Page 1

E450dn

User’s Guide

June 2006

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc.,

registered in the United States and/or other countries.

© 2006 Lexmark International, Inc.

All rights reserved.

740 West New Circle Road

Lexington, Kentucky 40550

www.lexmark.com

Page 2

Edition: June 2006

The following paragraph does not apply to any country where such provisions are inconsistent with local law: LEXMARK

INTERNATIONAL, INC., PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Some states do not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement may not

apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the information herein; these

changes will be incorporated in later editions. Improvements or changes in the products or the programs described may be made at any time.

Comments about this publication may be addressed to Lexmark International, Inc., Department F95/032-2, 740 West New Circle Road,

Lexington, Kentucky 40550, U.S.A. In the United Kingdom and Eire, send to Lexmark International Ltd., Marketing and Services

Department, Westhorpe House, Westhorpe, Marlow Bucks SL7 3RQ. Lexmark may use or distribute any of the information you supply in

any way it believes appropriate without incurring any obligation to you. To obtain additional copies of publications related to this product, visit

the Lexmark Web site at www.lexmark.com.

References in this publication to products, programs, or services do not imply that the manufacturer intends to make these available in all

countries in which it operates. Any reference to a product, program, or service is not intended to state or imply that only that product,

program, or service may be used. Any functionally equivalent product, program, or service that does not infringe any existing intellectual

property right may be used instead. Evaluation and verification of operation in conjunction with other products, programs, or services, except

those expressly designated by the manufacturer, are the user’s responsibility.

© 2006 Lexmark International, Inc.

All rights reserved.

UNITED STATES GOVERNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are commercial computer software and documentation

developed exclusively at private expense.

Trademarks

Lexmark, Lexmark with diamond design, and MarkVision are trademarks of Lexmark International, Inc., registered in the United States and/

or other countries.

Drag’N’Print and PrintCryption are trademarks of Lexmark International, Inc.

®

PCL

is a registered trademark of the Hewlett-Packard Company. PCL is Hewlett-Packard Company’s designation of a set of printer

commands (language) and functions included in its printer products. This printer is intended to be compatible with the PCL language. This

means the printer recognizes PCL commands used in various application programs, and the printer emulates the functions corresponding

to the commands.

Details relating to compatibility are included in the Technical Reference.

Other trademarks are the property of their respective owners.

Safety information

• Connect the power cord to a properly grounded electrical outlet that is near the product and easily accessible.

CAUTION: Do not set up this product or make any electrical or cabling connections, such as the

power cord or telephone, during a lightning storm.

• Refer service or repairs, other than those described in the operating instructions, to a professional service person.

• This product is designed, tested, and approved to meet strict global safety standards with the use of specific Lexmark components.

The safety features of some parts may not always be obvious. Lexmark is not responsible for the use of other replacement parts.

• Your product uses a laser.

CAUTION: Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• Your product uses a printing process that heats the print media, and the heat may cause the media to release emissions. You must

understand the section in your operating instructions that discusses the guidelines for selecting print media to avoid the possibility of

harmful emissions.

• Refer service or repairs, other than those described in the operating instructions, to a professional service person.

• This product is designed, tested, and approved to meet strict global safety standards with the use of specific Lexmark components.

The safety features of some parts may not always be obvious. Lexmark is not responsible for the use of other replacement parts.

2

Page 3

Contents

Chapter 1: Learning about the printer .............................................................................. 5

Printer overview ...............................................................................................................................................5

Understanding the control panel ......................................................................................................................9

Chapter 2: Understanding print media guidelines ......................................................... 12

What types of print media can be loaded? ....................................................................................................12

Tips on choosing the right print media ........................................................................................................... 13

Storing print media .........................................................................................................................................18

Avoiding jams ................................................................................................................................................18

Chapter 3: Printing ............................................................................................................ 19

Loading the 250-sheet tray ............................................................................................................................19

Loading the manual feeder ............................................................................................................................23

Linking trays ................................................................................................................................................... 25

Sending a job to print .....................................................................................................................................25

Canceling a print job ...................................................................................................................................... 26

Printing the menu settings page ....................................................................................................................27

Printing a network setup page .......................................................................................................................27

Printing a font sample list ...............................................................................................................................28

Printing held jobs ...........................................................................................................................................28

Chapter 4: Installing options ........................................................................................... 30

Accessing the system board ..........................................................................................................................30

Adding a memory card ...................................................................................................................................33

Adding a flash memory card .......................................................................................................................... 33

Installing an optional 550-sheet drawer ......................................................................................................... 35

Recognizing installed options ........................................................................................................................35

Chapter 5: Maintaining the printer .................................................................................. 36

Determining the status of supplies ................................................................................................................. 36

Photoconductor kit end-of-life ........................................................................................................................36

Conserving supplies ......................................................................................................................................37

Ordering supplies ...........................................................................................................................................37

Recycling Lexmark products ..........................................................................................................................44

Chapter 6: Clearing jams .................................................................................................. 45

Identifying jams .............................................................................................................................................. 45

Understanding jam messages .......................................................................................................................45

Clearing printer jams ......................................................................................................................................46

3

Page 4

Contents

Chapter 7: Troubleshooting ............................................................................................. 51

Online customer support ................................................................................................................................51

Calling for service ..........................................................................................................................................51

Checking an unresponsive printer ................................................................................................................. 51

Printing multiple-language PDFs ...................................................................................................................52

Solving printing problems .............................................................................................................................. 52

Turning on Reduced Curl mode ..................................................................................................................... 54

Solving option problems ................................................................................................................................ 54

Solving paper feed problems .........................................................................................................................55

Solving print quality problems ........................................................................................................................56

Chapter 8: Administrative support .................................................................................. 60

Adjusting control panel brightness and contrast ............................................................................................60

Disabling control panel menus .......................................................................................................................60

Enabling control panel menus .......................................................................................................................61

Restoring factory default settings ..................................................................................................................61

Adjusting Power Saver .................................................................................................................................. 62

Disabling Power Saver ..................................................................................................................................62

Selecting printer operating mode ...................................................................................................................63

Setting security using the Embedded Web Server (EWS) ............................................................................. 63

Notices ................................................................................................................................ 65

Product energy consumption .........................................................................................................................66

Index .................................................................................................................................... 69

4

Page 5

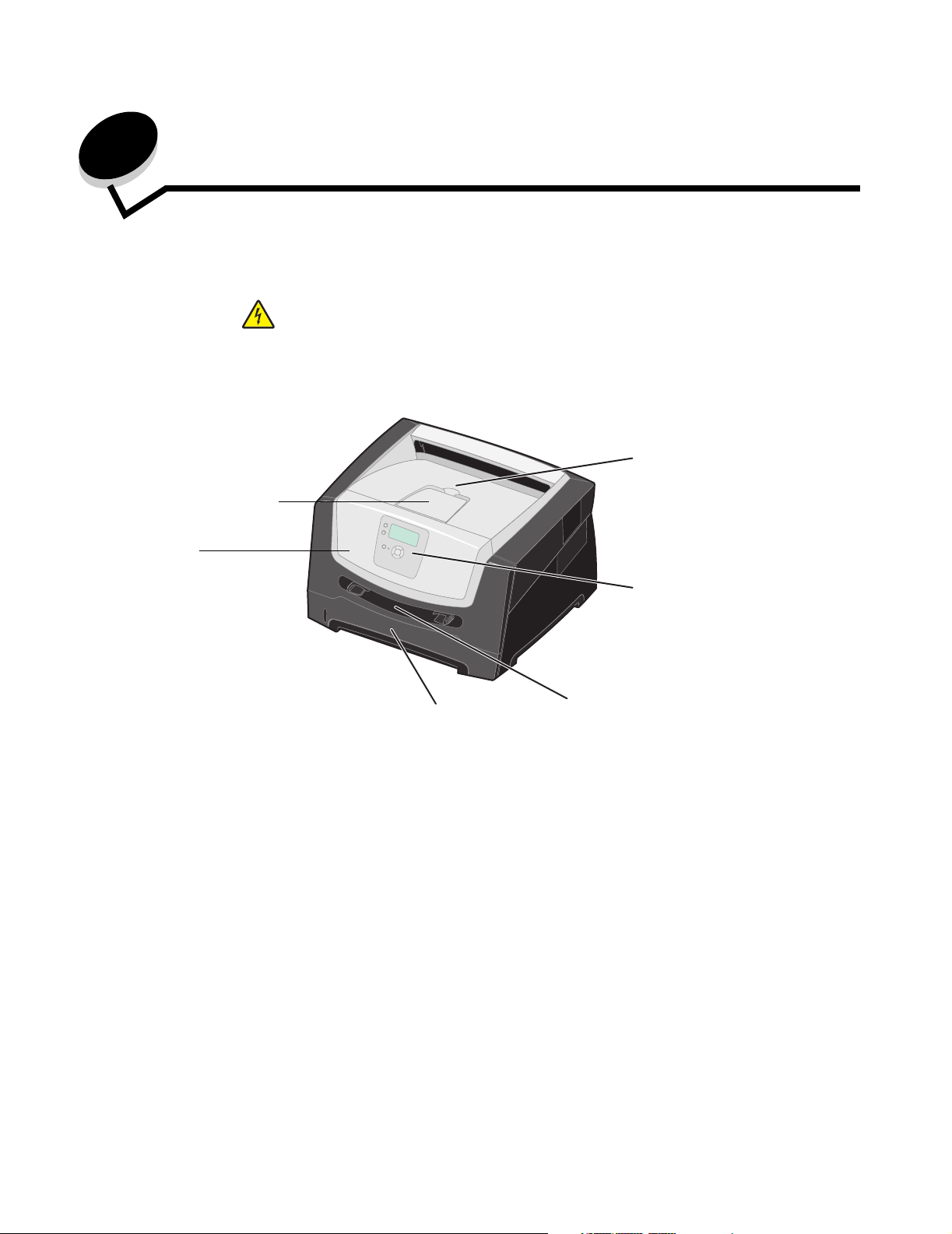

1

2

Learning about the printer

Printer overview

CAUTION: Do not set up this product or make any electrical or cabling connections, such as

the power cord or telephone, during a lightning storm.

Basic model

The following illustration shows a printer with its base features.

5

6

1

4

1 150-sheet output bin 4 250-sheet tray

2 Control panel and navigation buttons 5 Paper support

3 Manual feeder 6 Front door

Learning about the printer

5

3

Page 6

Learning about the printer

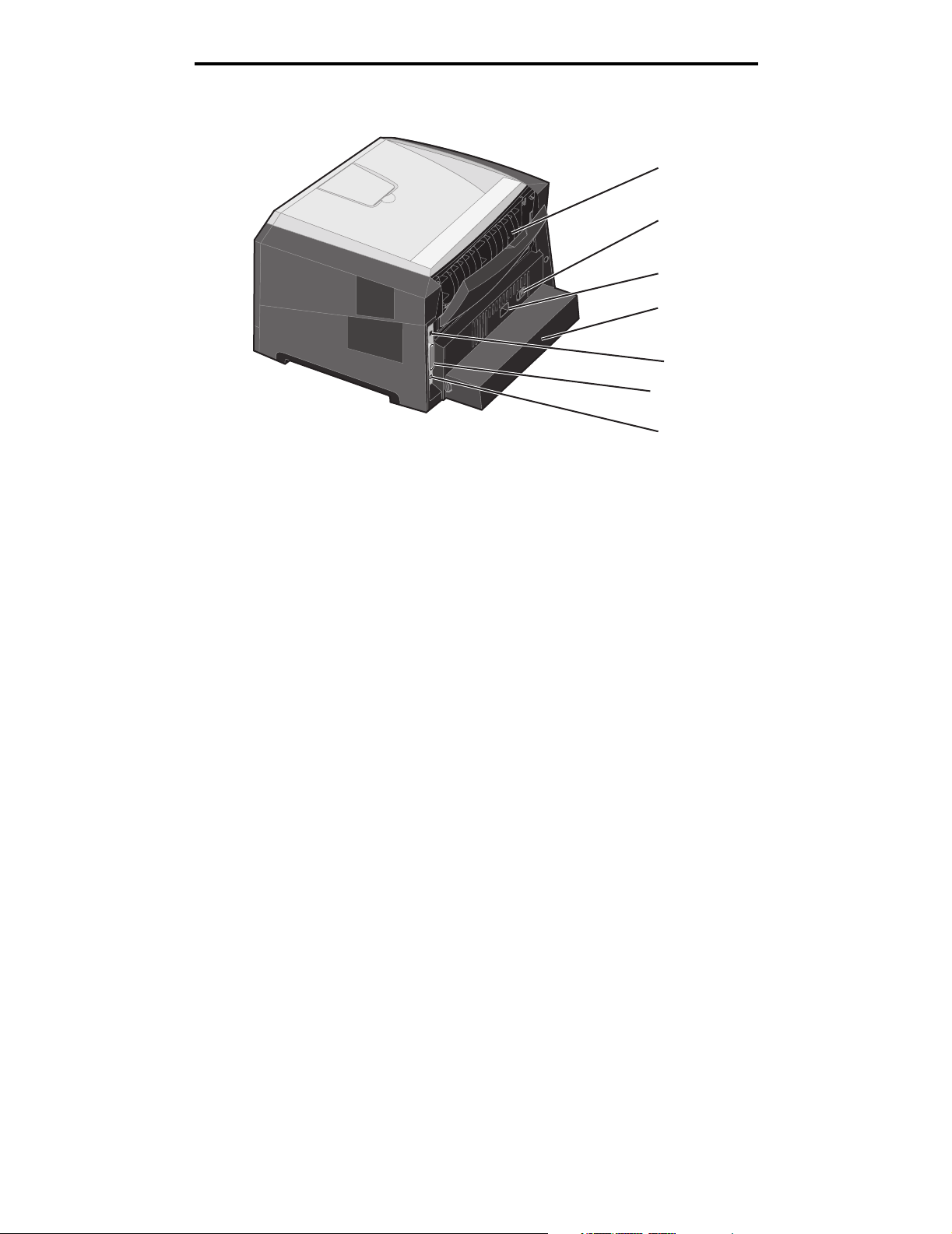

The following illustration shows a rear view of the printer with its base features.

