Page 1

C910 Color Printer

• Table of Contents

•Start Diagnostics

• Safety and Notices

• Trademarks

5055-01X

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trade ma rks of Lexmark

International, Inc., registered in the

United States and/or ot her countries.

Page 2

5055-01x

Edition: November 2001

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTERN ATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING , BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of express or implied warranties i n certain transactions; th erefore,

this statement may not apply to you.

This p ublic ation could inc lude technical inaccuracies or typographi cal erro rs. Ch anges

are periodically made to the information herein; these changes will be incorporated in

later editions. Improvements or changes in the products or the programs described may

be made at any tim e.

Comments may be addressed to Le xmark International, Inc., Department D22A/032-2,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or electronically mailed

(e-mail) to ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of

the information you supply in any way it believes appropriate without incurring any

obligation to you. You can purchase additional copies of publications related to this

product by calling 1-800-553-9727. In other countries, contact your point of purchase.

Lexmark and Lexmark with diamond design and OptraImage are trademarks of Lexmark

International , Inc., register ed in the U nited St ates and/or oth er countries.

Other trademarks are the property of their respective owners .

© Copyright Lexma rk Inte r na tion al, Inc. 20 01 .

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 an d in applicable FAR pro visions: Lexmark International, Inc.,

Lexington, KY 40550.

U.S.A. P/N 12G9081

Page 3

5055-01x

Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintenance Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Inspection and Cleaning Procedure . . . . . . . . . . . . . . . 1-1

Return Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Recommendations For Service . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Serial N umber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Processes and Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrophotography Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Development Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Transfer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Cleaning Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Paper Feeding / Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Cassette Paper Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Multi-P u rp os e Feeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Registration Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Separation Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -12

Fuser U nit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -13

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Belt Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -15

Belt Up/Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -16

Expansion Paper Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Duplex Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -17

Printing Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -18

OHP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Thick Paper Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Envelope / Postcard Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

High Capacity Paper Feeder (HCPF). . . . . . . . . . . . . . . . . . . . . 1 -25

Maintenance Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

High Capacity Paper Feed Sensor / Switch Test. . . . . . . . . . . . 1 -35

iii

Page 4

5055-01x

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Adjustments and Procedures Following Parts Replacement . . . .2 - 1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Initial Ch ec k. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Printer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Service Error Message Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Attendance Messages g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Maintenance Analysis Procedures (MAPS) . . . . . . . . . . . . . . . .2-43

Symptom Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

Drive 1 DC Motor Service Check . . . . . . . . . . . . . . . . . . . . . . . .2-55

Drive 2 Stepper Motor Service Check. . . . . . . . . . . . . . . . . . . . .2-55

Duplex Service Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

Expansion Paper Feed Service Check . . . . . . . . . . . . . . . . . . . .2-56

Face-Down Stacker Full Service Check . . . . . . . . . . . . . . . . . . .2-57

High Capacity Paper Feed (HCPF) Service Check. . . . . . . . . . .2-57

Operator Panel Service Check . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

Paper Carrying Service Check . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

Paper Exit, FU/FD Service Check. . . . . . . . . . . . . . . . . . . . . . . .2-63

Paper Tray Missing Service Check . . . . . . . . . . . . . . . . . . . . . . .2-63

Photodeveloper Missing Service Check . . . . . . . . . . . . . . . . . . .2-64

Power Supply Ser vice Check . . . . . . . . . . . . . . . . . . . . . . . . . . .2-65

Marks on Paper Service Check. . . . . . . . . . . . . . . . . . . . . . . . . .2-66

Transfer Belt Up/Down Service Check . . . . . . . . . . . . . . . . . . . .2-68

Image Quality Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-69

Print Quality Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-69

Options Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-77

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Power-On Self Test Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Using the Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Operator Panel Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Printing the Menu Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Operator Menu Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Print Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Hardware Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Device Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Diagnostics - Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Viewing and Resetting the Drum Counters . . . . . . . . . . . . . . . .3-22

Diagnostics - Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

iv Service Manual

Page 5

5055-01x

Repair Informatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Service Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

High Capacity Paper Feed Timing Belt Adjustment. . . . . . . . . . . 4-3

Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cover, Top Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Operator Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cover, Front Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Cover, Front Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cover, Rear Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Cover, Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cover, Left Side Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cover, Right Side Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Cover, RIP Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Tray, Paper Exit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

RIP Box Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Electronic Box Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

LED Printhead Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -12

Eraser Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Printhead Controller Board Removal . . . . . . . . . . . . . . . . . . . . . 4-15

Upper Fan Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -16

Multi-Purpose Feeder Tray Removal. . . . . . . . . . . . . . . . . . . . . 4 -17

Paper Feed Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Paper Carrying Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Paper Present Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4 -19

Paper Feed Frame Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Cassette Guide Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Temperature/Humidity Sensor Removal . . . . . . . . . . . . . . . . . . 4 -22

Paper Feed Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4 -22

Paper Remaining Sensor Removal . . . . . . . . . . . . . . . . . . . . . . 4-22

Gear Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Multi-Purpose Feeder Roll Removal . . . . . . . . . . . . . . . . . . . . . 4-23

Multi-Purpose Feeder Clutch Removal . . . . . . . . . . . . . . . . . . . 4-23

OHP Detection Sensor (Upper) Removal . . . . . . . . . . . . . . . . . 4-23

Fanning Pad Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Registration Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Multi-Purpose Feeder Paper Present Sensor Remov al. . . . . . . 4-27

Paper Carrying Frame Removal . . . . . . . . . . . . . . . . . . . . . . . . 4 -28

Paper Carrying Roller (Upper) Removal . . . . . . . . . . . . . . . . . . 4-28

Paper Carrying Clutch Removal. . . . . . . . . . . . . . . . . . . . . . . . . 4-28

OHP Detection Sensor (Lower) Removal . . . . . . . . . . . . . . . . . 4 -28

v

Page 6

5055-01x

Registration Frame, Registration Clutch Removal . . . . . . . . . . .4-29

Transfer Belt Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

Belt Up/Down Detection Sensor Removal. . . . . . . . . . . . . . . . . .4-34

Sensor Board Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Density Sensor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Separation Fingers Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Sensor Cleaner Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Printer Controller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

High Voltage Power Supply Board (HVU) Removal . . . . . . . . . .4-38

R Sub Frame Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Toner Remaining Sensor Removal . . . . . . . . . . . . . . . . . . . . . . .4-39

Drum Gear Sensor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

Sub Frame F1, Sub Frame F2 Removal . . . . . . . . . . . . . . . . . . .4-40

Drive Gear Unit Sensor Assembly Removal . . . . . . . . . . . . . . . .4-41

Belt Up/Down Clutch Removal . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

Power Supply 1 Remova l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

Power Supply 2 Remova l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

Drive Motor Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . .4-45

Motor Drive Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

Power Switch Remo va l. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Connector, Duplex Unit Removal . . . . . . . . . . . . . . . . . . . . . . . .4-47

Paper Size Sensor Board Assembly Removal . . . . . . . . . . . . . .4-48

Main Unit Fa n R emoval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Main Driv e Un it Re m o v al. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-50

Face-Up Paper Exit Assembly Removal . . . . . . . . . . . . . . . . . . .4-54

Face-Up/Down (Flapper Detection) Sensor Removal. . . . . . . . .4-54

Face-Up/Down Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . .4-54

Paper Delivery Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . .4-54

Paper Exit Tray Switch Removal. . . . . . . . . . . . . . . . . . . . . . . . .4-54

Face-Down Guide Assembly Removal . . . . . . . . . . . . . . . . . . . .4-55

Paper Exit Motor & Full Sensor Removal . . . . . . . . . . . . . . . . . .4-55

Turn Guide Cover Sensor Removal . . . . . . . . . . . . . . . . . . . . . .4-57

Right Slide Rail Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-58

Front Cover Open Switch Actuator Removal . . . . . . . . . . . . . . .4-58

Lock Handle Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . .4-59

Top Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

Stay Arm Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-61

Fuser Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-62

Options Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

Expansion Paper Feeder Removal . . . . . . . . . . . . . . . . . . . . . . .4-63

Duplex Unit Separation Removal . . . . . . . . . . . . . . . . . . . . . . . .4-71

Duplex Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

Duplex Timing Belt Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-72

vi Service Manual

Page 7

5055-01x

Duplex Pressure Roller and Solenoid Removal. . . . . . . . . . . . . 4-73

Duplex Feed Roller And Solenoid Removal. . . . . . . . . . . . . . . . 4 -73

Duplex Side Fence Motor Assembly / Side Fence Removal . . . 4-74

Duplex Paper Carrying Motor Removal . . . . . . . . . . . . . . . . . . . 4 -75

HCPF Covers Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

HCPF Call Roller, Paper Feed Roller, Reverse Roller Removal 4-77

HCPF Pickup Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . 4 -78

HCPF Paper End Sensor Removal . . . . . . . . . . . . . . . . . . . . . . 4-79

HCPF Paper Size Sensors (1, 2) Removal . . . . . . . . . . . . . . . . 4-79

HCPF Tray Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -81

HCPF Paper Level Sensor Removal . . . . . . . . . . . . . . . . . . . . . 4 -82

HCPF Power Supply Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4 -83

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Covers Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Major Parts Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Printer C on t ro lle r Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Printhead Controller Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

RIP Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Power Source Unit 1 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Power Source Unit 2 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

High Voltage Power Supply Board. . . . . . . . . . . . . . . . . . . . . . . . 5-8

Sensor Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Expansion Paper Feeder Controller Board . . . . . . . . . . . . . . . . . 5-9

Duplex Unit Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -10

Motor Drive Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -10

Size Sensor Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

High Capacity Paper Feed (HCPF) . . . . . . . . . . . . . . . . . . . . . . 5 -11

High Capacity Paper Feed Configuration. . . . . . . . . . . . . . . . . . 5 -12

Electrical Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Driving Parts Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Sensor and Switch Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -15

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Lubricants and Cleaners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

vii

Page 8

5055-01x

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How to Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Assembly 1: Covers 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Assembly 2: Covers 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Assembly 3: Covers 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Assembly 4: Covers 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Assembly 5: Covers 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Assembly 6: Upper Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Assembly 7: Base 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Assembly 8: Base 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Assembly 9: Base 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

Assembly 10: Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

Assembly 11: I/F Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28

Assembly 11: I/F Controller (Continued) . . . . . . . . . . . . . . . . . . .7-30

Assembly 12: Fuser Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

Assembly 13: Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

Assembly 14: Expansion Feeder 1 . . . . . . . . . . . . . . . . . . . . . . .7-36

Assembly 15: Expansion Feeder 2 . . . . . . . . . . . . . . . . . . . . . . .7-38

Assembly 16: Duplex Unit 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-40

Assembly 17: Duplex Unit 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-42

Assembly 18: High Capacity Paper Feed 1 . . . . . . . . . . . . . . . . .7-44

Assembly 19: High Capacity Paper Feed 2 . . . . . . . . . . . . . . . . .7-46

Assembly 20: High Capacity Paper Feed 3 . . . . . . . . . . . . . . . . .7-48

Assembly 21: High Capacity Paper Feed 4 . . . . . . . . . . . . . . . . .7-50

Assembly 22: High Capacity Paper Feed 5 . . . . . . . . . . . . . . . . .7-52

Assembly 23: High Capacity Paper Feed 6 . . . . . . . . . . . . . . . . .7-54

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x-1

viii Service Manual

Page 9

5055-01x

Safety Information

Safety Notice

• This product is designed, tested and approved to meet strict

global safety standards with the use of specific Lexmark

components. The safety features of some parts may not

always be obvious. Lexmark is not responsible for the use of

other replacement parts.

