Page 1

Edition: March 26, 2007

Lexmark™ C77x, Lexmark C78x printer

• Table of Contents

• Start Diagnostics

5061

• Safety and Notices

•Trademarks

• Index

Lexmark and Lexmark with diamond design are

trademarks of Lexmark International, Inc., registered

in the United States and/ or other countries.

Page 2

y

e

t

5061

Edition: Marc h 26, 2007

The following paragraph does not apply to any country where such provisions are inconsistent with local law:

LEXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warr anties in certain transactions; theref ore, this statement may not apply to you.

This public ati on could include technical inaccuracies or typographical errors. Changes a re periodically made to the

information herein; these changes will be incorporated in later editions. Improvements or changes in the products or the

programs described may be made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22A/032-2, 740 West New Circle Road,

Lexington, Kentucky 40550, U .S.A or e-mail at ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute an

of the info rmatio n you supply in any way it believes appropriate without incurring any obli gation to you.

References in this pub lication to products, programs, or services do not imply t hat the manufacturer inte nds to make the s

available in all countries in which it operates. Any reference to a pro duct, program, or service is not in tended to state or

imply that only t hat product , progr am, or s ervice ma y be use d. An y funct ional ly equi val ent pro duct , prog ram , or service th a

does not infringe any existing intel lectual property right may be used instead. Evaluation and verificati on of operation in

conjunction with other products, programs, or services, except those expressly designated by the manufacturer, are the

user’s responsibil ity.

Lexmark, Lexmark with diamond design, and Ma rkNet are trademarks of Lexm ark Int ernational, Inc., reg ist ered in the

United States and/or other countries.

PrintCryption is a trademark of Lexmark International, Inc.

StapleSmart is a trademark of Lexmark International, Inc.

LEXF AX is a service mark of Lexmark International , I nc.

PCL® is a registered trademark of the Hewlett-Packard Company.

Other trademarks ar e the property of their respective owners.

© 2006 Lexmark International, Inc.

All rights reserved.

UNITED STA TES GOVERNMENT RIGHTS

This softwar e and any accompanying doc um entation provided under this agreement are commer cial computer software

and documentation developed exclusively at private expense.

