Page 1

Color Jetprinter™ 4079 plus

IBM Color Jetprinter PS 4079

• Table of Contents

• Start Diagnostics

• Safety and Notices

4079-00X

• Trademarks

•Index

• Main Menu

Lexmark is a trademark of Lexmark

International, Inc., registered in the

United States and/or other countries.

Color Jetprinter is a trademark of

Lexmark International, Inc.

Page 2

4079-00X

Second Edition (May, 1997)

The following paragraph does not apply to the United Kingdom or any

country where such provisions are inconsistent with local law: LEXMARK

INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED T O , THE IMPLIED W ARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer of express or implied warranties in certain transactions, therefore,

this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will be

incorporated in later editions of the publication. Improvements or changes in the

products or the programs described in this publication may be made at any

time. Publications are not stocked at the address given below; requests for

publications should be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., Department

D22A/035-3, 740 New Circle Road NW, Lexington, Kentucky 40550, U.S.A.

Lexmark may use or distribute any of the information you supply in any way it

believes appropriate without incurring any obligation to you.

Lexmark is a trademark of Lexmark International, Inc., registered in the United

States and/or other countries.

Color Jetprinter is a trademark of Lexmark International, Inc.

Other trademarks are the property of their respective owners.

©Copyright Lexmark International, Inc. 1995, 1997

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS.

Use, duplication or disclosure by the Government is subject to restrictions as

set forth in subparagraph (c)(1)(ii) of the Rights in T echnical Data and Computer

Software clause at DFARS 252.227-7013 and in applicable FAR provisions:

Lexmark International, Inc., Lexington, KY 40550 USA.

Page 3

4079-00X

Contents

Notices and Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Coated Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Ink Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operating Temperatures And Humidity . . . . . . . . . . . . . . . . . 1-2

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Printhead Capping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Adjusting The Printhead Position Lever . . . . . . . . . . . . . . . . . 1-6

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Error Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Logged Error Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operator Codes And Symptom Table . . . . . . . . . . . . . . . 2-8

Service Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Carriage Drive Service Check . . . . . . . . . . . . . . . . . . . . 2-12

Carriage Motor Drive Data Service Check. . . . . . . . . . . 2-13

Carriage Position Service Check . . . . . . . . . . . . . . . . . . 2-14

Check Paper Service Check . . . . . . . . . . . . . . . . . . . . . 2-15

Cover Open Service Check . . . . . . . . . . . . . . . . . . . . . . 2-17

Hard Disk Service Check . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Head Cap Position Service Check. . . . . . . . . . . . . . . . . 2-18

Head Heater Service Check. . . . . . . . . . . . . . . . . . . . . . 2-20

Head Temp/Heat Pulse Service Check . . . . . . . . . . . . . 2-20

Host Print Service Check . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Ink Cartridge Service Check. . . . . . . . . . . . . . . . . . . . . . 2-22

Ink Flow Service Check . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Ink Sensor Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-26

Logic Board And Related Cables Service Check. . . . . . 2-29

Operator Panel Service Check. . . . . . . . . . . . . . . . . . . . 2-31

Paperfeed Electrical Service Check. . . . . . . . . . . . . . . . 2-32

Paperfeed Mechanical Service Check . . . . . . . . . . . . . . 2-36

Paperfeed Motor Service Check . . . . . . . . . . . . . . . . . . 2-38

Power Supply Service Check. . . . . . . . . . . . . . . . . . . . . 2-39

Print Escapement Service Check. . . . . . . . . . . . . . . . . . 2-41

1

Contents

iii

Page 4

4079-00X

Print Quality Service Check. . . . . . . . . . . . . . . . . . . . . . 2-43

Purge Unit Service Check . . . . . . . . . . . . . . . . . . . . . . . 2-45

RAM (Memory) Service Check . . . . . . . . . . . . . . . . . . . 2-46

Undetermined Problem Service Check . . . . . . . . . . . . . 2-47

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Testing The Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using The Menu System. . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operator Test Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Test Print A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Print Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Printhead Cleaning Procedures. . . . . . . . . . . . . . . . . . . . 3-4

Printing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Power-on Self Test (Post) . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Controller Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Paper Load Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Printer Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

LED Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

LCD Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

RAM Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Last Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Print Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Clean Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Quick Disk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Disk Test/Clean. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Format Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Software Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Service Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Lubrication Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-Sensitive Parts . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Head Gap Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Service Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Print Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Releasing Plastic Latches . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Ink Tube Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Printhead Uncapping and Carriage Centering. . . . . . . . . 4-9

Manual Carriage Centering (No Power) . . . . . . . . . . . . 4-10

Manual Printhead Capping (Disabled Machine) . . . . . . 4-11

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

iv

Page 5

4079-00X

Carriage Card, Carriage Card Holder Cover Removal. . 4-12

Carriage Encoder And Paper Width Sensor Removal . . 4-15

Carriage Frame Removal. . . . . . . . . . . . . . . . . . . . . . . . 4-19

Carriage Ribbon Cables Removal . . . . . . . . . . . . . . . . . 4-20

Carriage Cable Handling . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Carriage Shaft, Belt, And Ink Supply Removals. . . . . . . 4-23

Controller Board And Logic Board Removal . . . . . . . . . 4-27

Cover Removals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Hard Disk Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Ink Cartridge Assembly Removal. . . . . . . . . . . . . . . . . . 4-31

Inner Cover Spur Unit Removal . . . . . . . . . . . . . . . . . . . 4-34

Lower Frame Removal. . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Operator Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Paperfeed And Eject Rollers Removal. . . . . . . . . . . . . . 4-37

Paperfeed Motor Removal . . . . . . . . . . . . . . . . . . . . . . . 4-39

Paper Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Pickup Roller, Paper Lifting Plate Removal . . . . . . . . . . 4-41

Pinch Roller Base Unit Removal . . . . . . . . . . . . . . . . . . 4-42

Platen Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Printhead, Printhead Cover Removal. . . . . . . . . . . . . . . 4-46

Print Timing Slit Removal. . . . . . . . . . . . . . . . . . . . . . . . 4-47

Purge Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Separation Sheet Removal . . . . . . . . . . . . . . . . . . . . . . 4-50

Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Carriage Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Right Connector Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Left Connector Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Control Card 4079 - 001. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Control Card 4079 - 002. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Logic Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Ink Supply Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Safety Inspection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How To Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . 7-1

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Covers (Cont.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Inner Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Printer Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Power Supply and Control Panel . . . . . . . . . . . . . . . . . . 7-10

Contents

v

Page 6

4079-00X

Carriage and Printhead . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Purge Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Print Timing Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Carriage Ink Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Carriage Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Carriage Drive Frame . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Ink Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Ink Return Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Ink Cartridge Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Sheetfeed Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Sheetfeed Pinch Roller . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Paperfeed/Ejector Roller . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Sheetfeed Separation . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Paperfeed Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Hard Disk and Options . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .X-1

vi

Page 7

4079-00X

Notices and Safety Information

Safety Information

•

This product is designed, tested and approved to meet strict global

safety standards with the use of specific Lexmark components. The

safety features of some parts may not always be obvious. Lexmark is

not responsible for the use of other replacement parts.

•

The maintenance information for this product has been prepared for use

by a professional service person and is not intended to be used by

others.

•

There may be an increased risk of electric shock and personal injury

during disassembly and servicing of this product. Professional service

personnel should understand this and take necessary precautions.

Consignes de Sécurité

•

Ce produit a été conçu, testé et approuvé pour respecter les normes

strictes de sécurité globale lors de l'utilisation de composants Lexmark

spécifiques. Les caractéristiques de sécurité de certains éléments ne

sont pas toujours évidentes. Lexmark ne peut être tenu responsable de

l'utilisation d'autres pièces de rechange.

•

Les consignes d'entretien et de réparation de ce produit s'adressent

uniquement à un personnel de maintenance qualifié.

•

Le démontage et l'entretien de ce produit pouvant présenter certains

risques électriques, le personnel d'entretien qualifié devra prendre

toutes les précautions nécessaires.

Norme di sicurezza

•

Il prodotto è stato progettato, testato e approvato in conformità a severi

standard di sicurezza e per l’utilizzo con componenti Lexmark specifici.

Le caratteristiche di sicurezza di alcune parti non sempre sono di

immediata comprensione. Lexmark non è responsabile per l’utilizzo di

parti di ricambio di altri produttori.

•

Le informazioni riguardanti la manutenzione di questo prodotto sono

indirizzate soltanto al personale di assistenza autorizzato.

•

Durante lo smontaggio e la manutenzione di questo prodotto, il rischio

di subire scosse elettriche e danni alla persona è più elevato. Il

personale di assistenza autorizzato, deve, quindi, adottare le

precauzioni necessarie.

Notices and Safety Information vii

Page 8

4079-00X

Sicherheitshinweise

•

Dieses Produkt und die zugehörigen Komponenten wurden entworfen

und getestet, um beim Einsatz die weltweit gültigen

Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten

Funktionen der Bauteile und Optionen sind nicht immer offensichtlich.

Sofern Teile eingesetzt werden, die nicht von Lexmark sind, wird von

Lexmark keinerlei Verantwortung oder Haftung für dieses Produkt

übernommen.

•

Die Wartungsinformationen für dieses Produkt sind ausschließlich für

die Verwendung durch einen Wartungsfachmann bestimmt.

•

Während des Auseinandernehmens und der Wartung des Geräts

besteht ein zusätzliches Risiko eines elektrischen Schlags und

körperlicher Verletzung. Das zuständige Fachpersonal sollte

entsprechende Vorsichtsmaßnahmen treffen.

Pautas de Seguridad

•

Este producto se ha diseñado, verificado y aprobado para cumplir los

más estrictos estándares de seguridad global usando los componentes

específicos de Lexmark. Puede que las características de seguridad de

algunas piezas no sean siempre evidentes. Lexmark no se hace

responsable del uso de otras piezas de recambio.

•

La información sobre el mantenimiento de este producto está dirigida

exclusivamente al personal cualificado de mantenimiento.

•

Existe mayor riesgo de descarga eléctrica y de daños personales

durante el desmontaje y la reparación de la máquina. El personal

cualificado debe ser consciente de este peligro y tomar las

precauciones necesarias.

viii Service Manual

Page 9

4079-00X

Informações de Segurança

•

Este produto foi concebido, testado e aprovado para satisfazer os

padrões globais de segurança na utilização de componentes

específicos da Lexmark. As funções de segurança de alguns dos

componentes podem não ser sempre óbvias. A Lexmark não é

responsável pela utilização de outros componentes de substituição.

•

As informações de segurança relativas a este produto destinam-se a

profissionais destes serviços e não devem ser utilizadas por outras

pessoas.

•

Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais destes

serviços devem estar avisados deste facto e tomar os cuidados

necessários.

Informació de Seguretat

•

Aquest producte està dissenyat, comprovat i aprovat per tal d'acomplir

les estrictes normes de seguretat glob als amb la utililització de

components específics de Lexmark. Les característiques de seguretat

d'algunes peces pot ser que no sempre siguin òbvies. Lexmark no es

responsabilitza de l'us d'altres peces de recanvi.

