Page 1

C910 Color Printer

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

5055-01X

•Index

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

5055-01X

Edition: July 2002

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTERNATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of express or implied warranties in certain transactions; therefore,

this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes

are periodically made to the information herein; these changes will be incorporated in

later editions. Improvements or changes in the products or the programs described may

be made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22A/032-2,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or electronically mailed

(e-mail) to ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of

the information you supply in any way it believes appropriate without incurring any

obligation to you. You can purchase additional copies of publications related to this

product by calling 1-800-553-9727. In other countries, contact your point of purchase.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International,

Inc., registered in the United States and/or other countries.

ImageQuick, Optra Forms, and OptraImage are trademarks of Lexmark International, Inc.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 2002.

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

P/N 12G9112

Page 3

5055-01X

Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Toner Darkness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Color Correction Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer Packaging and Shipping Information . . . . . . . . . . . . . . . . 1-2

Print Speed and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Time to First Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printer Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Available Memory Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Flash Memory Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Memory and Expansion Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Input and Output Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Media Size Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Input Media Types and Weights. . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Output Media Types and Weights . . . . . . . . . . . . . . . . . . . . . . . 1-16

Input Capacity by Media and Source . . . . . . . . . . . . . . . . . . . . . 1-18

Output Capacity by Media and Source . . . . . . . . . . . . . . . . . . . 1-19

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Lexmark Glossy Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Print Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Options and Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Optional Internal Local Connections . . . . . . . . . . . . . . . . . . . . . 1-22

Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Data Streams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Operating Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Resident Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Power and Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . 1-25

iii

Page 4

5055-01X

Operating Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Physical Specifications and Weight. . . . . . . . . . . . . . . . . . . . . . .1-28

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

Standard Inspection and Cleaning Procedure. . . . . . . . . . . . . . .1-29

Return Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-30

Service Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-30

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-33

Processes and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

Electrophotography Process . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

Development Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-35

Transfer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-35

Cleaning Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-36

Paper Feeding / Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-36

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-37

Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-38

Cassette Paper Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-38

Multipurpose Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-39

Registration Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-40

Separation Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-41

Fuser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-42

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-43

Belt Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-44

Belt Up/Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-45

Expansion Paper Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-45

Duplex Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-46

Paper Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-47

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-48

High Capacity Feeder (HCF). . . . . . . . . . . . . . . . . . . . . . . . . . . .1-54

Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-62

High Capacity Paper Feed Sensor / Switch Test . . . . . . . . . . . .1-64

Finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-65

Finisher Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

Attaching the Docking Plate and Guide Rail . . . . . . . . . . . . . . . .1-79

Combining the Finisher and Stand . . . . . . . . . . . . . . . . . . . . . . .1-81

Attaching the Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-85

Aligning the Finisher and Printer . . . . . . . . . . . . . . . . . . . . . . . . .1-86

Adjusting the Wheels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-93

Attaching the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-95

Hole Punch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-99

iv Service Manual

Page 5

5055-01X

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Adjustments and Procedures Following Parts Replacement . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Initial Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Printer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Service Error Message Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Attendance Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Maintenance Analysis Procedures (MAPS) . . . . . . . . . . . . . . . . 2-56

Symptom Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Drive 1 DC Motor Service Check . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Drive 2 Stepper Motor Service Check . . . . . . . . . . . . . . . . . . . . 2-70

Duplex Unit Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

Expansion Paper Feed Service Check . . . . . . . . . . . . . . . . . . . 2-71

Face Down Stacker Full Service Check . . . . . . . . . . . . . . . . . . . 2-72

High Capacity Feeder (HCF) Service Check . . . . . . . . . . . . . . . 2-72

Finisher Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

Operator Panel Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Paper Carrying Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Paper Exit, FU/FD Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-83

Paper Tray Missing Service Check . . . . . . . . . . . . . . . . . . . . . . 2-83

Photodeveloper Missing Service Check. . . . . . . . . . . . . . . . . . . 2-84

Power Supply Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

Marks on Paper Service Check . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

Transfer Belt Up/Down Service Check. . . . . . . . . . . . . . . . . . . . 2-88

210 Staple Jam Service Check . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

Image Quality Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

Options Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-97

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power-On Self Test Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using the Operator Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Operator Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Printing the Menu Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operator Menu Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Adjustment Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Hardware Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Finisher Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Device Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

v

Page 6

5055-01X

Diagnostics - Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Viewing and Resetting the Drum Counters . . . . . . . . . . . . . . . . .3-26

Diagnostics - Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Service Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Handling Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

High Capacity Paper Feed Timing Belt Adjustment . . . . . . . . . . .4-3

Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Cover, Top Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Operator Panel Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Cover, Front Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Cover, Front Left Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Cover, Rear Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Cover, Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Cover, Left Side Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Cover, Right Side Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Cover, RIP Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Tray, Paper Exit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

RIP Box Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Electronic Box Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

LED Printhead Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Eraser Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Printhead Controller Board Removal. . . . . . . . . . . . . . . . . . . . . .4-15

Upper Fan Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Multipurpose Feeder Tray Removal . . . . . . . . . . . . . . . . . . . . . .4-17

Paper Feed Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Paper Carrying Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Paper Present Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Paper Feed Frame Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Cassette Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Temperature/Humidity Sensor Removal . . . . . . . . . . . . . . . . . . .4-22

Paper Feed Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Paper Remaining Sensor Removal . . . . . . . . . . . . . . . . . . . . . . .4-22

Gear Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Multipurpose Feeder Roll Removal . . . . . . . . . . . . . . . . . . . . . . .4-23

Multipurpose Feeder Clutch Removal . . . . . . . . . . . . . . . . . . . . .4-23

OHP Detection Sensor (Upper) Removal . . . . . . . . . . . . . . . . . .4-23

Fanning Pad Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Registration Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Multipurpose Feeder Paper Present Sensor Removal . . . . . . . .4-27

vi Service Manual

Page 7

5055-01X

Paper Carrying Frame Removal . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Paper Carrying Roller (Upper) Removal . . . . . . . . . . . . . . . . . . 4-28

Paper Carrying Clutch Removal. . . . . . . . . . . . . . . . . . . . . . . . . 4-28

OHP Detection Sensor (Lower) Removal . . . . . . . . . . . . . . . . . 4-28

Registration Frame, Registration Clutch Removal . . . . . . . . . . . 4-29

Transfer Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Belt Up/Down Detection Sensor Removal . . . . . . . . . . . . . . . . . 4-34

Sensor Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Density Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Separation Fingers Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Sensor Cleaner Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Printer Controller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

High Voltage Power Supply Board (HVU) Removal. . . . . . . . . . 4-38

R Sub Frame Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Toner Remaining Sensor Removal . . . . . . . . . . . . . . . . . . . . . . 4-39

Drum Gear Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Sub Frame F1, Sub Frame F2 Removal . . . . . . . . . . . . . . . . . . 4-40

Drive Gear Unit Sensor Assembly Removal . . . . . . . . . . . . . . . 4-41

Belt Up/Down Clutch Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Power Supply 1 Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Power Supply 2 Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Drive Motor Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Motor Drive Board Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Power Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Connector, Duplex Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . 4-47

Paper Size Sensor Board Assembly Removal. . . . . . . . . . . . . . 4-48

Main Unit Fan Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Main Drive Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Face Up Paper Exit Assembly Removal . . . . . . . . . . . . . . . . . . 4-54

Face Up/Down (Flapper Detection) Sensor Removal . . . . . . . . 4-54

Face Up/Down Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . 4-54

Paper Delivery Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Paper Exit Tray Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Face Down Guide Assembly Removal. . . . . . . . . . . . . . . . . . . . 4-55

Paper Exit Motor & Full Sensor Removal. . . . . . . . . . . . . . . . . . 4-55

Turn Guide Cover Sensor Removal . . . . . . . . . . . . . . . . . . . . . . 4-57

Right Slide Rail Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Front Cover Open Switch Actuator Removal . . . . . . . . . . . . . . . 4-58

Lock Handle Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Top Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Stay Arm Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

Fuser Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Options Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

vii

Page 8

5055-01X

Expansion Paper Feeder Removal . . . . . . . . . . . . . . . . . . . . . . .4-63

Duplex Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-71

Duplex Unit Separation Removal . . . . . . . . . . . . . . . . . . . . . . . .4-71

Duplex Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

Duplex Timing Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

Duplex Pressure Roller and Solenoid Removal . . . . . . . . . . . . .4-73

Duplex Feed Roller and Solenoid Removal . . . . . . . . . . . . . . . .4-74

Duplex Side Fence Motor Assembly / Side Fence Removal. . . .4-75

Duplex Paper Carrying Motor Removal. . . . . . . . . . . . . . . . . . . .4-76

High Capacity Feeder (HCF) Removals . . . . . . . . . . . . . . . . . . . . .4-77

HCF Covers Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-77

HCF Call Roller, Paper Feed Roller, Reverse Roller Removal . .4-78

HCF Pickup Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . .4-79

HCF Paper End Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . .4-80

HCF Paper Size Sensors (1, 2) Removal . . . . . . . . . . . . . . . . . .4-80

HCF Tray Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

HCF Paper Level Sensor Removal . . . . . . . . . . . . . . . . . . . . . . .4-83

HCF Power Supply Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-84

Finisher Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-85

External Covers Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-85

Hole Punch Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-87

Finisher Control Board Removal . . . . . . . . . . . . . . . . . . . . . . . . .4-88

Registration Roller Clutch Removal . . . . . . . . . . . . . . . . . . . . . .4-89

Registration Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-90

Feed Motor Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . .4-90

Timing Belts 1 and 2 Removal . . . . . . . . . . . . . . . . . . . . . . . . . .4-91

Patting Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-92

Inverter Paper Exit Roller Removal . . . . . . . . . . . . . . . . . . . . . . .4-94

Straight Paper Exit Roller Removal. . . . . . . . . . . . . . . . . . . . . . .4-96

Path Select Gate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-98

Tractor Drive Motor Assembly Removal . . . . . . . . . . . . . . . . . . .4-99

Straight Paper Exit Discharge Brush Removal . . . . . . . . . . . . .4-100

Inverter Paper Exit Discharge Brush Removal . . . . . . . . . . . . .4-100

Tractor Belt Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-101

Staple Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-103

Stack Area Discharge Brush Removal . . . . . . . . . . . . . . . . . . .4-103

Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-103

Jogging Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-105

Elevator Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-107

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Covers Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Major Parts Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

viii Service Manual

Page 9

5055-01X

Sensor and Switch Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Printer Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Printhead Controller Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

RIP Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Power Source Unit 1 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Power Source Unit 2 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

High Voltage Power Supply Board. . . . . . . . . . . . . . . . . . . . . . . 5-12

Sensor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Expansion Paper Feeder Controller Board . . . . . . . . . . . . . . . . 5-13

Duplex Unit Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Motor Drive Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Size Sensor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

High Capacity Feeder (HCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

High Capacity Paper Feed Configuration. . . . . . . . . . . . . . . . . . 5-16

Electrical Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Driving Parts Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Finisher Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Lubricants and Cleaners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: Covers 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Assembly 2: Covers 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Assembly 3: Covers 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Assembly 4: Covers 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Assembly 5: Covers 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Assembly 6: Upper Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Assembly 7: Base 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Assembly 8: Base 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Assembly 9: Base 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Assembly 10: Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Assembly 11: Rip Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Assembly 11: RIP Board (Continued) . . . . . . . . . . . . . . . . . . . . 7-30

Assembly 12: Fuser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Assembly 13: Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Assembly 14: Expansion Feeder 1 . . . . . . . . . . . . . . . . . . . . . . 7-36

Assembly 15: Expansion Feeder 2 . . . . . . . . . . . . . . . . . . . . . . 7-38

Assembly 16: Duplex Unit 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

ix

Page 10

5055-01X

Assembly 17: Duplex Unit 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-42

