Leybold Phoenix Quadro, Phoenix Quadro DRY User Manual

PHOENIX Quadro

PHOENIX Quadro dry

Helium leak detector

Operating instructions

300700189_002_C1

Catalog Numbers

250000V02 (EU)

251000V02 (US)

251100V02 (JP)

250001V02 (dry, all countries)

Table of Contents LEYBOLD

ii PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

Table of Contents

1 About these instructions ...................................................................................................................................6

1.1 Target groups ...........................................................................................................................................6

1.2 Warnings...................................................................................................................................................6

2 Safety ...............................................................................................................................................................7

2.1 Intended use .............................................................................................................................................7

2.2 Owner requirements .................................................................................................................................7

2.3 Duties of the operator ...............................................................................................................................8

2.4 Dangers ....................................................................................................................................................8

3 Shipment, Transport, Storage ........................................................................................................................10

4 Description......................................................................................................................................................13

4.1 Function ..................................................................................................................................................13

4.2 Operation modes ....................................................................................................................................13

4.2.1 Operation mode “Vacuum”.......................................................................................................... 13

4.2.2 Operation mode “Sniffing”........................................................................................................... 13

4.3 Device setup ...........................................................................................................................................14

4.3.1 Overall device .............................................................................................................................14

4.3.2 Operating unit ............................................................................................................................. 15

4.3.2.1 START button ....................................................................................................................16

4.3.2.2 STOP button ......................................................................................................................16

4.3.2.3 ZERO button ......................................................................................................................17

4.3.2.4 Meaning of the button LEDs...............................................................................................17

4.3.2.5 Meaning of the status LED.................................................................................................18

4.3.2.6 Assembly of the touchscreen .............................................................................................19

4.3.3 Vacuum connections................................................................................................................... 20

4.3.3.1 Inlet ....................................................................................................................................20

4.3.3.2 Exhaust ..............................................................................................................................21

4.3.3.3 Connection for venting and purging/gas ballast .................................................................21

4.3.4 Connections for accessories and control signals........................................................................ 23

4.3.5 Markings on the device ...............................................................................................................24

4.4 Technical data ........................................................................................................................................24

5 Installation ......................................................................................................................................................27

5.1 Setup ......................................................................................................................................................27

5.2 For oil-sealed backing pumps, remove the plug .....................................................................................29

5.3 Connecting the leak detector to the power supply system .....................................................................29

5.4 Check the Operation of the Device.........................................................................................................30

6 Operation........................................................................................................................................................32

LEYBOLD Table of Contents

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) - © Leybold GmbH iii

6.1 Switch ON...............................................................................................................................................32

6.2 Basic settings..........................................................................................................................................32

6.2.1 Set language on the user interface .............................................................................................32

6.2.2 Setting date, time and time zone ................................................................................................ 33

6.2.3 User profile settings ....................................................................................................................33

6.2.3.1 Overview of Rights Groups ................................................................................................33

6.2.3.2 Select, modify, create user profile......................................................................................33

6.2.3.3 Modify Personal Settings ...................................................................................................34

6.2.4 Switch off Automatic Login.......................................................................................................... 35

6.2.5 Switch on Automatic Login.......................................................................................................... 35

6.2.6 Presentation of the measurement screen ...................................................................................36

6.2.6.1 Changing the presentation of the line graph ......................................................................36

6.2.6.2 Changing the presentation of the bar graph.......................................................................37

6.2.6.3 Change general display settings ........................................................................................37

6.2.7 Change units............................................................................................................................... 38

6.2.8 Change audio settings ................................................................................................................38

6.2.9 Change the protection settings ...................................................................................................39

6.2.10 Activate or deactivate maintenance requests .............................................................................41

6.2.11 Modify Other Settings ................................................................................................................. 41

6.3 Settings for the measurements...............................................................................................................42

6.3.1 Select operation mode ................................................................................................................42

6.3.2 Select gas ...................................................................................................................................42

6.3.3 Setting setpoints ......................................................................................................................... 42

6.3.4 Change vacuum settings ............................................................................................................ 43

6.3.5 Setting the machine factor ..........................................................................................................44

6.3.6 Set external calibration leak........................................................................................................ 45

6.3.7 Change pressure limits ...............................................................................................................45

6.3.8 Set and use the function ZERO ..................................................................................................46

6.3.9 Change leak rate filter................................................................................................................. 47

6.3.10 Change background suppression ...............................................................................................47

6.3.10.1 Determine the background of the inlet area .......................................................................48

6.3.11 Change the sniffer line pressure monitoring ...............................................................................48

6.3.12 Set and use external partial flow system .................................................................................... 49

6.3.13 Calibrating ................................................................................................................................... 50

6.3.13.1 Internal calibration..............................................................................................................50

6.3.13.2 External calibration.............................................................................................................51

6.4 Measuring ...............................................................................................................................................52

6.5 Measurement data..................................................................................................................................53

6.5.1 Configure data recording ............................................................................................................ 53

6.5.2 Configure and implement export................................................................................................. 53

6.5.3 Measurement data database: Information and delete function................................................... 54

6.6 Information..............................................................................................................................................55

6.6.1 Retrieve information about the device ........................................................................................ 55

6.6.2 Call information on the assemblies .............................................................................................55

Table of Contents LEYBOLD

iv PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

6.6.3 Information on connected accessories ....................................................................................... 55

6.6.4 Call the energy data information .................................................................................................55

6.6.5 Call the latest information to the current measurement value..................................................... 56

6.6.6 Call the latest information to the current calibration value ..........................................................56

6.7 Log..........................................................................................................................................................56

6.7.1 Call the error and warning log..................................................................................................... 56

6.7.2 Call the TMP log ......................................................................................................................... 56

6.7.3 Call calibration log....................................................................................................................... 56

6.7.4 Call maintenance log .................................................................................................................. 57

6.8 Device settings .......................................................................................................................................57

6.8.1 Viewing and customizing individual parameters .........................................................................57

6.8.2 Saving and managing sets of parameters .................................................................................. 57

6.8.3 Exporting or importing sets of parameters ..................................................................................58

6.9 Updating the software.............................................................................................................................59

6.9.1 Update the user interface software .............................................................................................59

6.9.2 Updating the software of the basic unit....................................................................................... 59

6.9.3 Update the software in expert mode ...........................................................................................60

6.10 Lock screen ............................................................................................................................................60

6.11 Use external monitor...............................................................................................................................60

6.12 View vacuum diagram ............................................................................................................................61

6.13 Resetting to factory settings ...................................................................................................................61

6.14 Logging off from the device ....................................................................................................................61

6.15 Switching off the device. .........................................................................................................................62

7 Warning and error messages .........................................................................................................................63

7.1 List of warning and error messages........................................................................................................63

8 Cleaning and maintenance.............................................................................................................................73

8.1 Cleaning the housing ..............................................................................................................................73

8.2 Change the filter mat of the fan input......................................................................................................73

8.3 Check oil-sealed backing pump..............................................................................................................73

8.4 Service at Leybold ..................................................................................................................................74

9 Decommissioning the measuring instrument..................................................................................................75

10 Accessories ....................................................................................................................................................76

10.1 Accessories and spare parts ..................................................................................................................76

10.2 I/O module ..............................................................................................................................................78

10.2.1 Create a connection between the device and the I/O module ....................................................78

10.2.2 Configuring digital outputs .......................................................................................................... 78

10.2.3 Configure digital inputs ............................................................................................................... 80

10.2.4 Configure analog outputs ............................................................................................................ 81

LEYBOLD Table of Contents

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) - © Leybold GmbH v

10.2.5 Setting up the I/O module protocol ............................................................................................. 83

10.3 Bus module.............................................................................................................................................83

10.3.1 Creating a connection between the device and the bus module ................................................ 83

10.4 Operate leak detector via web browser ..................................................................................................84

10.4.1 Configure the WiFi connection of the leak detector ....................................................................84

10.4.2 Set-up the WiFi connection in the notebook or tablet .................................................................85

11 Appendix......................................................................................................................................................... 86

11.1 Menu path...............................................................................................................................................86

11.1.1 Diagnosis ....................................................................................................................................86

11.1.2 Settings ....................................................................................................................................... 87

11.2 CE Declaration of Conformity .................................................................................................................89

Index...............................................................................................................................................................90

1 | About these instructions LEYBOLD

6 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

1 About these instructions

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification pur-

poses only and belong to the respective owner of the rights.

