Page 1

IEC 60947...

IEC 60947...

IP 67

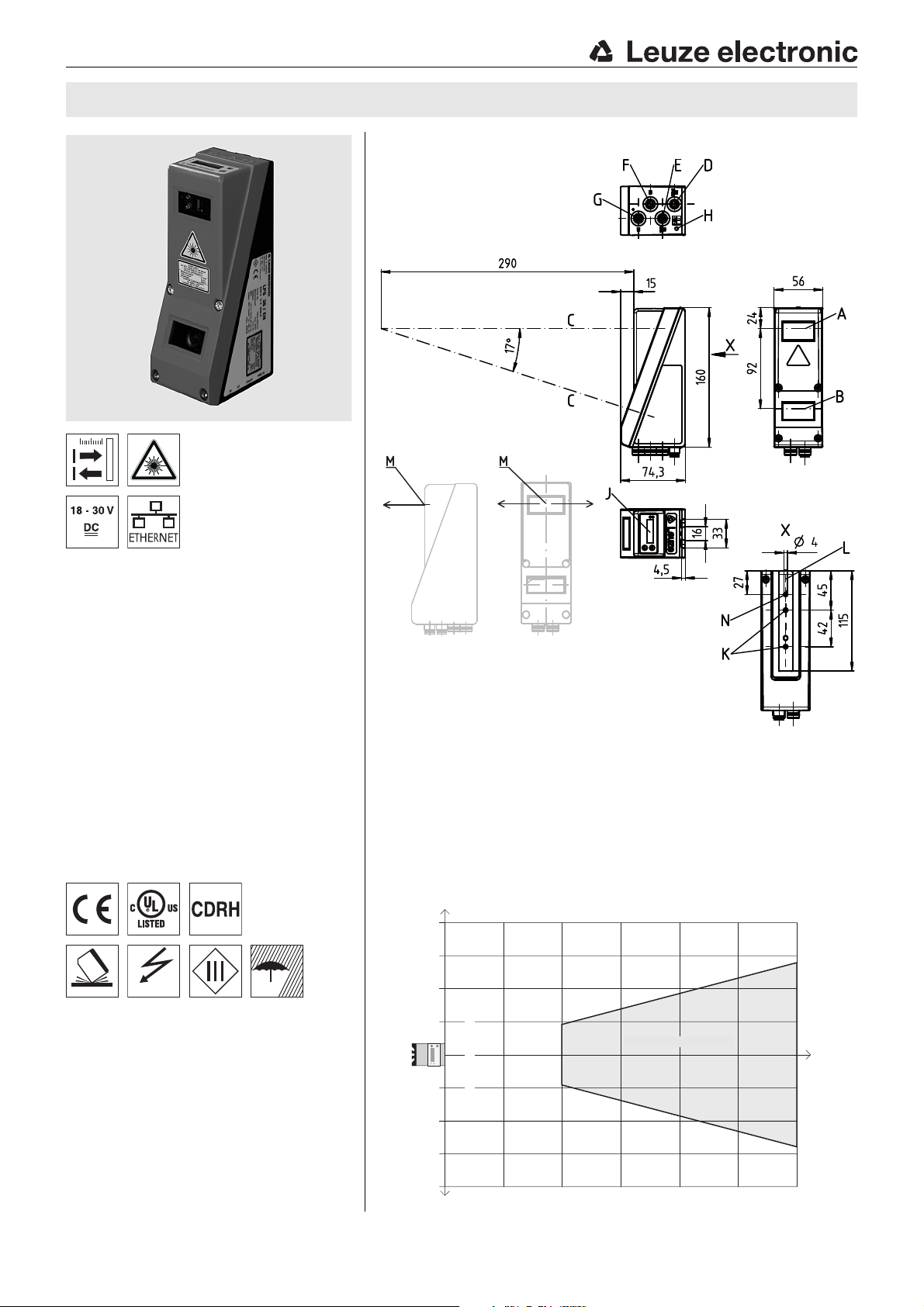

A Transmitter

B Receiver

C Optical axis

D X1: M12 x1 connector, 8-pin, A coded

E X2: M 12x1 socket, 4-pin, D coded

F X3: M12x 1 socket, 8-pin, A coded (LPS 36/EN only)

