Revised: 11/1/06

• Table of Contents

•Start Diagnostics

Optra™ S

4059-XXX

• Safety and Notices

• Trademarks

•Index

Lexmark and Lexmark with diamond

design are trade ma rks of Lexmark

International, Inc., registered i n the

United States and/or ot her countries.

First Edition: November 1, 2006

The followin g paragraph does not apply to any country where such

provisions are inc o n s istent with local law: LEXMARK INTERNATIONAL,

INC. PRO VIDES THIS PUBL ICATION “AS IS” WITHOUT WARRANTY OF ANY

KIND, EI THER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTI CULAR PURPO SE. Some states do not allow disclaimer of express or

implied warr anties in certain transact ions, therefore, this statement may not

apply to you.

This publica tion could include te chnical inaccuracies or typog raphical errors.

Changes are periodi cally made t o the inf ormati on herein; these changes will be

incorporated in later editions. Improvements or changes in the products or the

programs described may be made at any time. Publications are not stocked at

the address giv en bel ow; request s f or publ icati ons shoul d be made to yo ur p oint

of purchase.

A form for reader’s comments is provided at the back of this publication. If the

form has been removed, comments may be addressed to Le xmark

International, Inc., D22A/035-3, 740 New Circle Road NW, Lexington, K entucky

40550, U.S.A. Lexmark may use or distribute any of the information you supply

in any way it believ es appropriate without incurring any obligation to you.

Lexmark and Optra are trademarks of Lexmark International, Inc., registered in

the United States and/or other countries.

©Copyright Lexmark International, Inc. 1998, 2006

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS.

Use, duplicat ion or disclosure by the Government is subj ect to restrictions as

set forth in subpar ag raph ( c)(1) (ii) o f the Ri ghts i n Technical Data and Comp uter

Software clause at DFARS 252.227-7013 and in applicable FAR pr ovisions:

Lexmark International, Inc., Lexington, KY 40550.

USA P/N: 12G0139

Contents

Notices and Safety Information. . . . . . . . . . . . . . . . . . . . . 1-ix

Laser Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-ix

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-xvii

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-xxii

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Tools Required For Service. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Service Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

User Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

User Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Power-On Self Test (POST). . . . . . . . . . . . . . . . . . . . . . . 2-24

Symptom Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Charge Roll Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-29

Cover Open Switch/Cable Service Check . . . . . . . . . . . . 2-31

Dead Machine Service Check . . . . . . . . . . . . . . . . . . . . . 2-32

Duplex Option Service Check. . . . . . . . . . . . . . . . . . . . . . 2-35

Envelope Feeder Option Service Check . . . . . . . . . . . . . 2-39

Erase Lamp Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-46

Fan Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Fuser Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

Fuser Envelope Conditioner Solenoid Service Check . . . 2-51

Input Sensor Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-57

Input Tray(s) Option Service Check . . . . . . . . . . . . . . . . . 2-58

High Capacity Feeder Input Tray Service Check . . . . . . . 2-61

Main Drive Service Check . . . . . . . . . . . . . . . . . . . . . . . . 2-73

Operator Panel Service Check . . . . . . . . . . . . . . . . . . . . . 2-74

Options Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

Output Bin Sensor Standard Tray Service Check . . . . . . 2-78

Output Expander Service Check . . . . . . . . . . . . . . . . . . . 2-79

Paper Feed Service Check. . . . . . . . . . . . . . . . . . . . . . . . 2-86

Parallel Port Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-89

Printhead Service Check . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

Print Quality Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-91

Contents iii

Smart Cartridge Service Check . . . . . . . . . . . . . . . . . . . 2-102

Serial Port Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-104

Toner Sensor Service Check. . . . . . . . . . . . . . . . . . . . . 2-104

Transfer Roll Service Check . . . . . . . . . . . . . . . . . . . . . 2-105

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Device Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Quick Disk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Disk Test/Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Flash Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Disabling Download Emulations . . . . . . . . . . . . . . . . . . . . 3-3

Duplex Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Duplex Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Duplex Sensor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Duplex Motor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Duplex Feed 1 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Duplex Feed 2 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Viewing the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Clearing the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Hardware Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

LCD Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

DRAM Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

ROM Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Parallel Wrap Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Serial Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Input Tray Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Input Tray Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Input Tray Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Output Bin Test - Standard Bin . . . . . . . . . . . . . . . . . . . . 3-15

Output Bin Feed Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Output Bin Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Output Bin X Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Base Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Print Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Printer Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting the Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Viewing the Permanent Page Count . . . . . . . . . . . . . . . . 3-19

Maintenance Page Count (2420/2450/2455/3455) . . . . . 3-20

Setting Configuration ID. . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Restore EP Factory Defaults . . . . . . . . . . . . . . . . . . . . . . 3-21

iv 4059 Service Manual

Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Print Quality Test Pages. . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Printing Menu Settings Page . . . . . . . . . . . . . . . . . . . . . . 3-24

Autocompensator Operation . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Autoconnect System, Paper Tray Options, Envelope Feeder and

Output Expander Operations. . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Fuser Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Paper Feed Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-Sensitive Parts. . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Duplex Motor Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fuser Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Gap Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Printhead Assembly Adjustment. . . . . . . . . . . . . . . . . . . . . 4-4

Paper Alignment Assembly Adjustment . . . . . . . . . . . . . . . 4-5

Screw Identification Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Removal Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Center Pan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Developer Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Duplex Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Duplex Front Cover Assembly . . . . . . . . . . . . . . . . . . . . . 4-21

Duplex Front Cover Door . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Duplex Front Cover Door Switch . . . . . . . . . . . . . . . . . . . 4-21

Duplex Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Engine Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

EP Frame Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Fuser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Fuser Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Fuser Detack Fingers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Fuser Detack Housing Assembly . . . . . . . . . . . . . . . . . . . 4-29

Fuser Transfer Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Fuser Envelope Conditioner Solenoid . . . . . . . . . . . . . . . 4-31

Fuser Exit Flag Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Fuser Exit Roll Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Fuser Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Fuser Lower Exit Guide Assembly . . . . . . . . . . . . . . . . . . 4-33

High Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . 4-34

Contents v

Inner EMC Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Inner Paper Deflector Assembly . . . . . . . . . . . . . . . . . . . 4-36

Integrated Tray Compensator Assembly. . . . . . . . . . . . . 4-37

Integrated Tray Compensator Pick Roll Assembly . . . . . 4-38

Interconnect Board Assembly . . . . . . . . . . . . . . . . . . . . . 4-39

Left Side Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Low Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . 4-43

Main Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Main Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Multipurpose Tray/Lower Deflector Assembly . . . . . . . . . 4-46

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Operator Panel Cable/Cover Open Switch Assembly . . . 4-49

Optional 250/500 Paper Tray Assembly . . . . . . . . . . . . . 4-50

Outer EMC Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Paper Alignment Assembly . . . . . . . . . . . . . . . . . . . . . . . 4-52

Paper Input Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Paper Size Sensing Board. . . . . . . . . . . . . . . . . . . . . . . . 4-54

Pick Roll. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Redrive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Right Side Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Smart Cartridge Contacts . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Toner Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Transfer Roll Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Upper Paper Deflector Assembly . . . . . . . . . . . . . . . . . . 4-60

Upper Front Cover Hinge Assembly . . . . . . . . . . . . . . . . 4-61

Upper Front Cover Interlock Switch Assembly . . . . . . . . 4-62

Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Low Voltage Power Supply . . . . . . . . . . . . . . . . . . . . . . . . 5-1

High Voltage Power Supply. . . . . . . . . . . . . . . . . . . . . . . . 5-3

Engine Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Fuser Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Interconnect Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Envelope Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Duplex Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Autoconnect - Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Output Expander Control Board - Level 1 Stepper Motor 5-22

Output Expander Control Board - Level 2 DC Motor . . . . 5-24

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety Inspection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Scheduled Maintenance (2420/2450/2455/3455). . . . . . . . . . 6-2

vi 4059 Service Manual

Parts Catalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How To Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Assembly 2: Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Assembly 3: Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Assembly 4: Paper Feed (Autocompensator). . . . . . . . . . 7-12

Assembly 5: Paper Feed - Multipurpose Unit . . . . . . . . . . 7-14

Assembly 6: Paper Feed - Alignment. . . . . . . . . . . . . . . . 7-16

Assembly 7: Paper Feed - Output . . . . . . . . . . . . . . . . . . 7-18

Assembly 8: Integrated Paper Tray - 250 Sheet . . . . . . . 7-20

Assembly 9: Main Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Assembly 10: Developer Drive . . . . . . . . . . . . . . . . . . . . . 7-24

