Page 1

Lexmark 23XX Series

• Table of Contents

• Start Diagnostics

• Safety and Notices

• Trademarks

23XX-XXX

• Index

• Manuals Menu

Lexmark and Lexmark with diamond

design are trademarks of Lexmark

International, Inc., registered in the

United States and/or other countries.

Page 2

Page 3

Second Edition (May, 1997)

THE FOLLOWING PARAGRAPH DOES NOT APPLY TO THE UNITED

KINGDOM OR ANY COUNTRY WHERE SUCH PROVISIONS ARE

INCONSISTENT WITH LOCAL LAW: LEXMARK INTERNATIONAL, INC.

PROVIDESTHIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY

KIND,EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions, therefore, this statement may not

apply to you.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; thesechangeswillbe

incorporated in later editions of the publication. Improvements or changes in the

products or the programs described in this publication may be made at any

time. Publications are not stocked at the address given below; requests for

publications should be made to your point of purchase.

A form for reader’s comments is provided at the back of this publication. If the

form has been removed, comments may be addressed to Lexmark

International, Inc., Department F95/035-3, 740 New Circle Road NW,

Lexington, Kentucky 40511, U.S.A. Lexmark may use or distribute any of the

information you supply in any way it believes appropriate without incurring any

obligation to you.

Lexmark is a trademark of Lexmark International, Inc.

Copyright Lexmark International, Inc. 1996

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS.

Use, duplication or d isclosure by the Government is subject to restrictions as

set forth in subparagraph(c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013 and in applicable FAR provisions:

Lexmark International, Inc., Greenwich, CT 06836.

Page 4

Page 5

Contents

NoticesandSafetyInformation..........................vii

SafetyNotices...................................... vii

Preface...............................................xi

GeneralInformation...................................1-1

Description....................................... 1-1

Specifications.................................. 1-3

Recommended Machine Usage. . . ................. 1-3

Options.......................................... 1-4

Tools............................................ 1-4

Abbreviations..................................... 1-5

SetupMode ...................................... 1-6

How To Change The Printer Functions .............. 1-6

Serial Interface Adapters . . .......................... 1-7

SerialInterfaceSwitches............................ 1-8

FunctionSwitchSetting.......................... 1-8

DiagnosticInformation ................................2-1

Start............................................ 2-1

Voltage, Ground, And Continuity Readings . . . ........ 2-1

ErrorIndicationTable............................... 2-2

Symptom/CheckTable.............................. 2-6

IrrecoverableOperatorErrors........................ 2-13

ServiceChecks................................... 2-14

AbnormalNoiseServiceCheck................... 2-14

Auto Sheet Feeder (ASF) Service Check............ 2-15

Carrier Drive, Home Position Sensor, Ribbon Feed Service

Check....................................... 2-17

IntermittentProblemServiceCheck................ 2-20

No Print or Abnormal Print Service Check ........... 2-23

Operator Panel Service Check.................... 2-24

Paper Empty Sensor Service Check ............... 2-26

Paper Feed Service Check ...................... 2-27

Paper Select Sensor Service Check ............... 2-30

POSTServiceCheck........................... 2-31

PowerServiceCheck........................... 2-32

PrintSpeedServiceCheck ...................... 2-34

Printhead Service Check ........................ 2-36

PullTractorSensorServiceCheck................ 2-38

TopofFormsProblemServiceCheck.............. 2-39

Tractor2ServiceCheck......................... 2-40

Contents iii

Page 6

DiagnosticAids ......................................3-1

Power-OnSelfTest(POST) ......................... 3-2

PrintTest........................................ 3-3

HexDumpMode.................................. 3-5

Serial Interface Adapter Print T est..................... 3-6

RepairInformation....................................4-1

Handling ESD-Sensitive Parts ........................ 4-1

Adjustments...................................... 4-2

Printhead-to-Platen Gap Adjustment. ............... 4-2

Bidirectional Print Adjustment ..................... 4-5

RemovalProcedures............................... 4-7

Auto Sheet Feeder Gears Removal . ............... 4-8

Auto Sheet Feeder Pick-up Roller Removal .......... 4-9

BottomCoverRemoval......................... 4-10

CarrierRemoval .............................. 4-12

CarrierMotorAssemblyRemoval................. 4-16

CarrierPlateRemoval.......................... 4-18

Download or Print Buffer Module Removal .......... 4-21

FormThicknessLeverRemoval.................. 4-22

Head Gap Sensor Removal (238X-001) ............ 4-23

Head Gap Sensor Removal (23XX-002, 003) . . . ..... 4-24

HomePositionSensorRemoval.................. 4-25

Label Jam Removal............................ 4-26

LeftSideFrameRemoval....................... 4-28

LowerFeedRollerRemoval..................... 4-30

LowerPinchRollerRemoval..................... 4-32

Main Logic Board Removal ...................... 4-33

Operator Panel Assembly Removal . .............. 4-34

Paper Empty Sensor And Spring Removal .......... 4-36

Paper Feed Motor Removal ..................... 4-38

Paper Guide Removal (Left And Right)............. 4-39

Paper Guide / Platen Assembly Removal ........... 4-40

Paper Select Lever Removal..................... 4-42

Paper Select Sensor Removal ................... 4-43

Paper Separator Removal....................... 4-44

Power Supply Removal. . ....................... 4-46

PrintUnitRemoval............................. 4-47

Printhead Removal ............................ 4-48

Printhead Cables Removal ...................... 4-49

PullTractorRemoval........................... 4-50

PullTractorActuatorRemoval.................... 4-51

PullTractorSensorRemoval..................... 4-52

iv Service Manual

Page 7

PushTractorAssemblyRemoval.................. 4-53

Ribbon Drive Rack Gear Removal . ................ 4-54

RightSideFrameRemoval...................... 4-56

RightSideFrameGearsRemoval................. 4-58

SubLogicBoardRemoval....................... 4-59

TensionPulleyPlateAssembly................... 4-60

TopCoverRemoval............................ 4-61

Top of Form Sensor, S ensor Flag And Spring Removal 4-64

Upper Feed Roller Removal...................... 4-66

ConnectorLocations ..................................5-1

FrontView.................................... 5-2

RearView..................................... 5-3

Tractor 2 Cable Connectors ....................... 5-4

WiringDiagrams................................... 5-5

Block Diagram 238X-001 ......................... 5-5

Block Diagram 239X-001 ......................... 5-6

Block Diagram 238X-002 ......................... 5-7

Block Diagram 239X-002 ......................... 5-8

Block Diagram 238X-003 ......................... 5-9

Block Diagram 239X-003 ........................ 5-10

Signal Connections................................ 5-11

ConnectorLocations............................... 5-20

MainLogicBoard23XX-001 ..................... 5-20

MainLogicBoard23XX-002 ..................... 5-21

MainLogicBoard23XX-003 ..................... 5-22

SubLogicBoards.............................. 5-23

Power Supply ................................. 5-25

Operator Panel................................ 5-26

PreventiveMaintenance ...............................6-1

Lubrication ....................................... 6-1

Specified Lubricants. . . .......................... 6-1

Lubrication Points............................... 6-2

Lubrication Points (Oil). .......................... 6-3

Lubrication Points (Grease) ....................... 6-4

Contents v

Page 8

PartsCatalog ........................................7-1

HowToUseThisPartsCatalog....................... 7-1

Assembly 1: Major Components ...................... 7-2

Assembly2:Covers................................ 7-6

Assembly3:Carrier............................... 7-10

Assembly 4: Paper Guide / Platen / Feed Roller ......... 7-14

Assembly5:Electronics............................ 7-18

Assembly 6: ASF - Roller / Support ................... 7-24

Assembly7:ASF-SideFrame/Covers............... 7-26

Assembly8:Tractor2Option........................ 7-28

vi Service Manual

Page 9

Notices and Safety Information

Safety Notices

•

The maintenance information for this product has been

prepared for use by a professional service person and is not

intended to be used by others.

• There may be an increased risk of electric shock and personal

injury during disassembly and servicing of this product.

Professional service personnel should understand this and take

necessary precautions.

• The safety features of some parts may not always be obvious.

Therefore, replacement parts must have the identical or

equivalent characteristics as the original parts.

Sicherheitshinweise

• Die Wartungsinformationen für dieses Produkt sind

ausschließlich für die Verwendung durch einen

Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des

Geräts besteht ein zusätzliches Risiko eines elektrischen

Schlags und körperlicher Verletzung. Das zuständige

Fachpersonal sollte entsprechende Vorsichtsmaßnahmen

treffen.

• Ersatzteile müssen gleiche oder gleichwertige Merkmale wie

die Originalteile aufweisen, da nicht immer offensichtlich ist,

welche Teile des Geräts Sicherheitsmerkmale aufweisen.

Consignes de Sécurité

• Les consignes d'entretien et de réparation de ce produit

s'adressent uniquement à un personnel de maintenance

qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter

certains risques électriques, le personnel d'entretien qualifié

devra prendre toutes les précautions nécessaires.

• Les normes de sécurité de certaines pièces n'étant pas toujours

explicites, les pièces de rechange doivent être identiques ou

conformes aux caractéristiques des pièces d'origine.

Notices and Safety Information vii

Page 10

Norme di sicurezza

• Le informazioni riguardanti la manutenzione di questo prodotto

sono indirizzate soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il

rischio di subire scosse elettriche e danni alla persona è più

elevato. Il personale di assistenza autorizzato, deve, quindi,

adottare le precauzioni necessarie.

• Poiché non tutti i pezzi di ricambio garantiscono la stessa

sicurezza, questi devono avere caratteristiche identiche o

equivalenti a quelle dei pezzi originali.

Pautas de Seguridad

• La información sobre el mantenimiento de este producto está

dirigida exclusivamente al personal cualificado de

mantenimiento.

• Existe mayor riesgo de descarga eléctrica y de daños

personales durante el desmontaje y la reparación de la

máquina. El personal cualificado debe ser consciente de este

peligro y tomar las precauciones necesarias.

• Los dispositivos de seguridad de algunas piezas no siempre

pueden reconocerse a simple vista. Por lo tanto, los recambios

deben poseer características idénticas o equivalentes a las de

las piezas originales.

Informações de Segurança

• As informações de segurança relativas a este produto

destinam-se a profissionais destes serviços e não devem ser

utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a

desmontagem e manutenção deste produto. Os profissionais

destes serviços devem estar avisados deste facto e tomar os

cuidados necessários.

• Os dispositivos de segurança de algumas peças poderão não

ser sempre suficientemente evidentes. Assim, as peças

sobressalentes devem possuir características idênticas ou

equivalentes às peças originais.

viii

Page 11

Informació de Seguretat

• La informació pel manteniment d’aquest producte està

orientada exclusivament a professionals i no està destinada a

ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar

durant el procés de desmuntatge i de servei d’aquest producte.

El personal professional ha d’estar-ne assabentat i prendre les

mesures convenients.

• Les característiques de seguretat d’algunes de les peces poden

no ser òbvies. Per tant, les característiques dels recanvis

hauran de ser idèntiques o equivalents a les de les peces

originals.

Chinese Safety Information

Notices and Safety Information ix

Page 12

Korean Safety Information

x

Page 13

Preface

This manual is divided into the following chapters:

• “General Information” contains a general description of the

printer and the maintenance approach used to repair it. Special

tools and test equipment are listed in this chapter, as well as

general environmental and safety instructions.

• “Diagnostic Information” contains error code table, symptom

table,and service checks used to isolate failing field replaceable

units (FRUs).

• “Diagnostic Aids” contains tests and checks used to locate or

repeat symptoms of printer problems.

• “Repair Information” provides instructions for making printer

adjustments and removing and installing FRUs.

• “Connector Locations” uses illustrations to identify the major

components and test points on the printer.

• “Preventive Maintenance” contains lubrication specifications,

and maintenance information to prevent problems and maintain

optimum performance.

• “Parts Catalog” contains illustrations and part numbers for

individual FRUs.

Preface xi

Page 14

xii

Page 15

1. General Information

Description

The Lexmark 238X and 239X - XXX printers are small versatile

tabletopprinters suitable foruse in the home or small business. They

are especially well-suited for applications that use continuous or

multipart forms. The 2381 and 2391 are wide-carriage versions of

the 2380 and 2390.

The 23XX Plus (23XX-002) printers are enhanced versions of the

basic 23XX-001 printers. These printers have the following

additional features:

• Forms macro and smooth paper scrolling capability, available

from the operator panel.

• Option slot.

• Resident bar code.

• Quiet mode.

• Higher print speed (239X).

The 23XX Forms Printers (23XX-003), in addition to the features of

the 23XX-002 printers are 9% (9-wire machines) or 28% (24-wire

machines) faster in fast draft mode. They also support the Tractor 2

Options.

There is also a PS/1 version of the 2390-001, which has a distinctive

PS/1 logo but is otherwise identical to the 2390-001.