G X4: not used (dummy plug)

H PE screw

J OLED display and key pad

K M4 thread, 4.5 deep

L Holder for mounting system BT 56 / BT 59

M Zero point and orientation of the coordinate system for measurement data

N 4mm bore hole in transmitter axis

Measurement range z-axis

x = measurement range x-axis

Dimensions in mm

LPS 36 HI Light section sensor for object measurement

Dimensioned drawing

en 04-2014/06 50118357-03

200 … 600mm

Light section sensor for object measure-

ment

Calibrated system

Measurement range x-axis: 46 … 140mm

Measurement range z-axis: 200 … 600mm

Measurement time: 10ms

Measurement data transfer via

Fast Ethernet

Measurement value display in mm on OLED

display as an alignment aid

Incremental transmitter input

Up to 240 value pairs (x,z) along the laser

line

Up to 16 inspection tasks

Activation input, trigger input,

operational readiness output, cascading

output

+Z

-X+X

Measurement range, typical

-x

-100

Accessories:

(available separately)

Mounting systems BT 56, BT 59

Cable with M12 connector (K-D …)

Configuration memory

K-DS M12A-8P-0,75m-LxS36-CP

We reserve the right to make changes • DS_LPS36HI_en_50118357_03.fm

+100

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0

• www.leuze.com

+25

+50

+75

-75

-50

-25

+z

Leuze electronic

+x

1000

200 300 400 500 600

LPS 36HI… - 04

Page 2

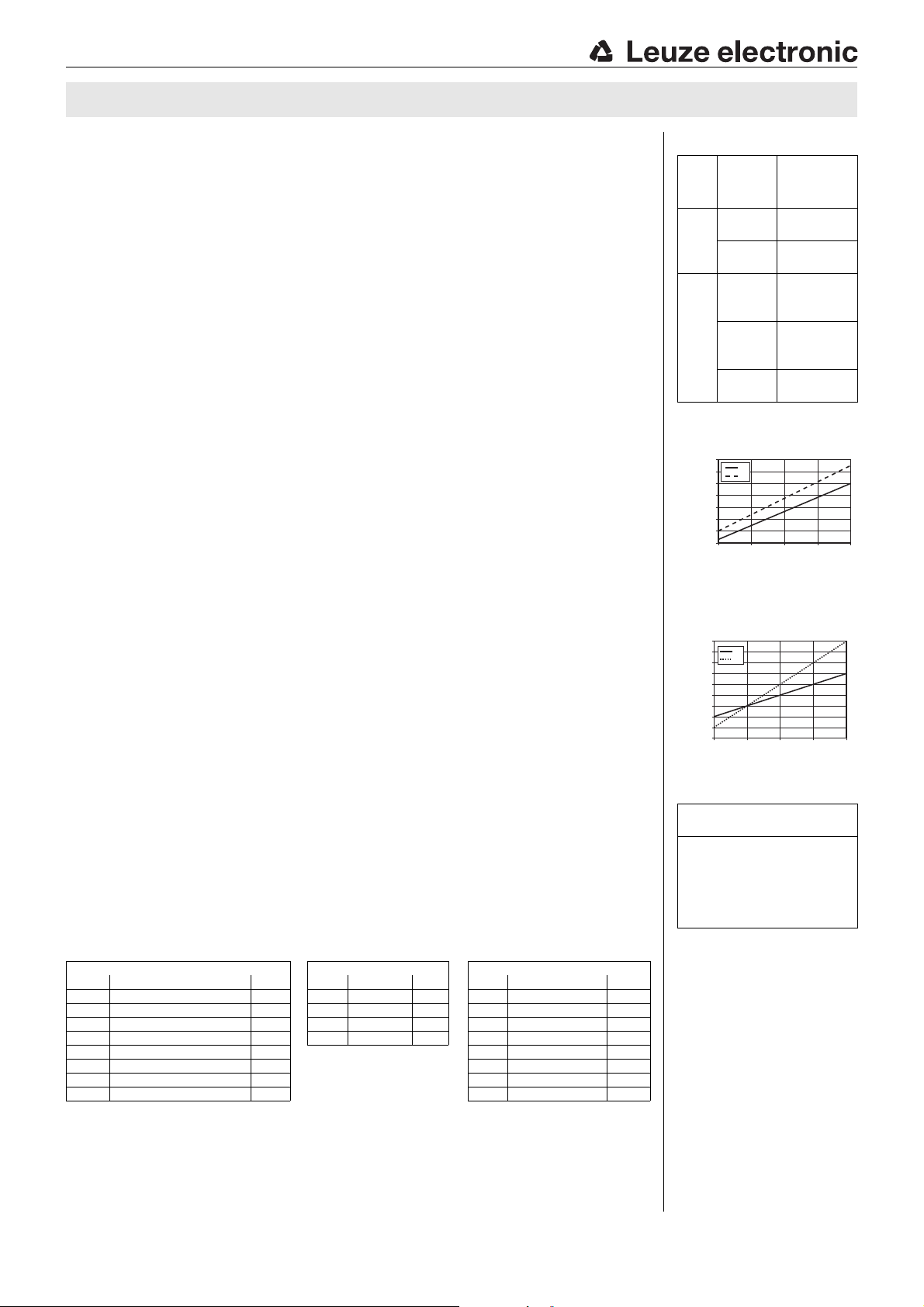

Line length/measurement range (ty-

pical)

Distance in mm

Line length/measurement range

in mm

Resolution (typical)

Distance in mm

Resolution in mm

LPS 36 HI

Specifications

Optical data

Measurement range

Light source laser

Wavelength 658nm (visible red light)

Max. output power < 8mW

Pulse duration < 3ms

Exposure time 60 … 1300μs

Laser line approx. 170x1.5 mm at 600mm

Error limits (relative to measurement distance)

Geometric resolution

Linearity z-axis

Repeatability z-axis

B/w detect. thresholds (6 … 90% rem.) ≤ ±0.5%

Timing

Measurement time 10ms

Delay before start-up approx. 1.5s

Electrical data

Operating voltage UB

Residual ripple ≤ 15% of U

Open-circuit current ≤ 200mA

Ethernet interface UDP

Switching outputs 1 (ready) / 100mA / push-pull

Inputs 1 (trigger) on X1