Assembly 18: High Capacity Feeder 1 . . . . . . . . . . . . . . . . . . . .7-44

Assembly 19: High Capacity Feeder 2 . . . . . . . . . . . . . . . . . . . .7-46

Assembly 20: High Capacity Feeder 3 . . . . . . . . . . . . . . . . . . . .7-48

Assembly 21: High Capacity Feeder 4 . . . . . . . . . . . . . . . . . . . .7-50

Assembly 22: High Capacity Feeder 5 . . . . . . . . . . . . . . . . . . . .7-52

Assembly 23: High Capacity Feeder 6 . . . . . . . . . . . . . . . . . . . .7-54

Assembly 24: Finisher Covers. . . . . . . . . . . . . . . . . . . . . . . . . . .7-56

Assembly 25: Finisher Frame . . . . . . . . . . . . . . . . . . . . . . . . . . .7-58

Assembly 25: Finisher Frame (Continued) . . . . . . . . . . . . . . . . .7-60

Assembly 26: Finisher Feed 1. . . . . . . . . . . . . . . . . . . . . . . . . . .7-62

Assembly 26: Finisher Feed 1 (Continued) . . . . . . . . . . . . . . . . .7-64

Assembly 27: Finisher Feed 2 . . . . . . . . . . . . . . . . . . . . . . . . . .7-66

Assembly 27: Finisher Feed 2 (Continued) . . . . . . . . . . . . . . . . .7-68

Assembly 28: Finisher Elevator. . . . . . . . . . . . . . . . . . . . . . . . . .7-70

Assembly 29: Finisher Electronics . . . . . . . . . . . . . . . . . . . . . . .7-72

Assembly 30: Finisher Docking 1 . . . . . . . . . . . . . . . . . . . . . . . .7-74

Assembly 31: Finisher Docking 2 . . . . . . . . . . . . . . . . . . . . . . . .7-76

Finisher Parts Packet P/N 56P9480 . . . . . . . . . . . . . . . . . . . . . .7-78

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

x Service Manual

Page 11

5055-01X

Safety Information

Safety Notice

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not

always be obvious. Lexmark is not responsible for the use of

other replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injury during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation

d'autres pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Safety Information xi

Page 12

5055-01X

Norme di sicurezza

• Il prodotto è stato progettato, testato e approvato in

conformità a severi standard di sicurezza e per l’utilizzo con

componenti Lexmark specifici. Le caratteristiche di sicurezza

di alcune parti non sempre sono di immediata comprensione.

Lexmark non è responsabile per l’utilizzo di parti di ricambio

di altri produttori.

• Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale di assistenza

autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit

gültigen Sicherheitsanforderungen zu erfüllen. Die

sicherheitsrelevanten Funktionen der Bauteile und Optionen

sind nicht immer offensichtlich. Sofern Teile eingesetzt

werden, die nicht von Lexmark sind, wird von Lexmark

keinerlei Verantwortung oder Haftung für dieses Produkt

übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

xii Service Manual

Page 13

5055-01X

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede

que las características de seguridad de algunas piezas no

sean siempre evidentes. Lexmark no se hace responsable

del uso de otras piezas de recambio.

• La información sobre el mantenimiento de este producto

está dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Informações de Segurança

• Este produto foi concebido, testado e aprovado para

satisfazer os padrões globais de segurança na utilização de

componentes específicos da Lexmark. As funções de

segurança de alguns dos componentes podem não ser

sempre óbvias. A Lexmark não é responsável pela utilização

de outros componentes de substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Safety Information xiii

Page 14

5055-01X

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de seguretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest

producte. El personal professional ha d’estar-ne assabentat i

prendre les mesures convenients.

xiv Service Manual

Page 15

5055-01X

Safety Information xv

Page 16

5055-01X

xvi Service Manual

Page 17

5055-01X

1. General Information

The Lexmark 910 is a high-speed, wide-format color LED

electrophotographic printer with superior print quality for high-

volume printing.

