Page 1

Card for IPDS and SCS/TNe

IPDS Emulation

User’s Guide

Printers Multifunction Products

• Lexmark C770, C772

• Lexmark C780, C782

• Lexmark C920

• Lexmark C935

• Lexmark T640, T642, T644

• Lexmark W840

• Lexmark X644e MFP, X646e MFP

• Lexmark X646ef MFP

• Lexmark X782e MFP

• Lexmark X850e MFP, X852e MFP, X854e MFP

• Lexmark X940e MFP, X945e MFP

Page 2

nd

2

edition, October 2007, E.C. 20G429

© Copyright Lexmark International, Inc., 2007

All rights reserved.

© Copyright Intermate A/S, 2007

Notice……………………………………..……………………..

The following paragraph does not apply to any country where such provisions are inconsistent with local

law:

LEXMARK INTERNATIONAL, INC. AND INTERMATE A/S PROVIDE THIS PUBLICATION "AS

IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied warranties in

certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically

made to the information herein; these changes will be incorporated in later editions. Improvements or

changes in the products or the programs described may be made at any time.

Trademarks and Credits

AFP, AIX, AS/400, IBM, iSeries, MVS, OS/2, OS/390, OS/400, Print Services Facility, PSF, System/390,

zSeries, and z/OS are trademarks of International Business Machines Corporation in the United States,

other countries, or both.

InfoPrint, Infoprint, Intelligent Printer Data Stream, IPDS, Bar Code Object Content Architecture and

BCOCA are trademarks or registered trademarks of Ricoh Co., Ltd. in the United States, other countries,

or both.

Lexmark and Lexmark with diamond design, MarkNet, and MarkVision are trademarks of Lexmark

International, Inc. registered in the United States and/or other countries.

Intermate is a trademark of Intermate A/S.

PCL is a registered trademark of the Hewlett-Packard Company.

PostScript is a registered trademark of Adobe Systems Incorporated.

Barcode Engine for Data Matrix, MaxiCode, and QR Code by TEC-IT Datenverarbeitung GmbH,

www.tec-it.com.

This product is based in part on the work of the Free Type Project.

Other trademarks are the property of their respective owners.

2

Page 3

Table of Contents

Notice……………………………………..…………………….............................................................2

Trademarks and Credits .......................................................................................................................2

Table of Contents ................................................................................................................................... 3

1 Introduction...............................................................................................................................8

1.1 About This Guide........................................................................................................................8

1.2 Equipment Requirements and Specifications for IPDS Emulation Printing...............................8

1.3 Customer Support .......................................................................................................................9

1.4 Conventions Used in the Manual .............................................................................................. 10

2 Using the Operator Panel or Touch Screen for IPDS MENU Setup.................................. 11

2.1 IPDS MENU Setup Options vs. Printer Setup Options ............................................................11

2.2 Changing IPDS Settings Using the Operator Panel ..................................................................12

2.2.1 Accessing the IPDS MENU....................................................................................................12

2.2.2 Example: Selecting a New Value as a Setting........................................................................ 12

2.2.3 Example: Changing a Numerical Setting............................................................................... 14

2.2.4 Saved Option Changes Become Active on New Session ........................................................15

2.2.5 Printing the Menu Settings Page (printers) ...........................................................................15

2.3 Changing IPDS Settings Using the MFP Touch Screen ...........................................................16

2.3.1 Accessing the IPDS MENU....................................................................................................16

2.3.2 Example: Selecting a New Value as a Setting........................................................................ 16

2.3.3 Example: Changing a Numerical Setting............................................................................... 17

2.3.4 Saved Option Changes Become Active on New Session ........................................................17

2.3.5 Printing the Menu Settings Page (MFPs) .............................................................................. 18

3 Setup Operations Reference...................................................................................................19

3.1 IPDS MENU - Map of All Options...........................................................................................19

3.2 Overview of EMULATION Menu Options and Values ........................................................... 20

3.3 EMULATION – Options Descriptions ..................................................................................... 22

3.3.1 IPDS Emulation .....................................................................................................................22

3.3.2 Host Resolution ...................................................................................................................... 22

3.3.3 Color Processing ................................................................................................................... 23

3.3.4 Text Processing ...................................................................................................................... 23

3.3.5 Toner Saver ............................................................................................................................ 23

3.3.6 BAR CODE ............................................................................................................................23

3.3.6.1 Bar Code Symbol ................................................................................................................23

3.3.6.2 Bar Code Size......................................................................................................................24

3.3.7 DEFAULT CODEPAGE ........................................................................................................ 24

3.3.8 Codepage Version .................................................................................................................. 25

3.3.9 DEFAULT FGID.................................................................................................................... 25

3.3.10 Default CPI ............................................................................................................................25

3.3.11 Page Counter .........................................................................................................................25

3.3.12 Printable Area........................................................................................................................26

3.3.13 Exception Control ..................................................................................................................27

3

Page 4

3.3.14 Font Control........................................................................................................................... 27

3.3.15 Font Type ...............................................................................................................................27

3.3.16 IPDS Print Res ....................................................................................................................... 28

3.3.17 Intervention Required ............................................................................................................ 28

3.3.18 IPDS Timeout .........................................................................................................................29

3.3.19 Print IPDS Fonts.................................................................................................................... 30

3.3.20 Trace Functions .....................................................................................................................31

3.3.21 IPDS Version ......................................................................................................................... 31

3.4 Overview of PAPER HANDLING Menu Options and Values ................................................32

3.5 PAPER HANDLING Menu – Option Descriptions.................................................................. 33

3.5.1 IPDS Blank Pages..................................................................................................................33

3.5.2 Offset Stacking .......................................................................................................................33

3.5.3 UNIVERSAL SIZE..................................................................................................................33

3.5.4 OTHER ENV SIZE ................................................................................................................. 34

3.6 MAP INPUT TRAYS Menu Options ....................................................................................... 37

3.7 MAP OUTPUT BINS Menu Options ....................................................................................... 40

3.7.1 Descriptions of Output Bin Values......................................................................................... 40

3.7.2 Descriptions of IPDS Bin Selection Numbers........................................................................41

3.7.3 Default Bin Mapping.............................................................................................................. 41

3.8 MARGINS Menu Options ........................................................................................................42

3.8.1 ALL INPUT TRAYS Menu......................................................................................................44

3.8.2 TRAY 1 ADJUST Menu .......................................................................................................... 44

3.8.3 TRAY 2 ADJUST Menu .......................................................................................................... 45

3.8.4 TRAY 3 ADJUST Menu .......................................................................................................... 45

3.8.5 TRAY 4 ADJUST Menu .......................................................................................................... 45

3.8.6 TRAY 5 ADJUST Menu .......................................................................................................... 46

3.8.7 MP FEEDER ADJUST Menu ................................................................................................ 46

3.8.8 ENV FEEDER ADJ Menu......................................................................................................46

3.8.9 MANUAL PAPER ADJ Menu ................................................................................................47

3.8.10 MANUAL ENV ADJ Menu ..................................................................................................... 47

3.9 Overview of the FONT CAPTURE Menu Options .................................................................. 48

3.10 FONT CAPTURE Menu Options .............................................................................................49

3.10.1 Capture Fonts ........................................................................................................................49

3.10.2 Remove Fonts ......................................................................................................................... 49

4 Duplex Printing Using Preprinted Media ............................................................................. 50

5 Finishing Support.................................................................................................................... 51

5.1 Offset Stacking.......................................................................................................................... 53

5.1.1 AS/400 and iSeries Offset Stacking ........................................................................................ 53

5.1.2 Mainframe Offset Stacking..................................................................................................... 54

5.2 Stapling .....................................................................................................................................56

5.2.1 AS/400 and iSeries Stapling...................................................................................................56

5.2.1.1 Lexmark C772, C782, C920, T640, T642, T644, X646ef MFP, and X782e MFP Optional

Finisher...............................................................................................................................