P/N 12G9688

Page 3

5061

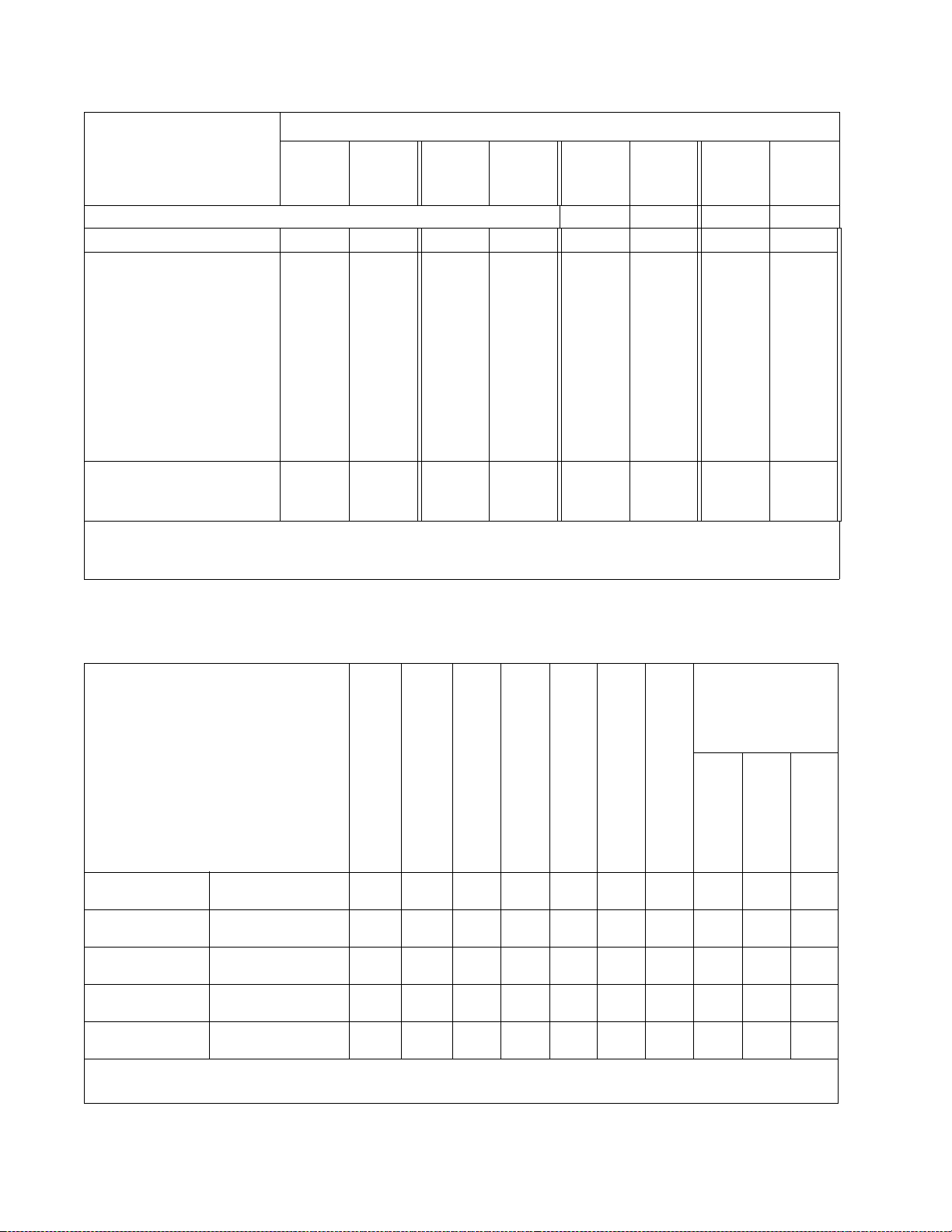

Table of contents

Notices and safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Laser notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Safety in fo r mation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tools required for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Options and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Options for all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Options for C772 and C782 (310 and 410) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Power and performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Media specificat ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Media guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Paper characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Unacceptable paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Selecting paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Web oiler upgrade kit and replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

POR (Power-On Reset) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Symptom table—base printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Symptom table—500-sheet drawer option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Symptom table—HCIT 2000-s heet option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Symptom table—output expander option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Symptom table—5-bin mailbox option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Symptom table—StapleSmart finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Service error code and paper jam message table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

100.01 ITU error service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

100.02 ITU error service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

122.01 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

122.02 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

122.03 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

122.04 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

122.05 and 122.06 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

122.07, 122.14, and 122.15 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

122.08 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

122.10 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

122.11 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

122.12 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

122.13 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

148.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

150.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

151.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Table of contents iii

Page 4

5061

152.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

153.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

177.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

200.03 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

200.04 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

200.05 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

200.06 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

200.07 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

200.16 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

200.21, 200.28, and 200.29 paper jam service chec k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

200.93 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3 1

200.96 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

201.xx and 202.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

230.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3 5

241.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

242.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

243.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

244.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

250.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4 7

271.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4 9

272.xx paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

282.98 paper jam service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

900.xx RIP Software Error service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

925.02 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

926.01 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

927.03 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

930.09 error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

940.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

941.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

942.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

943.xx error code service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-62

956.xx service error service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-64

982.xx error service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-64

990.01 error service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-65

5-bin mailbox option service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-67

500-sheet drawer opti on service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7 1

AC and DC power service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7 4

Autocompensator service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-76

Black only retract (BOR) service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -78

Close door/HVPS/printhead interlock switch service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-79

Duplex option service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-81

Envelope feeder option service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 8 3

HCIT 2000-sheet opt ion service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -84

Fuser drive assembly noise check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-87

Operator panel LCD/status LED/buttons service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-88

Output expander option service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-90

Print quality service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-93

Blank page (no image) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 9 3

Entire page is mostly one color—Full bleed planes in one color . . . . . . . . . . . . . . . . . . . . . . . .2-94

Missing colors—Complete or partially missing color planes . . . . . . . . . . . . . . . . . . . . . . . . . . .2-95

