Lexmark 3000 Color Jetprinter Service Manual

Lexmark 3000 Color Jetprinter™

• Table of Contents

• Start Diagnostics

4095-001

• Safety and Notices

• Trademarks

• Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

First Edition (June, 1997)

The following paragraph does not apply to any country where such

provisions are inconsistent with local law:LEXMARK

INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS”

WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of

express or implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical

errors. Changes are periodically made to the information herein; these

changes will be incorporated in later editions. Improvements or changes

in the products or the programs described may be made at any time.

Publications are not stocked at the address given below; requests for

publications should be made to your point of purchase.

A form for reader’s comments is provided at the back of this publication.

If the form has been removed, comments may be addressed to Lexmark

International, Inc., Department D22A/035-3, 740 New Circle Road N.W.,

Lexington,Kentucky 40550, U.S.A. In the United Kingdom and Eire, send

to Lexmark International Ltd., Marketing and Services Department,

Westhorpe House, Westhorpe, Marlow Bucks SL7 3RQ. Lexmark may

use or distribute any of the information you supply in any way it believes

appropriate without incurring any obligation to you. If your printer has

broken or missing parts, or if you are missing publications, call 1-8004LEXBMP. In other countries, contact your point of purchase. You can

obtain additional copies of publications related to this product by calling

1-800-553-9727. In the United Kingdom and Eire, call 0628-481500. In

other countries, contact your point of purchase.

Lexmark is a trademark of Lexmark International, Inc., registered in the

United States and/or other countries. Other trademarks are the property

of their respective owners.

© Copyright Lexmark International, Inc. 1997. All Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED

RIGHTS. Use, duplication or disclosure by the Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013

and in applicable FAR provisions: Lexmark International, Inc., Lexington,

KY 40550.

Preface..............................................v

SafetyInformation...................................vi

GeneralInformation...................................1-1

OperatorPanel....................................1-1

PowerConsumption................................1-1

MaintenanceApproach..............................1-2

Abbreviations.....................................1-2

DiagnosticInformation................................2-1

Start............................................2-1

ErrorIndicatorTable.............................2-1

SymptomTables...............................2-2

Power-OnSelfTest(POST)Sequence..............2-4

POSTSymptomTable...........................2-4

ServiceChecks....................................2-5

CarrierTransportServiceCheck...................2-5

EnvelopeFeedServiceCheck.....................2-6

MaintenanceStationServiceCheck................2-7

PaperFeedServiceCheck.......................2-8

............................................2-10

PaperPathServiceCheck.......................2-10

PowerServiceCheck...........................2-11

PrintQualityServiceCheck......................2-12

DiagnosticAids......................................3-1

PrintNVRAMContents..............................3-2

NVRAMDefaults...................................3-3

ResetNVRAMtoEMEADefaults...................3-3

ResetNVRAMtoU.S.Defaults....................3-3

TestPage........................................3-4

RepairInformation....................................4-1

HandlingESD-SensitiveParts........................4-1

Adjustments......................................4-2

RemovalProcedures...............................4-2

ReleasingPlasticLatches........................4-2

AccessCoverRemoval..........................4-3

BaseAssemblyRemoval.........................4-3

CarrierBeltRemoval............................4-3

CarrierFrameAssemblyRemoval..................4-4

CarrierHomeSensorRemoval....................4-4

CarrierTransportMotorRemoval...................4-5

DriveTrainAssemblyRemoval....................4-5

FrontCoverRemoval............................4-6

GutterPadRemoval.............................4-6

iii

LargeFeedRollRemoval........................4-7

MaintenanceStationAssemblyRemoval............4-7

MaintenanceWiperandCapRemoval..............4-7

MidFrameAssemblyRemoval....................4-8

PaperFeedMotorRemoval......................4-8

PowerSupplyRemoval..........................4-8

PrintheadCarrierAssemblyRemoval...............4-9

RearCoverRemoval............................4-9

SheetFeederRemoval..........................4-9

SmallFeedRollAssemblyRemoval...............4-10

SmallFeedRollBracketAssemblyRemoval........4-10

SystemBoardRemoval.........................4-11

Connectors..........................................5-1

PreventiveMaintenance...............................6-1

LubricationSpecifications...........................6-1

PartsCatalog........................................7-1

HowtoUseThisPartsCatalog.......................7-1

Assembly1:Covers.............................7-2

Assembly2:PaperFeed/CarrierTransport/Maintenance7-4

Assembly3:Electronics.........................7-8

Assembly4:Carrier............................7-12

Assembly5:SheetFeeder......................7-14

ivContents

Preface 1

Thismanualisdividedintothefollowingchapters:

1.GeneralInformationcontainsageneraldescriptionofthe

printerandthemaintenanceapproachusedtorepairit.Special

toolsandtestequipmentarelistedinthischapter,aswellas

generalenvironmentalandsafetyinstructions.

2.DiagnosticInformationcontainserrorindicatortable,symptom

table,andservicechecksusedtoisolatefailingfieldreplaceable

units(FRUs).

3.DiagnosticAidscontainstestsandchecksusedtolocateor

repeatsymptomsofprinterproblems.

4.RepairInformationprovidesinstructionsformakingprinter

adjustmentsandremovingandinstallingFRUs.

5.ConnectorLocationsusesillustrationstoidentifytheconnector

locationsandtestpointsontheprinter.

6.PreventiveMaintenancecontainsthelubricationspecifications

andrecommendationstopreventproblems.

7.PartsCatalogcontainsillustrationsandpartnumbersforindividualFRUs.

Prefacev

SafetyInformation

Thisproductisdesigned,testedandapprovedtomeetstrict

•

globalsafetystandardswiththeuseofspecificLexmark

components.Thesafetyfeaturesofsomepartsmaynot

alwaysbeobvious.Lexmarkisnotresponsiblefortheuseof

otherreplacementparts.

•Themaintenanceinformationforthisproducthasbeen

preparedforusebyaprofessionalservicepersonandisnot

intendedtobeusedbyothers.

•Theremaybeanincreasedriskofelectricshockand

personalinjuryduringdisassemblyandservicingofthis

product.Professionalservicepersonnelshouldunderstand

thisandtakenecessaryprecautions.