1.1 Target groups

This instruction manual is aimed at the operator of the device and at technically quali-

fied specialists, with experience in the field of leak testing technology.

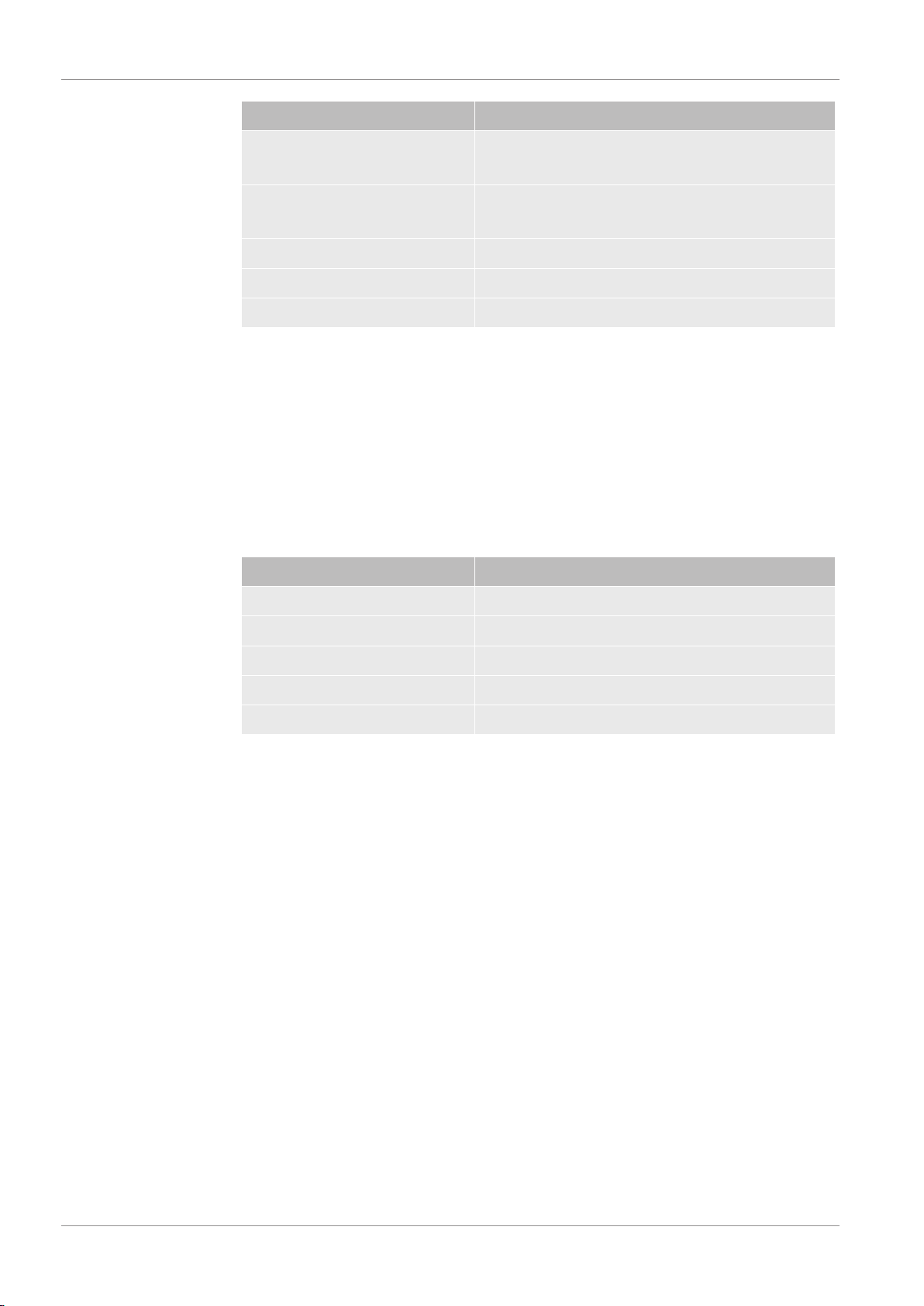

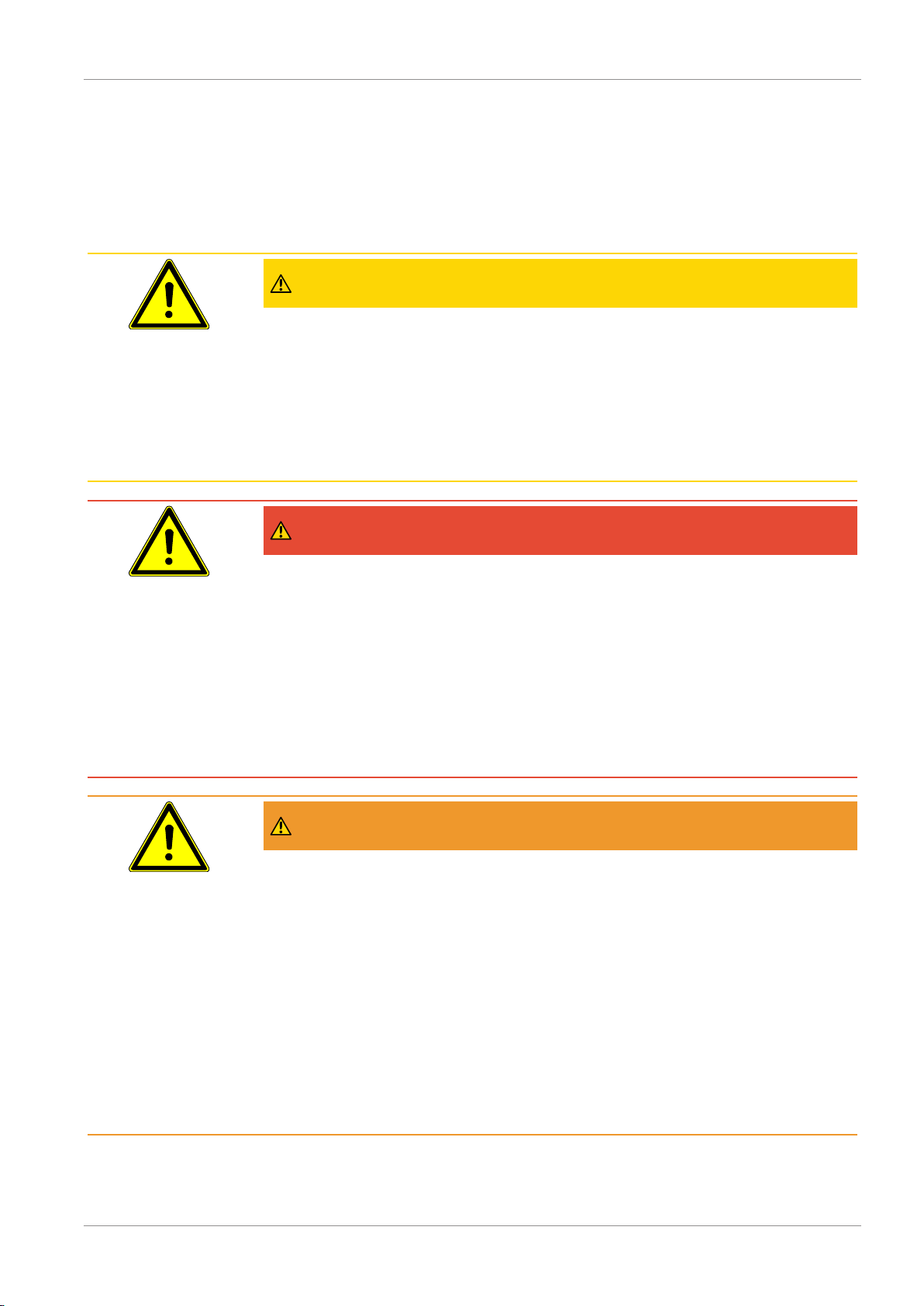

1.2 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

LEYBOLD Safety | 2

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 7 / 94

2 Safety

2.1 Intended use

The device is a leak detector for detecting and measuring leaks in test objects. The

device is suitable for leak testing as per the vacuum method and the sniffing method.

