Lexmark 4600 Service manual

• Table of contents

• Start diagnostics

Editio n: April 26 , 2007

Lexmark™ 4600 MFP option

4036-307

4036-308

• Safety and notices

•Trademarks

• Index

Lexmark and Lexmark with diamond design are

trademarks of Lexmark International, Inc., registered

in the United States and/ or other countries.

Edition: April 26, 2007

T

L

E

M

i

T

i

p

C

L

y

o

R

e

a

i

t

d

c

u

L

U

P

A

©

U

T

a

4036-307, -308

he following paragraph does not apply to an y country where such provisions are inconsistent with local law:

EXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

ITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

ERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

mplied warranties in certain transacti ons; therefor e, this statement ma y not apply to you.

his publi cation could include technical inaccuracies or typographical errors. Chang es are peri odically made to the

nformation her ein; these changes will be inco rporat ed in later editions . Improvements or changes in the products or the

rograms descri bed m ay be made at any time.

omments may be addressed to Lexmark Int ernational, Inc., Department D22A/032-2, 740 West New Circle Road,

exington, Kentucky 40550, U .S.A or e-mail at ServiceInfoAndTraining@Lexmark .com. Lexmark may use or distribute an

f the inf ormati on you supply in any way it believes appropriate without incurring any obligation to you.

eferences in this pub lication to products, progr am s, or services do not imply that the manufacturer intends to mak e thes

vailable in all countries in whic h it operates. Any reference to a product, program, or service is not intended to state or

mply that only that pr oduct, progr am, or service may be used. Any functi onall y equiv alent pro duct, progr a m, or service tha

oes not infringe any existing intellectual property right may be used instead. Evaluation and verification of operation in

onjunction with other products, programs, or service s, except those expressly desi gnated by the manufacturer, are the

ser’s responsibil ity.

exmark, Lexmark with diamond design, and M arkVi sion are trademarks of Le xmark International, Inc., registered in the

nited States and/or other countries.

CL® is a registered trademark of the Hewlett-P ackard Company.

ll other trademarks are the property of their respective owners.

2007 Lexmark International, Inc.

All rights reserved.

NITED STATES GOVERNMENT RIGHTS

his softwar e and any accompanying documentation pro vided under this agreemen t are commercial computer sof tware

nd documentation developed exclusively at private expense.

12G9664

4036-307, -308

Table of contents

Table of contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scanner specific ati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tools required for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power-On Self Test (POST) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Symptom tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Reading is not performed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Scan module does not move to home position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Error codes and messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Service error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Sub error codes for 8xx and 2xx er ror codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

User attendance messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

The power does not come on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Display panel remains blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Frequent paper jam, double feed, or skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Image does not appear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Image unclear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Large jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Reading position deviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Strange sound generated (ADF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Strange sound generate d (flatbed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

842.00 Scanner failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

843.00 Scanner failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

843.01 Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

844.00 Front scan module out put level error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

844.01 Rear scan module output level error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

844.02 Front scan module la mp level too low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

845.00 Front scan module cable failure or SCC card failure CCD channel failure . . . . . . . . . . 2-19

845.01 Rear scan module cable failure or SCC card failure CCD channel failure . . . . . . . . . . . 2-19

845.02 Cable/SCC failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

845.03 Cable/SCC failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

846.xx Front calibration strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

848.00 Modem/config ID mismatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

848.01 Modem/config ID mismatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

849.00 HD/config ID mismatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Control panel and menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Control panel and buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Table of contents iii

4036-307, -308

LCD touch-screen buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Sample screen one . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 2 6

Information on LCD touch-screen buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Sample screen two . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Information on LCD touch-screen buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

Other LCD touch-scr een buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Menu map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Diagnostic aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Accessing service menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Entering Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Available tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

EVENT LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Display Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Print Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 3

Clear Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

SCANNER TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

ASIC Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Scanner Manual Regist ration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Configuration menu (CONFIG MENU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Entering Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 6

Available menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Format Fax Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

ADF Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

FB Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Automatic Scanner Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -8

EVENT LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Jobs On Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Disk Encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Wipe Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Key Repeat Initial Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Key Repeat Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Wiper Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Exit Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Paper feed jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Identifying jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Access doors and trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Understanding jam messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3- 1 4

Clearing jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Clearing ADF Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

290, 291, 292, and 294 Scanner Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Repair information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-sensiti ve parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Service guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 -1

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 -2

Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Parts replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Alignment screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Flatbed CCD optical unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -3

ADF optical unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Document input tray removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

ADF lower cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

iv S e rv ice Manual

4036-307, -308

ADF outer cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

ADF upper cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

ADF lamp removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

ADF motor/distribution board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

ADF optical unit removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

ADF sensor board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

ADF upper cover sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Document cover assembl y removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Paper feed assembly rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Paper feed motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Paper feed roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Paper length sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Paper present and paper feed 1 sensors removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Paper stop removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Pick pad removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Scanner cushion removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Control panel keypad board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Control panel assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Keypad removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

LCD HV inverter board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Control panel display assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Flatbed cover with glass rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Carriage transport belt removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Flatbed CCD optical unit removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Flatbed lamp assembly rem oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Flatbed lamp inverter board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Bottom plate removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Hard disk drive , A1 board, scanner cont rol boar d, power sup ply board, and modem board removals

4-36

Scanner control board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Hard disk drive assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Modem board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Power supply board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

A1 board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Control cooling fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Document cover sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

C77X printer operator panel cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

C78X printer operator panel cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Mono printer operat or panel cover removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Connector locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Scanner mechanism overview and locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Scanner control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Modem board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Power supply board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

A1 board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Preventive mainte nan ce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Scheduled maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: ADF assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 2

Assembly 2: Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Assembly 3: Lower scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 6

Table of contents v

4036-307, -308

Assembly 4: Electronic boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Assembly 5: Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Part number index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-3

vi Se rvi c e M anua l

4036-307, -308

Safety informatio n

Safety information

• The safety of this product is based on testi ng and approvals of t he original design and specific

components . The manufacturer is not responsibl e for safety in the event of use of unauthorized

replacement parts .

• The maintenance information for this product has been prepared for use by a professional service person

and is not intended to be used by others.

• There may be an increased risk of electric shoc k and personal injury during disassem bly and servicing of

this product . Pro fessional service personnel should understand this and take necessary precautions.

• CAUTION: When you see th is symbol , ther e is a danger f rom hazard ous v olt age in the ar ea of the

product where y ou ar e working . Unplug the product bef ore you beg in, or use c autio n if t he produc t

must receive power in order to perform the task.

Consignes de sécurité

• La sécurité de ce produit repose sur des tests et des

agréations portant sur sa conception d'origine et sur des composants particulier s. Le fabricant n'ass ume

aucune respon sabilité concernant la sécurité en cas d'utilisation de pièces de rechange non agréées.

• Les consignes d'entretien et de répar ati on de ce produit s'adressent uniquement à un personnel de

maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains risques électriques, le personnel

d'entretien qualifié devra prendre toutes les précautions nécessai res.

• ATTENTION : Ce symbole indique la présence d'unetension dangereuse dans la partie du

produit sur laquelle vous tra vaillez. Débranchez le produit a vant de commencer ou f aites preuve

de vigilance si l' exécution de la t âche exige que le produit reste sous tension.

Norme di sicurezza

• La sicurezza del prodotto si basa sui test e sull'approvazione del progetto originale e dei componenti

specifici. Il produttore non è responsabile per la sicurezza in caso di sostituzion e non autorizzata delle

parti.

• Le informazioni riguardanti la manutenzione di questo prodotto sono indirizzate soltanto al personale di

assistenza autorizzato .

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni al la persona è più elev ato. Il per sonale di assistenza

autorizzato deve, quindi, adottare le precauzioni necessarie.

• ATTENZIONE: Questo simbolo indica la presenza ditensione pericolosa nell'area del prodotto.

Scollegare il pr odotto prima di iniziare o usare cautela se il prodotto deve essere alimentato per

eseguire l'intervento.

Safety information vii

4036-307, -308

Sicherheitshinweise

• Die Sicherheit di eses Produkts basiert auf Tests und Zulassungen des ursprüngl ichen Modells und

bestimmter Baut eil e. Bei Verwendung nicht genehmigter Ersatztei le wi rd vom Hersteller kei ne

Verantwortung oder Haft ung für die Sicherheit übernommen.

• Die Wartungsinformationen für dies es Produkt sind ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts besteht ein zusät zliches Risiko eines

elektrischen Schlags und körperlicher Verletzung. Das zus tändige Fachpersonal sollte entsprechende

Vorsichtsmaßn ahm en treffen.

• ACHTUNG: Dieses Symbol weist auf eine gefährliche elektrische Spannung hin, die in diesem

Bereich des Produkts auftreten kann. Zie hen Sie vor den Arbeiten am Gerät den Netzstecker des

Geräts, bzw. arbeiten Sie mit großer Vorsicht, wenn das Produkt für die Ausführung der Arbeiten

an den Strom angeschlossen sein muß.

Pautas de Segu ridad

• La seguridad de este prod ucto se basa en pruebas y aprobaciones del diseño original y component es

específico s. El fabricante no es responsable de la seguridad en caso de uso de piezas de repuesto no

autorizadas.

• La información sobre el mantenimiento de este producto está dirigida exclusivamente al personal

cualificado de mantenimiento.

• Existe may o r riesg o de de scarga el éctrica y de dañ os person al es duran te e l desmont aj e y la r eparac ión de

la máquina. El personal cualificado debe ser consciente de este peligro y tomar las precauciones

necesarias.

• PRECAUCIÓN: este símbolo indica que el voltaje dela parte del equipo con la que está

trabajando es peligroso. Antes de empezar, desenchufe el equipo o tenga cuidado si, para

trabajar con él, debe conectarlo.

Informações de Segurança

• A segurança deste produto baseia-se em testes e aprovações do mode lo original e de componentes

específico s. O fabricante não é responsável pela segunrança, no caso de uso de peças de substituição

não autorizadas.

• As informações de segurança relativas a este produto dest inam-se a profissionais destes serviços e não

dev em ser utilizadas por outr as pessoas.

• Risco de choques eléct ricos e ferimentos graves durante a desmontagem e manutenção deste produto .

Os profissio nais destes serviços devem estar avis ados deste facto e tomar os cuidados necessários .

• CUIDADO: Quando vir este sí m bolo, existe a possível presença de uma potencial tens ão

perigosa na zona do produto em que está a trabalhar. Antes de começar, desligu e o produto da

tomada eléctrica ou s eja cui dado so caso o pro duto te nha d e estar liga do à corrent e eléc trica para

realizar a tarefa necessária.

viii Service Manual

4036-307, -308

Inf ormació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i apr ovació del disseny original i els components

específics.