1

2

3

4

5

6

7

1 Rear paper exit 5 USB connect

2 Power button 6 Parallel connect

3 Power connect 7 Ethernet connect

4 Dust cover (not available for some

models)

Printer overview

6

Page 7

Learning about the printer

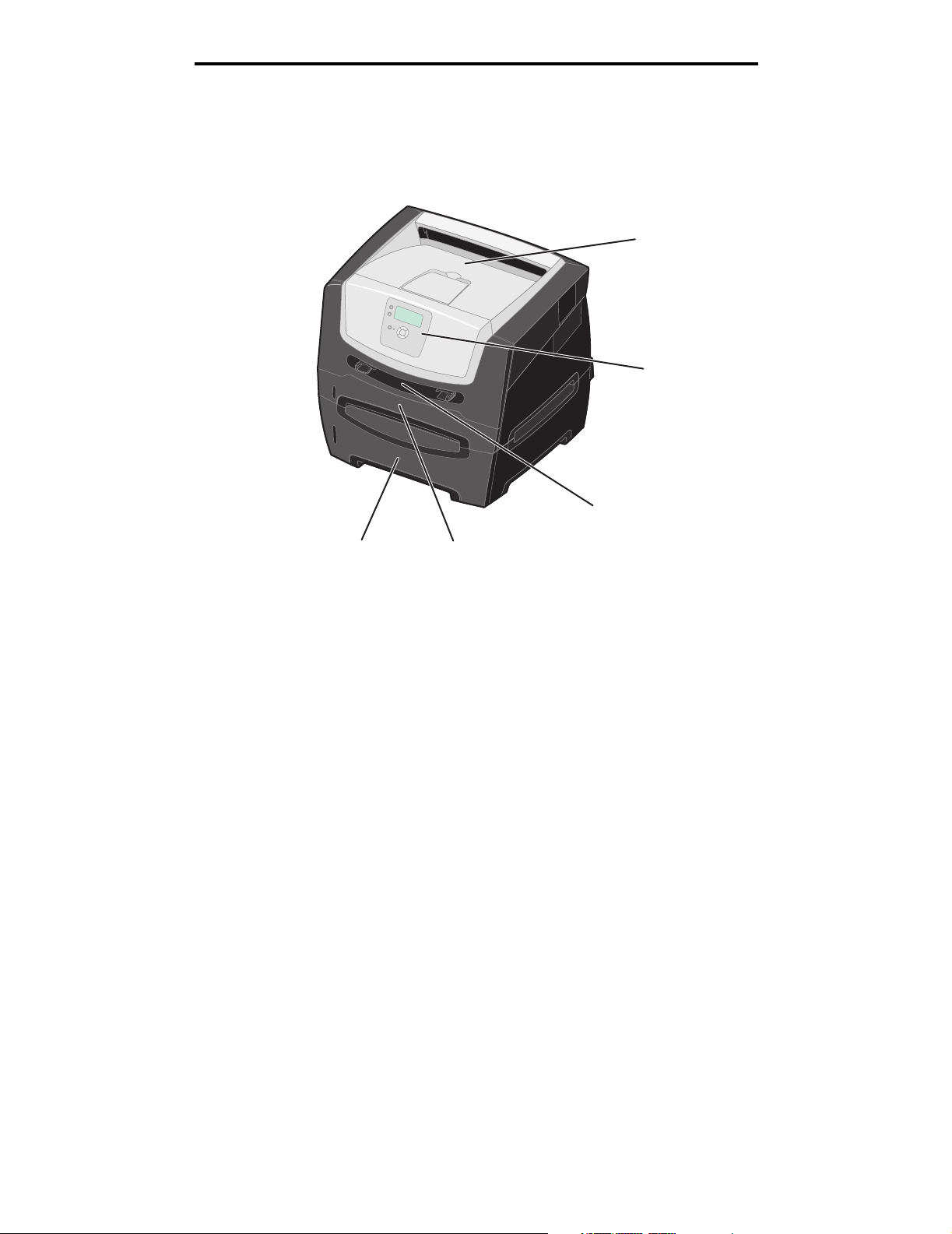

Configured model

The following illustration shows a fully configured printer. Items denoted with an asterisk (*) are options.

1

2

3

5*

1 150-sheet output bin 4 250-sheet tray

2 Control panel and navigation buttons 5 550-sheet drawer (optional)

3 Manual feeder

4

Printer overview

7

Page 8

Learning about the printer

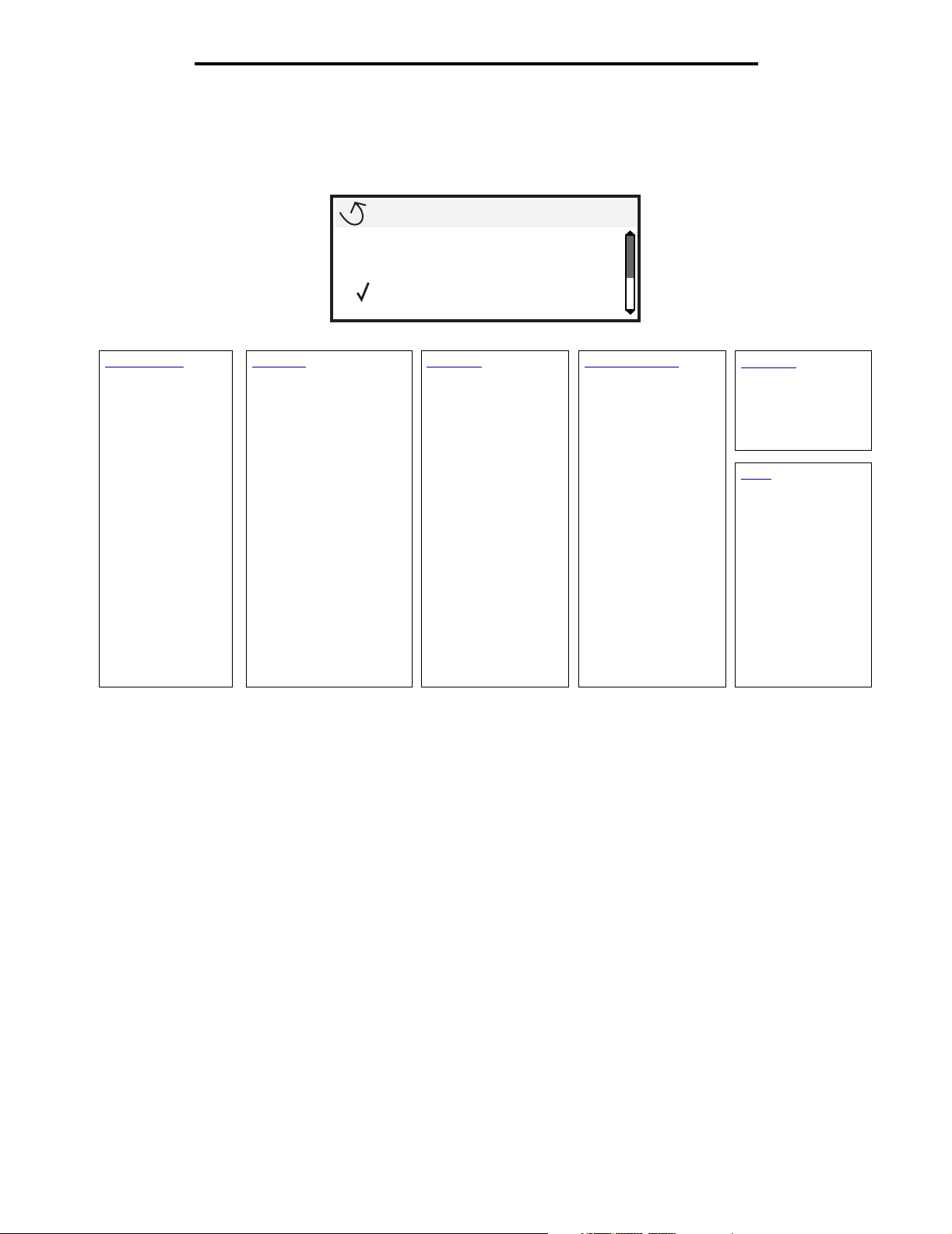

A number of menus are available to make it easy for you to change printer settings. The diagram shows the menu index on

the control panel and the menus and items available under each menu. For more information about menus and menu items,

see the Menus and Messages book on the Software and Documentation CD.

