Page 1

DDLS 548i

Optical Data Transmission for 100 Mbit/s

Ethernet

EN 2016/11 - 50134750

We reserve the right to

make technical changes

O r i g i n a l o p e r a t i n g i n s t r u c t i o n s

Page 2

© 2016

Leuze electronic GmbH & Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic DDLS 548i 2

Page 3

Table of contents

Table of contents

1 About this document ............................................................................................6

1.1 Used symbols and signal words .............................................................................................6

2 Safety .....................................................................................................................8

2.1 Intended use ...........................................................................................................................8

2.2 Foreseeable misuse ............................................................................................................... 8

2.3 Competent persons ................................................................................................................ 9

2.4 Disclaimer ...............................................................................................................................9

2.5 Laser safety notices................................................................................................................ 9

3 Device description ..............................................................................................12

3.1 Device overview.................................................................................................................... 12

3.1.1 General information...........................................................................................................12

3.1.2 Protocol-specific characteristics of the DDLS548i............................................................ 14

3.1.3 Performance characteristics and delivery options............................................................. 14

3.1.4 Accessories .......................................................................................................................14

3.1.5 Operating principle ............................................................................................................15

3.2 Connection technology .........................................................................................................15

3.3 Indicators and operational controls....................................................................................... 15

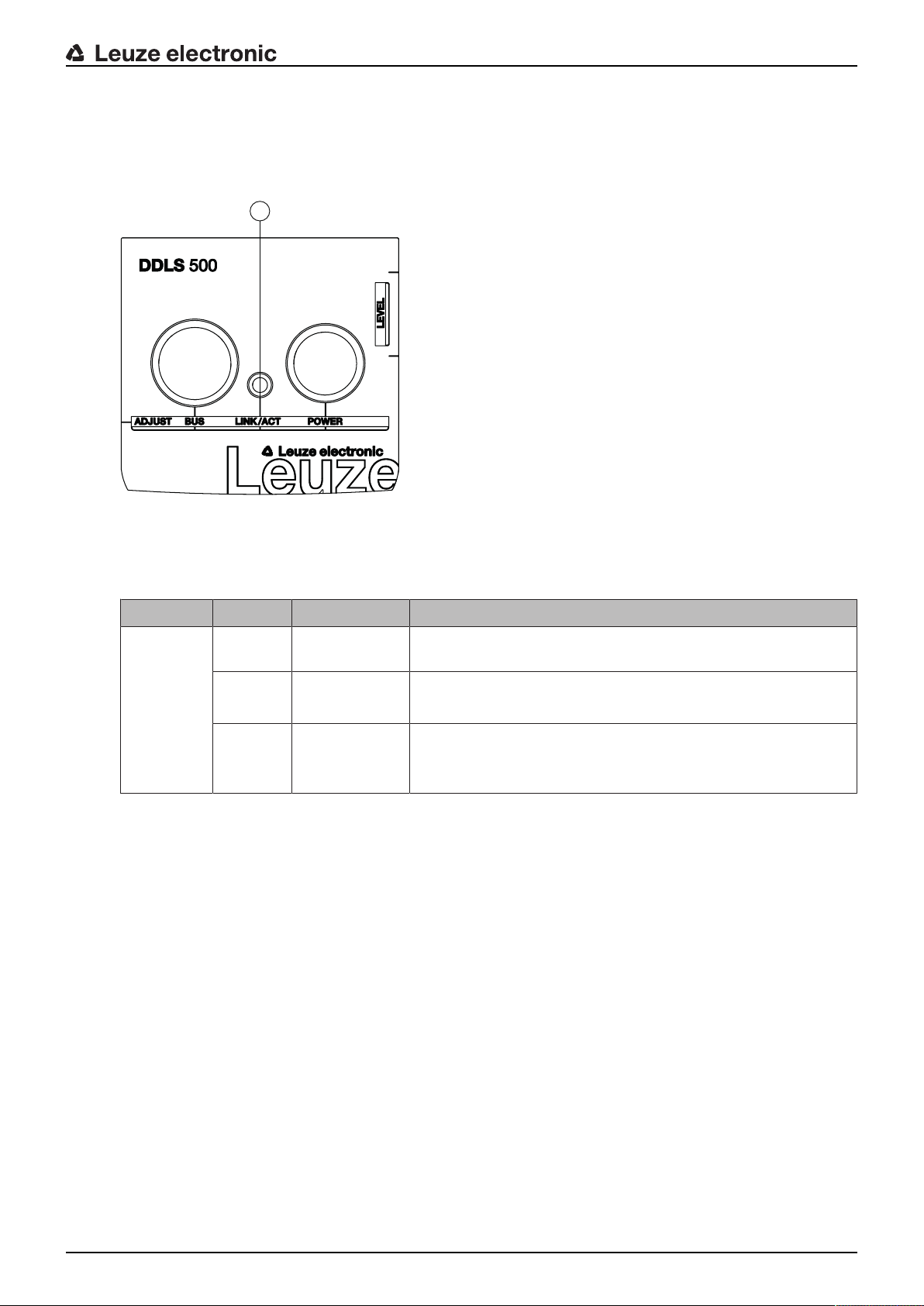

3.3.1 Indicators and operational controls in the control panel ....................................................15

3.3.2 Indicators in the optics area ..............................................................................................22

3.3.3 Indicators in the connection area ......................................................................................23

4 Mounting..............................................................................................................24

4.1 Mounting instructions............................................................................................................ 24

4.2 Mounting with alignment laser and level............................................................................... 24

4.2.1 Horizontal mounting (travel axis) with the alignment laser ................................................25

4.2.2 Vertical mounting (lifting axis) with the alignment laser..................................................... 30

4.3 Mounting without alignment laser .........................................................................................32

4.3.1 Horizontal mounting (travel axis) without alignment laser .................................................32

4.3.2 Vertical mounting (lifting axis) without alignment laser...................................................... 33

4.4 Mounting tolerances of the devices ......................................................................................34

4.5 Mounting distance for parallel operation of data transmission systems ............................... 35

4.6 Mounting distance for parallel operation with AMS300/AMS200 laser measurement sys-

tems ......................................................................................................................................37

4.7 Mounting distance for parallel operation with DDLS200 data transmission system ............37

4.8 Cascading (series connection) of multiple data transmission systems................................. 38

5 Electrical connection..........................................................................................39

5.1 Overview............................................................................................................................... 39

5.2 POWER (supply voltage / switching input and switching output) ......................................... 40

5.3 BUS (bus input, Ethernet)..................................................................................................... 41

6 Starting up the device ........................................................................................42

6.1 Setting the operating mode................................................................................................... 42

6.2 Fine adjustment ....................................................................................................................44

6.2.1 General procedure ............................................................................................................44

6.2.2 Fine adjustment with the single-handed adjustment (SHA) process................................. 44

6.2.3 Fine adjustment without the single-handed adjustment (SHA) process............................ 45

Leuze electronic DDLS 548i 3

Page 4

Table of contents

7 PROFINET............................................................................................................47

7.1 Configuring the PROFINET interface ................................................................................... 47

7.1.1 PROFINET‑communication profile ..................................................................................47

7.1.2 Conformance Classes .......................................................................................................48

7.1.3 DDLS548i single-port device............................................................................................ 48

7.2 Starting the device ................................................................................................................50

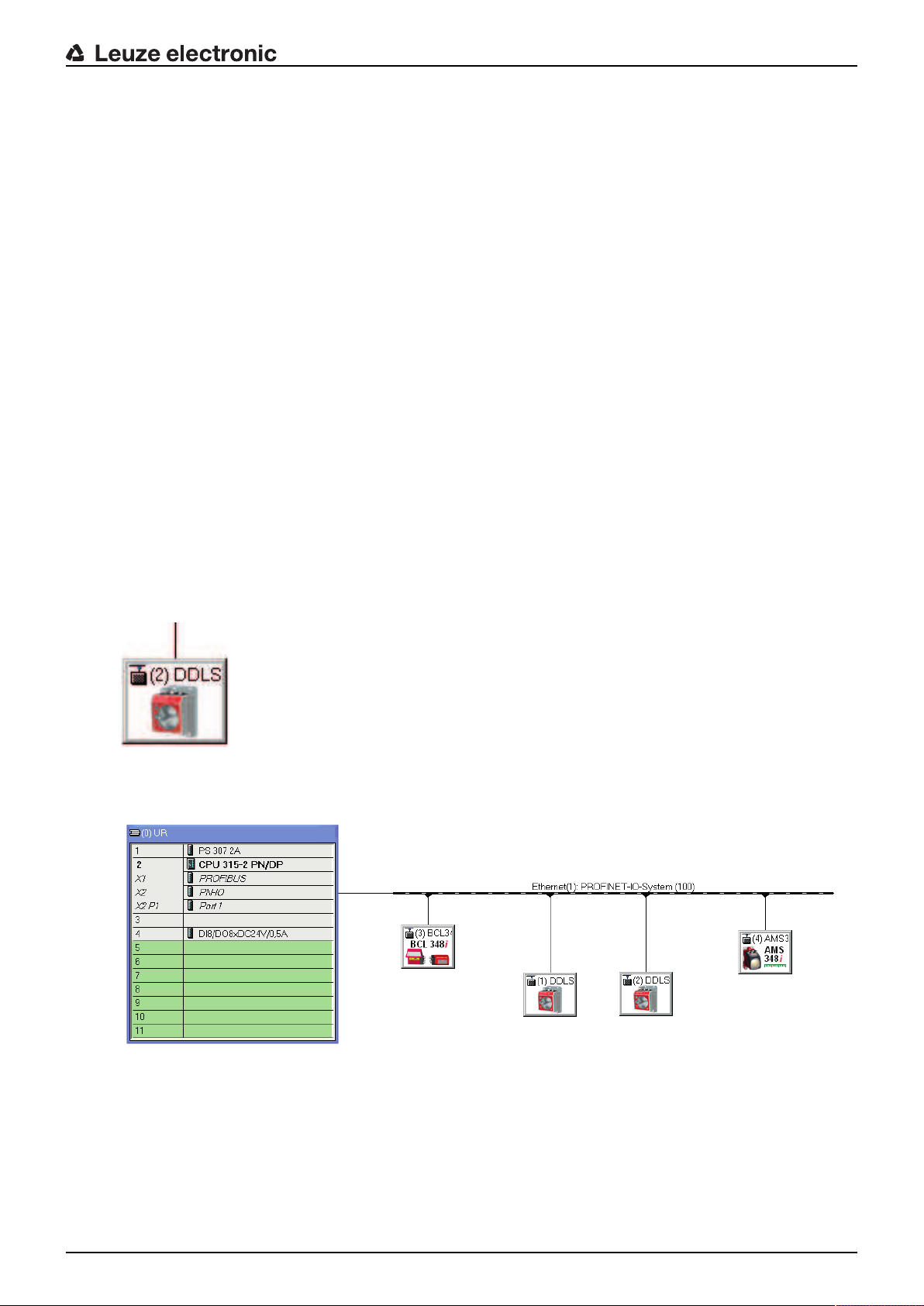

7.3 Configuring for the Siemens SIMATIC-S7 control ................................................................50

7.4 PROFINET project modules .................................................................................................52

7.4.1 Overview of the modules................................................................................................... 53

7.4.2 DAPmodule ......................................................................................................................53

7.4.3 Module 1 – Communication status and control .................................................................54

7.4.4 Module 2 – Link Loss Counter (LLC)................................................................................. 55

7.4.5 Module 3 – reception quality .............................................................................................55

7.4.6 Module60–Device status ................................................................................................56

8 Diagnostics and troubleshooting......................................................................57

8.1 Error displays of the operating state LEDs ...........................................................................57

8.2 Error displays and STATUS LED for remote diagnosis ........................................................60

8.3 Error displays of the operating mode LEDs ..........................................................................60

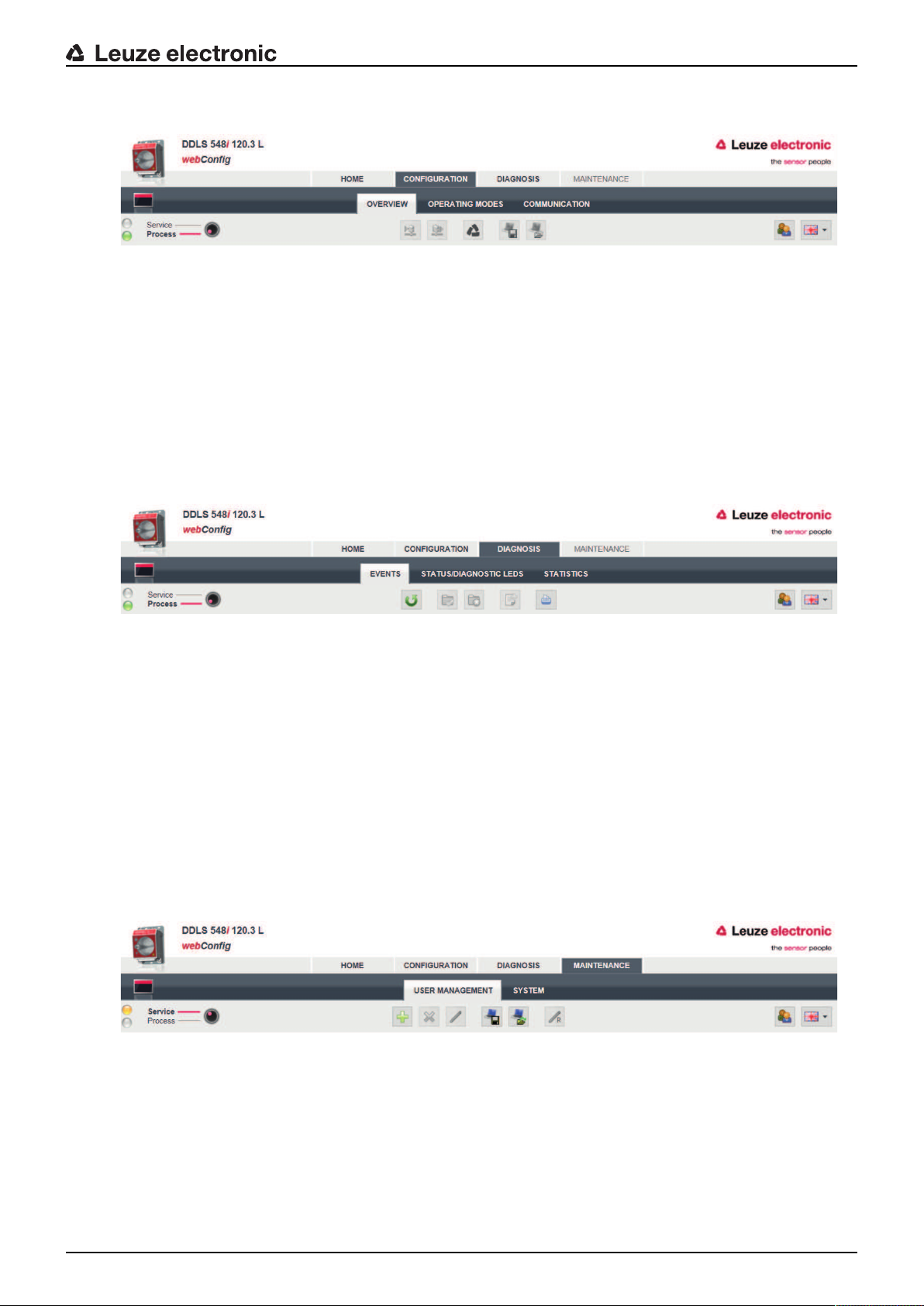

9 Leuzeelectronic webConfig tool–Remote maintenance...............................62

9.1 System requirements............................................................................................................ 62

