Page 1

inkjet printing

TECHNOLOGY, INKS AND PAPER FOR

M-real Digital imaging

Page 2

2

Inkjet Technology: an overview 3

Heads, Modes and Nozzles 5

Putting the INK into INKjet 8

Designs on Inkjet Paper 11

The question is?... 12

Inkjet’s different images 14

Cut to Size 14

The Larger Chunk 16

Colour in Profile 17

Jetting Trends 18

INKJET PRINTING IS A NON-IMPACT

DOT MATRIX PRINTING

TECHNOLOGY IN WHICH SMALL

DROPLETS OR PARTICLES OF INK

ARE JETTED FROM A SMALL

APERTURE

(IN RAPID SUCCESSION

AND UNDER COMPUTER CONTROL

)

DIRECTLY TO A SPECIFIED POSITION

ON THE SURFACE OF A SUBSTRATE

,

IN ORDER TO CREATE AN IMAGE.

Definition

Contents

Page 3

3

Inkjet Technology Overview

In the early days of inkjet print technology development,

poor colour image quality due to ink spreading and

inter-colour bleeding (that is where the penetration of

ink into the paper is too slow to absorb multiple ink

drops on the same spot in short intervals) were widely

recognized as the critical issues.

The initial solution which has continued to be built upon

was the use of special coated media, the design of which

takes into account drop volume, evaporation rate,

penetration rate, porosity, etc (see Designs on Inkjet

Paper, page 11).

But as inkjet print technology was developed and

alternative solutions to the use of special coated media

were sought, the use of solid (hot-melt) ink was

introduced.

The idea being that on contact with the media, the ink

solidifies almost immediately, without over-absorption or

too much spreading, enabling brilliant colour and image

reproduction. These inks have the advantage of being

able to print on a wide variety of substrates such as

glass and ceramics. However, they do not allow for a

very high print resolution, hence at present the

technology is not a market leader.

With this potential alternative solution, the door was now

open to deeper exploration of the true opportunities of

inkjet printing.