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injury during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les

normes strictes de sécurité globale lors de l'utilisation de

composants Lexmark spécifiques. Les caractéristiques de

sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation

d'autres pièces de rechange.

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

Safe ty In formation ix

Page 10

5055-01x

Norme di sicurezza

• Il prodotto è stato progettato, testato e approvato in

conformità a severi standard di sicurezza e per l’utilizzo con

componenti Lexmark specifici. Le caratteristiche di sicurezza

di alcune parti non sempre sono di immediata comprensione.

Lexmark non è responsabile per l’utilizzo di parti di ricambio

di altri produttori.

• Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale di assistenza

autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden

entworfen und getestet, um beim Einsatz die weltweit

gültigen Sicherheitsanforderungen zu erfüllen. Die

sicherheitsrelevanten Funktionen der Bauteile und Optionen

sind nicht immer offensichtlich. Sofern Teile eingesetzt

werden, die nicht von Lexmark sind, wird von Lexmark

keinerlei Verantwortung oder Haftung für dieses Produkt

übernommen.

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wart ung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

x Service Manual

Page 11

5055-01x

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para

cumplir los más estrictos estándares de seguridad global

usando los componentes específicos de Lexmark. Puede

que las características de seguridad de algunas piezas no

sean siempre evidentes. Lexmark no se hace responsable

del uso de otras piezas de recambio.

• La información sobre el mantenimiento de este producto

está dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

Inform ações de Segurança

• Este produto foi concebido, testado e aprovado para

satisfazer os padrões globais de segurança na utilização de

componentes específicos da Le xma rk. As fu n ções de

segurança de alguns dos componentes podem não ser

sempre óbvias. A Lexmark não é responsável pela utilização

de outros componentes de substituição.

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

Safe ty In formation xi

Page 12

5055-01x

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal

d'acomplir les estrictes normes de se guretat globals amb la

utililització de components específics de Lexmark. Les

característiques de seguretat d'algunes peces pot ser que no

sempre siguin òbvies. Lexmark no es responsabilitza de l'us

d'altres peces de recanvi.

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El ri sc d e xoc elèctric i de danys personals pot augmentar

durant el procés de desmun tatge i de ser vei d’aquest

producte. El personal professional ha d’estar-ne assabentat i

prendre les mesures convenients.

xii Service Manual

Page 13

5055-01x

Safety In fo rmation xiii

Page 14

5055-01x

xiv Service Manual

Page 15

5055-01x

1. Gen e r a l Informat io n

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, and service checks to determine the symptom and

repair the failure. The removals in the Repair Information chapter

may help you identify parts.

After you complete the repair, perform tests as needed to verify the

repair.

Standard Inspection and Cleaning Procedure

• Switch off Printer power, and disconnect the AC power cord

from the wall outlet.

• Remove and inspect the photodevelopers and toner cartridges,

shielding them from strong light.

• Inspect the interior of the printer, removing foreign matter such

as paper clips, staples, pieces of paper/transparencies, paper

dust, hair, oil, grease or toner.

• Clean the printer interior using a lint-free cloth, dampened

slightly with cold water. Do not use solvents or chemical

cleaners to clean the printer interior.

• Use only the specified oil or lubricant on printer part s (some

service parts are pre-lubed from the factory).

• Inspect and, if necessary, clean all rubber/plastic and D rollers

with A lint-free cloth, dampened slightly with cold water. Dry the

rollers with a lint-free cloth.

• While cleaning, inspect the interior of the printer for damaged

wires, loose connections, toner leakage, loose springs, and

damaged or worn par ts.

• Be sure the printer is on a single, flat, strong table or desk top.

• Inspect all supplies (OCR, Cartridges, photodeveloper/toner

cartridges, belts, fuser CRUs) and paper sources (cassettes,

trays, feeders, duplex drawers, finishers, mailbox trays) for

obvious damage and proper installation (paper under corner

bucklers, paper guides not too tight) Inspect for correct media

usage (paper, transparencies, labels).

General Information 1-1

Page 16

5055-01x

• Print a Demo page.

• If additional paper sources are installed, print a Demo page

from each of these, (if possible).

Note: Failure to print from an additional tray or feeder may imply

one or more pins are bent in the mating connector.

Return Parts

Engineering periodically analyzes returned parts for failure modes.

Please Include a printed test (DEMO) page, before and after the

repair, and tag any returnable parts with a description of the failure.

Recommendations For Service

Before leaving the printer check the following:

• Be sure printer is on a single, flat, strong tabletop. This is very

important for color printers that use belts. Check and set

registration as necessary.

• Shake all cartridges and be sure they are correctly installed and

fully seated.

• While the cover is open, wipe any residual toner from the LEDs

using a lint free cloth.

Tools

The removal and adjustment procedures require the following tools

and equipment:

• Magneti c t ip Phillips screwd rivers, large and sm all

• Flat-blade screwdrivers

• Analog volt ohmmeter (a digital volt ohmmeter may also be

used)

• Needle nose pliers

• Tweezers, C-ring pliers

• Magnifier (10 times or equivalent)

• 6-angle wrench (1.5 mm)

When you make voltage readings, always use frame ground unless

another ground is specified.

1-2 Service Manual

Page 17

5055-01x

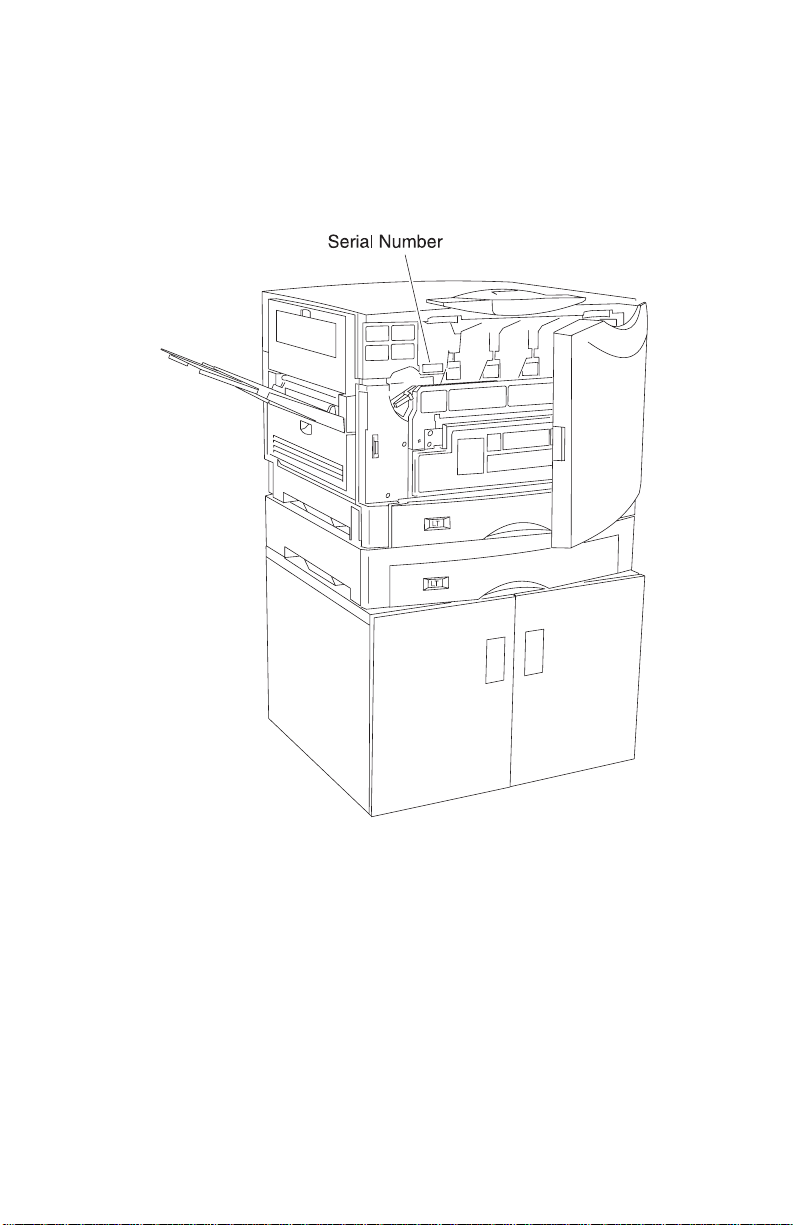

Serial Number

Open the front door, the serial number is located as shown. The

serial number is also on the menu settings page you can print from

the Test s Menu.

General Information 1-3

Page 18

5055-01x

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EPROM Erasable Programmable Read-Only Memory

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Net work

LASER Light Amplification by Stimulated Emission of

Radiation

LCD Liquid Cr ys tal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PICS Problem Isolation Charts

PIXEL Picture Element

POR Power-On Reset

POST Power-On Self Test

PQET Print Quality Enhancement Technology

RIP Raster Image Processor

ROS Read-Only Storage

SRAM S t atic Random Ac cess Memo ry

UPR Used Parts Replacement

V ac Vol ts alternating current

V dc Volts direct current

1-4 Service Manual

Page 19

5055-01x

Processes and Configuration

In this printer, the toner of four colors (magenta, cyan, yellow and

black) melts and deposits on paper, dots which record color image

information. This printing process is called the electrophotography

process.

Electrophotography Process

In the electrophotography process, electrically charged toner,

exposes, develops, transfers, and is cleaned with an aluminum

photosensitive drum. A photoconductive layer forms on the surface

of the drum when the drum is exposed to light.

The surface of the photosensitive drum is negatively charged,

forming the electrostatic image on the surface of the photosensitive

drum. This charge is directed to the photosensitive medium at a low

voltage, reducing the generation of ozone to a very low level. When

the drum surface is charged, the image is recorded by irradiating

light from the LED printhead, forming the electrostatic image. The

LED printhead array along with the Selfoc lens array provide a

single-dot line of the image, in a one-to-one arrangement. The

image data from the printhead controller causes the LED to emit

light in black dots. These black dots form an image of dots on the

photosensitive drum.

The LED printhead minimizes the displacement of images during the

color print process, when images of multiple printheads overlap,

causing dot position accuracy to be much higher. Since light from

the volume of the LED array varies depending on the LED

printheads, the light emitting value is recorded in the EPROM of the

printer controller. When the LED printhead is replaced, the light

emitting value should be entered for each printhead while the printer

is in maintenance mode.