9.2 Working with the webConfig tool .......................................................................................... 62

9.2.1 Electrical connection for the webConfig tool .....................................................................63

9.2.2 MAC address..................................................................................................................... 63

9.2.3 IP addresses .....................................................................................................................64

9.2.4 Start webConfig tool ..........................................................................................................65

9.3 Short description of the webConfigtool ................................................................................65

9.3.1 Process mode and service mode ......................................................................................65

9.3.2 Notes and language change .............................................................................................66

9.3.3 HOME................................................................................................................................ 66

9.3.4 CONFIGURATION ............................................................................................................67

9.3.5 DIAGNOSIS ......................................................................................................................67

9.3.6 MAINTENANCE ................................................................................................................67

10 Care, maintenance and disposal .......................................................................68

10.1 Cleaning................................................................................................................................ 68

10.2 Servicing ...............................................................................................................................68

10.3 Disposing ..............................................................................................................................68

11 Service and support ...........................................................................................69

11.1 What to do should servicing be required? ............................................................................ 69

12 Technical data .....................................................................................................70

12.1 General specifications .......................................................................................................... 70

12.1.1 Device without heater........................................................................................................70

12.1.2 Device with heating ...........................................................................................................72

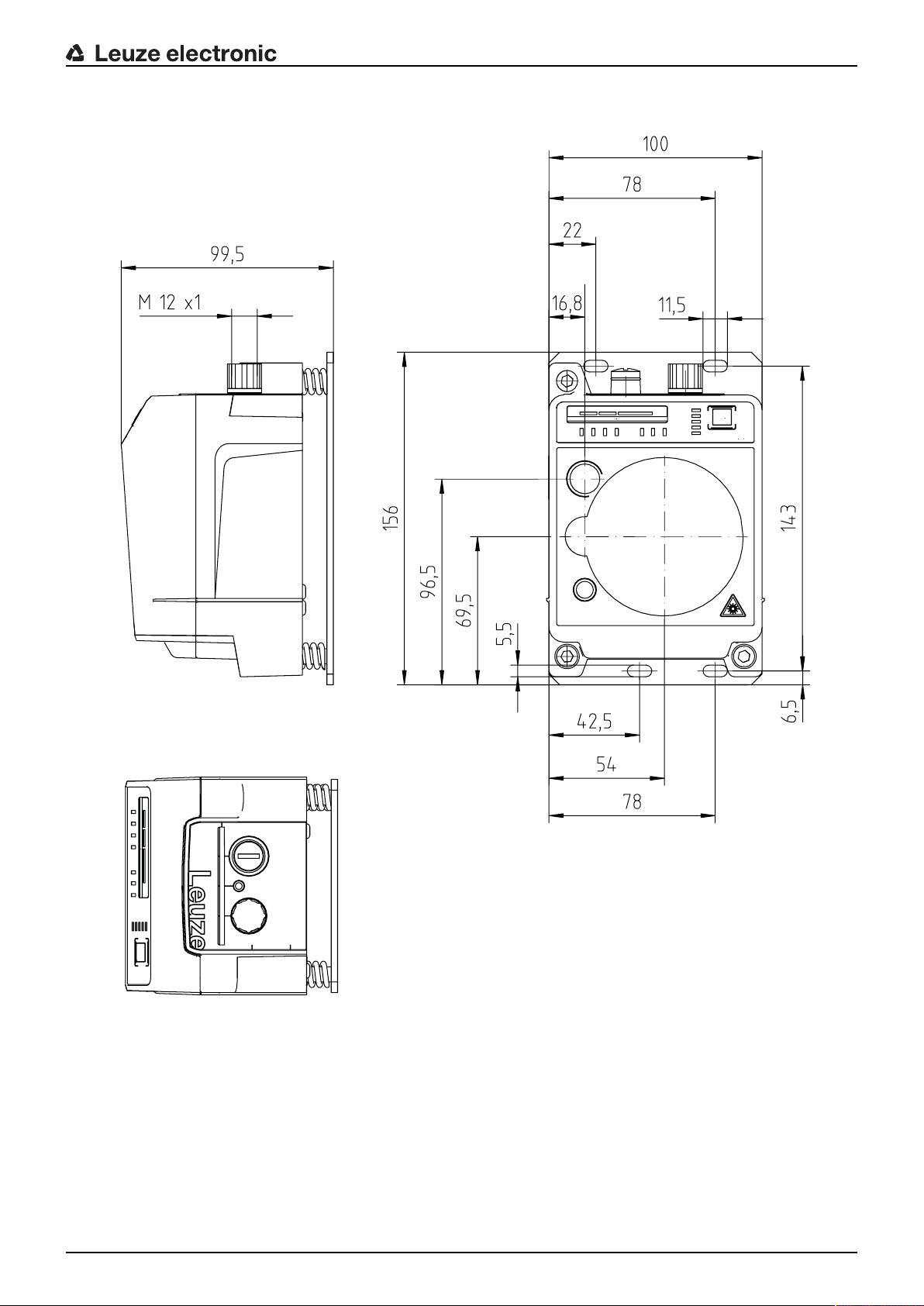

12.2 Dimensioned drawings ......................................................................................................... 73

12.3 Dimensional drawings: Accessories .....................................................................................75

13 Order guide and accessories.............................................................................76

13.1 Nomenclature ....................................................................................................................... 76

13.2 Cables accessories............................................................................................................... 76

13.3 Other accessories................................................................................................................. 77

Leuze electronic DDLS 548i 4

Page 5

Table of contents

14 EC Declaration of Conformity ............................................................................78

Leuze electronic DDLS 548i 5

Page 6

1 About this document

1.1 Used symbols and signal words

Tab.1.1: Warning symbols and signal words

Symbol indicating dangers to persons

Symbol indicating dangers from harmful laser radiation

Symbol indicating possible property damage

NOTE Signal word for property damage

Indicates dangers that may result in property damage if the measures for

danger avoidance are not followed.

CAUTION Signal word for minor injuries

Indicates dangers that may result in minor injury if the measures for danger

avoidance are not followed.

About this document

WARNING Signal word for serious injury

Indicates dangers that may result in severe or fatal injury if the measures

for danger avoidance are not followed.

Tab.1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

Symbol for action steps

Text passages with this symbol instruct you to perform actions.

Symbol for action results

Text passages with this symbol describe the result of the preceding action.

Leuze electronic DDLS 548i 6

Page 7

About this document

Tab.1.3: Terms and abbreviations

DAP Device Access Point

DCP Discovery and Configuration Protocol

DDLS Optical transceiver for digital data transmission

EN European standard

FE Functional earth

GSD Generic Station Description

GSDML Generic Station Description Markup Language

IO or I/O Input/Output

IP address Network address, which is based on the Internet Protocol (IP)

MAC address Media Access Control address; hardware address of a device in the net-

work

NEC National Electric Code; safety standard for electrical installations in the

U.S.A.

PELV Protective Extra-Low Voltage; protective extra-low voltage with reliable dis-

connection

HBS High-bay storage device

SHA Single-Handed Adjustment; fine adjustment of the devices by one person

TCP/IP Transmission Control Protocol/Internet Protocol; Internet protocol family

UDP User Datagram Protocol; network transmission protocol

UL Underwriters Laboratories

Web server Software for processing information via an Internet browser

Leuze electronic DDLS 548i 7

Page 8

2 Safety

This optical data transmission system was developed, manufactured and tested in line with the applicable

safety standards. It corresponds to the state of the art.

2.1 Intended use

Devices of the DDLS500 series have been designed and developed for the optical transmission of data in

the infrared range.

Areas of application

Devices of the DDLS500 series are designed for the following areas of application:

• Data transmission between stationary and/or moving devices. The devices must – with respect to the

transmission beam spread - be positioned opposite one another without interruption. A data transmission path consists of two devices designated with “FrequencyF3" and “FrequencyF4".

• Data transmission between two mutually opposing devices, whereby each device can rotate 360°. The

middle axes of the receiver lenses must – with respect to the transmission beam spread – be positioned opposite one another without interruption during the rotation.

For rotary transmission, a minimum distance of 500mm is necessary between the two devices.

NOTICE

For information about possible restrictions regarding the transmission of special protocols see

chapter 3.1.2 "Protocol-specific characteristics of the DDLS548i".

Safety

CAUTION

Observe intended use!

The protection of personnel and the device cannot be guaranteed if the device is operated in a

manner not complying with its intended use.

Ä Only operate the device in accordance with its intended use.

Ä LeuzeelectronicGmbH+Co.KG is not liable for damages caused by improper use.

Ä Read these operating instructions before commissioning the device. Knowledge of the oper-

ating instructions is an element of proper use.

NOTICE

Comply with conditions and regulations!

Ä Observe the locally applicable legal regulations and the rules of the employer's liability insur-

ance association.

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is considered improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• for medical purposes

NOTICE

Do not modify or otherwise interfere with the device!

Ä Do not carry out modifications or otherwise interfere with the device. The device must not be

tampered with and must not be changed in any way.

Ä The device must not be opened. There are no user-serviceable parts inside.

Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Leuze electronic DDLS 548i 8

Page 9

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the original operating instructions of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant standards

and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Disclaimer

LeuzeelectronicGmbH+Co.KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

Safety

2.5 Laser safety notices

Laser diode of the transmitter – laser class 1M

WARNING

INVISIBLE LASER RADIATION – LASER CLASS 1M

Never observe directly using telescope optics!

The device fulfills the IEC60825-1:2007 (EN60825-1:2007) requirements for a product in laser

class1M as well as the U.S.21CFR1040.10 regulations with deviations corresponding to

"Laser Notice No.50" from June 24th, 2007.

Ä Looking into the beam path for extended periods using telescope optics may damage the

eye's retina. Never look using telescope optics into the laser beam or in the direction of reflecting beams.

Ä CAUTION! The use of operating or adjusting devices other than those specified here or car-

rying out of differing procedures may lead to dangerous exposure to radiation.

The use of optical instruments or devices (e.g., magnifying glasses, binoculars) with the

product will increase eye danger.

Ä Observe the applicable statutory and local laser protection regulations.

Ä The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

The device emits invisible laser radiation with a wavelength of 785nm (device with designation “FrequencyF3") or 852nm (device with designation “FrequencyF4") through the laser aperture of the optical

window. The opening angle of the beam cone is ≤1° (± 0.5°).

The power density distribution in the light spot is homogeneous; there is no elevation of power density in

the center of the light spot. The average emitted laser power of the device is <12mW. For transmission of

the data, the emitted laser radiation is amplitude modulated (on-off keying). Pulses and pulse pauses of the

emitted laser light are between 8ns and 32ns long. The laser power emitted during the pulses is <24mW.

Leuze electronic DDLS 548i 9

Page 10

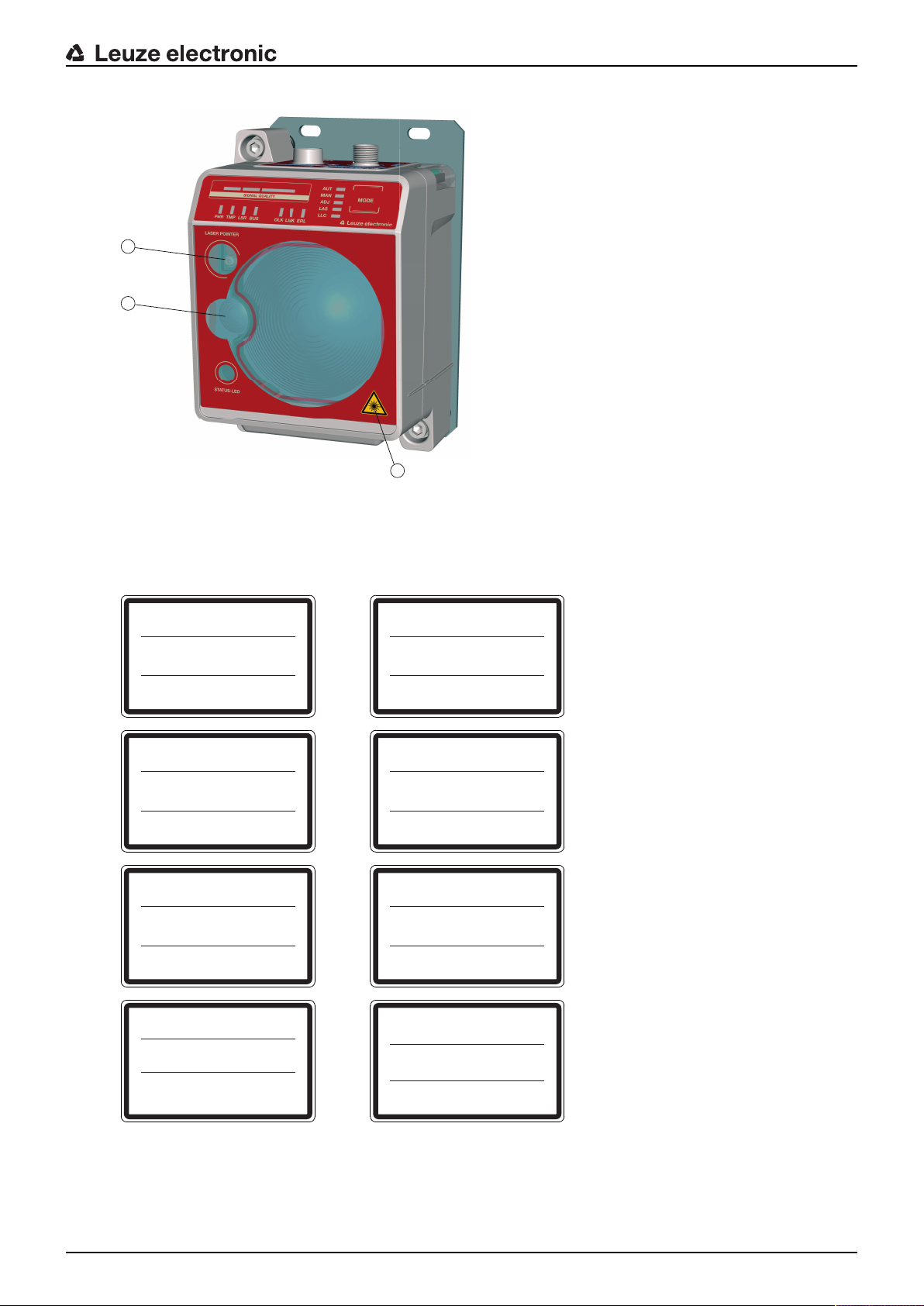

1

2

3

1 Laser aperture – alignment laser

UNSICHTBARE LASERSTRAHLUNG

Nicht direkt mit Teleskopoptiken betrachten!