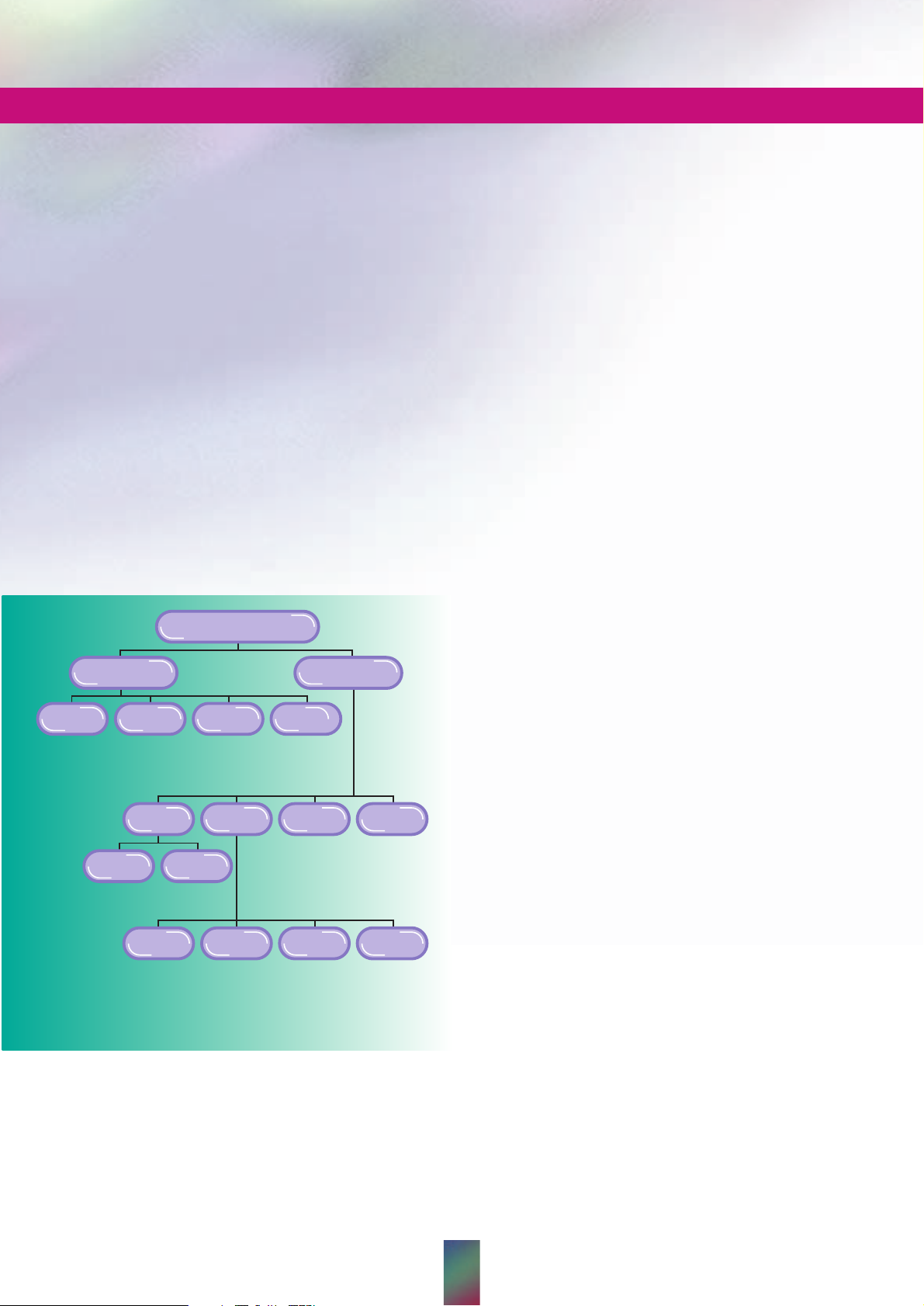

Continuous inkjet technology (The process in which a

continuous stream of ink droplets are given an

electrostatic charge which allows precise placement and

frequency of droplets) and drop-on-demand inkjet

technology (The procedure in which droplets of ink are

forced through a nozzle in a controlled fashion, rather

than in a continuous stream), soon became the two

primary categories (see Chart 1), spawning their own

technology sub-divisions. However, drop-on-demand is

at present the most widely used technology with the vast

majority of applications being printed using this method.

WHEN INKJET PRINTING FIRST CAME ON THE SCENE PRINT QUALITY WAS

GENERALLY UNSATISFACTORY

. HOWEVER, DUE TO DEVELOPMENTS IN HARDWARE

(PRINTERS), SOFTWARE, INKS AND SUBSTRATES, VERY GOOD PRINTED RESULTS

CANNOW BE ACHIEVED

. (IMPROVED PRINT QUALITY IS NOT ONLY DOWN TO BETTER

PAPER

, BUT A VARIETY OF CHANGES IN THE WHOLE ARENA)

Page 4

4

Continuous inkjet

Continuous inkjet – perhaps most widely used in the

industrial coding, marking and labelling markets - can

be designed using a binary or multiple deflection

system.

Put simply, with a binary deflection system some of the

ink-drops are charged and some are uncharged. It is the

charged drops that fly directly onto the media, while the

uncharged drops are ‘deflected’ into a gutter for

recirculation. Whereas with a multiple deflection system

(also known as raster imaging) the design is essentially

reversed, so while the uncharged ink-drops fly directly

into the gutter for recirculation, the charged drops are

‘deflected’ onto the media at different levels.

Meanwhile, another continuous inkjet concept - the Hertz

concept (named after Professor Hertz of the Lund

Institute of Technology in Sweden) - can be given

separate classification because of its unique way of

obtaining gray scale through a burst of small drops. By

varying the number of drops laid down, the amount of ink

volume in each pixel was controlled by Hertz, therefore

the density in each colour could be adjusted to create the

gray tone desired, making this ideal technology for high

quality colour images at a stage where drop-on-demand

quality could not really compete.

Drop-on-demand

But today, drop-on-demand technology can readily

compete, and the majority of activity in inkjet printing

currently available utilises one of two drop-on-demand

methods: thermal and piezo (or piezo-electric). That is to

say that the printing devices supplied by most of today’s

manufacturers are equipped with either thermal or piezo

print heads. This is mainly due to the cost effectiveness

of this technology over continuous inkjet.

Thermal inkjet print heads receive signals from the

control unit, which causes an internal heating device to

heat up rapidly and boil the ink present to form a bubble.

The heat increases until the bubble bursts and forces the

droplet out through the nozzle onto the substrate at high

speed. Droplet size may vary from half to full size by

heating one or two elements respectively.

Piezo processing on the other hand, works through the

piezoelectric effect. Here, currents pass through

piezoelectric crystals or ceramic chambers. This causes

the chambers to change shape, which squeezes ink from

the nozzles. To produce larger droplets the voltage must

be increased which displaces more ink, resulting in a

larger droplet. Manufacturers have also experimented

more recently with acoustic (also referred to as airbrush)

and electrostatic inkjet, but these technologies are still

very much in the developmental stage and few

commercial products employing them are yet available.

Chart 1

INK JET TECHNOLOGY

Continuous

Drop-on-Demand

Binary

Deflection

Elmjet

Scitex

Image

Hewlett-Packard

Olivetti

Lexmark

Canon

Xerox

Siemens

Gould

Tektronix

Sharp

Epson

On Target Tech.

Dataproducts

Epson

Trident

Spectra

Xaar

Nu-Kole

Brother

Microfab Tech.

Philips

Topaz Tech.

Videojet

Diconix

Domino Amjet

Linx

Iris Graphics Hitachi

Multiple

Deflection

Hertz

Microdot

Thermal

Roof-shooter Side-shooter

Squeeze Tube

Bend Mode Push Mode Shear Mode

Piezoelectric Electrostatic Accoustic

Page 5

5

Heads, Modes and Nozzles

NOT SO WITH PIEZO INKJET TECHNOLOGY, WHERE

THE ELECTRICALLY CHARGED PIEZOELECTRIC

CRYSTAL PRESSURISES THE FIRING CHAMBER IN

THE PRINT HEAD AND PUSHES THE INK OUT

. EVEN

THOUGH AN ELECTRIC PULSE IS UTILISED

, IT

ESSENTIALLY TRIGGERS A MECHANICAL

‘JETTING’

PROCESS, SO VAPOUR BUBBLES DO NOT HAVE TO BE

GENERATED AND THE INK IS NOT SUBJECT TO

THERMAL SHOCK

.

This gives more flexibility in the inks that can be used,

such as water based and solvent based ink types, and

the ink viscosity can be higher, so the risks of kogation

are reduced. It has also become easier now to develop

special inks for substrates that have special

requirements (see Putting the Ink into Inkjet, page 6).

