Page 1

IO-Link interface description

GSX14E, GSU14E, IGSU14E, IGSU14E SD

Ultrasonic fork sensor

We reserve the right to make technical changes

EN • 2020-07-08 • 50144571

Page 2

© 2020

Leuze electronic GmbH + Co. KG

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 2

Page 3

Table of contents

1 IO-Link interface....................................................................................................4

1.1 IO-Link identification ...............................................................................................................4

1.2 IO-Link process data............................................................................................................... 4

1.3 Device-specific IODD.............................................................................................................. 5

1.4 IO-Link parameters documentation ........................................................................................ 5

2 Functions configurable via IO-Link.....................................................................6

3 Recipe management ...........................................................................................15

Table of contents

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 3

Page 4

IO-Link interface

1 IO-Link interface

Sensors in the GSX14E/…, IGSU14E/…, IGSU14E/..SD.. and GSU14E/… variant have a dual channel architecture. Available on pin4 is the IO-Link interface in accordance with specification 1.1.2 (July 2013) with

support of Smart Sensor Profile 1.0 (March 2017) with profile type SSP2.6. You can easily, quickly and

economically configure the devices via the IO-Link interface. Furthermore, the sensor transmits the process

data via the IO-Link interface and makes diagnostic information available through it.

In parallel with the IO-Link communication, the sensor can output the continuous switching signal for object

detection on pin2 (SSC1 by default) by means of the dual channel architecture. The IO-Link communication does not interrupt this signal.