LASER KLASSE 1M

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER INVISIBILE

Non guardare direttamente con ottiche telescopiche!

APARRECCHIO LASER DI CLASSE 1M

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

< 36 mW

32

n

s

785 nm

< 36 mW

32 ns

785 nm

INVISIBLE LASER RADIATION

Never observe directly using telescope optics!

CLASS 1M LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER INVISIBLE

Ne pas regarder directement avec des optiques télescopiques !

APPAREIL À LASER DE CLASSE 1M

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulse:

Longueur d`ande émis:

< 36 mW

32 ns

785 nm

< 36 mW

32 ns

785 nm

RADIACIÓN LÁSER INVISIBLE

¡No mirar directamente con ópticas telescópicas!

PRODUCTO LÁSER DE CLASE 1M

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIACAO LASER INVISIVEL

Não olhe diretamente para as óticas telescópicas!

EQUIPAMENTO LASER CLASSE 1M

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

< 36 mW

32

n

s

785 nm

< 36 mW

32

n

s

785 nm

INVISIBLE LASER RADIATION

Never observe directly using telescope optics!

CLASS 1M LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (avg):

Pulse duration:

Wavelength:

⺞㉒匘䧋䦚ₜⒿ䤓䉏⏘⺓兎

䰐㷱抩扖㦪扫柫屑䦚

1M伊䉏⏘ℶ❐

GB7247.1-2001

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

< 36 mW

32

n

s

785 nm

< 36 mW

32 ns

785 nm

2 Laser aperture – transmitter

3 Laser warning sign

Safety

Fig.2.1: Laser apertures

Leuze electronic DDLS 548i 10

Fig.2.2: Laser warning and laser information signs for devices with frequencyF3

Page 11

Safety

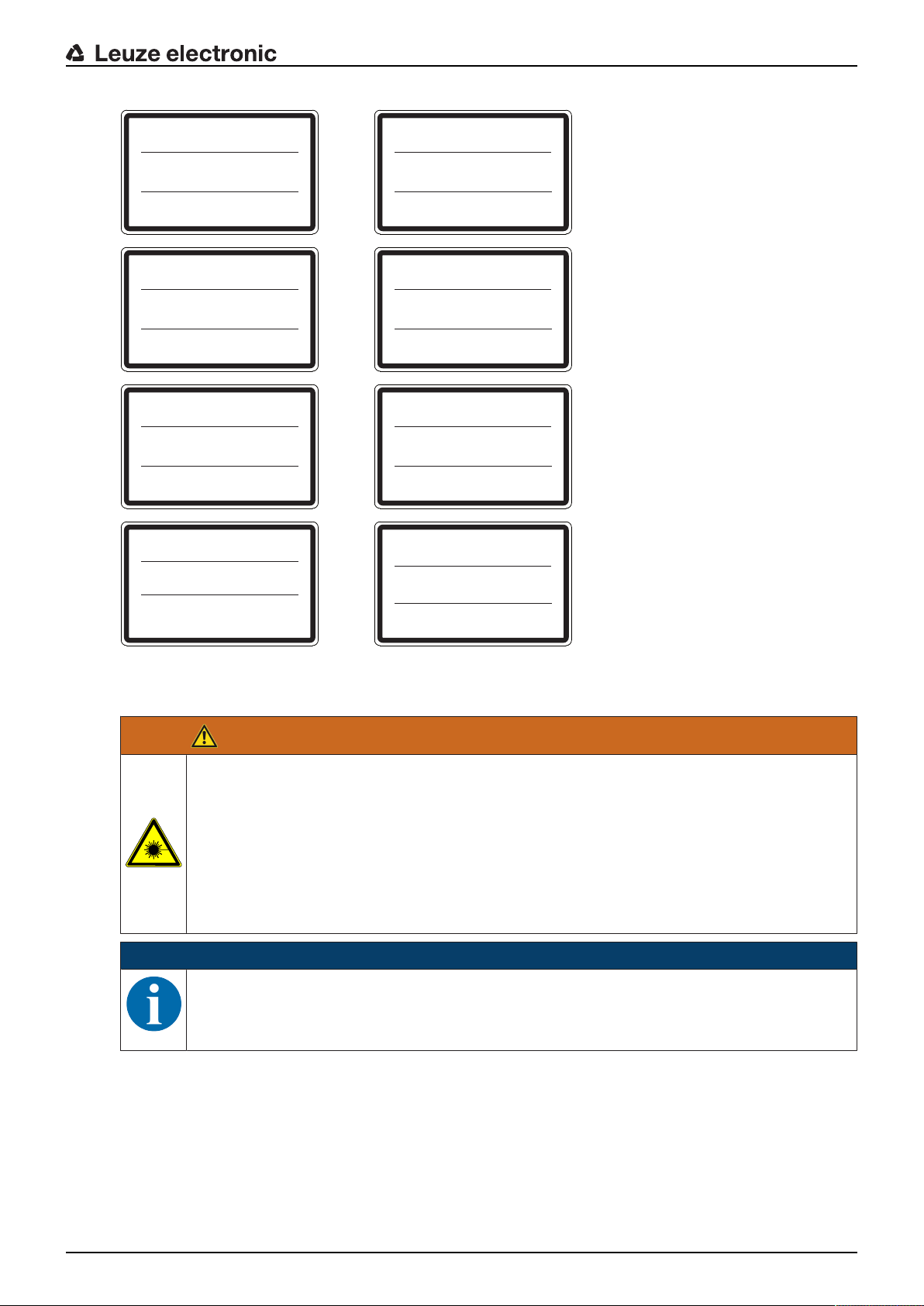

UNSICHTBARE LASERSTRAHLUNG

Nicht direkt mit Teleskopoptiken betrachten!

LASER KLASSE 1M

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER INVISIBILE

Non guardare direttamente con ottiche telescopiche!

APARRECCHIO LASER DI CLASSE 1M

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

< 36 mW

32

n

s

852 nm

< 36 mW

32 ns

852 nm

INVISIBLE LASER RADIATION

Never observe directly using telescope optics!

CLASS 1M LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER INVISIBLE

Ne pas regarder directement avec des optiques télescopiques !

APPAREIL À LASER DE CLASSE 1M

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulse:

Longueur d`ande émis:

< 36 mW

32 ns

852 nm

< 36 mW

32 ns

852 nm

RADIACIÓN LÁSER INVISIBLE

¡No mirar directamente con ópticas telescópicas!

PRODUCTO LÁSER DE CLASE 1M

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIACAO LASER INVISIVEL

Não olhe diretamente para as óticas telescópicas!

EQUIPAMENTO LASER CLASSE 1M

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

< 36 mW

32

n

s

852 nm

< 36 mW

32

n

s

852 nm

INVISIBLE LASER RADIATION

Never observe directly using telescope optics!

CLASS 1M LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (avg):

Pulse duration:

Wavelength:

⺞㉒匘䧋䦚ₜⒿ䤓䉏⏘⺓兎

䰐㷱抩扖㦪扫柫屑䦚

1M伊䉏⏘ℶ❐

GB7247.1-2001

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

< 36 mW

32

n

s

852 nm

< 36 mW

32 ns

852 nm

Fig.2.3: Laser warning and laser information signs for devices with frequencyF4

Alignment laser (optional) – laser class 1

WARNING

LASER RADIATION – LASER CLASS 1

The device satisfies the requirements of IEC60825-1:2007 (EN60825-1:2007) safety regulations for a product of laser class1 as well as the U.S.21CFR1040.10 regulations with deviations corresponding to "Laser Notice No.50" from June 24, 2007.

Ä Observe the applicable statutory and local laser protection regulations.

Ä The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG.

NOTICE

Devices with integrated alignment laser can be identified by part number code L in the part designation, e.g., DDLS5xxXXX.4L.

Laser class1M also applies for devices with integrated alignment laser.

Leuze electronic DDLS 548i 11

Page 12

3 Device description

3.1 Device overview

3.1.1 General information

The DDLS548i optical data transmission system transmits Ethernet network data on the basis of TCP/IP or

UDP transparently and without contact or wear via infrared light.

NOTICE

The DDLS548i devices are designed as PROFINET participants. During commissioning, the

devices are configured with a “name” during device naming as well as the corresponding IP address. Using standardized GSDML structures, the DDLS548i can itself supply information about

the device to the control (see chapter 7 "PROFINET").

A transmission path consists of two mutually opposing devices.

• One device is designated with “Frequency F3", the other with “Frequency F4".

• The devices can also be assigned via part number code DDLS5XX…3… and DDLS5XX…4….

Each device is delivered with an individual MAC address. The MAC address can be found on the name

plate and on an easily removable "Address Link Label” (see chapter 9.2.2 "MAC address") that is also attached to the device.

The devices are equipped with a web server for remote diagnosis.

Device description

Leuze electronic DDLS 548i 12

Page 13

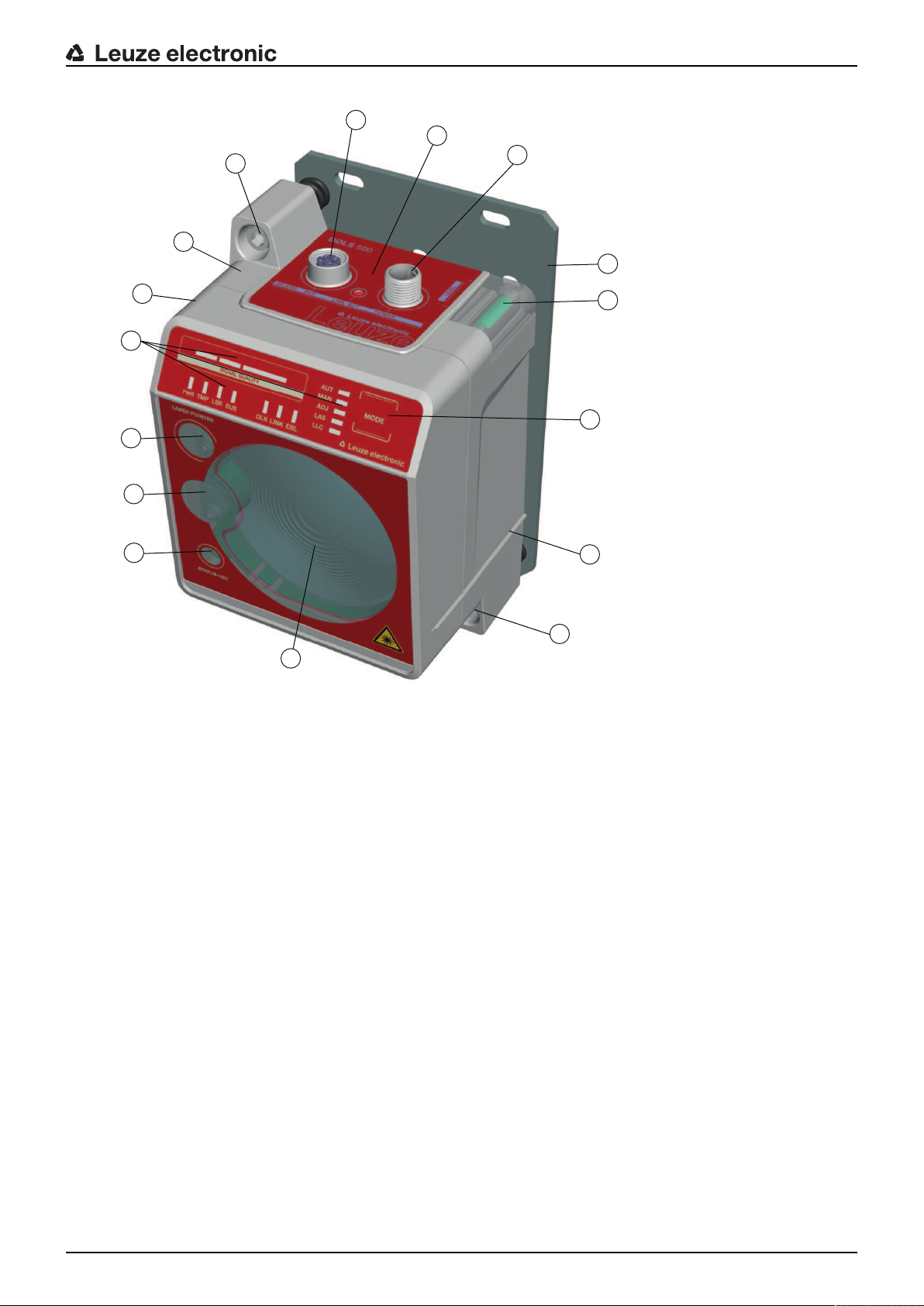

Device description

14

3

4

5

13

6

7

2

8

10

1

11

9

16

15

12

1 Device housing 9 Connection area

2 Mounting plate 10 Operating mode selector switch

3 Planar surface for supporting a bubble level or

alignment straightedge

4 Receiver optics 12 Alignment screw for horizontal alignment

5 Transmitter optics 13 STATUS LED for remote diagnosis

6 Alignment laser for mounting support (optional) 14 Supporting edge for bubble level or alignment straight-

7 LED indicators in the control panel 15 Ethernet connection, M12

8 Spirit level (for devices with alignment laser) 16 POWER connection, M12

Fig.3.1: Device construction

11 Alignment screw for vertical alignment

edge

Leuze electronic DDLS 548i 13

Page 14

3.1.2 Protocol-specific characteristics of the DDLS548i

The integrated switch to the web server of the DDLS548i for remote diagnosis can lead to restricted performance with some TCP/IP or UDP protocols.

It is particularly important for the user to check the usability of the DDLS548i for the following data transmission scenarios:

• Transmissions that make extremely high demands of real time

• Transmissions with extremely narrow specifications with regard to particular protocol architecture, delay

times and jitter tolerances.

NOTICE

Transmission problems with TCP/IP and UDP protocols!

It is the user's decision whether the DDLS548i is usable. LeuzeelectronicGmbH+Co.KG cannot accept any liability for any transmission problems that occur which are attributable to the

above-mentioned causes.

The following TCP/IP and UDP protocols must be checked individually. The list does not claim to be complete.

• PROFINET Profisafe

• PROFINET IRT

• All safety protocols

• The DDLS548i cannot be used in EtherCat networks.

