Page 1

Lexmark™ 8300 Series

• Table of contents

• Start diagnostics

• Safety and notices

All-In-One

4419-X6X

• Trademarks

•Index

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

4419-X6X

Edition: March 24, 2006

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMARK INTERNATIONAL, INC. PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

Comments may be addressed to Lexmark International, Inc., Department D22A/032-2,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or e-mail at

ServiceInfoAndTraining@Lexmark.com. Lexmark may use or distribute any of the

information you supply in any way it believes appropriate without incurring any obligation

to you.

References in this publication to products, programs, or services do not imply that the

manufacturer intends to make these available in all countries in which it operates. Any

reference to a product, program, or service is not intended to state or imply that only that

product, program, or service may be used. Any functionally equivalent product, program,

or service that does not infringe any existing intellectual property right may be used

instead. Evaluation and verification of operation in conjunction with other products,

programs, or services, except those expressly designated by the manufacturer, are the

user’s responsibility.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc.,

registered in the United States and/or other countries.

Other trademarks are the property of their respective owners.

© 2005 Lexmark International, Inc.

All rights reserved.

UNITED STATES GOVERNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are

commercial computer software and documentation developed exclusively at private

expense.

U.S.A. P/N 12G9490

Japanese P/N 12G9491

Page 3

4419-X6X

Table of contents

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-ix

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scanner specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Copy specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Print speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Using the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Maintenance approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Tools required for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Power-On Self Test (POST) sequence . . . . . . . . . . . . . . . . . . . . . . . 1-1

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

POST symptom table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Printer communication problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Scanner problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Carrier transport service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

CIS module assembly service check . . . . . . . . . . . . . . . . . . . . . . . . 1-15

PictBridge service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Maintenance station service check . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Paper feed service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Power service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Print quality service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Scan and copy quality service check. . . . . . . . . . . . . . . . . . . . . . . . 1-23

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Test page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Repair information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Handling ESD-sensitive parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Releasing plastic latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General precautions on removals . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Control panel cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Rear access cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

ADF scanner lid assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table of contents

iii

Page 4

4419-X6X

Scanner module assembly removal. . . . . . . . . . . . . . . . . . . . . . . . . . .1 -6

Midframe cover with control panel and risers removal . . . . . . . . . . . .1-8

Rear access door with sensor removal . . . . . . . . . . . . . . . . . . . . . . .1-10

Fax card removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Card reader card with PictBridge assembly and cables removal . . .1-13

System board removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Encoder strip removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Print engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Carrier assembly with cables, belt, and cable clip removal . . . . . . . .1-18

Maintenance station removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

Exit tray removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Printer base with cover and paper pick assembly removal . . . . . . . .1-22

Locations and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

System board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -1

Fax card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

PictBridge and card reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Lubrication specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

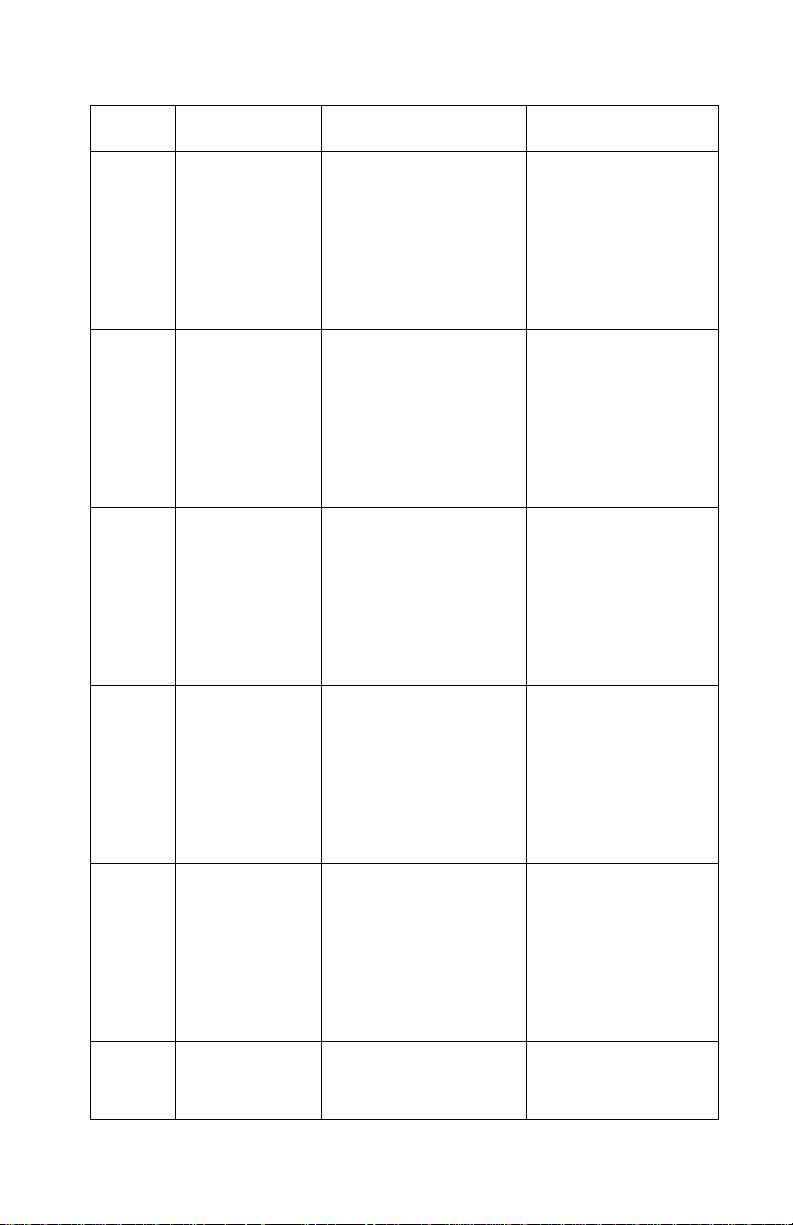

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Assembly 2: Engine, electronics, and carrier . . . . . . . . . . . . . . . . . . . . . .1-6

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Part number index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

iv Service Manual

Page 5

Safety information

• The safety of this product is based on testing and approvals of the

original design and specific components. The manufacturer is not

responsible for safety in the event of use of unauthorized replacement

parts.

• The maintenance information for this product has been prepared for

use by a professional service person and is not intended to be used by

others.

• There may be an increased risk of electric shock and personal injury

during disassembly and servicing of this product. Professional service

personnel should understand this and take necessary precautions.

Consignes de sécurité

• La sécurité de ce produit repose sur des tests et des

agréations portant sur sa conception d'origine et sur des composants

particuliers. Le fabricant n'assume aucune responsabilité concernant

la sécurité en cas d'utilisation de pièces de rechange non agréées.

• Les consignes d'entretien et de réparation de ce produit s'adressen t

uniquement à un personnel de maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains

risques électriques, le personnel d'entretien qualifié devra prendre

toutes les précautions nécessaires.

4419-X6X

Safety information v

Page 6

4419-X6X

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione del

progetto originale e dei componenti specifici. Il produttore non è

responsabile per la sicurezza in caso di sostituzione non autorizzata

delle parti.

• Le informazioni riguardanti la manutenzione di questo prodotto sono

indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più elevato.

Il personale di assistenza autorizzato deve, quindi, adottare le

precauzioni necessarie.

Sicherheitshinweise

• Die Sicherheit dieses Produkts basiert auf Tests und Zulassungen des

ursprünglichen Modells und bestimmter Bauteile. Bei Verwendung

nicht genehmigter Ersatzteile wird vom Hersteller keine Verantwortung

oder Haftung für die Sicherheit übernommen.

• Die Wartungsinformationen für dieses Produkt sind ausschließlich für

die Verwendung durch einen Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts

besteht ein zusätzliches Risiko eines elektrischen Schlags und

körperlicher Verletzung. Das zuständige Fachpersonal sollte

entsprechende Vorsichtsmaßnahmen treffen.

vi Service Manual

Page 7

Pautas de Seguridad

• La seguridad de este producto se basa en pruebas y aprobaciones del

diseño original y componentes específicos. El fabricante no es

responsable de la seguridad en caso de uso de piezas de repuesto no

autorizadas.

• La información sobre el mantenimiento de este producto está dirigida

exclusivamente al personal cualificado de mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños personales

durante el desmontaje y la reparación de la máquina. El personal

cualificado debe ser consciente de este peligro y tomar las

precauciones necesarias.

Informações de Segurança

• A segurança deste produto baseia-se em testes e aprovações do

modelo original e de componentes específicos. O fabricante não é

responsável pela segunrança, no caso de uso de peças de

substituição não autorizadas.

• As informações de segurança relativas a este produto destinam-se a

profissionais destes serviços e não devem ser utilizadas por outras

pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais destes

serviços devem estar avisados deste facto e tomar os cuidados

necessários.

4419-X6X

Informació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i aprovació del

disseny original i els components específics.

El fabricant no es fa responsable de les qüestions de

seguretat si s'utilitzen peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest producte està orientada

exclusivament a professionals i no està destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar durant el

procés de desmuntatge i de servei d’aquest producte. El personal

professional ha d’estar-ne assabentat i prendre

les mesures convenients.

Safety information vii

Page 8

4419-X6X

viii Service Manual

Page 9

Preface

This manual contains maintenance procedures for service personnel. It is

divided into the following chapters:

1. General information contains a general description of the All-In-One

and the maintenance approach used to repair it. Special tools and test

equipment are listed, as well as general environmental and safety

instructions.

2. Diagnostic information contains an error indicator table, symptom

tables, and service checks used to isolate failing field replaceable units

(FRUs).

3. Diagnostic aids contains tests and checks used to locate or repeat

symptoms of All-In-One problems.

4. Repair information provides instructions for making All-In-One

adjustments and removing and installing FRUs.

5. Locations and connectors uses illustrations to identify the connector

locations and test points on the All-In-One.

6. Preventive maintenance contains the lubrication specifications and

recommendations to prevent problems.

7. Parts catalo g contains illustrations and part numbers for individual

FRUs.

4419-X6X

Definitions

Note: A note provides additional information.

Warning: A warning identifies something that could damage the product

hardware or software.

CAUTION: A caution identifies something that could cause you harm.

Preface ix

Page 10

4419-X6X

x Service Manual

Page 11

4419-X6X

1. General information

The Lexmark™ 8300 Series All-In-One (4419-X6X) is a letter-quality print,

fax, copy, and scan machine. It is a standalone color/mono copier and fax.

The printhead uses small heater plates and nozzles to control ink flow and

the formation of characters on the print media. The printhead assembly and

ink supply are combined into a single-unit print cartridge available as a

customer replaceable supply item. Dual printheads provide color and true

black printing without changing printheads. The number and size of inkjets

or nozzles in the printhead determines the overall quality and capability of

the printer. The black cartridge has a total of 640 nozzles and installs on the

left. The color cartridge has a total of 480 nozzles and installs on the right.

The photo cartridge has a total of 480 nozzles and installs on the left. The

All-In-One is capable of printing in two directions from either cartridge.

