Lexmark 2580, 2581, 2590, 2591 Service Manual

Lexmark confident ial until announce

Lexmark Forms Printer 2500 Series

• Table of contents

• Start diagnostics

• Start diagnostics

25XX-100

25XX-110

• Safety and notices

•Trademarks

•Index

Lexmark and Lexmark with diam ond

design are trademar ks of Lexmark

International, Inc., registered in the

United States and/or ot her countries.

25XX-100, -110

Edition: September 17, 2007

The following paragraph does not apply to any country where such provisions are

inconsistent with local law: LEXMA R K INTER NATIONAL, INC. PR OVID E S THI S

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do

not all o w di sc la im er of e xpr ess or im pl ied w arr an tie s in ce rt ai n tr a ns acti on s; the r efor e , t hi s

statement may not apply to you.

This publ icat ion co uld in clude te chni cal in accura cies or typogr aph ical err ors. Change s are

periodically made to th e inform ation her ein; the s e changes will be incorporated in later

editions. Improvements or changes in the products or the programs described may be

made at any time.

Comments may be addressed to Lexmark Internatio nal, Inc., Department D22A/032-2,

740 West New Circle Road, Lexington, Kentucky 40550, U.S.A or e-mail at

ServiceInfoAndTra ining@Lexmark.com. Lexmark may use or distribute any of the

information y ou supply in any way it believe s appropriate without incur ring any obligation

to you.

Lexmark and Lexmark with di amond design are trademarks o f Lexmark International,

Inc., registered in the United States and/or other countries.

All other tr ad em ar ks are the prop er t y of t he ir r es pe c tiv e ow n er s .

© 2007 Lexmark International, Inc.

All rights reserved.

UNITED STATES GOVERNMENT RIGHTS

This software and any accompanying documentation provided under this agreement are

commercial computer software and documentation deve loped exclusively at private

expense.

U.S.A. P/N: 12G9774

25XX-100, -110

Table of co ntents

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-vii

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-xii

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer sp e c ifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Setup mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Entering Setup mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Exiting Setup mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Setup menu options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Interface menu options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Setting the tear off position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Setting Top-of-form (continuous-pull mode). . . . . . . . . . . . . . . . . 1-5

Setting Top-of-form (cut forms, envelopes) . . . . . . . . . . . . . . . . . 1-5

Printing a network setup page . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Diagnostic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Voltage, ground, and continuity readings . . . . . . . . . . . . . . . . . . . . . 2-1

Error indication table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Symptom check table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Irrecoverable operator errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -13

Service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Abnormal noise service check . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Auto Sheet Feeder (ASF) service check . . . . . . . . . . . . . . . . . . 2-16

Carrier service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Intermittent problem service check . . . . . . . . . . . . . . . . . . . . . . 2-20

No print or abnormal print service check . . . . . . . . . . . . . . . . . . 2-23

Operator panel service check . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Paper Present sensor service check . . . . . . . . . . . . . . . . . . . . . 2 -24

Paper feed service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 5

Paper Select sensor service check . . . . . . . . . . . . . . . . . . . . . . 2-28

POST service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -29

Power service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Print speed service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -31

Printhead service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

iii

25XX-100, -110

Pull Tractor sensor service check . . . . . . . . . . . . . . . . . . . . . . . .2-34

Top-of-forms service check. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Tractor 2 service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Network service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Diagnostic aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Print test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Hex Trace mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Printer default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

U.S. defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

World Trade defaul t s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Clearing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Cut sheet jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Continuous forms jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Web page at a glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Device settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Configuration page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Reports page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Flashing firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Importing and exporting INA settings . . . . . . . . . . . . . . . . . . . . .3-10

Resetting the INA to factory defaults. . . . . . . . . . . . . . . . . . . . . .3-11

Repa ir inform atio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Handling ESD-sensitive parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Printhead-to-platen gap adjustment . . . . . . . . . . . . . . . . . . . . . . . 4 -2

Bidirectional print adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Removal procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Covers, removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Cove r s, fron t r e m oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Covers, ribbon access removal. . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Covers, option removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Cove r s , top rem o val . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Covers, operator panel assembly removal . . . . . . . . . . . . . . . . .4- 1 0

Cove r s, botto m removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Electronics removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

EPROM remova l. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Logic board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Network card removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

INA support frame removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Power supply removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

iv Service Manual

25XX-100, -110

Carrier removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Carrier removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Carrier, motor assembly removal. . . . . . . . . . . . . . . . . . . . . . . . 4-22

Paper handling removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Paper Select lever removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Paper feed motor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

For ms Thi ckness leve r removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Print handling removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -27

Platen removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -27

Printhead removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -28

Printhead cables removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 8

Print unit removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Ribbon drive rack gear removal. . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Gears removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -32

Left side gears removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Right side gears, sub frame removal . . . . . . . . . . . . . . . . . . . . . 4-35

Rollers removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Roller, upper feed removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -37

Roller, lower pinch removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -39

Roller, lower feed removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Sensor removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -44

Sensor, Pull Tractor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -45

Sensor, Head Gap removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -45

Sensor, Top-of-form removal. . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -45

Sensor, Paper Select removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Sensor, Paper Present removal. . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Flags, Paper Present/Top-of-form removal . . . . . . . . . . . . . . . . 4 -46

Sensor, Home Position sensor removal. . . . . . . . . . . . . . . . . . . 4-4 7

Options removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Auto Sheet Feeder gears removal . . . . . . . . . . . . . . . . . . . . . . . 4-48

Auto Sheet Feeder pick-up roller removal . . . . . . . . . . . . . . . . . 4 - 4 9

Locations and connector s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Signal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Power supply (9w & 24w). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Logic board–Parallel interface cable (9w & 24w) . . . . . . . . . . . . 5-5

Logic board–Serial board (9w & 24w) . . . . . . . . . . . . . . . . . . . . 5-7

Logic board–USB cable (9w & 24w). . . . . . . . . . . . . . . . . . . . . . 5-9

Logic board–DC power (9w & 24w) . . . . . . . . . . . . . . . . . . . . . . 5-9

Logic board–Printhead (9w) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Logic board–Printhead (24w) . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

v

25XX-100, -110

Logic board–Printhead (24w) . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Logic board–Gap Set sensor (9w & 24w) . . . . . . . . . . . . . . . . .5 - 1 7

Logic board–Home Position sensor (9w & 24w) . . . . . . . . . . . .5-17

Logic board–(9w & 24w) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

Logic board–Paper Present sensor (9w & 24w) . . . . . . . . . . . .5-17

Logic board–Paper Select sensor (9w & 24w) . . . . . . . . . . . . . .5-19

Logic board–Pull Tractor sensor (9w & 24w). . . . . . . . . . . . . . .5-19

Logic board–Top-of-form sensor (9w & 24w) . . . . . . . . . . . . . .5-19

Logic board–Carrier motor (9w & 24w) . . . . . . . . . . . . . . . . . . .5-21

Logic board–Paper feed motor (9w & 24w) . . . . . . . . . . . . . . . . 5 - 2 1

Logic board–Operator panel (9w & 24w). . . . . . . . . . . . . . . . . .5-23

Logic board–Dual tractor cable (9w & 24w) . . . . . . . . . . . . . . .5-25

Serial board–Serial cable (9w & 24w) . . . . . . . . . . . . . . . . . . . .5-26

Tractor 2 cable connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Lubrication points (oil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Lubrication points (grease) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Assembly 1: Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Assembly 2: Carrier/paper feed (right side) . . . . . . . . . . . . . . . . . . . .7-6

Assembly 3: Carrier/paper feed (left side) . . . . . . . . . . . . . . . . . . . .7-10

Assembly 4: Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Assembly 5: ASF–Roller/support . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Assembly 6: ASF–Side frame/covers . . . . . . . . . . . . . . . . . . . . . . .7-18

Assembly 7: Tractor 2 option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Part number index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-5

vi Service Manual

25XX-100, -110

Safety information

• The safety of this product is based on test ing and approvals of the

original design and specific components. The manufacturer is not

responsible for safety in the event of use of unauthorized replacement

parts.

• The maintenance information for thi s product has been prepared for

use by a professional serv ice person and is not intended to be used by

others.

• There may be an increased risk of electric shock and personal injury

during disasse mbly and servicing of this pro duct. Professional service

personnel should understand this and take necessary precauti ons.

• CAUTION: When you see this symbol, there is a danger

from hazardous voltage in the area of the product where

you are working. Unplug the product before you begin, or

use caution if the product must receive power in order to

perform the task.