Black and whit e only—cyan, magenta, and yellow are missing . . . . . . . . . . . . . . . . . . . . . . . . .2-96

Light print over the entire page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 9 6

Vertical lines or streaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-98

Horizontal lines or streaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9 8

Low image density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-99

iv S e rvice Manual

Page 5

5061

Poor color alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-99

Transparency print quality is poor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-100

Negative ghosting or faded image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-101

Residual image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-101

Uneven printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-101

Toner smears or rubs off the page with no error code displayed . . . . . . . . . . . . . . . . . . . . . . 2-102

Smudged or distorted images on fused page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

Toner is on the back of the printed page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

Light lines or str eaks appear on the page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

White streak in color plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-104

Paper wrapped around the second transfer roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-104

User troubleshooting for quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

Second transfer roll service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-109

StapleSmart finisher service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-111

Tray 1 service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-115

Tray 1 media size sensing service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-116

User operator panel, menus, and messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-117

Understandin g the printer operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-117

Operator panel buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-117

Menu map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-119

Selected menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-120

Quality Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-120

Utilities Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-122

User attendance messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-124

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagnostic procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printhead dia gnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Print quality defect locator chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Partial Print Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

HCIT standalone test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Accessing service menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Diagnostics mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Entering Diagnostics mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Diagnostic mode menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Exiting the Diagnostics mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

ALIGNMENT MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting alignment for color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Drift Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

MISC TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Toggle ITU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Belt Tracking (ITU 4th point adjustment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Printhead Inst . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

PRINT TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Print Tests (input sources) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Print Quality Pgs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

HARDWARE TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

LCD Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

DRAM Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

CACHE Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Parallel Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Serial Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Table of contents v

Page 6

5061

DUPLEX TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Duplex Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Duplex Top Margin Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Duplex Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

INPUT TRAY TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

OUTPUT BIN TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Feed to All Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Diverter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

FINISHER TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Staple Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Finisher Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Finisher Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

BASE SENSOR TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

DEVICE TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Quick Disk T est . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Disk Test/Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Flash Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

PRINTER SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

PAGE COUNTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2 6

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Engine Setting x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Model Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Configuration ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Reset Color Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 2 8

Edge to Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Cal Ref Adj . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

EP SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

EP Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Fuser Temp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

DC Charge Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 8

Dev Bias Adj . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Transfer Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

ERROR LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Display Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Print Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 9

Clear Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

EXIT DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -31

Entering Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Exiting the Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Reset Fuser Cnt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Black Only Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Prt Quality Pgs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Color Trapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Tray Insert Msg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

SIZE SENSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

PPDS Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Demo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Energy Conserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

EVENT LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

vi Se rvic e M anual

Page 7

5061

Auto Color Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Paper Prompts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Env Prompts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Font Sharpening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Jobs On Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Disk Encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Exit Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Identifying jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Access doors and trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Understanding jam messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Paper jam me ssages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Clearing the enti re paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Area A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Area B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Area C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Area D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Area T1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Area E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Area T<x> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Area J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Area K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Area L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Clearing mailbox, finisher, or output e xpander jams (Area M) . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Clearing fuser jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Clearing image transfer unit jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

If you still need help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

Repair information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-sensiti ve parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Screw identification table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Operator panel bezel removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Lens removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Front cover rear pivot cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Front cover or front cover backplate assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Redrive cap removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Top cover assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Front lower left cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Paper path access door removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Front left handle cover assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Front lower right cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Front right handle cover assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Rear cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Lower right door assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Left lower cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Lower jam access door assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Redrive door removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Autocompensator pick assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

BOR drive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Cartridge contact assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Cartridge drive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Developer HVPS board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Friction buckler and buckler housing removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Front right light shield removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Fuser assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Table of co ntents vii

Page 8

5061

Fuser bottom duct removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

Fuser drive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Fuser fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Fuser top duct removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-47

Inner system board shield removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

ITU assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

ITU drive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

LVPS assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

Media size sensing assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Media size sensing board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5 8

Multipurpose feeder (MPF) removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5 9

Multipurpos e feeder (MPF) autocompensator or side restraints removal . . . . . . . . . . . . . . . . . . . . . .4-62

Multipurpose feeder (MPF) motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-64