General information 1-1

Page 12

4419-X6X

Scanner specifications

Scanner Type Flatbed, Hybrid CIS/CCD

Scan Modes True Color:

• 48 bit internal

• 24 bit external

Gray Mode:

• 16 bit internal

• 8 bit external

Text/L in e Art:

1 bit per pixel

Scan Method One-pass scanning

Scan Area ADF Maximum:

• 8.5 x 14 inches

• 218 x 355 mm

Minimum:

• 8.27 x 11 inches

• 210 x 279.4 mm

Scan Resolution Flatbed Scanning:

• Horizontal: 1200 ppi (optical)

• Vertical: 2400 ppi

• Interpolated: 19,200 x 19,200

ADF:

• Horizontal: 600 ppi (optical)

• Vertical: 1200 ppi

• Interpolated: 9,600 x 9,600

1-2 Service Manual

Page 13

Copy specifications

Copy Modes From the control panel and host:

•Color

•Black

4419-X6X

Resolution/Quality Standalone Mode

The following options are available in

standalone mode. These apply to color

copy:

Photo–600 X 600 ppi Color Scan

1200 X 1200 dpi print (by interpolation for

all papers including glossy paper)

Normal–300 X 300 ppi Color Scan

600 X 600 dpi print (by interpolation for all

papers including glossy paper)

Quick–150 X 150 ppi Color Scan

• 300 X 600 dpi print (by interpolation)

• 600 X 600 dpi print (by interpolation for

glossy paper)

The following options are available in

standalone mode. These apply to blackand-white copy:

Photo–600 X 600 ppi Grayscale Scan

1200 X 1200 dpi print (by interpolation)

Normal–300 X 300 ppi Grayscale Scan

600 X 600 dpi print (by interpolation)

Quick–150 X 150 ppi Grayscale Scan

• 300 X 600 dpi print (by interpolation)

General information 1-3

Page 14

4419-X6X

Resolution/Quality Host-Based Mode

The following options are available in hostbased mode. These apply to color/

grayscale copy:

Photo–300 X 300 ppi Scan

• 1200 X 1200 dpi print

• 4800 X 1200 dpi print (for glossy paper)

Normal–200 X 200 ppi Scan

• 600 X 600 dpi print

• 1200 X 1200 dpi print (for glossy paper)

Quick–150 X 150 ppi Scan

• 300 X 600 dpi print

• 600 X 600 dpi print (for glossy paper)

The following options are available in hostbased mode. These apply to black-andwhite copy:

Photo–600 X 600 ppi Scan

• 1200 X 1200 dpi print

• 4800 X 1200 (for glossy paper)

Normal–300 X 300 ppi Scan

• 600 X 600 dpi print

• 1200 X 1200 dpi print (for glossy paper)

Quick–150 X 150 ppi Scan

• 300 X 600 dpi print

• 600 X 600 dpi (for glossy paper)

Print speed

Print Speeds • Quick print: 25 ppm mono/19 ppm color

• Normal print: 10 ppm mono/5 ppm color

1-4 Service Manual

Page 15

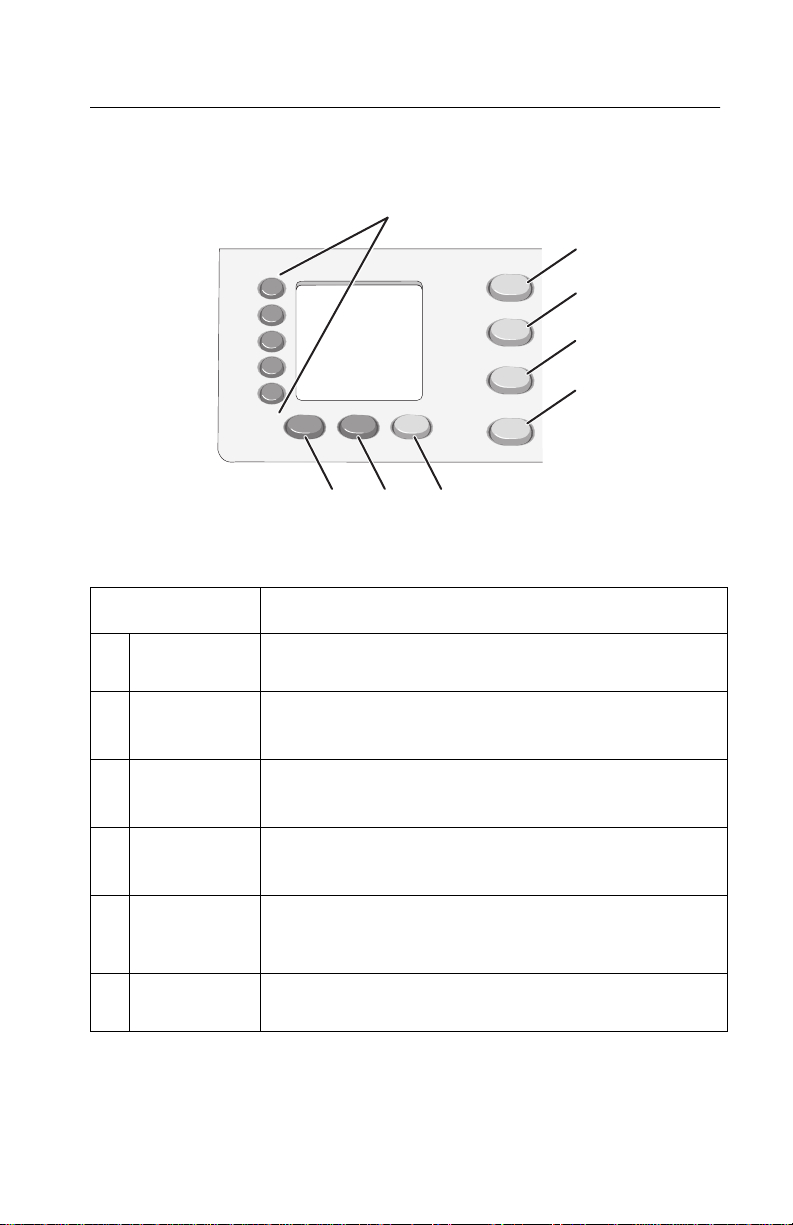

Using the control panel

7

8

Press To

4419-X6X

1

2

3

4

5

6

1 Quick Dial

buttons (1—5)

2 Copy Mode Access the copy menus and make copies.

3 Scan Mode Access the scan menus and scan documents.

4 Fax Mode Access the fax menus and send and receive faxes.

5 Photo Card Access the photo card menus. You can preview photos

6 Fax Auto

Answer

Access any of the five programmed Speed Dial

numbers.

Note: The mode is selected when the button light is on.

Note: The mode is selected when the button light is on.

Note: The mode is selected when the button light is on.

stored on a memory card or flash drive, edit the photos,

and print them.

Answer all incoming calls when lit.

General information 1-5

Page 16

4419-X6X

Press To

7 Redial/Pause • Redial the last number entered when the machine is

in Fax mode.

• Insert a three-second pause in the number to be

dialed. Enter a pause only when you have already

begun entering the number.

8 Phone Book Access any of the programmed Speed Dial numbers

(1—89) or Group Dial numbers (90—99).

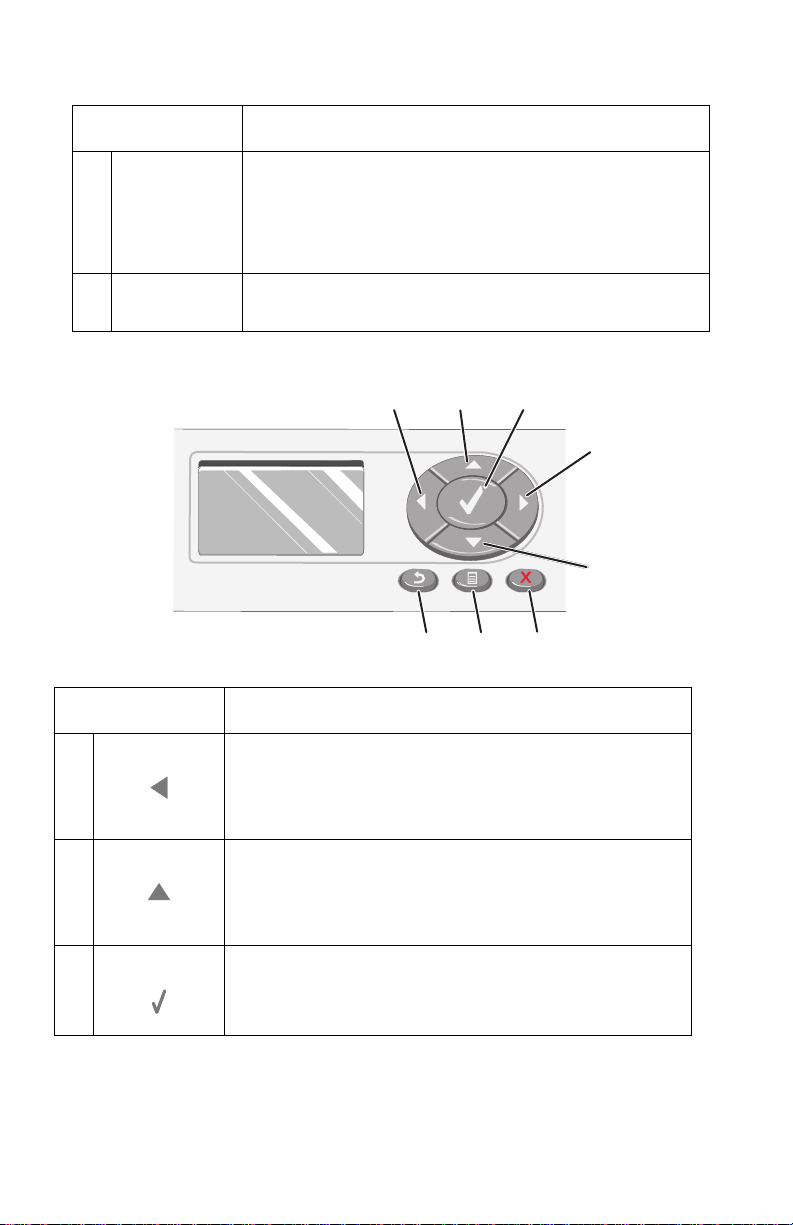

1

2

3

4

5

678

Press To

1 • Decrease a number.

• Scroll through options on the display.

• When cropping a photo, move the selected crop area

to the left.

2 • Increase a number.

• Scroll through menus or options on the display.

• When cropping a photo, move the selected crop area

up.

3 Choose the option that appears on the display, or save

settings. In Photo Card mode, select or deselect a

photo.

