Page 1

Lexmark 3000 Color Jetprinter™

• Table of Contents

• Start Diagnostics

4095-001

• Safety and Notices

• Trademarks

• Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

First Edition (June, 1997)

The following paragraph does not apply to any country where such

provisions are inconsistent with local law:LEXMARK

INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS”

WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of

express or implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical

errors. Changes are periodically made to the information herein; these

changes will be incorporated in later editions. Improvements or changes

in the products or the programs described may be made at any time.

Publications are not stocked at the address given below; requests for

publications should be made to your point of purchase.

A form for reader’s comments is provided at the back of this publication.

If the form has been removed, comments may be addressed to Lexmark

International, Inc., Department D22A/035-3, 740 New Circle Road N.W.,

Lexington,Kentucky 40550, U.S.A. In the United Kingdom and Eire, send

to Lexmark International Ltd., Marketing and Services Department,

Westhorpe House, Westhorpe, Marlow Bucks SL7 3RQ. Lexmark may

use or distribute any of the information you supply in any way it believes

appropriate without incurring any obligation to you. If your printer has

broken or missing parts, or if you are missing publications, call 1-8004LEXBMP. In other countries, contact your point of purchase. You can

obtain additional copies of publications related to this product by calling

1-800-553-9727. In the United Kingdom and Eire, call 0628-481500. In

other countries, contact your point of purchase.

Lexmark is a trademark of Lexmark International, Inc., registered in the

United States and/or other countries. Other trademarks are the property

of their respective owners.

© Copyright Lexmark International, Inc. 1997. All Rights Reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED

RIGHTS. Use, duplication or disclosure by the Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013

and in applicable FAR provisions: Lexmark International, Inc., Lexington,

KY 40550.

Page 3

Preface..............................................v

SafetyInformation...................................vi

GeneralInformation...................................1-1

OperatorPanel....................................1-1

PowerConsumption................................1-1

MaintenanceApproach..............................1-2

Abbreviations.....................................1-2

DiagnosticInformation................................2-1

Start............................................2-1

ErrorIndicatorTable.............................2-1

SymptomTables...............................2-2

Power-OnSelfTest(POST)Sequence..............2-4

POSTSymptomTable...........................2-4

ServiceChecks....................................2-5

CarrierTransportServiceCheck...................2-5

EnvelopeFeedServiceCheck.....................2-6

MaintenanceStationServiceCheck................2-7

PaperFeedServiceCheck.......................2-8

............................................2-10

PaperPathServiceCheck.......................2-10

PowerServiceCheck...........................2-11

PrintQualityServiceCheck......................2-12

DiagnosticAids......................................3-1

PrintNVRAMContents..............................3-2

NVRAMDefaults...................................3-3

ResetNVRAMtoEMEADefaults...................3-3

ResetNVRAMtoU.S.Defaults....................3-3

TestPage........................................3-4

RepairInformation....................................4-1

HandlingESD-SensitiveParts........................4-1

Adjustments......................................4-2

RemovalProcedures...............................4-2

ReleasingPlasticLatches........................4-2

AccessCoverRemoval..........................4-3

BaseAssemblyRemoval.........................4-3

CarrierBeltRemoval............................4-3

CarrierFrameAssemblyRemoval..................4-4

CarrierHomeSensorRemoval....................4-4

CarrierTransportMotorRemoval...................4-5

DriveTrainAssemblyRemoval....................4-5

FrontCoverRemoval............................4-6

GutterPadRemoval.............................4-6

iii

Page 4

LargeFeedRollRemoval........................4-7

MaintenanceStationAssemblyRemoval............4-7

MaintenanceWiperandCapRemoval..............4-7

MidFrameAssemblyRemoval....................4-8

PaperFeedMotorRemoval......................4-8

PowerSupplyRemoval..........................4-8

PrintheadCarrierAssemblyRemoval...............4-9

RearCoverRemoval............................4-9

SheetFeederRemoval..........................4-9

SmallFeedRollAssemblyRemoval...............4-10

SmallFeedRollBracketAssemblyRemoval........4-10

SystemBoardRemoval.........................4-11

Connectors..........................................5-1

PreventiveMaintenance...............................6-1

LubricationSpecifications...........................6-1

PartsCatalog........................................7-1

HowtoUseThisPartsCatalog.......................7-1

Assembly1:Covers.............................7-2

Assembly2:PaperFeed/CarrierTransport/Maintenance7-4

Assembly3:Electronics.........................7-8

Assembly4:Carrier............................7-12

Assembly5:SheetFeeder......................7-14

ivContents

Page 5

Preface 1

Thismanualisdividedintothefollowingchapters:

1.GeneralInformationcontainsageneraldescriptionofthe

printerandthemaintenanceapproachusedtorepairit.Special

toolsandtestequipmentarelistedinthischapter,aswellas

generalenvironmentalandsafetyinstructions.

2.DiagnosticInformationcontainserrorindicatortable,symptom

table,andservicechecksusedtoisolatefailingfieldreplaceable

units(FRUs).

3.DiagnosticAidscontainstestsandchecksusedtolocateor

repeatsymptomsofprinterproblems.

4.RepairInformationprovidesinstructionsformakingprinter

adjustmentsandremovingandinstallingFRUs.

5.ConnectorLocationsusesillustrationstoidentifytheconnector

locationsandtestpointsontheprinter.

6.PreventiveMaintenancecontainsthelubricationspecifications

andrecommendationstopreventproblems.

7.PartsCatalogcontainsillustrationsandpartnumbersforindividualFRUs.

Prefacev

Page 6

SafetyInformation

Thisproductisdesigned,testedandapprovedtomeetstrict

•

globalsafetystandardswiththeuseofspecificLexmark

components.Thesafetyfeaturesofsomepartsmaynot

alwaysbeobvious.Lexmarkisnotresponsiblefortheuseof

otherreplacementparts.

•Themaintenanceinformationforthisproducthasbeen

preparedforusebyaprofessionalservicepersonandisnot

intendedtobeusedbyothers.

•Theremaybeanincreasedriskofelectricshockand

personalinjuryduringdisassemblyandservicingofthis

product.Professionalservicepersonnelshouldunderstand

thisandtakenecessaryprecautions.

ConsignesdeSécurité

Ceproduitaétéconçu,testéetapprouvépourrespecterles

•

normesstrictesdesécuritéglobalelorsdel'utilisationde

composantsLexmarkspécifiques.Lescaractéristiquesde

sécuritédecertainsélémentsnesontpastoujoursévidentes.

Lexmarknepeutêtretenuresponsabledel'utilisation

d'autrespiècesderechange.

•Lesconsignesd'entretienetderéparationdeceproduit

s'adressentuniquementàunpersonneldemaintenance

qualifié.

•Ledémontageetl'entretiendeceproduitpouvantprésenter

certainsrisquesélectriques,lepersonneld'entretienqualifié

devraprendretouteslesprécautionsnécessaires.

vi

Page 7

Normedisicurezza

Ilprodottoèstatoprogettato,testatoeapprovatoin

•

conformitàaseveristandarddisicurezzaeperl’utilizzocon

componentiLexmarkspecifici.Lecaratteristichedisicurezza

dialcunepartinonsempresonodiimmediatacomprensione.

Lexmarknonèresponsabileperl’utilizzodipartidiricambio

dialtriproduttori.

•Leinformazioniriguardantilamanutenzionediquesto

prodottosonoindirizzatesoltantoalpersonalediassistenza

autorizzato.

•Durantelosmontaggioelamanutenzionediquestoprodotto,

ilrischiodisubirescosseelettricheedanniallapersonaèpiù

elevato.Ilpersonalediassistenzaautorizzato,deve,quindi,

adottareleprecauzioninecessarie.

Sicherheitshinweise

DiesesProduktunddiezugehörigenKomponentenwurden

•

entworfenundgetestet,umbeimEinsatzdieweltweit

gültigenSicherheitsanforderungenzuerfüllen.Die

sicherheitsrelevantenFunktionenderBauteileundOptionen

sindnichtimmeroffensichtlich.SofernTeileeingesetzt

werden,dienichtvonLexmarksind,wirdvonLexmark

keinerleiVerantwortungoderHaftungfürdiesesProdukt

übernommen.

•DieWartungsinformationenfürdiesesProduktsind

ausschließlichfürdieVerwendungdurcheinen

Wartungsfachmannbestimmt.

•WährenddesAuseinandernehmensundderWartungdes

GerätsbestehteinzusätzlichesRisikoeineselektrischen

SchlagsundkörperlicherVerletzung.Daszuständige

FachpersonalsollteentsprechendeVorsichtsmaßnahmen

treffen.

Prefacevii

Page 8

PautasdeSeguridad

Esteproductosehadiseñado,verificadoyaprobadopara

•

cumplirlosmásestrictosestándaresdeseguridadglobal

usandoloscomponentesespecíficosdeLexmark.Puede

quelascaracterísticasdeseguridaddealgunaspiezasno

seansiempreevidentes.Lexmarknosehaceresponsable

delusodeotraspiezasderecambio.