Assembly 11: Fuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Assembly 12: Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Assembly 13: Charging . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Assembly 14: Electronics . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Assembly 15: 250 Sheet Tray . . . . . . . . . . . . . . . . . . . . . 7-48

Assembly 16: 500 Sheet Tray . . . . . . . . . . . . . . . . . . . . . 7-52

Assembly 17: 500/500 Dual Tray . . . . . . . . . . . . . . . . . . . 7-56

Assembly 18: Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

Assembly 19: Output Expander . . . . . . . . . . . . . . . . . . . . 7-66

Assembly 20: Envelope Feeder . . . . . . . . . . . . . . . . . . . . 7-70

Assembly 21: High Capacity Feeder . . . . . . . . . . . . . . . . 7-74

Assembly 22: Kiosk - Vertical Paper Adapter. . . . . . . . . . 7-84

Assembly 23: Kiosk - Horizontal Paper Adapter. . . . . . . . 7-86

Assembly 24: Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-88

Assembly 25: Miscellaneous . . . . . . . . . . . . . . . . . . . . . . 7-90

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Contents vii

viii 4059 Service Manual

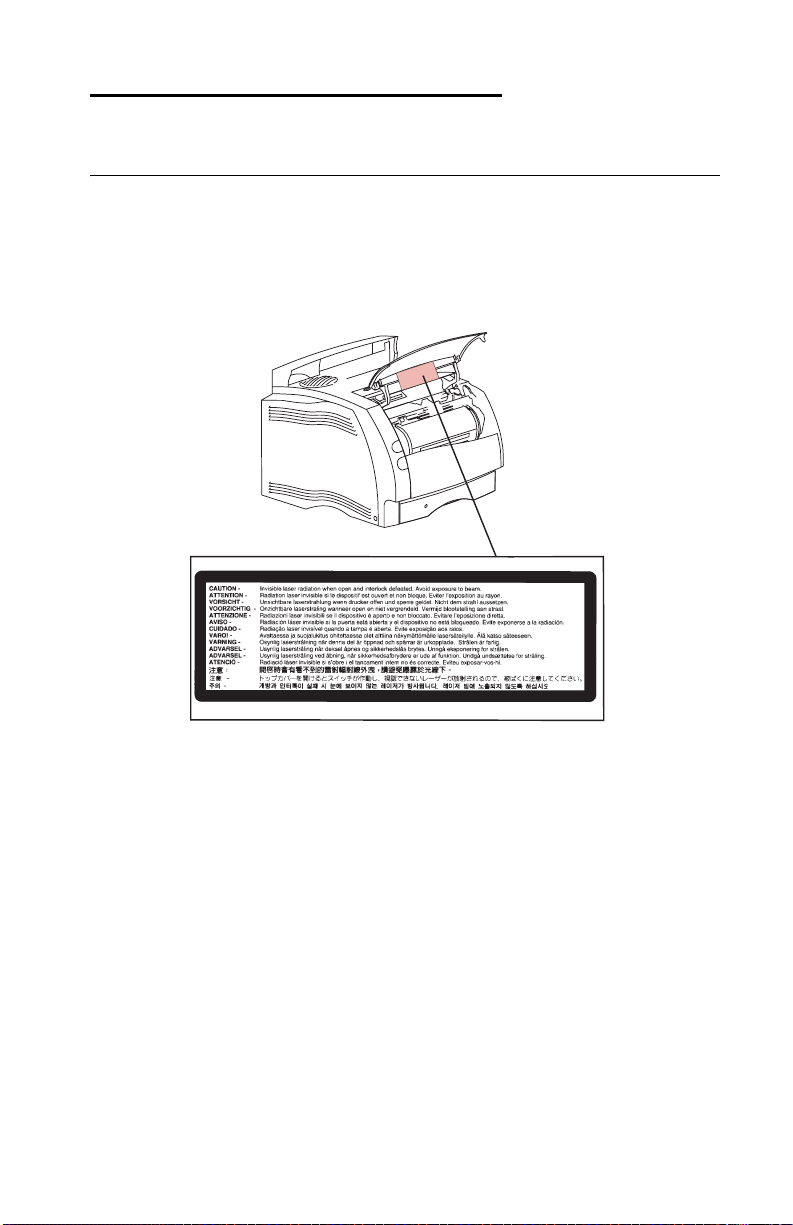

Notices and Safety Information

Laser Notices

The following laser notice labels may be affixed to this printer as

shown:

Laser Advisory Label

Notices and Safety Information ix

Class 1 Laser Statement Label

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL À LASER DE CLASSE 1

TO IEC 825

x 4059 Service Manual

Laser Notice

The printer is certified in the U.S. to conform to the requirements of

DHHS 21 CFR Subchapter J for Class I (1) laser products, and

elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 825.

Class I laser products are not considered to be hazardous. The

printer contains internally a Class IIIb (3b) laser that is nominally a 5

milliwatt gallium arsenide laser operating in the wavelength region of

770-795 nanometers. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed

service condition.

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die

Anforderungen der Bestimmung DHHS (Department of Health and

Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1).

In anderen Ländern gilt der Drucker als Laserprodukt der Klasse I,

der die Anforderungen der IEC (International Electrotechnical

Commission) 825 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des

Druckers befindet sich ein Laser der Klasse IIIb (3b), bei dem es

sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen

der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbetrieb, bei der Wartung

durch den Benutzer oder bei ordnungsgemäßer Wartung durch den

Kundendienst Laserbestrahlung, die die Klasse I übersteigen würde,

Menschen keinesfalls erreicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est certifiée conforme aux

provisions DHHS 21 CFR alinéa J concernant les produits laser de

Classe I (1). Pour les autres pays : cette imprimante répond aux

normes IEC 825 relatives aux produits laser de Classe I.

Notices and Safety Information xi

Les produits laser de Classe I sont considérés comme des produits

non dangereux. Cette imprimante est équipée d’un laser de Classe

IIIb (3b) (arséniure de gallium d’une puissance nominale de 5

milliwatts) émettant sur des longueurs d’onde comprises entre 770

et 795 nanomètres. L’imprimante et son système laser sont conçus

pour impossible, dans des conditions normales d’utilisation,

d’entretien par l’utilisateur ou de révision, l’exposition à des

rayonnements laser supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme

ai requisiti del DHHS 21 CFR Sottocapitolo J per i prodotti laser di

classe 1 ed è certificata negli altri Paesi come prodotto laser di

classe 1 conforme ai requisiti della norma CEI 825.

I prodotti laser di classe non sono considerati pericolosi. La

stampante contiene al suo interno un laser di classe IIIb (3b)

all’arseniuro di gallio della potenza di 5mW che opera sulla

lunghezza d’onda compresa tra 770 e 795 nanometri. Il sistema

laser e la stampante sono stati progettati in modo tale che le

persone a contatto con la stampante, durante il normale

funzionamento, le operazioni di servizio o quelle di assistenza

tecnica, non ricevano radiazioni laser superiori al livello della classe

1.

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los

requisitos para los productos láser de Clase I (1) establecidos en el

subcapítulo J de la norma CFR 21 del DHHS (Departamento de

Sanidad y Servicios) y, en los demás países, reúne todas las

condiciones expuestas en la norma IEC 825 para productos láser de

Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La

impresora contiene en su interior un láser de Clase IIIb (3b) de

arseniuro de galio de funcionamiento nominal a 5 milivatios en una

longitud de onda de 770 a 795 nanómetros. El sistema láser y la

impresora están diseñados de forma que ninguna persona pueda

verse afectada por ningún tipo de radiación láser superior al nivel de

xii 4059 Service Manual

la Clase I durante su uso normal, el mantenimiento realizado por el

usuario o cualquier otra situación de servicio técnico.

Declaração sobre Laser

A impressora está certificada nos E.U.A. em conformidade com os

requisitos da regulamentação DHHS 21 CFR Subcapítulo J para a

Classe I (1) de produtos laser. Em outros locais, está certificada

como um produto laser da Classe I, em conformidade com os

requisitos da norma IEC 825.

Os produtos laser da Classe I não são considerados perigosos.

Internamente, a impressora contém um produto laser da Classe IIIb

(3b), designado laser de arseneto de potássio, de 5 milliwatts

,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de

forma a nunca existir qualquer possiblidade de acesso humano a

radiação laser superior a um nível de Classe I durante a operação

normal, a manutenção feita pelo utilizador ou condições de

assistência prescritas.