Besides, the piezo print head is more resistant to

aggressive chemicals. Finally, a major advantage of

piezo is the possibility of making smaller units, resulting

in more nozzles per print head, which allows a higher

resolution of print to be achieved.

A THERMAL INKJET PRINT HEAD IS EQUIPPED WITH A RESISTOR, WHICH HEATS

THE INK USING ELECTRICITY

. THE VAPOUR INSIDE THE PRINT HEAD’S FIRING

CHAMBER EXPANDS AND PUSHES THE INK OUT OF THE NOZZLE

, WHILE THE

REMAINING VAPOUR BUBBLE COLLAPSES AFTER COOLING AND SUCKS NEW INK

INTO THE FIRING CHAMBER

. THROUGH CHANGING THE HEAT ENERGY, THE INK-

DROP SIZE CAN BE TUNED ACCORDING TO THE APPLICATION REQUIRED.

The main drawback with thermal inkjet print heads is

that they have a shorter lifetime. Problems can be

caused either through the collapse of the vapour

bubble - creating a rapid thermal shock, which can

cause damage to the print head - or through early drying

of the heated ink in the nozzle. The ink formulation,

therefore, usually has to be adapted to help the print

head withstand any thermal shock and to minimize any

such kogation.

Page 6

6

Print head configurations

Inkjet technology is used in many different architectures

and with different operating principles, depending on the

configuration of its print heads. With thermal inkjet

technology, for example, the print head can be a roof

shooter, with an orifice located on top of the heater, or a

side-shooter, where the orifice is located on the side

nearby the heater.

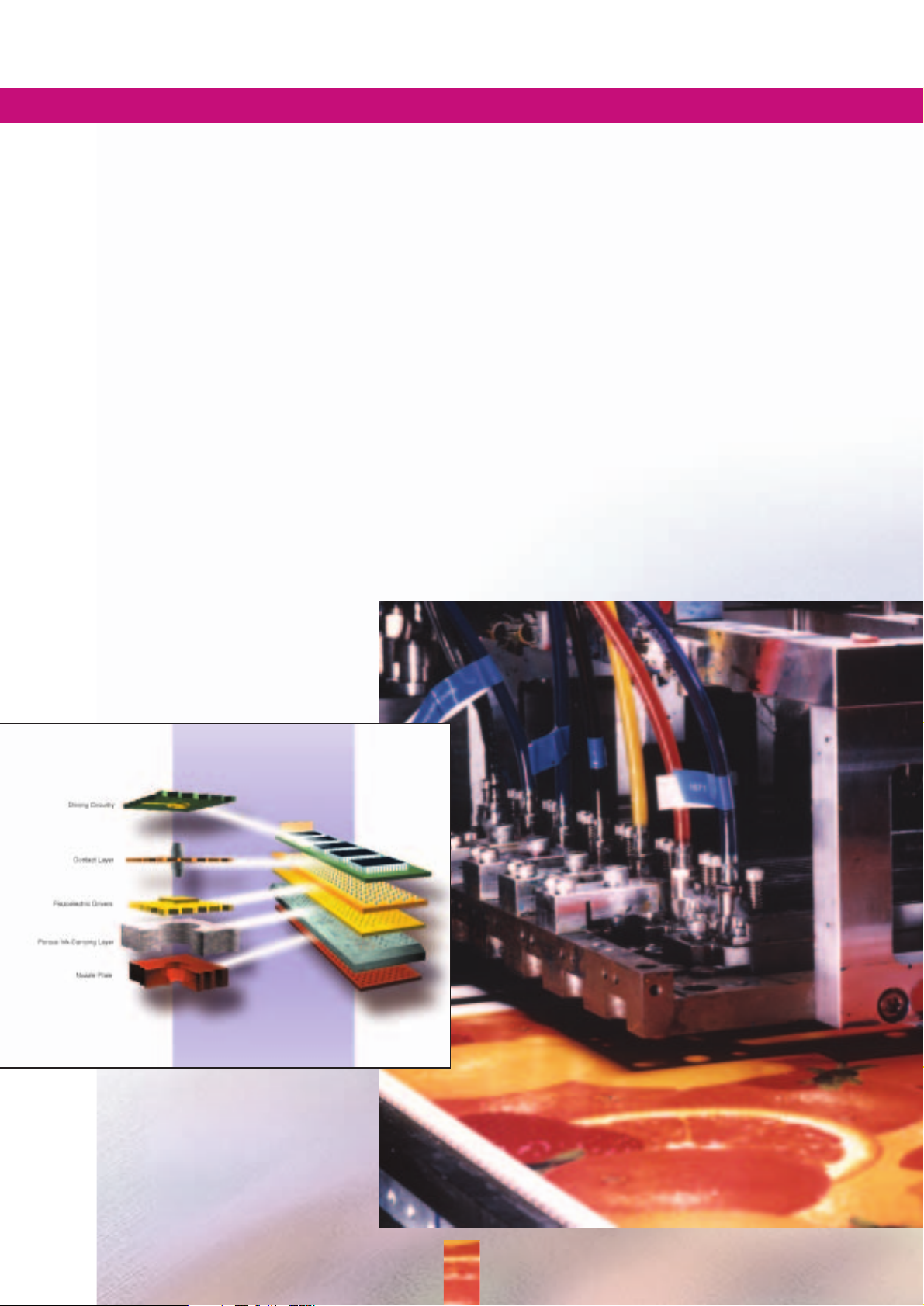

For piezo, there are four main types of print head

configuration - squeeze, bend, push, and shear –

dependent on what is called, the piezoceramic

deformation mode.