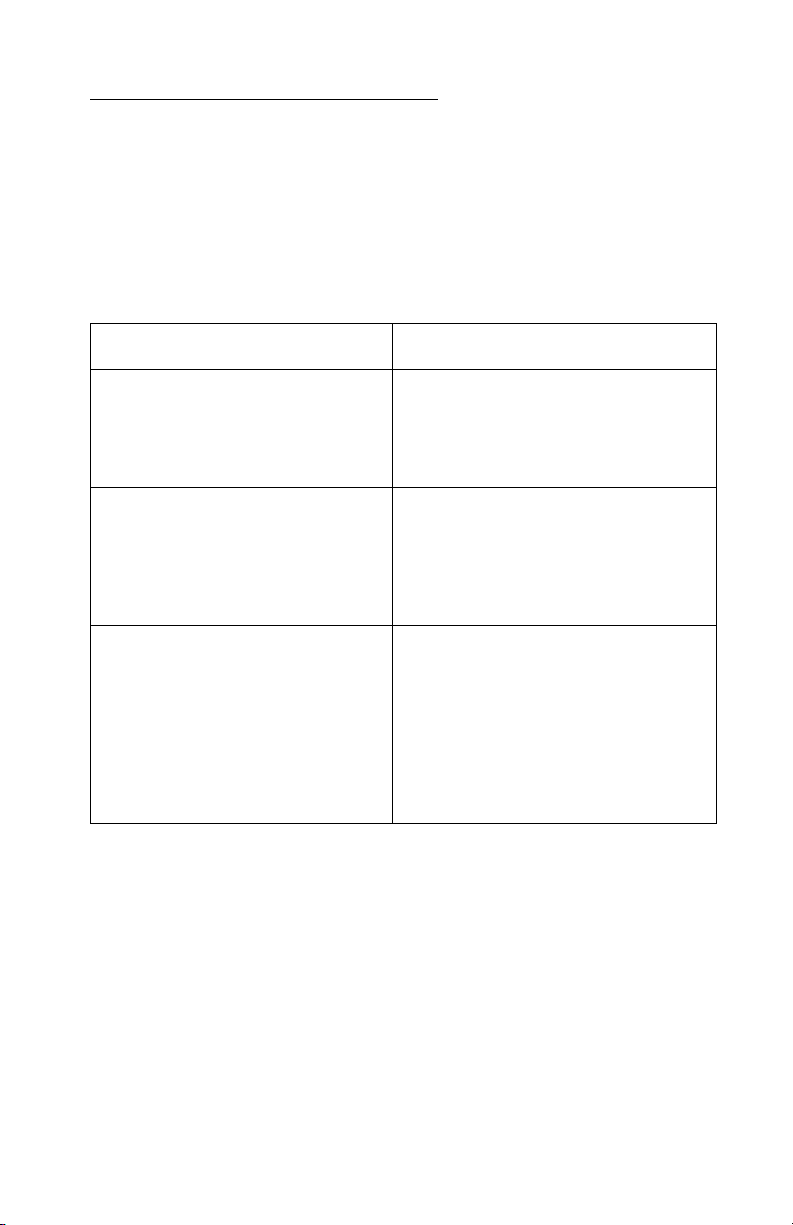

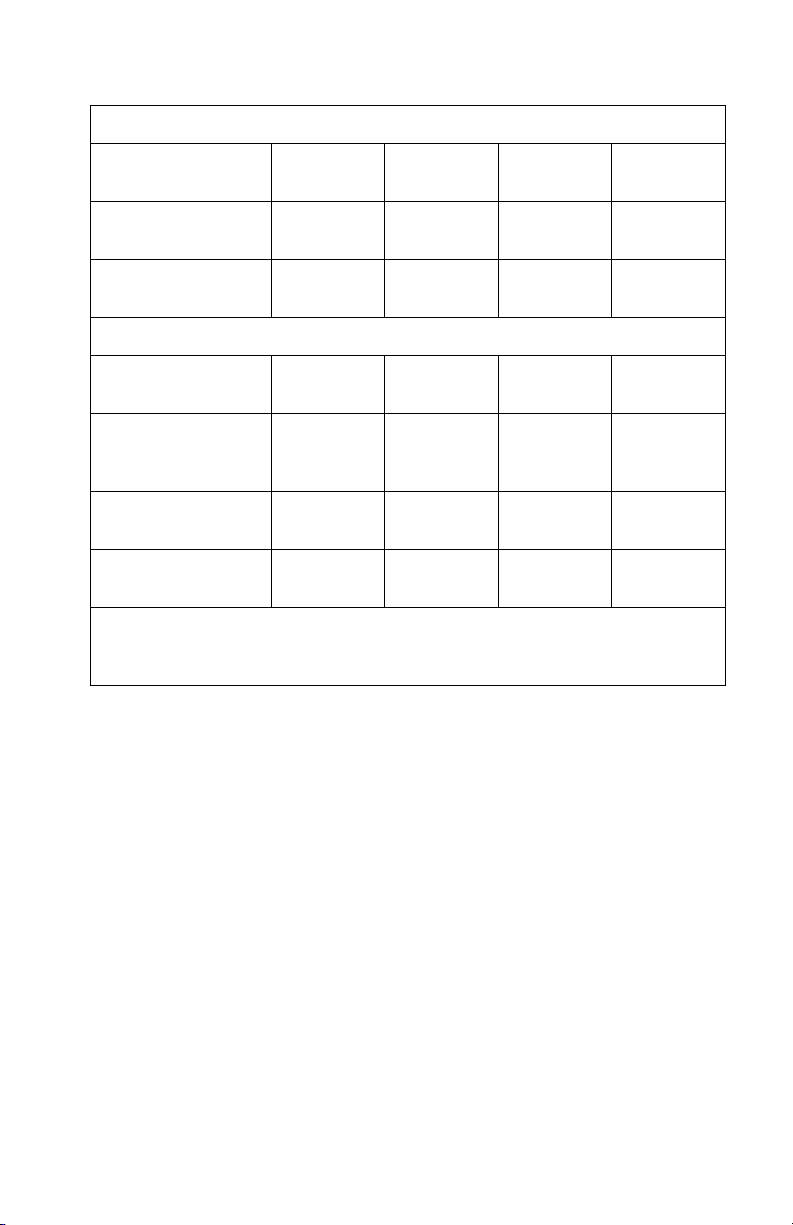

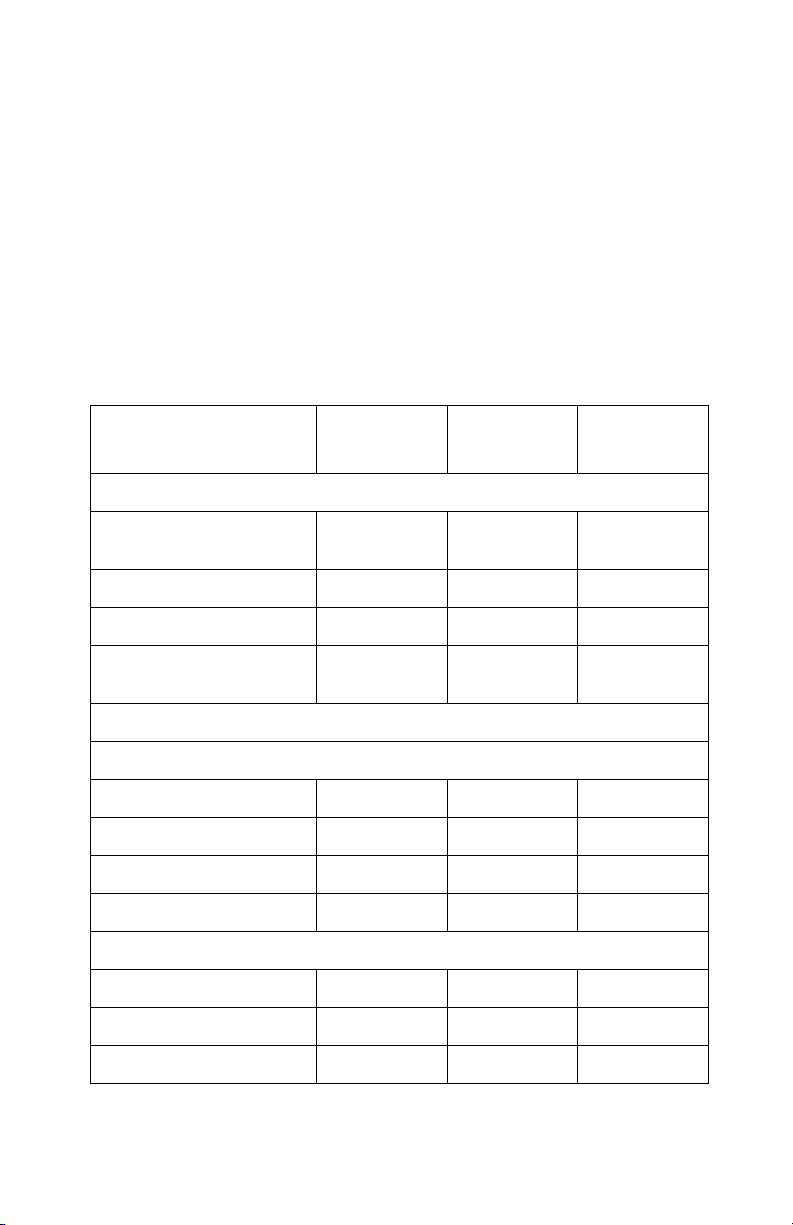

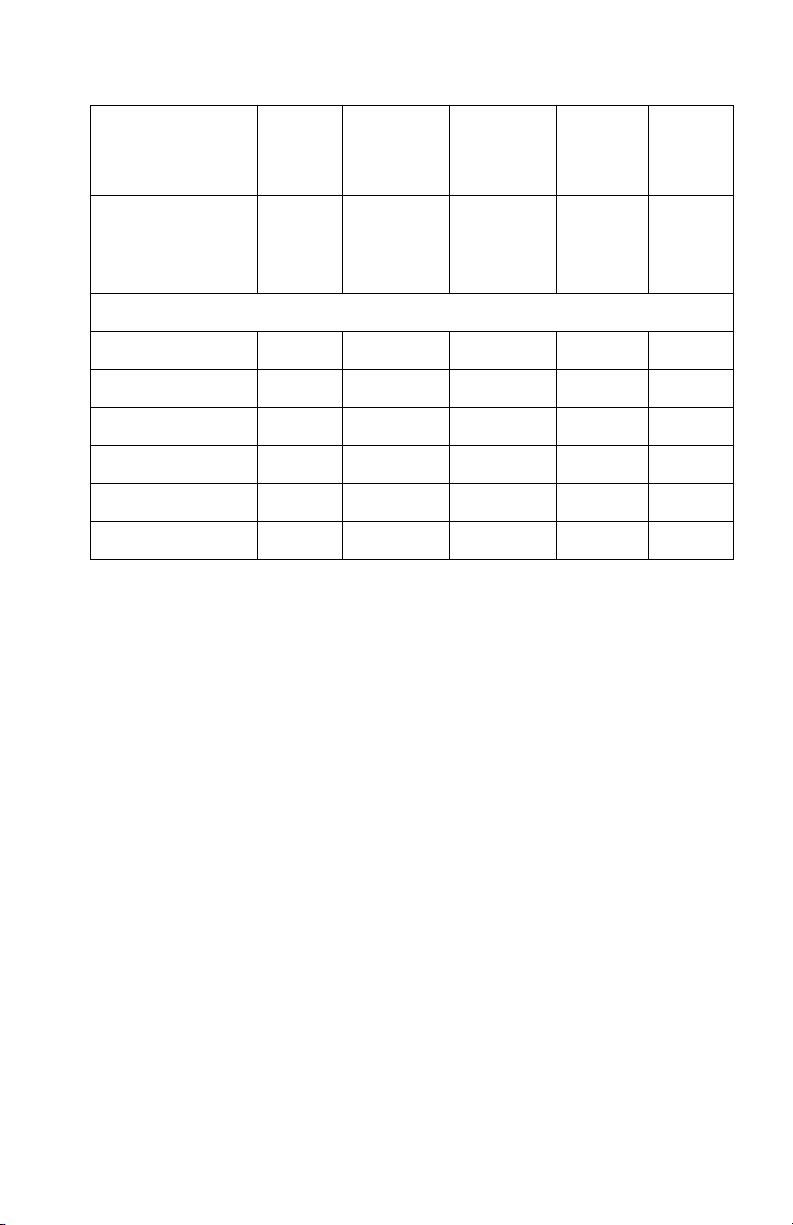

Model Differences

5055-010 5055-01N

28/29 ppm Engine

USB/Parallel

64MB

28/29 ppm Engine

USB/Ethernet

64MB

1 x 550-sheet option

28/29 ppm Engine

USB/Ethernet

128MB

1 x 550-sheet option

Duplex

28/29 ppm Engine

USB/Ethernet

128MB

1 x 550-sheet option

Duplex

Hard Disk Option

Staple Punch Finisher w/Stand

Printer Cabinet

Overview

The Lexmark C910 is a high-speed, wide-format color LED

Electrophotographic color printer with superior print quality for high-

volume printing.

Resolution

600 x 600 dpi

•

• 2400 image quality

General Information 1-1

Page 18

5055-01X

Toner Darkness

Toner darkness settings offer four (4) user-selectable settings to

balance print darkness and toner savings. The higher the setting,

the darker the print. The toner darkness default setting is 4.

The toner darkness setting is available through the operator panel

under the "Print Quality" menu.

Color Correction Settings

There are four (4) different color correction settings to provide

flexibility in choosing the type of color correction to be applied when

printing a file.

• Auto (default) - provides ease of use with no color science

knowledge required

• Vivid - adjusts CMYK components, with the result being colors

that are more saturated

• ff - no color correction is implemented from RGB or CMYK

applications

• CMYK - provides the application's color correction instead of the

printer's algorithms

Black and White Lock - (in configuration menu) allows printer and

network administrators to lock the Lexmark C910 printer in a mode

that will only print black. This feature cannot be overridden with any

other menu or driver selection.

Printer Packaging and Shipping Information

Description Width Depth Height Weight

Printers

Lexmark C910 32.6 in.

Lexmark C910n 32.6 in.

Lexmark C910dn

1-2 Service Manual

1

2

(828 mm)

(828 mm)

32.6 in.

(828 mm)

29.3 in.

(745 mm)

29.3 in.

(745 mm)

29.3 in.

(745 mm)

34.8 in.

(883 mm)

45.5 in.

(1,155 mm)

34.8 in.

(883 mm)

198 lb.

(90 kg)

246.4 lb.

(112 kg)

259.4 lb.

(117.9 kg)

Page 19

5055-01X

Options

High Capacity

Feeder

Duplex Unit 27.6 in.

Optional Drawer 28.5 in.

24.8 in.

(630 mm)

(700 mm)

(724 mm)

28.6 in.

(726 mm)

20.5 in.

(520 mm)

31.5 in.

(801 mm)

Supplies

Print Cartridge

3

(Black)

Print Cartridge

(Cyan, Magenta or

21.7 in.

(551 mm)

21.7 in.

(551 mm)

10.1 in.

(256 mm)

10.1 in.

(256 mm)

Ye l l o w )

Black

Photodeveloper

Color

Photodeveloper

1

Includes start-up kit (supplies)

2

“dn” model will ship unpackaged duplex inside printer

3

Oil coating roller will ship with black toner cartridge

18.4 in.

(467 mm)

18.4 in.

(467 mm)

4.1 in.

(105 mm)

12 in.

(306 mm)

32.3 in.

(820 mm)

10.6 in.

(270 mm)

10.7 in.

(272 mm)

6.4 in.

(162 mm)

6.4 in.

(162 mm)

4.3 in.

(110 mm)

4.5 in.

(114 mm)

75.7 lb.

(34.4 kg)

18.7 lb.

(8.5 kg)

48.4 lb.

(22 kg)

6.6 lb.

(3 kg)

5.7 lb.

(2.6 kg)

2.2 lb.

(1 kg)

6.6 lb.

(3 KG)