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een

laserprodukt van klasse I. Voor de Verenigde Staten zijn deze eisen

vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in

IEC 825.

Laserprodukten van klasse I worden niet als ongevaarlijk

aangemerkt. De printer is voorzien van een laser van klasse IIIb

(3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt met

een golflengte van 770-795 nanometer. Het lasergedeelte en de

printer zijn zo ontworpen dat bij normaal gebruik, bij onderhoud of

reparatie conform de voorschriften, nooit blootstelling mogelijk is

aan laserstraling boven een niveau zoals voorgeschreven is voor

klasse 1.

Notices and Safety Information xiii

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i

overenstemmelse med kravene i IEC 825.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren

indeholder internt en Klasse IIIB (3b)-laser, der nominelt er en 5

milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet

770-795 nanometer. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over

Klasse I-niveau ved normal drift, brugervedligeholdelse eller

obligatoriske servicebetingelser.

Huomautus laserlaitteesta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) laserlaitteiden DHHS

21 CFR Subchapter J -määrityksen mukainen ja muualla luokan I

laserlaitteiden IEC 825 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle.

Kirjoittimessa on sisäinen luokan IIIb (3b) 5 milliwatin

galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä.

Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei

altistu luokan I määrityksiä voimakkaammalle säteilylle kirjoittimen

normaalin toiminnan, käyttäjän tekemien huoltotoimien tai muiden

huoltotoimien yhteydessä.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina

näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21

CFR, underparagraf J för laserprodukter av Klass I (1). I andra

länder uppfyller skrivaren kraven för laserprodukter av Klass I enligt

kraven i IEC 825.

xiv 4059 Service Manual

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en

inbyggd laser av Klass IIIb (3b) som består av en laserenhet av

gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770795 nanometer. Lasersystemet och skrivaren är utformade så att det

aldrig finns risk för att någon person utsätts för laserstrålning över

Klass I-nivå vid normal användning, underhåll som utförs av

användaren eller annan föreskriven serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR,

underkapittel J, for klasse I (1) laserprodukter, og er i andre land

godkjent som et Klasse I-laserprodukt i samsvar med kravene i IEC

825.

Klasse I-laserprodukter er ikke å betrakte som farlige. Skriveren

inneholder internt en klasse IIIb (3b)-laser, som består av en

gallium-arsenlaserenhet som avgir stråling i bølgelengdeområdet

770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk, vedlikehold som utføres av brukeren, eller foreskrevne

serviceoperasjoner.

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora

compleix els requisits de DHHS 21 CFR, apartat J, pels productes

làser de classe I (1), i segons ha estat certificat en altres llocs, és un

producte làser de classe I que compleix els requisits d’IEC 825.

Els productes làser de classe I no es consideren perillosos. Aquesta

impressora conté un làser de classe IIIb (3b) d’arseniür de gal.li,

nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona

de 770-795 nanòmetres. El sistema làser i la impressora han sigut

concebuts de manera que mai hi hagi exposició a la radiació làser

per sobre d’un nivell de classe I durant una operació normal, durant

les tasques de manteniment d’usuari ni durant els serveis que

satisfacin les condicions prescrites.

Notices and Safety Information xv

Japanese Laser Notice

Chinese Laser Notice

xvi 4059 Service Manual

Korean Laser Notice

Safety Information

•

This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not always

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precautions.

Consignes de Sécurité

Ce produit a été conçu, testé et approuvé pour respecter les

•

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

Notices and Safety Information xvii

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres

pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Norme di sicurezza

•

Il prodotto è stato progettato, testato e approvato in conformità a

severi standard di sicurezza e per l’utilizzo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune parti

non sempre sono di immediata comprensione. Lexmark non è

responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

•

Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

xviii 4059 Service Manual

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

Pautas de Seguridad

Este producto se ha diseñado, verificado y aprobado para

•

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

siempre evidentes. Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

Este produto foi concebido, testado e aprovado para satisfazer

•

os padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utilização de outros componentes de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Notices and Safety Information xix

Informació de Seguretat

•

Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

xx 4059 Service Manual

Chinese Safety Information

Korean Safety Information

Ozone Information

This product does not produce measurable amounts of ozone gas.

Notices and Safety Information xxi

Preface

This manual is divided into the following chapters:

• “General Information” contains a general description of the

printer, options, and the maintenance approach used to repair it.

General environmental and safety instructions as well as

special tools and test equipment are listed in this chapter.

• “Diagnostic Information” contains a service error code table,

user status message table, user error message table, symptom

table, and service checks used to isolate failing field replaceable

units (FRUs).

• “Diagnostic Aids” contains tests and checks used to locate or

repeat symptoms of printer problems. Printer operation

information is provided to enhance the tests and checks.

• “Repair Information” provides instructions for making printer

adjustments and removing and installing FRUs.

• “Connector Locations” uses illustrations to identify the major

components and test points on the printer.

• “Preventive Maintenance” contains safety inspection guidelines,

lubrication specifications, and maintenance information to

prevent problems and maintain performance.

• “Parts Catalog” contains illustrations and part numbers for

individual FRUs.

xxii 4059 Service Manual

1. General Information

The Optra™ S Laser Printers are letter quality page printers

designed to attach to IBM-compatible PC’s and to most computer

networks.

The printer is available in eleven models.

Optra S Model

1250 (4059-121)

1255 (4059-125)

General Information 1-1

Optra S Models

1620 (4059-162)

1625 (4059-165)

1650 (4059-160)

1855 (4059-185)

1855 (4059-C01)

1-2 4059 Service Manual

Optra S Models

2420 (4059-242)

2450 (4059-240)

2455 (4059-245)

3455 (4059-345)