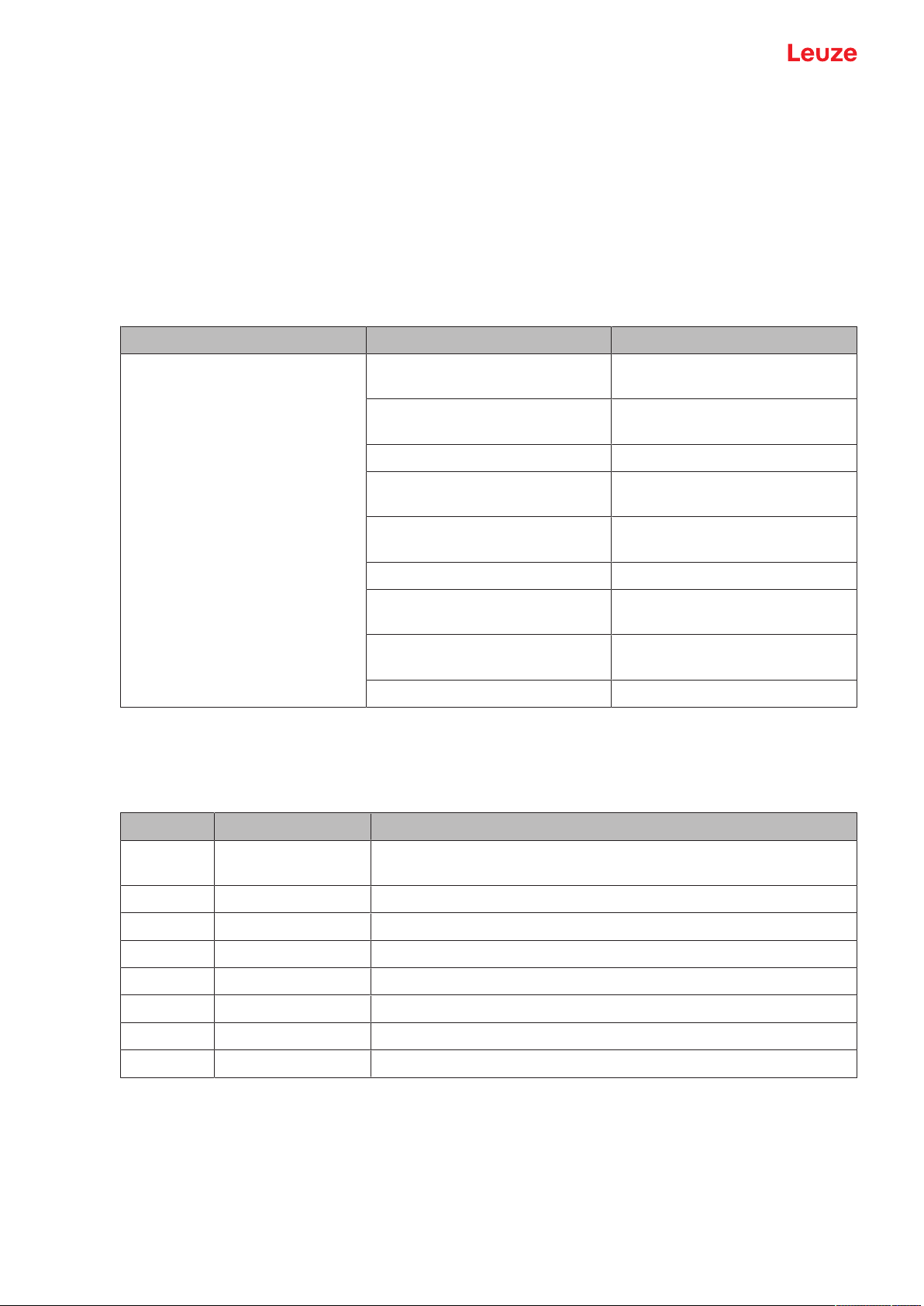

1.1 IO-Link identification

VendorID dec/hex DeviceID dec/hex Device

338/0x152 2500/0x0009C4 GSX14E/LWT.3-M12

GSX14E/LWT.3-M12V

2501/0x0009C5 GSX14E/1WT.3-M12

GSX14E/1WT.3-M12V

2502/0x0009C6 GSX14E/LGT.3-M12

2510/0x0009CE IGSU14E/LWT.3-M12

IGSU14E/LWT.3-M12V

Please refer to the respective product data sheet for the identification data of other IO-Link devices.

1.2 IO-Link process data

Device input data (PDout)

Data bit Assignment Meaning

0 Deactivation 0: transmitter active

1 Not assigned Free

2 Not assigned Free

3 Not assigned Free

2511/0x0009CF IGSU14E/1WT.3-M12

IGSU14E/1WT.3-M12V

2512/0x0009D0 IGSU14E/LWT.3SD-M12

2520/0x0009D8 GSU14E/LGT.3-M12

GSU14E/LGT.3-M12V

2521/0x0009D9 GSU14E/16T.3-M12

GSU14E/16T.3-M12V

… …

1: transmitter not active

4 Not assigned Free

5 Not assigned Free

6 Not assigned Free

7 Not assigned Free

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 4

Page 5

IO-Link interface

Device output data (PDin)

Data bit Assignment Meaning Present in de-

vice

0 Switching signal

SSC1

1 Not assigned Free

2 Not assigned Free

3 Sensor operation Sensor operation off when detection is not possi-

4 Measurement value Measurement value that indicates whether device

5 Warning Warning output

6 Teach-in method 0: Teach process not ended (or not yet started)

0: not active

1: active

ble (e.g if deactivated or during the teach event)

0: off

1: on

functionality is present

0: No valid measurement value

1: Measurement value available

0: no warning

1: warning

1: Teach process ended

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

7 ALC function (Auto-

Level-Control: automatic optimization of

the switching threshold)

0: ALC function not active

1: ALC function active

1.3 Device-specific IODD

At www.leuze.com in the download area for IO-Link sensors you will find the IODD zip file with all data required for the installation.

On the IODDfinder platform (https://ioddfinder.io-link.com/#/), a central cross-manufacturer database, you

can also find the description files (IODDs) of the IO-Link sensors.

1.4 IO-Link parameters documentation

The complete description of the IO-Link parameters can be found in the *.html files. Double-click on a language variant:

• German: *IODD*-de.html

• English: *IODD*-en.html

GSX14E/..

IGSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 5

Page 6

Functions configurable via IO-Link

2 Functions configurable via IO-Link

PC configuration and visualization is performed comfortably with the USB-IO-Link Master SET US2-IL1.1

(part no. 50121098) and the Sensor Studio configuration software (in the download area of the sensor at

www.leuze.com).

System commands

NOTICE

The system commands trigger an action in the device.

Parameter

System

command

Index Sub-

index

2 0 UInte-

Data

type,

octets

gerT, 1

Access

WO 65, 71,

Value

range

72, 79,

128,

130,

192,

193,

200,

214,

215,

226,

227

Default

Explanation Valid for

sensor

65: Perform static teach

71: Start dynamic teach

72: Stop dynamic teach

79: Cancel teach

128: Reset device

130: Reset factory settings

192: easyTune Down

(reduce sensitivity)

193: easyTune Up (increase sensitivity)

200: Delete error (teaching error, ALC function at

control limit, EasyTune

function at control limit)

214: Ultrasonic detection

principle active

215: Optical detection

principle active

226: Save work index

(save current teach value

as recipe - see chapter 3

"Recipe management")

227: Load work index

(load saved teach value

as recipe - see chapter 3

"Recipe management")

GSX14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 6

Page 7

Functions configurable via IO-Link

Parameter

System

command

Index Sub-

index

Data

type,

octets

2 0 UInte-

gerT, 1

Access

Value

range

WO 65, 71,

72, 79,

128,

130,

192,

193,

200,

226,

227

Default

Explanation Valid for

sensor

65: Perform static teach

IGSU14E/..

71: Start dynamic teach

72: Stop dynamic teach

79: Cancel teach

128: Reset device

130: Reset factory settings

192: easyTune Down

(reduce sensitivity)

193: easyTune Up (increase sensitivity)

200: Delete error (teaching error, ALC function at

control limit, EasyTune

function at control limit)

226: Save work index

(save current teach value

as recipe - see chapter 3

"Recipe management")

227: Load work index

(load saved teach value

as recipe - see chapter 3

"Recipe management")

System

command

2 0 UInte-

gerT, 1

WO 71, 79,

128,

130,

192,

193,

200,

226,

227

71: Start dynamic teach

79: Cancel teach

128: Reset device

130: Reset factory settings

192: easyTune Down

(reduce sensitivity)

193: easyTune Up (increase sensitivity)

200: Delete error (teaching error, EasyTune

function at control limit)

226: Save work index

(save current teach value

as recipe - see chapter 3

"Recipe management")

227: Load work index

(load saved teach value

as recipe - see chapter 3

"Recipe management")

IGSU14E/..SD..

(Model for

splice inspection)

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 7

Page 8

Functions configurable via IO-Link

Parameter

System

command

Index Sub-

index

Data

type,

octets

2 0 UInte-

gerT, 1

Access

Value

range

WO 71, 72,

79, 128,

130,

192,

193,

200,

226,

227

Default

Explanation Valid for

sensor

71: Start dynamic teach

GSU14E/..

72: Stop dynamic teach

79: Cancel teach

128: Reset device

130: Reset factory settings

192: easyTune Down

(reduce sensitivity)

193: easyTune Up (increase sensitivity)

200: Delete error (teaching error, EasyTune

function at control limit)

226: Save work index

(save current teach value

as recipe - see chapter 3

"Recipe management")

227: Load work index

(load saved teach value

as recipe - see chapter 3

"Recipe management")

General configuration

Parameter

Index Sub-

index

Data

type,

octets

Device

Access

12 0 UInte-

gerT, 2

Locks

SSC Config – Logic

57 0 UInte-

gerT, 1

TI Result 59 0 UInte-

gerT, 2

Access

Value

range

Default

Explanation Valid for

RW 0, 8 0 0: Teach button not

locked

8: All buttons locked

RW 0, 1 0, 1 0: SSC1 not inverted

(high active, light switching)

1: SSC1 inverted (low

active, dark switching)

The default settings are

device-dependent.

