Page 1

W820

User’s Guide

April 2001

www.lexmark.com

Page 2

Page 3

Table of Contents

Chapter 1: Printer overview .............................................................. 7

Chapter 2: Sending a job to print .....................................................9

Chapter 3: Canceling a print job ....................................................10

From the printer operator panel ......................................................................... 10

From a computer running Windows ................................................................... 10

From a Macintosh computer .............................................................................. 11

Chapter 4: Conserving supplies ....................................................12

Chapter 5: Using the Print and Hold function ..............................13

Selecting a user name ....................................................................................... 13

Printing and deleting held jobs ........................................................................... 13

Repeat Print ....................................................................................................... 14

Reserve Print ..................................................................................................... 15

Verify Print .......................................................................................................... 15

Confidential jobs ................................................................................................. 15

Chapter 6: Printing a confidential job ...........................................17

Chapter 7: Print media specifications ...........................................18

Chapter 8: Loading the trays ..........................................................23

Loading trays 1, 2, and 3 .................................................................................... 23

Loading trays 4 and 5 ......................................................................................... 27

Chapter 9: Linking trays ................................................................. 30

Chapter 10: Loading the multipurpose feeder .............................. 31

Chapter 11: Loading the envelope feeder .....................................34

i

Page 4

Chapter 12: Using the output bins .................................................37

Standard bin ....................................................................................................... 37

Mailbox bins ....................................................................................................... 38

Finisher bins ....................................................................................................... 38

Chapter 13: Linking bins ................................................................39

Chapter 14: Finishing capabilities .................................................40

Stapling .............................................................................................................. 40

Finishing and bin linking ..................................................................................... 41

Hole punching .................................................................................................... 41

Chapter 15: Tips for successful printing ......................................42

Storing print media ............................................................................................. 42

Avoiding jams ..................................................................................................... 42

Chapter 16: Checking an unresponsive printer ...........................44

Chapter 17: Solving print quality problems ..................................45

Chapter 18: Solving paper feed problems ....................................52

Chapter 19: Solving other printing problems ............................... 54

Chapter 20: Solving mailbox problems ......................................... 57

Chapter 21: Solving finisher problems ......................................... 58

Chapter 22: Solving other option problems .................................61

Chapter 23: Calling for service ......................................................62

Chapter 24: Clearing print media jams ..........................................63

Understanding jam messages ............................................................................ 63

Locating jams with messages ............................................................................ 68

Clearing jams from the printer ............................................................................ 71

Clearing jams from the optional duplex unit ....................................................... 84

Clearing jams from the optional envelope feeder ............................................... 86

Clearing jams from the optional mailbox ............................................................ 87

ii

Page 5

Clearing jams from the optional finisher ............................................................. 90

Chapter 25: Clearing staple jams ................................................... 99

Chapter 26: Ordering supplies and maintenance items ........... 102

Chapter 27: Replacing the print cartridge ...................................103

Removing the old print cartridge ...................................................................... 103

Installing the new print cartridge ...................................................................... 105

Chapter 28: Cleaning the printer ..................................................109

Chapter 29: Replacing a staple cartridge ....................................110

Chapter 30: Emptying the hole punch box ................................. 113

Chapter 31: Replacing the items in the maintenance kit ........... 115

Chapter 32: Replacing the fuser ..................................................116

Removing the old fuser .................................................................................... 116

Installing a new fuser ....................................................................................... 119

Chapter 33: Replacing the transfer roller ....................................122

Removing the old transfer roller ....................................................................... 122

Installing the new transfer roller ....................................................................... 124

Chapter 34: Replacing pick rollers ..............................................126

Removing old pick rollers ................................................................................. 126

Installing new pick rollers ................................................................................. 128

Closing up ........................................................................................................ 131

Chapter 35: Cleaning the wiper blade .........................................132

Chapter 36: Resetting the maintenance page counter .............. 135

Chapter 37: Determining the status of supplies .........................136

Chapter 38: Storing supplies ....................................................... 137

Chapter 39: Recycling used supplies ..........................................138

iii

Page 6

Chapter 40: Priming the stapler ...................................................139

Chapter 41: Understanding the printer operator panel ............. 140

Chapter 42: Configuring printer alerts ........................................142

Chapter 43: Removing the multipurpose feeder ........................ 143

Chapter 44: Removing the optional envelope feeder ................ 144

Reinstalling the envelope feeder ...................................................................... 145

Chapter 45: Removing the optional duplex unit .........................146

Chapter 46: Removing the optional mailbox .............................. 149

Preparing for disassembly ................................................................................ 149

Disconnecting the power cords ........................................................................ 149

Using the handling tool ..................................................................................... 150

Removing the mailbox from the printer and stand ........................................... 153

Removing the mailbox stand ............................................................................ 155

Chapter 47: Removing the optional finisher ...............................159

Preparing for disassembly ................................................................................ 159

Removing the bins ........................................................................................... 159

Disconnecting the finisher from the printer ....................................................... 160

Removing the finisher from the stand .............................................................. 163

Removing the divertor cover ............................................................................ 164

Removing the transport unit ............................................................................. 165

Disassembling the stand .................................................................................. 166

Removing the finisher plate .............................................................................. 167

Chapter 48: Reinstalling the stacking arm ..................................168

Chapter 49: Removing the optional high capacity feeder .........170

Chapter 50: Removing the printer from the base cabinet .........172

Chapter 51: Removing memory and option cards ..................... 173

Accessing the printer system board ................................................................. 173

Removing memory cards ................................................................................. 173

iv

Page 7

Removing option cards .................................................................................... 174

Removing an optional firmware card ................................................................ 176

Reinstalling the printer system board ............................................................... 177

Chapter 52: Disabling the operator panel menus ......................178

Enabling the menus ......................................................................................... 178

Chapter 53: Disabling Power Saver ............................................. 179

Chapter 54: Disabling Size Sensing ............................................180

Enabling auto size sensing .............................................................................. 180

Chapter 55: Sensing special print media sizes .......................... 181

Changing the size that is sensed ..................................................................... 182

Size sensing and tray linking ............................................................................ 182

Chapter 56: Printing a menu settings page ................................ 183

Chapter 57: Restoring factory default settings .......................... 184

Chapter 58: Changing menu settings ..........................................185

Chapter 59: Understanding fonts ................................................186

Bitmapped and scalable fonts .......................................................................... 187

Resident fonts .................................................................................................. 188

Symbol sets ...................................................................................................... 193

Downloadable fonts .......................................................................................... 194

Chapter 60: Printing sample fonts ...............................................195

Chapter 61: Using printer menus .................................................196

Chapter 62: Paper Menu ............................................................... 199

Chapter 63: Finishing Menu ......................................................... 208

Chapter 64: Utilities Menu ............................................................ 215

Chapter 65: Job Menu ...................................................................220

v

Page 8

Chapter 66: Quality Menu .............................................................224

Chapter 67: Setup Menu ............................................................... 226

Chapter 68: PCL Emul Menu ........................................................ 234

Chapter 69: PostScript Menu .......................................................240

Chapter 70: Parallel Menu ............................................................241

Chapter 71: Serial Menu ...............................................................246

Chapter 72: Network Menu ...........................................................252

Chapter 73: Infrared Menu ............................................................ 256

Chapter 74: LocalTalk Menu .........................................................261

Chapter 75: USB Menu .................................................................. 265

Chapter 76: Understanding printer messages ...........................268

Notices ............................................................................................ 314

Trademarks ...................................................................................................... 316

Licensing notice ............................................................................................... 317

Safety information ............................................................................................ 317

Cautions and warnings ..................................................................................... 318

Electronic emission notices .............................................................................. 318

German acoustics statement ........................................................................... 321

Energy Star ...................................................................................................... 321

Laser notice ...................................................................................................... 322

Index ................................................................................................323

vi

Page 9

1

Printer overview

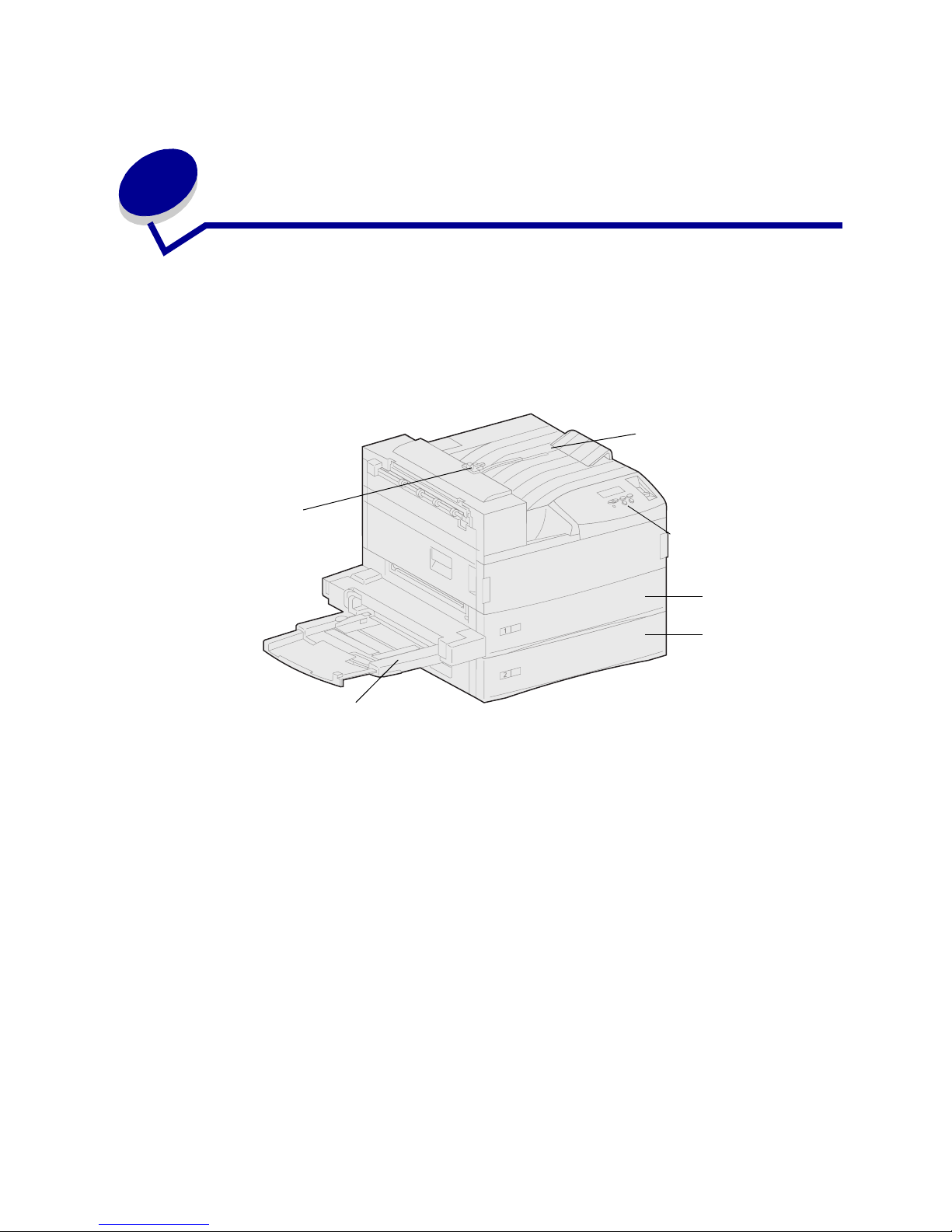

Standard printer

The following illustration shows the standard Lexmark W820. If you have attached paper handling

options to your printer, it may look more like one of the fully configured models shown on the following

pages.

Standard bin

Stacking arm

Operator panel

Tr ay 1

Tr ay 2

Multipurpose feeder

Note: This illustration shows the stacking arm. It is also shown in the Reinstalling the

stacking arm topic, but it is not shown in other topics.

7

Page 10

Fully configured printer with a mailbox

The following illustration shows the printer configured with an optional mailbox, duplex unit, and high

capacity feeder.

Optional mailbox

Optional duplex unit

Optional high

capacity feeder

(trays 3, 4, and 5)

Fully configured printer with a finisher

The following illustration shows the printer configured with an optional finisher, duplex unit, envelope

feeder, and high capacity feeder.