ConsignesdeSécurité

Ceproduitaétéconçu,testéetapprouvépourrespecterles

•

normesstrictesdesécuritéglobalelorsdel'utilisationde

composantsLexmarkspécifiques.Lescaractéristiquesde

sécuritédecertainsélémentsnesontpastoujoursévidentes.

Lexmarknepeutêtretenuresponsabledel'utilisation

d'autrespiècesderechange.

•Lesconsignesd'entretienetderéparationdeceproduit

s'adressentuniquementàunpersonneldemaintenance

qualifié.

•Ledémontageetl'entretiendeceproduitpouvantprésenter

certainsrisquesélectriques,lepersonneld'entretienqualifié

devraprendretouteslesprécautionsnécessaires.

vi

Normedisicurezza

Ilprodottoèstatoprogettato,testatoeapprovatoin

•

conformitàaseveristandarddisicurezzaeperl’utilizzocon

componentiLexmarkspecifici.Lecaratteristichedisicurezza

dialcunepartinonsempresonodiimmediatacomprensione.

Lexmarknonèresponsabileperl’utilizzodipartidiricambio

dialtriproduttori.

•Leinformazioniriguardantilamanutenzionediquesto

prodottosonoindirizzatesoltantoalpersonalediassistenza

autorizzato.

•Durantelosmontaggioelamanutenzionediquestoprodotto,

ilrischiodisubirescosseelettricheedanniallapersonaèpiù

elevato.Ilpersonalediassistenzaautorizzato,deve,quindi,

adottareleprecauzioninecessarie.

Sicherheitshinweise

DiesesProduktunddiezugehörigenKomponentenwurden

•

entworfenundgetestet,umbeimEinsatzdieweltweit

gültigenSicherheitsanforderungenzuerfüllen.Die

sicherheitsrelevantenFunktionenderBauteileundOptionen

sindnichtimmeroffensichtlich.SofernTeileeingesetzt

werden,dienichtvonLexmarksind,wirdvonLexmark

keinerleiVerantwortungoderHaftungfürdiesesProdukt

übernommen.

•DieWartungsinformationenfürdiesesProduktsind

ausschließlichfürdieVerwendungdurcheinen

Wartungsfachmannbestimmt.

•WährenddesAuseinandernehmensundderWartungdes

GerätsbestehteinzusätzlichesRisikoeineselektrischen

SchlagsundkörperlicherVerletzung.Daszuständige

FachpersonalsollteentsprechendeVorsichtsmaßnahmen

treffen.

Prefacevii

PautasdeSeguridad

Esteproductosehadiseñado,verificadoyaprobadopara

•

cumplirlosmásestrictosestándaresdeseguridadglobal

usandoloscomponentesespecíficosdeLexmark.Puede

quelascaracterísticasdeseguridaddealgunaspiezasno

seansiempreevidentes.Lexmarknosehaceresponsable

delusodeotraspiezasderecambio.

•Lainformaciónsobreelmantenimientodeesteproducto

estádirigidaexclusivamentealpersonalcualificadode

mantenimiento.

•Existemayorriesgodedescargaeléctricaydedaños

personalesduranteeldesmontajeylareparacióndela

máquina.Elpersonalcualificadodebeserconscientedeeste

peligroytomarlasprecaucionesnecesarias.

InformaçõesdeSegurança

Esteprodutofoiconcebido,testadoeaprovadopara

•

satisfazerospadrõesglobaisdesegurançanautilizaçãode

componentesespecíficosdaLexmark.Asfunçõesde

segurançadealgunsdoscomponentespodemnãoser

sempreóbvias.ALexmarknãoéresponsávelpelautilização

deoutroscomponentesdesubstituição.

•Asinformaçõesdesegurançarelativasaesteproduto

destinam-seaprofissionaisdestesserviçosenãodevemser

utilizadasporoutraspessoas.

•Riscodechoqueseléctricoseferimentosgravesdurantea

desmontagememanutençãodesteproduto.Osprofissionais

destesserviçosdevemestaravisadosdestefactoetomaros

cuidadosnecessários.

viii

InformaciódeSeguretat

Aquestproducteestàdissenyat,comprovatiaprovatpertal

•

d'acomplirlesestrictesnormesdeseguretatglobalsambla

utililitzaciódecomponentsespecíficsdeLexmark.Les

característiquesdeseguretatd'algunespecespotserqueno

sempresiguinòbvies.Lexmarknoesresponsabilitzadel'us

d'altrespecesderecanvi.

•Lainformaciópelmantenimentd’aquestproducteestà

orientadaexclusivamentaprofessionalsinoestàdestinada

aningúquenohosigui.

•Elriscdexocelèctricidedanyspersonalspotaugmentar

durantelprocésdedesmuntatgeideserveid’aquest

producte.Elpersonalprofessionalhad’estar-neassabentati

prendrelesmesuresconvenients.

Prefaceix

x

1. General Information

The Lexmark 3000 Color Jetprinter is a personal, near laser-quality

inkjet printer. The printer contains two print cartridges (color and

black), which are customer replaceable supply items. A single

printhead provides three colors and composite black printing. The

printer also supports a black print cartridge and provides 600 X 300

dpi edge definition for professional quality text image and graphics

printing.

