Page 1

12 - 30 V

DC

4 m/s

U

L

US

C

LISTED

IP 65

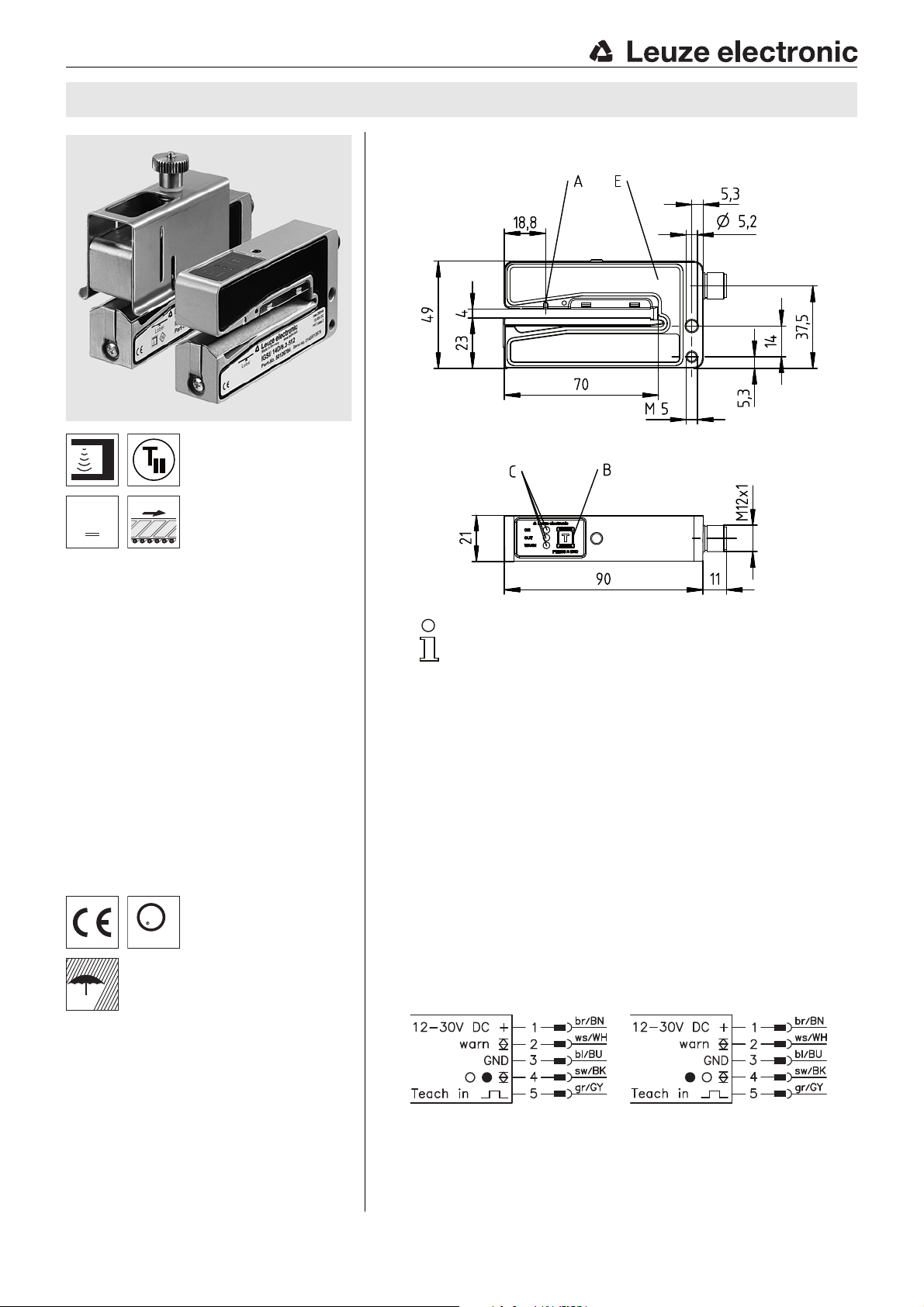

Dimensioned drawings for extended carriage and tape guide,

see Mechanical accessories on Page 10

IGSU14D…/6D.…-S12IGSU14D…/6.…-S12

IGSU 14D Ultrasonic label fork

Dimensioned drawing

en 03-2017/09 50125952-02

4mm

Ultrasonic forked sensor for universal

application

Large mouth width, hence also suitable for

booklets or fan-fold flyers

easyTeach function:

press button - dispense labels - done!