General Information 1-3

Page 20

5055-01X

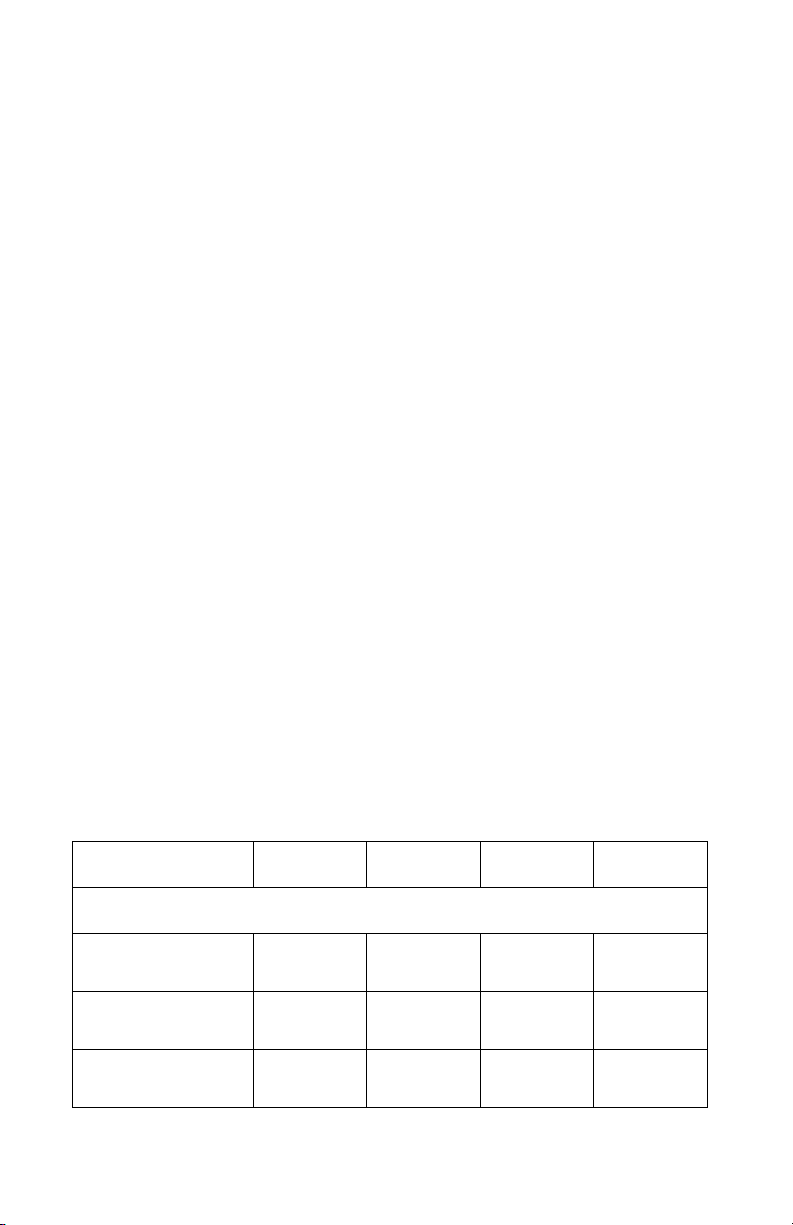

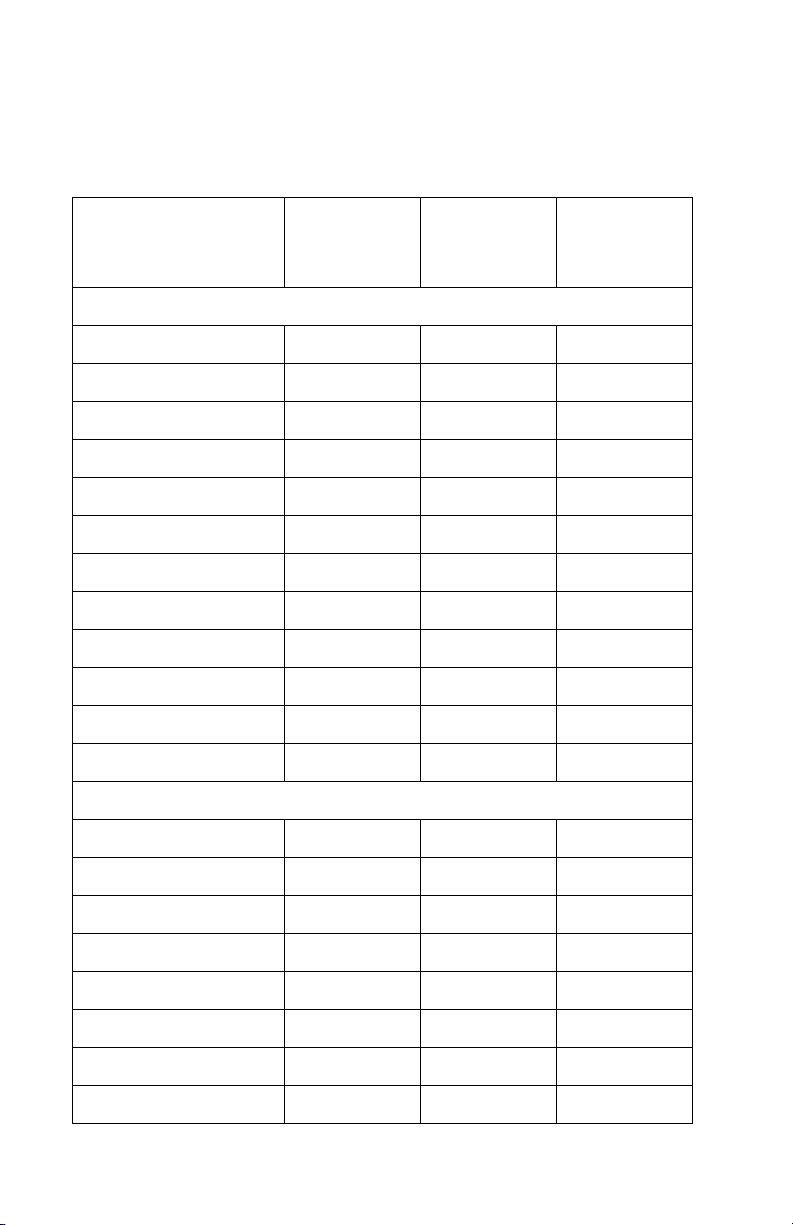

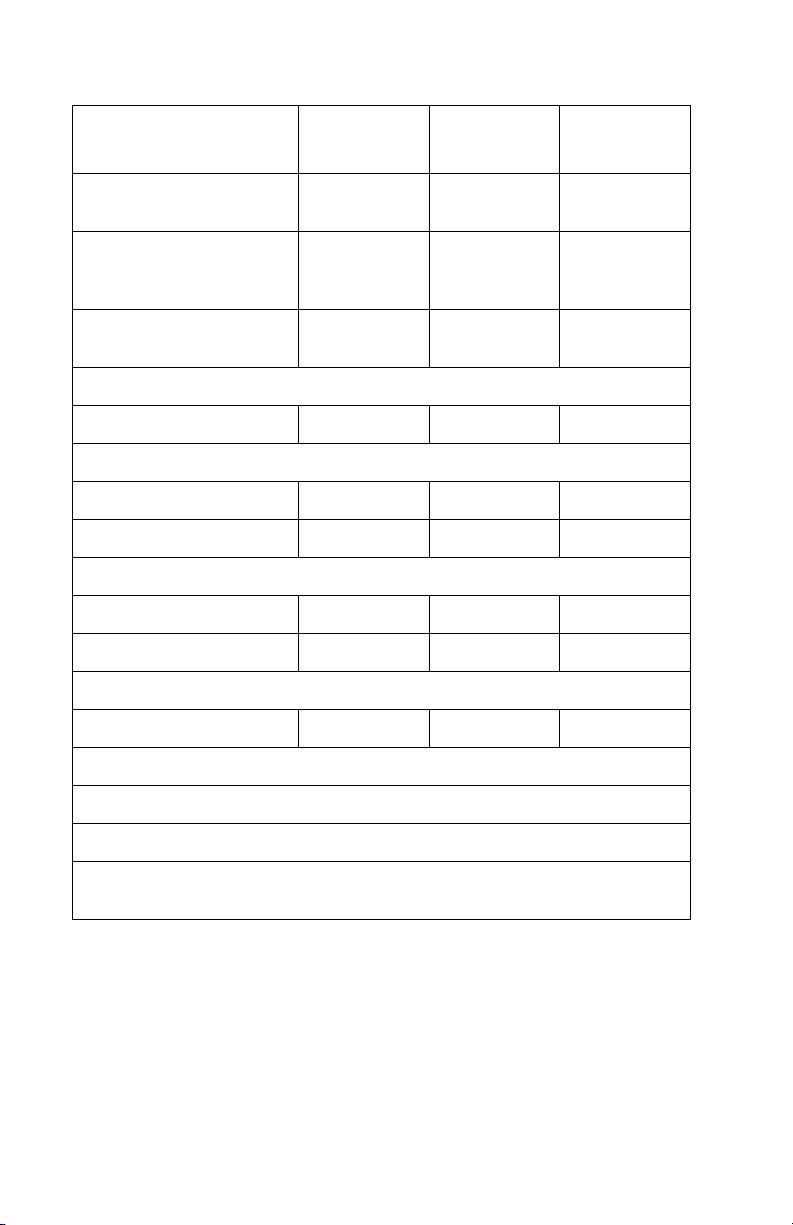

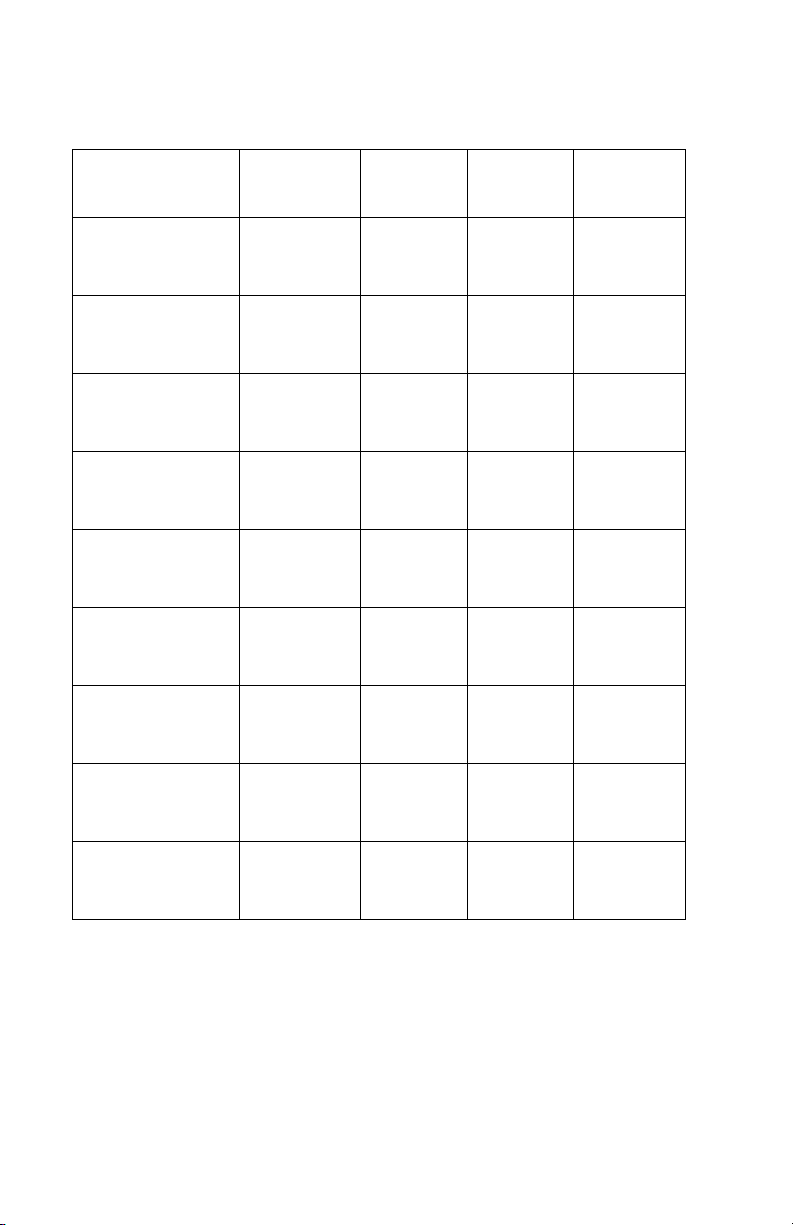

Print Speed and Performance

Print Speed

Standard and

Heavy Media

Tra y

Simplex printing on letter-size media (pages per minute)

Letter - 8.5 in. x 11 in. 28 28 28

Ledger 16 N/A 16

Legal - 8.5 in. x 14 in. 19 N/A 19

A3 16 N/A 16

A4 - 3.4 in. x 11.7 in. 29 29 29

A5/Executive N/A N/A 38

B4 18 N/A 18

B5 N/A N/A 32

Transparencies 22 N/A 22

Card Stock N/A N/A 11

Envelopes N/A N/A 11

Paper Labels 22 N/A 22

Duplex printing on letter-size media (sides per minute)

High

Capacity

Feeder

Multipurpose

Feeder

1

1,2,3,4

Letter - 8.5 in. x 11 in. 19 19 19

Ledger 11 N/A 11

Legal - 8.5 in. x 14 in. 12 N/A 12

A3 11 N/A 11

A4 - 3.4 in. x 11.7 in. 19 19 19

A5/Executive N/A N/A 20

B4 12 N/A 12

B5 N/A N/A 19

1-4 Service Manual

Page 21

5055-01X

LEF = Long Edge Feed

SEF = Short Edge Feed

N/S = Not Supported

1

Folio and statement paper support from multipurpose feeder

only

2

Speeds

3

When printing from the multipurpose feeder: Simplex - the first

three pages print a “legal” speed with the balance printing at the

speed consistent with the actual media size. Duplex - all pages

print at “legal” speed.

4

Average duplex print performance measured under the

following conditions: Simplex text document (Mr. Brown) from the

printer’s integrated tray to the printer’s standard output bin, with a

job stream sufficiently long for the printer system to enter the

maximum duplex print performance page sequence

(2,4,6,1,3,5...) The first two sides (2 and 4) are not included in the

performance computation since they “seed” the printer system’s

paper path to achieve the maximum duplex print performance.

Performance

The Lexmark C910 printers support the speeds listed above.

Performance depends on

• Interface to the host (USB, serial, parallel, network)

• Host system and application

• Page complexity and content

• Certain printer options installed or selected

• Printer memory

• Media size and type

Time to First Print

Time to first print:

•

– Black and color: 15 seconds

General Information 1-5

Page 22

5055-01X

Processor

• 400 MHz

Duty Cycle

• Up to 100,000-sheet maximum, based on a single month's

usage

• Up to 10,000 sheets per month

Printer Memory

Memory Configuration

DRAM Memory Lexmark C910(n) Lexmark C910dn

Standard 64MB 128MB

Maximum 512MB 512MB

Available Memory Options

Optional 64MB, 128MB and 256MB SDRAM DIMMs are available

from Lexmark.

Flash Memory Options

Optional 4MB, 8MM and 16MB DIMMs are available from Lexmark.