Finisher top cover

Transport unit and

transport unit cover

Bin 1

Finisher divertor

cover

Optional

duplex unit

Optional envelope

feeder

Bin 2

Finisher door

Finisher stand

8

Page 11

2

Sending a job to print

A

printer driver

Print from a software application, a window representing the printer driver opens. Select the

appropriate settings for the specific job you are sending to print. Print settings selected from the driver

override the default settings selected from the printer operator panel.

You may need to click Properties or Setup from the initial Print box to see all of the available printer

settings you can change. If you are not familiar with a feature in the printer driver window, open the

online Help for more information.

To support all the printer features, use the Lexmark custom printer drivers. Updated drivers, as well as

a complete description of the driver packages and Lexmark driver support, are available from the

Lexmark Web site. You can also use the system drivers built into your operating system. Refer to the

Setup Guide

To print a job from a typical Windows application:

1 Open the file you want to print.

2 From the File menu, select Print.

is software that lets your computer communicate with your printer. When you choose

for more information about choosing and installing drivers.

3 Verify that the correct printer is selected in the dialog box. Modify the printer settings as

appropriate (such as the pages you want to print or the number of copies).

4 Click Properties or Setup to adjust printer settings not available from the first screen, then click

OK.

5 Click OK or Print to send the job to the selected printer.

9

Page 12

3

Canceling a print job

From the printer operator panel

If the job you want to cancel is printing, and Busy appears on the display:

1 Press Menu to open the Job Menu.

Cancel Job appears on the second line of the display.

2 Press Select.

The message Canceling Job is displayed.

From a computer running Windows

Canceling a job from the taskbar

When you send a job to print, a small printer icon appears in the right corner of the taskbar.

1 Double-click the printer icon.

A list of print jobs appears in the printer window.

2 Selectthejobyouwanttocancel.

3 Press the Delete key on the keyboard.

Canceling a job from the desktop

1 Minimize all programs to reveal the desktop.

2 Double-click the My Computer icon.

3 Double-click the Printers icon.

A list of available printers appears.

4 Double-click the printer you selected when you sent the job.

A list of print jobs appears in the printer window.

5 Selectthejobyouwanttocancel.

6 Press the Delete key on the keyboard.

10

Page 13

From a Macintosh computer

When you send a job to print, the printer icon for your selected printer appears on the desktop.

1 Double-click the printer icon on your desktop.

A list of print jobs appears in the printer window.

2 Press Control and click the print job you want to cancel.

3 Select Stop Queue from the pop-up menu that appears.

11

Page 14

4

Conserving supplies

Several settings in your application software or on the display let you conserve toner and paper:

For more information,

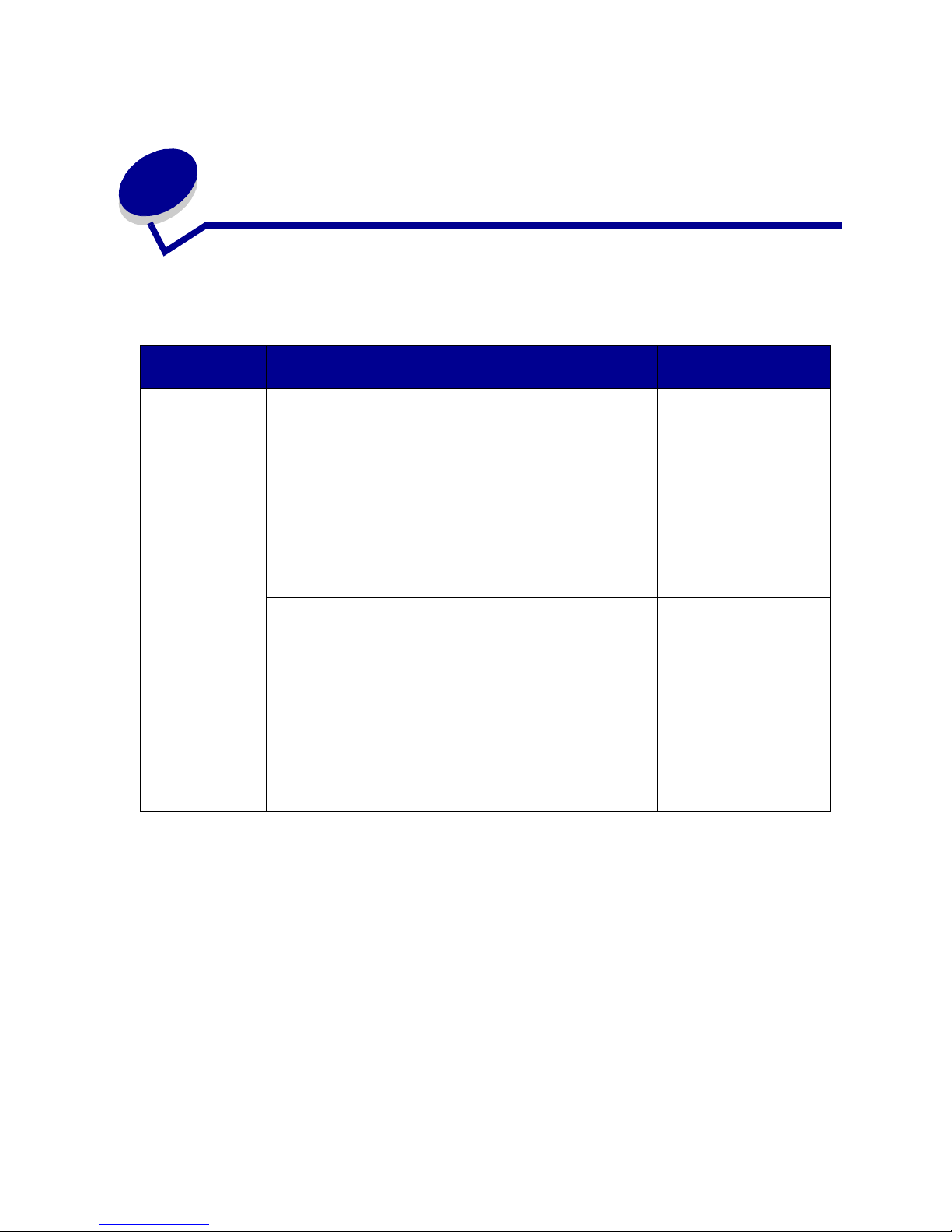

Supply Setting What the setting does

Toner Toner Darkness in

the Quality Menu

Lets you adjust the level of toner

released on a sheet of print media. The

values range from 1 (lightest setting) to

10 (darkest setting).

see ...

Toner Darkness

Print media Multipage Print in

the Finishing

Menu

Duplex in the

Finishing Menu

Print media Use your software

application or

printer driver to

send a Verify Print

job.

Use Held Jobs in

the Job Menu to

access your Verify

Print job.

Causes the printer to print the two or

more page images on one side of a

sheet. Values for Multipage Print are 2

Up, 3 Up, 4 Up, 6 Up, 9 Up, 12 Up, and

16 Up. Combined with the duplex setting,

Multipage Print lets you print up to 32

pages on one sheet of paper (16 images

onthefrontand16ontheback).

Duplex printing is available when you

attach the optional duplex unit. It lets you

print on both sides of a sheet of paper.

Lets you examine the first copy of a

multiple-copy job to be sure it is

satisfactory before you print the other

copies. If the job is unsatisfactory, you

cancel the job.

Multipage Print

Duplex

Verify Print

Canceling a print job

Held Jobs

12

Page 15

5

Using the Print and Hold function

When sending a job to the printer, you can specify in the driver that you want the printer to hold the job

in memory and not print it immediately. When you are ready to print the job, use the printer operator

held

panel menus to identify which

panel for information on using the operator panel.) You can use this function to delay printing a job,

verify one copy before printing additional copies, request extra copies of a job at a later time, or print a

confidential job when you can be at the printer to retrieve it.

For more information about each of the four types of held jobs, click a topic:

• Repeat Print

• Reserve Print

• Verify Print

• Confidential jobs

Selecting a user name

job you want to print. (See Understanding the printer operator

All confidential and held Jobs have a user name associated with them. To access all Held Jobs or

Confidential Jobs, you must first select your user name from a list of user names for print jobs. When

the list is presented, press

for your job.

Menu to scroll through the list. Press Select once you find your user name

Printing and deleting held jobs

Once held jobs are stored in printer memory, you can use the operator panel to specify what you want

to do with one or more of the jobs. From the Job Menu, you can select either Confidential Job or Held

Jobs (Repeat Print, Reserve Print, and Verify Print jobs). Then, you select your user name from a list.

If you select Confidential Job, you must then enter the personal identification number (PIN) you

specified in the driver when you sent the job. (See Confidential jobs for more information.)

From either the Confidential Job or the Held Jobs menu items, you have five choices:

• Print All Jobs

• Print A Job

• Delete All Jobs

• Delete A Job

• Print Copies

13

Page 16

To access held jobs from the operator panel:

1 Press Menu until you see Job Menu:

– If the printer displays the Busy message, press Menu to open the Job Menu.

– If the printer displays the Ready message, press Menu once to find Confidential Job or

Held Jobs (depending on the type of job you sent) on the second line of the display. Press

Select.

Note: If you sent both types of jobs, press Menu to scroll forward to Held Jobs if you want

to access this type first. Then, press

A list of user names and associated print jobs is presented.

Select.

2 Press Menu until you see your user name in the list, and then press Select.

Note: If you are looking for a confidential job, you are prompted to enter your PIN. See

Confidential jobs for more information.

3 Press Menu until you see the action you want to take (Print A Job, Delete A Job, and so on),

and then press

Select.

4 Press Menu until you see your print job, and then press Select. An asterisk (*) appears next to

the job name indicating you have chosen to print or delete that job.

If you are prompted to enter the number of copies you want to print, press

decrease the number on the display. Press

Select.

Menu to increase or

5 Press Go to print or delete the jobs you have selected.

The printer briefly shows messages indicating what Print and Hold functions it is performing,

and then returns to the Ready message.

Recognizing when format errors occur

If the symbol appears on the operator panel display, it indicates that the printer had trouble

formatting one or more of the held jobs. These formatting problems are most commonly the result of

insufficient printer memory or invalid data that might cause the printer to flush the job.

When a symbol appears next to a held job, you can:

• Print the job. However, only part of the job may print.

• Delete the job. You may want to free up additional printer memory by scrolling through the list

of held jobs and deleting others you have sent to the printer.

Repeat Print

If you send a Repeat Print job, the printer prints all requested copies of the job

memory so you can print additional copies later.

and

stores the job in

Note: Repeat Print jobs are automatically deleted from printer memory when the printer

requires extra memory to process additional jobs.

14

Page 17

Reserve Print

If you send a Reserve Print job, the printer stores the job in memory so you can print the job later. The

job is held in memory until you delete it from the Held Jobs menu. Unlike Repeat Print jobs, Reserve

Print jobs are not automatically deleted if the printer requires extra memory to process additional jobs.

See Printing and deleting held jobs for more information on Reserve Print jobs.

Verify Print

If you send a Verify Print job, the printer prints one copy and holds the remaining copies in printer

memory. Use Verify Print to examine the first copy to see if it is satisfactory before printing the

remaining copies.

See Printing and deleting held jobs if you need help printing the additional copies stored in memory.

Note: Once all copies are printed, the Verify Print job is deleted from printer memory.

Confidential jobs

When you send a job to the printer, you can enter a personal identification number (PIN) from the

driver. The PIN must be four digits using the numbers 1–6. The job is held in printer memory until you

enter the same four-digit PIN from the operator panel and choose to print or delete the job. This

ensures that the job does not print until you are there to retrieve it, and no one else using the printer

can print the job.

