Page 1

Lexmark E210

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4510-001

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

4510-001

Edition: June 2001

The following paragraph does not apply to any country where such provisions are

inconsiste nt with local law: LEXMARK INTERNATIONAL, INC. PROV IDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRE SS OR

IMPLIED , INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22A/032-2,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or e-mail at

ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of the

information you supply in any way it believes appropriate without incurring any obligation

to you. You can purchase additional copies of publications related to this product by

calling 1-800-553-9727. In other countries, contact your point of purchase.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International,

Inc., registered in the United States and/or other countries.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 2001.

All rights reserved.

UNITED STA TES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DF ARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

P/N 12G6119

Page 3

4510-001

Table of Contents

Laser Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

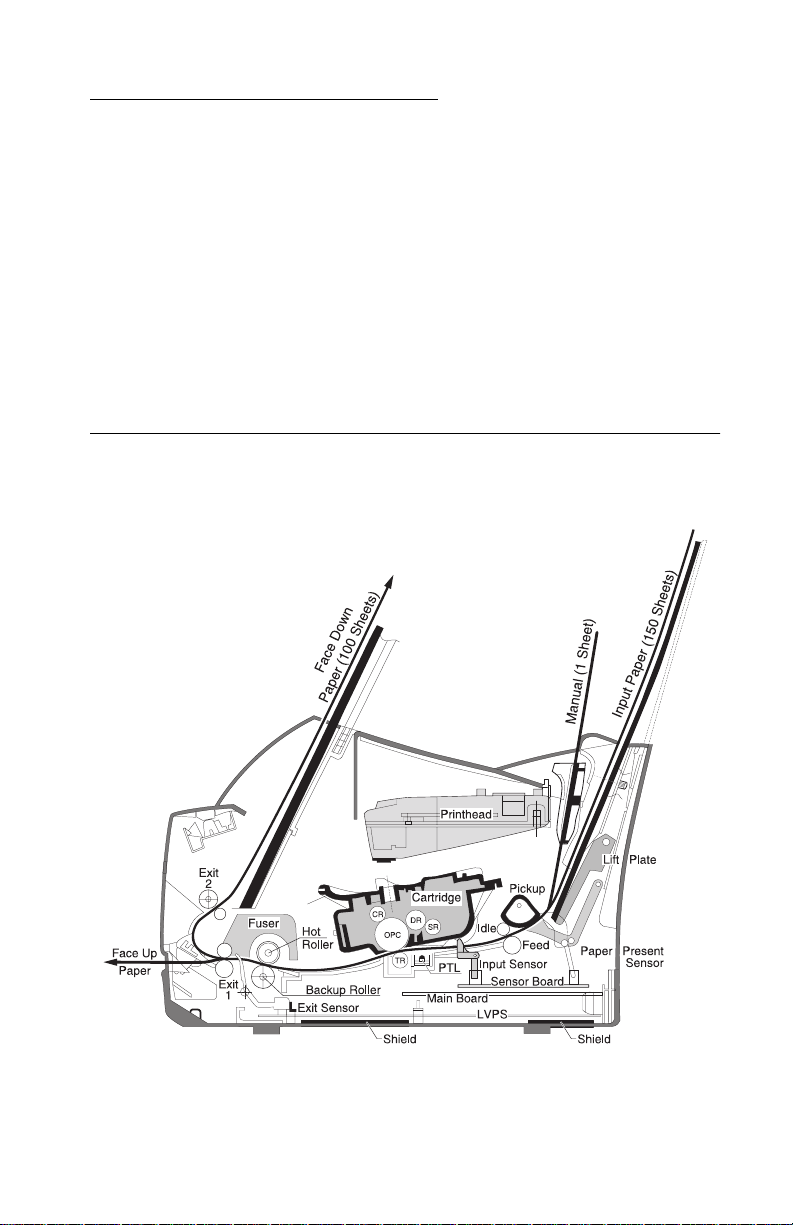

Printer Side View - Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tools Required for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

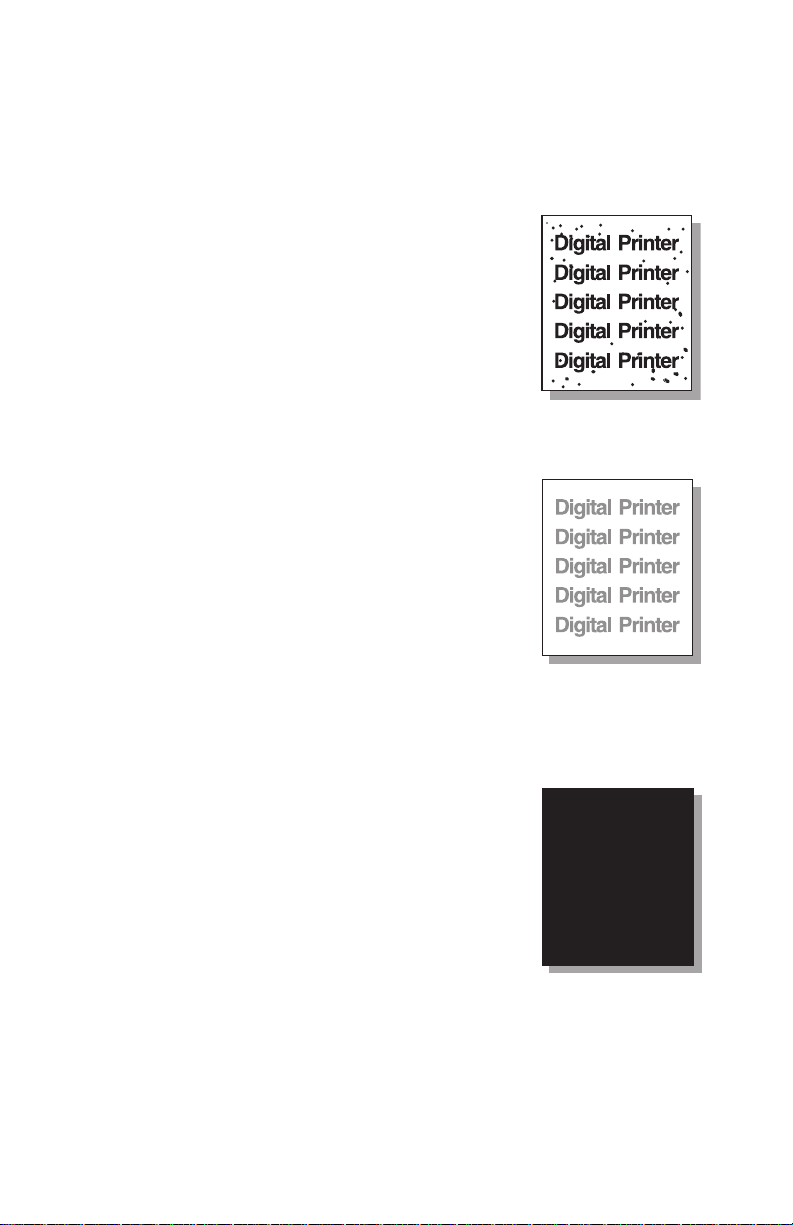

Print Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Vertical Black Line and Band . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Vertical White Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Horizontal Black Band. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Black/White Spots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Light Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Dark or Black Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Uneven Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