A squeeze-mode design usually has either a thin tube of

piezoceramic surrounding a glass nozzle,

or a piezoceramic tube cast in plastic

that encloses the ink channel.

In a typical bend-mode design, the piezoceramic plates

are bonded to the diaphragm forming an array of

bilaminar electromechanical transducers used to eject

the ink droplets.

For a push-mode design, as the piezoceramic rods

expand, they push against ink to eject the droplets.

And in a shear-mode print head, the shear action

deforms the piezoplates against ink to eject the

droplets. Interaction between ink and piezomaterial is

one of the key parameters of this design, as currently

pioneered by Xaar.

Page 7

7

All of these designs and their drop performances

ultimately determine the quality and throughput of a

printed image. The trend in the industry is in jetting

smaller droplets for image quality, generating faster

drop frequency through a higher number of nozzles for

additional print speed, while inevitably trying to keep the

cost of manufacture down. In an attempt to achieve this,

what we have seen is the continued miniaturization of

the inkjet print head design, where consequently,

reliability issues have become even more critical.

The nozzle

Independent of a print head’s configuration, one of the

most critical components in a print head design is its

nozzle. Nozzle geometry such as diameter and thickness

directly effects drop

volume, velocity, and

trajectory angle.

Variations in the

manufacturing process of

a nozzle plate can

significantly reduce the

resultant print quality.

Image banding is a

common result from an

out-of-specification nozzle

plate. Various nozzle

geometries have been

designed for inkjet print

heads: the two most

widely used methods for making the orifice plates being

electroformed nickel and laser ablation on the polymide

(other known methods include electro-discharged

machining, micro-punching, and micro-pressing).

Because smaller ink drop volume is required to achieve

higher resolution printing, the nozzle diameter of print

heads has become increasingly small. With the trends

towards smaller diameters and lower cost, the laser

ablation method has become increasingly popular in the

manufacture of inkjet nozzles. This trend towards

smaller nozzles can more easily be achieved using piezo

technology.

Thermal Piezo

+ Less expensive technology + Wide range of inks useable

+ Modulate drop size ->

better resolution

- Limited inks useable + Higher drop rates

- Limitations on ink properties + Longevity

- Limited number of

nozzles per row

- Higher costs per nozzle

Thermal vs. Piezo Technology

Page 8

Putting the Ink into Inkjet

ARGUABLY ONE OF THE MOST CRITICAL COMPONENTS OF INKJET PRINTING IS

THE INK USED

. INK CHEMISTRY AND FORMULATIONS CAN NOT ONLY DICTATE (IN

PART AT LEAST

) THE FINAL QUALITY OF THE PRINTED IMAGE - E.G. THE

BRILLIANCE OF COLOUR

, THE IMAGE’S LIGHTFASTNESS, ETC - BUT AN INK’S

VISCOSITY AND OTHER PROPERTIES CAN ALSO HAVE AN IMPACT ON THE DROP

EJECTION CHARACTERISTICS AND THEREFORE THE RELIABILITY OF THE

PRINTING SYSTEM USED

.

For this reason, many different types of inks have been

developed and experimented with, for use in inkjet

applications. These include:

Aequeous/Water-based Inks

Aqueous- or water-based inks are most commonly used

in Small Office and Home Office (SOHO) desktop inkjet

printers (e.g. the Hewlett-Packard DeskJet, Canon BJC

and Epson Color Stylus). In the case of thermal inkjet,

due to the basic vapour bubble formation process, water

is an obvious material of choice. Viscosity of waterbased inkjet inks range from 2 to 8 cps.

When a water-based ink droplet lands on

the surface of an uncoated media such

as bond, copy, or plain paper, the ink

tends to spread along the paper fibres

and penetrate into the bulk of the paper.

Such ink behaviour lowers colour density

and spot resolution on paper. Whilst

some evaporation takes place, a waterbased ink depends on penetration and

absorption for its drying mechanism.

Paper or other media with a coated

water-receiving layer can greatly improve

both colour density and resolution by

controlling the ink spreading and

penetration at the coated layer.

8

Print quality • Brilliant colours • High colour density

• Colour stability

Light fastness

Water fastness

Slow aging

Runnability

• Surface tension • Ink formulation flexibility

Important Ink Properties

Page 9

9

Pigmented/Dye-based Inks

Another major recent development in the inkjet printing

industry is the successful implementation and

commercialisation of pigmented inks in colour printing

applications. Many companies including recognised

colour quality leaders like 3M, Dupont and Kodak already

have pigmented inkjet ink products on the market.

Dye based inks are made by completely dissolving dyes

in a carrier that enables the dye to be easily applied.

Dyes are much stronger and produce more colour of a

given density per unit of mass. However, one significant

advantage of pigment-based as compared to dye-based

ink is its colour durability when exposed to light or

extreme weather conditions. This feature is critical to

applications such as billboards or other large-format

displays. Dyes will soak into the paper fibres and spread

out more, which means that they are less light fast and

fade quicker, often after only 6-12 months, whereas

pigmented inks can last several years. Dye inks are also

less water resistant, as the pigmented ink’s particles

tend to get stuck in paper fibres as the ink dries, so only

about 5-10% will re-dissolve if splashed with water. This

tendency of dye inks to soak into the fibres can also lead

to problems with bleed and wicking and result in poor

quality printing.