5.2.1.2 Lexmark C935, W840, X850e MFP, X852e MFP, X854e MFP, X940e MFP, and X945e MFP

Optional Standard Finisher ................................................................................................

5.2.1.2.1 Corner Staple ......................................................................................................................58

5.2.1.2.2 Dual Staple (IPDS Edge stitch with 2 staples)....................................................................59

5.2.1.3 Lexmark C935, X940e MFP, X945e MFP, X850e MFP, X852e MFP, and X854e MFP

Optional Advanced Finisher Functions ..............................................................................

4

57

58

60

Page 5

5.2.1.3.1 Double Dual Staple (IPDS Edge Stitch with four staples) .................................................. 61

5.2.1.3.2 Center Fold (IPDS Center Fold-in) ....................................................................................62

5.2.1.3.3 Saddle Staple (IPDS Saddle stitch-in).................................................................................62

5.2.2 Mainframe Stapling................................................................................................................ 63

5.2.2.1 Lexmark C772, C782, C920, T640, T642, T644, X646ef MFP, and X782e MFP Optional

Finisher...............................................................................................................................

5.2.2.2 Lexmark C935, W840, X850e MFP, X852e MFP, X854e MFP, X940e MFP, and X945e MFP

Optional Standard Finisher ................................................................................................

5.2.2.3 Lexmark C935, X940e MFP, X945e MFP, X850e MFP, X852e MFP, and X854e MFP

Optional Advanced Finisher Functions ..............................................................................

5.3 Hole Punching...........................................................................................................................66

5.3.1 Hole Punching From an Input Source ................................................................................... 66

5.3.2 Hole Punching to an Output Bin............................................................................................67

6 IPDS Job Cancel...................................................................................................................... 68

6.1 Canceling IPDS Jobs................................................................................................................. 68

6.2 How to Cancel a Job Using the Printer Operator Panel ............................................................ 68

6.3 How to Cancel a Job Using the MFP Touch Screen ................................................................. 69

7 Working with Captured Fonts...............................................................................................70

7.1 Capture Font and Remove Font ................................................................................................ 70

7.2 Preparing Fonts for Capture......................................................................................................70

7.2.1 Capturing Fonts from an AS/400 or iSeries........................................................................... 71

7.2.1.1 Program Requirements .......................................................................................................71

7.2.1.2 Making Fonts Eligible for Capture on the Host ................................................................. 71

7.2.2 Capturing Fonts from a Mainframe Host ..............................................................................72

7.2.2.1 Mainframe Program Requirements .................................................................................... 72

7.2.2.2 Making Fonts Eligible for Capture on a Mainframe .......................................................... 72

63

64

65

8 Remote Configuration of Printer IPDS Settings .................................................................. 76

8.1 Why Use a Browser ..................................................................................................................76

8.2 Remote Configuration Using a Browser ................................................................................... 76

8.3 Functions that Can Not be Operated Remotely......................................................................... 77

9 Printer Messages and Problems............................................................................................. 78

10 Command Reference............................................................................................................... 79

10.1 XOA Print Quality Control ....................................................................................................... 79

10.2 XOH OPC Product Identifier Self Defining Field ....................................................................80

10.3 Finishing Operations Self-Defining Field ................................................................................. 81

10.4 N-up Printing............................................................................................................................. 81

10.5 Color and Simulated Grey Scale Printing ................................................................................. 82

10.6 TrueType Fonts ......................................................................................................................... 82

10.7 Object Container Support.......................................................................................................... 82

10.8 IO Images as Resources ............................................................................................................ 82

10.9 Media Reporting by Object ID (OID) ....................................................................................... 83

11 Warranty..................................................................................................................................85

5

Page 6

Appendices……………………………………....................................................................................86

A. Technical Specifications ......................................................................................................... 87

A.1 Product Description...................................................................................................................87

A.2 IPDS Features List .................................................................................................................... 87

A.3 For Direct Network Attachment................................................................................................ 88

A.4 For Direct Twinaxial Attachment .............................................................................................89

A.5 For Direct Coaxial Attachment ................................................................................................. 90

B. Font and Code Page Information ..........................................................................................91

B.1 International Language Definitions...........................................................................................91

B.1.1 Latin 1 .................................................................................................................................... 91

B.1.2 Latin 2/ROECE, Latin 3, Latin 4, Latin 5..............................................................................91

B.1.3 Cyrillic and Greek.................................................................................................................. 92

B.1.4 Arabic and Hebrew ................................................................................................................ 92

B.1.5 Japanese (non-Latin) .............................................................................................................92

B.2 About the Three Types of Supported Font Sets........................................................................92

B.3 Compatibility Font Sets.............................................................................................................93

B.3.1 4028 Compatibility Font Set - 300 dpi bitmap fonts (Resident Emulation)...........................93

B.3.2 3812/3816 Compatibility Font Set - 240 dpi bitmap fonts.....................................................95

B.4 IBM Core Interchange Scalable Font Set..................................................................................97

B.5 IBM Core Interchange Font Set Code Page Support ................................................................98

B.5.1 Latin 1 Country Extended Code Pages .................................................................................. 98

B.5.2 Latin 1 EBCDIC Publishing Code Pages ..............................................................................99

B.5.3 Latin 1 ASCII Code Pages ..................................................................................................... 99

B.5.4 Latin 2, 3, 4, 5, and 9 Code Pages ......................................................................................... 99

B.5.5 Latin EBCDIC DCF Code Pages......................................................................................... 100

B.5.6 Cyrillic and Greek Code Pages ...........................................................................................100

B.5.7 Arabic Code Pages...............................................................................................................101

B.5.8 Hebrew Code Pages............................................................................................................. 101

B.5.9 Symbol Code Pages.............................................................................................................. 101

B.6 IBM Coordinated Font Set ...................................................................................................... 102

B.6.1 OCR Scalable Font Set ........................................................................................................102

B.7 POSTNET Font Support .........................................................................................................103

B.8 Font Substitution ..................................................................................................................... 104

B.8.1 Resident Emulation Font Substitution.................................................................................. 104

B.8.2 3812/3816 Emulation Font substitution............................................................................... 105

C. Bar Code Support: Linear (1-D) Bar Codes ....................................................................... 106

D. Bar Code Support: 2-D Bar Codes ......................................................................................113

D.1 Data Matrix Special Function Parameter Support...................................................................114

D.2 MaxiCode Special Function Parameter Support ..................................................................... 115

D.3 PDF417 Special Function Parameter Support......................................................................... 115

D.4 QR Code (Quick Response Code)........................................................................................... 115

E. Printing DBCS Characters...................................................................................................117

F. Memory Requirements and Recommendations .................................................................118

6

Page 7

G. Related Publications .............................................................................................................121

H. Glossary..................................................................................................................................122

Index ……………………………………...........................................................................................124

7

Page 8

1 Introduction

1.1 About This Guide

Thank you for purchasing the Card for IPDS and SCS/TNe which provides emulation support for

Intelligent Printer Data Stream (IPDS) and SNA Character String (SCS). This provides high quality IBM

host connectivity print output. With the appropriate adapter and host software, your printer becomes an

IBM host workstation printer capable of printing AFP, IPDS, or SCS documents from an AS/400, iSeries,

System/370, System/390, or zSeries. Unless otherwise stated, the term “printer” covers both printers

and Multifunction Products (MFPs).

This guide contains information to assist you in using the front panel to change IPDS MENU settings,

understand the IPDS MENU settings, and IPDS function support.

If you need information on configuring the printer and host settings to receive IPDS jobs, refer to the

IPDS Printer and Host Setup Guide.

If you need information on the SCS/TNe emulation provided with the Card, please refer to the SCS/TNe

Emulation User’s Guide.