Device description

3.1.3 Performance characteristics and delivery options

• Status information on the DDLS548i available in the control

• Protocol-independent data transmission of all TCP/IP and UDP protocols, e.g.

• PROFINET RT

• EthernetIP (Rockwell)

• …and more

• Data transmission over a range of up to 200m

• Optional alignment laser including spirit level for mounting support

• Planar surfaces on top and side for supporting a level or alignment straightedge

• Single-handed adjustment (SHA) for aligning the devices by one person

• Optional variants with integrated heating for operating temperatures below -5°C

Use to ‑35°C

• Transmission optics with larger beam spread on request

3.1.4 Accessories

For exact details and order information, see chapter 13 "Order guide and accessories".

• Adapter plate for installing instead of a DDLS200

• Ready-made cable for M12 connections

• Customizable connector plug

Leuze electronic DDLS 548i 14

Page 15

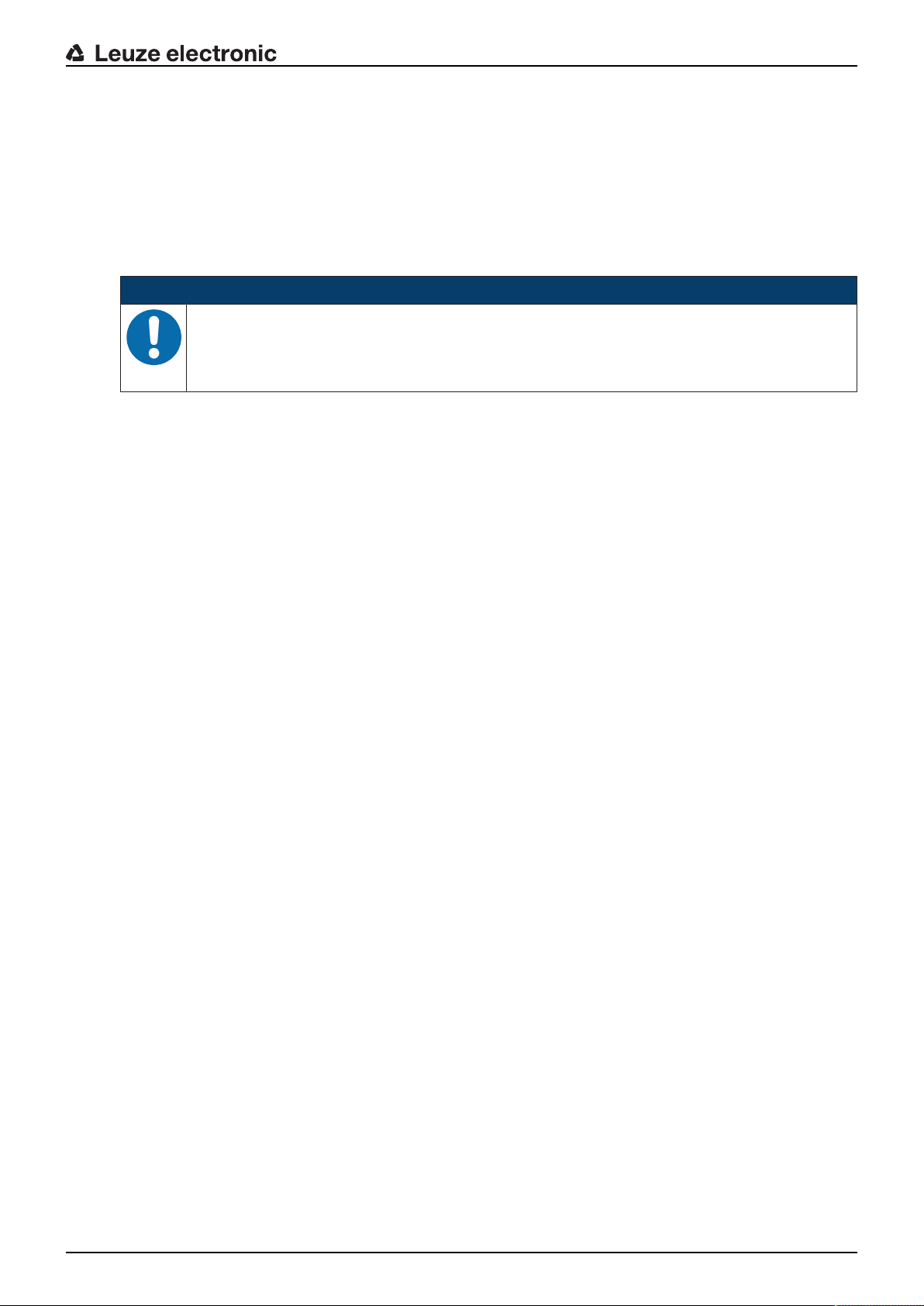

3.1.5 Operating principle

1

2

34

A pair of devices is necessary for establishing a data transmission path. To prevent the devices from mutually interfering with one another during data transmission, they use different frequencies.

• one device with frequency F3

Part designation: DDLS5XXxxx.3YY

Designation on the name plate: FrequencyF3

• one device with frequency F4

Part designation: DDLS5XXxxx.4YY

Designation on the name plate: FrequencyF4

NOTICE

Installation for devices with an operating range of 200m.

Ä Always install the Frequency F4 device as stationary device for devices with an operating

range of 200m (DDLS5XX200…).

Device description

1 Device with frequency F3 (DDLS5XXxxx.3YY)

2 Device with frequency F4 (DDLS5XXxxx.4YY)

3 FrequencyF3

4 FrequencyF4

Fig.3.2: Optical data transmission on two frequencies

The received signal level (SIGNALQUALITY) is measured on both devices. If the received signal level

drops below a certain value (SIGNALQUALITY indicator shows only red and orange), the intensity warning

is activated.

The intensity warning is applied on switching output IO1 of the POWER connection.

3.2 Connection technology

A-coded, M12 connection for the supply voltage with integrated switching input and output.

D-coded, M12 connection for the Ethernet connection.

3.3 Indicators and operational controls

3.3.1 Indicators and operational controls in the control panel

Operating mode selector switch and operating mode indicator

• Operating mode selector switch [MODE]

The operating mode selector switch is used to switch between the operating modes of the device (see

chapter 6 "Starting up the device").

• Operating mode LEDs AUT, MAN, ADJ, LAS, LLC

The operating mode LEDs indicate the active operating mode.