General Information 1-3

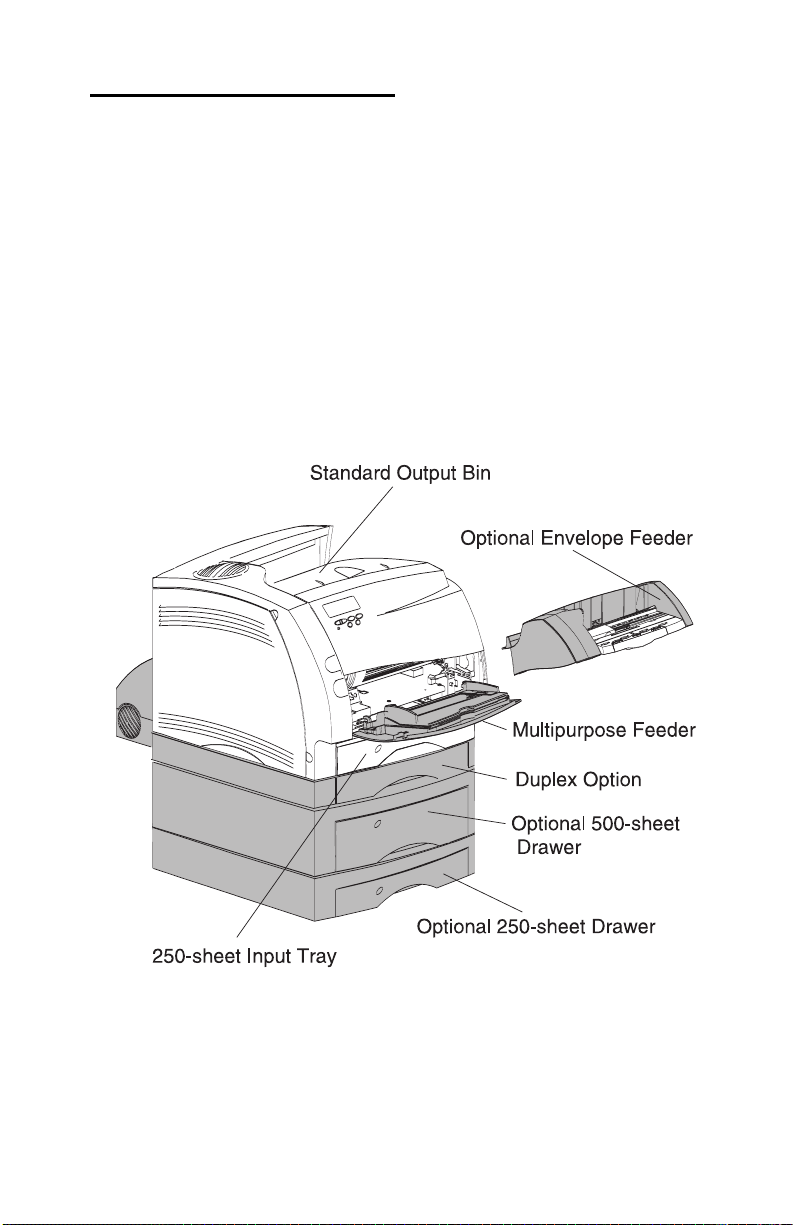

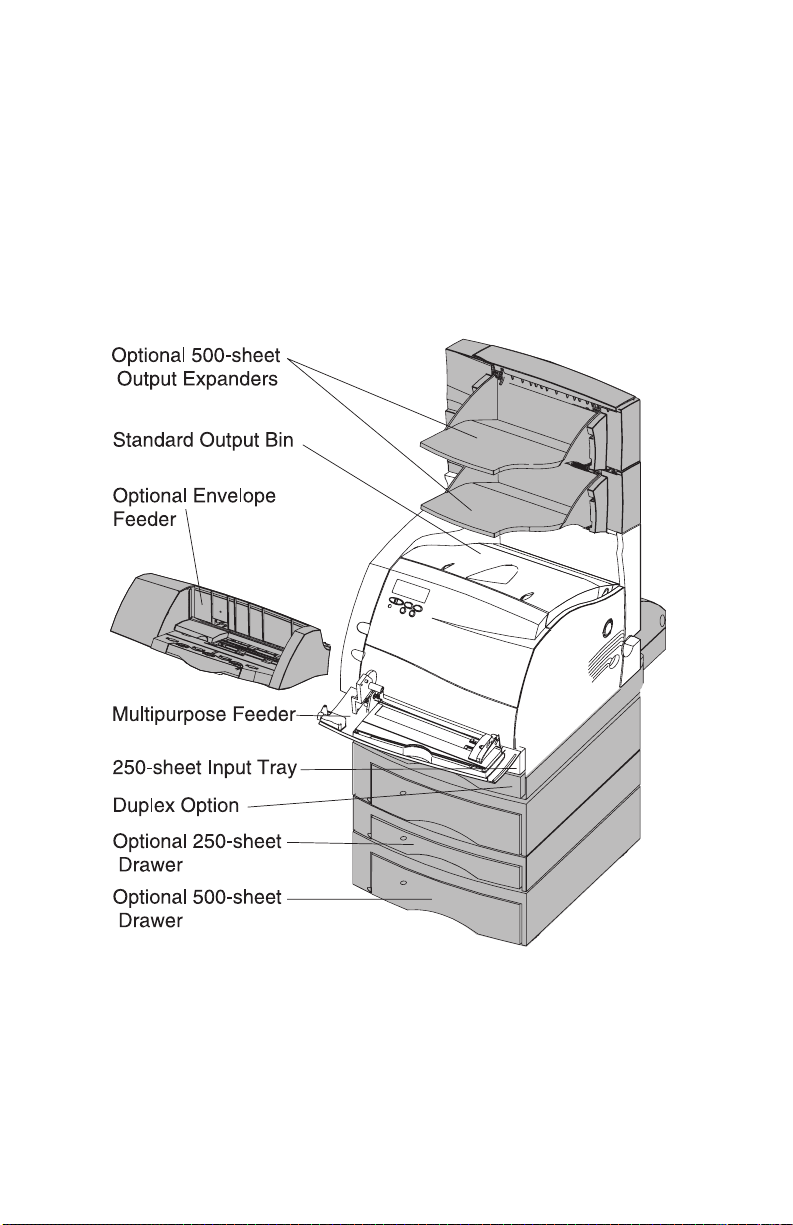

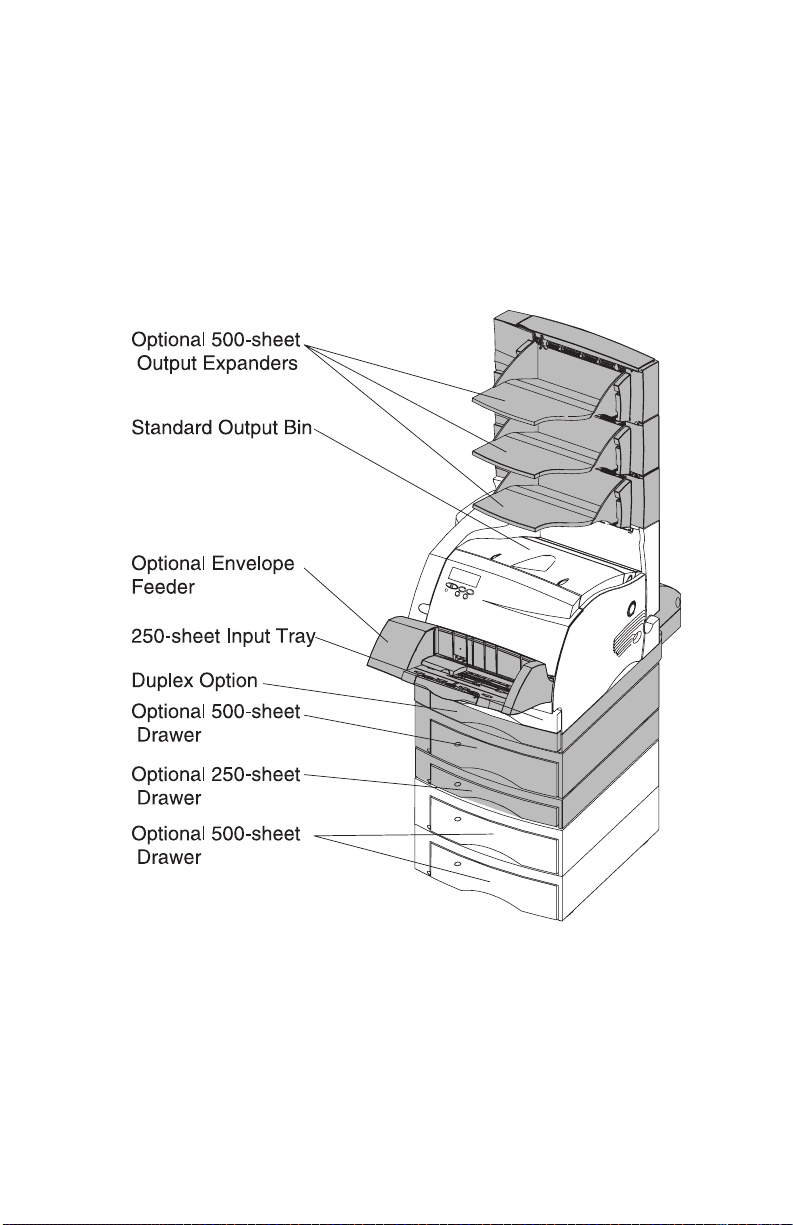

Options

The following options are available. Some options are not available

in every country. Contact your point of purchase for options available

in your country.

Memory options of 4MB, 8MB, 16MB and 32MB

Flash memory options of 4MB and 8MB

Integrated network options

Token-Ring

Ethernet

Tr i - Po r t

IR Adapter

IPDS

SCS

USB/Parallel Port

250 and 500-sheet paper trays of A5, letter, and legal size.

250 Sheet Special Media Tray Assembly

500/500-sheet dual trays (Models 2450, 2455 and 3455)

2000 Sheet High Capacity Feeder

Envelope feeder

Duplex option

Hard Disk - 1.4 GB (Models 1250, 1620, 1650, 2420 and 2450)

Hard Disk - 2.1 GB (Models 1255, 1625, 1855, 2455 and 3455)

Forms Hard Disk - 2.1 GB

Infrared Adapter

Kiosk Adapter

Output Expander (Models 1650, 1855, 2450, 2455 and 3455)

1-4 4059 Service Manual

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the service error codes,

user status messages, user error messages, service checks, and

diagnostic aids to determine the printer problem and repair the

failure. After you complete the repair, perform tests as needed to

verify the repair.