Information on how to install the Card is on separate documentation shipped with your printer. Refer to

the documentation that was shipped with your printer for information on how to install the Card.

If you need basic information about your printer setup and printer operation, please refer to the printer’s

specific documentation.

1.2 Equipment Requirements and Specifications for IPDS Emulation Printing

This manual applies to the following printers:

• Lexmark C770, C772 (IPDS color and monochrome printing, SCS monochrome printing only)

• Lexmark C780, C782 (IPDS color and monochrome printing, SCS monochrome printing only)

• Lexmark C920 (IPDS color and monochrome printing, SCS monochrome printing only)

• Lexmark C935 (IPDS color and monochrome printing, SCS monochrome printing only)

• Lexmark T640, T642, T644

• Lexmark W840

This manual applies to the following Multifunction Products (MFPs):

• Lexmark X644e MFP, X646e MFP

• Lexmark X646ef MFP

• Lexmark X782e MFP (IPDS color and monochrome printing, SCS monochrome printing only)

• Lexmark X850e MFP, X852e MFP, X854e MFP

• Lexmark X940e MFP, X945e MFP (IPDS color and monochrome printing, SCS monochrome

printing only)

To print IPDS jobs, the printer must have the optional Card for IPDS and SCS/TNe installed, a minimum

of 64 MB of user memory (DRAM), and one of the following:

• Standard Network (Ethernet connection integrated into printer system board on selected printer

models)

8

Page 9

• MarkNet internal LAN print server (optional card providing Ethernet or Fiber network connection)

• Lexmark 802.11g Wireless Print Adapter

• Coax/Twinax Adapter for SCS internal adapter for connection to a host via coax or twinax cables.

Refer to the IPDS Printer and Host Setup Guide for a list of printers that support this adapter.

1.3 Customer Support

Information on how to configure the host and printer during the initial installation is found in the Card for

IPDS and SCS/TNe IPDS Printer and Host Setup Guide.

If you can not find answers in this guide about using the IPDS emulation, or require firmware updates,

please contact your point of purchase, your local Lexmark office, or check the Lexmark support web site

http://support.lexmark.com

at

9

Page 10

1.4 Conventions Used in the Manual

• Printer menu keys and operator panel texts are written in bold.

Option names usually correspond to menu texts and are bold when used in sentences or shown as

••

the first column on a table listing options and general descriptions of the listed options.

• ”Option values” described within sentences are written in “quotation marks”. They are bolded

when shown as the first column on a table describing values for an option.

• Some book titles are written in italic.

On screen text is written in Courier typeface.

•

• Keyboard keys are written in angle brackets, e.g. <Enter> or <F1>.

• Bold is sometimes used for emphasis or as subheaders for blocks of text within a section.

• Italics are used to label Examples, Notes and blocks of text with very Important information.

• Unless otherwise stated, the term “printer” covers both printers and MFPs.

10

Page 11

2 Using the Operator Panel or Touch Screen for IPDS

MENU Setup

The IPDS emulation option settings may be changed from the control panel (either the printer operator

panel or MFP touch screen), from a browser, or from MarkVision Professional. This section of the guide

shows how to change and save option settings using the operator panel. If you are familiar with changing

IPDS options, skip this chapter. See

values for each option.

The following sections show how to change, save, and verify option settings:

2.2 Changing IPDS Settings Using the Operator Panel on page 12

•

•

2.3 Changing IPDS Settings Using the MFP Touch Screen on page 16

0

• Remote Configuration of Printer IPDS Settings on page

Note: Please refer to your printer's documentation for more detailed instructions on how to use the

operator panel. The layout of the operator panel may vary on the different models.

Note: Printer IPDS settings are for the most part used as default. They are only used in the absence of

specific instructions from the host. Thus, the settings you choose from your IPDS print job may

override default settings, including those you set yourself.

3 Setup Operations Reference on page 19 for a listing of all possible

76

2.1 IPDS MENU Setup Options vs. Printer Setup Options

Changes to the option settings under the IPDS MENU will only affect the way IPDS jobs print. These

changes will not affect PostScript™, PCL™, or SCS jobs.

Changes to printer settings under the various printer menus will affect the way PostScript and PCL jobs

are printed. Many of these printer settings will also affect IPDS jobs.

This guide discusses changing the IPDS MENU settings. Please refer to your printer's documentation for

information on changing other printer settings.

Refer to the SCS/TNe Emulation User's Guide for information on setting up and using the SCS/TNe

emulation.

11

Page 12

2.2 Changing IPDS Settings Using the Operator Panel

2.2.1 Accessing the IPDS MENU

Access the IPDS emulation options and settings from the IPDS MENU on the printer. To reach the

menu:

1. From a Ready status, press the Menu button

in the operator panel’s screen.

2. Use the navigation buttons

screen.

3. Each time you press a navigation button

choice that will be active when you select it.

4. When

5. When

The same method is used to scroll through lists of menus and options. As you move through the menus,

the top line in the screen shows the name of the group (menu or option) to which the displayed items

(options or settings) belong.

When you select an option, you will either scroll through the list of values presented, as shown in section

2.2.2, on page 12, or enter a number through one of the methods shown in section 2.2.3 on page 14.

9 is displayed next to the Option Card Menu, press the Select button .

9 is displayed next to IPDS MENU, press .

or to scroll through the main menus displayed on the

or , the 9 on the screen moves to indicate the

on the operator panel. This opens the menu index

User-selected default settings remain in effect until you save new settings or restore the factory defaults.

Concerning activation, see section

2.2.4 on page 15.

2.2.2 Example: Selecting a New Value as a Setting

1. Navigate to the IPDS MENU as explained in section

2. Press

12

or to scroll to the desired menu. The names of menus are shown in all capital letters.

Press

In the following example, you select EMULATION, which happens to be the first on the list.

.

2.2.1 on page 12.

Page 13

IPDS MENU

9 EMULATION

PAPER HANDLING

MAP INPUT TRAYS

3. Press or to scroll further until 9 is next to the item you need. Press .

In the following example, you select an option called Host Resolution.

EMULATION

IPDS Emulation

9 Host Resolution

Color Processing

4. Press

or to scroll further until 9 is next to the item you need. Press .

In the following example you select an option setting – “300 dpi” – in the following manner:

The * (asterisk) beside Auto means that Auto is the currently active setting. (It also happens to be

factory default in this example.) Scroll so that

Host Resolution

9 is next to 300 dpi and press .

* Auto

9 300 dpi

240 dpi

5. While the printer is saving the setting, it will display Submitting Selection.

6. When the setting is saved, the display will revert to the previous menu level.

EMULATION

IPDS Emulation

9 Host Resolution

Color Processing

If you want to check the value of the setting, press

currently active setting; in this example “300 dpi”.

Press the Back button

7. If you need to make additional settings within the same menu – such as EMULATION, scroll

through the list. To reach another menu, such as MAP OUTPUT BINS, press

in order to leave the screen without changing the setting.

again. You will see an asterisk * beside the

.

13

Page 14

8. When you are finished, exit by pressing

it several times until Ready appears.

to return to the Ready screen. You may need to press

2.2.3 Example: Changing a Numerical Setting

Example: If you select Option Card Menu > IPDS MENU > MARGINS > TRAY1 > ADJUST Top

Margin, you see the following display:

Top Margin

0

You can either use the numeric pad or the navigation buttons

the value. Press

When the setting is saved, the display will revert to the previous menu level.

MARGINS

to decrease a value or to increase

to save the desired value.

9 Top Margin

Left Margin

Top Margin Back

Some numerical values contain more than one field. For example, Option Card Menu > IPDS MENU >

EMULATION Default CPI.

Default CPI

10

The value before the decimal point and the value after the decimal point are set independently of each

other. Use the navigation buttons

marked with above the field and below it.