•Lainformaciónsobreelmantenimientodeesteproducto

estádirigidaexclusivamentealpersonalcualificadode

mantenimiento.

•Existemayorriesgodedescargaeléctricaydedaños

personalesduranteeldesmontajeylareparacióndela

máquina.Elpersonalcualificadodebeserconscientedeeste

peligroytomarlasprecaucionesnecesarias.

InformaçõesdeSegurança

Esteprodutofoiconcebido,testadoeaprovadopara

•

satisfazerospadrõesglobaisdesegurançanautilizaçãode

componentesespecíficosdaLexmark.Asfunçõesde

segurançadealgunsdoscomponentespodemnãoser

sempreóbvias.ALexmarknãoéresponsávelpelautilização

deoutroscomponentesdesubstituição.

•Asinformaçõesdesegurançarelativasaesteproduto

destinam-seaprofissionaisdestesserviçosenãodevemser

utilizadasporoutraspessoas.

•Riscodechoqueseléctricoseferimentosgravesdurantea

desmontagememanutençãodesteproduto.Osprofissionais

destesserviçosdevemestaravisadosdestefactoetomaros

cuidadosnecessários.

viii

Page 9

InformaciódeSeguretat

Aquestproducteestàdissenyat,comprovatiaprovatpertal

•

d'acomplirlesestrictesnormesdeseguretatglobalsambla

utililitzaciódecomponentsespecíficsdeLexmark.Les

característiquesdeseguretatd'algunespecespotserqueno

sempresiguinòbvies.Lexmarknoesresponsabilitzadel'us

d'altrespecesderecanvi.

•Lainformaciópelmantenimentd’aquestproducteestà

orientadaexclusivamentaprofessionalsinoestàdestinada

aningúquenohosigui.

•Elriscdexocelèctricidedanyspersonalspotaugmentar

durantelprocésdedesmuntatgeideserveid’aquest

producte.Elpersonalprofessionalhad’estar-neassabentati

prendrelesmesuresconvenients.

Prefaceix

Page 10

x

Page 11

1. General Information

The Lexmark 3000 Color Jetprinter is a personal, near laser-quality

inkjet printer. The printer contains two print cartridges (color and

black), which are customer replaceable supply items. A single

printhead provides three colors and composite black printing. The

printer also supports a black print cartridge and provides 600 X 300

dpi edge definition for professional quality text image and graphics

printing.

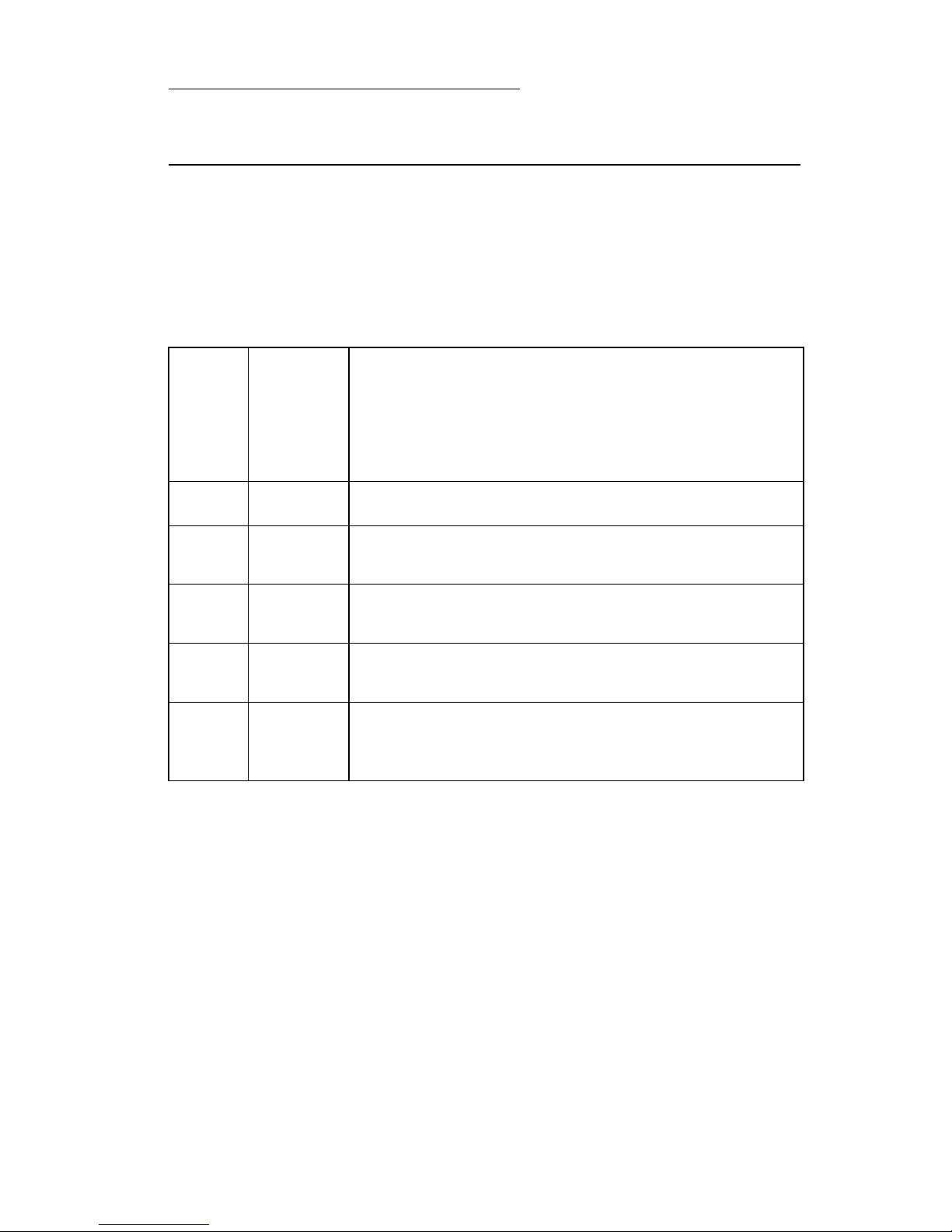

Operator Panel

Buttons Lights

Left Button

• Power On/Off

Right Button

• PaperFeed-clearsa paper jam

or loads paper when there is a

paper out condition.

Right Outer Button

• Install Cartridge -moves carrier

to the left for cartridge replacement.

Left Light

• Steady - Power On

• Blinking - Printer Error

Right Light

• Steady - Busy

• Blinking - Paper Out/Jam

Alternating Blinking Lights

• Printheads are in the load position

or printheads are installed incorrectly.

Power Consumption

•

Less than 3.5 Watts - power off and power to the printer

• 9 Watts - Idle Mode (power on - not printing)

• 12 Watts - Printing (average)

• 20 Watts - Printing (peak)

General Information 1-1

Page 12

Maintenance Approach

The diagnostic information in this manual leads you to the correct

field replaceable unit (FRU) or part. Use the symptom index, service

checks, and diagnostic aids to determine the symptom and repair

the failure. Begin with “Error Indicator Table” on page -1.

After you complete the repair, perform tests as needed to verify the

repair.

Abbreviations

EOF End of Forms

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LVPS Low Voltage Power Supply

OEM Original Equipment Manufacturer

V ac Volts alternating current

V dc Volts direct current

ZIF Zero Insertion Force

1-2

Page 13

2. Diagnostic Information

Start

Use the error indicator table, symptom tables, service checks, and

diagnostic aids in chapter 3, to determine the printer failure.