RO 0, 1, 4,

5, 7

0 Teach status:

0: Teach not yet started

1: Teach successfully finished

4: Teach waiting for input

5: Teach currently being

performed

7: Teach ended with error or last teach returned

error

The value range is device dependent.

sensor

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 8

Page 9

Functions configurable via IO-Link

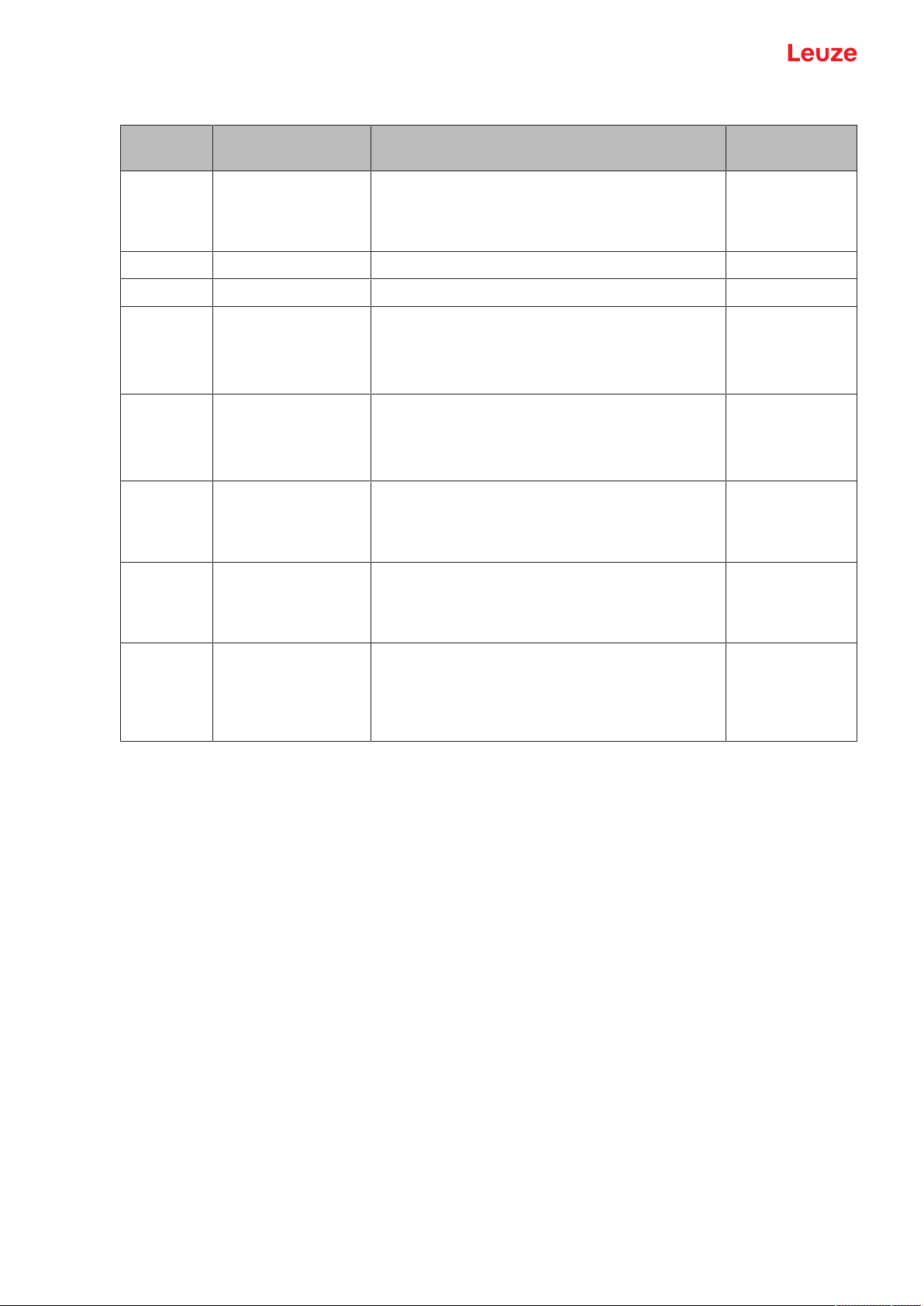

Parameter

Index Sub-

index

Data

type,

octets

Teach

Settings

71 0 UInte-

gerT, 1

Dynamic

System 80 0 UInte-

gerT, 4

Access

Value

range

Default

Explanation Valid for

RW 0, 1 0 0: easyTeach – Intelli-

gent mode

1: easyTeach – Manual

mode

RO Diagnostic information

Bit0 to 7: see chapter

1.2 "IO-Link process

data" device output data

(PDin)

Bit 8: Ultrasonic detection principle active

Bit 9: Optical detection

principle active

Bit 10: Device calibrated

Bit 11: Buttons locked

Bit 12: Device deactivated

Bit 14: ALC function:

readjusts

Bit 16: ALC function: error

Bit 17: Teach error

Bit 18: easyTune function: limit reached

Bit 19: Tape rupture

(only present in IGSU14E/..SD..)

Bit 20: Temperature error. Temperature above

specification

Bit 24: ALC function:

gain control at limit

Bit 25: ALC function:

threshold control at limit

sensor

GSX14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Amplitude 81 0 UInte-

gerT, 2

RO 0…

4095

Current reception signal GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Threshold 85 0 UInte-

gerT, 2

RO 0…

4095

Current switching threshold

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 9

Page 10

Functions configurable via IO-Link

Parameter

Working

Parameter

Working

Parameter

load /

save index

Index Sub-

index

Data

type,

octets

99 0 UInte-

gerT, 16

98 0 UInte-

gerT, 1

Access

Value

range

Default

Explanation Valid for

RW Teach value that is

stored after teaching.

The teach value contains

the taught switching

threshold, the hysteresis

and the used operating

principle for the label or

web material that is to be

detected.

With the possibility to

store multiple teach values in the device and to

call them back up later if

necessary, the user is

able process various label materials without the

operator needing to perform a teach event.

