B2650, M3250, MS621, and

MS622 printers

4600-830, -835, -895

Service Manual

• Start diagnostics

• Maintenance

• Safety and notices

• Trademarks

• Index

November 16, 2018 www.lexmark.com

Product information

Product name:

Lexmark B2650dn, Lexmark B2650dw, Lexmark M3250, Lexmark MS621dn, Lexmark MS622de printers

Machine type:

4600

Model(s):

830, 835, 895

4600-830, -835, -895

Edition notice

November 16, 2018

The following paragraph does not apply to any country where such provisions are inconsistent with local law: LEXMARK

INTERNATIONAL, INC., PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Some states do not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement

may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the information

herein; these changes will be incorporated in later editions. Improvements or changes in the products or the programs described

may be made at any time.

References in this publication to products, programs, or services do not imply that the manufacturer intends to make these available

in all countries in which it operates. Any reference to a product, program, or service is not intended to state or imply that only that

product, program, or service may be used. Any functionally equivalent product, program, or service that does not infringe any

existing intellectual property right may be used instead. Evaluation and verification of operation in conjunction with other products,

programs, or services, except those expressly designated by the manufacturer, are the user’s responsibility.

Trademarks

Lexmark and the Lexmark logo are trademarks of Lexmark International, Inc., registered in the United States and/or other countries.

PCL® is a registered trademark of the Hewlett-Packard Company. PCL is Hewlett-Packard Company’s designation of a set of printer

commands (language) and functions included in its printer products. This printer is intended to be compatible with the PCL language.

This means the printer recognizes PCL commands used in various application programs, and that the printer emulates the functions

corresponding to the commands.

PostScript is a registered trademark of Adobe Systems Incorporated in the United States and/or other countries.

All other trademarks are the property of their respective owners.

© 2018 Lexmark International, Inc.

All rights reserved.

P/N

4600-830, -835, -895

Table of contents

Product information......................................................................................2

Edition notice.................................................................................................2

Notices, conventions, and safety information.......................................... 9

Laser notice...........................................................................................................................................................9

Conventions.........................................................................................................................................................12

Safety information.............................................................................................................................................. 13

General caution statements............................................................................................................................ 18

Change history............................................................................................ 19

Change history....................................................................................................................................................19

General information....................................................................................21

Printer model configurations...........................................................................................................................21

Finding the serial number................................................................................................................................ 21

Paper support.....................................................................................................................................................22

Supported paper sizes...............................................................................................................................................22

Supported paper types.............................................................................................................................................. 23

Supported paper weights ......................................................................................................................................... 24

Tools required for service................................................................................................................................24

Diagnostics and troubleshooting............................................................. 25

Troubleshooting overview.............................................................................................................................. 25

Performing the initial troubleshooting check.......................................................................................................25

Fixing print quality issues................................................................................................................................25

Initial print quality check............................................................................................................................................ 26

Gray background or toner fog check..................................................................................................................... 27

Blank pages check......................................................................................................................................................29

Print is too dark check................................................................................................................................................35

Print is too light check.................................................................................................................................................37

Paper curl check..........................................................................................................................................................40

Folded or wrinkled paper check .............................................................................................................................. 41

Solid black pages check............................................................................................................................................ 42

Repeating defects check........................................................................................................................................... 45

Skewed print check ....................................................................................................................................................46

Streaked vertical lines appear on prints check................................................................................................... 48

Horizontal light bands check.................................................................................................................................... 49

Table of contents

3

4600-830, -835, -895

Vertical light bands check.........................................................................................................................................50

Vertical dark bands check..........................................................................................................................................51

Vertical dark streaks with print missing check ....................................................................................................53

White streaks and voided areas check .................................................................................................................55

Fine lines are not printed correctly (specifically Chinese characters) check .............................................. 58

Clipped pages or images check..............................................................................................................................59

Compressed images appear on prints check.......................................................................................................61

Incorrect margins on prints check ..........................................................................................................................62

Toner rubs o check ...................................................................................................................................................63

Toner specks appear on prints check....................................................................................................................64

Paper jams...........................................................................................................................................................66

Avoiding jams...............................................................................................................................................................66

Identifying jam locations............................................................................................................................................ 67

Paper jam in door A....................................................................................................................................................68

Paper jam in the rear door..........................................................................................................................................71

Paper jam in the standard bin.................................................................................................................................. 72

Paper jam in the duplex unit......................................................................................................................................73

Paper jam in trays.........................................................................................................................................................74

Paper jam in the multipurpose feeder ....................................................................................................................74

200 paper jams............................................................................................................................................................ 75

202 paper jams............................................................................................................................................................ 86

230 paper jams............................................................................................................................................................90

240-241 paper jams ....................................................................................................................................................93

242-244 paper jams ................................................................................................................................................... 97

User attendance messages (0–99.99)...................................................................................................... 102

User attendance messages.....................................................................................................................................102

Unsupported or unresponsive toner cartridge service check .......................................................................103

Unsupported or unresponsive imaging unit service check ............................................................................105

Mismatched supplies error service check...........................................................................................................106

Maintenance kit low service check........................................................................................................................106

Printer hardware errors.................................................................................................................................. 107

111 errors........................................................................................................................................................................107

121 errors.......................................................................................................................................................................108

126 errors.......................................................................................................................................................................114

128 errors.......................................................................................................................................................................116

133 errors.......................................................................................................................................................................119

140 errors......................................................................................................................................................................120

155 errors.......................................................................................................................................................................121

16y errors ......................................................................................................................................................................122

171 errors .......................................................................................................................................................................127

6yy errors......................................................................................................................................................................128

Procedure before starting the 9yy service checks ...........................................................................................130

900 errors ....................................................................................................................................................................132

Table of contents

4

4600-830, -835, -895

Service menus........................................................................................... 137

Understanding the printer control panel....................................................................................................137

Using the printer control panel...............................................................................................................................137

Understanding the status of the power button and indicator light...............................................................138

Using the home screen.............................................................................................................................................138

Diagnostics menu............................................................................................................................................ 140

Entering the Diagnostics menu ..............................................................................................................................140

Reports..........................................................................................................................................................................140

Advanced Print Quality Samples............................................................................................................................140

Event Log......................................................................................................................................................................140

Input tray quick print...................................................................................................................................................141

Output bin quick feed ...............................................................................................................................................142

Printer Setup................................................................................................................................................................142

Printer diagnostics and adjustments.....................................................................................................................144

Additional input tray diagnostics............................................................................................................................146

Configuration Menu.........................................................................................................................................147

Service Engineer menu..................................................................................................................................150

Entering Invalid engine mode.................................................................................................................................150

Entering the Service Engineer (SE) menu............................................................................................................150

General SE ...................................................................................................................................................................150

Network SE ..................................................................................................................................................................150

Parts removal.............................................................................................153

Removal precautions...................................................................................................................................... 153

Data security notice...................................................................................................................................................153

Handling ESD‑sensitive parts..................................................................................................................................154

Controller board/control panel replacement ......................................................................................................155

Restoring the printer configuration after replacing the controller board ....................................................155

Restoring solutions, licenses, and configuration settings ...............................................................................158

Updating the printer firmware ................................................................................................................................159

Backing up eSF solutions and settings ................................................................................................................160

Disconnecting ribbon cables....................................................................................................................................161

Ribbon cable connectors ..........................................................................................................................................161

Zero Insertion Force (ZIF) connectors...............................................................................................................161

Horizontal top contact connector .....................................................................................................................162

Horizontal bottom contact connector..............................................................................................................165

Vertical mount contact connector.....................................................................................................................168

Horizontal sliding contact connector ................................................................................................................171

Low Insertion Force (LIF) connector.................................................................................................................174

Printhead assembly adjustment .............................................................................................................................175

Removal procedures....................................................................................................................................... 177

Left side removals............................................................................................................................................ 177

Table of contents

5

4600-830, -835, -895

Left cover removal ..................................................................................................................................................... 177

Main drive gearbox removal....................................................................................................................................178

MPF gearbox removal...............................................................................................................................................179

Fuser actuator removal.............................................................................................................................................182

Reverse solenoid removal .......................................................................................................................................183

Cartridge gearbox removal......................................................................................................................................184

MPF solenoid removal ..............................................................................................................................................185

Right side removals.........................................................................................................................................186

Right cover removal...................................................................................................................................................186

Interconnect cable removal.....................................................................................................................................188

Sensor (tray present) removal.................................................................................................................................189

Cooling fan removal...................................................................................................................................................190

Controller board removal.........................................................................................................................................194