Pigmented inks are formed by suspending small

coloured particles in a carrier, as opposed to dissolving

them. Particles are coated in a polymer to generate a

static charge around the particle to keep them from

sticking together. The pigment sits on the surface of the

paper more readily than a dye; hence less ink is needed

to create the same density of colour and the small

particle size allows sharper image detail. However, as

compared to dye-base, pigment-based ink has the

inherent disadvantage of particle dispersion instability

that may lead to nozzle clogging, and with the

aforementioned design trend towards smaller nozzle

diameter, this could become more of a concern.

Pigmented inks also have a lower rub resistance and are

more sensitive to scratching.

Page 10

10

Solvent/Oil-based Inks

Solvent-based inks are commonly used in industrial

marking or coating applications where the printing is

done on a nonporous substrate such as plastic, metal,

or glass. Because no absorption or penetration

occurs, the printed image relies on quick evaporation

of the ink solvent to be fixed onto the substrate.

However, there are several disadvantages to these

types of inks, solvent inks tend to emit a strong smell

and over time the printed area can smudge. These

inks also have environmental and health and safety

issues, for example, inks that contain petroleum

solvents emit volatile organic compounds (VOCs) into

the air. VOCs can be an irritant for printshop workers

when present in the form of vapours, and also

contribute to the formation of smog. Inhalation of the

solvent can cause drowsiness and hallucinations and,

amongst other things, can be carcinogenic. Of course,

these solvent vapours cause environmental problems

when released in to the atmosphere and can be

flammable and there is substantial pressure on ink

manufacturers to develop solvent recovery and

incineration systems but the development of solvent

free inks remains the popular option.

Another more recent, non-aqueous ink option is oilbased ink. More often found in large-format inkjet

printers (several of which utilize Nu-Kote piezo shearmode print heads) the use of non-polar oil-based ink

minimizes the effect of electrical fields on the ink and

print head materials. There are also legitimate claims

that with some coated media, oil-based inks enjoy

faster drying time and the absence of cockle on paper

substrates, when compared with water-based inks.

Wax/Polymer-based Inks

Solid (hot-melt) ink, as referred to in the Inkjet

Technology Overview, is usually solvent-based and is

effectively solid at room temperature. This ink is jetted

out from the print head as a molten liquid and, upon

hitting a recording surface, the molten ink drop solidifies

immediately, thus preventing the ink from spreading or

penetrating the printed media. The quick solidification

feature ensures that image quality is good on a wide

variety of recording media.

Inkjet image quality and durability for water-based,

solvent and oil-based inks are generally acceptable

when they are printed on inkjet papers or coated

substrates. But when printing on non-absorbent

substrates such as metal, glass and plastic, these types

of inks are generally unable to produce durable and

sharp images. To solve this, the idea of using UVcurable, wax or polymer-based inks was discussed for a

long time. But factors relating to inkjet print head

capability, photo-initiator and low-toxicity monomer

availability, hindered the progress of UV-curable inkjet

ink development. Today, with recognised increases both

in the capability of and availability of inkjet print heads,

and with UV photoinitiators, monomers and even

oligomers readily available at economic scale, successful

development of UV-curable inkjet inks is on the horizon.

Page 11

Designs on

Inkjet Paper

•

Optimum print colour density (good fixation);

•

Fast drying time without paper curl or cockle (fast

absorption);

•

High brightness;

•

Lightfast and waterfast qualities;

•

Wet rub and scuff resistance (no ink smearing);

•

Lateral ink spread to enhance text resolution and

colour-to-colour bleed by controlling the dot diameter.

(The resolution specified by a printer can only be

achieved through using the right substrate);

•

Sufficient stiffness for feeding through printer.

Of these: printed colour density, ink drying time and

colour bleed all depend heavily on the coating structure

of the paper. Paper or other media with a coated waterreceiving layer can greatly improve both colour density

and resolution by controlling the ink spreading and

penetration at the coated layer.

For this reason, within the past few years, the market for

specialty-coated inkjet media has exploded, especially in

the home photo quality and large-format inkjet printing

areas.

Another important factor in achieving quality prints is

resolution. This relates to how much pictorial

information a file holds. The DPI (dots per inch), tells us

the resolution of an image; the higher the dpi, the higher

the resolution and hence the finer the detail of the

printed image. High resolution is generally considered to

be 1200-5000 dpi.

In conventional printing, variable sized dots are set down

in fixed patterns that in CMYK form 'rosettes'. These are

formed because the screen is orientated differently for

each colour. So screen angle, dpi and dot size all affect

the way that the transparent inks overlap and make

colours and images in conventional printing. Screen

angles are optimised for specific plates, presses,

processes, etc., to prevent moiré and maximize

sharpness and vibrance.

Unlike commercial four-colour process, most inkjet

printing forms images by printing small dots of the

same size at varying distances from each other – often

overlapping so dot gain is more critical (This is known as

stochastic screening). Dot gain relates to the tendency of

the dots to print larger than they appear on the original.

A drop in print contrast indicates that dot gain is too

great – the dots merge and the image loses definition.