ALC function (auto level control):

maximum function reserve via automatic

online optimization of the switching

threshold

Warning output for indicating teach or func-

tion errors

NEW – static teach on base material, no

loss of labels

NEW – easyTune for fine adjustment of the

switching threshold

A Sensor marker (center of label tape)

B Teach-in button

C Indicator diodes (ON, OUT, WARN)

E Sensor

Electrical connection

Accessories:

(available separately)

Short carriage (part no. 50114055)

As replacement for the series part.

Extended carriage (Part No. 50114056)

For better guiding of oversized labels.

The carriage can be shortened at any point.

We reserve the right to make changes • PAL_IGSU14D_en_50125952_02.fm

M12 connectors (KD …)

Cables with M 12 connector (KD...)

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0

IGSU 14D…-S12 - 03

Page 2

IGSU 14D

Technical data

Physical data

Mouth width 4mm

Mouth depth 68mm

Label length 5mm

Label width 10mm

Label gap 2mm

Conveyor speed 240m/min (4 m/s)

Conveyor speed during teach-in 50m/min (0.83 m/s)

Typ. response time 200μs

Repeatability

Readiness delay 300ms acc. to IEC 60947-5-2

Electrical data

Operating voltage UB

Residual ripple 15% of U

Open-circuit current 80mA

Switching output

Warning output

Function switching output IGSU Light/dark switching, adjustable

Signal voltage high/low (U

Output current 100mA

Capacitive load 0.5μF

Indicators

Green LED Ready

Green LED flashing Teach-in initiated

Yellow LED Switching point in the label gap

Red LED Teaching error / function error

Mechanical data

Housing IGSU14D… Diecast zinc, painted silver

Weight 270g

Ultrasonic transducer Piezoceramic

Connection type M12 connector, 5-pin

Environmental data

Ambient temp. (operation/storage) 0°C … +60°C/-40 °C … +70 °C

Protective circuit

VDE protection class III

Degree of protection IP 65

Standards applied IEC 60947-5-2, UL 508

Certifications UL 508, C22.2 No.14-13

Additional functions

Teach-in input

Active/Not active 8V/ 2V

Input resistance 15k

1) Depending on conveyor speed, label length and spacing between labels

2) For UL applications: use is permitted exclusively in Class 2 circuits according to NEC

3) The push-pull switching outputs must not be connected in parallel

4) The ceramic material of the ultrasonic transducer contains lead zirconium titanate (PZT)

5) 1=polarity reversal protection, 2=short circuit protection for all outputs

6) These proximity switches shall be used with UL Listed Cable assemblies rated 30V, 0.5 A min,

in the field installation, or equivalent (categories: CYJV/CYJV7 or PVVA/PVVA7)

1)

2)

3)

…/6D. 1 push-pull switching output

2)

IGSU14DN… Diecast zinc, chemically nickel-plated

5)

±0.2mm

12VDC (-5%) … 30VDC (incl. residual ripple)

…/6.

1 push-pull switching output

Pin 4: PNP light switching, NPN dark switching

Pin 4: PNP dark switching, NPN light switching

1 push-pull switching output

Pin 2: active low (normal operation high, event case low)

1, 2

-2V)/ 2V

B

B

4)

2) 6)