1-6 Service Manual

Page 17

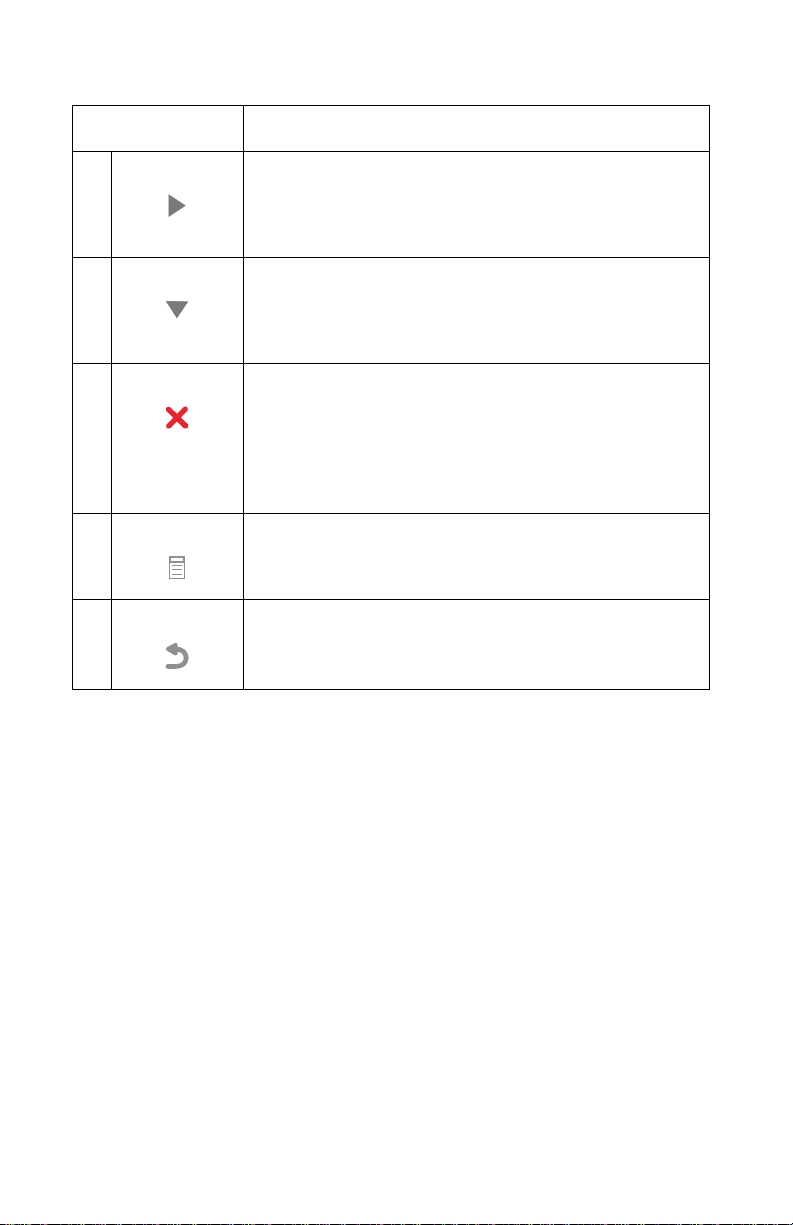

Press To

4 • Increase a number.

• Scroll through options on the display.

• When cropping a photo, move the selected crop area

to the right.

5 • De c re ase a number.

• Scroll through menus or options on the display.

• When cropping a photo, move the selected crop area

down.

6 • Cancel a scan, copy, or print job in progress.

• Clear a fax number or end a fax transmission, and

return the display to the fax default.

• Exit a menu.

• Clear current settings or error messages, and return

to default settings.

7 Display a control panel menu or submenu.

8 • Return to the previous submenu.

• Save the settings in a submenu, and return to the

previous menu.

4419-X6X

General information 1-7

Page 18

4419-X6X

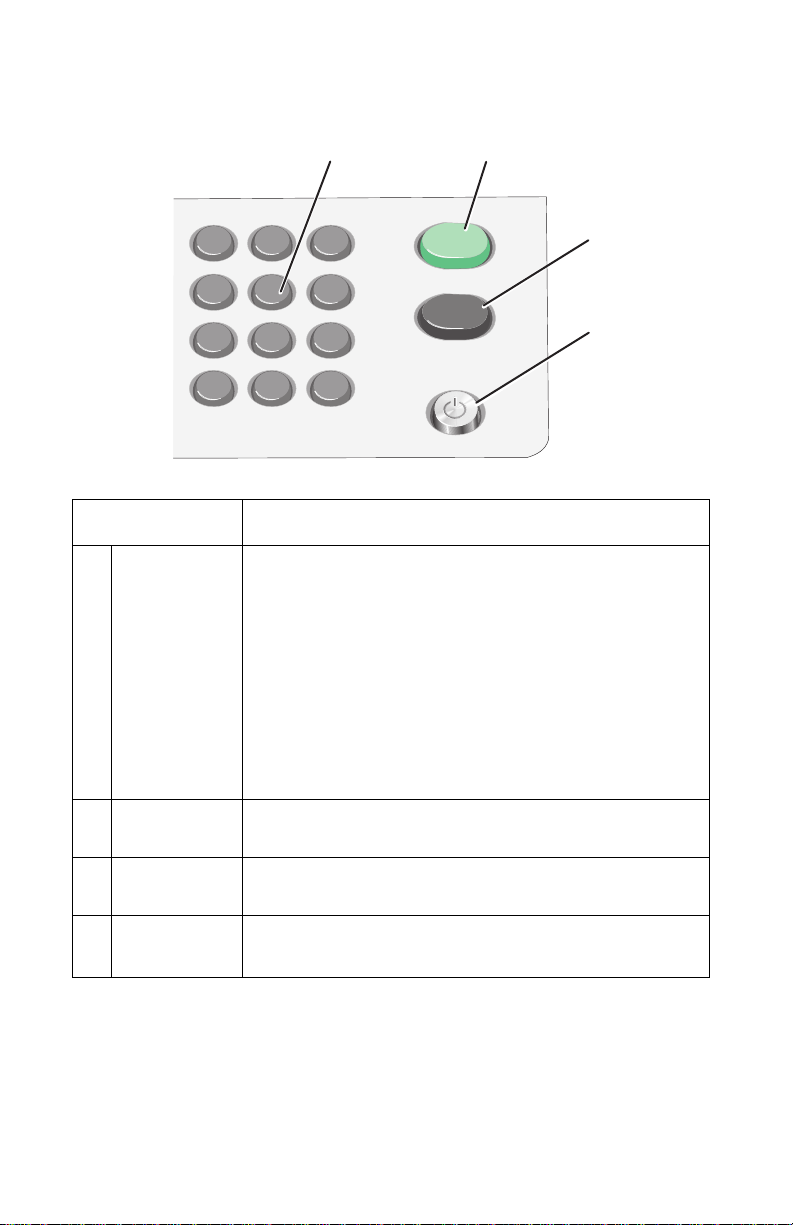

1

4

7

*

Press To

1 A keypad

number or

symbol

In Fax mode:

In Copy mode: Select the number of copies you want to

make.

In Photo Card mode: Select the number of photos you

want to print.

1

2

3

2

3

5 6

8 9

0

• Enter fax numbers.

• Navigate an automated answering system.

• Select letters when creating a Speed Dial list.

• Type numbers to enter or edit the date and time

#

shown on the display.

4

2 Start Color Start a color copy, scan, or photo job, depending on

3 Start Black Start a black-and-white copy, scan, fax, or photo job,

4 Power • Turn the All-In-One on and off.

which mode is selected.

depending on which mode is selected.

• Stop the print, copy, fax, or scan process.

1-8 Service Manual

Page 19

Maintenance approach

The diagnostic information in this manual leads you to the correct field

replaceable unit (FRU) or part. Use the error codes, symptom tables,

service checks, and diagnostic aids to determine the symptom and repair

the failure.

After you complete the repair, perform tests as needed to verify the repair.

Tools required for service

• Flat-blade screwdriver

• #1 Phillips screwdriver

• #2 Phillips screwdriver

• Spring hook

• Analog or digital multimeter

4419-X6X

General information 1-9

Page 20

4419-X6X

Acronyms

ADF Automatic Document Feeder

B/M Bill of Material

CCD Charge Coupled Device

CIS Contact Image Sensor

DBCS Double Byte Character Set

DPOF Digital Print Order Format

DPS Direct Print Service

EOF End of Form

ESD Electrostatic Discharge

FFC Flexible Flat Cable

FPC Flat Printhead Cable

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

KB Kilobyte

KBps Kilobytes per second (usually as Kbps)/KiloBytes per second

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

MPF Multipurpose Feeder

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

POR Power-On Reset

POST Power-On Self Test

ROM Read Only Memory

SBCS Single Byte Character Set

USB Universal Serial Bus

V ac Volts alternating current

V dc Volts direct current

ZIF Zero Insertion Force

(usually as KBps)

1-10 Service Manual

Page 21

4419-X6X

2. Diagnostic information

Use the error code tables, POST symptom table, symptom tables, and service

checks in this chapter to determine the All-In-One failure.

Start

Power-On Self Test (POST) sequence

Press the Power button to turn on the All-In-One.

1. The Power button light comes on.

2. The paper and transport carrier motors run, and then stop.

3. The CIS moves from the home position, and then returns.

4. The CIS lamp comes on, and then goes off.

5. The Fax Auto Answer, Copy Mode, Scan Mode, Fax Mode, Photo

Card, and Power button lights come on.

6. Lexmark X8300 All-In-One appears on the LCD.

7. The Fax Auto Answer, Copy Mode, and Power lights remain on.

8. Copy Mode appears on the LCD.

If the All-In-One completes POST with no errors, go to “Symptom tables”

on page 2-10, locate the symptom, and take the appropriate action.

If the All-In-One does not complete POST, go to the “POST symptom

table” on page 2-8, locate the symptom, and take the appropriate action.

Diagnostic information 2-1

Page 22

4419-X6X

Error codes

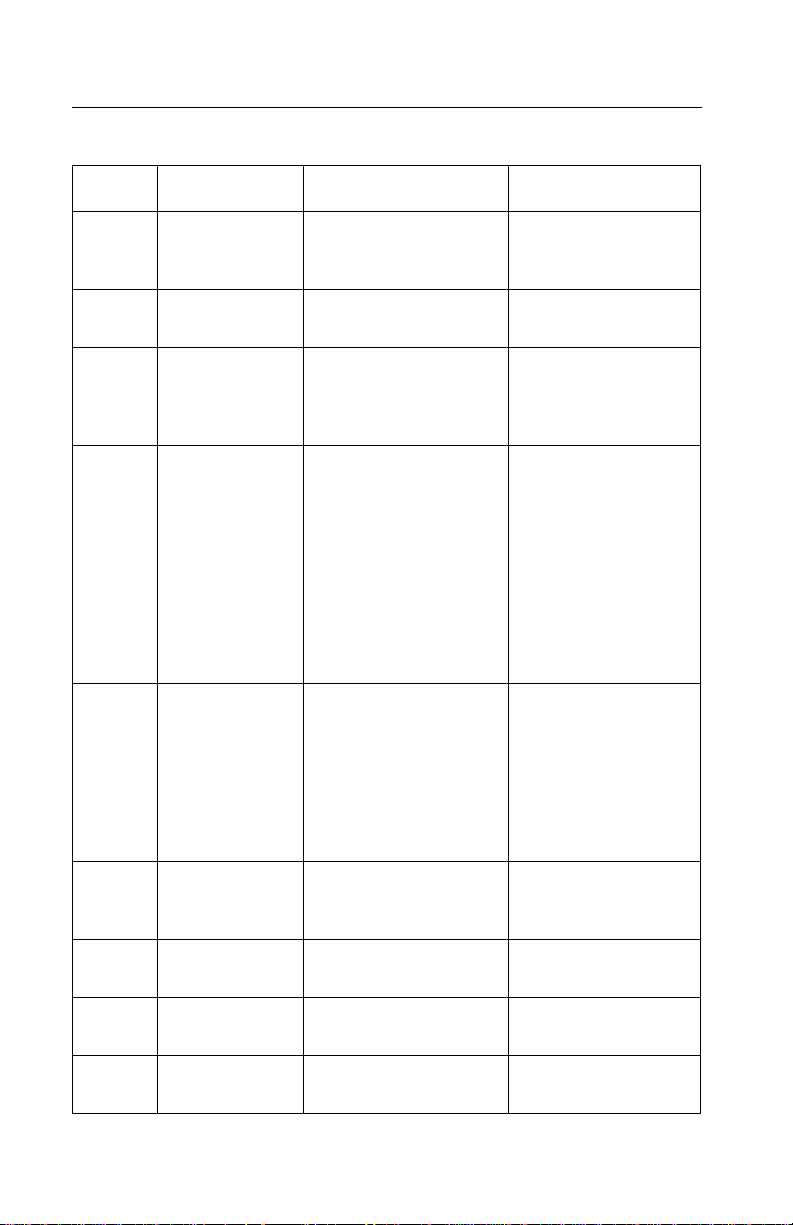

Code Name Description Action

0000 NVRAM R/W An error was detected

in reading or writing

NVRAM.