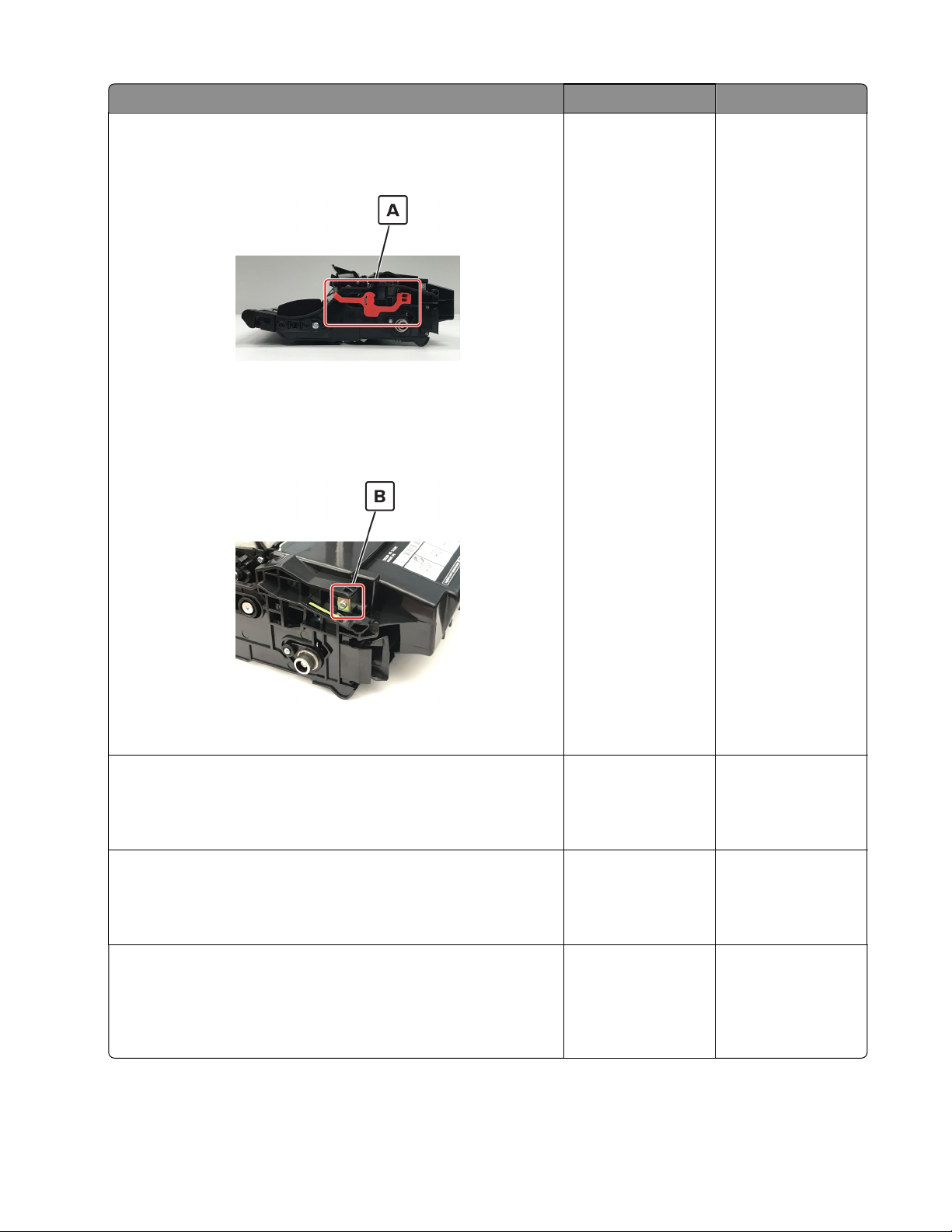

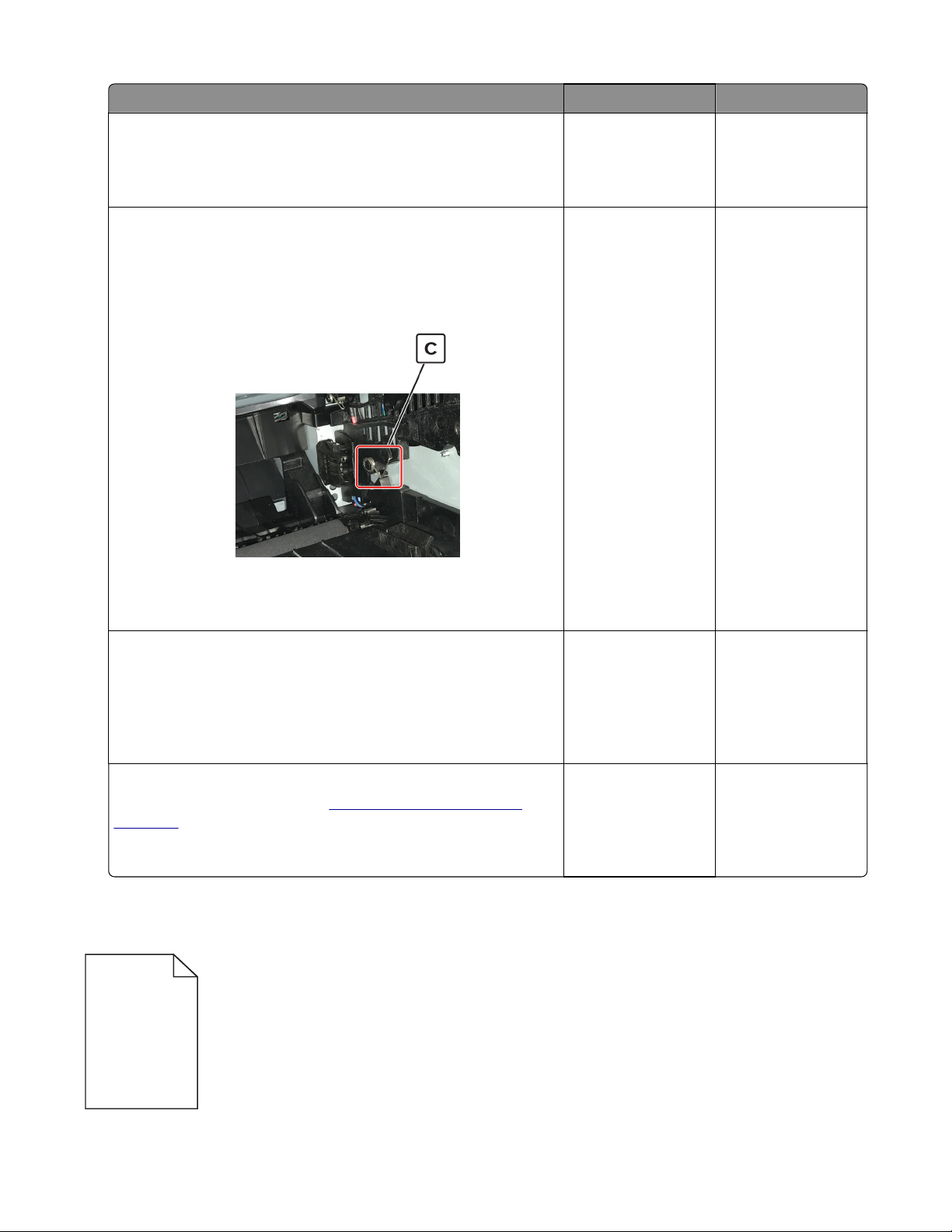

Toner cartridge smart chip contact removal .......................................................................................................195

Cartridge barrel shutter sensor kit removal ........................................................................................................198

Front removals..................................................................................................................................................201

Nameplate removal....................................................................................................................................................201

MPF with front access cover removal...................................................................................................................201

Control panel assembly removal (MS621dn)..................................................................................................... 202

Control panel assembly removal (MS622de and MS622dte) .......................................................................203

Control panel (2.4‑inch display) cover, buttons, and board removal...........................................................204

Control panel (4.3‑inch display) cover, buttons, and board removal ......................................................... 205

Transfer roller removal............................................................................................................................................ 206

Jam access cover removal .................................................................................................................................... 206

Sensor (front door) removal....................................................................................................................................207

MPF pick roller and separator pad removal...................................................................................................... 209

Sensor (MPF paper present) removal ...................................................................................................................212

Front input guide removal........................................................................................................................................213

Front USB port removal............................................................................................................................................213

Bottom removals..............................................................................................................................................216

Power supply removal...............................................................................................................................................216

Duplex assembly removal........................................................................................................................................218

Sensors (duplex and input) removal.................................................................................................................... 220

Sensor (index) removal ............................................................................................................................................222

Sensor (toner density) removal..............................................................................................................................222

Sensor (paper present) removal............................................................................................................................224

Sensor (trailing edge) removal...............................................................................................................................226

Paper present sensor flag removal.......................................................................................................................228

Pick roller assembly removal..................................................................................................................................230

Pick/lift motor gearbox removal.............................................................................................................................232

Rear side removals......................................................................................................................................... 234

Rear door and cover removal.................................................................................................................................234

Fuser removal.............................................................................................................................................................234

Sensor (bin full) removal..........................................................................................................................................235

Table of contents

6

4600-830, -835, -895

Redrive assembly removal......................................................................................................................................236

Redrive gear plate removal ....................................................................................................................................237

Top side removals...........................................................................................................................................238

Top cover removal.....................................................................................................................................................238

Printhead removal.....................................................................................................................................................239

Optional 250/550-sheet tray removals.................................................................................................... 242

Separator roller assembly removal.......................................................................................................................242

Component locations...............................................................................245

Printer configurations.....................................................................................................................................245

Attaching cables..............................................................................................................................................245

Printer roller locations....................................................................................................................................247

Printer sensor locations.................................................................................................................................249

Controller board connectors....................................................................................................................... 250

Maintenance............................................................................................. 255

Inspection guide............................................................................................................................................. 255

Scheduled maintenance...............................................................................................................................255

Maintenance kits........................................................................................................................................................255

Resetting the maintenance counter.....................................................................................................................256

Cleaning the printer....................................................................................................................................... 256

Cleaning the printhead lenses.................................................................................................................... 257

Parts catalog.............................................................................................258

Legend...............................................................................................................................................................258

Assembly 1: Covers........................................................................................................................................ 259

Assembly 2: Control panel............................................................................................................................261

Assembly 3: Electronics 1..............................................................................................................................263

Assembly 4: Electronics 2............................................................................................................................ 265

Assembly 5: Electronics 3.............................................................................................................................267

Assembly 6: Electronics 4............................................................................................................................ 269

Assembly 7: Paper transport 1.......................................................................................................................271

Assembly 8: Paper transport 2.................................................................................................................... 273

Assembly 9: MPF and standard tray.......................................................................................................... 275

Assembly 10: Optional trays......................................................................................................................... 277

Assembly 11: Maintenance kits.................................................................................................................... 279

Assembly 12: Miscellaneous......................................................................................................................... 281

Table of contents

7

4600-830, -835, -895

Printer

Power consumption....................................................................................................................................... 283

Selecting a location for the printer.............................................................................................................284

Noise emission levels....................................................................................................................................285

Temperature information.............................................................................................................................. 286

specifications

Product power consumption..................................................................................................................................283

Sleep Mode.................................................................................................................................................................283

Hibernate Mode.........................................................................................................................................................283

O mode......................................................................................................................................................................284

Total energy usage ...................................................................................................................................................284

............................................................................... 283

Options and features............................................................................... 287

Available internal options............................................................................................................................. 287

Input/output configurations and capacities..............................................................................................287

Theory of operation................................................................................. 289

POR sequence.................................................................................................................................................289

Print cycle operation......................................................................................................................................289

Print engine layout ....................................................................................................................................................289

Print cycle................................................................................................................................................................... 290

Printer operation.............................................................................................................................................296

Printer sections ..........................................................................................................................................................296

Printer paper path .....................................................................................................................................................297

Printer paper path sensors .....................................................................................................................................299

Main drive................................................................................................................................................................... 300

Tray drive......................................................................................................................................................................301

Acronyms...................................................................................................303

Index.......................................................................................................... 305

Part number index....................................................................................309

Part name index........................................................................................ 313

Table of contents

8

4600-830, -835, -895

Notices, conventions, and safety information

Laser notice

The printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, Chapter I, Subchapter J for

Class I (1) laser products, and elsewhere is certified as a Class I laser product conforming to the requirements

of IEC 60825-1: 2014.