• Operate the device only according to this instruction manual.

• Comply with application limits, see "Technical Data".

Improper use

Avoid the following, non-intended uses:

• Use outside the technical specifications, see "Technical Data".

• Test of wet or damp test objects

• Pumping down of explosive, aggressive, corrosive, flammable, toxic or reactive

substances

• Pumping down of condensable fluids and vapors.

• Pumping of gases contaminated with particles

• Shock loads or vibrations

• Using the device in potentially explosive atmospheres.

• Scanning of mains power cables with a sniffing probe

• Sudden ventilation of vacuum systems

• Connect a test object that is not vacuum resistant

• Pumping out gases containing halogens such as fluorine or chlorine in high con-

centration or over a long period of time. Use with refrigerants or SF6.

• Operation without exhaust pipe for devices with oil-sealed backing pump

Note: This device is not intended to be used in residential areas.

2.2 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employee or third party.

Safety conscious oper-

ation

• Only use the device when it is technically in good order and condition.

• Only operate the device in accordance with this instruction manual, in a safety and

risk conscious manner.

• Adhere to the following regulations and observe their compliance:

– Intended use

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

2 | Safety LEYBOLD

8 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

Personnel qualifica-

tions

• Only instructed personnel should be permitted to work with and on the device. The

instructed personnel must have received training on the device.

• Make sure that authorized personnel have read and understood the operating in-

structions and all other applicable documents.

2.3 Duties of the operator

• Read, observe, and follow the information in this manual and in the work instruc-

tions provided by the owner. This concerns in particular the safety instructions and

warnings.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, please contact Customer Service.

2.4 Dangers

The measuring instrument was built according to the state-of-the-art and the recog-

nized safety regulations. Nevertheless, improper use may result in risk to life and limb

on the part of the user or third parties, or damage to the measuring instrument or other

property may occur.

Hazards due to liquids

and chemicals

Liquids and chemical substances can damage the instrument.

• Never try to find toxic, caustic, microbiological, explosive, radioactive or other

harmful substances with the device.

Dangers from electric

power

There is a danger to life from the contact of conductive parts inside the device.

• Disconnect the device from the power supply prior to any installation and mainte-

nance work. Make sure that the electric power supply cannot reconnected without

authorization.

The device contains electric components that can be damaged from high electric volt-

age.

• Before connecting the device to the power supply, make sure that the supply volt-

age specified on the device is the same as the local power supply.

Explosion hazard

Hydrogen is a flammable and explosive gas.

• Use only tracer gases with a concentration of hydrogen that cannot explode in

combination with oxygen. The allowable composition of venal gas mixtures can be

read in the safety data sheets of the respective manufacturers.

LEYBOLD Safety | 2

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 9 / 94

Risk of uncontrolled

movements as a result

of being frightened

When operating the device in "vacuum” operation mode there will be a negative pres-

sure created at the inlet flange.

If the inlet flange is not properly closed by a blank flange or connected to a test set,

the vacuum pull on your hands or limbs could be alarming or frightening.

Injury from bursting ob-

jects

There is risk of injury from bursting objects causes by a test object notwithstanding the

vacuum pressure when a test object is connected.

• Take appropriate precautions.