Menu

Paper Menu

Reports

Settings

Paper Menu

Default Source

Paper Size/Type

Substitute Size

Paper Texture

Paper Weight

Paper Loading

Custom Types

Universal Setup

Reports

Menu Settings Page

Device Statistics

Network Setup Page

Profiles List

Print Fonts

Print Demo

Settings

Setup Menu

Finishing Menu

Quality Menu

Utilities Menu

PDF Menu

PostScript Menu

PCL Emul Menu

Network/Ports

TCP/IP

Standard Network

Standard USB

Parallel

AppleTalk

Security

Job Expiration

Help

Printing Guide

Supplies Guide

Media Guide

Print Defects

Menu Map

Information Guide

Connection Guide

Moving Guide

Printer overview

8

Page 9

Learning about the printer

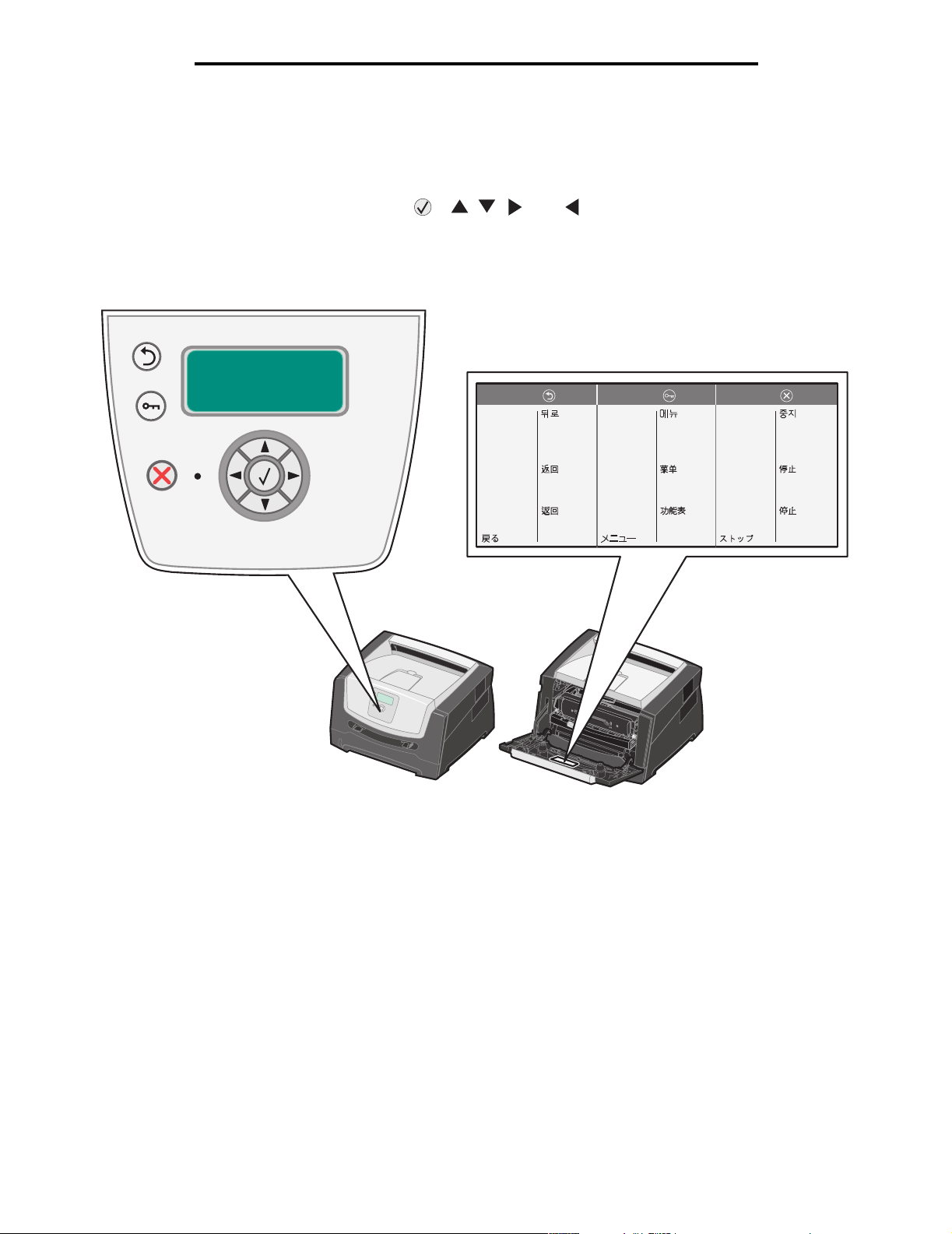

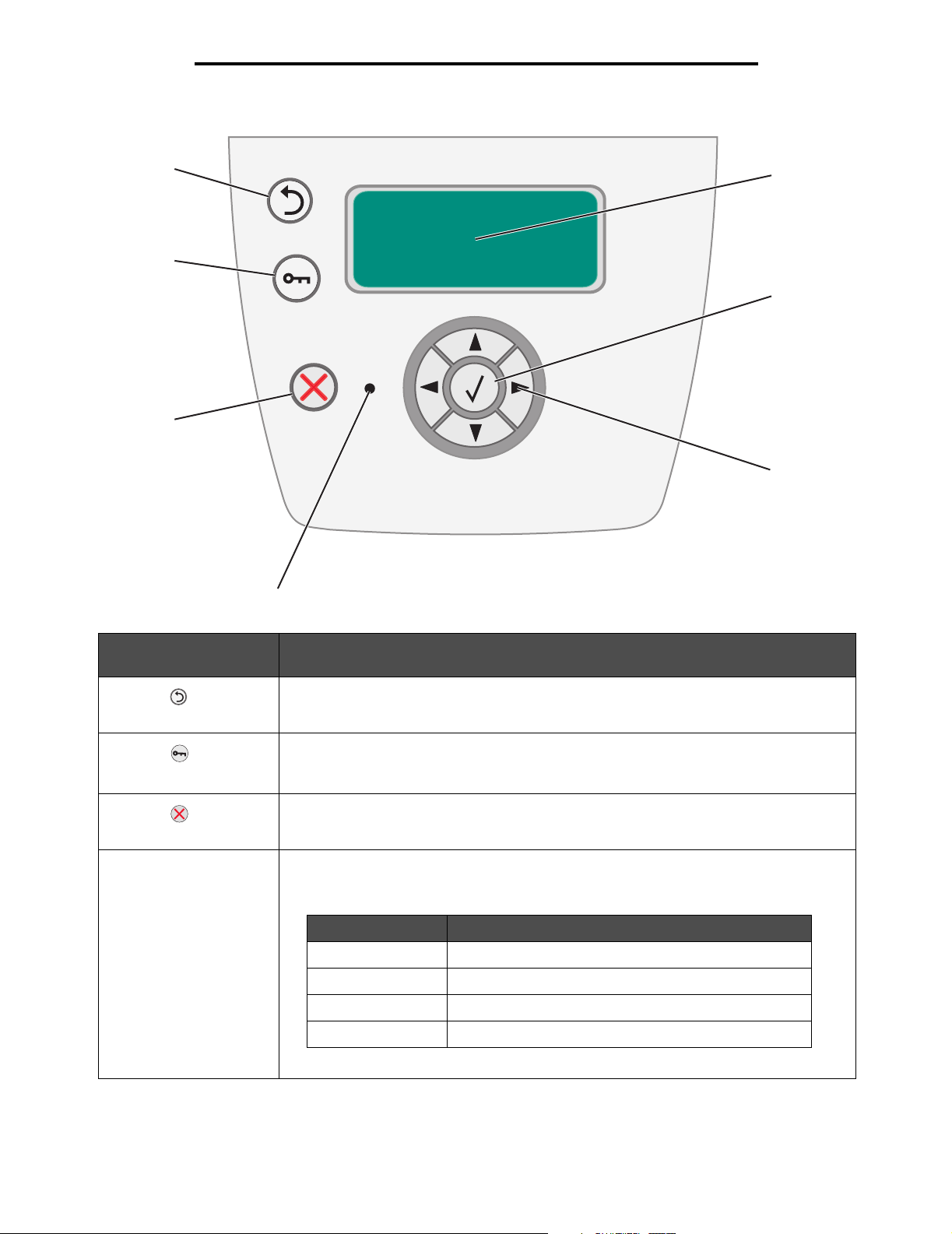

Understanding the control panel

The control panel consists of these items:

• A 4-line, liquid crystal display (LCD) that can show both graphics and text

• Eight buttons: Back, Menu, Stop, Select ( ), , , , and

• Indicator light

Note: A label located on the inside front door shows the control panel buttons in your language. An

additional translated label is included in the printer box.

Back Menu Stop

Voltar

Zp t

ě

Tilbage

Terug

Takaisin

Retour

Zurück

Vissza

Indietro

Tilbake

Wró

ć

aa

Hзд

Atrás

Bakåt

Geri

Menu

Nabídka

Menu

Menu

Valikko

Menu

Menü

Menü

Menu

Meny

Menu

Меню

Menú

Meny

Menü

Parar

Stop

Stop

Stop

Seis

Stop

Stopp

Leállítás

Stop

Stopp

Stop

Стоп

Parar

Stopp

Durdur

Understanding the control panel

9

Page 10

Learning about the printer

The use of the buttons and the layout of the display panel are described in the following table.

1

7

2

66

3

5

4

Button or control panel

item Function

1 Back Press the Back button to return to the last screen you viewed.

Note: Changes made on a screen will not be applied if you press the Back button.

2 Menu Press the Menu button to open the menu index.

Note: The printer must be in the Ready state to access the menu index. A message

indicating the menus are unavailable will appear if the printer is not ready.

3 Stop Press the Stop button to stop the mechanical operation of the printer. After pressing Stop,

4 Indicator light A two-toned LED is used on the control panel, one color being green and the other being

the message Stopping appears. When the printer has stopped, the status line in the

control panel will show Stopped, and a list of options will appear.

red. The lights indicate whether the printer power is on, the printer is busy, idle, processing a

job, or requires operator intervention.

Status Indicates

Off Power is off.

Solid green Printer is on, but idle.

Flashing green Printer is warming up, processing data, or printing a job.

Solid red Operator intervention is required.

Understanding the control panel

10

Page 11

Button or control panel

item Function

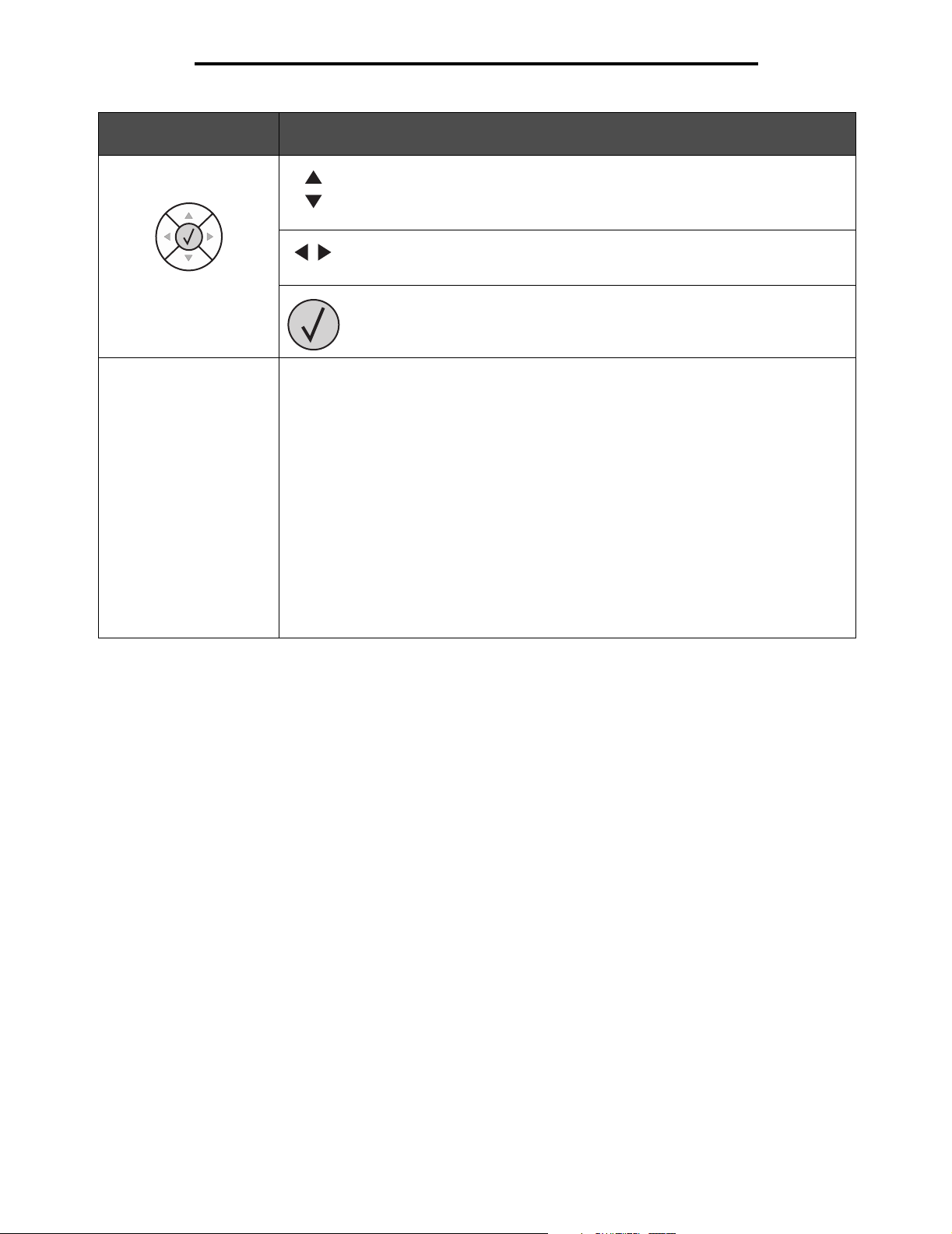

5 and 6 Navigation

buttons

Learning about the printer

The Up and Down buttons are used to move up or down lists.

When navigating through a list using the Up or Down button, the cursor moves

one line at a time. Pressing the Down button at the bottom of the screen changes

the screen to the next whole page.

The Left or Right buttons are used to move within a screen such as moving from

one menu index item to another. They are also used to scroll through text that will

not fit on the screen.

The Select button is used to initiate action on a selection. Press Select when the

cursor appears next to the selection you want such as following a link, submitting

a configuration item, or when you want to start or cancel a job.

7 Display The display shows messages and graphics describing the current state of the printer and

indicating possible printer problems you must resolve.

The top line of the display is the header line. If applicable, it will contain the graphic

indicating the Back button can be used. It will also display the current status and the

Supplies (Warnings) status. If multiple warnings are present, each warning will be

separated by a comma.

The other three lines of the display are the body of the screen. This is where you view

printer status, supplies messages, show-me screens, and make selections.