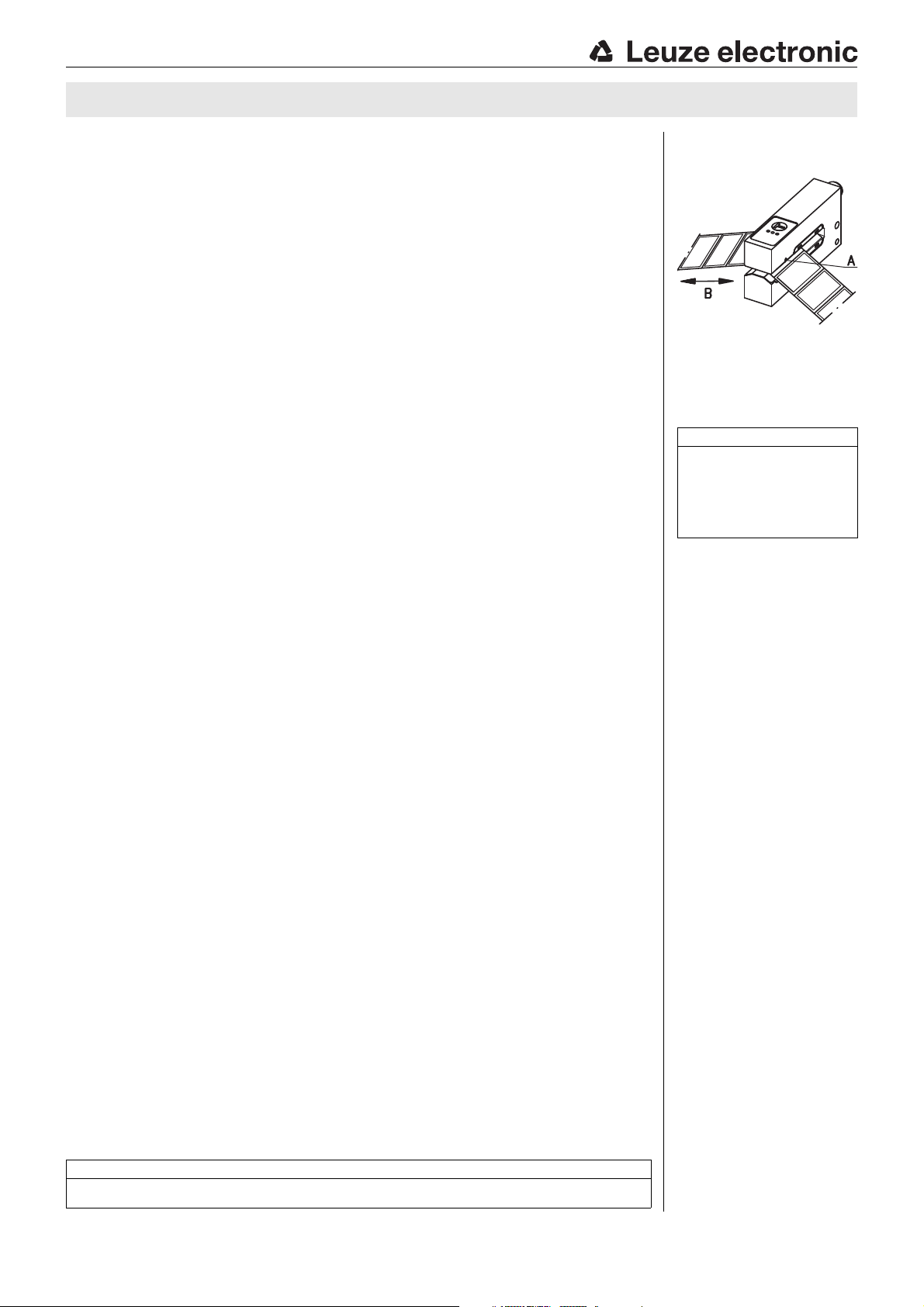

Marking on the

sensor

A Label center position

B Label run

Notes

Observe intended use!

This product is not a safety sensor

and is not intended as personnel

protection.

The product may only be put into

operation by competent persons.

Only use the product in accor-

dance with its intended use.

To achieve high repeat-

ability, the label tape must

be slightly under tension.

Align the label tape

according to the sensor's

marker "Label center

position" (see also marking on sensor).

The label material used

determines the achievable

precision and the reliability of gap detection!

Light switching: signal in

the label gap.

Dark switching: signal on

the label.

UL REQUIREMENTS

Ambient Temperature Rating: 50°C

Enclosure Type Rating: Type 1

IGSU 14D…-S12 - 03 2017/09

Page 3

IGSU 14D Ultrasonic label fork

Order guide

The sensors listed here are preferred types; current information at www.leuze.com.

Designation Part no.