•

La informació pel manteniment d’aquest producte està orientada

exclusivament a professionals i no està destinada a ningú que no ho

sigui.

•

El risc de xoc elèctric i de danys personals pot augmentar durant el

procés de desmuntatge i de servei d’aquest producte. El personal

professional ha d’estar-ne assabentat i prendre les mesures

convenients.

Notices and Safety Information ix

Page 10

4079-00X

Chinese Safety Information

Korean Safety Information

x Service Manual

Page 11

4079-00X

Preface

This service manual is designed to be used by printer repair

technicians during servicer training and when repairing a failing

printer. The technician should first understand the failing symptom.

Then begin at “Start” (page 2-1) in this service manual and follow the

steps to diagnose and fix the failure.

This manual is divided into the following chapters:

1. “

General Information

2. “

Diagnostic Information

step-by-step instructions to isolate the failing FRU.

3. “

Diagnostic Aids

diagnose problems and test the machine after repairs hav e been

made.

4. “

Repair Information

make necessary adjustments.

5. “

Connector Locations

illustrates the paper paths and ink supply system.

6. “

Preventive Maintenance

the printer.

7. “

Parts Catalog

” lists the part numbers for the FRUs.

” introduces the printer.

” includes the procedures that give you

” includes test procedures that are used to

” shows how to change the failing FRU and

” shows how to find test points and

” includes suggestions for maintaining

Notices and Safety Information xi

Page 12

4079-00X

1. General Information

This chapter introduces and describes the Lexmark™ Color

Jetrinter™ 4079 plus, the tools needed to repair it, and the customer

switch settings that control the features of the printer.

Description

The Color Jetprinter is a tabletop four-color inkjet printer for draft or

letter quality applications in an attended PC attach environment.

This printer uses four printheads with 64 nozzles each to produce

both letter-quality and draft output.

Graphics resolution is available up to 360 dots-per-inch (dpi),

depending on the printer menu selection and application. The printer

prints in one direction only when printing graphic images.

You may use cut-sheet paper up to 297 mm (11.7 in.) by 432 mm

(17.0 in.).

Coated Paper

Special coated papers are recommended for best printing results.

Included with each supply of paper is a special brown cleaning sheet

maintenance paper

called

the nozzle test on this paper in order to clean the pickup and feed

rollers.

After 2000 pages, wipe the platen and inside of the print cover to

remove any ink mist that ma y accumulate and pre v ent staining of the

print paper.

The capacity of the paper tray is approximately 100 sheets of coated

letter-size paper. Envelopes and postcards can be fed from the

paper tray as well.

An easy-to-use operator panel on the front of the printer provides

control of print resolution and style.

. After printing a number of pages, print

General Information

1-1

Page 13

4079-00X

Ink Cartridges

Each ink cartridge contains 30 grams of liquid ink, and is rated for as

much as 700 pages of text.

Each color cartridge is physically coded to fit in its own color slot.

Also, the ink cartridge has an electronic label which is sensed by the

cartridge sensor. The ink is nontoxic, but contains isopropyl alcohol

and should not be swallowed or gotten in the eyes. It will permanently stain clothing.

To prevent ink leaks, always ship the printer with the ink cartridges

installed, and with the carriage locked in place.

Also make sure the four printheads are capped before switching the

printer off. A star (*) is displayed when the heads are automatically

capped.

Operating Temperatures And Humidity

Temperature and humidity levels are important to the correct operation of the printer. The ranges are:

Temperature

Humidity

15-30° C (59-86° F)

5-95% (no condensation)

Tools

The removal and adjustment procedures described in this manual

require the following tools and equipment:

•

Phillips screwdriver (small)

•

Flat-blade screwdriver

•

Fuse puller

•

Analog volt ohmmeter(1) (a digital volt ohmmeter may also be

used).

•

Feeler gauge for head gap adjustment

•

Syringe

•

Drop cloth

General Information

1-2

Page 14

4079-00X

•

Grease

•

Cleaning tissue

•

Magnifier

Refer to the parts catalog for part numbers of special tools. When

taking voltage readings, always use frame ground unless another

ground is specified.

When you use the syringe, clip the end of the tip so it will fit over the

small tube connectors and into the ink joints.

NOTE: Be careful not to separate the syringe plunger from the body

of the syringe. The ink may leak and stain clothing and other items.

Make sure the machine is in a suitable service area and place a drop

cloth under the machine when you service it.

Printer Emulation

Before you use your printer with most software programs, you must

select the appropriate printer driver from that program’s printer

selection menu. When you select a printer from the list, a driver is

installed that allows your documents to be printed correctly on your

printer.

If the printer does not appear on the list in your program, you can

use any of the following printer driver emulations, listed here in the

order of their priority . Choose the first printer on the list that appears

in your program’s list of printers.

PRIORITY PRINTER

1

2

If none of these choices appear in your software, you may choose

another PostScript printer. However, if you choose a non-color

printer, your output will have only black print.

1-3

1 QMS ColorScript 100 (Postscript mode)

Seiko ColorPoint PS Model 14

Page 15

4079-00X

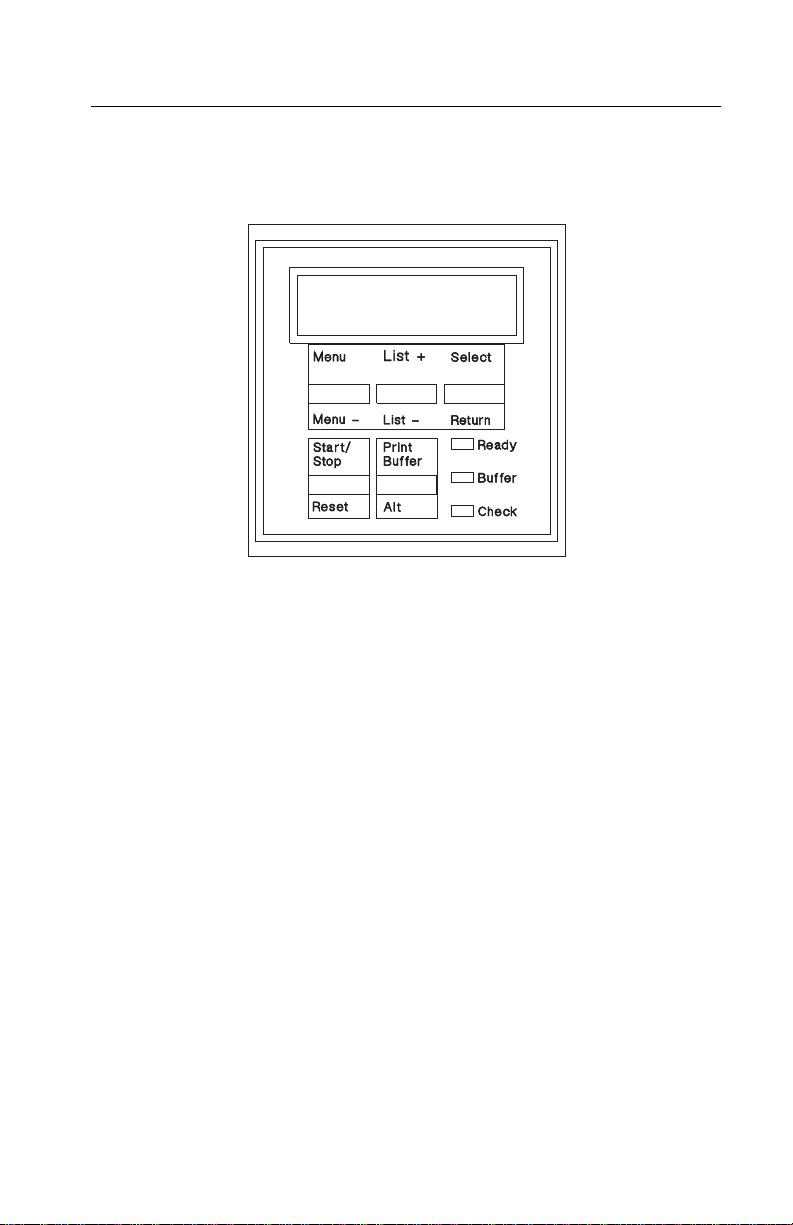

Operator Panel

You can access various printing functions and options using the

printer’s operator panel.

Indicators

There are several indicators in the operator panel that show the status of the machine.

Display

status, menu items and error messages.

For example, a star (*) is displayed when the printheads are capped.

Ready

the printer is off-line. The Ready indicator is turned off when

Stop

paper, or when

Buffer

printer. When the buffer indicator is on solid, it indicates the buffer is

full or a partial page is stored. Press

page.

Check

ator intervention, such as ink or paper problems. An error message

will also be displayed, indicating the type of problem.

This 2-line liquid crystal display (LCD) shows the printer’s

This indicator is on when the printer is on-line and is off when

Start/

is pressed, when there is a check condition such as out-of-

has been pressed to display the menu.

Menu

This indicator blinks when data is being received by the

Print Buffer

The Check indicator lights up when the printer requires oper-

to print the stored

General Information

1-4

Page 16

4079-00X

Buttons

Five buttons on the operator panel control the printer. There are two

operations for each button, depending on the state of the printer and

whether Alt is pressed.

1. Menu and Menu -

Press Menu to display the menu system, whether the printer is

Ready or Not-Ready. If a job is active, the Ready indicator is turned

off, and the menu is displayed after the current job has completed

printing. If the menu is already active, pressing Menu displays the

next menu item on the top line of the display.

Menu - is accessed by pressing Alt + Menu, and mov es to the pre vious menu item.

2. List+ and List -

When the menu is active, these buttons display the list of items on

the second line of the display. Press Alt + List+ (List - to move to

the previous list item.

3. Select And Return

Select only operates when the menu is active.

If the top line of the menu is active, pressing Select causes the lower

line to become active. If the lower line of the menu is activ e , pressing

Select selects the current value being display ed. If the current v alue

is a function, such as printing a test, it is executed. If the current

value is a setting, such as High Speed, it becomes the permanent

default.

Return is activated by pressing Alt + Select and it only operates

when the menu is active. If the lower line of the display is active,

pressing Alt causes the upper line of the displa y to become activ e . If

the upper line of the display is active, pressing Alt exits the menu

system in the Not-Ready state.

4. Start/Stop and Reset

If the Ready light is on, pressing Start/Stop turns off the Ready light

and the printer stops processing information. The current job will be

interrupted.

1-5

Page 17

4079-00X

If the Ready light is off, pressing

and the printer is ready to receive information.

When

Alt + Reset

tus.

5.

