis

▶ Data clear

llocating I/O address and type

▶

Input image area refresh

Input conditions are read and stored into the input image area

before starts processing.

Program operation processing

Program is sequentially executed from the first step to the last step

Program operation processing

Program starts

~

Program ends

Output image area refresh

The contents stored in the output image area is output to output part

when operation processing of a program is finished.

END processing

Stage for return processing after the CPU part has finished 1 scan.

The END processing following processing is executed.

▶ Self-diagnosis

▶ Change the present values of timer and counter, etc.

▶ Processing data communications between computer link module

and communications module.

▶ Checking the switch for mode setting.

5-6

Page 44

Chapter 5 Power Supply / CPU

r

r

2) Interrupt operation method

If a situation occurs which is requested to be urgently processed during execution of a PLC program, this opera

tion method processes immediately the operation, which corresponds to interrupt program. The signal, which infor

ms the CPU of those urgent conditions is called interrupt signal. The MASTER-K120S CPU has three kind of int

errupt operation methods, which are internal, external and high speed counter interrupt signal methods.

5.3.2 Operation Processing at Momentary Power Failure Occurrence

The momentary power failure occurs when the input line voltage to the power supply falls down below the rated

voltage. When momentary power failure within 10ms occurs, the CPU maintain operation processing. But If is exceeds

10ms, CPU stop processing and all output turns off. And The re-start process is executed as the power is re-applied.

1) Momentary power failure within 10 ms

Input powe

Momentary power failure

within 1Oms

2) Momentary power failure exceeding 10 ms

Input powe

Power failure exceeding 1Oms

→ The operation processing is maintained

→ The re-start process is executed as the power is re-applied.

REMARK

1) Momentary power failure

The PLC defining power failure is a state that the voltage of power has been lowered outside the allowable

variation range of it. The momentary power failure is a power failure of short interval (several to tens ms).

5-7

Page 45

Chapter 5 Power Supply / CPU

5.3.3 Scan Time

The processing time from a 0 step to the 0 step of next scan is called scan time.

1) Expression for scan time

Scan time is the sum of the processing time of scan program that the user has written, of the task program processing time

and the PLC internal processing time.

(1) Scan time = Scan program processing time + Interrupt program processing time + PLC internal processing time

• Scan program processing time = The processing time used to process a user program that is not specified

to a task program.

• Interrupt program processing time = Total of the processing times of interrupt programs executed during

one scan.

• PLC internal processing time = Self-diagnosis time + I/O refresh time + Internal data processing time

+ Communications service processing time

(2) Scan time differs in accordance with the execution or non-execution of interrupt programs and communications

processing, etc.

2) Flags

Scan time is stored in the following system flag area.

• F50 : Maximum scan time (unit: 1 ms)

• F51

: Minimum scan time (unit: 1 ms)

• F52 : Current scan time (unit: 1 ms)

5.3.4 Scan Watchdog Timer

1) Watchdog timer is used to detect a delay which is attributable to abnormal operation of sequence program

(Watchdog time is set in menu of basic parameter of KGLWIN.)

2) When watchdog timer detects an exceeding of preset watchdog time, the operation of PLC is stopped immediately

and all output is off.

3) If an exceeding of preset watchdog time is expected in sequence program, use ‘WDT’ instruction.

‘WDT’ instruction make elapsed watchdog time as zero.

4) In order to clear watchdog error, restarting the PLC or mode change to STOP mode are available.

REMARK

-. Setting range of watchdog : 10 ~ 6,000ms(unit : 10ms)

5-8

Page 46

Chapter 5 Power Supply / CPU

p

5.3.5 Timer Processing

The MASTER-K series use up count timer. There are 5 timer instructions such as on-delay (TON), off-delay (TOFF), integral

(TMR), monostable (TMON), and re-triggerable (TRTG) timer.

The measuring range of 100msec timer is 0.1 ~ 6553.5 seconds, 10msec timer is 0.01 ~ 655.35 seconds, and that of 1msec

timer is 0.001 ~ 65.53 seconds. Please refer to the ‘MASTER-K programming manual’ for details.

1) On delay timer

The current value of timer starts to increase from 0 when the input condition of TON instruction turns on. When the

Preset value

Timer output relay

Timer type

current value reaches the preset value, the timer output relay turns on.

When the timer input condition is turned off, the current value becomes 0 and the timer output relay is turned off.

input condition

Output relay

Pre value

t0

t0+PT

t1 t2 t3

t4

t5

t5 t4+PT

Current value

t0 t1

t2 t3 t4 t5

2) Off delay timer

The current value of timer set as preset value and the timer output relay is turned on when the input condition of TOFF

instruction turns on. When the input condition is turned off, the current value starts to decrease. The timer output relay is

turned off when the current value reaches 0.

Timer input condition

t0

t1

t2 t4

t3

t5

Timer out

Preset value

ut relay

PT

t5 + PT t1 + PT

PT

Current value

5-9

Page 47

Chapter 5 Power Supply / CPU

3) Integral timer

In general, its operation is same as on-delay timer. Only the difference is the current value will not be clear when the

input condition of TMR instruction is turned off. It keeps the elapsed value and restart to increase when the input

condition is turned on again. When the current value reaches preset value, the timer output relay is turned on.