Since the LED printhead and EPROM on the printhead controller

board of this printer are paired, the EPROM on the printhead

controller board should also be replaced whenever the printhead is

replaced.

General Information 1-5

Page 20

5055-01x

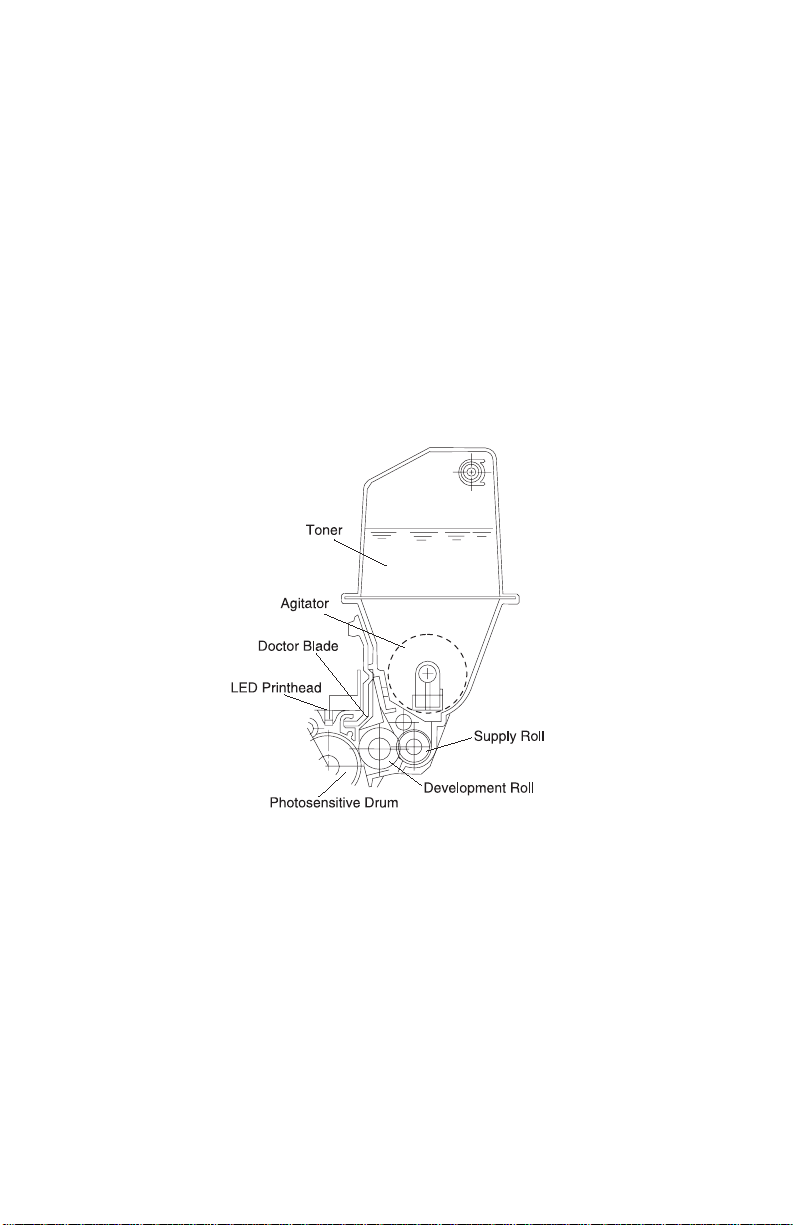

Development Unit

Ton er forms the electrostatic image on the photosen sitive drum

during exposure. The single component, non-magnetic toner and the

lusterless color toner are weather-resistant, and fade little under

ultraviolet rays. This is helpful in saving documents.

Toner in the hopper is agitated and supplied to the development roll

by the supply roll. A (conductive rubber) doctor blade is fitted to the

development roll. Toner enters between the development roll and

doctor blade by the rotating dev elopment roll and is negatively

charged, forming the electrostatic image on the photosensitive

drum. Toner attaches to the bright portion of the photosensitive drum

per the voltage of the development roll.

Transfer Unit

Paper feeds electrostatically by the transf er bel t and is carried to the

transfer unit which turn at the speed of the photoconductor drum. A

charge roller applies a positive charge to the paper. The toner image

formed on the photoconductor drum is transferred to the paper from

the back side by the positive dc voltage applied to the transfer sheet,

which is in contact with the paper through the transfer belt.

1-6 Service Manual

Page 21

5055-01x

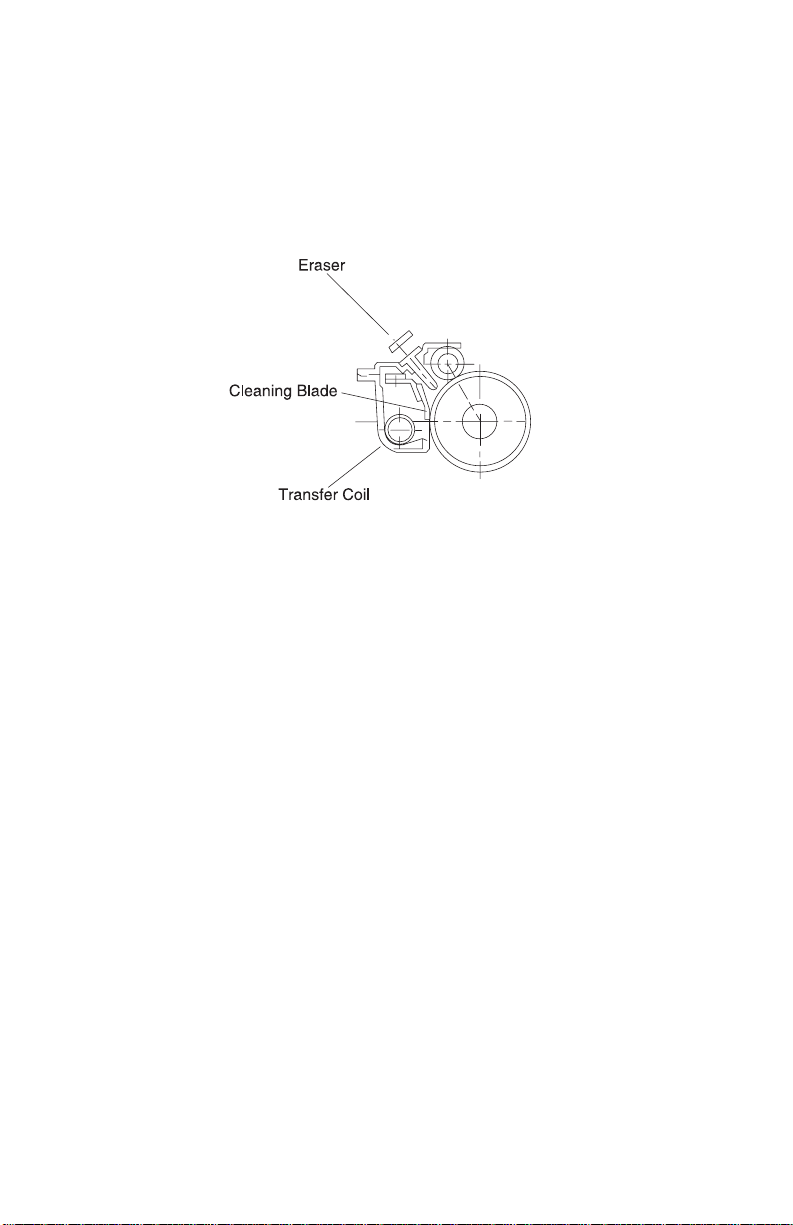

Cleaning Unit

Toner remaining on the photosensitive drum following transfer, is

scraped away with the cleaning blade, and collected in the recovery

bag as waste toner. Residual toner on the photosensitive medium is

removed by the eraser.

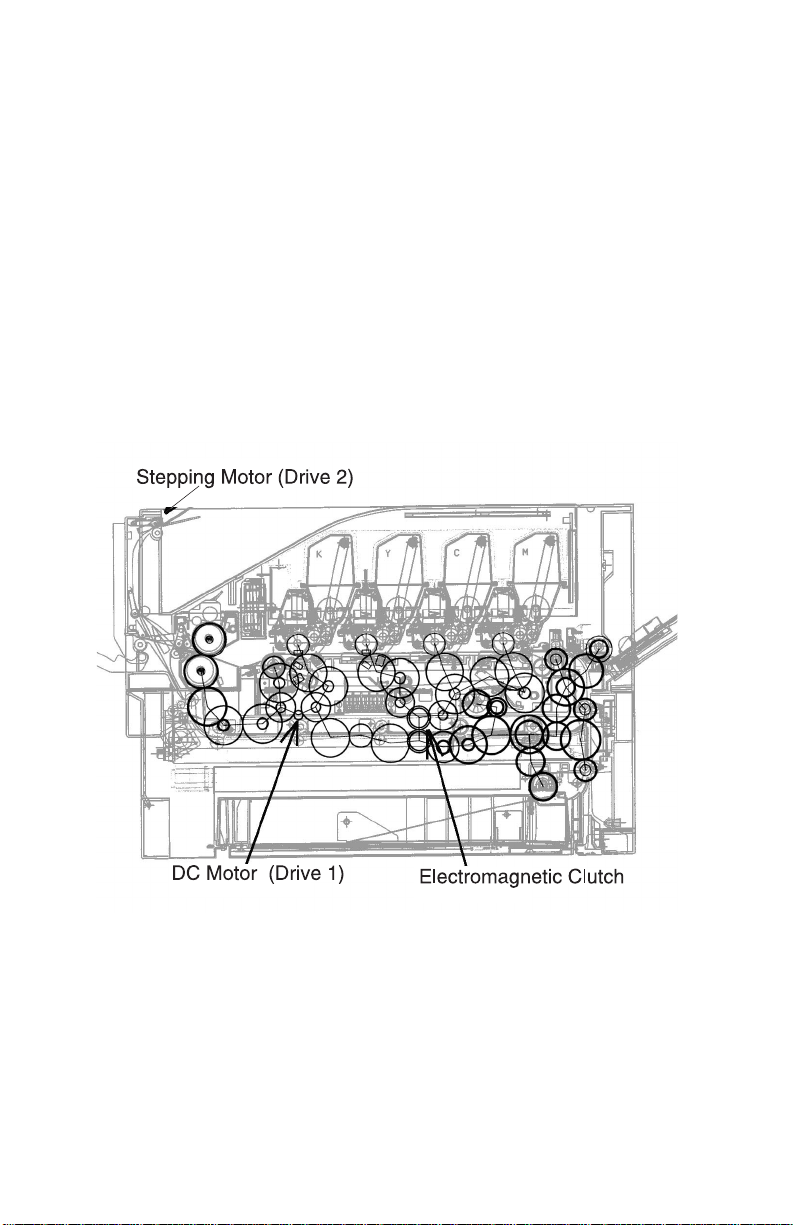

Paper Feeding / Fusing

The main unit drive is composed of drives 1 and 2. Drive 1 feeds

paper, stands by, drives the belt unit, separates, fuses, feeds the

face-up delivery unit, and drives the photodeveloper and toner

cartridge by rotations of the dc motor. Drive 2 drives the face-down

delivery unit by rotations of the stepper motor.