General Information 1-1

Page 16

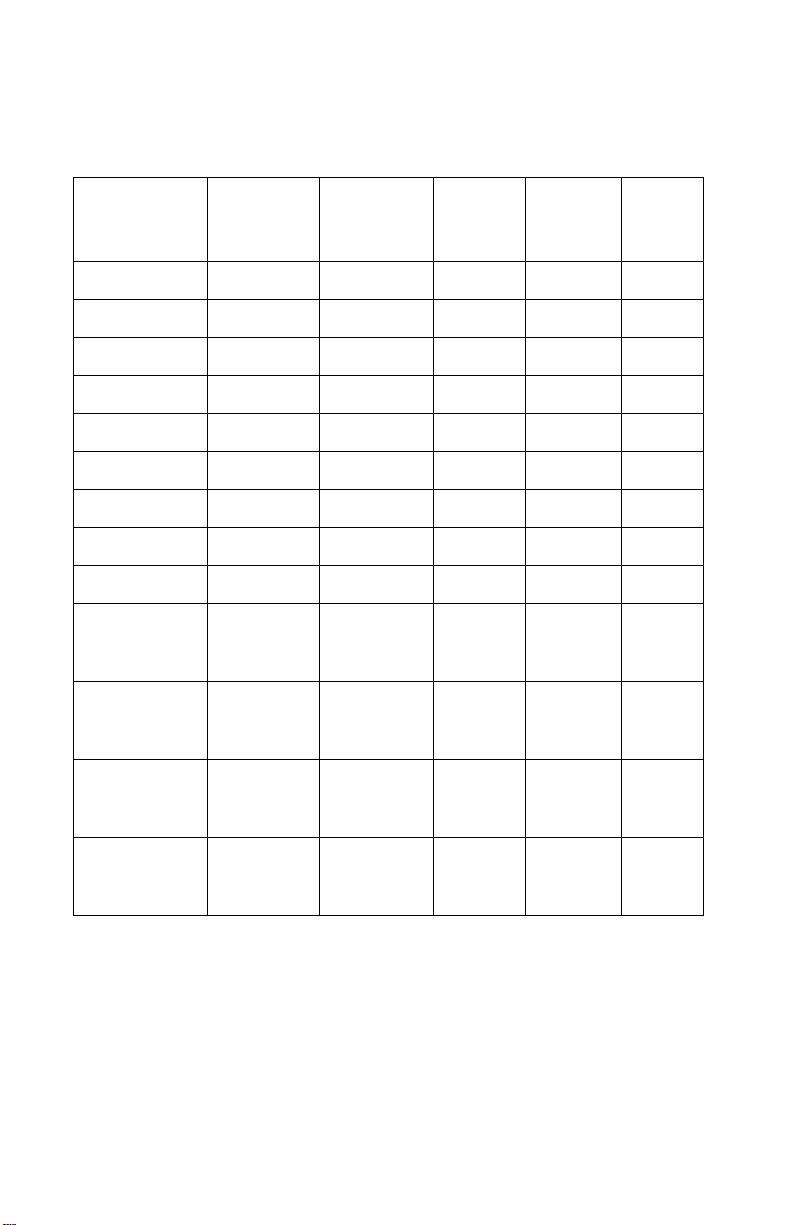

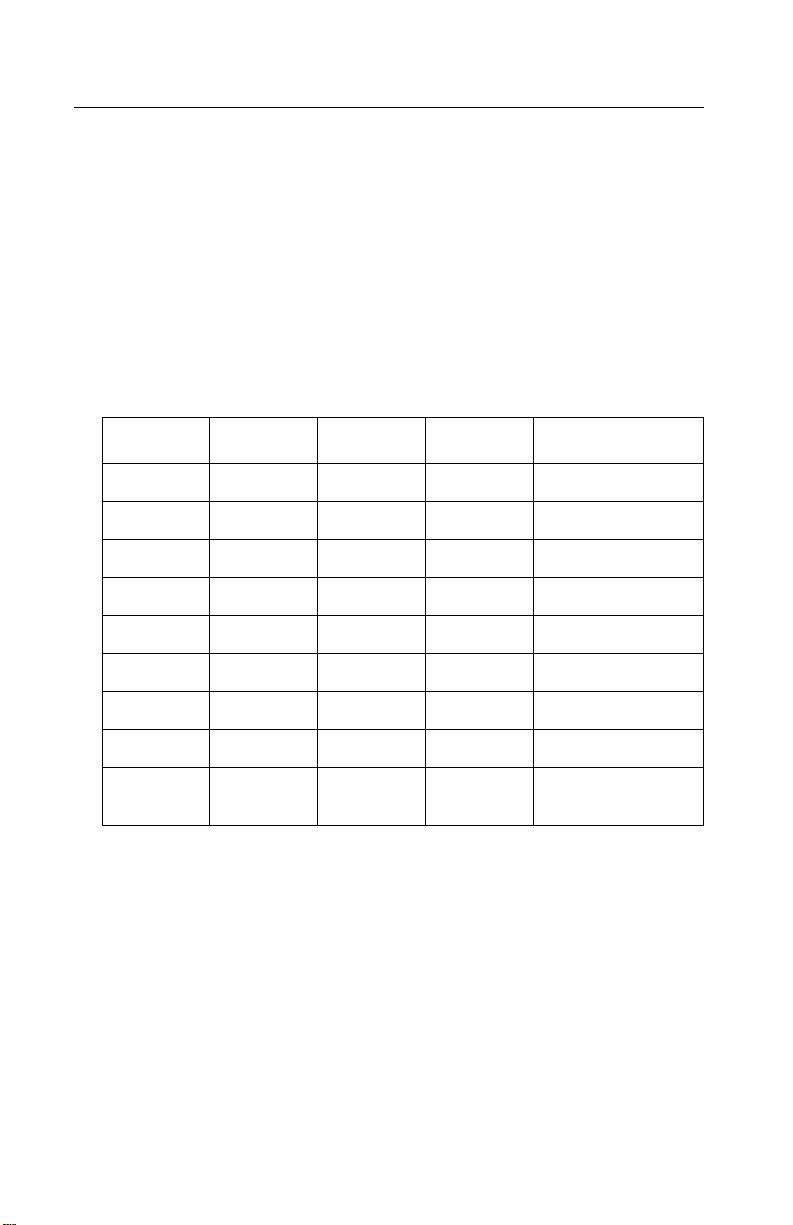

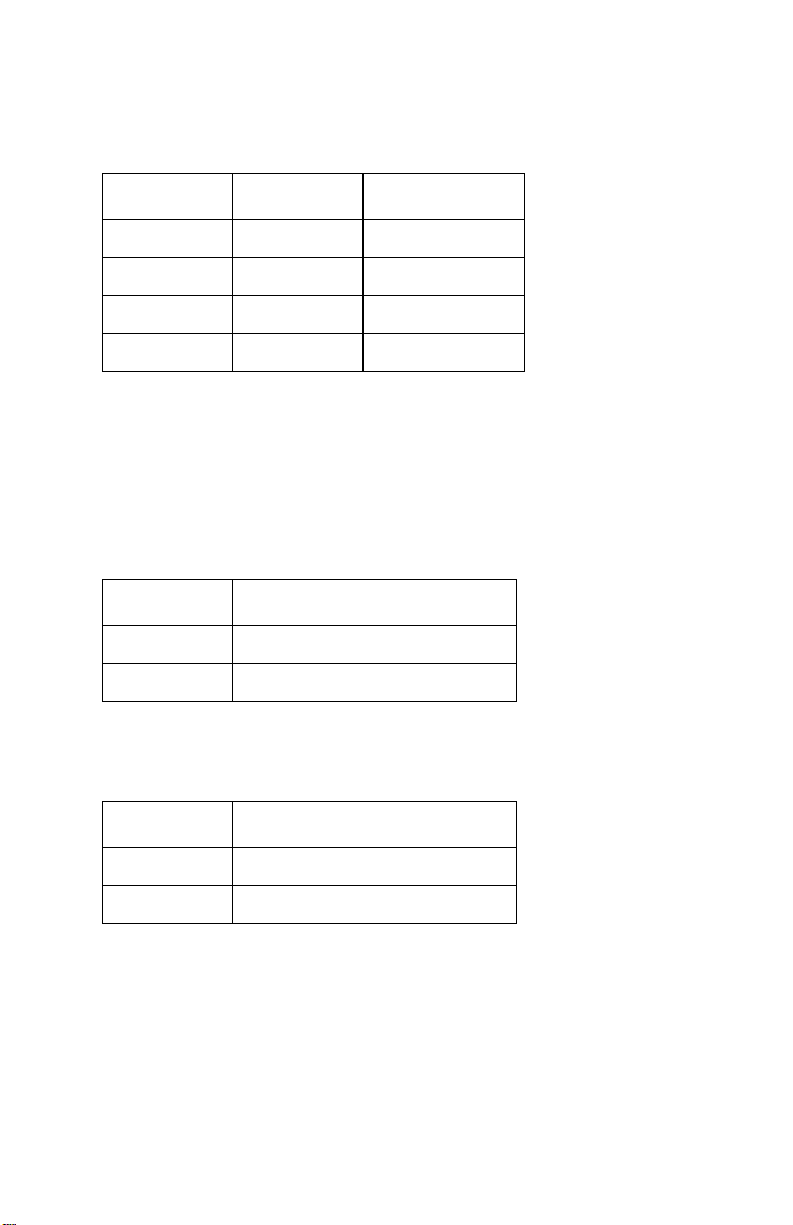

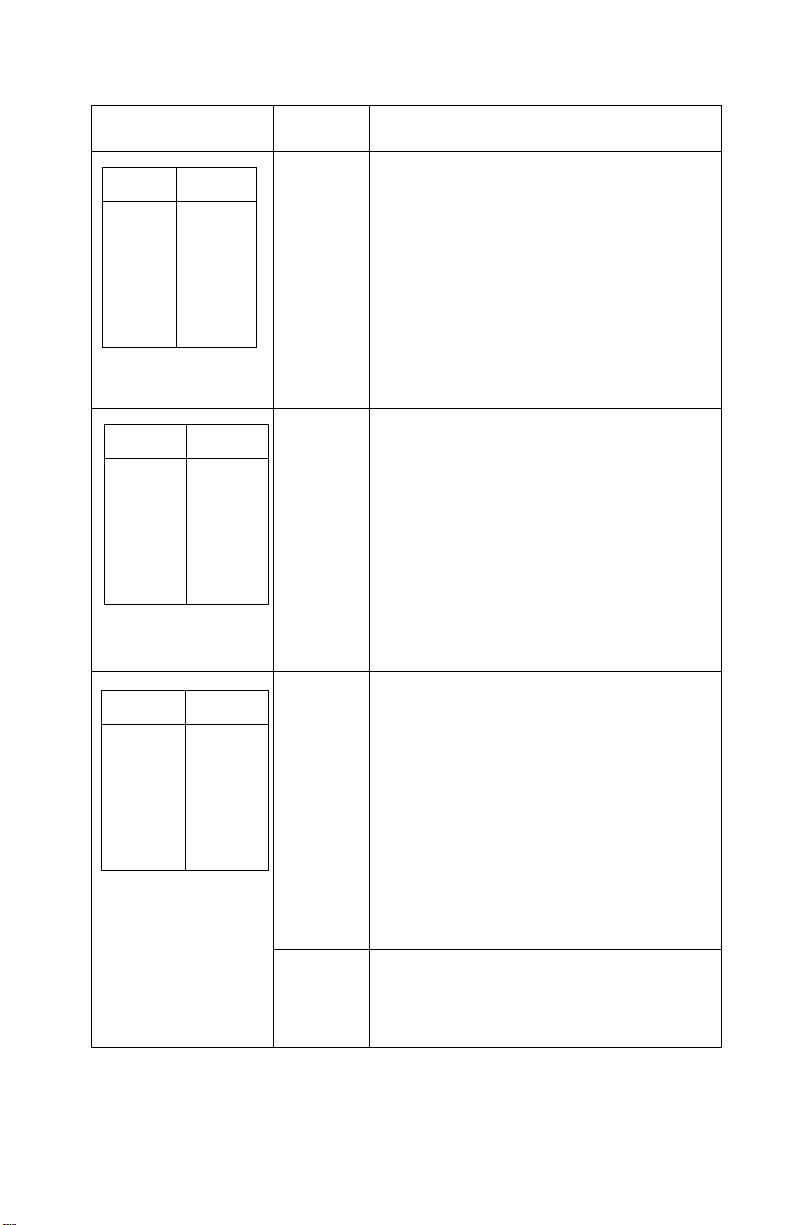

The followingtable summarizes the differences between the printers

in the 23XX family:

US Logo

Name

WTCLogo

Name

MachType

Model #

No. of

Print

Wires

Paper

Width

Paper

Knob

PPSII 2380 2380 2380-001 9 Narrow Yes

PPSII 2381 2381 2381-001 9 Wide Yes

PPSII 2390 2390 2390-001 24 Narrow Yes

PPSII 2391 2391 2391-001 24 Wide Yes

PS/1 N/A 2390-PS1 24 Narrow Yes

2380 Plus 2380 Plus 2380-002 9 Narrow No

2381 Plus 2381 Plus 2381-002 9 Wide No

2390 Plus 2390 Plus 2390-002 24 Narrow No

2391 Plus 2391 Plus 2391-002 24 Wide No

Forms

Printer

2380 Plus

Forms

Printer

2381 Plus

Forms

Printer

2390 Plus

Forms

Printer

2380 Plus

Forms

Printer

2381 Plus

Forms

Printer

2390 Plus

2380-003 9 Narrow No

2381-003 9 Wide No

2390-003 24 Narrow No

Forms

Printer

2391 Plus

1-2

Forms

Printer

2391 Plus

2391-003 24 Wide No

Page 17

Specifications

• Printhead life: 140 Million Characters

• Ribbon Life: 4 Million Characters

• Printer Life: 5 Years

• BTU: 409-Maximum/51 Idle (Per Hour)

• Power Consumption: 120 Watts-Maximum/15 Watts Idle

Recommended Machine Usage

• 23XX-001 - 10 million characters per year.