With painted housing

Pin 4: switching output PNP light switching; pin 2: warning output active low IGSU14D/6.3-S12 50126784

Pin 4: switching output PNP dark switching; pin 2: warning output active low IGSU14D/6D.3-S12 50126785

With painted housing and extended carriage

Pin 4: switching output PNP light switching; pin 2: warning output active low IGSU14D/6.31-S12 50126786

With chemically nickel-plated housing

Pin 4: switching output PNP light switching; pin 2: warning output active low IGSU14DN/6.3-S12 50126788

Pin 4: switching output PNP light switching; pin 2: warning output active low, customer-specific IGSU14DN/6.3K-S12 50126789

With chemically nickel-plated housing and tape guide

Pin 4: switching output PNP light switching; pin 2: warning output active low IGSU14DN/6.3G-S12 50125790

Part number code

IGSU14DN/6D. 31G-S12

Outputs

I Warning output (Pin 2)

Operating principle

GSU Ultrasonic forked sensors

Series

14D Series 14, generation D

Housing

N Diecast zinc, chemically nickel-plated

Free Diecast zinc, painted silver

Switching output type (pin 4)

6 Push-pull

Switching output function

D Pin 4: PNP switching on the label, NPN switching in the gap

Free Pin 4: PNP switching in the gap, NPN switching on the label

Teach-in

3 Teach-in by means of control button on the sensor

Equipment

1 With extended carriage

G With tape guide

1G With extended carriage and tape guide

K Customer-specific design

YN Customer-specific design

Connection technology

S12 M12 connector, 5-pin

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 IGSU 14D…-S12 - 03

Page 4

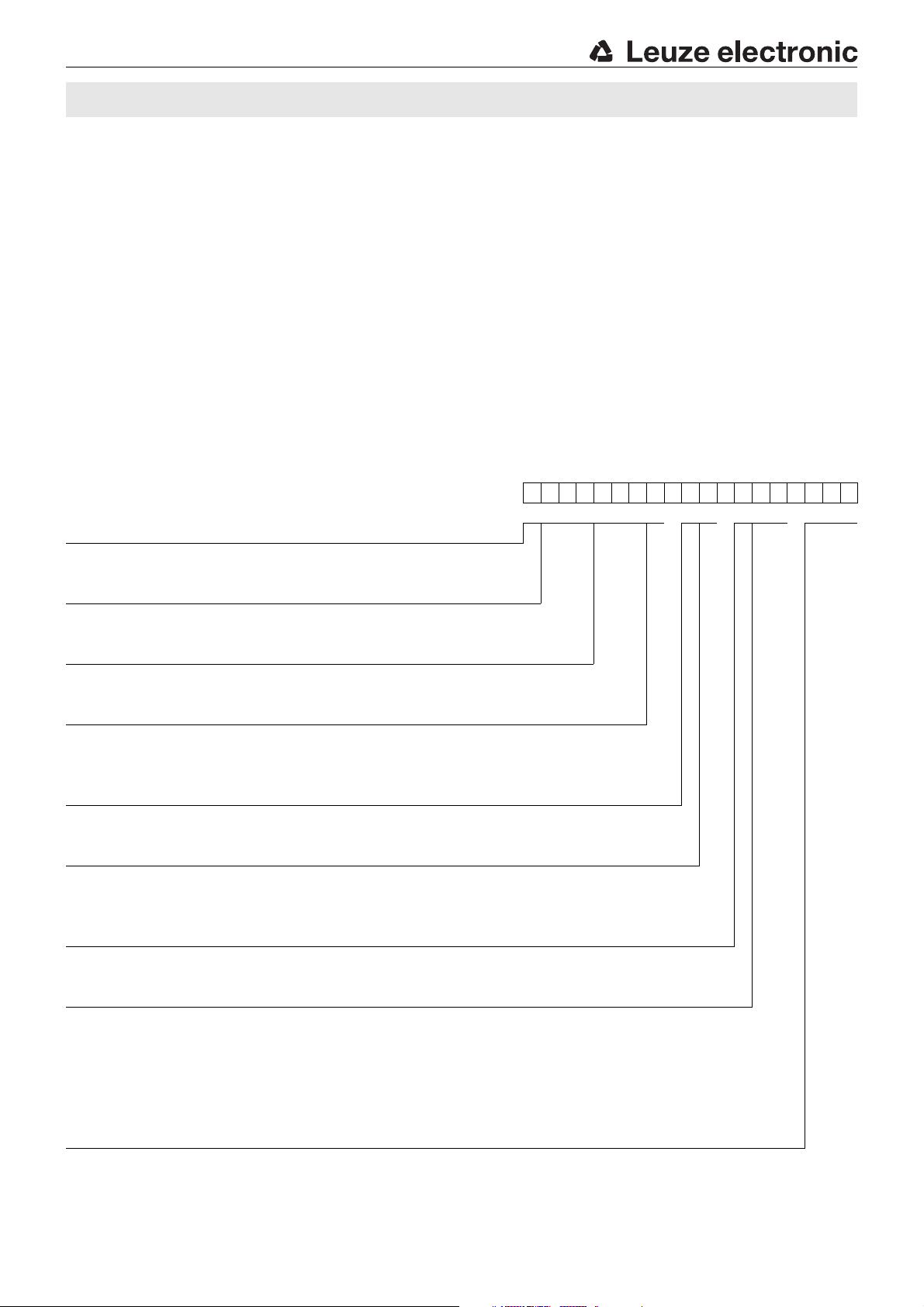

Overview of operating structure for IGSU 14D

Standard function

Normal operation after switch-on

ON LED - green= ready

OUT LED - yellow= switching output

WARN LED - red= warning output

easyTeach (Level 1)

Teach-in for best function

with ALC function

ON LED - green and OUT LED - yellow

flash synchronously 1 x per sec.

Release button

WARN LED - red is off

if teach is error-free

automatic

Static teach on label carrier (Level 2)

Teach switching threshold without loss of labels

with ALC function

ON LED - green and OUT LED - yellow

flash alternately 3 x per sec.,

Release button

Briefly press the button again

to end the teach event

Setting switching behavior (Level 3)

Setting of the light/dark switching output

ON LED - green flashes 3 x per sec.,

release button, green ON LED continues to flash

OUT LED - yellow: changed setting of the

switching output after releasing the button

on = light switching (in the gap)

off = dark switching (on the label)

= function lockable through constant application of UB on the teach input

≥ 2 s

IGSU 14D

≥ 7 s

≥ 12 s

IGSU 14D…-S12 - 03 2017/09

Page 5

Operation:

The teach button must be pressed for

at least 2 seconds to operate the

device. The button can be electrically

disabled to prevent accidental operation.

IGSU 14D Ultrasonic label fork

IGSU 14D standard functions

During operation the sensor is always in this function. The sensor detects label gaps with high precision and speed. This is indicated by the yellow LED and the switching output.