El fabricant no es fa responsable de les qüestions de

seguretat si s'u tilitzen peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest producte està orientada exclusiv ame nt a professional s i no està

destinada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augment ar durant el procés de desmuntatge i de servei

d’aquest producte. El personal professional ha d’estar-ne assabentat i prendre

les mesures con venients.

• PRECAUCIÓ: aquest símbol in dica que el voltatge de la part de l'equip am b la qual esteu

treballan t és perillós . Abans de començar, desendolleu l'equ ip o extremeu les precaucions si, per

treballar amb l'equip, l'heu de connectar.

Safety information ix

4036-307, -308

Preface

This manual contains maintenance procedures for service personnel. It is divided into t he following ch apters:

1. General in fo rma tion contains a general description of t he scanner and the maintenance approach used

to repair it. Spec ial tools and test equipment are, as well as general environmental and safety instructions.

2. Diagn o sti c information contains an error indicator table, symptom tables, and service checks used to

isolate failing field replaceable units (FRUs).

3. Diagn osti c aids contains tests and checks used to locate or repeat symptoms of printer problems.

4. Repair info rma tion provides instructions for making printer adjustments and removing and installing

FRUs.

5. Connecto r locations uses illustrations to identify the connector locations and test points on the printer.

6. Preventive maintenance contai ns the lubrication specifications and recommendations to prev ent

problems.

7. Parts catalog contains illustrations and part numbers for individual FRUs.

Appendix A contains service tips and info rmati on.

Appendix B contains representative print samples.

Conventions

Note: A note provides addition al i nformation.

Warning: A warning identifies something that might damage the product hardware or software.

The are several types of caution statements:

CAUTION

A caution identifies something that might cause a servicer harm.

CAUTION

This type of caution i ndicates there is a danger fro m haz ardous voltage in the area of the

product where you are working. Unplug the product befor e you begin, or use caution if the

product must recei ve power in order to perform the task.

CAUTION

This type of caution indicates a hot surface.

x Service Manual

CAUTION

This type of caution i ndicates a tipping hazard.

4036-307, -308

1. General information

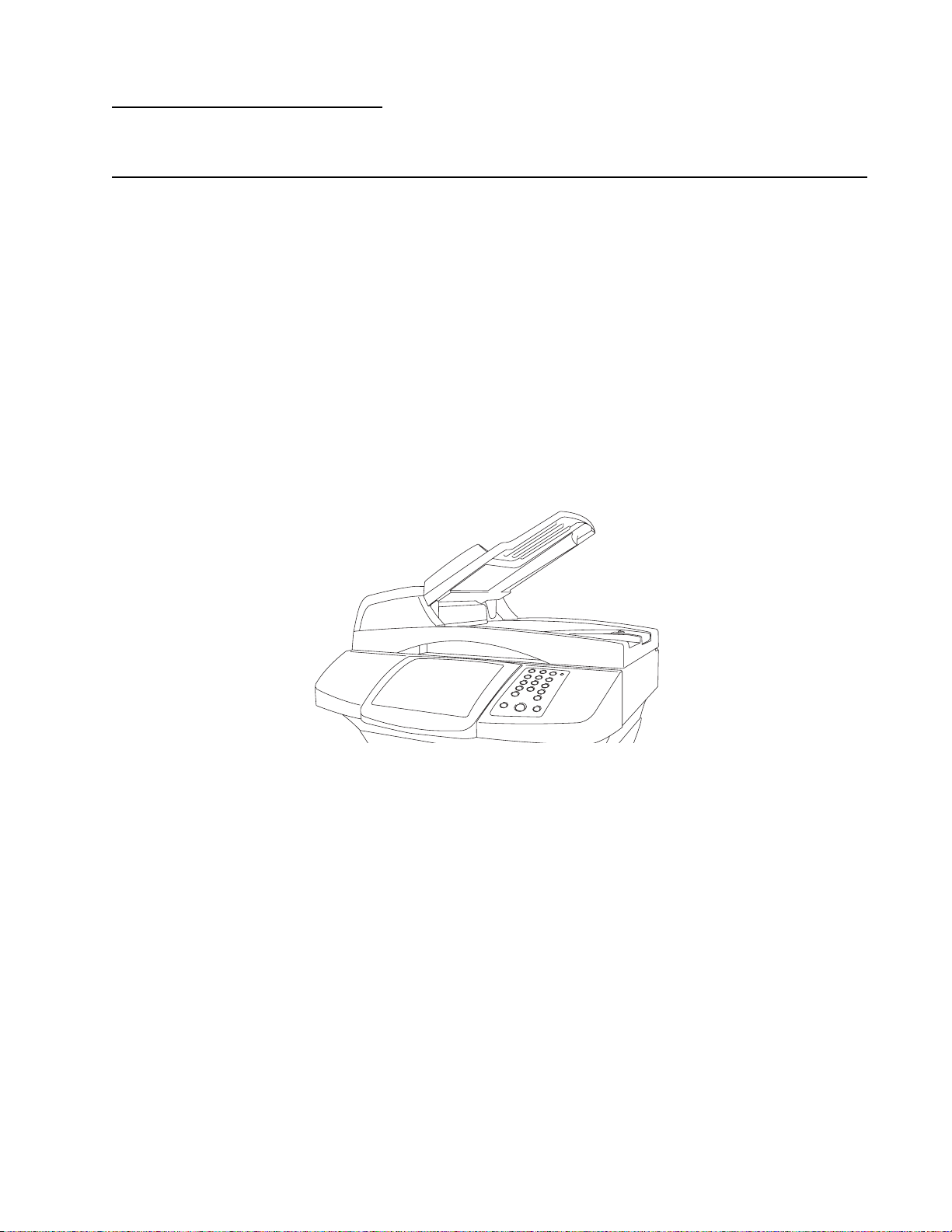

Overview

The Lexmark™ 4600 MFP option is a multifunction solution that offers integrated print, copy, fax, and color

network-scann ing capab il ities for increased small workgroup pr oduc tivi ty. The option is easy t o use and pr o vides

low-cost access to key office functions, including fax from workstation, network color copying, scanning, and

electronic docum ent routing.

Give your document to the option, and in a few steps, it scans to the network and delivers it wherev er, to

whomever you want. With this scanner, inefficient trips to the mailroom, copier, fax machine and to your

workstation are a thing of the past.

This manual is for maintenance eng ineers. It describes th e maintenance areas, installation, disassembly, and

the main troubleshooting guides.

Take your time to read this manual thoroughly to obtai n com prehensive know ledge about the scanner before

servicing the unit.

Features

Ease of use

The control pan el on the front o f the sca nner look s lik e a panel on a cop ier wi th stand ard phone k e ys added. The

operating steps follow the same procedure as that of a copier or fax machine.

Digital copier and full-function fax machine

When the option is connected to a Lexmark print er, it performs convenient dig it a l copying. When connected to a

telephone line, the scanner perf orms a full fax function—to send and to receiv e faxes .

Network scanning

The scanner uses two col or charge-coupled de vices (CCD) when scanning. Through a network port at the rear

of the printer, the product is able to do network scanning.

Duplex scanning through the auto document feeder (ADF)

To increase workgroup productivity, the scanner uses the advance duplex scanning capability. The scan speed

limit is 20 ppm at 300 dpi res olution. The auto document feeder can hold up to 50 pages at on e ti me .