3 | Shipment, Transport, Storage LEYBOLD

10 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

3 Shipment, Transport, Storage

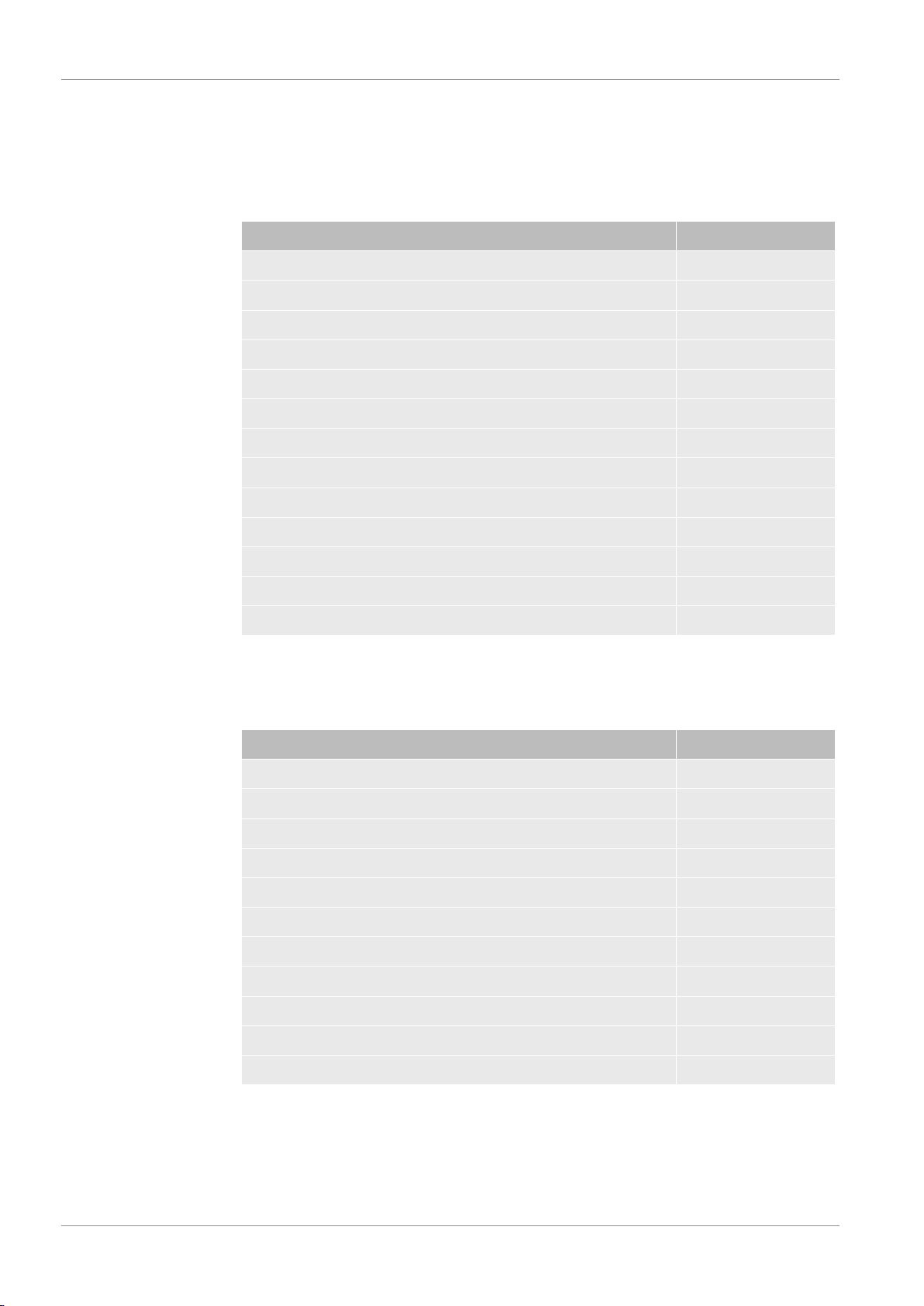

Scope of delivery

Device with oil-sealed backing pump (EU), catalog number 250000V02

Item Quantity

PHOENIX Quadro (EU) Leak detector 1

Power supply cable EU 1

Power supply cable UK 1

Blank flange DN25 KF 1

Clamping ring DN25 KF 1

Centering ring DN25 KF 1

Set of spare fuses 1

Plug for exhaust 1

Operating instructions (English) 1

Operating instructions (German) 1

Protocol Descriptions (English only) 1

Inspection certificate calibration leak 1

Inspection certificate leak detector 1

Device with oil-sealed backing pump (US), catalog number 251000V02

Item Quantity

PHOENIX Quadro (US) Leak detector 1

Power supply cable US 1

Blank flange DN25 KF 1

Clamping ring DN25 KF 1

Centering ring DN25 KF 1

Set of spare fuses 1

Plug for exhaust 1

Operating instructions (English) 1

Protocol Descriptions (English only) 1

Inspection certificate calibration leak 1

Inspection certificate leak detector 1

LEYBOLD Shipment, Transport, Storage | 3

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 11 / 94

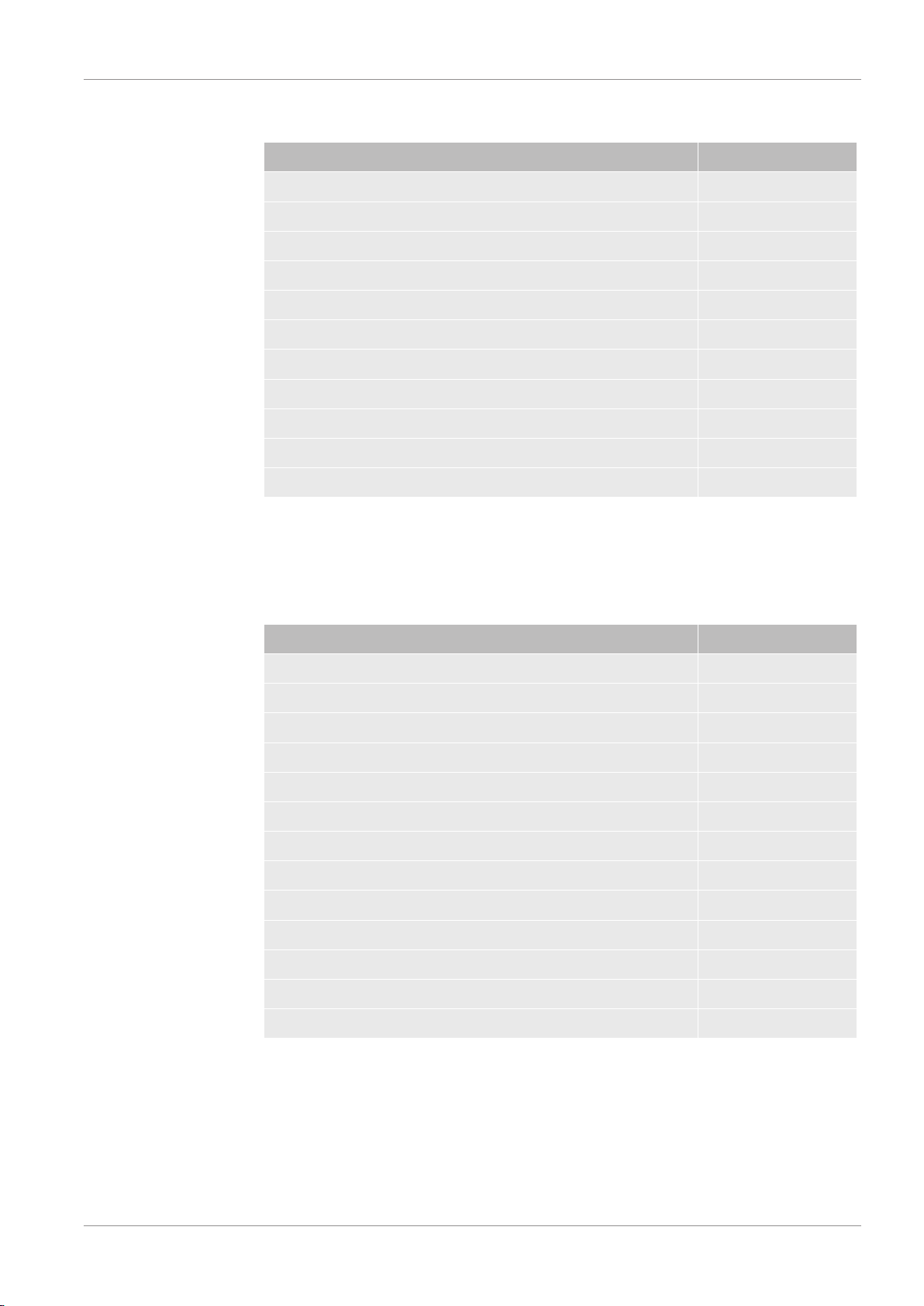

Device with oil-sealed backing pump (JP), catalog number 251100V02

Item Quantity

PHOENIX Quadro (JP) Leak detector 1

Power supply cable US 1

Blank flange DN25 KF 1

Clamping ring DN25 KF 1

Centering ring DN25 KF 1

Set of spare fuses 1

Plug for exhaust 1

Operating instructions (English) 1

Protocol Descriptions (English only) 1

Inspection certificate calibration leak 1

Inspection certificate leak detector 1

Device with dry backing pump (all countries), catalog number

250001V02

Item Quantity

PHOENIX Quadro dry Leak detector 1

Power supply cable US 1

Power supply cable EU 1

Power supply cable UK 1

Blank flange DN25 KF 1

Clamping ring DN25 KF 1

Centering ring DN25 KF 1

Set of spare fuses 1

Operating instructions (German) 1

Operating instructions (English) 1

Protocol Descriptions (English only) 1

Inspection certificate calibration leak 1

Inspection certificate leak detector 1

►

Check the delivery contents after receiving the product to ensure it is complete.

Transport

3 | Shipment, Transport, Storage LEYBOLD

12 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

WARNING

Danger of injury due to high tare weight

Transport of the unpacked device over a shorter distance

► Do not lift the device by the inlet flange.

► Lift and transport the device only in pairs.

► To lift, grasp the handle grips on the sides of the device.

NOTICE

Material damage if incorrect transport packaging is used

Transport over long distances

► Keep the original packaging.

► Only transport the device in its original packaging.

Storage

Store the device taking into consideration the specifications, see "Specifications".

See also

2 Technical data [}24]

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 13 / 94

4 Description

4.1 Function

The device is a leak detector for detecting and measuring leaks in test objects. The

device is suitable for leak testing using the vacuum method and the sniffer method.

• When using the vacuum method the test object is evacuated and subjected to He-

lium or forming gas from the outside. To do this it is necessary to establish a vac-

uum connection between the device and the test object.

• When using the sniffer method an over-pressure is established in the test object

using Helium or a forming gas. The test object is then inspected on the outside us-

ing a sniffer probe.

4.2 Operation modes

4.2.1 Operation mode “Vacuum”

The inlet flange is located on the upper side of the device.

You can mount a suitable external calibration leak on the inlet flange and perform an

external calibration, see also “External calibration [}51]“. Alternatively, you can per-

form an internal calibration, see also “Internal calibration [}50]“.

To be able to perform leak testing using the vacuum method the inlet flange must be

connected to the desired specimen.

If the pressure in the specimen is less than the surrounding pressure, then Helium

(which is sprayed over the specimen) can penetrate into the specimen if there is a

leak. Helium can be detected in the leak detector using a mass spectrometer.

4.2.2 Operation mode “Sniffing”

To be able to inspect test objects under overpressure with a sniffer line you can con-

nect the sniffer SL300.

SL300

The vacuum connection of the sniffer line SL300 is connected to the upper side of the

device on the inlet flange.

The electrical connection of the sniffer line SL300 is connected to the connector "AC-

CESSORIES" on the rear of the device, see "Connections for accessories and control

signals [}23]".

