Page 1

ExecJet™ II and ExecJet IIc

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

4076-0XX

•Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

4076-0XX

Second Edition (May, 1996)

The following paragraph doesnot apply tothe United Kingdom or any country where such

provisions are inconsistent with local law: LEXMARK INTERNATIONAL,INC.PROVIDES

THIS PUBLICATION“AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not allow disclaimer of expressor implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in later

editions of the publication. Improvements or changes in the products or the programs

described in this publication may be made at any time. Publications are not stocked at the

address given below; requests for publications should be made to your point of purchase.

Comments may be addressed to Lexmark International, Inc., Department D22A/035-3,

740 New Circle Road, Lexington, Kentucky 40550, U.S.A. Lexmark may use or distribute

any of the information you supply in any way it believes appropriate without incurring any

obligation to you.

ExecJet and Lexmark are trademarks of Lexmark International, Inc., registered in the

United States and/or other countries.

AppleTalk and LocalTalk are trademarks of Apple Computer, Inc. registered in the United

States and other countries.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 1994, 1996.

All Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use,

duplication or disclosure by the Government is subject to restrictions as set forth in

subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS252.227-7013 and in applicable FAR provisions: Lexmark International, Inc.,

Lexington, KY 40550.

Page 3

4076-0XX

Contents 1

NoticesandSafetyInformation ............................vi

ElectronicEmissionNotices........................... vi

SafetyInformation...................................viii

General Information .....................................1

PowerConsumption...............................1

Options.........................................2

MaintenanceApproach ............................2

Abbreviations....................................3

UniqueToolsRequiredForService...................3

DiagnosticInformation ...................................4

Start..............................................4

ErrorIndicatorTable...............................5

Power-on-self-test (Post) Sequence ..................7

POSTSymptomTable. ............................8

SymptomTables .................................9

CarrierTransportProblems .....................9

ServiceChecks.....................................11

EnvelopeFeedServiceCheck......................11

FirstPrintLineServiceCheck......................11

MaintenanceStationServiceCheck.................12

Operator Panel Service Check......................13

Paper Feed Service Check ........................14

Paper Path Service Check.........................17

ParallelPortServiceCheck........................18

PowerServiceCheck.............................19

PrintQualityServiceCheck........................20

SimmServiceCheck.............................22

TransportServiceCheck..........................22

DiagnosticAids........................................24

DemoTest.....................................24

PrintFontsTest.................................24

PurgeTest.....................................25

PrintNvram ....................................25

TestPage......................................26

Paper Sensor Test ...............................26

Encoder Sensor Test . . ...........................27

HexPrint.......................................27

ParallelPortTest................................28

InitializeNvram..................................28

Serial Adapter Test...............................29

iii

Page 4

4076-0XX

Repair Information . . . ...................................30

HandlingEsd-sensitiveParts....................... 30

Adjustments....................................... 31

Bi-directionalAlignmentAdjustment................. 31

RemovalProcedures................................ 32

ReleasingPlasticLatches......................... 32

Auto Sheet Feed (ASF) Assembly Removal ........... 33

ASF Envelope Buckler And Pick Roller Hub Removal . . . 33

ASF Right And Left Edge Guide Assemblies Removal. . . 34

ASF Paper Load Lever Removal.................... 34

CarrierRemoval ................................ 34

CarrierTransportBeltRemoval..................... 35

CarrierGuideRemoval........................... 35

CarrierTransportMotorRemoval................... 35

CarrierTransportMotorFrameRemoval ............. 36

EncoderStripRemoval........................... 36

End-of-formsFlagRemoval........................ 37

ExitRollerAssemblyRemoval ..................... 37

EpromRemoval................................. 37

FeedArmAssemblyRemoval...................... 37

InsideIdlerGearsRemoval........................ 38

LargeFeedRollerAssemblyRemoval............... 38

LeftSideFrameRemoval......................... 39

Maintenance Drive And Rocker Assemblies Removal . . . 40

MiddleFrameRemoval........................... 40

Operator Panel Removal. ......................... 40

OutsideIdlerGearsRemoval...................... 41

Paper Ejectors Removal . ......................... 41

Paper Feed Motor Removal ....................... 41

Paper Guide Removal. . . ......................... 41

Paper Release Lever Removal ..................... 42

Power Supply Removal. . ......................... 42

PrintHeadCableRemoval........................ 43

RightSideFrameRemoval........................ 44

Rubber Backer Removal . ......................... 45

SmallFeedRollerAssemblyRemoval............... 45

StarRollerRemoval ............................. 45

SystemBoardRemoval........................... 46

TopCoverRemoval.............................. 47

Connector Locations . ...................................48

System Board Connectors......................... 48

Preventive Maintenance .................................50

Lubrication Specifications ......................... 50

iv

Page 5

4076-0XX

PartsCatalog .........................................51

HowToUseThisPartsCatalog.....................51

Assembly1:Covers ..........................52

Assembly2:Frames..........................54

Assembly3:PaperFeed ......................56

Assembly3:PaperFeed(Cont.) ................58

Assembly4:Electronics .......................60

Assembly4:Electronics(Cont.) .................62

Assembly4Electronics(Cont.)..................64

Assembly5:Carrier ..........................66

Assembly6:CarrierTransport ..................68

Assembly 7: Auto Sheet Feed ..................70

Assembly 8: Maintenance Station ...............72

Assembly9:Options..........................74

Index................................................76

v

Page 6

4076-0XX

Notices and Safety Information 2

References in this publication to products, programs, or services

do not imply that the manufacturer intends to make these

available in all countries in which it operates. Any reference to a

product, program, or service is not intended to state or imply that

only that product, program, or service may be used. Any

functionally equivalent product, program, or service that does not

infringe any existing intellectual property rights may be used

instead. Evaluation and verification of operation in conjunction

with other products, programs, or services, except those

expressly designated by the manufacturer, are the user’s

responsibility.

Electronic Emission Notices

Consult the following list for any emission notices that may apply

in your country.

Federal Communications Commission (FCC) Statement

This printer has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

vi

Page 7

4076-0XX

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult your point of purchase or service representative for

additional suggestions.

The manufacturer is not responsible for any radio or television

interference caused by using other than recommended cables or

by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s

authority to operate the equipment.

To assure compliance with FCC regulations for a Class B

computing device, use a properly shielded and grounded

Lexmark or IBM parallel interface cable, such as Lexmark part

number 1525612.

Use of a substitute cable not properly shielded and grounded

may result in violation of FCC regulations.

Industry Canada Compliance Statement

This Class B digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Avis de conformité aux normes d’Industrie Canada

Cet appareil numérique de la classe B respecte toutes les

exigences du Règlement sur le matériel brouilleur du Canada.

The United Kingdom Telecommunications Act 1984

This apparatus is approved under the approval number NS/G/

1234/J/100003 for the indirect connections to the public

telecommunications systems in the United Kingdom.

vii

Page 8

4076-0XX

Japanese VCCI Notice

European Community (EC) Electromagnetic Compatibility

Directive

This product is in conformity with the protection requirements of

EC Council directive 89/336/EEC on the approximation of the

laws of the Member States relating to electromagnetic

compatibility.

A declaration of conformity with the requirements of the Directive

has been signed by the Director of Manufacturing and Technical

Support, Lexmark International, Ltd., Boigny, France.

This product satisfies the Class B limits of EN 55022.

Safety Information

• The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and

personal injur y during disassembly and servicing of this

product. Professional service personnel should understand

this and take necessary precautions.

• The safety features of some parts may not always be

obvious. Therefore, replacement parts must have the

identical or equivalent characteristics as the original parts.

viii

Page 9

4076-0XX

Sicherheitshinweise

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

• Ersatzteile müssen gleiche oder gleichwertige Merkmale wie

die Originalteile aufweisen, da nicht immer offensichtlich ist,

welche Teile des Geräts Sicherheitsmerkmale aufweisen.

Consignes de Sécurité

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

• Les normes de sécurité de certaines pièces n'étant pas

toujours explicites, les pièces de rechange doivent être

identiques ou conformes aux caractéristiques des pièces

d'origine.

Norme di sicurezza

• Le informazioni riguardanti la manutenzione di questo

prodotto sono indirizzate soltanto al personale di assistenza

autorizzato.

• Durantelo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

ix

Page 10

4076-0XX

• Poiché non tutti i pezzi di ricambio garantiscono la stessa

sicurezza, questi devono avere caratteristiche identiche o

equivalenti a quelle dei pezzi originali.

Pautas de Seguridad

• La información sobre el mantenimiento de este producto

está dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

• Los dispositivos de seguridad de algunas piezas no siempre

pueden reconocerse a simple vista. Por lo tanto, los

recambios deben poseer características idénticas o

equivalentes a las de las piezas originales.

Informações de Segurança

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto.Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

• Os dispositivos de segurança de algumas peças poderão

não ser sempre suficientemente evidentes. Assim, as peças

sobressalentes devem possuir características idênticas ou

equivalentes às peças originais.

Informació de Seguretat

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada

a ningú que no ho sigui.

x

Page 11

4076-0XX

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest

producte. El personal professional ha d’estar-ne assabentat i

prendre les mesures convenients.

• Les característiques de seguretat d’algunes de les peces

poden no ser òbvies. Per tant, les característiques dels

recanvis hauran de ser idèntiques o equivalents a les de les

peces originals.

Chinese Safety Information

xi

Page 12

4076-0XX

Korean Safety Information

xii

Page 13

4076-0XX

General Information 3

This manual is used to service both the IBM ExecJet II by Lexmark

4076 and the ExecJet IIc 4076 printers. The ExecJet IIc is capable of

using a color print cartridge or a black print cartridge. The ExecJet II

uses only a black print cartridge.

Both the Execjet II and the ExecJet IIc are general purpose highquality ink jet printers with a customer-replaceable print cartridge

containing the ink and the print head. The black pr int cartridge has a

total of 56 nozzles in the print head and can print at 16.7 ips in Letter

Quality mode and 30.0 ips in Draft m ode. With the black print cartridge installed, the printer prints in two directions with a resolution of

300 x 300 pels per inch in text and graphics. Print Quality Enhancement Technology (PQET) smooths the edges.

The color print cartridge used in the ExecJet IIc has a total of 48

nozzles in the print head using three major colors; cyan, magenta,

and yellow. Printing is from left-to-right with the color print cartridge

installed and print speeds are 12.0 ips in Letter Quality mode and

24.0 ips in Draft mode.

The ExecJet IIc electronically senses for the correct print cartridge

when a print job is sent to the printer. The Ink Low and Busy lights

will flash alternately to indicate to the user the correct print cartridge

must be installed.

Both printers can handle a variety of paper sizes as well as envelopes and other media using an integrated automatic sheet feeder

and manual insert tray.

Power Consumption

• Less than 2 Watts - power off and power to the printer

• 7.5 Watts - Idle Mode (power on - not printing)

• 12 Watts - Printing (average)

• 25 Watts - Printing (peak)

General Information 1

Page 14

4076-0XX

Options

• The following options are available.Some options are not avail-

able in every country. Contact your point of purchase for options

available in your country.

• Serial Adapter

• Flash Memory Simm - 256K, 1MB, 2MB

• SRAM SIMM - 256K

Maintenance Approach

The diagnostic information in this manual will lead you to the correct

field replaceable unit (FRU) or part. Use the error code charts,

symptom index, service checks, and diagnostic aids to determine

the symptom and repair the failure. Begin with “Start” on page 2-2.