Print Buffer

Print Buffer

Buffer indicator is on solid, the buffer contains a partial page of information.

is used to access the secondary function on the other buttons by

Alt

pressing and holding Alt while pressing another button.

is pressed, the printer returns to its power-on sta-

and

Alt

prints the contents of the print buffer, if any. When the

Start/Stop

turns on the Ready light

Printhead Capping

The printheads are capped automatically after they have been in the

home position for a few seconds. When the printheads are capped,

a star (*) appears in the display. Do not turn the printer off without

the heads being capped. If the heads are left uncapped, the ink dries

out and print quality is affected.

Adjusting The Printhead Position Lever

The printhead position lever is the green lever attached to the carriage.

For optimum print quality, make sure this lever is adjusted according

to the density of the ink in the document and the thickness of the

paper being used. Setting the lever at position 1 sets the distance

between the printhead and the paper at the minimum distance.

Follow these recommendations:

Position 1

the paper.

Position 2

Position 3

very densely inked graphics.

: Use for normal documents with normal ink density on

: Use for documents with densely inked graphics.

: Use for envelopes or thick paper, or for documents with

General Information

1-6

Page 18

4079-00X

If the head is positioned too close to thick paper, envelopes, or

densely inked graphics, the ink could be smeared. In general, keep

the head position as close as possible to the paper.

Also, be sure that quality coated paper is being used for best print

quality.

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EEPROM Electrically Erasable Programmable Read-

Only Memory

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PICS Problem Isolation Charts

PIXEL Picture Element

POR Power-On Reset

POST Power-On Self Test

PQET Print Quality Enhancement Technology

RIP Raster Image Processor

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

VAC Volts alternating current

VDC Volts direct current

1-7

Page 19

4079-00X

2. Diagnostic Information

Start

When the covers are remov ed, y ou will get a Cov er Open error code.

To prevent this, tape the cover open interlock arm in the closed position on the operator panel.

All voltages in the service checks are positive unless otherwise

noted. When measuring voltages, always use frame ground unless

otherwise specified.

Visually check the machine for obvious problems such as ink leakage, and worn or missing parts. Also reseat all cables, and check for

good connections.

Note the error code number, if one is displa yed in the oper ator panel,

and the number of beeps sounded. If you have an error code, go to

the “Error Code Table” on page 2-2 and follow the instructions for

that error code.

If no error code is present, check the NVRAM for the Last Error

code. (See the procedure in “Controller Diagnostics” on page 3-9).

If no error code number is displayed, or you cannot access Controller Diagnostics to check the last error code, or you have no clear

symptom, continue with this Start procedure.

If you proceed through Start, the Error Code T ab le, and the Operator

Codes and Symptom Table without determining an error code or

symptom, go to “Undetermined Problem Service Check” on page

2-47 and then return here to Start.

When a service check instructs you to end the call, you should run

“Test Print A” on page 3-3.

Check the following:

1. Turn the printer off. Make sure the carriage lock is disengaged,

then turn the printer on. If there is no indication of power in the

printer, go to the “Power Supply Service Check” on page 2-39.

Diagnostic Information 2-1

Page 20

4079-00X

2. If the printer has power but does not complete POST, with

Ready on the display, go to the “Operator Panel Service Check”

on page 2-31.

3. Run Test Print A. To enter Controller Diagnostics, press and

hold Menu and Print Buffer while turning on the printer. After the

POST is complete, the first item in the Controller Diagnostics

menu is displayed. Use coated paper if a vailable. If you use regular paper, allow f or some color conv ergence. If an error code or

detectable symptom occurs, go to the “Error Code Table”. If you

have a symptom only, go to the “Operator Codes And Symptom

Table” on page 2-8.

4. Turn the printer off and connect it to a host computer. Turn the

printer on and send data from the computer to the printer. You

can use the test print for this. If the data does not print as it was

sent, go to the “Host Print Service Check” on page 2-22.

Error Code Table

To use this error code table:

1. Turn off the printer, wait four or more seconds, then turn on the

printer.

2. Note any error code number that appears in the display, look for

that code in the tables below, and take the indicated action.

•

If two error codes are listed in the table: the top number is displayed if the controller board is installed; the bottom number is

displayed if the controller board is removed.

•

Some error codes are operator-correctable. See “Operator

Codes And Symptom Table” on page 2-8.

•

Other codes indicate the printer is performing an operation; no

action is needed. For example, “04 Reset”, or “05 Self Test”

means the printer is running POST.

3. If no error code is displayed, count the number of beeps and

look for that number in the tables.

4. If no error code is displayed, and no beeps are heard, look for

the symptom in the table and take the indicated action.

5. If you are unable to correct the problem using this index, go to

the “Undetermined Problem Service Check” on page 2-47.

Note: If POST fails and a message is displayed, disregard the message and count the number of beeps.

2-2

Page 21

4079-00X

Logged Error Code

If no error code number is displayed, you can enter Controller Diagnostics mode and check for Last Error code number . See “Controller

Diagnostics” on page 3-9.