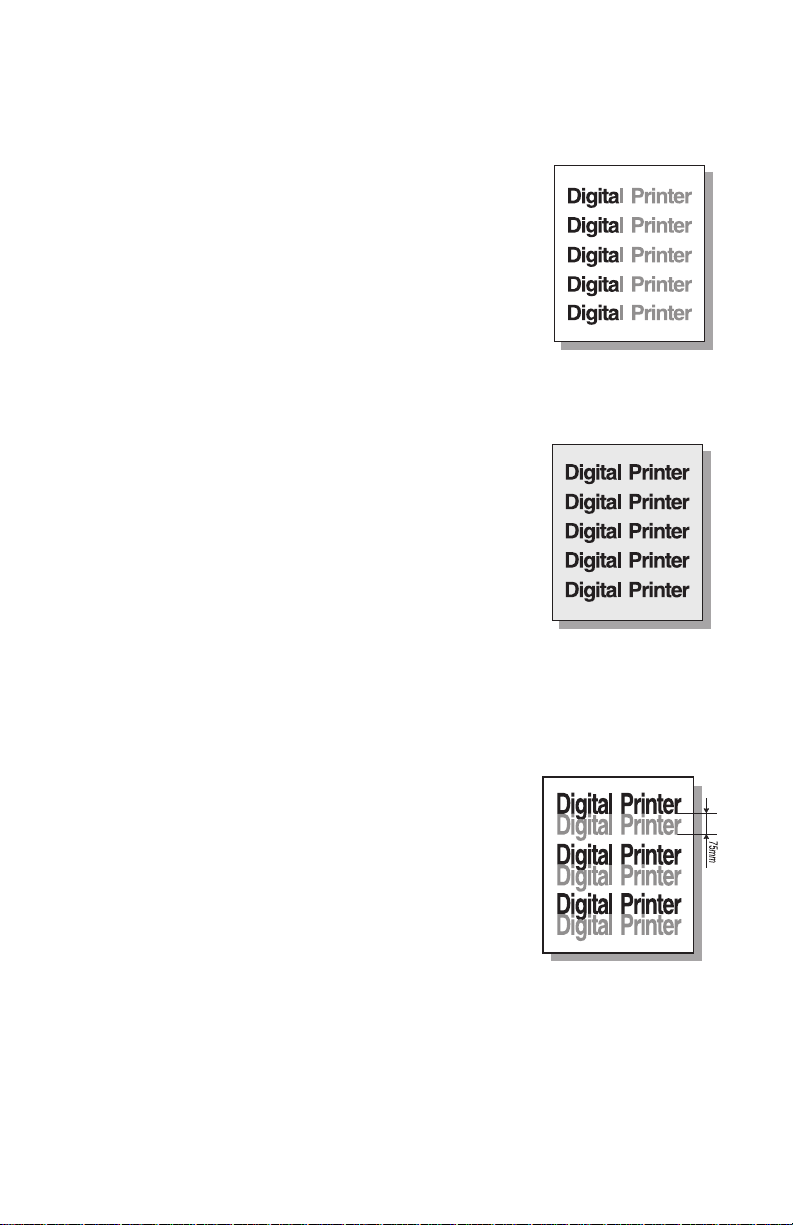

Residual Image at 75 mm Intervals (1) . . . . . . . . . . . . . . . . . . 2-3

Residual Image at 75 mm Intervals (2) . . . . . . . . . . . . . . . . . . 2-4

Residual Image at 32 mm Intervals. . . . . . . . . . . . . . . . . . . . . 2-4

Residual Image at 57 mm Intervals. . . . . . . . . . . . . . . . . . . . . 2-4

Toner on Front of Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Toner on Back of Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Blank Page Printout (1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Blank Page Printout (2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Repeated marks or voids down page . . . . . . . . . . . . . . . . . . . 2-6

Paper Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Printing in wrong position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Paper stopping, jamming, or feeding multiple sheets . . . . . . . 2-7

Paper Path Jam 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Paper Path Jam 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Paper Path Jam 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

All LEDs blinking (Printhead Error) during a print job . . . . . . 2-10

All LEDs blinking (Fuser Error) at power up . . . . . . . . . . . . . 2-11

The LED blinks once then all other LEDs blink (Over Heat Error)

iii

Page 4

4510-001

2-11

The LED blinks once then all other LEDs blink (Low Heat Error).

2-12

The LED blinks once then all other LEDs blink (Open Fuser Error)

2-13

False Paper Empty Indication . . . . . . . . . . . . . . . . . . . . . . . .2-13

False Pape r Present Indication . . . . . . . . . . . . . . . . . . . . . . .2-14

False Cover Open Indicator. . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Error LED Off When Cover Open. . . . . . . . . . . . . . . . . . . . . .2-15

Drive Motor Does Not Operate. . . . . . . . . . . . . . . . . . . . . . . .2-15

No Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Handling ESD-Sensitive Parts . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Other Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Operator Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Transfer Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Pick Roller Clutch Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

HVPS Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Fuser Thermostat and Lamp . . . . . . . . . . . . . . . . . . . . . . . . .3-15

LVPS Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Main Board and Input/Exit Sensor Board. . . . . . . . . . . . . . . .3-20

Pre-Transfer LED Assembly (PTL). . . . . . . . . . . . . . . . . . . . .3-21

Pick Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

iv Service Manual

Page 5

4510-001

Laser Notices

Laser notice

The printer is certified in the U.S. to conform to the requirements of

DHHS 21 CFR Subchapter J for Class I (1) laser products, and

elsewhere is certified as a Class I laser product conforming to the

requirements of IEC 60825.