Nip relief handle removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-65

Operator panel assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6 8

Outer system board shield removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-69

Pick rolls removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-70

Printhead remov al and adj ustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 -72

Mechanical alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7 2

Black printhead electronic alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 77

Color printhead electronic alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

Rear bellcrank removal (cyan, magenta, yellow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-79

Rear bellcrank (black) removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-81

Redrive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-82

Registration motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-83

Rib housing removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-84

RIP fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-86

S2/narrow media/ tr ansparency/multi purpose feeder cable remov al . . . . . . . . . . . . . . . . . . . . . . . . . .4-87

S2/narrow media/ transparency/mul tipurpose feeder senso rs removal . . . . . . . . . . . . . . . . . . . . . . . .4-88

Second transfer roll removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-88

System board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-89

Transfer HVPS board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-91

Transfer plate assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-94

Vacuum transport belt (VTB) removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9 5

Vacuum transport belt (VTB) fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 9 7

Waste container door removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-97

Waste container latch removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-98

Web oiler fuser ass em bly and card removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-99

Connector locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Printer boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Printer motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Printer sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Cartridge contact assembly pin locations (cyan, magenta and yellow) . . . . . . . . . . . . . . . . . . . . . . . .5-4

Cartridge contact assembly pin locat ions (black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

System board cabli ng reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

System board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Autoconnect— top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Autoconnect— bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Transfer high volt age power supply (HVPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Developer high voltage power supply (HVPS) board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

viii Service Manual

Page 9

5061

Low voltage power supply (LVPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

LVPS cab le connectors to system board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

LVPS fuser connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Media size sensing board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

High-capaci ty i nput tray (HCIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

StapleSmart finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Preventive mainte nan ce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety inspection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Scheduled maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Standard fuser s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

ITU Maintenance ki ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Lubrication spec if ications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Lubrication for replacement motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Fuser drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Cartridge drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

ITU drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Assembly 2: Cartridg e mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Assembly 3: Fuser assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Assembly 4: Fuser drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 10

Assembly 5: Vacuum transport belt (VTB) assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Assembly 6: Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Assembly 7: Printheads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Assembly 8: Paper feed output (redrive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Assembly 9: Paper feed input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Assembly 10: Media si ze sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Assembly 11: Paper fe ed transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Assembly 12: Multipurpose feeder (MPF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Assembly 13: 500-Sh eet i ntegrated tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Assembly 14: Autocompensator assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Assembly 15: ITU assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Assembly 16: ITU drive assem bly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 23

Assembly 17: ITU lo a ding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Assembly 18: Waste tone r. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 26

Assembly 19: BOR drive asse mbly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Assembly 20: Cartridge contact assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Assembly 21: Cartridge drive assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Assembly 22: Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Assembly 23: Electronics—cabling interconnections 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Assembly 24: Electronics—cabling interconnections 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Assembly 25: Electronics—cabling interconnections 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Assembly 26: Electronics—cabling interconnections 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Assembly 27: Output expander. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Assembly 28: 5-Bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 46

Assembly 29: 500-Sh eet drawer option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Assembly 30: Duplex option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Assembly 31: High-capacity input tray (HCIT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58

Assembly 32: StapleSmart finisher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Assembly 33: Env e lope option

Assembly 34: Outdoor media tr ay option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-68

Assembly 35: Banner opt ion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-69

Assembly 36: Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66

Table of contents ix

Page 10

5061

Appendix A—Service tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Identifying the printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Redrive belt routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Duplex option deflector button replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B—Print quality samples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Print tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Print Quality Pages—Title page (total of fiv e) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B - 1

Print Quality Pages—Page 1 (total of five) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Print Quality Pages—Page 2 (total of five) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Print Quality Pages—Page 3 (total of five) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Print Quality Pages—Page 4 (total of five) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Registration and alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Quick Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Printhead mechani cal alignment test page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B - 7

Printhead electronic alignment test page—Magenta (one of two). . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Printhead electronic alignment test page— Ma genta (two of two) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Part number index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-9

x Service Manual

Page 11

5061

Notices and safety information

The foll owing laser notice label s m ay be affixed t o this printer.