Understanding the control panel

11

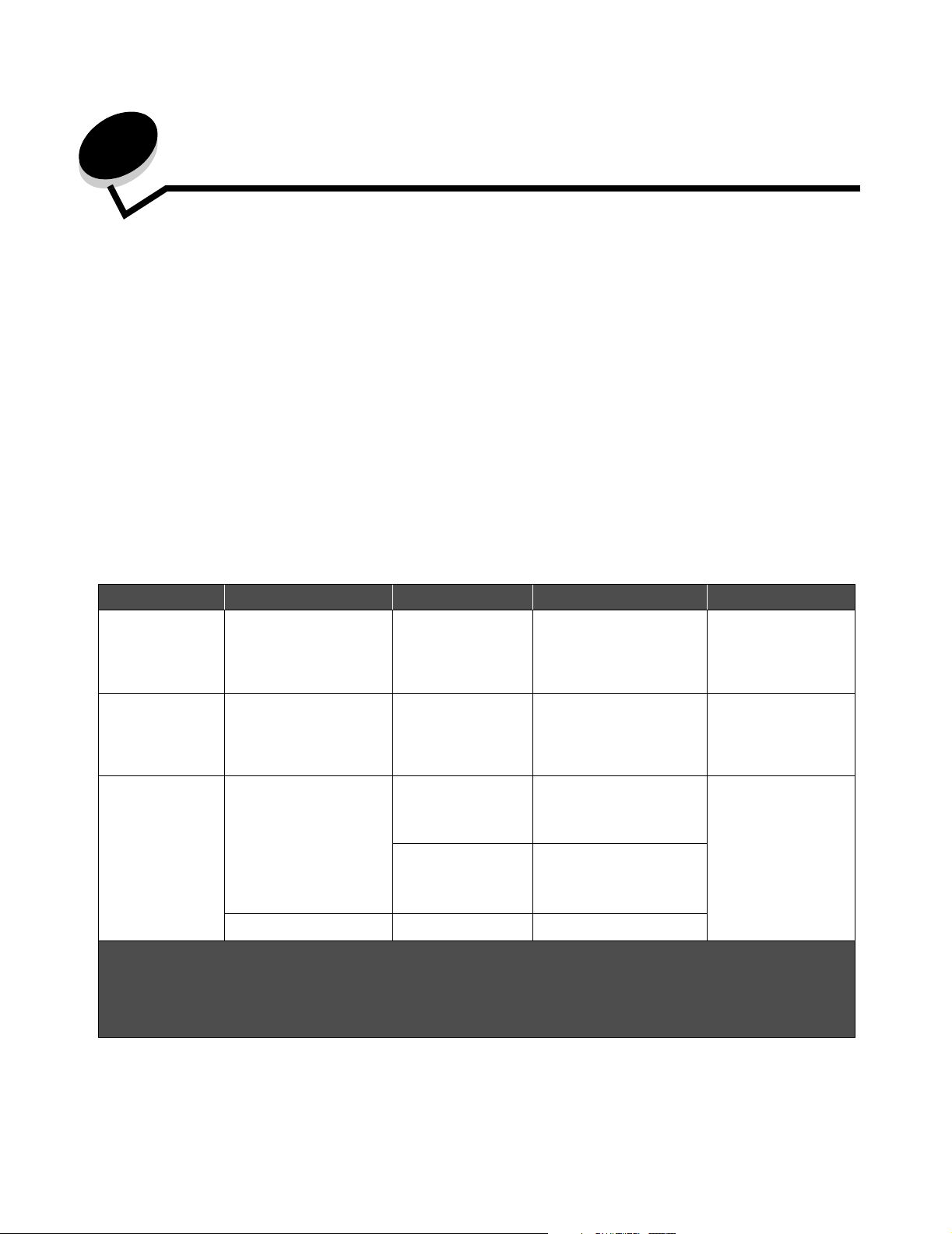

Page 12

2

Print media is paper, card stock, transparencies, labels, and envelopes. The last four are sometimes referred to as specialty

media. The printer provides high-quality printing on a variety of media. A number of things must be considered concerning

media before printing. This chapter provides information on making media selections and caring for media.

• What types of print media can be loaded?

• Tips on choosing the right print media

• Storing print media

• Avoiding jams

For more details about the types of paper and specialty media your printer supports, see the Card Stock & Label Guide

available on our Lexmark Web site at www.lexmark.com.

We recommend that you try a limited sample of any paper or specialty media you are considering using with the printer

before purchasing large quantities.

Understanding print media guidelines

What types of print media can be loaded?

Get the most from your printer by properly loading the trays. Never mix media types within a tray.

Source Sizes Types Weight Capacity* (sheets)

250-sheet tray A4, A5, A6 (grain long

550-sheet drawer

(optional)

Manual feeder A4, A5, A6 (grain long

only), JIS B5, letter,

legal, executive, folio,

statement

A4, A5, JIS B5, letter,

legal, executive, folio,

statement

only), JIS B5, letter,

legal, executive, folio,

statement, Universal

7¾, 9, 10, DL, C5, B5 Envelopes 75 g/m

‡

Plain paper, bond,

letterhead,

transparencies,

paper labels (singlesided only)

Plain paper, bond,

letterhead,

transparencies,

paper labels (singlesided only)

Plain paper,

transparencies,

paper labels (singlesided only)

Card stock

†

2

(20 lb)

2

2

2

2

2

60–90 g/m

(16–24 lb)

60–90 g/m

(16–24 lb)

60–163 g/m

(16–43 lb)

• 120–163 g/m

(66–90 lb) Index Bristol

• 75–163 g/m

(46–100 lb) Tag

• 250 paper

• 50 labels

• 50 transparencies

• 550 paper

• 50 labels

• 50 transparencies

1

* Capacity for 20 lb print media, unless otherwise noted.

†

Grain short is recommended. Use rear exit for best results.

‡

Universal size ranges:

– Manual feeder: 76–216 x 127–356 mm (3.0–8.5 x 5.0–14.0 in.) (includes 3 x 5 in. cards)

Understanding print media guidelines

12

Page 13

Understanding print media guidelines

Tips on choosing the right print media

Selecting the right paper or other print media reduces printing problems. For best print quality, try a sample of the paper or

other print media you are considering before buying large quantities.

Note: Certain paper types will not print at maximum speed.

See the Card Stock & Label Guide available on our Lexmark Web site at www.lexmark.com/publications for more

information about which print media provides optimum results for your printing environment.

Paper

• For the best print quality, use 20 lb (75 g/m2) xerographic, grain long paper.

The printer can automatically feed paper weights from 60 to 90 g/m2 (16 to 24 lb bond) grain long. Paper lighter

than 60 g/m2 (16 lb) might not be stiff enough to feed properly, causing jams. Paper heavier than 90 g/m2 (24 lb)

should be fed through the manual feeder.

• The laser printing process heats paper to high temperatures of 210°C (410°F). Use only paper able to withstand

these temperatures without discoloring, bleeding, or releasing hazardous emissions. Check with the manufacturer

or vendor to determine whether the paper you have chosen is acceptable for laser printers.

• The duplex unit only supports certain sizes and types of print media. Only A4, letter, legal and folio size paper can

be used for duplex printing. The printer does not support duplex printing on any other type of print media.

Paper characteristics

The following paper characteristics affect print quality and reliability. It is recommended that these guidelines are followed

when evaluating new paper stock.

For detailed information, see the Card Stock & Label Guide available on the Lexmark Web site at www.lexmark.com/

publications.

Weight

The printer can automatically feed paper weights from 60 to 90 g/m2 (16 to 24 lb bond) grain long in the integrated and

optional trays and paper weights from 60 to 163 g/m2 (16 to 43 lb bond) grain long in the manual feeder. Paper lighter than

2

60 g/m

grain long paper. To use paper narrower than 182 x 257 mm (7.2 x 10.1 in.), it is recommended that the weight be equal to

90 g/m

Curl

Curl is the tendency of media to curve at its edges. Excessive curl can cause paper feeding problems. Curl can occur after

the paper passes through the printer, where it is exposed to high temperatures. Storing paper unwrapped in hot, humid,

cold and dry conditions, even in the trays, can contribute to paper curling prior to printing and can cause feeding problems.

Smoothness

The degree of smoothness of paper directly affects print quality. If the paper is too rough, the toner does not fuse to the

paper properly, resulting in poor print quality. If the paper is too smooth, it can cause paper feeding or print quality issues.

Smoothness needs to be between 100 and 300 Sheffield points; however, smoothness between 150 and 250 Sheffield

points produces the best print quality.

(16 lb) might not be stiff enough to feed properly, causing jams. For best performance, use 75 g/m2 (20 lb bond)

2

(24 lb bond).

Moisture content

The amount of moisture in the paper affects both print quality and the ability of the printer to feed the paper properly. Leave

the paper in its original wrapper until it is time to use it. This limits the exposure of the paper to moisture changes that can

degrade its performance.

Tips on choosing the right print media

13

Page 14

Understanding print media guidelines

Condition paper while it is still in the original wrapper. To condition it, store it in the same environment as the printer for 24

to 48 hours before printing to let the paper stabilize in the new conditions. Extend the time several days if the storage or

transportation environment is very different from the printer environment. Thick paper may also require a longer

conditioning period because of the mass of material.

Grain direction

Grain refers to the alignment of the paper fibers in a sheet of paper. Grain is either grain long, running the length of the

paper, or grain short, running the width of the paper.

For 60 to 90 g/m2 (16 to 24 lb bond) paper, grain long fibers are recommended.

Fiber content

Most high-quality xerographic paper is made from 100% chemically pulped wood. This content provides the paper with a

high degree of stability resulting in fewer paper feeding problems and better print quality. Paper containing fibers such as

cotton possess characteristics that can result in degraded paper handling.

Recycled paper

Lexmark supports US executive order 13101 which strongly encourages the use of recycled papers in government

agencies. Ask for warranty information and performance claims from your paper supplier, and/or test small quantities before

buying large amounts. A list of suppliers and approved papers used by the US Government Printing Office can be found at

http://www.gpo.gov/qualitycontrol/cpypaper.htm.

Unacceptable paper

The following papers are not recommended for use with the printer:

• Chemically treated papers used to make copies without carbon paper, also known as carbonless papers,

carbonless copy paper (CCP), or no carbon required (NCR) paper

• Preprinted papers with chemicals that may contaminate the printer

• Preprinted papers that can be affected by the temperature in the printer fuser

• Preprinted papers that require a registration (the precise print location on the page) greater than ±0.09 in., such as

optical character recognition (OCR) forms

In some cases, you can adjust registration with your software application to successfully print on these forms.

• Coated papers (erasable bond), synthetic papers, thermal papers

• Rough-edged, rough or heavily textured surface papers or curled papers

• Recycled papers containing more than 25% post-consumer waste that do not meet DIN 19 309

• Recycled paper having a weight less than 60 g/m

• Multiple-part forms or documents

2

(16 lb)

Selecting paper

Proper paper loading helps prevent jams and ensures trouble-free printing.

To help avoid jams or poor print quality:

• Always use new, undamaged paper.

• Before loading paper, know the recommended print side of the paper. This information is usually indicated on the

paper package.

• Do not use paper that has been cut or trimmed by hand.

• Do not mix media sizes, weights, or types in the same source; mixing results in jams.

• Do not use coated papers unless they are specifically designed for electrophotographic printing.

• Do not remove trays while a job is printing or Busy appears on the control panel.

Tips on choosing the right print media

14

Page 15

Understanding print media guidelines

• Make sure the Paper Type, Paper Texture, and Paper Weight settings are correct. (See “Paper Menu” in the Menus

and Messages Guide located on the Software and Documentation CD for detailed information about these

settings.)

• Make sure the paper is properly loaded in the source.

• Flex paper back and forth, and then fan. Do not fold or crease the paper. Straighten the edges on a level surface.

Selecting preprinted forms and letterhead

Use the following guidelines when selecting preprinted forms and letterhead paper for the printer:

• Use grain long papers for best results for 60 to 90 g/m

• Use only forms and letterhead printed using an offset lithographic or engraved printing process.

• Avoid papers with rough or heavily textured surfaces.

Use papers printed with heat-resistant inks designed for use in xerographic copiers. The ink must withstand temperatures

of 210°C (410°F) without melting or releasing hazardous emissions. Use inks that are not affected by the resin in toner.

Inks that are oxidation-set or oil-based should meet these requirements; latex inks might not. When in doubt, contact the

paper supplier.

Preprinted papers such as letterhead must be able to withstand temperatures up to 210°C (410°F) without melting or

releasing hazardous emissions.

2

weights.

Printing on letterhead

Check with the manufacturer or vendor to determine whether the chosen preprinted letterhead is acceptable for laser

printers.

Page orientation is important when printing on letterhead. Use the following table for help when loading letterhead in the

media sources.

Media source or process Print side Top of page

250-sheet tray and

550-sheet drawer

Duplex (two-sided) printing from

trays

Manual feeder Printed letterhead faceup The top edge of the sheet with the logo enters

Duplex (two-sided) printing from

Manual feeder

Printed letterhead facedown The top edge of the sheet with the logo is

placed at the front of the tray.

Printed letterhead face up The top edge of the sheet with the logo is

placed at the front of the tray.

the printer first.