• 23XX-002, 003 - 12 million characters per year.

The character usage per day is calculated by dividing the yearly

usage rating by 1300 characters per page, divided by 12 months per

year, by 22 working days per month. To reduce the probability of

reliability/service problems, field data has shown printer usage

should not exceed twice the daily page usage.

Notes:

• All numbers are average or estimates.

• Performance of individual printers may vary.

• Lexmark does not represent or warrant that printers will achieve

these results. (See the applicable statement of Limited Warranty

for all warranty information).

General Information 1-3

Page 18

Options

The following options may be installed on 238X/239X printers:

• Auto Sheet Feeder (ASF)

• 32Kb Memor y Module, Volatile

• 32Kb Memor y Module, Non-volatile

• Serial Interface Attachment (RS232/RS422).

• Extended National Language Support modules (World Trade

only)

• Acoustics Option

• Extended Cut-sheet Paper Guides

• Tractor 2 (23XX-003 Only)

Tools

The basic tools needed are:

• Basic CE tool kit

• #1 Phillips screwdriver

• #2 Phillips screwdriver

• Feeler gauges 0.35 mm (0.014 in.) 0.4 m m (0.016 in.)

• Analog or digital volt-ohmmeter

1-4

Page 19

Abbreviations

ASIC Application-Specific Integrated Circuit

CSU Customer Setup

DRAM Dynamic Random Access Memory

EPROM Erasable Programmable Read-Only Memory

ESD Electrostatic Discharge

FRU Field Replaceable Unit

HVPS High Voltage Power Supply

LAN Local Area Network

LCD Liquid Crystal Display

LED Light-Emitting Diode

LVPS Low Voltage Power Supply

NVRAM Nonvolatile Random Access Memory

OEM Original Equipment Manufacturer

POR Power-On Reset

POST Power-On Self Test

PQET Print Quality Enhancement Technology

ROS Read-Only Storage

SRAM Static Random Access Memory

UPR Used Parts Replacement

V ac Volts alternating current

V dc Volts direct current

General Information 1-5

Page 20

Setup Mode

How To Change The Printer Functions

1. Make sure continuous forms are in the printer.

2. Press Alt and then press Setup to enter Setup Mode.The

printer prints out the Main Menu.

3. To select a function, press the buttons listed on the printout.

4. To save the setting and leave Setup Mode, press Start/Stop

until out of the menu.

1-6

Page 21

Serial Interface Adapters

The 23XX printer product line uses three different serial adapters.

• 23XX-001:

• Snaps on back of the printer and plugs into the parallel port.

• Power lead plugs into the printer’s +5 V port.

• Switch settings are for “Snap-On”.

• 23XX-002:

• In-line gray box with a short cable to the parallel port.

• Some units have a separate power lead to the +5 V port.

• Units without the power cord will not work on the 23XX-001.

• Switch settings are for “Gray”.

• 23XX-003:

• Similar to the 23XX-002, but different switch definitions.

• All units have a power lead.

• Switch settings are for “Black”.

Notes:

• Except as noted, all adapters work with all printers.

• Some adapters may be installed on printers other than what is

listed.

• Only the “Black” adapter is available as a FRU.

• Changes to switch settings are valid only after printer power is

turned off and then on again.

• Contact Lexmark Technical Support for questions about serial

adapters.

General Information 1-7

Page 22

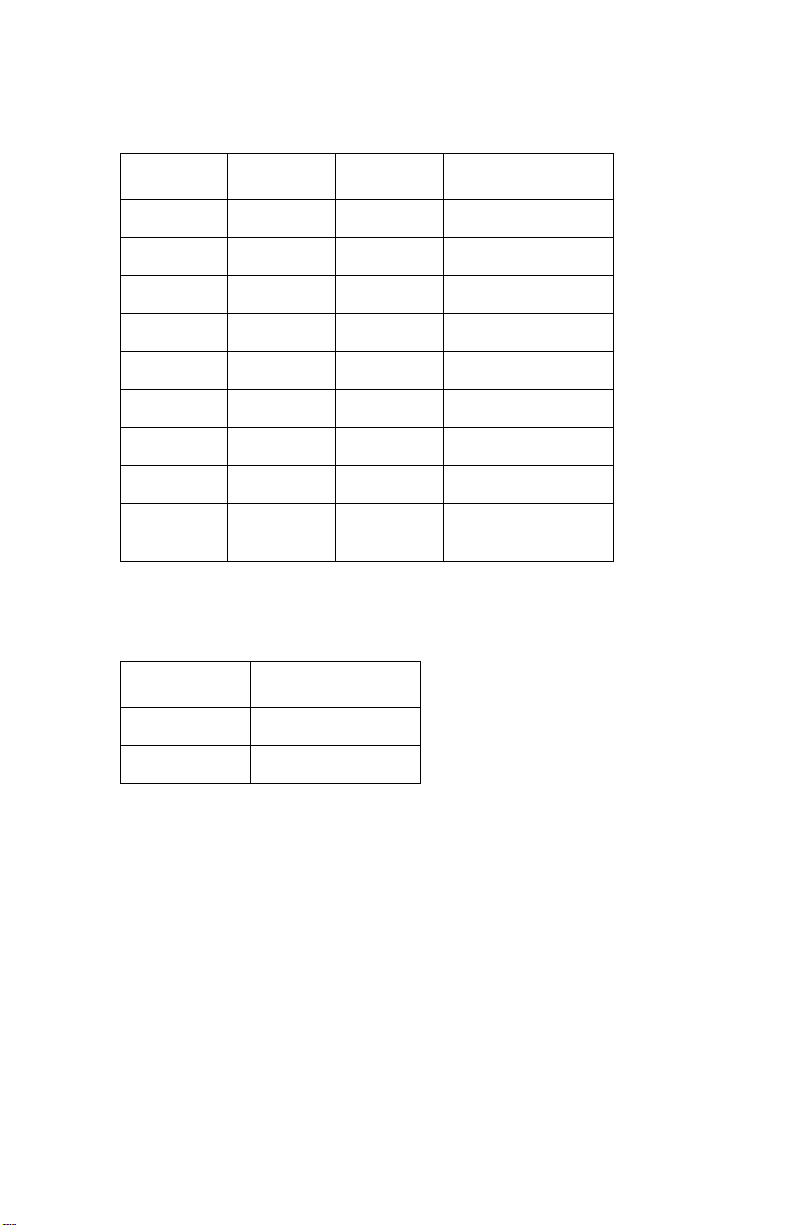

Serial Interface Switches

The serial interface has 12 function switches which determine how

the printer receives data from the computer or terminal. Set the

switches according to your particular equipment requirements.

Function Switch Setting

Switches 1 To 4 - Speed:

Define the serial interface speed in bits per second (bps).

Snap-On and Gray Serial Adapters

Switch1 Switch 2 Switch 3 Switch 4 Speed (bps)

On On Off Off 150

On Off On Off 300

On Off Off Off 600

Off On On Off 1,200

Off On Off Off 2,400

Off Off On Off 4,800

1-8

Off Off Off Off 9,600

On On On Off 19,200

OffOffOffOn 38,400

(RS-422 only)

Page 23

Black Serial Adapter

Switch1 Switch 2 Switch 3 Speed (bps)

N/A N/A N/A 150

On Off On 300

On Off Off 600

Off On On 1,200

Off On Off 2,400

Off Off On 4,800

Off Off Off 9,600

On On On 19,200

On On Off 38,400

(RS-422 Only)

Switch 5 - Data Bits:

Selects the number of data bits (7 or 8) in each data frame.

Switch 5 Data Bits

Off 8

On 7

General Information 1-9

Page 24

Switches 6 and 7 - Parity:

Select the interface parity.

Switch 6 Switch 7 Parity

Off Off No

Off On Ignore

On Off Odd

On On Even

Note: When setting the “Ignore” for parity, the printer ignores the

received parity and transmits using even parity. For all other par ity

settings, the transmitted parity matches the received parity.

Switch 8 - Stop Bits (Snap-On):.

Switch 8 Stop Bits

Off 1 Stop Bit

On 2 Stop Bits

Switch 8 - Buffer Size (Gray and Black):

Selects the buffer size.

Switch 8 Buffer Size

Off Normal (2048 bytes)

On Minimum (2 bytes)

1-10

Page 25

Switch9-Protocol:

Selectsthetypeofprotocol.Differsdependingonwhichserial

interfaceunitisinstalled.

Snap-OnandGrayUnits

Protocol

Switch9

Snap-On Gray

Off XON/XOFF DTRPacing(RS232only)

On DTRpacing(RS232only) XON/XOFF

BlackUnits

Switch4 Switch9 Protocol

Off On XON/XOFF

Off Off DTRpacing(RS232only)

On Off DTR+XON/XOFF

Off On RobustXON/XOFF

Note:DTRprotocolisforRS-232Conly.

Switch10-PrintTest(AllUnits):

Selectstheprinttestfortheserialinterfaceadapter.Referto“Serial

InterfaceAdapterPrintTest”onpage3-6.

Switch10 PrintTest

Off Normalmode

On Testmode

GeneralInformation1-11

Page 26

Switch 11- Polarity For RS-422 Serial Interface (All Units):

NOR/REV reverses the polarity of the receive and transmit data line

for the RS-422 serial interface.

Switch 11 Mode

Off Normal

On Reverse

Switch 12 - Serial Interface Mode Select: (All Units)

Switch 232/422 sets the serial interface in either

RS-232C or RS-422 mode.

Switch 12 Mode

Off RS-232C

On RS-422

1-12

Page 27

2. Diagnostic Information

Start

Make a quick visual check for defects (loose or broken parts,

unplugged connectors, paper jams, and so on).

Voltage, Ground, And Continuity Readings

Voltage Readings

All DC voltages must be within +5% through -10% of the values to

be considered correct. Unless stated otherwise, all connectors

should be connected normally when a voltage measurement is

done.

When a “Line Voltage” measurement is to be done, the voltage on

United States and Canada machines should be between 100 V ac

and 127 V ac. On World Trade machines, the voltage is according to

each country’s specification.

Ground Checks

To check for a correct ground, measure the voltage between the

ground and a known good voltage source. The voltage

measurement must be the same as the source voltage to consider

that the ground is correct. Continuity measurements may be used to

check grounds, however, be sure to measure to a known good

ground using the lowest ohms scale and check for zero ohms.

Note: Always unplug the power cord before doing any continuity

measurement.

Continuity Readings

When measuring continuity, be sure no back circuits affect the

measurement. If necessary, unplug connectors to remove any back

circuits. Zero the ohm range on the lowest scale (X1). An open

circuit will read infinity. A circuit with correct continuity will read zero

ohms.

Diagnostic Information 2-1

Page 28

ErrorIndicationTable

Thefollowingtabledescribestheservicecheckentriesfortheprinter

errorindicationcodes.

Whenanerrorindicationchangesafteryouhaveenteredaservice

check,youhaveanintermittentproblem.Ifthisoccurs,leavethe

servicecheckandgoto“Symptom/CheckTable”onpage2-6.

Indication Alarm Action

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

None PostError

Goto“POSTServiceCheck”onpage

2-31.

None RAM,ROM,TimerInterruptController

Error

Turnthemachineoffandthenon.Ifyou

getthesameerrorduringpower-up,

replacethemainlogicboardand

readjustthebidirectionalprint

adjustment.Iftheprintercompletes

POSTsuccessfullyandeventuallygets

thesameerror,goto“Intermittent

ProblemServiceCheck”onpage2-20.