Leuze electronic DDLS 548i 15

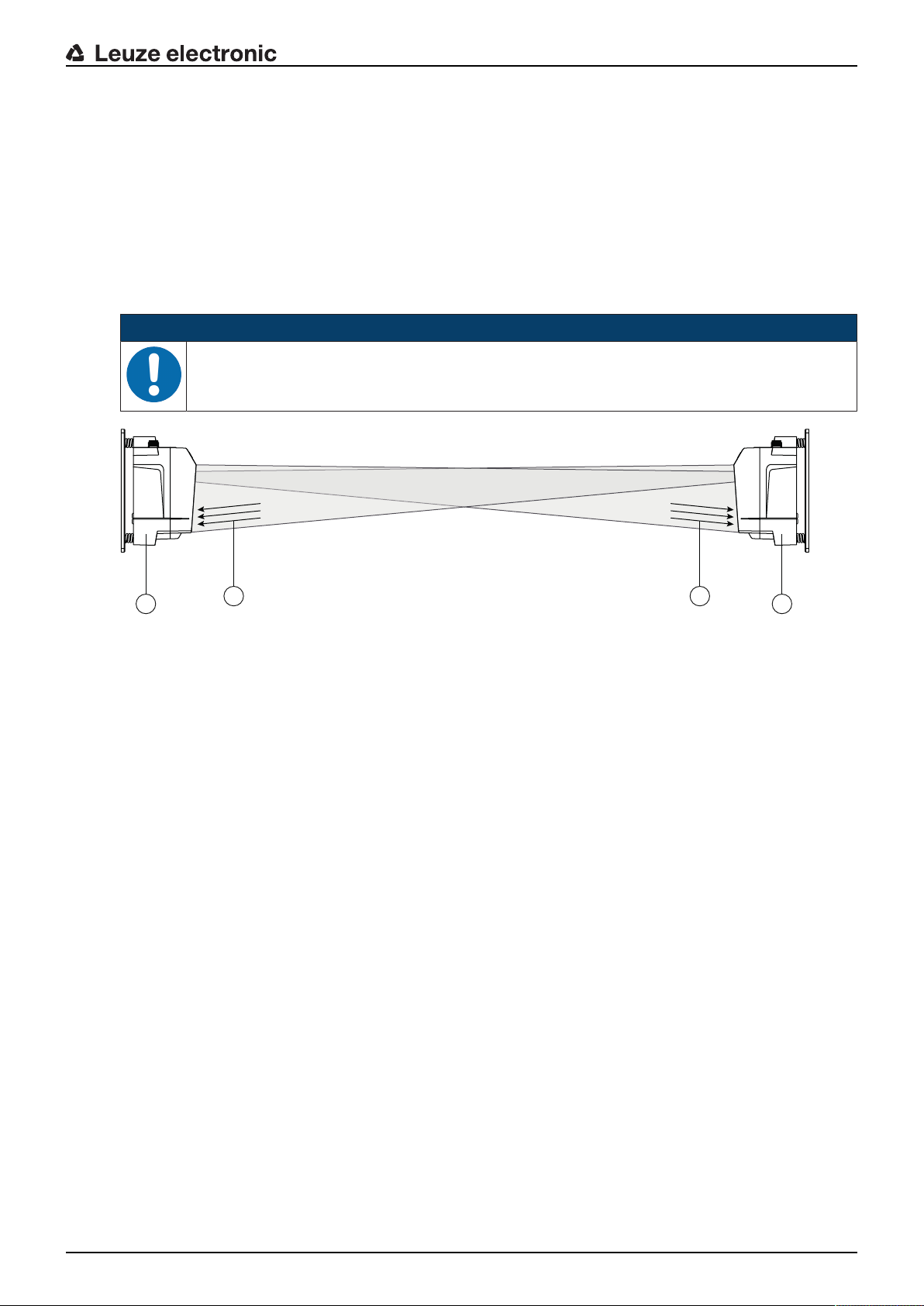

Page 16

4 5

1

2 63

1 AUT – Automatic

2 MAN – Manual

3 ADJ – Adjust

4 LAS – Alignment laser for mounting support

5 LLC – LinkLossCounter

6 MODE – Operating mode selector switch

Device description

Fig.3.3: Operating mode LEDs and operating mode selector switch

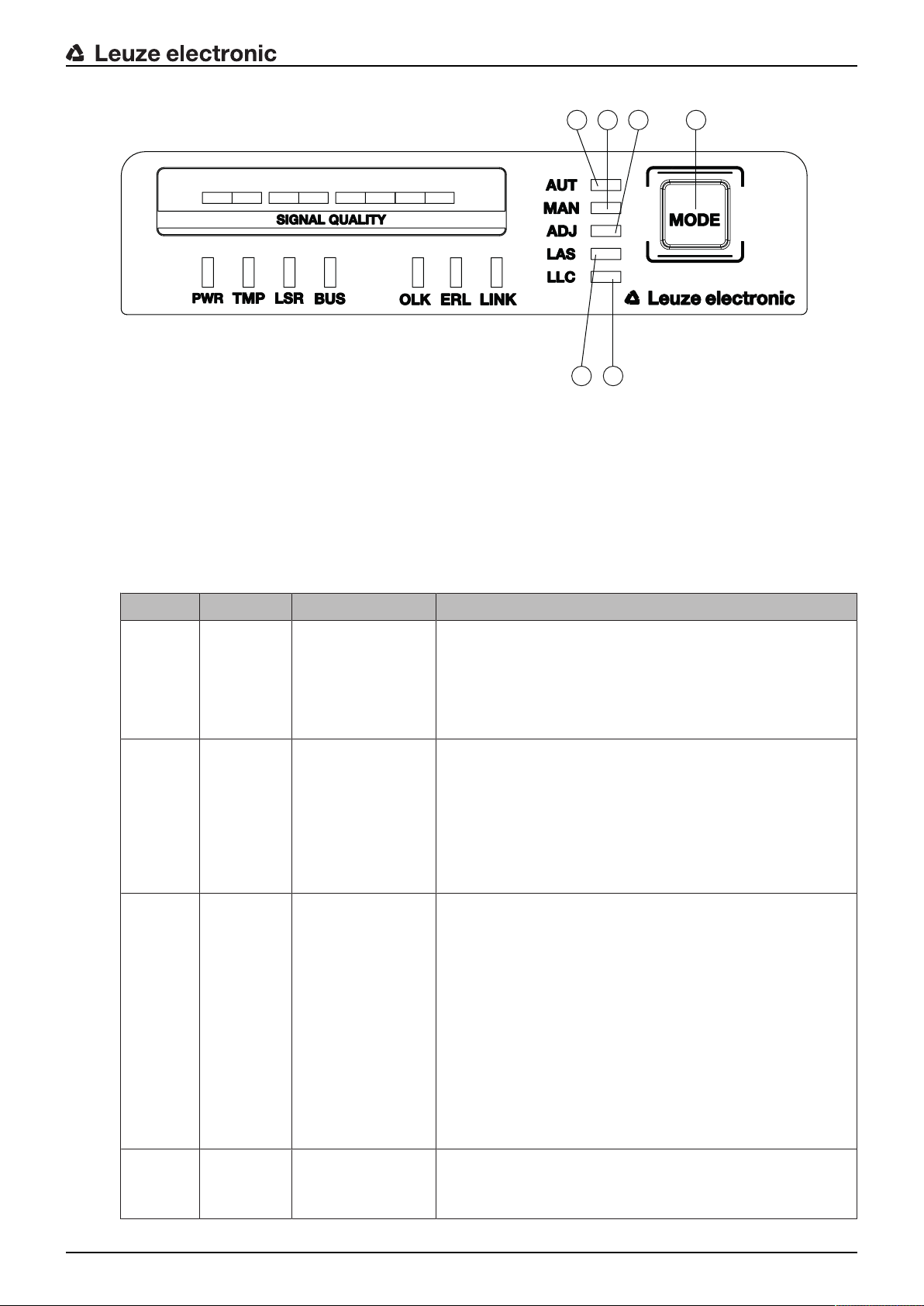

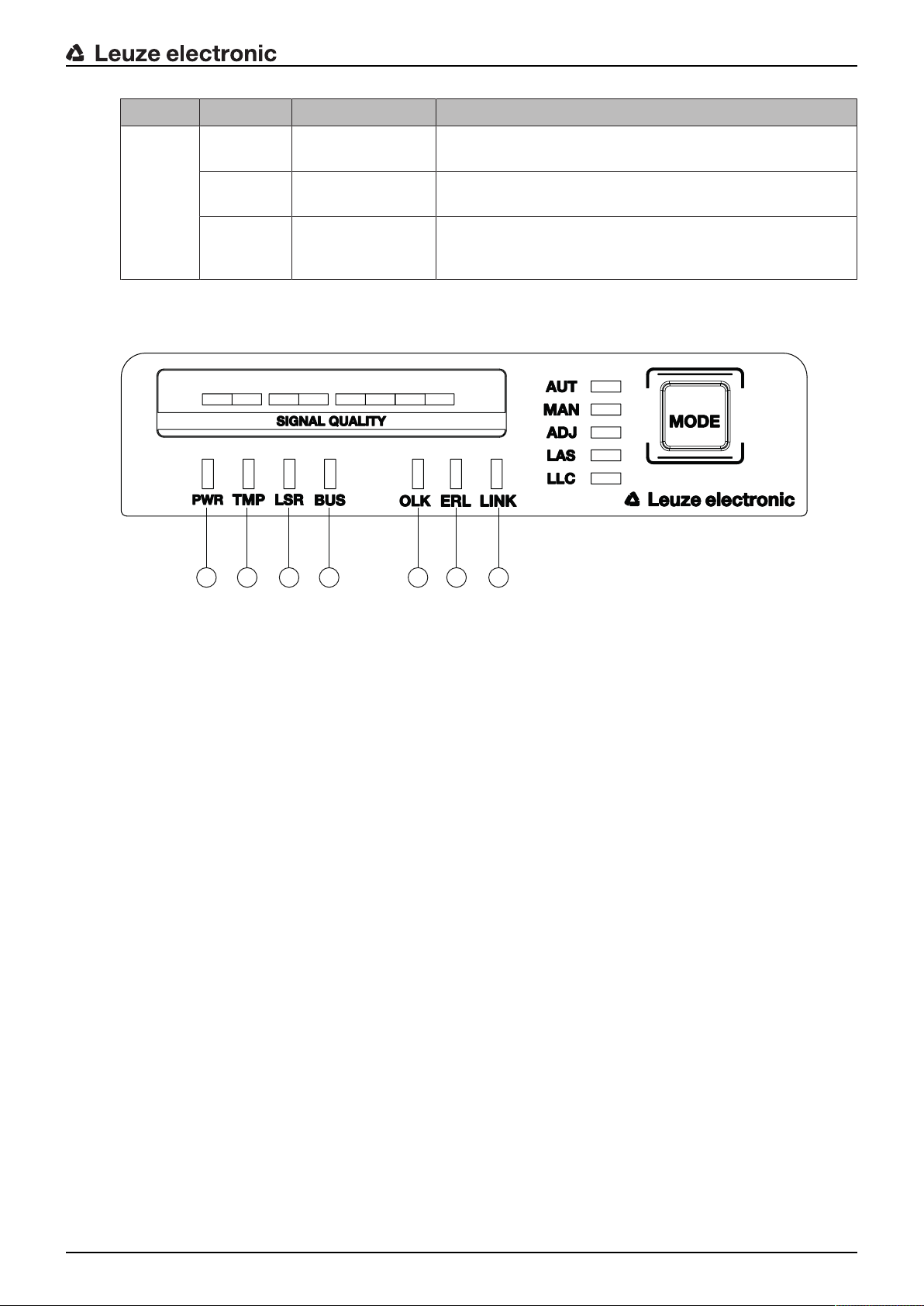

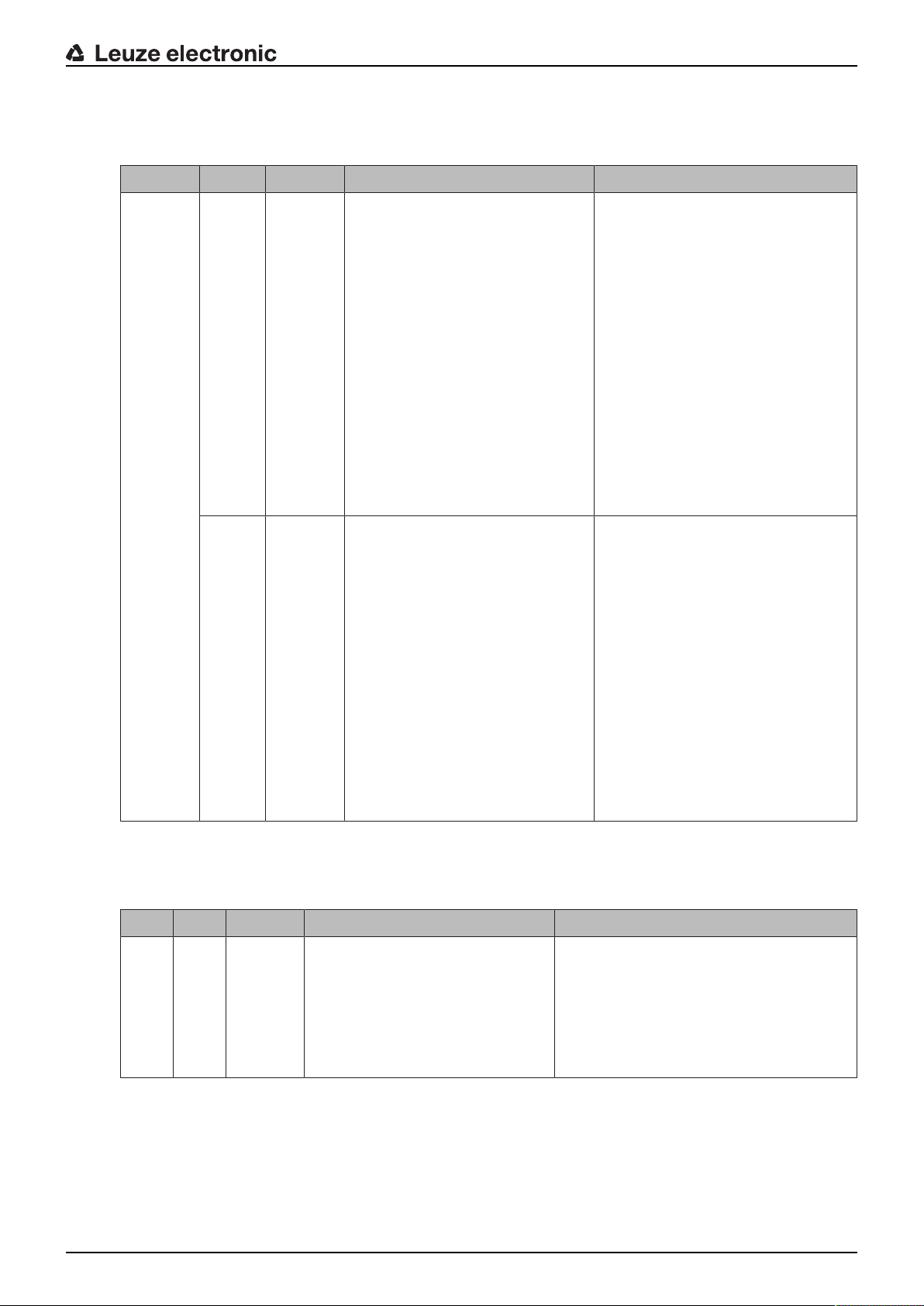

Tab.3.1: Meaning of the operating mode indicators

LED Color State Description

AUT Green Continuous light AUT operating mode (Automatic) active

Standard operating mode for data transmission

Note:

The optical link remains activated until the last orange LED

in the SIGNALQUALITY indicator switches off.

MAN Green Continuous light MAN operating mode (Manual) active

Operating mode for fine adjustment of the devices via SHA

(see chapter 6.2.2 "Fine adjustment with the single-handed

adjustment (SHA) process").

Note:

The optical link remains activated until the last green LED in

the SIGNALQUALITY indicator switches off.

ADJ Green Continuous light ADJ operating mode (Adjust) active

Operating mode for fine adjustment of the devices via SHA

(see chapter 6.2.2 "Fine adjustment with the single-handed

adjustment (SHA) process").

Note:

• Data transmission to the connected participants is deactivated.

• The optical link remains activated until the last orange

LED in the SIGNALQUALITY indicator switches off.

• The received signal level (SIGNALQUALITY) of the

second device is transmitted to the SIGNALQUALITY

indicator of the first device.

LAS Green Continuous light LAS operating mode (Laser Adjustment System) active

The alignment laser mounting support is activated (see

chapter 4.2 "Mounting with alignment laser and level").

Leuze electronic DDLS 548i 16

Page 17

Device description

1

2 3 4 5 6 7

LED Color State Description

LLC --- OFF LLC operating mode (LinkLossCounter, interruption diag-

nostics) not activated.

Green Continuous light The optical link was interruption-free since activation of the

LLC.

Red Continuous light The optical link was interrupted at least once since activa-

tion of the LLC (see chapter 8.3 "Error displays of the operating mode LEDs").

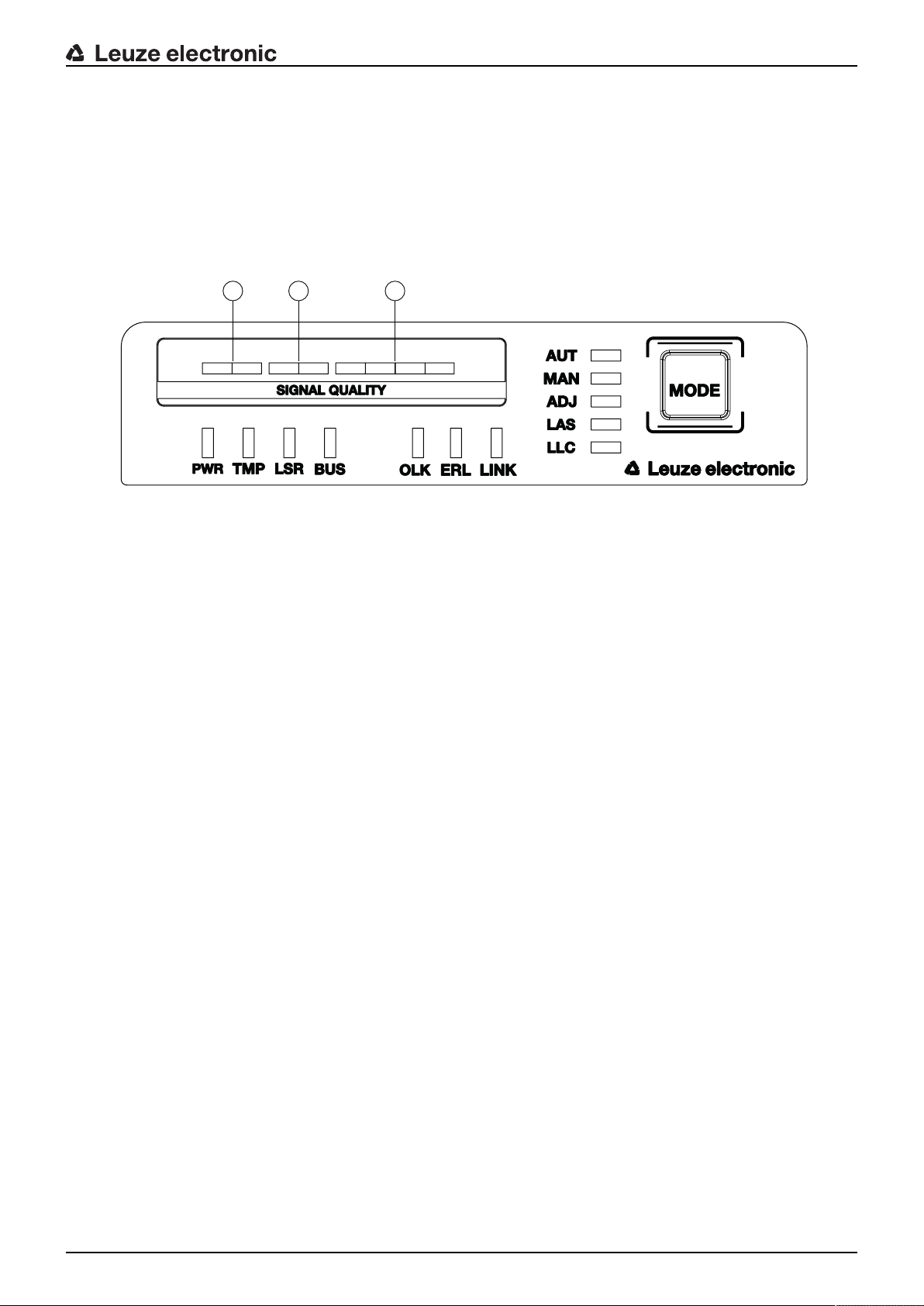

Operating state indicator

The PWR, TMP, LSR, OLK, ERL and LINK LEDs indicate the operating state of the device.

1 PWR – Supply voltage (Power)

2 TMP – Temperature warning/error

3 LSR – Laser prefailure message

4 BUS – PROFINET status of the network connection of the participant

5 OLK – Optical link

6 ERL – Error Link

7 LINK – M12 cable-connected link

Fig.3.4: Operating state LEDs in the control panel

Leuze electronic DDLS 548i 17

Page 18

Device description

Tab.3.2: Meaning of the operating state indicators

LED Color State Description

PWR --- OFF No supply voltage (see chapter 8.1 "Error displays of the op-

erating state LEDs")

Green Flashing Device is being initialized.

• Supply voltage connected

• Initialization running

• No data is sent or received.

Green Continuous light Data transmission path ready

• Initialization finished

Red Flashing Warning set (see chapter 8.1 "Error displays of the operating

state LEDs")

• No green and orange LEDs in SIGNALQUALITY indicator

• The optical link is interrupted.

• The laser diode of the transmitter is defective.

Red Continuous light Device error (see chapter 8.1 "Error displays of the operating

state LEDs")

• The function of the device is limited.

The displays of the other operating state LEDs may provide information on the cause of the error.

Orange Flashing PROFINET wave function activated

• The PWR and BUS LEDs flash in sync in orange.

TMP --- OFF Operating temperature in the specified working range

Orange Continuous light • Warning: The operating temperature is above or below

the specified working range by a maximum of 5°C (see

chapter 8.1 "Error displays of the operating state LEDs").

• Data transmission remains active.

Red Continuous light • The operating temperature is above or below the speci-

fied working range by more than 5°C (see chapter 8.1

"Error displays of the operating state LEDs").

• The operating time outside of the permissible operating

temperature is detected by the device.

• Data transmission remains active.

LSR --- OFF Laser diode of the transmitter with sufficient function reserve

Orange Continuous light • Warning: The laser diode of the transmitter signals the

imminent end of the life expectancy (see chapter 8.1 "Error displays of the operating state LEDs").

Limits to the maximum data transmission distance may

occur.

• Data transmission remains active.