4 | Description LEYBOLD

14 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

4.3 Device setup

4.3.1 Overall device

Connection flange for test object

Operating unit

Fig.1:

Front view

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 15 / 94

Connections for accessories and control signals

Connection flange for test object

VENT / PURGE

Connection for power cable, power switch and fuses

Filter ventilator inlet

EXHAUST

Fig.2:

Back view

4.3.2 Operating unit

Fig.3:

Control unit - front view

The control unit consists of a touchscreen and a control panel with the buttons

START, STOP and ZERO (background suppression) on the housing.

See also "Assembly of the touchscreen [}19]", see also "START button [}16]".

The LED lighting of the buttons on the control panel changes its display color accord-

ing to the device state, see also "Meaning of the button LEDs [}17].

4 | Description LEYBOLD

16 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

The remote control RC310 is optionally available, see also "Accessories and spare

parts [}76].

You can also operate the device using a notebooks or tablets, see also "Operate leak

detector via web browser [}84]".

See also

2 Updating the software [}59]

2 Measurement data [}53]

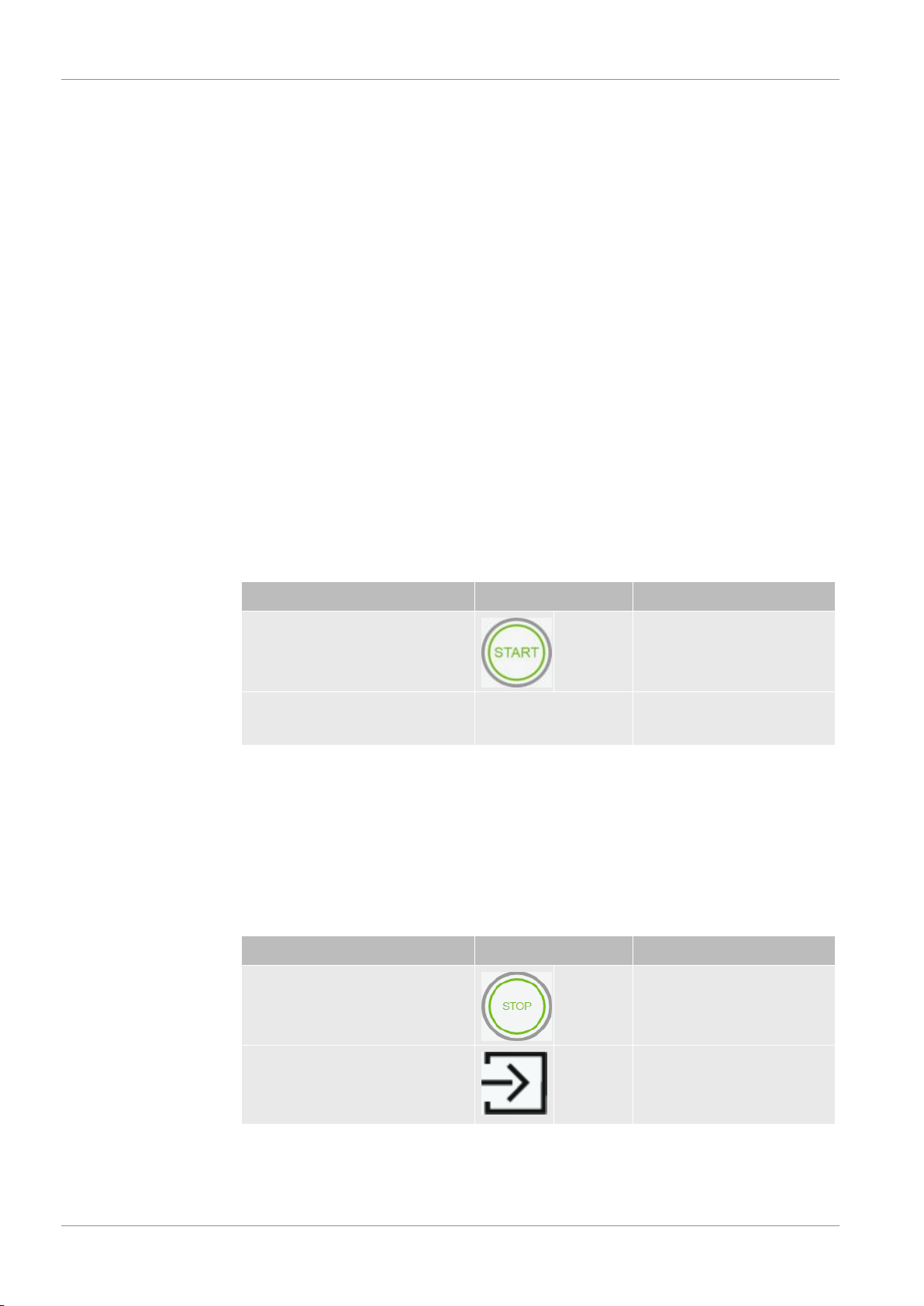

4.3.2.1 START button

• To start the measurements.

• Can be operated via touchscreen or on the control panel (Hardware button).

• If you press the START button on the control panel again during measurement,

the maximum leak rate (Q

max

) that has occurred since START is displayed. See

also “Assembly of the touchscreen [}19]“.

• If you press the START button on the control panel during measurement, the max-

imum leak rate display is updated.

Function Touchscreen Control panel

Starting START button

Display maximum leak rate Cannot be operated

via touchscreen

Press the START button

again.

4.3.2.2 STOP button

• To stop the measurements.

• Can be operated via the touchscreen of the control panel.

• Using the STOP button on the control panel you can do more than just stopping

the measurements but also perform ventilation.

Function Touchscreen Control panel

Stop STOP button

Vent Press the STOP button

again and keep it pressed

for approx. 2 seconds.

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 17 / 94

Function Touchscreen Control panel

(Prerequisite is the setting

“ventilation mode” “man-

ual”, see Change vacuum

settings [}43] “ “.)

4.3.2.3 ZERO button

• To hide the "Background signal", see also "Definition of terms”.

• Can be operated via the touchscreen of the control panel.

• Using the ZERO button you can switch ZERO on and off. For further details see

"Set and use the function ZERO [}46]”.

Function Touchscreen Control panel

Background suppression ON ZERO button

Background suppression OFF Press the ZERO button again and

keep it pressed for approx. 2 sec-

onds.

The actual measured leak rate is considered to be a background signal. Depending on

the selected variant of operation mode the background signal is hidden until the dis-

play limit of the respective vacuum range is reached.

After pressing the ZERO button, background suppression is automatically adjusted to

the course of the falling leak rate signal. As a result, the detection of leaks is possible

even with slowly falling signal.

Display limits according to factory setting:

1×10

-7

mbar l/s in GROSS

1×10

-10

mbar l/s in FINE

1×10

-12

mbar l/s in ULTRA

To switch-off the function ZERO again, press the button ZERO for about 2 seconds.

The function ZERO should be activated only if the leak rate signal is stable and no

leak is measured. See also “Set and use the function ZERO [}46]“.

See also

2 Change vacuum settings [}43]

4.3.2.4 Meaning of the button LEDs

START button LED STOP button LED Meaning

Off Flashing red No connection to the control unit

4 | Description LEYBOLD

18 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

START button LED STOP button LED Meaning

Pulsing blue Pulsing blue Run-up

Off Green Standby vented (Vent valve open)

Off Blue green Standby pumped out (Vent valve

close)

Pulsing green Off Pump down

Off Flashing green Internal calibration

Flashing green Off External calibration

Green Off Measuring

Yellow (warning, faulty

measurement possible)

Off Measuring with warning not ac-

knowledged

Off Red Error

Red Red Service mode is activated

ZERO button LED

Off No measurement operation

Off ZERO blocked

Blue ZERO OFF

Flashing blue ZERO blocked by SMART-ZERO

Green ZERO ON

Red Service mode is activated

4.3.2.5 Meaning of the status LED

The status LED is located on the back of the instrument inside of the connector block

for the equipment and control signals, see also Connections for accessories and con-

trol signals [}23].