Class I laser products are not considered to be hazardous. The

printer contains internally a Class IIIb (3b) laser that is nominally a 5

milliwatt gallium arsenide laser operating in the wavelength region of

770-795 nanometers. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I

level during normal operation, user maintenance, or prescribed

service condition.

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die

Anforderungen der Bestimmung DHHS (Department of Health and

Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1).

In anderen Ländern gilt der Drucker als Laserprodukt der Klasse I,

der die Anforderungen der IEC (International Electrotechnical

Commission) 60825 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des

Druckers befindet sich ein Laser der Klasse IIIb (3b), bei dem es

sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen

der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbetrieb, bei der Wartung

durch den Benutzer oder bei ordnungsgemäßer Wartung durch den

Kundendienst Laserbestrahlung, die die Klasse I übersteigen würde,

Menschen keinesfalls erreicht.

Laser Notice s v

Page 6

4510-001

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est certifiée conforme aux

provisions DHHS 21 CFR alinéa J concernant les produits laser de

Classe I (1). Pour les autres pays : cette imprimante répond aux

normes IEC 60825 relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comme des produits

non dangereux. Cette imprimante est équipée d’un laser de Classe

IIIb (3b) (arséniure de gallium d’une puissance nominale de 5

milliwatts) émettant sur des longueurs d’onde comprises entre 770

et 795 nanomètres. L’imprimante et son système laser sont conçus

pour impossible, dans des conditions normales d’utilisation,

d’entretien par l’utilisateur ou de révision, l’exposition à des

rayonnements laser supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme

ai requisiti del DHHS 21 CFR Sottocapitolo J per i prodotti laser di

classe 1 ed è certificata negli altri Paesi come prodotto laser di

classe 1 conforme ai requisiti della norma CEI 60825.

I prodotti laser di classe non sono considerati pericolosi. La

stampante contiene al suo interno un laser di classe IIIb (3b)

all’arseniuro di gallio della potenza di 5mW che opera sulla

lunghezza d’onda compresa tra 770 e 795 nanometri. Il sistema

laser e la stampante sono stati progettati in modo tale che le

persone a contatto con la stampante, durante il normale

funzionamento, le operazioni di servizio o quelle di assistenza

tecnica, non ricevano radiazioni laser superiori al livello della classe

1.

vi Service Manual

Page 7

4510-001

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los

requisitos para los productos láser de Clase I (1) establecidos en el

subcapítulo J de la norma CFR 21 del DHHS (Departamento de

Sanidad y Servicios) y, en los demás países, reúne todas las

condiciones expuestas en la norma IEC 60825 para productos láser

de Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La

impresora contiene en su interior un láser de Clase IIIb (3b) de

arseniuro de galio de funcionamiento nominal a 5 milivatios en una

longitud de onda de 770 a 795 nanómetros. El sistema láser y la

impresora están diseñados de forma que ninguna persona pueda

verse afectada por ningún tipo de radiac ión láser superior al nivel de

la Clase I durante su uso normal, el mantenimiento realizado por el

usuario o cualquier otra situación de servicio técnico.

Declaração sobre Laser

A impressora está certificada nos E.U.A. em conformidade com os

requisitos da regulamen t ação DHHS 21 CFR Subcapítulo J para a

Classe I (1) de produtos laser. Em outros locais, está certificada

como um produto laser da Classe I, em conformidade com os

requisitos da norma IEC 60825.

Os produtos laser da Classe I não são considerados perigosos.

Internamente, a impressora contém um produto laser da Classe IIIb

(3b), designado laser de arseneto de potássio, de 5 milliwatts

,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de

forma a nunca existir qualquer possiblidade de acesso humano a

radiação laser superior a um nível de Classe I durante a operação

normal, a manutenção feita pelo utilizador ou condições de

assistência prescritas.

Laser Notices vii

Page 8

4510-001

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een

laserprodukt van klasse I. Voor de Verenigde Staten zijn deze eisen

vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in

IEC 60825.

Laserprodukten van klasse I worden niet als ongevaarlijk

aangemerkt. De printer is voorzien van een laser van klasse IIIb

(3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt met

een golflengte van 770-795 nanometer. Het lasergedeelte en de

printer zijn zo ontworpen dat bij normaal gebruik, bij onderhoud of

reparatie conform de voorschriften, nooit blootstelling mogelijk is

aan laserstraling boven een niveau zoals voorgeschreven is voor

klasse 1.

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i

overenstemmelse med kravene i IEC 60825.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren

indeholder internt en Klasse IIIB (3b)-laser, der nominelt er en 5

milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet

770-795 nanometer. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over

Klasse I-niveau ved normal drift, brugervedligeholdelse eller

obligatoriske servi c ebet ing el se r.

Laser Notices viii

Page 9

4510-001

Huomautus laserlaitteesta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) laserlaitteiden DHHS

21 CFR Subchapter J -määrityksen mukainen ja muualla luokan I

laserlaitteiden IEC 60825 -määrityksen mukainen.

Luokan I laserlaitteiden ei katsota olevan vaarallisia käyttäjälle.

Kirjoittimessa on sisäinen luokan IIIb (3b) 5 milliwatin

galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä.

Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei

altistu luokan I määrityksiä voimakkaammalle säteilylle kirjoittimen

normaalin toiminnan, käyttäjän tekemien huoltotoimien tai muiden

huoltotoimien yhteydessä.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina

näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21

CFR, underparagraf J för laserprodukter av Klass I (1). I andra

länder uppfyller skr ivaren kraven för laserprodukter av Klass I enligt

kraven i IEC 60825.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en

inbyggd laser av Klass IIIb (3b) som består av en laserenhet av

gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770795 nanometer. Lasersystemet och skrivaren är utformade så att det

aldrig finns risk för att någon person utsätts för lasers tr ålning över

Klass I-nivå vid normal användning, underhåll som utförs av

användaren eller annan föreskriven serviceåtgärd.

Laser Notices ix

Page 10

4510-001

Laser-melding

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR,

underkapittel J, for klasse I (1) laserprodukter, og er i andre land

godkjent som et Klasse I-laserprodukt i samsvar med kravene i IEC

60825.

Klasse I-laserprodukter er ikke å betrakte som farlige. Skriveren

inneholder internt en klasse IIIb (3b)-laser, som består av en

gallium-arsenlaserenhet som avgir stråling i bølgelengdeområdet

770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk, vedlikehold som utføres av brukeren, eller foreskrevne

serviceoperasjoner.