Leuze electronic DDLS 548i 18

Page 19

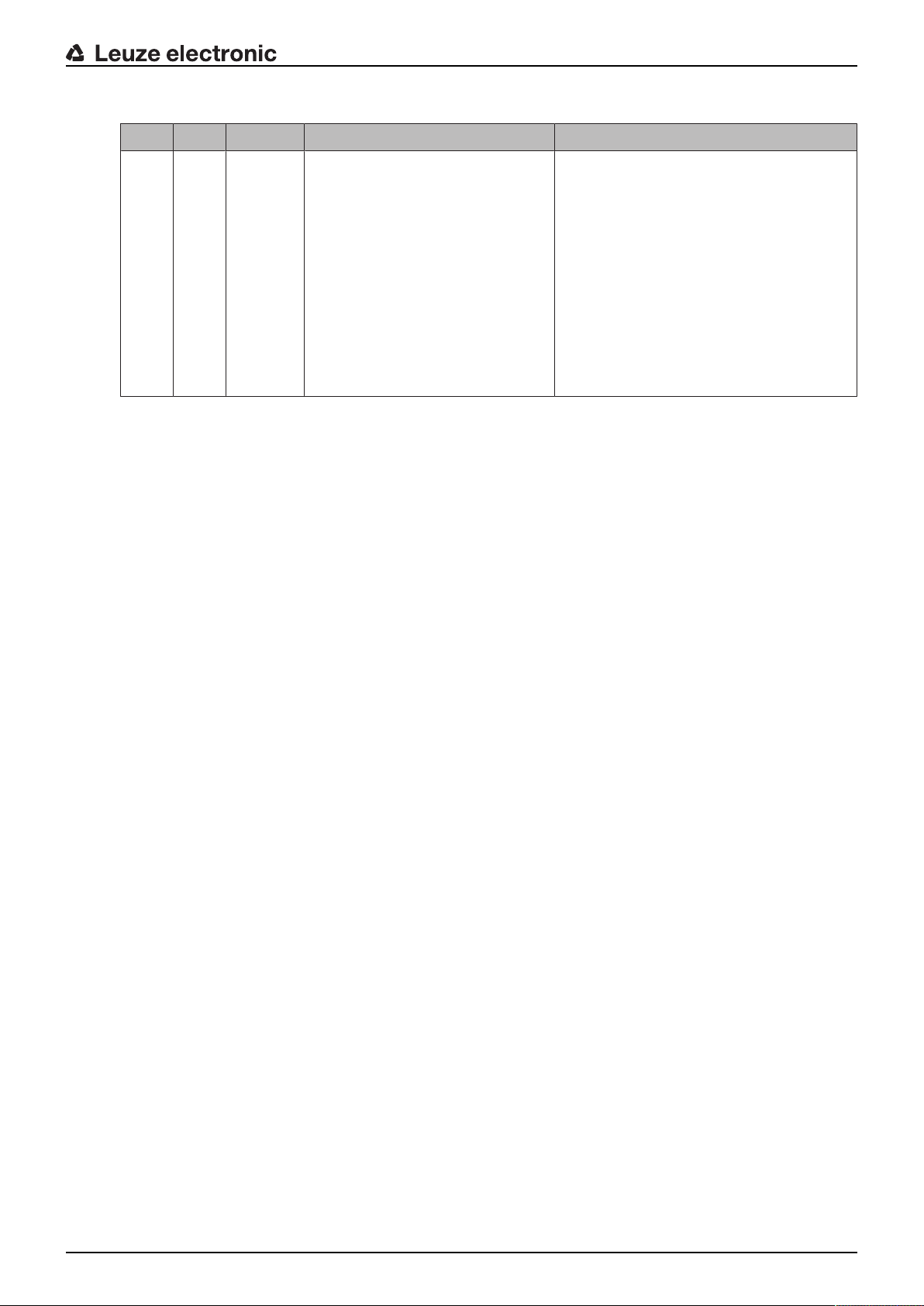

LED Color State Description

BUS OFF No supply voltage

Green Flashing • Device waiting for communication to be re-established.

• No data exchange

Green Continuous light • Communication with IO-Controller established

• Data exchange active

Orange Flashing PROFINET wave function activated

• The PWR and BUS LEDs flash in sync in orange.

Red Flashing • Parameterization or configuration failed

• No data exchange

Red Continuous light Bus error‑no communication established to the IO controller

OLK --- OFF No optical data connection

No data transmission

Causes (see chapter 8.1 "Error displays of the operating state

LEDs"):

• Optical window soiled

• Insufficient alignment

• Range exceeded

• Environmental influences (snow, rain, fog)

• Wrong F3/F4 frequency assignment of the devices

• Transmitter deactivated

• Transmitter of the second device deactivated

Device description

Green Continuous light • The optical link exists.

• No data is sent or received.

Orange Continuous light/

Data is sent and received.

flickering light

ERL --- OFF No link error

Orange Continuous light • Missing link (Ethernet cable connection) on the second

device (see chapter 8.1 "Error displays of the operating

state LEDs").

• SIGNALQUALITY indicator on the second device without

green and orange LED (see chapter 8.1 "Error displays of

the operating state LEDs").

Red Continuous light • No cable-connected link to the connected device (see

chapter 8.1 "Error displays of the operating state LEDs").

• SIGNALQUALITY indicator without green and orange

LED (see chapter 8.1 "Error displays of the operating

state LEDs").

LINK --- OFF No cable-connected link to the connected device (see chapter

8.1 "Error displays of the operating state LEDs").

Green Continuous light • The link to the connected device is OK.

• No data is sent or received.

Orange Continuous light/

flickering light

Leuze electronic DDLS 548i 19

• The link to the connected device is active.

• Data is sent and received.

Page 20

Device description

1

2 3

SIGNALQUALITY indicator

Eight individual LEDs are available for displaying the received signal level (SIGNALQUALITY):

• two red LEDs

• two orange LEDs

• four green LEDs

At the optimum received signal level, all LEDs (red, orange, green) are activated.

If the received signal level drops, the LEDs are successively switched off, beginning with the green LEDs.

1 two red LEDs

2 two orange LEDs

3 four green LEDs

Fig.3.5: SIGNALQUALITY indicator of the received signal level

Leuze electronic DDLS 548i 20

Page 21

Tab.3.3: Meaning of the SIGNALQUALITY indicators

LED Color State Description

Device description

SIGNAL

QUALITY

Green Continuous light

4-stage

Orange Continuous light

2-stage

Red Continuous light

2-stage

• Received signal level with function reserve.

• The optical link exists.

Warning: Received signal level with minimal function reserve (see chapter 8 "Diagnostics and troubleshooting").

• The optical link exists.

AUT operating mode (Automatic): Data transmission is

active.

MAN (Manual), ADJ (Adjust) operating modes: Data

transmission is deactivated.

• Switching output IO1 of the POWER connection is activated in operating modes AUT (Automatic), MAN (Manual) and ADJ (Adjust).

Causes:

• Optical window soiled

• Range exceeded

• Environmental influences (snow, rain, fog)

• Insufficient alignment

The optical link is interrupted. The received signal level is

not sufficient (see chapter 8 "Diagnostics and troubleshooting").

• No data is sent or received.

• Switching output IO1 of the POWER connection is activated.

Causes:

• Optical window soiled

• Range exceeded

• Environmental influences (snow, rain, fog)

• Insufficient alignment of the devices

• Wrong F3/F4 frequency assignment of the devices

• Transmitter of the second device deactivated

Leuze electronic DDLS 548i 21

Page 22

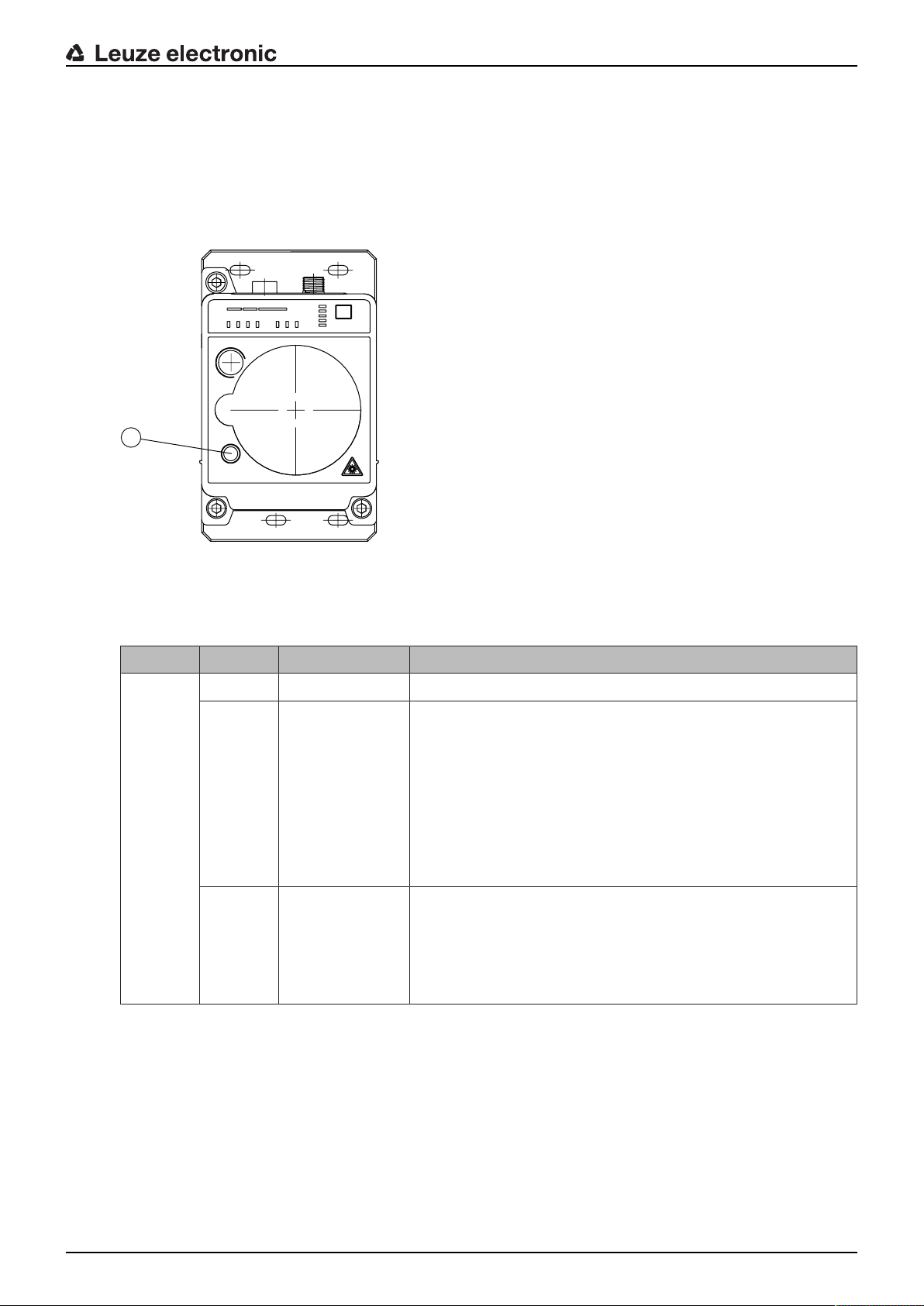

3.3.2 Indicators in the optics area

1

For simple, quick diagnosis, the device is equipped with a STATUS LED in the optics area.

The STATUS LED enables a quick summary diagnosis of the operating state of the device.

• The STATUS LED summarizes the displays of the individual LEDs of the control panel in a single indicator.

• The STATUS LED illuminates very brightly and can also be seen from a relatively long distance.

Device description

1 STATUS LED

Fig.3.6: STATUS LED in the optics area

Tab.3.4: Meaning of the STATUS LED display

LED Color State Description

STATUS

LED

Green Continuous light Not a warning or error message.

Green Flashing There is/are warning message(s) (see chapter 8.2 "Error dis-

plays and STATUS LED for remote diagnosis"):

• SIGNALQUALITY indicator without green LED in operating

modes AUT (Automatic), MAN (Manual), ADJ (Adjust)

• Temperature, warning or error (TMP)

• Laser pre-failure (LSR)

• LinkLossCounter has triggered (LLC)

Data transmission is active.

--- OFF • No supply voltage.

• SIGNALQUALITY indicator shows only red LEDs.

• The LINK and LINK/ACT LEDs are off.

• The transmitter is deactivated (see chapter 8.2 "Error displays and STATUS LED for remote diagnosis").

Leuze electronic DDLS 548i 22

Page 23

3.3.3 Indicators in the connection area

1

For the status display of the Ethernet connection, the device is equipped with a split, two-colored LINK/ACT

LED in the connection area.

The LINK/ACT LED indicates the same state as the LINK LED in the control panel.

Device description

1 LED, Ethernet (split, two-colored) LINK/ACT

Fig.3.7: LINK/ACT LED in the connection area

Tab.3.5: Meaning of the LINK/ACT displays

LED Color State Description

LINK/ACT --- OFF No cable-connected link to the connected device (see chapter

8.1 "Error displays of the operating state LEDs").

Green Continuous

light

Orange Continuous

light/

• The link to the connected device is OK.

• No data is sent or received.

• The link to the connected device is active.

• Data is sent and received.

flickering light

Leuze electronic DDLS 548i 23

Page 24

4 Mounting

The optical data transmission systems of series DDLS500 support simple and quick basic assembly of

both mutually opposing devices.

• An optical data transmission system, consisting of two devices, involves mounting each of the devices

on mutually opposing, plane-parallel, flat and usually vertical walls with unobstructed view of the opposing device.

• For installation with an integrated laser pointer (optional) see chapter 4.2 "Mounting with alignment

laser and level".

• For installation without the optional laser pointer see chapter 4.3 "Mounting without alignment laser".

NOTICE

Interruption of data transmission!

Data transmission is interrupted if the beam spread of the transmitters is no longer sufficient for

maintaining the optical link.

Ä Make certain that data transmission is not interrupted, e.g., by jolts, vibrations or inclination,

while moving a mobile device due to irregularities in the floor or path.

Ä For mobile arrangement of a device, ensure good tracking stability.

4.1 Mounting instructions

Mounting

NOTICE

Select the mounting location!

Ä Make certain that the required environmental conditions (humidity, temperature) are main-

tained.

Ä For low ambient temperatures, e.g., in cold stores, use data transmission systems with inte-

grated heating.

Ä Avoid rapid temperature changes at the data transmission system to prevent condensation.

Ä Protect the data transmission system from direct sunlight.

Ä For parallel mounting of data transmission systems and other optical measurement systems,

make certain that the minimum distance between the systems is maintained (see chapter

4.5 "Mounting distance for parallel operation of data transmission systems", see chapter 4.6

"Mounting distance for parallel operation with AMS300/AMS200 laser measurement systems", see chapter 4.7 "Mounting distance for parallel operation with DDLS200 data transmission system").

NOTICE

Installation for devices with an operating range of 200m.

Ä Always install the Frequency F4 device as stationary device for devices with an operating

range of 200m (DDLS5XX200…).