The expansion paper feeder and the duplex unit use independent

motors to drive the paper delivery unit.

General Information 1-7

Page 22

5055-01x

Drive System

Drive 1, composed of a 100 dc motor and gear unit, feeds the

registration paper from the paper feeder and drives the belt unit,

photodeveloper / toner cartridge, fusing unit, and face-up delivery

unit. The motor rotates by the ON signal from the printer controller/

motor drive unit and sends a rotation synchronization detection

signal to the motor drive unit.

Note: The gear unit of drive 1 is adjusted in phase and should not

be disassembled.

Drive 2, composed of a hybrid stepping motor and gear unit, drives

the face-down delivery unit.

1-8 Service Manual

Page 23

5055-01x

Paper Feeding

The paper feeder is a two-way system composed of the multi-paper

feeder (100 sheets maximum) and an integrated 550 sheet tray).

Optionally, the expansion paper feeders (550 sheets) can be

increased to four layers. A high capacity paper feeding system

(3,000 sheets) may be used. Combining the multi-paper feeder,

expansion paper feeders, and high capacity paper feeding system

the printer has a maximum paper supply of up to 5,850 sheets.

Cassette Paper Feeder

The paper feeding solenoid turns on by the signal from the printer

controller. The paper feeding roller interconnected with drive 1,

rotates with the spring clutch and picks the paper in the paper

cassette.

General Information 1-9

Page 24

5055-01x

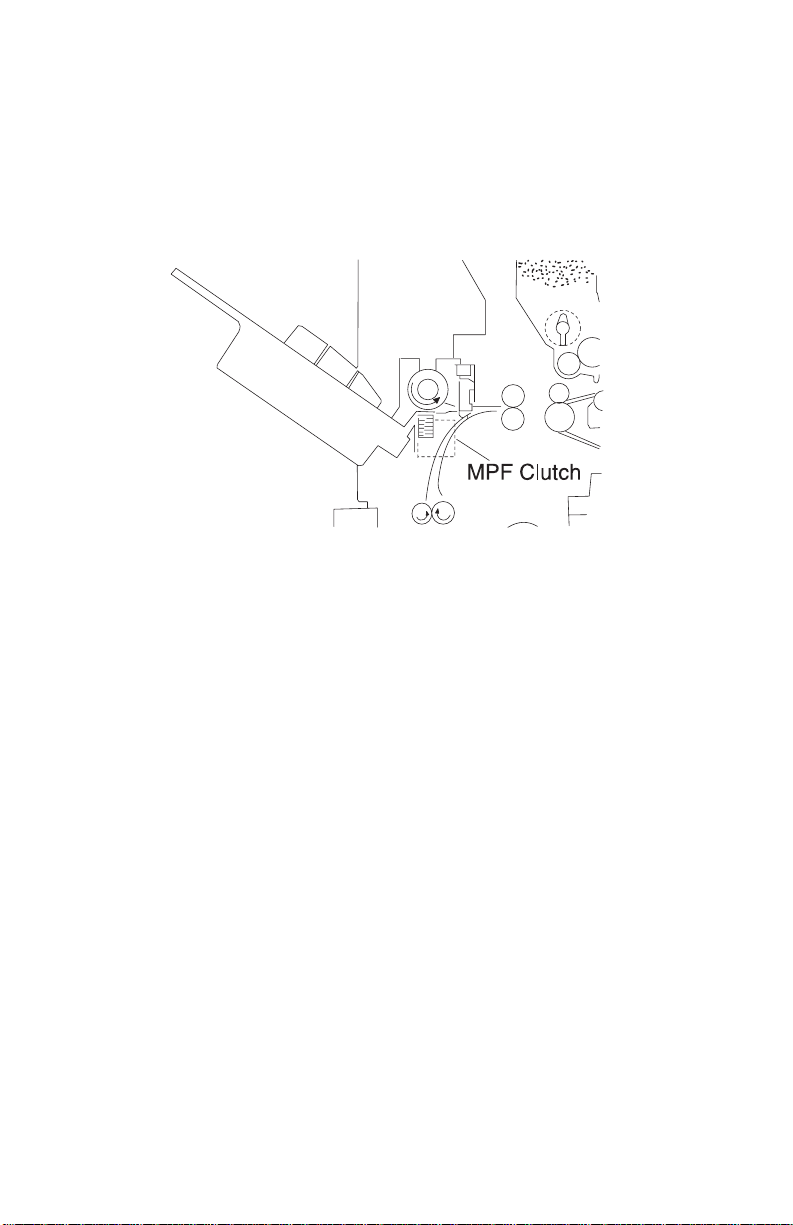

Multi-Purpose Feeding

The multi-paper feed solenoid turns on by the signal from the printer

controller. The multi-purpose feed roll interconnected with the drive 1

through the spring clutch, rotates and picks the paper in the multipurpose feeder.

1-10 Service Manual

Page 25

5055-01x

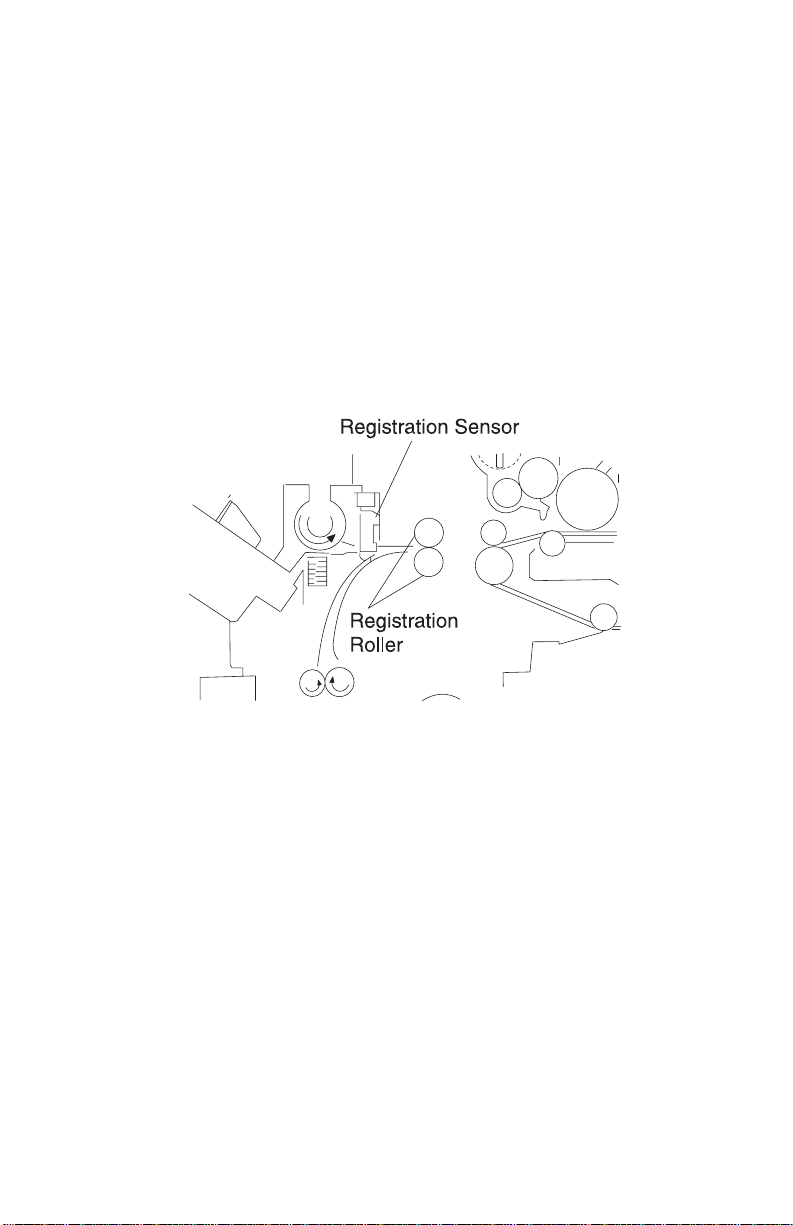

Registration Unit

Media temporarily stops (registration) when adjusting the paper

leading edge parallel with that of the image, or when adjusting the

timing with the black image.

The upper and lower registration rolls are arranged in parallel with

the photosensitive drum for blac k imaging. The lower registration roll

incorporates a registration clutch which feeds or stops the paper.

In the forward direction of the registration roll, a registration sensor

(photo interrupter) is provided to detect paper fed from the paper

feeder and to stop paper jam feeding.

General Information 1-11

Page 26

5055-01x

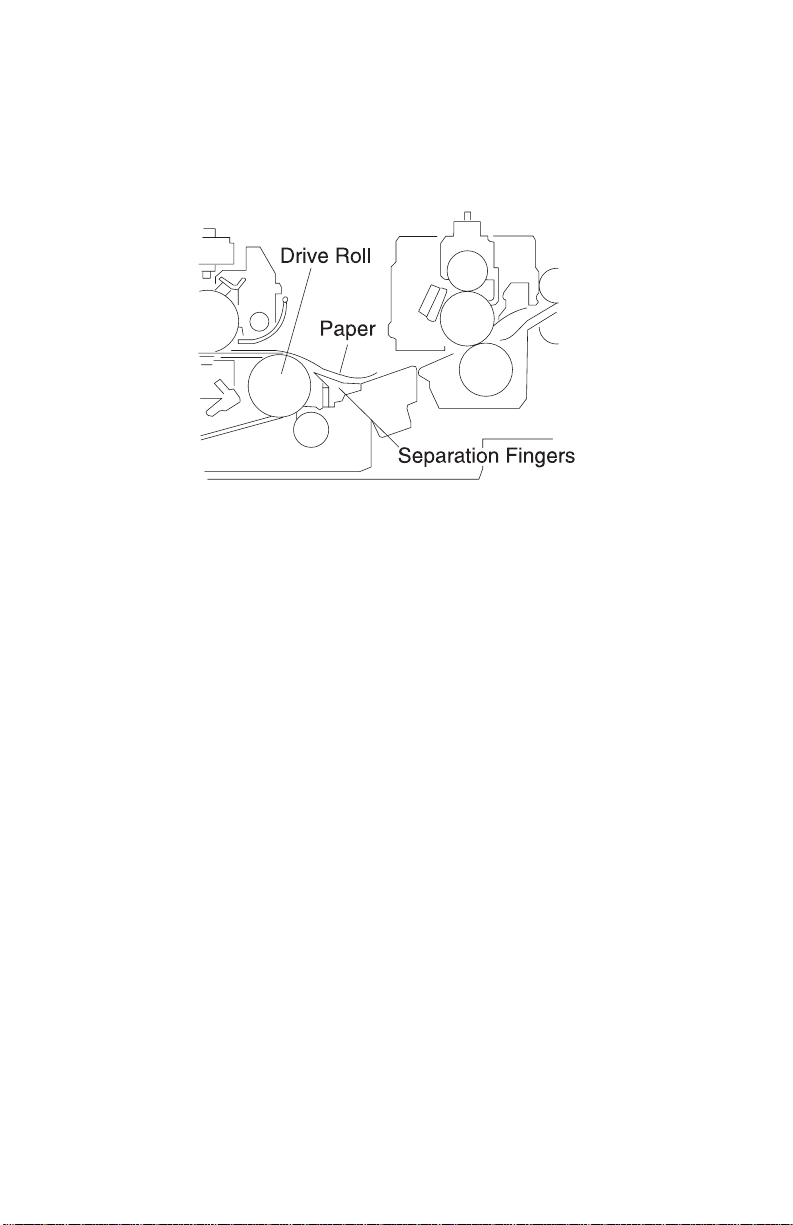

Separation Unit

The transfer belt and paper are separated with the belt drive roll by

separation fingers.