Tools Required For Service

Flat-blade screwdriver

#1 Phillips screwdriver

#2 Phillips screwdriver

7.0 mm nut driver

5.5 mm wrench

Needlenose pliers

Diagonal pliers

Spring hook

Feeler gauges

Analog or digital multimeter

Parallel wrap plug 1319128

Serial wrap plug 1329048

Twinax/serial debug cable 1381963

Coax/serial debug cable 1381964

General Information 1-5

Acronyms

CSU Customer Setup

DRAM Dynamic Random Access Memory

EDO Enhanced Data Out

EP Electrophotographic Process

EPROM Erasable, Programmable Read-Only

Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

GB Giga Byte

HVPS High Voltage Power Supply

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

MROM Masked Read Only Memory

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PC Photoconductor

POST Power-On Self Test

RIP Raster Imaging Processor

ROM Read Only Memory

SIMM Single In-Line Memory Module

SRAM Static Random Access Memory

UPR Used Parts Return

V ac Volts alternating current

V dc Volts direct current

1-6 4059 Service Manual

2. Diagnostic Information

Start

CAUTION: Remove power from the printer before you connect or

disconnect any cable or electronic board or assembly for personal

safety and to prevent damage to the printer. Use the hand grips on

the side of the printer. Make sure your fingers are not under the

printer when you lift or set the printer down.

Use the service error code, user status message, user error

message, symptom table, service checks, and diagnostic aids in this

chapter to determine the corrective action necessary to repair a

malfunctioning printer.

Service error codes are indicated by a three digit error code. If a

service error code is displayed, go to the “Service Error Codes” on

page 2-2.

User status messages provide the user with information on the

current status of the printer. Ready is displayed on the first line of the

display unless Power Saver is invoked, then Power Saver is

displayed. If a user status message is displayed, go to the “User

Status Messages” on page 2-12.

User error messages are indicated by a two or three digit error code

that provides the user with information that explains a problem with a

print cartridge, paper jam, option, port, and so on. If a user error

message is displayed, go to the “User Error Messages” on

page 2-16.

If your machine completes the “Power-On Self Test (POST)” on

page 2-24 without an error, and you have a symptom, go to the

“Symptom Tables” on page 2-25. Locate your symptom and take the

appropriate action.

If a service error code appears while you are working on the

machine, go to the “Service Error Codes” on page 2-2 and take the

indicated action for that error.

Diagnostic Information 2-1

Service Error Codes

Service Error Codes are generally non-recoverable except in an

intermittent condition when you can POR the printer to temporarily

recover from the error condition.

Error Code Action

900 RIP Software Contact the next support level or call Lexmark..

901 Engine Flash This error indicates that the flash which the engine board

902 General

Engine Software

903 Paperport

Link Driver Error

904 Interface

Violation by the

controller

software

905 Interface

Violation by

Paperport Device

906 ControllerEngine Link

Driver Error

code is programmed into is bad. Replace the engine

board.

These errors indicate an unrecoverable engine software

error. Replace the engine board.

2-2 4059 Service Manual

Error Code Action

910 DC Pick

Motor DC Pick

Motor Stall

911 DC Pick

Motor Excessive

PWM

912 DC pick

motor below

speed

913 DC pick

motor over speed

914 DC pick

motor: No

encoder feedback

917 Transfer Roll Indicates a problem in the transfer roll area. Go to the

920 Fuser Error Indicates that the fuser is below temperature when

921 Fuser Error Indicates that the fuser is below standby temperature

Error Codes 910,911,912,913 and 914 are indications

that a Tray 1 paper feed problem has been detected. Go

to the “Input Tray(s) Option Service Check” on

page 2-58.

“Transfer Roll Service Check” on page 2-105.

printing. Go to the “Cold Fuser Service Check” on

page 2-48.

when the printer is idle. Go to the “Cold Fuser Service

Check” on page 2-48.

922 Fuser Error Fuser failed to reach standby temperature. Go to the

923 Fuser Error Fuser is too hot during printing or when printer is idle. Go

924 Fuser Error An open circuit has been detected in the Fuser

925 Fuser Error Wrong fuser lamp installed. Check the fuser lamp for the

927 Fan Stalled Indicates a printer fan stalled. Go to the “Fan Service

928 Erase Lamps Indicates that the engine has detected that either the

“Cold Fuser Service Check” on page 2-48.

to the “Hot Fuser Service Check” on page 2-50.

Thermistor Circuit. Go to the “Hot Fuser Service Check”

on page 2-50.

correct type of lamp that should be installed.

Check” on page 2-47.

erase lamp assembly is missing or disconnected. Go to

the “Erase Lamp Service Check” on page 2-46.

Diagnostic Information 2-3

Error Code Action

929 Toner Sensor The toner sensor is not operating properly, the developer

drive assembly is not operating properly or the print

cartridge is defective. Go to the “Toner Sensor Service

Check” on page 2-104.

930 Printhead

Error

931-935

Printhead Error

931 - Printhead:

no first Hsync

932 - Printhead:

Lost HSYNCS

934 - Mirror Motor

Lost Lock

935 - Mirror Motor

unable to reach

operating speed.

936-937

Transport Motor

936 - Main Drive

Motor initial lock

failure

937 - Main Drive

Motor lost lock

939 Controller Engine

Communications

Error

The wrong printhead is installed. Replace with the

correct printhead.

These errors represent a problem with the printhead. Go

to the “Printhead Service Check” on page 2-89.

Indicates a problem with the main drive motor. Go to the

“Main Drive Service Check” on page 2-73.

The controller board and the engine board cannot

communicate with one another. The controller board,

engine board or interconnect board is defective. Check

each board for correct installation and secure ground. If

no problem is found, replace the FRUs in the following

order:

controller board

engine board

interconnect board

Note: The controller software also can cause a 939 error

code. Contact your next level for software support.

2-4 4059 Service Manual

Error Code Action

941 Controller

Code CRC

941 Controller

Font CRC

943 Controller

Font Version

944 Controller

Board Failure

945 Controller

Board Failure ASIC Failure

946 Controller

Board Failure SRAM Failure

947 Engine

Board

953 NVRAM

Failure

954 NVRAM

Failure

956 Configuration IDIndicates a problem with the Configuration ID. This error

Replace the controller board.

Replace the controller board.

Indicates that the controller code and FONT ROM are

incompatible.

Replace the controller board.

Replace the controller board.

Replace the controller board.

Replace the engine board.

Indicates the NVRAM Chip on the engine board has

failed. Replace the engine board.

Indicates the NVRAM experienced a CRC failure.

Replace the engine board.

occurs because the engine received a configuration ID

from the controller software which is not valid for the

level of engine code existing in the printer. Setting the

configuration ID correctly should fix this error. The ID can

be set via the NPA data stream or operator panel.

960 RAM

Memory Error

961 RAM in Slot

1 is Bad.

Note: This error is not generated at POR to allow the

servicer a method of resetting the configuration ID.

However, setting the configuration ID is the only

operation that the servicer can perform. See “Setting

Configuration ID” on page 3-20.

Indicates a DRAM Memory Error on the controller board.

Replace the controller board.

Replace the SIMM in Slot 1. If this does not fix the

problem, replace the controller board.

Diagnostic Information 2-5

Error Code Action

962 RAM in Slot

2 is Bad.

964 Emulation

Error

965 Emulation

Error

975 - 979

Network Card X

980 <device>

Comm

981 <device> The engine protocol violation detected by the specified

Replace the SIMM in Slot 2. If this does not fix the

problem, replace the controller board.

Indicates a failure within the Download Emulation which

is programmed into the code overlay SIMM. The specific

error is as follows:

964 - Download Emulation CRC Failure. Checksum

Failure.

965 - Download Emulation Outdated, The Download

Emulation and the controller code are incompatible. Go

to “Disabling Download Emulations” on page 3-3.

The following errors indicate a failure with the network

card in the specified slot. X=any card installed in slots

1,2 or 3. 975 - Unrecognizable Network Card x. Replace

Network Card x.

976 - Unrecoverable software error in Network Card x.

977 - Controller software detects that a Network Card is

installed in slot x but cannot establish communications

with it.

978 - Bad checksum while programming Network Card

x. Replace Network Card x.

979 - Flash parts failed while programming Network

Card x.

The engine is experiencing unreliable communications

to the specified device.

device.

982 <device>

Comm

983 <device> Invalid command received by the specified device.

984 <device> Invalid command parameter received by the specified

Communications error detected by the specified device.

device.

Note: Service Errors 980 thru 984 <device> can be one

of the following: engine board, duplex, tray x (1,2,3,4 or

5), envelope feeder or bin x (1,2 or 3).

2-6 4059 Service Manual

Error Code Action

990 <device> Indicates an equipment check condition has occurred in

the specified device, but the device is unable to identify

the exact component failure.

Note: <device> can be one of the following: duplex, tray

x (1,2,3,4 or 5), envelope feeder or output bin x(1,2 or 3).

991 <device>

Card

The specified device has detected an equipment check

in its system card.