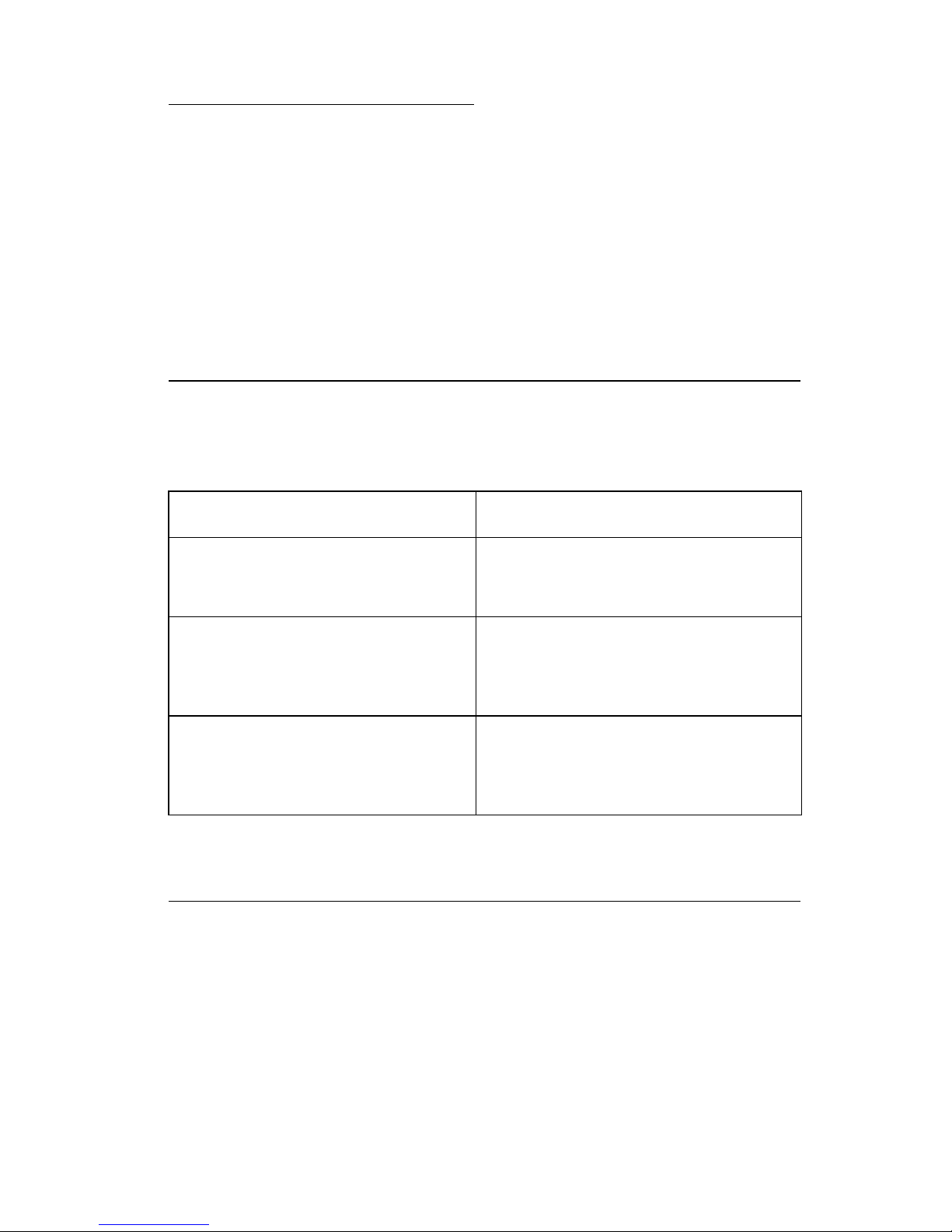

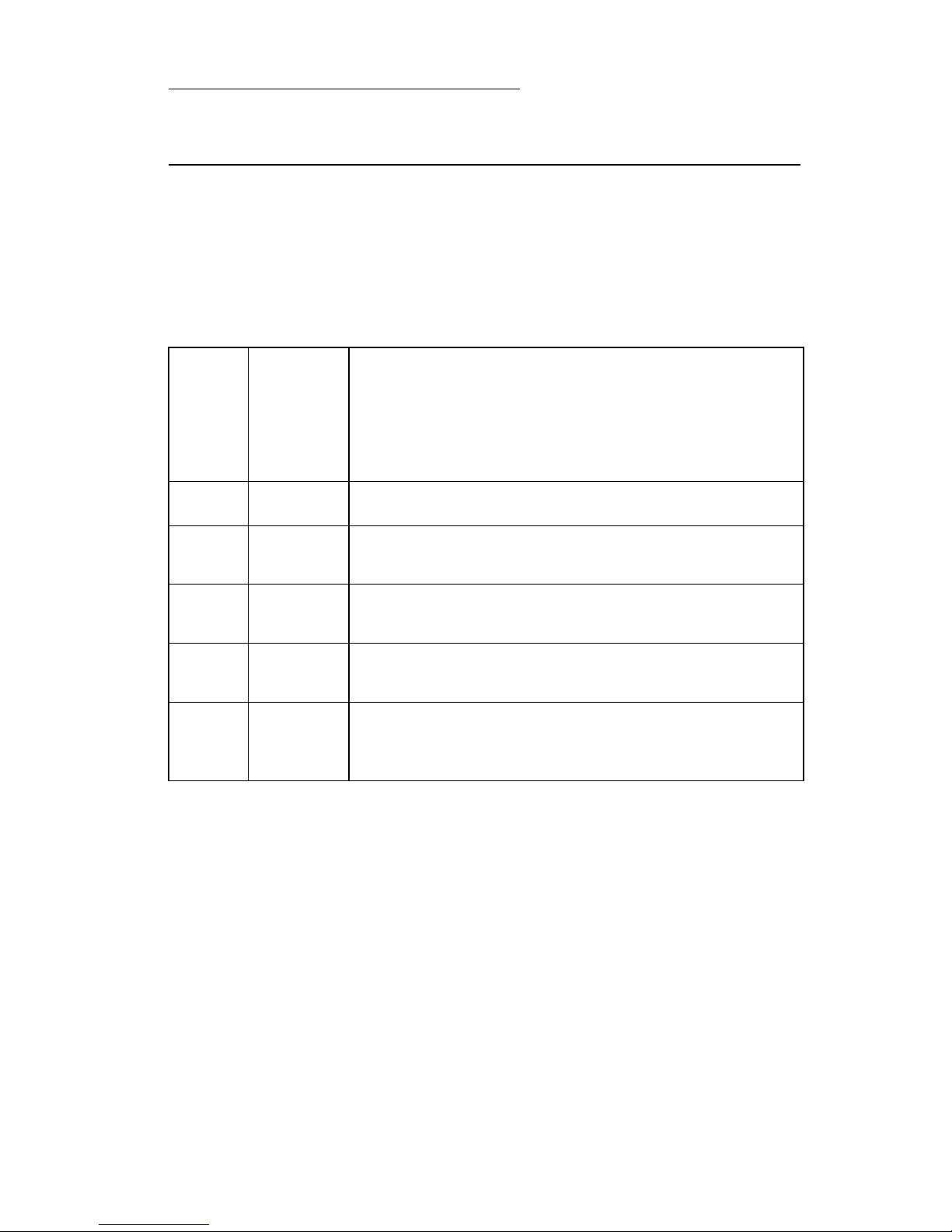

Operator Panel

Buttons Lights

Left Button

• Power On/Off

Right Button

• PaperFeed-clearsa paper jam

or loads paper when there is a

paper out condition.