Consig n es de sécu ri té

• La sécurité de ce produit repose sur des tests et des

agréations por tant sur sa conception d'or igi ne et sur des composants

particuliers. Le fabricant n'assu me aucune responsabilité concernant

la sécurité en cas d'ut ilisation de pièces de re change non agréées.

• Les consignes d'entretien et de réparation de ce produit s'adressent

uniquement à un personnel de ma intenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains

risques électriques, le personnel d'entretien qualifié devra prendre

toutes les précautions nécessaires.

• ATTENTION : Ce symbole indique la présence

d'une tension dangereuse dans la partie du produit sur

laquelle vous travaillez. Débranchez le produit avant de

commencer ou faites preuve de vigilance si l'exécution de

la tâche exige que le produit reste sous tension.

vii

25XX-100, -110

Norme di sicurezza

• La sicurezza del prod ott o si basa sui test e sull'app rovazione del

progetto original e e dei componenti specifici. Il produttore non è

responsabile per la sicurezza in caso di sostituzione non autorizzata

delle parti.

• Le informazioni riguardanti la manutenzione di questo prodotto sono

indirizzate sol tanto al personale di assis tenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto,

il rischio di subire scosse elettriche e danni alla persona è più elevato .

Il personale di assis tenza autorizzato deve, qui ndi, adottare le

precauzioni neces sarie.

• ATTENZIONE: Questo simbolo indica la presenza

di tensione pericolosa nell'area del prodotto. Scollegare il

prodotto prima di ini ziare o usare cautela se il prodotto

deve essere alimentato per eseguire l'intervento.

Sicherheitshinweise

• Die Sicherheit dieses Produkts basiert auf Tests und Zulassungen des

ursprünglich en Mod ells und bestimmter Bauteil e. Bei Verw endung

nicht genehmigter Ersatzteile wi rd vom Hersteller keine Verantwortung

oder Haftung für die Sicherheit übernommen.

• Die Wartungsinformationen fü r di eses Produkt sind ausschließlich für

die Verwendung durch einen Wartungsfachmann bestimmt.

• Während des Auseinande rnehmens und der Wartung des G eräts

besteht ein zusätzliches Risiko eines elektrischen Schlags und

körperlicher Verletzung. Das zuständige Fachper sonal sollte

entsprechende Vorsichtsmaßnahmen treffen.

• ACHTUNG: Dieses Symbol weist auf eine gef ährliche

elektrische Spannung hin, die in diesem Bereich des

Produkts auftreten kann. Ziehen Sie vor den Arbeiten am

Gerät den Netzstecker des Geräts, bzw. arbeiten Sie mit

großer Vorsicht, wenn das Produkt für die Ausführung der

Arbeiten an den Strom angeschlossen sein muß.

viii Service Manual

25XX-100, -110

Pautas de Seg u rid ad

• La seguridad de este producto se basa en pruebas y aprobaciones del

diseño original y componentes específicos. El fabricante no es

responsable de l a seguridad en ca so de uso de piezas de repuesto no

autorizadas.

• La información sobre el mantenimi ento de este producto está diri gida

exclusivament e a l per sonal cualificado de mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños personales

durante el desmonta je y l a reparación de la máquina. El perso nal

cualificado debe ser consciente de este pel igro y tomar las

precauciones necesarias.

• PRECAUCIÓN: este símbolo indi ca que el voltaje de la

parte del equipo con la que está trabajando es peligr oso.

Antes de empezar, desenchufe el equi po otenga cuidado

si, para trabajar con él, debe conectarlo.

Inform ações de Segura nça

• A segurança deste produto baseia-se em testes e aprovações do

modelo original e de componentes específico s. O fabr icante não é

responsável pel a segunrança, no caso de uso de peças de

substituição não autorizadas.

• As informações de segurança relativas a este produto destinam-se a

profissionais destes serviços e não devem ser utilizadas por out ras

pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profi ssionais destes

serviços devem estar avisados deste facto e tomar os cuidados

necessários.

• CUIDADO: Quando vir este símbolo, existe a possível

presença de uma potencial tensão perigosa na zona do

produto em que está a trabalhar. Antes de começar,

desligue o produto da tomada eléctrica ou seja cuidadoso

caso o produto tenha de est ar l igado à corrente eléctri ca

para realizar a tarefa necessária.

ix

25XX-100, -110

Informació de Seguretat

• La seguretat d'aquest producte es basa en l'avaluació i aprovació del

disseny original i els components específics.

El fabricant no es fa respon sable de les qüestions de

seguretat si s'utilitzen peces de recanvi no autoritzades.

• La informació pel manteniment d’aquest producte està orientada

exclusivament a professionals i no està dest inada

a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmenta r durant el

procés de desmuntatge i de servei d’aquest producte. El personal

professional ha d’estar-ne assabentat i prendre

les m e s ures convenients.

• PRECAUCIÓ: aquest símbol indi ca que el voltatge de la

part de l'equip amb la qual esteu treballant és perillós.

Abans de començar, desendolleu l' equip o extremeu les

precaucions si, per tr eballar amb l'equip, l'heu de

connectar.

x Service Manual

25XX-100, -110

xi

25XX-100, -110

Preface

This manual contai ns m aintenance procedures for service personnel. I t is

divided into the following chapters:

1. General inf o rm ation contains a general description of the printer and

the maintenance approach used to repair it. Special tools and test

equipment are listed, as well as general environmental and safety

instructions.

2. Diagnostic information contains an error indicator table, symptom

tables, and service che cks us ed to isolate failing f ie ld replaceab le unit s

(FRUs).

3. Diagnostic aids contains tests and checks used to locate or repeat

symptoms of printer problems.

4. Repair information provides instructions for making printer

adjustments and removi ng and installing FRUs.

5. Connector locations uses illustrations to identify the conne ctor

locations and test points on the printer.

6. Preventive maintenance contains the lubrication specifications and

recommendations to prevent problems.

7. Parts catalog contains illustrations and part numbers for individual

FRUs.

Definitions

Note: A note provides additional information.

Warni ng: A warning identifies something that might damage the product

hardware or software.

CAUTION: A caution identifi es som ething that might cause a servi cer

harm.

CAUTION: When you see this symbol , there i s a danger fr om

hazardous volta ge in the area of the product where you are

working. Unplug the product before you begin, or use ca ution

if the product must receive power in order to perform the task.

xii Ser vice Manual

25XX-100, -110

1. Gen e r a l inform a tion

Printer description

The Lexmark™ Forms Printer 25XX-100 and 25XX-110 are small,

versatile tabletop printers suitable for use in the home or small

business. They are especially well-suited for applications that use

continuous or mult i- p ar t f or ms .