This printer can be serviced without being connected to a host.

After you complete the repair, perform tests as needed to verify the

repair.

2

Page 15

4076-0XX

Abbreviations

CE Customer Engineer

CPU Central Processing Unit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EP Electrophotographic Process

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LASER Light Amplification by Stimulated Emission

of Radiation

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

MAP Maintenance Analysis Procedures

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

PC Photoconductor

PCA Printed Circuit Assemblies

PICS Problem Isolation Charts

PIXEL Picture Element

POST Power-On Self Test

PQET Print Quality Enhancement Technology

PSO Printer Sharing Option

SRAM Static Random Access Memory

UPR Used Parts Replacement

V AC Volts alternating current

V DC Volts direct current

ZIF Zero Insertion Force

Unique Tools Required For Service

Wrap Plug (Parallel) P/N = 1319128

General Information 3

Page 16

4076-0XX

Diagnostic Information 4

Use the error code charts, symptom index, service checks, and

diagnostic aids in this chapter to determine the failing part in a malfunctioning printer.

Start

Service error indications show up as flashing operator panel lights. A

flashing Draft light always indicates a service related error. If your

machine has an error indication, locate the pattern of alternating

flashing lights in the following table and take the indicated action.

If your machine does not have an error indicator, go to “Power-on-

self-test (Post) Sequence” on page 7. If an error indicator appears

while you are working on the machine, go to the error indicator table

and take the indicated action for that error.

The printer also logs the last occurring error. If you think you may

have an intermittent error, or the error indicator lights have been

cleared, you can retrieve the error from the Test Page printout:

1. Run the “Test Page” on page 26.

2. The error is the last number to print on the page in the lower right

corner. Note the number.

3. Run “Initialize Nvram” on page 28 to clear the log (the number

may not be the result of a current error).

4. Run Test Page again to verify a current error. If no error prints,

go to “Power-on-self-test (Post) Sequence” on page 7.