Default CPI

10

. 0

to move between the fields. The currently editable field is

. 0

14

Page 15

2.2.4 Saved Option Changes Become Active on New Session

All saved settings will become active on the next IPDS host session.

If the printer IPDS Timeout is NOT set to “Host Controlled” (Option Card Menu > IPDS MENU >

EMULATION > IPDS Timeout = “Host Controlled”), power the printer OFF and ON to activate the

new settings. For more information on IPDS Timeout, see page

29.

2.2.5 Printing the Menu Settings Page (printers)

Make sure the printer is ON..

11..

Press

22..

Press

33..

Menus

on the operator panel.

until the 9appears next to Reports, and then press .

Paper Menu

9Reports

Settings

4. Press

until the 9appears next to Menu Settings Page, and then press .

Reports

9 Menu Settings Page

Device Statistics

Network Setup Page

5. The message Printing Menu Settings is displayed.

6. The printer returns to Ready state after the list of current active settings prints.

15

Page 16

2.3 Changing IPDS Settings Using the MFP Touch Screen

2.3.1 Accessing the IPDS MENU

The IPDS emulation options and settings are accessed from the IPDS MENU. To reach the menu:

1. Make sure the printer is powered ON and the Ready message appears.

2. Touch the key icon (Menus)

3. Use the icons

4. Touch Option Card Menu.

5. Now you will see a list of options. Touch IPDS MENU.

The same method is used to scroll through lists of menus and options. As you move through the menus,

the top line in the screen shows the navigation path, so that you can always see the name of the group

(menu or option) to which the displayed items (options or settings) belong.

When you select an option, you will either scroll through the list of values presented, as shown in section

2.3.2 on page 16, or enter a number as shown in section 2.3.3 on page 17.

User-selected default settings remain in effect until you save new settings or restore the factory defaults.

Concerning activation of saved settings, see section

or to scroll through the main menus displayed on the screen.

on the touch screen.

2.3.4 on page 17.

2.3.2 Example: Selecting a New Value as a Setting

1. Navigate to IPDS MENU as explained in section

2. For this example, touch EMULATION, which happens to be the first option group on the list.

3. Now you will see a list of options. Touch

item you need. In this example, locate and touch Host Resolution.

4. Now you will see a list of settings. The currently active setting, in this example Auto, is always

presented first. Touch

this example locate and touch “300 dpi”.

orto scroll through the settings until you see the item you need. In

or to scroll through the options until you see the

2.3.1 on page 16.

5. Touch

Note: If you just want to check the active setting of an option without making changes, touch

6. While the printer is saving the setting, Submitting Selection will be displayed.

7. When the setting is saved, the screen will revert to the previous menu level.

16

(Submit).

(Back) and no changes will be saved.

Page 17

8. If you need to change multiple settings within the same menu – such as EMULATION, scroll

through the menu options and change the settings. When you touch

will be saved.

9. When you are finished in this list of menu options, exit by touching

previous menu level or

(Home) to return to the Ready state.

(Submit), all changes

(Back) to return to the

2.3.3 Example: Changing a Numerical Setting

Example: If you select Menus > Option Card Menu > IPDS MENU > MARGINS > TRAY1 >

ADJUST > Top Margin, you see the following on the screen:

Top Margin

Use the navigation icons,

save the desired value.

When the setting is saved, the screen will revert to the previous menu level.

0

to decrease the value orto increase a value. Touch (Submit) to

Some numerical values contain more than one field. For example, Menus > Option Card Menu > IPDS

MENU > EMULATION > Default CPI.

Default CPI 10

The value before the decimal point and the value after the decimal point are set independently of each

other. Set each field independently using the

. 0

above the field and/or the below it.

2.3.4 Saved Option Changes Become Active on New Session

All saved settings will become active on the next IPDS host session.

If the printer IPDS Timeout is NOT set to “Host Controlled” (Menus > Option Card Menu > IPDS

MENU > EMULATION > IPDS Timeout = “Host Controlled”), power the printer OFF and ON to

activate the new settings. For more information on IPDS Timeout, see page

29.

17

Page 18

2.3.5 Printing the Menu Settings Page (MFPs)

Make sure the printer is powered ON and the Ready message appears.

11..

2. Touch

3. Scroll down

4. Now you will see a list of items. Scroll down

5. The message Printing Menu Settings is displayed.

6. The printer returns to Ready state after the list of current active settings prints.

(Menus).

if necessary, then touch Reports.

if necessary, then touch Menu Settings Page.

18

Page 19

3 Setup Operations Reference

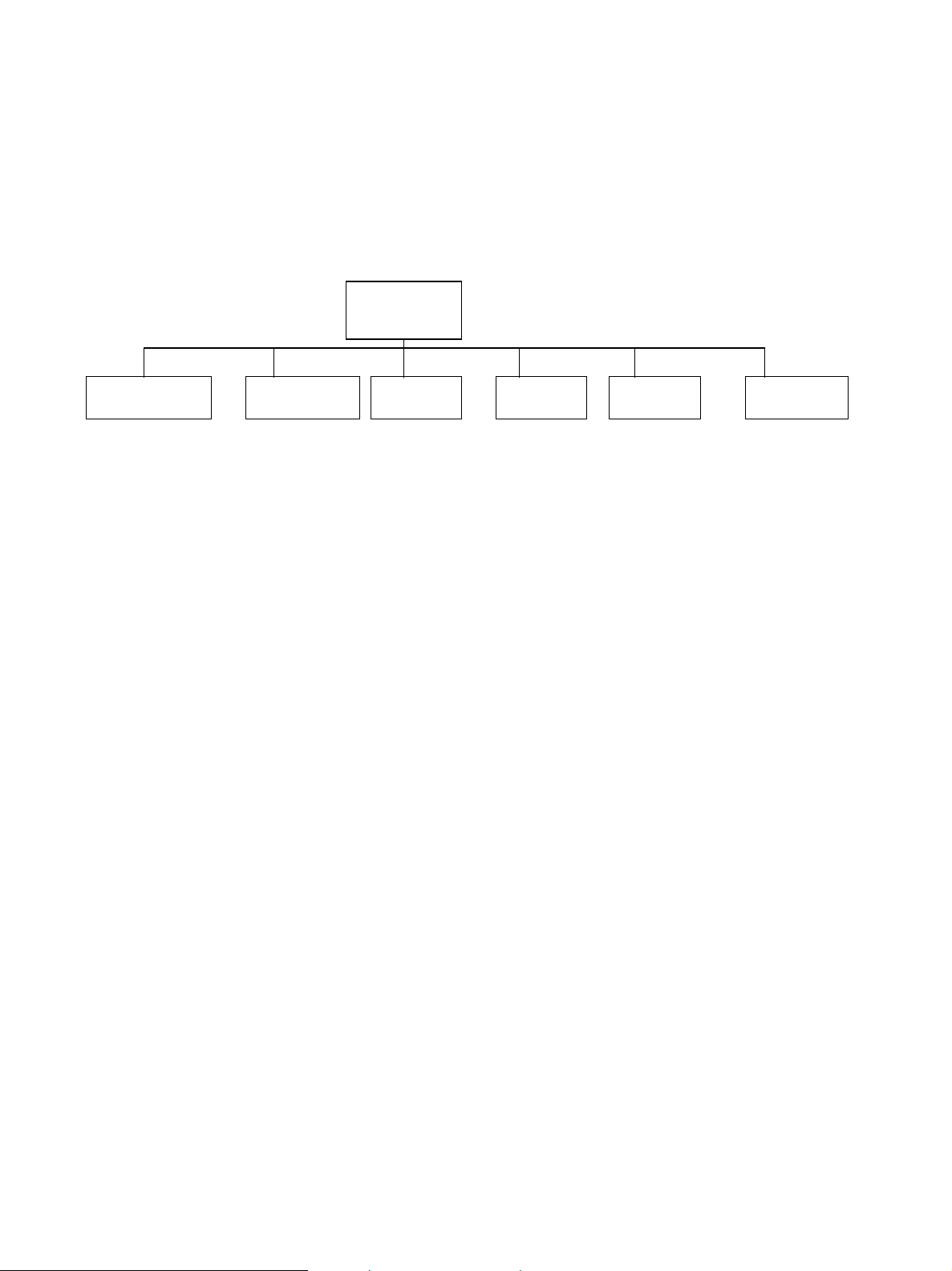

3.1 IPDS MENU - Map of All Options

This section describes the menu structure for the IPDS emulation. Settings are displayed on the printer

under the sub-menus reached from the IPDS MENU, located under the Option Card Menu.