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora

compleix els requisits de DHHS 21 CFR, apartat J, pels productes

làser de classe I (1), i segons ha estat certificat en altres llocs, és un

producte làser de classe I que compleix els requisits d’IEC 60825.

Els productes làser de classe I no es consideren perillosos. Aquesta

impressora conté un làser de classe IIIb (3b) d’arseniür de gal.li,

nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona

de 770-795 nanòmet re s. El siste ma làser i la impressora han sigut

concebuts de manera que mai hi hagi exposició a la radiació làser

per sobre d’un nivell de classe I durant una operació normal, durant

les tasques de manteniment d’usuari ni durant els serveis que

satisfacin les condicions prescrites.

Laser Notice s x

Page 11

4510-001

Japanese Laser Notice

Chinese Laser Notice

Laser Notices xi

Page 12

4510-001

Kore an Laser Notice

Laser Notices xii

Page 13

4510-001

Safety Information

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not always

be obvious. Lexmark is not responsible for the use of other

replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessar y pr ec autions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation d e

composants Lexmark sp écifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres

pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Safety Information xiii

Page 14

4510-001

Norme di sicurezza

• Il prodotto è stato progettato, testato e approvato in conformità a

severi standard di sicurezza e per l’utilizzo con componenti

Lexmark specifici. Le caratteristiche di sicurezza di alcune parti

non sempre sono di immediata comprensione. Lexmark non è

responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von

Lexmark sind, wird von Lexmark keinerlei Verantwortung oder

Haftung für dieses Produkt übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende V orsichtsmaßnahmen

treffen.

xiv Service Manual

Page 15

4510-001

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede que

las características de seguridad de algunas piezas no sean

siempre evidentes. Lexmark no se hace responsable del uso de

otras piezas de recambio.

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

• Este produto foi concebido, testado e aprovado para satisfazer

os padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns

dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela utiliza ção de outros componentes de

substituição.

• As informações de segurança relativas a este produto

destinam-se a profissio nai s destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Safety Information xv

Page 16

4510-001

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de serv e i d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

xvi Service Manual

Page 17

4510-001

Safety Information xvii

Page 18

4510-001

Preface

This manual contains maintenance procedures for service

personnel. It is divided into the following chapters:

1. General Information contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed.

2. Diagnostic Aids contains error indications and symptom tables

used to isolate failing field replaceable units (FRUs).

3. Repair Information provides instructions for making printer

adjustments and removing and installing FRUs.

4. Parts Catalog contains illustrations and part numbers for

individual FRUs.

xviii Service Manual

Page 19

4510-001

1. General Information

The Lex mark™ E210 is a versatile, productive laser printer equipped

with special features that improve print quality. The Lexmark E210

provides the customer the option to select either 300 dpi or 600 dpi

resolution. The E210 allows the customer to customize documents

by using watermarks, printing preprinted forms, letterhead and

posters on plain paper. The E210 can print on a wide variety of laser

media including envelopes, transparencies, bond paper up to 43 lb,

labels and card stock. The E210 is compatible with a wide range of

systems including Windows 95/98/Me/NT 4.0/2000 and Linux.

Printer Side View - Locations

General Information 1-1

Page 20

4510-001

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the user error messages,

and diagnostic aids to determine the printer problem and repair the

failure. After you complete the repair, perform tests as needed to

verify the repair.

Tools Required for Service

• Analog or digital multimeter

• Pliers: diagonal and needle-nose

• Screwdrivers: #1 and #2 Phillips

• Cotton Swab

Abbreviations

ESD Electrostatic Discharge

FRU Field Replaceable Unit

LED Light-Emitting Diode

PTL Pre-Transfer LED

V ac Volts alternating current

V dc Volts direct current

1-2 Service Manual

Page 21

4510-001

2. Diagnostic Aids

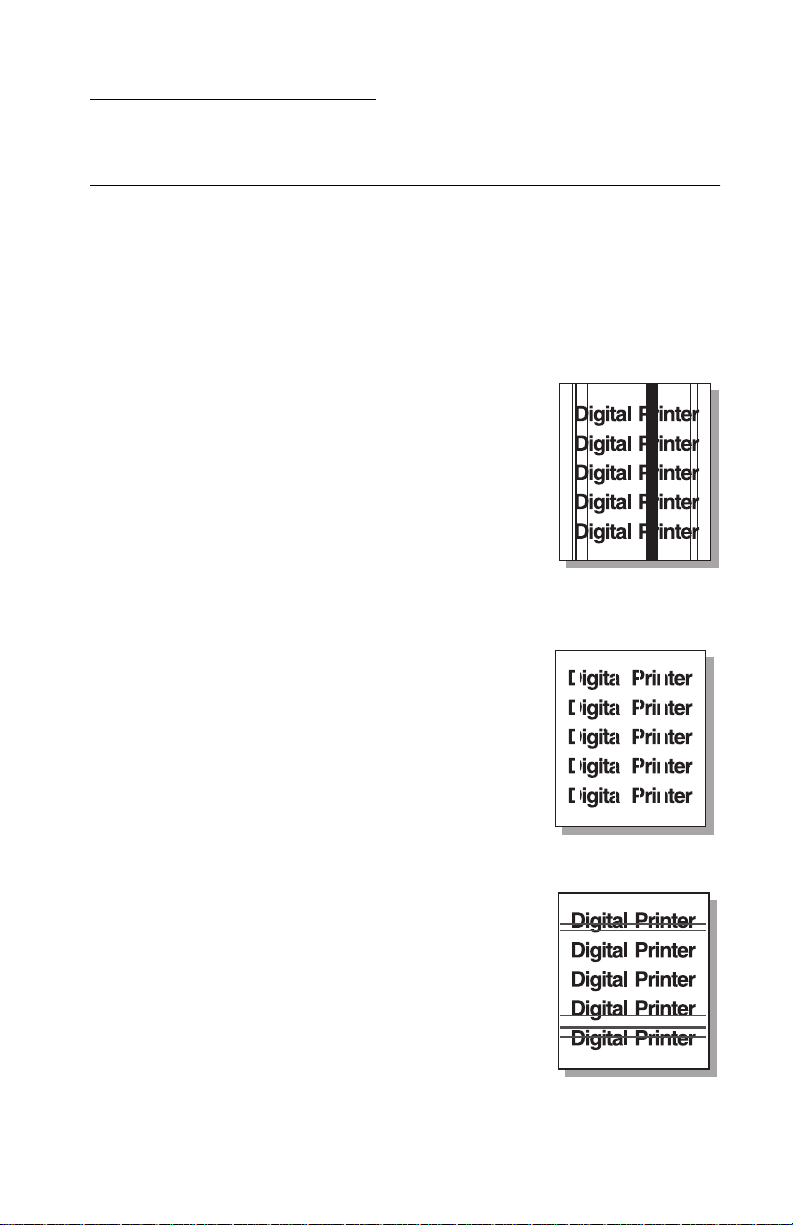

Print Quality

Vertical Black Line and Band

Description:

1. Straight thin black vertical line

2. Dark black vertical bands

Possible causes:

• Toner cartridge failure

• Foreign material between transfer/

charge/development rollers

• Deformed transfer roller

Vertical White Line

Description: White vertical voids

Possible causes:

• Toner cartridge failure

• Printhead f ailure

• Fuser failure

Horizontal Black Band

Description: Dark or blurry horizontal stripes

Possible causes:

• Toner cartridge failure

• Bad or dirty voltage contacts

Diagnostic Aids 2-1

Page 22

4510-001

Black/White Spots

Description:

1. Dark or blurry black spots occur

periodically.

2. White spots occur periodically.

Possible Causes:

• Toner cartridge failure

• Transfer roller failure

Light Image

Description: The printed image is light, with no

residual image.

Possible causes:

• Toner save mode on

• Toner cartridge failure

• Bad or dirty voltage contacts

• HVPS failure

Dark or Black Image

Description: The printed image is dark.

Possible causes:

• Bad or dirty high voltage contacts

• Loose HVPS cable connection at the

engine board

• HVPS failure

2-2 Service Manual

Page 23

4510-001

Uneven Density

Description: Print density is uneven from left

to right.

Possible causes:

• Toner cartridge failure

• Improper transfer roller installation

• Transfer roller failure

Background

Description: Background appears in print

area.

Possible causes:

• Recycled or poor quality paper

• Toner cartridge failure

• Dirty transfer roll

• Transfer roll failure

• HVPS failure

Residual Image at 75 mm Intervals (1)

Description: Residual image occurs at 75

mm intervals.

Possible causes:

• Toner cartridge failure

• Bad or dirty high voltage contacts

• Transfer roller failure

• Engine board failure

Diagnostic Aids 2-3

Page 24

4510-001

Residual Image at 75 mm Intervals (2)

Description: Residual image occurs at 75

mm intervals when printing card stock or

transparencies.

Possible cause:

• Software not set to card stock or

transparency mode

Residual Image at 32 mm Intervals

Description: Residual image occurs in the

black image printing at 32 mm intervals.

Possible causes:

• Toner cartridge failure

• Bad or dirty high voltage contacts

Residual Image at 57 mm Intervals

Description: Residual image occurs at 57

mm intervals.

Possible causes:

• Fuser temperature maintained too

high. Check for toner buildup on hot

roller and thermistor surface. Clean

or replace fuser if necessary.

2-4 Service Manual

Page 25

4510-001

Toner on Front of Page

Description: The background on the front of

the printed page is stained with toner.

Possible causes:

• Toner cartridge failure

• Transfer roller failure

Toner on Back of Pa ge

Description: The back of the page is stained

with toner at 47 mm intervals.

Possible causes:

• Transfer roller failure

• Fuser failure (dirty)

Blank Page Printout (1)

Description: Blank page is printed.

Possible cause:

• Bad or dirty high voltage contacts

Diagnostic Aids 2-5

Page 26

4510-001

Blank Page Printout (2)

Description:

1. Blank page is printed.

2. One or several blank pages are printed.

3. When the printer turns on, several blank

pages print.

Possible causes:

• Bad or dirty high voltage contacts

• Pick solenoid failure

• Main board failure

Repeated marks or voids down page

Distance

Between

Repeated

Mark

Related Printer

Components

Action

27 mm Supply Roller Replace Toner Cartridge

32 mm Develop Roller Replace Toner Cartridge

37 mm Charge Roller Replace Toner Cartridge

47 mm Transfer Roller Replace Transfer Roller

58 mm Fuser Hotroll Replace Fuser

60 mm Fuser Backup Roll Replace Fuser

75 mm OPC Drum Replace Toner Cartridge

2-6 Service Manual

Page 27

4510-001

Paper Feed

Printing in wrong position

Printing begins at the

Step

wrong position on

the paper

Yes No

1 Check for obstructions

in the input tray that

could cause incorrect

feeding. Are there

obstructions?

2 Check the paper

present actuator for

binds. Is it binding?

Remove the

obstructions

Correct the

binding problem

Go to step 2

Replace the paper

present actuator

Paper stopping, jamming, or feeding multiple sheets

Paper stops or jams

Step

1 Does the paper e xit the

2 Does the paper stop

3 Is the paper jammed in

at various points in

the printer or feeds

multiple sheets

input tray? See “Paper

Path Jam 0” on

page 2-9.

just after exiting input

tray? See “Paper Path

Jam 1” on page 2-9.

front of or just inside

the fuser? See “Paper

Path Jam 2” on

page 2-10.

Yes No

Go to step 2 Go to step 4

Go to step 8 Go to step 3

Go to step 9 Go to step 7

4 Check for obstructions

in the input tray. Are

there obstructions?

Remove

obstructions

Go to step 5

Diagnostic Aids 2-7

Page 28

4510-001

Step

Paper stops or jams

at various points in

the printer or feeds

multiple sheets

Yes No

5 Clean the feed rollers.

Did this resolve the

problem?

6 Check for loose or

damaged input tray

side pads. Are they in

good condition?

7 Is the paper jammed

inside the fuser as it

exits the printer? See

“Paper Path Jam 2”

on page 2-10.

8 Check the paper feed

actuator for binding. Is

it binding?

9 Check the paper feed

actuator for dama ge or

binds. It it damaged or

binding?

10 Is the Paper LED on

after the paper exits

the printer?

11 Check the exit sensor

actuator for binds or

damage. Is it binding

or damaged?