Note: <device> can be one of the following: duplex, tray

x(1,2,3,4 or 5), envelope feeder or output bin x (1,2 or 3).

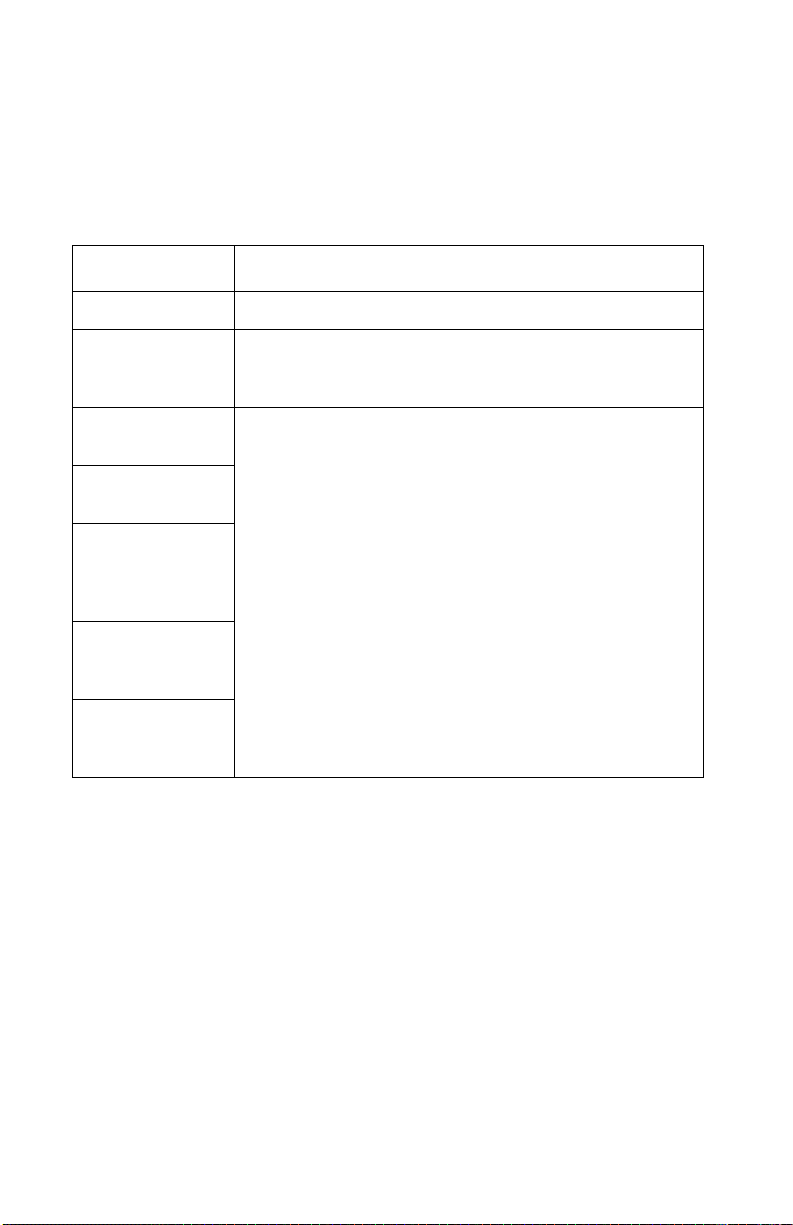

Sub Error Codes For 9XX and 2XX Error Codes

The sub error codes are helpful troubleshooting a paper path

problem, especially paper jams in the base printer, envelope feeder

and duplex unit.

The following is an example of how the printer displays a duplex unit

sub error code.

Byte 4

XX

XX

Byte 8

DU

DU

Byte 1

XX

XX

Byte 5

Byte 2

XX

XX

Byte 6

Byte 3

XX

XX

Byte 7

Diagnostic Information 2-7

Base Printer Sub Error Codes

Each status byte has a different level of troubleshooting value for

each area of the printer. The following table displays status bytes 1,

2 and 3. This set of status bytes is designed to help isolate paper

jams and paper feed problems in the base printer.

Status

Bytes 1, 2,3

84 xx 00 The input sensor is still covered by the first sheet of paper

84 xx 01 Video information has not started on the page at the input

84 xx 02 The media takes too long to complete a pass through the

84 xx 04 This can occur when a sheet of paper is in the machine

84 xx 05 This error is generated whenever media is seen at the input

84 xx 06 A paper jam is detected by the tray you are trying to feed

84 xx 07 A paper jam is detected by a smart option and an error

84 xx 08 Paper Tray 5 pass thru sensor is not activated by a sheet of

84 xx 09 Paper Tray 4 pass thru sensor is not activated by a sheet of

Explanation

through the printer and the second sheet is ready to arrive at

the sensor.

sensor within two inches after activating the input sensor flag.

input sensor.

during POST and the input sensor flag has tripped the input

sensor.

sensor before the sensor flag activates the input sensor.

from.

message displays.

paper.

paper.

84 xx 0A Paper Tray 3 pass thru sensor is not activated by a sheet of

paper.

84 xx 0B Paper Tray 2 pass thru sensor is not activated by a sheet of

84 xx 0C Paper Tray 5 pass thru sensor is not activated and never

paper.

deactivated. A sheet of paper may still be over the sensor or

the flag is still activated.

2-8 4059 Service Manual

Status

Bytes 1, 2,3

Explanation

84 xx 0D Paper Tray 4 pass thru sensor is not activated and never

84 xx 0E Paper Tray 3 pass thru sensor is not activated and never

84 xx 0F Paper Tray 2 pass thru sensor is not activated and never

84 xx 11 The paper activated the input sensor too soon.

84 xx 13 The paper activated the input sensor too soon.

84 xx 1D The envelope feeder pass thru sensor is activated and never

84 xx 1E The envelope feeder pass thru sensor is not activated.

84 xx 1F The paper fed too early from Tray 1.

84 xx 21 The smart option did not pick the paper.

84 xx 22 The smart option did not pick the paper.

8E xx 02 The input sensor is not activated even though the paper is

8E xx 0B The autocompensator DC motor stalls when attempting to

deactivated. A sheet of paper may still be over the sensor or

the flag is still activated.

deactivated. A sheet of paper may still be over the sensor or

the flag is still activated.

deactivated. A sheet of paper may still be over the sensor.

deactivated.

picked from the source.

pick a sheet of paper.

8E xx 11 The autocompensator DC motor takes too long to ramp up.

Diagnostic Information 2-9

Envelope Feeder Sub Error Codes

Status byte 1 contains the most valuable information to help isolate a

feed problem with the envelope feeder and is the only byte contained

in the following table.

Status

Byte 1

00 There was no envelope feeder error reported.

10 Printer failed POST - Homing of Envelope feeder

11 Printer failed POST - Halted Envelope Feeder

21 The envelope feeder failed to feed, envelope jam.

30 The D.C. motor failed to reach operating speed.

32 The motor stalled.

36 The motor failed to stop.

Explanation

Duplex Unit Sub Error Codes

Status byte 4 contains the most valuable information to help isolate a

failing part or assembly in the duplex option and is the only byte

contained in the following table.

Status

Byte 4

00 No duplex error. No problem was reported to the engine by the

Explanation

duplex system card.

01 The leading edge of the sheet of paper never arrived at the input

sensor.

02 The duplex option system board never received media notification

from the printer.

03 The trailing edge of the sheet of paper never cleared the input

sensor.

2-10 4059 Service Manual

Status

Byte 4

Explanation

04 The leading edge of the sheet of paper never arrived at the exit

05 The duplex logic thinks a sheet of paper is feeding to the duplex

06 The exit sensor detected a sheet of paper too early.

07 The sheet of paper’s trailing edge did not clear the exit sensor in

08 The feed motor experienced a complete motor stall.

0E The D.C. motor is under speed. The motor never reached the

13 There is paper left in the duplex option. Paper was sensed during

15 There is paper left in the duplex option. Paper was sensed during

18 The D.C. motor experienced an acceleration error.

3D There is paper left in the duplex option. Paper was sensed during

sensor.

Note: This error is the most common due to the long length of the

paper path between the input sensor and the exit sensor.

unit due to a sensor malfunction in the paper path when in fact the

printer has not sent a command to send a sheet of paper to the

duplex unit.

the desired length of time.

correct operating speed.

the homing operation during POST.

the DC motor diagnostic test during POST.

IR clear during POST.

Diagnostic Information 2-11

User Status Messages

User Status Message Status Action

Ready The printer is ready to

receive and process

data.