On press dot gain is normally due to ink spreading as it

hits the paper, and is affected by many factors; ink

viscosity, substrate absorbency, paper coating and half

tone screen ruling (fine and stochastic screen give

higher dot gain)

IF WHAT INK IS USED FOR INKJET PRINTING IS

IMPORTANT

, SO IS THE CHOICE OF STOCK. THE

IDEAL WISH

-LIST WHEN LOOKING AT DESIRED

PROPERTIES OF PAPER USED IN INKJET PRINTING

,

WOULD INCLUDE:

11

Page 12

12

After a while the image looks like it has a metallic

sheen in dark areas

‘Bronzing’ occurs when dye-to-dye interactions compete

with the dye to substrate interactions. The dyes in the

ink aggregate or crystallise on the paper surface, which

leads to a loss in optical density. It can be limited by

reducing the amount of black in the image.

Different colours seem to have merged

Colour to colour bleed is a common problem when the

wrong stock is chosen. The ink doesn’t dry fast enough

and its dyes are not immobilised quickly enough, with

the result that they blend together. Bleed does not

always happen immediately, but may happen some time

after printing, particularly in the case of exposure to heat

or humidity or by oil based/solvent based inks over time.

Edges look jagged

If the resolution of the file is too low or the enlargement

too great then this can lead to ‘jaggies’, these are where

the individual pixels of the image become visible and are

especially obvious in the curved parts of the text that

have been over-enlarged.

The image looks very grainy and pixelated, curves

have a stepped appearance

Many images from the web or free CD’s can be of low

resolution. In general a full-page bitmap file will be

several megabytes in size, although the stored version

may be smaller if it is compressed (e.g. jpeg).

An important factor in achieving quality prints is

resolution. This related to how much pictorial

information a file holds. The DPI (dots per inch), tells us

the resolution of an image; the higher the dpi, the higher

the resolution and hence the finer the detail of the

printed image. High resolution is generally considered to

be 1500-5000 dpi.

The ink seems to leak through to the other side of

the paper

This is known as ‘strike through’ and occurs when the

paper has insufficient absorption capacity for the density

of ink. – Use a higher grade or heavier coated paper.

The image is not the right colour

This can have many origins: the colour of the print may

well not match that of the screen or the original unless

great care has been taken to calibrate each element of

the system. The colour of an image can be corrected

either in the imaging application or in the printer driver.

If you have several images from the same source, e.g.

camera, scanner or CD, then they are likely to all have

the same characteristics. Images that come from

varying sources may need to be calibrated before use.

The image is too light or dark

This could be because the original image is very dark, or

light, either change this in the application or use the

controls of the driver to try to lighten the image. When

scanning an image, try to use the white and black point

controls to set the range of light and dark for the image.

If it doesn’t print like the screen image this may be

because your screen is not calibrated. Several tools exist

to help set up the monitor, these are often shipped

either with the image application or with the graphics

card.

Paper is too

adsorbent and

ink can be seen

on back of sheet

Inks do not dry

fast enough and

blend together

The eye is very sensitive to ‘breaking’ of smooth curves.

The figure on the right is double the resolution of the

figure on the left, it’s easy to see that if the resolution is

higher a smoother curve can be produced.

Low resolution output High resolution output -

2400-3200dpi

The questions is ? . . .

Page 13

13

The shadow areas look grainy but the rest of

the print it OK

The effect, often referred to as ‘coalescence’, refers to

the way in which the ink is absorbed into the media.

Several things can be done to counter it, the most

important is to choose the correct print mode in the

printer driver. In general terms the highest quality

settings available will give the best results. Choose the

highest resolution possible, the finest drop size possible

and the highest quality media.

The image appears speckled

‘Mottling’ is due to uneven ink density on the sheet and

can be caused by: Poor paper formation, poor coating

coverage or drying. When using pigmented inks

improper ink absorption or binding can cause ‘rub off’.

The media takes too long to dry

The time taken for a print to dry depends on several

factors, i.e. The printer, ink and ink coverage. The

amount of ink printed which in turn depends on the

density of the image. Photographic and graphical images

use much more ink than text. Check your printer

settings to avoid the use of to much ink for the image.

The temperature and humidity of the room and the

amount of air movement also play an important role in

determining how long a print needs to dry. High humidity

will slow down the drying process. Inkjet media is

designed to work best in environmental conditions

ranging from 20ºC to 28ºC and 30% to 70% humidity.

For the best results carefully remove the print from the

printer once it had finished printing and place it flat in a

warm dry environment with good air circulation.

Normally a print will dry in several minutes, however if

you plan to print on the back it is advisable to wait a

couple of hours.

Sheets stick together when they collect in the output

tray of the printer.

Check you printer setting to avoid the use of too much

ink, avoid having multiple prints landing on each other,

remove the print once finished and place it elsewhere to

dry for several minutes

The sheet is not flat after drying

Too much ink has been used causing curl, check you are

using the correct material and if you have used the

correct printer settings.

Unprinted material sticks together

Working or storage conditions for relative humidity are

important. See your paper instructions for the optimum

storage conditions.

The paper won’t load into the printer

Check that the driver is not set to manual loading.

Ensure the paper is flat and not creased, that there is

nothing obstructing the paper entering the printer such

as tears etc. Ensure the paper is correctly positioned on

the media tray. Try feeding the paper manually, one

sheet at a time or using a different media tray.

It takes a long time before it prints

Photo and graphical images can be very large files and

take longer to process, be patient and see if it works

eventually. If it is just slow this might indicate that you

need more memory, or are running low on disk space.

Trying to do other tasks in parallel will slow the machine

down. Shut down all other applications and try again.