0001 Memory Failure Unable to initialize

memory

0002 Hardware

Failure

0200 Flash

Programming

1003 Paper System

Failure

General hardware

failure (unable to

localize failure to a

specific system)

Unable to program

Flash memory

Failure in initializing

DC paper feed system.

Replace the system

board.

Replace the system

board.

Replace the system

board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

USB cable. If the

error continues,

replace the system

board.

Unplug the All-InOne; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

11 00 Paper Jam There is paper jammed

in the All-In-One, or the

feed roller is stalled.

1 101 Paper Out The All-In-One is out of

paper.

1102 Incorrect

Printhead

1103 Missing

Printhead

Printhead ID is not

valid.

Printhead is missing. Install print cartridge.

2-2 Service Manual

Clear the paper jam,

and resend print job.

Load paper.

Replace the print

cartridge.

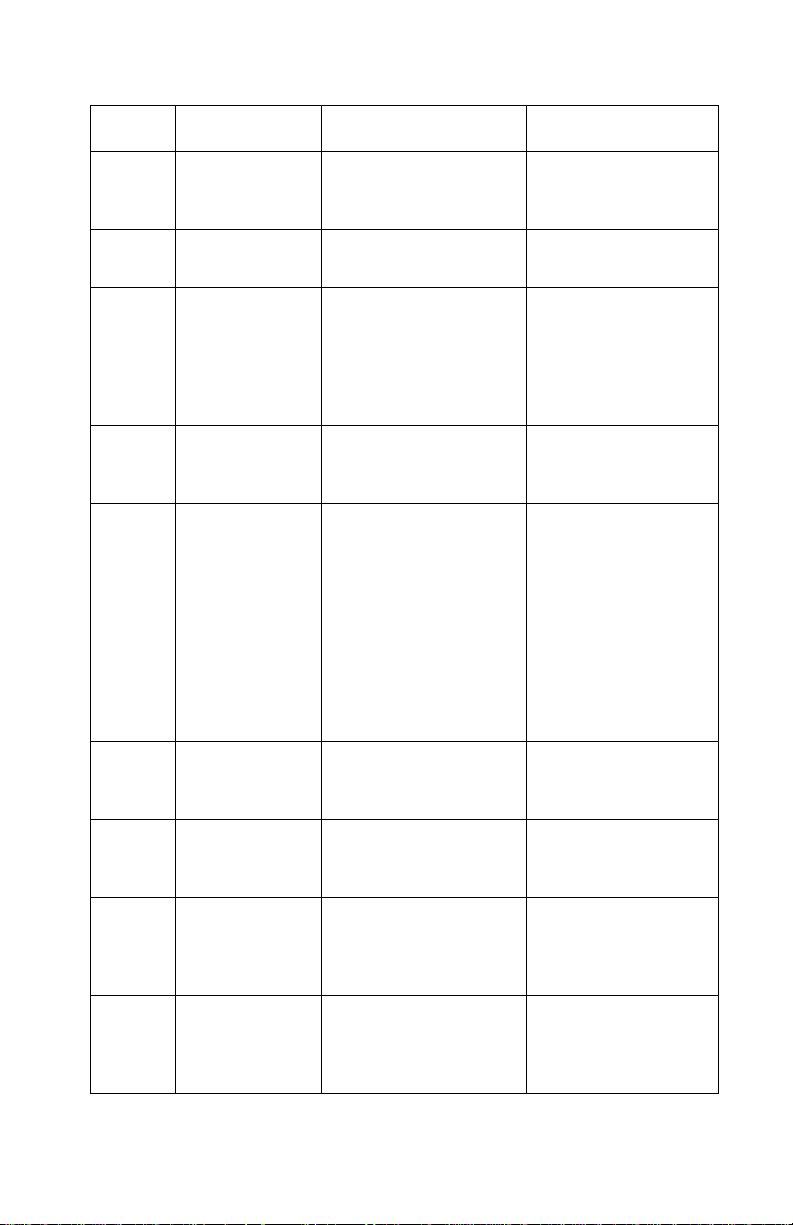

Page 23

Code Name Description Action

4419-X6X

1104 Printhead

Order

1105 Auto Alignment

Failed

1200 Print Carrier

Stall

1201 Print

Incomplete

1202 Data Error Incorrect data has

Unsupported order of

printheads

Automatic alignment

has failed.

The All-In-One print

carrier has stalled.

The print carrier

stopped before all the

data was used.

been sent from the

host computer to the

All-In-One.

Install the print

cartridges in the

correct slots.

Replace the print

cartridge.

Unplug the All-InOne; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on.

Resend the print job.

Unplug the All-InOne; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

USB cable. If the

error continues,

replace the system

board.

1203 Printhead Short A short test detected a

short-circuit in the

printhead.

1204 Printhead

Programming

1205 Mono TSR

Error

1206 Color TSR

Error

Unable to program

pseudo-random

printhead ID

Problem in mono TSR

circuit; cannot

determine printhead

temperature.

Problem in color TSR

circuit; cannot

determine printhead

temperature.

Diagnostic information 2-3

Replace the print

cartridge.

Replace the print

cartridge.

Replace the print

cartridge.

Replace the print

cartridge.

Page 24

4419-X6X

Code Name Description Action

1207 Paper System

Error

1208 Incorrect Home

Position

1209 Flash

Programming

Error

1210 Mode Select An invalid print mode

A paper system error

control failure was

detected.

The All-In-One is

unable to locate print

cartridge home

position.

Cannot program Flash

memory

was selected in print

command.

Clear the paper path.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the All-InOne; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

USB cable. If the

error continues,

replace the system

board.

Select a valid print

mode.

1211 USB Error An error was detected

in USB hardware, or

invalid results occurred

in USB code.

2-4 Service Manual

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

USB cable. If the

error continues,

replace the system

board.

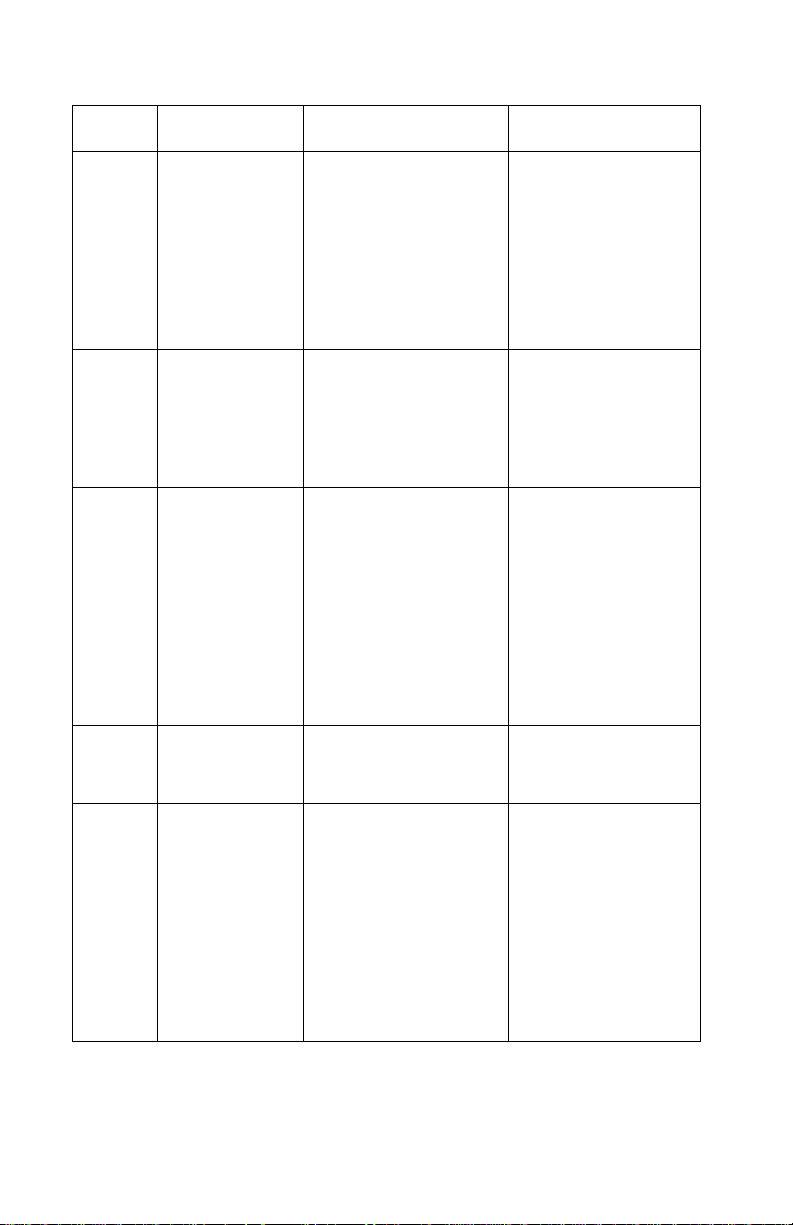

Page 25

Code Name Description Action

4419-X6X

1212 Watchdog Error Indicates printer

system was reset by

Watchdog timer;

Subsystem stall failure.

1213 Data Abort

Error

1214 Invalid

Processor

Mode Error

1215 Math Error There is a problem

Firmware attempts to

load or store to an

invalid address.

Indicates the ARM

processor was in an

incorrect mode to

perform the requested

operation

doing math, such as

dividing by zero.

Unplug the

All-In-One; wait five

minutes, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

1216 Mailbox Error There is a problem

with the internal

mailbox messaging

system.

1217 Temperature

Error

There is a problem

determining

temperature.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Replace the print

cartridge.