Right Outer Button

• Install Cartridge -moves carrier

to the left for cartridge replacement.

Left Light

• Steady - Power On

• Blinking - Printer Error

Right Light

• Steady - Busy

• Blinking - Paper Out/Jam

Alternating Blinking Lights

• Printheads are in the load position

or printheads are installed incorrectly.

Power Consumption

•

Less than 3.5 Watts - power off and power to the printer

• 9 Watts - Idle Mode (power on - not printing)

• 12 Watts - Printing (average)

• 20 Watts - Printing (peak)

General Information 1-1

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the symptom index, service

checks, and diagnostic aids to determine the symptom and repair

the failure. Begin with “Error Indicator Table” on page -1.

After you complete the repair, perform tests as needed to verify the

repair.

Abbreviations

EOF End of Forms

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LVPS Low Voltage Power Supply

OEM Original Equipment Manufacturer

V ac Volts alternating current

V dc Volts direct current

ZIF Zero Insertion Force

1-2

2. Diagnostic Information

Start

Use the error indicator table, symptom tables, service checks, and

diagnostic aids in chapter 3, to determine the printer failure.

Error Indicator Table

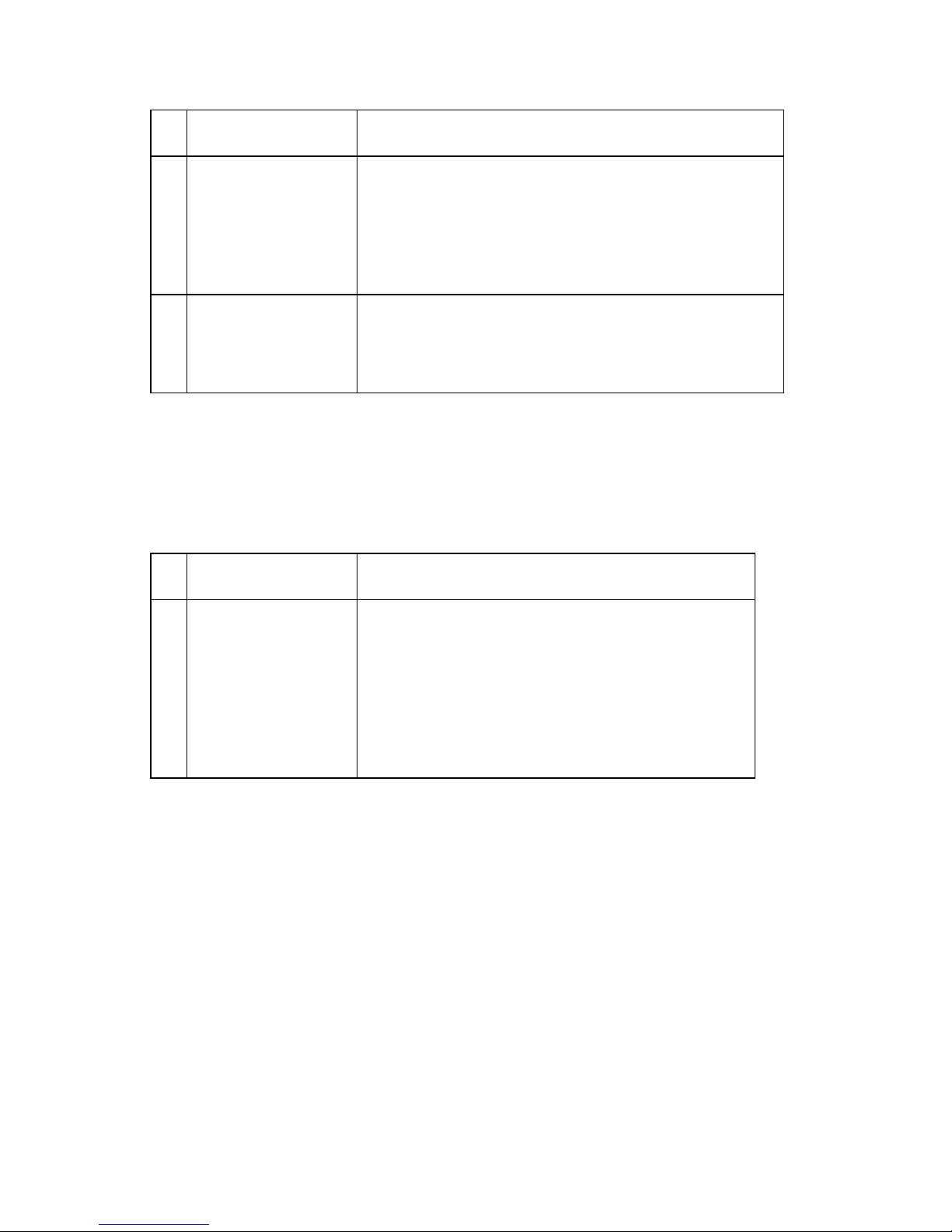

Number

Error

Code

of

Power

Light

Flashes

Action

Blank

64

65

81

89

127

and

up

8

7

1

4

10

Replace the system board.

Replace the system board.

Go to the ’Carrier Transport Service Check’ on page

2-5.

Go to the ’Carrier Transport Service Check’ on page

2-5.

Replace the system board.