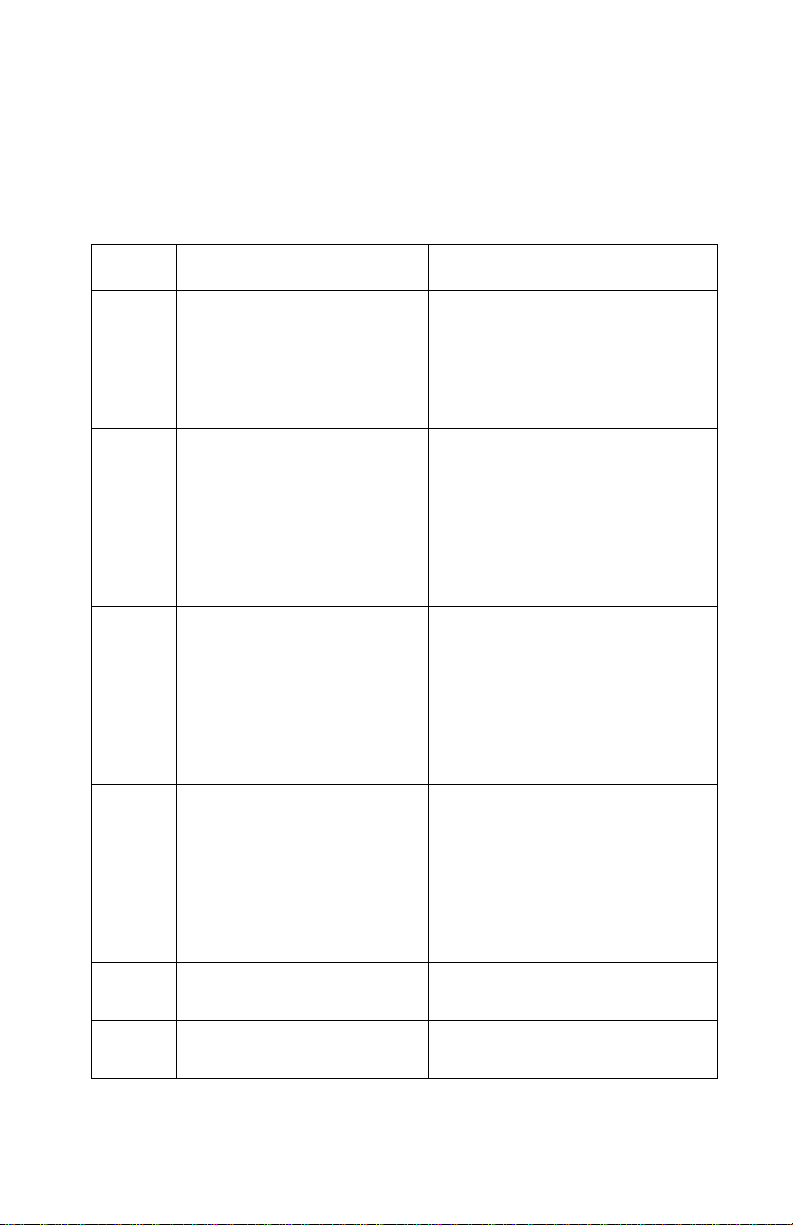

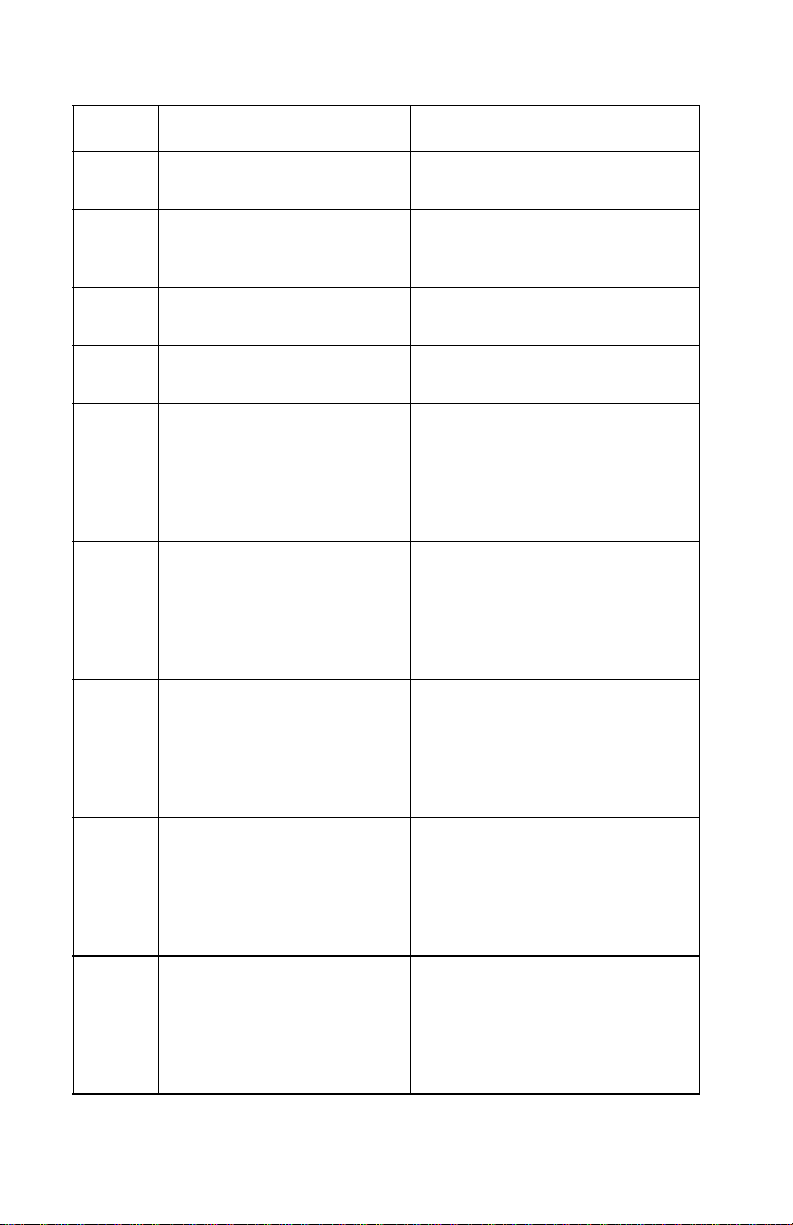

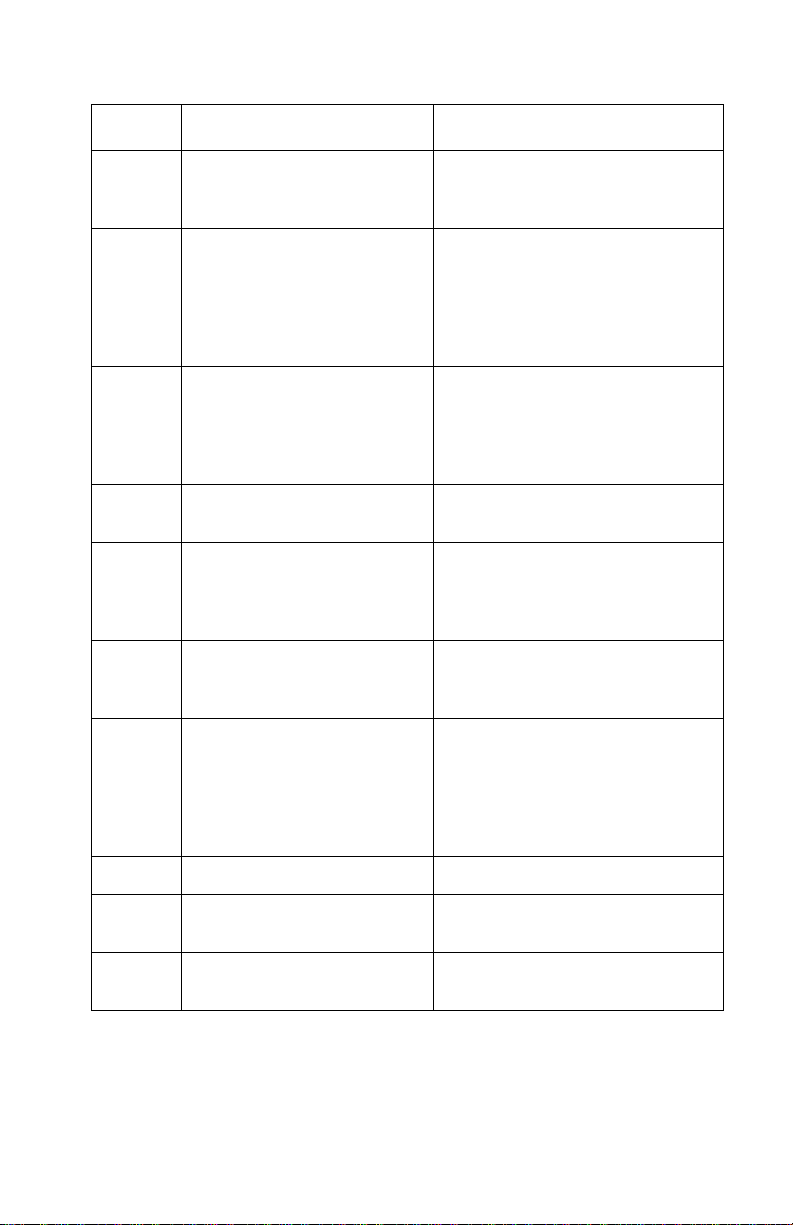

Code No Of Beeps Or Symptom Action Or Failing Fru

101

65

102

65

103

65

104

65

1 Beep - ROM error Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

2 Beeps - RAM error Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

3 Beeps - Printer controller Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

4 Beeps - Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

105

65

106

65

5 Beeps - “Logic Board And Related Cables

Service Check” on page 2-29.

6 Beeps - “Logic Board And Related Cables

Service Check” on page 2-29.

Diagnostic Information

2-3

Page 22

4079-00X

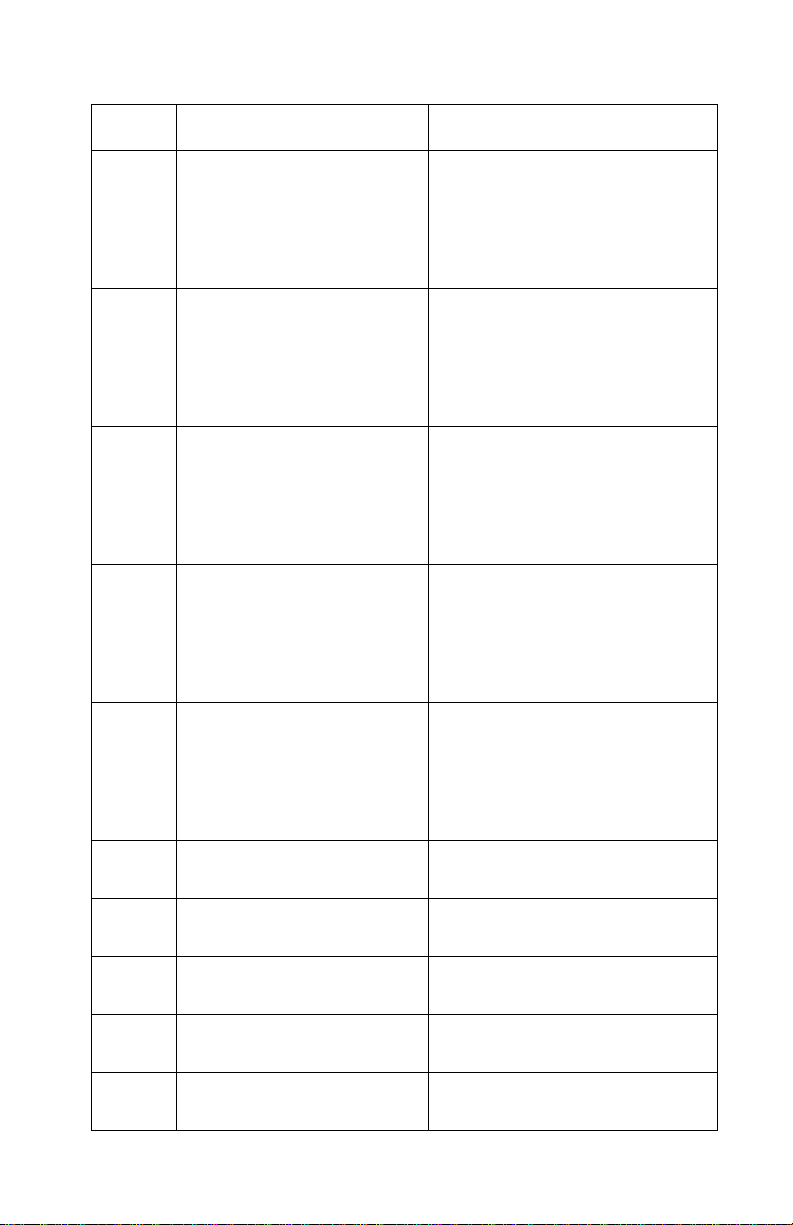

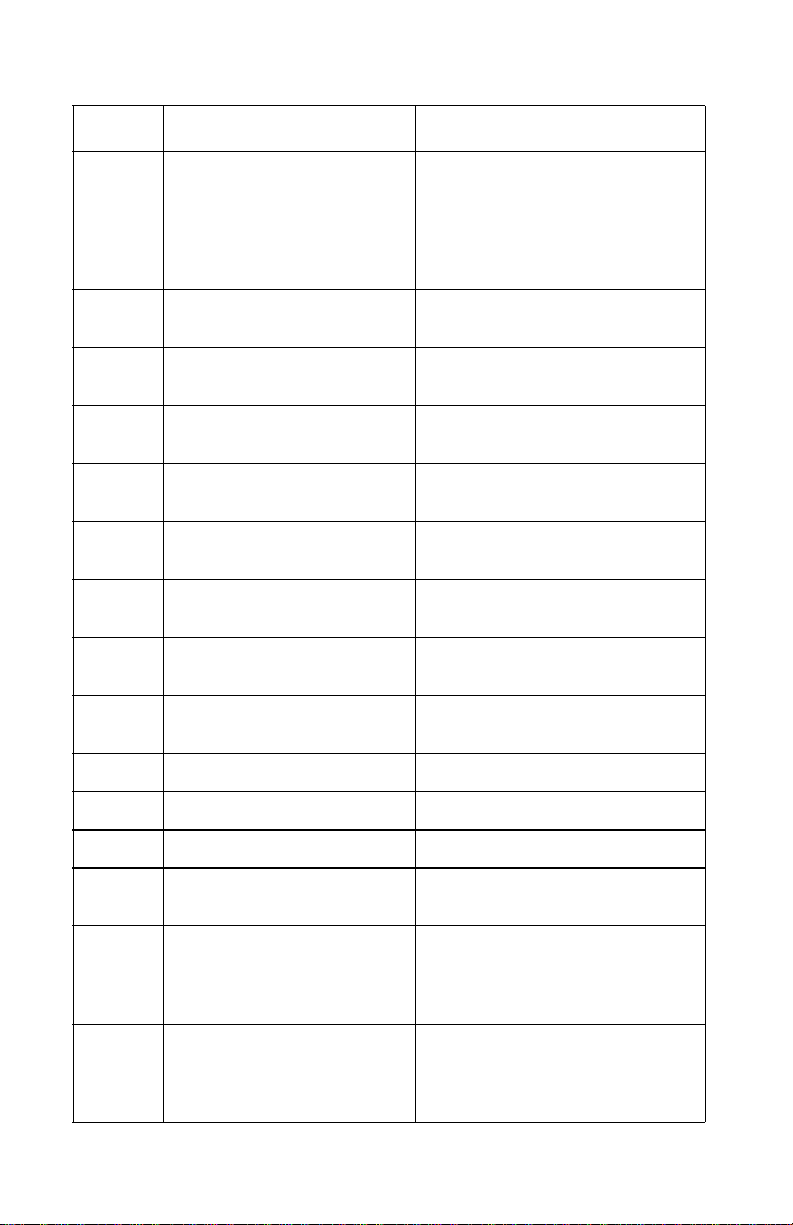

Code No Of Beeps Or Symptom Action Or Failing Fru

107

65

none No Beeps - Operator panel

108

65

109

68

125

72

126

72

127

72

7 Beeps “Logic Board And Related Cables

does not work correctly (buttons or display)

8 Beeps - Read/write error Logic board

10 Beeps - NVRAM error Logic board

10 Beeps - Controller carriage motor disable

10 Beeps - Communications error

10 Beeps - Communications error

Service Check” on page 2-29.

“Operator Panel Service Check”

on page 2-31.