Diagnostic information 2-5

Page 26

4419-X6X

Code Name Description Action

1218 Serial Flash

Error

1219 Undefined

Signal Error

2100 Unlock

Scanner

2200 Scan Carrier

Stall

Invalid parameters

have been passed to

ReadFlashPage.

Microprocessor has

encountered a bad

signal (other than an

abort, illegal

instruction, or

arithmetic exception).

The scanner

mechanism is locked in

place or unable to

move due to other

failure.

The scan carrier has

stalled.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unlock the scanner.

Unplug the All-InOne; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, check all

connections to the

scanner. If

connections are okay

and the error

continues, replace

the system board.

3100 Fax Error There is a general

error receiving or

sending fax.

4100 Invalid Media

Card

The inserted media

card is not valid for the

slot.

2-6 Service Manual

Try resending or

receiving fax.

Insert card in the

correct slot.

Page 27

Code Name Description Action

4419-X6X

4101 Media Card

R/W Error

120A Undefined Error Microprocessor has

120B Address Error Firmware attempted to

120C NVRAM Error An error was detected

There is a problem

reading or writing the

media card.

encountered an abort

or undefined

instruction.

access invalid address

space.

in reading or writing

NVRAM.

Replace the media

card.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

120D Never Error Stack over and under

120E Software

Detected Error

flow error; Code error

An error condition was

detected in the

software control code.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Diagnostic information 2-7

Page 28

4419-X6X

Code Name Description Action

120F Printhead

Select

121A Loop Timeout

Error

121B NVRAM

Control Section

Corrupted

POST symptom table

Symptom Action

Installed printhead ID,

print command

printhead ID, or loaded

printhead records do

not agree.

Error detected that a

while loop or similar

loop timed out before

the event it was waiting

on finished.

Indicates that the

Control Section of

NVRAM is corrupted

Replace the print

cartridge.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Unplug the

All-In-One; wait a few

seconds, then plug

the All-In-One back

in, and turn the power

on. If the error

remains, replace the

system board.

Power, Copy, or

Scan lights do

not come on;

motors do not

operate.

The paper feed

gears do not

turn.

2-8 Service Manual

Go to the “Power service check” on page 2-19. If okay,

go to “Control panel problems” on page 2-10.

Go to the “Paper feed service check” on page 2-17.

Page 29

Symptom Action

4419-X6X

• The carrier

does not

move.

• The carrier

slams the

side frame.

• The CIS does

not move.

• The CIS lamp

does not

come on.

Go to the “Carrier transport service check” on

page 2-13.

Go to the “CIS module assembly service check” on

page 2-15.

Diagnostic information 2-9

Page 30

4419-X6X

Symptom tables

Locate the symptom in the following tables, and take the appropriate action.

Carrier transport problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slams the side frame

Go to the “Carrier transport

service check” on page 2-13.

Maintenance station problems

Symptom Action

• Fails to cap the printheads

• Fails to clean the printheads

Go to the “Maintenance station

service check” on page 2-15.

Control panel problems

Symptom Action

• Butto ns do not work.

• LCD does not display.

If the LCD, buttons, or power light

fails, check the control panel cable

connection J6 on the system board,

and then run the “Power-On Self

Test (POST) sequence” on

page 2-1. If the problem remains,

replace the midframe cover with

control panel and risers. Go to

“Midframe cover with control

panel and risers removal” on

page 4-8.

If the problem continues, replace the

system board. Go to “System

board removal” on page 4-15.

2-10 Service Manual

Page 31

Printer communication problems

Symptom Action

4419-X6X

The computer does not

communicate with the printer.

Check the USB cable and system

board cable connections. If

connections are okay, replace the

system board. Go to the “System

board removal” on page 4-15.

Scanner problems

Symptom Action

• CIS does not move.

• Lamp does not come on.

• Scanned images are faded, or

colors are dull, blurry, or fuzzy.

Images are slanted or crooked

and the straight lines in the

image appear to be jagged or

uneven.

• Blank copies

PictBridge problems

Symptom Action

Go to the “CIS module assembly

service check” on page 2-15.

Go to the “Scan and copy quality

service check” on page 2-23.

The camera does not

communicate with the printer.

Check USB cable connections. If

connections are okay, go to the

“PictBridge service check” on

page 2-15.

Diagnostic information 2-11

Page 32

4419-X6X

Paper feed problems

Symptom Action

• Fails to pick up paper

• Picks up more than one sheet

of paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper pick motor

• Noisy paper feed

• Envelopes fail to feed

• Paper skews

Go to the “Paper feed service

check” on page 2-17.

Power problems

Symptom Action

There is no power in the

All-In-One; motors do not operate.

Go to the “Power service check”

on page 2-19.

Print quality problems

Symptom Action

• Voids in characters

• Light print

• Prints off the page

• Fuzzy print

• Carrier moves but nothing

prints

• Printhead dries prematurely

• Colors print incorrectly

• Vertical alignment off

Go to the “Print quality service

check” on page 2-20.

2-12 Service Manual

Page 33

Service checks

Carrier transport service check

Unit/Problem Action

4419-X6X

Carrier Transport

Motor

Carrier Guide Rod Clean and lubricate the carrier rod.

Encoder Strip Verify that the encoder strip is installed correctly and is

Check the carrier transport motor connector J10 on the

system board. If it is connected, check for

approximately 30 V dc on pins 1 and 2 or at the wire

connections located on the rear of the carrier transport

motor. If voltage is incorrect, replace the system board.

Go to “System board removal” on page 4-15. If

voltage is correct, check the motor for binds or a loose

motor pulley.

A noisy or chattering motor or a motor that fails to turn

can be caused by:

• A broken circuit or short-circuit in the motor

• A bind in the carrier transport mechanism

Disconnect the carrier transport motor cable J10 from

the system board, and check for 15 ohms between the

two wires on the carrier transport motor. If the reading

is incorrect, replace the print engine. Go to “Print

engine removal” on page 4-17.

Lubricate the carrier rod and the carrier rod bearing

surfaces with grease P/N 40X0179.

free of grease or dirt. If the encoder strip is not installed

correctly, it can cause the carrier to slam against the

side frame. If the encoder strip is damaged, replace it.

Go to “Encoder strip removal” on page 4-16.

If the encoder strip and all connections are okay, but

the carrier slams the side frame, replace the system

board. Go to “System board removal” on page 4-15.

Diagnostic information 2-13

Page 34

4419-X6X

Unit/Problem Action

Carrier Assembly Check the following parts for wear or damage:

• Printhead cartridge latch

• Latch spring

• Carrier

• Printhead cables

Ensure that all printhead cables are fully seated.

If any of these parts are defective, replace the carrier

assembly . Go to “Carrier assembly with cables, belt,

and cable clip removal” on page 4-18.

Check the gold-plated contacts located on the inside

(rear) of the printhead carrier for dirt, wear, and

damage. Use a clean cloth dampened with water to

clean the contacts. Let the contacts dry completely. If

the gold contacts are damaged, replace the carrier

assembly . Go to “Carrier assembly with cables, belt,

and cable clip removal” on page 4-18.

If the symptom remains, replace the system board. Go

to “System board removal” on page 4-15.

2-14 Service Manual

Page 35

CIS module assembly service check

Unit/Problem Action

4419-X6X

CIS Module

Assembly

If the CIS module does not move, ensu re th at th e be lt

is installed and is not binding. Check the scanner

motor connector JP3 on the system board for proper

connection. If the CIS module still does not move,

replace the system board. Go to “System board

removal” on page 4-15.

If the lamp does not come on as the CIS module

assembly is scanning, check connector J12 on the

system board. If the connection is okay and the

problem remains, replace the scanner module

assembly. Go to “Scanner module assembly

removal” on page 4-6.

PictBridge service check

Unit/Problem Action

PictBridge

Card

Check system board connector P1 for approximately

4.9 V dc on pin 1. If the voltage is incorrect, replace the

system board. Go to “System board removal” on

page 4-15. If the voltage is correct but the problem

remains, replace the card reader card with PictBridge

assembly and cables. Go to “Card reader card with

PictBridge assembly and cables removal” on

page 4-13.

Maintenance station service check

The maintenance station has three functions:

1. Wipes (cleans) the printhead nozzle plates

2. Provides a place for printheads to fire all nozzles, keeping them clean

for printing

Diagnostic information 2-15

Page 36

4419-X6X

3. Seals the printheads when they are not being used to prevent the

nozzles from drying

Unit/Problem Action

Maintenance

Station

Assembly

As the carrier moves to the left over the maintenance

station, a slot on the bottom of the carrier engages a tab

on the sled of the maintenance station, causing the cap

to rise and seal the printheads. When the carrier moves

to the right, it uncaps the printheads. The wipers clean

the printhead nozzle plates as the carrier leaves the

maintenance station. The wipers clean the printheads

only when the carrier is moving to the right. After the

cleaning operation is complete, a tab on the

maintenance station engages a tab on the carrier,

causing the wipers to lower.

Worn wipers can cause poor print quality after printhead

cleaning. Check for loose or worn wipers.

Worn caps cause the printhead nozzles to dry and clog.

Check for loose or worn caps.

If any worn or broken parts are found, replace the

maintenance station. Go to “Maintenance station

removal” on page 4-19.

2-16 Service Manual

Page 37

4419-X6X

Paper feed service check

If the All-In-One does not have paper jam problems, continue with this

service check. If the All-In-One has paper jam problems, examine the printer

for the following before you begin the service check:

• Check the entire paper path for obstructions.

• Ensure there is not too much paper in the paper tray.

• Ensure the correct type of paper is being used.

• Check for static in the paper.

Unit/Problem Action

• Paper Feed

Motor

• System Board

Run the “Power-On Self Test (POST) sequence” on

page 2-1.

A noisy or chattering motor or a motor that fails to turn

can be caused by:

• A broken circuit or short-circuit in the motor

• A bind in the paper feed mechanism

Disconnect paper feed motor cable J11 from the

system board, and check for approximately 25 ohms

between the two wires on the paper feed motor. If the

reading is incorrect, replace the print engine. Go to

“Print engine removal” on page 4-17. If the reading

is correct, check for approximately 30 V dc at

connector J11 on pins 1 and 2. If the voltage is

incorrect, replace the system board. Go to “System

board removal” on page 4-15.

Although the paper feeds in one direction, the paper

feed motor turns in two directions. If the paper feed

motor turns in one direction only, replace the system

board. Go to “System board removal” on page 4-15.

Binds in the paper feed motor or gear train can cause

intermittent false paper jam errors. Remove the paper

feed motor, and check the shaft for binds. Also check

for a loose or worn motor gear. If the gear is defective,

replace the print engine. Go to “Print engine

removal” on page 4-17.

Diagnostic information 2-17

Page 38

4419-X6X

Unit/Problem Action

Paper Pick

Assembly

ADF Scanner Lid

Assembly

Midframe

Assembly

Check the paper pick motor connector J17 on the

system board. If it is connected, check for

approximately 30 V dc on pins 1 and 2 or at the wire

connections located on the rear of the paper pick

motor. If voltage is incorrect, replace the system board.