Problem resolved Go to step 6

Replace the pa per

feed solenoid

Replace th e fuser Go to step 10

Correct the

binding or replace

the paper feed

actuator

Correct the

binding or replace

the paper feed

actuator

Go to step 11 Go to step 12

Correct the

binding or replace

the paper feed

actuator

Replace the side

pads

Replace the

sensor board

Replace the LVPS

Replace the LVPS

12 Is the pape r jammed in

the fuser?

13 Is the printer feeding

multiple sheets?

14 Did cleaning the

friction pad resolve th e

problem?

2-8 Service Manual

Replace th e fuser Go to step 13

Clean the friction

pad. Go to step 14

Problem resolved Replace the

No problem found

solenoid

Page 29

4510-001

Paper Path Jam 0

Paper Path Jam 1

Diagnostic Aids 2-9

Page 30

4510-001

Paper Path Jam 2

Service

All LEDs blinking (Printhead Error) during a print job

Step

1 Are all the printhead

2 Did printhead

3 Did main board

2-10 Service Manual

All LEDs blink when

attempting a print job

cables correctly

connected?

replacement resolve

the problem?

replacement resolve

the problem?

Yes No

Replace th e

printhead. Go to

step 2.

Problem resolved. Replace the main

Problem resolved. Replace the

Properly connect

the cables.

board. Go to

step 3.

printhead cables .

Page 31

4510-001

All LEDs blinking (Fuser Error) at power up

All LEDs blink when

Step

attempting at power upYes No

1 Check the thermostat

for continuity. Is there

continuity?

2 Check the lamp for

continuity. Is there

continuity?

3 Check the thermistor

for wear. Is the

thermistor worn?

4 Check for 110 V ac

across the 2 pins of

connector CN502 on

the LVPS. Is 110 V ac

present?

5 Check the fuser gears

for wear or other

damage. Is the gear

damaged?

Go to step 2. Replace the

thermostat.

Go to step 3. Replace the lamp.

Replace the fuser. Go to step 4.

Go to step 5. Replace LVPS.

Replace the fuser. Replace the main

board.

The LED blinks once then all other LEDs blink

(Over Heat Error)

This message is displayed when the printer detects the fuser is

hotter than it should be via feedback through the fuser thermistor.

Step Yes No

1 Replace the fuser. Did

this resolve the problem?

2 Did LVPS replacement

resolve the problem?

Problem

Resolved.

Problem

Resolved.

Replace the LVPS. Go

to step 2.

Replace the engine

board.

Diagnostic Aids 2-11

Page 32

4510-001

The LED blinks once then all other LEDs blink

(Low Heat Error)

This message occurs when the printer is warming up. If the

temperature is not correct at a certain threshold, this message is

posted.

Step Yes No

1 Check the fuser lamp. Is

the correct volta ge lamp

installed?

2 Replace the LVPS. Did

this resolve the problem?

3 Did fuser replacement

resolve the probl em ?

4 Did engine board

replacement resolve the

problem?

Go to step 2. Replace with proper

voltage lamp. Go to

step 2 if problem

persists.

Problem

Resolved.

Problem

Resolved.

Problem

resolved.

Replace the fuser. Go

to step 3.

Replace the engine

board. Go to step 4.

Replace the controller

board.

2-12 Service Manual

Page 33

4510-001

The LED blinks once then all other LEDs blink

(Open Fuser Error)

This message occurs when the printer detects no change of

temperature in the fuser

Step Yes No

1 Is there continuity across

the fuser lamp wires?

2 Remove the TCO . Is there

3 Is there continuity across

4 Replace the LVPS. Did

5 Did replacement of the

continuity across the

TCO?

the lamp?

LVPS replacement

resolve problem?

engine board resolve the

problem?

False Paper Empty Indication

Paper LED on when

Step

1 Check the paper

paper is present in

the input tray

present sensor

actuator for breakage

or binding. Is there

breakage or binding?

Yes No

Replace the pa per

present actuator.

Go to step 4. Replace the TCO.

Problem resolved.

Go to step 3. Replace the lamp.

Go to step 4. Replace the engine

Problem

Resolved.

Problem

resolved.

Problem resolved.

board. Go to step 5.

Replace the engine

board. Go to step 5.

Replace the controller

board.

Replace the

sensor board.

Diagnostic Aids 2-13

Page 34

4510-001

False Paper Present Indication

Paper LED off when

Step

paper is not present

in the input tray

Yes No

1 Check the paper

2 Replace the sensor

present sensor

actuator for breakage

or binding. Is there

breakage or binding?

board.

False Cover Open Indicator

The error LED is on

Step

1 Open the front cover

2 Disconnect the co ver

when the cover is

closed

and check the cover

open switch actuator

that is attached to the

front cover. Is the

actuator broken?

open sensor connector

from the main board.

Check for continuity at

the connector while

deflecting the actuator

on the switch. Does

the continuity change

with deflection of the

actuator?

Replace the pa per

present actuator.

Yes No

Replace th e front

cover.

Replace the main

board.

Go to step 2.

Go to step 2.

Replace the cover

open switch.

2-14 Service Manual

Page 35

4510-001

Error LED Off When Cover Open

The error LED is off

Step

when the cover is

open

Yes No

1 Disconnect the cover

open sensor connector

from the main board.

Check for continuity at

the connector while

deflecting the actuator

on the switch. Does

the continuity change

with deflection of the

actuator?

Replace th e main

board.

Drive Motor Does Not Operate

Motor does not run

Step

1 Check for proper

2 Check for continuity of

when attempting to

run a print job

connection of the

motor connector on the

SMPS board. Is it

properly connected?

the cable between the

drive motor and the

LVPS. Is there

continuity?

Yes No

Go to step 2. Properly connect

Go to step 3. Replace the cable.

Replace the cover

open switch.

the connector.

3 Replace the drive

motor. Did this resolve

the problem?

Problem resolved. Replace the LVPS.

Diagnostic Aids 2-15

Page 36

4510-001

No Power

Step

When printer power

is turned on, LEDs

not on

Yes No

1 Check the power cord

for damage a nd correct

connection. Did you

find damage or a f aulty

connection?

2 Replace the LVPS. Did

this resolve the

problem?

3 Did operator panel

replacement resolve

the problem?

Repair or replace

the power cord as

necessary.

Problem resolved. Replace the

Problem resolved. Replace main

Go to step 2.

operator panel.

board.