Printer specific ations

• Printhead life: 300 million characters

• Sta ndar d ribbon life: 4 milli on ch aracters

• High-yield ribbon life: 8 million characters

• Printer life: 5 years

• Power co nsump tion: 38 watts-maximu m/9 watts idle

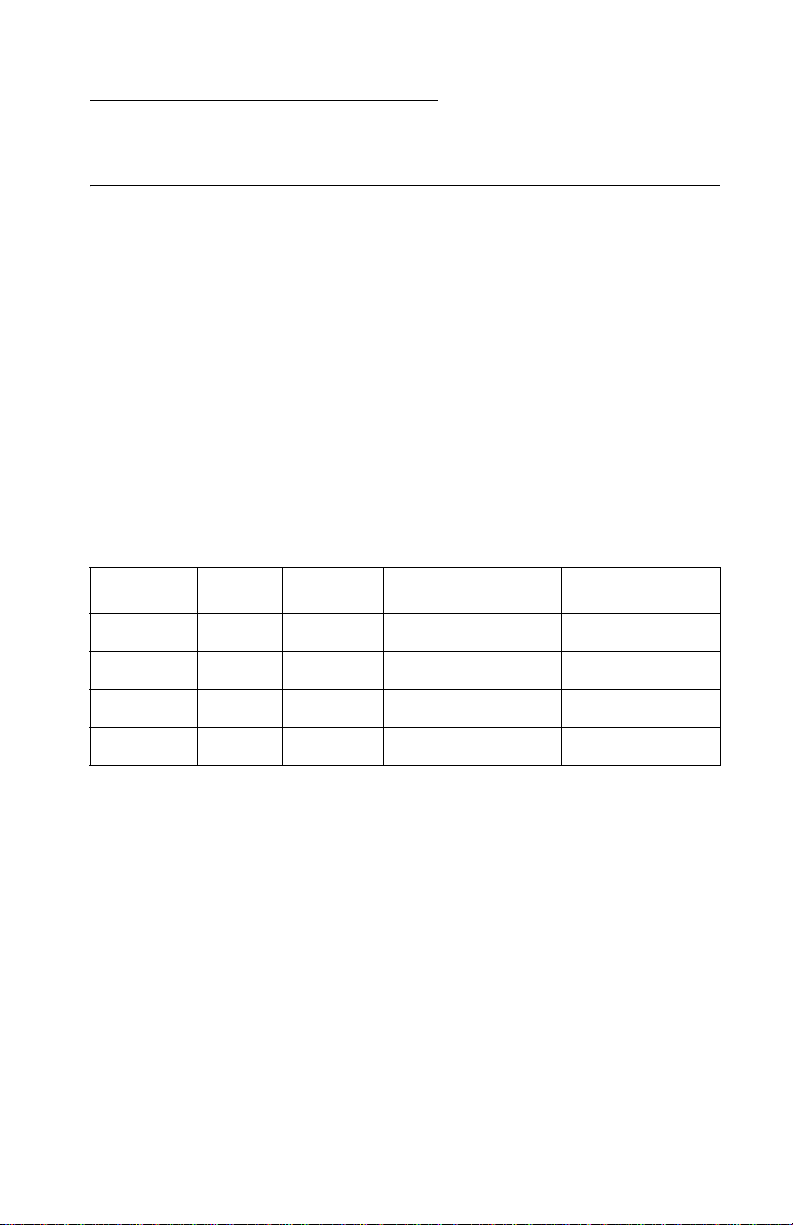

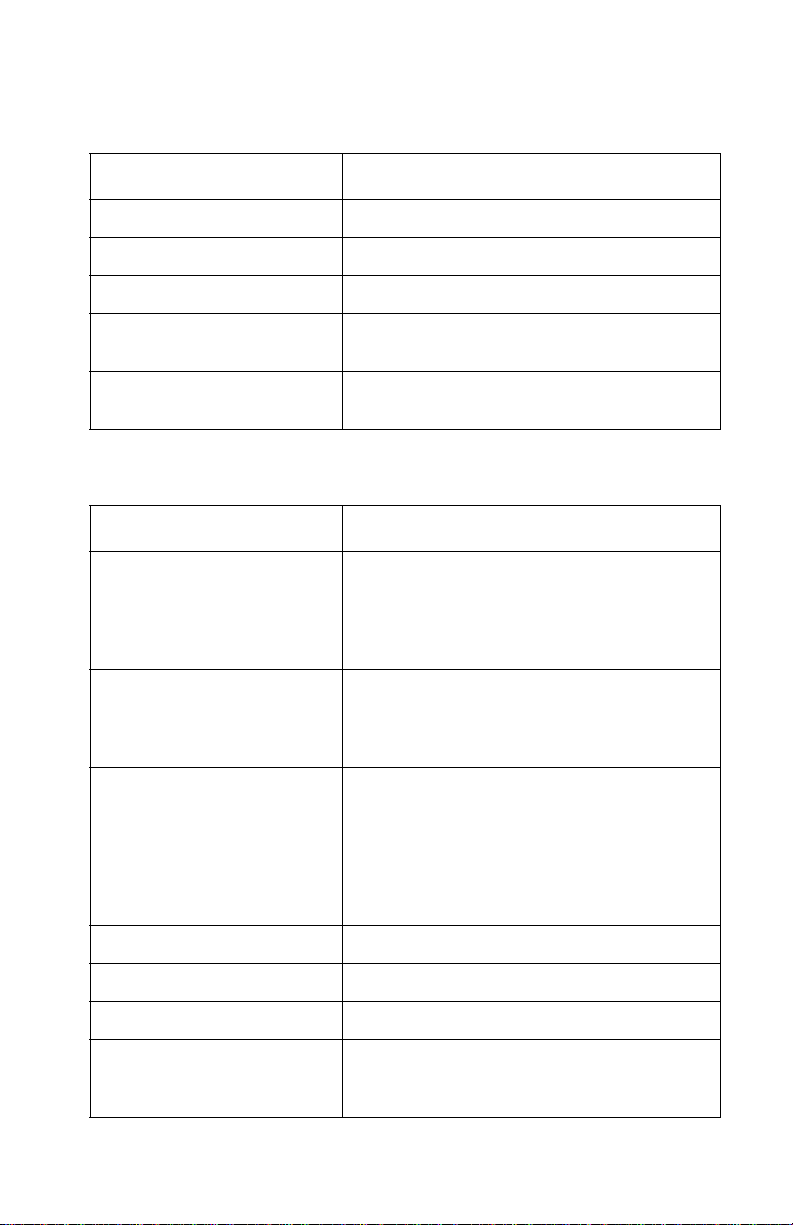

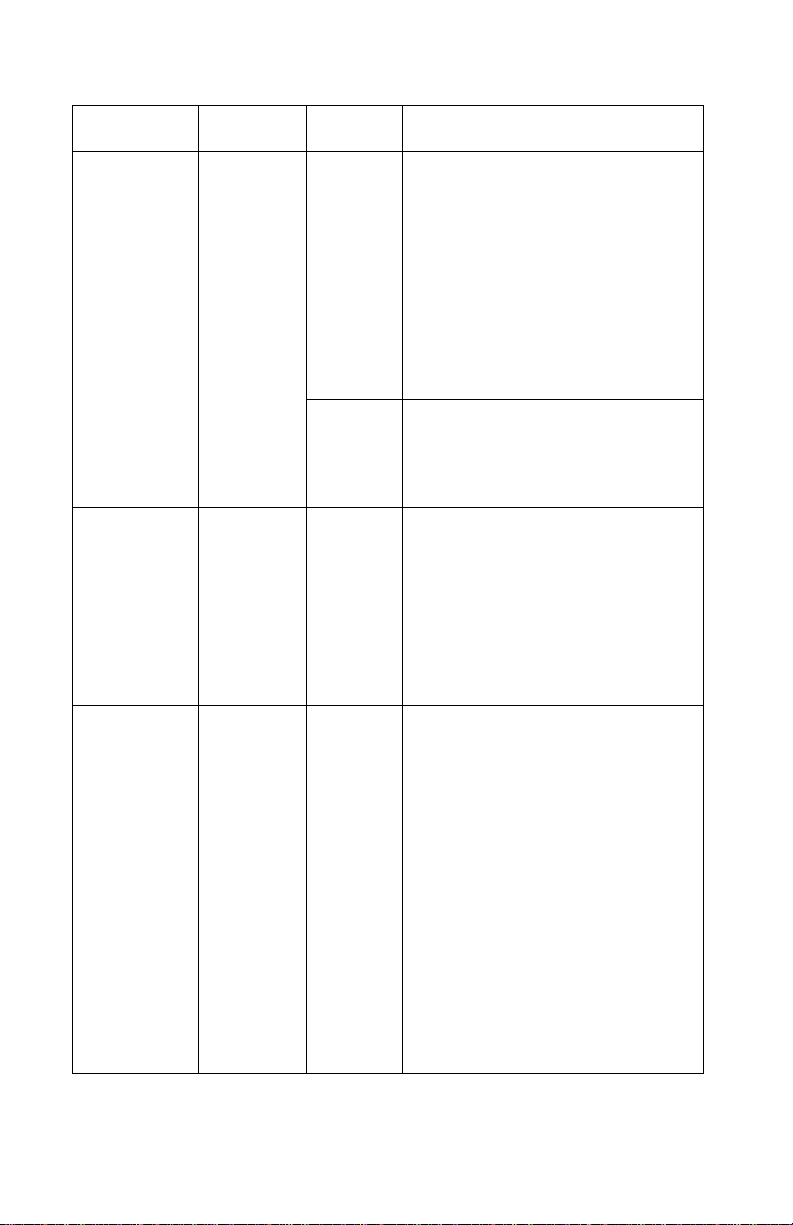

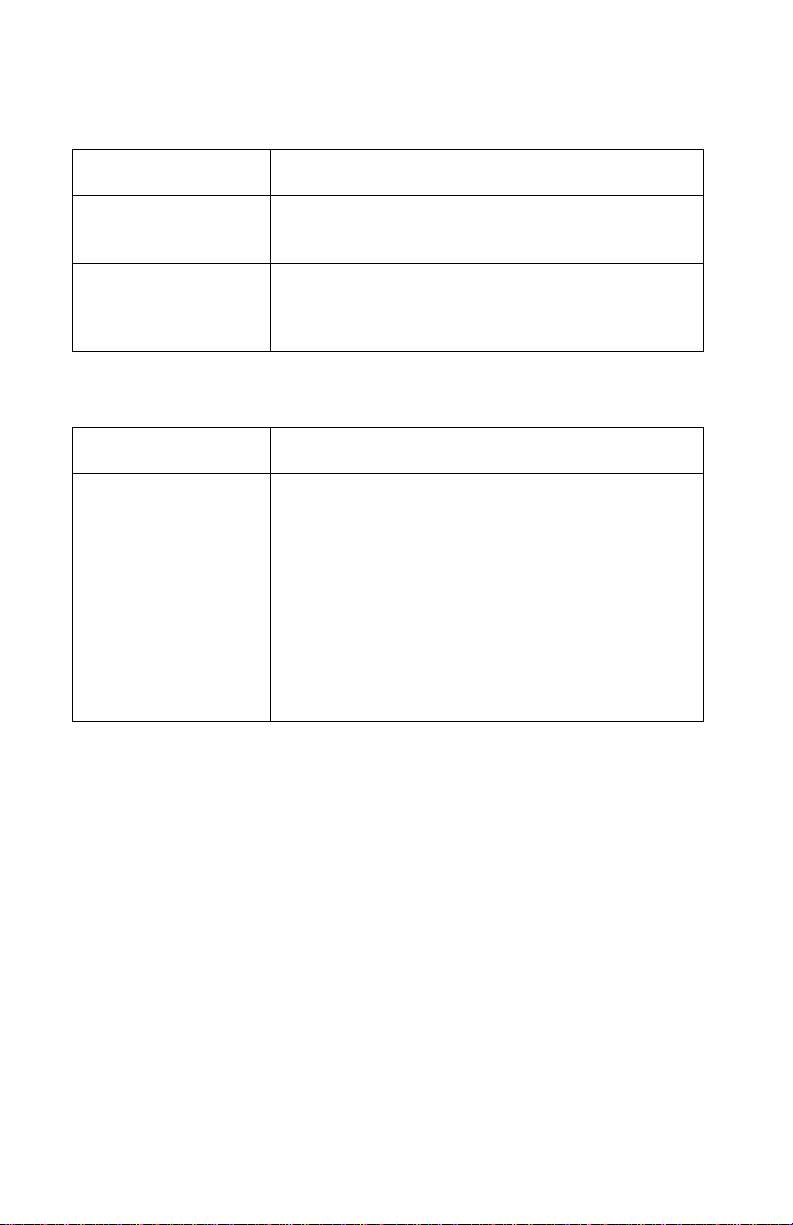

Model 9-Wire 24-Wire Short carriage Long carriage

2580-XXX X X

2581-XXX X X

2590-XXX X X

2591-XXX X X

General information 1-1