Class I laser products are not considered to be hazardous. The printer contains a Class IIIb (3b) AlGaInP laser

that is nominally 15 milliwatts operating in the wavelength region of 650–670 nanometers and enclosed in a

non-serviceable printhead assembly. The laser system and printer are designed so there is never any human

access to laser radiation above a Class I level during normal operation, user maintenance, or prescribed service

conditions.

Avis relatif à l'utilisation du laser

Cette imprimante est certifiée conforme aux exigences de la réglementation des Etats-Unis relative aux produits

laser de classe I (1) (DHHS 21 CFR, Chapitre I, Sous-chapitre J). Pour les autres pays, elle est certifiée conforme

aux exigences des normes CEI 60825-1: 2014 relatives aux produits laser de classe I.

Les produits laser de Classe I ne sont pas considérés comme dangereux. L'imprimante contient un dispositif

laser AlGaInP (aluminium, gallium, indium et phosphore) de classe IIIb (3b) d'une puissance nominale de

15 milliwatts fonctionnant dans la plage de longueurs d'onde allant de 650 à 670 nanomètres et scellé dans

un compartiment de têtes d'impression non réparable. Le système laser ainsi que l'imprimante ont été conçus

de manière à ce que personne ne soit jamais exposé à des radiations laser dépassant le niveau de classe I

dans le cadre d'un fonctionnement normal, de l'entretien par l'utilisateur ou de la maintenance.

Notificació

La impressora està certificada als EUA per complir els requeriments de DHHS 21 CFR, capítol I, subcapítol J

per a productes de làser Classe I (1), i a la resta del món s’ha certificat com productes de làser Classe I segons

els requeriments de la norma IEC 60825-1: 2014.

Els productes de làser Classe I no es consideren perillosos. La impressora conté un làser intern Classe IIIb (3b)

AlGaInP que normalment és de 15 miliwatts, que funciona a la regió de longitud d’ona de 650 a 670 nanòmetres

i es troba dins d’una unitat de capçals d’impressió no substituïble. El sistema làser i la impressora estan

dissenyats de manera que les persones no estiguin exposades a una radiació del làser superior al nivell de

Classe I durant el funcionament normal, el manteniment de l’usuari o les condicions de servei prescrites.

del làser

Aviso de láser

Esta impresora se ha

subcapítulo J para los productos láser de Clase I (1) y en otros países está certificada como un producto láser

de Clase I de acuerdo con los requisitos de IEC 60825-1: 2014.

certificado

en EE.UU. cumpliendo con los requisitos de DHHS 21 CFR, capítulo I,

Los productos láser de Clase I no se consideran peligrosos. Este producto contiene un láser interno de Clase

IIIb (3b) AlGaInP que opera nominalmente a 15 milivatios en una longitud de onda de 650–670 nanómetros

cerrado en un conjunto de cabezal de impresión que no se puede reparar. El sistema láser y la impresora se

han diseñado para que el ser humano no acceda nunca a las radiaciones láser por encima del nivel de Clase

I durante su uso normal, ni en tareas de mantenimiento o intervenciones de servicio técnico prescritas.

Notices, conventions, and safety information

9

4600-830, -835, -895

Aviso sobre laser

Esta impressora foi certificada nos EUA por estar em conformidade com os requisitos do DHHS 21 CFR capítulo

I, subcapítulo J, para produtos a laser de Classe I (1) e, nos demais países, foi certificada como um produto a

laser de Classe I em conformidade com os requisitos da IEC 60825-1: 2014.

Os produtos a laser de Classe I não são considerados prejudiciais. A impressora contém, internamente, um

laser de Classe IIIb (3b) AlGaInP que funciona nominalmente a 15 miliwatts no comprimento de onda de 650-670

nanômetros, incluso em um conjunto do cabeçote de impressão sem possibilidade de manutenção. O sistema

do laser e a impressora foram projetados para que jamais haja acesso humano à radiação do laser acima do

nível da Classe I durante a operação normal ou a manutenção pelo usuário ou sob as condições de manutenção

prescritas.

Avvertenze sui prodotti laser

La stampante è certificata negli Stati Uniti come prodotto conforme ai requisiti DHHS 21 CFR Capitolo I,

Sottocapitolo J per i prodotti laser di Classe I (1), mentre in altri paesi è certificata come prodotto laser di Classe

I conforme ai requisiti IEC 60825-1: 2014.

I prodotti laser di Classe I non sono considerati pericolosi. La stampante contiene internamente un laser AlGaInP

di Classe IIIb (3b) con valore nominale di 15 milliwatt, funzionante nella regione della lunghezza d'onda dei

650-670 nanometri e contenuto in un gruppo testina di stampa non riparabile. Il sistema laser e la stampante

sono stati progettati in modo da impedire l'esposizione a radiazioni laser superiori al livello previsto dalla Classe

I durante le normali operazioni di stampa, manutenzione o assistenza.

Laserinformatie

De printer is in de Verenigde Staten gecertificeerd als een product dat voldoet aan de vereisten van DHHS 21

CFR hoofdstuk 1, paragraaf J voor laserproducten van klasse I (1). Elders is de printer

laserproduct van klasse I dat voldoet aan de vereisten van IEC 60825-1: 2014.

Laserproducten van klasse I worden geacht geen gevaar op te leveren. De printer bevat intern een laser van

klasse IIIb (3b) AlGaInP met een nominaal vermogen van 15 milliwatt in een golflengtebereik van 650-670

nanometer in een niet-bruikbare printkopeenheid. Het lasersysteem en de printer zijn zodanig ontworpen dat

gebruikers nooit blootstaan aan laserstraling die hoger is dan het toegestane niveau voor klasse I-apparaten,

tijdens normaal gebruik, onderhoudswerkzaamheden door de gebruiker of voorgeschreven

servicewerkzaamheden.

gecertificeerd

als een

Lasererklæring

Printeren er

laserprodukter og er andre steder

2014.

Klasse I-laserprodukter er ikke anset som farlige. Printeren indeholder internt en Klasse IIIb (3b) AlGaAs-laser,

der nominelt er en 15 milliwatt laser, som fungerer i bølgelængdeområdet 650–670 nanometer og indbygget

i en printhovedenhed, der ikke er servicerbar. Lasersystemet og printeren er designet på en sådan måde, at

der ikke er en direkte laserstråling, der overskrider Klasse I-niveauet under normal brug, brugers

vedligeholdelse eller de foreskrevne servicebetingelser.

certificeret

i USA i henhold til kravene i DHHS 21 CFR kapitel I, underafsnit J for klasse l (1)

certificeret

som et klasse I-laserprodukt i henhold til kravene i IEC 60825-1:

Notices, conventions, and safety information

10

4600-830, -835, -895

Laser-Hinweis

Der Drucker wurde in den USA zertifiziert und entspricht den Anforderungen der Vorschriften DHHS 21 CFR

Kapitel I für Laserprodukte der Klasse I (1), andernorts ist er als Laserprodukt der Klasse I zertifiziert, das den

Anforderungen von IEC 60825-1: 2014 entspricht.

Laserprodukte der Klasse I werden nicht als gefährlich betrachtet. Der Drucker enthält im Inneren einen Laser

der Klasse IIIb (3b) AlGaInP mit 15 Milliwatt, im Wellenlängenbereich von 650 bis 670 Nanometern arbeitet.

Dieser befindet sich in einer Druckkopfeinheit, die nicht gewartet werden kann. Das Lasersystem und der

Drucker sind so konstruiert, dass unter normalen Betriebsbedingungen, bei der Wartung durch den Benutzer

oder bei den vorgeschriebenen Wartungsbedingungen Menschen keiner Laserstrahlung ausgesetzt sind, die

die Werte für Klasse I überschreitet.

Laserilmoitus

Tämä tulostin on sertifioitu Yhdysvalloissa DHHS 21 CFR, Chapter I, Subchapter J -standardin mukaiseksi luokan

I (1) -lasertuotteeksi ja muualla IEC 60825-1: 2014 -standardin mukaiseksi luokan I lasertuotteeksi.

Luokan I lasertuotteita ei pidetä haitallisina. Tulostimen sisällä on luokan IIIb (3b) AlGaInP -laser, jonka

nimellisteho on 15 mW milliwatts, joka toimii 650–670 nanometrin aallonpituuksilla ja joka on suljettu

tulostuspäähän, jota käyttäjä ei voi huoltaa. Laserjärjestelmä ja tulostin ovat rakenteeltaan sellaisia, että käyttäjä

ei joudu alttiiksi luokkaa 1 suuremmalle säteilylle normaalin käytön, ylläpidon tai huollon aikana.

Lasermerknad

Skriveren er sertifisert i USA for samsvar med kravene i DHHS 21 CFR, kapittel I, underkapittel J for

laserprodukter av klasse I (1) og er andre steder sertifisert som et laserprodukt av klasse I som samsvarer med

kravene i IEC 60825-1: 2014.

Laserprodukter av klasse I anses ikke som helseskadelige. Skriveren inneholder en intern AlGaInP-laser av

klasse IIIb (3b) på nominelt 15 milliwatt, som opererer i bølgelengder på 650–670 nanometer, inne i en

skrivehodeenhet som ikke kan vedlikeholdes. Lasersystemet og skriveren er utformet slik at mennesker ikke

utsettes for laserstråling utover nivået i klasse I under normal drift, vedlikehold eller foreskrevet service.

Meddelande om laser

Skrivaren är certifierad i USA i enlighet med kraven i DHHS 21 CFR kapitel I, underkapitel J för klass I (1)laserprodukter, och på andra platser

2014.