Diagnostic Information 4

Page 17

4076-0XX

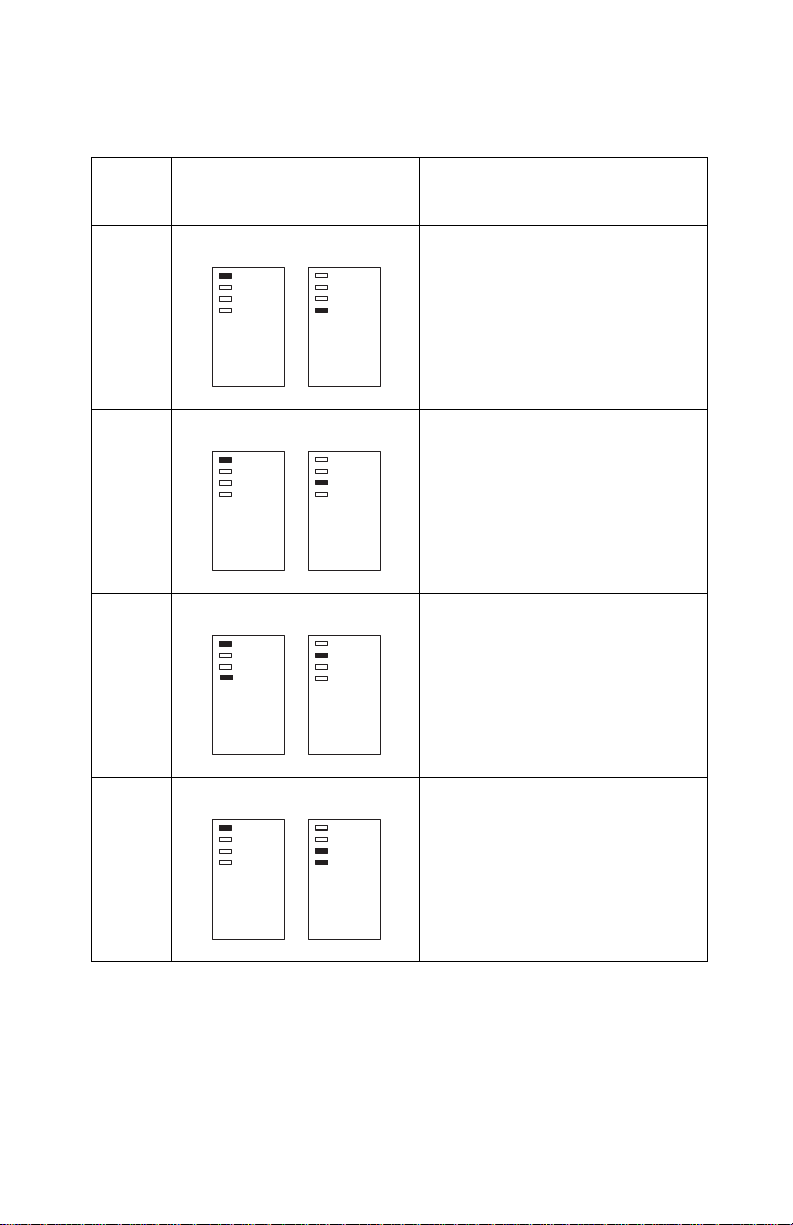

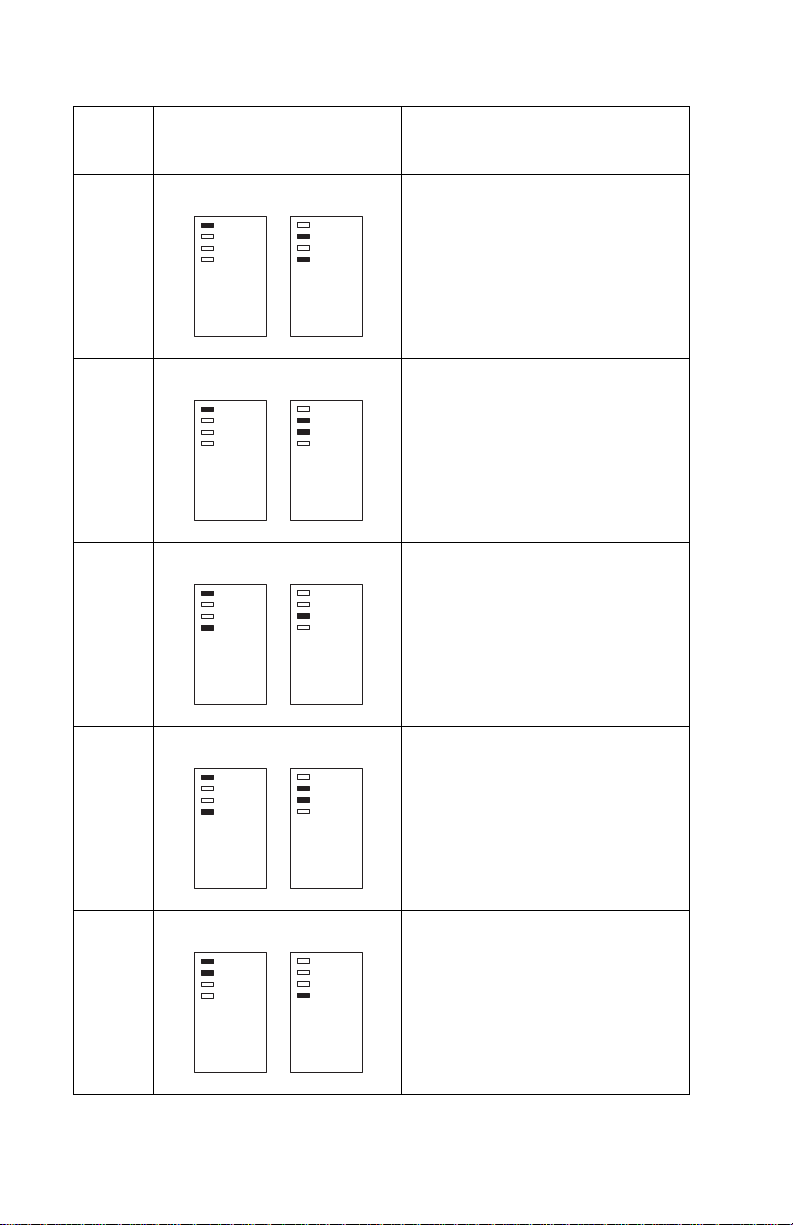

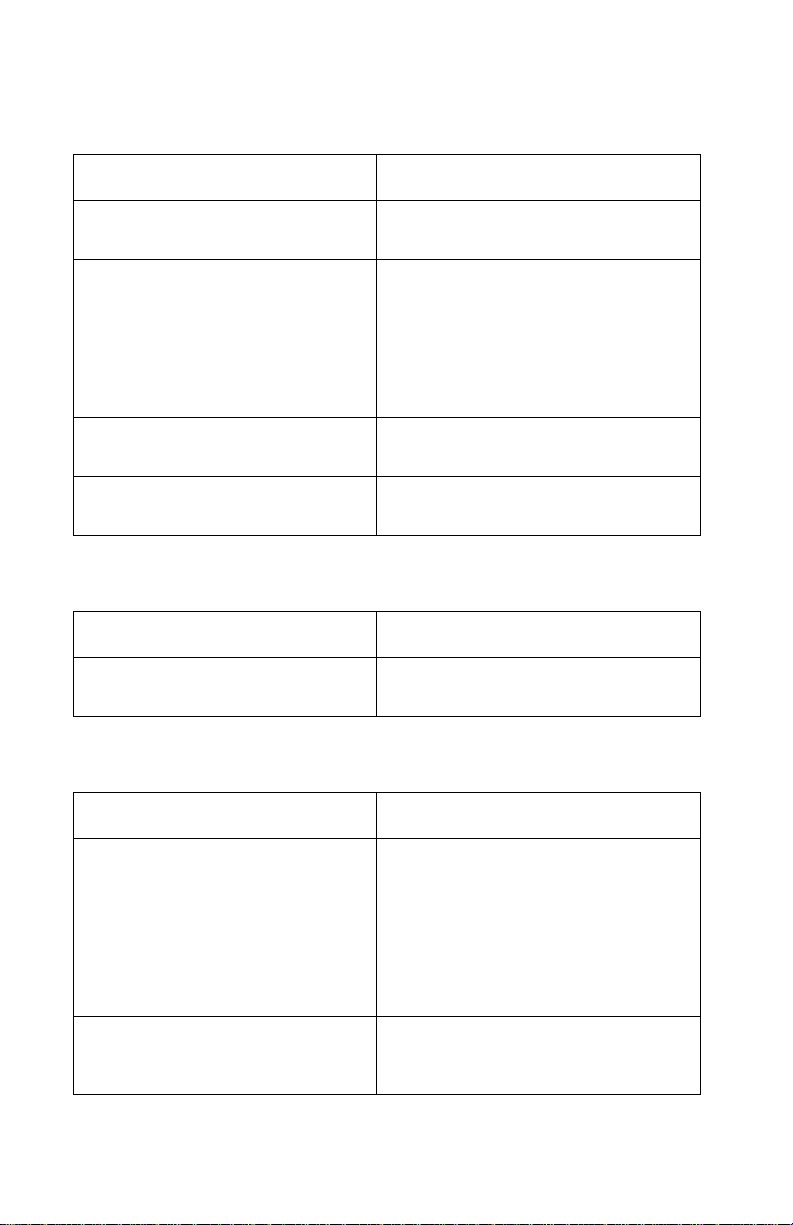

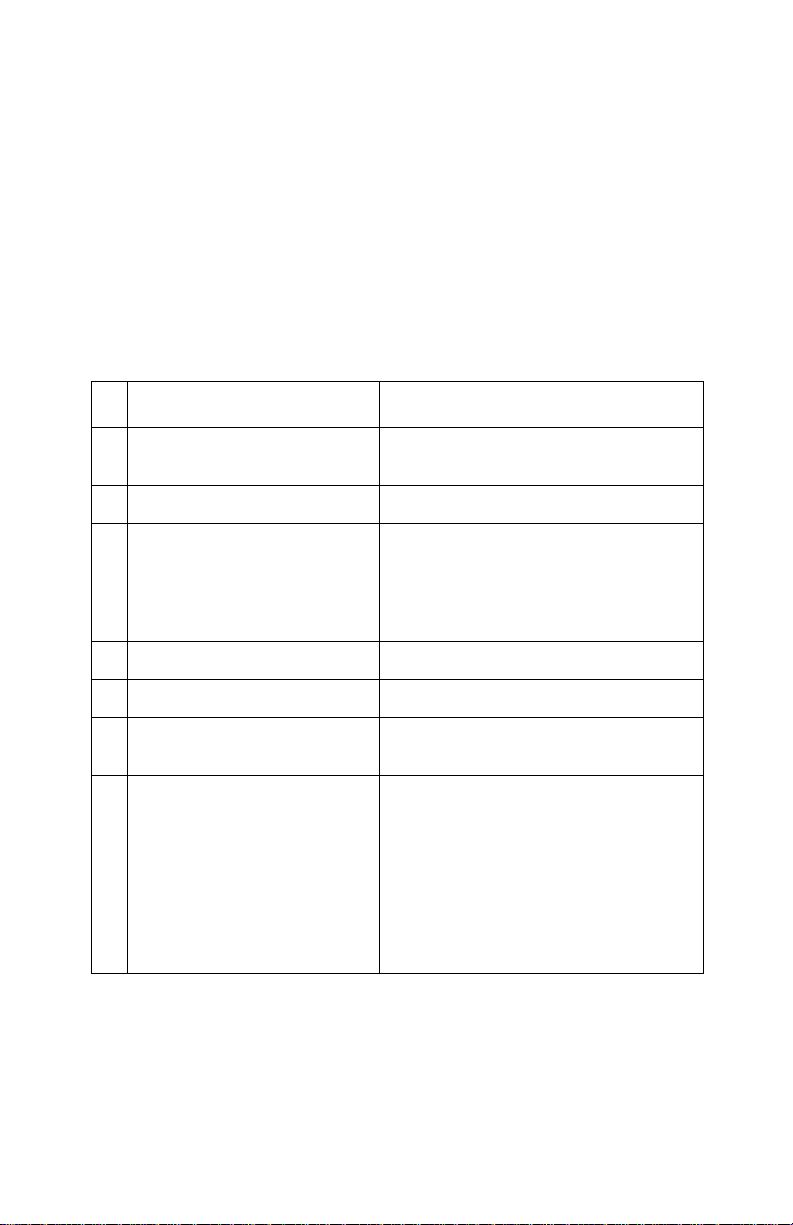

Error Indicator Table

Error

Code

64

65

66 to

78

No

Log

Alternating Light Pattern Action

Replace the EPROM and/or

system board.

Replace the EPROM and/or

system board.

Replace the EPROM and/or

system board.

79 Replace the EPROM and/or the

system board.

Diagnostic Information 5

Page 18

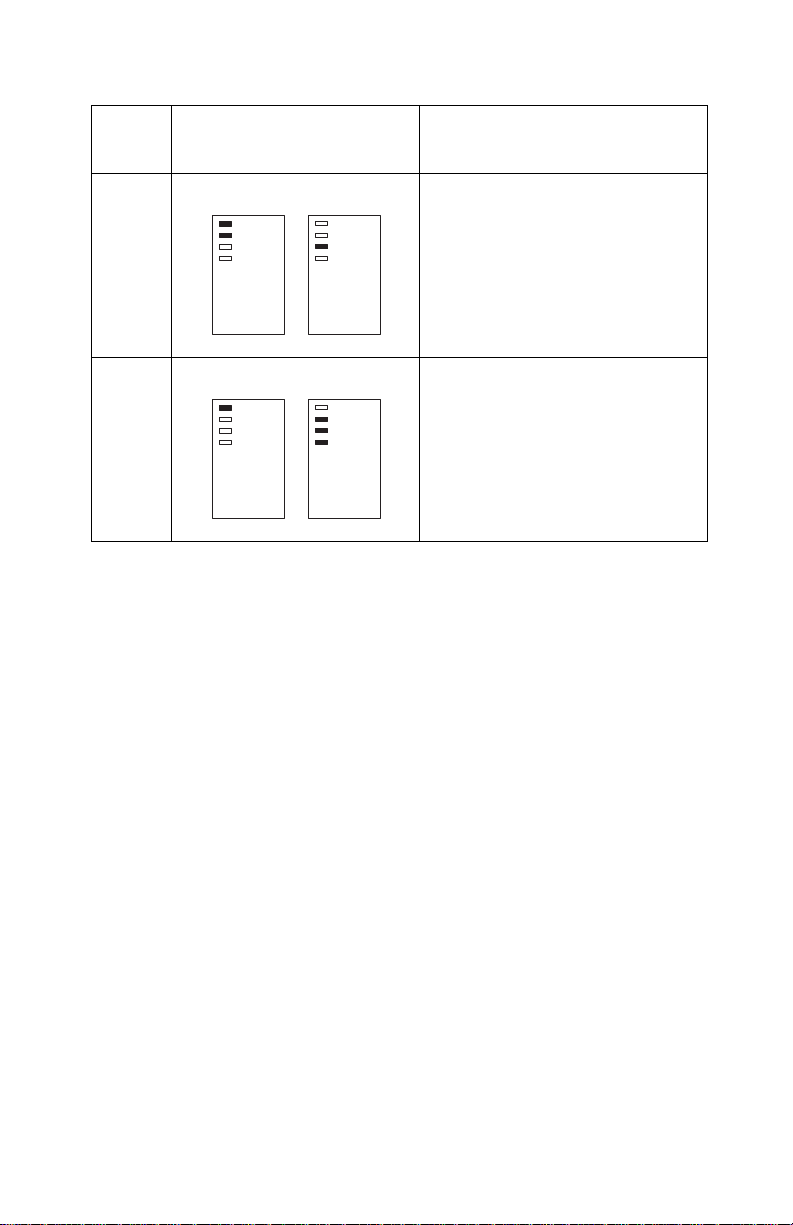

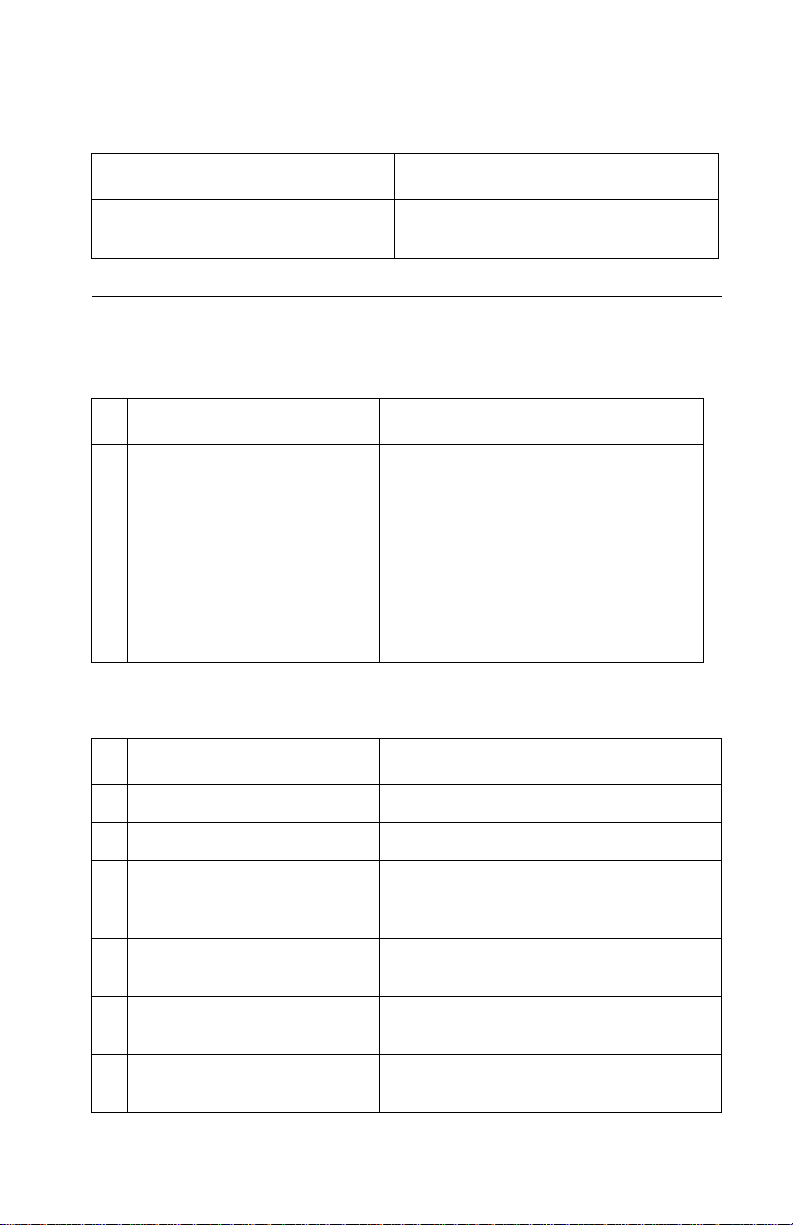

4076-0XX

Error

Code

80 Go to the “Maintenance Station

81 Go to the “Transport Service

85 Go to the “Transport Service

Alternating Light Pattern Action

ServiceCheck”onpage12.

Check” on page 22.

Check” on page 22.

84 86

87 88

89 Go to the “Transport Service

Go to the “Simm Service Check”

on page 22.

Check” on page 22.