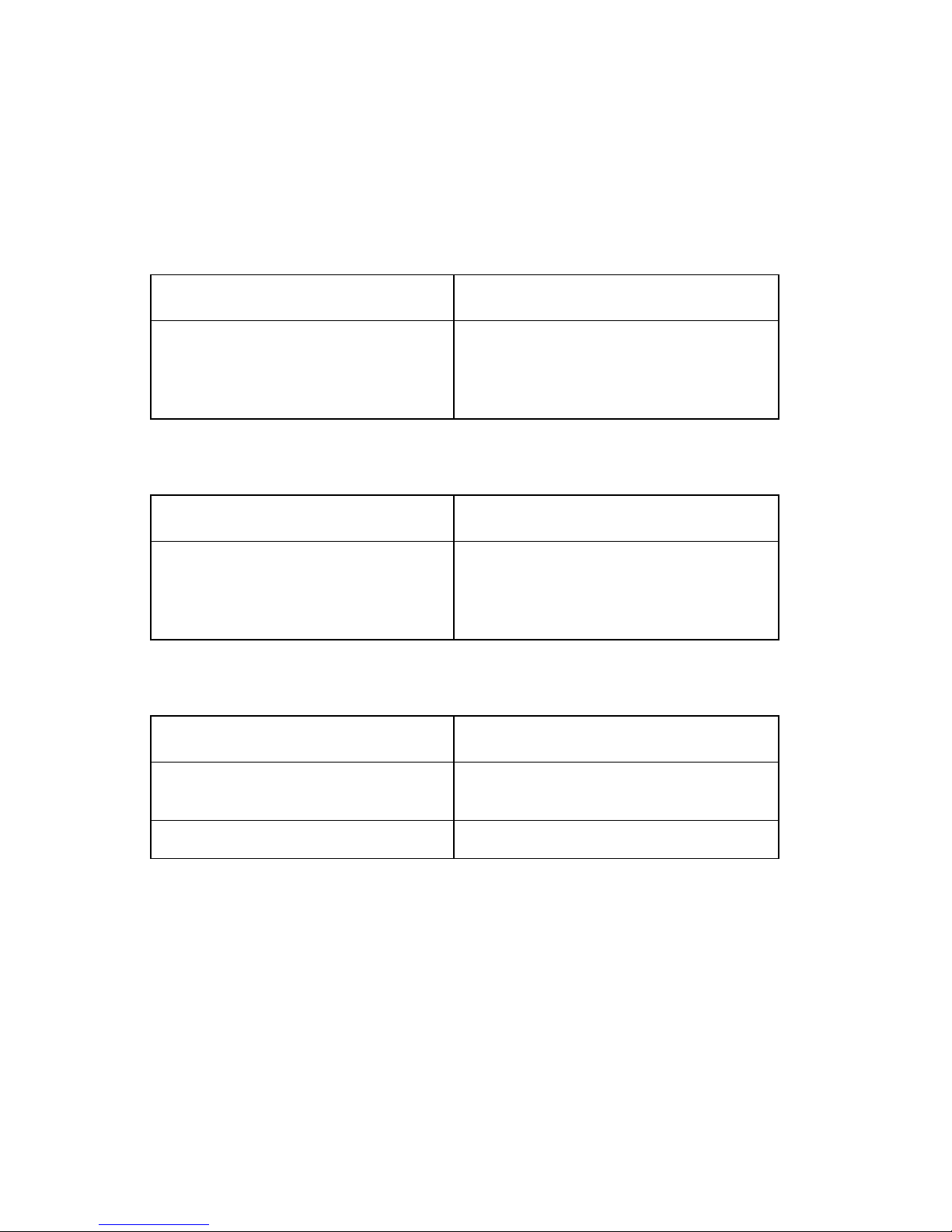

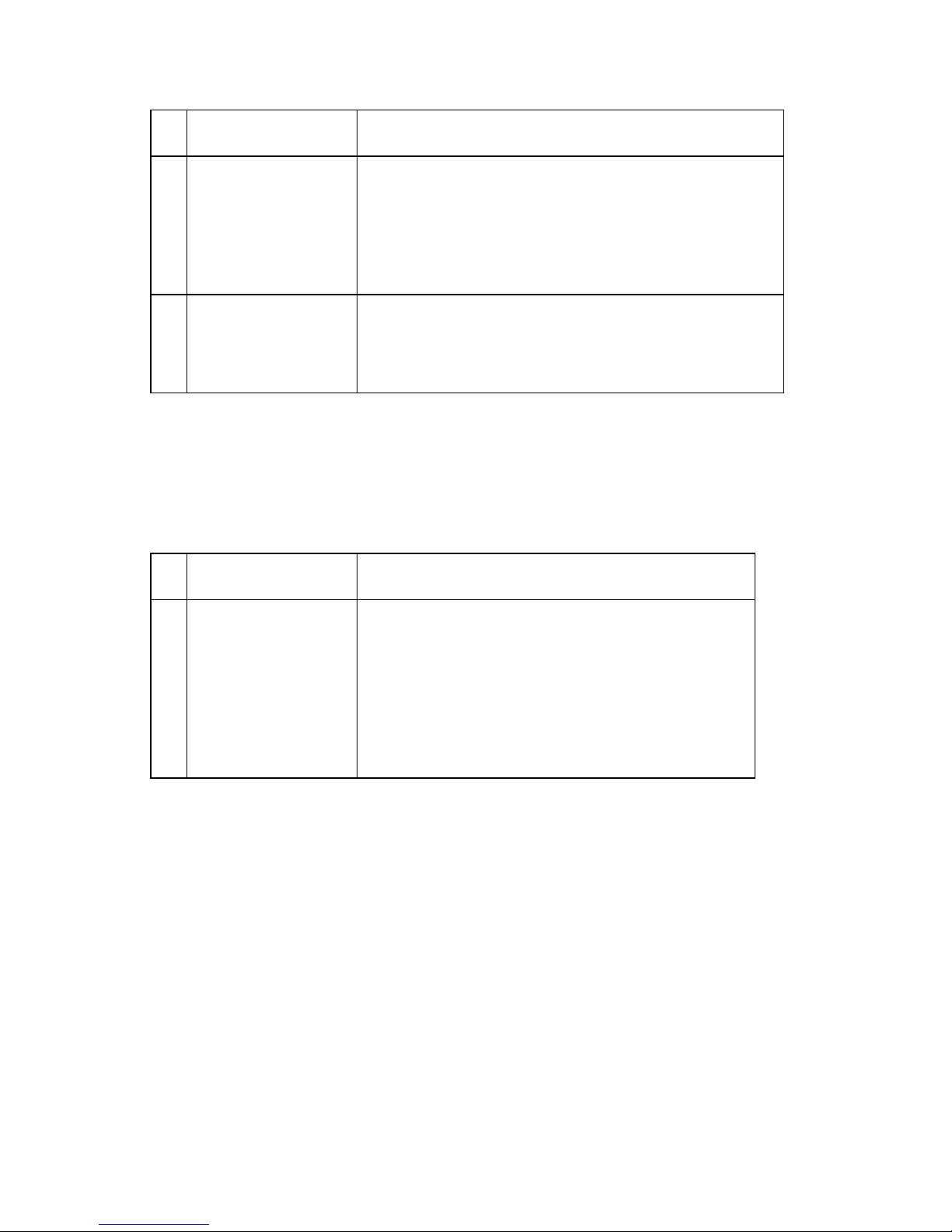

Error Indicator Table

Number

Error

Code

of

Power

Light

Flashes

Action

Blank

64

65

81

89

127

and

up

8

7

1

4

10

Replace the system board.

Replace the system board.

Go to the ’Carrier Transport Service Check’ on page

2-5.

Go to the ’Carrier Transport Service Check’ on page

2-5.

Replace the system board.

Diagnostic Information 2-1

Page 14

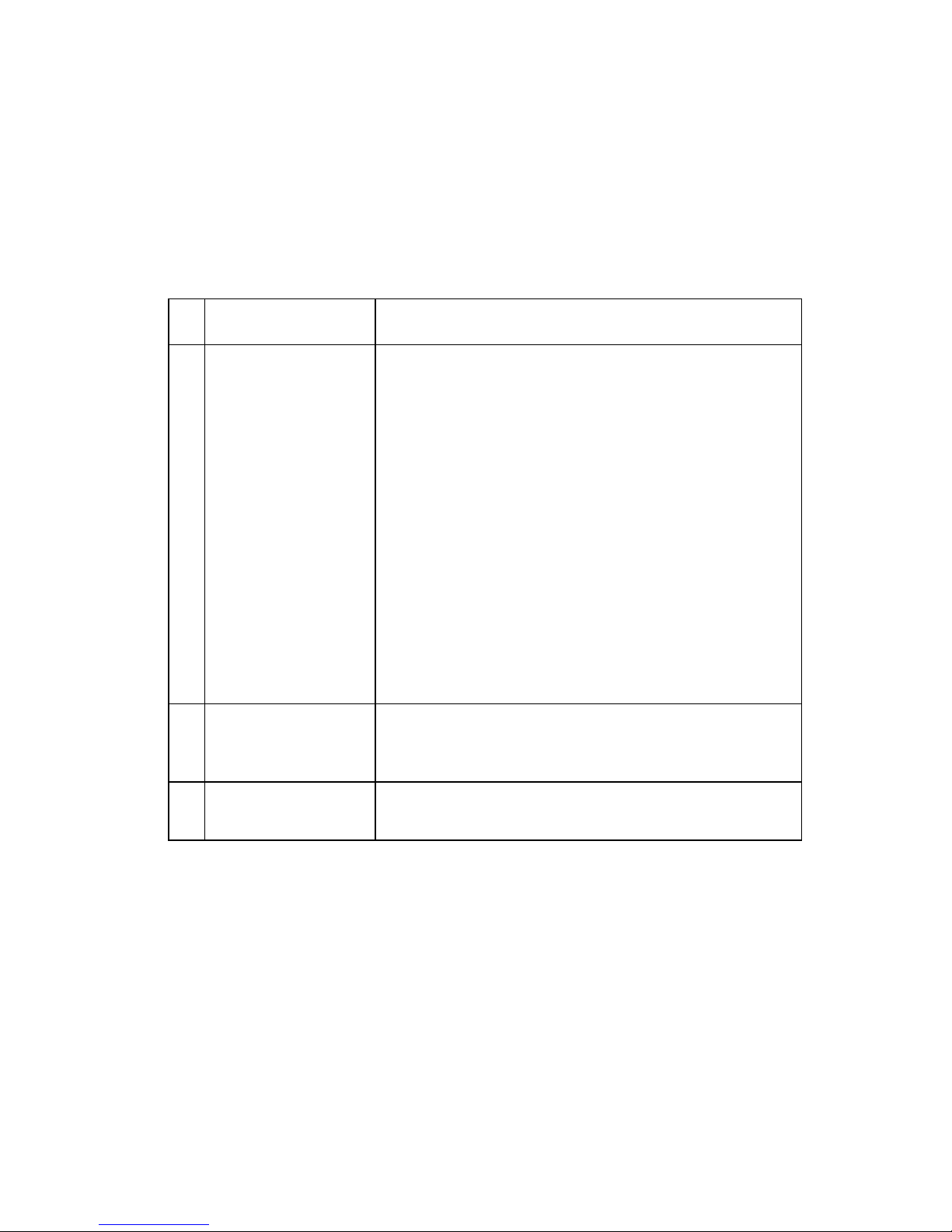

Symptom Tables

Locate the symptom in the following tables and take the appropriate

action.