EMULATION

PAPER

HANDLING

IPDS Emulation IPDS Blank Pages Tray Mapping 1 Bin Mapping 1 ALL INPUT TRAYS Capture Fonts

Host Resolution Offset Stacking Tray Mapping 2 Bin Mapping 2 TRAY 1 ADJUST Remove Fonts

Color Processing UNIVERSAL SIZE Tray Mapping 3 Bin Mapping 3 TRAY 2 ADJUST

Text Processing OTHER ENV SIZE Tray Mapping 4 Bin Mapping 4 TRAY 3 ADJUST

Toner Saver * Tray Mapping 5 Bin Mapping 5 TRAY 4 ADJUST

BAR CODE Tray Mapping 6 Bin Mapping 6 TRAY 5 ADJUST

Bar Code Symbol Tray Mapping 7 Bin Mapping 7 MP FEEDER ADJUST

Bar Code Size Tray Mapping 8 Bin Mapping 8 ENV FEEDER ADJ

DEFAULT CODEPAGE Tray Mapping 9 Bin Mapping 9 MANUAL PAPER ADJ

Codepage Version Tray Mapping 10 Bin Mapping 10 MANUAL ENV. ADJ

DEFAULT FGID Bin Mapping 11

Default CPI Bin Mapping 12

Page Counter

Printable Area

Exception Ctrl

Font Ctrl

Font Type

IPDS Print Res

Intervention Req

IPDS Timeout

Print IPDS Fonts

Trace Functions

IPDS Version

* Available only in monochrome products

Note: Only those menu items that are supported by the product are displayed.

IPDS

MENU

MAP INPUT

TRAYS

MAP OUTPUT

BINS

MARGINS

FONT

CAPTURE

In all of the following descriptions an asterisk “*” indicates the default factory value.

19

Page 20

3.2 Overview of EMULATION Menu Options and Values

The following lists all menu options found under the EMULATION menu. Values only display when they

are available on your printer.

An asterisk “*” indicates the default factory value. The selected value for each of these options can be

printed; see

(MFPs) on page

Option name Values

IPDS Emulation Resident*, 3812/3816

Host Resolution Auto*, 240, 300, 600

Color Processing Black (Default on mono printers)

Text Processing Black (Default on mono printers)

Toner Saver Printer Setting*, Host Controlled

BAR CODE

Bar Code Symbol Host Controlled, Always Print*

Bar Code Size Resident*, 4028, 43xx

DEFAULT CODEPAGE Codepages A – E

Arabic Eur 420…Estonian 1157

Codepages F – K

Fin/Swe 278...Int. Set 5 500*...Katakana 290

Codepages L – Z

Latin 2 870…USA/Canada 1140

Codepage Version Version 1*, Version 0

DEFAULT FGID See the option description on page

Default CPI 10.0*, range: 5.0 – 30.0

Page Counter Normal Update*, Early Update

Printable Area Whole Page*, Print Page, Physical Page, Full Page, 4028 Whole Page,

4028 Print Page

Exception Ctrl Report All*, Sup Beyond VPA, Sup Undef Char, Suppress Both

Printing the Menu Settings Page (printers) on page 15 or Printing the Menu Settings Page

18.

Shades of Grey

Color (Default on color printers)

Shades of Grey

Color (Default on color printers)

(Available only in mono printers)

25.

20

Page 21

Font Ctrl Relaxed*, Strict

Font Type Use Scalable*, Use Bitmap

IPDS Print Res 600 dpi, 1200 dpi, 1200 Image Q, 2400 Image Q, 4800 CQ

Default values are dependent on printer or MFP model.

Printers:

Lexmark C770, C772 4800 CQ

Lexmark C780, C782 4800 CQ

Lexmark C920 2400 Image Q

Lexmark C935 2400 Image Q

Lexmark T640, T642, T644 600 dpi

Lexmark W840 600 dpi

MFPs:

Lexmark X644e MFP, X646e MFP 600 dpi

Lexmark X646ef MFP 600 dpi

Lexmark X782e MFP 4800 CQ

Lexmark X850e MFP, X852e MFP,

X854e MFP

Lexmark X940e MFP, X945e MFP 2400 Image Q

Intervention Req Report*, Do not report

IPDS Timeout Host Controlled*, 15 seconds, 30 seconds, 60 seconds, 90 seconds,

2 minutes, 3 minutes, 5 minutes, 10 minutes

Print IPDS Fonts Yes*, No

Trace Functions Disable*, PAR Std. Output, PAR Slot 1 Output, PAR Slot 2 Output,

USB Std. Output, USB Slot 1 Output, USB Slot 2 Output

IPDS Version Display IPDS version number in the operator panel.

A description of each EMULATION menu option follows.

600 dpi

21

Page 22

3.3 EMULATION – Options Descriptions

In the following an asterisk “*” indicates the default factory value. The selected value for each of these

options can be printed; see

Settings Page (MFPs) on page

3.3.1 IPDS Emulation

This option selects the printer emulation to be used when processing IPDS data. It is important to select the

correct emulation before receiving IPDS data. The IPDS Printer and Host Setup Guide includes guidelines

for selecting the emulation.

Resident* This printer’s native emulation

3812/3816 IBM 3812/3816 emulation

Printing with Double Byte Character Set (DBCS) is not supported in the “3812/3816” emulation.

3.3.2 Host Resolution

Specifies the resource resolution support for raster font and IM1 image reported to the host in the XOA

OPC command. The resolution selected determines the printer resident raster fonts which are activated.

For example, 240 dpi raster fonts will be activated with a setting of “240”, but not at the “300” or “600”

setting.

Printing the Menu Settings Page (printers) on page 15 or Printing the Menu

18.

Auto*

240

300

600

Note: If you select the “3812/3816” emulation in the IPDS Emulation option, the Host Resolution is

forced to “240 dpi”.

Reply to host indicates support for IM1 image and any dpi raster fonts. Captured raster

fonts of any resolution are only activated when the activation request is accompanied

by a matching Font Resolution and Metric Technology Triplet.

240 dpi raster font and 240 IM1 image support is reported to the host. Captured raster

fonts of other resolutions will not be activated unless a matching Font Resolution and

Metric Technology Triplet is received with the request.

300 dpi raster font and 300 IM1 image support is reported to the host. Captured raster

fonts of other resolutions will not be activated unless a matching Font Resolution and

Metric Technology Triplet is received with the request.

600 dpi raster font and 600 IM1 image support is reported to the host. Captured raster

fonts of other resolutions will not be activated unless a matching Font Resolution and

Metric Technology Triplet is received with the request.

22

Page 23

3.3.3 Color Processing

Specifies how graphics, image, and bar code color commands are processed. See section 10.5, on page

82, for more information on color printing.

Color

Shades of Grey

Black

Print in full color. (Default for color printers.)

Process color commands and print all colors as shades of grey.

Process color commands and print all colors as black. (Default on mono printers.)

3.3.4 Text Processing

Specifies how text color commands are processed.

Color

Shades of Grey

Black

Print in full color. (Default for color printers.)

Process color commands and print all colors as shades of grey.

Process color commands and print all colors as black. (Default on mono printers.)