Signal voltage high/low ≥ (U

Indicators

Green LED continuous light ready

Yellow LED continuous light Ethernet connection available

Mechanical data

Housing aluminum frame with plastic cover

Optics cover glass

Weight 620g

Connection type M12 connector

Environmental data

Ambient temp. (operation/storage) -30°C … +50°C/-30 °C … +70 °C

Protective circuit

VDE safety class III, protective extra-low voltage

Protection class IP 67

Laser class 2M (according to EN 60825-1 and 21 CFR 1040.10 with

Standards applied IEC/EN 60947-5-2

Certifications UL 508, C22.2 No.14-13

1) Luminosity coefficient 6% ... 90%

2) Minimum and maximum value dependent on the measurement distance, at 20 °C after 30min. warmup time,

average range U

3) Reflectivity 90%, identical object, identical environment conditions, measurement object ≥ 20 mmx 20 mm

4) For UL applications: for use in class 2 circuits according to NEC only

5) The push-pull switching outputs must not be connected in parallel

6) 1=transient protection, 2=polarity reversal protection, 3=short circuit protection for all outputs

7) These sensors shall be used with UL Listed Cable assemblies rated 30V, 0.5 A min,

in the field installation, or equivalent (categories: CYJV/CYJV7 or PVVA/PVVA7)

1)

2)

x-axis

3)

3)

4)

x-axis

z-axis

z-axis

46 … 140mm

200 … 600mm

0.2 … 0.6mm

0.1 … 0.9mm

≤ ±0.5%

≤ ±0.25%

18 … 30VDC (incl. residual ripple)

B

5)

1 (cascading) / 100mA / push-pull 5) on X1

1 (activation) on X1

-2V)/≤ 2V

B

off no voltage

flashing Ethernet data transmission active

off no Ethernet connection available

6)

1, 2, 3

Laser Notice No. 50)

4) 7)

, z resolution at factory setting median "3"

B

on X1

Tables

LED State Display during

green continuous

light

off Sensor not

yellow continuous

light

flashing Ethernet data

off No Ethernet

measurement

operation

Sensor

ready

ready

Ethernet

connection

established

transmission

active

connection

Diagrams

180

A

160

B

140

120

100

80

60

40

200 300 400 500 600

A Measurement range

B Line le ngth

0,9

X

0,8

Z

0,7

0,6

0,5

0,4

0,3

0,2

0,1

0

200 300 400 500 600

Remarks

Operate in accordance with

intended use!