1-12 Service Manual

Page 27

5055-01x

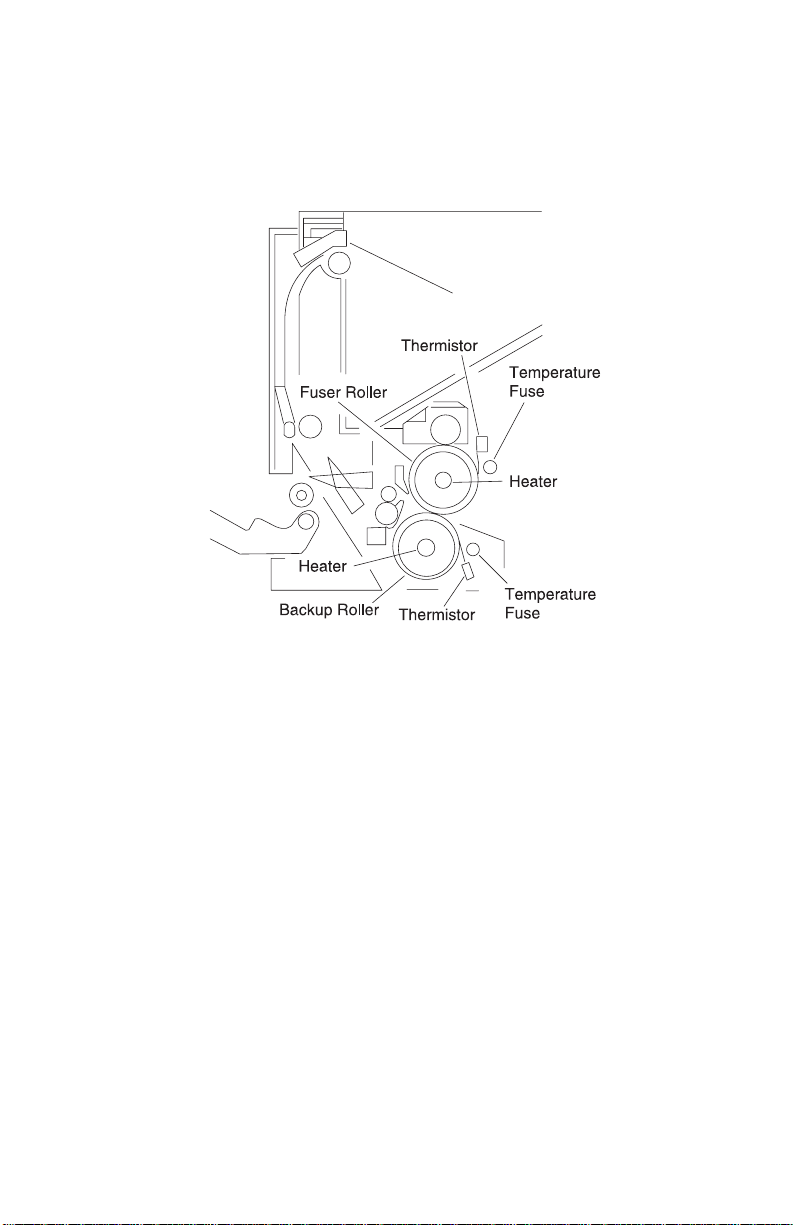

Fuser Unit

By applying heat and pressure, the image is melted and fused to the

paper.

The upper and lower rollers are heated and pressure-fitted. A heater

is positioned in the roller tube and a thermistor and therm ostat

remain in contact with the outside of the tube. Separation fingers are

attached near the upper roller to separate the paper from the roller .

Each thermistor sends the surface temperature of the roller to the

printer controller. The printer controller turns the heater on or off

according to the voltage of each thermistor. If the controller f ai ls and

the temperature of the roller exceeds specifications, the temperature

fuse (TCO) connected to each heater opens, preventing

overheating.

General Information 1-13

Page 28

5055-01x

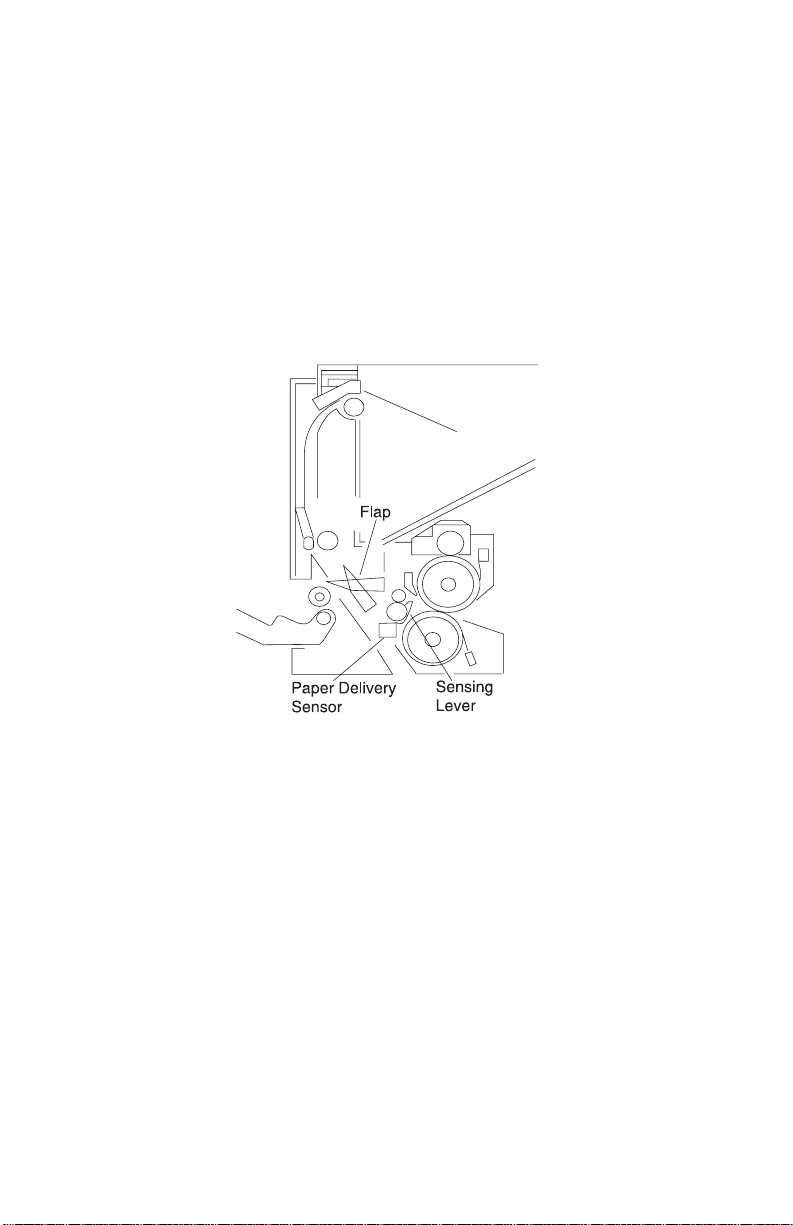

Delivery

After completing the fusing process, paper is discharged from the

printer. The delivery sensor detects the paper condition and the

FU/FD deflector switches between the face-up and face-down paper

delivery. The paper from the fuser pulls down the sensing lever

turning on the delivery sensor (photo interrupter). If the delivery unit

remains on longer than specified, the printer controller determines

that the printer is jammed, and the paper delivery flap lever switches

to either face-down or face-up.

1-14 Service Manual

Page 29

5055-01x

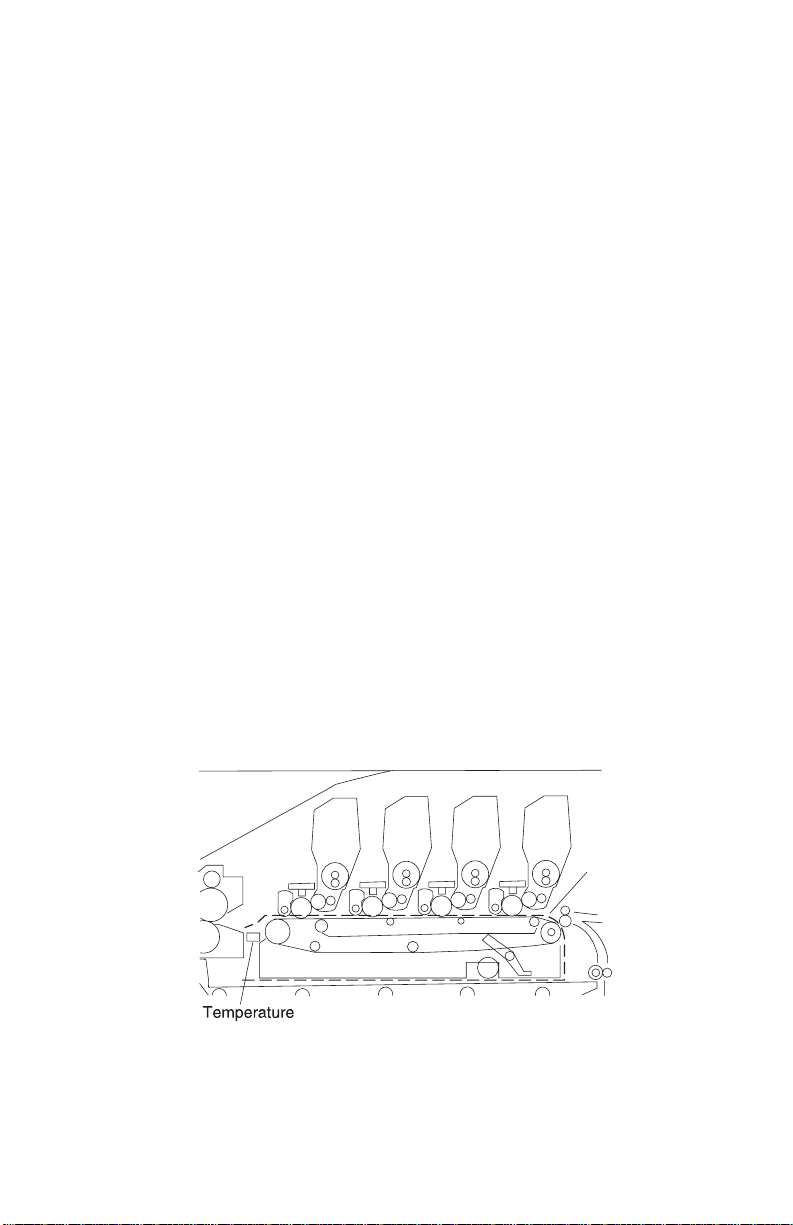

Belt Unit

After passing through the registration unit, paper is electrostatically

fed by the transf er belt through the positively charged feed rol l at the

inlet of the belt unit and fed by the running belt. The belt runs at the

same speed as the photosensitive drum causing the image on the

C, M, Y and K developer to transfer to paper.