Memory and Expansion Slots

Memory slots for extra flash or DRAM

•

– Lexmark C910(n): 2

– Lexmark C910(dn): 1

• Expansion slots for optional interface cards: 1

• Optional firmware expansion slots (application solution firmware

cards): 1

• On-board hard disk interface (for optional hard disk): 1

SDRAM and flash memory options are interchangeable within any of

the memory slots available on the Lexmark C910 system board.

However, only one flash memory Maintenance Approach option will

1-6 Service Manual

Page 23

5055-01X

be recognized. If multiple flash memory options are installed, the

system will recognize the largest one.

Paper Handling

Capacity may vary and is subject to media specifications and printer

operating environment. Capacities listed are based on plain paper at

2

75g/m

.

Input and Output Configurations

Sources and Capacities

Input Sources

Number of standard

sources

Optional input drawers 3 2 2

High Capacity Feeder 1 1 1

Maximum number of input

sources

Input Capacities (sheets)

Standard

Primary tray 550 550 550

Second tray N/A 550 550

Multipurpose tray 100 100 100

Total standard capacity 650 1,200 1,200

Optional

500-sheet drawer 550 550 550

Heavy-media tray

High capacity feeder

2

1

Lexmark

C910

233

666

Ye s Ye s Ye s

3,000 3,000 3,000

Lexmark

C910n

Lexmark

C910dn

General Information 1-7

Page 24

5055-01X

Sources and Capacities

Maximum additional

Lexmark

C910

322

Lexmark

C910n

Lexmark

C910dn

drawers

Maximum input capacity

2,300 2,300 2,300

(without high capacity

feeder

Maximum input capacity +

5,300 5,300 5,300

high capacity feeder

Output Destination

Number (standard) 1 1 1

Output Capacities sheets

Standard Output Bin 550 550 550

Face up Bin 100 100 100

Optional

Finisher

3,4

1,000 1,000 1,000

Maximum output capacity 1,650 1,650 1,650

Other

Duplex unit Yes Yes Standard

1

A maximum of one high capacity input drawer is supported on any model

2

The heavy-media tray is supported only as Tray 1 (top).

3

A maximum of one finisher is supported on any model.

4

The finisher requires installation of the 2 x 550-sheet drawer with the base

or printer cabinet.

1-8 Service Manual

Page 25

5055-01X

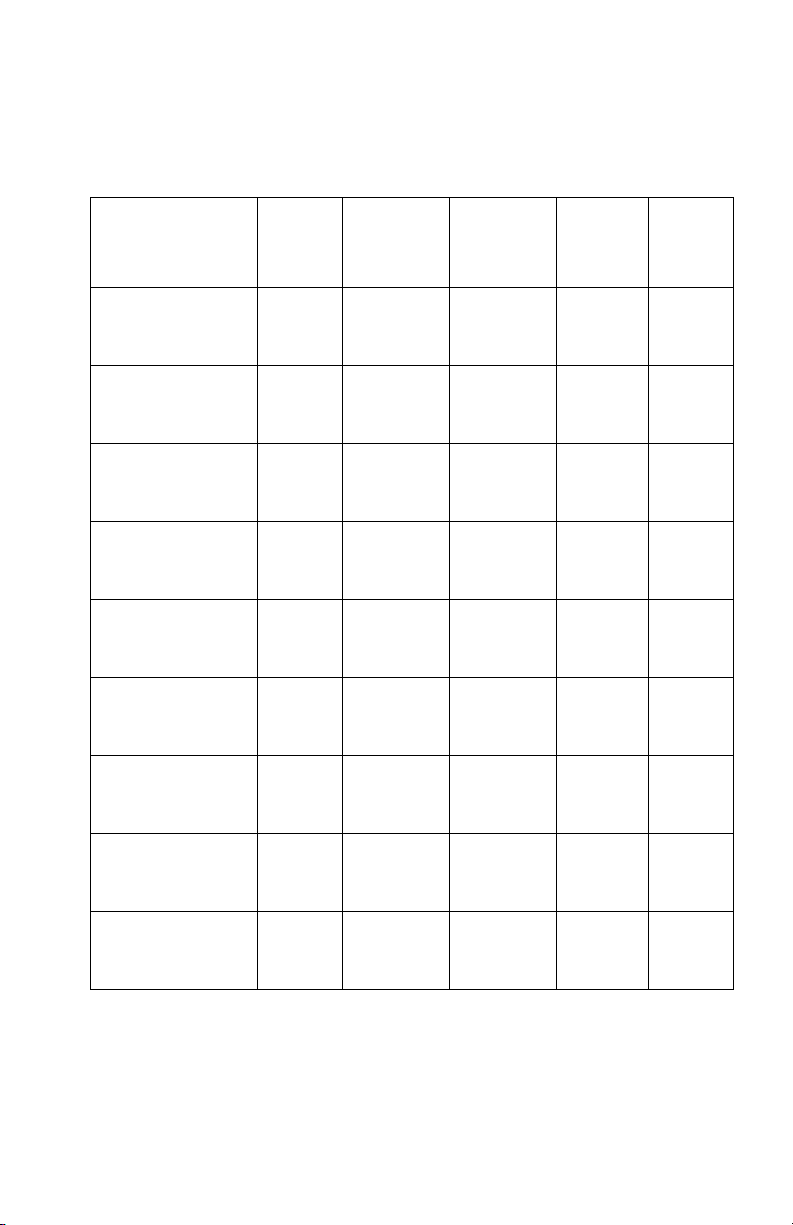

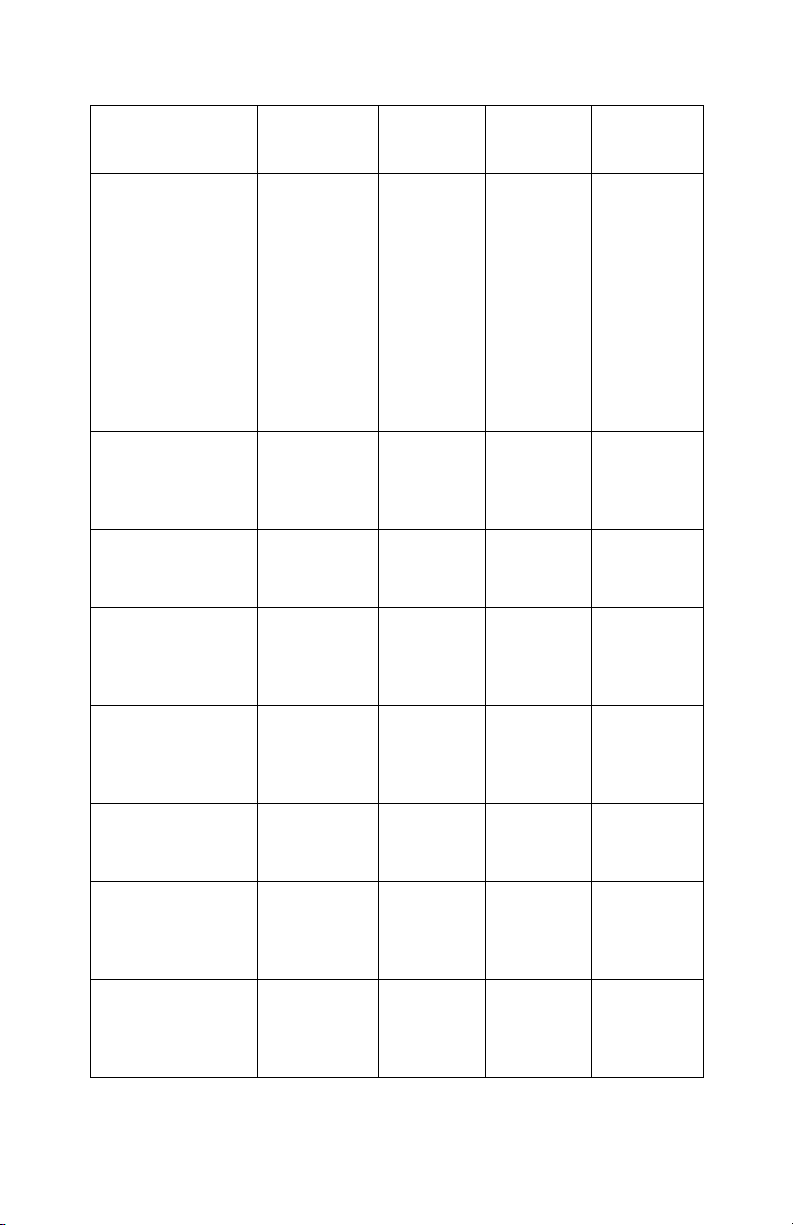

Media Size Supported

Input

A4-8.27” x 11.7”

(210 mm x 297

mm)

A5-5.83” x 8.27”

(148 mm x 210

mm

JIS-B5-7.17” x

10.23” (182 mm

x 257mm)

JIS-B4-14.34” x

10.1” (364 mm x

252 mm)

Letter-8.5” x 11”

(216 mm x 279

mm)

Legal-8.5” x 14”

(216 mm x 256

mm)

Executive-7.25”

x 10.5” (184 mm

x 267 mm)

500sheet

Input

XX X XX

XX XX

XX X XX

XX XX

Multipurpose

Feeder

XXX

XX

XX

High

Capacity

Feeder

Duplex

Hevay

Media

Tra y

Tabloid-11” x 17”

(279.4 mm x

431.8 mm)

A3-11.69” x

16.54” (297 mm

x 420 mm)

XX XX

XX XX

General Information 1-9

Page 26

5055-01X

Universal

1,2

2.75 x 5 in. to 8.5

x 14in. (69.85 x

127 mm to 229 x

355.6 mm)

5.83 x 7.17 in to

8.5 x 14 in. (148

x 182 mm to

215.9 x 355.6

mm)

7 3/4 Envelope-

3.875” x 7.5”

(98 mm x 191

mm)

9 Envelope -

3.875” x 8.9” (98

mm x 225.4 mm)

10 Envelope -

4.125” x 9.5”

(105 mm x 241

mm)

500sheet

Input

Multipurpose

Feeder

X

X

X

X

X

High

Capacity

Feeder

Duplex

3

X

3

X

Hevay

Media

Tra y

DL Envelope -

4.33” x 8.66”

(110 mm x 220

mm)

C4 Envelope - 9”

x 12.75” (229

mm x 324 mm)

C5 Envelope -

6.38” x 9.01”

(162 mm x 229

mm)

B5 Envelope -

6.93” x 9.84”

(176 mm x 250

mm)

1-10 Service Manual

X

X

X

X

Page 27

5055-01X

Other Envelope

500sheet

Input

4

Multipurpose

Feeder

X

High

Capacity

Feeder

Duplex

Hevay

Media

Tra y

11.69 x 11.69 in.