Diagnostic Information 2-1

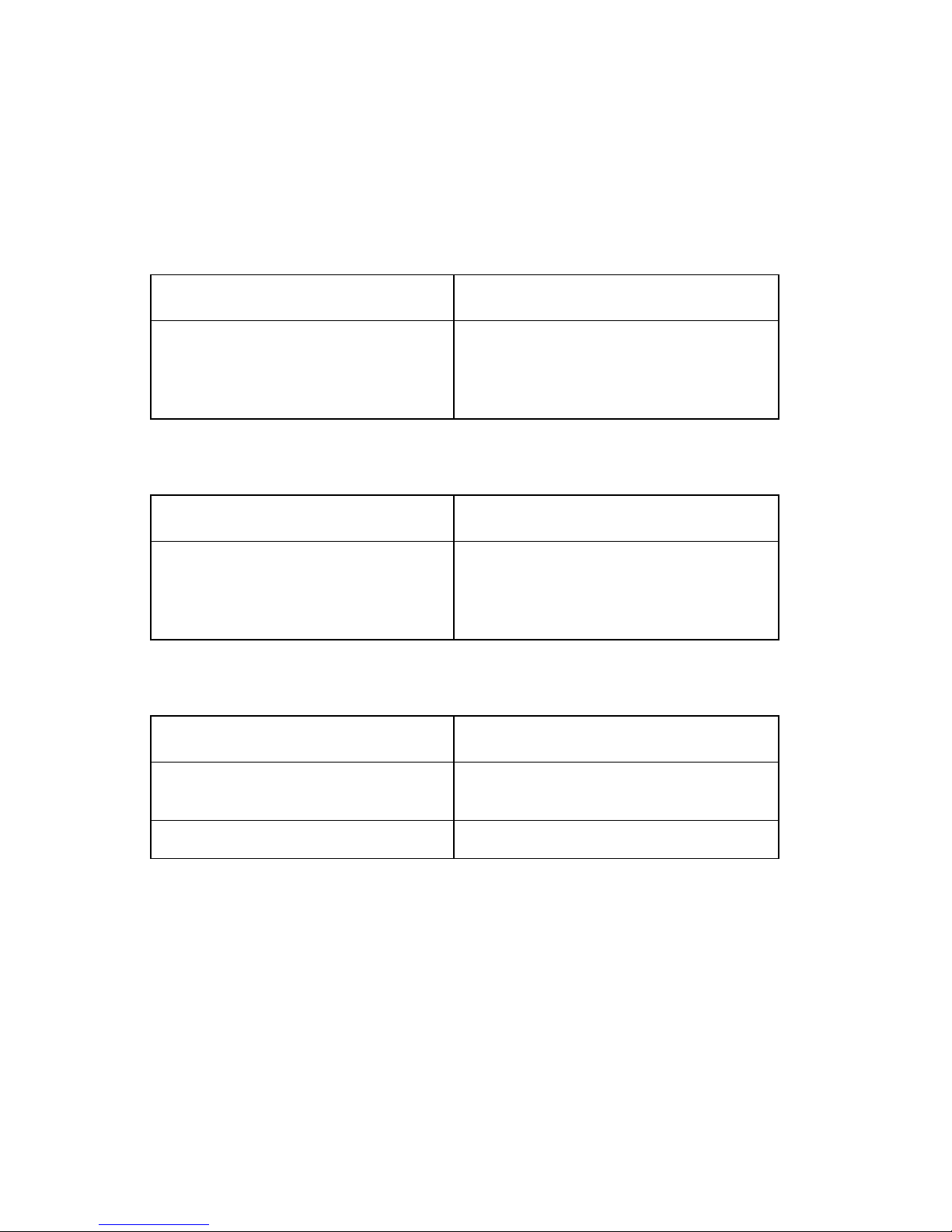

Symptom Tables

Locate the symptom in the following tables and take the appropriate

action.

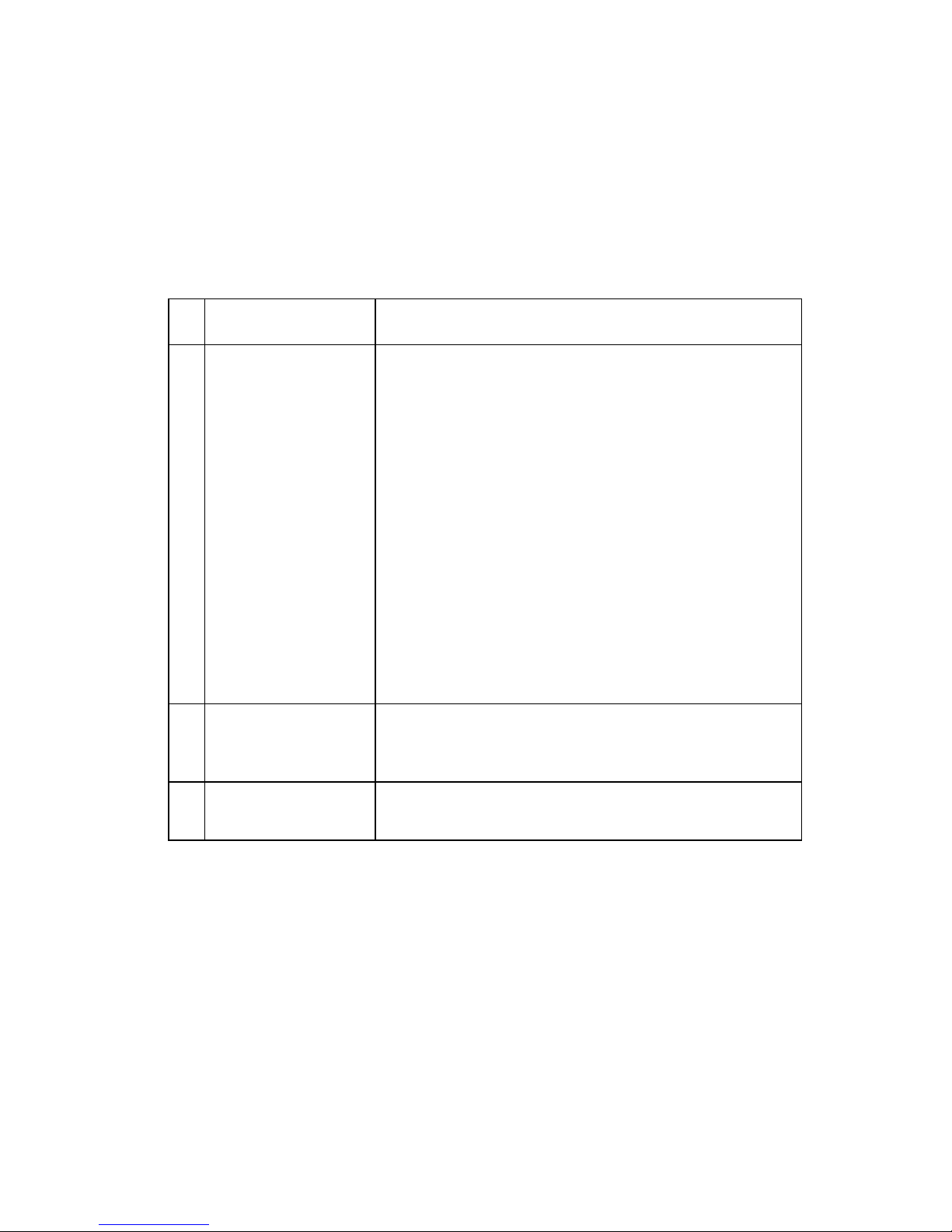

Carrier Transport Problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slams side frame

Go to the ’Carrier Transport Service

Check’ on page 2-5.