6

Page 19

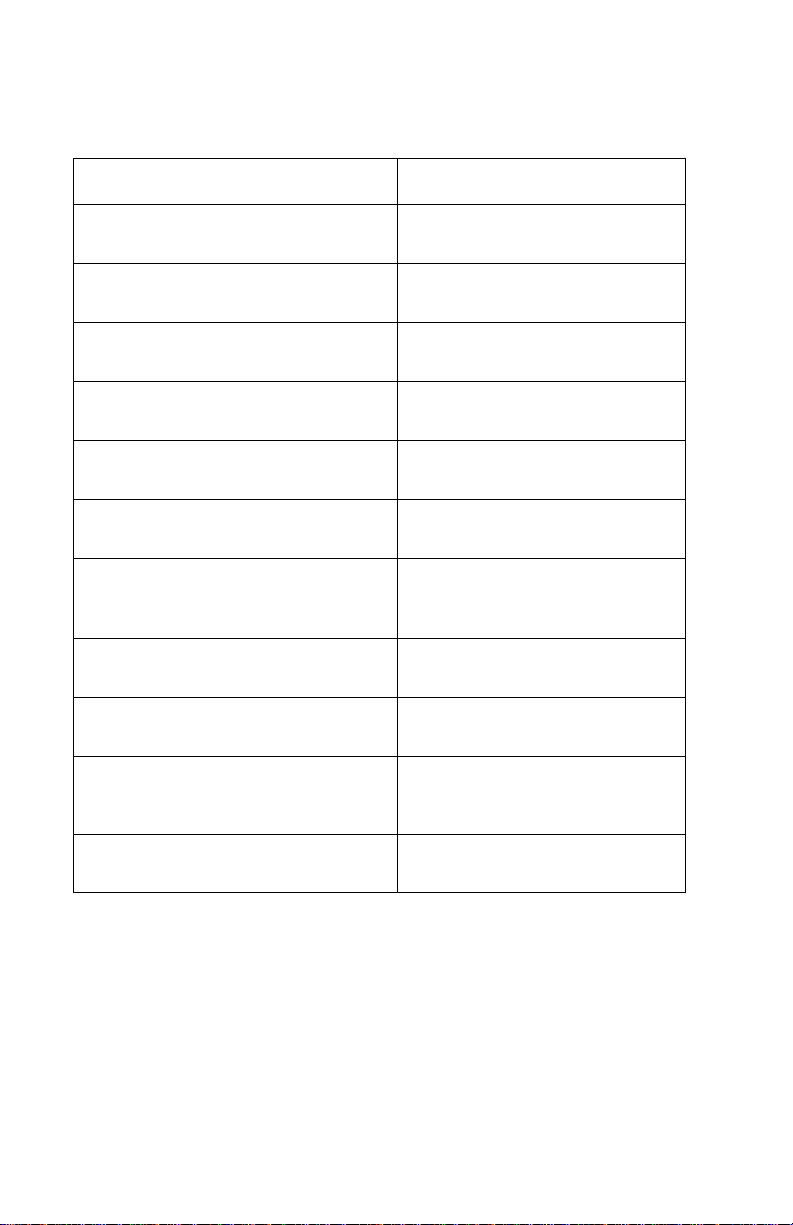

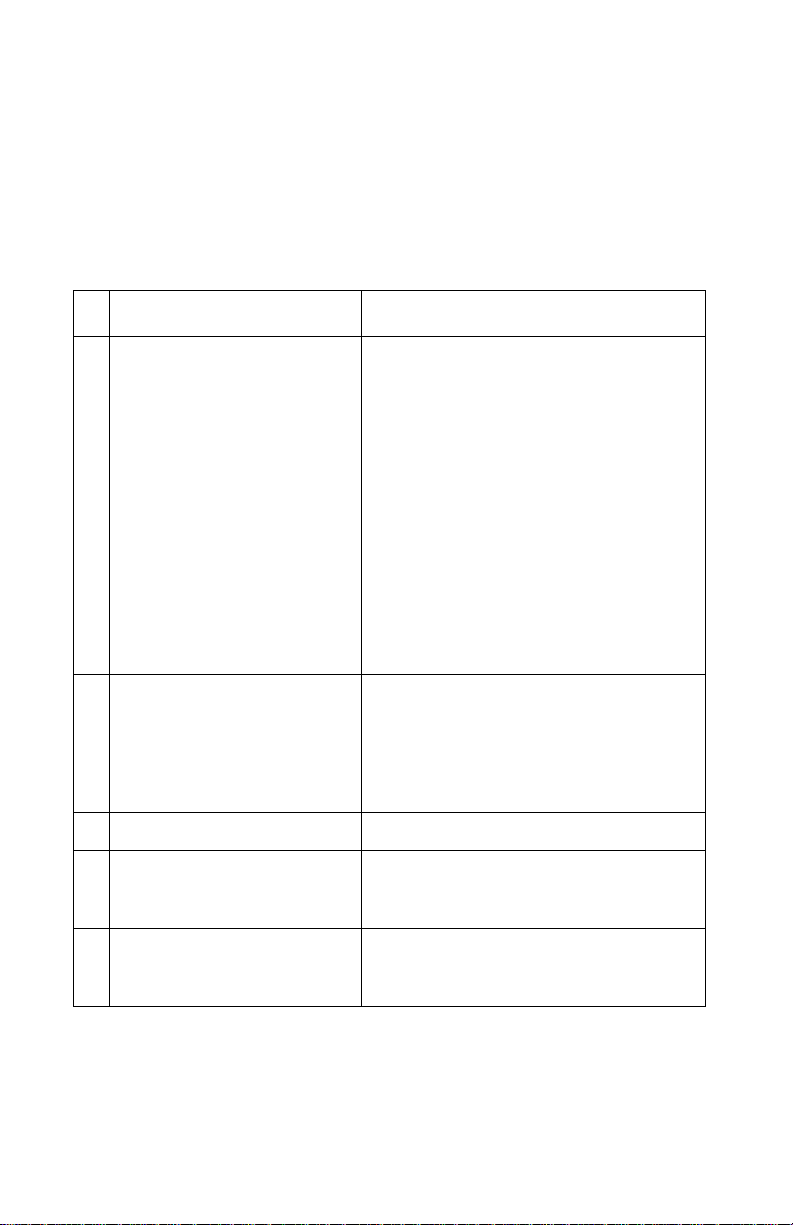

4076-0XX

Error

Code

90 Go to the “Transport Service

127

and

up

Alternating Light Pattern Action

Check” on page 22.

Go to the “Maintenance Station

Service Check” on page 12.

Power-on-self-test (Post) Sequence

When you turn the printer on it performs a POST. Turn your machine

on and check for a correct POST operation by observing the following:

1. The power light comes on.

2. All four function lights come on and then go off one light at a time

starting with the Busy light. The Draft light may take longer than

the others to go off.

3. The paper feed gears turn.

4. The carrier moves to the left and right at least one time.

5. The maintenance station cleans and caps the print head.

6. All motors stop and the power light stays on.

If your machine completes POST with no errors, go to the. “Symp-

tom Tables” on page 9, locate your symptom and take the indicated

action.

If your machine does not complete POST locate your symptom in

the following table and take the indicated action

Diagnostic Information 7

Page 20

4076-0XX

POST Symptom Table.

Symptom Action

No lights come on and no motors run Go to the “Power Service

Check” on page 19.

The Powerlight is the only light that

comes on

One or more operator panel lights do

not come on

One or more operator panel lights do

not go off

Feeds paper Go to the “First Print Line Ser-

Paper feed gears do not turn Go to the “Paper Feed Service

Feeds paper and prints Go to the “ Note: if the failure

Carrier doesn’t move Go to the “Transport Service

Maintenance station doesn’t move Go to the “Maintenance Station

The printer prints “HARDWARE

ERROR HAVE PROTOCOL CONVERTER SERVICED”

The carrier moves then error 85

appears

Go to the “Operator Panel Ser-

vice Check” on page 13.

Go to the “Operator Panel Ser-

vice Check” on page 13.

Go to the “Operator Panel Ser-

vice Check” on page 13.

vice Check” on page 11.

Check” on page 14.

remains, replace the system

board” on page 12.

Check” on page 22.

ServiceCheck”onpage12.

Replace the serial adapter.

Replace the system board.

8

Page 21

4076-0XX

Symptom Tables

Locate your symptom in the following tables and take the appropriate action.

Carrier Transport Problems

SYMPTOM ACTION

• No carrier movement

• Slow carrier movement

• Carrier stops

Go to the “Transport Service Check”

on page 22.

Communications Problem

SYMPTOM ACTION

Printer not communicating with

host.

Go to the “Parallel Port Service

Check” on page 18.

Maintenance Station Problems

SYMPTOM ACTION

• Maintenance station doesn’t

move

• Failsto cap fails to cap the print

head the print head

• Fails to clean the print head

Go to the “Maintenance Station Ser-

vice Check” on page 12.

Operator Panel Problems

SYMPTOM ACTION

• Panel light(s) not working

• Panel button(s) not working

• Power Lights the only light that

comes on

• Panel cover closed, open functions not working

Go to the “ Note: if the failure

remains, replace the system board”

on page 12.

Diagnostic Information 9

Page 22

4076-0XX

Paper Feed Problems

SYMPTOM ACTION

Paper fails to stop at first print

line

• Fails to pick paper

• Picks more than one sheet of

paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper feed

Envelopes fail to feed Go to the “Envelope Feed Service

Paper skews Go to the “Paper Path Service

Go to the “First Print Line Service

Check” on page 11.

Go to the “Paper Feed Service

Check” on page 14.

Check” on page 11.

Check” on page 17.

Power Problems

SYMPTOM ACTION

No power in machine, no lights,

no motors

Go to the “Power Service Check” on

page 19.

Print Quality Problems

SYMPTOM ACTION

• Voids in characters

•Lightprint

• Prints off the page

• Prints satellites

• Carrier moves but does not print

• Print head drying out prematurely

• Vertical alignment off

• Ink smearing

• Vertical streaks on paper

• Print lines crowded

Go to the “Print Quality Service

Check” on page 20.

Go to the “Paper Feed Service

Check” on page 14.

10

Page 23

4076-0XX

SIMM Problem

SYMPTOM ACTION

Can’t write to SIMM Go to the “Simm Service Check” on

page 22.

Service Checks

Envelope Feed Service Check

FRU OR PROCEDURE ACTION

1 Envelope Loading Be sure the envelope guides have

been turned to the envelope load

positions

Besuretheenvelopeguidesare

against the envelopes

Go to and perform the “Paper Feed

Service Check” on page 14.

First Print Line Service Check

FRU OR PROCEDURE ACTION

1 End-of-Forms Flag Check the flag for binds or damage.

2 End-of-Forms Sensor Check the sensor for dirt.

3 System Board Perform the “Paper Sensor Test” on

page 26 to check the end-of-forms sen-

sor.

4 Feed Arm Assembly Check all parts of the feed arm assem-

bly for binds, wear, or damage.

5 Software Setting Use Toolkit, on the setup diskette, to

6 Operator Panel Go to the “ Note: if the failure remains,

adjust the Top of Form setting.

replace the system board” on page 12.

Diagnostic Information 11

Page 24

4076-0XX

Maintenance Station Service Check

The maintenance station has two functions:

1. Cleans the print head nozzles during the print operation.

2. Seals the print head when it is not being used to prevent the nozzles from drying..

FRU OR PROCEDURE ACTION

1 Maintenance Drive Assem-

bly

2 System Board Turn the printer off and disconnect J4

3 Maintenance Rocker Am. Check for binds or wear.

4 Wiper A worn wiper will cause degraded print

Disconnect J4 from the system board.

Check for 18 ohms (±4 ohms) between

pins 1 and 2 at the motor. If the reading

is incorrect, replace the maintenance

drive assembly,

Check for motor pins shorted to the

motor housing. If you find a shorted pin,

replace the maintenance drive assembly. If the symptom remains, replace the

system board.

Abindinthedriveassemblycanprevent

the motor from turning. Check for binds

and loose or worn parts in the drive

assembly. Also check the motor gear

from the system board. Turn the printer

on and check for a pulse of 15 V dc

between J4-1 and ground on the system

board as the printer goes through

POST.

quality just after a maintenance cleaning. Check for loose or worn wiper.

5 Cap A worn cap will cause the print head

nozzles to dry and clog. Check for loose

or worn cap.