25XX-100, -110

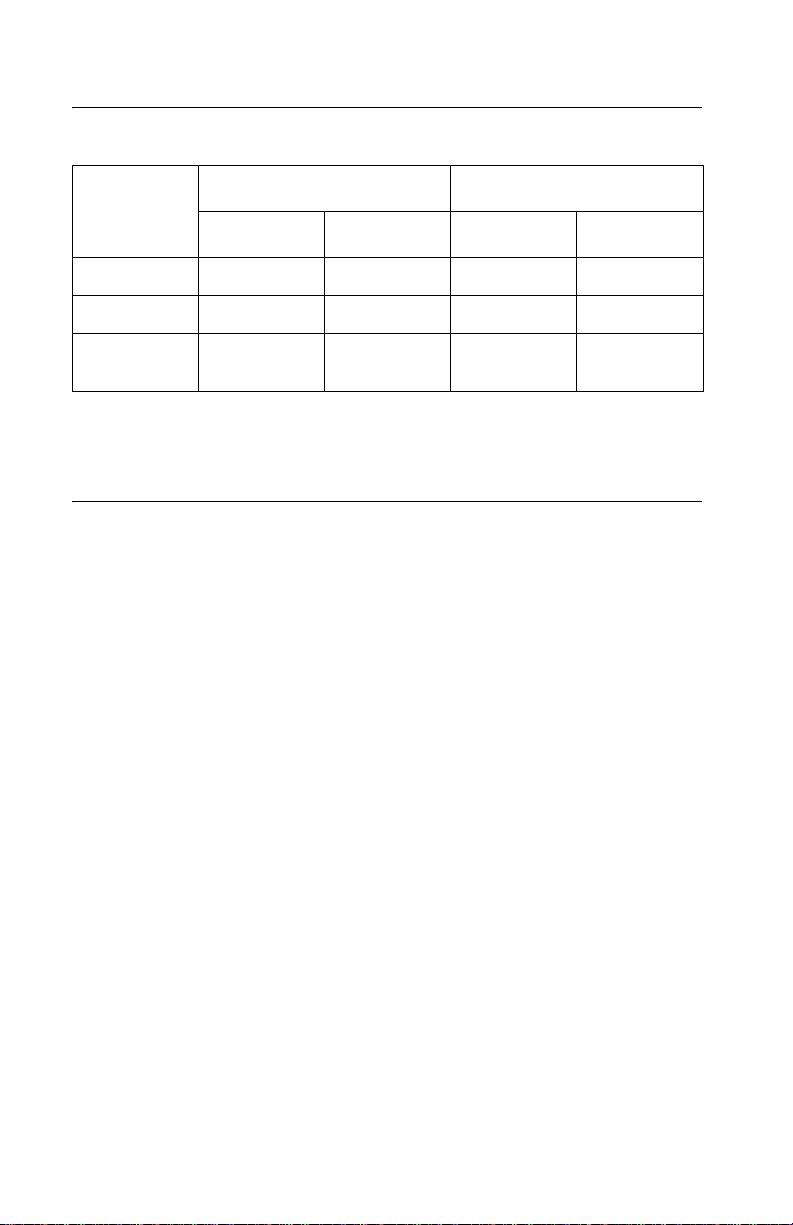

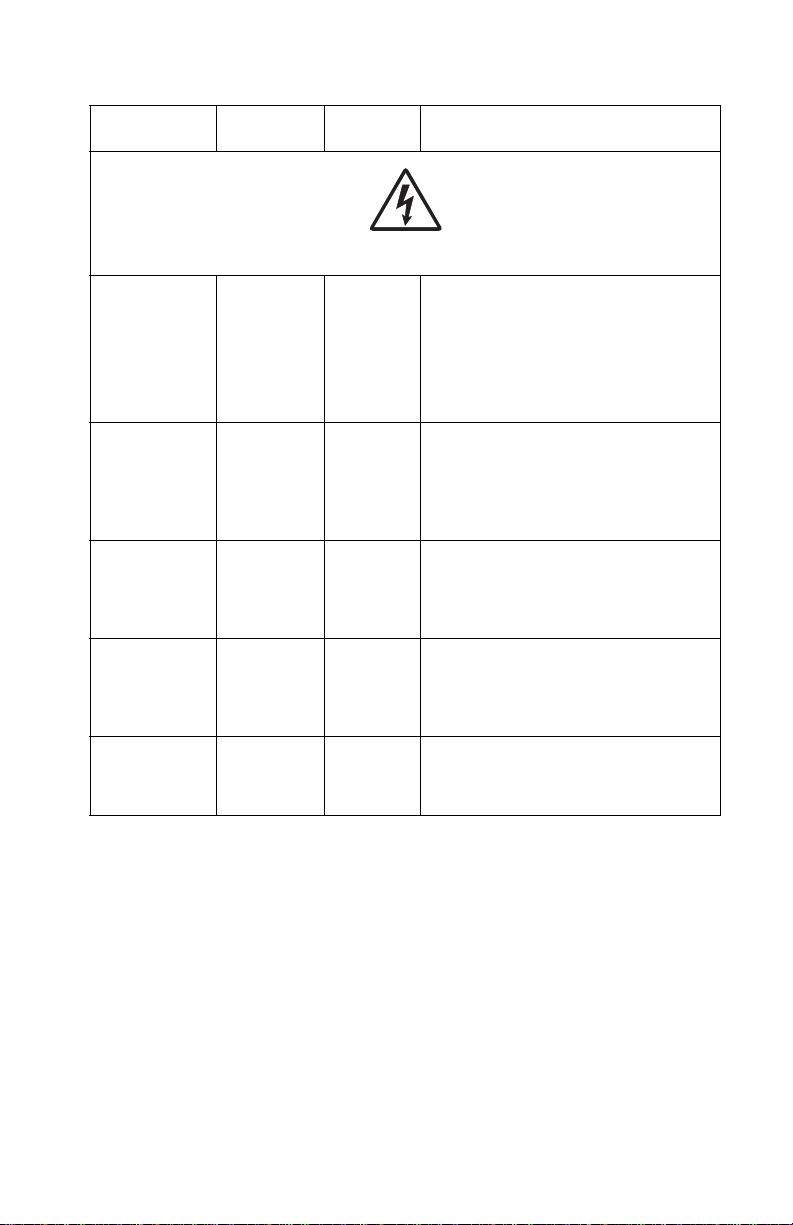

Printer speeds

9-Wire 24-Wire

10 cpi 12 cpi 10 cpi 12 cpi

Fast draft 438 cps 510 cps 409 cps 465 cps

Draft 309 cps 304 cps 274 cps 328 cps

NLQ–

Near

Letter Quality

cpi = characters per inc h

cps = characters per second

77.5 cps 77.5 cps 91.7 cps 109 cps

Setup mode

Entering Setup mode

1. Open the operator panel cover to access layer two.

2. Press Setup to put the printer in Setup mode and print the Main

Menu.