Maintenance Station Problems

Symptom Action

Maintenance station:

• Fails to cap the printheads

• Fails to clean the printheads

Go to the ’Maintenance Station

Service Check’ on page 2-7.

Operator Panel

Symptom Action

Paper Feed and / or Install print

cartridge buttons do not operate

Replace the system board.

Busy light does not come on Replace the system board

2-2

Paper Feed Problems

Symptom Action

• Fails to pick paper

• Picks more than one sheet of

paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper feed

Envelopes fail to feed Go to the ’Envelope Feed Service

Paper skews Go to the ’Paper Path Ser vice

Go to the ’Paper Feed Service

Check’ on page 2-8.

Check’ on page 2-6.

Check’ on page 2-10.

Power Problems

Symptom Action

No power in machine, motors do

not operate

Go to the ’Power Service Check’ on

page 2-11.

Print Quality Problems

Symptom Action

• Voids in characters

• Light print

• Prints off the page

• Fuzzy print

• Carrier moves but no print

• Printhead drys prematurely

• Colors print incorrectly

• Vertical alignment off

• Ink smearing

• Vertical streaks on paper

• Print lines crowded

Go to the ’Print Quality Service

Check’ on page 2-12.

Go to the ’Paper Feed Service

Check’ on page 2-8.

Diagnostic Information 2-3

Power-On Self Test (POST) Sequence

When you turn the printer on it performs a POST. Turn yourmachine

on and check for a correct POST operation by observing the

following:

1. The lights come on.

2. The carrier moves.

3. The paper feed gears turn.

4. After 30 seconds the carrier moves over the maintenance station and caps the printhead.

5. All motors stop and the power light stays on.

If your machine completes POST with no errors, go to the ’Error

Indicator Table’ on page 2-1, locate the symptom and take the

indicated action.

If your machine does not complete POST, locate the symptom in the

following table and take the indicated action.