My printer doesn’t print

Check that everything is turned on and that all cables

are attached correctly, if possible use the driver to

perform a communication test with the printer. Try

printing a test page from the driver. If all of this works,

try printing using a different application. E.g. a wordprocessing package to check the printer/computer

communication. Finally, try printing a small image (most

packages have tutorial or sample images which are

small files), the image may be too complex for your

computer and printer to handle. Try printing the

document without the image to see if this is the case. If

so, reduce the resolution of the graphics as the higher

the resolution the more memory and time the process

will take. If you are printing several graphical pages or

pages with heavy formatting try to print just one or two

pages at a time.

The printer loads more than one sheet at once

Try putting fewer sheets in the tray and fanning them

before loading them, if this fails then try loading them

manually one sheet at a time.

Properties Key factors to achieving:

Sharpness Uniform and circular dots, exact placement,

controlled dot gain

Contrast Minimal ink penetration into substrate,

controlled dot gain

Properties Key factors to avoiding:

Mottling Homogeneous paper, uniform distribution of

fibres and fillers

Ink bleed Rapid drying through good and even ink

absorption

Factors Influencing Image Quality

Page 14

14

Inkjet’s different images

In newly emerging areas like medical

imaging and 3-D printing, significant

improvement still needs to be made to

the print head design and ink

formulations in order to fulfil the high

expectations of printer reliability and

image durability demanded.

But drop-on-demand inkjet’s capacity to

print vivid colour images at relatively low

cost has already led to the technology’s

particular dominance in both the cutsize,

Small Office and Home Office (SOHO)

sector and in the large-format colour

printer market.

Cut to Size

In the office network colour printer

market, the battle between colour laser

and colour inkjet printing technologies is

still ongoing: the delicate balance

between print speed, image quality,

image durability, purchase price and

operation cost all key factors.

The facts are that:

•

by end 2002, over 50% of the SOHO

printer market is expected to have turned

to colour - this statistic includes both

laser and inkjet printer options, with the

latter steadily gaining dominant market

share;

•

there is a continued decentralisation of

office printing away from the photocopier

towards personal ‘desktop’ printers;

•

high quality colour documents such as

proposals and presentations, previously

outsourced to printers and copy shops,

are being printed more and more inhouse;

•

the growing range of digital cameras

and desktop scanners has seen

widescale escalation of desktop printing

of images.

ASTOUCHED ON THROUGHOUT THIS DOCUMENT, INKJET PRINTING

TECHNOLOGIES ARE USED IN A WIDE RANGE OF APPLICATIONS INCLUDING

HOME

, OFFICE, LARGE FORMAT, INDUSTRIAL, THREE-DIMENSIONAL, MEDICAL,

PACKAGING, TEXTILE AND OTHER SPECIALTY PRINTING SECTORS AND EVEN

COMMERCIAL WEB

-FED PRINT WORK.

Market/Application Key Player

Current Markets

Small office/ Hewlett-Packard,

and Applications: home office Canon, Epson

Office network Tektronix, Hewlett-Packard

Graphic arts Iris, Tektronix, Epson

Industrial/postal VideoJet, Marsh, Image,

marking Willet

Large format ColorSpan, Encad, Hewlett-

Packard, Mimaki, Epson

Emerging Markets Home photo Hewlett-Packard, Epson,

and Applications: Canon

Multifunction Hewlett-Packard, Canon

Digital color press Scitex, ACS, Tektronix

Grand format Idanit, Vutek, Nur,

ColorSpan, Mutoh

Textile Canon, Seiren, Stork, Toxot

Medical imaging Iris, Sterling Diagnostic

3-D printing 3D System, Z Corporation

Applications in Inkjet Printing

Page 15

15

SOHO Paper Demands

Cut size stock for SOHO printing

environments can be split into four main

types:

- Glossy coated paper is ideal for photorealistic imaging, but often considerably

more expensive due to the PE coating,

the binding systems, the different

pigments, namely special pigments

which allow high transparence and high

absorption and/or the fixation agent.

- Matt coated paper typically has a silicabased coating, but still holds good colour

graphics quality.

- Lightly coated multi-function papers are

becoming increasingly popular due to the

added imaging flexibility they allow at a

comparatively low sheet cost, making

them ideal for multi-purpose print

environments.

- Uncoated surface papers for

monochrome printing where colour

quality is not even an issue.

•

Presentations

•

Reports

•

Promotional documents

•

Leaflets

•

Flyers

•

Charts

•

Direct mail

•

Posters

•

Letterheads

•

Business cards

•

Photographs

•

Proofs

•

CD Covers and labels

•

Greeting cards

Cut size Applications

Broadly speaking then, paper demands

for SOHO inkjet printing include:

• Excellent print quality (good fixation of

the ink on the substrate)

• Fast ink drying time

• Good light stability

• High dimensional stability (i.e. low or

no cockling/curling)

• High ink absorption capability

• Adequate surface friction to enable

better feeding

• Good printed opacity (particularly in a

duplex printing environment)

Page 16

16

The Larger Chunk

The introduction of wider print heads and multiple

arrays coupled with the availability of increasingly high

performance inks - UV curing, water-resistant,

pigmented inks (see Putting the Ink into Inkjet, pages

8-10) - have brought about a revolution in the large

format application capabilities of inkjet. And, as a

considerably faster printing technology with a wider

colour spectrum (now up to 8 colours) than, for example,

screen printing, there has been an understandable

explosion of interest in large format inkjet printing

systems.