Carrier Transport Problems

Symptom Action

• No carrier movement

• Slow carrier movement

• Carrier stops

• Carrier slams side frame

Go to the ’Carrier Transport Service

Check’ on page 2-5.

Maintenance Station Problems

Symptom Action

Maintenance station:

• Fails to cap the printheads

• Fails to clean the printheads

Go to the ’Maintenance Station

Service Check’ on page 2-7.

Operator Panel

Symptom Action

Paper Feed and / or Install print

cartridge buttons do not operate

Replace the system board.

Busy light does not come on Replace the system board

2-2

Page 15

Paper Feed Problems

Symptom Action

• Fails to pick paper

• Picks more than one sheet of

paper

• Picks paper but fails to feed

• Paper jams

• Paper fails to exit

• Noisy paper feed

Envelopes fail to feed Go to the ’Envelope Feed Service

Paper skews Go to the ’Paper Path Ser vice

Go to the ’Paper Feed Service

Check’ on page 2-8.

Check’ on page 2-6.

Check’ on page 2-10.

Power Problems

Symptom Action

No power in machine, motors do

not operate

Go to the ’Power Service Check’ on

page 2-11.

Print Quality Problems

Symptom Action

• Voids in characters

• Light print

• Prints off the page

• Fuzzy print

• Carrier moves but no print

• Printhead drys prematurely

• Colors print incorrectly

• Vertical alignment off

• Ink smearing

• Vertical streaks on paper

• Print lines crowded

Go to the ’Print Quality Service

Check’ on page 2-12.

Go to the ’Paper Feed Service

Check’ on page 2-8.

Diagnostic Information 2-3

Page 16

Power-On Self Test (POST) Sequence

When you turn the printer on it performs a POST. Turn yourmachine

on and check for a correct POST operation by observing the

following:

1. The lights come on.

2. The carrier moves.

3. The paper feed gears turn.

4. After 30 seconds the carrier moves over the maintenance station and caps the printhead.

5. All motors stop and the power light stays on.

If your machine completes POST with no errors, go to the ’Error

Indicator Table’ on page 2-1, locate the symptom and take the

indicated action.

If your machine does not complete POST, locate the symptom in the

following table and take the indicated action.