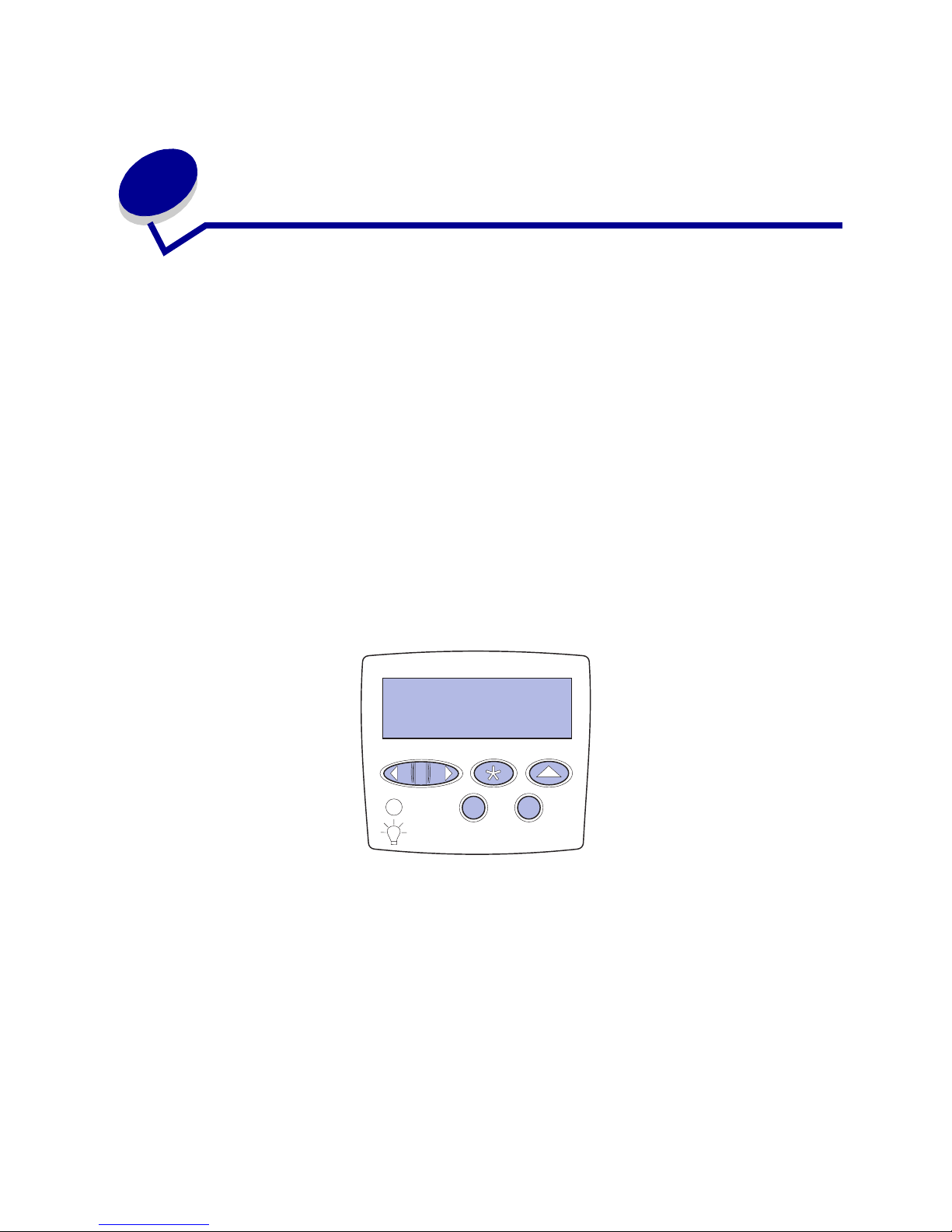

Entering a personal identification number (PIN)

When you select Confidential Job from the Job Menu, the following prompt appears on the display

after you select your user name:

Enter PIN:

=____

Use the buttons on the operator panel to enter the four-digit PIN associated with your confidential job.

The numbers next to the button names identify which button to press for each digit (1–6). As you enter

the PIN, asterisks appear on the display to ensure confidentiality

Enter PIN

=****

1

Menu

2

Select3Return

5

Go

Stop

4

6

15

Page 18

If you enter an invalid PIN, the message No Jobs Found. Retry? appears. Press Go to reenter the

PIN, or press

Stop to exit the Confidential Job menu.

Once you enter a valid PIN, you can choose to print or delete jobs matching the PIN you entered. (See

Printinganddeletingheldjobsfor more information.) After printing all requested copies of the job,

the printer deletes the confidential job from memory.

16

Page 19

6

Printing a confidential job

If you print a job that is personal or confidential, and you do not want anyone else to see it, the printer

can hold your job in memory until you arrive at the printer.

Note: This will only work with the Lexmark custom drivers that came on the drivers CD

which shipped with your printer.

To print a confidential job:

1 In your word processor, spreadsheet, browser, or other application, select File, Print.

2 Click Properties.(IfthereisnoProperties button, click Setup, and then click Properties.)

3 Click Help and refer to the topic confidential print or print and hold. Follow instructions for

printing a confidential job.

4 Go to the printer when you are ready to retrieve your confidential print job, and follow these

steps:

a Press Menu until you see Confidential Job, and then press Select..

Enter PIN

=****

1

Menu

2

Select3Return

5

Go

Stop

4

6

b Press Menu until you see your user name, and then press Select.

c Use the numbered buttons on the operator panel to enter your four-digit personal

identification number (PIN). As you enter your PIN, asterisks appear on the display.

Note: If you enter an invalid PIN, the message No Jobs Found, Retry appears. Press

Go to reenter the PIN, or press Stop to exit the Confidential Job menu item.

d Press Select to print your confidential jobs.

e Your jobs print and are deleted from printer memory.

17

Page 20

7

Print media specifications

The following table details print media sizes and types supported by each input and output device. For

details about the types of print media your printer supports, refer to the

availableonLexmark’sWebsiteatwww.lexmark.com.Werecommendthatyoutryalimitedsampleof

any print media you are considering using with the printer before purchasing large quantities.

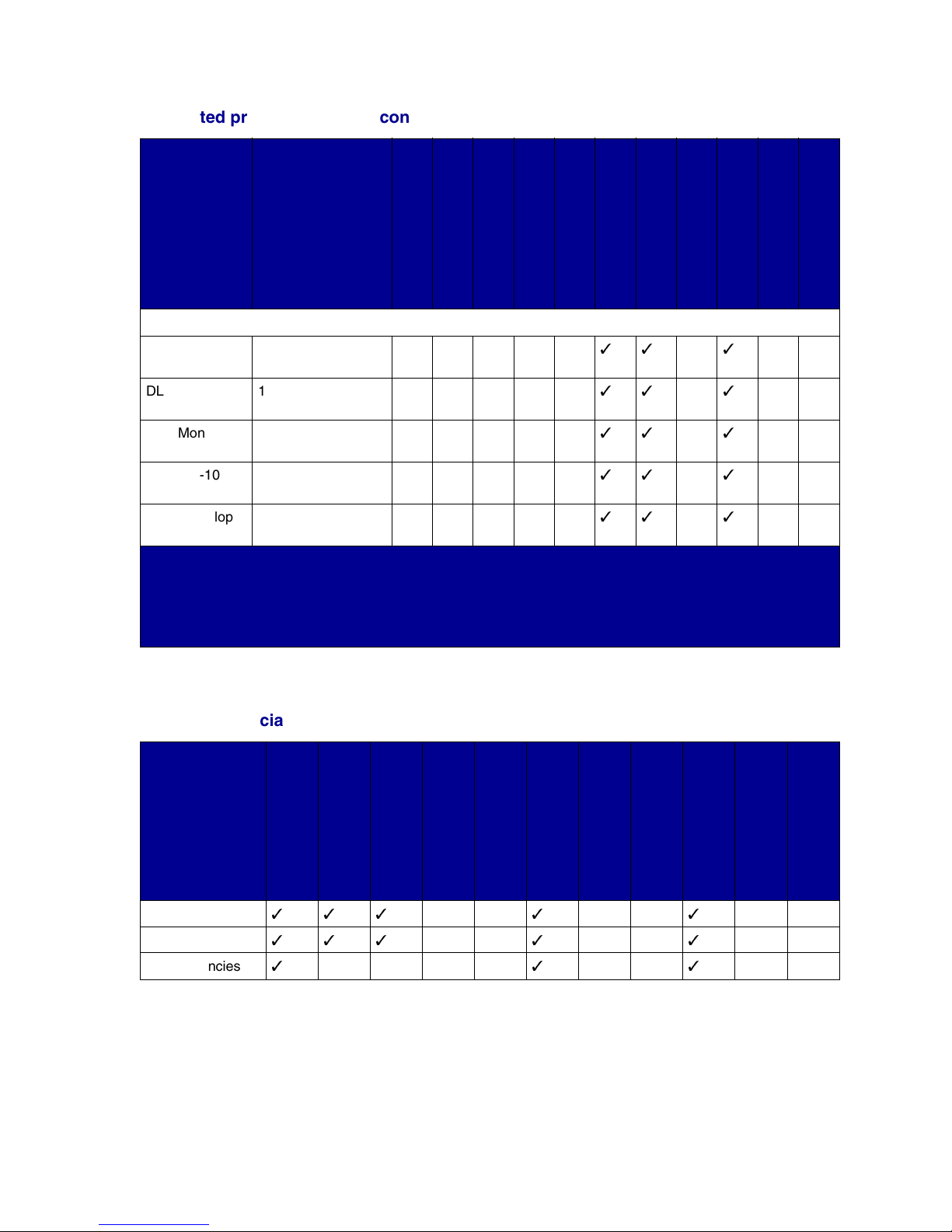

Supported print media sizes

Print media

sizes

Dimensions

Tray 1 (standard)

Tray 2 (standard)

Tray 3 (optional)

Tray 4 (optional)

Paper

Card Stock & Label Guide

Tray 5 (optional)

Multipurpose feeder

(standard)†Envelope feeder

(optional)

Duplex unit (optional)

Standard bin (standard)

10 bins in the mailbox

(optional)

2binsinthefinisher

(optional)

A3 297 x 420 mm

A4 210x297mm(8.27

A5 148x210mm(5.83

Folio 215.9 x 330 mm (8.5

JIS B4* 257 x 364 mm

JIS B5* 182 x 257 mm (7.17

Executive* 184.2 x 266.7 mm

*

Executive and Legal are supported under factory default conditions. For JIS B4 or JIS B5, see Sensing special

print media sizes.

†

The multipurpose feeder does not support auto size sensing. Print media sizes must be selected from the

printer operator panel.

‡

The dimensions for Universal must be set in the printer driver.

(11.69 x 16.54 in.)

x 11.7 in.)

x8.27in.)

x13in.)

(10.12 x 14.33 in.)

x 10.12 in.)

(7.25 x 10.5 in.)