2-2

Page 29

Indication Alarm Action

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

ON

BLINK

BLINK

OFF

BLINK

OFF

OFF

ON

BLINK

BLINK

BLINK

OFF

OFF

OFF

ON

BLINK

BLINK

BLINK

BLINK

OFF

OFF

None SwitchScanTestError

Goto“OperatorPanelServiceCheck”

onpage2-24.

None NVRAMRead/WriteError

Turnthemachineoffandthenbackon.

Ifyougetthesameerrorduringpowerup,replacethemainlogicboardand

readjustthebidirectionalprint

adjustment.Iftheprintercompletes

POSTsuccessfullyandeventuallygets

thesameerror,goto“Intermittent

ProblemServiceCheck”onpage2-20.

Beeps

10

times

HomePositionError

Goto“CarrierDrive,HomePosition

Sensor,RibbonFeedServiceCheck”on

page2-17.

Tractor2HomePositionError

IfTractor2isinstalled,removeitto

determinewhethertheproblemiswith

thecarrierhomesensorortheTractor2

homesensor.Refertothe“Tractor2

ServiceCheck”onpage2-40.

None HomePositionErrorWithoutAlarm

Goto“PowerServiceCheck”onpage

2-32.

DiagnosticInformation2-3

Page 30

Indication Alarm Action

None LogicalError

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

ON

BLINK

BLINK

BLINK

OFF

BLINK

OFF

Turnthemachineoffandthenbackon.

Ifyougetthesameerrorduring

power-up,replacethemainlogicboard

andreadjustthebidirectionalprint

adjustment.Iftheprintercompletes

POSTsuccessfullyandeventuallygets

thesameerrorcheck,goto“Intermittent

ProblemServiceCheck”onpage2-20.

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

ON

BLINK

BLINK

OFF

BLINK

BLINK

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

None HardwareDriveError

Theprintheadortheprintheadcables

cancausethiserror.Goto“Printhead

ServiceCheck”onpage2-36.

Turnthemachineoffandthenbackon.

Ifyougetthesameerror,replacethe

mainlogicboardandreadjustthe

“BidirectionalPrintAdjustment”onpage

4-5.IftheprintercompletesPOST

successfullyandeventuallygetsthe

sameerror,goto“IntermittentProblem

ServiceCheck”onpage2-20.

Iftheproblemstillexists,removethe

newmainlogicboard,installtheold

mainlogicboard,thenreplacethesub

logicboard.

None PowerFailure

Checkthecontinuityofthepowercord

andthevoltageoftheuser’soutlet.If

theyarecorrect,goto“PowerService

Check”onpage2-32.

2-4

Page 31

Indication Alarm Action

LED Status

Power

Ready

Paper

Font

Pitch

Alt

Others

IfotherLED

combinations

alongwiththe

PowerLEDareon.

AnyLEDonbut

thePowerLEDoff.

IfthePowerLED

blinksorchanges

intensity.

Any Beeps

ON

OFF

OFF

OFF

OFF

OFF

OFF

None OperatorPanelFailure

None Goto“POSTServiceCheck”onpage

None Goto“OperatorPanelServiceCheck”

None Goto“PowerServiceCheck”onpage

7

times

Goto“OperatorPanelServiceCheck”

onpage2-24.

2-31.

onpage2-24.

2-32.

(OptionalSerialInterfaceAdapter

installed)

•Turntheprinteroffandcheckthe

connectionfromtheserialinterface

adaptertotheprinter.

•Turntheprinteroffandthenon.If

yougetthesameerror,replacethe

serialinterfaceadapter.

•Ifturningtheprinteroffandthenon

issuccessful,runthe“Serial

InterfaceAdapterPrintTest”on

page3-6.

DiagnosticInformation2-5

Page 32

Symptom/CheckTable

1.Selectthesymptomthatbestdescribestheproblem.

2.Performtheappropriateactionbeforeyougototheindicated

servicecheck.

AbnormalIndications

Symptom Action

7ormorelightsturn

onbutdonotturn

off.

ThePowerlightis

on,butPOSTwill

notrun.

Disconnecttheinterfacecablefromtheprinterand

turntheprinteroffandthenon.IfPOSTnowruns

correctly,theproblemisinthecomputeror

interfacecable.

Gotothe“POSTServiceCheck”onpage2-31.

AbnormalNoiseProblems

Symptom Action

DuringPOST,

abnormalnoise

comesfromthe

carrier.

Duringidling,

abnormalnoise

comesfromthe

printer.

Whenfeedingpaper,

abnormalnoiseis

created.

Duringprintingor

POST,abnormal

noiseiscreated.

Checktheribboncartridgeforbindsordamage.

Gotothe“CarrierDrive,HomePositionSensor,

RibbonFeedServiceCheck”onpage2-17.

Goto“AbnormalNoiseServiceCheck”onpage

2-14.

2-6

Page 33

AbnormalPrintOperationProblems

Symptom Action

Printerwillnotprint,

orbecomeReady.

Abnormaloperation,

incorrectcharacters,

orincorrectline

width.

Printerisreadybut

willnotprintfromthe

computercorrectly.

Undefinedor

incorrect

character(s).

Slowprintingspeed. Gotothe“PrintSpeedServiceCheck”onpage

Besuretheinterfacecableisconnectedproperly.

Iftheserialinterfaceadapterisinstalled,besureit

anditspowerinterfacecableareinstalled

correctly.(Someadaptersdonothaveaseparate

powercable.)

Gotothe“NoPrintorAbnormalPrintService

Check”onpage2-23.

2-34.

AutoSheetFeederProblems

Symptom Action

Autosheetfeeder

willnotfeedpaper.

Autosheetfeeder

doublefeeds.

Autosheetfeeder

hasintermittentfeed

problems.

BesureSheetFeedisenabledintheSetupMode.

Besurethepaperselectleverisinthecutsheet

position.

Gotothe“AutoSheetFeeder(ASF)Service

Check”onpage2-15.

DiagnosticInformation2-7

Page 34

ErrorIndications

Symptom Action

ReadyandPaper

Outlightsblinkto

indicateaHardware

Error.

PaperOutandAlt

lightsblinkto

indicateanoperator

error.

Turntheprinteroffandthenon.

Goto“AbnormalIndications”onpage2-6.

Turntheprinteroffandthenon.

Goto“IrrecoverableOperatorErrors”onpage

2-13.

PaperFeedProblems

Symptom Action

PaperOutis

blinkingwithpaperin

theprinter.

PaperOutdoesnot

blinkwhennopaper

isintheprinterand

ASFisnotinstalled.

Printoperationstarts

withoutpaper.

Alt+Park/Load

doesnotfunction

whenthepush

tractorisinstalled.

Formfeedlengthis

notcorrect.

Gotothe“PaperEmptySensorServiceCheck”on

page2-26.

Besurethepaperemptysensorisnotblocked.

Gotothe“PaperEmptySensorServiceCheck”on

page2-26.

Besurethepaperselectleverisinthecorrect

position.

Gotothe“PaperSelectSensorServiceCheck”on

page2-30.

Alt+Park/Load

functionswithcut

sheetsinuse.

2-8

Page 35

Symptom Action

Paperfeeds,but

AutoLoadingdoes

notwork.

Alt+Park/Load

functionswhenthe

pulltractoris

installed.

WithPaperOut

blinking,FormFeed

doesnotoperate

untilpaperislocated

atfirstprintline.

Lowerfeedrollshaft

rotates,butpaper

doesnotfeed.

PressingFormFeed

doesnotfeedpaper.

Abnormalnoise

createdwhile

feeding.

Besurethepaperselectleverisinthecutsheet

position.

BesureAutoLoadingisenabledintheSetup

Mode.

Gotothe“PaperSelectSensorServiceCheck”on

page2-30.

Besurethepaperselectleverisinthetractor

position.

Gotothe“PullTractorSensorServiceCheck”on

page2-38.

Besurethepaperselectleverisinthecorrect

position.

Gotothe“PaperFeedServiceCheck”onpage

2-27.

Paperjams,skews

orcreases.

Incorrectornoline

spacing:wider,

narrower,or

overlappinglines.

Push/PullTractor

doesnotwork.

IncorrectTopof

Formpositioning.

Gotothe“TopofFormsProblemServiceCheck”

onpage2-39.

DiagnosticInformation2-9

Page 36

OperatorPanelProblems

Symptom Action

Start/Stopdoesnot

functionbutnoerror

isindicated.

OnlythePowerlight

turnson.

Oneormorebuttons

donotfunction.

Oneormorelights

donotfunction.

Turntheprinteroffandthenon.

Gotothe“OperatorPanelServiceCheck”onpage

2-24.

PowerProblems

Symptom Action

Whenthepower

switchison,the

Powerlightdoesnot

turnonortheprinter

doesnotstart.

ThePowerlight

blinksorchanges

intensity.

Checkcontinuityofthepowercordandthevoltage

oftheuser’soutlet.

Gotothe“PowerServiceCheck”onpage2-32.

2-10

Page 37

PrintQualityProblems

Symptom Action

Noprint,butcarrier

movesasifprinting.

Printdensityislight. Verifythattheribbondensitycontrolknobonthe

Unevenprintdensity

acrosstheprintline.

Specificdots

missing.

Extradotsorlines

printing.

Adjusttheformthicknesslevertoalowernumber.

Besuretheprintheadcablesarenotlooseor

damaged.

Besuretheinterfacecableisconnectedproperly.

Besuretheserialinterfaceadapterisinstalled

correctlyandthedipswitchesaresetcorrectly.

Checktheribboncartridgeforbindsordamage.

Gotothe“PrintSpeedServiceCheck”onpage

2-34.

ribboncartridgeisnotsetto0.

Iftheribbonhasreacheditsendoflifeorisworn,

theribboncartridgeneedstobereplaced.

Gotothe“CarrierDrive,HomePositionSensor,

RibbonFeedServiceCheck”onpage2-17.

Besuretheprintheadcablesareconnected

correctlytotheprintheadandthesublogicboard.

Cleantheprinthead.

Settheformthicknesslevertoposition“1”andrun

theprinttest.

Gotothe“CarrierDrive,HomePositionSensor,

RibbonFeedServiceCheck”onpage2-17.

Scatteredink

smearing,blurred

characters.

Fuzzyprint.

Cleantheprintheadnose.

Cleantheribbonguideandshield.

Iftheribbonhasreacheditsendoflifeorisworn,

theribboncartridgeneedstobereplaced.

Gotothe“CarrierDrive,HomePositionSensor,

RibbonFeedServiceCheck”onpage2-17.

DiagnosticInformation2-11

Page 38

Symptom Action

Wavyverticallines,

unevenleftmarginor

characterwidthis

reduced.

Cleanandlubricatethecarriershaft.

Ifthecarrierdrivebeltiswornorbroken,replace

thecarrierunit.

Gotothe“CarrierDrive,HomePositionSensor,

RibbonFeedServiceCheck”onpage2-17.

RibbonFeedProblems

Symptom Action

Ribboncomesoff,

becomeslooseor

folded,orjams.

Ribbonfeeds

correctlybutisnoisy.

Checktheribboncartridgeforbindsordamage.

Gotothe“CarrierDrive,HomePositionSensor,

RibbonFeedServiceCheck”onpage2-17.

2-12

Page 39

IrrecoverableOperatorErrors

AltandPaperOutlightsblinktoindicateanoperatorerror.Ifthis

indicationcannotberecovered,theproblemmaybethepaper

emptysensororthepaperselectsensor.Checkthefollowinginthe

orderlistedandiftheprinterdoesnotworkcorrectly,gotothe

indicatedservicecheck.

PaperEmptySensor

Action Check

Removeallpaper

fromtheprinter.

Turnthepoweron.

PaperOutblinkswhenpaperdoesnotexist.

PaperOutturnsoffwhenpaperexists.

Gotothe“PaperEmptySensorServiceCheck”on

page2-26.

PaperSelectSensor

Action Check

Turnthepoweroff.

InstallthePush

Tractor.

Setthepaperselect

levertothetractor

positionandloadthe

continuousforms.

Turnthepoweron.

Removethe

continuousforms.

Setthepaperselect

levertothecutsheet

positionandinserta

cutsheet.

Alt+Park/Loadfunctioncorrectly.

Gotothe“PaperSelectSensorServiceCheck”on

page2-30.

WhenAutoLoadingisenabled,paperfeeds

automatically.

WhenAutoLoadingisdisabled,pressFormFeed

toloadacutsheet.CheckthatAlt+Park/Load

doesnotfunction.

Gotothe“PaperSelectSensorServiceCheck”on

page2-30.

DiagnosticInformation2-13

Page 40

Service Checks

Abnormal Noise Service Check

Check the entire printer for loose parts.