Status LED Meaning

Flashing red No communication with operating unit

Flashing blue Run-up

Blue Standby

Flashing green Evacuate (pumping)

Flashing green Calibrating

Green Measuring

Yellow Measuring with warning not acknowl-

edged

Red Error

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 19 / 94

4.3.2.6 Assembly of the touchscreen

The display is a touchscreen.

The touchscreen responds to being touched lightly. To correctly select the chosen

function, avoid strong pressure.

You can always see symbols for the navigation on the display.

Additionally, you can see, depending on the context, other symbols and elements.

Operation

Information

Vacuum

access control

Settings

Diagnosis

Measuring mode

Operation mode

Gas

Time

Navigation button

Measurement value

Navigation button

Navigation button

Setpoints

Measurement value

ULTRA

Vacuum

Volume

Calibrating

ZERO ON

ZERO OFF

Measurement data recording

Switching:

Line graph

Bar graph

Helium

ULTRA

Inlet pressure

Navigation buttons

The buttons can appear in different grey tones:

• Hidden: Function inactive

• Light grey: Function can be activated

• Dark grey: Function is active

Settings

Operation

Diagnosis

Table1:

Navigation buttons

Function buttons

The buttons can appear in two different grey tones:

• Light grey: Function can be activated

• Dark grey: Function is active

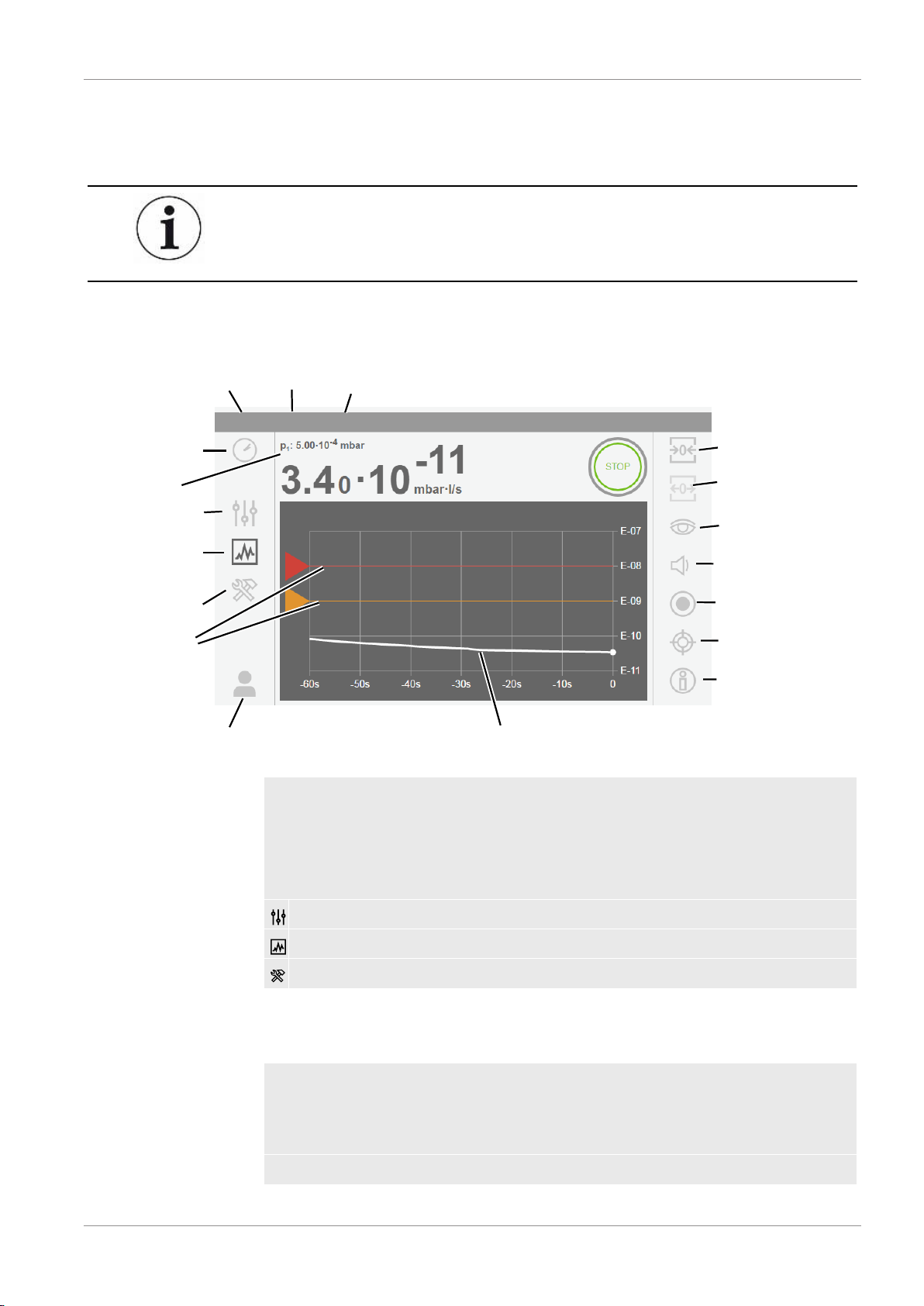

General function symbols

4 | Description LEYBOLD

20 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

Cancel ongoing function

Confirm entry or selection

Load

Save

Edit

Delete

Table2:

Function buttons

Other symbols

Authorization “User“

Authorization “Operator“

Authorization “Supervisor“

View the time or set the time

See also “Overview of Rights Groups [}33]“.

4.3.3 Vacuum connections

4.3.3.1 Inlet

The inlet is located on the upper part of the device. This is a DN 25 KF flange.

If you select the vacuum leak test mode, connect the test object or the vacuum cham-

ber onto the flange.

If you are testing applications where dust or dirt is accumulating, use the O-ring with

filter. In this case, the pump down times are extended.

Use the inlet for connecting the sniffer line SL300, too.

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 21 / 94

4.3.3.2 Exhaust

DANGER

Health risk due to exhaust fumes and vapors

Depending on the connected container and the gas it is holding hazardous gases can

enter the surrounding air via the exhaust of the leak detector.

If you have a device with an oil-sealed backing pump, dangerous combustion products

can arise, i.e. smoke, mist, sulfur oxide, aldehyde, and free carbon dioxide.

► Make sure you have protection measure to prevent inhaling hazardous gases.

► Connect an exhaust pipe at the exhaust, see also “Exhaust [}21]“.

User profile

1

2

EXHAUST

VENT

Fig.4:

Connections for exhaust, for venting and purging/gas ballast on the left of the device

1 EXHAUST: Exhaust 2 VENT: To vent the inlet. This connection can

be used also for purging/gas ballast.

At the left side of the device there is the an exhaust, see “Connections for accessories

and control signals [}23]“. This is a quick connection for hoses with an outside diam-

eter of 8 mm.

4.3.3.3 Connection for venting and purging/gas ballast

At the left side of the device there is the connection for venting and purging/gas bal-

last, next to “Exhaust [}21]“.

Via this connection the inlet is vented, the backing pump purged (when the backing

pump is wet: gas ballast) and the TMP vented when “power off”. This is a quick con-

nection for hoses with an outside diameter of 8 mm.

Vent

Normally, the specimens are ventilated with ambient air after completion of the test. If

necessary, the test specimens can be ventilated with a different gas (e.g., fresh air,

dry air, nitrogen, etc.) to a maximum of 1050 mbar pressure.

4 | Description LEYBOLD

22 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

Purging/gas ballast

To purge use a Helium free gas at atmospheric pressure. The surrounding air may be

contaminated with traces of Helium due to spraying or filling up large containers. In

such cases connect a gas supply line (this means Nitrogen or fresh air or similar) over

the purge gas connection. The pressure of the gas line should not be more than 1050

mbar.