NOTICE

You will achieve greater flexibility during basic installation and fine adjustment if you mount the

devices on C profile rails.

NOTICE

If the device is mounted instead of a DDLS200, use the adapter plate – to be ordered separately – if necessary (see chapter 13.3 "Other accessories").

4.2 Mounting with alignment laser and level

The optional alignment laser simplifies mounting of the mutually opposing devices.

Leuze electronic DDLS 548i 24

Page 25

• The alignment laser consists of an integrated laser with special beam optics. In addition, a level is integrated in devices with alignment laser.

• Alignment laser, level, transmission optics and installation in a device housing form an axially parallel

unit.

• The laser spot of the alignment laser shows the installation position of the mutually opposing device.

4.2.1 Horizontal mounting (travel axis) with the alignment laser

A drilling template is included with the packaging.

Mounting

all dimensions in mm

Fig.4.1: Drilling template

NOTICE

When performed using the drilling template, the described mounting procedure results in a setup with the housings of the devices offset relative to one another (see figure). The transmitted

beam of one device is thereby aligned with the center of the receiver optics of the mutually opposing device.

Leuze electronic DDLS 548i 25

Page 26

Mounting

30 mm

Fig.4.2: Mounting with offset housings

Overview:

• The alignment laser projects a target spot on the opposing side.

In addition to the target spot, the beam optics produce four individual laser spots that are projected on

the floor.

• The device is aligned vertically and horizontally with two alignment screws using the integrated level

and the laser spots that are projected on the floor.

• The second device is mounted on the horizontally opposing target spot with the aid of the supplied

drilling template.

Ä Depending on mechanical conditions, mount the stationary or mobile device with four M5 screws via

the fastening holes in the mounting plate of the device.

ð Check the vertical mounting with a separate level.

ð Place the level on the edge of the mounting plate.

Ä Connect the device electrically (see chapter 5 "Electrical connection"). The AUT LED (continuous light)

indicates that the start-up phase of the device after "POWER on" has been concluded.

ð After the start-up phase, the operating mode can be changed.

Ä Switch on the alignment laser. Activate the LAS (Alignment laser) operating mode to switch on the

alignment laser (see chapter 6.1 "Setting the operating mode").

NOTICE

Data transmission is active while changing the operating mode and with activated alignment

laser.

The alignment laser projects four spots along a straight line on the floor and a target spot on the opposing

wall.

Leuze electronic DDLS 548i 26

Page 27

5

6

1 2 3 4

1 Laser spot1

2 Laser spot2

3 Laser spot3

4 Laser spot4

5 Alignment laser

6 Target spot

Mounting

Fig.4.3: Alignment laser

The distance of the laser spots is dependent on the mounting height of the device. The values in the table

will help you find the laser spots on the floor.

For marking and for better visibility of the laser spots on the floor, four self-adhesive labels are included in

the package.

NOTICE

The integrated alignment laser, the level, as well as the device transmitter are optimally

matched to one another ex works. Minimal mechanical tolerances are, however, unavoidable

and generate a very small error angle. The use of the alignment laser is therefore limited to a

maximum distance between the devices.

Ä In the table, you can find information on the distance to which the alignment laser can be

used as a function of the mounting height of the device.

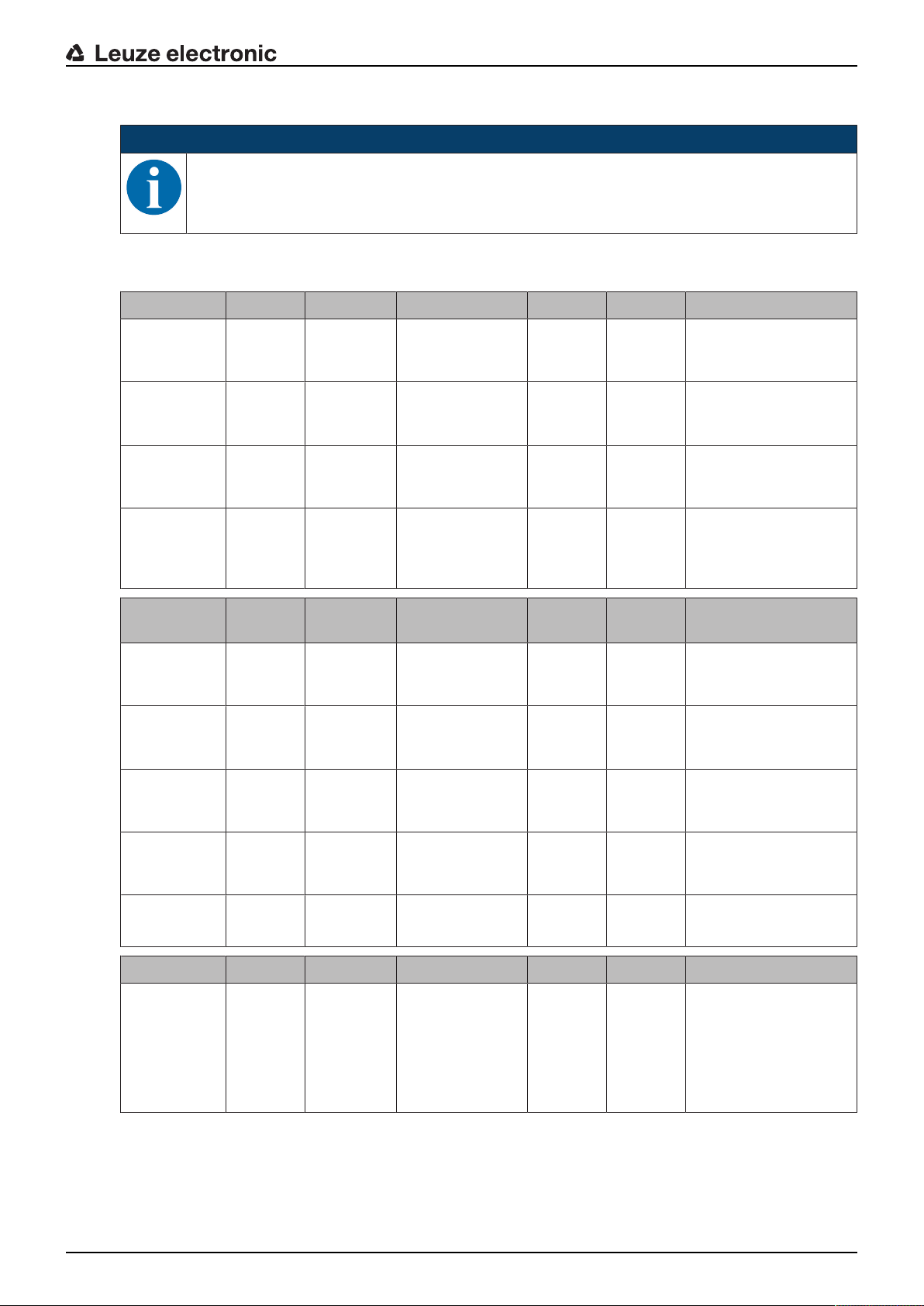

Tab.4.1: Distance of laser spots

Mounting height

of the device

Distance of laser spots on floor Alignment laser

Usable to

Laser spot1 Laser spot2 Laser spot3 Laser spot4

3.0m 6.7m 9.2m 14.1m 28.5m 44m

2.5m 5.6m 7.7m 11.8m 23.8m 40m

2.0m 4.5m 6.2m 9.4m 19.0m 37m

1.5m 3.4m 4.6m 7.1m 14.3m 32m

1.0m 2.2m 3.1m 4.7m 9.5m 25m

0.5m 1.1m 1.5m 2.4m 4.8m 16m

Note:

The listed mounting heights of the device are examples. The device can be mounted at any desired

height. The distances of the laser spots on the floor change according to the selected mounting height.

Leuze electronic DDLS 548i 27

Page 28

Horizontal alignment

7

x x x x

8

5

6

1 2 3 4

65

63 64 66 67 68 69 71 72

70

Ä Align the laser spots using the alignment screw (8) at the lower right.

Mounting

1 Laser spot1

2 Laser spot2

3 Laser spot3

4 Laser spot4

5 Alignment laser

6 Target spot

7 Reference edge

8 Alignment screw for horizontal alignment

X Distance of laser spots to the reference edge

Fig.4.4: Horizontal alignment of the target spot

Ä Turn the alignment screw (8) until at least two laser spots (1-4) are the same distance (X) to the guide

rail or to a reference edge (7) that is parallel to the guide rail.

ð If possible, use laser spot1 and laser spot3 for alignment.

ð Set the distances of the laser spots to the reference edge exactly to 1mm.

Fig.4.5: Measure distance from laser spot to reference edge

Leuze electronic DDLS 548i 28

Page 29

Mounting

1

2

Vertical alignment

Ä Adjust the vertical setting of the device using the alignment screw (2) at the upper left. Turn the align-

ment screw until the air bubble in the level is centered between the limit marks.

NOTICE

Small changes to the alignment screw cause the air bubble in the level to move slowly. Before

making further settings, wait until the air bubble stops moving.

1 Spirit level

2 Alignment screw for vertical alignment

Fig.4.6: Vertical alignment of the target spot

The target spot of the alignment laser on the opposing wall exactly marks the position at which the second

device must be mounted.

Mounting the second device

Ä Affix the drilling template at the target spot of the alignment laser. Use the supplied self-adhesive la-

bels.

Ä Drill the holes for mounting the device with the aid of the drilling template or, if C profile rails are

present, align them according to the drilling template. Mount the device with four M5 screws via the fastening holes in the mounting plate.

ð The device must be mounted in a vertical position.

ð Check the vertical mounting with a separate level. Place the level on the edge of the mounting

plate.

Ä Switch off the alignment laser of the device that was mounted first. Activate the AUT (Automatic) oper-

ating mode to switch off the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Detach the contour of the optical window from the drilling template along the perforation. Affix the re-

moved drilling template to the optical window of the device that was mounted first using the supplied

self-adhesive labels.

Ä Connect the second device electrically (see chapter 5 "Electrical connection").

ð The AUT LED (continuous light) indicates that the start-up phase of the device after "POWER on"

has been concluded.

ð After the start-up phase, the operating mode can be changed.

Ä Switch on the alignment laser of the second device. Activate the LAS (Alignment laser) operating mode

to switch on the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Point the alignment laser of the device that was mounted second at the drilling template on the device

that was mounted first. To do this, align the second device using the alignment screws.

Leuze electronic DDLS 548i 29

Page 30

ð The level as well as the parallelism of the laser spots to the guide rail does not need to be taken

30 mm

into account here.

NOTICE

Do not change the mounting position of the device that was mounted first!

Ä When aligning the second device, note that the mounting position of the device that was

mounted first must not be changed.

Ä Switch off the alignment laser of the second device. Activate the AUT (Automatic) operating mode to

switch off the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Remove the drilling template from the device that was mounted first.

ð This concludes the mounting of the devices in the travel axis.

Further procedure:

• Perform the fine adjustment for the travel axis (see chapter 6.2 "Fine adjustment").

4.2.2 Vertical mounting (lifting axis) with the alignment laser

NOTICE

Vertical mounting only with the target spot of the alignment laser!

For the vertical mounting of the devices, only the target spot of the alignment laser is used (see

chapter 4.2.1 "Horizontal mounting (travel axis) with the alignment laser").

Ä The level and laser spots 1…4 cannot be used.

Mounting

Ä Mount the two devices opposite one another with a lateral offset of 30mm. Mount the devices so that

the center of the transmitter of one device is opposite the center of the receiver of the other device.

Fig.4.7: Lateral offset of the devices with vertical mounting

Leuze electronic DDLS 548i 30

Page 31

Mounting

NOTICE

You will achieve greater flexibility during basic installation and fine adjustment if you mount the

devices on C profile rails.

Ä Detach the contour of the optical window from the drilling template along the perforation.

Ä Affix the removed drilling template to the optical window of the mobile device using the supplied self-ad-

hesive labels.

Ä Switch on the alignment laser of the stationary device. Activate the LAS (Alignment laser) operating

mode to switch on the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Move the mobile device on the lifting axis in manual operation to maximum distance.

Ä Align the stationary device using the alignment screws (see chapter 3.1.1 "Device construction",

point11 and point12) and, if necessary, using the C-profile rails.

ð The target spot of the alignment laser must be in the center of the drilling template on the mobile

device.

Ä Move the mobile device on the lifting axis in manual operation to minimum distance.

ð The target spot of the alignment laser must not extend beyond the outer ring of the drilling template

on the mobile device.

ð If necessary, realign the stationary device.

Ä Switch off the alignment laser of the stationary device. Activate the AUT (Automatic) operating mode to

switch off the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Affix the detached drilling template to the optical window of the stationary device using the supplied

self-adhesive labels.

Ä Switch on the alignment laser of the mobile device. Activate the LAS (Alignment laser) operating mode

to switch on the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Move the mobile device on the lifting axis in manual operation to maximum distance.

Ä Align the mobile device using the alignment screws (see chapter 3.1.1 "Device construction", point11

and point12) and, if necessary, using the C-profile rails.

ð The target spot of the alignment laser must be in the center of the drilling template on the stationary

device.

Ä Move the mobile device on the lifting axis in manual operation to minimum distance.

ð The target spot of the alignment laser must not extend beyond the outer ring of the drilling template

on the stationary device.

ð If necessary, realign the mobile device.

Ä Switch off the alignment laser of the mobile device. Activate the AUT (Automatic) operating mode to

switch off the alignment laser (see chapter 6.1 "Setting the operating mode").

Ä Remove the drilling template from the stationary device.

ð This concludes the mounting of the devices in the lifting axis.

Further procedure:

• Perform the fine adjustment for the lifting axis (see chapter 6.2 "Fine adjustment").

Leuze electronic DDLS 548i 31

Page 32

4.3 Mounting without alignment laser

30 mm

Ä Observe the mounting instructions (see chapter 4.1 "Mounting instructions").

NOTICE

You will achieve greater flexibility during basic installation and fine adjustment if you mount the

devices on C profile rails.

4.3.1 Horizontal mounting (travel axis) without alignment laser

Ä Depending on mechanical conditions, mount the stationary or mobile device with four M5 screws via

the fastening holes in the mounting plate.

Ä Move the mobile device as close as possible to the stationary device.

Ä Determine the vertical mounting position of both devices.

ð Place an alignment straightedge or level on top of the planar support surfaces in the connection

area of both devices.

ð Move the devices until they are at the same height.

Ä Determine the horizontal mounting position of both devices.

ð Place an alignment straightedge or level on the lateral support edge of one of the devices.

ð Move the devices towards one another horizontally so that there is an offset of 30mm between

them (see figure). The transmitter of one device is positioned opposite the receiver of the other device.

Mounting

Fig.4.8: Mounting with offset housings

ð Mounting of the device is concluded.

Further procedure:

• Connect the devices electrically (see chapter 5 "Electrical connection").