General inf ormation 1-1

4036-307, -308

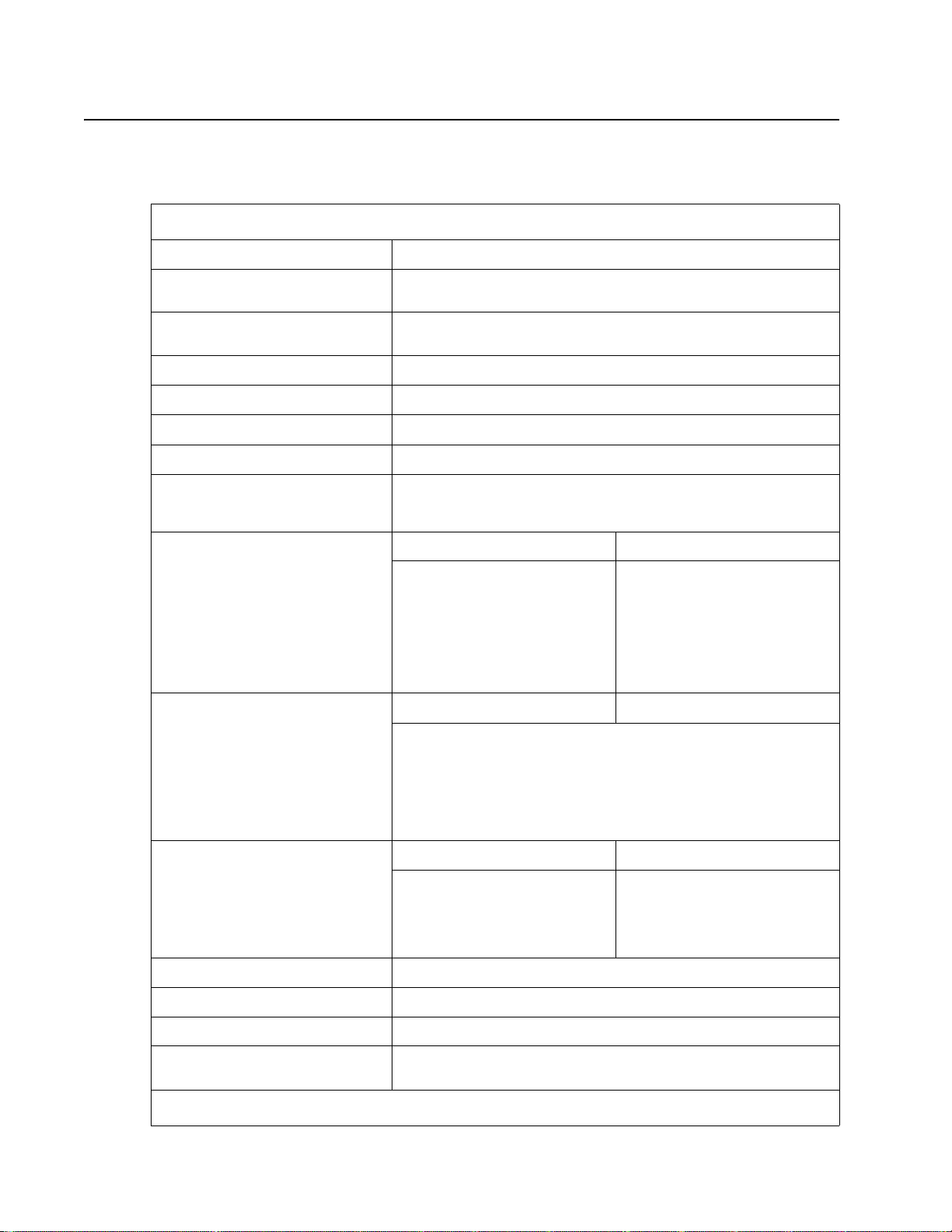

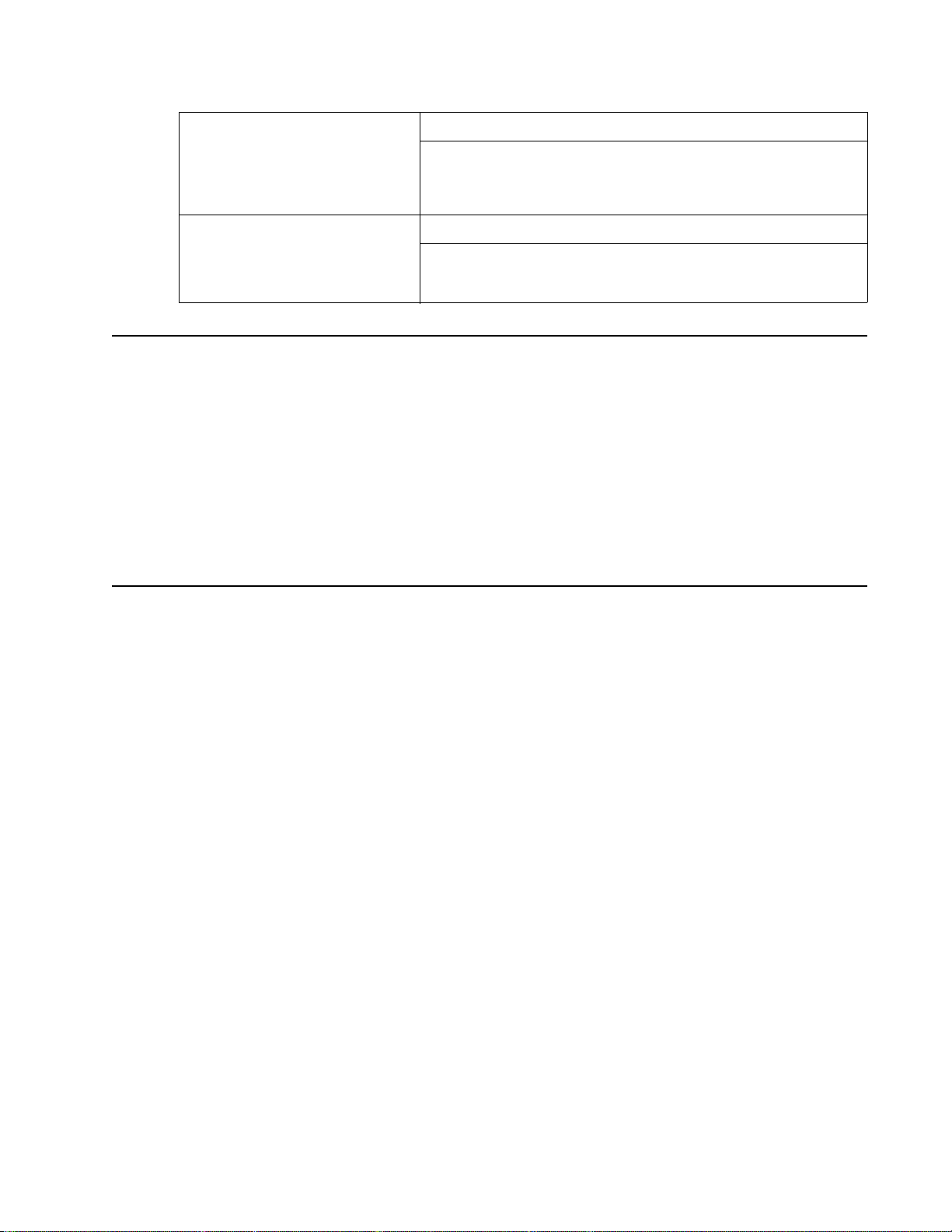

Scanner specifications

The scanner is desi gned to meet the following product specifications:

Scanner

Scanner Type Flatbed Scanner with ADF bui lt in

Optical Resolution 600 x 600 dpi (mono)

Scan Speed 17 ppm at 600 dpi color for single page scanning

Scan Method Color Charge-Coupled Device (CCD)

Light Source Cold Cathode Fluorescent Lamp (CCFL)

Scan Area Max. 8.5 x 14.0 inch (legal size) for ADF

Display 640 x 480 color VGA touch screen

Image Types 42-bit color (internal)

Scan Accuracy Flatbed ADF

• Leading Edge <-1 ~ +2 mm <2.5 ~ +2.5 mm

• Side Edge <-1 ~ +2 mm <2.5 ~ +2.5 mm

• Skew <1 mm <2 mm

• Magnification Rate Toleranc e

(width and length)

Physical Dimension

600 x 300 dpi (color)

40 spm at 600 dpi line-art, duplex for ADF

14-bit gray (internal)

1-bit line-art, Dither, Error Diffusion

-1.5% ~ +1.5% -1.5% ~ +1.5%

• Width 525 mm

• Depth 515 mm

• Height 370 mm

• Weight 14.51 kg

Environment Temperature Humidity

• Operating 15.6°C to 32.2°C (60°F to 90°F) 8% to 80% RH (relative

• Storage -40°C to 65°C (-40°F to 149°F) 8% to 90% RH (Relative

Acoustic noise Operating: 58 dB or less

Electrostatic discharge EC 1000-4-2 ESD Standard

Safety regulation UL, CSA, TUV/GS, SEMKO

EMC regulation FCC Part 15 Subchapter J Class A

ADF

1-2 Se rvice Ma nual

humidity)

Humidity)

CE Marking, C-Tick

4036-307, -308

General specifications

• Optical Resolution 600 x 600 dpi (mono)

• Document Capacity 50 sheets

Document

• Document siz e Max. 8.5 x 14 inch (W x L) Min. 4.5 x 5.5 inch (W x L)

• Thickness 0.05~0.15 mm

Tools required for service

Flat-blade screwdriver

#1 Phillips screwdriver, magnetic

#2 Phillips screwdriver, magnetic

#2 Phillips screwdriver, magnetic short-blade

Needlenose pli ers

Diagonal side cutters

Spring hook

Feeler gauges

Analog or digital multimeter

Acronyms

600 x 300 dpi (color)

ADF Automatic Document Feeder

CCD Charge-Couple Device

CCFL Cold Cathode Fluorescent Lamp

CDB Comm and Descriptor Blocks

CRU Customer Replaceable Unit

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HV High Voltage

LCM Liquid Crystal Module

LED Light-Emitting Diode

LV Low Voltage

MFD Mult i F unct ion Devi ce

PCBA Pri nted Circuit Board Assembly

PPM Page per minute

SPM Sides per minute

V ac V olts alternating current

V dc Volts direct current

General inf ormation 1-3

4036-307, -308

1-4 Se rvice Ma nual

4036-307, -308

2. Diagnostic information

Start

CAUTION

Unplug all power from the el ectrical outlet before you connect or disconnect any cable or

electronic board or assembly for personal safety and to prevent damage to the scanner.

Disconnect any connections between the scanner and the printer.

This chapter desc ribes two methods to solv e the operational problems. The first rel ies on the scanner internal

diagnostic s to report error codes. The second uses troubleshooting techniques to isolate the problem. In man y

cases, the in ternal err or codes will help you to loc ate the source of the problem quickly. If no error codes are

reported, or if the error codes do not locate the source of the problem, refer to th e Sym ptom Tables.

• If you have an error message or user message, check the followi ng:

– “Error codes and messages” on page 2-3

– “User attendance messa ges” on page 2-6

• Does the POR stop? Check the “P ower-On Self Test (POST) sequence” on page 2-2.

• Do you hav e a sym ptom, rather than an error mes sage?

– “Symptom tables ” on page 2-2

– “Scan module does not move to home position” on page 2-2

– “Reading is not performed” on page 2-2

– “Image does not appear” on page 2-2

– “Large jitter” on page 2-2

– “Reading position deviation” on page 2-2

– “Image unclear” on page 2-2

– “Strange sound generated (flatbed)” on page 2-2

– “Frequent paper jam, double feed, or skew” on page 2-2

– “Strange sound generated (ADF)” on page 2-2

• Additional information can be found at the following locations:

– “Control panel and but tons” on page 2-22

– “Menus” on page 2-32

– “Service checks” on page 2-13

Note: There may be printer error m essages that are not contain ed in this service manual. Call your next level of

support for assistance.

Diagnostic information 2-1

4036-307, -308

Po wer-On Self Test (POST) sequence

When you turn the printer on, it per forms a Power-On Self Test. Check for correct POST functioning by

observing the following:

1. The printer LED (green light) turns on.

2. The oper ator panel turns on.

3. The operator panel displays counting the memory.

4. The oper ator panel displays a progression bar with the Lexmark splash logo.

5. You can hear the scanner doing a scanner calibration.

6. You can hear the printer starting up. I t takes the prin ter longer to start up from a cold start rather than f rom

a warm start.