3.3.5 Toner Saver

Specifies the action taken on mono printers when the IPDS Print Quality Control command is received.

Printer Controlled*

Host Controlled

Use the values in the printer menu’s Settings > Quality Menu > Toner

Darkness option to control print quality. The value specified in the IPDS Print

Quality Control command is ignored.

Use the value specified in the IPDS Print Quality Control command to control

print quality. See

information.

XOA Print Quality Control on page 79 for additional

3.3.6 BAR CODE

3.3.6.1 Bar Code Symbol

Specifies the action taken when the IPDS data stream specifies suppress printing of the bar code symbol.

The default setting of “Always Print” is useful when older applications have accidentally specified

suppression of the bar code symbol.

Host Controlled

Always Print*

Use the value specified in the Write Bar Code command to control printing of

the bar code.

Always print the bar code. Ignore the value specified in the Write Bar Code

command to control printing of the bar code.

23

Page 24

3.3.6.2 Bar Code Size

This option controls the size of the bar code when using the Resident IPDS emulation. When the

3812/3816 emulation is selected, this setting is ignored. Bar codes will be printed in a size that closely

matches the IBM 3812/3816 family of printers.

Resident*

Prints the bar code in a size that gives best quality on this printer.

4028

Bar codes are printed in a size that closely matches the IBM 4028

printer.

43xx

Bar codes are printed in a size that closely matches the IBM 43xx

family of printers.

3.3.7 DEFAULT CODEPAGE

• This option defines the default code page with the appropriate character set to be used. The list is a

limited selection of all supported code pages associated with the three types of supported fonts,

which are known as “Compatibility”, “Core Interchange”, and “Coordinated”. For details see

Appendix

Font and Code Page Information, starting on page

Values are in alphabetical order. The operator panel will display codepage options beginning with the

letters A - E, then F – K and L - Z. Select the appropriate path to reach the desired code page. See table

below.

Codepages A – E CPGID Codepages F – K CPGID Codepages L – Z CPGID

Arabic Eur 420 Fin/Swe 278 Latin 2 870

ASCII 367 Fin/Swe 1143 Latin 2 1110

Aus/Ger 273 Fin/Swe Alt 288 Latin 2 1153

Aus/Ger 1141 French/Cat 297 Latin 3 905

Aus/Ger Alt 286 French/Cat 1147 Latin 4 1069

Baltic 1112 Greek 423 Latin 9 Eur 924

Baltic 1156 Greek Eur 875 OCR-A 892

Belgium 274 Hebrew Eur 424 OCR-B 893

Brazil 275 Hebrew Set A 803 PC Multi 850

Can. French 260 Iceland 871 PC Multi Eur 858

Can. French 276 Iceland 1149 PC std 437

Cyrillic 880 Int. Set 5 500* Portugal 037

Cyrillic 1025 Int. Set 5 1148 Portugal 282

Cyrillic 1154 Italy 280 Publishing 361

Den/Nor 277 Italy 1144 Spain/L. Am 284

Den/Nor 1142 Japan (Eng) 281 Spain/L. Am 1145

Den/Nor Alt 287 Katakana 290 Spain Alt 289

Estonian 1122 Turkish Lat 3 905

Estonian 1157 Turkish Lat 5 1026

Turkish 1155

UK 285

UK 1146

USA/Canada 037

USA/Canada 1140

Note 1: The code pages with the designation “Alt” – as well as Can. French 276, ASCII 367, OCR-A 892,

and OCR-B 893 – are supported by one or both of the Compatibility Font Sets. OCR-A 892 and

OCR-B 893 are also supported by the Coordinated Font Set. All of the other code pages in the

above list are in the Core Interchange Font Set.

on

91.

24

Page 25

Note 2: The Euro symbol is supported in code pages 1140-1159, 1153-1158 and in code pages whose text

description includes the designation Eur, such as Arabic Eur 420.

3.3.8 Codepage Version

This option determines which version of a code page is used. Some of the code pages are available in two

versions. Some characters differ between the two versions of the same code page. If characters print

differently than those entered on the keyboard, check the code page version.

Version 1* Use version 1 of appropriate code pages.

Version 0 Use version 0 of appropriate code pages.

3.3.9 DEFAULT FGID

Selects the default Font Global Identifier (FGID) to be used by the IPDS emulation when the host does

not send an FGID at the start of a job.

Select an FGID for the emulation chosen in the IPDS Emulation option. In the table below the

emulations are cross-referenced to pages in the appendix on “Font and Code Page Information”, starting

on page

Option name

Resident FGID

3812/3816 FGID

91. The FGIDs in the referenced tables are available in the operator panel.

Values

See page

When using a CPI value of 10.0 FGID 416 is equal to FGID 11.

See page

3812/3816 is 11*.

93, 97, and 102 for a list of supported FGIDs. Default FGID is 416*.

95, 97, and 102 for a list of supported FGIDs. Default FGID for

3.3.10 Default CPI

Selects the default characters per inch (CPI) to be used by the IPDS emulation when the host does not

send a CPI value at the start of a job. The option does not apply to the fixed pitch fonts.

10.0* Default CPI. The range is 5.0 to 30.0.

3.3.11 Page Counter

This option selects the method used for updating IPDS page counters. (This option is not available on all

printers.)

Normal Update* Jam and stacked page counters are updated when pages are printed.

Early Update All page counters are updated when they are processed but not printed. Pages may

be lost if power or printer failure occurs and when a paper jam occurs.

Note: When “Early Update” is selected, Intervention Required messages are not reported to the IPDS

Host.

25

Page 26

3.3.12 Printable Area

This option defines the printable area on the page and how clipping is performed. Top, bottom, and side

margins for your print jobs are set through your print application.

Whole Page*

Print Page

Physical Page

The printable area is 50 pels (4 mm) inside the physical page. The printable area is

reported to the host. Clipping occurs if data is printed outside the printable area. All

four edges will clip.

The printable area is 50 pels (4 mm) inside the physical page. The printable area is

reported to the host. If the logical page is outside the printable area it is moved down

and to the right. The right and bottom edges will be clipped.

The printable area is the physical page (edge to edge). The physical page printable

area is reported to the host.

Important: Printing within 50 pels of the paper edge may result in poor print

quality. Continual printing within 50 pels (4 mm) of the paper edge is not

recommended. It can result in paper jams due to toner contamination of the paper

path and toner appearing on the back side of duplex jobs. Toner contamination of the

paper path can make more frequent maintenance necessary.

Note 1: The Lexmark T640, T642, T644, and W840 printers, and the Lexmark

X644e MFP, X646e MFP, X646ef MFP, X850e MFP, X852e MFP, X854e

MFP can physically print edge to edge. The logical page is not clipped.

Full Page

4028 Whole Page

4028 Print Page

Note 2: The Lexmark C770, C772, C780, C782, and X782e MFP can print to within

approximately 40 pels (3.4 mm) from all four edges of the paper.

Note 3: The Lexmark C920, can print to within approximately 20 pels (1.7 mm) of

the feed direction top and bottom edge and to within approximately 3 pels

(.25 mm) of the non-feed direction edges.

Note 4: The Lexmark C935 and the Lexmark X940e MFP and X945e MFP can print

to within approximately 4 mm of the leading paper edge and to within

approximately 2 mm of all other edges.

The job is formatted for a page using a printable area of edge to edge. When the

page is printed, the page image is compressed approximately 2% in both the

horizontal and vertical directions.

Note: Full Page is not available on all products. Full page will only appear in

the menu when supported by the printer.

The printable area is 50 pels (4 mm) inside the physical page. A printable area that

more closely matches the values reported by the IBM 4028 printer is reported to the

host. Clipping occurs if data is printed outside the printable area. All four edges will

be clipped.

The printable area is 50 pels (4 mm) inside the physical page. A printable area that

more closely matches the values reported by the IBM 4028 printer is reported to the

host. If the logical page is outside the printable area it is moved down and to the

right. The right and bottom edges will be clipped.