Since the photosensitive drum has a small diameter and the paper is

electrostatically fed by the transfer belt, the paper is easily

separated, after toner image transfer, and fed to the next developer.

Excess toner is scraped from the drum with a cleaning blade and

recovered into the waste toner bottle.

Adjust the registration when the belt unit is replaced. The

registration is adjusted at the leading edge of the image or by

adjusting the color image. This should be adjusted in maintenance

mode, when the belt unit is replaced.

The transfer belt is conductive and seamless. If the transfer belt is

damaged, toner can cling to the belt and contaminate the paper.

When fingerprints or other stains appear on the belt, wipe them

away with a dry cloth or cloth moistened with alcohol.

A density sensor is positioned facing the belt drive roller for

automatic density adjustment and registration adjustment. A

mechanism is provided to clean the sensor surface, which is

interconnected with the opening and closing of the front cover.

General Information 1-15

Page 30

5055-01x

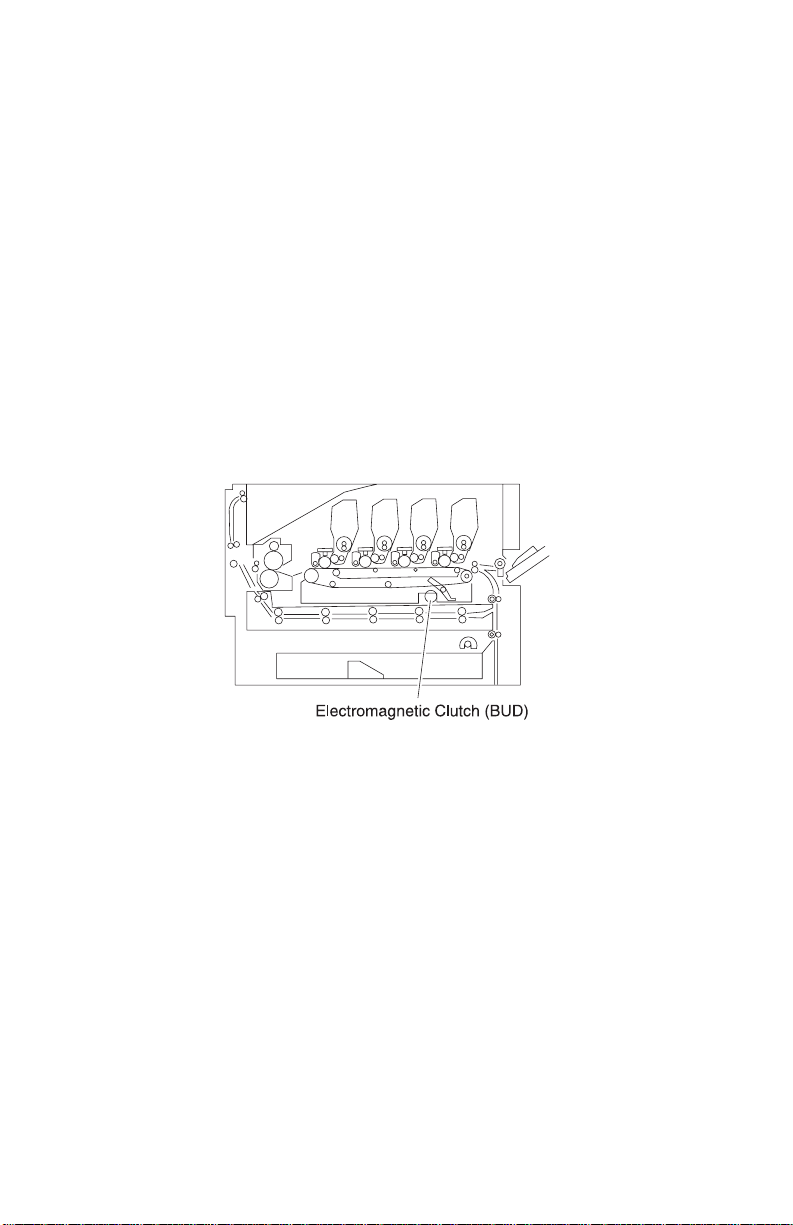

Belt Up/Down

In monochrome printing, switching to color printing is not required.

To avoid unnecessar y wear of the photosensitive drum by the

cleaning blade, this operation is stopped with the electromagnetic

clutch in drive 1. The transfer belt is lowered so as not to touch the

photosensitive drum during color printing.

The transfer belt moves up and down with the switching shaft cam by

the electromagnetic clutch in drive 1. The belt position is used to

detect the cam position with the photo sensor, using the fan shaped

light blocking plate attached to the switching shaft. Printing with the

transfer belt lowered is called monochrome mode and color printing

is called color mode.

Expansion Paper Fee der

The optional expansion paper feeder can be installed at the lower

part of the main unit. Including the main unit, up to five layers of

cassettes can be used for cassette paper feeding.

1-16 Service Manual

Page 31

5055-01x

Duplex Unit

A duplex unit can be optionally installed in the main unit, allowing

two-sided printing.

Selecting Paper feeding, Registration, Transfer, Separation,

Fusing, or Face-Down pa per di s cha rgi ng w ith the pulse motor in

the duplex unit, feeding is stopped before the paper is delivered.

Paper delivery is then reversed and fed to the duplex unit.

Paper fed with the duplex unit stops once, and the center position is

corrected by the operation of the side guide plate. Paper is then refed by the printer controller signal to the main unit, and, following

printing on the back side, is delivered to the normal feeding path.

General Information 1-17

Page 32

5055-01x

Printi ng Mod e

Usually printing is performed in normal mode, OHP mode, thick

paper mode, and envelope/postcard mode. The mode is switched by

a command from the interface controller.

Mode Paper/Media Weight PPM (Color)

Normal 16 - 29 lb 28

Thick paper 32 lb (glossy) 22

Enve lope/postcard 90 lb or more 10

OHP Transparency 6

OHP Mode

OHP mode is used for improving color printing on transparencies.

With an overhead projector (OHP), light transmitted through OHP

paper (original document) projects an image on the lens. If the

smoothness of the surface of the toner image on the OHP paper is

too low, transmission is prevented due to the diffused reflection.

Images projected in color printing appear in monochrome.

When non-offset type color toner is used, the process speed in the

OHP mode is decreased, causing toner to melt sufficiently with the

fusing unit, while the fusing temperature is set higher than usual to

increase the smoothness on the surface of the toner image.

This mode restricts paper feeding to multi-paper feeding, not

cassette feeding.

Thick Paper Mode

Thick paper mode is used to improve print quality on thick paper.

(More than 105 g/m

1-18 Service Manual

2

(90kg)).

Page 33

5055-01x

Envelope / Postcard Mode

Envelope / postcard mode is used to improve printing quality on thick

paper of small width. In this mode, the fusing temperature is set

higher than usual and transfer voltage is switched according to the

temperature.

Operation Mode

Operation modes such as sleep mode and registration mode are

switched by command from the interface controller.

By carefully selecting print media and loading them properly, you

can avoid most paper jams. If jams do occur, follow the steps

outlined in this section.

To resolve the paper jam messages, you must clear the jammed

area and then press Go to clear the message and resume printing.

The printer prints a new copy of the page that jammed if Jam

Recovery is set to On or Auto; however, the Auto setting does not

guarantee the page will print.

General Information 1-19

Page 34

5055-01x

Clearing Paper Jams

200 Paper Jam <x> Pages Jammed (Check Areas A-F)

A 200 Paper Jam message indicates that paper is jammed. The

display alternates between 200 Paper Jam <x> Pages Jammed and

Check Areas A-F.

If there is a paper jam when you turn the printer on, the second line

of the 200 Paper Jam message will be blank. To res olve the

message, you must clear all paper from the paper path. Check and

clear areas A through F.

Check Areas A,B

This message indicates a paper jam in the transfer belt, fuser, or

output roller area. To clear areas A–B:

1. Open the top cover. Never touch the photodeveloper drum on

the underside of the toner cartridge. The paper may be covered

with un-fused toner, which can stain clothing.

2. Remove any paper on the transfer belt.

3. If the paper source was the multipurpose feeder, check the area

between the multipurpose feeder and the transfer belt. Do not

use any pointed objects to remove the paper. This could cause

permanent damage to the transfer belt.

4. Check the fuser area and top cover for additional jams.

5. If there is no jam in the fuser area or top cover, close the top

cover and front door, and then press Go. If a jam is present,

continue with step 4.

6. Lift the fuser pressure release lever and slowly pull the paper

out of the fuser toward the inside of the printer.

7. Rotate the fuser pressure release lever down.The top cover will

not close until the lever is in the down position.

8. Check the top cover for additional jams.

9. If there is no jam in the top cover, close the top cover and front

door, and then press Go.

10. Remove the jam from the top cover.

11. Close the top cover and the front door.

1-20 Service Manual

Page 35

5055-01x

Check Area C

Jams that cause a Check Area C message require opening the

duplex jam access door. If you are printing on small paper, the

following steps may not clear the jam. See “Removing Small Size

Pape r From the Dupl ex Uni t” on page 1-22.

1. Open the duplex jam access door on the right side of the printer.

2. Remove the jam.

3. Press Go.

Note: If the paper jam message continues, check and clear all

paper from the paper path.

Check Area D

This message indicates a paper jam in the duplex unit area. To clear

area D:

1. Open the duplex jam access door on the right side of the printer.

2. Gently pull out the duplex unit.

3. Tur n the paper forwarding dial counterclockwise. If the paper

advances out of the duplex unit, remove the jam and go to step

7. If the paper does not advance, go to step 4.

4. Open the duplex unit covers.

5. Remove the jam.

6. Close the duplex unit covers.

7. Push the duplex unit back into the printer.

8. Close the access door.

9. Press Go. If the paper jam message continues, check and clear

all paper from the paper path.