Printed letterhead face down The top edge of the sheet with the logo enters

the printer first.

Transparencies

Feed transparencies from the 250-sheet tray or the manual feeder. Try a sample of any transparencies being considered

for use with the printer before buying large quantities.

When printing on transparencies:

Tips on choosing the right print media

15

Page 16

Understanding print media guidelines

• Be sure to set the Paper Type to Transparency from the printer driver or from MarkVision™ Professional to avoid

damaging the printer.

• Use transparencies designed specifically for laser printers. Transparencies must be able to withstand

temperatures of 175°C (350°F) without melting, discoloring, offsetting or releasing hazardous emissions.

• To prevent print quality problems, avoid getting fingerprints on the transparencies.

• Before loading transparencies, fan the stack to prevent sheets from sticking together.

Selecting transparencies

The printer can print directly on transparencies designed for use in laser printers. Print quality and durability depend on the

transparency used. Always print samples on the transparencies being considered for use before buying large quantities.

We recommend Lexmark part number 70X7240 letter size transparency and Lexmark part number 12A5010 for A4 size

transparency.

The Paper Type setting should be set to Transparency to help prevent jams. (See “Paper Type” on the publications CD for

detailed information about this setting.) Check with the manufacturer or vendor to determine whether the transparencies are

compatible with laser printers that heat transparencies to 175°C (350°F). Use only transparencies that are able to withstand

these temperatures without melting, discoloring, offsetting, or releasing hazardous emissions. For detailed information, see

the Card Stock & Label Guide, which is available on the Lexmark Web site at www.lexmark.com/publications.

Transparencies can be fed automatically from the paper trays or manually from the manual feeder. See What types of

print media can be loaded? on page 12 for information about transparency compatibility with input bins.

Be careful when you handle transparencies. Fingerprints on the surface of the transparency cause poor print quality.

Envelopes

Try a sample of any envelope you are considering using with the printer before buying large quantities. See Loading the

manual feeder on page 23 for instructions on loading envelopes.

When printing on envelopes:

• To achieve the best possible print quality, use only high-quality envelopes that are designed for use in laser

printers.

• Set the Paper Source in the Paper menu to manual, set the Paper Type to Envelope, and select the correct

envelope size from the control panel, the printer driver, or from MarkVision Professional.

• For best performance, use envelopes made from 90 g/m

weight for the manual feeder as long as the cotton content is 25% or less. Envelopes with 100% cotton content

must not exceed 90 g/m

• Use only new, undamaged envelopes.

• For best performance and to minimize jams, do not use envelopes that:

– Have excessive curl or twist.

– Are stuck together or damaged in any way.

– Contain windows, holes, perforations, cutouts or embossing.

– Use metal clasps, string ties, or metal folding bars.

– Have an interlocking design.

– Have postage stamps attached.

– Have any exposed adhesive when the flap is in the sealed or closed position.

– Have nicked edges or bent corners.

– Have rough, cockle, or laid finishes.

• Use envelopes that can withstand temperatures of 175°C (350°F) without sealing, excessive curling, wrinkling, or

releasing hazardous emissions. If you have any doubts about the envelopes you are considering using, check with

the envelope supplier.

• Adjust the width guide to fit the width of the envelope.

• Load only one envelope at a time.

• A combination of high humidity (over 60%) and the high printing temperatures may seal the envelopes.

2

(24 lb bond) weight.

2

(24 lb bond) paper. Use up to 105 g/m2 (28 lb bond)

Tips on choosing the right print media

16

Page 17

Understanding print media guidelines

Labels

The printer can print on many labels designed for use with laser printers, except for vinyl labels. These labels are supplied

in letter size, A4 size, and legal size sheets. Label adhesives, face sheet (printable stock), and topcoats must be able to

withstand temperatures of 210°C (410°F) and pressure of 25 pounds per square inch (psi).

Try a sample of any label you are considering using with the printer before purchasing a large quantity.

For detailed information on label printing, characteristics, and design, see the Card Stock & Label Guide available on the

Lexmark Web site at www.lexmark.com/publications.

When printing on labels:

• Set the Paper Type menu item to Labels in the Paper menu. Set the Paper Type from the printer control panel, the

printer driver, or from MarkVision Professional.

• Do not load labels together with paper or transparencies in the same source; mixing media can cause feeding

problems.

• Do not use label sheets with a slick backing material.

• Do not use vinyl labels.

• Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a jam. Partial sheets

also contaminate the printer and the cartridge with adhesive, and could void the printer and cartridge warranties.

• Use labels that can withstand temperatures of 210°C (410°F) without sealing, excessive curling, wrinkling, or

releasing hazardous emissions.

• Do not print within 1 mm (0.04 in.) of the edge of the label, of the perforations, or between die-cuts of the label.

• Do not use label sheets that have adhesive to the edge of the sheet. Zone coating of the adhesive at least 1 mm

(0.04 in.) away from edges is recommended. Adhesive material contaminates the printer and could void the

warranty.

• If zone coating of the adhesive is not possible, remove a 3 mm (0.125 in.) strip on the leading and driver edge, and

use a non-oozing adhesive.

• Remove a 3 mm (0.125 in.) strip from the leading edge to prevent labels from peeling inside the printer.

• Portrait orientation is preferred, especially when printing bar codes.

• Do not use labels that have exposed adhesive.

For detailed information on label printing, characteristics, and design, see the Card Stock & Label Guide, available on the

Lexmark Web site at www.lexmark.com/publications.

Card stock

Card stock is single ply, and has a large array of properties, such as the moisture content, thickness, and texture, that can

significantly affect print quality. For information on the preferred weight and for the grain direction of print media, see What

types of print media can be loaded? on page 12.

Try a sample of any card stock you are considering using with the printer before purchasing a large quantity.

When printing on card stock:

• Cardstock can only be printed from the Manual Feeder.

• Set the Paper Type menu item in the Paper Menu to Card Stock from the control panel, from the printer driver, or

from MarkVision Professional. Set the Paper Weight to CardStock Weight, and select the CardStock Weight as

Normal or Heavy for the value. Set this from the control panel, the printer driver, or from MarkVision Professional.

Use Heavy for card stock weighing more than or heavier than 163 g/m

• Be aware that preprinting, perforation, and creasing can significantly affect the print quality and cause media

handling or jamming problems.

• Avoid using card stock that may release hazardous emissions when heated.

Tips on choosing the right print media

17

2

(90 lb).

Page 18

Understanding print media guidelines

• Do not use preprinted card stock manufactured with chemicals that may contaminate the printer. Preprinting

introduces semi-liquid and volatile components into the printer.

• The use of grain short card stock is recommended.

Storing print media

Use the following guidelines to avoid paper feeding problems and uneven print quality.

• For best results, store media in an environment where the temperature is approximately 21°C (70°F) and the

relative humidity is 40%.

Most label manufacturers recommend printing in a temperature range of 18 to 24°C (65 to 75°F) with a relative

humidity of 40 to 60%.

• Store cartons of media on a pallet or shelf, rather than directly on the floor.

• When storing individual packages of media out of the original carton, make sure they rest on a flat surface so the

edges do not buckle or curl.

• Do not place anything on top of the media packages.

• Store paper in its original wrapper until you load it into the printer.

Avoiding jams

Use appropriate print media (paper, transparencies, labels, and card stock) to help ensure trouble-free printing. See What

types of print media can be loaded? on page 12 for more information.

Note: Try a limited sample of any print media you are considering using with the printer before purchasing

large quantities.

By selecting the appropriate print media and loading it properly, you can avoid most jams. For detailed tray loading

instructions, see the following:

• Loading the 250-sheet tray on page 19

• Loading the manual feeder on page 23

The following hints can help you avoid jams:

• Use only recommended print media.

• Do not overload the print media sources. Make sure the stack height does not exceed the maximum height

indicated by the stack line on the labels in the sources.

• Do not load wrinkled, creased, damp, or curled print media.

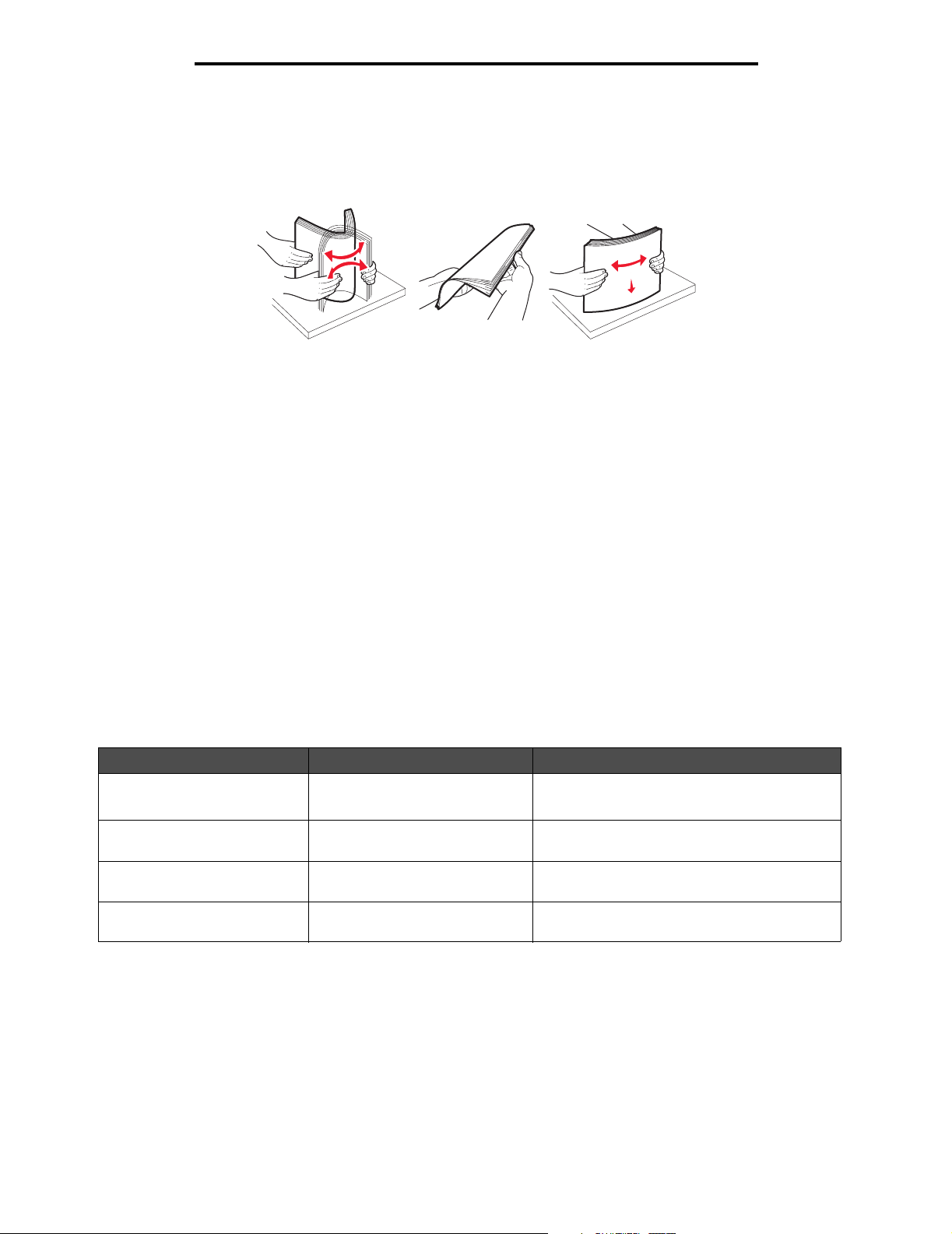

• Flex, fan, and straighten print media before you load it. If jams do occur with print media, try feeding one sheet at

a time through the manual feeder.

• Do not use print media that you have cut or trimmed yourself.

• Do not mix print media sizes, weights, or types in the same print media source.

• Make sure the recommended print side is loaded in the source according to your simplex or duplex needs.

• Keep print media stored in an acceptable environment. See Storing print media on page 18.

• Do not remove trays during a print job.

• Push all trays in firmly after loading them.

• Make sure the guides in the trays are properly positioned for the size of print media you have loaded. Make sure

the guides are not placed too tightly against the stack of print media.

Storing print media

18

Page 19

3

Printing

This chapter covers information about loading print media, sending a job to print, canceling a print job, printing a menu

settings page, and printing a font list. For tips on paper jam prevention and print media storage, see Avoiding jams on

page 18 or Storing print media on page 18.