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

128

72

128

72

2-4

10 Beeps - Communications error

10 Beeps - Communications error

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

Page 23

4079-00X

Code No Of Beeps Or Symptom Action Or Failing Fru

138

61

none,

63

none,

66

none,

72

none,

40

10 Beeps - ROM error Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

10 Beeps - RAM error Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

10 Beeps - Printer controller

error

10 Beeps - Communications error

10 Beeps - Communications error

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

Logic board. If you replace the

logic board, go to the “Service

Adjustment Mode” on page 4-4

and perform the print position

adjustment, and the direction offset adjustment.

110

55

111

54

112

53

113

52

120

55

10 Beeps - Yellow head

heat-pulse resistance error

10 Beeps - Magenta head

heat-pulse resistance error

10 Beeps - Cyan head heatpulse resistance error

10 Beeps - Black head heatpulse resistance error

10 Beeps - Yellow head temperature detection error

“Head Heater Service Check” on

page 2-20.

“Head Heater Service Check” on

page 2-20.

“Head Heater Service Check” on

page 2-20.

“Head Heater Service Check” on

page 2-20.

“Head Temp/Heat Pulse Service

Check” on page 2-20.

Diagnostic Information

2-5

Page 24

4079-00X

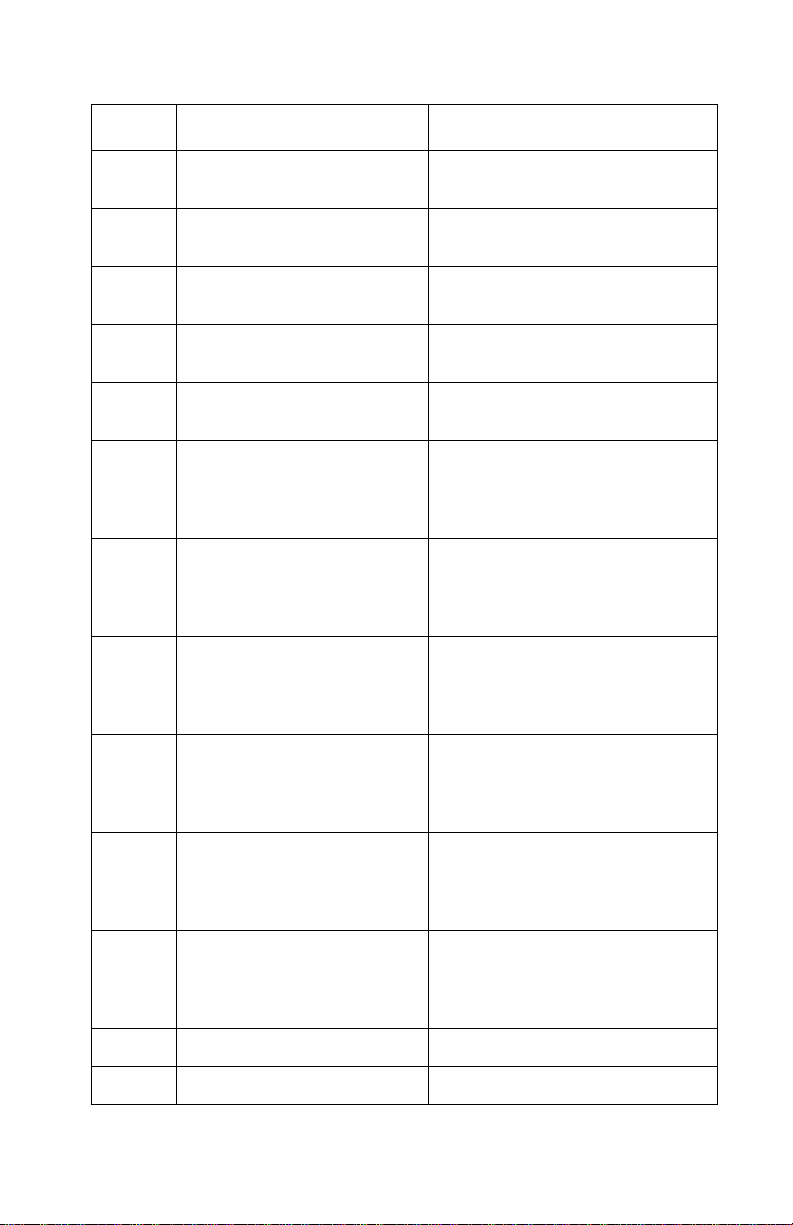

Code No Of Beeps Or Symptom Action Or Failing Fru

121

54

122

53

123

52

124

5F

12C,

5F

12A,

51

12B,

50

12D,

50

12E,

5E

12F

5E

10 Beeps - Magenta head

temperature detection error

10 Beeps - Cyan head temperature detection error

10 Beeps - Black head temperature detection error

10 Beeps - Printer internal

temperature error - Check

installation temperature

standards

10 Beeps - Carriage motor

drive data error

10 Beeps - Cap position

error

10 Beeps - Linear encoder

error

10 Beeps - Home position

detection error

10 Beeps - Carriage motor

over-current error

10 Beeps - POST does not

complete

“Head Temp/Heat Pulse Service

Check” on page 2-20.

“Head Temp/Heat Pulse Service

Check” on page 2-20.

“Head Temp/Heat Pulse Service

Check” on page 2-20.

Check installation temperature

standards. “Carriage Motor Drive

Data Service Check” on page

2-13.“

“Carriage Motor Drive Data Service Check” on page 2-13.

“Head Cap Position Service

Check” on page 2-18.

“Print Escapement Service

Check” on page 2-41.

“Print Escapement Service

Check” on page 2-41.

“Carriage Position Service

Check” on page 2-14.

“Carriage Position Service

Check” on page 2-14.

12F

5F

130

59

131

58

132

57

133

56

134

5D

2-6

10 Beeps - Complete POST;

Test Print A will not run

10 Beeps - Yellow head

heater error

10 Beeps - Magenta head

heater error

10 Beeps - Cyan head

heater error

10 Beeps - Black head

heater error

10 Beeps - Yellow head ink

sensor error

“Carriage Motor Drive Data Service Check” on page 2-13.

“Head Heater Service Check” on

page 2-20.

“Head Heater Service Check” on

page 2-20.

“Head Heater Service Check” on

page 2-20.

“Head Heater Service Check” on

page 2-20.

“Ink Sensor Service Check” on

page 2-26.

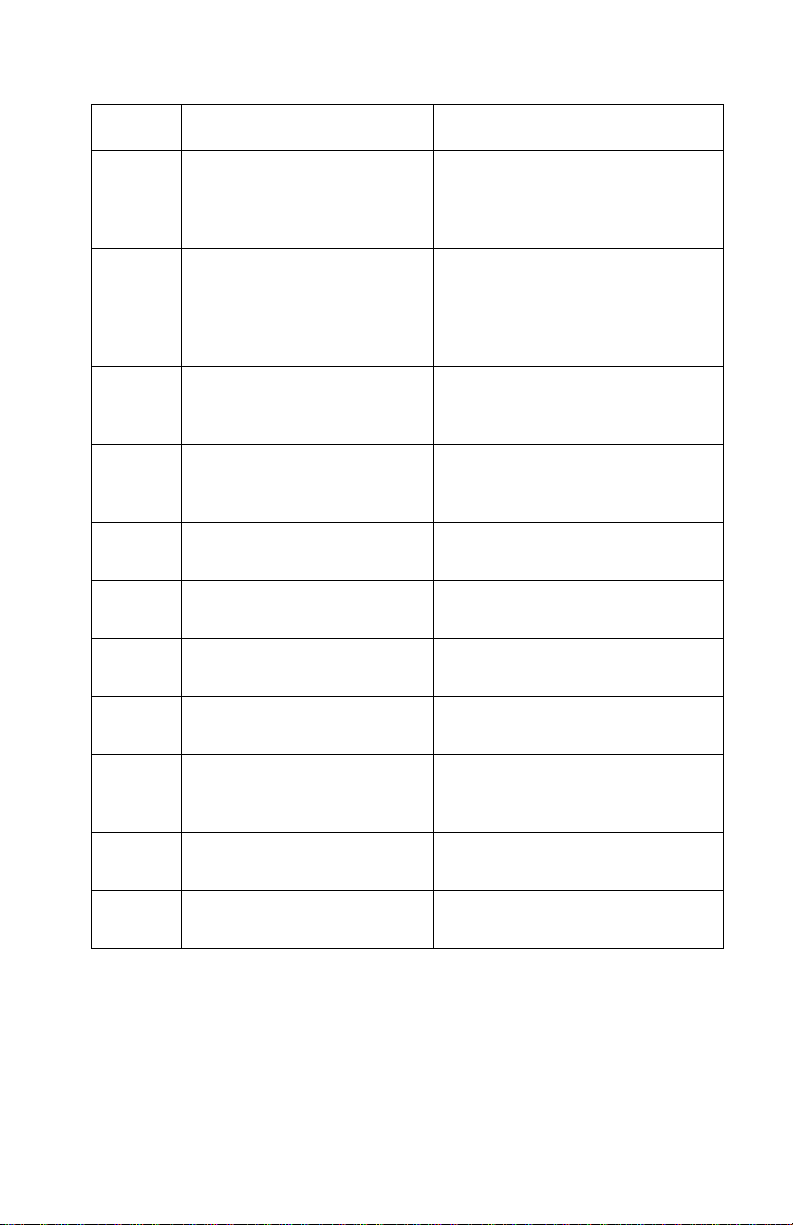

Page 25

4079-00X

Code No Of Beeps Or Symptom Action Or Failing Fru

135

5C

136

5D

137

5A

901 Insufficient memory to run

941 Incorrect checksum

945 Controller board failure Controller board. Be sure to

946 Controller board failure Controller board. Be sure to

950 Controller board failure Controller board. Be sure to

10 Beeps - Magenta head

ink sensor error

10 Beeps - Cyan head ink

sensor error

10 Beeps - Black head ink

sensor error

POST

(EPROM)

“Ink Sensor Service Check” on

page 2-26.

“Ink Sensor Service Check” on

page 2-26.

“Ink Sensor Service Check” on

page 2-26.

“RAM (Memory) Service Check”

on page 2-46.

EPROM Controller board (J7),

RAM (J8) (4079-002)

transfer the EPROM controller

card and memory SIMMs from

the old board to the new one.

transfer the EPROM controller

card and memory SIMMs from

the old board to the new one.

transfer the EPROM controller

card and memory SIMMs from

the old board to the new one.

951 Controller board failure Controller board. Be sure to

transfer the EPROM controller

card and memory SIMMs from

the old board to the new one.

952 Controller board failure Controller board. Be sure to

transfer the EPROM controller

card and memory SIMMs from

the old board to the new one.

953 Controller board failure Controller board. Be sure to

transfer the EPROM controller

card and memory SIMMs from

the old board to the new one.