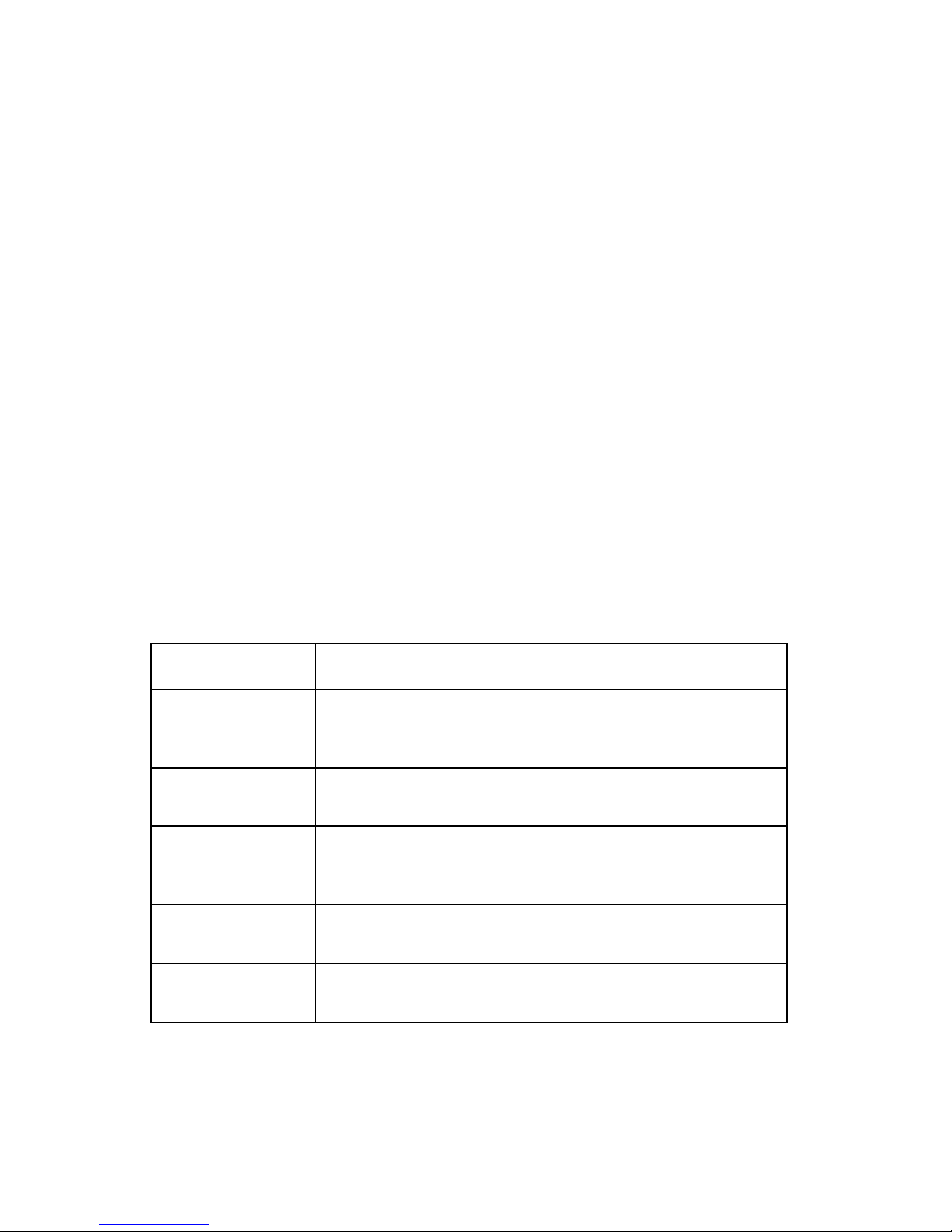

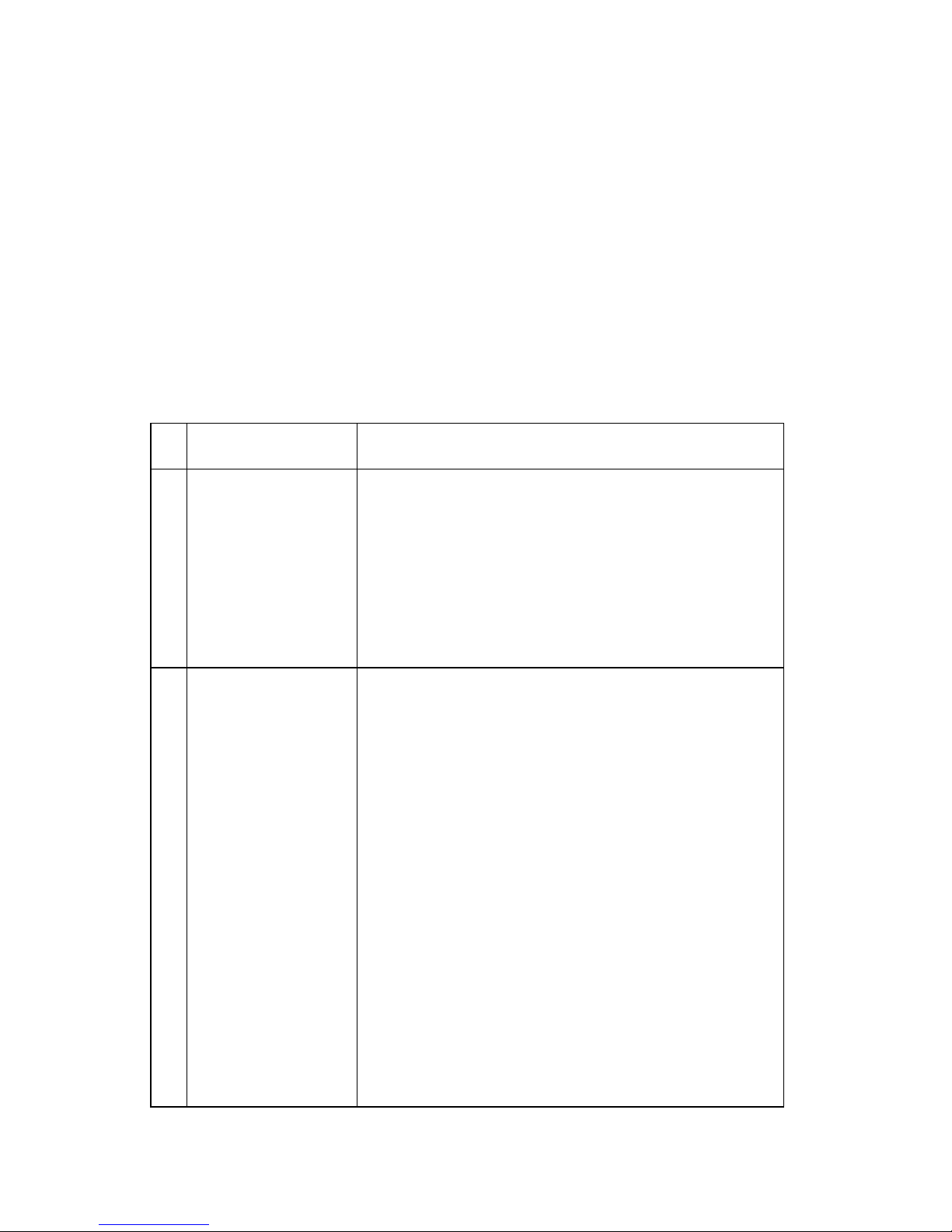

POST Symptom Table

Symptom Action

No Power On

light and no

motors run

Power light, but

no busy light

Paper feed

gears do not

turn

Carrier doesn’t

move

Carrier slams

side frame

Go to the ’Power Service Check’ on page 2-11.

Replace the system board.

Go to the ’Paper Feed Service Check’ on page 2-8.

Go to the ’Carrier Transport Service Check’ on page

2-5.

Go to the ’Carrier Transport Service Check’ on page

2-5.

2-4

Page 17

Service Checks

Carrier Transport Service Check

FRU Action

1 System Board Unplug the printer and disconnect CN2 from the

system board. Plug in the pri nter and check for a

pulse of (approximately) 10 V dc between

CN2-1 and ground, on the system board. If the

voltage is not present, check for motor pins

shorted to the motor housing. If you find a pin

shorted to the housing, replace the motor. If the

failure remains, replace the system board.

2 Carrier Transport

Motor

3 Carrier Guide Rod Clean the carrier rod.

Check the motor for binds, or loose motor pulley.

A noisy or chattering motor or a motor that fails to

turncanbecausedby:

• An open or short in the motor.

• An open or short in the motor driver on the

system board.

• A bind in the carrier transport mechanism.

With the carrier transport motor cable

disconnected from the system board, check for

zero to ten (0 - 10) ohms between the following

pins on the motor:

CN2-1 and CN2-2

CN2-3 and CN2-4

If the readings are incorrect, replace the motor.

Note: Lubricate the rod and the carrier rod bearing

surfaces with grease P/N 1329301.

4 Carrier Transport

Belt

Idler Pulley Parts

Carrier Frame

Check for worn, loose or broken parts. Check for

obstructions blocking carrier movement.

Carrier to carrier frame engagement should be

lubricated with grease P/N 1329301.

Diagnostic Information 2-5

Page 18

FRU Action

5 Home Position

Sensor

6 Maintenance

Station

Unplug the printer and disconnect CN1 from the

system board. Plug in the printer and check for

5 V dc between CN1-3 and ground, at the system

board. If the voltage is present, replace the home

position sensor. If the voltage is not present,

replace the system board.

A problem with the maintenance station can cause

carrier movement problems at the right margin. Go

to the ’Maintenance Station Service Check’ on

page 2-7.

Envelope Feed Service Check

FRU Action

1 Envelope Guide Be sure the envelope guide has been turned to

theenvelopeloadposition.

Be sure the envelope guide is against the

envelopes.

Perform the ’Paper Feed Service Check’ on

page 2-8.

2-6

Page 19

Maintenance Station Service Check

The maintenance station has two functions:

• Cleans the printhead nozzles during the print operation.

• Seals the printhead when it is not being used to prevent the

nozzles from drying.

FRU Action

1 Maintenance

Station Assembly

2 Wiper Worn wipers cause degraded print quality just after

3 Cap Worn caps cause the printhead nozzles to dry and

As the carrier moves to the right over the

maintenance station, a slot on the bottom of the

carrier engages a tab on the sled of the

maintenance station causing the cap to rise and

seal the printhead. Carrier movement to the left

uncaps the printhead. The wiper cleans the

printhead nozzles as the carrier leaves the

maintenance station. The wiper cleans the

printhead only when the carrier is moving to the

left. There should be no wiping action of the

printhead nozzles when the carrier is moving to

the right. After the cleaning operation is complete,

a tab on the maintenance station engages a tab on

the carrier, causing the wiper to lower.

Check the maintenance s tation for worn or broken

parts.

a maintenance cleaning. Check for loose or worn

wipers.

clog. Check for loose or worn caps.

Diagnostic Information 2-7

Page 20

Paper Feed Service Check

If your machine does not have paper jam problems, continue with

the service check. If your machine does have a paper jam problem,

examine it for the following before you begin the service check:

• Check the entire paper path for obstructions.

• Be sure there is not too much paper in the sheet feeder.

• Be sure the correct type of paper is being used.

• Check for static in the paper.

FRU Action

1 System Board Unplug the printer and disconnect CN3 from the

system board. Plug the printer in and check for a

pulse of 24 V dc between CN3-1 and ground and

CN3-2andgroundonthesystemboard.Ifthe

voltage is not present, check for motor pins

shorted to the motor housing. If you find a shorted

pin, replace the motor. If you still have a failure

after replacing the motor, replace the system

board.

2 Paper Feed Motor A noisy or chattering motor or a motor that fails to

turn, can be caused by an open or short in the

motor, an open or short in the motor driver on the

system board, or a bind in the paper feed

mechanism. With the paper feed motor cable

disconnected from the system board, check for 60

ohms (±15 ohms) between the following pins on

the motor:

Pin2toPin5,Pin2toPin6

130 ohms (±20 ohms) between pins 5 and 6. If the

readings are incorrect, replace the motor.

Although the paper feeds in a forward direction

only, the paper feed motor turns in two directions.

If the paper feed motor turns in one direction only,

replace the system board.

Binds in the paper feed motor or gear train can

cause intermittent false paper jam errors. Remove

the paper feed motor and check the shaft forbinds.

Also check for loose or worn motor gear.

2-8

Page 21

FRU Action

3DriveTrain

Assembly

Check for binds in the gear train and paper feed

mechanism by removing the paper feed motor and

rotating the large gear by hand. If you notice a

bind, replace the drive train assembly. Check the

feed clutch inside the large feed gear. Remove the

sheet feeder.Turn the clutch gear and check that it

rotates freely in one direction and locks when

turned in the opposite direction.

4 Auto Sheet

Check the pick rollers for wear.

Feeder

5 Mid Frame Asm Check the friction wheels, exit roller and star

rollers for wear.

6End-of-Forms

Flag and Spring

Check for binds or damage. If binds are found,

replace the small feed roll bracket assembly.

Diagnostic Information 2-9

Page 22

Paper Path Service Check

Examine the machine for the following before you begin this service

check:

• Check the entire paper path for obstructions.

• Be sure the correct type of paper is being used.

• Be sure the printer is installed on a flat surface.

FRU Action

1 Large and Small

Feed Rollers

2 Small Feed Roller

Springs

3 Auto Sheet

Feeder

4 Mid Frame Asm Check the following for wear:

5 End-of-Forms

Flag

Check for wear and binds.

Check for damage.

Check the pick rollers for wear.

• Friction wheels

•Exitroller

•Starrollers

Check for binds or damage.

2-10

Page 23

Power Service Check

FRU Action

1 Power Supply Disconnect CN9 from the system board and check

the following voltages on the power supply cable:

• CN9-1 to GND = +5 V dc

• CN9-3 to GND = + 24 V dc

If you do not have correct voltage, replace the

power supply. Be sure to unplug the machine

before you reconnect the power supply to the

system board.

2 Printhead Cable

Carrier Home

Sensor

Parallel Cable

Paper Feed Motor

Carrier Transport

Motor

3 System Board If the symptom has not changed, replace the

Unplug the printer. Disconnect one of the

printhead cables and plug in the printer. Look for a

symptom change. Check the failing part for shorts

and replace as necessary.

Repeat this procedure for the carrier home sensor,

parallel cable, carrier transport motor and paper

feed motor.

system board.

Diagnostic Information 2-11

Page 24

Print Quality Service Check

FRU / Function Action

1 Print Cartridge Be sure the machine contains good print

cartridges.

2ColorPrint

Cartridge Cross

Contamination

3 Printhead Carrier

Assembly

Cross contamination of color inks results in

incorrect colors printed, as when green prints for

yellow, (when yellow and blue are mixed in the

print cartridge). This problem resolves quickly as

the print cartridge is used.

If cross contamination occurs, check the following:

• Maintenance station wiper for damage.

• Printhead nozzle plate was resealed with tape.