This product is not a safety sensor

and is not intended as personnel

protection.

The product may only be put into

operation by competent persons.

Only use the product in accor-

dance with the intended use.

Interface assignments

Pin No. Signal Color Pin No. Signal Color Pin No. Signal Color

1 +24 VDC WH 1 Tx+ YE 1 Enc. +24VDC WH

2 InAct (activation) BN 2 Rx+ WH 2 (GND) BN

3 GND GN 3Tx- OR 3GND GN

4 OutReady (ready) YE 4 Rx- BU 4 Enc. A+ YE

5 InTrig (trigger) GY 4-pin M 12 socket, D coded 5 Enc. A- GY

6 OutCas (cascading) PK 6 Enc. B+ PK

7 Do not connect BU 7 Enc. B- BU

8 Do not connect RD 8 +5 VDC Out RD

8-pin M12 plug, A coded 8-pin M12 socket, A coded

Order guide

Line profile sensor

With encoder interface LPS 36HI/EN 50111334

LPS 36HI… - 04 2014/06

X1 - logic and power X2 - Ethernet X3 - encoder

Designation Part no.

Warmup time:

After a warmup time of

30 min., the light section sensor has reached the operating

temperature required for an

optimum measurement.

Encoder interface

(LPS 36HI/EN):

24V single ended

(A+, B+) or

5V differential

(A+/A-, B+/B-)

Current consumption max.

140mA,

pulse frequency

max. 300kHz.

Page 3

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

ODER DIREKT MIT OPTISCHEN

INSTRUMENTEN BETRACHTEN

LASER KLASSE 2M

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelenght:

RADIAZIONE LASER

NON FISSARE IL FASCIO AD OCCHIO

NUDO NÉ GUARDARE DIRETTAMENTE

CON STRUMENTI OTTICI

APARRECCHIO LASER DI CLASSE 2M

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

NI À L`ŒIL NU NI Á L`AIDE D`UN

INSTRUMENT D`OPTIQUE

APPAREIL À LASER DE CLASSE 2M

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

NI MIRAR DIRECTAMENTE CON

INSTRUMENTOS ÓPTICOS

PRODUCTO LÁSER DE CLASE 2M

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

NEM OLHAR DIRECTAMENTE

COM INSTRUMENTOS ÓPTICOS

EQUIPAMENTO LASER CLASSE 2M

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 2M LASER PRODUCT

EN 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

0伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

䉏⏘戟⺓

▎䦃展㒥抩扖⏘ⷵ

ⅹ⣷䦃㘴屑䦚⏘㧮

8,7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8,7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

8.7 mW

3 ms

658 nm

50111877-01

A Laser exit opening

B Laser warning sign

C Laser information sign with laser parameters

B

C

A

LPS 36 HI Line profile sensor

Laser safety notices

ATTENTION, LASER RADIATION – LASER CLASS 2M

Never look directly into the beam or point the beam in the direction of telescope users!

The device fulfills the EN 60825-1:2008-05 (IEC 60825-1:2007) safety regulations for a product in laser class 2M as well as the

U.S. 21 CFR 1040.10 regulations with deviations corresponding to "Laser Notice No. 50" from June 24th, 2007.

Never look directly into the laser beam or in the direction of reflecting laser beams!

If you look into the beam path over a longer time period, there is a risk of injury to the retina.

Do not point the laser beam of the device at persons!

Intercept the laser beam with an opaque, non-reflective object if the laser beam is accidentally directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflective surfaces!

CAUTION! Use of controls or adjustments or performance of procedures other than specified herein may result in hazardous light

exposure.

The use of optical instruments or devices (e.g., magnifying glasses, binoculars) with the product will increase eye hazard.

Adhere to the applicable legal and local regulations regarding protection from laser beams acc. to EN 60825 (IEC 60825) in its latest

version.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

NOTICE

Affix laser information and warning signs!