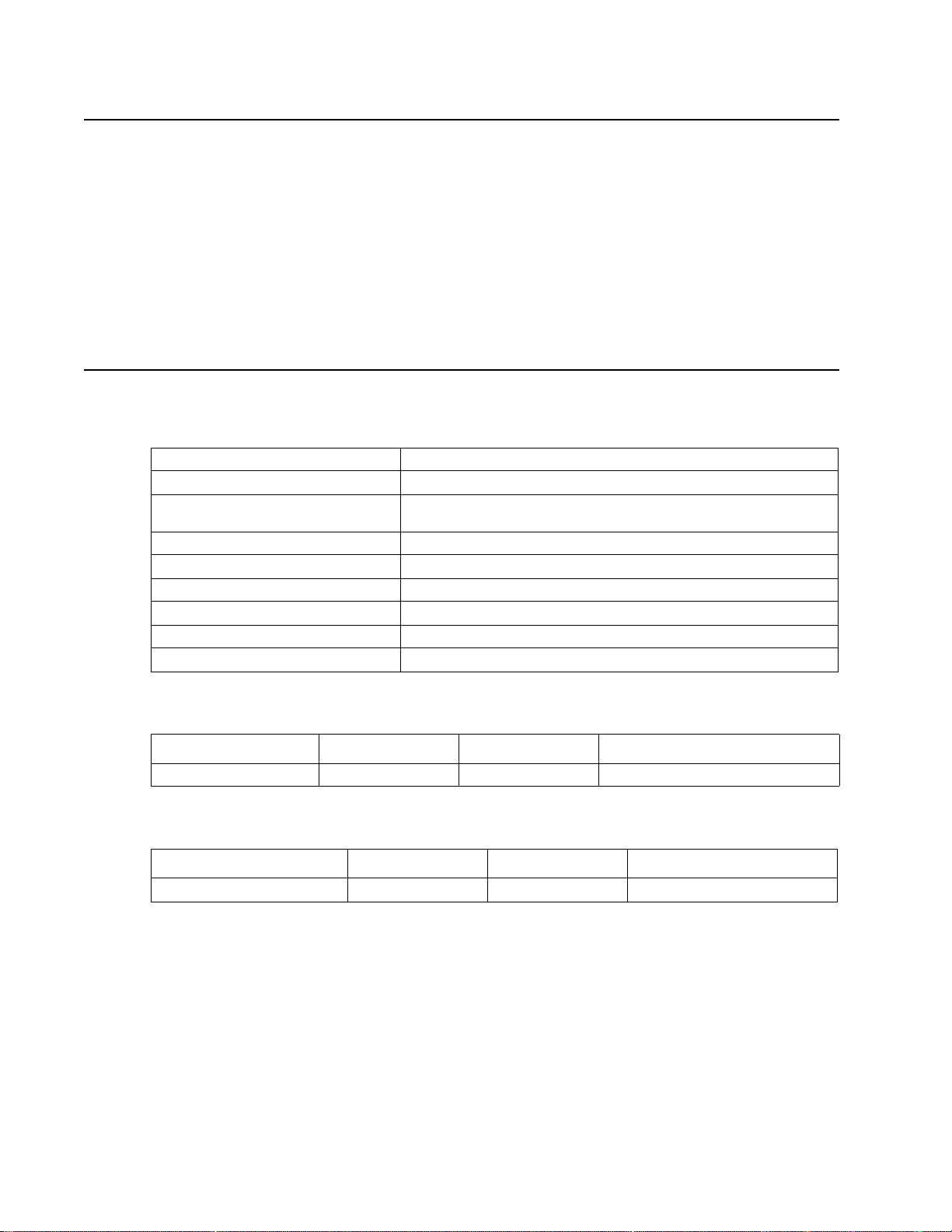

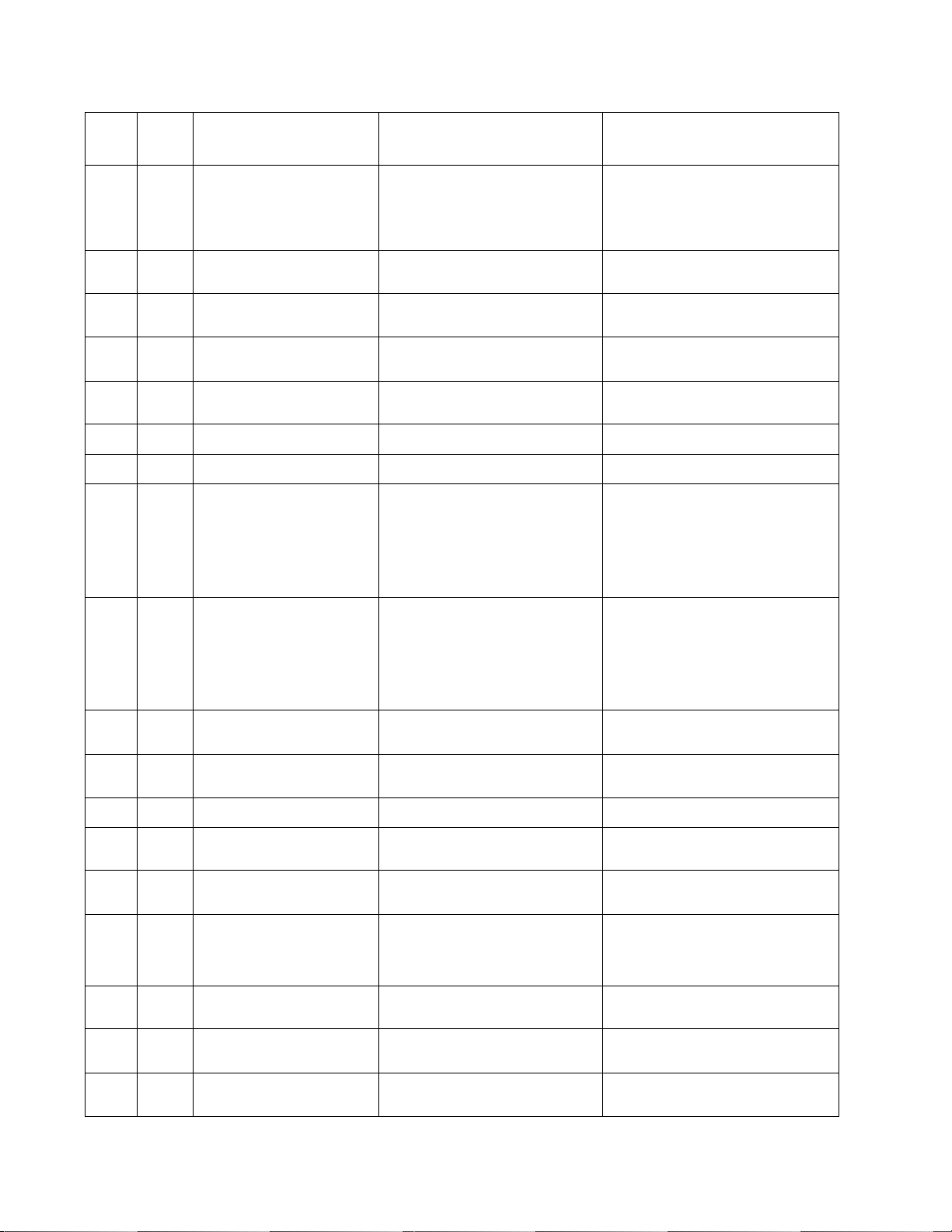

Sympto m tables

The tables in this section provide detailed troubleshooting information.

The power does not come on. Go to “The power does not come on” on page 4-13.

Display panel Go to “Display panel remains blank” on page 4-14.

Freque nt paper jam, double feed, or

skew

Image does not appear Go to “Image does not appear” on page 4-14.

Image unclear Go to “Image unclear” on page 4-15.

Large jitter Go to “Large jitter” on page 4-15.

Reading position deviation Go to “Reading position deviation” on page 4-15.

Strange sound generated (ADF) Go to “” on page 4-15.

Strange sound generated (flatbed) Go to “Strange sound generat ed (f latbed)” on page 4-16.

Go to “Frequent paper jam, double feed, or skew” on page 4-14.

Reading is not performed

Cause Relevant unit C heck Action

ADF cover open ADF cover Visual check Close the ADF cover.

Scan module does not move to home position

Cau s e Rel evant Unit Check Actio n

Carrier is in locked position None Visual check Unlock carrier

2-2 Se rvice Ma nual

4036-307, -308

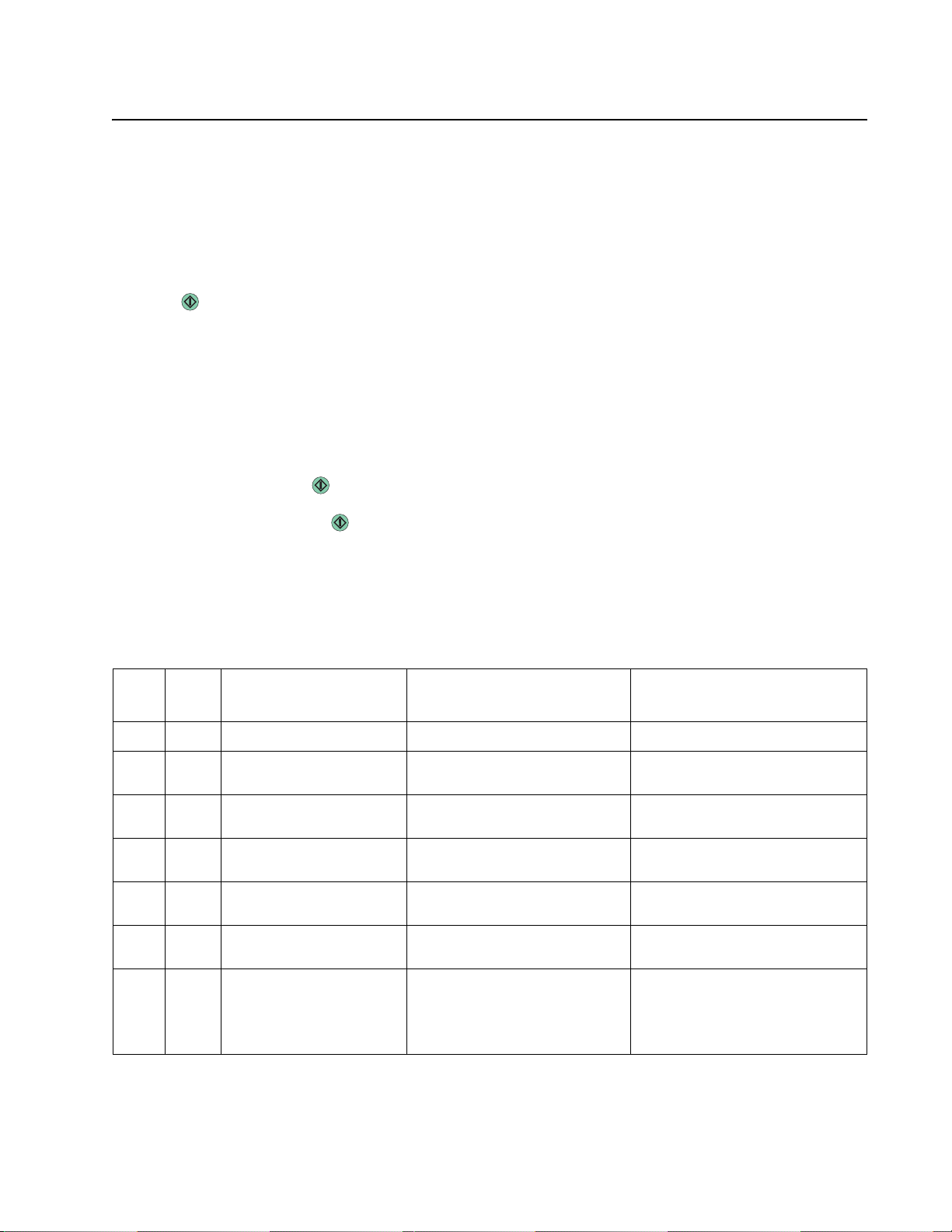

Error codes and messages

Service error codes

Service error codes are gener ally non-recoverable except in an intermittent condi tion when you can POR the

printer to temporarily recover f rom the error condition.

Service error codes are ind icated by a three-digi t er ror code follow ed by a period and additional numbers in the

format XXX.YY. In most cases, five digits are sho wn. Additional sub error cod es display if you press and hold

and 2 when an error message is displayed. Not all error conditions have additional sub error information.

Sub error codes for 8xx and 2xx error codes

The sub error codes are helpf u l when troubleshoo ti ng a paper path problem, especially paper jams in the base

printer , envelope feeder, and duplex opti on.

To display sub error codes (where available)

When an 8xx or 2xx error displays:

1. Press and hold and 2 to view sub error codes.

The first screen of information displ ays. Write down the information.