Reseat the printhead cables in the system board

and check the following parts for wear or damage:

• Print Cartridge Latch

• Latch Spring

•Carrier

2-12

Page 25

FRU / Function Action

4 System Board

Printhead Cable

Rubber Backer

• Run the ’Test Page’ on page 3-4. Look for a

break in the diagonal line of the test pattern. A

broken line indicates one or more print nozzles

are not working. Run the test again to verify the

failure. If there are even breaks in the diagonal

line similar to the pattern shown below, ensure

the printhead cables are connected properly. If

the symptom remains, replace the system

board.

If there is a single break or random breaks in the

diagonal line, check the following:

• Check the gold-plated contacts, on the end of

the cable that connect to the carrier, for dirt and

wear. Use only a clean dry cloth to clean the

contacts. Also check the cable for damage. You

mayneedtoremovethecablefromthecarrier

to inspect it.

• A worn rubber backer results in poor contact

between the printhead cable and the print

cartridge. Check the rubber backer for wear.

5 Maintenance

Station

Intermittent nozzle failures can be caused by worn

parts in the maintenance station. Perform the

’Maintenance Station Service Check’ on page 2-7,

then return to this check.

6 Paper Feed Ink smudging and smearing can be caused by

paper problems or problems in the paper feed

area.

Check the following:

• Correct type of paper is being used. Also check

the paper for curl or wrinkles.

• Feed rollers for wear, dirt, or looseness.

• Gears for wear or binds.

• Paper path for obstructions.

Diagnostic Information 2-13

Page 26

FRU / Function Action

7 Carrier Transport Blurredprint and voids can be caused by problems

in the carrier transport area. Check the following:

• Carrier transport belt for wear.

• Carrier guide rod for wear or dirt. If dirty, clean

and lubricate.

• Carrier to carrier frame engagement should be

lubricated with grease P/N 1329301.

• Idler pulley parts for wear, damage, or

looseness.

8 Alignment Uneven vertical lines can be adjusted by

performing the bidirectional alignment. The user is

directed, through the Printer Control program, to

perform the bidirectional printing alignment, when

replacing a print cartridge.

2-14

Page 27

3. Diagnostic Aids

Use these diagnostic test procedures to verify a repair. The test

procedures are entered by pressing and holding a button, or buttons,

as you turn on the printer. To begin the test, hold the buttons until

both the operator panel lights come on and then release the buttons

after five seconds. Some tests require the End-of-Form Flag to be

out of the sensor.

To remove the End-of-Form Flag from the sensor

1. Open the sheet feeder.

2. Place a sheet of paper in the paper path until the End-of-Form

Flag is tripped.

To terminate the test, turn the printer off.

:

Diagnostic Aids 3-1

Page 28

Print NVRAM Contents

ThistestprintsthecontentsofNVRAM,whichcanbeusedfor

diagnostic purposes.

To run the test:

1. Place a sheet of paper in the sheet feeder far enough to push

the End-of-Form flag out of the sensor.

2. Load paper into the sheet feeder.

3. With the printer off, press and hold the Paper Feed button and

turn the printer on. The contents of NVRAM print.

3-2

Page 29

NVRAM Defaults

Reset NVRAM to EMEA Defaults

This test resets the user defaults area of NVRAM to the EMEA

factory defaults. The page count and the error log do not change.

Note: Factory defaults are initially set to U.S.

To run the test

1. With the printer off, press and hold the Paper Feed and Install

Print C artridge buttons while turning the printer on.

2. Release the buttons to reset NVRAM to the EMEA factory

defaults.

A sheet of paper feeds and verifies the defaults have been set by

printing “EMEA”.

:

Reset NVRAM to U.S. Defaults

This test resets the user defaults area of NVRAM to the U.S. factory

defaults. The page count and the error log do not change.

Note: Factory defaults are initially set to U.S.

To run the test:

1. With the printer off, press and hold the Install Print

Cartridge button while turning the printer on:

2. Releasing the buttons resets NVRAM to the U.S. factory

defaults.

A sheet of paper will feed and verify the defaults have been set by

printing “U.S.”.

Diagnostic Aids 3-3

Page 30

Test Page

This test prints the test page.

To run a complete test page of black and color patterns, be sure the

print cartridge is in good condition. Install a black print cartridge.

To enter the test:

• Press and hold the Paper Feed button while turning the printer

on. Paper feeds from the sheet feeder and prints the test page.

Pagescontinue to print until you turn off the power or unplug the

printer.

The test page prints the following lines:

Line 1 - Code level and date.

Line 2 - Manufacturer name.

Line 3 - Model name.

Line 4 - U.S. or EMEA defaults.

Line 5 - Page count followed by the last error.

Line6-Motortype.

The next line is the black print cartridge nozzle pattern. The next

three lines are the purge pattern where all nozzles are printing. This

action cleans (purges) the nozzles. Another nozzle test pattern

follows.

These test patterns are used to verify all print cartridge nozzles are

working. There should be no breaks in the diagonal line. A break in

the diagonal line indicates one or more nozzles are not working.

The rest of the page contains the user defaults followed by a printout

of the printer resident fonts.

3-4

Page 31

4. Repair Information

This chapter explains how to make adjustments to the printer and

how to remove defective parts.

Note: Read the following before handling electronic parts.

Handling ESD-Sensitive Parts

Many electronic products use parts that are known to be sensitive to

electrostatic discharge (ESD). To prevent damage to ESD-sensitive

parts, follow the instructions below in addition to all the usual

precautions, such as turning off power before removing logic boards:

• Keepthe ESD-sensitive part in its original shipping container (a special

“ESD bag”) until you are ready to install the part into the machine.

• Make the least-possible movements with your body to prevent an

increase of static electricity from clothing fibers, carpets, and furniture.

• Put the ESD wrist strap on your wrist. Connect the wrist band to the

system ground point. This discharges any static electricity in your body

to the machine.

• Hold the ESD-sensitive part by its edge connector shroud (cover); do

not touch its pins. If you are removing a pluggable module, use the correct tool.

• Do not place the ESD-sensitive part on the machine cover or on a

metal table; if you need to put down the ESD-sensitive part for any reason, first put it into its special bag.

• Machine covers and metal tables are electrical grounds. They increase

the risk of damage because they make a discharge path from your

body through the ESD-sensitive part. (Large metal objects can be discharge paths without being grounded.)

• Prevent ESD-sensitive parts from being accidentally touched by other

personnel. Install machine covers when you are not working on the

machine, and do not put unprotected ESD-sensitive parts on a table.

• If possible, keep all ESD-sensitive parts in a grounded metal cabinet

(case).

• Be extra careful in working with ESD-sensitive parts when cold weather

heating is used because low humidity increases static electricity.

Repair Information 4-1

Page 32

Adjustments

In the Printer Control program, the user is directed to perform the

head to head and bidirectional alignment adjustments, after

replacing a print cartridge.

Removal Procedures

The following procedures are arranged according to the name of the

printer part discussed.

CAUTION: Unplug the power cord before removing any parts.

Releasing Plastic Latches

Many of the parts are held in place with plastic latches. The latches

break easily; release them carefully. To remove such parts, press the

hook end of the latch away from the part to which it is latched.

4-2

Page 33

Access Cover Removal

1. Open the access door.

2. Push the mounting tabs toward the center of the machine.

3. Remove the access cover.

Base Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Disconnect the power supply connector at the system board.

5. Remove the two screws that secure the carrier frame to the

base assembly.

6. Remove the screw that secures the power supply frame to the

carrier frame.

7. Slide the machine off the base assembly.

Carrier Belt Removal

1. Remove the front cover.

2. Remove the retainer spring from the left side of the carrier guide

rod.

3. Remove the screw from the right side of the carrier guide rod.

4. Slide the carrier rod to the left, out of the machine.

5. Remove the carrier belt from the rear of the carrier.

6. Remove the carrier belt from the carrier transport motor pulley.

7. Remove the carrier belt.

Repair Information 4-3

Page 34

Carrier Frame Assembly Removal

The carrier rail mounted by two screws on the carrier frame is

included with the carrier frame (11B5584). The carrier rail, which is

not available as a FRU, is mounted in the elongated slots at the

factory. During adjustment, the rail is pushed to the rear as far as it

will go, before the mounting screws are tightened.

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Disconnect the power supply connector at the system board.

5. Remove the two screws that secure the carrier frame to the

base assembly.

6. Remove the screw that secures the power supply frame to the

carrier frame.

7. Slide the carrier frame assembly off the base assembly.

8. To replace the carrier frame, remove all associated parts from

the old carrier frame and install them on the new carrier frame.

Carrier Home Sensor Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Disconnect the sensor cable from the system board.

4. Remove the screw that secures the sensor to the carrier frame.

5. Remove the sensor.

4-4

Page 35

Carrier Transport Motor Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Disconnect the carrier transport motor connector from the

system board.

4. Remove the belt from the carrier transport motor pulley.

5. Remove the two screws securing the carrier transport motor to

the carr ier frame and remove the motor. Note the routing of the

motor cable.

Drive Train Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Unplug the paper feed motor assembly. Note the routing of the

motor cable.