3. Press LineFeed to print a list of all the available options.

4. Select any option from the Main Menu by pressing the

corresponding button. A new menu prints each time you press a

button, displaying new selections.

5. After making a selection, the printer prints a page with the

changes shown.

Exiting Setup mode

1. Press Set TOF until the printer returns to the Main Menu, or

press Pitch from any menu containing a Return to Main Menu

selection.

2. Press Set TOF again to exit Setup mode. New settings are

saved only when the printer exits Setup mode.

Note: If the printer runs out of paper while in Setup mode, load

more paper into the tractor pins, and press Setup to continue.

1-2 Service Manual

25XX-100, -110

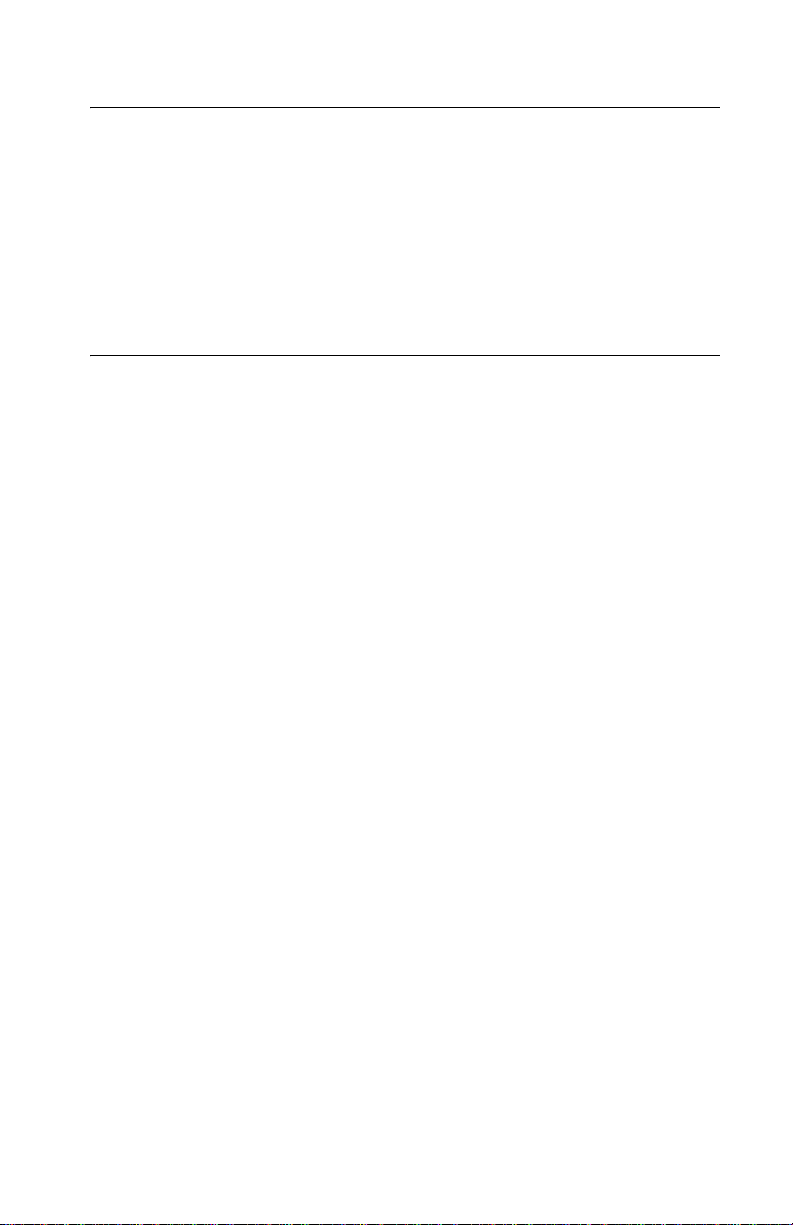

Setup menu options

Menu Function

Forms Macro options Customize macros to print a variety of forms.

Data options Define how information is pro cessed.

Control options Define how the printer performs basic tasks.

Emulation options Determine how the printer interacts with

software applicat ions.

Interface option s Define how information is transferred from a

computer to the printer.

Interface menu options

Menu Function

Interf ac e • Automa ti ca ll y s el e ct the prin te r interfac e .

• Use the parallel cable.

• Use the USB cable.

• Use the serial cable (only appears if

optional ser ial adapter is installed).

Honor init • Enable honors the init signal on the

parallel p or t.

• Disable ignore s the i nit signal on the

parallel p or t.

Data speed • 300 bps

• 600 bp s

• 1200 bps

• 2400 bps

• 4800 bps

• 9600 bps

• 19200 bps

Data bits 7, 8

Parity No, Ignore, Odd, Even

Stop bits 1, 2

Protocol • XON/XOFF

• MultiXON/XOFF

•DTR Pacing

General information 1-3

25XX-100, -110

Printer settings

Setting the tear off position

When Auto Tear Off is on, or set to One Second, it moves the top

perforation of a continuous form to the tear off position, when all of

the following are true:

• The printer has finished printing.

• The paper has advanced to the Top-of-form on the next page.

• No data, printer control codes, or escape codes have been sent

to the printer after advancing to the Top-of-form.

• The print buffer has not received data for one second.

If you have already set Top-of-Form and now want to change the

tear off bar position, follow these steps:

1. Press Start/Stop to ta ke the pri nter offline.

2. Press and hold Tear Off until the printer beep s.

3. Open the operator panel cover to access layer two.

4. Press Micro↑ or Micro ↓ t o mo ve the paper to the correct

position on the tear off bar.

5. Close the operator panel cover. The printer beeps twice. The

paper rolls backward, then goes to the new tear off position.

The Ready light is on.

The paper remains at the current tear off position until you send

another job to the printer . The paper moves from the tear off position

to the Top-of-form and begins printing.

1-4 Service Manual

25XX-100, -110

Setting Top-of-form (continuous-pull mode)

1. Turn the printer on. The Paper Out light blinks if no paper is

loaded.

2. Move the Paper Select lever down to the continuous forms

position.

3. Load continuous form paper on the pull tractor feed pins.

4. Open the operator panel cover to access layer two.

5. Press any paper movement button (LineFeed, Micro↑, or

Micro ↓) to move the paper to the Top-of-form position.

6. Use the second sheet of continuous forms to set Top-of-form.

7. Press Set TOF to set and save Top-of-form.

8. Close the operator panel cover. Top-of-form is not saved if the

printer is turned off, or if it runs out of paper when the printer is

in Pull Tractor mode.

9. Press Start/Stop to set the printer online.

Setting Top-of-form (cut forms, envelopes)

Top-of-form can range from minus 1 to plus 22 inches from the top

of cut sheet paper. To set and save Top-of-form:

1. Turn the printer on. The Paper Out light blinks if no paper is

loaded. If the Paper Out light is off, tear off excess forms and

press Load/Unload. If an individual form is loaded, press

FormFeed to clear the paper path.

2. Move the paper select lever up to the cut forms position.

3. Load a cut sheet of paper or envelope through the manual feed

door. The printer moves the paper or envelope to the current

Top-of-form if Auto Cut Sheet is set to on. If not, press

FormFeed when the Paper Out light goes off.

4. Open the operator panel cover to access layer two.

5. Press any paper movement button (LineFeed, Micro↑, or

Micro ↓) to align the horizontal lines (located on the platen) with

the Top-of-form you want.

6. Press Set TOF to set and save Top-of-form.

7. Close the operator panel cover.

8. Press Start/Stop to set the printer online.

General information 1-5

25XX-100, -110

Printing a network setup page

If the printer is attached to a network, print a network setup page to

verify the network connection and find the printer address.

Note: This function is disabled if a USB cable is connected.

1. Make sure the printer is on and the paper is loaded.

2. With a paper clip or the tip of a pen, press the recessed button

located just above the Network connection.

3. Check the first section on the network setup page, and confirm

that the status is Connected. If the status is Not Connected,

the LAN drop may not be active, or the network cable may be

malfunctioning. See Networking service check.

4. Check the network setup page to find the IP Address and the

Fully Qualified Domain Nam e. Th e F ully Qualifie d D omain

Name is useful in situations where the Address changes. For

instance, the Address changes if the printer is moved; however,

the Fully Qualified Domain Name does not change.

Note: The network setup page also provides important network

configuration information.