FRU Action

1 Ribbon Cartridge Remove and reinstall the ribbon cartridge.

2 Printhead Disconnect the printhead cables.

Run the print test (do not fold or damage the

cables during the test).

Replace the printhead if the noise is gone.

3 Carrier Motor

Ribbon Drive

Mechanism

4 Paper Feed

Mechanism

Disconnect the carrier motor connector CN9

from the main logic board, and tur n the printer

off and then on.

If the abnormal noise is gone, look for a

problem with the carrier motor or ribbon drive

mechanism.

Disconnect the paper feed motor from CN10

from the main logic board.

Perform the Print Test.

If the abnormal noise is gone, look for the

problem in the paper feed mechanism.

2-14

Page 41

AutoSheetFeeder(ASF)ServiceCheck

Note:Besurethesheetfeederisenabled.Referto“SetupMode”

onpage1-6.

AutoSheetFeederPrinciplesofOperation

Theauto-sheetfeeder(ASF)feedsintothecutsheetpaperentry

throat.TousetheASF:

•Thepaperselectlevermustbesettocutsheet.

•AutoSheetFeedermustbeselectedintheSetupmenu.

ContinuousformscanbeusedwiththeASFinstalledbymovingthe

paperselectlevertocontinuousformsandpressingStarttofeedthe

continuousformstothefirstprintline.

TheASFcontainsnoelectricalparts.Itisdrivenfromthegearon

theinsideoftheprinter’srightsideframe.

ThecombinationlockmechanismisaclutchthatcausestheASF

pickrollerstofeedonlyonesheetofpaperatatime.WhenAuto

SheetFeederisselectedontheSetupMenu,thecutsheetpaper

drivereversesitselfforashortdistanceduringpaperloading.This

reversalengagestheclutchandthusengagesthepaperpicker

rollers,whichfeedthetopsheetfromthecutsheetpaperstack.The

sheetisfedabout5inches(125mm)andthepaperpathbriefly

reversesagain;thisdisengagestheclutchandthepickerrollers.The

sheetisthenfedtotheprintlinebytheASF’supperandlowerfeed

rollersandtheprinter’slowerfeedrollers.AlthoughtheASFpicker

rollerscontinuetoturnasthepaperisfed,theirdriveisdisengaged

andtheyareactuallybeingturnedbythepaper.

FRU Action

1 PaperSelect

Sensor

Withthepaperselectleverinthecutsheet

position,dothefollowing:

•TrytoloadasheetwithAlt+Park/Load.

(Thisbuttonshouldnotwork)

•Ifthepaperloadsgotothe“PaperSelect

SensorServiceCheck”onpage2-30.

DiagnosticInformation2-15

Page 42

FRU Action

2 PaperFeed Ifthepaperdoesnotfeed,dothefollowing:

•RemovetheASF.

•Besurethebaseprinterfeedspaper

correctly.

•Ifitdoesnotfeedpapercorrectly,goto

the“PaperFeedServiceCheck”onpage

2-27.

3 GearTrain BesuretheASFdrivegearontheinsideofthe

printer’srightframerotates.

Inspecttherightsidegeartrainfordamageor

debris.

RemovetheASFrightcoverandensurethat

allgearsareingoodcondition.

4 CombinationLock

Mechanism

5 LeftandRight

Hoppers

InstalltheASFandpressFormFeed.

Ifthepickerdriveshaftdoesnotrotate,replace

thecombinationlockmechanism.

IftheASFpickerrollersrotatebutasingle

sheetisnotpicked,inspectthespringsand

cornerseparatorsontheleftandrighthoppers.

Makesurethepaperloadleverisinthecorrect

position.

2-16

Page 43

Carrier Drive, Home Position Sensor, Ribbon Feed

Service Check

23XX-001 only: If the carrier stops but the print wires continue to fire

(printing one vertical column of dots), or if the carrier does not move

after turning the printer off and then on, inspect the area of the main

logic board that is below the paperfeed motor. If this area is

damaged or cracked, replace the main logic board. Also check the

continuity of soldered-on fuse FU1 located on the main logic board

near the paper empty sensor. If this fuse is open, replace the main

logic board. Turn the printer off and then on. The carrier should

move to the left, contact the home position sensor on the left side

frame, and immediately move slightly away from the sensor.

A Home Position Error occurs when:

• The sensor is not closed.

• The sensor is not quickly opened.

• The sensor is closed any time other than when the printer is

turned off and then on.

Diagnostic Information 2-17

Page 44

.

FRU Action

1 Carrier If there is no Home Position Error, check the

carrier belt and the ribbon cartridge for wear or

damage. Check the belt and pulley

engagement.

Manually move the carrier the full length of the

carriage to check for binds and to make sure

the ribbon advances when the carriage moves

in either direction.

If the carrier binds check the following:

• Correct printhead-to-platen gap.

• Clean and lubricated carrier shaft.

• Idler pulley not binding.

• Ribbondrive rack gear teeth not

damaged.

If the carrier still binds:

Remove the belt and move the carrier again. If

the bind is gone, replace the carrier motor. If

the bind still exists, replace the carrier.

2 Home Position

Sensor

Sub Logic Board

Short Flexible

Cable

2-18

If the carrier moves manually without binding

but the Home Position Error still occurs, verify

that the main logic board is receiving +26 V dc

on pin CP11-1. Check that the 5 V dc home

position sensor signal is getting to the main

logic board. Check CP3-7 on the main logic

board. Check CP6-1 on the sub logic board.

Replace the sensor, the sub logic board, or the

short flexible cable as necessary.

Page 45

FRU Action

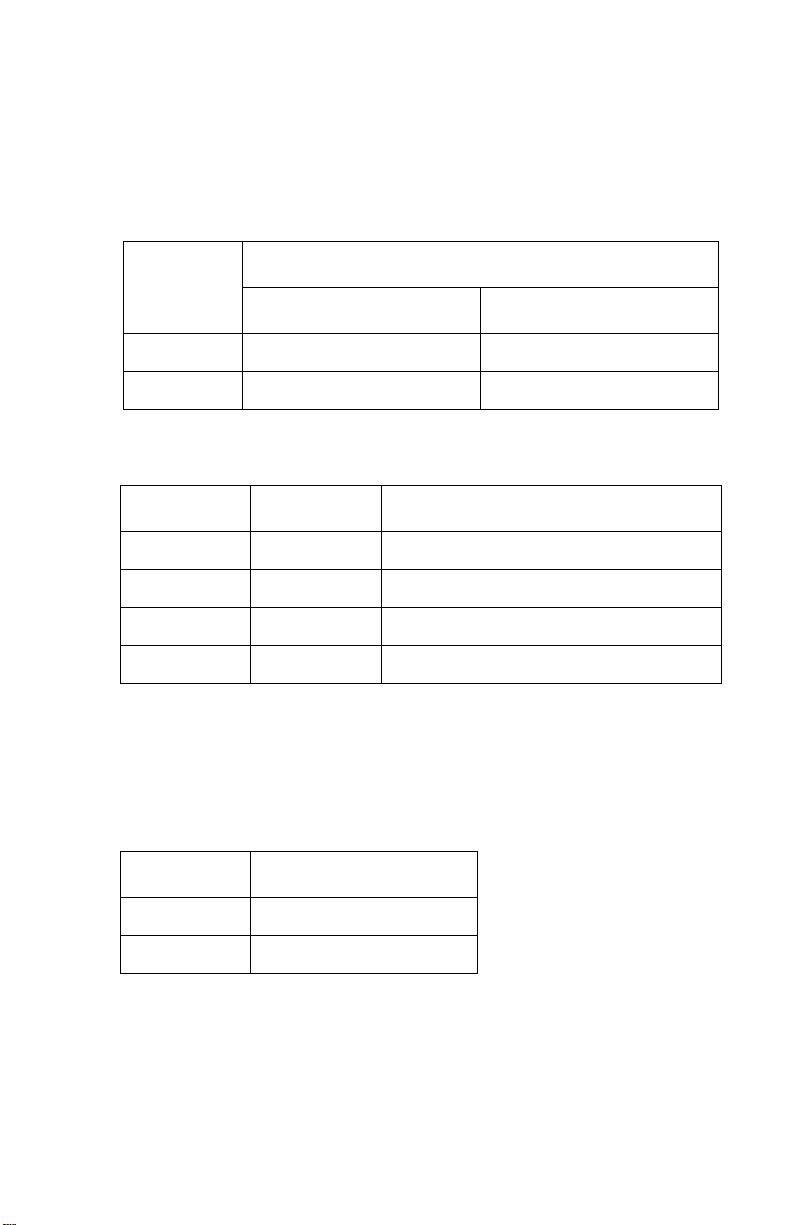

3 CarrierMotor IfthehomepositionsensorisOK,refertothe

tableandmakesuretheresistanceofthe

carriermotorwindingsarefrom1to5ohmsfor

allprinters.

238X-001,002,003

239X-002,003 239X-001

CP9-1&CP9-5 CP9-1&CP9-6

CP9-2&CP9-6 CP9-2&CP9-5

CP9-3&CP9-5 CP9-3&CP9-6

CP9-4&CP9-6 CP9-4&CP9-5

4 MainLogicBoard IfallpartsappearOKbuttheHomePosition

Errorstilloccurs,replacethemainlogicboard.

Afterreplacingthemainlogicboardorany

partsaffectingthecarrier,performthe

bidirectionalprintadjustment.See

“BidirectionalPrintAdjustment”onpage4-5.

DiagnosticInformation2-19

Page 46

IntermittentProblemServiceCheck

FRU/Symptom Action

1Themachine

sometimesfails

beforePOSTis

complete.

Checkforthefollowing:

1.Looseconnectors.Reconnectall

connectorstothemainandsublogic

boards.

2.Electricalnoiseorstaticdischarge.

Checkthefollowingitems:

•Powersupplyground.

•Machineframeground.

•Printerinterfacecableisgroundedand

shielded.

•Iftheupperfeedrollshaftdoesnothavea

groundspring,installP/N1368036.

3.Intermittentlylowvoltages.Checkforacand

alldcvoltagesandshortcircuitsonthemain

andsublogicboards.

a.Checkthecustomer’soutletvoltageand

ensurethatitiswithintolerance.

b.Checkthecontinuityofthepower

cord.

c.Disconnectthepowersupplycable

fromtheconnectorsCN11onthe

mainlogicboardandCN1onthesub

logicboard.Turntheprinterpoweron

andcheckalldcoutputvoltagesat

CP11andCP1.

2-20

Ensuretheoutputvoltagesare:

CP11-1(+26Vdc±10%)&CP11-2(GND)

CP11-3(+5Vdc±5%)&CP11-4(SignalGND)

CP1-1(+26Vdc±10%)&CP1-2(GND)

CP1-3(+5Vdc±5%)&CP1-4(SignalGND)

Ifthevoltagesarenotcorrect,replacethe

PowerSupplyUnit.

Ifthefailureremains,replacethemainlogic

boardandsublogicboard.

Note:Whenreplacingthemainlogicboard,

alwaysresetthebidirectionalprintadjustment.

Referto“BidirectionalPrintAdjustment”on

page4-5.

Page 47

FRU/Symptom Action

2 Machinepower

sometimesturns

off.

3 Intermittentlypoor

printquality.

Thecauseofthisproblemmaybethatthe

powercircuitisfailing,orthewiringis

intermittentlyopen.Checkthefollowingin

sequence:

1.Checkthecustomer’soutletvoltageand

besureitiswithintolerance.

2.Checkthecontinuityofthepowercord.

3.Disconnectthepowersupplycablefromthe

connectorsCN11onthemainlogicboard

andCN1onthesublogicboard.Turnthe

printerpoweronandcheckalldcoutput

voltagesatCP11andCP1.

Besuretheoutputvoltagesareasfollows:

CP11-1(+26Vdc±10%)&CP11-2(GND)

CP11-3(+5Vdc±5%)&CP11-4(SignalGND)

CP1-1(+26Vdc±10%&CP1-2(GND)

CP1-3(+5Vdc±5%)&CP1-4(SignalGND)

Ifoneofthevoltagesis0,gotothe“Power

ServiceCheck”onpage2-32.Ifthevoltages

arenot0butareincorrect,replacethepower

supplyunit.

Dothefollowing:

•Removepaperjamsfromthepaperpath.

•Cleanallfeedrollersurfaces.

•Cleantheribbonshieldandprinthead.

•Cleantheplatensurface.

•Installtheribboncartridgecorrectly.

•Iftheribbonendoflifehasbeenreached,

havethecustomerreplacetheribbon

cartridge.

DiagnosticInformation2-21

Page 48

FRU/Symptom Action

4 Iftheprior

suggestionshave

notcorrectedthe

problem.

5 Problemoccurs

onlyinspecific

customer

applications.

Theservicecheckhasnotdefinedthefailure,

orthemachineishavingintermittentfailures.