Note: if the failure remains, replace the system board

12

Page 25

4076-0XX

Operator Panel Service Check

FRU OR PROCEDURE ACTION

1 Power Supply Disconnect J11 from the system

board and check the following voltages on the power supply cable:

J11-1 to GND = +5V dc

J11-3 to GND = +24V dc

If you do not have correct voltage,

replace the power supply. Be sure to

unplug the machine before you reconnect the power supply to the system

board.

2 System Board Turn the printer on. Check for +5 V dc

at test point CE/TP near the operator

panel connector on the system board

3 Operator Panel Cover The operator panel cover actuates

the operator panel sensor on the

operator panel. Check the cover for

any broken parts. Check the operator

panel sensor for dirt.

4 Operator Panel Card

Operator Panel Cable

Check the operator panel cable for

continuity. If the cable is good,

replace the operator panel. If the

symptom remains, replace the system board.

Diagnostic Information 13

Page 26

4076-0XX

Paper Feed Service Check

If your machine does not have paper jam problems, go on to the service check. If your machine does have a paper jam problem, examine it for the following before you begin the service check.

• Check the entire paper path for obstructions.

• Make sure there is not too much paper in the ASF.

• Make sure the correct type of paper is in the machine.

• Check for static in the paper.

• Make sure the rear of the carrier guide is on top of the paper

guide.

FRU OR PROCEDURE ACTION

1 System Board With J5 disconnected and power on,

check for +24 V dc between J5-3 and

ground, and between J5-4 and

ground on the system board. If the

voltage is not present, check for

motor pins shorted to the motor housing. If you find a shorted pin, replace

the motor. If you still have a failure

after replacing the motor, replace the

system board.

14

Page 27

4076-0XX

FRU OR PROCEDURE ACTION

2 Paper Feed Motor Anoisy or chattering motor or a motor

that fails to turn, can be caused by:

• An open or short in the motor

• An open or short in the motor driver

on the system board

• Abind in the paper feed mechanism

Check for 100 ohms (±20 ohms)

between the following pins on the

motor:

Pin 1 to Pin 4

Pin 2 to Pin 4

Pin 3 to Pin 5

Pin 3 to Pin 6

If the readings are incorrect, replace

the motor. Check for motor pins

shorted to the motor housing. If you

find a shorted pin, replace the motor.

If the failure remains, replace the system board.

Although the paper feeds in a forward

direction only, the paper feed motor

turns in two directions. If the paper

feed motor turns in one direction only,

replace the system board. Binds in

thepaperfeedmotororgeartraincan

cause intermittent false paper jam

errors. Remove the paper feed motor

and check the shaft for binds Also

check for loose or worn motor gear

3 Gears Check for binds in the gear train and

paper feed mechanism. To do this,

rotate the largest gear by hand. If you

noticeabindisolateitbyremoving

thesmallidlergearontheoutsideof

the right side plate. Replace any worn

or binding gears, rollers, or bearings.

Diagnostic Information 15

Page 28

4076-0XX

FRU OR PROCEDURE ACTION

4 Feed Arm Assembly At the beginning of the paper feed

operation, the paper feed motor

reverses momentarily to allow the

feed arm pawl to drop off the home

position notch in the ASF side plate. If

the pawl fails to drop off the notch,

check the feed arm assembly for

binds, and worn or broken parts.

5 Auto Sheet Feeder Check the following for wear or dam-

age:

Pick Rollers

Envelope Bucklers

All parts inside the left and right edge

guides

6 End-of-Forms Flag Check for binds or damage.

7 Star Rollers Check for worn or binding rollers.

Check for broken star roller springs.

8 Ejectors After the paper exits from the exit roll-

ers, the paper feed motor reverses

causing the feed arm pawl to restore

tothehomepositionintheASFside

plate. At the same time, the paper

ejectors move the last sheet of paper

into the exit tray. If the ejectors do not

moveor restore, checkthem for worn,

loose, or broken parts.

16

Page 29

4076-0XX

Paper Path Service Check

Examine the machine for the following before you begin this service

check:

• Check the entire paper path for obstructions.

• Be sure the paper guides are not worn or broken and are posi-

tioned against the paper without binding or buckling the paper.

• Be sure the correct type of paper is in the machine.

• Be sure the rear of the carrier guide is on top of the paper guide.

FRU OR PROCEDURE ACTION

1 Large and Small Feed Roll-

ers

2 Large Feed Roller Springs Check for damage.

3 Auto Sheet Feeder Check the following for wear or dam-

4 End-of-Forms Flag Check for binds or damage.

5 ExitRoller Checkforwearorbinds.

6 Star Rollers Check for wear or binds. Check for

7 Ejectors After the paper exits from the exit roll-

Check for wear and binds.

age:

Envelope Bucklers

All parts inside the left and right edge

guides

broken star roller springs

ers, the paper feed motor reverses

causing the feed arm pawl to restore

tothehomepositionintheASFside

plate. At the same time, the paper

ejectors move the last sheet of paper

into the exit tray. If the ejectors do not

restore, check them for worn, loose,

or broken parts.

Diagnostic Information 17

Page 30

4076-0XX

Parallel Port Service Check

FRU OR PROCEDURE ACTION

1 Parallel Port Run a test page to be sure the printer

can print. Run the “Parallel Port Test”

on page 28. If the test fails, replace

the system board.

2 Serial Adapter Check the serial adapter green light.

If the light is off, replace the serial

adapter.

Run the “Serial Adapter Test” on

page 29. Compare the printout of the

switch setting configuration to the

switch settings on the serial adapter.

If they do not match, the switches

could be failing. Try running the Serial

Adapter Test again. If the printout still

doesn’t match the switchsettings,or if

you don’t get a printout replace the

serial adapter.

18

Page 31

4076-0XX

Power Service Check

FRU OR PROCEDURE ACTION

1 Power Supply Disconnect J11 from the system

board and check the following voltages on the power supply cable:

J11-1 to GND = +5V dc

J11-3 to GND = +24 V dc

If you do not have correct voltage,

replace the power supply. Be sure to

unplug the machine before you reconnect the power supply to the system

board.

2 Operator Panel With the power button depressed,

check for 0 ohms at J10-11 on the

front of the operator panel connector.

If the reading is incorrect, check the

operator panel cable for continuity. If

the cable has continuity, replace the

operator panel.

3 Print Head Cable

Simm Card

Parallel Cable

4 System Board If the symptom has not changed,

Turn off the printer. Disconnect one of

the listed components and turn on the

printer. Look for a symptom change.

Check the failing part for shorts and

replace as necessary. Repeat this

procedure for the remaining listed

parts.

replace the system board.

Diagnostic Information 19

Page 32

4076-0XX

Print Quality Service Check

FRU OR PROCEDURE ACTION

1 Print Cartr idge Be sure the machine has a known

good print cartridge.

2 Print Head Carrier Assembly Reseat the print head cable in the

3 Purge Test Perform the “Purge Test” on page 25.

system board and check the following

parts for wear or damage:

Print Cartridge Latch

Latch Spring

Carrier

Look for a break in the diagonal line

at the bottom of the test pattern. A

broken line indicates one or more

print nozzles are not working. Run the

test again to verify the failure If there

are even breaks in the diagonal line

similar to the pattern shown below,

replace the system board.

If there is a single break or random

breaks in the diagonal line check the

following:

• Print head cable - check the goldplated contacts on the end of the

cable that connects to the carrier for

dirt and wear. Use only a clean dry

cloth to clean the contacts. Also

check the cable for damage. You

mayneedtoremovethecablefrom

the carrier to inspect it.

• Rubber Backer - a worn rubber

backer will result in poor contact

between the print head cable and

the print cartridge. Check the rubber backer for wear

20

Page 33

4076-0XX

FRU OR PROCEDURE ACTION

4 Maintenance Station Intermittent nozzle failures can be

caused by worn parts in the maintenance station. Go to and perform the

“Maintenance Station Service Check”

on page 12, then return to this check.

5 Paper Feed Ink smudging and smearing can be

caused by paper problems or problems in the paper feed area. Check:

• Correct type of paper is in the

machine. Also check the paper for

curl and wrinkles.

• Feed roller for wear, dirt, or looseness

• Gears for wear or binds

• Paper path for obstructions

• Star rollers for binds or dirt. The exit

roller and star rollers keep tension

on the paper by moving slightly

faster than the feed rollers. A binding star roller can put vertical marks

on the paper.

6 Transport Blurred print and voids can be caused

by problems in the transport area.

Check the following:

• Transport belt for wear.

• Carrier guide and carrier guide rod

for wear or dirt.

• Idler pulley parts for wear, damage,

or looseness.

•Encoderstripforwearordirt.

7 BiDirectional Alignment Uneven vertical lines can be adjusted

by performing the “Bi-directional

Alignment Adjustment” on page 31.

Diagnostic Information 21

Page 34

4076-0XX

Simm Service Check

FRUU or PROCEDURE Action

1 SIMM Card Try the following:

1. Reseat the SIMM card.

2. Use Toolkit, on the setup diskette,

to format the SIMM card.

3. Try a known good SIMM card. If

the failure continues, replace the

system board.

Transport Service Check

FRU OR PROCEDURE ACTION

1 Transport Motor Check the motor for binds, or loose

motor pulley.

Disconnect the transport motor (J6)

from the system board. Check for 8 to

18 ohms between pins 1 and 2 on the

motor cable. If the reading is incorrect, replace the motor.

Check for motor pins shorted to the

motorhousing.Ifyoufindapin

shorted to the housing, replace the

motor. If the failure remains, replace

the system board.

2 System Board Turn the printer off and disconnect J6

from the system board. Turn the

printer on and check for a pulse of 3

to 5 V dc between J6-1 and ground

and between J6-2and ground on the

system board as the machine goes

through POST.

3 Transport Belt

Carrier Guide or Guide Rod

Idler Pulley Parts

Cable Clip

4 Encoder Strip Check for wear and dirt.

Check for worn, loose or broken

parts. Clean the carrier guide rod. Do

not lubricate the rod or the carrier rod

bearings. Check for obstructions

blocking carrier movement.

22

Page 35

4076-0XX

FRU OR PROCEDURE ACTION

5 Print Head Cable Be sure connector J1 is fully seated.

Check the cable for damage.

6 Encoder Strip

Print Head Cable,

System Board

7 Maintenance Station A problem with the maintenance sta-

Perform the “Encoder Sensor Test” on

page 27. If you cannot enter the test,

replace the system board.

tion can cause carrier movement

problems at the right margin. Go to

the “Maintenance Station Service

Check” on page 12.