2-16 Service Manual

Page 37

4510-001

3. Repair Information

Handling ESD-Sensitive P arts

Many electronic products use parts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual

precautions, such as turning off power before removing logic boards:

• Keep the ESD-sensitive part in its ori gi nal shipping container

(a special “ESD bag”) until you are ready to install the part into

the printer.

• Make the least-possible movements with your body to prevent

an increase of static electricity from clothing fibers, carpets, and

furniture.

• Secure the ESD wrist strap around your wrist and connect the

wrist band to the engine ground point. This discharges any

static electricity, in your body, to the printer.

• Hold the ESD-sensitive part by its edge connector shroud

(cover); do not touch the pins. If you are removing a pluggable

module, use the correct tool.

• Do not place the ESD-sensitive part on the printer cover or on a

metal table, as electrical grounding may occur, which increases

the risk of damage due to the discharge path your body could

establish through the ESD-sensitive part. (Large metal objects

can be discharge paths without being grounded.)

• When laying the ESD-sensitive part down, always return it to

the ESD-sensitive bag.

• If possible, keep all ESD-sensitive parts in a grounded metal

cabinet (case).

• Take care working with ESD-sensitive parts when cold weather

heating is used, as low humidity increases static electricity.

Repair Information 3-1

Page 38

4510-001

Front Cover

1. Pull the cover open.

2. Remove the screw and remove the stopper that holds the

printer cover.

3-2 Service Manual

Page 39

4510-001

3. Pull the right lower side off the post and to the right. Then push

the cover in the direction of the arrow to loosen the lower left

part.

Repair Information 3-3

Page 40

4510-001

4. Remove the screw that secures the operator panel harness

cover, disconnect the connector and remove the cover.

3-4 Service Manual

Page 41

4510-001

Other Covers

1. Rear Cover: Remove the cover in the direction of (a).

2. Top Cover: Remove the cover in the direction of (b).

3. Side cover L, R: Remove the cover in the direction of (c).

Repair Information 3-5

Page 42

4510-001

Operator Panel

1. Before removing the operator panel, you should remove the

front cover.

2. Remove two screws of the operator panel cover, and widen the

hooks (a) (b) (c) to remove.

3-6 Service Manual

Page 43

4510-001

3. Remove two screws, and remove the operator panel.

4. Remove the operator panel from the operator panel cover.

Repair Information 3-7

Page 44

4510-001

Printhead

1. Before removing the printhead, remove the rear cover and the

top cover.

2. Remove three screws securing the printhead.

3-8 Service Manual

Page 45

4510-001

3. Remove two connectors from the printhead, and then remove

the printhead.

Repair Information 3-9

Page 46

4510-001

Transfer Roller

1. Open the front cover.

2. Use a flat blade screwdriver to pry the right end of the roller up

and remove the transfer roller.

3-10 Service Manual

Page 47

4510-001

Motor Assembly

1. Before removing the motor assembly, remove the front cover,

top cover, rear cover, right side cover, and the metal bottom

cover.

2. Remove five screws securing the motor assembly and remove a

connector from the motor assembly. Then remove the motor

assembly.

Pick Roller Clutch Solenoid

1. Before removing the solenoid, remove the top cover, rear cover,

right side cover and the metal bottom cover.

2. Disconnect the solenoid connector from the LVPS.

3. Remove the screw securing the solenoid.

4. Remove the solenoid.

Repair Information 3-11

Page 48

4510-001

HVPS Board

1. Before removing the HVPS board, remove the top cover, rear

cover, and left side cover.

2. Remove four screws and a connector from the HVPS board,

and then remove board.

Note: When you reassemble the HVPS board, make sure that the

five terminals are in place.

3-12 Service Manual

Page 49

4510-001

Fuser Assembly

1. Before rem oving t he fuser a ssembl y, remove the front co ve r and

left cover.

2. Remove two terminal screws and a connector.

Repair Information 3-13

Page 50

4510-001

3. Remove remaining screws. Use a flat blade screwdriver to

unlatch the fuser assembly and remove.

3-14 Service Manual

Page 51

4510-001

Fuser Thermostat and Lamp

1. Remove screw from the fuser assembly and remove the

thermostat cover. Remove the two screws securing the

thermostat.

Repair Information 3-15

Page 52

4510-001

2. Remove two screws from the fuser assembly, and remove the

hot roller.

3. Remove the lamp from the hot roller.

Note: When you reassemble the lamp, handle it with care as it is

fragile.

3-16 Service Manual

Page 53

4510-001

LVPS Board

1. Before removing the L VPS board, remove the rear cover.

2. Remove two screws.

Repair Information 3-17

Page 54

4510-001

3. Remove the screws and remove the bottom cover.

3-18 Service Manual

Page 55

4510-001

4. Unplug connector (CN5) from the main board and connectors

(CN1, CN2, CN501, CN502) from LVPS. Remove the clip that

secures the LVPS to the metal bottom pan. Remove five screws

from the LVPS and remove the LVPS board.

Repair Information 3-19

Page 56

4510-001

Main Board and Input/Exit Sensor Board

1. Before removing the main board, remove the rear cover, metal

bottom cover, and the LVPS board.

2. Unplug all connectors, remove two screws from the main board,

and then remove the board.

3. To remove the input/exit sensor board, release four snap-fits

securing the insulator and then remove the insulator.

3-20 Service Manual

Page 57

4510-001

4. Release four snap-fits securing the sensor board and then

remove the input/exit sensor board.

Pre-Transfer LED Assembly (PTL)

1. Remove the transfer roller.

2. Remove the bottom metal cover and disconnect CN6 on the

main board.

3. Remove the four screws securing the printhead plate.

4. Slide the printhead plate left to disengage the pick roller from

the pick roller shaft.

5. Remove the two screws securing the PTL cover plate.

6. Remove the PTL.

Repair Information 3-21

Page 58

4510-001

Pick Roller

There is more than one way to remove the pick roller, but the

procedure below is the easiest.

1. Open the front cover, and remove the toner cartridge.

2. Remove the rear and top covers along with the paper input tray

assembly.

3. Remove the four screws securing the printhead bracket to the

plastic frame.

4. Lift the printhead bracket (with printhead still attached) upward

and to the left to disconnect the pick roller assembly from the

pick roller shaft.

5. Remove two screws securing the pick roller assembly to the

printhead bracket.

6. Remove the pick roller assembly from the bracket.

3-22 Service Manual

Page 59

4510-001

Installation Note:

When repositioning the printhead bracket (with the pick roller

assembly) to the plastic frame, push the lift plate down while

carefully engaging the pick roller shaft to the pick roller assembly.