960 Memory error Controller board RAM (J5 or J8)

961 Memory Error Memory SIMM failure, J8

Diagnostic Information

2-7

Page 26

4079-00X

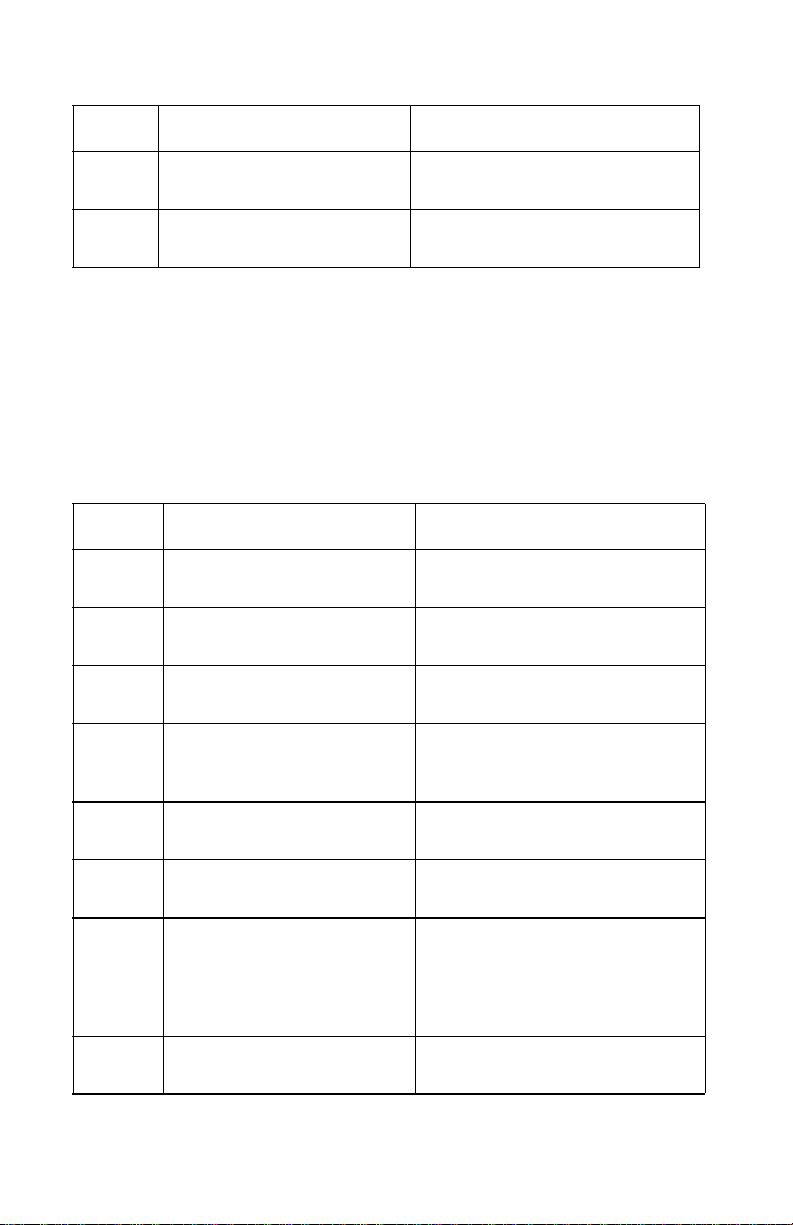

Code No Of Beeps Or Symptom Action Or Failing Fru

980 Incorrect checksum

(EPROM)

991 8 Beeps - communications

error

Controller board EPROM (J6),

RAM (J5 or J8)

“Undetermined Problem Service

Check” on page 2-47.

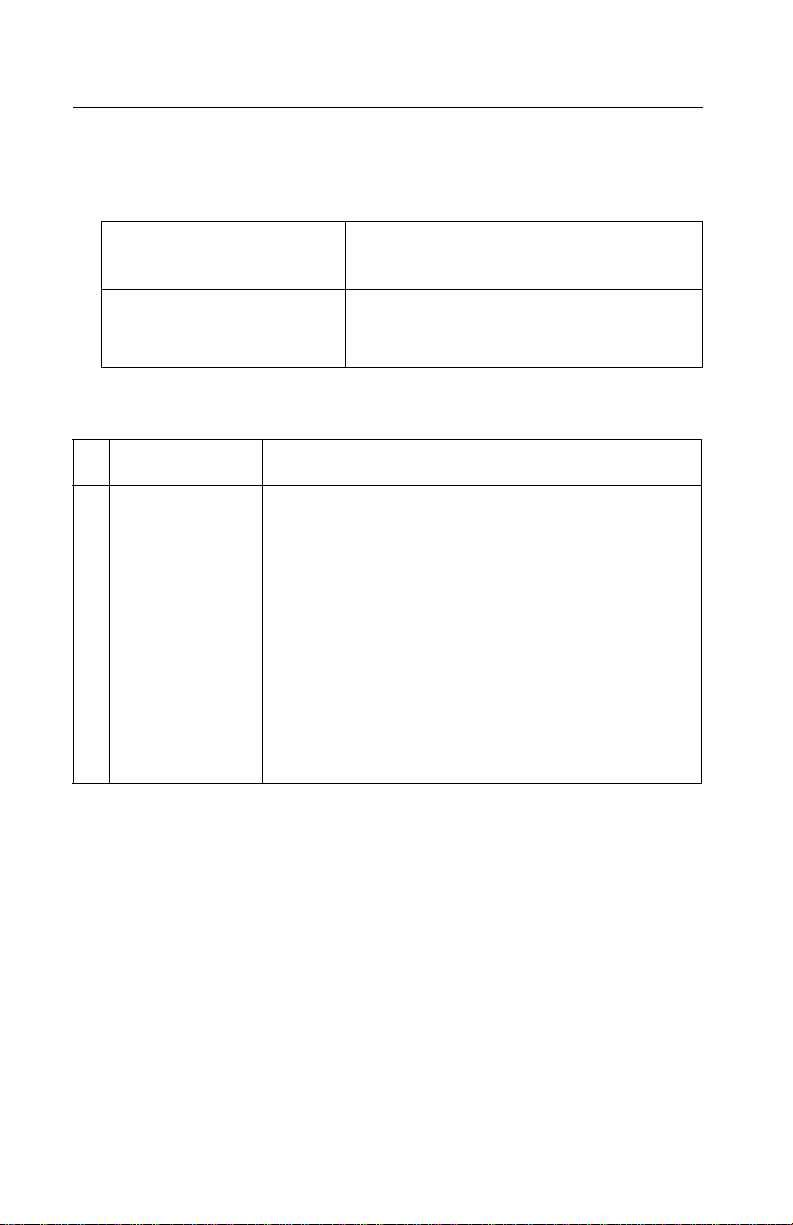

Operator Codes And Symptom Table

The following code numbers are operator instructions and messages. In some cases, no action is required; others are operator-correctable; others may require service. An error code may require up

to one minute to appear. Some symptoms ma y not generate an error

code. Locate your symptom in the table and take the indicated

action. .

Code Beeps - Symptom Action Or Fru

05 Po wer-on self-test (POST) is

being performed.

06 Print test or other menu

function being performed.

07 Printhead cleaning operation

being performed.

08 Page Postscript due to lan-

guage error; ending when

End of Job is found.

No Action

No Action

No Action

No Action

09 Printhead refresh operation

being performed.

Not

Active

22

13

23 Paper too short to print data;

A key was pressed that is

currently not active.

Paper feeds into printer , then

jams; error code displayed

when carriage moves from

home position when printing

Test Print A.

extra data will be discarded.

2-8

No Action

Release the key. Wait until the

key is active.

Check and clear paper path. If

error persists, go to “Paperfeed

Electrical Service Check” on

page 2-32.

Use correct length paper.

Page 27

4079-00X

Code Beeps - Symptom Action Or Fru

31 Paper loaded is incorrect

size; correct size indicated

on second line of display.

36

10

none Paperfeed problem; more

none No pickup of paper; paper-

none Paper skews. “Paperfeed Mechanical Service

none 1 Beep - completes POST. A

36 1 Beep - completes POST.

Paper tray empty or paper

did not feed; POST completes, tries to feed paper

when printing Test Print A;

paperfeed motor does not

rotate.

than one sheet feeds into

printer; pickup plate repeatedly raises and lowers while

printing.

feed roller turning normally.

bumping or scraping noise is

heard during printing.

When Test Print A is run,

printer feeds paper into

printer; error code appears

at different positions of carriage

Change paper size loaded.

Load paper tray. If error persists,

go to “Check Paper Service

Check” on page 2-15.

“Paperfeed Mechanical Service

Check” on page 2-36.

“Paperfeed Mechanical Service

Check” on page 2-36.

Check” on page 2-36. Paper tray

overloaded; wrong type of media

used or selected.

Printhead cover not in place correctly.

“Paperfeed Electrical Service

Check” on page 2-32.

none Paper sticks together . F an paper; put less in paper tray.

30

12

38,

SIMMS

Top cover open “Cover Open Service Check” on

Insufficient printer memory

to print page

page 2-17.

Make page less complicated.

Add memory to printer.

Diagnostic Information

2-9

Page 28

4079-00X

Code Beeps - Symptom Action Or Fru

54 Serial error (framing or par-

60

16

61

16

62

16

63

16

64

14

65

14

66

14

67

14

ity) detected; possibly the

serial link is set up incorrectly.

Black ink cartridge empty “Ink Sensor Service Check” on

Yellow ink cartridge empty “Ink Sensor Service Check” on

Magenta ink cartridge empty “Ink Sensor Service Check” on

Cyan ink cartridge empty “Ink Sensor Service Check” on

Black ink cartridge not

installed

Yellow ink cartridge not

installed

Magenta ink cartridge not

installed

Cyan ink cartridge not

installed

Press Start/Stop to continue.

Once the serial error has been

displayed, serial error reporting is

suppressed until interface parameters are changed or printer is

powered off.

page 2-26.

page 2-26.

page 2-26.

page 2-26.

“Ink Cartridge Service Check” on

page 2-22.

“Ink Cartridge Service Check” on

page 2-22.

“Ink Cartridge Service Check” on

page 2-22.

“Ink Cartridge Service Check” on

page 2-22.

72 Disk Full No Action

73 Unformatted Disk No Action

74 Defective Disk Replace the disk.

none Missing data or additional

data in print job.

none Bad print quality; missing

dots, white streaks. Ink flow

observed through large

purge waste lines.

none Light print followed by voids

in print, in one color or all

colors; no ink flow through

large purge waste lines

“RAM (Memory) Service Check”

on page 2-46.

Clean heads. Seat ink cartridges

firmly. Check type of media

selected. “Print Quality Service

Check” on page 2-43.

“Ink Flow Service Check” on

page 2-24.

2-10

Page 29

4079-00X

Code Beeps - Symptom Action Or Fru

none Blurring or smudging of print Printhead position lever too low.