5. Remove the two screws securing the drive train to the carrier

frame.

6. Push the drive train to the left and remove it from the carrier

frame.

Repair Information 4-5

Page 36

Front Cover Removal

1. Turn the printer over to expose the base. Remove the two cover

mounting screws [A] from the front cover. When reassembling,

do not overtighten these screws as they will break. The cover

replacement screws can be found in parts packet 11B5600.

2. Slide the cover upward and off the machine.

To reassemble:

1. Align the tabs on the front cover over the front edge of the base

assembly.

2. Rotate the front cover over the top edge of the rear cover and

press in on both sides opposite the cover latches, until they

latch.

Gutter Pad Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Remove the base assembly.

5. Remove the gutter pad from the base assembly.

4-6

Page 37

Large Feed Roll Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Removethebaseassembly.

5. Remove the system board.

6. Remove the printhead carr ier assembly.

7. Remove the small feed roll assemblies.

8. Remove the small feed roll bracket assembly.

9. Remove the mid frame assembly.

10. Remove the maintenance station assembly.

11. Turn and remove the retainer at the right end of the large feed

roller.

12. Remove the large feed roller from the carrier frame.

Maintenance Station Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Removethebaseassembly.

4. Depress the clip on the left and right side of the carrier frame

that secures the maintenance station assembly and slide the

assembly out of the machine.

Maintenance Wiper and Cap Removal

1. Remove the front cover.

2. Push the carrier to the left away from the maintenance station.

3. Gently pull the cap and wiper off their mountings.

Repair Information 4-7

Page 38

Mid Frame Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Remove the system board.

5. Remove the small feed roll assemblies.

6. Remove the small feed roll bracket assembly.

7. Remove the printhead carrier assembly.

8. Lift up the rear of the mid frame assembly and remove it from

the carrier frame.

Paper Feed Motor Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Disconnect the paper feed motor from the system board.

4. Remove the two screws mounting the paper feed motor to the

drive train assembly and remove the motor.

Power Supply Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Disconnect the power supply connector from the system board.

4. Remove the screws that secure the power supply to the carrier

frame on the left and right sides.

4-8

Page 39

Printhead Carrier Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Unlock the four printhead cable connectors and disconnect the

printhead cable from the system board.

5. Unlatch the cable retainer from the carrier frame.

6. Remove the retainer spring from the left end of the carrier guide

rod.

7. Remove the screw from the right end of the carrier guide rod.

8. Slide the carrier guide rod out the left side of the machine.

9. Remove the belt from the back of the carrier.

10. Lift the carri er out of the machine.

Rear Cover Removal

1. Remove the screws from the bottom assembly.

2. Remove the front cover.

3. Pry upward on the two rear cover latches.

4. Work the tabs of the rear cover free from the base assembly.

5. To reassemble, place the cover over the tabs in the base

assembly and press toward the front of the machine until the

cover latches. Be sure the parallel connector snaps do not get

trapped behind the cover.

Sheet Feeder Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the two sheet feeder mounting screws from the rear of

the carrier frame.

4. Unlatch the right sheet feeder latch from the front of the carrier

frame. Note: For reassembly, the cables are routed through tab

slots in the sheet feeder.

5. Remove the sheet feeder.

Repair Information 4-9

Page 40

Small Feed Roll Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Remove the system board.

5. Remove the four small feed roller springs from the carrier frame.

6. Push down on each of the small feed roll assemblies to remove

them from the small feed roll bracket.

Small Feed Roll Bracket Assembly Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the sheet feeder.

4. Remove the system board.

5. Remove the four small feed roller springs from the carrier frame.

6. Push down on each of the small feed roll assemblies to remove

them from the small feed roll bracket.

7. Push the two locking tabs [A] to the rear to release the small

feed roll assembly from the carrier frame.

4-10

Page 41

System Board Removal

1. Remove the front cover.

2. Remove the rear cover.

3. Unlock the four printhead cable connectors and disconnect the

printhead cables from the system board.

4. Disconnect the other cables from the system board.

5. Remove the three screws securing the system board to the

carrier frame and remove the system board. Note the routing of

all the cables.

6. Remove the system board being careful not to damage the Endof-Form flag.

7. Set NVRAM to the proper country defaults. See "NVRAM

Defaults" on page 3-3.

Repair Information 4-11

Page 42

4-12

Page 43

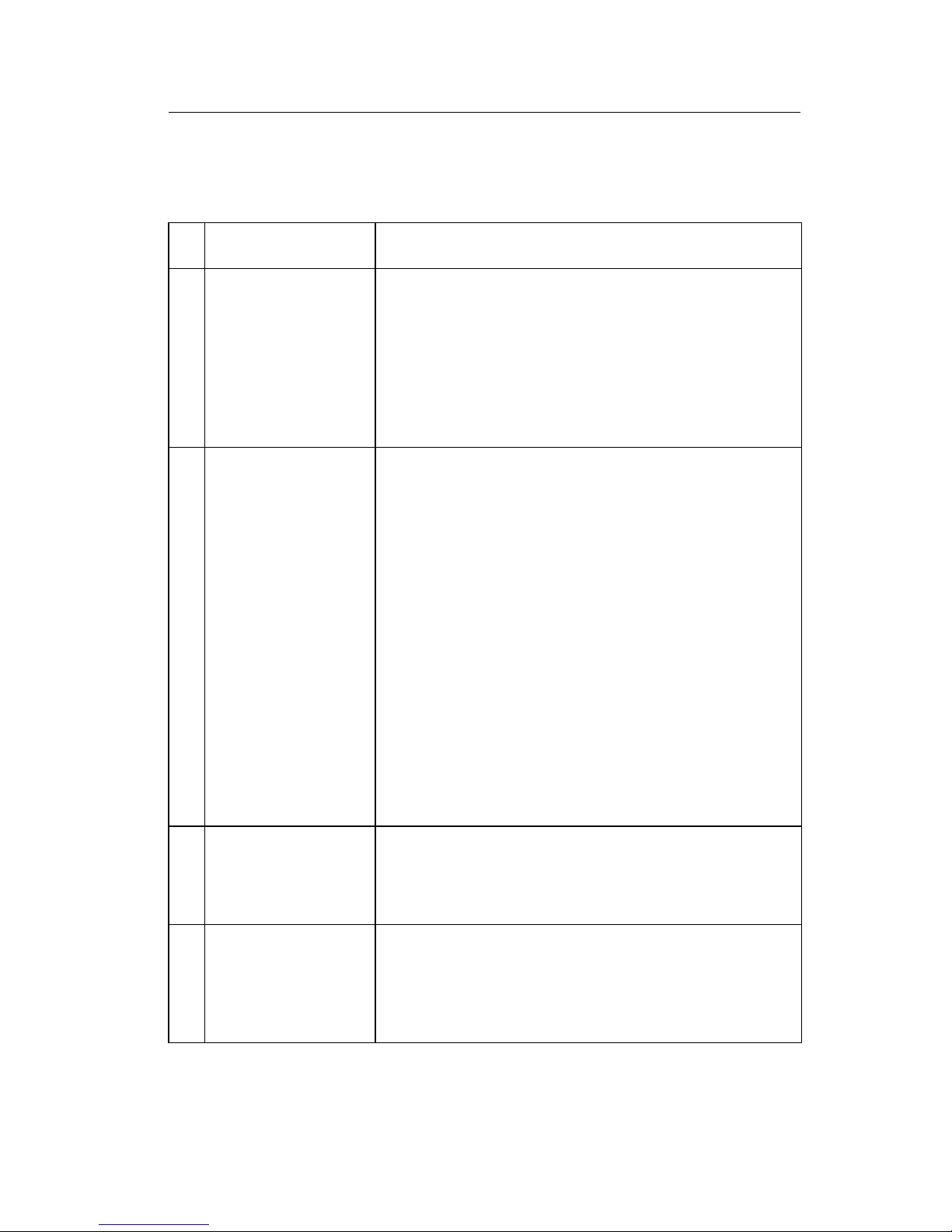

5. Connectors

CN1 Home Position

Sensor

CN2 Carrier Transport

Motor

CN3 Paper Feed Motor

CN4 Printhead Cable 1

CN5 Printhead Cable 2

CN6 Printhead Cable 3

CN7 Printhead Cable 4

CN8 Parallel Port

CN9 Power Supply

PH1 EOF Sensor

U14 Code Module

SW1 Power Switch

SW2 Paper Feed

Switch

SW3 Install Print

Cartridge Switch

LED1 Busy Light

LED2 Power-On Light

Connectors 5-1

Page 44

5-2

Page 45

6. Preventive Maintenance

This chapter contains lubrication specifications. Follow these

recommendations to prevent problems and maintain optimum

performance.

Lubrication Specifications

Lubricate only when parts are replaced or as needed, not on a

scheduled basis. Use grease P/N 99A0394 to lubricate the following:

• All gear mounting studs.

• The left and right ends of the large feed roller at the side frames.

• The carrier to carrier frame engagement.

• The carri er guide rod, and carrier guide rod bearings.