Laser no tice

The printer is certified in the U .S. to confo rm to the requir ements of DHHS 21 CFR Subchapter J for Class I (1)

laser product s, and elsewhere is certified as a Class I laser product conforming to the requirements of IEC

60825-1.

Class I laser products are not considered to be hazardous. The printer contains int ernally a Class IIIb (3b) laser

that is nominally a 5 milliwatt galli um arsenide laser operati ng in the wavelength region of 770-795 nanometers.

The laser system and printer are designed so there is never an y hum an access to laser radiation above a Class

I level during normal operation, user maintenance, or pr escri bed service condition.

Laser

Der Drucker erfüllt gemäß amtlicher Bestätigu ng der USA die Anforderungen der Bestimmung DHHS

(Department of Health and Human Services) 21 CFR Teil J für Laserprodukte der Klasse I (1). In anderen

Ländern gilt der Drucker als Laserprodukt der Klasse I, der die Anforderungen der IEC (International

Electrotechnical Commission) 60825-1 gemäß amtlicher Bestäti gung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des Druckers befindet sich ein Laser der Klasse

IIIb (3b), bei dem es sich um einen Galliumarsenlaser mit 5 Milliwatt handelt, der Wellen der Länge 770-795

Nanometer ausstrahlt. Das Lasersystem und der Drucker sind so konzipiert, daß im Normalbetrieb, bei der

Wartung durch den Benutzer oder bei ordnungsgemäßer Wartung durch den Kundendienst Laserbestrahlung,

die Klasse I überstei gen würde, Menschen k einesfalls erreicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est certifiée conforme aux provisions DHHS 21 CFR alinéa J concernant

les produits laser de Classe I (1). Pour les autres pa ys: cette imprimante répond aux normes IEC 60825-1

relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comm e des produits non dangereux. Cette imprimante est

équipée d’un l aser de Classe IIIb (3b) (arséniure de gall ium d’une puissance nominale de 5 milliwatts) émettant

sur des longueurs d’onde comprises entre 770 et 795 nanomètres. L’imprimante et son sys tème laser sont

conçus pour impossible, dans des conditions normales d’utilisation, d’entr etien par l’utilisateur ou de révision,

l’exposition à des rayonnements lase r supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampant e è certificata negli St ati Uniti per ess ere conforme ai requisiti del DHHS 21 CFR Sottocapitolo

J per i prodotti las er di classe 1 ed è certificata negli altri Paesi come prodotto laser di classe 1 conf orme ai

requisiti del la norma CEI 60825-1.

I prodotti laser di class e non sono con sider ati pericol osi. La stampan te contiene al suo interno un l aser di classe

IIIb (3b) all’arseniuro di gallio dell a potenza di 5mW che opera sulla lunghezza d’onda compresa t ra 770 e 795

nanometri. Il sistema laser e la stampante sono stati progettati in modo tale che le persone a contatto con la

stampante, durante il normale funzionam ento, le operazioni di servizio o quelle di assistenza tecnica, non

ricevano radiazioni laser superiori al livello della classe 1.

Notices and safety information xi

Page 12

5061

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los requisitos para los productos láser de Clase I (1)

establecidos en el subcapítulo J de la norma CFR 21 del DHHS (Departamento de Sanidad y Servicios) y, en

los demás países, reúne todas las condiciones expuestas en la norma IEC 60825-1 para productos láser de

Clase I (1).

Los productos láser de Clase I no se consideran pel igrosos. La impre sora contiene en su interior un láser de

Clase IIIb (3b) de arseniuro de galio de funcionamiento nomin al a 5 miliv atios en una longi tud de onda de 770 a

795 nanómetros. El sistema láser y la impresora están diseñados de forma que ninguna persona pueda verse

afectada por ningún tipo de radiac ión láser superior al nivel de la Clase I durante su uso normal, el

mantenimiento realizado por el usuario o cualqui er otra situación de servic io técnico.