2. Continue pressing and 2 until each screen of informat ion is obtained.

3. When the las t screen displays, the original message displays .

Printed error codes

Additional codes are available in the Menus and M essages Guide fo r t his option and the Service Manual for the

base printer . Wo rding for the codes may diff er when t hi s optio n is instal led. Unique sc anner and f axing c odes a re

listed bel ow:

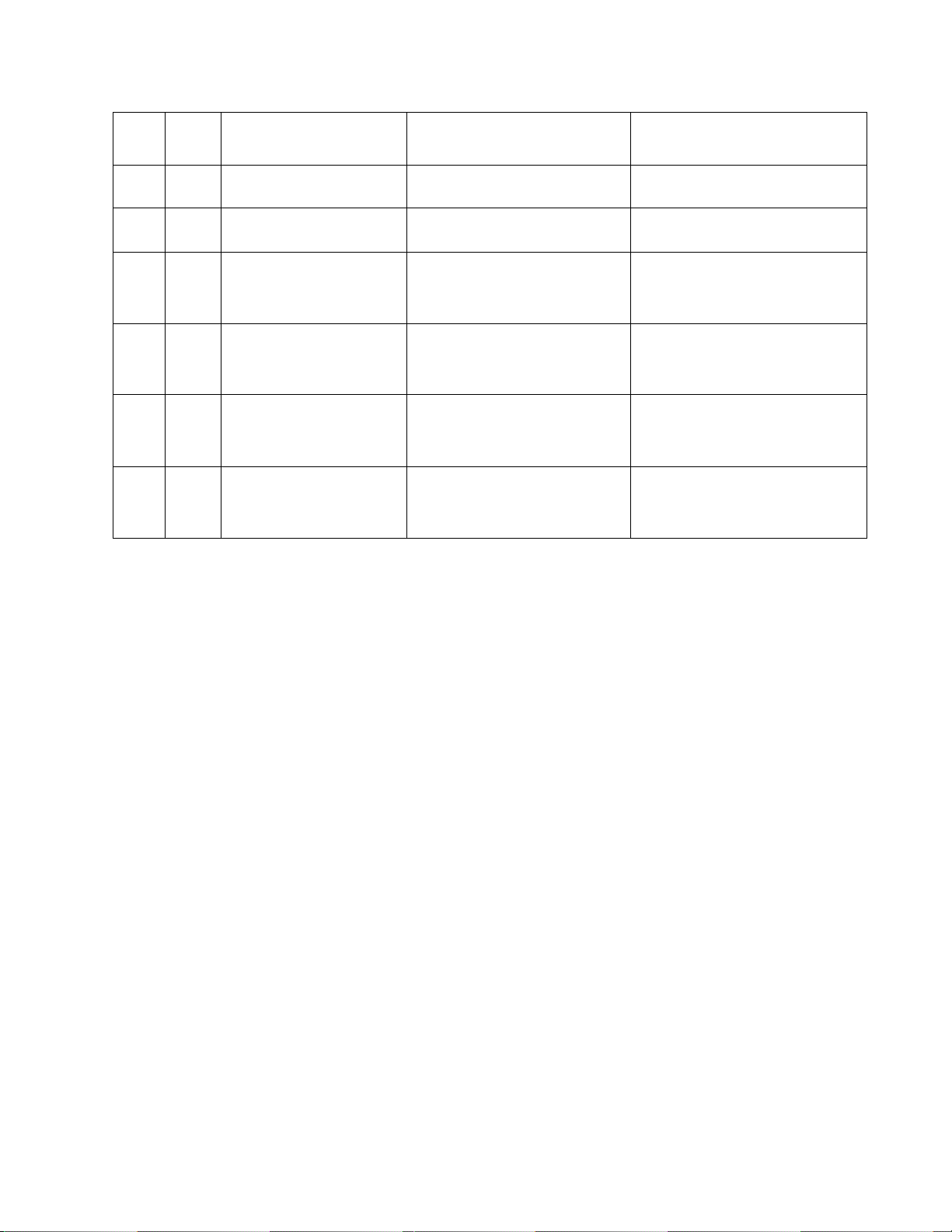

Error

code

841 .00 Image Pipeline Image pipeline ASIC Replace scanner control board

842 .00 Scanner Failure Communication failure between

843 .00 Scanner Failure Carriage mechanical failure See “843.00 Scanne r fai lure” on

843 .01 Scanner Failure ADF mechanical failure See “843.01 Failure” on page 4-

844 .00 Front scan modu le out put

844 .01 Rear scan module output

844 .02 Front scan modu le l am p

Sub

codes

Displayed message Description Action

See “842.00 Scanner failure” on

page 4-16.

page 4-17.

17.

output level error” on page 4-18.

output level error” on page 4-18.

See “844.02 Front scan module

lamp level too low ” on page 4-18.

level error

level error

level too low

A1 and scanner control boards

Flatbed See “844.00 Front scan module

ADF See “844.01 Rear scan module

Front Mono channel, Front Color

channels, Front Red channel,

Front Green Channel, and/or

Fr ont Blue channel is detected to

have low la mp level.

Diagnostic information 2-3

4036-307, -308

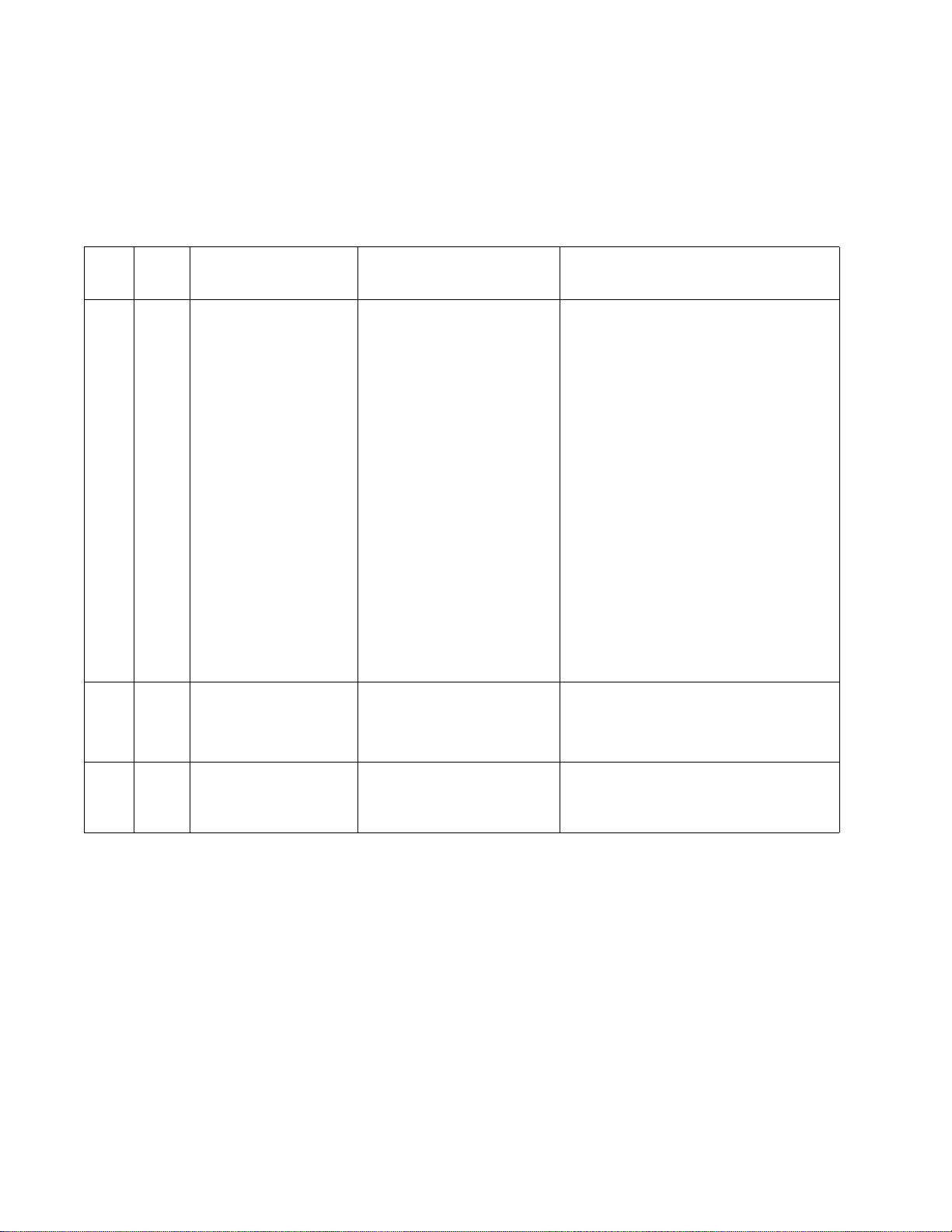

Error

code

844 .03 Rear scan module lamp

844 .04 Front scan modu le has

844 .05 Rear scan module has

844 .06 Front scan modu le has

844 .07 Rear scan module has

844 .08 Front scan modu le banding Replace flatbed optical unit

844 .09 Rear scan module banding Replace ADF optical unit

845 .00 Front scan modu le cable

Sub

codes

Displayed message Description Action

level too low

excessive noise

excessive noise

exces s i ve va riabi l ity

exces s i ve va riabi l ity

failure or SCC card failure

CCD channel failure

Rear Mono channel, Rear Color

channels, Rear Red channel,

Rear Green chann el, an d/o r Rear

Blue channel is detected to have

low lamp level.

This will man ifes t it se lf by

creating a fuz zy image.

This will man ifes t it se lf by

creating a fuz zy image.

Check eac h channel (mono , R, G,

B) for ide nti cal values indicating

bad cable and/or SCC card.

Excessive noise test for the dark

data indicating some sort of CCD

or analog elect ronics issue on

that channel or channels.

Replace ADF optical unit

Replace flatbed opti cal unit

Replace ADF optical unit

Replace flatbed opti cal unit

Replace ADF optical unit

See “845.00 Front scan module

cable failure or SCC card failure

CCD channel failure” on page 4-

19.