General Information 1-21

Page 36

5055-01x

Removing Small Size Paper From the Duplex Unit

When printing on both sides of A5 or other small size paper, you

may need to partially remove the duplex unit to clear the jam.

1. Turn off the printer.

2. Open the duplex unit door.

3. Loosen t he tw o screws.

4. Pull out the duplex unit far enough to see the duplex unit inlet.

5. Remove jam from the duplex unit inlet.

6. Slide the duplex unit in.

7. Align the thumbscrews on the duplex unit with the holes in the

printer.

8. Tighten the thumbscrews to secure the duplex unit.

9. Close the duplex unit door.

Check Area E

This message indicates a jam in the top, middle, or bottom optional

drawer paper path area. If you have a high capacity feeder, pull the

feeder away from the printer.

1. Open the jam access door on the top optional drawer.

2. Remove the jam.

3. Close the jam access door.

4. Open the jam access door on the middle optional drawer.

5. Remove the jam.

6. Close the jam access door.

7. Open the jam access door on the bottom optional drawer.

8. Remove the jam.

9. Close the jam access door.

10. Press Go.

Note: If the paper jam message continues, check and clear all

paper from the paper path.

1-22 Service Manual

Page 37

5055-01x

Check Area F

1. Pull the high capacity feeder away from the printer.

2. Open the jam access door on the top optional drawer.

3. Remove any jams.

4. Close the jam access door.

5. Slide the high capacity feeder until the feeder locks to the

docking frame. When the feeder is in the correct position, you

hear a click.

6. Press Go.

Note: If the paper jam message continues, check and clear all

paper from the paper path.

240 Paper Jam Check MP Feeder

1. Slowly pull the jam straight out of the multipurpose feeder. If the

paper will not come out, continue.

2. Open the top cover.

3. Remove the paper on the transfer belt.

4. Close the top cover.

5. Press Go.

24<x> Paper Jam Check Tray <x>

Jams in five areas result in a 24<x> Paper Jam message, where x

represents the tray number where the jam has occurred. Paper jam

messages 241–244 indicate a jam has occurred in one of the trays.

241-244 Paper Jam

1. Pull out the tray indicated on the display.

2. Remove any wrinkled or creased paper.

3. Push down on the remaining paper in the tray until the bottom

plate clicks into place.

4. Close the tray.

5. Press Go.

Note: If the paper jam message continues, check and clear all

paper from the paper path.

General Information 1-23

Page 38

5055-01x

249 Paper Jam Check Tray <x>

A 249 Paper Jam Check T ray <x> message indicates a jam has

occurred in the high capacity feeder.

1. Open the top cover.

2. Remove the jam.

3. Close the top cover.

4. Press Go.

1-24 Service Manual

Page 39

5055-01x

High Capacity Paper Feeder (HCPF)

Paper Feed and Separation Mechanism

The high capacity paper feeder consists of a tray and paper transfer .

The paper feed and separation mechanism uses a friction roller

separation and paper feed system with a non-contact magnet type

maintenance-free torque limiter.

When the paper feed clutch turns on, the paper feed roller shaft

rotates and the paper feed roller is driven with the one-way clutch.

The call roller rotates with the relay gears to feed the top paper. The

reverse roller rotates along with the paper feed roller.

During paper feed, if two sheets feed, the reverse roller rotates by

the torque limiter, returning the lower sheet. When the paper feed

sensor (reflection type sensor) detects the paper, the pickup

solenoid turns off to raise the call roller, transferring the paper to the

registration roller.

General Information 1-25

Page 40

5055-01x

Registration Operation

When the paper feed motor rotates, the transfer roller is driven with

relay gears. The reverse roller shaft rotates the gears on the paper

feed clutch in the direction of the arrow and stops b y the friction forc e

of the paper feed roller.

1-26 Service Manual

Page 41

5055-01x

Tray Up/Down Mechanism

The driving force of the tray motor transmits to the tray driving pulley

through the gears. Moving the tray moves up and down through the

tray driving belt. After the paper loads, and the top cover is set, the

pickup solenoid turns on to lower the call roller. When the tra y moves

up, the call roller is raised by the top surface of the paper, and the

shield plate on the up sensor is released from the up sensor which

turns off the tray motor.

Also, when the top surface of the paper lowers during printing and

the up sensor is shielded, the tray motor again rotates forward to

raise the paper.

General Information 1-27

Page 42

5055-01x

When the down button is pressed, the tray motor reverses to move

the tray down. During the down motion of the tray, as the top surface

of paper passes the paper level sensor, the tray motor stops. The

tray moves down by about 500 sheets. The down sensor detects the

tray lower limit position.

1-28 Service Manual

Page 43

5055-01x

Tray Up Condition

Tray up motion stops when the:

• Up sensor is OFF (not shielded)

• Power cord is connected and the joint SW is ON

• Up sensor is ON (shielded) during printing

• Top cover is closed, or when up sensor is ON

Tray Down Condition

Tray down motion stops when the:

• Paper level sensor is OFF

• Down button is pressed

• Paper end is detected

General Information 1-29

Page 44

5055-01x

Size Detection Mechanism

The paper size can be switched between A4 and letter (11 inches)

by changing the side fence position.

The paper size sensor 2 detects the fixing screw 2 at the A4

position.

The paper size sensor 1 detects the fixing screw 1 at the letter

position. Tray up motion stops when the up sensor is OFF, not

shielded.

1-30 Service Manual

Page 45

5055-01x

Residual Paper Detection Mechanism

The residual paper quantity in the tray is detected with four photo

interrupters. The quantity of pages remaining in the sheet feeder,

displays in the following increments:

• Near end, about 80 sheets

• About 300 sheets

• About 1,000 sheets

• About 2,000 sheets

General Information 1-31

Page 46

5055-01x

Paper End Detection

A reflection type sensor is provided on the top stay to detect the

paper top surface and the paper end.

1-32 Service Manual

Page 47

5055-01x

Maintenance Mode

DIP Switch Specifications

The DIP switches on the high capacity paper feed board have the

following functions:

• Function switching and initial setting of t he standard machine or

optional machine.

Function Switch Maintenance Switch

DIP

Switch

43 2 1

Description

OFF 1 Standard machi ne

ON XX

OFF X 2 Optional machine

ON X

initial s et ti ng

initial s et ti ng

• Maintenance switch (test mode selection) is valid without

connecting to the printer controller board.

Function Switch Maintenance Switch

DIP

Switch

43 2 1

OFF Test OFF mode

ON XX

OFF X Linear velocity 101

ON X

OFF XXLinear velocity 129

ON

T est paper feed

mode

(stand alone)

mm/s

Thick paper mode

mm/s

Plain paper mode

OFF X Linear velocity 180

ON X

mm/s

General Information 1-33

Page 48

5055-01x

• Test pap er feed operation.

1. Turn on the docking safety switch with a non-metallic object.

The interface cable with the printer controller board need not be

connected.

2. Close the top cover or manually activate the cover switch.

3. Load paper.

4. Wait until the paper tray stops and the pickup solenoid turns off

5. With the cover closed or with the cover switch activated, press

and hold the tray down button for more than 1/2 second. In

steps 1 and 2, paper feeding starts and is continuously fed until

the cover is opened. The test ends when the tray motor stops

and the paper ejects or the tray down button is released.

• Test Sequence

1. The tray motor moves the tray to the upper limit.

2. The pickup solenoid activates then de-activates.

3. When the tray down switch is pressed for longer than 1/2

second, the paper feed motor starts, the paper feed clutch

operates and feeding begins.

4. Feeding can be stopped by releasing the tray down button.

1-34 Service Manual

Page 49

5055-01x

High Capacity Paper Feed Sensor / Switch Test

The condition of each sensor can be checked from the lighting of

LEDs on the high capacity paper feed board. When each sensor

operates with the power supplied, the associated LED lights.

To perform the test:

Interrupt the photointerrupter sensor signal or actuate the micro-

switch being tested while observing the associated LED on the high

capacity paper feed board.

LED Sensor Name

1 Paper size sensor 1 switch (letter size 11 inches)

2 Paper size sensor 1 switch (A4 size)

3 Residual paper sensor 1 switch

4 Residual paper sensor 2 switch

5 Residual paper sensor 3 switch

6 Residual paper sensor 4 switch

7 Paper le vel sensor switch

8 Lower limit switch

9 Cover open sensor switch

10 Docking sensor switch

11 Upper limit switch

12 Paper sens or switch

13 Paper feed sensor switch

General Information 1-35

Page 50

5055-01x

1-36 Service Manual

Page 51

5055-01x

2. Diagnostic Information

The diagnostic information in this chapter leads you to the failing

part. Before you replace an entire assembly, determine if just the

defective part is available in the parts catalog. Use the error code

tables, symptom table, service checks and the diagnostic aids

chapter to determine the symptom and repair the failure. The

removal procedures in the Repair Information chapter may help you

identify parts. After you complete the repair, perform the appropriate

tests to ver i fy the rep a i r.

If an error is displayed, locate it in the “Service Error Message

Table” on pag e 2-4, the “Attendance Messages g” on page 2-25,

or the “Symptom Table” on page2-52 and take the appropriate

action.

If an error message appears while you are working on the printer, go

to the error message table and take the indicated action.

Adjustments and Procedures Following Parts

Replacement

Note: When trouble shooting, or prior to making any adjustment to

print quality, always be sure:

• The printer is installed on a level rigid surface.

• The photodevelopers are never exchanged. Do not exchange a

black photodeveloper for a color photodeveloper, as they have

different surface phase counts.

• The Alignment Page is used when adjusting print registration.

Whenever you replace any of the following parts be sure to perform

the required adjustments or procedures. The adjustments are in the

Repair Information and Diagnostic Aids chapters.

Diagnostic Information 2-1

Page 52

5055-01x

Printer Controller Board/Prin ter Contr ol EPROM (U5)

If you replace the printer controller board, remove EPROM (U5) and

install it on the new board. Also check the printhead alignment.

If you change the EPROM, the following items must be checked and

adjusted in the diagnostic mode.

• LED Printhead Light Quantity

• Printer Alignment (X, Y, and Theta)

• Counters

• Configuration ID

RIP Controller Board

If you replace the RIP controller board be sure to move the solid

state drive, memory, and option cards from the old card to the new

one.

Transfer Belt

If you replace the transfer belt, check the printer alignment (X, Y, and

Theta), adjusted in diagnostic mode.

LED Printhead Controller Board or LED Printhead

If you replace the LED printhead controller board or LED printhead,

the following items must be checked and adjusted in diagnostic

mode:

• LED printhead light quantity

• Printer alignment (X, Y, and Theta)

2-2 Service Manual

Page 53

5055-01x

Start

Initial Check

Before you start troubleshooting, check the following:

Installation Environment

• The power supply line voltage is plus or minus 10% of the rated

line voltage.

• The machine is securely installed on a level surface in a well-

ventilated place.