Declaração sobre Laser

A impressora está ce rtificada no s E. U .A. e m conf ormidade co m os r equi sito s da reg ulamenta ção DHHS 2 1 CFR

Subcapítulo J para a Cla sse I (1) de produt os laser. Em outros locais, está certifi cada como um produto lase r da

Classe I, em conf ormidade com os requisitos da norma IEC 60825-1.

Os produtos lase r da Classe I não sã o conside rados peri gos os. I nternamente , a impr esso ra cont ém um produ to

laser da Classe IIIb (3b), designado laser de arseneto de potássio , de 5 milliwatts ,oper ando numa faixa de

comprimento de onda entre 770 e 795 nanómetros. O sistema e a impressora laser foram concebidos de forma

a nunca ex ist ir qualquer possiblidade de acesso humano a radi ação laser superior a um nív el de Classe I

durante a operação normal, a manutenção feita pelo utilizador ou condições de assist ência prescritas.

Laserinformatie

De printer v oldoet aan de eis en die ges teld w orde n aan ee n laserprodukt v an klass e I. Voor de Ver enigde Stat en

zijn deze eisen vastgelegd in DHHS 21 CFR Subchapter J, voor andere landen in IEC 60825-1.

Laserprodukten van klasse I worden nie t al s ongevaarlij k aangemerkt. De printer is voor zien van een laser van

klasse IIIb (3b), dat wil zeggen een gallium arsenide-laser van 5 milliwatt met e en g ol flengte van 770-795

nanometer . Het laser gedeelt e en de printer zij n zo ont worpen dat bij normaal gebru ik, bij onde rho ud of repar atie

conform de voorschriften, nooit blootstelling mogelijk is aan laserst raling boven een niveau zoals

voorgeschreven is voor klasse 1.

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i overenstemmelse med kravene i IEC 60825-1.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren indeholder internt en Klasse IIIB (3b)-laser, der

nominelt er en 5 milliwatt galliumarsenid laser, som arbejder på bølgelængdeområdet 770-795 nanometer.

Lasersystem et og printeren er udformet således, at mennesk er al drig udsættes for en l aserstråling over Klasse

I-niveau ved normal drift, brugervedligeholdelse eller obligatoriske servicebetingelser.

xii Service Manual

Page 13

5061

Laserilmoitus

Tämä tulostin on sertifioitu Yhdysvalloissa DHHS 21 CFR Subchapter J -standardin mukaiseksi luokan I (1) lasertuotteeksi j a m uualla IEC 60825-1 -standardin mukaiseksi luo kan I l asertuot teeksi.

Luokan I lasertuottei ta ei pidet ä hai talli sina. Tulostimen sisäl lä on luo kan IIIb (3b) laser, joka on nimellisteholt aan

5 mW:n galliumarsenidilaser ja toimii 770 - 795 nanometrin aallonpituuksilla. Laserjärjestelmä ja tulostin ovat

rakenteeltaan sellaisi a, että käyttäjä ei joudu alttiiksi luokkaa 1 suur em ma lle säteilylle normaalin käytön,

ylläpidon tai huollon aikana.

Huomautu s las er laitteesta

Tämä kirjoi tin on Yh dysv alloi ssa lu okan I ( 1) lase rlait teide n DHHS 21 CFR Subchapt er J -mää rityks en muk ainen

ja muualla luo kan I l aserl aitteiden IEC 60825-1 -määri tyksen mukainen.

Luokan I las e r la itt e id e n e i ka ts o ta ol evan vaarallis ia käyttäjä lle . K irjoittimessa on sisäi nen lu ok a n IIIb (3 b ) 5

milliwatin galliumarsenidilaser, joka toimii aaltoalueella 770 - 795 nanometriä. Lase rjärjestelmä ja kirjoitin on

suunnitelt u siten, että käyttäj ä ei al tistu luokan I määrityksi ä voimakkaammall e säteilylle kirj oittimen normaalin

toiminnan, käyttäjän tekemien huoltotoimien tai muiden huoltotoimien yhteydessä.

VARO! Av attaessa ja suojalukitus ohitettaessa olet alttiina näkymä ttömälle lasersäteilylle. Älä katso

säteeseen.

VARNING! Osynlig laserst rålning när denna del är öppnad och spär ren är urkopplad. Betrakta ej strålen.