Indicators:

ON LED - green Constantly ON when operating voltage is applied.

Indicates the switching signal.

OUT LED - yellow

LED is ON if the sensor detects label gaps.

The display is independent of the output setting.

WARN LED - continuous red light

WARN LED flashing red

OFF: error-free operation.

ON: teaching error caused by unfavorable label material,

ALC function outside of the control window.

Short-circuit at the switching output and/or warning output.

All outputs are switched to tri-state until the

error is rectified.

ALC function (auto level control):

In each teach event, the current signal values in the sensor are digitally determined, resulting in the optimum switching threshold

being calculated for maximum function reserve. All values are saved and are non-volatile, retaining their validity as long as the

dynamic parameters of the system remain unchanged and the material is not changed.

Signal changes can result each time the roll is changed, even with labels that are apparently the same. This is caused, for example, by material variations (material thickness, homogeneity, etc.) which affect the acoustic impedance of the system. Even

changes of the dynamic parameters (e.g. tape tension, middle position, jitter, etc.) can have a negative affect on the function

reserve of the sensor.

The ALC function now automatically corrects the switching threshold in such a way that the maximum function reserve is always

available during operation - the sensor works absolutely reliably and free of errors.

Note

When changing to another type of label, a new adjustment must generally be carried out by carrying out a new

teach-in event.

Warning output

The warning output is activated if the red LED on the device is illuminated. This is the case for the following states:

Teaching error (see description)

"ALC function faulty" error (control limit reached: clean device, align and reteach)

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 IGSU 14D…-S12 - 03

Page 6

Sensor adjustment (teach-in) via teach button

2…7s

The green and the yellow LEDs

flash synchronously

approx. 1x per sec.

7…12s

The green and the yellow LEDs

flash alternately

approx. 3x per sec.

easy Teach while the label tape is passing through

Preparation: Insert label tape into the sensor.

Press the teach button until green and yellow LEDs flash synchronously

Release teach button.

Advance the label tape through the sensor at a max. speed of 50 m/min. The

sensor indicates the tape transport by faster simultaneous flashing of the green

and yellow LED.

Ready.

If sufficient teach values are determined, the sensor automatically terminates the teach

event and goes into standard mode. The transport of the label tape can be stopped

immediately. The number of labels to be transported is always based on the material

combination: from experience, the value is between 2 and 10 labels.

If the teach event is faulty (e.g. unfavorable material combination, uneven transport, jittering during transport), the red LED illuminates and the warning output is activated.