ANOTHER MARKET SECTOR WHERE INKJET PRINTING

HAS MADE HUGE INROADS IN RECENT YEARS IS LARGE

FORMAT PRINTING

.

Inkjet’s inherent economies of scale and its capacity for photo-realistic

image quality at speed and at a reasonable cost per page, have also

recently led to an inkjet assault on the world of colour proofing, where

optimum colour quality is an essential as distinct from a value-added

component (see Colour in Profile, on the next page).

With this and other large format inkjet applications in mind, paper

demands for large format inkjet printing centre around:

• Appropriate print quality for a specific application (e.g. CAD paper,

photo paper, etc)

• Fast ink drying time

• Good light stability and lightfastness

• High dimensional stability (i.e. low or no cockling/curling)

• High ink absorption capability

• Proper surface friction

• Suitability for hot and cold laminating

• High opacity

• Water resistance

•

Point of sale displays

•

Banners and signs

•

Architectural renderings

•

Project plans

•

Packaging prototypes

•

Comps and proofs

•

Posters and Photos

•

Vehicle graphics

•

Trade show graphics

•

Maps

•

Entertainment industry

•

Museums and art galleries

•

Wall coverings

•

Fine art

•

Proofing

Large format Applications

Page 17

17

This variable is known as metemerism and essentially

points to the fact that an optimum digital inkjet colour

proof system must deliver 4,000-6,000 colours in a

gamut to match offset printing. A seemingly short order

if you consider that the human eye can distinguish up to

ten million colours in its gamut. But still a significantly

tall technology order, even given the recent advances in

inkjet.

This is where ICC profiling comes in. The International

Colour Consortium (ICC) was established in 1993 by

eight industry vendors for the purpose of creating,

promoting and encouraging the standardization and

evolution of an open, vendor-neutral, cross-platform

colour management system architecture and

components. The resultant ICC profile format essentially

provides a cross-platform device profile format that can

be used to translate

colour data created on one

device into another

device's native colour

space. Furthermore,

embedded ICC profiles

allow users to

‘transparently’ move

colour data between

different computers,

networks and even

operating systems without

having to worry if the

necessary profiles are

present on the destination

systems.

ICC profiles permit tremendous flexibility

to both users and vendors. For example,

it allows users to be sure that their

image will retain its colour fidelity when

moved between systems and

applications, assuming the new system is

capable of reproducing all the original

colours. While it allows an inkjet printer

manufacturer to create a single profile

for multiple operating systems.

The specification divides colour devices

into three broad classifications: input

devices, display devices and output

devices. For each device class, a series of

base algorithmic models are described

which perform the transformation

between colour spaces. These models

provide a range of colour quality and

performance results which provide

different trade-offs in memory footprint,

performance and image quality. The

device profiles obtain their openness by

using a well-defined reference colour

space and by being capable of being

interpreted by any ICC operating system

or application that is compliant with the

specification.

Colour in Profile

BEFORE EVEN GETTING INTO PRINTED BEHAVIOURAL QUIRKS

CAUSED BY THE USE OF DIFFERENT INKS ON DIFFERENT PAPERS

,

OR HOW THE SAME INKJET DEVICE MAKE AND MODEL CAN

PERFORM DIFFERENTLY UNDER CHANGING ENVIRONMENTAL

CONDITIONS

, LIKE DIFFERING HUMIDITY LEVELS OR

TEMPERATURES

, IT IS WORTH NOTING TOO THAT COLOURS LOOK

DIFFERENT UNDER VARYING VIEWING CONDITIONS

.

Page 18

18

Jetting Trends

In spite of multiple advances in inkjet printing technology

over the last decade, all the indications are that the

technology is set to grow even more over the coming

decade. The advent of the Internet, far from reducing the

desire for printed information as initially expected, has

actually seen it grow, creating a spiralling demand for

PCs and printers in households the world over, bringing

with it the capability of desktop ‘on demand’ printing.

Furthermore, through inkjet, outstanding colour print

quality at a low price is now possible, with most devices

supporting (or are moving towards support of) six-colour

printing/proofing capability (CMYK and two additional

colours). Similarly, through advances in ink technology

and glossy paper grades, photo-realism image quality is

now readily attainable.

As a backdrop to all this, inkjet printer manufacturers

are continually looking at new ways of creating a

competitive edge. With R&D spending continually being

ploughed into means of decreasing drop size and

increasing resolution and multi-drop / variable drop

technological advances. Continuous inkjet technology,

developed by Scitex for example, can already reach

speeds of 300 m/min.

‘INFORMATION IS KING. THE SUNDAY EDITION OF THE NEW YORK TIMES ON

AVERAGE CONTAINS MORE INFORMATION THAN WAS PRINTED IN THE WHOLE OF

THE

15TH CENTURY.’ MARTHA BECK, O MAGAZINE, APRIL 2002)

Page 19

19

Page 20

Produced for M-real Digital imaging by The Bespoke Agency 2002. Printed on silver digital matt 200/150 g/m

2

on an hp indigo press 3000

M-real Digital imaging

AN DER GOHRSMÜHLE

51465 BERGISCH GLADBACH

DEUTSCHLAND/GERMANY

TEL.: +49(0)2202 - 152052

FAX: +49(0)2202 - 152805

M-real Digital imaging would

like to thank all the companies

that contributed to the

production of this brochure.

Loading...

Loading...