Laser-notis

Denna skrivare är i USA certifierad att motsvara kraven i DHHS 21 CFR, underparagraf J för laserprodukter av

Klass I (1). I andra länder uppfyller skriv aren kraven för laserprodukter av Kl ass I enligt kraven i IEC 60825-1.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en inbyggd laser av Klass IIIb (3b) som består av

en laserenhet av gallium-arsenid på 5 milliwatt som arbetar i våglängdsområdet 770-795 nanometer.

Lasersystem et och skrivaren är utformade så att det aldrig finns ris k för att någon person utsätts f ör

laserstrå lning över Klass I-ni vå vid normal användning, underhåll som utförs av användaren eller annan

föreskriv en serviceåtgärd.

Laser-melding

Skriveren er godkjent i USA etter kra vene i DHHS 21 CFR, underkapittel J, for klasse I (1) laserprodukter , og er

i andre land godkjent som et Klasse I-laserprodukt i samsvar med kravene i IEC 60825-1.

Klasse I-la serprodukter er ikke å betrakte som f arlige. Skriveren inneholder internt en klasse IIIb (3b)-laser, som

består av en gallium-arsenlaserenhet som avgir stråling i bølgelengdeområdet 770-795 nanometer .

Lasersystem et og skriveren er utformet slik at personer al dri utsettes for laserstråling ut over klasse I-nivå under

vanlig bruk , vedlikehol d som utf øres av brukeren, eller foreskrevne serviceoperasjoner.

Notices and safety information xiii

Page 14

5061

Avís sobre el Làser

Segons ha estat certificat al s Estats Units , aquesta impressor a complei x els req uisits de DHHS 21 CFR, apartat

J, pels productes làser de classe I (1), i segons ha estat certificat en altres llocs, és un producte làser de classe

I que compleix els requisits d’IEC 60825-1.

Els productes l àser de classe I no es consideren perillosos. Aquesta impressora conté un làse r de cl asse IIIb

(3b) d’arseniür de gal.li, nominalment de 5 mil.liwats, i funciona a la regió de longitud d’ona de 770-795

nanòmetres. El sistema làser i la impressora han sigut concebuts de manera que mai hi hagi exposició a la

radiació làser per sobre d’un niv ell de classe I durant una oper ació normal, durant les tasques de manteniment

d’usuari ni durant els serveis que satisfacin les condicions prescrites.

xiv Service Manual

Page 15

5061

Notices and saf ety information xv

Page 16

5061

xvi Service Manual

Page 17

5061

Safety information

• The safety of this product is based on testi ng and approvals of t he original design and specific

components . The manufacturer is not responsibl e for safety in the event of use of unauthorized

replacement parts .

• The maintenance information for this product has been prepared for use by a professional service person

and is not intended to be used by others.

• There may be an increased risk of electric shoc k and personal injury during disassem bly and servicing of

this product . Pro fessional service personnel should understand this and take necessary precautions.

• CAUTION: When you see th is symbol , ther e is a danger f rom hazard ous v olt age in the ar ea of the

product where y ou ar e working . Unplug the product bef ore you beg in, or use c autio n if t he produc t

must receive power in order to perform the task.

Consignes de sécurité

• La sécurité de ce produit repose sur des tests et des

agréations portant sur sa conception d'origine et sur des composants particulier s. Le fabricant n'ass ume

aucune respon sabilité concernant la sécurité en cas d'utilisation de pièces de rechange non agréées.

• Les consignes d'entretien et de répar ati on de ce produit s'adressent uniquement à un personnel de

maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains risques électriques, le personnel

d'entretien qualifié devra prendre toutes les précautions nécessai res.

• ATTENTION : Ce symbole indique la présence d'une tension dangereuse dans la partie du

produit sur laquelle vous tra vaillez. Débranchez le produit a vant de commencer ou f aites preuve

de vigilance si l' exécution de la t âche exige que le produi t reste sous tension.

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione del progetto originale e dei componenti

specifici. Il produttore non è responsabile per la sicurezza in caso di sostituzion e non autorizzata delle

parti.

• Le informazioni riguardanti la manutenzione di questo prodotto sono indirizzate soltanto al personale di

assistenza autorizzato .