(297 mm to 297

mm)

Media Type

Paper X X X X X

Card Stock X

Transparencies X

5

Envelopes X

Glossy Paper X X

Paper Labels X

6

7

XX

X

8

X

General Information 1-11

Page 28

5055-01X

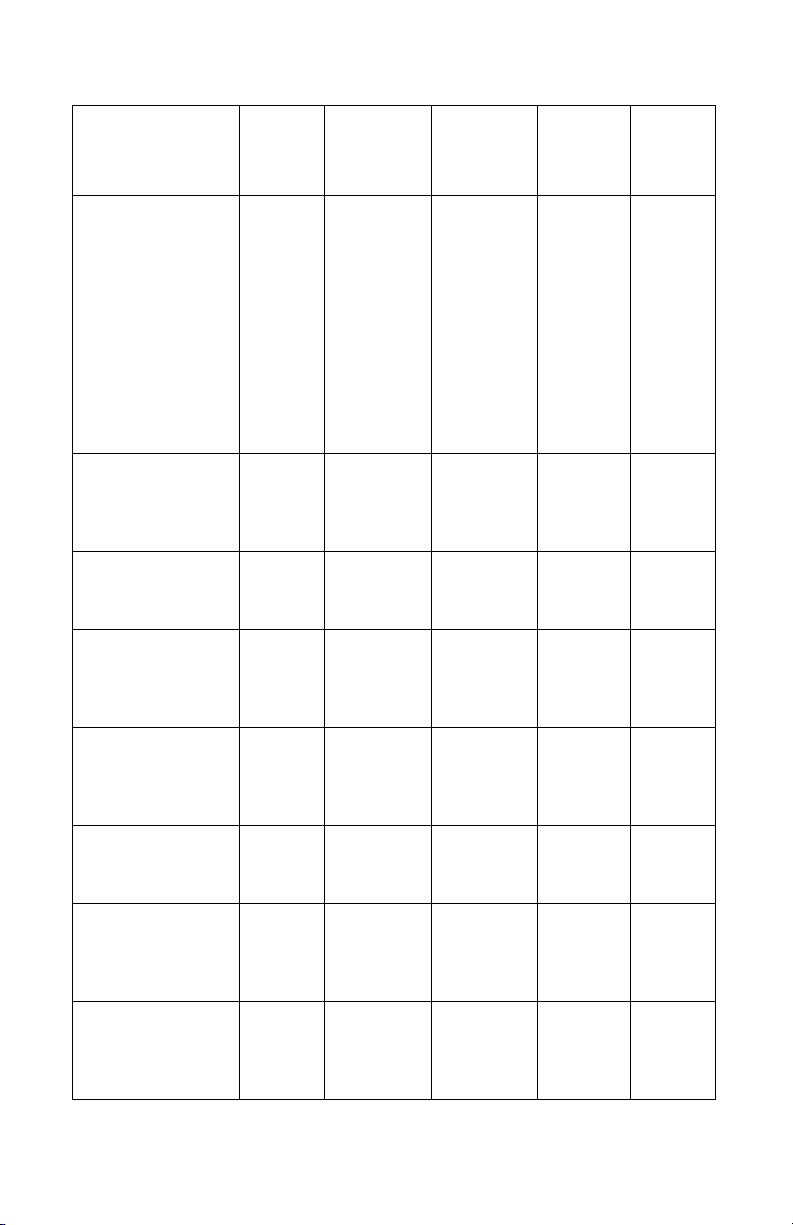

Output

A4-8.27” x 11.7”

(210 mm x 297

mm)

A5-5.83” x 8.27”

(148 mm x 210

mm

JIS-B5-7.17” x

10.23” (182 mm

x 257mm)

JIS-B4-14.34” x

10.1” (364 mm x

252 mm)

Letter-8.5” x 11”

(216 mm x 279

mm)

Legal-8.5” x 14”

(216 mm x 256

mm)

Executive-7.25”

x 10.5” (184 mm

x 267 mm)

Standard

Output

XXXX

XXX

XXX

XXXX

XXX

XXX

Bin 1

XX

Finisher

Bin 1

Finisher

Bin 2

Tabloid-11” x 17”

(279.4 mm x

431.8 mm)

A3-11.69” x

16.54” (297 mm

x 420 mm)

1-12 Service Manual

XXX

XXX

Page 29

5055-01X

Universal

2.75 x 5 in. to 8.5

x 14in. (69.85 x

127 mm to 229 x

355.6 mm)

5.83 x 7.17 in to

8.5 x 14 in. (148

x 182 mm to

215.9 x 355.6

mm)

7 3/4 Envelope-

3.875” x 7.5”

(98 mm x 191

mm)

9 Envelope -

3.875” x 8.9” (98

mm x 225.4 mm)

10 Envelope -

4.125” x 9.5”

(105 mm x 241

mm)

1,2

Standard

Output

Bin 1

Finisher

Bin 1

X

X

X

X

X

X

X

Finisher

Bin 2

DL Envelope -

4.33” x 8.66”

(110 mm x 220

mm)

C4 Envelope - 9”

x 12.75” (229

mm x 324 mm)

C5 Envelope -

6.38” x 9.01”

(162 mm x 229

mm)

B5 Envelope -

6.93” x 9.84”

(176 mm x 250

mm)

X

XX

XX

XX

General Information 1-13

Page 30

5055-01X

Other Envelope

4

Standard

Output

Bin 1

XX

Finisher

Bin 1

Finisher

Bin 2

11.69 x 11.69 in.

(297 mm to 297

mm)

Media Type

Paper X X X X

Card Stock X X X

Transparencies X X

Envelopes X X

Glossy Paper X X X X

Paper Labels X

1

When Universal is selected, the page is formatted for 8.5 x 14 in. (215.9

X

x 355.6 mm) unless the size is specified in the software application.

2

Narrow media should be loaded with the length in the feed direction

(portrait).

3

A5 paper 5.83 x 8.27 in. (148 x 210 mm) is the smallest size the C910

can duplex

4

When Other Envelope is selected, the page is formatted for 8.5 x 14 in.

(215.9 x 355.6 mm) unless the size is specified in the software

application.

5

Maximum stack of 50 sheets; if more input is required, use Heavy Media

Tr ay.

6

Manual feed (one sheet at a time) only; if more input is required, use

Heavy Media Tray

7

Maximum stack of 30 sheets; if more input is required, use Heavy Media

Tr ay.

8

Refer to Cardstock & Label Guide for media guidelines.

1-14 Service Manual

Page 31

5055-01X

Input Media Types and Weights

Media Weight

Standard Trays

Paper Xerographic or business

1, 2, 3

16 to 28 lb. bond (60 to 105 g/m2)

paper

Specialty papers Glossy laser 80 lb. book (32 lb. bond) (120 g/m

Heavy Media Tray1

Paper

28 to 47 lb. bond (105 to 176 g/m

Xerographic or business paper

Specialty papers Glossy laser4 80 lb. book (32 lb. bond) (120 g/m

2

Transparencies Laser printer

47 lb. bond (175 g/m

)

type5

2

Labels - upper limit Paper 48 lb. bond (180 g/m

Multipurpose Feeder

Paper Xerographic or business

1

16 to 28 lb. bond (60 to 105 g/m2)

)

paper

Specialty papers Glossy laser 80 lb. book (32 lb. bond)(120 g/m

Card stock - upper limit Index

90 lb. index (44 lb. bond) (165 g/m2)

Bristol

Transparencies Laser printer type 47 lb. bond (175 g/m

Labels - upper limit Paper 48 lb. bond (180 g/m

2

)

2

)

2

)

2

)

2

)

2

)

Envelopes Sulfite, Wood-free - up

to 100% cotton

20 to 28 lb. bond2, 3 (75 to 105

2

)

g/m

High Capacity Feeder1

Paper Xerographic or business

16 to 28 lb. bond (60 to 105 g/m2)

paper

1

The duplex option supports the same weights and types as the printer,

except for transparencies, envelopes, labels and paper less than 75 g/m

(20 lb. bond) or greater than 105 g/m

2

100% cotton content maximum weight is 90 g/m2 (24 lb. bond)

2

(29 lb. bond)

General Information 1-15

2

Page 32

5055-01X

Media Weight

3

105 g/m2 (28 lb. bond) envelopes are limited to 25% cotton content

4

Part numbers 12A5950 (letter) and 12A5951 (A4)

5

Part numbers 12A5940 (letter) and 12A5941 (A4)

6

Refer to Cardstock & Label Guide for media guidelines

Output Media Types and Weights

Media Weight

Standard Output

3

Paper

Xerographic or business paper

Specialty papers

Glossy laser

Card stock - upper limit

Index Bristol

Transparencies

Laser printer type

Labels - upper limit

Paper

3, 4

Bin 1

Paper

Xerographic or business paper

Specialty papers

Glossy laser

1

Card stock - upper limit

Index Bristol

Transparencies

Laser printer type

2

Labels - upper limit

Paper

16 to 28 lb. bond (60 to 105 g/m2)

80 lb. book (32 lb. bond) (120 g/m

90 lb. index (44 lb. bond) (165 g/m

2

47 lb. bond (175 g/m

48 lb. bond (180 g/m

)

2

)

16 to 28 lb. bond (60 to 105 g/m2)

80 lb. book (32 lb. bond) (120 g/m2)

90 lb. index (44 lb. bond) (165 g/m

47 lb. bond (175 g/m2)

48 lb. bond (180 g/m

2

)

2

)

2

)

2

)

1-16 Service Manual

Page 33

5055-01X

Media Weight

Envelopes

20 to 28 lb. bond

6,7,8

Sulfite, Wood-free - up to 100%

cotton

Finisher Bin 1

Paper

3,4

(75 to 105 g/m2)

16 to 28 lb. bond (60 to 105 g/m2)

Xerographic or business paper

Specialty papers

Glossy laser

1

Card stock - upper limit

80 lb. book (32 lb. bond) (120 g/m2)

90 lb. index (44 lb. bond) (165 g/m

Index Bristol

Transparencies

Laser printer type

2

Labels - upper limit

47 lb. bond (175 g/m2)

48 lb. bond (180 g/m

2

)

Paper

Finisher Bin 2

Paper

3, 4, 5

16 to 28 lb. bond (60 to 105 g/m2)

Xerographic or business paper

1

Part numbers 12A5950 (letter) and 12A5951 (A4)

2

Part numbers 12A5940 (letter) and 12A5941 (A4)

3

The duplex option supports the same weights and types as the printer,

except for transparencies, envelopes, labels and paper less than 75 g/m

(20 lb. bond) or greater than 105 g/m2 (29 lb. bond)

4

Bin 1 represents engine side output and Finisher Bin 1 (face-up)

5

Finisher supports hole punch, job offset and stapling.

6

Finisher only supports long-edge fed envelopes wider than 5.8 in. (148

mm) - feed direction dimension

7

100% cotton content maximum weight is 90 g/m2 (24 lb. bond)

8

105 g/m2 (28 lb. bond) envelopes are limited to 25% cotton content

2

)

2

General Information 1-17

Page 34

5055-01X

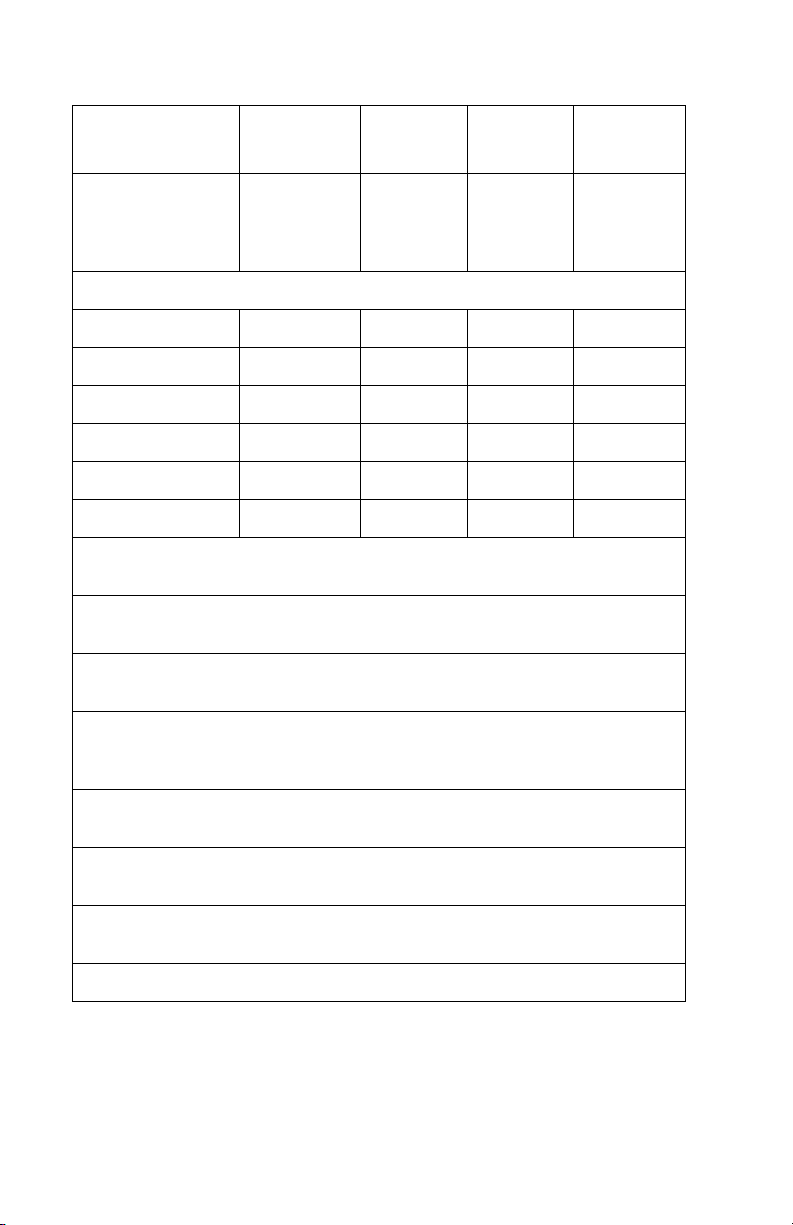

Input Capacity by Media and Source

Media Stack Height Capacity

500-Sheet Trays

Plain Paper (letter,

A4, legal, tabloid, A3)