18

Page 21

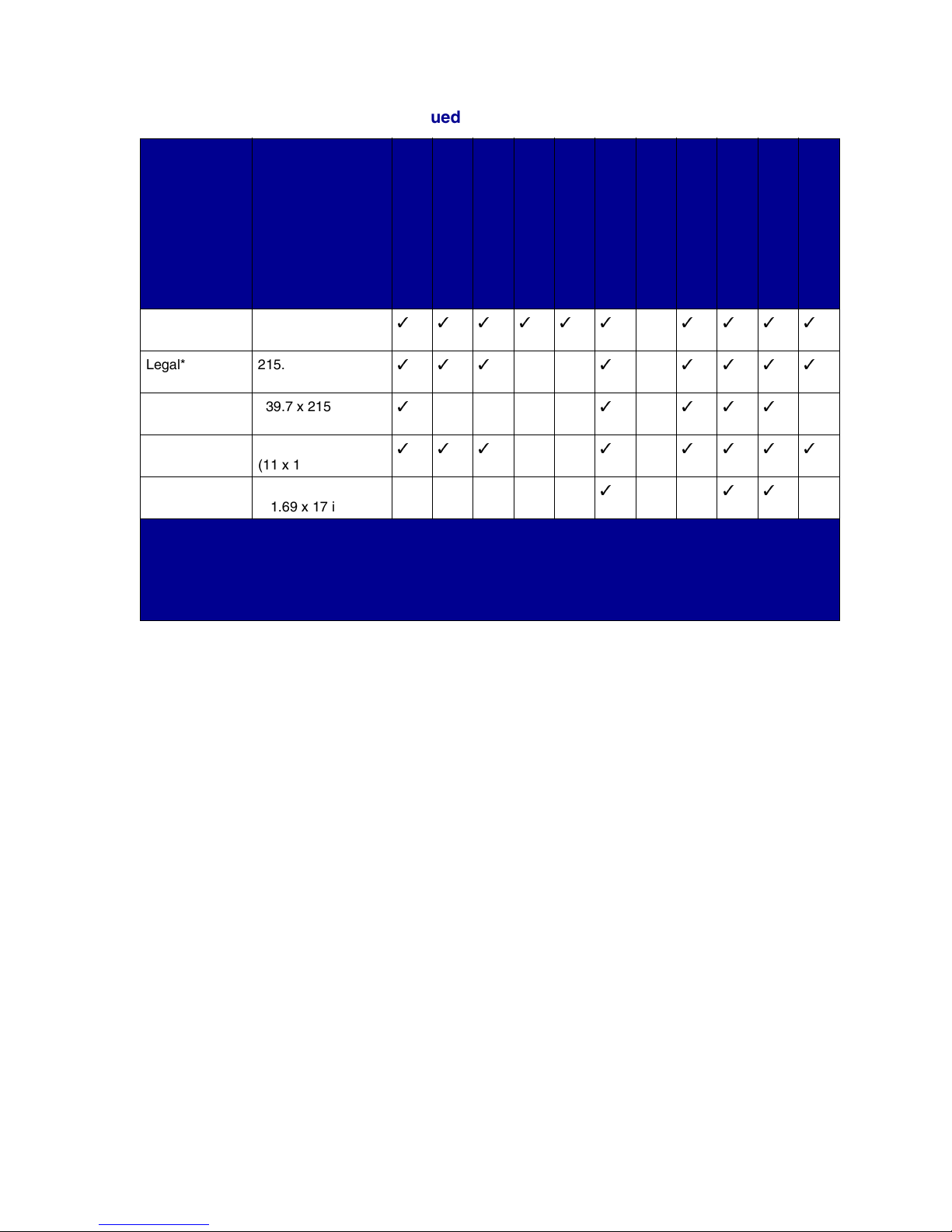

Supported print media sizes (continued)

Print media

sizes

Letter 215.9 x 279.4 mm

Legal* 215.9 x 356 mm (8.5

Statement 139.7 x 215.9 mm

11x17 279.4 x 431.8 mm

Universal

*

Executive and Legal are supported under factory default conditions. For JIS B4 or JIS B5, see Sensing special

‡

print media sizes.

†

The multipurpose feeder does not support auto size sensing. Print media sizes must be selected from the

printer operator panel.

‡

The dimensions for Universal must be set in the printer driver.

Dimensions

(8.5 x 11 in.)

x14in.)

(5.5 x 8.5 in.)

(11 x 17 in.)

297 x 431.8 mm

(11.69 x 17 in.)

Tray 1 (standard)

Tray 2 (standard)

Tray 3 (optional)

Tray 4 (optional)

Tray 5 (optional)

Multipurpose feeder

(standard)†Envelope feeder

(optional)

Duplex unit (optional)

Standard bin (standard)

10 bins in the mailbox

(optional)

2 bins in the finisher

(optional)

19

Page 22

Supported print media sizes (continued)

Print media

sizes

Dimensions

Tray 1 (standard)

Tray 2 (standard)

Tray 3 (optional)

Envelopes

Tray 4 (optional)

Tray 5 (optional)

Multipurpose feeder

(standard)†Envelope feeder

(optional)

Duplex unit (optional)

Standard bin (standard)

10 bins in the mailbox

(optional)

2 bins in the finisher

(optional)

C5 162 x 229 mm

DL 110 x 220 mm

7 ¾ (Monarch) 98.4 x 190.5 mm

10 (Com-10) 104.8 x 241.3 mm

Other envelope 245 x 215.9 mm

*

Executive and Legal are supported under factory default conditions. For JIS B4 or JIS B5, see Sensing special

print media sizes.

†

The multipurpose feeder does not support auto size sensing. Print media sizes must be selected from the

printer operator panel.

‡

The dimensions for Universal must be set in the printer driver.

(6.38 x 9.01 in.)

(4.33 x 8.66 in.)

(3.875 x 7.5 in.)

(4.125 x 9.5 in.)

(9.65x8.5in.)

Supported special print media types

Print media

types

Card stock

Labels

Transparencies

Tray 1 (standard)

Tray 2 (standard)

Tray 3 (optional)

Tray 4 (optional)

Tray 5 (optional)

Multipurpose feeder

(standard)

Envelope feeder

(optional)

Duplex unit

Standard bin

10 bins in the mailbox

(optional)

2binsinthefinisher

(optional)

20

Page 23

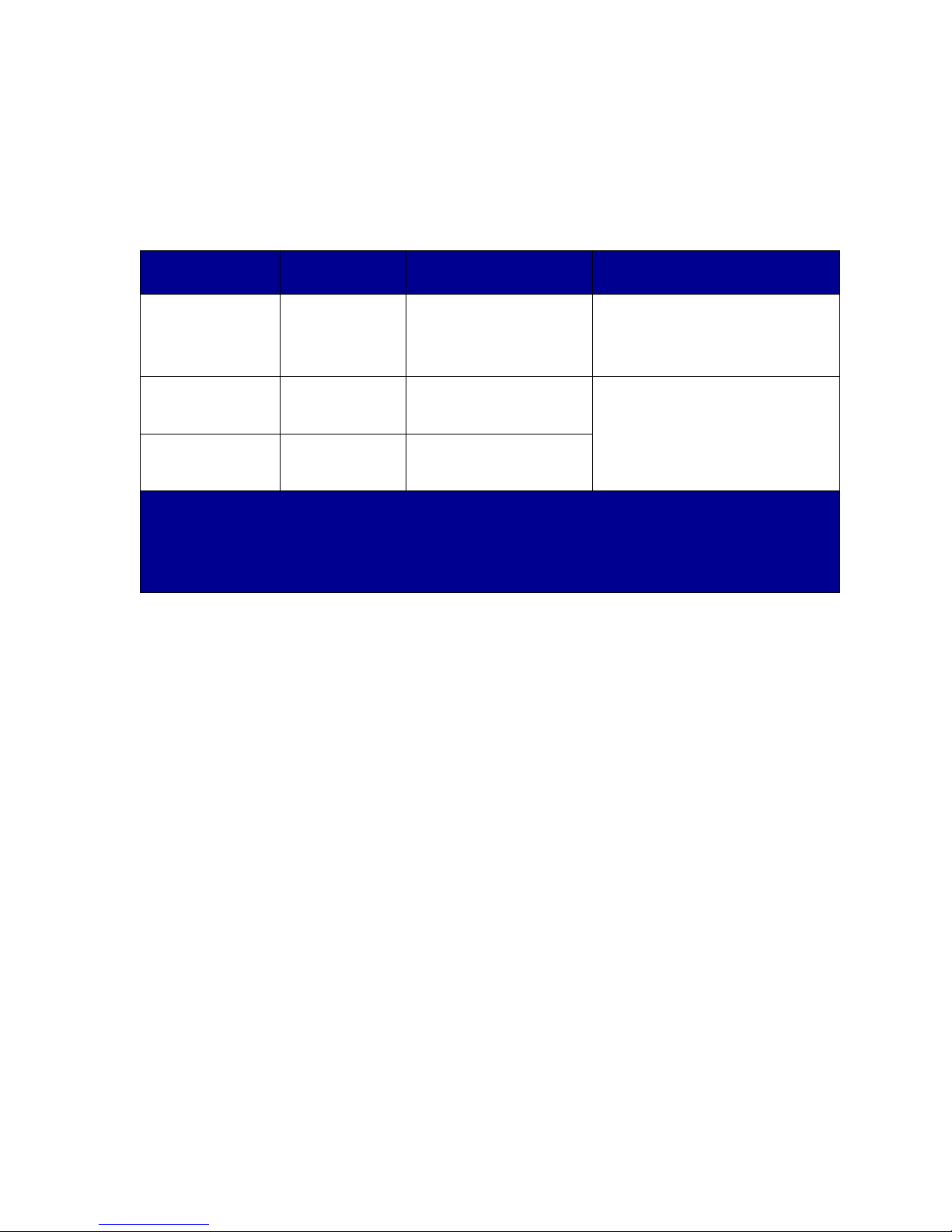

The printer has three standard print media sources: trays 1 and 2, each of which hold 500 sheets of 20

lb paper; and the multipurpose feeder, which holds approximately 35 sheets of 20 lb paper. You can

also attach an optional high capacity feeder, which contains three trays. With all trays attached, you

can have a maximum input supply of 3,500 sheets of paper. The following table details the types, sizes,

and quantities of print media you can load in each of the sources.

Print media source, size, and capacity specifications

Print media

Source

Tray 1 (standard) Paper,

Tray 2 (standard) Paper, labels,

Tray 3 (optional)

*

Trays 3, 4, and 5 comprise the optional high capacity feeder.

†

Executive and Legal are supported under factory default conditions. For JIS B4 or JIS B5, see Sensing special

print media sizes.

‡

The multipurpose feeder does not support auto size sensing. Print media sizes must be selected from the

printer operator panel.

supported

transparencies,

labels, card stock

card stock

*

Paper, labels,

card stock

Sizes supported Capacity

A3, A4, A5, Folio, JIS B4

†

JIS B5

,Executive†, Letter,

Legal†, Statement, 11x17

†

• 500 sheets of 20 lb paper

,

• 250 sheets of labels

• 300 transparencies

• 250 sheets of card stock

A3, A4, Folio, JIS B4

†

,Executive†, Letter,

B5

†

, 11x17

Legal

A3, A4, Folio, JIS B4†,JIS

†

,Executive†, Letter,

B5

†

,JIS

• 500 sheets of 20 lb paper

• 250 sheets of labels

• 250 sheets of card stock

Legal†, 11x17

21

Page 24

Print media source, size, and capacity specifications (continued)

Print media

Source

Tray 4 (optional)

Tray 5 (optional)

Multipurpose feeder

(standard)

‡

supported

*

Paper only A4, Letter, Executive 1000 sheets of 20 lb paper

*

Paper only A4, Letter, Executive

Paper,

transparencies,

labels, card stock

Sizes supported Capacity

A3, A4, A5, Folio, JIS B4,

JIS B5, Executive, Legal,

Letter, Statement,11x17,

Universal

• 35 sheets of 20 lb paper

• 15 labels

• 25 transparencies

• 15 sheets of card stock

Envelopes 7 ¾, 10, DL, C5, Other

10 envelopes

Envelope

Envelope feeder

(optional)

*

Trays 3, 4, and 5 comprise the optional high capacity feeder.

†

Executive and Legal are supported under factory default conditions. For JIS B4 or JIS B5, see Sensing special

Envelopes 7 ¾, 10, DL C5, Other

Envelope

100 envelopes

print media sizes.

‡

The multipurpose feeder does not support auto size sensing. Print media sizes must be selected from the

printer operator panel.