see chapter 3 "Recipe

management"

RW 0…19 0 Storage location of the

teach value that is stored

after teaching.

Up to 20 teach values

can be stored simultaneously in the sensor.

With the help of this

function, recipe management can be realized by

means of which the

teach event can be eliminated when changing to

a different label format.

The teach value that corresponds to the given label material is simply

loaded in the sensor and

the sensor works reliably

with the previously

taught teach values.

see chapter 3 "Recipe

management"

sensor

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Ultrasonic

Analysis

Depth

135 0 IntegerT,1RW 1…100 2 1…100: Range of anal-

ysis depth

Analysis depth: to suppress interference,

changing of the switching

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

output is delayed by this

number of identical measurement results.

The default setting in the

factory settings refers to

the specified response

time in the device data

sheet.

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 10

Page 11

Functions configurable via IO-Link

Parameter

Ultrasonic

AutoLevelControl

(Tracking

Enable

US)

Index Sub-

index

Data

type,

octets

136 0 BooleanT

, 1

Access

Value

range

Default

Explanation Valid for

RW 0, 255 255 0: Auto-Level-Control not

active

255: Auto-Level-Control

active

ALC function (AutoLevel-Control):

With the ALC function,

the sensor automatically

corrects the switching

threshold in such a way

that the maximum function reserve is always

available during operation. As a result, signal

changes that could negatively affect the function

reserve of the sensor,

e.g., due to material fluctuations of the label/carrier or changes of the dynamic system parameters, are automatically

corrected.

sensor

GSX14E/..

IGSU14E/..

Optical

145 0 IntegerT,1RW 1…100 2 Analog to parameter Ul-

Analysis

Depth

Optical

Auto-

146 0 BooleanT

, 1

LevelControl

(Tracking

Enable

Opt)

Timer Unit 192 0 BooleanT

, 1

Function

of Timer

193 0 UInte-

gerT, 1

Unit

trasonic Analysis Depth

RW 0, 255 255 Analog to parameter Ul-

trasonic Auto-Level-Control

RW 0, 255 0 0: time module not active

(off)

255: time module active

(on)

Time module: On (255)

activates the internal

time function.