Repeat teach event. If the fault cannot be rectified, the label material cannot be detected

with the IGSU 14C.

Static teach on the label carrier without transport

Preparation: depending on the label size, pull off one or more labels from the carrier and

transport the blank area into the sensor.

Press the teach button until green and yellow LEDs flash alternately

Release teach button.

Briefly press the button again to end the teach event

With this teach event, a one-point calibration is performed on the blank carrier. This process is particularly advantageous because there is no loss of labels during the teach.

.

.

IGSU 14D

Note

With the easy Teach process, a two-point calibration is performed which, with respect to detection reliability,

is generally to be preferred over the static teach.

IGSU 14D…-S12 - 03 2017/09

Page 7

press briefly

(2ms … 200ms)

or

press and hold

down

(200ms … 2s)

The green LED flashes

onetime quickly or for a

longer period time after the

button is pressed

Reception signal for

homogeneous label material

Long press of the button –> increase switching threshold

Short press of the button –> reduce switching thresh old

Label tape

Reception signal for

inhomogeneous label material

Switching threshold too low, yellow LED/switching output flickers

Optimum switching threshold

Equally high function reserve on the label (A ) and in the gap (B )

Function reserve on the label (C) less than in the gap (D)

IGSU 14D Ultrasonic label fork

easyTune – Manual fine tuning of the switching threshold

With homogeneous label material, the signal in the gap between two labels is

much larger compared to the signal on the label. For the taught switching threshold, there is a high function reserve in both the gap as well as on the label, and

the sensor functions reliably.

To achieve a better function reserve, it can be advantageous to change the

taught switching threshold, especially for inhomogeneous label material. Used

for this purpose is the easyTune function, which is similar in principle to a poten-

tiometer. The switching threshold can be adjusted by pressing the button quickly

or for a longer period of time.

Pressing the teach button quickly (2ms … 200 ms) reduces the switching

threshold slightly; pressing the button for a longer period of time

(200ms … 2s) increases the switching threshold slightly. The change resulting

from each press of the button is small. The button may need to be pressed several times in order to achieve a stable operating point. The sensor confirms each

press of the button with short or long flash of the green LED. If the upper or lower

end of the adjustment range is reached, the green and yellow LEDs flash at a

considerably faster frequency and the red LED is illuminated for one second.

Note

Please note:

easyTune deactivates the ALC function!

Example:

B

A

D

C

Recommended settings:

Observation Change to the switching threshold Measure

After teaching, the yellow LED and the switching output flicker if the label is moved

through the sensor, i.e., the function reserve on the label ( (C ) in the example) is too

low.

In rare cases, a highly inhomogeneous carrier tape can affect the functional reliability. The yellow LED and the switching output flicker if the blank carrier tape is moved

through the sensor without labels, i.e., the function reserve on the carrier is insufficient.

Increase

Decrease

Repeatedly press the teach button for a longer period of time until the sensor detects

the moving label stably and without interruption.

Repeatedly press the teach button quickly

until the sensor detects the moving carrier

tape without labels stably and without flickering.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 IGSU 14D…-S12 - 03

Page 8

>12s

The green LED flashes

approx. 3x per sec.

U

Teach low

t

U

Teach high

Button disabled

Button enabled

IGSU 14D

Adjusting the switching behavior of the switching output (light/dark switching)

Press teach button until only the green LED flashes.

Release the teach button - the green LED continues to flash, the yellow LED

indicates the changed switching behavior after the button was released.

Yellow LED ON = output switches on light (in the gap).

Yellow LED OFF = output switches on dark (on the label).

Ready.

Sensor adjustment (teach-in) via teach input

The following description applies to PNP switching logic!

U

Te ac h

Not connected Internal pull-down resistor pulls

the input down to zero

U

Tea c h l o w

U

Tea c h h ig h

U

Te ac h

2V Low level Teach button can be operated;

(UB-2V) High level Teach button disabled;

>2V…<(UB-2V) Not permitted Level not defined;

The device setting is stored in a fail-safe way. A reconfiguration following power failure or switch-off is thus not required.

Teach button can be operated;

all functions adjustable

all functions adjustable

button has no function

current state is retained

easyTeach while label tape is passing through

Preparation: Insert the label tape in the correct position in the sensor (align the middle of the tape to the sensor marking).