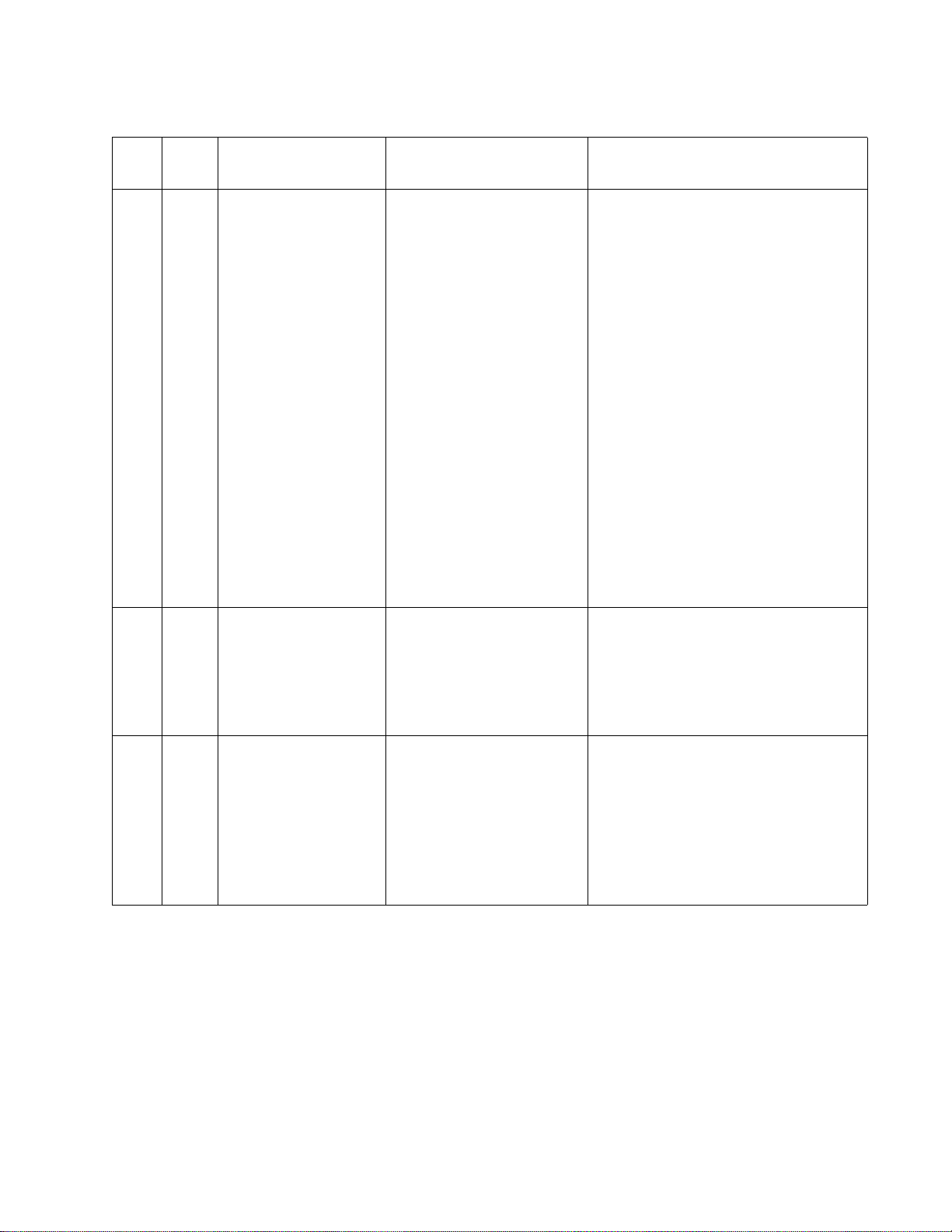

845 .01 Rear scan module cable

failure or SCC card failure

CCD channel failure

845 .02 Cable/SCC Failure Front scan module connector or

845 .03 Cable/SCC Failure Rear scan module connector or

845 .04 Cable Fa il ure The connector cable is defective. Replace PCI Cable

846 .00 Front calibration strip

unusable

846 .01 Rear calibration strip

unusable

846 .02 Front calibration strip too

far left (The Front

Calibration Strip i s plac ed

too high or too low.)

846 .03 Front calibration strip too

far right

846 .04 Front calibration strip has

excessive skew

Check eac h channel (mono , R, G,

B) for ide nti cal values indicating

bad cable and/or SCC card.

Excessive noise test for the dark

data indicating some sort of CCD

or analog elect ronics issue on

that channel or channels.

cable failure

cable failure

See “845.01 Rear scan module

cable failure or SCC card failure

CCD channel failure” on page 4-

19.

See “845.02 Cable/SCC failure”

on page 4-20.

See “845.03 Cable/SCC failure”

on page 4-20.

See “” on page 4-20.

Replace ADF optical unit

See “” on page 4-20.

See “” on page 4-20.

See “” on page 4-20.

846 .05 Front calibration strip has

exces s i ve b ow

2-4 Se rvice Ma nual

See

“” on page 4-20.

4036-307, -308

Error

code

846 .06 Front calibration strip

846 .07 Front magnification

847 .00 Modem Failur e The Configuration ID bit that

848 .00 Modem/Config ID

848 .01 Modem/Config ID

849 .00 HD/Config ID Mismatch A device doesn’t have a hard

Sub

codes

Displayed message Description Action

insufficient dark area

exceeds limits

Mismatch

Mismatch

Front excessive variability for

Mono, Red, Gre en, or Blue

Rear excessive variability for

Mono, Red, Gre en, or Blue

describes the device’s modem

doesn’t match the actual modem

installed in the device.

A device doesn’t have a modem

installed, even though it s

Configurat ion ID indicates that a

modem should be present.

A device has a mo dem inst alled,

but its Conf iguration ID indicat es

that a modem shouldn’t be

present.

drive inst alled, even though its

Configurat ion ID indicates that a

hard drive should be present.

See “” on page 4-20.

See “” on page 4-20.

Replace modem card

See “848.00 Modem /config ID

mismatch” on page 4-21.

See “848.01 Modem /config ID

mismatch” on page 4-21.

Replace hard drive

See “849.00 HD/c onfi g ID

mismatch” on page 4-21.

Diagnostic information 2-5

4036-307, -308

User attendance messages

Additional messages may appear, and most are documented in the Menus and Messages Guide for this option

and the Servic e Man ual for the base printer. The messages listed below pertain to the scanner portion rather

than the base printer.

User attendance messages

Error

code

Sub

codes

Display text Description Action

Clean sc ann er

glass

Disk Full – Scan

Job Canc ele d

During a scanner calibration,

the firmware detects that a

scanner ADF or the flatbed

(scanner) gl ass m ay be dirty.

The scan job cancel s or stops

due to insufficient hard disk

space.

Touch Cancel Job if a scan job is

processing when the attendance message

appears. This cancels the job and clears

the message.

Touch Scan fro m Aut o m a ti c Do c u ment

Feeder if the page jam re covery is activ e.

Scanning resumes fr om the ADF

immediately after the last succ essfully

scanned page.

Touch Scan fro m fla tbed if page jam

recovery is act iv e . Scannin g resumes from

the flatbed immed iately after the last

successfully scanned page.

Touch Finish job without further

scanning if page jam recovery is active.

The job ends at the last successfully

scanned page , but the job is not canceled.

Successfull y scanned pages go to their

destination: copy, fax, e-mail, or FTP.

Touch Restart job if job recovery is active

and the job is restartable. The message

clears. A ne w scan job containing the

same parameter s as the previous job

starts.

Note: The scanner finishes scanning

currently committed pages in the ADF, but

data is lost when the job can cels itself.

Touch Continue to clear the messa g e.

Fax Memo ry Fu ll There is no memory to

2-6 Se rvice Ma nual

complete a fax job. Any

Touch Continue to clear the message.

attempted fax jobs are

canceled.

4036-307, -308

User attendance messages (continued)

Error

code

Sub

codes

Display text Description Action

If restarting job,

replac e ori gi nals

that have not

begun to exit the

scanner.

One or more messages that

interrupted a scan job are

now cleare d. A sit uation ex ists

where a page is not

completely scanned, but it

has not fully exited the ADF.

Replace the original documents in the

scanner to resta rt the scan job.

Touch Restart job if page l evel recovery is

active and t he job is restartable. The

message clears. A new scan job

containing the sam e parameters as the

previous job starts.

Touch Cancel Job if a scan job is

processing when the attendance message

appears. This cancels the job and clears

the message.

Touch Scan fro m Aut o m a ti c Do c u ment

Feeder if the page jam re covery is activ e.

Scanning resumes fr om the ADF

immediately after the last succ essfully

scanned page.

Touch Scan fro m fla tbed if page jam

recovery is act iv e . Scannin g resumes from

the flatbed immed iately after the last

successfully scanned page.

Touch Finish job without further

scanning if page jam recovery is active.

The job ends at the last successfully

scanned page , but the job is not canceled.

Successfull y scanned pages go to their

destination: copy, fax, e-mail, or FTP.

Insufficient

Memory to Support

Scanne r Att ac hment

Memory full,

cannot print faxes

The mono printer does not

have at least 256 MB of total

memory or the color printer

does not hav e 768 MB or total

memory; therefore, it cannot

support the scanner. This

message occurs only during a

power-on res et.

The attempt to print the fax

jobs is automatically

canceled. The Fax code

recognizes that the fax job is

canceled and does not delete

pages in the fax job that hav e

not printed. The Fax code

does not at t empt t o repri nt t he

fax causing the memory error

until the MFP goes through a

power on reset.

1. Turn the printer off. Turn the scanner

off.

2.Install additional memory in the printer,

so the scanner will function with the

printer.

3.Turn the printer on.

Touch Continue to clear the messa g e.

Turn the printer off and then on to reset it.

Diagnostic information 2-7

4036-307, -308

User attendance messages (continued)

Error

code

Sub

codes

Display text Description Action

Replac e all

originals if

restar ti ng jo b.

Replac e jam me d

originals if

restar ti ng jo b.

One or more messages that

interrupted a scan job are

now cleared. Replace the

original documen ts i n the

scanner to rest art the scan

job.

One or more messages that

interrupted a scan job are

now cleared. Replace the

original documen ts i n the

scanner to rest art the scan

job.

Touch Restart job if job level recovery is

active and t he job is restartable. The

message clears. A new scan job

containing the sam e parameters as the

previous job starts.

Touch Cancel Job if a scan job is

processing when the attendance message

appears. This cancels the job and clears

the message.

Touch Scan fro m Aut o m a ti c Do c u ment

Feeder if the page jam re covery is activ e.

Scanning resumes fr om the ADF

immediately after the last succ essfully

scanned page.

Touch Scan fro m fla tbed if page jam

recovery is act iv e . Scannin g resumes from

the flatbed immed iately after the last

successfully scanned page.

Touch Finish job without further

scanning if page jam recovery is active.

The job ends at the last successfully

scanned page , but the job is not canceled.

Successfull y scanned pages go to their

destination: copy, fax, e-mail, or FTP.

Touch Restart job if page l evel recovery is

active and t he job is restartable. The

message clears. A new scan job

containing the sam e parameters as the

previous job starts.

Touch Cancel Job if a scan job is

processing when the attendance message

appears. This cancels the job and clears

the message.

Touch Scan fro m Aut o m a ti c Do c u ment

Feeder if the page jam re covery is activ e.

Scanning resumes fr om the ADF

immediately after the last succ essfully

scanned page.

Touch Scan fro m fla tbed if page jam

recovery is act iv e . Scannin g resumes from

the flatbed immed iately after the last

successfully scanned page.