1-6 Service Manual

25XX-100, -110

Options

The 25XX printers support the following options:

• Automatic Sheet Feeder (ASF)

• Internal serial interface (RS232)

• OKI emulation (9 wire only)

• Tractor 2 sheet feeder

Tools

The basic tools necessary to service the 25XX printers are:

• Basic CE tool kit

• #1 Phillips screwdriver

• #2 Phillips screwdriver

• Feeler gauges 0.33 mm (0.013 in.) and 0.37 mm (0.015 in.)

• Analog or digital volt-ohmmeter

General information 1-7

25XX-100, -110

Abbreviations

AFE Analog front end

ASF Automatic sheet feeder

CPU Central processing unit

EPROM Erasable Programmable Read-Only Mem ory

ESD Electrostatic discharge

FRU Field replaceable unit

HTTP Hypertext transport protocol

HV High voltage

LED Light emitting diode

LV Low voltage

MFP Multifunction Printer

mm Millimeter

NIC Network interface card

NVRAM Nonvolatile Random Access Memory

POST Power-On Self Test

RAM Random access memory

ROM Read-only storage

TCP/IP Transport control protocol/Internet protocol

USB Universal Serial Bus

V ac Volts alternating current

V dc Volts direct current

1-8 Service Manual

25XX-100, -110

2. Diagnostic information

Start

Make a quick visual check for defects (loose or broken parts,

unplugged connectors, paper jams, and so on).

Voltage, ground, and continuity readings

Voltage readings

All DC voltages must be within +5% through -10% of the values to

be considered correct. Unless stated otherwise, all connectors

should be connected normally when a voltage measurem ent is

performed.

When a “line voltage” measurement is to be performed, the voltage

on United States and Canada printers should be between 100 V ac

and 127 V ac. On World Trade printers, the voltage is according to

each country’s specification.

Ground checks

To check for a correct ground, measure the voltage between the

ground and a known good voltage source. The voltage

measurement must be the same as the source voltage to consider

that the ground is correct. Continuity measurements may be used to

check grounds; however, be sure to measure to a known good

ground using the lowest ohms scale and check for zero ohms.

Warning: Always unplug the power cord before doing any

continuity measurement.

Diagnostic information 2-1

25XX-100, -110

Continuit y readin gs

When measuring continuity , be sure no back circuits affect the

measurement. If necessary , unplug connectors to remove any back

circuits. Zero the ohm range on the lowest scale (X1). An open

circuit will read infinity. A circuit with correct continuity will read zero

ohms.

2-2 Service Manual

25XX-100, -110

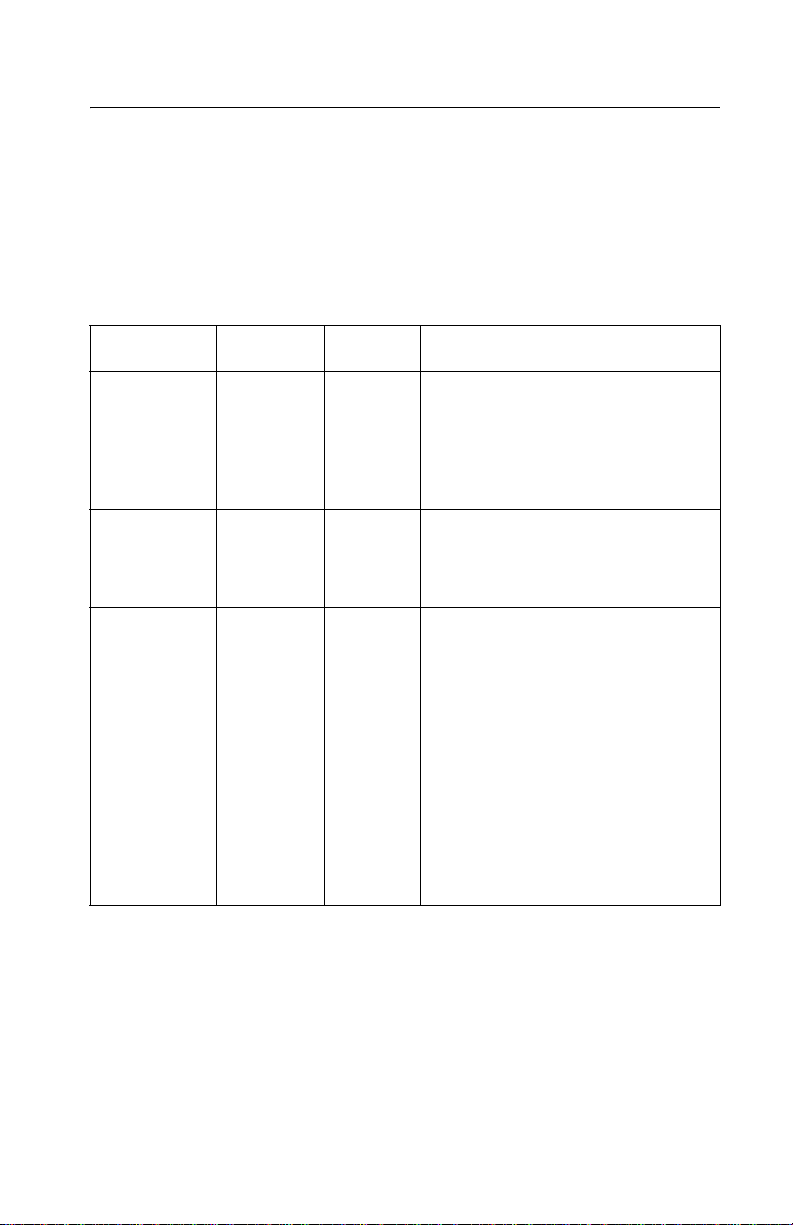

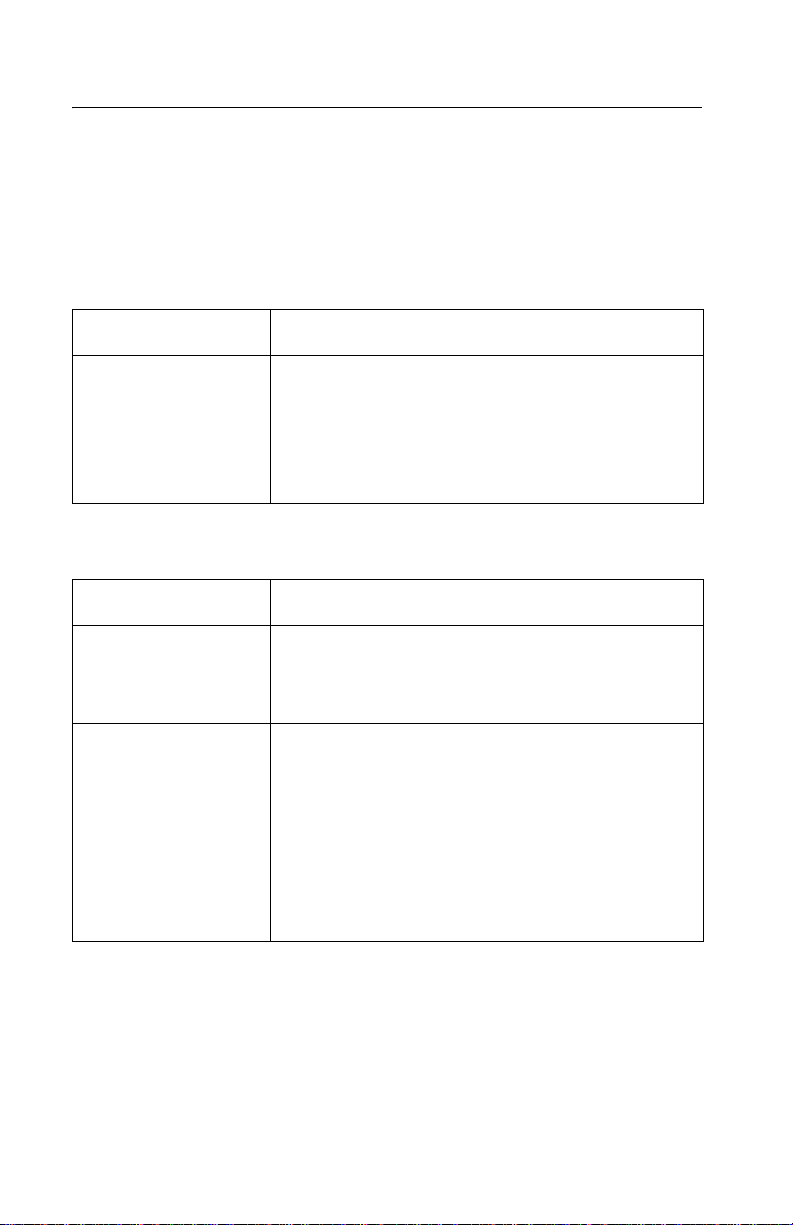

Error indic ation table

The following table describes the service check entries for the

printer error indication codes.