Plain Paper (letter,

A4, legal, tabloid, A3)

Glossy Paper 0.6 in. (15 mm) 130 sheets

2.2 in. (56 mm) 550 sheets

20 lb. (75 g/m

1 in. (25 mm)

240 sheets

24 lb. (90 g/m

32 lb. (120 g/m

2

)

2

)

2

Multipurpose Feeder

Plain Paper

100 sheets

20 lb. (75 g/m

2

)

Transparencies 50 transparencies

0.4 in. (11 mm)

Envelopes 10 envelopes

Card Stock 55 sheets

90 lb. index (163 g/m

Paper Labels 55 sheets

up to 48 lb. (180 g/m

Glossy Paper (Manual) 1 sheet

32 lb. (120 g/m

2

High Capacity Feeder

Plain Paper 12.5 in. (317 mm) 3,000 sheets

20 lb. (75 g/m

2

)

)

2

)

2

)

)

Heavy Media Tray

Plain Paper 1.6 in. (40 mm) 300 sheets

32 lb. (120 g/m

Transparencies 0.8 in. (20 mm) 150 transparencies

47 lb. (175 g/m

Paper Labels 1.6 in. (40 mm) 200 sheets

up to 48 lb. (180 g/m

Glossy Paper 1.6 in. (40 mm) 360 sheets

32 lb. (120 g/m

1-18 Service Manual

2

)

2

)

2

)

2

)

Page 35

5055-01X

Output Capacity by Media and Source

Media Stack Heights Capacity

Standard Output Bin

Plain Paper Varies 550 sheets

Glossy Paper Varies 130 sheets

Bin 1 and Staple Punch Finisher Bin 1

Plain Paper Varies 100 sheets

Transparencies Varies 50 transparencies

Bin 2 - Staple Punch Finisher

Plain Paper 6.0 in.

(152 mm)

Notes:

- Performance may vary subject to media specifications and printer

operating environment

- Media at ambient environment

- All media is letter/A4, unless otherwise noted

- All paper weights are stated in bond, unless otherwise noted

20 lb. (75 g/m

32 lb. (120 g/m

20 lb. (75 g/m

47 lb. (175 g/m

1,000 sheets

20 lb. (75 g/m

2

)

2

2

)

2

2)

)

)

Paper

Following are media guidelines for successful printing:

• Rough, highly textured, limp or pre-curled papers will result in

lower print quality and more frequent paper feed failures.

• Colored papers, treated and preprinted papers, letterhead and

labels must be able to withstand 338 deg. F (170 deg. C) fusing

temperature.

• Preprinted forms and letterhead should be selected using

guidelines found in the printer User's Guide. The chemical

General Information 1-19

Page 36

5055-01X

process used in preprinting may render some papers

unsuitable.

• Unsuitable papers include multipart forms and documents;

chemically treated papers; coated, synthetic and thermal

papers; and preprinted papers requiring a high degree of

registration.

• Recycled paper less than 21 lb. (80 g/m

unacceptable results.

2

) may cause

Envelopes

•

Envelopes should be fed long edge first, with flap trailing.

• When Finisher is attached, only long edge fed envelopes wider

than 5.8 in. (148 mm) - feed direction dimension - may be used.

To print smaller envelopes, the finisher must be undocked

during the job.

• If envelope wrinkling occurs, refer to the User's Guide for correct

weight, type, loading and stacking of envelopes.

• All envelopes should be new, unused and without package

damage.

• Envelopes with excessive curl or twist exceeding 0.12 in. (6

mm), stuck together, with bent corners or nicked edges or those

that interlock should not be used.

• Minimum weight: 20 lb. (75 g/m

2

)

• The following envelopes should not be used:

– Envelopes with windows, holes, perforations, cutouts, deep

embossing or package damage

– Envelopes with metal clasps, string ties or metal folding bars

– Envelopes with exposed flap adhesive when the flap is in the

closed position

2

For best results, printing on new 24 lb. (90 g/m

cotton bond envelopes is recommended.

Note: Under high-humidity conditions (over 60%) the envelopes

may seal during printing.

) sulfite or 25%

Transparencies

•

Use letter sheets (p/n 12A5940) or A4-size sheets (p/n

12A5941) only

1-20 Service Manual

Page 37

5055-01X

Labels

Labels should be selected using guidelines found in the User's

Guide or the Cardstock and Label Guide, and tested for

acceptability.

Lexmark Glossy Paper

• Use letter sheets (p/n 12A5950) or A4-size sheets (p/n

12A5951) only

• Glossy paper is only supported from Tray 1, Multipurpose

Feeder and Heavy Media Tray.

Print Area

Printable area for the C910 printers

• To within 0.16 in. (4.2 mm) of all edges of the media (except

envelopes)

Options and Features

Lexmark C910 printers support only Lexmark C910 paper-handling

options. These options are not compatible with any other Lexmark

printer.

• 550-Sheet Drawer - (includes 550-sheet tray and support unit)

installs beneath the printer and holds approximately 550 sheets

of 20 lb. paper. Multiple optional drawers (up to 3) are supported

simultaneously.

• High-Capacity Feeder - is designed to provide an additional

input tray (Tray 3 or Tray 5, depending on the configuration) with

a total capacity of 3,000 sheets (plain paper - letter or A4 -- 20

lb. (75 g/m

and attaches to the right side of the printer.

2

). The High-Capacity Feeder is customer installable

• Heavy-Media Tray - is intended for special media such as

transparencies, labels and glossy paper. This is supported only

as Tray 1 (top drawer location).

• Duplex Unit - offers two-side printing and is designed to

complement the Lexmark C910 printers.

• Finisher - offers stapling, hole punching, offset stacking and an

additional output bin. Two models will be available. 3- or 4-hole

left-edge hole punching will be available. The single staple

General Information 1-21

Page 38

5055-01X

position is the upper left corner. The Finisher can support up to

1,100 sheets of unstapled, unpunched media. For stapled

media, the output bin supports up to 30 stapled sets or 1,000

sheets. The stapler can staple a maximum of 30 sheets per set.

Each C910 can support one Finisher.

• C910 Printer Cabinet - is customer installable and attaches

below the printer - printer sits on top of the printer stand. The

printer cabinet raises the printer to the correct height for use

with the optional finisher and high-capacity feeder. The printer

cabinet and high-capacity feeder can be installed concurrently.

• Printer Base - is customer installable and attaches below the

printer - printer sits on top of the printer base. If used with two

optional 550-sheet drawers, the printer base raises the printer

to the correct height for use with the optional finisher and highcapacity feeder. The printer base and high-capacity feeder can

be installed concurrently.

– C910 -3 optional drawers

– C910n and C910dn -2 optional drawers

Connectivity

Standard

• Lexmark C910

– Bidirectional parallel and USB

• Lexmark C910n and Lexmark C910dn

– 10/100BaseTX Ethernet and USB

Optional Internal Local Connections

• Tri-Port Adapter (RS-232/RS-422 Serial, LocalTalkTM and

Infrared)

• RS-232C Serial/Parallel-C Interface Card

Note: USB is supported only under Windows 98, Windows Me,

Windows XP, Windows 2000 operating systems, Sun's Sun Ray

appliances running Sun Ray Server code version 1.2 or later, Sun

Blade workstations and Apple Macintosh iMac computer with

Operating System 8.6 or higher. A USB cable is included with this

card.

1-22 Service Manual

Page 39

5055-01X

Network Connections

Internal Network Connections

• Lexmark MarkNet N2000 Series Internal Print Servers

– MarkNet N2000t for Token-Ring attachment

– MarkNet N2001e for Ethernet 10BaseT/100BaseTX

– MarkNet N2002e for Ethernet 10BaseT/10Base2

• Lexmark MarkNet N2003 Series Internal Fiber Print Servers,

including:

– MarkNet N2003fx SC

– MarkNet N2003fx MTRJ

External Network Connections

• MarkNet X2000 Series External Print Servers

– MarkNet X2011e (1-port) for Ethernet 10BaseT/100BaseTX

– MarkNet X2012e (1-port) for Ethernet 10BaseT/100BaseTX,

10BaseT/10Base2

– MarkNet X2031e (3-port) for Ethernet 10BaseT/100BaseTX

– MarkNet X2030t (3-port) for Token-Ring attachment

Standard Ethernet and MarkNet Compatibility

The standard Ethernet connection, MarkNet N2000 series and

MarkNet N2003 series internal and MarkNet X2000 series external

print servers support NetPnP 7.0 or later on Windows NT 4.0,

Windows 2000 and Windows XP systems.

The Ethernet and Token-Ring print servers and the standard

Ethernet connection support the following protocols:

• TCP/IP

• Novell (IPX/SPX including NetWare Directory Services)

• AppleTalk™

• LexLink (DLC/LLC)

The TCP/IP standard set of application services is supported,

including DHCP, WINS, SNMP (industry standard printer MIB), http,

lpr/lpd, ftp, tftp, ping, finger, telnet, bootp and rarp. The following

protocols are also supported:

General Information 1-23

Page 40

5055-01X

• IPP: Internet Printing Protocol

• SLP: Service Location Protocol

• NTP: Network Timing Protocol

Printers with standard Ethernet, MarkNet N2000 series and MarkNet

N2003 series internal print servers and MarkNet X2000 series

external print servers support a resident Web page with Microsoft

Internet Explorer 4.0 or later and Netscape Navigator 4.5 or later for

Windows 95, Windows 98, Windows Me, Windows 2000, Windows

XP or Windows NT. The remote operator panel is available using the

standard Ethernet connection, MarkNet N2000, MarkNet N2003 or

MarkNet X2000 Series external print servers installed in or used

with a Lexmark C910 printer.