Wrong type of media. Wrong

print mode selected see “Printing

Mode” on page 3-4.

none Smeared print, poor quality Printhead position lever in wrong

none Failing LED or button on

operator panel; printer operates normally otherwise.

none 1 Beep - POST completed,

but operator panel does not

operate normally

none No lights or beeps; printer

will not begin POST

none All LEDs are on; POST

started; display blank.

none 8 Beeps - POST started; all

LEDs are on, display blank.

none 10 Beeps - POST started; all

LEDs on, display blank.

none Printer will not print from

host computer; Test Print A

runs normally.

position see “Adjusting The Print-

head Position Lever” on page

1-6.“Print Quality Service

Check” on page 2-43.

“Diagnostic Aids” on page 3-1.

“Operator Panel Service Check”

on page 2-31.

“Power Supply Service Check”

on page 2-39.

“Power Supply Service Check”

on page 2-39.

“Power Supply Service Check”

on page 2-39.

“Power Supply Service Check”

on page 2-39.

Make sure printer is on-line “Host

Print Service Check” on page

2-22.

none Carrier motor stops in the

error

code

middle of the writing line.

Symptom or error code not

listed

Go to the “Paperfeed Electrical

Service Check” on page 2-32.

“Undetermined Problem Service

Check” on page 2-47.

Diagnostic Information

2-11

Page 30

4079-00X

Service Checks

Carriage Drive Service Check

Symptom Explanation

You have an error code or

a failing carriage drive

motor.

FRU Action

1 • Carriage

Drive Motor

• Carriage

Board

• Logic Board

Conditions That Could Cause This

Symptom

• Carriage motor

• Logic board

Check the carriage drive motor winding resistance.

Connector pins 5 and 6 are one phase; pins 7 and 8

are the other phase. The resistance should be

approximately 0.8 Ohms per phase.

If the resistance is incorrect, replace the carr iage

drive motor.If the resistance is correct, replace the

carriage board.

If you still have a problem, replace the logic board. If

you replace the logic board, go to the “Service

Adjustment Mode” on page 4-4 and perform the print

position adjustment, and the direction offset adjustment.

2-12

Page 31

4079-00X

Carriage Motor Drive Data Service Check

Symptom Explanation

You have an error code

indicating a carriage drive

data error.

Conditions That Could Cause This

Symptom

• Carriage belt and idler assembly

• Carriage motor

• Linear encoder/paper width sensor

• Carriage board

• Logic board

Be sure the printer is not installed in an unusually hot or cold environment. See

for installation standards.

ence

FRU Action

1 Belt and Idler

Assembly

2 • Carriage

Motor

• Carriage

Motor Cable

• Linear

Encoder/

Paper Width

Sensor

the Lexmark Color Jetprinter 4079 Plus User’s Refer-

Proper belt tension is required for good escapement.

Check the condition of the belt and idler assembly.

Replace any damaged or worn parts.

The carriage motor and linear encoder/paper width

sensor assembly work together to move the carriage

and maintain proper escapement. Check the carriage motor cable for continuity and then replace the

following FR Us in the order shown to see if the error

code is recovered and the machine completes

POST.

1. Carriage Motor

2. Carriage Motor Cable

3. Linear Encoder/Paper Width Sensor

3 • Carriage

Board

• Carriage Ribbon Cable

• Logic Board

The carriage motor transfers signals to the carriage

board on the logic board. If an incorrect signal is

received and error code is displayed. Chec k the continuity of the carriage ribbon cables. If the cables are

all right, replace the carriage board. If the error

doesn’t go away, replace the logic board. If you

replace the logic board, go to the “Service Adjust-

ment Mode” on page 4-4 and perform the print posi-

tion adjustment, and the direction offset adjustment.

Diagnostic Information

2-13

Page 32

4079-00X

Carriage Position Service Check

Symptom Explanation

You have an error code

indicating a carriage motor

or carriage linear encoder/

paper width sensor error.

Conditions That Could Cause This

Symptom

• Carriage lock

• Carriage drive path obstructed

• Carriage belt or idler

• Carriage motor

• Print timing slit

• Brown carriage ribbon cables

• Linear Encoder/Paper Width Sensor

• Logic board

The carriage should attempt to move when the machine is turned

on. If it does not, go to the “Carriage Motor Drive Data Service

Check” on page 2-13.

FRU Action

1 Carriage Lock The carriage lock is used to hold the carriage in a

2 • Carriage

Drive Belt

• Idler Pulley

locked position during shipping or to prevent unauthorized use. Be sure the lock is in the unlocked

position. Replace it if it is damaged.

Be sure the carriage drive belt and the idler gear are

not damaged.

3 Print Timing Slit The print timing slit has coded carriage escapement

identification on it. If the characters are not printed in

their correct positions, the timing slit may be damaged and must be replaced. Check for dirt, damage,

or folds.

4•Brown Car-

riage Ribbon

Cables

• Carriage Linear Encoder/

Paper Width

Sensor

The carriage linear encoder checks the position of

the carriage by reading timing data on the timing slit.

If the linear encoder is failing, the carriage loses

position and an error codes is displayed.

Check the brown carriage ribbon cables for continuity. If the continuity is incorrect, replace the carriage

linear encoder (Asm 9-2).

2-14

Page 33

4079-00X

FRU Action

5 Logic Board If the characters are printed in their correct position

and you still receive an error code, replace the logic

board. If you replace the logic board, go to the “Ser-

vice Adjustment Mode” on page 4-4 and perform the

print position adjustment, and the direction offset

adjustment.

Check Paper Service Check

Symptom Explanation

Paper insertion problems;

Paper tries to enter

machine; error code 36/

10 displayed.

FRU Action

1 Pickup Roller A dirty pickup roller can cause paper timing prob-

lems. Visually check the paperfeed parts. If necessary, clean the pickup roller with a clean cloth and

isopropyl alcohol.

Conditions That Could Cause This

Symptom

• Dust on pickup roller

• Paperfeed motor drive

• Paper out photo sensor

Diagnostic Information

2-15

Page 34

4079-00X

FRU Action

2 Paper Out

Photo Sensor

Paper Out

Photo Sensor

Cable

Check the paper sensor signal at CNPE pin 1 on the

right connector card, with the card plugged in.

You can manually feed paper to check this signal.

Push the paper lift spring clutch plate (Asm.20-10) to

the right, and turn the rear ejector roller (Asm. 18-2).

The spring plate is under the carriage shaft to the

left of the carriage motor.

Voltage should be high (4-5 V dc) when the paper

sensor arm blocks the light path (paper is not

present).

Voltage should be low (<2 V dc) when the paper

sensor arm does not block the light path (paper is

present).

If the voltage is not correct, remove the card cover

(asm. 4-8), then adjust the paper out photo sensor

holder mounting screw so the sensor is as high in its

slot as possible. Check the voltages again. If the

voltages are still not correct, replace the paper out

photo sensor or the paper out photo sensor cable as

needed.

If the symptom remains, replace the logic board. If you replace the

logic board, go to the “Service Adjustment Mode” on page 4-4 and

perform the print position adjustment, and the direction offset adjustment.

2-16

Page 35

4079-00X

Cover Open Service Check

Symptom Explanation

The Cover Open message is displayed with the

inner cover closed.

FRU Action

1 Inner Cover The inner cover actuates the operator panel cover

interlock lever. Check the cover for damage and be

sure it can fully close.

2 Operator Panel A damaged or obstructed cover interlock lever

located on the operator panel will not allow the cover

open sensor to turn off the Open Cover message.

Remove any obstructions or replace the operator

panel if it is damaged.

3 Logic Board The Open Cover message is sent from the logic

board when the operator panel cover interlock is not

pushed down. Push the lever down, if the Open

Cover message does not go off, replace the logic

board.

If you replace the logic board, go to the “Service

Adjustment Mode” on page 4-4 and perform the print

position adjustment, and the direction offset adjustment.

Conditions That Could Cause This

Symptom

• Inner cover not closed correctly

• Operator panel

• Logic board

Diagnostic Information

2-17

Page 36

4079-00X

Hard Disk Service Check

FRU Action

1 Hard Disk Inter-

face Card

2 Hard Disk Enter the Controller Diagnostic Menu

Be sure the hard disk interface card is correctly

installed and not damaged.

Select Disk Menu and run the Quick Disk T est. If you

get a failure, replace the hard disk.

If you do not have the disk menu in the Diagnostic

Menu, check for proper installation of the hard disk

and the hard disk interface card.I

Head Cap Position Service Check

Symptom

Explanation

You have an error

code or a purge

motor or purge sensor failure.

Turn on the printer and observe the purge motor. If the motor does

not run, go to the “Purge Unit Service Check” on page 2-45.

Conditions That Could Cause This

Symptom

• Purge motor

• Purge sensor, cable assembly

• Purge assembly

• Left connector cable

• Logic board

FRU Action

1 Purge Sensor

Cable Assembly

2-18

1. Center the heads. See “Printhead Uncapping and

Carriage Centering” on page 4-9.

2. Turn off the printer.

3. Remove the purge assembly and lay it on its side.

Use absorbent material to protect from leaking

ink.

4. Check the sensor on the bottom of the purge

assembly. If it is broken, or has dirty contacts,

replace it.

Page 37

4079-00X

FRU Action

2 Purge Assem-

bly

• Left Connector Cable

• Logic Board

Be sure all the ink lines are connected.

With the purge assembly removed and laying on its

side, check the voltage on the contact straps. The

voltage should be +5 V dc with the contacts open.

As the contacts close, the voltage should drop to 0

V dc.

If the voltage is incorrect, check the continuity of the

left connector cable. If the continuity is incorrect,

replace the cables as needed. If the continuity is correct, replace the logic board. If you replace the logic

board, go to the “Service Adjustment Mode” on page

4-4 and perform the print position adjustment, and

the direction offset adjustment.

Diagnostic Information

2-19

Page 38

4079-00X

Head Heater Service Check

Symptom Explanation

You have a head heater

error code.

FRU Action

1 Printhead Use the codes in the“Error Code Table” on page 2-2

to identify the printhead you think may be failing. Be

sure the printhead is seated properly and the head

cover is fully closed.

2 Brown Carriage

Cables

3 • Carriage

Board

• Logic Board

• Printhead

Check the continuity of the brown carriage cables.

Replace if necessary.

Replace the carriage board and run Test Print A to

check the print quality.

If the problem is not corrected, replace the logic

board. Be sure to go to the “Service Adjustment

Mode” on page 4-4 and perform the print position

adjustment, and the direction offset adjustment.

If the problem is still not corrected, replace the print-

head.

Conditions That Could Cause This

Symptom

• Carriage board

• Logic board

• Printhead

• Carriage cables

Head Temp/Heat Pulse Service Check

Symptom Explanation

You have an error code

indicating a head temperature error or heat pulse

resistance error.