When an error indication changes after you have entered a service

check, you have an intermittent problem. If this occurs, leave the

service check and go to “Symptom check table” on page 2-6.

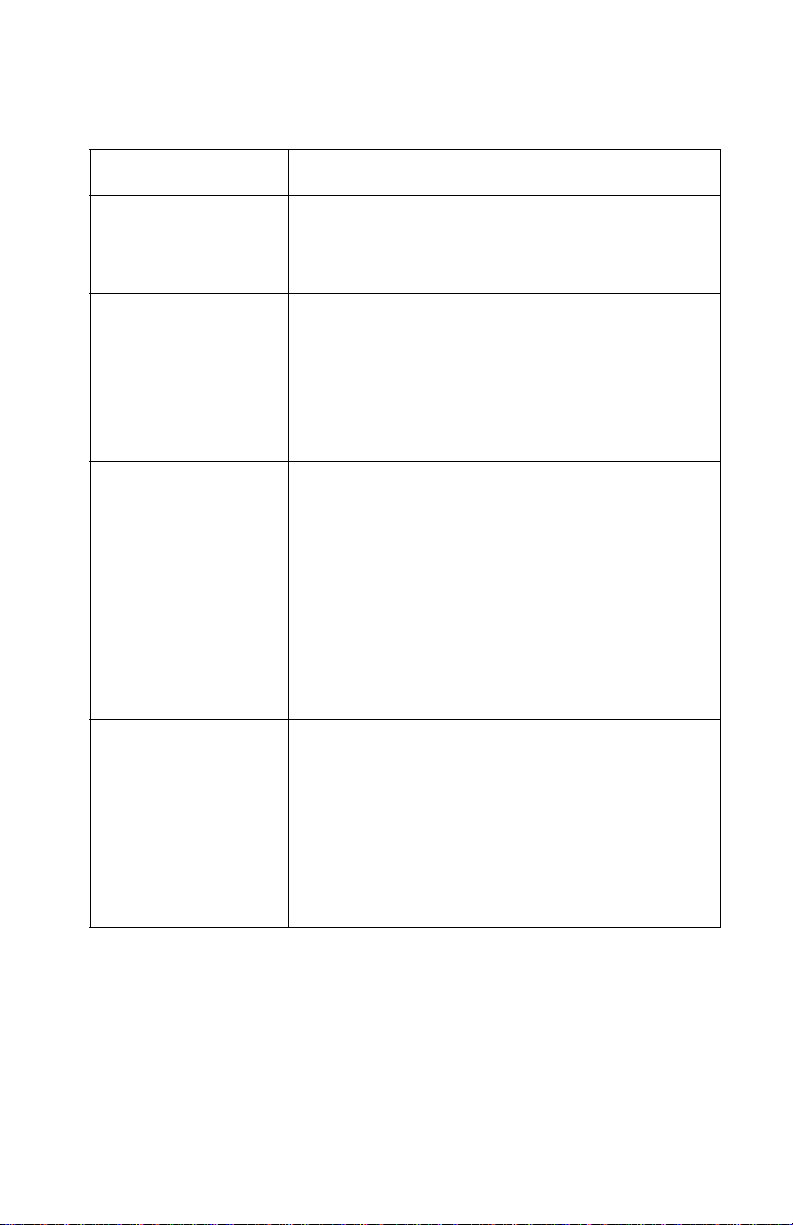

LED Status Alarm Action

Power

Ready

Tractor 2

Paper Out

Panel Lock

Font Lock

Power

Ready

Paper Out

Panel Lock

Power

Ready

Paper Out

Font Lock

ON

ON

ON

ON

ON

ON

ON

Blinking

Blinking

Blinking

ON

Blinking

Blinking

Blinking

None POST

RAM, ROM Controller Error

Go to “POST service check” on

page 2-29.

None Switch Scan Test Error

Go to “Operator panel service

check” on page 2-23.

None NVRAM Read/Write Error

Turn the printer of f and then back

on. If you get the same error

during power-up , replace the logic

board and readjust the

bidirectional print adjustment. Go

to “B i d ir ec t io n a l pr in t

adjustment” on page 4-4.

If the printer completes POST

successfull y and eventually gets

the same error, go to

“Intermittent problem service

check” on page 2-20.