This procedure is to ensure the lift plate properly rests under the pick

roller.

Repair Information 3-23

Page 60

4510-001

3-24 Service Manual

Page 61

4510-001

4. Parts Catalog

Parts Catalog 4-1

Page 62

4510-001

Assembly 1: Co vers

4-2 Service Manual

Page 63

4510-001

Assembly 1: Covers

AsmIndex

1-1 12G6768 1 Tray Assembly, Input

2 12G6765 1 Cover Assembly, Rear

3 12G6763 1 Extender , Paper Exit

4 12G6760 1 Guide, Stacker

5 12G6767 1 Cover, Right

6 12G6762 1 Cover, Front

7 12G6255 1 Support, Cover Open

8 12G6761 1 Panel, Operator

9 12G6796 1 Cover, Operator Panel

10 12G6776 1 Cable, Operato r Panel

11 12G6766 1 Cover , Lef t

12 12G6764 1 Cover , Top

Part

Number

Unit Description

Parts Catalog 4-3

Page 64

4510-001

Assembly 2: Engine

4-4 Service Manual

Page 65

4510-001

Assembly 2: Engine

AsmIndex

2-1 12G6795 1 Printhead Assembly Complete

2 12G6256 1 Plate, Printhead Mount

3 12G6784 1 Shaft, Pick Roller

4 12G6777 1 Plate, Lift

5 12G6259 1 Bushing, Transfer Roll Right

6 12G6262 1 Spring, Bushing, Right

7 12G6269 1 Housing, Transfer Roll Bushing

8 12G6785 1 Pad, Left Separator

9 12G6786 1 Pad, Right Separator

10 12G6778 1 Holder, Pad

11 12G6779 1 Pad, Main Separator

12 12G6769 1 Frame, Lo w er

13 12G6783 1 Solenoid, Pick Roller Clutch

14 12G6780 1 Clutch Assembly, Pick Roller Gear

15 12G6265 1 Bushing, Shaft

16 12G6771 1 Fan, Cooling

17 12G6266 1 Roller, Paper Feed

18 12G6798 1 Motor, Main

19 12G6794 1 Drive Assembly, Main

20 12G6799 1 Cable, Main Motor

22 12G6782 1 Card Assembly, Input/Exit Sensor

23 12G6267 1 Housing, Paper Feed Roller

24 12G6789 1 Flag, Exit Sensor

25 12G6788 1 Flag, Input Sensor

26 12G6263 1 Holder, Exit Roller

27 12G6257 1 Switch, Cover Open

Part

Number

Unit Description

Parts Catalog 4-5

Page 66

4510-001

Assembly 2 (cont.): Engine

4-6 Service Manual

Page 67

4510-001

Assembly 2 (cont.): Engine

AsmIndex

2-28 12G6787 1 Roll Assembly, Pick

29 12G6781 1 Contact Assembly, Toner Cartridge

30 12G6770 1 Roller, Transfer

31 12G6261 1 Spring, Bushing, Left

32 12G6260 1 Bushing, Transfer Roll Left

33 12G6258 1 Card Assembly, Pre-Transfer LED

34 12G6264 1 Cover, PTL Board

35 12G6797 1 Cable, Printhead

Part

Number

Unit Description

Parts Catalog 4-7

Page 68

4510-001

Assembly 3: Fuser

4-8 Service Manual

Page 69

4510-001

Assembly 3: Fuser

AsmIndex

3-1 12G6772 1 Fuser Assembly, Complete, 220 V

1 12G6773 1 Fuser Assembly, Complete, 110 V

2 12G0075 1 Thermostat (TCO)

3 12G6774 1 Lamp, Fuser, 220 V

3 12G6775 1 Lamp, Fuser, 110 V

Part

Number

Unit Description

Parts Catalog 4-9

Page 70

4510-001

Assembly 4: Electronics

4-10 Service Manual

Page 71

4510-001

Assembly 4: Electronics

AsmIndex

4-1 12G6790 1 Card Assembly, Main

2 12G6791 1 Power Supply, Low Voltage, 220 V

2 12G6792 1 Power Supply, Low Voltage, 110 V

3 12G6793 1 Power Supply, High Voltage

Part

Number

Unit Description

Parts Catalog 4-11

Page 72

4510-001

4-12 Service Manual

Page 73

4510-001

Index

A

Abbreviations 1-2

E

ESD-Sensitive Parts 3-1

P

Paper Feed 2-7

Parts Catalog

Print Quality

4-1

2-1

R

Removals

Front Cover

Fuser Assembly

Fuser Thermostat and Lamp

HVPS Board

LVPS Board

Main Board and Sensor Board

Motor Assembly

Operator Panel

Other Covers

Pick Roller Clutch

Pre-Transfer LED Assembly (PTL)

Printhead

Transfer Roller

Repair Information

3-2

3-13

3-15

3-12

3-17

3-20

3-11

3-6

3-5

3-11

3-21

3-8

3-10

3-1

S

Safety Information xiii

2-10

Service

T

Tools 1-2

Part Numbers

12G0075 4-9

12G6255

4-3

12G6256

12G6257

12G6258

12G6259

12G6260

12G6261

12G6262

12G6263

12G6264

12G6265

12G6266

12G6267

12G6269

12G6760

12G6761

12G6762

12G6763

12G6764

12G6765

12G6766

12G6767

12G6768

12G6769

12G6770

12G6771

12G6772

12G6773

12g6774

12G6775

12G6776

12G6777

12G6778

12G6779

12G6780

12G6781

12G6782

12G6783

12G6784

12G6785

12G6786

12G6787

12G6788

12G6789

4-5

4-5

4-7

4-5

4-7

4-7

4-5

4-5

4-7

4-5

4-5

4-5

4-5

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-3

4-5

4-7

4-5

4-9

4-9

4-9

4-9

4-3

4-5

4-5

4-5

4-5

4-7

4-5

4-5

4-5

4-5

4-5

4-7

4-5

4-5

Index I-1

Page 74

4510-001

12G6790 4-11

12G6791

12G6792

12G6793

12G6794

12G6795

12G6796

12G6797

12G6798

12G6799

4-11

4-11

4-11

4-5

4-5

4-3

4-7

4-5

4-5

I-2 Service Manual

Loading...

Loading...