Laser information and warning signs are affixed to the device(see

(stick-on labels) are supplied in several languages (see

).

Affix the laser information sheet with the language appropriate for the place of use to the device.

When using the device in the US, use the stick-on label with the "Complies with 21 CFR 1040.10" notice.

Affix the laser information and warning signs near the device if no signs are attached to the device (e.g. because the device is too

small) or if the attached laser information and warning signs are concealed due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing the reader to the laser radiation of the device

or other optical radiation.

). In addition, self-adhesive laser information and warning signs

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 LPS 36HI… - 04

• www.leuze.com

Page 4

LPS 36 HI

Establish connection to PC

The LPS is configured via a PC using the LPSsoft program before it is integrated into the process control.

In order to be able to establish an UDP communication with the PC, the IP address of your PC and the IP address of the LPS must lie in

the same address range. The LPS has no built-in DHCP client, so that you need to set the address manually. This is done the easiest

way via the PC.

Notice!

If you are using a desktop firewall, please ensure that the control can communicate with the LPS via the Ethernet interface

on ports 9008 and 5634 using UDP. Furthermore, the firewall must allow ICMP echo messages to pass through for the

connection test (ping).

If the PC is usually connected to a network using DHCP address allocation, the easiest way to access the LPS is by applying an alternative configuration in the TCP/IP settings of the PC and connecting the LPS directly to the PC.

Check the network address of the LPS by pressing the

LPS twice in succession, then by pressing twice and followed by pressing the button again.

This will take you to the Ethernet submenu and enable you to read the current settings of the LPS consecutively when pressing

repeatedly.

Make a note of the values for IP-Address and Net Mask Addr..

The value in Net Mask Addr. specifies which digits of the IP address of the PC and LPS must match so that they can communicate

with each other.

Address of the LPS Net mask Address of the PC

192.168.060.003 255.255.255.0 192.168.060.xxx

192.168.060.003 255.255.0.0 192.168.xxx.xxx

Instead of xxx you can now allocate any numbers between 000 and 255 to your PC, but NOT THE SAME numbers as contained in the

address of the LPS.

For example 192.168.060.110 (but not 192.168.060.003!). If LPS and PC have the same IP address, they cannot communicate with each

other.

Configuring the IP address for a PC

Log in to your PC as an administrator.

Using Start->System control go to the Network connections

(Windows XP) menu or to the Network center and release center

(Windows Vista) menu.

There select the

by right clicking with the mouse.

Select the Internet protocol (TCP/IP) (by scrolling down, if necessary) and

click on Properties.

In the Internet protocol (TCP/IP) Properties window select the

Alternate configuration tab.

Configure the IP address of the PC in the address range of the LPS.

Attention: do not use the same as for the LPS!

Set the Subnet mask of the PC to the same value as the one for the LPS.

Close the configuration dialog by confirming all windows using OK.

Connect the interface X2 of the LPS directly to the LAN port of your PC. Use a

KB ET-…-SA-RJ45 cable for the connection.

The PC will first try to establish a network connection via the automatic configuration. This will take a few seconds. Following that the alternative configuration, which

you have just set up, is activated, and thus the PC can communicate with the LPS.

Information about configuring the LPS using LPSsoft software can be found in the

Technical Description.

LAN connection

and bring up the associated Features page

button on the key pad of the sensor during normal operation of the

LPS 36HI… - 04 2014/06

Page 5

LPS 36 HI Line profile sensor

Commissioning

For the commissioning and integration of the sensor in the process control the following steps are necessary:

1.Configuring the LPS - see chapter 8 of the Technical Description.

2.Programming process control - see chapter 9 of the Technical Description.

3.Adapt the IP configuration of the LPS such that it can communicate with the process control. This can be done either via the

display of the LPS or in LPSsoft in the Configuration area. Here you can change network address and associated net mask

as well as the ports via which the LPS communicates with process control.

4.Save the changed settings in the LPS using the Configuration->Transmit to sensor command.

5.Connect LPS to process control via the Ethernet interface.

6.Establish connections for activation, triggering and cascading, if necessary.

Installing the software

System requirements

The PC used should meet the following requirements:

-Pentium

(Athlon 64, Opteron, Sempron). The processor must support the SSE2 instruction set.