Thefollowingmaycauseundefinedor

intermittentfailures:

1.Customer’soutletvoltage.Besurethatit

iswithinthetolerance.

2.Looseconnectorpinsorkeysthatfailto

contact.

Checkthefollowing:

a.ReconnecttheconnectorsofallFRUs

andprinterinterfacecables.

b.Checkthecontinuityofthelinecord.

3.Electricalnoise.

Checkthefollowing:

a.Powersupplyground.

b.Machineframeground.

c.Printerinterfacecableisgrounded

orshielded.

4.Undefineddataincustomerapplications.

Checkthebaudrateatthecontroller.Check

thattheprinterinterfacecablematchesthe

printer.

PerformtheTracePrint(hexadecimalprinting)

bythefollowingprocedureandcheckthedata

streams.

1.Turnthepoweroff.

2.Turnthepoweronwhilepressingand

holdingAlt.

3.Havethecustomerprintthefailingjob.

4.Tostopprinting,turnthepowerswitchoff.

2-22

Ifthefailurestilloccurs,replacethemainlogic

board.Besuretoresetthebidirectionalprint

adjustment,refertothe“BidirectionalPrint

Adjustment”onpage4-5.

Page 49

NoPrintorAbnormalPrintServiceCheck

FRU/Function Action

1 MainLogicBoard IfthePrintTestdoesnotcompletecorrectly,

dothefollowing:

•Replacethemainlogicboard.

•Resetthebidirectionalprintadjustment.

Referto“BidirectionalPrintAdjustment”

onpage4-5.

2 InterfaceCable Checktheconnectionandcontinuityofthe

3 EmulationMode EntertheSetupMenuandmakesurethe

4 SerialInterface

Adapter

interfacecable.

printerisinthecorrectemulationmodeforthe

computer,eitherIBMorEpson.

Iftheserialinterfaceadapterisinstalled,make

surethedipswitchesmatchthecomputer

settings.

•Makesuretheserialadapterpowercable,

ifpresent,issecurelyconnectedtothe

printerpowerconnectorCN5.

•Onnewermodels,makesuretheserial

interfaceadapter’spowerLEDisonwhen

printerpowerison.

Runthe“SerialInterfaceAdapterPrintTest”on

page3-6.Ifthetestisnotsuccessfulreplace

theserialinterfaceadapter.

Ifnodefectisfound,theprinterandserial

interfaceadapterareworkingcorrectly.The

problemmaybewiththeinterfacecable,the

computer,theprinterdriver,orthespecificjob

beingsent.

DiagnosticInformation2-23

Page 50

Operator Panel Service Check

Note: If the Op-Panel Asm is locked, only the Start/Stop, Form

Feed, Alt + Tear Off and Alt + Park/Load buttons are active. Model

2 and 3 printers have a “Lock” LED to indicate that the operator

panel is locked. Tounlock the operator panel, turn the printer off and

then on while pressing Micro

FRU Action

and Micro.

1 Op-Panel Cable

Sub Logic Board

Check the connections from the operator panel

to the sub logic board and from the sub logic

board to the main logic board.

Disconnect the operator panel from its cable

and make sure +5 V dc is present on the

following pins on the cable:

23XX-001 23XX-002,003

CP1-1 CP1-2

CP1-7 CP1-8

If there is a voltage problem make sure the sub

logic board is receiving +5 V dc on CN1-3.

Replace the operator panel cable, the sub logic

board, or the power cable as necessary.

2-24

Page 51

FRU Action

2ShortFlexible

Cable

Disconnecttheshortflexiblecablefromthe

mainlogicboard.

Checkthecontinuityoftheoperatorpanel

signallinesbetweentheendoftheshort

flexiblecableandtheoperatorpanelconnector

onthesublogicboard.

238X-001 238X-002,003

CP3-4&CN8-5 CP3-4&CN8-2

CP3-3&CN8-6 CP3-3&CN8-4

CP3-2&CN8-4 CP3-2&CN8-8

CP3-1&CN8-8 CP3-1&CN8-6

239X-001 239X-002,003

CP3-4&CN7-5 CP3-4&CN7-2

CP3-3&CN7-6 CP3-3&CN7-4

CP3-2&CN7-4 CP3-2&CN7-8

CP3-1&CN7-8 CP3-1&CN7-6

Replacetheshortflexiblecableorthesublogic

boardasnecessary.

Ifthereisstillaproblem,replacetheoperator

panel.Ifthatdoesnotfixtheproblem,re-install

theoldoperatorpanelandreplacethemain

logicboard.Ifyoureplacethemainlogic

board,resetthe“BidirectionalPrint

Adjustment”onpage4-5.

DiagnosticInformation2-25

Page 52

PaperEmptySensorServiceCheck

Note:23XX-001machineshaveasinglepapersensorthatserves

asapaperemptysensorandalsodeterminesthetopofform

setting.

23XX-002and23XX-003machineshavetwosensors:

•Theleftsensorispaperempty.

•TherightsensorisTopofForm.

FRU Action

1 PaperEmpty

Sensor

2 MainLogicBoard IftheASFisbeingused,itisnormalforthe

Withnopaperintheprinter,thetractorinthe

pushposition,andthepaperselectleversetto

continuousforms,pressAlt+Park/Load;the

geartrainshouldturnforward(totrytoload

paper).

Activatethepaperemptysensorwitha

screwdriverandpressAlt+Park/Loadagain;

thegeartrainshouldturnbackward(totryto

parkpaper).

MeasurethevoltagebetweenCN7-2(paper

emptysignal)andCN7-3(GND)onthemain

logicboard.Thereshouldbe0Vdcwhen

thereispaperintheprinter,and+5Vdcwhen

thereisnopaperintheprinter.

Makesurethesensoranditsactuatorare

properlyinstalledandundamaged.Correctthe

problemorreplacethesensor.

PaperOutLEDnottoblinkwhenthereisno

paperintheprinter.Dothefollowing:

•EntertheSetupMenu.

•MakesuretheASFsettingisoffunless

theASFisinstalled.

•IfthesensorandtheASFsettingareOK,

replacethemainlogicboard.

•Resetthe“BidirectionalPrintAdjustment”

onpage4-5.

2-26

Page 53

PaperFeedServiceCheck

Note:Iftheproblemisfrequentjamsorpapercreases,verifythat

thepaperisneitherverythicknorverythin.Ifnecessaryreferthe

customertotheUser’sGuideforspecificationsofacceptable

papers.On23XX-001printerscheckforequalgapbetweenthe

lowerfeedrollersandlowerpinchrollers.Ifthegapissmalleronthe

left,installShimKit,P/N1368067.

Ifthepaperdoesnotstopinthecorrectlocation,refertothe“Paper

EmptySensorServiceCheck”onpage2-26andthe“TopofForms

ProblemServiceCheck”onpage2-39.

FRU/Symptom Action

1 AutoSheet

Feeder

2 GearTrain Removeallpaperfromthemachine.

IftheAutoSheetFeederisinstalled,removeit.

EntertheSetupMenuandreset“ASF”tooff.

Verifythatthemachineworkscorrectlywithout

theASFinstalled.

IftheprinterfailsonlywiththeAutoSheet

Feederinstalled,refertothe“AutoSheet

Feeder(ASF)ServiceCheck”onpage2-15.

PressFormFeedseveraltimesandexamine

allrotatingpartstofindtheproblem.

Forbettervisibility,removethecoversand

reconnecttheoperatorpaneltothesublogic

board.

Theupperandlowerfeedrollersandtheupper

andlowerpinchrollersshouldallbecleanand

ingoodcondition,andshouldallrotateduring

FormFeed.

Toturnthegeartrainmanuallyona23XX-002

or23XX-003,turntherightendofthelower

feedrollershaftwitha6mmwrench.

DiagnosticInformation2-27

Page 54

FRU/Symptom Action

3 PaperSelector

Lever

4 OperatorPanel Ifpaperdoesnotmoveatall,verifythatthe

5 PaperFeedMotor DisconnectthepaperfeedmotorcableCN10

Makesuretheselectorleveralternately

engagesanddisengagesthetractorgearand

theASFdrivegear.

Checktheoperationofthefollowingpartsas

youmovethepaperselectlever:

•Thetractorgearengagescorrectlyinthe

continuousformsposition.

•Thetractorbeltsareingoodconditionand

rotatecorrectly.

•Thepinchrollershaftsmovedownwardas

thelevermovestothecutsheetposition.

•Thepaperseparatormovesupwardas

thelevermovestothecutsheetposition.

FormFeedbuttonisworkingasfollows:

Withthetractorinthepushposition,poweroff,

poweron,thenpressAlt/Load.Thecarrier

shouldmovetothecenteroftheplaten.Ifit

doesnot,gotothe“OperatorPanelService

Check”onpage2-24.

fromthemainlogicboard.Nopinshouldhave

continuitytoground.Theresistancesshould

beasfollows:

2-28

23XX-001,002=21to24ohms.

CP10-1toCP10-5 CP10-1toCP10-6

CP10-2toCP10-5 CP10-2toCP10-6

CP10-3toCP10-5 CP10-3toCP10-6

CP10-4toCP10-5 CP10-4toCP10-6

23XX-003=8to9ohms.

CP10-1toCP10-5

CP10-2toCP10-5

CP10-3toCP10-5

CP10-4toCP10-5

Page 55

FRU/Symptom Action

6 PaperSelect

Sensor

7 PullTractor

Sensor

Removeallpaperfromtheprinterandplace

thetractorinthepushposition.

PressFormFeedandtimehowlongthegear

trainrotates.

•Withthepaperselectleverinthecut

sheetposition(sensoropen)thegear

trainshouldrotateforlessthan2

seconds;

•Withtheleverinthecontinuousforms

position(sensorclosed),thegeartrain

shouldrotateformorethan3seconds.

Iftheprinterdoesnotdothis,inspectthe

sensortomakesureitisbeingopenedand

closedbythepaperseparator.

DisconnectCN5fromthesublogicboardand

measurethepaperselectorsensorresistance

fromCP5-1toCP5-2.

Replacethesensoriftheresistancedoesnot

changefromzerotoinfiniteasthepaperselect

leverismoved.

Ifthepulltractorsensorhasfailedtoclose,

Park/LoadandAutoTearOffwillnotwork

whenusingpushtractors.

Ifthesensorhasfailedtoopen,Park/Loadwill

trytoparkpaperwhenusingpulltractors,but

thepaperwillfeedallthewayoutofthe

tractorsandcannotreload.Refertothe“Pull

TractorSensorServiceCheck”onpage2-38.

8 MainLogicBoard Ifnootherproblemisfoundreplacethemain

logicboard.Resetthe“BidirectionalPrint

Adjustment”onpage4-5.

DiagnosticInformation2-29

Page 56

Paper Select Sensor Service Check

If form feed length is off by about 1 inch (25 mm), enter Setup Mode

and verify that the form length setting is correct. See the Setup

Mode and Switch Settings section.

FRU Action

1 Paper Select

Sensor

Remove all paper from the printer and place

the tractor in the push position. Make sure the

Auto Sheet Feed (ASF) is set to OFF in the

Setup Mode.

Press Form Feed and time how long the gear

train rotates.

With the paper select lever in the cut sheet

position (sensor open) the gear train should

rotate for less than 2 seconds; with the lever in

the continuous forms position (sensor closed),

the gear train should rotate for more than 3

seconds. If the printer does not do this, inspect

the sensor to make sure it is being opened and

closed by the paper separator.

Disconnect CN5 from the sub logic board and

measure the paper selector sensor resistance

from CP5-1 to CP5-2.

Replace the sensor if the resistance does not

change from zero to infinite as the paper select

lever is moved from cut sheet to continuous

forms.

If the sensor is good but the gear train does not

run the right length of time, set the head gap to

position 1 and disconnect the short flexible

cable from CN3 on the main logic board.

Check the continuity between CP3-6 (paper

select sensor) and GND while actuating the

paper select lever.

Cut Sheet Continuous Forms

23XX-001

1K ± 0.5K ohms 0K ± 0.5K ohms

12K ± 0.5K ohms 3.5K ± 0.5K ohms

23XX-002

2-30

If the resistance is correct, replace the main

logic board. If the resistance is incorrect,

replace the sub logic board.

Page 57

FRU Action

2 PullTractor

Sensor

Afailedpulltractorsensorcancause

Alt+Park/Loadnottofunction.Withthe

tractorinthepushposition,pressAlt+Park/

Loadseveraltimeswhilealternatelyholding

downandreleasingtheleftpulltractor

actuator.Thepapershouldnotparkorload

whenthepulltractoractuatorishelddown.Ifit

does,gotothe“PullTractorSensorService

Check”onpage2-38.

POSTServiceCheck

FRU Action

1 PowerLED IfthepowerLEDisnoton,gotothe“Power

ServiceCheck”onpage2-32.