Preventive Maintenance 6-1

Page 46

6-2

Page 47

7. Parts Catalog

How to Use This Parts Catalog

• SIMILAR ASSEMBLIES: If two assemblies contain a majority of

identical parts, they are broken down on the same list. Common

parts are shown by one index number. Parts peculiar to one or

the other of the assemblies are listed separately and identified

by description.

• NS: (Not Shown) in the Asm-Index column indicates that the

part is procurable but is not pictured in the illustration.

• PP: in the parts description column indicates the part is

available in the listed parts packet.

Parts Catalog 7-1

Page 48

Assembly 1: Covers

7-2

Page 49

AsmIndex

Part

Number

Units Description

1 -1 11B5741 1 Base Assembly

2 11A5431 1 Felt Pad, Ink Absorption

3 11B5742 1 Cover, Front Assembly and Paper Scale

4 11B5743 1 Cover, Rear Assembly

5 11B5744 1 Cover, Access Assembly

6 11B5600 2 Front Cover Mounting Screws (PP)

N/S 7349474 1 Replaceable Package B/M - Includes:

(Carton, Cushion Set, Sealing Tape)

Parts Catalog 7-3

Page 50

Assembly 2: Paper Feed / Carrier Transport / Maintenance

7-4

Page 51

AsmIndex

Part

Number

Units Description

2 -1 11B5584 1 Frame, Carrier with cable guide

system board stand off.

2 11B5586 1 Sensor, Carrier Home

3 11B5598 1 Motor, Carrier Transport Assembly

4 11B5600 2 Screw, (PP)

6 11B5601 1 Feed Roll Assembly, Small and

Spring

7 11B5589 1 Mounting Bracket,

Small Feed Roll Assembly

8 11B5590 1 Drive Train Assembly

9 11B5738 1 Motor, Paper Feed Assembly

10 11B5600 5 Screws, Paper Feed Motor

Mounting (PP)

11 11B5588 1 Arm, Tensioner

12 11B5597 1 Belt, Carrier

13 11B5600 1 Spring, Large Feed Roll

Dampening (PP)

14 11A5440 1 Feed Roll Assembly, Large

15 11B5587 1 Frame, Mid Assembly

16 11B5599 1 Maintenance Station Assembly

17 11B5741 1 Base Assembly

Parts Catalog 7-5

Page 52

Assembly 2: Paper Feed / Carrier Transport / Maintenance

7-6

Page 53

AsmIndex

Part

Number

Units Description

2- 18 11B5600 2 Screw, (PP)

19 11B5600 1 Screw, (PP)

20 11B5600 1 Screw, (PP)

21 1367389 1 Cap and Wiper B/M (One of each)

22 11B5595 1 Star Roller Asm

23 11B5600 2 Screw (PP)

NS 11B5600 2 Bearings, Large Feed Roll (PP)

NS 11B5600 2 Screws, Star Roller Assembly Mounting

(PP)

Parts Catalog 7-7

Page 54

Assembly 3: Electronics

7-8

Page 55

AsmIndex

Part

Number

Units Description

3 -1 11B5745 1 System Board with ROM

2 11B5746 1 Power Supply

3 11B5600 3 Screws, System Board (PP)

4 11B5600 2 Screws, Base Asm (PP)

NS 11B5602 1 Cable, Parallel Port

Parts Catalog 7-9

Page 56

Assembly 3: Electronics (Continued)

7-10

Page 57

AsmIndex

Part

Number

Units Description

3 - 5 1339526

1342536

1339520

1339520

1342514

1342526

1342536

1339526

1342534

1342514

1342514

1339525

1342514

1339519

1342514

1339520

1339520

1339520

1342514

1342514

1339521

1339524

70G0496

1342514

1339520

1342514

1339520

1342514

1342536

1342514

1339520

1339517

1339523

1339520

1339520

1339522

1339519

1342536

1342514

1PowerCord,U.S.

Power Cord, Argentina

Power Cord, Austria

Power Cord, Belgium

Power Cord, Bolivia

Power Cord, Brazil (LV)

Power Cord, Brazil (HV)

Power Cord, Canada

Power Cord, Chile

Power Cord, Columbia

Power Cord, Costa Rica

Power Cord, Denmark

Power Cord, Ecuador

Power Cord, Egypt

Power Cord, El Salvador

Power Cord, Finland

Power Cord, France

Power Cord, Germany

Power Cord, Guatemala

Power Cord, Honduras

Power Cord, Israel

Power Cord, Italy

Power Cord, Japan

Power Cord, Mexico

Power Cord, Netherlands

Power Cord, Nicaragua

Power Cord, Norway

Power Cord, Panama

Power Cord, Paraguay

Power Cord, Peru

Power Cord, Portugal

Power Cord, Saudi Arabia

Power Cord, South Africa

Power Cord, Spain

Power Cord, Sweden

Power Cord, Switzerland

Power Cord, United Kingdom

Power Cord, Uruguay

Power Cord, Venezuela

Parts Catalog 7-11

Page 58

Assembly 4: Carrier

7-12

Page 59

AsmIndex

Part

Number

Units Description

4 -1 11B5596 1 Carrier Assembly

2 11B5585 1 Rod, Carrier Guide

3 11B5584 1 Frame, Carrier

4 11B5600 1 Screw, Carrier Guide Rod (PP)

5 11B5600 1 Spring, Carrier Guide Rod (PP)

Parts Catalog 7-13

Page 60

Assembly 5: Sheet Feeder

7-14

Page 61

AsmIndex

Part

Number

Units Description

5 -1 11B5584 1 Frame, Carrier

2 11B5600 2 Screws,

Sheet Feeder Mounting (PP)

3 11B5747 1 Sheet Feeder Asm

4 11B5743 1 Cover, Rear Asm

Parts Catalog 7-15

Page 62

7-16

Page 63

Index

A

Abbreviations1-2

Adjustments4-2

Assemblies

Carrier

CarrierTransport7-4,7-6

Covers7-2

Electronics7-8

MaintenanceStation7-4,7-6

PaperFeed7-4,7-6

SheetFeeder7-14

7-12

C

Connectors5-1

D

DiagnosticAids3-1

DiagnosticInformation2-1

E

ErrorIndicatorTable2-1

ESD-SensitiveParts4-1

G

GeneralInformation1-1

L

LubricationSpecifications6-1

OperatorPanel2-2

PaperFeed2-3

Power2-3

PrintQuality2-3

R

Removals

AccessCover

BaseAssembly4-3

CarrierBelt4-3

CarrierFrame4-4

CarrierHomeSensor4-4

CarrierTransportMotor4-5

DriveTrainAssembly4-5

FrontCover4-6

GutterPad4-6

LargeFeedRoll4-7

MaintenanceStation4-7

MidFrameAssembly4-8

PaperFeedMotor4-8

PowerSupply4-8

PrintheadCarrier4-9

RearCover4-9

ReleasingPlasticLatches4-2

SheetFeeder4-9

SmallFeedRollAssembly4-10

SmallFeedRollBracket4-10

SystemBoard4-11

WiperandCap4-7

RepairInformation4-1

4-3

M

Maintenance2-7

MaintenanceApproach1-2

P

PartsCatalog7-1

POST

Sequence

SymptomTable2-4

Power2-11,4-8

PowerConsumption1-1

PreventiveMaintenance6-1

Problems

CarrierTransport

MaintenanceStation2-2

2-4

2-2

S

SafetyInformationvi

ServiceChecks

CarrierTransport

EnvelopeFeed2-6

MaintenanceStation2-7

PaperFeed2-8

PaperPath2-10

Power2-11

PrintQuality2-12

Transport2-5

SymptomTable(POST)2-4

SymptomTables2-1,2-2

2-5

X-1

Page 64

T

Tests

Print NVRAM Contents

Reset NVRAM Defaults

EMEA

U.S. 3-3

Test Page 3-4

3-3

3-2

X-2

Page 65

Lexmark 3000 Color Jetprinter

Service Manual

P/N 11B5909

Reader’s

Comment

Form

You may use this form to communicate your comments about this

publication, with the understanding that Lexmark may use or

distribute whatever information you supply in any way it believes

appropriate without incurring any obligation to you.

1. Did you find the book well organized?

No

No

No

Yes

2. Was the content of the book accurate and complete?

Yes

3. Was the book easy to use?

Yes

4. What can we do to improve the book?

5. What is your job title?

Questions or comments about supplies, service, applications, and

so on will slow response time considerably. Please refer those

questions or comments to your authorized dealer or point of

purchase.

Note: Please direct all requests for copies of publications to your

point of purchase. Publications are not stocked at the location to

which this form is addressed.

Page 66

BUSINESS REPLY MAIL

FIRST CLASS MAIL PERMIT NO 2659 LEXINGTON, KY

POSTAGE WILL BE PAID BY ADDRESSEE

Lexmark International Inc.

Department D22A, Building 035-3

740 New Circle Road NW

Lexington, Ky 40550

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

–––––––––––––––––––––––––––––––––––––––––––

|| | ||||||||||| | ||||||||||||||||| |||||| ||||| |||||| | ||

––––––––––––––––––––––––––

Fold Here

Cut Along Line

Tape Please Do Not Staple Tape

Loading...

Loading...