Diagnostic information 2-3

25XX-100, -110

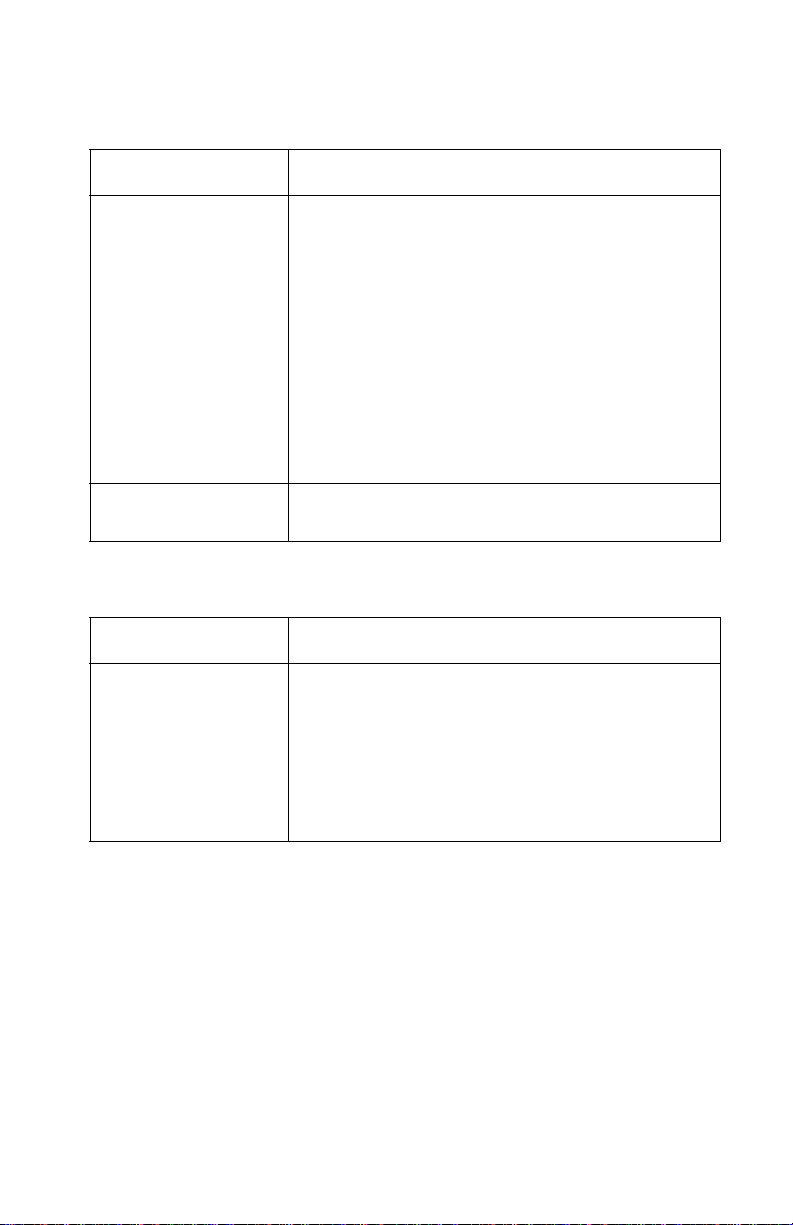

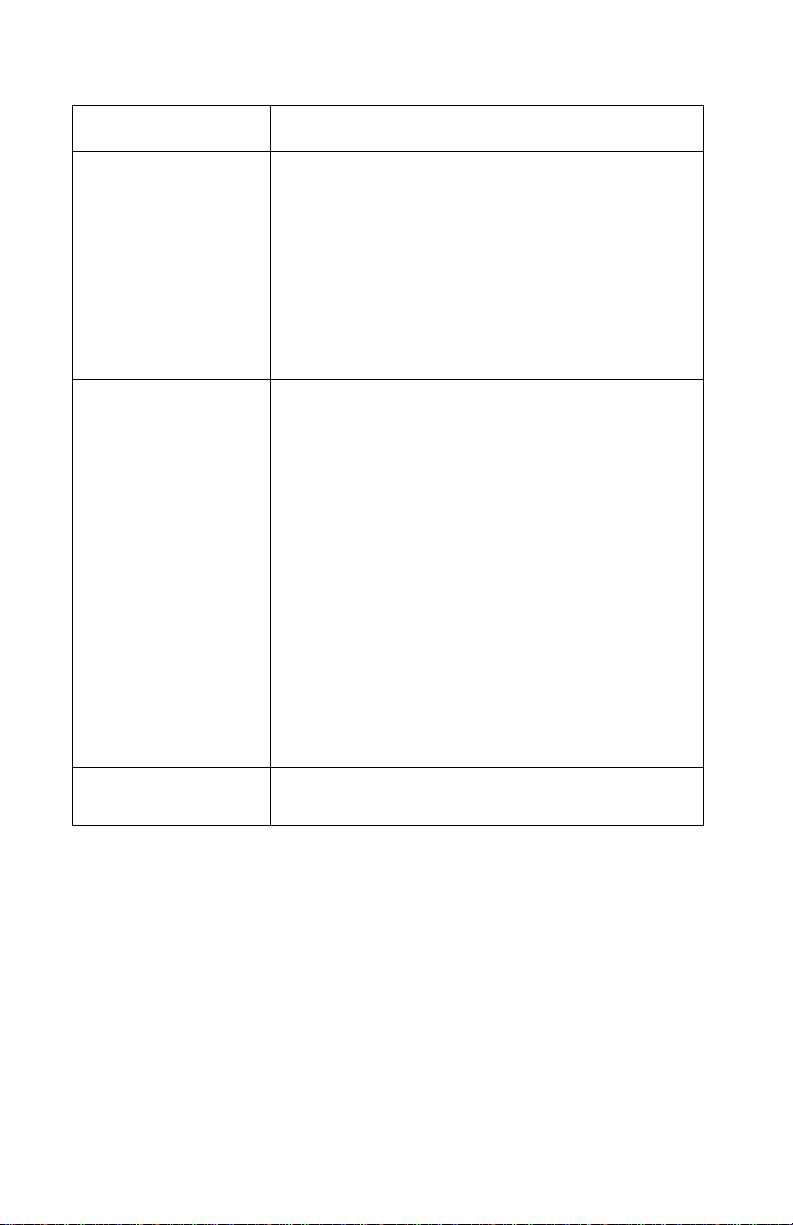

LED Status Alarm Action

Power

Ready

Paper Out

Panel Lock

Font Lock

Power

Ready

Tractor 2

Paper Out

Font Lock

Power

Ready

Tractor 2

Paper Out

Font Lock

ON

Blinking

Blinking

Blinking

Blinking

ON

Blinking

Blinking

Blinking

Blinking

ON

Blinking

Blinking

Blinking

Blinking

Beeps

10

times

None Home Position Error Without

None Timer Error

None Hardware Drive Error

Home Position Error

Go to “C arrier service check”

on page 2- 18.

Tractor 2 Home Posi ti on Error

If Tracto r 2 is installed, remove it

to determine whether t he problem

is with the Carrier Home Position

sensor or the Tr actor 2 Home

Position sensor . See the “Tractor

2 service check” on page 2-36.

Alarm

Go to “P ower service check”

on page 2- 30.

Turn the printer off and then back

on. If you get the same error

during power- up, replace the logic

board and readjust the

bidirectional print adjustment.

Go to “B idirectional print

adjustment” on page 4-4.

The printhead or the printhead

cable(s) can cause this error. Go

to “Printhead service check”

on page 2- 32.

Turn the printer off and then back

on. If you get the same error,

replace the logic board and

readjust the bidir ectional print

adjustment. Go to “Bidirectional

print adjustment ” on page 4-4.

If the printer completes POST

successfully and eventually gets

the same error, go to

“Intermittent problem service

check” on page 2-20.

2-4 Service Manual

25XX-100, -110

LED Status Alarm Action

All LEDs OFF None Power Failure

Check the continuity of the power

cord and the voltage of t he user’s

outlet. If they are correct, go to

“Power service check” on

page 2-30.

Power

Tractor 2

Paper Out

Panel Lock

Font Lock

Any LED

on and

Power LED

off

The Power

LED blinks

or changes

intensity.

Power

Ready

Font Lock

ON

OFF

OFF

OFF

OFF

ON

Blinking

Blinking

None Operator Panel Failure

Go to “Operator panel service

check” on page 2-23.

None Go to “Operator panel service

check” on page 2-23.

None Go to “Power service check”

on page 2-30.

None Ethernet option not installed. Go

to “Network service check” on

page 2-40.

Diagnostic information 2-5

25XX-100, -110

Sympto m check tab le

1. Select the symptom that best describes the problem.

2. Perform the appropriate action before you go to the indicated

service check.

Abno rmal in d ications

Symptom Action

7 or more lights turn

on but do not turn

off.

The Power light is

on, but POST will

not run.

Disconnect the interf ace cable from the print er and

turn the printer off and then back on. If POST now

runs correctly, the problem is in the computer or

interface cable.

Go to “PO S T service check” on page 2-29.

Abnorma l no ise problems

Symptom Action

During POST,

abnormal noise

comes fr om the

carrier.

Durin g idling,

abnormal noise

comes fr om the

printer.

Abnormal noise

when feeding paper

Abnormal noise

during printing or

POST

Check the ribbon cart ri dge for binds or damage.

Go to “C arrier service check” on page 2-18.

Go to “Abnormal noise service check” on

page 2-15.

2-6 Service Manual

25XX-100, -110

Abnormal print operation problems

Symptom Action

Printer will not print,

or become ready.

Abnormal operat ion,

incorrect charact er s,

or incorrect line

width

Printer is ready but

will not print from the

computer correctly .

Undefined or

incorrect

character(s)

Slow printing speed Go to “Print speed service check” on

Be sure the interface cable is connected prope rl y.

Go to “No print or abnormal print service

check” on page 2-23.

page 2-31.

Auto Sheet Feeder problems

Symptom Action

Auto Sheet Feeder

does not feed paper.

Auto Sheet Feeder

double feeds.

Auto Sheet Feeder

has intermit tent feed

problems.

Be sure Sheet Feed i s enabl ed in t he Setup m ode.

Be sure the Paper Select lever is in the cut sheet

position.

Go to “Auto Sheet Feeder (ASF) servic e chec k”

on page 2-16.

Diagnostic information 2-7

25XX-100, -110

Error indications

Symptom Action

Ready and Paper

Out ligh ts blink.

Paper Out and Font

lights blin k .

Turn the printer off and then back on.

Go to “A bnormal indications” on page 2-6.

Turn the printer off and then back on.

Go to “Irrecoverable operator errors” on

page 2-13.

Operator panel problems

Symptom Action

The Start/Stop

button does not

function, bu t no error

is indicat e d.

Only the Power light

turns on.

One or more buttons

do not function.

One or more lights

do not function.

Turn the printer off and then back on.

Go to “Operator panel service check” on

page 2-23.

2-8 Service Manual

25XX-100, -110

Paper feed problems

Symptom Action

The Paper Out light

is blinking when

there is paper in the

printer.

The Paper Out light

does not blink when

there is no paper in

the printer and the

ASF is not installed.

Print operati on starts

without paper.

The Load/Unload

button does not

function when the

push tractor is

installed.

Form feed length is

not correct.

The Load/Unload

button funct ions

when cut sheets are

being used.

Continuous for m s

feed, but cut shee ts

fail to load.

Go to “Paper Present se nsor s ervi ce check” on

page 2-24.

Be sure the paper present sensor is not blocked.

Go to “Paper Present se nsor s ervi ce check” on

page 2-24.

Be sure the Paper Select lever is in the corr ect

position.

Go to “Paper Select sensor service check” on

page 2-28.

Be sure the Paper Select lever is in the cut sheet

position.

Ver if y that continuous form s have been parked

using the Load/Unload button.

Be sure Auto Cut Sheet is enabled in the Set up

mode.

Go to “Paper Select sensor service check” on

page 2-28.

Diagnostic information 2-9

25XX-100, -110

Symptom Action

The Load/Unload

button functions

when the pull tractor

is installe d .

The Paper Out light

blinks, and the

FormFeed button

does not operate

until paper is located

at first print line.

Lower feed roll shaft

rotates, but paper

does not feed.

Pressing FormFeed

does not feed paper.

Abnormal noise

created while printer

is feeding.

Paper jams, skews,

or creases.

Incorrect or no lin e

spacing: wider,

narrower, or

overlapping lines.

Push/Pull Tractor

does not work.

Be sure the Paper Select lever is in the tractor

position.

Go to “Pull Tractor sensor service check” on

page 2-34.

Be sure the Paper Select lever is in the cor rect

position.

Go to “Paper feed service check” on page2-25.

Incorrect Top-ofform position ing.

2-10 Service Manual

Go to “Top-of-forms service check” on

page 2-35.

Loading...

Loading...