2 Cables AfaultyinterfacecablecancausePOST

errors.Disconnecttheinterfacecablefromthe

printerandturntheprinteroffandthenon.

Checktheconnectionsoftheshortflexible

cableandthepowercabletothemainlogic

boardandsublogicboard.

Checktheconditionandcontinuityofthe

operatorpanelcable.

3 OperatorPanel Ifnoproblemisfound,theproblemmaybein

eithertheoperatorpanelorthemainlogic

board.Replacetheoperatorpanelandretest

theprinter.

4 MainLogicBoard Replacethemainlogicboardifnecessary.

Resetthebidirectionalprintadjustment;refer

to“BidirectionalPrintAdjustment”onpage4-5.

DiagnosticInformation2-31

Page 58

Power Service Check

If the symptom is that the Power light varies in intensity, make sure

the upper feed roll shaft has the ground spring. If it does not, install

ESD Kit P/N 1368036.

FRU Action

1 Power Supply If the carrier does not move to the left after

turning the printer off and then on, do the

following:

• Make sure the line cord voltage to the

power supply is correct.

• Make sure the power supply outputs are

+5 V dc at CN1-2 and +26 V dc at CN1-4.

If the voltage is incorrect, check the

internal fuses before replacing the power

supply. Generally if F3 is blown it is due to

a short in the printhead; replace the

printhead and the fuse before powering

on again.

• Check for +5 V dc at main logic board

CN11-3 and sub logic board CN1-3, and

for +26 V dc at main logic board CN11-1

and sub logic board CN1-1.

• Make sure the short flexible cable is

undamaged and correctly installed.

2 Sub Logic Board If the carrier moves to the left after turning the

printer off and then on, do the following:

• Move the carrier to the right and turn

power on. The carrier should move to the

left. The power LED should be on steady

whenever the printer is on. If the carrier

moves to the left during after turning the

printer off and then on, but the power LED

is not on steady: Make sure the sub logic

board is receiving voltage by checking for

+5 V dc at sub logic board CN1-3.

• If no voltage or power cable problem is

found, make sure there is +5 V on pins 3

and 9 of the sub logic board connector for

the operator panel cable. If the voltage is

incorrect replace the sub logic board.

2-32

Page 59

FRU Action

3 Op-Panel

Op-PanelCable

4 CarrierMotor Disconnectthecarriermotorfrommainlogic

5 PaperFeedMotor Disconnectthepaperfeedmotorfrommain

6 Printhead

PrintheadCables

7 MainLogicBoard Ifnoproblemisfoundwithothercomponents

IfthereisstillapowerLEDproblem,checkthe

operatorpanelcablecontinuityandreplacethe

cableortheoperatorpanel.

boardCN9andturntheprinteroffandthenon.

IfthepowerLEDlightscorrectlyonlywiththe

carriermotordisconnected,replacethecarrier

motor.

logicboardCN10andturntheprinteroffand

thenon.IfthepowerLEDlightscorrectlyonly

withthepaperfeedmotordisconnected,

replacethepaperfeedmotor.

Disconnecttheprintheadcablefromthesub

logicboardandturntheprinteron.Ifthepower

LEDlightscorrectlyonlywiththeprinthead

cablesdisconnectedfromthesublogicboard,

thereisashortintheprintheadorprinthead

cables.

Disconnecttheprintheadcablefromthesub

logicboardandmakesurenoneoftheleads

onthecableareshortedtoground.

buttheprinterstillhasapowerproblem,

replacethemainlogicboard.

Resetthebidirectionalprintadjustment;refer

to“BidirectionalPrintAdjustment”onpage4-5.

DiagnosticInformation2-33

Page 60

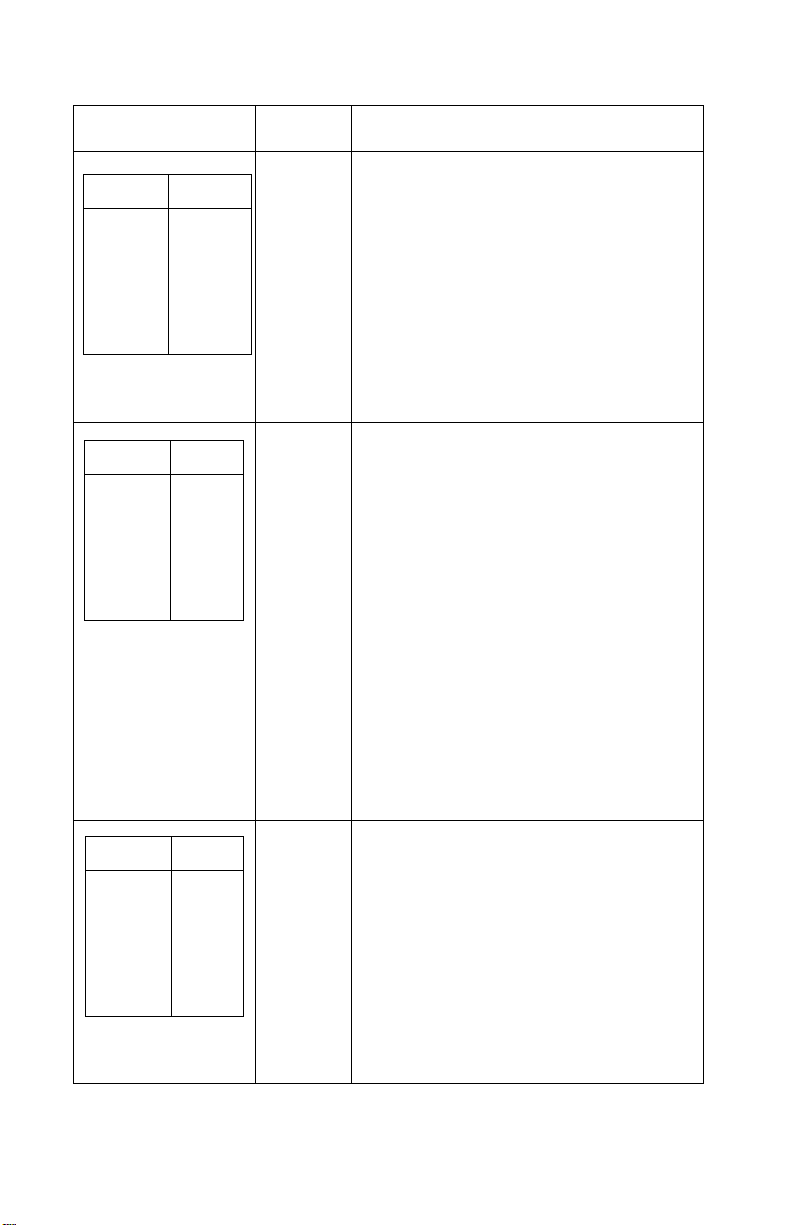

Print Speed Service Check

Reduced speed while printing the top 2 inch (51 mm) of a job is

normal; for Model 003 printers, the slow down can be eliminated by

entering Setup Mode and disabling TOF Read.Thespeedofthe

23XX printers varies with the font, forms thickness setting and

printhead temperature. Graphics output may print slowly due to data

throughput limitations. Thermal sensing is built into the printhead on

239X printers and protects the printhead from overheating.

Depending on the job content, thermal slowdown may occur after 5

to 10 minutes of continuous operation on 239X-001 printers and

after 10 to 20 minutes on 239X-002, 003 printers.

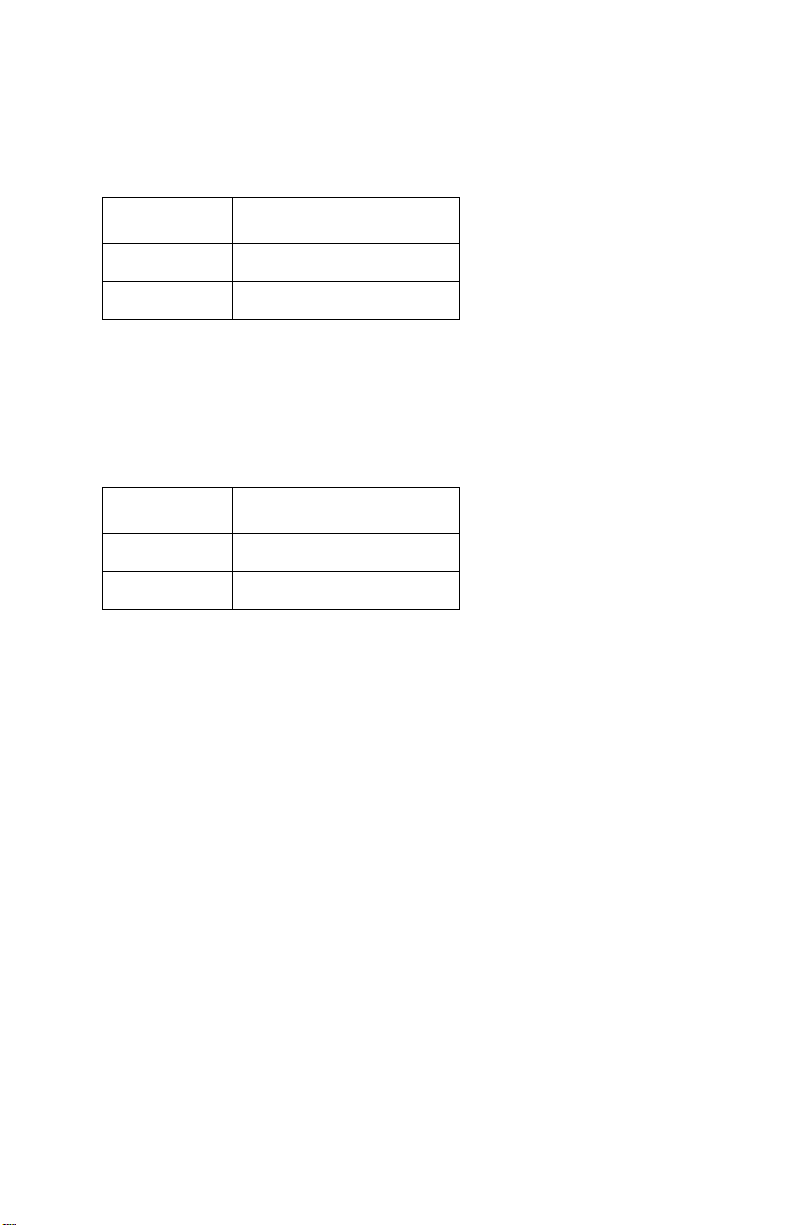

Print slowdown modes are as follows:

Thermal

Slowdown

238X-001 No 26% speed reduction at Forms

239X-001 Yes No Forms Thickness speed

238X-002

238X-003

239X-002

239X-003

No Reduced print wire force at Forms

Yes Reduced print wire force at Forms

Forms Thickness Slowdown

Thickness 7.

Head Gap Sensor contains one

switch.

reduction.

No Head Gap Sensor.

Thickness 1.

23% speed reduction at Forms

Thickness 4 through 7.

HeadGap Sensor Assembly contains

two switches.

Thickness 1.

20% speed reductions at Forms

Thickness 4 through 7.

HeadGap Sensor Assembly contains

two switches.

2-34

Page 61

FRU Action

1 Head Gap Sensor

23XX-001

2 Head Gap Sensor

23XX-002

23XX-003

Check the function of the head gap sensor by

moving the forms thickness lever from 6 to 7

and back while printing the Demo Page

Alt + Demo. Print speed is reset at the

beginning of each line; listen for the printer to

slow down in position 7.

Disconnect the head gap sensor from

connector CN3 on the sub logic board. Check

the resistance of the sensor while moving the

forms thickness lever. Resistance should be 0

ohms at forms thickness position 7 and infinite

at positions 1 through 6.

Check the function of the head gap sensor by

turningthepoweronwiththeAlt + Macro

buttons pressed.

• Withthe forms thickness leverat 1, Macro

LED 1 will light.

• Withthe forms thickness lever at 2 and 3,

Macro LED 2 will light.

• With the forms thickness lever at 4

through 7, Macro LED 3 will light.

Disconnect the head gap sensor asm from

connector CN3 on the sub logic board. Check

the resistance of the sensor while moving the

forms thickness lever. Resistance should be 0

ohms at position 1 and infinite at positions 2

through 7.

Disconnect the head gap sensor asm from

connector CN4 on the sub logic board. Check

the resistance of the sensor while moving the

forms thickness lever. Resistance should be 0

ohms at positions 1 through 3 and infinite at

positions 4 through 7.

Diagnostic Information 2-35

Page 62

Printhead Service Check

FRU Action

1 Printhead Cables

Printhead

If the problem is missing or extra dots or lines,

do the following:

• Check the continuity and connection of

the printhead cables and the short flexible

cable.

• Make sure the voltages to the sub logic

board are correct.

If dots are missing:

• Perform the print test to determine which

wire is not firing.