26

Page 27

3.3.13 Exception Control

It is often practical to suppress exception reporting on undefined characters and on position errors

(printing outside the valid printable area, VPA). This option overrides the Exception Handling Control

in the IPDS data stream.

Report All*

Sup Beyond VPA

Sup Undef Char

Suppress Both

No suppression of exceptions. Exception reporting is controlled by the IPDS data

stream.

Exception reporting on position errors (outside VPA) is suppressed. The printer

IPDS emulation will print the IPDS job but not report "08C1" printable area

exceptions or "0411" bar code exceptions to the host.

If an undefined character is found, exception reporting is suppressed. The printer

IPDS emulation will print the IPDS job but not report "0821" undefined character

exceptions to the host.

Both position errors and undefined character exceptions are suppressed.

3.3.14 Font Control

This option defines how strict the reporting will be if a selected font does not correspond to a valid

combination of code page and character set.

Relaxed*

Strict

The printer makes an intelligent decision concerning whether the selected combination of

code page and character set is adequately supported. A “Relaxed” setting will report very

few exceptions. If the selected font is not found, the printer will substitute with the

closest matching font. If a font/code page combination is selected, which is not fully

supported, characters may be missing.

A “Strict” setting reports exceptions when a requested font/code page or substituted

font/code page combination is not valid. The “Strict” setting prints all characters.

3.3.15 Font Type

This option selects the type of fonts used by the printer when a standard resident fixed pitch Courier,

Prestige, or Letter Gothic Font is requested by the host.

Use Scalable*

Use Bitmap

Use printer resident scalable fonts for Courier, Prestige, and Letter Gothic fonts when

bitmap font IDs are received from the host.

Use printer resident bitmap fonts for Courier, Prestige, and Letter Gothic fonts when

bitmap font IDs are received from the host.

27

Page 28

3.3.16 IPDS Print Res

This option defines the internal print resolution used to print IPDS jobs. Host resources received in the

job are converted to the IPDS Print Res setting before printing. This is a separate setting from Print

Resolution menu option in the printer’s Settings > Quality Menu.

This setting alters the quality of text with scalable fonts, bar codes, graphics, and scalable images. Bitmap

fonts and non-scalable images are not affected.

The default setting usually produces the best print quality. Refer to

default settings for all products. Resolutions that are not available on are not displayed.

600 dpi

1200 dpi

1200 Image Q

2400 Image Q

4800 CQ

Memory Considerations

Additional memory above the total recommended may be required when receiving color or complex

pages. Additional memory may also increase print speed. See page

total recommended memory for each resolution setting.

Print at 600 pel resolution.

Print at 1200 pel resolution.

Print with 1200 Image Quality. Select 1200 Image Q when your job contains

grayscaled images that will benefit from enhanced line screening.

Print with 2400 Image Quality. Select 2400 Image Q when your job contains

grayscaled images that will benefit from enhanced line screening.

Print with 4800 Color Quality

IPDS Print Res on page 21 for

118 for information on the minimum

3.3.17 Intervention Required

This option defines if the emulation should report Intervention Required messages to the host. Types of

Intervention Required messages include a paper jam, paper out, cover open or offline message. These

types of messages mean the printer is not ready to print.

Report*

Do Not Report

Note:

28

Report Intervention Required messages to the host. This is the typical setting.

Do not report Intervention Required messages to the host. Used only in special cases.

When Page Counter is set to “Early Update”, Intervention Required messages are

not reported to the host.

Page 29

3.3.18 IPDS Timeout

This option is also called the printer IPDS Timeout. It allows the host to directly control when an IPDS

LAN session with a printer ends (disconnects), or allows the printer IPDS emulation to determine when to

timeout and print jobs waiting on other ports.

Notes: The Option Card Menu > IPDS MENU > EMULATION >IPDS Timeout value is only used

by the printer IPDS emulation when the printer is LAN attached using the Standard Network port

or the MarkNet internal print server.

The Option Card Menu > IPDS MENU > EMULATION > IPDS Timeout value is not active

when the printer is connected to a host through an Adapter for SCS card. The IPDS timeout is

controlled by the Coax or Twinax timeout value on the Adapter for SCS card.

The printer is capable of receiving jobs on multiple printer ports. While the printer is busy printing jobs

from one printer port, jobs on other printer ports remain in a waiting status. When the host disconnects

from the printer or when the printer IPDS emulation times out, the printer automatically switches to

another printer port to start a new job.

“Host Controlled” should be selected as the IPDS Timeout value when the host port value is 9100. The

printer defaults to “Host Controlled” when receiving IPDS jobs on port 9100.

“Host Controlled” or a timeout value (“15 seconds” to “10 minutes”) may be used when the host port

value is 5001 or 9600.

Note: The host port value is specified when configuring the printer parameters on the host. Refer to the

IPDS Printer and Host Setup Guide to determine the port values supported by your printer and

valid host settings compatible with the printer IPDS Timeout values.

Host Controlled*

15 seconds

30 seconds

60 seconds

90 seconds

2 minutes

10 minutes

The printer IPDS emulation remains active until the host disconnects from the

printer. Host timer/timeout values control when the host will disconnect. When the

host disconnects, the printer will print jobs from other printer ports.

Host Timer/Timeout Values and Actions:

The host timer/timeout value should be set to a small value (15 to 30 seconds) so

the host will quickly disconnect after an IPDS job is printed. All IPDS resources

downloaded to the printer will be deleted when the host disconnects. A disabled or

large host timer/timeout value will cause the printer IPDS emulation to remain

active. The BUSY message will remain on the printer operator panel even though the

printer has completed processing and printing the IPDS job.

IPDS emulation timeout values.

These values are only used by the printer IPDS emulation when the host sends IPDS

jobs on port 5001or 9600 to the Standard Network port or a MarkNet internal print

server. If the host does not send another IPDS job or send additional IPDS resource

data to the printer within the printer IPDS timeout value specified, the printer IPDS

emulation will time out, place all IPDS resources in temporary storage (see Storage

of IPDS Resources below), and allow the printer to print jobs from other printer

ports.

Host Timer/Timeout Values and Actions:

While the printer is printing jobs from other printer ports, the host is still connected

to the printer. The host timer/timeout value must be disabled or set to a large value

to prevent the host from disconnecting and deleting the resources downloaded to the

printer. If the

communication errors may also occur.

host timer/timeout value is not disabled or set to a very large value,

29

Page 30

Important: The host timer/timeout value and the printer IPDS Timeout value must

not be set to the same number of seconds. The difference in these values should

always be 30 or more seconds.

Notes:

Up to two sessions are available on port 9600. When all 9600 sessions are active, the printer will

open a new TCP/IP session and immediately close the session.

On port 5001, up to 5 sessions are available when the printer IPDS Timeout is set to “Host

Controlled”. Only two sessions are available when the printer IPDS Timeout is set to “15

seconds” – “10 minutes”. When these two sessions are active, the printer will continually respond

busy to any other TCP/IP session requests.

Storage of IPDS Resources

IPDS resources from the last active port 5001 or 9600 session are temporarily stored in the printer

memory when IPDS Timeout values (“15 seconds” to “10 Minutes”) are selected and the host

timer/timeout values are set to a large value or disabled. Operator actions and processing of other jobs

may cause the resources to be deleted. Events such as the following will cause deletion of the downloaded

resources.

• The host ends the IPDS port 5001 or 9600 session.

• TCP/IP communications is interrupted on the port 5001 or 9600 session.

• Another IPDS session is started on port 5001, 9100, or 9600.

• IPDS MENU option values are changed.

• Processing of a non-IPDS job that requires more memory than is available in printer memory.

• The printer is powered OFF.