22

Page 25

8

Loading the trays

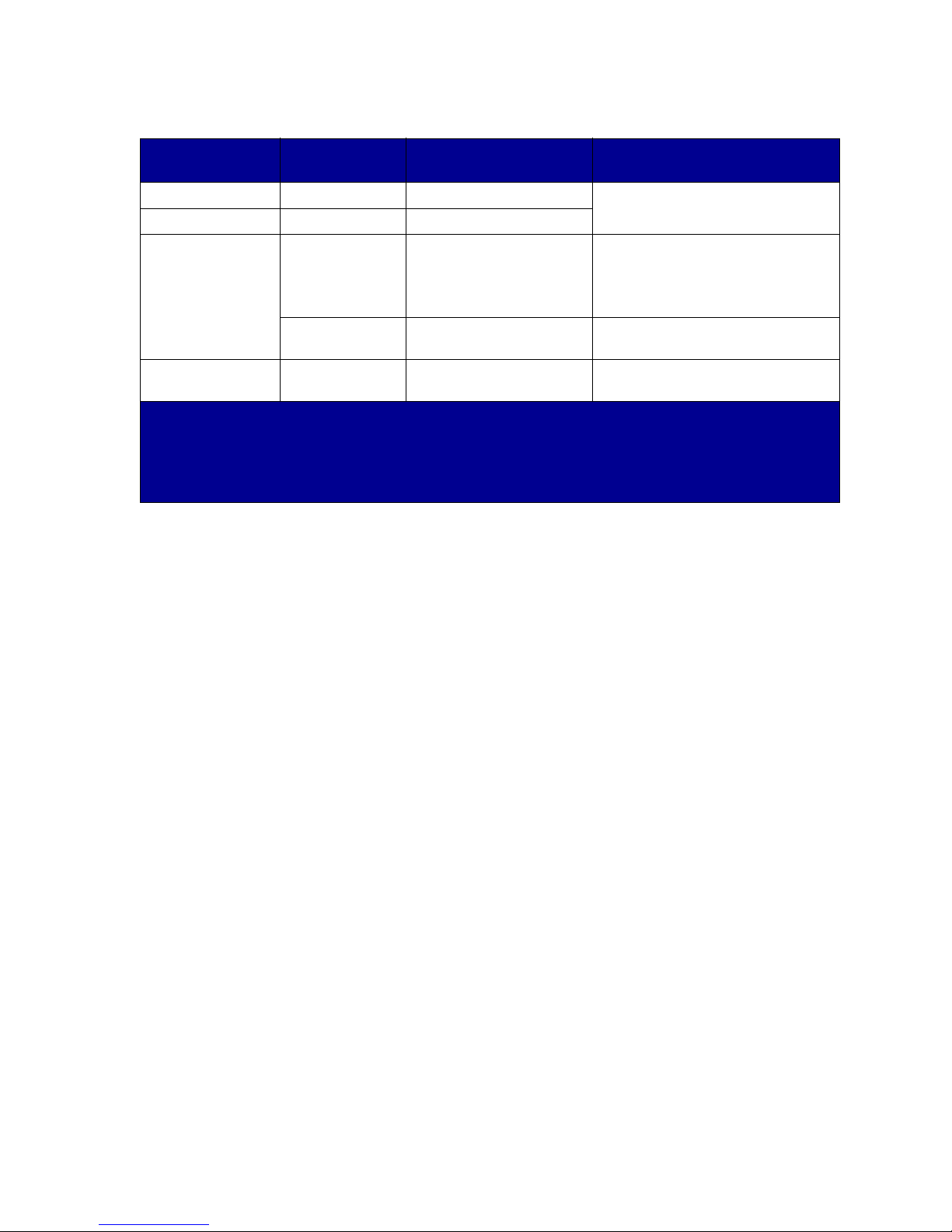

Loading trays 1, 2, and 3

For suggestions on avoiding jams, see Avoiding jams.SeePrint media source, size, and capacity

specifications for tray capacities.

1 Pull the tray open until it stops.

Handhold

2 Press down on the lever on the back guide and slide the back guide toward the back of the

printer.

23

Page 26

3 Lift the side guide up slightly and slide it to the right.

Note: Labels with print media size names are located on the bottom surface of the tray.

Each major indicator on the labels is marked with a number or paper-size name.

24

Page 27

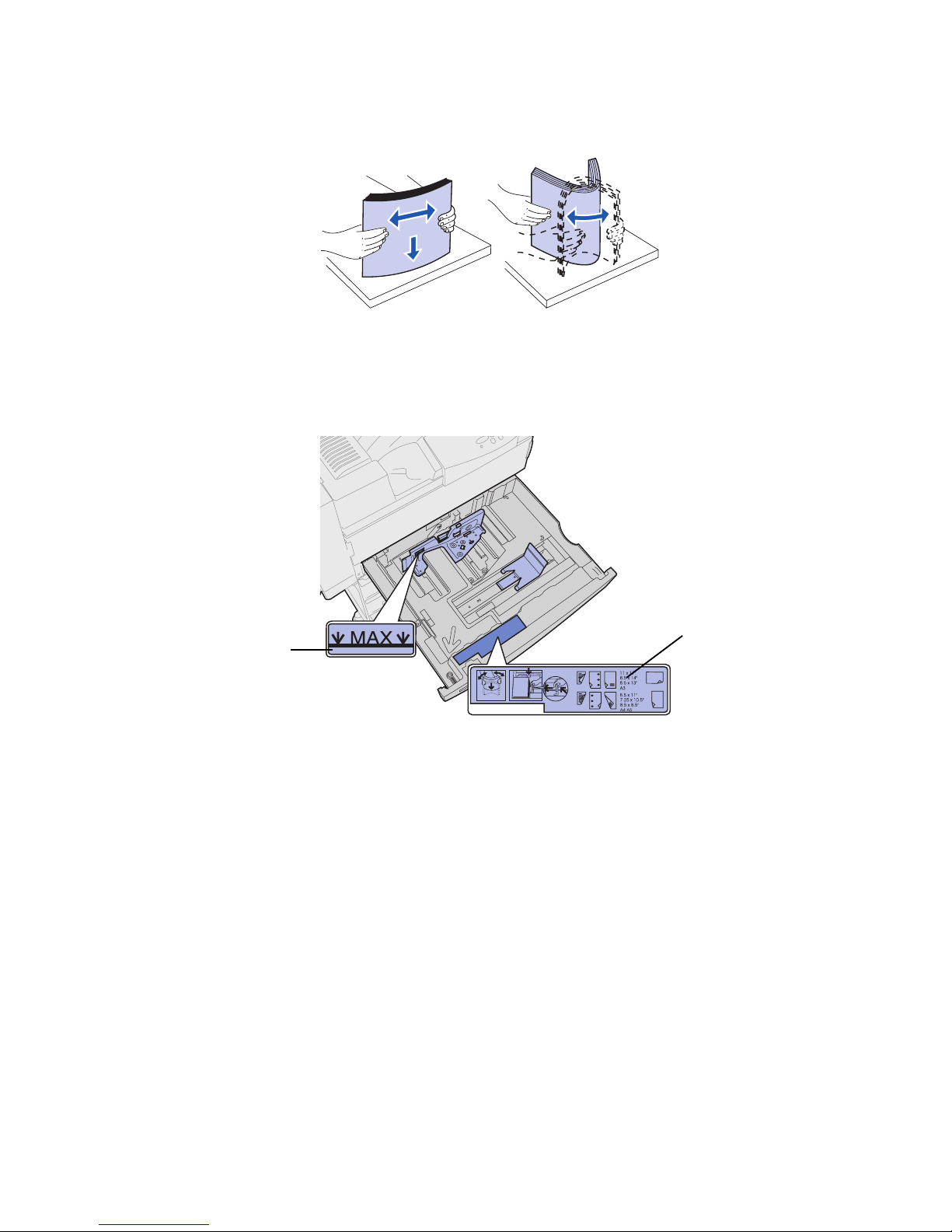

4 Flex the sheets back and forth to loosen them, and then fan them. Do not fold or crease the

print media. Straighten the edges of the stack on a level surface.

5 Orient the stack of print media correctly for the size you are loading. Refer to the icons on the

front inside surface of the tray.

Note: Do not exceed the maximum stack height indicated by the label on the back guide.

Overfilling the tray may cause paper jams. Do not load bent or wrinkled print media.

Maximum

stack height

indicator

Orientation

icons

25

Page 28

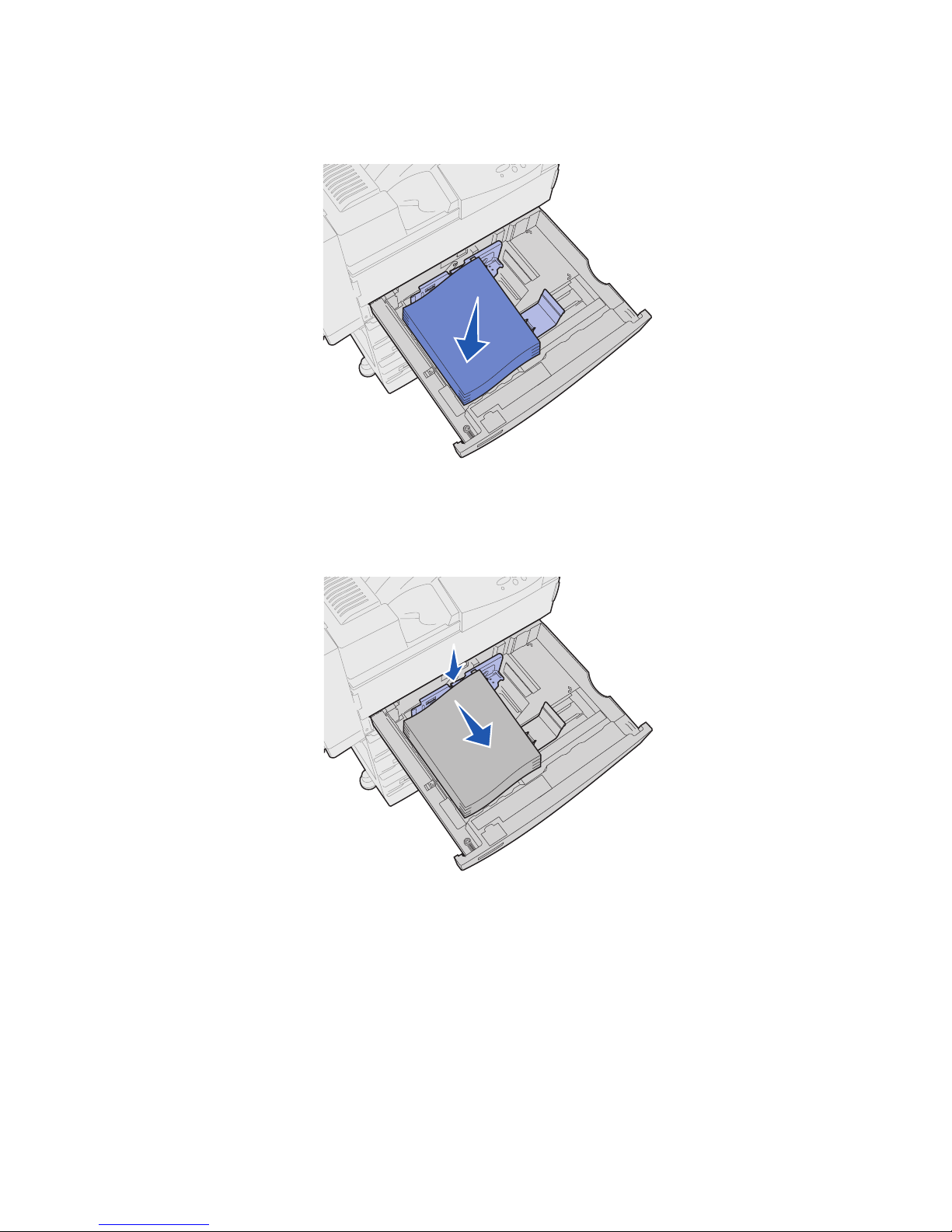

6 Place the print media against the front left corner of the tray.

7 Press down on the lever on the back guide, and then slide the back guide toward the front of

the tray until it lightly touches the stack of print media.

26

Page 29

8 Lift the side guide up slightly and slide it to the left until it lightly touches the side of the print

media. Make sure the guide locks into place in one of the detents at the bottom of the tray.

Paper-size

indicator label

goes in this slot

Note: To install a paper-size label in the paper-size indicator window, refer to the

Setup Guide

.