Diagnostic Information 23

Page 36

4076-0XX

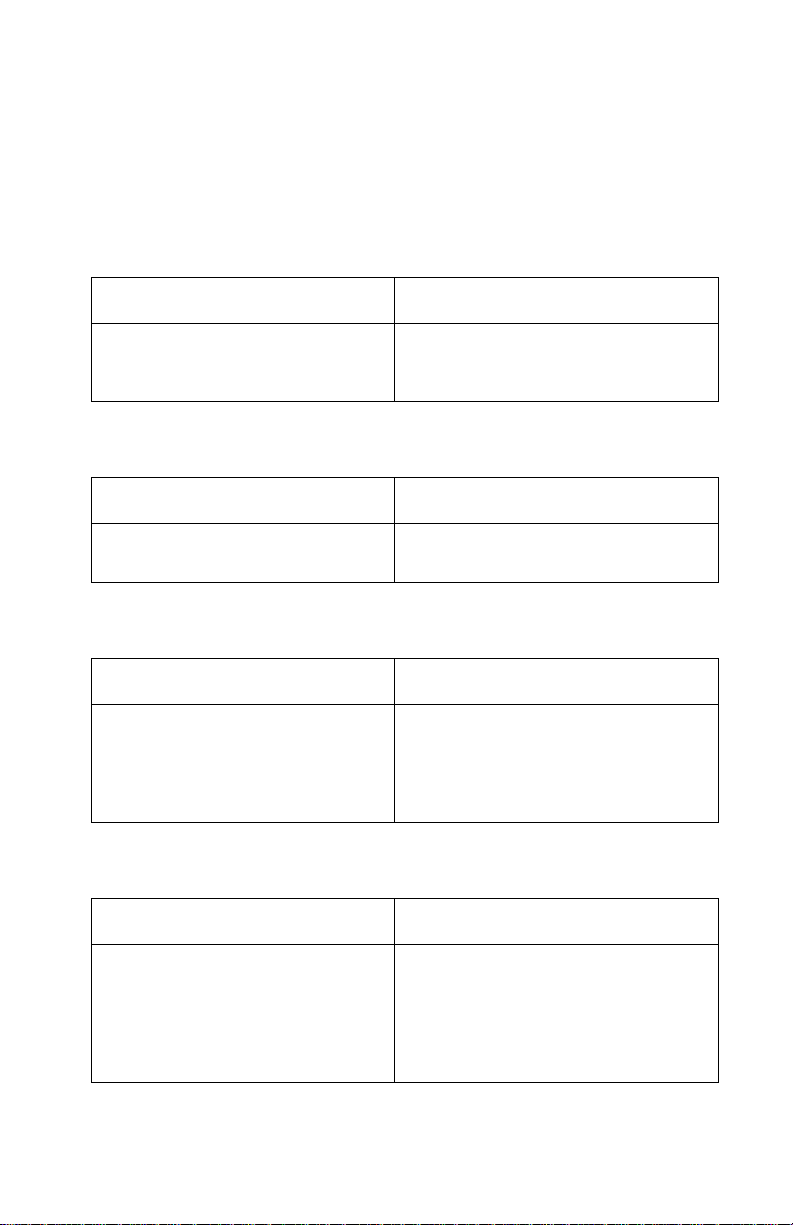

Diagnostic Aids 4

Use these diagnostic test procedures to verify a repair. The test procedures are entered by pressing and holding a button, or buttons,as

you turn on the printer. Except for the Hex Print test procedure, the

printer does not need to be attached to a host to run the tests. You

can press the buttons with the operator panel cover open or closed.

You must hold the buttons until all the lights are off. To terminate a

test press the Reset button, or turn the printer off. The button pattern

is illustrated for each test. Press the buttons that are shaded.

Demo Test

Perform this test with a black print cartridge installed.

This test prints a two-page demo pattern. Use this test to check the

overall quality of line print and graphics.

Print Fonts Test

Perform this test with a black print cartridge installed.

This test prints a sample of each font installed in the printer. This

includes resident fonts and fonts stored in FLASH memory. Fonts

downloaded to RAM cannot be printed with this test because the

power off/on sequence deletes all RAM fonts. This test also lists the

emulation mode and the installed options.

Diagnostic Aids 24

Page 37

4076-0XX

Purge Test

Perform this test with a black print cartridge installed.

This test prints out a nozzle test pattern followed by several grey

lines and another nozzle test pattern. Use this test to check the function of all the nozzles in the print cartridge. This test also checks the

electronic connection to the print cartridge. D uring the test, the print

cartridge head goes through a maintenance cleaning at the maintenance station.

Running this test with a color print cartridge installed will clear the

nozzles in the cartr idge.

Print Nvram

Perform this test with a black print cartridge installed. In addition to

holding down the buttons, ExecJet IIc requires that youplace a piece

of paper in the manual feed slot to push the EOF flag out of the sensor.

This test prints the contents of NVRAM.

Diagnostic Aids 25

Page 38

4076-0XX

Test Page

Perform this test with a black print cartridge installed.

This test repeatedly prints the nozzle test pattern followed by a sample of each font installed in the printer including resident fonts as well

as fonts stored in FLASH memory. This test continues until you

press the Reset button or turn off the printer.The error number is the

last number to print on the page in the lower right corner.

Paper Sensor Test

Release the buttons after the maintenance station uncaps the print

head.

In the paper sensor mode, the draft light displays the status of the

paper sensor (On=paper not present). Check the paper sensor by

either activating the end-of-forms flag or by placing a piece of paper

in the paper sensor. The draft light goes on and off as you move the

flag past the sensor. If the test fails, replace the system board.

26

Page 39

4076-0XX

Encoder Sensor Test

Release the button after the maintenance station uncaps the print

head.

For this test the bottom three operator panel lights display the current carrier position as determined by the carrier encoder. The

printer motors are disabled during this test to allow you to manually

move the carrier to verify the encoder is working correctly. The bottom 3 lights will repeat a count of 0 to 7 as you move the carrier

across the machine with the Ink Low Light = 1, the Paper Out Light =

2, and the Busy Light = 4.

If the lights do not change, replace the print head cable.If the lights

appear to have a break in the sequence, replace the encoder strip.If

the bottom 3 lights do not come on, replace the print head cable. If

the symptom remains, replace the system board.

Hex Print

Perform this test with a black print cartridge installed.

Use this test to put the printer in hex mode. The printer prints in

hexadecimal instead of ASCII.

Diagnostic Aids 27

Page 40

4076-0XX

Parallel Port Test

This test requires a parallel port wrap plug. Install the wrap plug in

the parallel port before you start the test. This test performs a wraparound test between the pr inter parallel port and the parallel port

test connector.If the test is successful, the top two lights and bottom

two lights blink alternately. If the test is not successful, only the bottom two lights will blink.

Initialize Nvram

Use this procedure to reset the error log portion of NVRAM. The

paper sensor must be open to perform this function. To do this, place

a piece of paper in the manual paper feed slot before you turn the

machine on. Except for bi-directional alignment settings, all user settings and defaults will not be reset. Resetting the error log allows you

to track new errors. The error log is especially helpful in diagnosing

intermittent or difficult problems. Check the bi-directional alignment

after you do this procedure.

28

Page 41

4076-0XX

Serial Adapter Test

Perform this test with a black print cartridge installed.

This test checks out the connection between the serial adapter and

the printer. To run the test:

1. Turn the machine off.

2. Set switch 10 on the serial adapter card to ON.

3. Turn the machine on to print out the current switch settings and a

test pattern.

4. You may have to press Forms Feed to print the test.

Diagnostic Aids 29

Page 42

4076-0XX

Repair Information 5

This chapter explains how to make adjustments to the printer and

how to remove defective parts.

WARNING: Read the following before handling electronic parts.

Handling Esd-sensitive Parts

Many electronic products use parts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual precautions, such as turning off power before removing logic boards:

• Keep the ESD-sensitive part in its original shipping container (a

special “ESD bag”) until you are ready to install the part into the

machine.

• Make the least-possible movements with your body to prevent an

increase of static electricity from clothing fibers, carpets, and

furniture.

• Put the ESD wrist strap on your wrist. Connect the wrist band to

the system ground point. This discharges any static electricity in

your body to the machine.

• Hold the ESD-sensitive part by its edge connector shroud

(cover); do not touch its pins. If you are r emoving a pluggable

module, use the correct tool.

• Do not place the ESD-sensitive part on the machine cover or on

a metal table; if you need to put down the ESD-sensitive part for

any reason, first put it into its special bag.

• Machine covers and metal tables are electrical grounds. They

increase the risk of damage because they make a discharge

path from your body through the ESD-sensitive part. (Large

metal objects can be discharge paths without being grounded.)

• Prevent ESD-sensitive parts from being accidentally touched by

other personnel. Install machine covers when you are not working on the machine, and do not put unprotected ESD-sensitive

parts on a table.

• If possible, keep all ESD-sensitive parts in a grounded metal

cabinet (case).

Repair Information 30

Page 43

4076-0XX

• Be extra careful in working w ith ESD-sensitive parts when cold-

weather heating is used because low humidity increases static

electricity.

Adjustments

Bi-directional Alignment Adjustment

Perform this adjustment with the black print cartridge installed.

1. Turn off the printer.

2. Hold down the Install Print Cartridge button and the Line Feed

Button, then turn on the printer. Release the buttons when all the

lights go out.

3. A page loads and the bi-directional alignment pattern prints. The

pattern consists of three lines of vertical bars. The bars are

aligned when the adjustment is correct. The following sample

requires the center vertical bars to be moved to the right.

4. The center bars can be coarse aligned or fine aligned. Coarse

alignment moves the center bar 1/300” (.085mm). Fine alignment moves the center bar 1/1200” (.021mm). To perform the

coarse alignment, open the operator panel coverand use the top

two buttons to move the center bar. Press the left button to move

the bar to the left. Press the right button to move the bar to the

right. Each time you press the button the three lines will print.

5. To fine align the bars, close the operator panel cover and use the

two bottom buttons. Press the left button to move the center bar

to the left. Press the right button to move the bar to the right.

Each time you press a button the three lines will print.

6. When the alignment is correct, press the Draft button to switch to

the draft mode. Followthe same procedure as aboveto align the

bars in the draft mode.

7. When you complete the adjustment and turn off the printer the

settings will be saved in NVRAM.

Repair Information 31

Page 44

4076-0XX

Removal Procedures

The following procedures are arranged in alphabetical order according to the name of the printer part discussed. When there is artwork

to support a procedure, it follows the text.

Releasing Plastic Latches

Many of the parts are held in place with plastic latches. To remove

such parts, press the hook end of the latch away from the part to

which it is latched. The latches break easily. Release them carefully.

Never apply excessive force

Hook

when releasing the hook.

32

Page 45

4076-0XX

Auto Sheet Feed (ASF) Assembly Removal

1. Remove the top cover.

2. Push in the two latches [ A] that secure the auto sheet feed to the

side frame, then lift up the auto sheet feed to remove it from the

machine.

A

A

When you reinstall the auto sheet feed, be sure the feed arm assembly is vertical, with the feed pawl at the top.

ASF Envelope Buckler And Pick Roller Hub Removal

1. Remove the ASF.

2. Remove the inside C-clip from the pick roller shaft and pull the

shaft to the right far enough to remove the envelope bucklers

and pick rollers.

3. Remove the pick roller hubs from the bucklers.

Repair Information 33

Page 46

4076-0XX

ASF Right And Left Edge Guide Assemblies Removal

1. Remove the auto sheet feed.

2. Remove the manual insert tray by prying one of the side frames

away from it.

3. Remove the inside C-clip from the pick roller shaft and pull the

shaft out to the right.

4. Remove the pick roller and buckler assemblies.

5. Remove the paper load lever knob from the load lever.

6. Remove the auto sheet feed right side cover by prying up at the

slots in the rear.

7. Remove the paper load lever and shaft by pulling them out from

the right side of the ASF assembly. Be careful not to lose the

small gear on the left end of the shaft. When you reinstall this

shaft, it must be parallel with the ASF housing.