Touch Finish job without further

scanning if page jam recovery is active.

The job ends at the last successfully

scanned page , but the job is not canceled.

Successfull y scanned pages go to their

destination: copy, fax, e-mail, or FTP.

2-8 Se rvice Ma nual

4036-307, -308

User attendance messages (continued)

Error

code

Sub

codes

Display text Description Action

Restor e hel d jo bs? Held jobs are found on the

Scan Document Too

Long

hard disk after a power-on

reset of the MFP.

The scan job exceeds the

maximum number of pages.

Touch Yes to restore the held jobs to the

hard disk and make them available. The

jobs data remains on the hard disk;

howe ver , the job control information is

stored in the MFP memory. Touch Quit to

stop restoring held jobs before all jobs are

restored. Unrestored jobs remain on the

hard disk and are retrievable again only at

the next power-on reset.

A pop-up screen appears to indicate

Restoring held jobs(s) xxx/yyy, where xxx

indicates the num ber of the current job

being restor ed, and yyy i s the tot al num be r

of jobs to be restored.

Touch Do not restore to have the held

jobs remain on the hard disk until they are

deleted.

Note: The scanner finishes scanning

current pages in the ADF, but data is lost

when the job cancels itself after reachin g

the maximum number of pages.

Touch Continue to clear the messa g e.

Touch Cancel Job to clear the message if

the job is restartable.

Touch Restart job if the job is restartable.

The message clears, and a new scan job

containing the sam e parameters as the

previous job starts.

Scanne r ADF Cov er

Open

Scanner

registration

successfully

completed

Some held jobs

were not restored

35 Insufficient

memory to support

Resource Save

feature

36 Pr in te r service

required

The scanner automatic

document feed cover is open.

Scanner registration is

successful.

Some held jobs are not

restored; they remain on the

hard disk and are

inaccessible.

Note: This message appears

once after the MFP firmware

tries to restore al l t he held

jobs on the hard disk

regardless of the number of

held jobs not restored.

The MFP lacks the memory

needed to enable Resource

Save. This message usually

indicates too m uch memory is

allocated for one or more of

the MFP link buffers.

The MFP requires servicing. Touch Continue to c le ar the message,

The message clears when the cover is

closed.

Touch Continue to clear the messa g e.

Touch Continue to clear the messa g e.

Touch Continue to disab le Resour ce Sa v e

and continue printing.

Install additional memory.

continue prin ti ng, and show the nex t

message about the service needed, such

as Toner Low. Complete the necessary

service for the MF P.

Diagnostic information 2-9

4036-307, -308

User attendance messages (continued)

Error

code

37 Insufficient

37 Insufficient

37 Insufficient

Sub

codes

Display text Description Action

memory for Flash

Memory Defragment

operation

memory to collate

job

memory , som e He ld

Jobs were deleted

The MFP cannot defragment

flash memory because the

memory used to store

undeleted fl ash resources is

full.

The MFP cannot collat e the

job because the memory is

full.

Held jobs ar e deleted in order

to process the cur rent job.

Touch Continue to clear the messa g e.

To perform the defragment operation,

install additional memory, or delete f onts,

macros, and other data to free some

memory space.

Touch Reset Active Bin to change to

another linked bin.

Touch Continue to print the pages

processed bef ore the memory became full .

Some memory frees up, so collating

begins for the remainder of the print job.

For e xample, if a 50-page print job is sent,

and 10 copies ar e reques ted , and th e MFP

runs out of memory at page 30, the MFP

would collate and print 10 copies of pages

1–30. The MFP would then print and

collate pages 31–50 and print 10 copies of

these pages.

Touch Continue to c lear the message and

continue prin ti ng.

To avoid this error in the future for other

jobs, insta ll m o re me m o r y.

Touch Cancel Job to cancel the current

job if needed.

38 Memory full The MFP is processing data,

57 Configuration

change , som e he ld

jobs were not

restored

290 .00 Scan ne r jam ,

remove all

originals from the

scanner

but the memory used to stor e

pages is full.

This message appea rs once

after the firmware tries to

restore all of the jobs on the

hard disk regardless of the

number of held jobs that were

not restored.

Configurati on of t he MFP ma y

have changed due to:

• print media option(s)

remov a l, such as a tray or

bin being removed

• the hard disk wa s installed

from a different MFP

model

• the speed of the MFP

The scanner detect s an

original documen t at t he

automatic document feeder

(ADF) feed sensor while it is

idle. This is a type of jam.

To avoid this error in the future:

Simplify the print job by reducing the

amount of text or graphics on a page and

deleting un necessary downloaded fonts or

macros.

Install additional memory.

Touch Cancel Job to cancel the current

job if needed.

Touch Reset Active Bin to change to

another linked bin.

Touch Continue

restored. They stay on the hard disk and

are inaccessi ble.

Remove al l original documents from the

ADF to clear the jam . The message clears

and either page or job recovery completes.

. Some held jobs are not

2-10 Service Manual

4036-307, -308

User attendance messages (continued)

Error

code

290 .01 Scan ne r jam ,

290 .01 Scan ne r jam ,

290 .02 Scan ne r jam ,

290 .10 Scan ne r jam ,

291 .00 Scan ne r jam ,

291 .01 Scan ne r jam ,

Sub

codes

Display text Description Action

remove all

originals from the

scanner

remove jammed

originals from the

scanner

remove all

originals from the

scanner

remove all

originals from the

scanner

remove all

originals from the

scanner

remove all

originals from the

scanner

The scanner fails to pull a

sheet from the ADF.

The scanner fails to pull a

sheet from the ADF.

The scanner fails to feed a

sheet f ar enough i nto t he ADF

so that t he ADF recogni zes i ts

presence.

The scanner detect s an

original documen t ja m at the

first paper feed sensor while

the scanner is id le.

The scanner detect s an

original documen t ja m at the

second paper feed sensor

while the scanner is idle.

The scanner detect s an

original documen t ja m at the

first paper feed sensor.

The message clears when the scanner

knows that the sheet is removed from the

ADF. Either page or job recov ery

completes.

The message clears when the scanner

knows that the sheet is removed from the

ADF. Either page or job recov ery

completes.

The message clears when the scanner

knows that the sheet is removed from the

ADF. Either page or job recov ery

completes.

Clear the jam from t he sca nner to c lear t he

message. Either page or job recovery

completes.

Clear the jam from t he sca nner to c lear t he

message.

Clear the jam from t he sca nner to c lear t he

message.

291 .02 Scan ne r jam ,

remove all

originals from the

scanner

292 Scanne r jam ,

remove all

originals from the

scanner

The scanner detect s an

original documen t ja m at the

second paper feed sensor .

The ADF cover is open while

the ADF is fee ding the original

document.

Remove al l original documents from the

scanner to clear the j am . The message

clears.

Remove al l original documents from the

scanner to clear the j am . The message

clears.

Diagnostic information 2-11

4036-307, -308

User attendance messages (continued)

Error

code

293 Replac e all

Sub

codes

Display text Description Action

originals if

restar ti ng jo b

The MFP receives a sc an job ;

howe ver , th ere i s no original

document in the ADF.

Touch Continue if no scan job is active

when the attendance message appears.

This clears th e message.

Touch Cancel Job if a scan job is

processing when the attendance message

appears. This cancels the job and clears

the message.

Touch Scan fro m Aut o m a ti c Do c u ment

Feeder if the page jam recovery is acti ve.

Scanning resumes fr om the ADF

immediately after the last succ essfully

scanned page.

Touch Scan fro m fla tbed if page jam

recovery is act iv e . Scannin g resumes from

the flatbed immed iately after the last

successfully scanned page.

Touch Finish job without further

scanning if page jam recovery is active.

The job ends at the last successfully

scanned page , but the job is not canceled.

Successfull y scanned pages go to their

destination: copy, fax, e-mail, or FTP.

Touch Restart job if job recovery is active

and the job is restartable. The message

clears. A ne w scan job containing the

same parameter s as the previous job

starts.

294 .00 Scan ne r jam ,

remove all

originals from the

scanner

294 .01 Scan ne r jam ,

remove all

originals from the

scanner

296 Scanne r loc ke d,

release lock un der

scanner

298 .01 Scan ne r Mis sing –

Cable Un plu gg ed

The scanner detect s a jam at

the ADF second paper feed

sensor.

The scanner detect s a jam at

the ADF second paper feed

sensor while the scanner is

idle.

The scanner carriage lock is

engaged.

The MFP detects after

powering on that a scanner

cable is unpl ugged.

Remove al l original documents from the

ADF. The message clears.

Remove al l original documents from the

ADF to clear the jam. The message clears.

Release the loc k under the scanner.

Touch Continue.

1.Turn the printer off.

2.Plug both scanner cables i nto the

connector.

3.Turn the printer on.

If this does not clear the problem, then:

1.Turn the printer off.

2.Reseat the cables g oin g to th e sca nner

control board (J1 and J47) and the A1

board (J5).

3.Turn the printer on.

If this does not clear the problem, then:

1.Turn the printer off.

2.Replace the A1 board. See “A1 board

removal” on page4-40

3.Turn the printer on.

.

2-12 Service Manual

4036-307, -308

Service checks

The power does not come on

Step Action and Question Y es No

1 Is the AC cord unplugged? Plug in cords Go to st ep 2

Is the printer power switch OFF? Turn on power s w itch Go to step 3

2

Is the PCI cable unplugged? Plug in cable and/or

3

Remove the printer operator cover. Is the

4

printer control panel active?

Is the PCI cable PS_RC signal at +5V at the

5

scanner end of the cable?

Are the PCI card and printer scanner card

6

seated properly in the printer?

Is the PS_RC signal at +5V on the PCI card? Replace PCI card and

7

At this point, you will need to remove the

8

document cover (see “Document cover

assembly removal” on page 4-14), remove

the bottom pl ate ( see “Botto m plate removal ”

on page 4-35), and reconnect the flatbed

cables in order to check the scanner.

Is there +24V on the power supply board

(connector P2 pins 1 and 4, see “Scanner

control boar d” on page4-3)?

Is there +24V on the scanner control board

9

(connector J46 pin 1, see “Scanner contr ol

board” on page 4-3)?

tighten screws

Go to step 5 See printer service

Go to step 8 Go to step 6

Go to step 7 Reseat card(s)

printer scanner ca rd

assembly

Go to step 9 Replace power

Replace scanner

control board

Go to step 4

manual

Replace PCI cable

supply board

Replace power

cable

Diagnostic information 2-13

4036-307, -308

Display panel remains blank

Step Action and Question Yes No

1 Check the display cable.

1.See “Control panel assembly removal” on page 4-

24 to locate the dis p lay cable.

2.Disconnect and reconnect the display cable

connection (A).

3.Reassemble the scanner and power it on.

Is the displa y panel still blank?

Replace the display panel assembl y.

2

Is the displa y panel still blank?