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 23 / 94

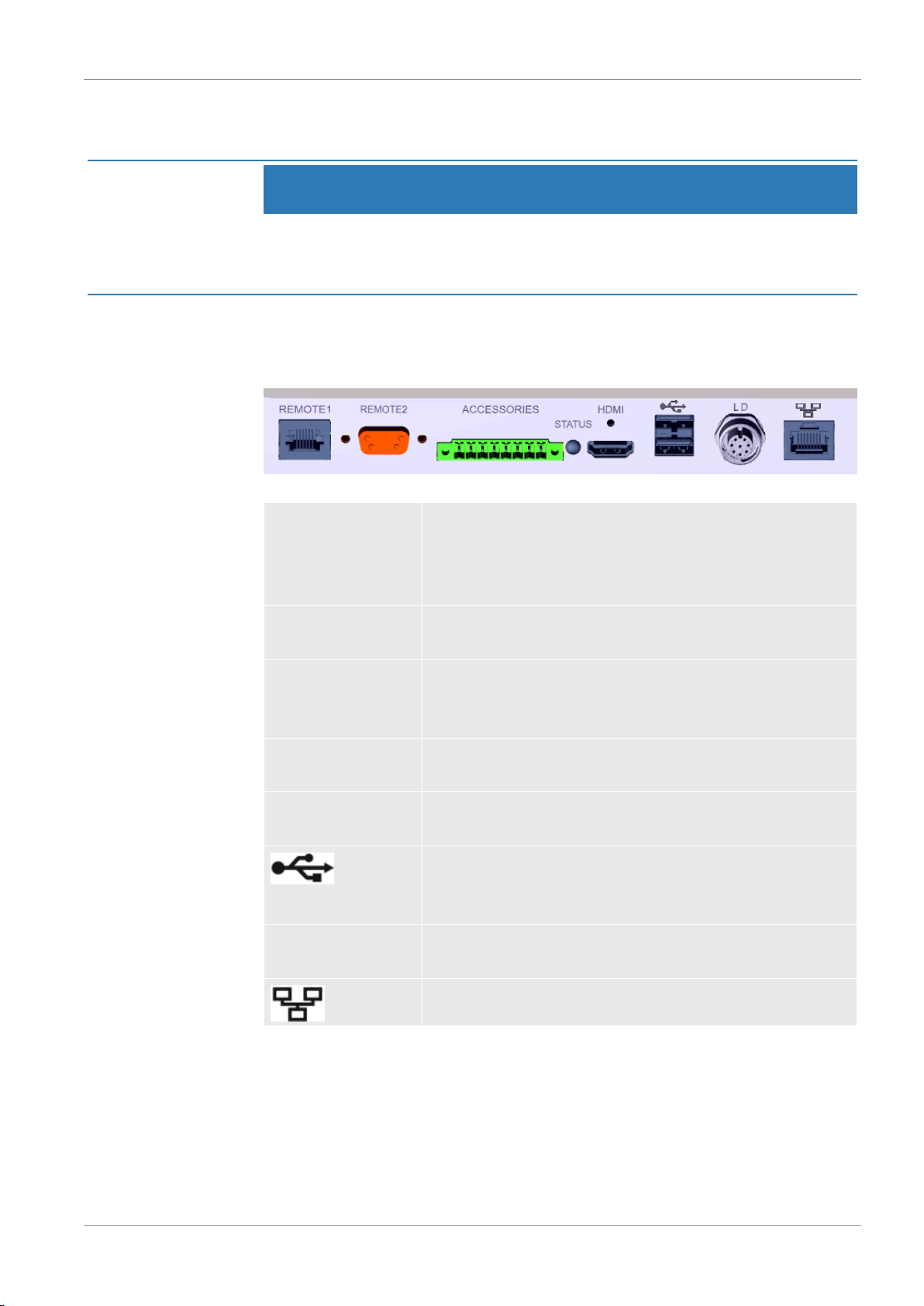

4.3.4 Connections for accessories and control signals

NOTICE

The electronics of the device can be destroyed.

► Only connect devices which are provided for the appropriate interfaces.

The connections for the external devices show a safe disconnection from the mains

and are within the range of the safety extra low voltage (SELV).

Fig.5:

Connections for accessories and control signals at the back side of the device.

REMOTE1

For connecting the remote control RC310C via cable, maxi-

mum length 28 m, or for direct connection of the radio trans-

mitter via an adapter. The remote control is not part of the

scope of delivery of the device.

REMOTE2

Enables the connection via radio transmitter for the radio

control via a special adapter.

ACCESSORIES

Electrical connection for sniffer line SL300 or partial flow sys-

tem. For partial flow system see also “Set and use external

partial flow system [}49]“.

STATUS

To display the status of the device, see also “Meaning of the

status LED [}18]“.

HDMI

For connection to the HDMI interface of a touch monitor,

maximum cable length 3 m.

2 USB connections. To transfer data and to perform updates

with an USB stick (FAT32-formatted). To connect a touch

monitor via USB cable.

LD

Connection for bus module or I/O module, maximum line

length 10 m

Network interface, maximum length 3 m

See also

2 Connection for venting and purging/gas ballast [}21]

2 Exhaust [}21]

2 Connecting the leak detector to the power supply system [}29]

4 | Description LEYBOLD

24 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

4.3.5 Markings on the device

Device cannot be scrapped with the normal domestic waste.

4.4 Technical data

Mechanical data

Device with oil-sealed backing pump, catalog numbers:

250000V02 (EU), 251000V02 (US), 251100V02 (JP)

PHOENIX Quadro

Dimensions (L×W×H) 495 mm x 318 mm x 475 mm

Weight 41 kg

Inlet flange test object DN 25 KF

Inlet flange prevacuum -

Device with dry backing pump, catalog number:

250001V02 (all countries)

PHOENIX Quadro dry

Dimensions (L×W×H) 495 mm x 318 mm x 475 mm

Weight 35 kg

Inlet flange test object DN 25 KF

Inlet flange prevacuum -

Electrical data

Device with oil-sealed backing pump, catalog numbers:

250000V02, 251000V02, 251100V02

PHOENIX Quadro

Main fuse 2 x 250 V T10 A

Max. power 640 VA

Power port for backing pump -

Supply voltage EU 220 – 240 V, 50 Hz

230 V, 60 Hz

Supply voltage US 110 -120 V, 60 Hz

LEYBOLD Description | 4

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 25 / 94

PHOENIX Quadro

Supply voltage JP 100 V, 50 / 60 Hz

Supply voltage multi-range

power unit

-

Ingress protection IP 30

Excess voltage category II

Electronic interfaces REMOTE1, REMOTE2, ACCESSORIES, HDMI,

USB, LD, Ethernet

Device with dry backing pump, catalog number:

250001V02

PHOENIX Quadro dry

Main fuse 2 x 250 V T10 A

Max. power 470 VA

Power port for backing pump -

Supply voltage EU -

Supply voltage US -

Supply voltage JP -

Supply voltage multi-range

power unit

100 - 240 V, 50 / 60 Hz

Ingress protection IP 30

Excess voltage category II

Electronic interfaces REMOTE1, REMOTE2, ACCESSORIES, HDMI,

USB, LD, Ethernet

Physical data

Catalog numbers:

250000V02, 251000V02, 251100V02, 250001V02

PHOENIX Quadro, PHOENIX Quadro dry

Minimum detectable helium leak

rate vacuum mode

5·10

-12

mbar l/s

Response time < 1 s

Maximum inlet pressure 15 mbar

Helium pumping speed ULTRA >3.1 l/s

Detectable masses

4

He, H

2

, mass 3

4 | Description LEYBOLD

26 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

PHOENIX Quadro, PHOENIX Quadro dry

Minimum detectable helium leak

rate sniffer mode

1·10

-9

mbar l/s *)

Gas flow through sniffer line

SL300

20 - 25 sccm

Measurement range 12 decades

Run-up time 110 s

Ion source 2 long lasting iridium cathodes

*) Under normal environmental conditions, the smallest detectable leak rate and leak

rate indication is after ZERO 1·10

-8

mbar l/s. In special devices, where the air helium is

removed, for example, by flooding with nitrogen, the minimum detectable leak rate can

be adjusted to 1·10

-9

mbar l/s. Please contact Leybold in this case.