8. Pivot the guide assembly up and pry it off the back plate.

ASF Paper Load Lever Removal

1. Remove the auto sheet feed assembly.

2. Pull the paper load lever knob from the load lever.

3. Remove the auto sheet feed right side cover by prying up the

slots in the rear.

4. Remove the paper load lever from the mounting stud.

Carrier Removal

1. Remove the top cover.

2. Remove the print cartridge.

3. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

4. Move the carrier in line with the opening in the carrier transport

motor frame.

5. Reach through the opening and pull the belt from the carrier.

6. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier guide rod through the

opening in the left side frame. Be careful not to damage the

encoder strip.

7. Pull the ends of the print head cables into the machine, then

remove the cables from the 4 r etainers in the paper guide

starting from the right.

34

Page 47

4076-0XX

Carrier Transport Belt Removal

1. Remove the top cover.

2. Move the carrier in line with the opening in the carrier transport

motor frame.

3. Reach through the opening and pull the belt from the carrier.

4. Remove the belt from the carrier transport motor pulley.

5. Remove the belt from the idler pulley and pull it through the

opening in the left side frame.

Note: When you reinstall the belt be sure to insert the bottom of

the belt into BOTH the lower and upper belt grips on the carrier.

DO NOT INSERT THE TOP OF THE BELT INTOTHE TOP GRIP.

Carrier Guide Removal

You may remove the carrier guide without removing the covers if you

carefully follow this procedure.

1. Open and remove the access cover.

2. Remove the print cartridge.

3. With the carrier centered, carefully release the 2 carrier guide

rod latches and lift the shaft slightly.

4. Unlatch the 2 carrier guide latches by pushing to the rear.

5. Gently push the carrier to the extreme right and remove the carrier guide.

When you reinstall the carrier guide, be sure the fingers on the bottom of the carrier engage the groove on the carrier guide before you

snap the carrier guide rod down.

Carrier Transport Motor Removal

1. Remove the top cover.

2. Disconnect the carrier transport motor (J6) from the system

board.

3. Remove the 2 motor mounting screws and remove the motor.

Repair Information 35

Page 48

4076-0XX

Carrier Transport Motor Frame Removal

1. Remove the top cover.

2. Disconnect J6 from the system board.

3. Move the carrier in line with the opening in the carrier transport

motor frame.

4. Reach through the opening and pull the belt from the carrier.

5. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier guide rod through the

opening in the left side frame. Be careful not to damage the

encoder strip.

6. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames and pivot the carrier transport motor frame down

and out of the side frames.

Encoder Strip Removal

1. Remove the top cover.

2. Move the carrier in line with the opening on the carrier transport

motor frame.

3. Reach through the opening and pull the belt from the carrier.

4. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches at each end of the rod

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Place the carrier on top of the paper guide.

5. Remove the encoder strip from the left mounting peg. To do this,

push the right latch slightly to the left.

6. Remove the encoder strip from the right latch.

When you install the encoder strip, be sure it is fully seated on the

left mounting peg.

36

Page 49

4076-0XX

End-of-forms Flag Removal

1. Remove the top cover.

2. Remove the ASF.

3. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables

4. Disconnect connectors J4, J5, and J6 from the system board. 5.

Remove the machine from the base. To do this, unlatch the 4

base frame latches. Lift the machine from the base and set it on

its front with the bottom facing you.

5. Pivot the weighted end of the end-of-forms flag through the

opening in the middle frame.

6. Lift the flag up and out of the machine.

Exit Roller Assembly Removal

1. Remove the top cover.

2. Remove the carrier transport frame.

3. Pivot the paper ejector pusher toward the front then pull it to

remove the paper ejector from the shaft.

4. Removethe bushing from the left end of the exit shaft. To do this,

pull the tab and rotate the bushing.

5. Slide the exit roller to the left and lift it out of the machine.

Eprom Removal

1. Remove the top cover.

2. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

3. Disconnect connectors J4, J5, and J6 from the system board.

4. Remove the machine from the base. To do this, push the frame

latches out as you lift the machine from the base. Set the

machine aside.

5. Gently pry the EPROM from the system board.

Feed Arm Assembly Removal

1. Remove the top cover.

2. Remove the auto sheet feed.

3. Remove the C-clip from the center of the large gear and remove

the feed arm assembly.

Repair Information 37

Page 50

4076-0XX

Inside Idler Gears Removal

1. Remove the top cover.

2. Remove the auto sheet feed.

3. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

4. Remove the paper guide.

5. Remove the C-clip from the feed arm assembly and remove the

feed arm assembly.

6. Pull the idler gears off the mounting studs.

Large Feed Roller Assembly Removal

1. Remove the top cover.

2. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

3. Disconnect connectors J4, J5, and J6 from the system board. 4.

Remove the machine from the base. To do this, push the frame

latches out as you lift the machine from the base. Set the

machine aside.

4. Place the machine on its front with the bottom facing you.

5. Disconnect the 3 springs from the bottom of the middle frame

assembly.

6. Remove the large feed roller assembly.

38

Page 51

4076-0XX

Left Side Frame Removal

1. Remove the top cover.

2. Remove the print cartridge.

3. Remove the auto sheet feed.

4. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

5. Disconnect connectors J4, J5, and J6 from the system board.

6. Remove the machine from the base. To do this, push the frame

latches out as you lift the machine from the base. Set the

machine aside.

7. Move the carrier in line with the opening in the carrier transport

motor frame.

8. Reach through the opening and pull the belt from the carrier.

9. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier guide rod through the

opening in the left side frame. Be careful not to damage the

encoder strip.

10. Pull the ends of the print head cables into the machine, then

remove the cables from the 4 retainers in the paper guide starting from the right.

11. Disengage the left paper guide latch by carefully moving the rear

of the left side frame to the left.

12. Disengage the right side of the paper guide from the latch and lift

it from the machine.

13. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames, then pivot the carrier transport motor frame down

and out of the side frames.

14. Place the machine on its back and push the left side frame latch

to the rear and remove the frame from the machine.

When you reinstall the paper guide, be sure the front edge goes

under the rear of the carrier guide. If the paper guide is on top of the

carrier guide, push down the front, bottom edge. It will snap under

the carrier guide.

Repair Information 39

Page 52

4076-0XX

To install the left side frame onto the middle frame, align the right

side frame latch with the latching surface on the middle frame before

you align the roller shafts and carrier guide. It may be easier to do

this with the machine on its right side.

Maintenance Drive And Rocker Assemblies Removal

1. Remove the top cover.

2. Remove the auto sheet feed.

3. Remove the right side frame.

4. Gently unlatch the maintenance assembly latches, and slide out

the maintenance drive assembly, then the rocker assembly.

When you reassemble the drive assembly, be sure the forks engage

the pins on the rocker assembly.

Middle Frame Removal

1. Remove the top cover.

2. Remove the print cartridge.

3. Remove the auto sheet feed.

4. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

5. Disconnect J4, J5, and J6 from the system board.

6. Remove the machine from the base. To do this, unlatch the 4

base frame latches. Lift the machine from the base and set it

aside.

7. Remove the paper ejectors from the middle frame.

8. Remove the left side frame.

9. Remove the exit shaft.

10. Remove the small feed roller shaft.

11. Remove the large feed roller shaft and springs.

12. Remove the end-of-forms flag.

13. Remove the right side frame.

14. Remove the maintenance station.

Operator Panel Removal

1. Remove the top cover.

2. Remove the 3 operator panel mounting screws.

3. Remove the operator panel.

40

Page 53

4076-0XX

Outside Idler Gears Removal

1. Remove the top cover.

2. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

3. Each gear is latched in place. Push up the latch and remove the

gear from the side frame stud by pulling the gear from the bottom.

Paper Ejectors Removal

1. Remove the top cover.

2. Pivot the paper ejector pusher toward the front then pull it to

remove the paper ejector from the shaft.

3. Unsnap the paper ejectors from the middle frame.

Paper Feed Motor Removal

1. Remove the top cover.

2. Disconnect the paper feed motor from the system board.

3. Removethe two mounting screws or rotate the paper feed motor

counter-clockwise to remove it from the right side frame.

Paper Guide Removal

1. Remove the top cover.

2. Remove the auto sheet feed.

3. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

4. Pull the ends of the print head cables into the machine, then

remove the cables from the 4 retainers in the paper guide starting from the right.

5. Disengage the left paper guide latch by c arefully movingthe rear

of the left side frame to the left.

6. Disengage the right side of the paper guide from the latch and lift

it from the machine.

Note: When you reinstall the paper guide, be sure the front edge

goes under the rear of the carrier guide. If the paper guide is on top

of the carrier guide, push down the front, bottom edge. It will snap

under the carrier guide.

Repair Information 41

Page 54

4076-0XX

Paper Release Lever Removal

1. Remove the top cover.

2. Pull the paper release lever forward.

3. Place a screw driver into the slot [A] of the paper release lever.

Push the screw driver down to release the latch, then remove

the lever.

A

Power Supply Removal

1. Remove the top cover.

2. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

3. Disconnect connectors J4, J5, and J6 from the system board.

4. Remove the machine from the base. To do this, push the frame

latches out as you lift the machine from the base. Set the

machine aside.

5. Disconnect the power supply cable from the system board.

6. Remove the 4 power supply mounting screws and remove the

power supply.

NOTE: The fuse on the power supply is for safety pur- poses only. If

it blows, there is a bad component on the board. Do not replace the

fuse. A new fuse will not correct the failure.

42

Page 55

4076-0XX

Print Head Cable Removal

1. Remove the top cover.

2. Remove the print cartridge.

3. Remove the carrier.

4. Remove the cable clip [A] from the left side of the carrier.

5. Remove the pointer from the front of the carrier.

A

6. Remove the 2 sensor mounting screws.

7. Push down the 2 latches that secure the cradle to the carrier and

pull the cradle up from the carrier.

8. Remove the print head cable from the alignment pins.

The new cable comes without the folds in it. Place the new cable

next to the old cable and fold the new cable in the appropriate

places.

Repair Information 43

Page 56

4076-0XX

Right Side Frame Removal

1. Remove the top cover.

2. Remove the print cartridge.

3. Remove the auto sheet feed.

4. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

5. Disconnect connectors J4, J5, and J6 from the system board.

6. Remove the machine from the base. To do this, push the frame

latches out as you lift the machine from the base. Set the

machine aside.

7. Move the carrier in line with the opening in the carrier transport

motor frame.

8. Reach through the opening and pull the belt from the carrier.

9. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier rod guide latches, at each end of the rod,

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Remove the carrier rod guide through the

opening in the left side frame. Be careful not to damage the

encoder strip.

10. Pull the ends of the print head cables into the machine, then

remove the cables from the 4 retainers in the paper guide starting from the right.

11. Disengage the left paper guide latch by carefully moving the rear

of the left side frame to the left.

12. Disengage the right side of the paper guide from the latch and lift

the guide from the machine.

13. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames, then pivot the carrier transport motor frame down

and out of the side frames.

14. Place the machine on its back, then unlatch the right frame latch

from the middle frame and remove the side frame.

NOTE:for reassembly you may want to remove the carrier guide and

reinstall it after you install the paper guide.

When you reinstall the paper guide, be sure the front edge goes

under the rear of the carrier guide. If the paper guide is on top of the

44

Page 57

4076-0XX

carrier guide, push down the front, bottom edge. It will snap under

the carrier guide.