9 Slide the tray all the way into the printer.

Paper-size

indicator window

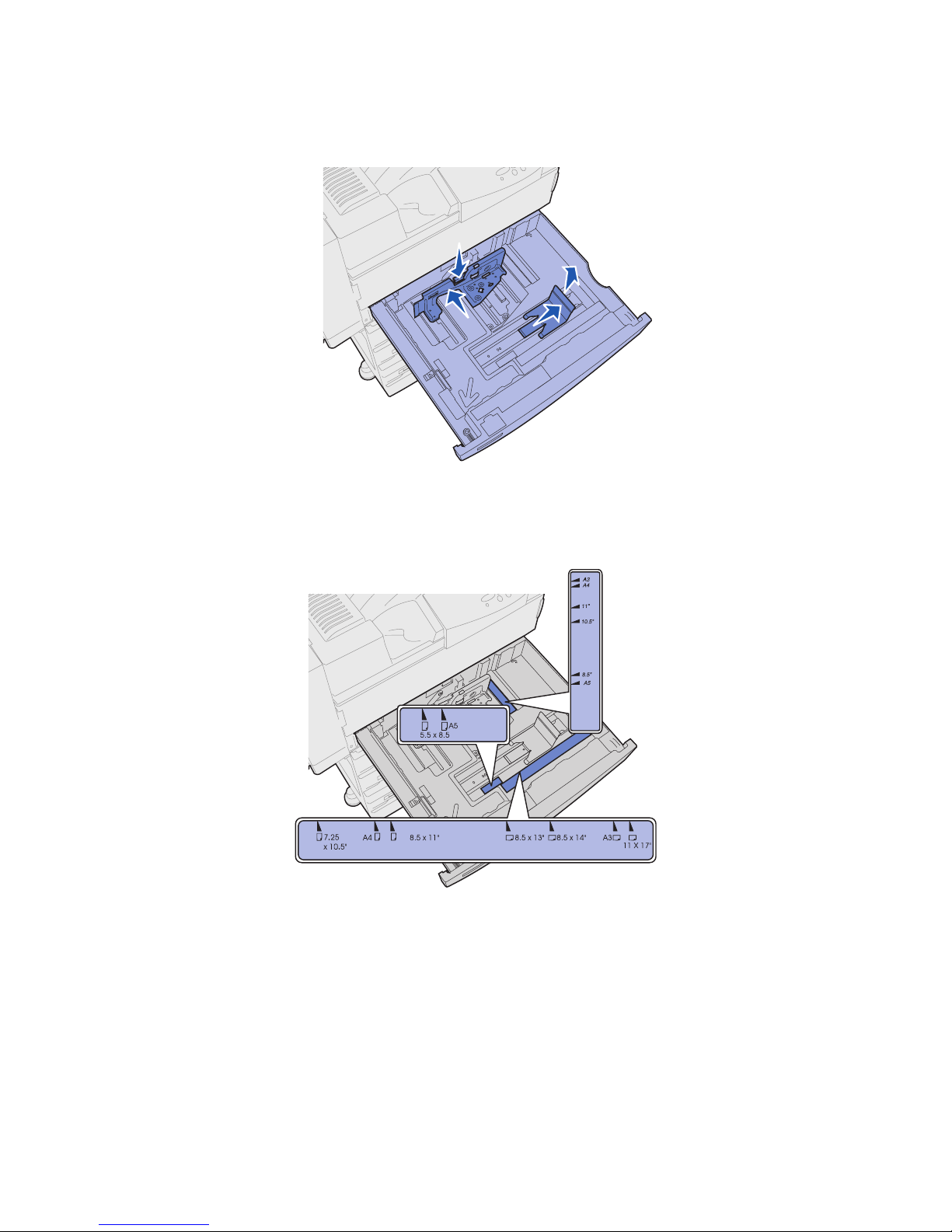

Loading trays 4 and 5

Load trays 4 and 5 in the optional high capacity feeder in the same way. See Print media source,

size, and capacity specifications for tray capacities.

Note: Do not load any print media other than paper in trays 4 and 5.

1 Pull the tray toward you.

27

Page 30

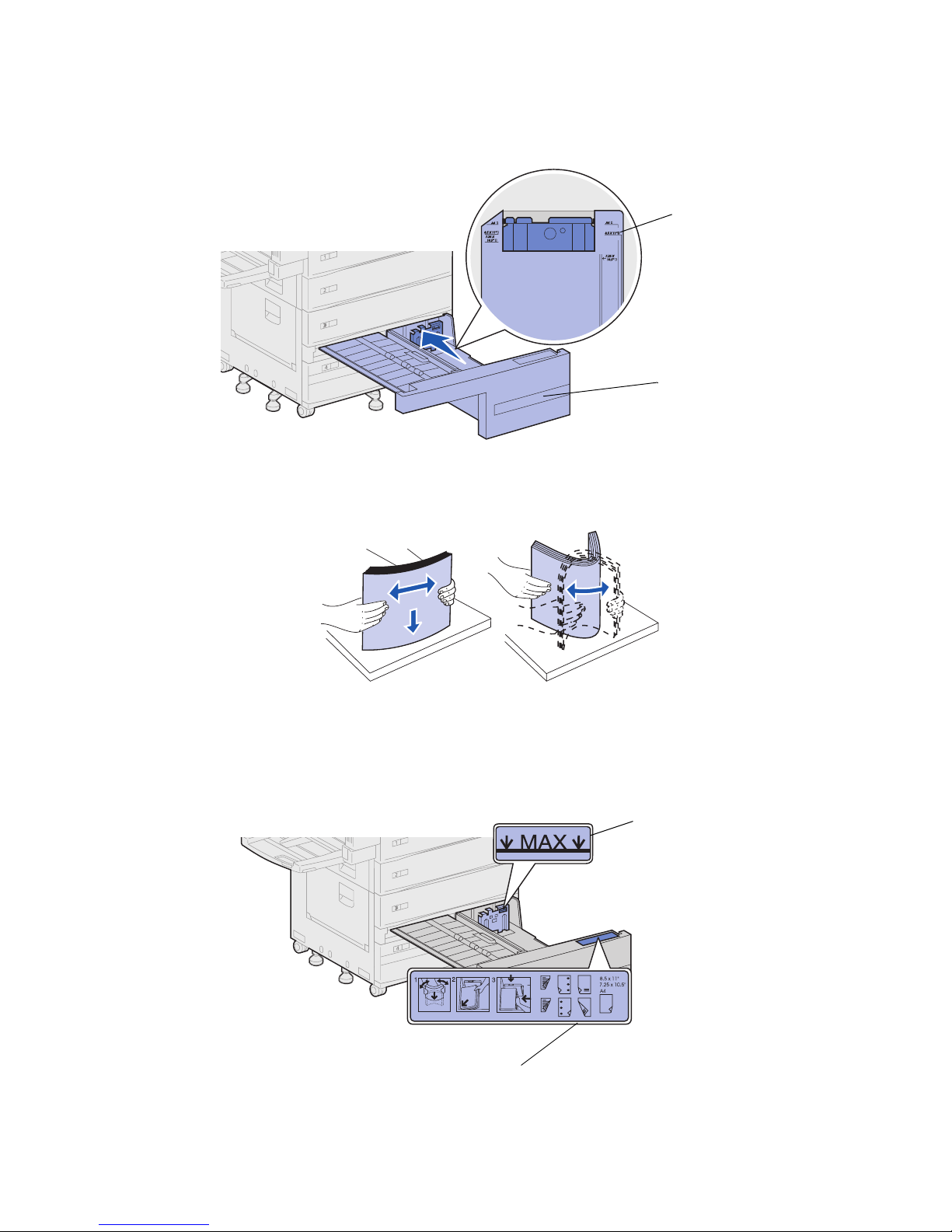

2 Slide the guide to the rear of the tray.

Markings on the bottom of the tray indicate paper sizes.

Markings

Handhold

3 Flex the sheets back and forth to loosen them, and then fan them. Do not fold or crease the

print media. Straighten the edges of the stack on a level surface.

4 Orient the stack of print media correctly for the size and type you are loading. Refer to the

icons on the tray.

Note: Do not exceed the maximum stack height indicated on the guide. Overfilling the

tray may cause paper jams. Do not load bent or wrinkled print media.

Maximum

stack

height

indicator

Orientation icons

28

Page 31

5 Place the print media against the front left corner of the tray.

6 Slide the guide forward until it lightly touches the stack of print media.

7 Gently push on the right side of the stack to make it even.

Note: To attach a paper-size sticker on trays 4 and 5, refer to the

8 Slide the tray all the way into the printer.

Paper-size sticker

Setup Guide

29

Page 32

9

Linking trays

If you load the same size and type of print media in more than one tray, the printer automatically links

the trays; when one tray is empty, print media feeds from the next linked tray.

For example, if you have the same size and type of print media loaded in tray 2 and tray 4, the printer

selects print media from tray 2 until it becomes empty, and then it feeds paper from the next linked tray

—tray4.

By linking all five trays, you effectively create a single source with a capacity of 3,500 sheets.

Ifyouloadthesamesizeprintmediaineachtray,makesuretheprintmediaisallthesametypetolink

the trays.

Once the trays you selected are loaded with the same size and type of print media, select the same

Paper Type setting in the Paper Menu for these sources.

To disable tray linking, set the Paper Type to a unique value in each one of the trays.

Note: To link trays loaded with Executive, Legal, JIS B4, or JIS B5 size print media, see

Sensing special print media sizes.

30

Page 33

10

Loading the multipurpose feeder

The multipurpose feeder holds approximately 35 sheets of 20 lb paper.

Note: You can load the multipurpose feeder with or without the duplex unit attached to

the printer.

1 Open the multipurpose feeder.

2 Slide the side guide all the way to the back.

3 Adjust the extension guide to the length of the print media to be used.

31

Page 34

4 Orient the stack of print media correctly for the size, type, and print method you are loading.

Refer to the icons on the feeder.

Note: Do not exceed the maximum stack height indicated on the side guide. Overfilling

the feeder may cause paper jams.

Paper size icons

Maximum stack height indicator label

Loading

and

orientation

icons

5 Place the print media along the front side of the multipurpose feeder and push the print media

into the printer as far as it will go. Do not force the print media.

32

Page 35

6 Slide the side guide forward until it lightly touches the stack.

Note: Once you load print media into the multipurpose feeder, set the Paper Size, Paper

Type, and Paper Source from the operator panel or from your software

application.

When you are not using the multipurpose feeder, remove any print media from the feeder,

push the extension guide back in, and push the multipurpose feeder to the closed position.

33

Page 36

11

Loading the envelope feeder

The optional envelope feeder holds approximately 100 envelopes.

1 Slidetheguideallthewaytotheback.

2 Fan the envelopes. Make sure all the flaps are turned correctly and the envelopes are not

stuck together.

3 Orient the stack of envelopes correctly for the size and position of the flap. Refer to the icons

on the feeder.

Note: Do not exceed the maximum stack height indicated on the guide. Overfilling the

feeder may cause paper jams.

34

Page 37

Loading and flap position icons

Maximum stack height

indicator

4 Lift the envelope weight and hold it.

Envelope

orientation icons

5 Place the envelopes along the front edge of the envelope feeder with the flap going in long

edge first.

35

Page 38

6 Lower the envelope weight.

7 Push the guide to the front until it lightly touches the stack.

Note: Do not add envelopes during a print job. Doing so may cause jams.

36

Page 39

12

Using the output bins

Standard bin

The printer has one standard bin, which holds approximately 500 sheets of print media that exit face

down.

Standard bin

37

Page 40

Mailbox bins

The optional mailbox has 10 bins, which hold approximately 100 sheets of 20 lb paper each. Print

media exits face down. Bin 1 is the bin closest to the standard bin.

Bins 1 – 10

Optional

mailbox

Finisher bins

The optional finisher has two bins. Bin 1 holds 250 sheets of 20 lb paper. Bin 2 holds 3,000 sheets of

20 lb paper. Print media exits face down to both bins.

Bin 1

Bin 2

38

Page 41

13

Linking bins

If you attach an optional finisher or mailbox to your printer, you can link output bins, or otherwise

specify how the printer sends jobs to the bins, by changing the Configure Bins settings in the Paper

Menu.

By default, the output bins for the finisher or the mailbox are configured in Mailbox mode. In this mode,

you select an output bin when you send a job to print. (If you prefer, you can select a default output bin

for all print jobs to go to.) The printer alerts you when the bin you selected becomes full, and stops

printing until you empty the bin.

If you prefer, you can change the Configure Bins setting to Link mode. All available bins are then linked

so that when one bin becomes full, the printer sends jobs to the next linked bin.

In Mail Overflow mode (only available if you’ve attached an optional mailbox), the printer automatically

sends jobs to a preassigned overflow bin when the current bin becomes full.