The default settings are

device-dependent.

RW 0…3 2 0: Start-up delay

1: Switch-off delay

2: Pulse stretching

3: Pulse suppression

Function selection of the

switching delay. Activation of a suitable switching delay is possible. It is

not possible to combine

switching delays.

GSX14E/..

GSX14E/..

GSX14E/

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 11

Page 12

Functions configurable via IO-Link

Parameter

Index Sub-

index

Data

type,

octets

Time 194 0 UInte-

gerT, 2

Number of

Objects

Tempera-

195 0 UInte-

gerT, 4

220 0 IntegerT,2RO The device is equipped

ture

Access

Value

range

RW 1…

50000

RW 0…42

949672

95

De-

Explanation Valid for

fault

200 Definition of the time ba-

sis in 100µs increments,

configurable from 100µs

to 5000ms

0 Object counter: The de-

vice has an internal,

volatile object counter.

This counts the switching

events and can be freely

read out, edited and reset. This function enables a simple validation

of the process. As soon

as the object counter has

reached the maximum

end value, the count

process starts over again

at 0.

with an integrated temperature sensor for

transmitting the internal

temperature in 1/10°Celsius.

sensor

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Minus

Button

easyTune

Disable

Teach

Button

easyTune

Disable

227 0 BooleanT

, 1

230 0 BooleanT

, 1

RW 0, 255 0 easyTune function –

Manual fine tuning of the

switching threshold:

The sensitivity of the

sensor and, thus, the

switching threshold can

be adjusted with the

easyTune function,

which is in principle comparable to a potentiometer.

0: easyTune active

1: easyTune not active

RW 0, 255 0 Analog to parameter Mi-

nus button easyTune disable

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 12

Page 13

Functions configurable via IO-Link

Parameter

Minus

Button

Function

Level1

Index Sub-

index

Data

type,

Access

Value

range

octets

238 0 IntegerT,1RW -1, 0, 1,

2, 3, 7,

8, 15,

16, 21,

24, 27,

31

De-

Explanation Valid for

fault

-1, 8,27Assignment of teach

level 1 (2…7s) via the

minus button:

-1 = Disable

0 = Teach level not assigned

1 = easyTeach

2 = Manual teach

3 = Static teach

7 = Toggle button lock

(On/Off)

8 = Toggle method (ultrasonic/optical)

15 = easyTune Down

16 = easyTune Up

21 = Toggle logic (On/

Off)

24 = Toggle pulse

stretching (On/Off)

27 = Toggle ALC (AutoLevel-Control) (on/off)

31 = Toggle easyTeach

mode (intelligent/manual)

The value range and the

default setting are device

dependent.

sensor

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Minus

Button

Function

Level2

Minus

Button

Function

Level3

Teach

Button

Function

Level1

Teach

Button

Function

Level2

239 0 IntegerT,1RW -1, 0, 1,

2, 3, 7,

8, 15,

16, 21,

24, 27,

31

240 0 IntegerT,1RW -1, 0, 1,

2, 3, 7,

8, 15,

16, 21,

24, 27,

31

241 0 IntegerT,1RW -1, 0, 1,

2, 3, 7,

8, 15,

16, 21,

24, 27,

31

242 0 IntegerT,1RW -1, 0, 1,

2, 3, 7,

8, 15,

16, 21,

24, 27,

31

-1, 8,27Assignment of teach

level 2 (7…12s) via the

minus button:

Analog to parameter Mi-

nus Button Function

Level1

-1, 8,27Assignment of teach

level 3 (>12s) via the

minus button:

Analog to parameter Mi-

nus Button Function

Level1

-1, 8,27Assignment of teach

level 1 (2…7s) via the

teach button:

Analog to parameter Mi-

nus Button Function

Level1

-1, 8,27Assignment of teach

level 2 (7…12s) via the

teach button:

Analog to parameter Mi-

nus Button Function

Level1

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/…

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 13

Page 14

Functions configurable via IO-Link

Parameter

Teach

Button

Function

Level3

Pin4

function

Pin2

function

Index Sub-

index

Data

type,

Access

Value

range

octets

243 0 IntegerT,1RW -1, 0, 1,

2, 3, 7,

8, 15,

16, 21,

24, 27,

31

251 0 UInte-

gerT, 1

252 0 UInte-

gerT, 1

RW 0, 1, 2,

7, 8

RW 0, 1, 2,

7, 8

De-

Explanation Valid for

fault

-1, 8,27Assignment of teach

level 3 (>12s) via the

teach button:

Analog to parameter Mi-

nus Button Function

Level1

1 Assignment of pin4:

0 = No function

1 = SSC1

2 = SSC1 inverted

7 = Warning

8 = Warning inverted

The value range is device dependent.

2, 7 Assignment of pin2:

Analog to parameter Pin

4 function

The default settings are

device-dependent.

sensor

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/..

IGSU14E/..SD..

GSU14E/..

GSX14E/..

IGSU14E/

IGSU14E/..SD..

GSU14E/..

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 14

Page 15

Recipe management

3 Recipe management

General description

The forked sensors of the GSX14E/.., IGSU14E/.., IGSU14E/..SD.. as well as GSU14E/.. variant can be

used to realize recipe management by means of IO-Link. At the same time, up to 20 teach values can be

stored directly in the sensor and called up if necessary. As a result, the teach settings are stored in the sensor for 20 different label formats.

When changing a roll to a new label format, it is then possible to simply load the corresponding recipe without needing to perform a teach event. After calling up the recipe for the new label format, the sensor operates reliably with the teach value stored for that format. This eliminates the need to re-teach the sensor

when changing a roll to a different label format, and the format change is performed faster and more easily.

Tab.3.1: Parameters for recipe management

Index Parameter Action

99 Working Parameter Save current teach value after the teach event.

98 Working parameter

Storage location of the recipe (values 0…19)

load/save index

2 System command Value 226: Save work index

Save current teach value as recipe.

Value 227: Load work index

Load saved teach value as recipe.

The current teach value, which is saved after the teach event, is stored under parameter Working parame-

ter at index 99. It contains the taught switching threshold, the hysteresis and the used operating principle

for the label or web material that is to be detected.

The recipes are stored under parameter Working parameter load/save index at index 98.

New recipes are saved or existing recipes loaded via parameter System command at index 2.

Save current teach value as recipe

Ä Select the storage location of the recipe for the current teach value by writing a value from 0…19 in in-

dex98 (parameter Working parameter load/save index).

Ä Save the recipe in the selected storage location by writing value 226 (parameter Save work index) in in-

dex 2 (parameter System command).

Example:

1. Save teach value for label format A in storage location 3:

Write value 3 in index 98.

2. Save label format A as recipe at storage location 3:

Write value 226 in index 2.

If the sensor is taught to a new label format (e.g., label format B), the teach value for the new label format B

is again stored under parameter Working parameter at index 99. The teach value for label format A is still

available as a recipe in the sensor and can be reloaded if necessary.

Using the steps described above, up to 20 different recipes can be stored in the sensor.

Load saved teach value as recipe

Ä Select the storage location of the desired recipe by writing the corresponding value (0…19) in in-

dex98 (parameter Working parameter load/save index).

Ä Load the recipe form the selected storage location by writing value 227 (parameter Load work index) in

index 2 (parameter System command).

ð The recipe for label format A is thereby loaded with the corresponding teach value and active in the

sensor. The labels of this label format can be detected without reteaching the sensor.

Example:

1. Select recipe with the teach value for label format A from storage location 3:

Write value 3 in index 98.

2. Load selected recipe:

Write value 227 in index 2.

Leuze electronic GmbH + Co. KG GSX14E, GSU14E, IGSU14E, IGSU14E SD 15

Loading...

Loading...