Go to “System board removal” on page 4-15. If the

voltage is correct, replace the printer base assembly

with cover and paper pick assembly. Go to “Printer

base with cover and paper pick assembly removal”

on page 4-22.

Check the pick roller for wear. If the pick roller is worn

and causing a paper feed problem, replace the printer

base assembly with cover and paper pick assembly.

Go to “Printer base with cover and paper pick

assembly removal” on page 4-22.

Check the ADF paper feed motor connector J4 on the

system board for proper connection.

Check the ADF paper feed sensor connector J15 on

the system board. If it is connected, check for

approximately 1.2 V dc on pin 1 and 3.2 V dc on pin 3.

If the voltage is incorrect, replace the ADF scanner lid

assembly. Go to “ADF scanner lid assembly

removal” on page 4-5.

Check the following for wear:

• Small feed rollers

• Large feed roller

• Exit roller

• Star rollers

End-of-Forms

Flag

ADF

End-of-Forms

Flag

2-18 Service Manual

If any of the rollers are worn and causing a paper feed

problem, replace the print engine. Go to “Print engine

removal” on page 4-17.

Check for binds or damage. If the flag is defective,

replace the print engine. Go to “Print engine

removal” on page 4-17.

Check for binds or damage. If the flag is defective,

replace the ADF scanner lid assembly. Go to “ADF

scanner lid assembly removal” on page 4-5.

Page 39

Power service check

Unit/Problem Action

4419-X6X

External Power

Supply

• Printhead

Cables

• Paper Feed

Motor

• Carrier

Transport

Motor

• Control Panel

Plug the external power supply into an outlet, and

check for 30 V dc. If the voltage is incorrect, replace

the power supply.

Unplug the All-In-One. Check all connections on the

system board, and plug the All-In-One back in. Look for

a symptom change.

If the printhead cables are defective, replace the carrier

assembly . Go to “Carrier assembly with cables, belt,

and cable clip removal” on page 4-18.

Check for broken circuits or short-circuits in the paper

feed and carrier transport motors. If either motor is

defective, replace the print engine. Go to “Print

engine removal” on page 4-17.

If the control panel LCD, buttons, or power light fails,

check cable connection J6 on the system board, and

then run the “Power-On Self Test (POST) sequence”

on page 2-1. If the problem remains, replace the

midframe cover with control panel and risers. Go to

“Midframe cover with control panel and risers

removal” on page 4-8.

If the problem continues, replace the system board. Go

to “System board removal” on page 4-15.

Diagnostic information 2-19

Page 40

4419-X6X

Print quality service check

Unit/Problem Action

Alignment Uneven vertical lines and characters not properly

formed (jagged or rough) or not aligned at the left

margin can be adjusted by performing the print

cartridge alignment.

Aligning print cartridges using the control panel

1. Load plain paper.

2. From the control panel, press Copy Mode.

3. Press .

4. Press or repeatedly until Maintenance is

highlighted.

5. Press .

6. Press or repeatedly until Align

Cartridges is highlighted.

7. Press .

An alignment page prints.

If you aligned the cartridges to improve print quality,

print your document again. If print quality has not

improved, clean the print cartridge nozzles.

Aligning print cartridges using the Productivity

Suite

1. Load plain paper.

2. From the desktop, double-click the Productivity

Suite icon, and then click Maintain/Troubleshoot.

3. Click the Maintenance tab.

4. Click Align to fix blurry edges.

5. Click Print.

An alignment page prints.

If you aligned the cartridges to improve print quality,

print your document again. If print quality has not

improved, clean the print cartridge nozzles.

2-20 Service Manual

Page 41

Unit/Problem Action

Print Cartridge Ensure that the All-In-One contains good print

cartridges.

Clean the print cartridge nozzles when:

• Characters are not printing completely.

• White dashes appear in graphics or printed text.

• Print is smudged or too dark.

• Vertical, straight lines are not smooth.

• Colors on print jobs are faded, or they dif fer from the

colors on the screen.

Cleaning the print cartridge nozzles using the

control panel

1. Load plain paper.

2. Press Copy Mode.

3. Press .

4. Press .

5. Press .

6. Press until Clean Cartridges is highlighted.

7. Press .

8. A page prints, forcing ink through the print cartridge

nozzles to clean them.

9. Print the document again to verify that the print

quality has improved.

If print quality has not improved, try cleaning the

nozzles up to two more times.

Cleaning the print cartridge nozzles using the

Productivity Suite

1. Load plain paper.

2. From the desktop, double-click the Productivity

Suite icon, and then click Maintain/Troubleshoot.

3. Click the Maintenance tab.

4. Click Clean to fix horizontal streaks.

5. Click Print.

A page prints, forcing ink through the print cartridge

nozzles to clean them.

6. Print the document again to verify that the print

quality has improved.

7. If print quality has not improved, try cleaning the

nozzles up to two more times.

4419-X6X

Diagnostic information 2-21

Page 42

4419-X6X

Unit/Problem Action

Color print

cartridge cross

contamination

Maintenance

Station

Paper Feed Ink smudging and smearing can be caused by paper

Be sure the print cartridge nozzle plate is clean. Clean

with a clean, lint-free cloth dampened with water.

If cross contamination occurs, check for:

• Maintenance station wiper damage

• Used tape on the printhead nozzle plate

If the wiper is damaged, replace the maintenance

station. Go to “Maintenance station removal” on

page 4-19.

Note: Do not retape the printhead nozzle plate.

Intermittent nozzle failures can be caused by worn

parts in the maintenance station. If you find worn parts,

replace the maintenance station. Go to “Maintenance

station removal” on page 4-19.

problems or problems in the paper feed area. Check

for:

• Correct type of paper

• Curled or wrinkled paper

• Paper path obstructions

• Feed roller wear or looseness

• Worn gears or binds

If the paper feed roller or gears are defective, replace

the print engine. Go to “Print engine removal” on

page 4-17.

Carrier Transport Blurred print and voids can be caused by problems in

the carrier transport area. Check the following:

• Carrier transport belt for wear

• Idler pulley parts for wear, damage, or looseness

• Carrier guide rod for wear or dirt. If the rod is dirty,

clean and lubricate it.

The carrier to carrier frame engagement should be

lubricated with grease P/N 40X0179.

If the carrier transport belt is worn, replace the carrier

assembly . Go to “Carrier assembly with cables, belt,

and cable clip removal” on page 4-18.

If the idler pulley parts are defective, replace the print

engine. Go to “Print engine removal” on page 4-17.

2-22 Service Manual

Page 43

Scan and copy quality service check

Unit/Problem Action

4419-X6X

Scanned images

have:

• Blank pages

• Checkerboard

pattern

•Distorted

graphics or

pictures

• Missing

characters

• Faded print

• Dark print

• Skewed lines

• Smudges

• Streaks

• Unexpected

characters

• White lines in

print

If the scanner glass is dirty, gently wipe it with a clean,

lint-free cloth dampened with water.

Make sure all ink or corrective fluid is dry before

placing a document on the scanner glass.

Make sure the document or photo is loaded correctly in

the ADF or on the scanner glass.

Check the ink levels, and install a new print cartridge if

necessary.

To adjust the Brightness setting:

1. Load the document face down on the scanner glass.

2. From the control panel, press Copy Mode.

3. Press or repeatedly until Lighter /

Darker is highlighted.

4. Press or to lighten or darken the copy.

5. Press .

Diagnostic information 2-23

Page 44

4419-X6X

2-24 Service Manual

Page 45

4419-X6X

3. Diagnostic aids

Test page

This test prints the test page.

To run a complete test page of black and color patterns, be sure the

printhead cartridges are in good condition.

To enter the test:

1. Turn on the All-In-One.

2. Lift the scanner unit.

3. Install a good black print cartridge in the left side of the carrier and a

good color cartridge in the right.

4. Close the scanner unit.

5. Load paper in the paper support.

6. Press until Maintenance appears on the LCD.

7. Highlight Maintenance and press .

8. Print Test Page appears on the LCD.

9. Highlight Print Test Page and press to print the test page.

The test page consists of the following information:

• Build Date

• Code Level

• Page Count

• ASIC Version

• Temps

• USB Product

• USB Manufacturer

• USB Serial Number

• MFG

• CMD

• Model

• Class

• DES

• USB Vendor ID

There is a black and color purge pattern used to clear all printhead nozzles.

The nozzle test pattern prints all nozzles on a diagonal line. There should be

no breaks in the nozzle test pattern. A break in the pattern indicates one or

more nozzles are not working.

Diagnostic aids 3-1

Page 46

4419-X6X

If a print quality problem exists, see “Print quality service check” on

page 2-20.

3-2 Service Manual

Page 47

4419-X6X

4. Repair information

This chapter explains how to make adjustments to the All-In-One and how to

remove defective parts.

Warning: Read the following before handling electronic parts.

Handling ESD-sensitive parts

Many electronic products use parts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive parts,

follow the instructions below:

• Keep the ESD-sensitive part in its original shipping container (a special

“ESD bag”) until you are ready to install the part into the machine.

• Make as few movements as possible with your body to prevent an

increase of static electricity from clothing fibers, carpets, and furniture.

• Put the ESD wrist strap on your wrist. Connect the wrist band to the

system ground point. This discharges any static electricity in your body

to the machine.

• Hold the ESD-sensitive part by its edge connector shroud (cover); do

not touch its pins. If you are removing a pluggable module, use the

correct tool.

• Do not place the ESD-sensitive part on the machine cover or on a

metal table; if you need to put down the ESD-sensitive part for any

reason, first put it into its special bag.

• Machine covers and metal tables are electrical grounds. They increase

the risk of damage because they make a discharge path from your

body through the ESD-sensitive part. (Large metal objects can be

discharge paths without being grounded.)

• Prevent ESD-sensitive parts from being accidentally touched by other

personnel. Install machine covers when you are not working on the

machine, and do not put unprotected ESD-sensitive parts on a table.

• If possible, keep all ESD-sensitive parts in a grounded metal cabinet

(case).

• Be extra careful in working with ESD-sensitive parts when cold-

weather heating is used, because low humidity increases static

electricity.

Repair information 4-1

Page 48

4419-X6X

Adjustments

The user is directed in the Lexmark Solution Center to perform the printhead

alignment adjustments after replacing a print cartridge.

Removal procedures

The following procedures are arranged according to the name of the

All-In-One part discussed.

CAUTION: Unplug the power cord before removing any parts.

Releasing plastic latches

Many of the parts are held in place with plastic latches. The latches break

easily; release them carefully. To remove such parts, press the hook end of

the latch away from the part to which it is latched.

4-2 Service Manual

Page 49

4419-X6X

Removals

General precautions on removals

Use caution when disassembling and reassembling components. The close

proximity of cables to moving parts makes proper routing a must. When

components are removed or replaced, any cables disturbed must be

replaced as closely as possible to their original positions. Before removing

any component from the machine, be sure you note the cable routing.

When servicing the machine:

• Verify that documents are not stored in memory.

• Move the print cartridge to the far right to cap the nozzles.

• Unplug the power cord.

• Use a flat and clean surface.

• Use only authorized replacement parts.

• Do not force plastic parts.

Control panel cover removal

1. Lift the scanner module assembly until the risers extend.

2. Separate the cover from the base of the control panel, and lift to

remove.