After switching on the supply

voltage and after the delay

before start-up has concluded ( 300ms), the teach

button on the device can be

operated.

2x

4 … 100ms

Only if the teach button was disabled

before the teach.

The teach button is disabled

easyTeach:

t

Tea ch

after the 1st edge transition.

= 4 … 900ms

4 … 100ms Teach event starts: The green and yellow LEDs flash simultaneously approx. 1x per second.

Advance labels at a tape running speed of max. 50m/min through the sensor until the teach

event is automatically terminated by the sensor, i.e. the LEDs no longer flash.

The number of labels which must be transported depends on the carrier and label material.

During the event, the button on the device is disabled, it can be operated again after this.

The red LED illuminates if a teaching error occurs (e.g. the label cannot be reliably detected due to insufficient signals).

Regardless of the state, the green LED illuminates upon conclusion of the teach event; the yellow LED indicates the current

switching state.

IGSU 14D…-S12 - 03 2017/09

Page 9

U

Teach low

t

U

Teach high

Button disabled

Button enabled

t

2100 … 3000ms 4 … 900ms 1100 … 2000ms

Button disabled

Button enabled

IGSU 14D Ultrasonic label fork

Static teach on the label carrier without transport

Preparation: Pull off one label from the tape and insert the empty spot into the fork (al ign the middle of the tape to the sensor marking).

After switching on the supply

voltage and after the delay

before start-up has concluded ( 300 ms), the teach

button on the device can be

operated.

2x

4 … 100ms

Only if the teach button was disabled

before the teach.

The teach button is disabled

after the 1st edge transition.

Static teach:

t

Tea ch

= 1,000 … 2,000ms

4 … 100ms Teach event starts: The green and yellow LEDs flash alternately approx. 1x per second.

At the end of the teach event, the yellow LED illuminates.

During the event, the button on the device is disabled, it can be operated again after this.

The red LED illuminates if a teaching error occurs (e.g. the label cannot be reliably detected due to insufficient signals).

Adjusting the switching behavior of the switching output – light/dark switching

After switching on the supply

voltage and after the delay

before start-up has concluded ( 300 ms), the teach

button on the device can be

operated.

2x

4 … 100ms

Teach switching output:

= 2,100 … 3,000ms

t

Tea ch

Switching output light switching (4 … 900ms)

Switching output dark switching (1100 … 2000ms)

The teach button is enabled again.

The teach button is disabled

after the 1st edge transition.

The teach button is disabled

after the 1st edge transition.

Notices for integrating the sensor in a control concept

If the sensor is taught externally via a control, it may be necessary to receive acknowledgment from the sensor with respect to

its current teach state. Use the following chart for this purpose:

Operating mode Reaction from sensor

Dispensing mode Dynamic output signal: alternates between gap and label

Teach Static output signal: the state prior to the teach event is frozen (output in tri-state)

Teach OK Output signal is dynamic again—warning output not active

Teach faulty Output signal is dynamic again—warning output active; repeat teach event if necessary

Locking the teach button via the teach input

A static high signal ( 4 ms) at the teach input locks the teach button on the

device if required, such that no manual operation is possible (e.g., protection from erroneous operation or manipulation).

If the teach input is not connected or if there is a static low signal, the button

is unlocked and can be operated freely.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 IGSU 14D…-S12 - 03

Page 10

Mechanical accessories

E Sensor

F Fastening screw for carriage

A Sensor marker (center of label tape)

B Teach-in button

C Indicator diodes (ON, OUT, WARN)

E Sensor

F Fastening screw for carriage

G Adjustment screw for height of tape holder

Extended carriage

The extended carriage (part no. 50114056)

can be replaced by the customer with the

standard carriage (part no. 50114055).

The carriage can be shortened at any point.

Alternatively, the sensor can also be delivered in the version with factory-mounted carriage (see order guide).

IGSU 14D

Tape guide

The correct transport of the label tape is decisive for the

switching accuracy and the operational safety of the sensor.

To achieve an optimum result, a tape guide was developed for the sensor.

Adjusting the tape holder:

If correctly adjusted, the tape more or less follows the

contour of the carriage and the label tape slides over the

lower fork of the forked sensor (see also figure "Marking

on the sensor" on page 2).

We recommend the use of forked sensors with factorymounted tape guide (see order guide).

IGSU 14D…-S12 - 03 2017/09

Loading...

Loading...