Laserprodukter av klass I anses inte vara skadliga. Skrivaren innehåller en klass IIIb (3b) AlGaInP-laser på

nominellt 15 mW som arbetar inom en våglängd på 650–670 nm och är innesluten i en icke-servicebar

skrivhuvudenhet. Lasersystemet och skrivaren är utformade så att människor aldrig utsätts för laserstrålning

över klass I-nivå under normala förhållanden vid användning, underhåll eller service.

certifierad

som en klass I-laserprodukt i enlighet med kraven i IEC 60825-1:

レーザーについて

本機は、米国において クラス I(1)レーザー製品に対する DHHS 21 CFR、Chapter I、Subchapter J の要件

に準拠し、その他の国では IEC 60825-1: 2014 の要件に準拠するクラス I レーザー製品として認可されてい

ます。

クラス I レーザー製品は、危険性がないとみなされています。 本機には、クラス IIIb(3b)AlGaInP レーザ

ーが内蔵されています。これは、650 ~ 670 ナノメートルの波長で、定格 15 ミリワットで動作するレーザ

ーであり、整備不可のプリントヘッドアセンブリに収容されています。 レーザーシステムとプリンタは、

Notices, conventions, and safety information

11

4600-830, -835, -895

通常の操作、ユーザーによるメンテナンス、または所定のサービス条件の下で、ユーザーがクラス I レベル

を超えるレーザー放射に絶対にさらされないように設計されています。

레이저 고지사항

프린터는 미국에서 레이저 제품용 DHHS 21 CFR Chapter I, Subchapter J의 요구 사항을 준수하며 이외 지역에

서 IEC 60825-1: 2014의 요구 사항을 준수하는 클래스 I(1) 레이저 제품으로 승인되었습니다.

Class I 레이저 제품은 위험한 제품으로 간주되지 않습니다. 프린터에는 650~670 나노미터 범위의 파장 영역

에서 공칭 작동하는 15밀리와트 AlGaInP 레이저인 클래스 IIIb(3b) 레이저가 내부에 포함되어 있으며 서비스 불

가 프린트 헤드 어셈블리가 포함되어 있습니다. 레이저 시스템과 프린터는 정상적인

는 사전 설명된 서비스 조건에는 사람에게 클래스 I 수준 이상의 레이저 방사가 노출되지 않도록 설계되었습니

다.

작동, 사용자 유지 관리 또

激光注意事项

本打印机在美国认证合乎 DHHS 21 CFR Chapter I,Subchapter J 对分类 I(1)激光产品的标准,而在其他地

区则被认证是合乎 IEC 60825-1: 2014 的分类 I 激光产品。

一般认为分类 I 激光产品不具有危险性。本打印机内部含有分类 IIIb(3b)的磷化铝镓铟激光,标称值为 15 毫

瓦,其工作波长范围在 650–670nm 之间,并被封闭在不可维修的打印头配件中。本激光系统及打印机的设

计,在一般操作、使用者维护或规定内的维修情况下,不会使人体接触分类 I 以上等级的辐射。

雷射聲明

本印表機係經過美國核可,符合 DHHS 21 CFR,Chapter I,Subchapter J 規定的 I (1) 級雷射產品;在美國以

外的地區,為符合 IEC 60825-1: 2014 規定的 I 級雷射產品。

根據 I 級雷射產品的規定,這類產品不會對人體造成傷害。 本印表機所採用之 IIIb (3b) 級 AlGaInP 雷射在 650

至 670 奈米 (nanometer) 波長範圍內運作時通常為 15 毫瓦特 (milliwatt),且含括在不可修復列印頭組件中。 使

用者只要以正確的方法操作及維護保養,並依照先前所述之維修方式進行修護,此印表機與其雷射系統絕不會

產生 I 級以上的放射線,而對人體造成傷害。

Conventions

Note: A note identifies information that could help you.

Warning: A warning

CAUTION: A caution indicates a potentially hazardous situation that could injure you.

Dierent types of caution statements include:

CAUTION—POTENTIAL INJURY: Indicates a risk of injury.

CAUTION—SHOCK HAZARD: Indicates a risk of electrical shock.

CAUTION—HOT SURFACE: Indicates a risk of burn if touched.

identifies

something that could damage the product hardware or software.

CAUTION—TIPPING HAZARD: Indicates a crush hazard.

CAUTION—PINCH HAZARD: Indicates a risk of being caught between moving parts.

Notices, conventions, and safety information

12

Safety information

4600-830, -835, -895

• The safety of this product is based on testing and approvals of the original design and

The manufacturer is not responsible for safety in the event of use of unauthorized replacement parts.

specific

components.

• The maintenance information for this product has been prepared for use by a professional service person

and is not intended to be used by others.

• There may be an increased risk of electrical shock and personal injury during disassembly and servicing of

this product. Professional service personnel should understand this risk and take necessary precautions.

CAUTION—SHOCK HAZARD: When you see this symbol, there is a danger from hazardous voltage

in the area of the product where you are working. Unplug the product before you begin, or use

caution if the product must receive power in order to perform the task.

CAUTION—POTENTIAL INJURY: The lithium battery in this product is not intended to be replaced.

There is a danger of explosion if a lithium battery is incorrectly replaced. Do not recharge,

disassemble, or incinerate a lithium battery. Discard used lithium batteries according to the

manufacturer's instructions and local regulations.

Consignes de sécurité

• La sécurité de ce produit est basée sur des tests et

composants spécifiques. Le fabricant décline toute responsabilité en cas d'utilisation de pièces de rechange

non autorisées.

certifications

• Les informations de maintenance de ce produit sont destinées à des professionnels qualifiés et ne sont pas

conçues pour être utilisées par d'autres personnes.

• Il existe un risque potentiel de choc électrique et de blessures lors du démontage et de la maintenance de

ce produit. Le personnel professionnel de maintenance doit comprendre les risques et prendre les

précautions nécessaires.

de sa conception d'origine et de ses

ATTENTION—RISQUE D'ELECTROCUTION : Ce symbole indique un danger lié à des niveaux de

tension dangereux dans la zone du produit à manipuler. Débranchez le produit avant de commencer,

ou agissez avec prudence si le produit doit être alimenté pour eectuer l'opération.

ATTENTION—RISQUE DE BLESSURE : La batterie lithium de ce produit n'est pas destinée à être

remplacée. Si vous ne respectez pas les instructions de remplacement de la batterie, vous risquez

de provoquer une explosion. Ne rechargez pas, ne désassemblez pas et ne brûlez pas la batterie au

lithium. Mettez les batteries lithium usagées au rebut selon les instructions du fabricant et les

réglementations locales.

Informació de seguretat

• La seguretat d'aquest producte es basa en les proves i les homologacions del disseny original i dels

components específics. El fabricant no és responsable de la seguretat en el cas d'ús de peces de recanvi

no autoritzades.

• La informació de manteniment d'aquest producte s'ha preparat per a l'ús d'un professional tècnic i no per

a l'ús d'altres persones.

• És possible que el risc de descàrrega elèctrica i lesions personals augmenti durant el desmuntatge i les

tasques de manteniment d'aquest producte. El professional tècnic ha de comprendre aquest risc i prendre

les precaucions necessàries.

PRECAUCIÓ. PERILL DE DESCÀRREGA ELÈCTRICA: Quan vegeu aquest símbol, indica que hi ha

un perill de voltatge elevat en l'àrea del producte on esteu treballant. Desconnecteu el producte

abans de començar o tingueu precaució si el producte ha de rebre alimentació per realitzar la tasca.

Notices, conventions, and safety information

13

4600-830, -835, -895

PRECAUCIÓ. POSSIBLES DANYS: La bateria de liti d'aquest producte no ha estat dissenyada

perquè se substitueixi. Hi ha perill d’explosió si no es substitueix correctament la bateria de liti. No

recarregueu, desmunteu o incinereu una bateria de liti. Desfeu-vos de les bateries de liti usades

d’acord amb les instruccions del fabricant i les regulacions locals.

Información de seguridad

• La seguridad de este producto se basa en las pruebas y comprobaciones del diseño original y los

componentes específicos. El fabricante no se hace responsable de la seguridad en caso de uso de piezas

de repuesto no autorizadas.

• La información de mantenimiento de este producto se ha preparado para su uso por parte de un profesional

de asistencia técnica y no está diseñada para su uso por parte de otros usuarios.

• Es posible que haya un mayor riesgo de descarga eléctrica y daños personales durante el desmontaje y el

mantenimiento de este producto. El personal de asistencia profesional debe conocer este riesgo y tomar

las precauciones necesarias.

PRECAUCIÓN: PELIGRO DE DESCARGAS ELÉCTRICAS: Cuando vea este símbolo, existe peligro

de tensiones peligrosas en el área del producto en la que está trabajando. Desconecte el producto

antes de empezar o tenga cuidado si el producto debe recibir alimentación a fin de realizar la tarea.

PRECAUCIÓN: POSIBLES DAÑOS PERSONALES: La batería de litio de este producto no debe

reemplazarse. Existe riesgo de explosión si se sustituye incorrectamente una batería de litio. No

recargue, desmonte ni incinere una batería de litio. Deseche las baterías de litio usadas según las

instrucciones del fabricante y las normativas locales.

Informações sobre segurança

• A segurança deste produto é baseada em testes e aprovações do design original e de componentes

específicos. O fabricante não é responsável por segurança em caso de uso não autorizado de peças de

substituição.

• As informações sobre manutenção deste produto foram preparadas para utilização por um técnico

profissional experiente e não se destinam ao uso por outros.

• Pode haver maior risco de choque elétrico e danos pessoais durante a desmontagem e manutenção deste

produto. Os técnicos

necessárias.

ATENÇÃO—RISCO DE CHOQUE: Se você vir este símbolo, existe perigo de tensão elétrica na área

do produto onde está trabalhando. Desligue o produto antes de começar ou tenha cuidado se o

produto precisar receber energia para executar a tarefa.

ATENÇÃO—RISCO DE FERIMENTO: A bateria de lítio neste produto não deve ser substituída. Existe

o risco de explosão se uma bateria de lítio for substituída incorretamente. Não recarregue, desmonte

nem incinere uma bateria de lítio. Descarte as baterias de lítio usadas de acordo com as instruções

do fabricante e regulamentos locais.

profissionais

experientes devem entender esses riscos e tomar as precauções

Informazioni sulla sicurezza

• La sicurezza di questo prodotto è basata sui test e sulle approvazioni del design originale e dei componenti

specifici.

autorizzate.