Ready/Hex The printer is ready and

HEX Trace is active,

which is known as HEX

Trace Ready.

Busy The printer is busy

receiving or processing

data, or printing data.

Note: The printer

indicator light blinks

while the printer is

processing data.

Press Menu> or

<Menu to take the

printer out of Ready

and enter all the

Menus except the

TESTS MENU (Busy

State).

Press Menu> or

<Menu to take the

printer out of Ready

and enter the TESTS

MENU (Busy State).

Press Select for the

values. Press Menu>

until Reset Printer is

on the second line of

the display. Press

Select to Reset the

printer.

Press Stop to take the

printer out of Busy.

The Not Ready

message is displayed.

No more data is

processed, but the

printer processes all

paper currently in the

printer paper path.

Press Go to return to

Ready.

Flushing Buffer The printer is flushing

corrupted print data and

the current print job is

being discarded.

2-12 4059 Service Manual

No button actions are

possible while this

message is displayed.

User Status Message Status Action

Printing Menu Settings The printer is processing

or printing a list of

current settings menus

because Print Menu

Settings is selected from

the menu.

Printing Directory List A directory of the flash

and disk contents is

processing or printing

because Print Directory

is selected from the

menu.

Press Stop to take the

printer out of Ready.

The Not Ready

message is displayed.

No more data is

processed, but the

printer processes all

paper currently in the

printer paper path.

Press Go to return to

Ready after the page

prints. Press Menu>

or <Menu to take the

printer out of Ready

and enter the TESTS

MENU (Busy State).

Press Select for the

values. Press Menu>

until Reset Printer is

on the second line of

the display. Press

Select to reset the

printer.

Press Stop to take the

printer out of Ready.

The Not Ready

message is displayed.

No more data is

processed, but the

printer processes all

paper currently in the

paper path. Press Go

to return to Ready

after the page prints.

Press Menu> or

<Menu to take the

printer out of Ready

and enter the TESTS

MENU (Busy Stat).

Press Select for the

values. Press Menu>

until Reset Printer is

on the second line of

the display. Press

Select to reset the

printer.

Diagnostic Information 2-13

User Status Message Status Action

Restoring Factory

Defaults

Performing Self Tests The printer is running

Not Ready

(Press Go)

Resetting Printer The printer is deleting

The printer is restoring

factory defaults.

the normal series of

start-up tests after it is

powered On. When the

tests are complete, the

printer returns to Ready.

The printer is in the Not

Ready State, which

means it is not ready to

receive or process data.

This message displays

when Menu> or <Menu

is pressed during a print

job.

any print jobs in process

and restoring all settings

to user defaults.

No button actions are

possible while this

message is displayed.

No button actions are

possible while this

message is displayed.

Press Go to take the

printer out of the Not

Ready state. Press

Menu> or <Menu to

take the printer out of

Ready and enter the

TESTS MENU (Busy

State). Press Menu>

until Reset Printer is

on the second line of

the display. Press

Select to reset the

printer.

No button actions are

possible while this

message is displayed.

Formatting Flash

(Do Not Power Off)

Program Flash

(Do Not Power Off)

Formatting Disk The disk is being

The flash memory is

being formatted.

The flash memory is

being programmed,

which means fonts or

macros are being written

to flash memory.

formatted.

2-14 4059 Service Manual

No button actions are

possible while this

message is displayed.

Do not perform any

button actions while

this message is

displayed.

No button actions are

possible while this

message is displayed.

User Status Message Status Action

Programming Disk

(Do Not Power Off)

Menus Disabled The printer menus have

Activating Menu

Changes

The disk is being

programmed, which

means fonts or macros

are being written to disk.

been disabled. This

occurs when Menu> or

<Menu is pressed while

the printer is Ready and

Menu Lockout is active.

The printer display

shows this message for

one second and then

returns to the Ready

message.

The printer is reset to

activate a printer setting

changed in the menus.

No button actions are

possible while this

message is displayed.

Note: If information is

written to flash

memory and to disk at

the same time, the

Program Flash

message is displayed.

No button actions are

possible while this

message is displayed.

No button actions are

possible while this

message is displayed.

Diagnostic Information 2-15

User Error Messages

User Error Message Explanation

200 Paper Jam

Remove Cartridge

201 Paper Jam

Remove Cartridge

202 Paper Jam

Open Rear Door

230 Paper Jam

Check Duplex

24X Paper Jam

Check Tray X

250 Paper Jam

Check MP Feeder

Paper is jammed at the printer Input Sensor.

Open the printer’s upper front door and remove

the print cartridge to access the paper jam area.

Paper is jammed between the printer’s input and

exit sensors. Open the printer’s upper front door

and remove the print cartridge to access the jam

area.

Paper is jammed at the printer exit sensor. Open

the printer rear door to access the jam area.

The paper is most likely jammed in the Duplex

Unit. Remove the duplex front cover to access the

jam area. If the paper is jammed in the rear of the

duplex, then replace the duplex front cover and

open the duplex rear door. If the paper is not

jammed in the duplex unit, then it may be jammed

in the rear of the printer. Open the printer rear

door to access the jam.

Paper is jammed around Tray X (X=tray 1 thru 5).

Try opening Tray X. If the tray is difficult to

remove, then you may have to remove the tray

above or below tray X to remove the jammed

pages.

Paper is jammed in the multipurpose feeder.

260 Paper Jam

Check Envelope Feeder

27X Paper Jam

Check Output Bin X

Insert Cartridge or Close

Door

2-16 4059 Service Manual

Paper is jammed in the envelope feeder.

Paper is jammed in output bin X (X=1 thru 3).

Open the rear door of Output Bin X to access the

jammed pages.

This message displays when the printer’s front

door is open or the print cartridge is missing.

If this message cannot be cleared go to “Cover

Open Service Check”.

User Error Message Explanation

31 Defective Print

Cartridge

32 Unsupported Print

Cartridge

Error code 31 is displayed when the top front

cover is closed and a defective print cartridge is

detected. It may take the printer 10-20 seconds to

determine if the print cartridge is defective.

Depending on the setting of the Machine Class ID

the printer may be allowed to print pages during

this 10-20 second interval. If pages are allowed to

print, they are not reprinted once a good print

cartridge is inserted.

Note: This error indicates the printer was able to

read the cartridge ID, but the ID did not pass the

verification test. To pass the verification test, the

ID read from the print cartridge must match the ID

from the last “good” print cartridge or the same ID

must be read from the print cartridge twice. The

last “good” print cartridge ID is stored in NVRAM.

Error 32 is displayed when the top cover is closed

and an unsupported print cartridge is detected. It

may take the printer 10-20 seconds to determine

if the print cartridge is supported. Depending on

the setting of the Machine Class ID the printer

may be allowed to print pages during this 10-20

second interval. If pages are allowed to print, then

they are not reprinted once a good print cartridge

is inserted. This error message also displays on a

model 3455 printer if the smart cartridge or smart

cartridge hardware is not operating correctly. Try

another model 3455 print cartridge. If this does

not fix the problem, go to “Smart Cartridge

Service Check” on page 2-102.

34 Short Paper The printer determines the paper length is too

short to print the formatted data. This occurs

when the printer does not know the actual paper

size loaded in the tray. For auto-size sensing

trays, this error occurs if the paper stop is in the

incorrect position. Make sure the Paper Size

setting is correct for the size paper that is being

used.

Diagnostic Information 2-17

User Error Message Explanation

36 Resolution Reduced The resolution of the page has been reduced

from 600 dpi to 300 dpi in order to prevent a

Memory Full error. This message can only occur if

the Resolution Reduction setting is turned on.

Note: 1200 dpi pages are not resolution reduced.

If a 1200 dpi job runs out of memory, a Memory

Full error is displayed.

37 Insufficient Collation

Memory

38 Memory Full This message is displayed when the printer

39 Complex Page This message is displayed when the page is too

51 Defective Flash This message is displayed when the printer

52 Flash Full This message is displayed when there is not

53 Unformatted Flash This message is displayed when the printer

This message is displayed when the printer

memory used to store pages is too full to collate

the print job.

memory used to store pages is full.

complex to print.

detects a defective flash. This error may occur at

power on, or during flash format and write

operations. Press Go to clear the message. The

flash is marked as bad and normal operation

continues. Flash operations are not allowed until

the problem is resolved.

enough free space in the flash memory to hold

the resources that have been requested to be

written to flash.

detects an unformatted flash at power on. Press

Go to clear the message. The flash is marked as

bad and normal operation continues. Flash

operations are not allowed until the flash is

formatted.