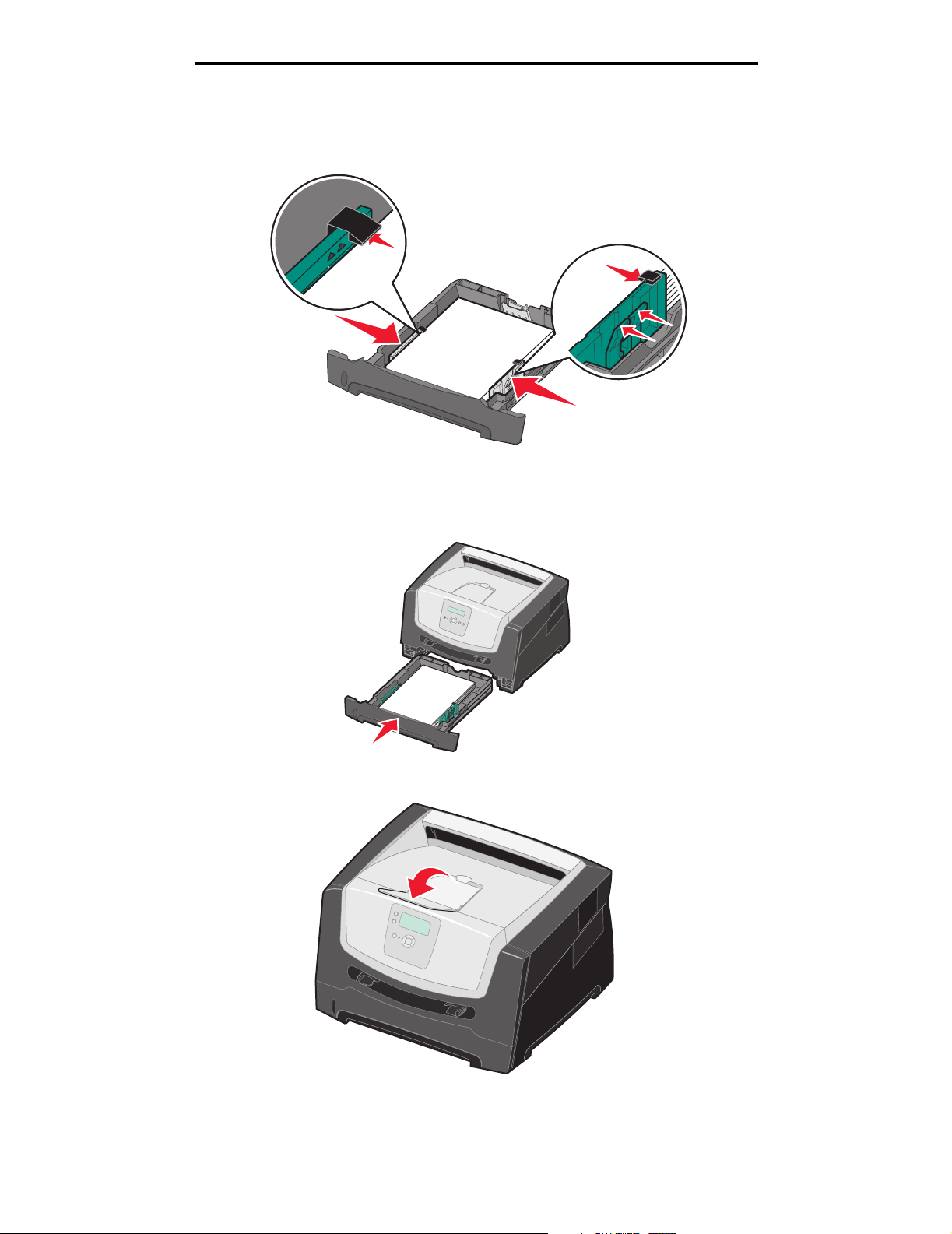

Loading the 250-sheet tray

Your printer has a 250-sheet tray. You may have also purchased an optional 550-sheet drawer. Print media is loaded into

both components the same way.

To load print media:

Note: Do not remove a tray when a job is printing or when the control panel indicator light is blinking. Doing

so may cause a jam.

1 Remove the tray.

Note: To load legal or folio size paper, extend the length of the paper tray. See Extending the tray for legal

or folio size paper on page 22 for instructions.

Printing

19

Page 20

Printing

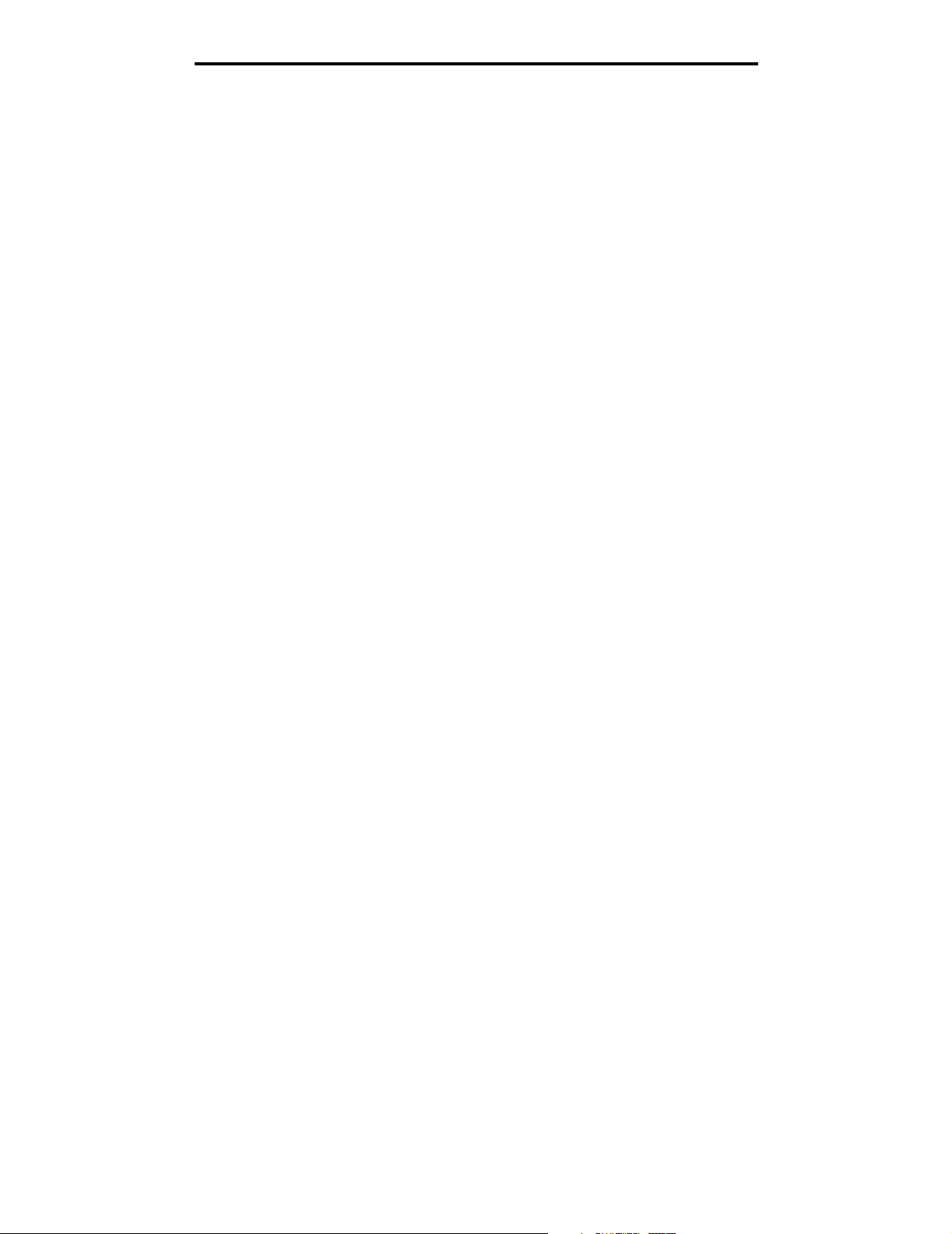

2 Squeeze the side guide tab, and slide the guide to the outside of the tray.

3 Squeeze the rear guide tab, and slide the guide to the correct position for the size media you are loading.

4 Flex the sheets back and forth to loosen them, then fan them. Do not fold or crease the print media. Straighten the

edges on a level surface.

5 Load print media in the tray.

Note: Load letterhead paper with the design side facing down. The top edge of the sheet with the logo

should be placed at the front of the tray.

Make sure the print media is below the paper fill indicator on the side guides. Overloading may cause jams.

Loading the 250-sheet tray

20

Page 21

Printing

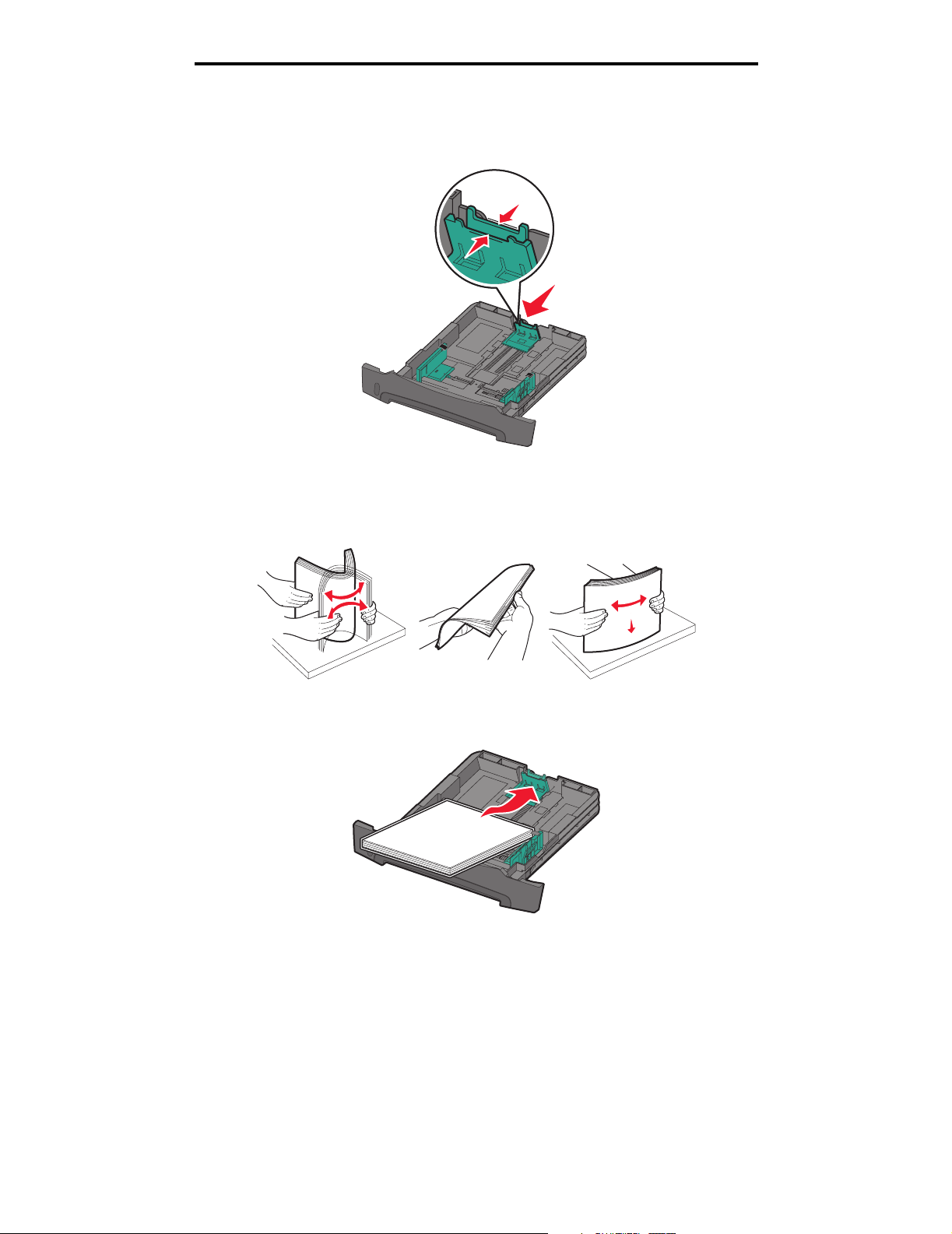

6 Pinch the side guide tab, and slide the guide until it lightly rests against the edge of the media.

7 Insert the tray.

8 Extend the paper support on the output bin.

Loading the 250-sheet tray

21

Page 22

Printing

Extending the tray for legal or folio size paper

To load legal or folio size paper, extend the paper tray. You may also attach a dust cover (not available for all models) on

the back of the printer to protect the tray while it is extended.

1 Press down on the latch at the back of the tray.

2 Expand the tray until the extender locks into place.

Attaching the dust cover

The dust cover helps protect the paper tray from the environment. It also keeps the tray from being knocked out of position

while it is extended.