Type Assignment mode lets you assign different types of media to specific output bins or set of linked

bins. The printer then sends all printed media to the bin or set of linked bins that you designated to

receive each type of print media.

To change the Configure Bins setting:

1 Press Menu until you see Paper Menu, and then press Select.

2 Press Menu until you see Configure Bins, and then press Select.

Mailbox appears on the second line of the display.

3 Press Menu to scroll through the list of available configuration modes.

4 When you see the correct configuration mode, press Select to save the mode as the bin

configuration default.

5 Press Go to return the printer to the Ready state.

Note: The

For more information, see Configure Bins and Bin <x> Full.

Select button selects the menu shown on the second line of the display.

39

Page 42

14

Finishing capabilities

Stapling

The optional finisher can staple up to 50 sheets of 20 lb paper.

Staple positions

The finisher can staple print jobs in four positions, as defined by the Staple Job menu item in the

Finishing Menu. If you select Auto, the finisher places the staple based on the feed orientation of the

page. You can also select Front, Back, or Dual.

A4, A5, JIS B5, Executive, and Letter

Portrait Landscape

ABC

ABC

Illustration of staple positions:

Back

Dual

Front

A3, JIS B4, and 11x17 Legal

Portrait Landscape

ABC

ABC

ABC

Feed direction

Print side down (as print

media exits the printer)

40

Page 43

Staple position mapping for the Auto value

A3, A4, A5, JIS B4, JIS B5, Executive, Letter, Legal, and 11x17

Portrait Landscape

ABC

ABC

Stapling and offsetting

The finisher cannot staple

job, but does not offset it.

Note: You cannot offset, but stapling can occur in 3 different positions. Based on the

The standard bin and finisher bin 2 are capable of accepting offset print jobs.

and

offset a print job. If both functions are selected, the printer staples the

staple position selected, the offset stack is positioned differently in the tray.

Staplingandbinusage

Stapled jobs are sent to finisher bin 2.

Finishing and bin linking

The finisher stacks all stapled jobs in bin 2. Offset jobs go to in bin 2 first until it is full and the jobs go

to the standard bin when the bins are linked. If bin 1 and bin 2 are linked and bin 2 is full, the printer

reports that bin 1 is also full even if it is empty. In this case, the printer assumes there is no bin

available to perform the finishing functions requested by the print job because the bin is full. To clear

the message, remove the stack of paper from the bin. The printer can then receive additional stapled

or offset jobs. For more information, see Linking bins.

Hole punching

Select On as the value for the Hole Punch menu item in the Finishing Menu to punch holes along the

edge of all printed output. Select Hole Punch from the printer driver to punch holes only in output for a

specific job.

Bins 1 and 2 are capable of accepting hole punched print jobs.

41

Page 44

15

Tips for successful printing

Storing print media

Use the following guidelines to avoid paper feeding problems and uneven print quality.

• Store print media in an environment where the temperature is approximately 21°C (70°F) and

the relative humidity is 40%.

• Store cartons of paper on a pallet or shelf rather than directly on the floor.

• If you store individual packages of paper out of the original carton, make sure they rest on a

flat surface so the edges do not buckle or curl.

• Do not place anything on top of paper packages.

Avoiding jams

If you select appropriate print media (paper, transparencies, labels, and card stock) for your printer,

you’ll be well on your way to trouble-free printing.

By carefully selecting print media and loading them properly, you should be able to avoid most jams.

See the following for instructions on loading print media:

• Loading trays 1, 2, and 3

• Loading trays 4 and 5

• Loading the multipurpose feeder

• Loading the envelope feeder

If you do experience a paper jam, see Clearing print media jams for instructions on clearing the jam.

The following hints can help you avoid paper jams:

• Use only recommended print media. Refer to the

Lexmark’s Web site at www.lexmark.com for more information about which print media will

provide optimum results for your printing environment.

• If you need detailed information before purchasing large quantities of customized print media,

refer to the

• Do not load wrinkled, creased, or damp paper.

• Flex, fan, and straighten paper before you load it.

Card Stock & Label Guide

.

Card Stock & Label Guide

available on

42

Page 45

• Do not overload the print media sources. Make sure the stack height does not exceed the

maximum height indicated by the labels in the sources.

• Push all trays

firmly

into the printer after loading them.

• Make sure the guides in the trays are properly positioned for the size print media you have

loaded.

• Do not load print media in a tray while a job is printing by selecting print media from this same

tray. Wait for a Load Tray <x> message before you remove the tray from the printer. After

you reinstall the loaded tray, press

load it so long as the print job is not selecting the print media from it.

Go to continue printing. You may remove another tray and

• Do not send jobs to staple, hole punch, or offset for transparencies, labels, or card stock.

• We recommend that transparencies, labels, card stock, and envelopes not be sent to the

optional mailbox or optional finisher. These print media types should be sent to the standard

bin.

• If an optional finisher or mailbox is attached to your printer, make sure the printer and option

are correctly aligned. Refer to the

Setup Guide

for alignment instructions.

• Make sure all cables that connect the duplex unit, high capacity feeder, finisher, or mailbox to

the printer are correctly attached. Refer to the

Setup Guide

for more information.

• If a jam should occur, check the operator panel message to locate the correct jam access

doors. See Message maps for more information.

43

Page 46

16

Checking an unresponsive printer

Sometimes printer problems are very easy to solve. If your printer is not responding, first make sure:

• The power cord is plugged into the printer and a properly grounded electrical outlet.

• The electrical outlet is not turned off by any switch or breaker.

• Other electrical equipment plugged into the outlet is working.

• The printer is turned on.

• The printer cable is securely attached to the printer and the host computer, print server,

option, or other network device.

Once you’ve checked each of these possibilities,

problem.

If the printer does not respond, check the printer circuit breaker switch. It should be in the On position.

turn the printer off and back on

.Thisoftenfixesthe

44

Page 47

17

Solving print quality problems

You may be able to correct many print quality problems by replacing a supply or maintenance item that

has reached the end of its intended life. Check the operator panel for a message about a printer

consumable. See Determining the status of supplies for information about other ways to identify

consumables that need to be replaced.

Use the following table to find solutions to any print quality problems you have detected.

Symptom Cause Solution

Blank pages The printer was priming the

stapler.

The print cartridge is defective

or empty.

The transfer roller is defective. Replace the transfer roller.

Black pages The print cartridge is

defective.

Your printer requires

servicing.

If you primed the stapler, a blank sheet of

paper prints.

See Priming the stapler.

Replace the print cartridge.

See Replacing the print cartridge.

See Replacing the items in the

maintenance kit.

Replace the print cartridge.

See Replacing the print cartridge.

Call for service.

45

Page 48

Symptom Cause Solution

Print too light The Toner Darkness setting is

too light.

Youareusingprintmediathat

does not meet the printer

specifications.

Print too light The print cartridge is low on

toner.

The print cartridge is defective

or has been installed in more

than one printer.

Select a different Toner Darkness setting

from the printer driver before sending the

job to print.

• Use recommended paper and other print

media. Refer to the

Guide

available on Lexmark’s Web site

at www.lexmark.com for detailed

specifications.

• Load print media from a new package.

• Avoid textured paper with rough finishes.

• Make sure the paper you load in the

trays is not damp.

Replace the print cartridge.

See Replacing the print cartridge.

Replace the print cartridge.

See Replacing the print cartridge

Card Stock & Label

46

Page 49

Symptom Cause Solution

Print too dark The Toner Darkness setting is

too dark.

The print cartridge is defective

or has been installed in more

than one printer.

Gray background The Toner Darkness setting is

too dark.

The print cartridge is

defective.

Uneven print density The print cartridge is

defective.

Thetransferrolleriswornor

defective.

Select a different Toner Darkness setting

from the printer driver before sending the

job to print.

Replace the print cartridge.

See Replacing the print cartridge.

Select a different Toner Darkness setting

from the printer driver before sending the

job to print.

Replace the print cartridge.

See Replacing the print cartridge.

Replace the print cartridge.

See Replacing the print cartridge.

Replace the transfer roller.

See Replacing the items in the

maintenance kit.

Print irregularities The paper has absorbed

moistureduetohighhumidity.

Youareusingprintmediathat

does not meet the printer

specifications.

Thetransferrolleriswornor

defective.

The fuser is worn or defective. Replace the fuser.

Load paper from a fresh package in the

paper tray.

For information on storing paper, see

Storing print media.

Use recommended paper and other print

media. Avoid textured paper with rough

finishes.

Refer to the

availableonLexmark’sWebsiteat

www.lexmark.com for detailed

specifications.

Replace the transfer roller.

See Replacing the items in the

maintenance kit.

See Replacing the items in the

maintenance kit.

Card Stock & Label Guide

47

Page 50

Symptom Cause Solution

White or black line The print cartridge or fuser is

defective.

Streaked horizontal lines The print cartridge, transfer

roller, or fuser may be

defective, empty, or worn.

Replace the print cartridge.

See Replacing the print cartridge.

Replace the fuser.

See Replacing the items in the

maintenance kit.

Replace the printer cartridge, the transfer

roller, or fuser as needed.

See Replacing the print cartridge,

Replacing the transfer roller,and

Replacing the fuser for more information.

48

Page 51

Symptom Cause Solution

Streaked vertical lines Toner is smeared before

fusing to the paper.

If print media is stiff, try feeding from

another tray.

49

Page 52

Symptom Cause Solution

Toner specks The print cartridge is

Toner rubs off the print

media easily when you

handle the sheets.

Skewed print The guides in the selected tray

defective.

Thetransferrolleriswornor

defective.

The fuser is worn or defective. Replace the fuser.

The paper pick rollers are

dirty.

Toner is in the paper path. Call for service.

The two removable screws on

the fuser were not removed.

Thetexturesettingiswrong

for the type of print media you

are using.

are not in the correct position

for the print media size loaded

in the tray.

Replace the print cartridge.

See Replacing the print cartridge.

Replace the transfer roller.

See Replacing the items in the

maintenance kit.

See Replacing the items in the

maintenance kit.

Replace the pick rollers.

See Replacing the items in the

maintenance kit.

Remove the screws.

See Replacing the fuser.

Change Paper Texture from Normal to

Smooth or Rough.

Move the guides in the tray to the proper

positions for the size loaded.

See Loading the trays for detailed

instructions on adjusting the guides in each

tray.

The paper pick rollers are dirty

or worn.

Incorrect margins The guides in the selected tray

are set for a different size print

media than what is loaded in

the tray.

Auto size sensing is set off,

but you loaded a different size

print media in a tray. For

example, you inserted A4 size

paper into the selected tray

butdidnotsetthePaperSize

to A4.

Replace the pick rollers.

See Replacing the items in the

maintenance kit.

Move the guides in the tray to the proper

positions for the size loaded.

See Loading the trays for detailed

instructions on adjusting the guides in each

tray.

Set the Paper Size to A4.

50

Page 53

Symptom Cause Solution

Incorrect margins

continued

(

Clipped images The guides in the selected tray

Ghost images Low toner level in the print

)

The paper pick rollers are

worn.

are set for a different size print

media than what is loaded in

the tray.

cartridge.

Replace the pick rollers.

See Replacing the items in the

maintenance kit.

Move the guides in the tray to the proper

positions for the size loaded.

See Loading the trays for detailed

instructions on adjusting the guides in each

tray.

Make sure the Paper Type setting is

correct for the print media you are using.

Replace the print cartridge.

See Replacing the print cartridge.

The print media curls

badly once it prints and

exits to a bin.

Thetexturesettingiswrong

for the type of print media you

are using.

51

Change Paper Texture from Rough to

Normal or Smooth.

Page 54

18

Solving paper feed problems

If print media has trouble traveling through the printer, paper jams or other paper feed problems can

result. Use the following table to find solutions to paper feed problems you are experiencing. For

information about paper feed problems in output options, see Solving mailbox problems or Solving

finisher problems.

For detailed instructions on clearing paper jams, see Clearing print media jams. For tips on avoiding

paper jams, see Avoiding jams.

Symptom Cause Solution

Paper frequently

jams.

Paper frequently

jams in the printer

(continued).