• Remove the printhead and check the

printhead resistance according to the

followingtable.Makesurenopinshave

continuity to the printhead housing.

2-36

Page 63

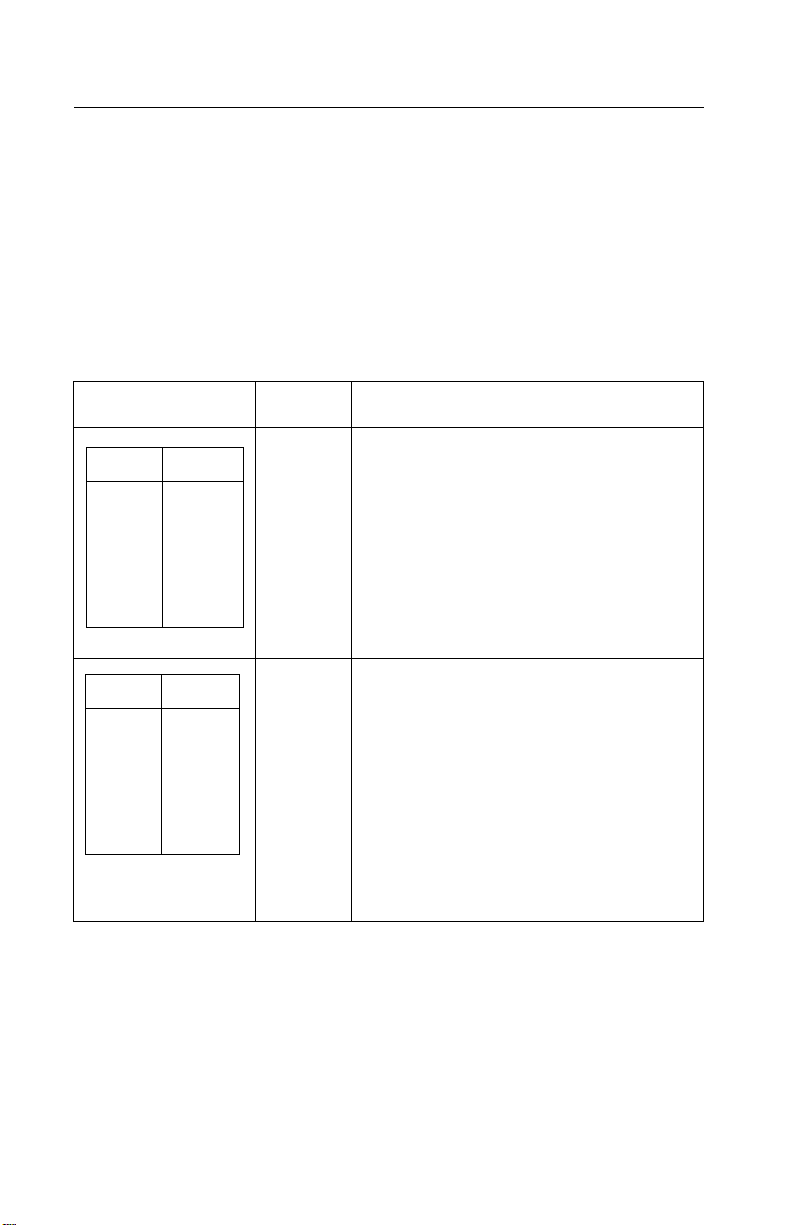

FRU Action

1 Printhead Continuity Table

The correct resistance is:

2.8to3.8ohms(238X)or7to15ohms(239X).

238X

CP9-10 & CP9-12 (Dot1)

CP9- 6 & CP9- 4 (Dot2)

CP9-17 & CP9-14 (Dot3)

CP9- 7 & CP9- 3 (Dot4)

CP9-15 & CP9-11 (Dot5)

CP9- 1 & CP9- 5 (Dot6)

CP9-18 & CP9-13 (Dot7)

CP9- 2 & CP9- 8 (Dot8)

CP9-16 & CP9- 9 (Dot9)

239X

CP8-10 & CP8-13 (Dot1)

CP8- 8 & CP8- 7 (Dot2)

CP8-12 & CP8-13 (Dot3)

CP8- 6 & CP8- 7 (Dot4)

CP8-14 & CP8-11 (Dot5)

CP8- 4 & CP8- 7 (Dot6)

CP8-16 & CP8-11 (Dot7)

CP8- 2 & CP8- 9 (Dot8)

CP8-18 & CP8-11 (Dot9)

CP8- 1 & CP8- 9 (Dot10)

CP8-17 & CP9-10 (Dot11)

CP8- 3 & CP8- 9 (Dot12)

CP8-15 & CP9-10 (Dot13)

CP8- 5 & CP9- 8 (Dot14)

CP9-16 & CP9-12 (Dot15)

CP9- 4 & CP9- 8 (Dot16)

CP9-17 & CP9-12 (Dot17)

CP9- 2 & CP9- 8 (Dot18)

CP9-15 & CP9-12 (Dot19)

CP9- 1 & CP9- 6 (Dot20)

CP9-13 & CP9-14 (Dot21)

CP9- 3 & CP9- 6 (Dot22)

CP9-11 & CP9-14 (Dot23)

CP9- 5 & CP9- 6 (Dot24)

If the problem is not missing or extra dots or

lines, do the following:

• Make sure the printhead is securely

installedinthecarrier.

• Perform the Printhead-to-Platen Gap

adjustment.

Diagnostic Information 2-37

Page 64

FRU Action

2 CarrierShaft

CarrierUnit

PlatenAssembly

PrintheadNose

RibbonGuide

Checkandreplacewornordamagedparts.

PullTractorSensorServiceCheck

Note:Thepulltractorsensordetectsthetractorinthepullposition

anddisablespark/loadandautotear-off.Afailedsensormay

preventpark/loadfromfunctioningwiththetractorinthepush

position.

FRU Action

1 PullTractor

Sensor

Withthetractorinthepushposition,press

Alt+Park/Loadseveraltimeswhilealternately

holdingdownandreleasingtheleftpulltractor

actuator.Thepapershouldparkandloadwhen

theactuatorisnothelddown,andshouldnot

parkorloadwhenthepulltractoractuatoris

helddown.

Ifthepaperdoesnotmovecorrectly:

2-38

•DisconnectCN4fromthemainlogic

board.

•Thereshouldbe0ohmsfrom

CP4-1toCP4-2whentheleftpulltractor

actuatorispressed,andinfinite

resistancewhentheactuatorisnot

pressed.

•Replacethesensorifnecessary.

Ifthesensorisgoodbutthepaperstilldoesnot

movecorrectly:

•Replacethemainlogicboard.

•ResettheBidirectionalAlignment,see

“BidirectionalPrintAdjustment”onpage

4-5.

Page 65

TopofFormsProblemServiceCheck

Note:Thisservicecheckappliestothe23XX-002and23XX-003

printersonly.23XX-001machineshaveasinglepapersensorthat

servesasapaperemptysensorandalsodeterminesthetopofform

setting.Fortopofformsproblemson23XX-001printers,refertothe

“PaperEmptySensorServiceCheck”onpage2-26.

23XX-002and23XX-003machineshavetwosensors:

•Theleftsensorispaperempty.

•Therightsensoristopofform.

FRU Action

1TopofForm

Sensor

2 MainLogicBoard Removethepaperandsetthepaperselect

Checkthatthetopofformsensoranditsflag

areproperlyinstalledandareundamaged.

levertothecutsheetpositionandturnthe

poweron.

Measurethevoltagebetweenmainlogicboard

CN8-2(TOFsignal)andCN8-3(GND).

•Whenthereispaperintheprinterthe

voltageshouldbe0Vdc.

•Whenthereisnopaperintheprinterthe

voltageshouldbe5Vdc.

Replacethesensorifthevoltageisincorrect.

Replacethemainlogicboardifthevoltageis

correctandthereisstillaproblem.

Resetthe“BidirectionalPrintAdjustment”on

page4-5.

DiagnosticInformation2-39

Page 66

Tractor 2 Service Check

Note: This option can be used only on 23XX-003 printers.

The Tractor 2 in-place sensor opens during installation, when its

actuator touches the printer cover. The home sensor detects the

position of the slider.

• When Tractor 2 is selected the motor-driven Tractor 2 slider

pushes the printer sub slider cam lever to engage the printer

gear train which drives the Tractor 2 tractors.

• When the Tractor 2 is deselected, the motor retracts the slider,

disengaging the Tractor 2 gear drive and reengaging the printer

tractors.

2-40

Page 67

10BeepsandBlinkingReady,Paper,FontandPitchLEDs

Tractor2homesensornevermadeafterturningtheprinteroffandthenon,

ormadeatthewrongtime.

(Thesameerrorindicationisusedforcarrierhomefailure.)

FRU Action

1Tractor2

HomeSensor

2 MainLogicBoard RemoveTractor2fromtheprinterbutleavethe

RemovetheTractor2andturntheprinteroff

andthenonagaintodetermineifthefaultisin

theprinterorTractor2.

Ifthegearteethchatterjustbeforethebeeps,

replacethehomesensor.

cableconnected.Makesuretheslider(the

blackplasticpiecejustabovetherightcover)

movesafterturningtheprinteroffandthenon.

Ifthesliderdoesnotmoveafterturningthe

printeroffandthenon:

•Makesurethesliderandgeartrainare

properlyconnectedandmovefreelywith

thepoweroff.

•MakesuretheTractor2boardis

receiving:

+26VdconCN1-1and

+5VdconCN1-5.

Ifnot,checkthecableconnectionandthe

voltagesatmainlogicboardCN6-1.

TheupperrightpinatCN6ispin1(+26Vdc)

andthepinjustbeneathitispin5(+5Vdc).

Ifthesevoltagesarenotpresentreplacethe

mainlogicboard.

3 Tractor2Motor

Board/CableAsm

ChecktheresistancesoftheTractor2motor

windings:thereshouldbe101±5ohms

betweenpins:1and5,3and5,2and6and

4and6.Ifthemotorisgood,replacethe

board/cableassembly.

ForinformationontheTractor2cable

connectors,see“Tractor2CableConnectors”

onpage5-4.

DiagnosticInformation2-41

Page 68

3BeepsandTractor2LEDblinks3times

Tractor2selectedfromoperatorpanelbutprinterdoesnotdetectTractor2

ordetectsthattheTractor2mechanismisnotinstalled.

FRU Action

1Tractor2

Board/CableAsm.

2 MainLogicBoard CheckthecableconnectionfromTractor2to

ChecktheTractor2in-placesensororthe

cableconnection.

Thein-placesensoractuatorextendsthrough

theTractor2coverandrestsontheprinter

coverwhenTractor2isinstalled.

RemovetheTractor2coverandmakesurethe

in-placesensoropenswhentheTractor2is

installed.ThevoltageatTractor2CN1-13

shouldbe+5Vdcwiththesensoropenand0

withitclosed.

ReplacetheTractor2board/cableasmifthe

sensorsignaliswrong.

ForinformationontheTractor2cable

connectors,see“Tractor2CableConnectors”

onpage5-4.

theprinter.

Ifpossible,trytheTractor2withanotherprinter

todetermineiftheproblemistheTractor2

board/cableassemblyortheprintermainlogic

board.

2-42

Page 69

PaperFeedProblems

FRU Action

1 Tractor2 Ontheprinter,makesurethegearthatdrives

Tractor2turnsfreelywhentheleverisnot

pressed,butremainstillwhentheleveris

pressed.

RemoveTractor2fromtheprinterandremove

allpaper.Withthepaperselectleverinthe

continuousformsposition,pressLineFeed;

thetractorsshouldrotate.

PressthesubslidercamleverbelowtheASF/

Tractor2drivegearandpressLineFeedagain;

thetractorsshouldnotrotatebutthedrivegear

should.

Checktheconditionofthepinfeedbelts.With

thepoweroff,makesurethesliderdoesnot

bind.

:

Verify

•Whentheslideristotherear,thewhite

geardrivesthetractors;

•Whentheslideristothefrontthegear

andtractorsarenotconnected.

RemovetheTractor2coverandreinstall

Tractor2intheprinter(ifnecessaryremovethe

printercoversalso).Notethatthesmallidler

gearjustbelowthesliderisheldinplacebythe

cover;withthecoverremoveditwilltendto

moveoffthestud.Alsonotethatwhen

operatingtheTractor2withtheprintercover

removed,theTractor2in-placesensormustbe

heldopen.

Turntheprinteronandlookformechanical

problems.

ForinformationontheTractor2cable

connectors,see“Tractor2CableConnectors”

onpage5-4.

DiagnosticInformation2-43

Page 70

2-44

Page 71

3. Diagnostic Aids

The printer contains self tests to help find and solve problems. You

need not connect the printer to a computer or terminal to run these

tests.

Types of self tests are as follows:

• Power-On Self Test (POST)

• Print Test