• Le informazioni di manutenzione per questo prodotto sono state predisposte per essere utilizzate da un

tecnico dell'assistenza professionale e non sono state previste per l'uso da parte di altre persone.

Il produttore non è responsabile della sicurezza in caso di utilizzo di parti di ricambio non

Notices, conventions, and safety information

14

4600-830, -835, -895

• È possibile che vi sia un maggior rischio di scosse elettriche e lesioni personali durante lo smontaggio e la

manutenzione di questo prodotto. Il personale dell'assistenza deve comprendere questo rischio e prendere

le precauzioni necessarie.

ATTENZIONE - PERICOLO DI SCOSSE ELETTRICHE: Questo simbolo indica la presenza di un

rischio per tensioni pericolose nell'area del prodotto in cui si lavora. Scollegare l'alimentazione prima

di iniziare, o prestare la massima attenzione se per eettuare l'operazione il prodotto deve ricevere

l'alimentazione.

ATTENZIONE - PERICOLO DI LESIONI: La batteria al litio contenuto nel prodotto non deve essere

sostituita: in caso di sostituzione errata della batteria al litio, potrebbe verificarsi un'esplosione. Non

ricaricare, smontare o bruciare batterie al litio. Smaltire le batterie al litio usate seguendo le istruzioni

del produttore e le norme locali.

Informatie over veiligheid

• De veiligheid van dit product is gebaseerd op testen en goedkeuringen van het oorspronkelijke ontwerp

en specifieke onderdelen. De fabrikant is niet verantwoordelijk voor de veiligheid bij gebruik van

ongeautoriseerde vervangende onderdelen.

• De informatie over het onderhoud van dit product is opgesteld voor gebruik door een professionele

onderhoudsmonteur en is niet bedoeld voor gebruik door anderen.

• Tijdens demontage en onderhoud van dit product bestaat mogelijk een hoger risico op elektrische

schokken en lichamelijk letsel. Professionele onderhoudsmonteurs dienen op de hoogte te zijn van dit risico

en de noodzakelijke voorzorgsmaatregelen te nemen.

LET OP: GEVAAR VOOR ELEKTRISCHE SCHOKKEN: Wanneer u dit symbool ziet, bestaat er een

gevaar voor gevaarlijke spanning in het gebied van het product waaraan u werkt. Haal de stekker

van het product uit het stopcontact voordat u begint, of let extra goed op als het product stroom

nodig heeft om een taak te kunnen uitvoeren.

LET OP: RISICO OP LETSEL: De lithiumbatterij in dit product moet niet worden vervangen. Wanneer

de lithiumbatterij niet juist wordt vervangen, bestaat er explosiegevaar. Probeer nooit

lithiumbatterijen op te laden, open te maken of te verbranden. Gooi gebruikte lithiumbatterijen weg

volgens de aanwijzingen van de fabrikant en houd hierbij de plaatselijke regelgeving in acht.

Sikkerhedsoplysninger

• Sikkerheden for dette produkt er baseret på afprøvning og godkendelser af det oprindelige design og

specifikke

til udskiftning.

• Vedligeholdelsesoplysninger om dette produkt er udarbejdet til brug af en

er ikke beregnet til at blive brugt af andre.

• Der kan være en forøget risiko for elektrisk stød eller personskade ved afmontering og service af dette

produkt. Professionelt servicepersonale bør forstå denne risiko og tage nødvendige forholdsregler.

komponenter. Producenten er ikke ansvarlig for sikkerhed i tilfælde af brug af uautoriserede dele

kvalificeret

FORSIGTIG - ELEKTRISK STØD: Når du ser dette symbol, er der risiko for elektrisk spænding i

nærheden af produktet, hvor du arbejder. Tag strømstikket ud inden du begynder, eller udvis

forsigtighed, hvis produktet skal modtage strøm for at udføre opgaven.

servicetekniker og

FORSIGTIG - RISIKO FOR SKADE: Litium-batteriet i dette produkt er ikke beregnet til at blive

udskiftet. Der er fare for eksplosion, hvis et litium-batteri udskiftes forkert. Du må ikke genoplade,

demontere eller arænde et litium-batteri. Brugte litium-batterier skal bortskaes i

overensstemmelse med producentens instruktioner og lokale retningslinjer.

Notices, conventions, and safety information

15

4600-830, -835, -895

Sicherheitshinweise

• Die Sicherheit dieses Produkts basiert auf Tests und Zulassungen des Originaldesigns und der spezifischen

Komponenten. Sofern nicht autorisierte Ersatzteile eingesetzt werden, übernimmt der Hersteller keinerlei

Verantwortung in Bezug auf die Sicherheit dieses Produkts.

• Die Wartungsinformationen für dieses Produkt wurden für ausgebildete Servicemitarbeiter

zusammengestellt und dürfen nicht von anderen verwendet werden.

• Möglicherweise besteht bei der Demontage und Wartung dieses Produkts eine erhöhte Stromschlag- und

Verletzungsgefahr. Ausgebildete Servicemitarbeiter sollten sich dieser Gefahr bewusst sein und die

notwendigen Vorsichtsmaßnahmen ergreifen.

VORSICHT – STROMSCHLAGGEFAHR: Wenn Sie dieses Symbol sehen, besteht eine Gefahr durch

gefährliche Spannungen in dem Produktbereich, in dem Sie arbeiten. Trennen Sie das Produkt von

seiner Stromverbindung, bevor Sie beginnen, oder gehen Sie vorsichtig vor, wenn das Produkt für

die Durchführung der Aufgabe mit Strom versorgt werden muss.

VORSICHT – MÖGLICHE VERLETZUNGSGEFAHR Die Lithiumbatterie in diesem Produkt darf nicht

ausgetauscht werden. Wird eine Lithiumbatterie nicht ordnungsgemäß ausgetauscht, besteht

Explosionsgefahr. Lithiumbatterien dürfen auf keinen Fall wieder aufgeladen, auseinander

genommen oder verbrannt werden. Befolgen Sie zum Entsorgen verbrauchter Lithiumbatterien die

Anweisungen des Herstellers und die örtlichen Bestimmungen.

Turvallisuusohjeet

• Tämän laitteen turvallisuus perustuu alkuperäisen rakenteen ja tiettyjen osien testaukseen ja

hyväksymiseen. Valmistaja ei vastaa turvallisuudessa, jos laitteessa on käytetty luvattomia vaihto-osia.

• Tämän tuotteen huoltoa koskevat tiedot on tarkoitettu vain ammattitaitoisen huoltohenkilön käyttöön.

• Tämän tuotteen purkamiseen ja huoltoon voi liittyä kasvanut sähköiskun tai henkilövahingon vaara.

Ammattitaitoisen huoltohenkilön on ymmärrettävä tämä vaara ja toimittava sen edellyttämällä tavalla.

HUOMIO – SÄHKÖISKUN VAARA: Tämä symboli ilmaisee, että tuotteen työskentelyalueella on

olemassa vaarallinen jännite. Irrota laite verkkovirrasta ennen kuin aloitat tai toimi erittäin varovasti,

jos laitteessa on oltava virta työn aikana.

HUOMIO – TAPATURMAN MAHDOLLISUUS: Tuotteessa olevaa litiumakkua ei ole tarkoitettu

vaihdettavaksi. Litiumakun poistaminen väärin aiheuttaa räjähdysvaaran. Älä lataa, pura tai polta

litiumakkua. Hävitä käytetyt litiumakut valmistajan ohjeiden ja paikallisten säädösten mukaisesti.

Sikkerhetsinformasjon

• Sikkerheten til dette produktet er basert på testing og godkjenning av originaldesignet og bestemte

komponenter. Produsenten er ikke ansvarlig for sikkerheten ved bruk av uautoriserte reservedeler.

• Vedlikeholdsinformasjonen for dette produktet er tilrettelagt for bruk av profesjonelt servicepersonale, og

er ikke ment for bruk av andre.

• Det kan være en økt risiko for elektrisk støt og personskade under demontering og vedlikehold av produktet.

Profesjonelt servicepersonell må være innforstått med denne risikoen og ta nødvendige forholdsregler.

FORSIKTIG – FARE FOR STØT: Dette symbolet betyr at det er fare for farlig spenning i det området

av produktet der du arbeider. Koble fra produktet før du begynner, eller vær forsiktig hvis produktet

må ha strøm for å kunne utføre oppgaven.

Notices, conventions, and safety information

16

4600-830, -835, -895

FORSIKTIG – POTENSIELLE SKADER: Litiumbatteriet i dette produktet er ikke beregnet for å byttes.

Det er fare for eksplosjon hvis litiumbatteriet skiftes ut på feil måte. Ikke lad opp, demonter eller

destruer et litiumbatteri. Kast brukte litiumbatterier i henhold til produsentens instruksjoner og lokale

regelverk.

Säkerhetsinformation

• Säkerheten för denna produkt baseras på tester och godkännanden av ursprungsdesignen och av specifika

komponenter. Tillverkaren har inget ansvar vid användning av oauktoriserade reservdelar.

• Underhållsinformationen för produkten är avsedd att användas av utbildade servicetekniker och inte avsedd

att användas av andra.

• Risken för elektriska stötar och personskador kan vara förhöjd vid isärtagning och service av produkten.

Professionell servicepersonal bör vara medvetna om denna risk och vidta nödvändiga försiktighetsåtgärder.

VAR FÖRSIKTIG– RISK FÖR ELEKTRISK STÖT: När du ser denna symbol är det risk att det

farlig spänning i den del av produkten du arbetar med. Koppla från strömmen innan du börjar, eller

var försiktig om produkten måste vara strömförsörjd för att uppgiften ska kunna utföras.