The current value can be cleared by the RST instruction only.

Timer input condition

Timer output relay

Preset value

Current value

Timer reset input

t0 t1 t2

t0

t4

PT = (t1-t0)+(t3-t2)

t2

t1

t3

t5

t5

t5+PT

4)

Monostable timer

In general, its operation is same as off-delay timer. However, the change of input condition is ignored while the timer is

operating (decreasing). When current value reaches preset value the timer output relay is turned off and current value is

cleared.

Timer input condition

Timer output relay

Preset value

t0

t0

t0+PT

t1

t2

t3

t2

t2+PT

t4

t4

t4+PT

Current value

t0

t1

t2

t4

5 - 10

Page 48

Chapter 5 Power Supply / CPU

5) Retriggerable timer

The operation of retriggerable timer is same as that of monostable timer. Only difference is that the retriggerable timer is

not ignore the input condition of TRTG instruction while the timer is operating (decreasing). The current value of

retriggerable timer will be set as preset value whenever the input condition of TRTG instruction is turned on.

Timer input condition

Timer output relay

Preset value (PV)

Current value

PT

(On operation)

REMARK

The Maximum timing error of timers of MASTER-K series is ‘1 scan time + the time from 0 step to timer instruction’

5 - 11

Page 49

Chapter 5 Power Supply / CPU

5.3.6 Counter Processing

The counter counts the rising edges of pulses driving its input signal and counts once only when the input signal is switched

from off to on. MASTER-K series have 4 counter instructions such as CTU, CTD, CTUD, and CTR. The followings shows

brief information for counter operation. Refer to the ‘MASTER-K Instruction Manual’ for details.

1) Up counter (CTU)

-. The counter output relay is turned on when the current value reaches the preset value.

-. When the reset input is turned on, the counter output relay and current value is cleared as 0.

2) Down counter (CTD)

-. When the CPU is switched to the RUN mode, the current value is set as preset value.

-. The current value is decreased by 1 with the rising edge of counter input signal.

-. The counter output relay is turned on when the current value reaches 0.

3) Up-down counter

-. The current value is increased with the rising edge of up-count input signal, and decreased with the rising edge of

down-count input signal.

-. The counter output relay is turned on when the current value is equal or greater than the preset value otherwise off.

5 - 12

Page 50

Chapter 5 Power Supply / CPU

4) Ring counter

-. The current value is increased with the rising edge of the counter input signal, and the counter output relay is turned on

when the current value reaches the preset value. Then the current value and counter output relay is cleared as 0 when

the next counter input signal is applied.

5) Maximum counting speed

(1) The maximum counting speed of counter is determined by the length of scan time. Counting is possible only when the

on/off switching time of the counter input signal is longer than scan time.

)(C speed counting Maximum max

100

n

1

×=

times/sec)(

t

s

where, n : duty (%), ts : scan time

(2) Duty

Duty is the ratio of the input signal’s on time to off time as a percentage.

If T1 ≤ T2,

If T1 > T2,

T1 T2

OFF ON

T1

n (%100×

=

T2T1

+

T2

n (%100×

=

T2T1

+

OFF

)

)

5 - 13

Page 51

Chapter 5 Power Supply / CPU

g

5.4 Program

5.4.1 Classifications of Program

All functional elements need to execute a certain control process are called as a ‘program’. In MASTER-K120 series, a

program is stored in the EEPROM mounted on a CPU module or flash memory of a external memory module. The following

table shows the classification of the program.

Program type Description

Scan program The scan program is executed regularly in every scan

Time-driven interrupt

program (TDI)

Process driven interrupt

program (PDI)

High speed counter driven

interrupt program(HSCDI)

Subroutine program

The TDI programs are executed with a constant time interval specified with parameter settin

The PDI programs are executed when external interrupt input is applied and the corresponding

interrupt routine is enabled by EI instruction.

This interrupt programs are executed when comparison task signal is applied.

(Standard Type only)

The subroutine programs are executed when they are called by the scan program with a CALL

instruction.

5.4.2 Program Execution Procedure

The following diagram shows that how the CPU module process programs when the CPU module is powered on or switched to

RUN mode.

Start processing

.

Scan program

HSCDI program

END processing

5 - 14

Subroutine program

PDI program

TDI program

Page 52

Chapter 5 Power Supply / CPU

1) Scan program

-. The scan program is executed regularly in every scan from 0 step to last step.

-. When interrupts has occurred, CPU pauses scan program and executes corresponding interrupt program first.

-. When this interrupt program finished, scan program is to resume.

2) Interrupt program

-. When an interrupt occurs, the CPU module will stop the current operation and execute the corresponding interrupt routine

first. After finish the interrupt routine, the CPU resume the sequence program from the stopped step.

-. MASTER-K102S series provides 3 types of interrupt.

• The TDI (Time driven interrupt) occurs with the constant period

• The PDI (Process driven interrupt) occurs with the status of external input.