Note: This feature may not be available for all models.

Attach the dust cover (if available) to the back of the printer by aligning the tabs on the cover to the holes on the printer, then

snap the cover into place.

Loading the 250-sheet tray

22

Page 23

Printing

Loading the manual feeder

The manual feeder can feed different types of print media, such as a transparency, postcard, note card, or envelope. It can

be used for single-page printing only.

To load print media:

Note: Do not add or remove print media when the printer is printing from the manual feeder or when the

control panel indicator light is blinking. Doing so may cause a jam.

1 Slide the width guides to the outside of the feeder.

2 Place a sheet of the selected print media, print side facing up, at the center fo the manual feeder, but only to the

point where its leading edge can contact the paper guides. Load one sheet of the media in the feeder.

• Hold transparencies by the edges and avoid touching the print side.

• Insert envelopes with the flap side face down.

• Load letterhead faceup, with the top of the sheet entering first.

• If you experience problems with paper feed, turn the paper over.

Loading the manual feeder

23

Page 24

Printing

3 Slide the width guides until they lightly rest against the edge of the media.

4 Hold both sides of the print media close to the manual feeder, and push it into the printer until it automatically

engages.

There is a brief pause between the time the printer engages the print media and when it feeds into the printer.

Warning: Do not force the print media into the feeder. Forcing the media causes jams.

5 Set the Paper Size and Paper Type for the manual feeder (Manual Feeder Size and Manual Feeder Type) to the

correct value for the print media you loaded.

a Press on the control panel.

b Press until Paper Menu appears, and then press .

c Press until Paper Size/Type appears, and then press .

d Press until Manual Paper Size/Type or Manual Env Size/Type appears, and then press .

e Press until the appears next to the media size you loaded, and then press .

f Press until the media type you loaded appears, and then press .

g Press repeatedly to return to the Ready state.

Loading the manual feeder

24

Page 25

Printing

Linking trays

Tray linking enables the automatic linking feature for trays when you load the same size and type of print media in multiple

sources.

For example, if you have the same size and type of print media loaded in the paper tray and the optional paper drawer, the

printer selects print media from the paper tray until it becomes empty, and then the printer automatically feeds print media

from the next linked source—the optional drawer.

If you load the same size print media in each paper source, make sure the paper type is all the same type in order to link

the trays.

To set the paper type or size:

1 Press on the control panel.

2 Press until Paper Menu appears, and then press .

3 Press until Paper Size/Type appears, and then press .

4 Press until Tray <x> Size/Type appears, and then press .

5 Press until the appears next to the media size you loaded, and then press .

6 Press until the media type you loaded appears, and then press .

7 Press repeatedly to return to the Ready state.

Once the trays you selected are loaded with the same size and type of print media, select the same Paper Type setting in

the Paper menu for these sources.

To disable tray linking, set the Paper Type to a unique value in each one of the trays. If all the trays do not have the same

type of print media when they are linked, you could mistakenly print a job on the wrong paper type.

Sending a job to print

A printer driver is software that lets your computer communicate with your printer. When you choose Print from a software

application, a window representing the printer driver opens. You can then select the appropriate settings for the specific job

you are sending to the printer. Print settings selected from the driver override the default settings selected from the printer

control panel.

You may need to click Properties or Setup from the initial Print box to see all of the available printer settings you can

change. If you are not familiar with a feature in the printer driver window, open the online Help for more information.

To support all the printer features, use the Lexmark custom printer drivers supplied with your printer. Updated drivers, as

well as a complete description of the driver packages and Lexmark driver support, are available from the Lexmark Web site.

You can also use the system drivers built into your operating system.

To print a job from a typical Windows application:

1 Open the file you want to print.

2 From the “File” menu, select Print.

3 Select the correct printer in the dialog. Modify the printer settings as appropriate (such as the pages you want to

print or the number of copies).

4 Click Properties or Setup to adjust printer settings that were not available on the first screen, and then click OK.

5 Click OK or Print to send the job to the selected printer.

Linking trays

25

Page 26

Printing

Canceling a print job

There are several methods for canceling a print job.

• Canceling a job from the printer control panel

• Canceling a job from a computer running Windows

– Canceling a job from the taskbar

– Canceling a job from the desktop

• Canceling a job from a Macintosh computer

– Canceling a job from a Macintosh computer running Mac OS 9.x

– Canceling a job from a Macintosh computer running Mac OS X

Canceling a job from the printer control panel

Note: For more information about the control panel, see Understanding the control panel on page 9.

If the job you want to cancel is printing, and Busy appears on the display, press until Cancel a job appears, and

then press . The message Canceling Job appears until the job is canceled.

Canceling a job from a computer running Windows

Canceling a job from the taskbar

When you send a job to print, a small printer icon appears in the right corner of the taskbar.

1 Double-click the printer icon.

A list of print jobs appears in the printer window.

2 Select the job you want to cancel.

3 Press the Delete key on the keyboard.

Canceling a job from the desktop

1 Minimize all programs to reveal the desktop.

2 Double-click the My Computer icon.

3 Double-click the Printers icon.

A list of available printers appears.

4 Double-click the printer you selected when you sent the job.

A list of print jobs appears in the printer window.

5 Select the job you want to cancel.

6 Press the Delete key on the keyboard.

Canceling a print job

26

Page 27

Printing

Canceling a job from a Macintosh computer

Canceling a job from a Macintosh computer running Mac OS 9.x

When you send a job to print, the printer icon for your selected printer appears on the desktop.

1 Double-click the printer icon on your desktop.

A list of print jobs appears in the printer window.

2 Select the print job you want to cancel.

3 Click the trash can icon.

Canceling a job from a Macintosh computer running Mac OS X

1 Open Applications Æ Utilities, and then double-click Print Center or Printer Setup.

2 Double-click the printer you are printing to.

3 In the printer window, select the print job you want to cancel.

4 Press Delete.

Printing the menu settings page

You can print a menu settings page to review the default printer settings and to verify printer options are installed correctly.

1 Make sure the printer is on and Ready.

2 Press on the control panel.

3 Press until Reports appears, and then press .

4 Press until Menu Settings Page appears, and then press .

Printing Menus Settings appears on the display.

The printer returns to the Ready state after the menu settings page prints.

Printing a network setup page

If the printer is attached to a network, print a network setup page on the printer to verify the network connection. This page

also provides important information that helps in configuring for network printing.

1 Make sure the printer is on.

2 Press on the control panel.

3 Press until Reports appears, and then press .

4 Press until Network Setup Page appears, and then press .

Note: If an optional internal print server is installed, Print Net1 Setup appears on the display.

5 Check the first section on the network setup page, and confirm that Status is “Connected.”

If Status is “Not Connected” the LAN drop may not be active, or the network cable may be malfunctioning. Consult a system

support person for a solution, and print another network setup page to verify that the printer is connected to the network.

Printing the menu settings page

27

Page 28

Printing

Printing a font sample list

To print samples of the fonts currently available for your printer:

1 Make sure the printer is on and the Ready message appears.

2 Press on the control panel.

3 Press until Reports appears, and then press .

4 Press until Print Fonts appears, and then press .

5 Press until the appears next to PCL Fonts, or PostScript Fonts, and then press .

Printing held jobs

Printing and deleting held jobs

Held jobs such as Verify Print, Reserve Print, Repeat Print, and Bookmarks differ in function. These jobs are printed or

deleted from the printer control panel.

Verify Print

If you send a Verify Print job, the printer prints one copy and holds the remaining copies you requested in printer memory.

Use Verify Print to examine the first copy to see if it is satisfactory before printing the remaining copies. Once all copies are

printed, the Verify Print job is automatically deleted from printer memory.

Reserve Print

If you send a Reserve Print job, the printer does not print the job immediately. It stores the job in memory so you can print

the job later. The job is held in memory until you delete it from the Held Jobs menu. Reserve Print jobs may be deleted if the

printer requires extra memory to process additional held jobs.

Repeat Print

If you send a Repeat Print job, the printer prints all requested copies of the job and stores the job in memory so you can

print additional copies later. You can print additional copies as long as the job remains stored in memory.

Note: Repeat Print jobs are automatically deleted from printer memory when the printer requires extra

memory to process additional held jobs.

Windows

1 From a word processor, spreadsheet, browser, or other application, select File Æ Print.

2 Click Properties. (If there is no Properties button, click Setup, and then click Properties.)

3 Depending on the operating system, you may have to click the Other Options tab, and then click Print and Hold.

Note: If you have difficulty finding Print and Hold

Print and Hold, then follow the driver instructions.

4 Select the type of held job you want, and then send your job to the printer.

Go to the printer when you are ready to retrieve your print job, and follow the At the printer steps on page 29.

Printing a font sample list

Æ Held Jobs, click Help, and see the topic Held Jobs or

28

Page 29

Printing

Macintosh

1 From a word processor, spreadsheet, browser, or other application, select File Æ Print.

2 In the Copies & Pages or General pop-up menu, select Job Routing.

a When using Mac OS 9, if Job Routing is not a choice on the pop-up menu, select Plug-in Preferences

Print Time Filters.

b Turn down the disclosure triangle to the left of Print Time Filters, and select Job Routing.

c In the pop-up menu, select Job Routing.

3 In the radio group, select the type of held job you want, enter a user name, and then send your job to the printer.

Go to the printer when you are ready to retrieve your print job, and follow the At the printer steps on page 29.

At the printer

1 Press until Held jobs appears, and then press .

2 Press until the appears next to your user name, and then press .

3 Press until the appears next to the type of action you want to perform:

Print All Jobs Delete All Jobs

Print A Job Delete A Job

Print Copies

Æ

4 Press .

5 Press until the appears next to the job you want, and then press .

The job will print or be deleted according to the type of print job and action you selected.

Printing held jobs

29

Page 30

4

Installing options

Accessing the system board

CAUTION: To install memory, you must access the printer system board. Turn the printer off, and

unplug the power cord from the wall outlet before continuing.

1 Remove the paper tray.

Installing options

30

Page 31

Installing options

2 Press button on the left side of the printer to release and lower the front door.

3 Open the rear exit.

Accessing the system board

31

Page 32

Installing options

4 Press both buttons on the front right side of the machine to release the side access door.

5 Loosen the four screws of the cover to gain access to the system board.

Accessing the system board

32

Page 33

Installing options

Adding a memory card

The system board has one connector for an optional memory card.

CAUTION: If you are installing a memory card after setting up the printer, turn the printer off, and

unplug the power cord from the wall outlet before continuing.

Note: Memory options designed for other Lexmark printers may not work with your printer.

1 Access the system board (see Accessing the system board on page 30).

2 Push open the latches on both ends of the memory connector.

3 Unpack the memory card.

Warning: Memory is easily damaged by static electricity.

Touch something metal, such as the printer frame,

before you touch a memory card.

Avoid touching the connection points along the edge of the card.

4 Align the notches on the bottom of the card with the notches on

the connector.

5 Push the memory card firmly into the connector until the

latches on either end of the connector snap into place.

It may require some force to fully seat the card.

6 Make sure each latch fits over the notch on each end of the

card.

7 Close the side access door.

8 Close the rear exit.

9 Close the front door.

Adding a flash memory card

The system board has two connectors for an optional flash memory card.

CAUTION: If you are installing a flash memory card after setting up the printer, turn the printer

off, and unplug the power cord from the wall outlet before continuing.

Note: Flash memory card options designed for other Lexmark printers may not work with your printer.

1 Access the system board (see Accessing the system board on page 30).

2 Unpack the flash memory card.

Warning: Flash memory is easily damaged by static electricity. Touch

something metal, such as the printer frame, before you touch

a flash memory card.

Avoid touching the connection points along the edge of the card.

Adding a memory card

33

Page 34

Installing options

3 Squeeze the retainers, and align the plastic pins on the flash memory card with the holes on the system board.

4 Push the flash memory card firmly into the holes of the system board until it snaps into place.

Note: The flash card can be installed in the top or the bottom set of connector pin holes.

5 Close the side access door.

6 Close the rear exit door.

7 Close the front door.

8 Plug the power cord into the wall outlet and turn the printer on to continue print functions.

Adding a flash memory card

34

Page 35

Installing options

Installing an optional 550-sheet drawer

CAUTION: Turn the printer off, and unplug the power cord from the wall outlet before continuing.

Place the printer unit directly on top of the 550-sheet drawer.

Recognizing installed options

The printer driver should automatically recognize the newly-installed option when the printer is turned on. If it does not, you

can add the appropriate option manually.