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni al la persona è più elev ato. Il per sonale di assistenza

autorizzato deve, quindi, adottare le precauzioni necessarie.

• ATTENZIONE: Questo simbolo indica la presenza ditensione pericolosa nell'area del prodotto.

Scollegare il pr odotto prima di iniziare o usare cautela se il prodotto deve essere alimentato per

eseguire l'intervento.

Safety information xvii

Page 18

5061

Sicherheitshinweise

• Die Sicherheit di eses Produkts basiert auf Tests und Zulassungen des ursprüngl ichen Modells und

bestimmter Baut eil e. Bei Verwendung nicht genehmigter Ersatztei le wi rd vom Hersteller kei ne

Verantwortung oder Haft ung für die Sicherheit übernommen.

• Die Wartungsinformationen für dies es Produkt sind ausschließl ich für die Verwendung durch ein en

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts besteht ein zusät zliches Risiko eines

elektrischen Schlags und körperlicher Verletzung. Das zus tändige Fachpersonal sollte entsprechende

Vorsichtsmaßn ahm en treffen.

• ACHTUNG: Dieses Symbol weist auf eine gefährliche elektrische Spannung hin, die in diesem

Bereich des Produkts auftreten kann. Zie hen Sie vor den Arbeiten am Gerät den Netzstecker des

Geräts, bzw. arbeiten Sie mit großer Vorsicht, wenn das Produkt für die Ausführung der Arbeiten

an den Strom angeschlossen sein muß.

Pautas de Segu ridad

• La seguridad de este prod ucto se basa en pruebas y aprobaciones del diseño original y component es

específico s. El fabricante no es responsable de la seguridad en caso de uso de piezas de repuesto no

autorizadas.

• La información sobre el mantenimiento de este producto está dirigida exclusivamente al personal

cualificado de mantenimiento.

• Existe may o r riesg o de de scarga el éctrica y de dañ os person al es duran te e l desmont aj e y la r eparac ión de

la máquina. El personal cualificado debe ser consciente de este peligro y tomar las precauciones

necesarias.

• PRECAUCIÓN: este símbolo indica que el voltaje dela parte del equipo con la que está

trabajando es peligroso. Antes de empezar, desenchufe el equipo o tenga cuidado si, para

trabajar con él, debe conectarlo.

Informações de Segurança

• A segurança deste produto baseia-se em testes e aprovações do mode lo original e de componentes

específico s. O fabricante não é responsável pela segunrança, no caso de uso de peças de substituição

não autorizadas.

• As informações de segurança relativas a este produto dest inam-se a profissionais destes serviços e não

dev em ser utilizadas por outr as pessoas.

• Risco de choques eléct ricos e ferimentos graves durante a desmontagem e manutenção deste produto .

Os profissio nais destes serviços devem estar avis ados deste facto e tomar os cuidados necessários .

• CUIDADO: Quando vir este sí m bolo, existe a possível presença de uma potencial tens ão

perigosa na zona do produto em que está a trabalhar. Antes de começar, desligu e o produto da

tomada eléctrica ou s eja cui dado so caso o pro duto te nha d e estar liga do à corrent e eléc trica para

realizar a tarefa necessária.

xviii Service Manual

Page 19

5061

Inf ormació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i apr ovació del disseny original i els components

específics.

El fabricant no es fa responsable de les qüestions de

seguretat si s'u tilitzen peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest producte està orientada exclusiv ame nt a professional s i no està

destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augment ar durant el procés de desmuntatge i de servei

d’aquest producte. El personal professional ha d’estar-ne assabentat i prendre

les mesures con venients.

• PRECAUCIÓ: aquest símbol in dica que el voltatge de la part de l'equip am b la qual esteu

treballan t és perillós . Abans de començar, desendoll eu l'equ ip o extremeu les precaucions si, per

treballar amb l'equip, l'heu de connectar.

Sa fety informat ion xix

Page 20

5061

Preface

This manual contains maintenance procedures for service personnel. It is divided into t he following ch apters:

1. General in form a tion contains a general description of the printer and the maintenance approach used to

repair it. Speci al tools and test equipment, as well as general environmental and safety instructions, are

discussed.