If the IPDS resources are deleted, the printer will return a Printer Reset exception to the host. The

message Resources Lost may be displayed for a short time on the printer operator panel. The host will

download the resources again with the next IPDS job.

3.3.19 Print IPDS Fonts

This option prints a font sample list of all the printer resident fonts available in the current emulation

followed by a list of currently captured IPDS fonts.

Yes Print IPDS font list.

No Do not print IPDS fonts.

To prevent loss of host downloaded resources a font list can not be printed when an IPDS session is active

with a host. Note that the printer can be in the Ready state and still have a port 5001 or port 9600 active

LAN IPDS session or a Coax or Twinax IPDS session active through the Adapter for SCS. The message

Active IPDS Ses. Ignoring Request will be displayed when you select Yes on the operator panel and an

IPDS host session is active. You must end the IPDS session from the host or power the printer OFF and

ON to print a font list. Host downloaded resources will be deleted when you end the IPDS session or

power the printer OFF.

Note: This function can not be operated remotely.

30

Page 31

3.3.20 Trace Functions

This option determines if the Trace function is enabled. Trace data is sent to the selected port. Unless you

have a computer running a capture program attached to the port selected to receive the trace data, the

printer may hang BUSY. Print performance is degraded when the trace function is active.

Note: Port selections will only appear when the port is available on the printer. The Trace function is

used by service personnel for trouble shooting and service.

Disable*

PAR Std. Output

PAR Slot 1 Out

PAR Slot 2 Out

USB Std. Output

USB Slot 1 Out

USB Slot 2 Out

Note: This function can not be operated remotely.

Disable Trace

Enable the standard parallel port for trace data output

Enable the optional parallel port in slot 1 for trace data output

Enable the optional parallel port in slot 2 for trace data output

Enable the standard USB port for trace data output

Enable the optional USB port in slot 1 for trace data output

Enable the optional USB port in slot 2 for trace data output

3.3.21 IPDS Version

This option displays the current IPDS version / level.

Note 1: This option can not be used remotely.

Note 2: The IPDS level is also shown on the printed Menu Settings Page. It is found as “IPDS Emulation”

under the Device Information heading. See

or

Printing the Menu Settings Page (MFPs) on page 18.

Printing the Menu Settings Page (printers) on page 15

31

Page 32

3.4 Overview of PAPER HANDLING Menu Options and Values

The following lists all menu options found under the PAPER HANDLING menu. Values only display

when they are available on your printer. An asterisk “*”indicates the default factory value. The selected

value for each of these options can be printed; see

Printing the Menu Settings Page (MFPs) on page 18.

or

Option Name Values

IPDS Blank Pages

Offset Stacking

UNIVERAL SIZE

OTHER ENV SIZE

A description of each PAPER HANDLING option follows.

Print*, Do Not Print

Host Controlled*, Disabled

The valid values for Paper Length and Paper Width are listed in section

on page

The valid values for Envelope Length and Envelope Width are listed in

section

33.

3.5.4 on page 34.

Printing the Menu Settings Page (printers) on page 15

3.5.3

32

Page 33

3.5 PAPER HANDLING Menu – Option Descriptions

In the following an asterisk “*” indicates the default factory value. The selected value for each of these

options can be printed; see

Settings Page (MFPs) on page

3.5.1 IPDS Blank Pages

This option determines if blank pages in IPDS jobs are printed.

Print* Print all IPDS pages.

Do Not Print Skip printing of blank IPDS pages. Duplex pages are skipped only if both sides are blank.

3.5.2 Offset Stacking

This option controls the offset stacking function. It is only displayed when offset stacking is supported in

the printer standard bin or when an optional finisher with offset stacking capability is installed. Offset

stacking is only available in selected bins and may be limited to selected media.

Bin selection has a higher priority than offset stacking commands in the IPDS job. The job must be routed

to a bin that supports offset stacking and have offset stacking specified in the job before offset stacking

will be performed.

Printing the Menu Settings Page (printers) on page 15 or Printing the Menu

18.

See section

Host Controlled*

Disabled

5.1 on page 53 for additional information on offset stacking.

Offset stacking is controlled by the commands received in the IPDS job.

Offset stacking is not performed. Offset stacking commands received in the

IPDS jobs are ignored.

3.5.3 UNIVERSAL SIZE

The IPDS emulation uses the paper size setting specified in the printer menu to determine the size loaded.

The paper size is returned to the host. A printer paper size of “Universal” is displayed in the printer menu

when a non-standard size paper is detected in an auto size sensing tray or is selected as the paper size

loaded into a non-size sensing tray or feeder.

This option allows you to specify the physical paper size returned to the host when a non-standard paper

size is loaded. The paper size is specified in 300 dots per inch.

Important: A 34 Short Paper, 34 Wrong Paper Size, or paper jam error may be displayed if printing

occurs past the length of the physical paper. You should specify the actual paper size to avoid errors.

33

Page 34

Product Menu Option Value

Range

Lexmark C920

Lexmark C770, C772, C780, C782,

C935

Lexmark T640, T642, T644

Lexmark X644e MFP, X646e MFP,

X646ef MFP, X782e MFP, X850e

MFP, X852e MFP, X854e MFP,

X940e MFP, X945e MFP

Lexmark W840

UNIVERSAL SIZE >

Paper Length

UNIVERSAL SIZE >

Paper Width

UNIVERSAL SIZE >

Paper Length

UNIVERSAL SIZE >

Paper Width

UNIVERSAL SIZE >

Paper Length

UNIVERSAL SIZE >

Paper Width

5100*,

1749 to 6824

3510*,

1062 to 3510

4200*,

1500 to 4200

2550*,

825 to 2703

6000*

1200 to 6000

3510*

825 to 3510

Function

Specifies Universal paper

length. See note below.

Specifies Universal paper

width. See note below.

Specifies Universal paper

length. See note below.

Specifies Universal paper

width. See note below.

Specifies Universal paper

length. See note below.

Specifies Universal paper

width. See note below.

Note: The printer paper trays and feeders are limited to feeding of specific media sizes. Refer to your

printer documentation when loading a non-standard media size to determine if that media size can

be fed from that tray or feeder.

Note: The printer Paper Menu > Universal Setup settings for paper width and paper height must be set

equal to the IPDS MENU > PAPER HANDLING > UNIVERSAL SIZE menu settings.

Otherwise, a paper jam, 34 Short Paper or 34 Wrong Paper Size error may be displayed.

Conversion example:

3.5.4 OTHER ENV SIZE

The IPDS emulation uses the envelope size setting specified in the printer menu to determine the

envelope size loaded. The envelope size is returned to the host. A printer envelope size of “Other

Envelope” may be selected in some printer menus when a non-standard size envelope is loaded into a

non-size sensing tray or feeder.

This option allows you to specify the envelope size returned to the host when “Other Envelope” is

selected in the printer menu as the envelope size. The envelope size is specified in 300 dots per inch. See

the conversion example for UNIVERSAL SIZE (section

Important: A 34 Short Paper Error may be displayed if printing occurs past the length of the physical

envelope. You must specify the actual envelope size to avoid incorrect text positioning or clipping of text.

Some printers do not report an error when the size is incorrect and the text is clipped.

3.5.3).

34

Page 35

Product Menu Option Value Range Function

Lexmark C770, C772, C780, C782,

C920, C935

Lexmark T640, T642, T644,

Lexmark X644e MFP, X646e MFP,

X646ef MFP, X782e MFP, X850e MFP,

X852e MFP, X854e MFP, X940e MFP,

X945e MFP

Lexmark W840

OTHER ENV SIZE

> Envelope Length

OTHER ENV SIZE

> Envelope Width

OTHER ENV SIZE

> Envelope Length

OTHER ENV SIZE

> Envelope Width

4200*,

1500 to 4200

2550*,

825 to 2550

5100*,

1200 to 5100

3510*,

825 to 3510

Specifies Other Envelope