Frequent paper jam, double feed, or skew

Go to step 2 Done

Replace the

keypad board

Done

Step Action and Question Yes No

1 Is the paper correctly set in the tray ? Go to step 2 Properly position paper in

Is the specified paper used? Go to step 3 Use correct feede r

2

Is the pick pad damaged? Replace pick pad Go to step 4

3

Is the pick roll er damaged or worn? Replace paper feed

4

Image does not appear

Step Action and Question Yes No

1 Are you placing the original on the

flatbed?

Is the flatbed CCD cabl e connected? Replace the scanner control

2

Is the ADF cover open? Close the cover Go to step 4

3

Is the ADF/CCD data cable connected? Replace the ADF optical unit Connect cable and

4

document feeder

Replace pick roller assembly

assembly

Go to step 2 Go to step 3

Connect cable

board

tighten screws

2-14 Service Manual

4036-307, -308

Image unclear

Step Action and Question Yes No

Large jitter

Step Action and Question Yes No

1 Print a test page from the printer. Is the test

page image unclear?

Are you placi ng the original on the flatbed? Go to step 2 Go to step 3

2

Is there dirt on the ADF mirror? Clean the mirrors with

3

Is the flatbed glas s dirty? Clean the mirrors with

4

Is there dirt on the flatbed mirror ? Clean the mirrors with

5

1 Are you placing the original on the flatbed? Go to step 2 Go to step 3

Inspect the carriage transport belt.

2

Is the belt damaged?

Is the pick pad damaged? Replace pick pad Go to step 4

3

Is the pick roller damaged or worn? Replace paper feed

4

See pr inte r se rv ice

manual

isopropyl alcohol

isopropyl alcohol

isopropyl alcohol

Replace the carriage

transport belt

assembly

Go to step 2

Replace the ADF optical

unit

Go to step 4

Replace the flatbed

CCD assembly

Replace the flatbed

CCD assembly

Replace the pick rol ler

assembly

Reading position deviation

Step Action and Question Yes No

1 Are you placing the original on the flatbed? Go to step 2 Go to step 3

Inspect the carriage transport belt.

2

Is the belt damaged?

Is the pick pad damag ed? Replace the pick pad Go to step 4

3

Is the pick roller damaged or worn? Replace the paper feed

4

Replace the carriage

transport belt

assembly

Replace the flatbed

CCD assembly

Replace the pick roller

assembly

Diagnostic information 2-15

4036-307, -308

Strange sound generated (ADF)

Step Action and Question Yes No

1 Is the paper correctly set in the document feeder? Go to step 2 Properly position

Does the sound com e from the pick roller assembly? Replace the pick

2

Does the sound come from the paper feed motor? Replace the

3

Strange sound generated (flatbed)

Step Action and Question Yes No

1 Inspect the carriage transport belt.

Is the belt damaged?

Is the rail dirty? Clean the rail with isopropyl

2

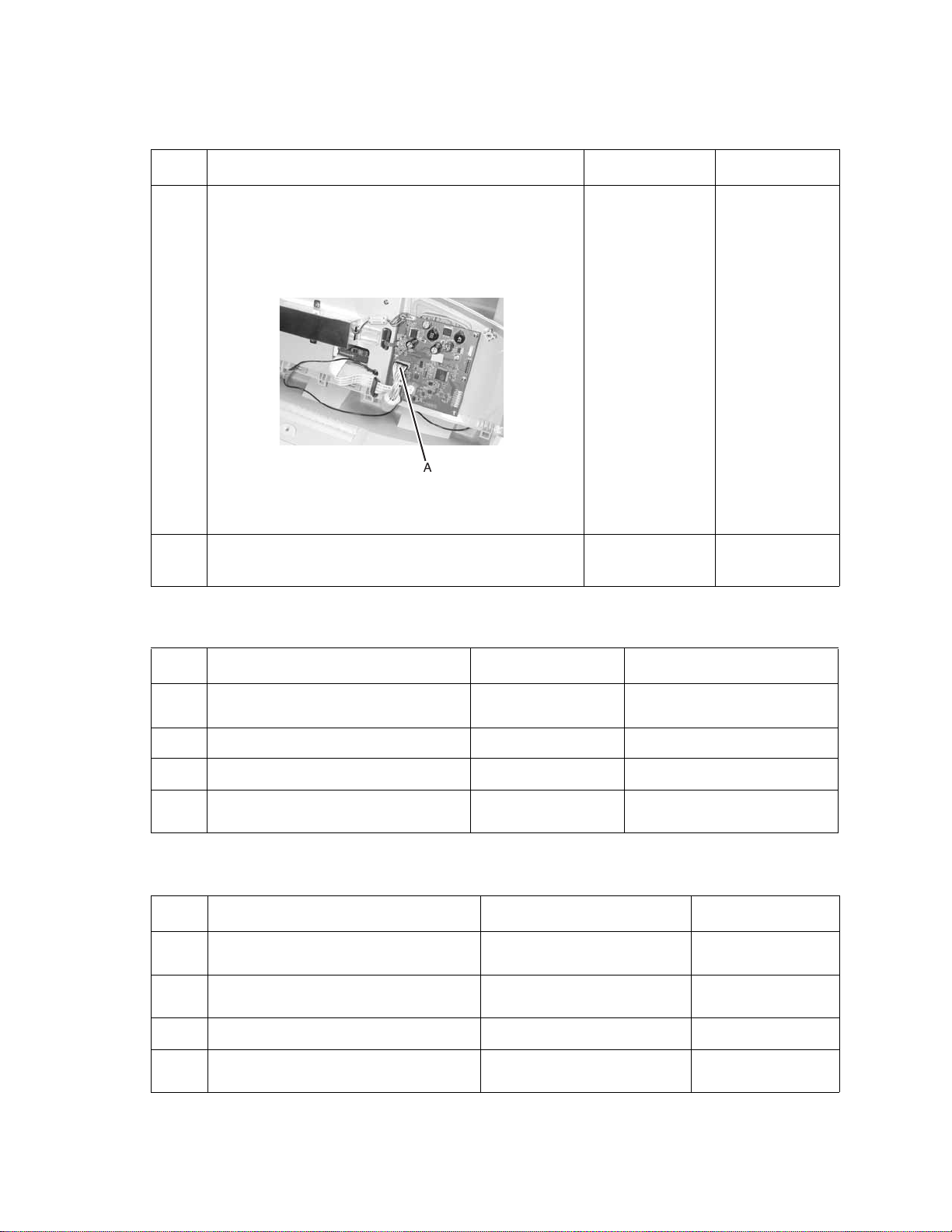

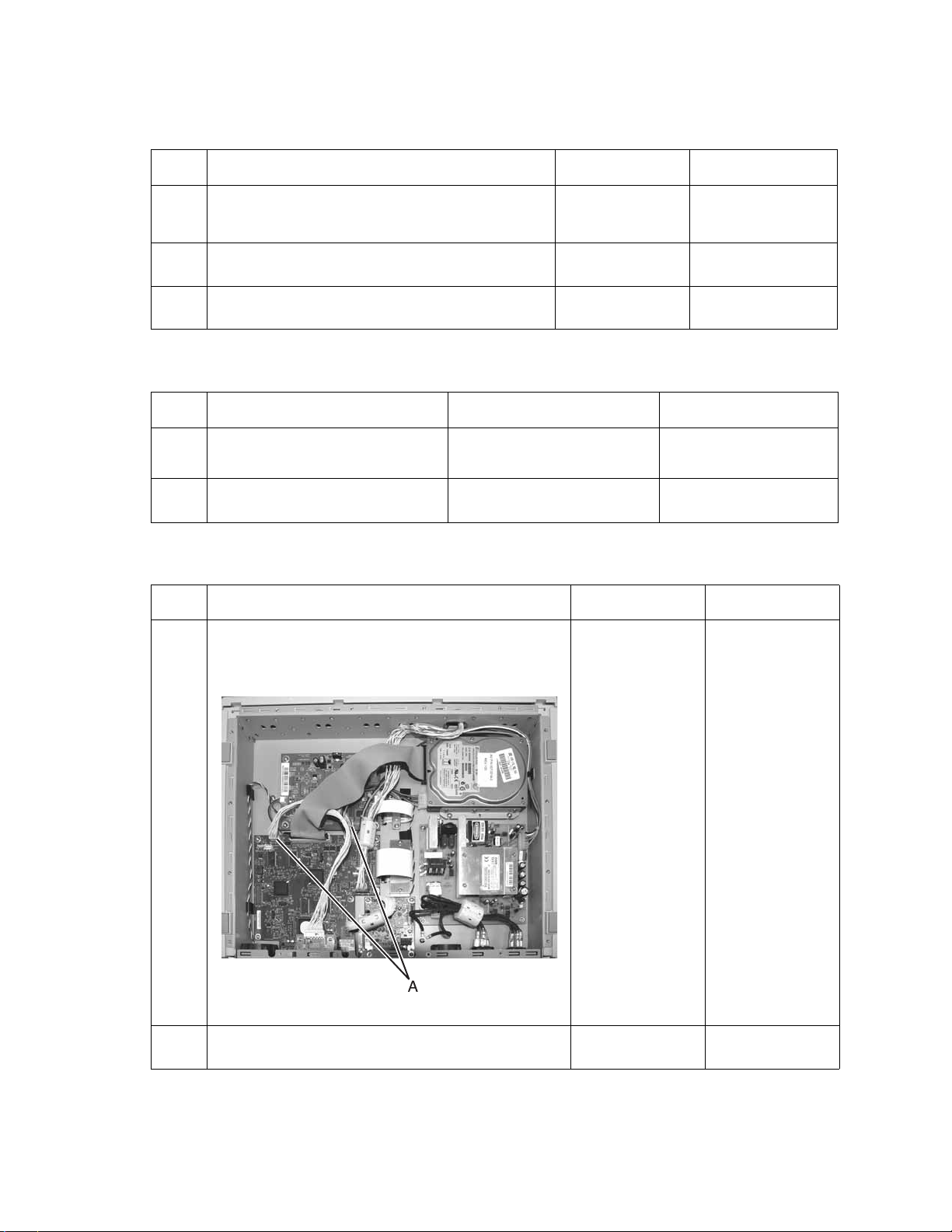

842.00 Scanner failure

Step Action and Question Y es No

1 Check the A1 to scan cont cable (A).

Note: Remov e the bottom plate to expose the cable.

See “Bottom plate remo val” on page 4-35 for more

information.

roller assembly

paper feed motor

Replace the carriage

transport belt

alcohol

Reseat A1 to

scan cont cable

paper in document

feeder

Go to step 3

Replace the ADF

unit

Go to step 2

Replace the flatbed CCD

assembly

Go to step 2

2

2-16 Service Manual

Is either end of the cable loose?

Does the A1 to scan cont cabl e have any vi sible

damage?

Replace A1 to

scan cont cable

Replace A1

board

Loading...

Loading...