- At least 512 MB free main memory (RAM), 1024 MB recommended.

-CD-ROM drive.

- Hard disk with at least 1 GB available memory.

-Ethernet port.

- Microsoft® Windows XP SP2/3 / Vista SP1 / Windows 7 (32 bit, 64 bit).

Installation procedure

®

or faster Intel® processor > 1.5 GHz (Pentium 4, Celeron, Xeon) or compatible models by AMD®

Notice!

If present, uninstall Matlab Runtime before beginning with the installation of the LXSsoft Suite.

The LXSsoft_Suite_Setup.exe installation program is located on the supplied CD.

Notice!

Copy this file from the CD to an appropriate

folder on your hard drive.

Administrator privileges are required for the next

steps.

To start the installation process, double-click on

file LXSsoft_Suite_Setup.exe.

In the first window, click on Next.

In the next window, you can select whether you would

like to install LPSsoft only, or LRSsoft in addition.

You will need LRSsoft in addition, for configuring light

section sensors of the LRS series with your PC.

You cannot deselect the first option, MATLAB

Compiler Runtime, since this component is needed

in all cases.

Select the desired options and click on Next

and, in the next window, click on Install.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 LPS 36HI… - 04

• www.leuze.com

Page 6

The installation routine starts. After a few seconds, the window for

selecting the installation language for the Matlab Compiler Runtime (MCR) appears. The MCR is used for 3D visualization in

LPSsoft. It is only available in English or Japanese.

Therefore keep in the Choose Setup Language window

the selection English and click on OK.

Depending on the configuration of your Windows system the

adjacent dialog can also appear (missing component

VCREDIST_X86).

Click on Install

Two additional installation windows will appear, which do not

require any further entry.

LPS 36 HI

After some time (up to several minutes depending on the system

configuration) the start screen of the MCR installer will appear.

Click on Next.

The window for entering user data appears.

Enter your name and the company name and then click on

Next.

It is essential that you retain the default folder in the window

for the selection of the installation path (Destination

Folder).

The standard path is

C:\Programs\MATLAB\MATLAB Compiler Runtime\.

Click on Next and in the next window click on Install.

LPS 36HI… - 04 2014/06

Page 7

LPS 36 HI Line profile sensor

The installation will start and the adjacent status window will be

displayed. This can again take several minutes.

Following successful MCR installation, the InstallShield

Wizard Completed window appears.

Click on Finish to end the MCR-installation.

The window for selecting the installation path for LPSsoft now

appears.

Keep the default folder and click on Next.

The installation of LPSsoft starts. If you also selected LRSsoft for

installation, upon completion of the LPSsoft installation, the same

window then reappears for entering the installation path for LRS-

soft.

Keep the default folder in this case as well and click on

Next.

Upon completion of the installation process, the adjacent window

appears.

The installation routine added a new Leuze electronic program group in your Start menu that contains the installed programs LPSsoft and, if selected, LRSsoft.

Click on Finish and then start the desired program from

the Start menu.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 LPS 36HI… - 04

• www.leuze.com

Page 8

Possible error message

Depending on the system configuration the adjacent

error message can appear at this point.

The cause of this error message is a bug in the MCR

installation routine, which does not set the environment

variable Path correctly in some systems.

That, however, can easily be corrected without reinstallation of the MCR.

Open the

tem control

Go to the

ables

The Environment variables window opens.

Scroll down in the

Path entry.

Click on

The Edit system variable window opens.

There in the Variable value field you will find the ;C:\Pro-

grams\MATLAB\MATLAB Compiler

Runtime\v79\runtime\win32 entry right at the end.

If this entry is missing, copy the entry from this document and

insert it together with the preceding semicolon.

Then click on

Shut Windows down, restart Windows and then start LPSsoft

by double-clicking on it.

Now the start screen of LPSsoft appears, as described in

chapter 8 of the technical description LPS.

System properties window located in the Sys-

of Windows under System.

Advanced tab and click on Environment vari-

.

System variables area until you find the

Path and then on Edit.

OK and close also all further windows using OK.

LPS 36 HI

LPS 36HI… - 04 2014/06

Loading...

Loading...