1 Click Start Æ Settings Æ Printers.

2 Select the printer icon.

3 Click File Æ Properties.

4 Click the Install Options tab.

5 Add the appropriate options to your configuration:

Memory Card—Increase the printer memory to the appropriate number.

550-sheet drawer

6 Click OK.

Installing an optional 550-sheet drawer

35

Page 36

5

Maintaining the printer

Periodically, you need to complete certain tasks to maintain optimum print quality. These tasks are covered in this chapter.

If several people are using the printer, you may want to designate a key operator to do the setup and maintenance of your

printer. Refer printing problems and maintenance tasks to this key operator.

In the U.S., contact Lexmark at 1-800-539-6275 for information about Lexmark Authorized Supplies Dealers in your area. In

other countries or regions, visit the Lexmark Web site at www.lexmark.com, or contact the place where you bought your

printer.

Storing supplies

Choose a cool, clean storage area for your printer supplies. Store supplies right side up in their original packaging until you

are ready to use them.

Do not expose supplies to:

• Direct sunlight

• Temperatures above 35°C (95°F)

• High humidity (above 80%)

• Salty air

• Corrosive gases

• Heavy dust

Determining the status of supplies

The printer control panel alerts you once a supply item or maintenance is required. You can also view the status of supplies

in your printer on the control panel unless the printer is printing or in a busy state. The header or gray area at the top of the

display will indicate the printer is Ready and lets you know if any trays are low. Selecting Status / Supplies on the

display will open the Status / Supplies screen where you can view the status of the various trays and open the supplies

screen to view the current status of your toner cartridge.

Photoconductor kit end-of-life

To ensure print quality and to avoid damage to the printer, the printer stops operating after the photoconductor kit has

reached a maximum of 110% of its life. The message 84 Replace Photoconductor is displayed when the printer reaches

this point. If the Toner Alarm setting is set to Single or Continuous (default is Off), the printer automatically notifies you

before the photoconductor kit reaches this point and displays the message 84 Photoconductor Life Warning. To avoid

having the printer stop operating, replace the photoconductor kit when you first receive the 84 Photoconductor Life

Warning message. While the printer may continue to function properly after the photoconductor kit has reached its official

end-of-life (approximately 30,000 pages), print quality begins to significantly decrease until the photoconductor stops

operating at the maximum of 110% of its life. Once the photoconductor kit has been replaced, and the counter has been

reset, normal printer operation resumes. For more information, see the instruction sheet that came with your

photoconductor kit.

Maintaining the printer

36

Page 37

Maintaining the printer

Conserving supplies

Several settings in your application software or on the display let you conserve toner and paper. For more information on

changing these settings, see the Menus and Messages Guide.

Supply Menu selection item What the setting does

Toner Toner Darkness in the

Print media Multipage Print in the

Defaults

Defaults

Duplex in the Defaults

Finishing Menu

Use your software application

or printer driver to send a

Verify Print job.

Æ Quality Menu

Æ Finishing Menu

Æ

Lets you adjust the level of toner released on a sheet of print media. The

values range from 1 (lightest setting) to 10 (darkest setting).

Causes the printer to print the two or more page images on one side of a

sheet. Values for Multipage Print are 2 Up, 3 Up, 4 Up, 6 Up, 9 Up, 12 Up,

and 16 Up. Combined with the duplex setting, Multipage Print lets you print

up to 32 pages on one sheet of paper (16 images on the front and 16 on the

back).

Duplex printing lets you print on both sides of a sheet of paper.

Lets you examine the first copy of a multiple-copy job to be sure it is

satisfactory before you print the other copies. If the job is unsatisfactory,

you can cancel the job.

See Printing and deleting held jobs on page 28 for more information

about a Verify Print job.

Ordering supplies

To order supplies in the U.S., contact Lexmark at 1-800-539-6275 for information about Lexmark Authorized Supplies

Dealers in your area. In other countries or regions, visit the Lexmark Web site at www.lexmark.com, or contact the place

where you bought your printer.

Conserving supplies

37

Page 38

Maintaining the printer

Ordering a toner cartridge

Part number Description Average cartridge yield

World Wide

E250X22G Photoconductor kit Up to 30,000 standard pages

For the USA and Canada

E450A21A Toner Cartridge 6,000 standard pages

E450H21A High Yield Toner Cartridge 11,000 standard pages

E450A11A Return Program Toner Cartridge 6,000 standard pages

E450H11A High Yield Return Program Toner Cartridge 11,000 standard pages

For Europe, the Middle East, and Africa

E450A21E Toner Cartridge 6,000 standard pages

E450H21E High Yield Toner Cartridge 11,000 standard pages

E450A11E Return Program Toner Cartridge 6,000 standard pages

E450H11E High Yield Return Program Toner Cartridge 11,000 standard pages

For the Asia Pacific Region

E450A21P Toner Cartridge 6,000 standard pages

E450H21P High Yield Toner Cartridge 11,000 standard pages

E450A11P Return Program Toner Cartridge 6,000 standard pages

E450H11P High Yield Return Program Toner Cartridge 11,000 standard pages

For Latin America

E450A21L Toner Cartridge 6,000 standard pages

E450H21L High Yield Toner Cartridge 11,000 standard pages

E450A11L Return Program Toner Cartridge 6,000 standard pages

E450H11L High Yield Return Program Toner Cartridge 11,000 standard pages

1

Approximately 5% coverage.

2

Declared yield value in accordance with ISO/IEC 19752.

3

Designed for use only in the USA and Canada.

4

Designed for use only in Europe, Middle East, and Africa.

5

Designed for use only in Asia Pacific Region, Australia, and New Zealand.

6

Designed for use only in Latin America.

3

2

2

2

2

4

2

2

2

2

5

2

2

2

2

6

2

2

2

2

1

When the 88 Toner Low message appears, you should order a new toner cartridge. You can print a few hundred pages

after the 88 Toner Low message appears. You need to have a new cartridge available when the current one no longer

prints satisfactorily.

Ordering supplies

38

Page 39

Maintaining the printer

Changing a toner cartridge

1 Turn the printer off.

2 Press the button on the left side of the printer to release and lower the front door.

3 Remove the toner cartridge.

a Press the release button on the base of the print cartridge assembly.

b Grasp the handle, pulling up and out to remove the toner cartridge.

1

2

Ordering supplies

39

Page 40

Maintaining the printer

4 Unpack the new toner cartridge.

Note: You can use the packing material from the new toner cartridge to ship the old toner cartridge back to

Lexmark for recycling. For more information, see Recycling Lexmark products on page 44.

5 Firmly shake the toner cartridge in all directions to distribute the toner.

6 Install the new toner cartridge by aligning the white rollers on the toner cartridge with the white arrows on the

tracks of the photoconductor and pushing the toner cartridge in as far as it will go. The toner cartridge clicks into

place when correctly installed.

7 Close the front door.

8 Turn the printer back on.

Ordering a photoconductor kit

When the 84 PC Life Warning message appears, you should order a new photoconductor kit. You can print a few

hundred pages after the 84 PC Life Warning message appears.

Ordering supplies

40

Page 41

Maintaining the printer

Changing a photoconductor kit

Warning: When replacing a photoconductor kit, do not leave the new photoconductor kit exposed to direct light

for an extended period of time. Extended light exposure can cause print quality problems.

1 Turn the printer offc

2 Remove the print cartridge assembly.

a Press the button on the left side of the printer to release the front door.

b Lower the front door.

c Grasp the toner cartridge handle, and pull up and out.

Note: Do not press the button on the print cartridge assembly

1

2

3

Place the print cartridge assembly on a flat, clean surface.

Ordering supplies

41

Page 42

Maintaining the printer

3 Remove the toner cartridge:

a Press the button on the base of the print cartridge assembly.

b Grasp the toner cartridge handle, and pull up and out.

1

2

4 Unpack the new photoconductor kit.

5 Install the toner cartridge into the new print cartridge assembly by aligning the white rollers on the toner cartridge

with the white arrows on the tracks of the photoconductor and pushing the toner cartridge in as far as it will go. The

cartridge clicks into place when correctly installed.

Ordering supplies

42

Page 43

Maintaining the printer

6 Install the print cartridge assembly into the printer by aligning the green arrows on the guides of the print cartridge

assembly with the green arrows on the tracks in the printer and pushing the print cartridge assembly in as far as it

will go.

7 Close the front door.

8 Turn the printer back on.

9 Reset the photoconductor counter (see the instruction sheet that shipped with the new photoconductor kit).

Note: Print your printer menu settings pages. For more information, see Printing the menu settings page

on page 27. If Photoconductor is listed under Warnings, the photoconductor counter has not been

properly reset.

Maintenance kit

80 Scheduled Maintenance appears on the display after 120,000 pages have printed to let you know it is time to replace

printer maintenance items. Order a maintenance kit when 80 Scheduled Maintenance first appears on the display. The

maintenance kit contains all the items necessary to replace the pick rollers, the fuser, and the transfer roller.

Note: The maintenance kit may not be available in all geographies.

See the following table for the maintenance kit part number for your specific printer.

Machine voltage Part numbers

110 V 40X2847

220 V 40X2848

100 V 40X2849

Ordering supplies

43

Page 44

Maintaining the printer

Recycling Lexmark products

To return Lexmark products to Lexmark for recycling:

1 Visit our Web site:

www.lexmark.com/recycle

Follow the instructions on the computer screen.

Recycling Lexmark products

44

Page 45

6

Clearing jams

By carefully selecting print media and loading it properly, you should be able to avoid most paper jams. For more

information on avoiding paper jams, see Avoiding jams on page 18. If jams do occur, follow the steps outlined in this

section.

To resolve the paper jam messages, you must clear the entire paper path, and then press to clear the message and

resume printing. The printer prints a new copy of the page that jammed if Jam Recovery is set to On or Auto; however, the

Auto setting does not guarantee the page will print.

Identifying jams

When the printer jams, the appropriate jam message appears on the printer control panel.

Understanding jam messages

The following table lists the jam messages that can occur and the action necessary to clear the message. The jam

message indicates the area where the jam occurred. However, it is best to clear the entire paper path to ensure you have

cleared all possible jams.

Message What to do

200 Paper Jam - Remove Cartridge Open the front door, remove the toner cartridge, and remove the

201 Paper Jam - Remove Cartridge Open the front door, remove the toner cartridge, and remove the

202 Paper Jam - Open Rear Door Open the rear printer exit, and remove the jammed print media.

231 Paper Jam - Open Rear Door Open the rear printer exit, and remove the jammed print media.

233 Paper Jam - Remove Tray Remove the paper tray, push down the green lever, and remove the

234 Paper Jam - Check Duplex Remove the paper tray, push down the green lever, and remove the

235 Paper Jam - Open Rear Door Open the rear printer exit, and remove the jammed print media.

241, 242 Paper Jam - Check tray <x> Open tray <x> to remove the jammed print media.

251 Paper Jam - Check Man Feeder Remove jammed print media from the manual feeder.

jammed print media.

jammed print media.

jammed print media.

jammed media. If no jammed media is present, open the rear paper

exit, and remove the jammed print media.

Clearing jams

45

Page 46

Clearing jams

Clearing printer jams

Clearing a jam

We recommend clearing the entire paper path when a paper jam occurs. To clear the jam:

1 Open the paper tray. If necessary, remove the tray from the printer.

2 Remove the jammed media.

Clearing printer jams

46

Page 47

Clearing jams

3 Press down on the green duplex flap to release jammed pages from the duplex area.

4 Remove any crumpled paper from the tray.

CAUTION: Fuser or fuser area may be hot.

5 Open the front door, and remove the print cartridge assembly.

Clearing printer jams

47

Page 48

Clearing jams

6 Lift the flap at the front of the printer, and remove the jammed pages beneath the flap.

CAUTION: Fuser or fuser area may be hot.

7 Open the rear exit, and remove the jammed pages.

8 After you have cleared the jams, reinstall the print cartridge assembly, and make sure all printer doors and trays

are closed.

9 Press .

Note: Jam recovery is set to Auto by default. When jam recovery is set to Auto, the memory that holds the

image of a page may be reused after the page is printed but before it has successfully exited the

printer if that memory is needed for another use. Therefore, a jammed page may or may not be

reprinted, depending on the overall memory usage in the printer.

Clearing printer jams

48

Page 49

Clearing jams

Clearing a jam in the manual feeder

1 Remove the paper from the manual feeder.

2 Open the front door, and remove the print cartridge assembly.

Clearing printer jams

49

Page 50

Clearing jams

3 Lift the flap at the front of the printer, and remove the jammed pages beneath the flap.

4 Open the rear exit, and remove the jammed pages.

CAUTION: Fuser or fuser area may be hot.

5 After you have cleared the jams, reinstall the print cartridge assembly, and make sure all printer doors and trays

are closed.

6 Press .