Ambient conditions

Catalog numbers:

250000V02, 251000V02, 251100V02, 250001V02

PHOENIX Quadro, PHOENIX Quadro dry

Max. altitude above sea level 2000 m

Maximum relative humidity 80% at 30°C, linear decreasing to 50% at 40°C

Storage temperature - 10°C to +60°C

Operating temperature + 10°C … + 40 °C

Pollution degree 2

LEYBOLD Installation | 5

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 27 / 94

5 Installation

5.1 Setup

CAUTION

Risk of injury from lifting the heavy device

The device is heavy and can slip out of hand.

► Do not use the inlet flange to lift the device.

► Lift and transport the device only in pairs.

► To lift, grasp the handle grips on the sides of the device.

DANGER

Health risk due to exhaust fumes and vapors

Depending on the connected container and the gas it is holding hazardous gases can

enter the surrounding air via the exhaust of the leak detector.

If you have a device with an oil-sealed backing pump, dangerous combustion products

can arise, i.e. smoke, mist, sulfur oxide, aldehyde, and free carbon dioxide.

► Make sure you have protection measure to prevent inhaling hazardous gases.

► Connect an exhaust pipe at the exhaust, see also “Exhaust [}21]“.

WARNING

Danger from moisture and electricity

Moisture entering the device can lead to personal injury due to electric shocks as well

as damage to property due to short circuiting.

► Only operate the device in dry environments and only in buildings.

► Operate the device away from sources of liquid and moisture.

► Place the device where you can always reach the mains plug.

► Do not operate the device standing water and do not let even a drop of water or

other liquids on the device.

► Prevent the device from coming into contact with bases, acids and solvents.

5 | Installation LEYBOLD

28 / 94 PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801)

NOTICE

Material damage from overheated device

The device heats up during operation and can overheat without sufficient ventilation.

► Please note the technical specifications.

► Ensure sufficient ventilation, especially on the ventilation slots on the left and right

of the device: There should be free space in the front, to the rear and sides of the

unit of at least 10 cm.

► Keep heat sources away from the device.

NOTICE

Operating system can be attacked via USB or Ethernet

The Linux operating system used in the leak detector is not updated automatically and

can therefore contain security gaps. This vulnerability may be exploited through the

Ethernet and USB interfaces of the leak detector to provide unauthorized access to

the system.

► Ensure that no unauthorized person has access to these interfaces, for example

through a USB port / Ethernet port lock.

► In order not to jeopardize the security of your company network, never connect the

leak detector directly to the public Internet. This is true for connections over WLAN

as well as over Ethernet.

► However, if you want to access the web interface of the leak detector remotely, we

recommend an encrypted Virtual Private Network (VPN) connection. However, we

cannot assume any guarantee for the security of VPN connections, which are pro-

vided by third parties.

Prevention of measurement errors due to leaks in the Helium source in the de-

vice surroundings

We recommend that you regularly check around the device to a distance of 10 m all

large Helium sources for gross leaks. Use a sniffer line to do this.

LEYBOLD Installation | 5

PHOENIX-Quadro-Operating-instructions-300700189_002_C1-(1801) 29 / 94

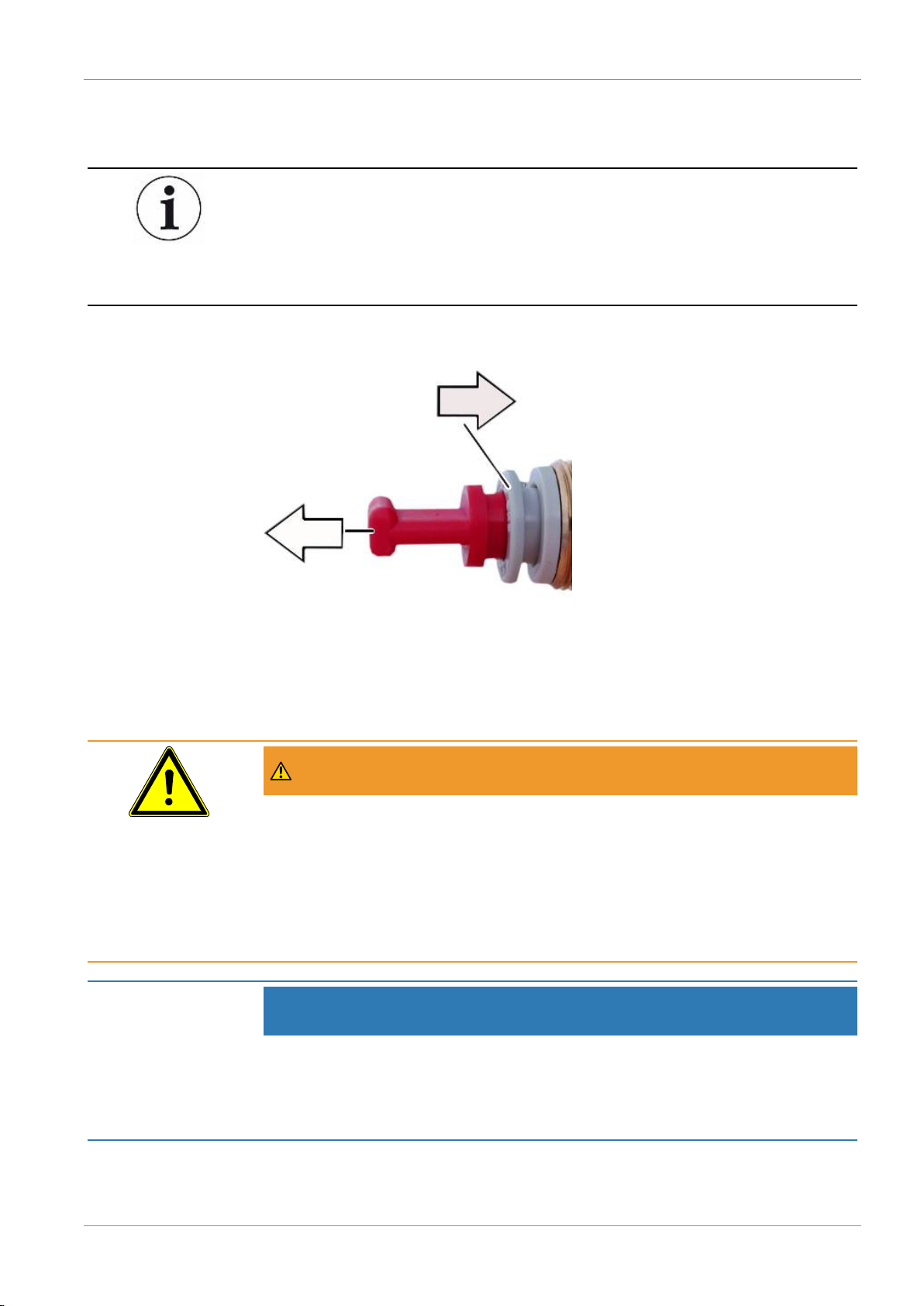

5.2 For oil-sealed backing pumps, remove the plug

Malfunction of the pump system with inserted plug in the exhaust line

On devices with oil-sealed backing pump, the exhaust is protected by a plug against

leaking oil.

► For devices with oil-sealed backing pump, remove the plug before switching it on.

►

To remove the plug press the release ring in the direction of the device so that the

locking device releases. Pull the plug out while release ring is pressed.

5.3 Connecting the leak detector to the power

supply system

WARNING

Danger from electric shock

Improperly earthed or protected products may be dangerous to life in case of a fault.

The use of the device is not permitted without a connected protective conductor.

► Only use the included 3-wire power cable.

► Make sure that the mains plug is always accessible.

NOTICE

Damage through wrong power supply

► Only connect the device to the power supply when the tension shown on the type

plate corresponds to the one of your power supply connection.

Loading...

Loading...