VAR FÖRSIKTIG – RISK FÖR SKADA: Litiumbatteriet i produkten är inte utbytbart. Om ett

litiumbatteri byts ut på fel sätt finns det risk att det exploderar. Du får inte ladda om, ta isär eller elda

upp ett litiumbatteri. Gör dig av med använda litiumbatterier enligt tillverkarens instruktioner och

lokala föreskrifter.

finns

安全情報

• 本製品の安全性は、本来の設計、特定コンポーネントの試験、承認に基づいています。承認されていない交換

部品をお客様が使用した場合、メーカーは安全性に対して責任を負いません。

• 本製品のメンテナンス情報は、専門のサービス担当者による利用を目的としており、その他の人を対象としてい

ません。

• 本製品の分解や保守サービスを行う場合は、感電や傷害の危険性があります。専門のサービス担当者はこの

危険性を理解し、十分な対策を講じる必要があります。

注意—感電危険: この表記がある場合、対象製品の作業領域には、高電圧による危険性が生じています。

作業を始

場合は、十分に注意するようにしてください。

注意—傷害の恐れあり: この製品に使用されているリチウム

電池の交換を誤ると破裂する危険性

用済みのリチウム電池を廃棄

める前に

、製品から電源コードを

する際は

取り外してください

があります

、製造元の指示およびお使いの地域の法律に

。リチウム電池の

。また作業時に、製品に給電する

電池は

、交換を前提としていません。リチウム

充電

、解体、焼却はしないでください。使

必要がある

従ってください

。

안전 정보

• 이 제품의 안전은 기본 디자인 및 특정 구성품의 승인 및 테스팅을 기반으로 합니다. 제조업체는 권한 없는

교체 부품 사용 시 안전에 대해 책임을 지지 않습니다.

• 이 제품의 유지관리 정보는 전문 서비스 요원을 대상으로 하며 다른 사람은 사용할 수 없습니다.

• 제품 분해 및 서비스 중에는 감전 및 상해 위험이 증가할 수 있습니다. 전문 서비스 요원은 이와 같은 위험

을 이해하고 필요한 예방 조치를 취해야 합니다.

주의—감전 위험: 이 기호가 표시된 경우 작업 중인 제품 주변에서 위험 전압 위험이 있습니다. 사용

전/후에 전원 코드를 뽑아 두시고 제품에서 작업을 수행하는 데 반드시 전원이 필요한 경우에는 주의

하여 사용하십시오.

Notices, conventions, and safety information

17

4600-830, -835, -895

주의—상해 위험: 이 제품에 들어 있는 리튬 배터리는 교체할 수 없습니다. 리튬 배터리를 잘못 교체

하면 폭발할 위험이 있습니다. 리튬 배터리를 충전, 분해하거나 불에 태우지 마십시오. 제조업체의

지침과 지역 규정에 따라 다 쓴 리튬 배터리를 폐기하십시오.

安全信息

• 本产品的安全性以原始设计和特定组件的测试和审批为基础。如果使用未经授权的替换部件,制造商不对

安全性负责。

• 本产品的维护信息仅供专业服务人员使用,并不打算由其他人使用。

• 本产品在拆卸和维修时,遭受电击和人员受伤的危险性会增高。专业服务人员对这点必须有所了解,并采

取必要的预防措施。

小心—电击危险:当您看到此符号时,在您工作的产品区域内存在危险电压的威胁。在您开始操作之

前请拔掉产品电源,如果产品必须接收功率才能执行任务,请务必谨慎操作。

小心—可能的伤害:本产品中的锂电池不可更换。如果不正确更换锂电池,可能会有爆炸危险。不要

再充电、拆解或焚烧锂电池。丢弃旧的锂电池时应按照制造商的指导及当地法规进行处理。

安全資訊

• 本產品安全性係以原始設計及特定元件之測試與核准為依據。如有使用未獲授權替換組件之情形者,製造

商對安全性概不負責。

• 本產品之維護資訊僅供專業維修人員使用,而非預定由他人使用。

• 拆裝及維修本產品時,有可能造成電擊與人員損傷之危險。專業維修人員應瞭解前項危險並採取必要措施。

請當心—觸電危險:當您看到此符號時,表示您所在產品工作區有危險電壓。開始工作之前,請先拔

掉產品電源線,若產品必須接上電源方能執行作業,用電時請務必小心。

請當心—潛在受傷危險性:本產品中的鋰電池原本並不需要予以更換。若未正確更換鋰電池,可能會

有爆炸的危險。請勿將鋰電池充電、拆裝或焚燒。請遵照製造商的指示及當地法規,丟棄用過的電

池。

General caution statements

CAUTION—POTENTIAL INJURY: To avoid the risk of fire or electrical shock, connect the power cord to

an appropriately rated and properly grounded electrical outlet that is near the product and easily

accessible.

CAUTION—POTENTIAL INJURY: To avoid the risk of fire or electrical shock, use only the power cord

provided with this product or the manufacturer's authorized replacement.

CAUTION—POTENTIAL INJURY: Do not use this product with extension cords, multioutlet power strips,

multioutlet extenders, or UPS devices. The power capacity of these types of accessories can be easily

overloaded by a laser printer and may result in a risk of fire, property damage, or poor printer

performance.

CAUTION—POTENTIAL INJURY: Only a Lexmark Inline Surge Protector that is properly connected

between the printer and the power cord provided with the printer may be used with this product. The

use of non-Lexmark surge protection devices may result in a risk of fire, property damage, or poor

printer performance.

Notices, conventions, and safety information

18

4600-830, -835, -895

Change history

Change history

November 16, 2018

• Controller board (MS622) (41X2512) was added to the Electronics 1 Parts catalog. Notes regarding

compatibility were also added.

• 41X1369 FRU PN was changed to 41X2526 on the Control panel Parts catalog.

September 14, 2018

• 41X1219 FRU PN was changed to 41X2605 on the MPF and standard tray Parts catalog.

September 7, 2018

• 41X1189 FRU PN was changed to 41X1627 on the Control panel Parts catalog.

• 41X1190 FRU PN was changed to 41X1628 on the Control panel Parts catalog.

• Control panel cover and buttons FRU descriptions were changed to Control panel covers on the Control

panel Parts catalog.

August 2, 2018

• Date security notice was updated.

• Software CD and Smart card were added to the Miscellaneous Parts catalog.

July 6, 2018

• Output device diagnostics section under Service menus was deleted.

May 4, 2018

• For the right cover removal, an image was added showing how to open the controller board access cover.

• Printhead assembly adjustment was updated to include a note referring to the Registration adjust procedure.

April 27, 2018

• Reference to print defects guide on the Repeating defects check was removed.

• Reference to second transfer roller on the Enable edge-to-edge (printing) was removed.

Change history

19

4600-830, -835, -895

20

4600-830, -835, -895

General information

Printer model configurations

The LexmarkTM MS622de, MS621dn, B2650dn, and M3250 printers are network‑capable, multifunction laser

printers. The printers support monochrome printing and are embedded with home screen solutions and

applications. All information in this service manual pertains to all models unless explicitly noted.

The printers are available in the following models:

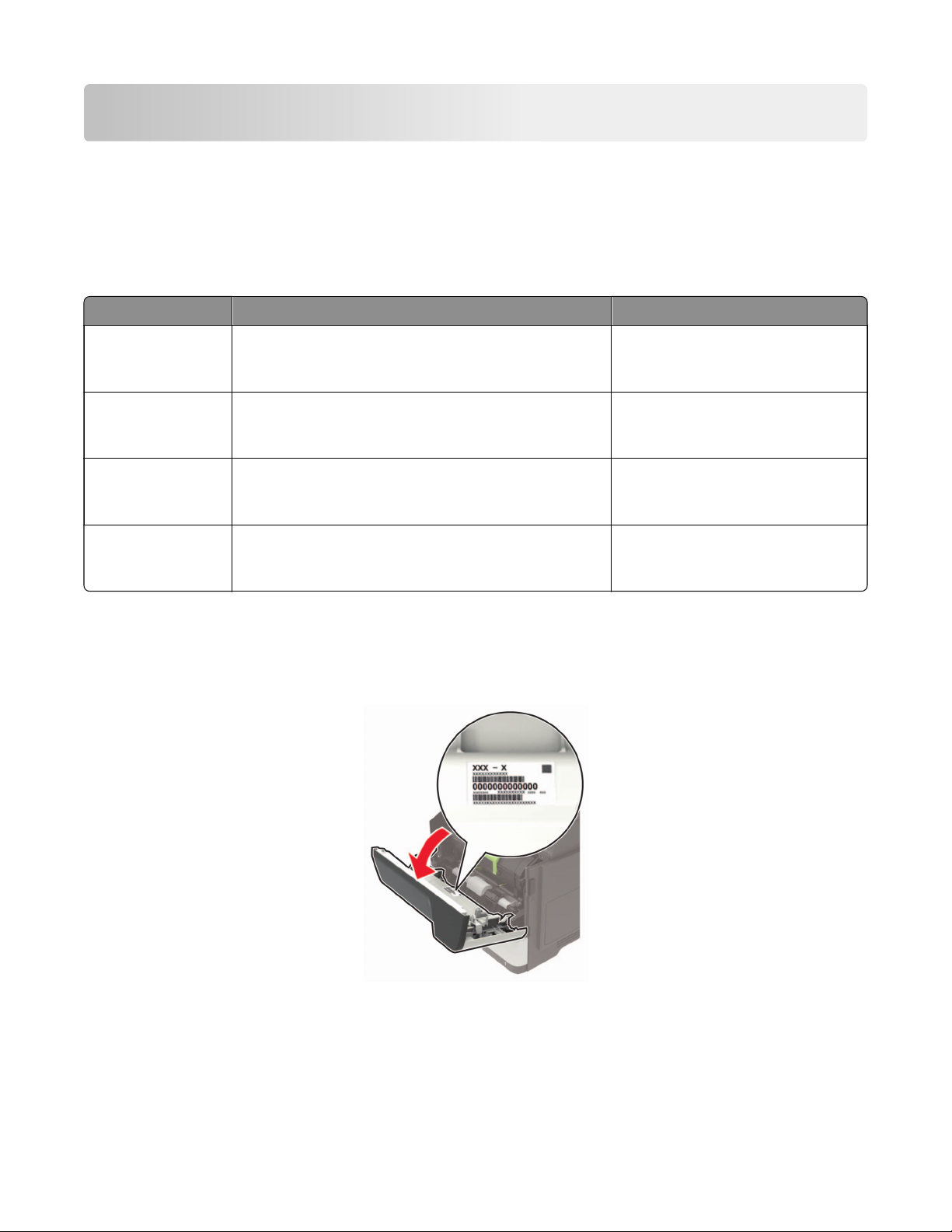

Model Configurations Machine type/model number

MS622de Network-ready e-Task monochrome laser printer with

4.3" color touch screen display and internal duplex for

medium workgroups with USB HDD installed

MS621dn Network-ready monochrome laser printer with 2.4"

color display and internal duplex for medium

workgroups

B2650dn Network-ready monochrome laser printer with 2.4"

color display and internal duplex for medium

workgroups

M3250 Network-ready e-Task monochrome laser printer with

4.3" color touch screen display and internal duplex for

medium workgroups with USB HDD installed

Finding the serial number

Open door A, and then

the serial number at the right side of the printer.

find

4600-835

4600-830

4600-830

4600‑895

General information

21

4600-830, -835, -895

Paper support

The following tables provide information on standard and optional paper sources and the sizes, types, and

weights of paper they support.