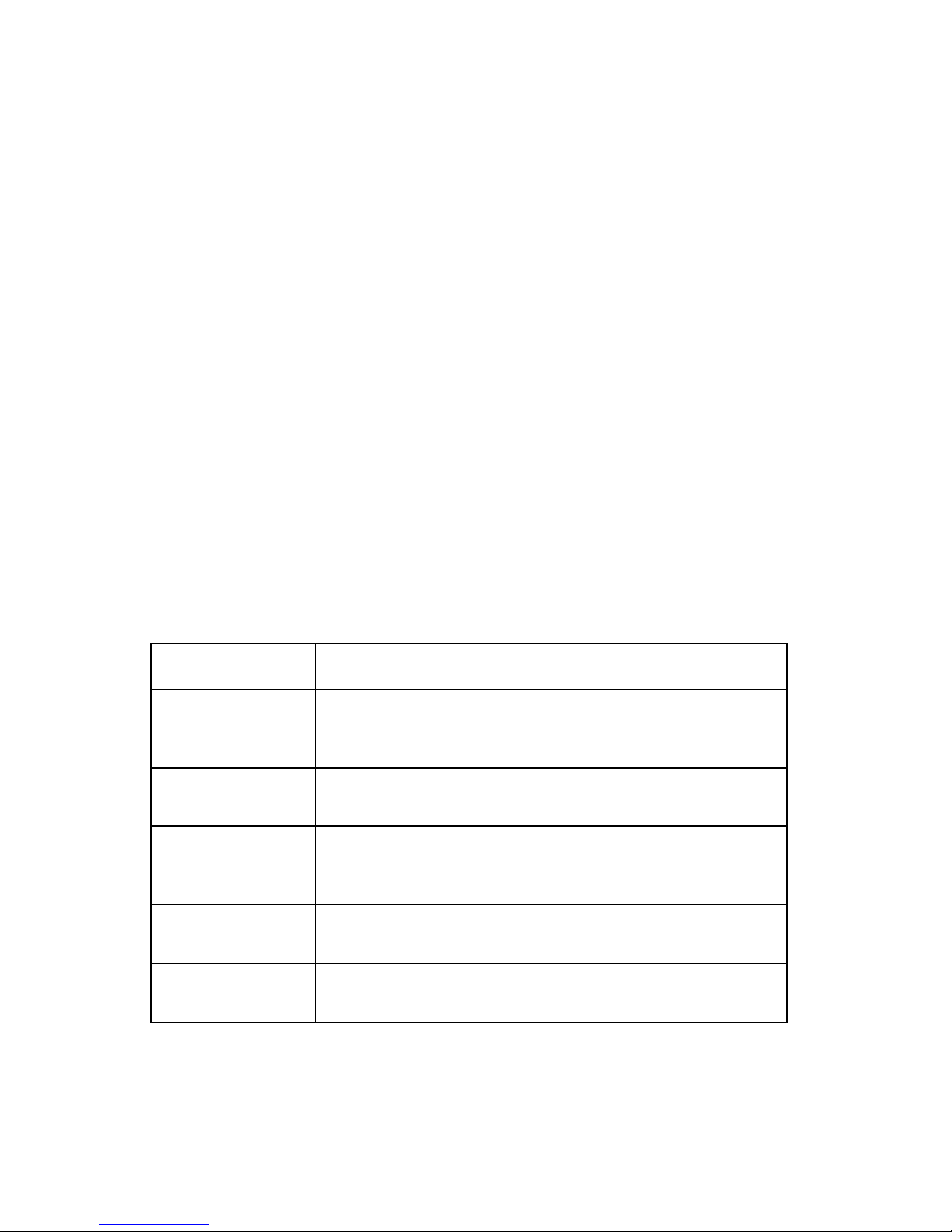

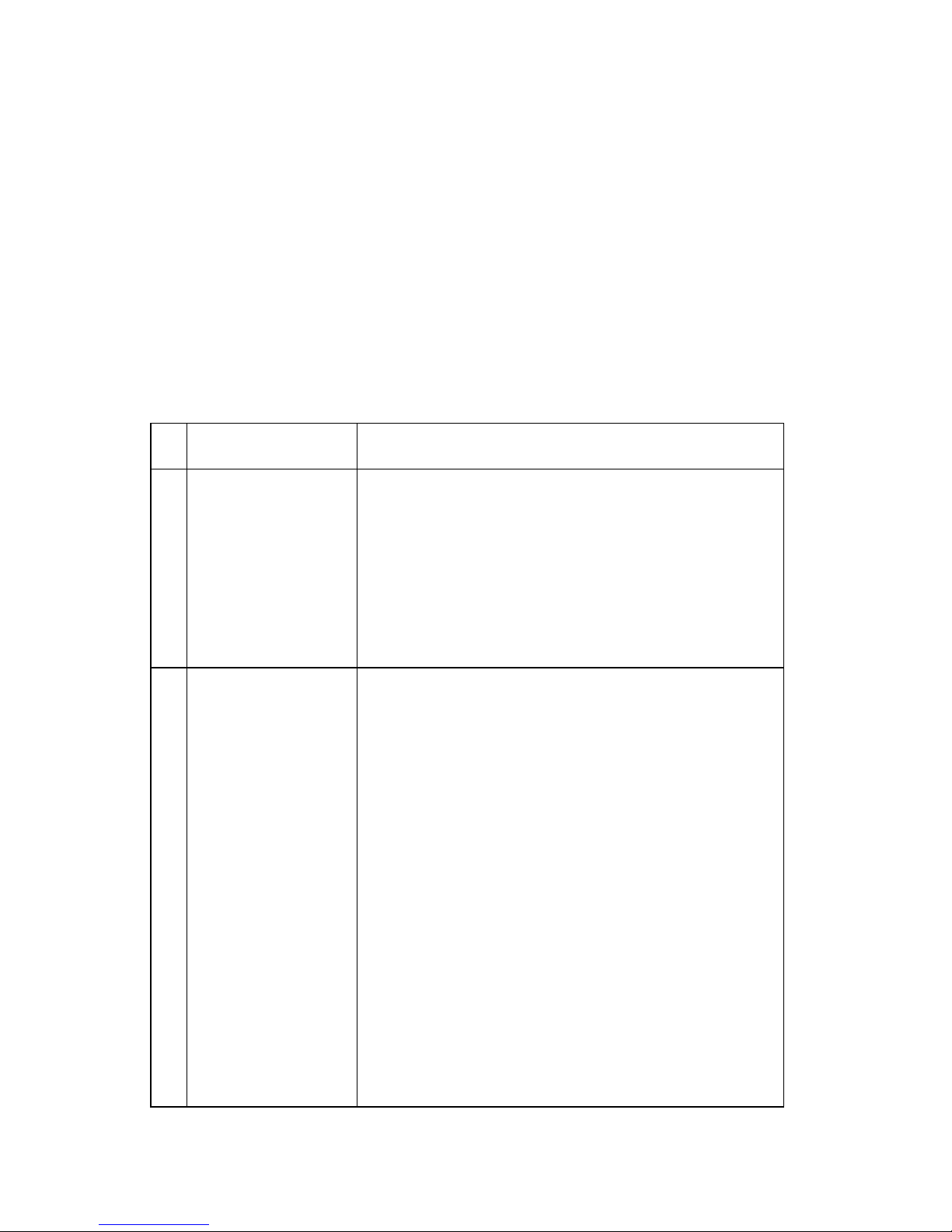

POST Symptom Table

Symptom Action

No Power On

light and no

motors run

Power light, but

no busy light

Paper feed

gears do not

turn

Carrier doesn’t

move

Carrier slams

side frame

Go to the ’Power Service Check’ on page 2-11.

Replace the system board.

Go to the ’Paper Feed Service Check’ on page 2-8.

Go to the ’Carrier Transport Service Check’ on page

2-5.

Go to the ’Carrier Transport Service Check’ on page

2-5.