Repair information 4-3

Page 50

4419-X6X

Rear access cover removal

1. Remove screw (A).

2. Remove the rear access cover.

4-4 Service Manual

Page 51

ADF scanner lid assembly removal

1. Remove the rear access cover.

2. Remove ground cable screw (A), and disconnect three cables (B) from

the system board.

4419-X6X

3. Raise the ADF scanner lid assembly to the upright position.

4. Separate the ADF scanner lid hinges (C) from the scanner module

assembly.

Repair information 4-5

Page 52

4419-X6X

5. Lift to remove.

Scanner module assembly removal

1. Remove the rear access cover.

2. Disconnect J12 (A) and JP3 (B) from the system board.

3. Lift the scanner module assembly until the risers extend.

4-6 Service Manual

Page 53

4. Disconnect both risers.

5. Lift the scanner module assembly, and remove.

4419-X6X

Repair information 4-7

Page 54

4419-X6X

Midframe cover with control panel and risers removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the control panel cover.

5. Remove ten screws (A).

4-8 Service Manual

Page 55

4419-X6X

6. Lift the midframe cover to disconnect J6 (B) from the system board.

7. Remove the midframe cover with control panel and risers.

Repair information 4-9

Page 56

4419-X6X

Rear access door with sensor removal

1. Remove the rear access cover.

2. Disconnect JP2 (A) from the system board.

4-10 Service Manual

Page 57

4419-X6X

3. Use a flat thin-blade screwdriver to separate the rear access door

hinge from the base cover.

4. Remove the rear access door with sensor.

Repair information 4-11

Page 58

4419-X6X

Fax card removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Disconnect J7 (A) from the fax card.

5. Remove three screws (B).

6. Lift and remove the fax card.

4-12 Service Manual

Page 59

4419-X6X

Card reader card with PictBridge assembly and cables removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Remove the fax card.

6. Disconnect P3 (A) and P1 (B) from the system board.

Repair information 4-13

Page 60

4419-X6X

7. Remove two screws (C).

8. Remove the card reader card with PictBridge assembly and cables.

4-14 Service Manual

Page 61

System board removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Disconnect all cables from the system board.

6. Remove six screws (A).

4419-X6X

7. Lift and remove the system board.

Repair information 4-15

Page 62

4419-X6X

Encoder strip removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Disconnect both ends of the encoder strip (A).

6. Remove the encoder strip.

4-16 Service Manual

Page 63

Print engine removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Remove the rear access door with sensor.

6. Remove the fax card.

7. Disconnect power supply and existing cable from the system board.

8. Remove seven screws (A).

4419-X6X

9. Lift, tilt, and remove the print engine.

Repair information 4-17

Page 64

4419-X6X

Carrier assembly with cables, belt, and cable clip removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Remove the print engine assembly.

6. Remove the encoder strip.

7. Remove the carrier shaft retainer clips (A).

8. Remove the carrier shaft through the left side.

9. Press the carrier belt tensioner (B), and remove the belt (C).

10. Unplug the carrier cables from the system board.

4-18 Service Manual

Page 65

4419-X6X

11. Press cable latch (D), pull the cables through the slot, and remove the

carrier assembly.

Maintenance station removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Remove the print engine assembly.

Repair information 4-19

Page 66

4419-X6X

6. Press two latches (A).

7. Slide the maintenance station forward and remove.

4-20 Service Manual

Page 67

Exit tray removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Remove the print engine assembly.

6. Use a flat thin-blade screwdriver to separate the exit tray hinge from

the base cover.

4419-X6X

7. Lift and remove the exit tray.

Repair information 4-21

Page 68

4419-X6X

Printer base with cover and paper pick assembly removal

1. Remove the rear access cover.

2. Remove the ADF scanner lid assembly.

3. Remove the scanner module assembly.

4. Remove the midframe cover with control panel and risers.

5. Remove the print engine assembly.

6. Remove the exit tray.

The printer base with cover and paper pick assembly remains.

• kkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkk

kkkkkkkkkkkkkkkkkkkkk

4-22 Service Manual

Page 69

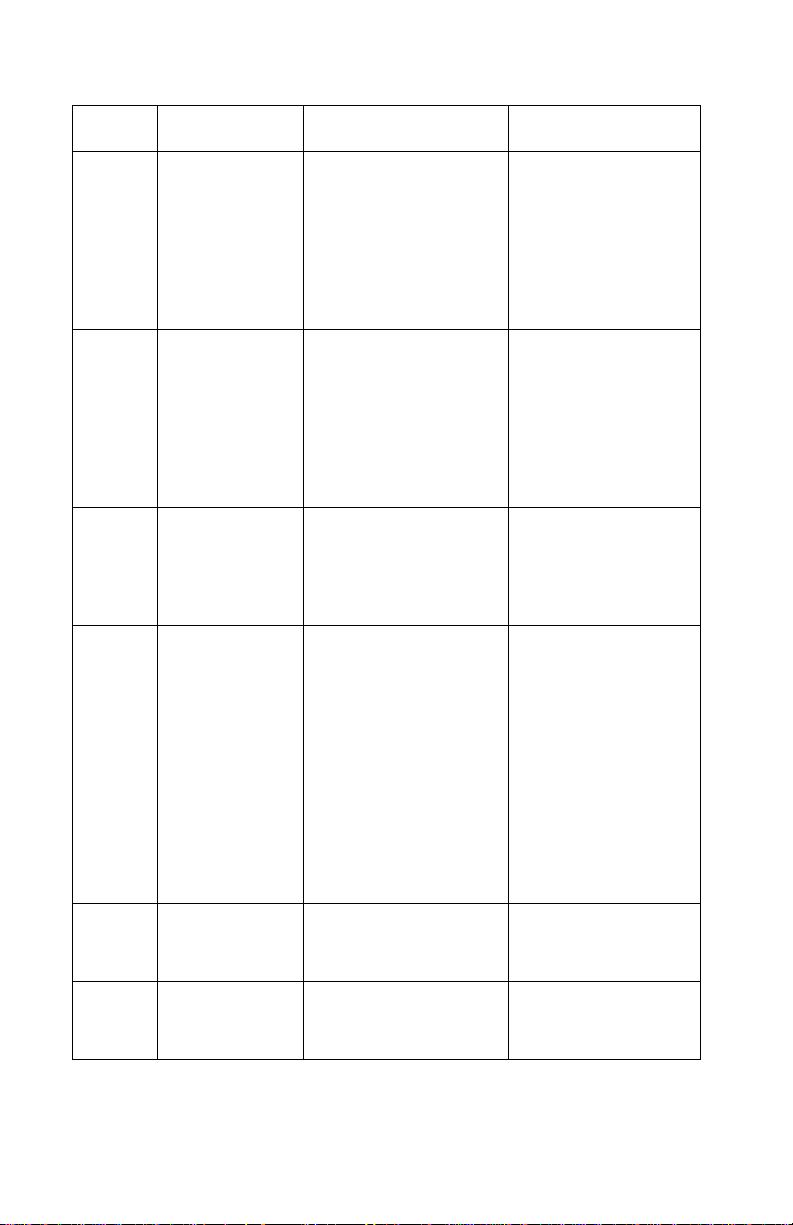

5. Locations and connectors

System board

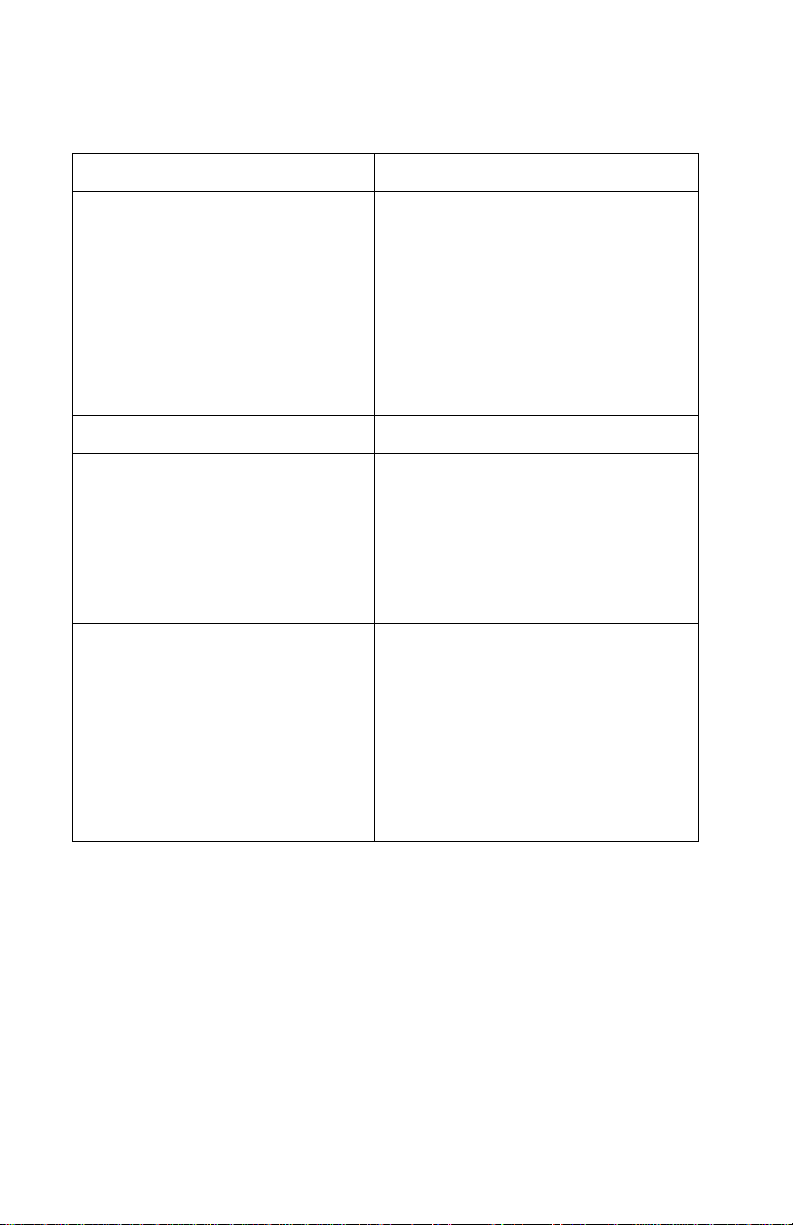

Connector Description Approximate voltage

J1 Power Supply Pin 1–30 V dc 2

4419-X6X

Connector

(total number

of pins)

J4 ADF Paper

Feed Motor

J5 Fax Card

J6 Control Panel Ribbon

J7 Carrier Ribbon

J8 Carrier Ribbon

J9 Carrier Ribbon

J10 Carrier

Transport

Motor

J11 Paper Feed

Motor

J12 CIS Scanner

Lamp

J15 ADF Paper

Feed Sensor

J16 ADF End of

Forms Sensor

J17 Paper Pick

Motor

Pins 1 and 2–30 V dc 2

Pins 1 and 2–30 V dc 2

Pin 1–1.2 V dc

Pin 3–3.2 V dc

Pin 1–1.2 V dc

Pin 3–3.2 V dc

Pins 1 and 2–30 V dc 2

4

Ribbon

4

4

J18 Paper Pick

Sensor

P1 PictBridge Pin 1–4.9 V dc 5

P2 USB

Locations and connectors 5-1

4

Page 70

4419-X6X

Connector Description Approximate voltage

P3 Card Reader Pin 3–2.9 V dc 5

Connector

(total number

of pins)