• The HSCDI(High speed counter driven interrupt) occur with comparison task signal from high speed counter.

(Standard type only)

5.4.3 Interrupt Programs

1) Usage of interrupt program

(1) Before to use interrupt function in sequence program, the parameter setting should be done properly. Then the

corresponding interrupt routine should be written after END instruction. (Refer chapter 4 for details) If interrupt routines

are not matched with parameter settings, an error occurs and the operation of CPU will be stopped.

(2) To execute an interrupt routine, use the EI instruction to enable the corresponding interrupt. The interrupt routine is not

executed if an interrupt factor occurs before execution of an EI instruction. Once an interrupt is enabled with EI

instruction.

(3) When multiple interrupt factors occur simultaneously, interrupt routines are executed according to the priority given to

the each interrupt. If an interrupt factor that has higher priority occurs while other interrupt that has lower priority are

executing, the interrupt routine of lower priority will be stopped and the interrupt of higher priority will be executed first.

Following figure show how CPU handles multiple interrupts

1

Program starts

2

2

Interrupt 2 occurs

Scan Program

1

Interrupt routine 1

Interrupt routine 2

7

5

3

6

3

Stop main program and execute interrupt routine 2

4

Interrupt 1 occurs (higher priority)

5

Stop routine 2 and run routine 1

6

Finish routine 1 and return to routine2

4

7

Finish routine 2 and return to main program

5 - 15

Page 53

Chapter 5 Power Supply / CPU

2) parameter setting

3) Time driven interrupt

TDI occurs periodically with the constant interval assigned in parameter setting. The interrupt routine of TDI starts with the

TDINT instruction and ends with the IRET instruction.

When multiple interrupt factors occur simultaneously, interrupt routines are executed according to the priority given to the

each interrupt. If an interrupt factor has higher priority occurs while other interrupt of lower priority is executing, the interrupt

routine of lower priority will be stopped and the interrupt of higher priority will be executed first. In standard types of MK120S

series, Available TDI is P000 ~ P007 (8 points) assigned in parameter setting and period can be designated for each other.

In economic types, Available TDI is P000 ~ P003 (4 points) .

4) Process driven interrupt

In standard types of MK120S series, Available PDI is P000 ~ P007 (8 points) assigned in parameter setting.

In the parameter setting window, TDINT indicates time driven interrupt and INT indicates process driven interrupt.

PDI occurs when the input status of P000 ~ P007 is changed from Off to On or from On to Off or both.

In economic types of MK120S series, Available PDI is P000 ~ P003 (4 points), and occurs when the input status of P000 ~

P003 is changed from Off to On. It isn’t occurs falling edge of input condition.

5) HSC driven interrupt

HSCDI occurs when comparison task of HSC occurs and Available HSCDI is Ch0 ~ Ch4 (4 points) .

5 - 16

Page 54

Chapter 5 Power Supply / CPU

REMARK

Total available interrupt points is 8(In standard type).

-. Time driven interrupt + process driven interrupt + high speed counter driven interrupt ≤ 8 points

Interrupt signal is ignored when self-interrupt occurs more than 2 times during interrupt processing is executing.

ignored

Interrupt executing time

Interrupt signal (ex : rising edge)

5.4.4 Error Handling

1) Error Classification

Errors occur due to various causes such as PLC system defect, system configuration fault or abnormal operation

result. Errors are classified into fatal error mode, which stops system operation for system stability, and ordinary

error mode, which continues system operation with informing the user of its error warning.

The main factors that occurs the PLC system error are given as followings.

• PLC hardware defect

• System configuration error

• Operation error during execution of the user programs

• External device malfunction

2) Operation mode at error occurrence

In case of error occurrence, the PLC system write the error contents the corresponding flags and stops or conti

nues its operation complying with its operation mode.

(1) PLC hardware defect

The system enters into the STOP state if a fatal error such as the CPU module defect has occurred, and

continues its operation if an ordinary error such as operation error has occurred.

(2) System configuration error

This error occurs when the PLC hardware configuration differs from the configuration defined in the

K120S series. The system enters into the STOP state.

(3) Operation error during execution of the user programs

It the numeric operation error of these errors occurs during execution of the user program, its contents are

marked on the error flags and the system continues its operation. If operation time overruns the watchdog

time or I/O modules loaded are not normally controlled, the system enters into the STOP state.

5 - 17

Page 55

Chapter 5 Power Supply / CPU

(4) External device malfunction

The PLC user program detects malfunctions of external devices. If a fatal error is detected the system ent

ers into the STOP state, and if an ordinary error is detected the system continues its operation.

REMARK

1) In occurrence of a error, the state is to be stored in the representative system error flag F006.

2) For details of flags, refer to Chapter 11. Troubleshooting.

5 - 18

Page 56

Chapter 5 Power Supply / CPU

t

5.5 Operation Modes

The CPU operates in one of the four modes - RUN, STOP, PAUSE and DEBUG mode. The following describes ope

ration processing in each operation mode.

5.5.1 RUN Mode