2-4

Service Checks

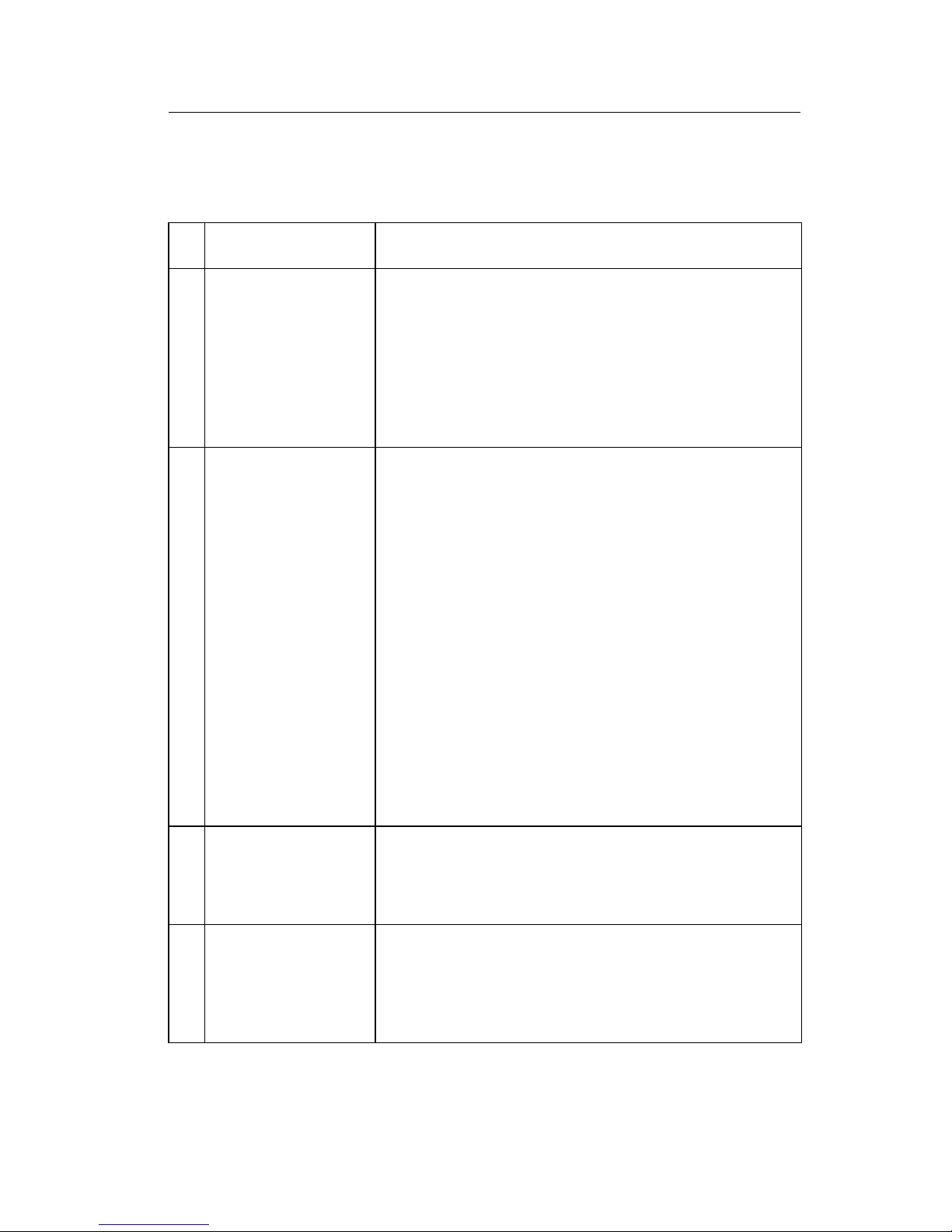

Carrier Transport Service Check

FRU Action

1 System Board Unplug the printer and disconnect CN2 from the

system board. Plug in the pri nter and check for a

pulse of (approximately) 10 V dc between

CN2-1 and ground, on the system board. If the

voltage is not present, check for motor pins

shorted to the motor housing. If you find a pin

shorted to the housing, replace the motor. If the

failure remains, replace the system board.

2 Carrier Transport

Motor

3 Carrier Guide Rod Clean the carrier rod.

Check the motor for binds, or loose motor pulley.

A noisy or chattering motor or a motor that fails to

turncanbecausedby:

• An open or short in the motor.

• An open or short in the motor driver on the

system board.

• A bind in the carrier transport mechanism.

With the carrier transport motor cable

disconnected from the system board, check for

zero to ten (0 - 10) ohms between the following

pins on the motor:

CN2-1 and CN2-2

CN2-3 and CN2-4

If the readings are incorrect, replace the motor.

Note: Lubricate the rod and the carrier rod bearing

surfaces with grease P/N 1329301.

4 Carrier Transport

Belt

Idler Pulley Parts

Carrier Frame

Check for worn, loose or broken parts. Check for

obstructions blocking carrier movement.

Carrier to carrier frame engagement should be

lubricated with grease P/N 1329301.

Diagnostic Information 2-5

FRU Action

5 Home Position

Sensor

6 Maintenance

Station

Unplug the printer and disconnect CN1 from the

system board. Plug in the printer and check for

5 V dc between CN1-3 and ground, at the system

board. If the voltage is present, replace the home

position sensor. If the voltage is not present,

replace the system board.

A problem with the maintenance station can cause

carrier movement problems at the right margin. Go

to the ’Maintenance Station Service Check’ on

page 2-7.

Envelope Feed Service Check

FRU Action

1 Envelope Guide Be sure the envelope guide has been turned to

theenvelopeloadposition.

Be sure the envelope guide is against the

envelopes.

Perform the ’Paper Feed Service Check’ on

page 2-8.

2-6

Maintenance Station Service Check

The maintenance station has two functions:

• Cleans the printhead nozzles during the print operation.

• Seals the printhead when it is not being used to prevent the

nozzles from drying.

FRU Action

1 Maintenance

Station Assembly

2 Wiper Worn wipers cause degraded print quality just after

3 Cap Worn caps cause the printhead nozzles to dry and

As the carrier moves to the right over the

maintenance station, a slot on the bottom of the

carrier engages a tab on the sled of the

maintenance station causing the cap to rise and

seal the printhead. Carrier movement to the left

uncaps the printhead. The wiper cleans the

printhead nozzles as the carrier leaves the

maintenance station. The wiper cleans the

printhead only when the carrier is moving to the

left. There should be no wiping action of the

printhead nozzles when the carrier is moving to

the right. After the cleaning operation is complete,

a tab on the maintenance station engages a tab on

the carrier, causing the wiper to lower.

Check the maintenance s tation for worn or broken

parts.

a maintenance cleaning. Check for loose or worn

wipers.

clog. Check for loose or worn caps.

Diagnostic Information 2-7

Paper Feed Service Check

If your machine does not have paper jam problems, continue with

the service check. If your machine does have a paper jam problem,

examine it for the following before you begin the service check:

• Check the entire paper path for obstructions.

• Be sure there is not too much paper in the sheet feeder.

• Be sure the correct type of paper is being used.

• Check for static in the paper.

FRU Action

1 System Board Unplug the printer and disconnect CN3 from the

system board. Plug the printer in and check for a

pulse of 24 V dc between CN3-1 and ground and

CN3-2andgroundonthesystemboard.Ifthe

voltage is not present, check for motor pins

shorted to the motor housing. If you find a shorted

pin, replace the motor. If you still have a failure

after replacing the motor, replace the system

board.

2 Paper Feed Motor A noisy or chattering motor or a motor that fails to

turn, can be caused by an open or short in the

motor, an open or short in the motor driver on the

system board, or a bind in the paper feed

mechanism. With the paper feed motor cable

disconnected from the system board, check for 60

ohms (±15 ohms) between the following pins on

the motor:

Pin2toPin5,Pin2toPin6

130 ohms (±20 ohms) between pins 5 and 6. If the

readings are incorrect, replace the motor.

Although the paper feeds in a forward direction

only, the paper feed motor turns in two directions.

If the paper feed motor turns in one direction only,

replace the system board.

Binds in the paper feed motor or gear train can

cause intermittent false paper jam errors. Remove

the paper feed motor and check the shaft forbinds.

Also check for loose or worn motor gear.

2-8

Loading...

Loading...