JP1 Paper Encoder

Dial Sensor

JP2 Rear Door

Media Sensor

JP3 Scanner Motor 4

U6 Cartridge

Access Sensor

Pin 1–4.8 V dc

Pin 2–4.8 V dc

Pin 3–4.8 V dc

Pin 4–4.8 V dc

Ribbon

4

5-2 Service Manual

Page 71

4419-X6X

Locations and connectors 5-3

Page 72

4419-X6X

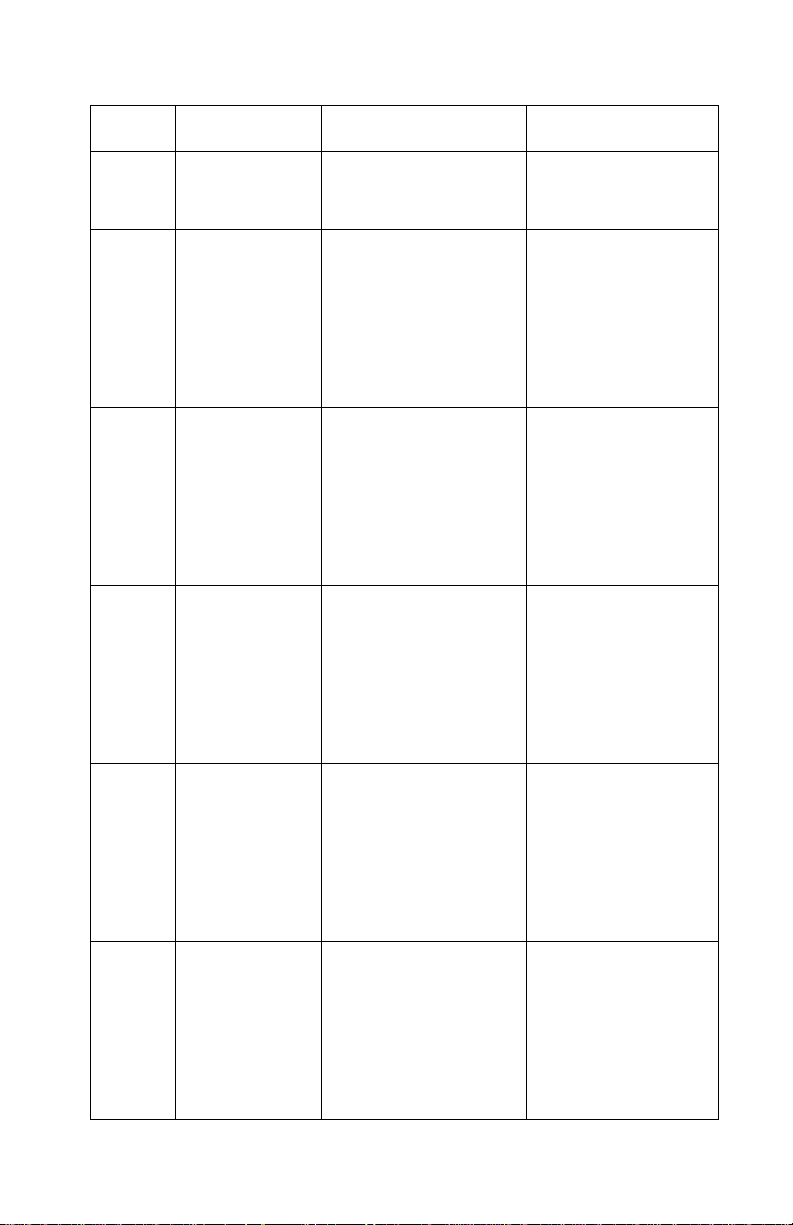

Fax card

Connector Description Approximate voltage

J7 Speaker 2

Connector

(total number

of pins)

5-4 Service Manual

Page 73

PictBridge and card reader

Connector Description Approximate voltage

J1 PictBridge Pin 1–4.9 V dc 5

J1 Card Reader Pin 3–2.9 V dc 5

4419-X6X

Connector

(total number

of pins)

Locations and connectors 5-5

Page 74

4419-X6X

5-6 Service Manual

Page 75

4419-X6X

6. Preventive maintenance

This chapter contains lubrication specifications. Follow these

recommendations to prevent problems and maintain optimum performance.

Lubrication specifications

Lubricate only when parts are replaced or as needed, not on a scheduled

basis. Use grease P/N 40X0179 to lubricate the following:

• All gear mounting studs

• The left and right ends of the large feed roller at the side frames

• The carrier to carrier frame engagement

• The carrier guide rod, and carrier guide rod bearings

Warning: Keep grease from coming into contact with any electrical

components, as this may cause All-In-One damage or failure. Do not

lubricate the scanner rod or bearing after replacing.

Preventive maintenance 6-1

Page 76

4419-X6X

6-2 Service Manual

Page 77

7. Parts catalog

How to use this parts catalog

The following legend is used in the parts catalog:

4419-X6X

AsmIndex

Part

number

Units/

mach

Units/

FRU

Description

• Asm-index: Identifies the assembly and the item in the diagram. For

example, 2-1 indicates assembly 2 and item number 1.

• Part number: Identifies the unique number that identifies this FRU.

• Units/mach: Refers to the number of units actually used in the

machine or product.

• Units/FRU: Refers to the number of units packaged together and

identified by the part number.

• NS: (Not shown) in the Asm-Index column indicates that the part is

procurable but is not pictured in the illustration.

• PP: (Parts Packet) in the parts description column indicates that the

part is contained in a parts packet.

Parts catalog 7-1

Page 78

4419-X6X

Assembly 1: Covers

7-2 Service Manual

Page 79

Assembly 1: Covers

4419-X6X

AsmIndex

1—1 40X2468 1 1 Cover, midframe with control panel

NS 7375511 1 1 Plain package B/M includes: carton,

Part

number

2 21M0835 1 1 Cover, control panel English

2 21M0837 1 1 Cover, control panel Dutch

2 21M0839 1 1 Cover, control panel French

2 21M0841 1 1 Cover, control panel German

2 21M0843 1 1 Cover, control panel Greek

2 21M0845 1 1 Cover, control panel Hebrew

2 21M0847 1 1 Cover, control panel Italian

2 21M0849 1 1 Cover, control panel Japanese

2 21M0851 1 1 Cover, control panel Korean

2 21M0853 1 1 Cover, control panel Polish

2 21M0855 1 1 Cover, control panel Brazilian

2 21M0857 1 1 Cover, control panel Russian

2 21M0859 1 1 Cover, control panel Simplified

2 21M0861 1 1 Cover, control panel Spanish

2 21M0863 1 1 Cover, control panel Traditional

2 21M0865 1 1 Cover, control panel Turkish

3 40X2471 1 1 Door, rear access with sensor

4 40X2470 1 1 Cover, rear access

5 40X2469 1 1 Base, printer with cover

6 40X2473 1 1 Tray, exit

Units/

mach

Units/

FRU

Description

and risers

Portuguese

Chinese

Chinese

cushion set, and sealing tape

Parts catalog 7-3

Page 80

4419-X6X

Assembly 1 (cont.): Covers

7-4 Service Manual

Page 81

Assembly 1 (cont.): Covers

4419-X6X

AsmIndex

1—1 40X2462 1 1 Lid, ADF scanner assembly

Part

number

2 40X2463 1 1 Module, scanner assembly

Units/

mach

Units/

FRU

Description

Parts catalog 7-5

Page 82

4419-X6X

Assembly 2: Engine, electronics, and carrier

7-6 Service Manual

Page 83

Assembly 2: Engine, electronics, and carrier

4419-X6X

AsmIndex

2—1 40X2466 1 1 Card, fax

NS 11B6502 1 1 Cord, power Australia

NS 11B6503 1 1 Cord, power UK, Hong Kong

NS 11B6504 1 1 Cord, power Europe, Asia

NS 11B6507 1 1 Cord, power South Africa

NS 11B6508 1 1 Cord, power Chile

NS 11B6510 1 1 Cord, power Brazil

NS 11B6511 1 1 Cord, power Japan

NS 11B6512 1 1 Cord, power Argentina

NS 11B6513 1 1 Cord, power Peoples Republic of

NS 11B6514 1 1 Cord, power Korea

NS 11B6515 1 1 Cord, power Taiwan

NS 11B6516 1 1 Cord, power India

NS 11B6532 1 1 Cord, power Japan - 2.5 Amp 6 foot

Part

number

2 40X2465 1 1 Board, system

3 40X2461 1 1 Strip, encoder

4 40X2464 1 1 Engine, print

5 40X2467 1 1 Card, reader card and Pictbridge

6 40X2472 1 1 Carrier, assembly with cables, belt,

7 40X2460 1 1 Station, maintenance

8 21H0302 1 1 Supply, power universal 32 W

9 11B6501 1 1 Cord, power USA, Peru, Canada,

Units/

mach

Units/

FRU

Description

assembly

and cable clip

LAD

China

3 conductor

Parts catalog 7-7

Page 84

4419-X6X

7-8 Service Manual

Page 85

Index

A

acronyms 1-10

adjustments

B

buttons

Cancel

Copy Mode

Down Arrow

Fax Auto Answer

Fax Mode

Keypad

Left Arrow

Menu

Phone Book

Photo Card

Power

Quick Dial

Redial/Pause

Return

Right Arrow

Scan Mode

Select (check)

Start Black

Start Color 1-8

Up Arrow

C

carrier transport problems 1-10

CIS module assembly

control panel 1-5

control panel problems

copy specifications

D

diagnostic aids

test page 1-1

diagnostic information

error codes

POST (Power-On Self Test)

sequence

POST symptom table

1-2

1-7

1-5

1-7

1-5

1-5

1-8

1-6

1-7

1-6

1-5

1-8

1-5

1-6

1-7

1-7

1-5

1-6

1-8

1-6

1-15

1-10

1-3

1-1

1-2

1-1

1-8

4419-X6X

1-1

start

symptom tables

1-10

E

error codes 1-2

ESD-sensitive parts

1-1

G

general information 1-1

H

handling ESD-sensitive parts 1-1

L

LCD 1-1, 1-10

locations and connectors

fax card

PictBridge and card reader

system board

lubrication specifications

1-4

1-1

1-1

1-5

1-1

M

maintenance approach 1-9

maintenance station 1-15

maintenance station problems

1-10

P

paper feed 1-17

paper feed problems

paper jam 1-12

parts catalog

carrier

covers 1-2, 1-4

electronics

how to use

print engine 1-6

PictBridge 1-15

PictBridge problems

plastic latches 1-2

POST (Power-On Self Test) sequence

1-1

1-1

1-6

1-6

1-1

1-12

1-11

Index I-1

Page 86

4419-X6X

POST symptom table

power problems