Note: For an unlisted paper size, select the closest larger listed size.

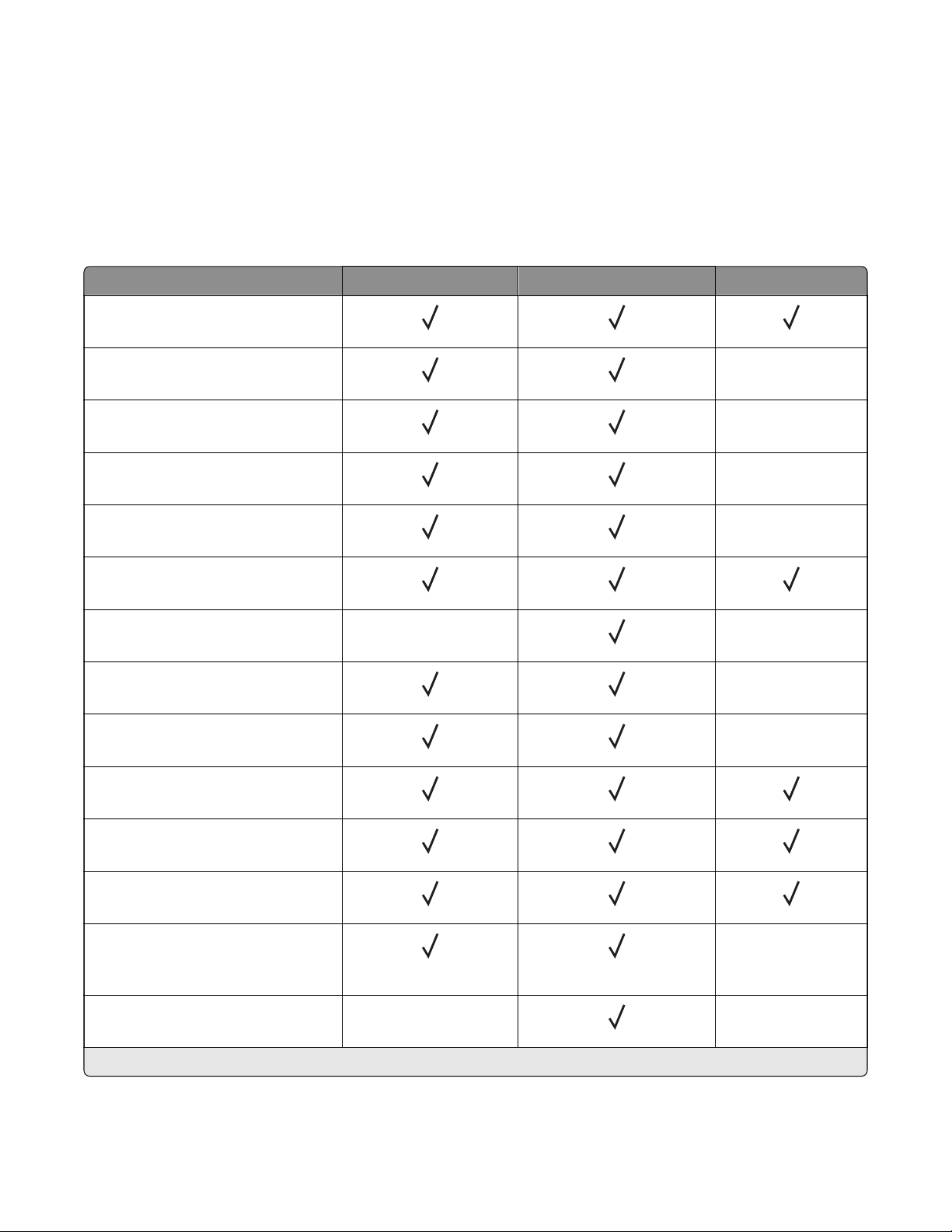

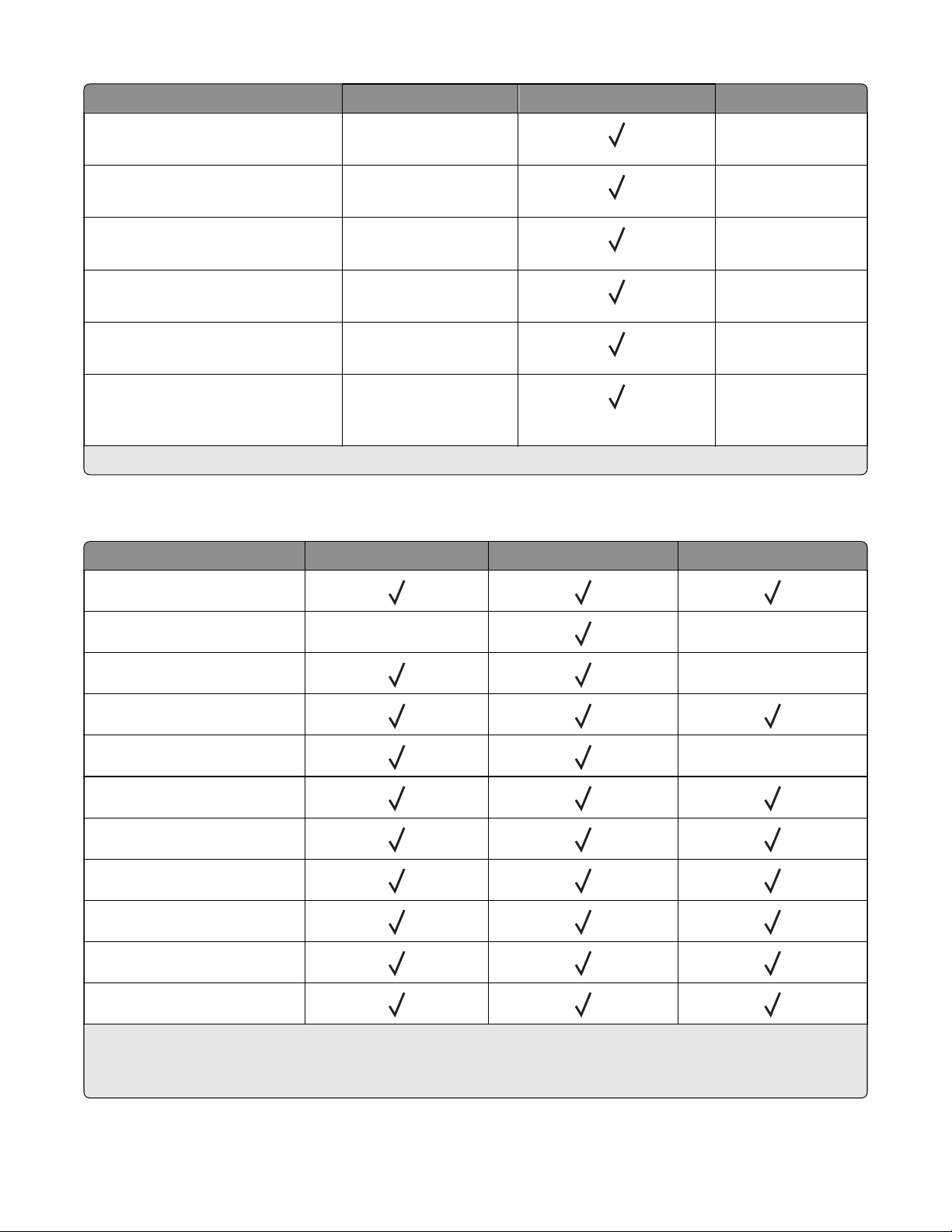

Supported paper sizes

Paper size Tray Multipurpose feeder Two‑sided printing

A4

210 x 297 mm (8.3 x 11.7 in.)

A5

210 x 148 mm (5.8 x 8.3 in.)

A5 LEF*

148 x 210 mm (5.8 x 8.3 in.)

A6*

105 x 148 mm (4.1 x 5.8 in.)

JIS B5

182 x 257 mm (7.2 x 10.1 in.)

Oficio (Mexico)

216 x 340 mm (8.5 x 13.4 in.)

Hagaki

100 x 148 mm (3.9 x 5.8 in.)

Statement

140 x 216 mm (5.5 x 8.5 in.)

Executive

184 x 267 mm (7.3 x 10.5 in.)

Letter

216 x 279 mm (8.5 x 11 in.)

X

X

X

X

X

X

X

X

Legal

216 x 356 mm (8.5 x 14 in.)

Folio

216 x 330 mm (8.5 x 13 in.)

Universal

76.2 x 127 mm (3 x 5 in.) to

216 x 356 mm (8.5 x 14 in.)

7 3/4 Envelope (Monarch)

98 x 191 mm (3.9 x 7.5 in.)

* This paper size is not supported in the optional tray.

X

General information

X

X

22

4600-830, -835, -895

Paper size Tray Multipurpose feeder Two‑sided printing

9 Envelope

X

X

98 x 225 mm (3.9 x 8.9 in.)

10 Envelope

X

X

105 x 241 mm (4.1 x 9.5 in.)

DL Envelope

X

X

110 x 220 mm (4.3 x 8.7 in.)

C5 Envelope

X

X

162 x 229 mm (6.4 x 9 in.)

B5 Envelope

X

X

176 x 250 mm (6.9 x 9.8 in.)

Other Envelope

X

X

76.2 x 127 mm (3 x 5 in.) to

216 x 356 mm (8.5 x 14 in.)