The Paper Jam

message remains

after you remove the

jammed print media.

You are using print media that does not

meet the printer specifications.

You have loaded too much paper or too

many envelopes.

The guides in the selected tray are not set

to the appropriate position for the size

print media loaded.

Paper has absorbed moisture due to high

humidity.

The paper pick rollers are dirty or worn. Replace the pick rollers.

You have not cleared the entire paper

path, or you did not open the door

specified by the message to check for

jams in this area.

Use recommended paper and other print

media. Refer to the

Guide

availableonLexmark’sWebsiteat

www.lexmark.com for detailed

specifications.

Make sure the stack of paper you load

does not exceed the maximum stack

height indicated at the back of the tray or

on the multipurpose feeder. Make sure the

stack of envelopes you load does not

exceed the maximum stack height

indicated on the envelope feeder.

Move the guides in the tray to the correct

position.

See Loading the trays for detailed

instructions.

• Load paper from a fresh package.

• Store paper in its original wrapper until

you load it.

See Storing print media for more

information on properly storing media.

See Replacing the items in the

maintenance kit.

Clear print media from the entire paper

path, open the door indicated by the

operator panel message, clear the jam,

andclosethedoor.Theprinterresumes

printing.

See Clearing print media jams for more

information.

Card Stock & Label

52

Page 55

Symptom Cause Solution

The page that

jammed does not

reprint after you

clear the jam.

Envelopes fail to

feed through the

optional envelope

feeder.

Jam Recovery in the Setup Menu is set to

Off.

The envelope stack is too deep. Decrease the stack of envelopes by half.

Set Jam Recovery to Auto or On.

53

Page 56

19

Solving other printing problems

Use the following table to find solutions to other printing problems.

Symptom Cause Solution

The operator panel

displayisblankor

displays only

diamonds.

Jobs don’tprint. The printer is not ready to

The printer self test failed. Turn the printer off, wait about 10 seconds, and turn

receive data.

the printer back on.

Performing Self Test appears on the display.

When the test is completed, the Ready message is

displayed.

If the messages do not appear, turn the printer off

and call for service.

Make sure the system board is pushed back in place

and option cards are fully seated. See Reinstalling

the printer system board.

Make sure Ready or Power Saver appears on the

display before sending a job to print. Press

return the printer to the Ready state.

Go to

54

Page 57

Symptom Cause Solution

Jobs don’tprint

(continued)

It takes longer than

expected to print a

job.

.

The specified output bin is full. Remove the stack of paper from the output bin as

The specified tray is empty. Load paper in the tray as indicated by the operator

Youareusingthewrong

printerdriverorareprintingto

afile.

Your MarkNet™ print server is

not set up properly or is not

connected properly.

Youareusingthewrong

interface cable, or the cable is

not securely connected.

The job is too complex. Reduce the complexity of your print job by

Page Protect is set to On. Set Page Protect to Off from the Setup Menu.

Print Resolution is set to

1200 Image Quality.

indicated by the operator panel message, and then

Go.

press

panel message.

See Loading the trays for detailed instructions.

• Verify that you selected the printer driver

associated with the W820.

• If you are using a USB port, make sure you are

running Windows 98/Me or Windows 2000, and

using a

Windows 98/Me or Windows 2000 compatible

printer driver.

Verify that you have properly configured the printer

for network printing. Refer to the drivers CD or to

Lexmark’s Web site at www.lexmark.com for

information.

Make sure you are using a recommended interface

cable. Refer to the

specifications.

eliminating the number and size of fonts, the number

and complexity of images, and the number of pages

in the job.

If your job includes complex images, it may take

longer to print when the resolution is set to 1200

Image Quality. To print the job faster, select another

print resolution from the printer driver before sending

the job to print. You may notice some reduction in

print quality.

Setup Guide

for cable

The job prints from

the wrong tray or on

the wrong print

media.

Incorrect characters

print.

Tray linking does not

work.

The printer driver settings are

overriding the operator panel

menu settings.

Youareusinganincompatible

parallel cable.

The printer is in Hex Trace

mode.

Tray linking is not configured

properly.

55

Make sure the Paper Size and Paper Type

specifiedintheprinterdriverarecorrectforthejob

you are printing.

If you’re using a parallel interface, make sure you’re

using an IEEE 1284-compliant parallel cable. We

recommend Lexmark part number 1329605 (10 ft) or

1427498 (20 ft) for the standard parallel port.

If Ready Hex appears on the display, you must exit

Hex Trace mode before you can print your job. Turn

the printer off and back on to exit Hex Trace mode.

To configure the linked trays:

• Make sure the Tray x Type value in the Paper

Type menu item in the Paper Menu is the same

for all linked trays.

• Make sure the Tray x Size value in the Paper

Size menu item in the Paper Menu is the same

for all linked trays.

Page 58

Symptom Cause Solution

Large jobs do not

collate.

Unexpected page

breaks occur.

Collate is not set to On. Set Collation to On in the Finishing Menu or

The job is too complex. Reduce the complexity of the print job by eliminating

The printer does not have

enough memory.

The job has timed out. Set Print Timeout to a higher value from the Setup

through the printer driver.

the number and size of fonts, the number and

complexity of images, and the number of pages in

the job.

Add printer memory or an optional hard disk.

Refer to the

selecting memory options to install.

Menu.

Setup Guide

for information on

56

Page 59

20

Solving mailbox problems

Use the following table to find solutions to problems with the optional mailbox.

Symptom Cause Solution

Paper jams before

reaching the mailbox.

Paper jams in the

mailbox at the plastic

deflector area.

The mailbox and the printer

are misaligned because the

mailbox deflector is caught.

The mailbox cable is not

connected properly.

Thestackingarmhasnot

been removed.

Realign the mailbox and the printer. Refer to the

Setup Guide

Check the cable connection. Refer to the

for instructions on connecting the mailbox to the

printer.

Refer to the

for instructions.

Setup Guide

Setup Guide

for instructions.

57

Page 60

21

Solving finisher problems

Use the following table to find solutions to problems with the optional finisher.

Symptom Cause Solution

Paper frequently

jams in the finisher.

The printer only

prints to bin 1.

You cannot clear the

280 Paper Jam /

Open Cover H

message.

The finisher and the printer

are misaligned.

The printer and finisher have

been moved.

The transport unit is not

properly installed.

You are trying to staple, hole

punch, or offset print jobs on

print media other than paper.

The finisher cables are not

connected properly.

The transport unit is not

properly installed.

Properly align the finisher with the printer. Refer to the

Setup Guide

Alignthetopoftheguiderailwiththelineonthe

holding plate by rotating the two alignment knobs

closest to the holding plate. This action raises or

lowers the guide rail, depending on which way the

knobs are turned. The edge of the guide rail should

line up with the sticker where the white and gray

portions divide.

Verify that you have properly installed the transport

unit on top of the printer. If the 28x Paper Jam /

Open Cover H message recurs, then it is not properly

installed. The gears must be completely engaged for

paper to travel successfully from the printer to the

finisher.

Refer to the

instructions.

Restrict use of the special finishing features to paper

meeting the printer specifications.

Check the cable connections. Refer to the

Setup Guide

to the printer.

Correctly install the transport unit on top of the printer.

Refer to the

for instructions.

Setup Guide

for instructions on connecting the finisher

Setup Guide

for detailed installation

for instructions.

The finisher does not

offset the print job as

requested.

You’ve selected both

offsetting

job.

and

stapling for the

The finisher cannot staple

functions are selected, the printer staples the job, but

does not offset it.

and

offset a print job. If both

58

Page 61

Symptom Cause Solution

Pages are not

stapled.

Staple priming fails.

The Priming

Failed, Retry

message displays. See

Priming Failed,

Retry for more

information.

You are trying to staple too

many sheets.

The staple cartridge holder is

not installed or is not installed

correctly.

The staple cartridge is empty. Install a new staple cartridge. See Replacing a staple

The stapler is jammed. Check the stapler for a staple jam. See Clearing

Staples are not properly

positioned in the stapler.

The staple cartridge is empty. Insert a new staple cartridge.

Thestapleprimingsource

tray is empty.

Bin 2 is full. Remove the stack of paper from bin 2.

The staple cartridge holder is

not installed or is not installed

correctly.

Reduce the number of pages in the staple job.

The finisher can staple up to 50 sheets of 20 lb paper.

If you attempt to staple a larger stack of paper, the

finisher ejects the stack without stapling it.

Reinstall the stapler cartridge holder into the stapler.

See Replacing a staple cartridge for instructions.

cartridge for instructions.

staple jams.

Prime the stapler. See Priming the stapler.

See Replacing a staple cartridge for instructions.

Load paper in the staple priming source tray specified

in the Finishing Menu. See Staple Prime Src for more

information.

Reinstall the staple cartridge holder.

See Replacing a staple cartridge for instructions.

The staple is in the

wrong corner of the

stack.

The stapler is jammed. Clear the staple jam.

See Clearing staple jams for instructions.

The correct staple position

was not selected in the

Staple Job menu item in the

Finishing Menu.

Select a different staple position. The Auto menu item

staples the stack based on the feed method of the

paper in relation to the leading edge of the paper. For

more information on positions, see Staple Job and

Staple positions.

If necessary, reformat your print job from the software

application or rotate your print job using the printer

driver to avoid stapled sets that are difficult to read.

A4, A5, JIS B5, Executive, and Letter

Portrait Landscape

ABC

A3, JIS B4, and 11x17 Legal

Portrait Landscape

ABC

ABC

ABC

ABC

59

Page 62

Symptom Cause Solution

A printer message

indicates that all

linked bins are full,

butsomebinsare

empty.

The 287 Paper Jam

Open Deflector G

message displays

after you install the

finisher.

Feed direction

streaks are on stacks

of paper exiting to

the bins.

There is no bin available to

perform the finishing

functions requested by the

print job because the bin is

full.

The divertor cover is installed

incorrectly.

The wiper blade is dirty or

installed incorrectly.

To clear the message, remove the stack of paper from

the bin.

Remove and realign the divertor cover. Refer to the

Setup Guide

Remove, clean, and reinstall the wiper blade. See

Cleaning the wiper blade or refer to the instruction

sheet in the maintenance kit box.

for instructions.

60

Page 63

22

Solving other option problems

Use the following table to find solutions to problems with other options.

Symptom Cause Solution

An option does not operate

correctly after it is installed, or it

stops working.

You cannot print using the

infrared port on the optional

Tri-Port Adapter.

You cannot print using the

infrared port on the optional

Tri-Port Adapter

(continued)

.

The option is not installed correctly. Remove the option and reinstall it.

The cables connecting the option to

the printer are not attached

correctly.

The printer driver does not

recognize that the option is

installed.

The infrared port is not configured

properly.

The connection between the two

infrared devices cannot be made.

Check the cable connections. Refer

Setup Guide

to the

Your printer driver may not

automatically recognize that an

option is attached to your printer.

Open the driver and verify that all

the printer configuration settings

are correct.

Make sure neither Infrared Port

nor Infrared Buffer is set to

Disabled in the Infrared Menu.

Also make sure the Window Size

and Transmit Delay settings are

correct.

Make sure the distance between

the two infrared ports is 3 m (10 ft)

or less. If necessary, move the

ports closer together.

Make sure no objects are between

the two ports.

Make sure the computer is set on a

level surface.

If necessary, turn off the lights in

the room or close window shades

or blinds. Bright light, such as direct

sunshine or nearby artificial lights,

may interfere with communication.

for instructions.

You cannot print using the

LocalTalk port.

The LocalTalk port is not set up

correctly.

61

• Make sure neither LocalTalk

Port nor LocalTalk Buffer is set

to Disabled in the LocalTalk

Menu.

• For Macintosh users, verify that

the printer is set up correctly in

the Macintosh Chooser.

• If you have two Tri-Port Adapters

installed, only one LocalTalk and

one infrared port works. The

Tri-Port Adapter installed in

connector slot 1 is active.

Page 64

23

Calling for service

When you call for printer service, be prepared to describe the problem you are experiencing or the

error message on the display.

You’ll also need to know your printer model type and serial number. Refer to the label on the back of