To install the right side frame onto the middle frame, align the right

side frame latch with the latching surface on the mid frame before

you align the roller shafts and carrier guide. It may be easier to do

this with the machine on its left side.

Rubber Backer Removal

1. Remove the top cover.

2. Remove the print cartridge.

3. Remove the print head cable.

4. Remove the rubber backer from the carrier.

Small Feed Roller Assembly Removal

1. Remove the top cover.

2. Remove the auto sheet feed.

3. Remove the paper guide

4. Carefully remove the paper release lever.

5. Remove the bushing from the left end of the small feed roller

shaft. To do this, pull the tab and rotate the bushing.

6. Slide the small feed roller assembly to the left and lift it out of the

machine.

Star Roller Removal

1. Remove the top cover.

2. Move the carrier in line with the opening on the carrier transport

motor frame.

3. Reach through the opening and pull the belt from the carrier.

4. To unlock the carrier guide rod latches, rotate the rod top-to-rear.

Gently push the carrier guide rod latches at each end of the rod

to the rear and lift up the rod until the sensor on the carrier clears

the encoder strip. Place the carrier on top of the paper guide.

5. A latch on the top front end of each side frame holds the transport motor frame in place. Push up the latches on the front of the

side frames and pivot the carrier transport motor frame down

and out of the side frames. Place the carrier transport motor

frame face down in front of the machine.

6. Removethe star roller by pushing it forward off the mounting peg

in the carrier transport motor frame.

Repair Information 45

Page 58

4076-0XX

System Board Removal

1. Remove the top cover.

2. Disconnect the print head cables from the system board. You

mayhave to open the print head cable connectors on the system

board first, then disconnect the cables.

3. Disconnect connectors J4, J5, and J6 from the system board. 4.

Remove the machine from the base. To do this, push the frame

latches out as you lift the machine from the base. Set the

machine aside.

4. Disconnect the power supply cable from the system board.

5. Remove the 6 system board mounting screws and remove the

system board.

6. Check the bi-directional alignment adjustment.

After replacing the system board, reset the printer to the factory

defaults as follows:

For countries using 8.5 x 11 paper:

1. Turn off the printer.

2. Hold down the Form Feed, Line Feed, and Install Ink Cartridge

buttons and turn on the printer. Continue to hold down the buttons until all the lights are off.

3. Check the bi-directional alignment.

For countries using A4 paper:

1. Turn off the printer.

2. Place a piece of paper in the manual feed slot to push the EOF

flag out of the sensor.

3. Holddown the Install Print Cartridge, Form Feedand Draft/Letter

Quality buttons and turn on the printer. Continue to hold down

the buttons until all the lights are off.

4. Check the bi-directional alignment.

46

Page 59

4076-0XX

Top Cover Removal

1. Unplug the power cord and the interface cable from the back of

the printer.

2. Pull up the tab latch on the print cartridge storage unit and

remove the unit from the machine.

3. Unlatch the auto sheet feed left cover by pushing it up from the

bottom, then slide it off the machine.

4. Turn the machine around to remove the rear cover. Remove the

screw and washer from the rear cover. Place a screwdriver in the

left slot [A] and push the latch down. At the same time push the

right latch [A]down.

A

A

5. Pull the rear cover out until the latches clear the top cover, then

lift the cover off the base.

6. Turn the machine to the front and pull the paper tray forward.

7. Pull the top cover forward until it stops. Be sure the paper

release lever clears the slot in the top cover. The operator panel

cable is still connected, so carefully lift the cover off the base.

8. Set the cover down in front of the machine.

9. Pull the operator panel cable from the connector on the system

board.

NOTE: When you reinstall the top cover, pull out the exit tray to prevent it from being trapped under the cover.

Repair Information 47

Page 60

4076-0XX

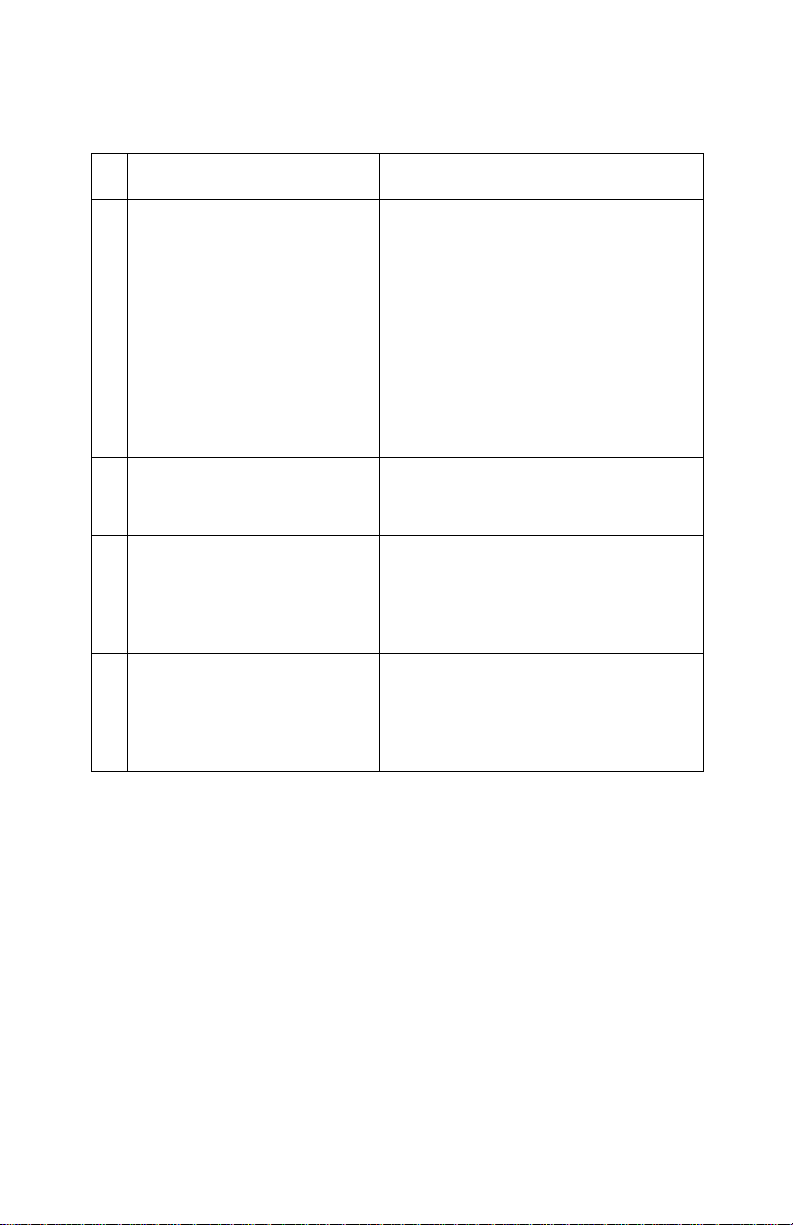

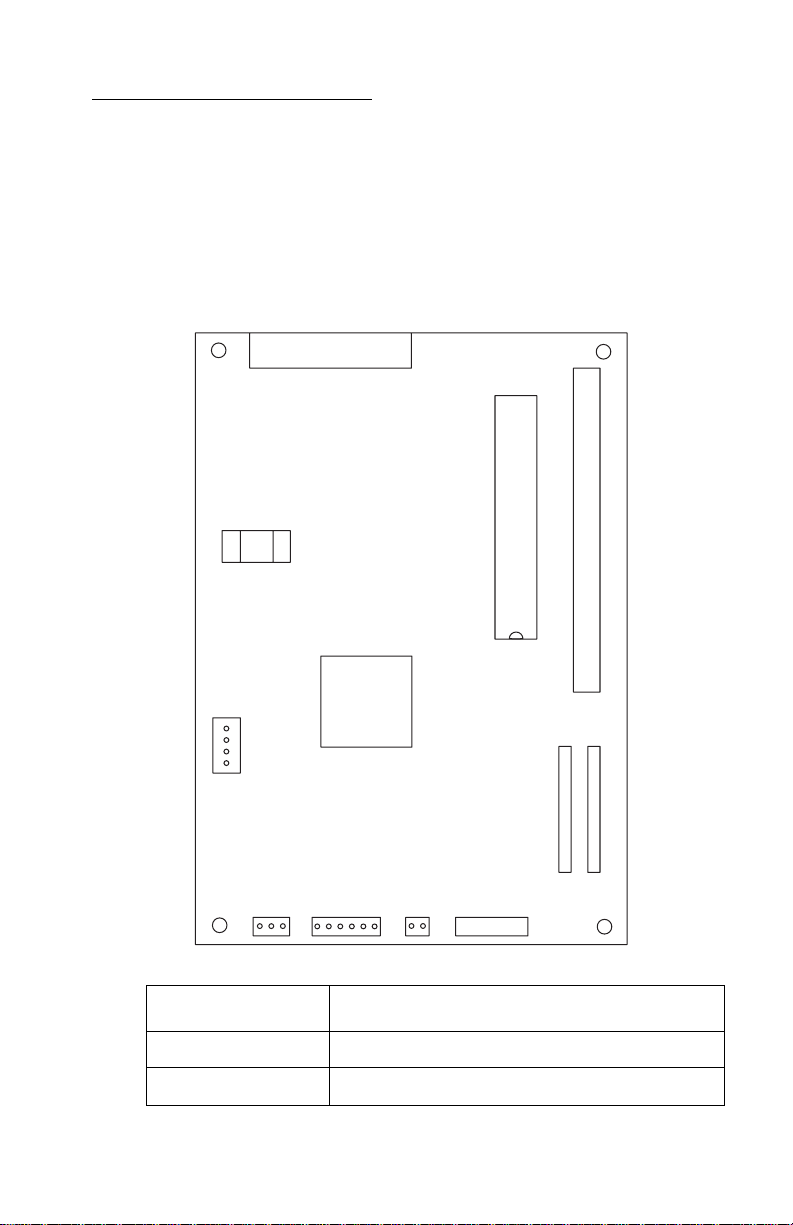

Connector Locations 10

This chapter shows the locations of major printer assemblies, connectors, and ground straps.

System Board Connectors

J9

S1

U23

1

J11

J6

1

J5

J4

1

1

U20

J7

J1

1

J10

1

.CE/TP

1

1

J2

Connector Connector Names

J1 Print Head Cable

J2

Print Head Cable

Connector Locations 48

Page 61

4076-0XX

Connector Connector Names

J4

J5

J6

J7

J9

J10

J11

U20

Maintenance Motor

Paper Feed Motor

Transport Motor

FLASH/RAM SIMM Option

Parallel Port

Operator Panel

PowerSupply

Code Module

Connector Locations 49

Page 62

4076-0XX

Preventive Maintenance 11

This chapter contains the lubrication specifications. Following these

recommendations can help prevent problems and maintain optimum

performance.

Lubrication Specifications

Lubricate only when parts are replaced or as needed, not on a

scheduled basis. Use no. 23 grease to lubricate the following:

• All gear mounting studs

• The right end of the exit roller at the right side frame

• The right end of the small feed roller at the right side frame

• The left end of the large feed roller at the left side frame

• Both ends of the ASF pick roll shaft at the ASF side frames

• Transport belt idler pulley hole

• Inside surface of the transport idler pulley tension wedge where it

touches the left side frame.