* This paper size is not supported in the optional tray.

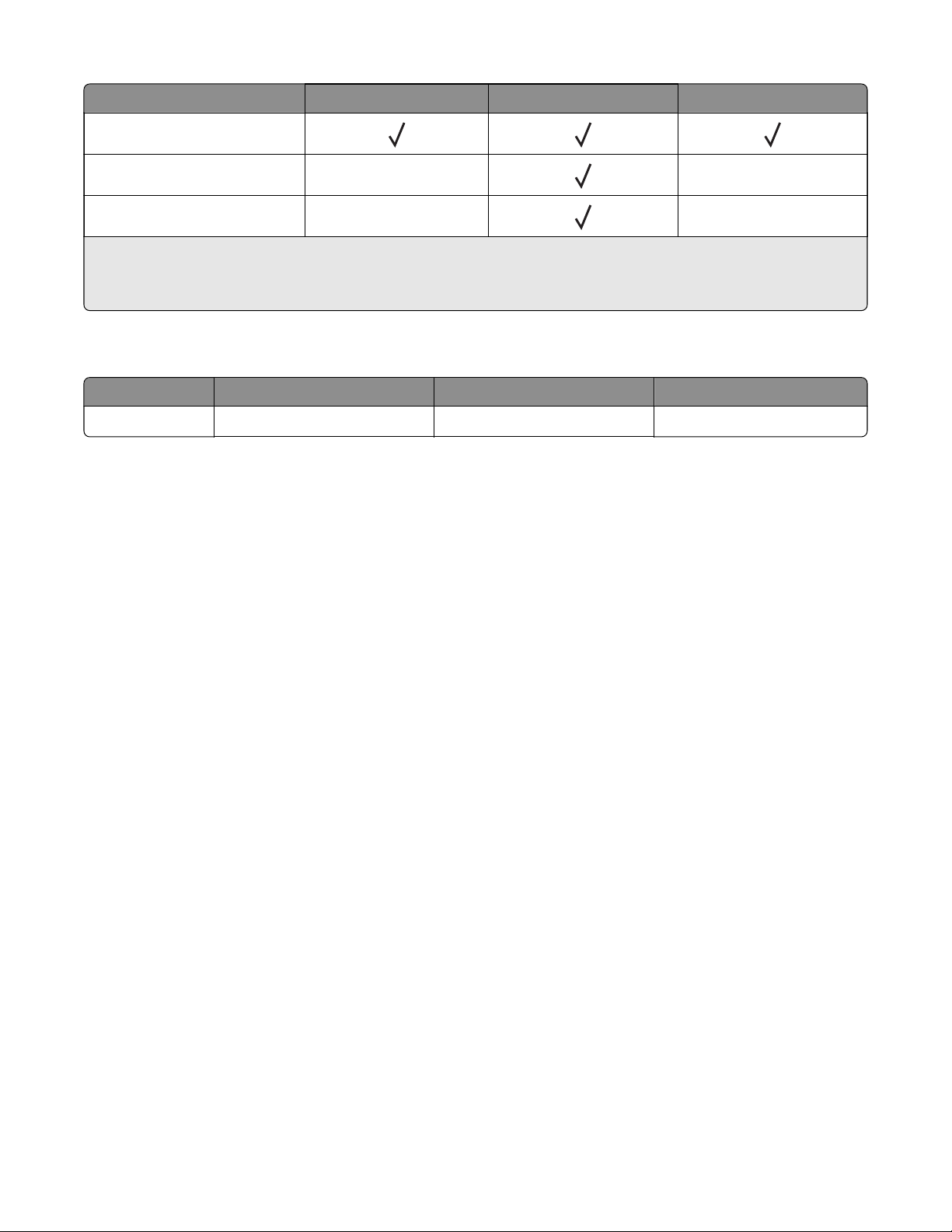

Supported paper types

Paper type Tray Multipurpose feeder Two‑sided printing

Plain paper

Card stock X X

Transparency

X

Recycled

Paper labels

2

Bond

1

X

Letterhead

Preprinted

Colored Paper

Light Paper

Heavy Paper

1

One‑sided paper labels designed for laser printers are supported for occasional use. It is recommended to print

2

20 or fewer pages of paper labels per month. Vinyl, pharmacy, and two‑sided labels are not supported.

2

Bond and Heavy Paper are supported in two‑sided printing up to 90‑g/m2 (24‑lb) paper weight.

General information

23

4600-830, -835, -895

Paper type Tray Multipurpose feeder Two‑sided printing

Rough/Cotton

Envelope X X

Rough envelope X

1

One‑sided paper labels designed for laser printers are supported for occasional use. It is recommended to print

20 or fewer pages of paper labels per month. Vinyl, pharmacy, and two‑sided labels are not supported.

2

Bond and Heavy Paper are supported in two‑sided printing up to 90‑g/m2 (24‑lb) paper weight.

X

Supported paper weights

Tray Multipurpose feeder Two‑sided printing

Paper weight

60–120 g/m

2

(16–32 lb) 60–216 g/m2 (16–58 lb) 60–90 g/m2 (16–24 lb)

Tools required for service

• Flat-blade screwdrivers, various sizes

• #1 Phillips screwdriver, magnetic

• #2 Phillips screwdriver, magnetic

• #2 Phillips screwdriver, magnetic short-blade

• Torx screwdriver (T20 head)

• Needle‑nose pliers

• Diagonal side cutters

• Spring hook

• Feeler gauges

• Analog or digital multimeter

• 3‑mm ball hex wrench

• Ton er vac uu m

• Flashlight

General information

24

4600-830, -835, -895

Diagnostics and troubleshooting

CAUTION—SHOCK HAZARD: This product uses a soft power switch. It does not physically disconnect

the input AC voltage. To avoid the risk of electrical shock, always remove the power cord from the

printer when removal of the input AC voltage is required.

CAUTION—SHOCK HAZARD: To avoid the risk of electrical shock and to prevent damage to the printer,

remove the power cord from the electrical outlet and disconnect all connections to any external devices

before you connect or disconnect any cable, electronic board, or assembly.

CAUTION—HOT SURFACE: The inside of the printer might be hot. To reduce the risk of injury from a hot

component, allow the surface to cool before touching it.

CAUTION—PINCH HAZARD: To avoid the risk of a pinch injury, use caution in areas marked with this

label. Pinch injuries may occur around moving parts, such as gears, doors, trays, and covers.

Troubleshooting overview

Performing the initial troubleshooting check

Before you start the troubleshooting procedures, perform the following checks:

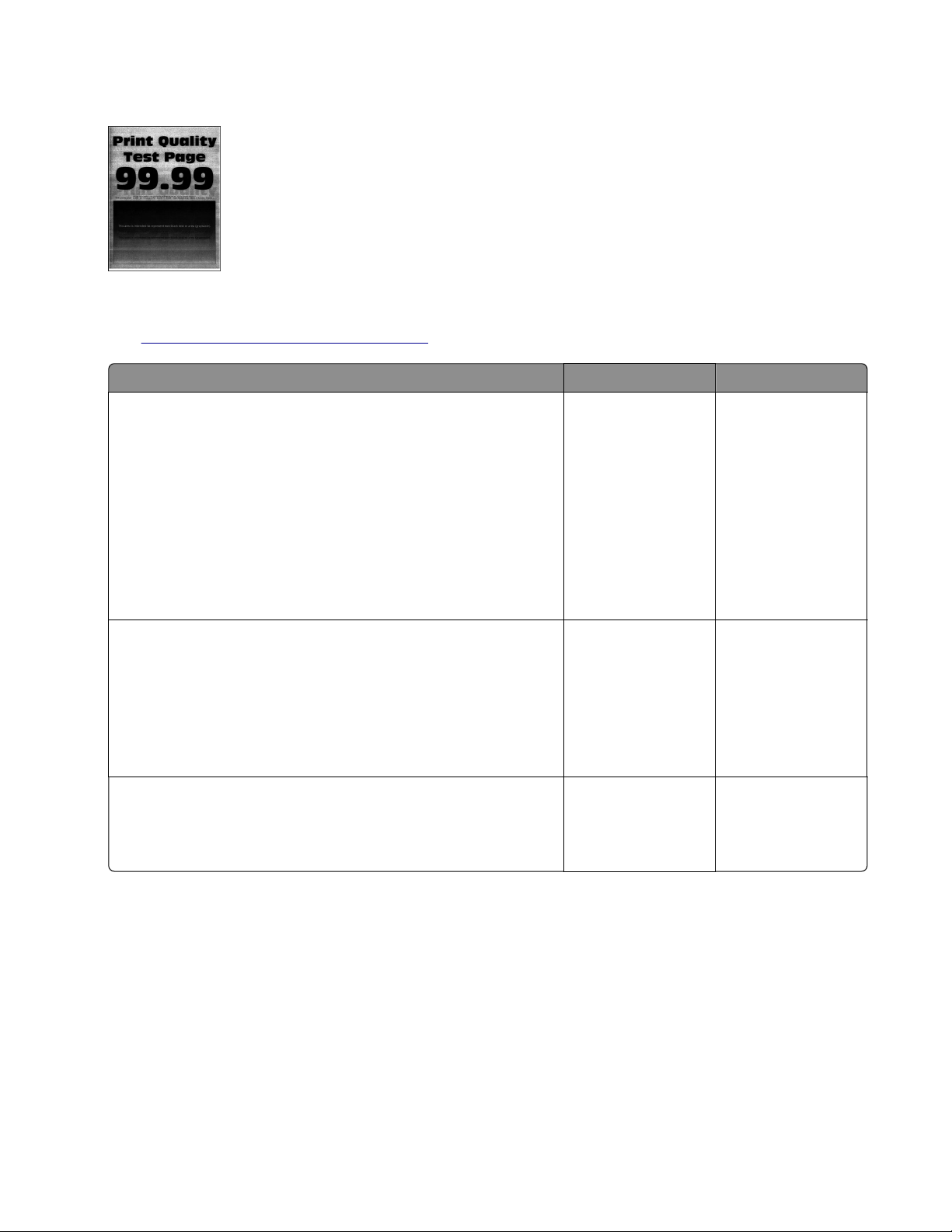

• Use genuine Lexmark supplies and parts for the best results. Third-party supplies or parts may aect the