Data Streams

• PostScript® 3 Emulation

• Hewlett-Packard Company PCL® 6 Emulation

Operating Systems

The Lexmark C910 printers are compatible with applications running

under the following operating systems for either local or network

connections

Resident Fonts

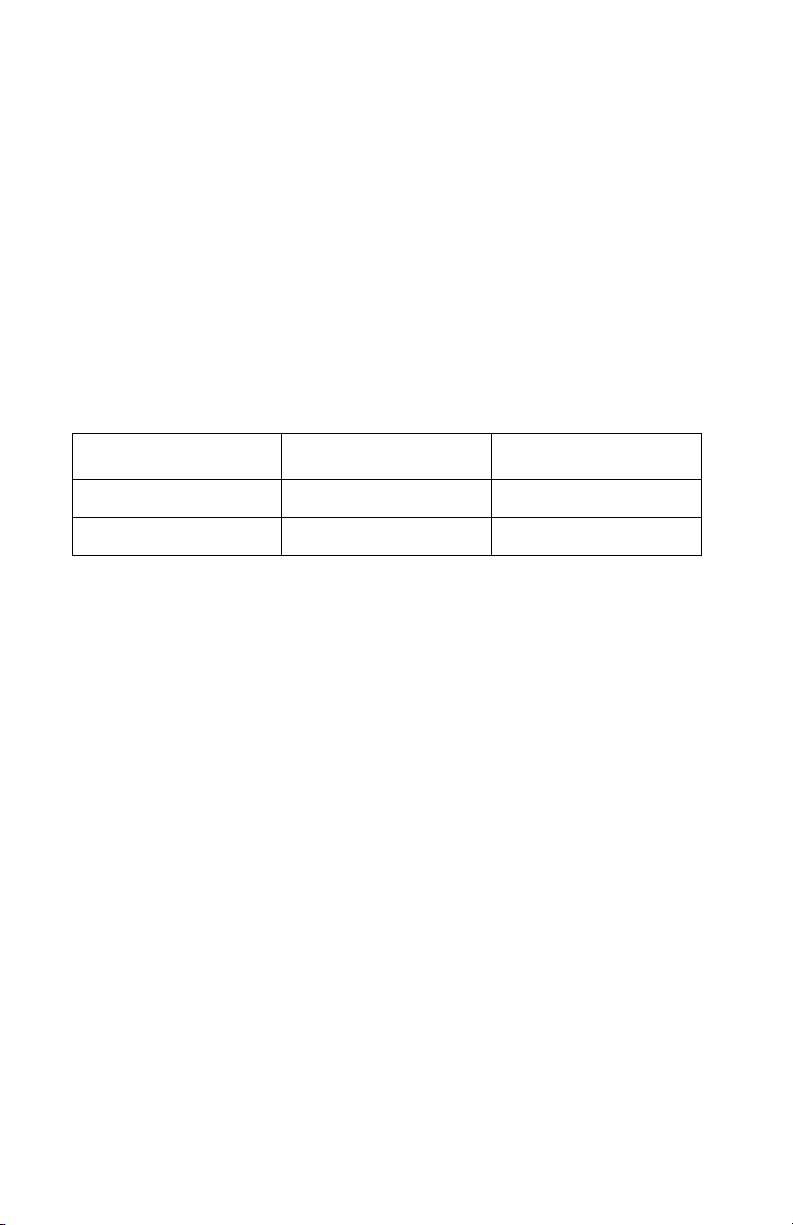

Emulation Scalable Fonts Bitmapped Fonts

PCL 6 84 2

PostScript 3 156 0

For a listing of specific fonts, visit www.lexmark.com.

There are 83 symbol sets in the PCL 6 emulation to support all the

languages that use these characters.

Not all symbol sets are supported by all fonts. Refer to the Technical

Reference manual or use the printer operator panel to find which

symbol sets are supported by each font.

1-24 Service Manual

Page 41

5055-01X

Support for the euro currency character is included in all applicable

fonts for both PostScript and PCL emulations. Twelve PCL symbol

sets support the euro character, including all seven Windows symbol

sets.

Additional fonts can be downloaded to the printer RAM, optional

Flash DIMM or hard disk. PCL emulation supports both scalable and

bit mapped downloadable fonts. PostScript emulation supports only

downloadable scalable fonts. Font cards and font cartridges are not

supported.

Power and Electrical Specifications

Power Requirements

Average nominal power requirements for the base printer

configuration (110 volt). Power level are shown in watts.

Printing

States

(average

Power)

Printing 1,250 1,830 1,600

Idle

Sleep Mode

Lexmark

C910(n)[dn]

45 45 45

Lexmark

C910(n)[dn]

with High

Capacity

Feeder

Lexmark

C910(n)[dn]

with Finisher

Note: Using a 220 to 110 power converter with the 110 volt

printer is not recommended.

General Information 1-25

Page 42

5055-01X

Electrical Specifications

110 Volt Model

• 120 to 127 VAC at 50 to 60 hertz (hz) nominal

110 Volt Model with High-Capacity Feeder or Finisher

• 120 to 240 VAC at 50 to 60 hertz (hz) nominal

Operating Clearances

•

Left side: 13 in. (330 mm)*

• Right side:

– C910(n) 6 in. (152 mm)**, ***

– C910dn 13 in. (330 mm)**, ***

• Front: 26 in. (660 mm)

• Rear: 5 in. (127 mm)

• Top:****

– 91029 in. (736.6 mm)

– C910n(dn)34.3 in. (871.2 mm)

Note: * Clearance on left side should be 9 in. (228.6 mm) with the

finisher attached.

** Clearance on right side should be 30 in. (762 mm) with the highcapacity feeder attached.

*** Clearance on the right side should be 13 in. (330 mm) with the

duplex attached, but not the high-capacity feeder.

**** With the high-capacity feeder or finisher attached, the top

clearance needs to be 43.8 in. (1,113 mm).

1-26 Service Manual

Page 43

5055-01X

Environment

• Printer Temperature and Humidity

– Operating

- Temperature: 60 to 90

- Relative Humidity: 8 to 80%

o

F (15.6 to 32.3o C)

- Maximum Wet Bulb Temperature: 73

o

F (22.8o C)

- Altitude: 10,000 ft. (0 to 3,048 meters)

- Atmospheric Pressure: 74.6 kPa

– Power Off

- Temperature: 50 to 110

o

F (10 to 43.3o C)

- Relative Humidity: 8 to 80%

- Maximum Wet Bulb Temperature: 80.1o F (26.7

- Altitude: 10,000 ft. (0 to 3,048 meters)

– Shipping Printer without Print Cartridges

- Temperature: 0 to 140

o

F (0.6 to 60o C)

- Relative Humidity: 5 to 100%

o

- Maximum Wet Bulb Temperature: 85

F (30o C)

- Altitude: 34,000 ft. (10,300 meters)

o

C)

– Storing Printer without Print Cartridges

- Temperature: 0 to 140

o

F (0.6 to 60o C)

- Relative Humidity: 5 to 80%

- Maximum Wet Bulb Temperature: 85

- Altitude: 34,000 ft. (10,300 meters)

– Shipping Supply Items

General Information 1-27

o

F (30o C)

Page 44

5055-01X

o

- Temperature: -40 to 104

F (-40 to 40o C)

- Relative Humidity: 5 to 100%

- Maximum Wet Bulb Temperature: 80

o

F (27o C)

– Storing Supply Items

- Temperature: 0 to 104

o

F (0.6 to 40o C)

- Relative Humidity: 5 to 80%

- Maximum Wet Bulb Temperature: 80

o

F (27o C)

• In some cases, performance specifications (such as paper OCF,

EP cartridge usage) are specified to be measured at an

ambient condition.

Physical Specifications and Weight

Width Depth Height Weight

Printers

Lexmark C910 27.4in

(695 mm)

Lexmark C910n 27.4 in.

(695 mm)

25.8 in.

(655 mm)

25.8 in.

(655 mm)

20.2 in.

(512 mm)

25.2 in.

(641 mm)

177.1 lb.

(80.5 kg)

217.8 lb.

(99 kg)

Lexmark C910dn 27.4 in.

(695 mm)

Options

Duplex Option 27.4 in.

(695 mm)

550-Sheet

Drawer

High Capacity

Feeder

27.4 in

(695 mm)

14.2 in.

(360 mm)

1-28 Service Manual

25.8 in.

(655 mm)

13.8 in

(350 mm)

25.8 in.

(655 mm)

20.7 in

(525 mm)

25.2 in.

(641 mm)

4.7 in.

(120 mm)

5.1 in.

(129 mm)

25 in.

(635 mm)

230.8 lb.

(104.9 kg)

13 lb.

(5.9 kg)

40.8 lb.

(18.5 kg)

50 lb.

(22.6 kg)

Page 45

5055-01X

Width Depth Height Weight

Staple Punch

Finisher, 1,100

Sheet (with

stand)

Furniture

Printer Cabinet 26.6 in.

Printer Base 26.6 in.

19.5 in.

(495 mm)

(675 mm)

(675 mm)

20.5 in.

(520 mm)

23.6 in.

(598 mm)

21.6 in.

(547 mm)

41.7 in

(1,060

mm)

20.4 in.

(517 mm)

10.2 in.

(260 mm)

48.6 lb.

(22 kg)

57.5 lb.

(26 kg)

33 lb.

(15 kg)

Note: Weight includes cartridges and supplies.

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, and service checks to determine the symptom and

repair the failure. The removals in the Repair Information chapter

may help you identify parts.

After you complete the repair, perform tests as needed to verify the

repair.

Standard Inspection and Cleaning Procedure

• Switch off Printer power, and disconnect the AC power cord

from the electrical outlet.

• Remove and inspect the photodevelopers and toner cartridges,

shielding them from strong light.

• Inspect the interior of the printer, removing foreign matter such

as paper clips, staples, pieces of paper/transparencies, paper

dust, hair, oil, grease or toner.

• Clean the printer interior using a lint-free cloth, dampened

slightly with cold water. Do not use solvents or chemical

cleaners to clean the printer interior.

• Use only the specified oil or lubricant on printer parts (some

service parts are lubricated at the factory).

General Information 1-29

Page 46

5055-01X

• Inspect and, if necessary, clean all rubber/plastic and D rollers

with A lint-free cloth, dampened slightly with cold water. Dry the

rollers with a lint-free cloth.

• While cleaning, inspect the interior of the printer for damaged

wires, loose connections, toner leakage, loose springs, and

damaged or worn parts.

• Be sure the printer is on a single, flat, strong table or desk top.

• Inspect all supplies (OCR, cartridges, photodevelopers/toner

cartridges, belts, fuser CRUs) and paper sources (cassettes,

trays, feeders, duplex drawers, finishers, mailbox trays) for

obvious damage and proper installation (paper under corner

bucklers, paper guides not too tight) Inspect for correct media

usage (paper, transparencies, labels).

• Print a Demo page.

• If additional paper sources are installed, print a Demo page

from each of these, (if possible).

Note: Failure to print from an additional tray or feeder may imply

one or more pins are bent in the mating connector.

Return Parts

Engineering periodically analyzes returned parts for failure modes.

Include a printed test (DEMO) page, before and after the repair, and

tag any returnable parts with a description of the failure.

Service Recommendations

Before leaving the printer check the following:

• Be sure printer is on a flat, level, strong tabletop or level floor.

This is very important for color printers that use belts. Check

and set registration as necessary.

• Shake all cartridges and be sure they are correctly installed and

fully seated.

• While the cover is open, wipe any residual toner from the LEDs

using a lint free cloth.

• If you have serviced the finisher option, and in the process

pulled it away from the printer during repair, ensure that it is

properly aligned with the printer.

1-30 Service Manual

Page 47

5055-01X

Tools

The removal and adjustment procedures require the following tools

and equipment:

• Magnetic tip Phillips screwdrivers, large and small

• Flat-blade screwdrivers

• Analog volt ohmmeter (a digital volt ohmmeter may also be

used)

• Needle nose pliers

• Tweezers, C-ring pliers

• Magnifier (20 times or higher)

• 6-angle wrench (1.5 mm)

When you make voltage readings, always use frame ground unless

another ground is specified.

General Information 1-31

Page 48

5055-01X

Serial Number

Open the front door, the serial number is located as shown. The

serial number is also on the menu settings page you can print from

the Tests Menu.

1-32 Service Manual

Page 49

5055-01X

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EP Electrophotographic Process

EPROM Erasable Programmable Read-Only Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LASER Light Amplification by Stimulated Emission of

Radiation

LCD Liquid Crystal Display