2-20

Conditions That Could Cause This

Symptom

• Printhead

• Carriage board

• Logic board

Page 39

4079-00X

FRU Action

1 • Printhead

• Carriage

Board

Use the codes in the“Error Code Table” on page 2-2

to identify the printhead you think may be failing. Be

sure the printhead is seated properly and the head

cover is fully closed.

Check the voltage to the printhead as read by the

analog switch IC2 on the carriage board.Check the

resistance and voltage between each pin and frame

ground. Be sure to turn off the printer when you

check resistance.

Black Head - pin 12 should read 2k - 4k Ohms, and

1.02 - 5.03 V dc. Black head, pin 4 should read 1.74

- 4.46 V dc.

Cyan Head - pin 15 should read 2k - 4k Ohms, and

1.02 - 5.03 V dc. Cyan head, pin 2 should read 1.74

- 4.46 V dc.

Magenta Head - pin 14 should read 2k - 4k Ohms,

and 1.02 - 5.03 V dc. Magenta head, pin 1 should

read 1.74 - 4.46 V dc.

Yellow Head - pin 13 should read 2k - 4k Ohms, and

1.02 - 5.03 V dc. Y ellow head, pin 5 should read 1.74

- 4.46 V dc.

If the signals are incorrect, replace the defective

printhead. If the signals are correct, replace the carriage board.

Diagnostic Information

2-21

Page 40

4079-00X

If the problem is not corrected, replace the logic board. Be sure to go

to the “Service Adjustment Mode” on page 4-4 and perform the print

position adjustment, and the direction offset adjustment.

Host Print Service Check

Symptom Explanation

The printer does not communicate with the host

computer.

FRU Action

1 • Incorrect Pro-

tocol Set

• Controller

Board

Run Test Print A.To enter Controller Diagnostics,

press and hold Menu and Print Buffer while turning

on the printer. After the POST is complete, the first

item in the Controller Diagnostics menu is displayed.

If the test runs successfully, disconnect the serial/

parallel interface cable, install the wrap plug (PN

1319128), and then run the wrap test (see “Paper

Load Test” on page 3-10. If the test fails, replace the

controller board.

Conditions That Could Cause This

Symptom

• Incorrect protocol set

• Controller board

Ink Cartridge Service Check

Symptom Explanation

Conditions That Could Cause This

Symptom

The printer does not

sense an ink cartridge

when one is installed.

• Cartridge detection resistor

• Cartridge sensor cable

• Cartridge sensor

If you are instructed to remove the ink cartridge assembly, it is recommended that you remove all ink cartridges, carefully drain the ink

from the lines into a plastic-lined waste can or absorbent material,

then replace the cartridges and wrap a packet of cleaning cloths or

paper towels over the connector end, secured with a rubber band.

2-22

Page 41

4079-00X

Keep the assembly on a level plane while servicing with the black

cartridge end slightly elevated. Cover any open ink lines with absorbent cloth, secured with a rubber band, when possible.

FRU Action

1 Ink Cartridge The error code should indicate which cartridge is

2 Logic Board Disconnect the CNID connector from the left con-

3 • Sensor Cable

• Ink Cartridge

Sensor

suspected. Check the ink cartridge detection resistor

pad (top left of each cartridge). The resistance

should be 15K to 25K Ohms. If the resistance is

incorrect, replace the ink cartridge.

nector card. With the ink cartridge installed, check

the resistance between the pins designated for each

cartridge sensor (pins 1 and 2; 3 and 4; 5 and 6; 7

and 8). Pin 9 is not used. The resistance should be

correc

15K to 25K Ohms. If the resistance is

replace the logic board, left connector card, and left

connector cable.

If you replace the logic board, go to the “Service

Adjustment Mode” on page 4-4 and perform the print

position adjustment, and the direction offset adjustment.

Remove the ink cartridge assembly . Check the continuity on the sensor cable. Match pin numbers at

both ends of the cable.

t,

If the continuity is correct, replace the ink cartridge

sensor. If the continuity ius incorrect, replace the

sensor cable.

Diagnostic Information

2-23

Page 42

4079-00X

Ink Flow Service Check

Symptom Explanation

You have no ink flow, with

no error code displayed.

Conditions That Could Cause This

Symptom

• Ink Cartridge Supply Lines

• Carriage supply and waste lines

• Purge waste lines

• Ink cartridge waste lines

• Purge Unit

• Ink supply assembly

• Printhead

Important: A long cleaning uses a significant amount of ink. To minimize ink flow while you troubleshoot ink flow problems, it is helpful

to be familiar with normal ink flow. If needed, study the “Ink Supply

Diagram” on page 5-6, and the text on the following page. Start with

the flow of ink from the ink cartridge.

It is also helpful to be familiar with this service check. Read the

entire service check to become familiar with the parts you need to

check. Check as many parts as possible during the long cleaning

rather than performing a long cleaning for each step.

FRU Action

1 • Carriage Ink

Supply

Assembly

• Ink Cartridge

Supply Lines

2 Purge Unit Be sure the purge assembly motor is operating nor-

Perform a Long Cleaning. Be sure the carriage supply lines are full of ink at the cartridge assembly connection (smaller lines). If they are not, check the

carriage ink supply line for blockage. F ollow the lines

to see whether they are filled or empty.

mally. If it is not, replace it.

Be sure the carriage waste lines at the purge

assembly connector are full of ink. If they are not,

replace the carriage ink supply assembly (Asm.

10-1).

Be sure ink flows through the large purge waste

lines when the purge motor runs. If it does not,

replace the purge unit.

2-24

Page 43

4079-00X

FRU Action

3 Carriage Ink

Supply Assembly

4 • Ink Cartridge

Assembly

Waste Lines

• Ink Cartridge

5 Printhead Be sure ink is flowing through the ink supply assem-

Be sure the carriage ink supply assembly waste

lines fill when the purge motor completes its cycle.

The purge unit discharges ink back to the ink cartridge through the waste line in the ink return unit.

Be sure the waste lines are not blocked. Also, be

sure the ink cartridge is good.

bly (asm. 10-1).

Perform a Long Cleaning.

Replace the printhead for the color that fails to flow.

Diagnostic Information

2-25

Page 44

4079-00X

Ink Sensor Service Check

Symptom Explanation

You have problems with

ink sensing. The sensor

may indicate no ink when

a good cartridge is

installed, or may fail to

indicate when the cartridge is empty.

Conditions That Could Cause This

Symptom

• Ink cartridge

• Ink sensor

• Ink sensor cable

• Logic board

If you are instructed to remove the ink cartridge assembly, it is recommended that you remove all ink cartridges, carefully drain the ink

from the lines into a plastic-lined waste can or absorbent material,

then replace the cartridges and wrap a packet of cleaning cloths or

paper towels over the connector end, secured with a rubber band.

Keep the assembly on a level plane while servicing with the black

cartridge end slightly elevated. Cover any open ink lines with absorbent cloth, secured with a rubber band, when possible.

FRU Action

1 Ink Cartridge The ink sensor determines whether an individual ink

cartridge is empty and causes an error code.

Remove the ink cartridge. Hold a cloth over the sensor end, and gently shake the cartridge. If you do not

feel or hear ink movement in the cartridge, replace it.

2-26

Page 45

4079-00X

FRU Action

2 Ink Sensor Check the ink sensor by checking for 5 V dc

between the pins designated for each cartridge sensor on the CNINK connector as you push the sensor

down and up.

Cyan = pins 1 - 2

Magenta = pins 3 - 4

Yellow = pins 5 - 6

Black = pins 7 - 8

To push down the ink sensor: insert a thin screwdriver just above the ink cartridge assembly and

below the paper lift plate, then push the ink sensor

plunger down. The voltage should be low when the

sensor is on (the center of the sensor is up), and

high when the sensor is off (the center of the sensor

is down). If the voltage is correct, replace the ink

sensor.

Diagnostic Information

2-27

Page 46

4079-00X

FRU Action

3 • Sensor Cable

• Logic Board

Check the sensor cable continuity, matching pins on

CNINK at the left connector card with wires to the

ink sensor units. If the continuity is not correct,

replace the sensor cable.

If the continuity is correct, replace the logic board. If

you replace the logic board, go to the “Service

Adjustment Mode” on page 4-4 and perform the print

position adjustment, and the direction offset adjustment.

2-28

Page 47

4079-00X

Logic Board And Related Cables Service Check

Symptom Explanation

You have problems with

the logic board or cables.

.

FRU Action

1•Brown Car-

riage Cable 2

• White Ribbon Cable 2

• Carriage

Board

• Logic Board

Conditions That Could Cause This

Symptom

• System cables

• Carriage board

• Logic board

Follow these steps if 5 beeps are sounded, checking

the error after each action:

1. Check for correct connection of the brown carriage cable 2 to the carriage board and the right

connector card.

2. Check for correct connection of the white ribbon

cable 2 to the right connector card and the logic

board.

3. Check continuity of the white ribbon cable 2 (23

pin) and brown carriage cable 2 (19 pin), checking

pin-for-pin.

4. Replace the carriage board.

5. Replace the logic board.If you replace the logic

board, go to the “Service Adjustment Mode” on

page 4-4 and perform the print position adjust-

ment, and the direction offset adjustment.

Diagnostic Information

2-29

Page 48

4079-00X

FRU Action

2•Brown Car-

riage Cable 1

• White Ribbon Cable 1

• Carriage

Board

• Logic Board

3 • Operator

Panel Cable

• Operator

Panel

• Logic Board

Follow these steps if 6 beeps are sounded, checking

the error after each action:

1. Check for correct connection of the brown carriage cable 1 to the carriage board and the right

connector card.

2. Check for correct connection of the white ribbon

cable 1 to the right connector card and the logic

board.

3. If the problem persists, check continuity of the

white ribbon cable 1 (23 pin) and brown carriage

cable 1 (19 pin), checking pin-for-pin.

4. Replace the carriage board.

5. Replace the logic board. If you replace the logic

board, go to the “Service Adjustment Mode” on

page 4-4 and perform the print position adjust-

ment, and the direction offset adjustment.

Follow these steps if 7 beeps are sounded, checking

the error after each action:

1. Make sure the operator panel cable is correctly

connected at the right connector card.

2. Replace the operator panel. Replace the logic

board. If you replace the logic board, go to the

“Service Adjustment Mode” on page 4-4 and per-

form the print position adjustment, and the direction offset adjustment.

2-30

Page 49

4079-00X

Operator Panel Service Check

Symptom Explanation

Nothing appears on the

display, buttons or LEDs

fail, but the printer starts

POST.

FRU Action

1 Power Supply 1. Disconnect the power supply connector from the

controller board.

2. Remove the controller board.

3. Check for 5 V dc at pin 2 of the CNPOW connector with the connector plugged into the logic

board. If it is not correct, replace the power supply.

Conditions That Could Cause This

Symptom

• Power supply

• Operator panel

• Logic board

• Controller board

2 • Operator

Panel

• Logic Board

1. Disconnect the power supply connector from the

controller board.