54 Standard Serial Error This error is displayed when a serial error

54 Serial Option X Error This error is displayed when a serial error

(framing or parity) is detected on the standard

serial port. This usually indicates the serial port is

not set up correctly.

(framing or parity) is detected on the optional

serial port. This usually indicates the optional

serial port is not set up correctly.

2-18 4059 Service Manual

User Error Message Explanation

56 Standard Serial

Disabled

56 Parallel Port Disabled This error is displayed when data is sent to the

58 Too Many Trays

Attached

58 Too Many Bins

Attached

58 Too Many Disks

Installed

61 Defective Disk This error code is displayed when the printer

This error is displayed when data is sent to the

printer across the standard serial port, but the

port has been disabled.

printer across the parallel port, but the parallel

port has been disabled. Once this message is

displayed, reporting of further errors is

suppressed until the menus are entered, or the

printer is reset.

This error code is displayed when too many input

trays are attached to the printer.

This error code is displayed when too many

optional output bins are attached to the printer.

This error is displayed when too many disks are

attached to the printer.

detects a defective disk. This error may occur at

power on or during disk format and write

operations. The following actions may be taken

while this message is displayed: Press Go to

clear the message. The disk is marked defective

and normal printer operations continue. Disk

operations are not allowed with a defective disk.

The Format Disk menu is not shown.

62 Disk Full This error code is displayed when there is not

enough free space on the disk to hold the

resources that have been requested to be written

to the disk. This message displays for both

resource and PostScript Disk operators when the

disk is full.

63 Unformatted Disk This error code displays when the printer detects

an unformatted disk at power on. Press Go to

clear the message. The disk is marked as bad

and normal operation continues. Disk operations

are not allowed until the disk is formatted.

Diagnostic Information 2-19

User Error Message Explanation

80 Scheduled

Maintenance

81 Engine Code CRC

Failure

88 Toner Low This error displays when toner low occurs and the

The operator panel displays this message at each

250K page count interval. It is necessary to

replace the fuser assembly, transfer roller,

compensator pick-rolls and charge roll at this

interval to maintain the print quality and reliability

of the printer. The parts are available as a

maintenance kit. For more information, go to

“Scheduled Maintenance (2420/2450/2455/

3455)” on page 6-2.

This error displays when the microcode to be

programmed in the engine flash code module has

failed a CRC check. Press Go to clear the

message. The microcode data is discarded and

must be re-transmitted from the host computer.

toner low alarm is activated. Press Go to clear

this message.

User Line 2 Messages

If none of the conditions exist that are listed in the following table,

line 2 is blank. If any of the messages in the table are displayed the

following actions can be taken:

Press Menu> or <Menu to take the printer offline and access the

Ready Menu group.

Note: The Menu buttons are not active if Menu Lockout is turned

on.

Press Stop to take the printer offline. The Not Ready message is

displayed. No more data is processed from the host computer. Press

the Go button to return the printer to the Ready state.

2-20 4059 Service Manual

.

User Message Explanation

Toner Low If the toner cartridge is low, then “Toner Low”

Tray X Missing If any of the input trays are missing, then “Tray X

Tray X Empty If any of the input trays are empty, then “Tray X

Tray X Low If any of the input trays are low, then “Tray X Low”

displays. The Toner Low condition clears

whenever the upper front door is opened, and

Toner Low displays again if the condition exists

after the upper front door is closed.

Missing” displays (where X designates which Tray

(1 through 5) is missing. If multiple trays are

missing, they are prioritized in this order: Tray 1,

2..., then tray 5. Tray X Missing status clears

whenever Tray X is reinserted.

Empty” displays where X designates which tray

(Tray 1 through 5) is empty. If multiple trays are

empty, then they are prioritized in this order: Tray

5, Tray 4,...Tray 1.

Note: Tray X Empty status clears whenever Tray

X is removed. When Tray X is reinserted, it is

examined and the appropriate status, if any,

displays. Also note that Empty status is not

displayed for the Envelope Feeder or

Multipurpose Feeder.

displays where X designates which tray (1

through 5) displays. If multiple trays are low, they

are prioritized in the following order: Tray

5,4,3,2,1.

Note: Tray X Low clears whenever Tray X goes

empty, or Tray X is removed. When Tray X is

reinserted, it is examined and the appropriate

status, if any, displays.

Note: The printer cannot detect when the

envelope feeder or multipurpose feeder are low.

Diagnostic Information 2-21

User Line 2 Link Messages

If the printer is locked on a particular link, the link indication displays.

If the printer is ready to process any link, none display. The link

messages are listed in the following table.

User Message Explanation

Parallel Standard Parallel Port, if available.

Serial Standard Serial Port, if available.

Serial X Serial Port, where X=1,2,3, is attached to PCI

Network X Network card X, X=1,2,3, is attached to PCI

LocalTalk X LocalTalk Card X,X=1,2,3, is attached to PCI

Infrared Standard Infrared port, if available.

Infrared X Infrared Port X, X=1,2,3, is attached to PCI

connector X.

connector X.

connector X.

connector X.

Check Device Connection Messages

The messages in the following table display when the printer looses

communications with one of the following devices.

User Status Message Explanation

Check Output Bin X

Connection

Check Env Feeder

Connection

Check Tray X

Connection

Check Output Bin X (X=1,2,or 3).

Check Envelope Feeder Option Connection.

Check Tray X (X=1,2,3,4 or 5).

Check Duplex

Connection

2-22 4059 Service Manual

Check Duplex Option Connection.

The messages in the following table can occur in two ways. The

specified device could have been removed from the printer, for

instance to clear a paper jam. Otherwise, the device can still be

attached to the printer, but is experiencing a communications

problem, not fully connected, or having a hardware failure.

• If the device is temporarily removed or not connected properly,

then reattach it. When the option is recognized, the printer

automatically clears the error and continues.

• If the option is experiencing a hardware problem, turn the printer

off and back on. If the error occurs again, turn the printer off,

remove the option and call for service.

User Status Message Explanation

Turn Printer OFF to

Enable Option

Insert Duplex Front

Cover

Close Duplex Rear Door This message displays when the duplex rear door

This message displays when a printer option,

Input Tray, Output Bin or Envelope Feeder, has

been attached while the printer is powered On. In

order to use the option, the printer must first be

powered off and back on again. Data loss results

if print jobs are active when the printer is power

cycled. If a print job is active, then remove the

option and finish the job. The printer automatically

clears the message once the option is removed.

Once the job is complete, turn off the printer and

attach the option again.

This message displays when the duplex front

access cover is not installed.

is open.

Diagnostic Information 2-23

Power-On Self Test (POST)

When you turn the printer On, it performs a Power-On Self Test.

Check for correct POST functioning of the base printer by observing

the following:

1. The LED comes on.

2. The operator panel displays one and a half row of pels, then

clears.

3. Diamonds scroll across the display, then clear.

4. “Performing Self Test” appears on the display.

– The 2000 sheet high capacity option elevator tray moves to

the uppermost position if installed.

– The duplex option is checked if installed.

– The output expander option exit rollers turn if installed.

5. “Busy” appears on the display.

6. The fuser lamp turns on. The fuser takes longer to warm up

from a cold start than a warm start.

7. The main fan turns on.

8. The main drive motor turns on.

9. The developer drive assembly drives the developer shaft in the

toner cartridge.

10. The exit rollers turn.

11. The operator panel LED starts blinking.

12. Models 2420, 2450 2455 and 3455 only - The auxiliary fan turns

on and continues to run until the printer is powered off.

13. “Ready” appears on the display.

2-24 4059 Service Manual

Symptom Tables

Symptom Table - Base Printer

Symptom Action

Auxiliary Fan (2420/2450/2455/

3455) fails to run or is noisy.

Dead Machine Go to the “Dead Machine Service

Operator Panel - One or more

buttons do not work.

Operator Panel - Display is blank.

Printer sounds 5 beeps.

Operator Panel - Display is blank.

Printer does not emit 5 beeps.

Operator Panel continuously

displays all diamonds - 5 beeps

and does not complete POST.

Paperfeed problems - Base

printer or Integrated 250 Paper

Tr ay

Paper jams at exit of Redrive

Assembly - No Duplex Option

installed.

Paper jams at exit of Redrive

Assembly - Duplex Option

installed

Go to the “Auxiliary Fan Service