• The room temperature is between 10 and 32°C (50 and 90°F)

and the relative humidity between 20 and 80%.

• Avoid sites generating ammonia gas, high temperature, high

humidity (near water faucets, kettles, humidifiers), cold spaces,

near open flames, and dusty areas.

• A void sites exposed to direct sunlight.

Print Paper Checks

• Be sure to use the recommended paper for this printer.

• Check the paper for dampness. Make a trial print with paper

from a newly opened package, and check the result.

Diagnostic Information 2-3

Page 54

5055-01x

Printer Messages

The printer displays three types of messages: service messages,

status messages, and attendance messages. Service messages

indicate a problem that requires a service technician. Status

messages provide information about the current state of the printer,

requiring no action. Attendance messages alert the operator to

printer problems that require operator intervention.

Service Error Message Table

900 - Unrecoverable Software Error (Operator Manual)

910 Ser v ice

Motor Error

910 - Drive Motor Error

Step

1

2

3

4

5

Question s /

Actions

Are connectors CN1

and CN5 on the motor

drive board connected

properly?

Is connector CN33 on

the printer controller

board connected

properly?

Is there an abnormal

load on the toner or

drum unit?

Did replacement of the

printer controller board

solve the problem?

Did replacement of the

motor drive board

solve the problem?

Yes No

Go to step 2. Connect CN1

and CN5.

Go to step 3. Connect CN33.

Replace the

toner or drum

unit.

Problem

solved.

Problem

solved.

Replace the

printer controller

board and go to

step 4.

Replace the

motor drive

board and go to

step 5.

Replace the

drive motor.

2-4 Service Manual

Page 55

5055-01x

911 - Paper Exit Motor Error

Step

1

2

Questions /

Actions

Is connector CN4 on

the printer controller

board securely

connected?

Did replacement of the

paper exit motor solve

the problem?

Yes No

Replace the

paper exit

motor and go to

step 2.

Problem solved. Replace the

Plug the

connector in

securely.

printer controller

board.

912 - High Capacity Paper Feed Motor Error

Step

1

Questions /

Actions

Is connector CN40 on

the printer controller

board securely

connected?

Yes No

Go to “High

Capacity Paper

Feed (HCPF)

Service

Check” on

page 2-57.

Plug the

connector in

securely.

Diagnostic Information 2-5

Page 56

5055-01x

917 - RIP Fan Error

917 Ser v ice

Fan Error

Step Questions / Actions Yes No

Is connector J5 on the

1

RIP board connected

properly?

2 Is 24 V dc present

between pins 1 and 3 of

connector J5 on the RIP

board?

Go to step 2.

Replace the RIP

fan.

Properly

connect J5.

Replace the

RIP board.

918 - Main Unit Fan Error

Step Questions / Actions Yes No

1 Is +24 V present betwe en

pins 1 and 3 on

connectors CN17 (upper

left fan) and CN5 (upper

right fan) on the printer

controller board?

Replace the failing

fan.

Replace the

printer

controller

board.

919 - Power Supply Fan Error

Step Questions / Actions Yes No

1 Is +24 V present betwe en

pins 1 and 3 of connector

CN6 on the printer

controller board?

2-6 Service Manual

Replace the power

supply fan.

Replace the

printer

controller

board.

Page 57

5055-01x

920 - Fuser Error - Fuser Heater Trouble

92x Service

Fuser E rror

Step

1 Replace the fuser.

2 Did replacing

Questions /

Actions

Did thi s fix the

problem?

power supply 2 fix

the problem?

Yes No

Problem solved. Return the fuser,

replace the power

supply 2 and go to

step 2.

Problem solved. Return power supply

2 and replace the

printer controller

board.

923 - Upper Fuser Thermistor Open Error

Step

1 Is connector CN44

2 Is error 923

Questions /

Actions

on the printer

controller board

connected

properly?

displayed?

Yes No

Disconnect CN44

and turn the printer

on.

Go to step 2.

Power off and

reconnect CN44.

Go to step 3.

Plug the connect or in

securely.

Replace the printer

controlle r board.

3 Power the printer

off and short pins

1 and 4 of CN44

and power on. Is

error 923

displayed?

Replace the fuser. Replace the printer

controlle r board.

Diagnostic Information 2-7

Page 58

5055-01x

924 - Lower Fuser Thermistor Open Error

Step

1 Is connect or CN44

2 Is error 924

3 Power the printer

Questions /

Actions

on the printer

controller board

connected

properly?

displayed?

off and short pins

8 and 11 of CN44

and turn the

printer on.

Is error 924

displayed?

Yes No

Disconnect CN44

and turn the printer

on.

Go to step 2.

Turn the printer off

and reconnect

CN44.

Go to step 3.

Replace the fuser. Replace the printer

925 - High Pressure Controller Error

Step

Questions /

Actions

Yes No

Plug the connector i n

securely.

Replace the printer

controller board.

controller board.

1 Is connect or CN42

on the printer

controller board

connected

properly?

2 Did replacing the

printer controller

board fix the

problem?

2-8 Service Manual

Replace the printer

controller board.

Go to step 2.

Problem solved. Replace the high

Plug the connector i n

securely.

voltage power board

(HVU).

Page 59

5055-01x

926(K), 927(C), 928(Y), 929(M) - Toner Sensor Error

92x Service

Toner Sensor

Step

1 Is the ton er c artridg e

2 Is the ton er c artridg e

3 Replace the toner

4 Test the sensors.

Questions /

Actions

the cor re c t ty p e for

the printer?

encoder wheel dirty?

cartridge for the

color with the error.

Did this fix th e

problem?

While actuatin g the

sensor, does the

voltage fluctuate

between

0 V and +5 V

between pins 1 and

2 on connectors

CN22(K), CN21(Y),

CN18(M), and

CN19(C) on the

printer controller

board?

Yes No

Go to step 2. Recommend the

customer replace

the cartridge with

the correct type.

Clean the encoder

wheel and toner

sensor.

Problem solved. Go to step 4.

Replace the printer

controller board.

Go to step 3.

Replace the

affected toner

sensor.

Diagnostic Information 2-9

Page 60

5055-01x

930 - Yellow Printhead Error

930 Ser v ice

Printhead Error

Step

1 Is fuse 5 on the

Questions /

Actions

printhead control

board open?

Replace the

printhead control

board, cables, and

LED printhead.

931 - Magenta Printhead Error

Step

1 Is fuse 6 on the

Questions /

Actions

printhead control

board open?

Replace the

printhead control

board, cables, and

LED printhead.

932 - Cyan Printhead Error

Step

Questions /

Actions

Yes No

Replace the

printhead

controller board.

Yes No

Replace the

printhead controll er

board.

Yes No

1 Is fuse 3 on the

printhead control

board open?

2-10 Service Manual

Replace the

printhead control

board, cables, and

LED printhead.

Replace the

printhead controll er

board.

Page 61

5055-01x

933 - Black Printhead Error

Step

1 Is fuse 4 on the

Questions /

Actions

printhead control

board open?

Replace the

printhead control

board, cables , and

LED printhead.

934 - Color Drum Sensor Error

934 Servic e

Drum Sensor

Step

1 Is connector CN28

2 Clean the color drum

3 Did replacing the

Question s /

Actions

Go to step 2. Plug the connector

connected properly?

Problem solved. Replace the color

sensor LED. Did this

fix the prob lem?

Problem solved. Replace the

color drum sensor f ix

the problem?

Yes No

Replace the

printhead

controller board.

Yes No

in securely.

drum sensor.

Go to step 3.

printer controller

board.

Diagnostic Information 2-11

Page 62

5055-01x

935 - Black Drum Sensor Error

Step

1 Is connector CN27

2 Clean the black

3 Did replacing the

Questions /

Actions

connected properl y?

drum sensor LED.

Did thi s fix the

problem?

black drum sensor

fix the problem?

936 - 939 Cassette Error

936 Ser v ice

Paper Option

Step

1 Are connectors

Questions /

Actions

CN35 and CN36

on the printer

controller board

connected

properly?

Yes No

Go to step 2. Plug the connector

in securely.

Problem solved. Replace the black

drum sensor.

Go to step 3.

Problem solved. Replace the printer

controller board.

Yes No

Replace the printer

controller board.

Plug the connector i n

securely.

2-12 Service Manual

Page 63

5055-01x

940 - High Capacity Paper Feed Sensor Error

Step

1 Is connector CN40

Questions /

Actions

on the printer

controller board

connected properly?

Yes No

Go to “High

Capacity Paper

Feed (HCPF)

Service Check” on

page 2-57.

941 - High Capacity Paper Feed Tray Error

Step

1

Questions /

Actions

Is connector CN40

on the printer

controller board

connected properly?

Yes No

Go to “High

Capacity Paper

Feed (HCPF)

Service Check”

on page 2-57.

942 - Duplex Error

942 Servic e

Duplex

Plug the con nector

in secure ly.

Plug the con nector

in secure ly.

Step

1 Is connector CN37

Questions /

Actions

on the printer

controller board

connected properly ?

Yes No

Replace the printer

controller board.

Diagnostic Information 2-13

Plug the connect or

in securely.

Page 64

5055-01x

945 - Engine Flash Error

945 Ser v ice

Engine Flash

Reflash the engine code.

946 - Printer / Printhead Controller Board

Communication Error

946 Ser v ice

Communication

Step

1

Questions /

Actions

Replace the

printhead controller

board. Did this f ix the

problem?

Yes No

Problem solved. Repla ce the

printer controller

board.

2-14 Service Manual

Page 65

5055-01x

948 - Machine ID Error

948 Servic e

Machine ID

Step

1 Turn the printer off

2 Are the EPROMs

3 Did replacing the

Question s /

Actions

and wai t 30 second s.

Turn the printer on.

Did this fix the

problem?

installed correctly?

printer controller

board fix the

problem?

952 - NVRAM Chip Failure

952 Servic e

NVRAM Failure

Yes No

Problem solved. Verify proper

installat ion of th e

EPROMs on both

the printer

controller board

and the printhead

controller board.

Go to step 2.

Replace the printer

controller board.

Go to step 3.

Problem solved. Replace the

Install the

EPROMs

correctly.

printhead

controller board.

Replace the printer controller board.

954 - NVRAM CRC Failure

Replace the RIP board.

955 - Code CRC

955 Servic e

Code CRC <loc>

Replace the RIP board.

Diagnostic Information 2-15

Page 66

5055-01x

956 - Processor Failure

956 Ser v ice

System Board

Replace the RIP board.

957 - ASIC Failure

Replace the RIP board.

958 - NAND Failure

958 Ser v ice

NAND Failure

Replace the RIP board.

960 - RAM Slot 1 Bad

960 Ser v ice

RAM Memory Error

Replace RAM Card or the RIP board.

961 - RAM Slot 2 Bad

Replace RAM Card or the RIP board.

962 - RAM Slot 3 Bad

Replace RAM Card or the RIP board.

964 - Emulation Error