• Perform the fine adjustment for the travel axis (see chapter 6.2 "Fine adjustment").

Leuze electronic DDLS 548i 32

Page 33

4.3.2 Vertical mounting (lifting axis) without alignment laser

30 mm

Ä Mount the two devices opposite one another with a lateral offset of 30mm.

ð Place an alignment straightedge or level on the lateral support edge of one of the devices.

ð Move the devices towards one another horizontally so that there is an offset of 30mm between

them (see figure). The transmitter of one device is positioned opposite the receiver of the other device.

Mounting

Fig.4.9: Lateral offset of the devices with vertical mounting

Ä Determine the horizontal mounting position of both devices.

ð Place an alignment straightedge or level on the planar support surfaces in the connection area of

both devices.

ð Move the devices until both are flush with one another. To do this, use the vertical level of a bubble

level.

ð Mounting of the device is concluded.

Further procedure:

• Connect the devices electrically (see chapter 5 "Electrical connection").

• Perform the fine adjustment for the lifting axis (see chapter 6.2 "Fine adjustment").

Leuze electronic DDLS 548i 33

Page 34

4.4 Mounting tolerances of the devices

a

a

3

3

1

4

4

2

1

2

III

B

B

B B

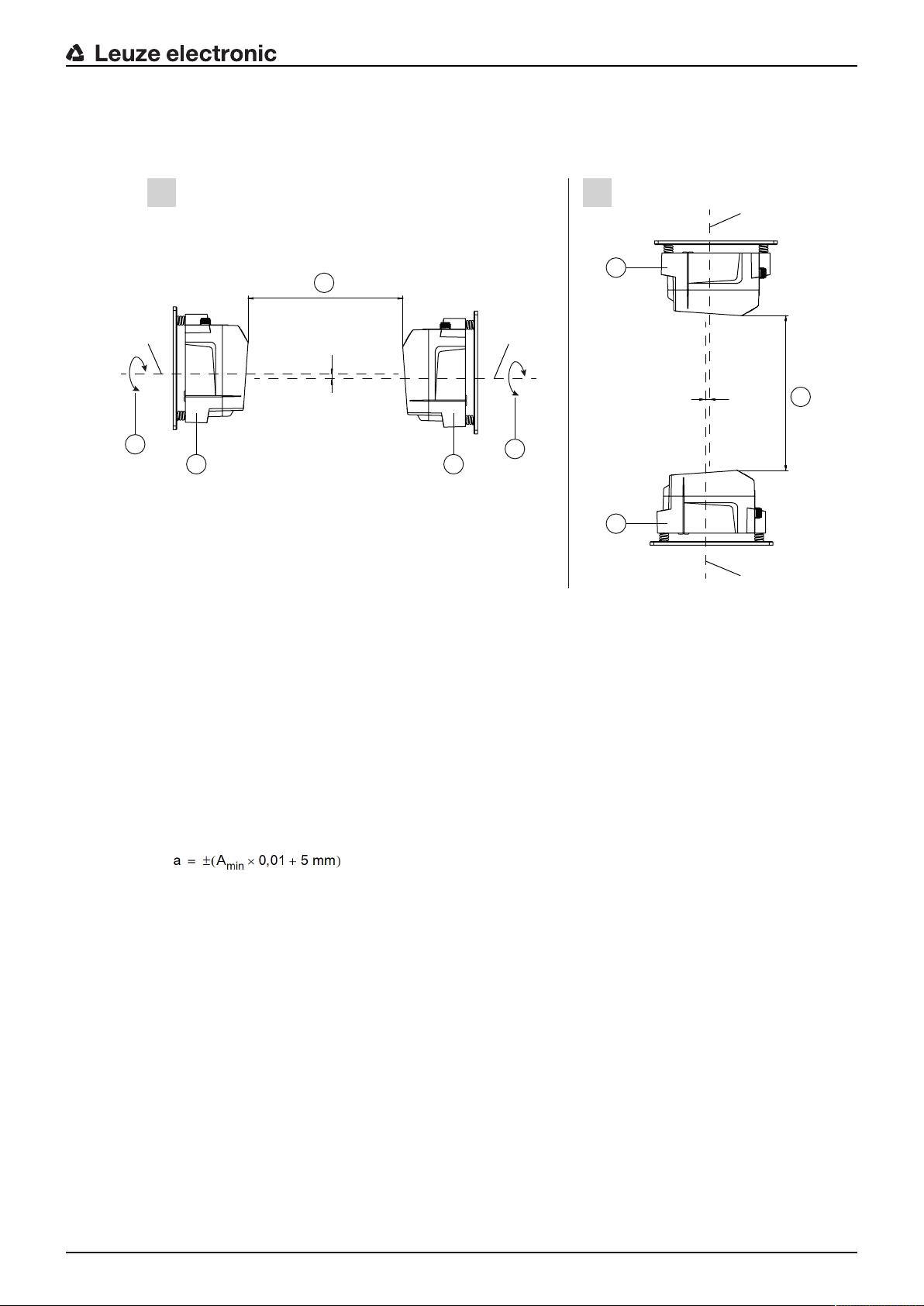

The maximum allowed mounting tolerances of the devices are dependent on the minimum distance of the

devices in the system.

Mounting

I Horizontal mounting (travel axis)

II Vertical mounting (lifting axis)

B Center axis of transmitter and receiver (see chapter 12.2 "Dimensioned drawings")

a Maximum mounting tolerance

1 Device with frequency3 (FrequencyF3)

2 Device with frequency4 (FrequencyF4)

3 Minimum distance between the devices, A

4 Rotary transmission possible with device separation (3) of greater than 500mm

Fig.4.10: Maximum allowed mounting tolerance

The maximum mounting tolerance is calculated using the following formula:

a [mm] Maximum mounting tolerance of the devices

A

[mm] Applied minimum distance in the system

min

min

Leuze electronic DDLS 548i 34

Page 35

Maximum lateral mounting tolerance

3

3

1

2

1

2

III

a

a

C

C

C

C

I Horizontal mounting (travel axis)

II Vertical mounting (lifting axis)

C Center axis of receiver (see chapter 12.2 "Dimensioned drawings")

a Maximum lateral mounting tolerance

1 Device with frequency3 (FrequencyF3)

2 Device with frequency4 (FrequencyF4)

3 Minimum distance between the devices, A

min

Mounting

Fig.4.11: Maximum lateral mounting tolerance

The maximum lateral mounting tolerance is calculated using the following formula:

a [mm] Maximum mounting tolerance of the devices

A

[mm] Applied minimum distance in the system

min

4.5 Mounting distance for parallel operation of data transmission systems

If it is necessary to operate multiple optical data transmission systems next to one another, the minimum

mounting distances must be maintained.

The minimum mounting distance between two optical data transmission systems is determined by the following criteria:

• Maximum data transmission distance

• Frequency-offset mounting (F3/F4/F4/F3)

• Identical frequency mounting (F3/F4/F3/F4)

• Transmission beam spread of the devices

The standard beam spread is ±0.5°.

Leuze electronic DDLS 548i 35

Page 36

Frequency-offset mounting

1 2

2 1

a

1 2

1 2

a

a Minimum mounting distance

1 evice with frequency 3 (FrequencyF3, DDLS5XXxxx.3YY)

2 Device with frequency 4 (FrequencyF4, DDLS5XXxxx.4YY)

Mounting

Fig.4.12: Frequency-offset mounting

Tab.4.2: Minimum mounting distance for frequency-offset mounting of the devices

Range of the device Minimum mounting distance between the devices

40m (DDLS5XX40...) 300mm

120m (DDLS5XX120...) 300mm

200m (DDLS5XX200...) 500mm

Identical-frequency mounting

Leuze electronic DDLS 548i 36

a Minimum mounting distance

1 Device with frequency 3 (FrequencyF3, DDLS5XXxxx.3-YY)

2 Device with frequency 4 (FrequencyF4, DDLS5XXxxx.4-YY)

Fig.4.13: Identical-frequency mounting

Page 37

Minimum mounting distance

With identical-frequency mounting of the devices, the minimum mounting distance is determined using the

following formula:

a [mm] Minimum mounting distance

tan(x) [-] Tangent of the transmission beam spread of the device

Distance [mm] Maximum data transmission distance in the system

NOTICE

On request, the devices can be delivered with transmission optics with beam spread of greater

than ±0.5°. The larger transmission beam spread must be used in the calculation for identicalfrequency parallel mounting of these device versions.

4.6 Mounting distance for parallel operation with AMS300/AMS200 laser measurement

systems

The mounting of an AMS 300/AMS 200 laser measurement system does not affect data transmission if the

devices are correctly aligned.

• The reflector size of the AMS300/AMS200 determines the minimum mounting distance of the device

to the AMS.

Reflector sizes from 200x200mm to 1000x1000mm are permissible.

Details on the permissible reflector types can be found in the "Technical description" of the AMS300/

AMS200.

• The device can be mounted directly next to the reflectors of the AMS300/AMS200.

Mounting

4.7 Mounting distance for parallel operation with DDLS200 data transmission system

For the determination of the minimum mounting distance, the details for identical-frequency mounting apply

(see chapter 4.5 "Mounting distance for parallel operation of data transmission systems").

Leuze electronic DDLS 548i 37

Page 38

4.8 Cascading (series connection) of multiple data transmission systems

1 2

If there are multiple optical data transmission paths between two participants (TN), one speaks of cascading.

1 Optical data transmission path 1

2 Optical data transmission path 2

Fig.4.14: Example: Cascading of multiple data transmission systems

Cascading the devices

Cascading is possible if the specifications of the protocols to be transmitted are not violated with respect to

delay times or jitter tolerances (see chapter 3.1.2 "Protocol-specific characteristics of the DDLS548i").

Due to the very short delay times of the devices, cascading is possible without problem for very many Ethernet protocols.

For transmission protocols that are very tightly specified with respect to delay times and jitter tolerances

(e.g., for synchronous transmissions), the user must check the suitability of the devices individually.

• Protocol propagation times:

Constant delay time per path (2 devices): 5µs

• Distance-dependent delay:

Distance 0m: 0µs

Distance 200m: 0.66µs

Mounting

Leuze electronic DDLS 548i 38

Page 39

5 Electrical connection

2

1

5.1 Overview

The electrical connection of the device is performed using M12 connectors.

Electrical connection

1 POWER

2 BUS

Fig.5.1: Position and designation of the M12 connections

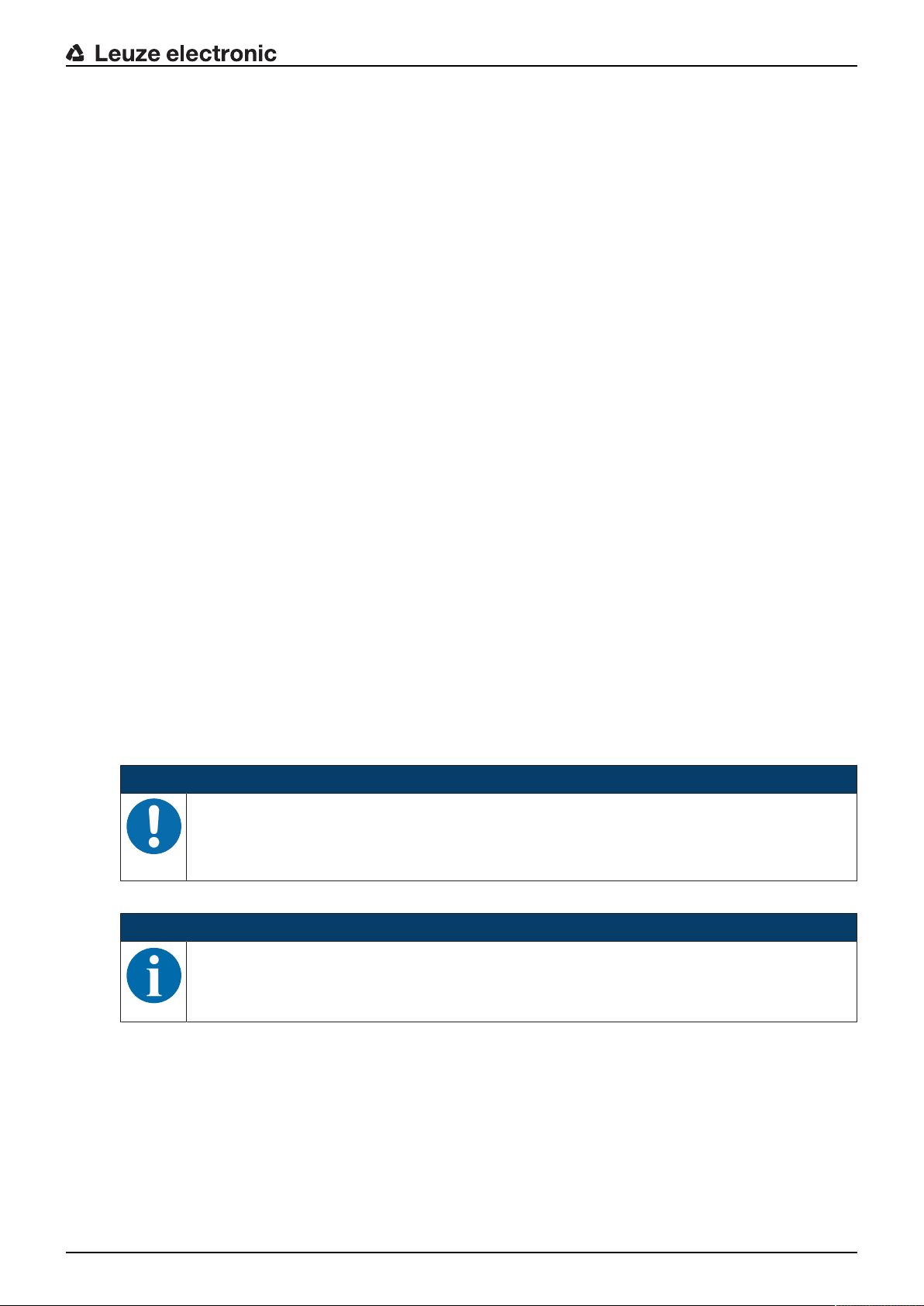

CAUTION

Safety notices!

Ä Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

Ä Only have the electrical connection performed by certified electricians.

Ä Ensure that the functional earth (FE) is connected correctly. Fault-free operation is only

guaranteed if the functional earth is connected properly.

Ä If faults cannot be rectified, take the device out of operation. Protect the device from acci-

dentally being started.

NOTICE

UL applications!

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National Electric Code).

NOTICE

Protective Extra Low Voltage (PELV)!

The device is designed in accordance with protection classIII for supply with PELV (Protective

Extra-Low Voltage).

NOTICE

Laying cables!

Ä Lay all connection cables and signal lines within the electrical installation space or perma-

nently in cable ducts.

Ä Lay the cables and lines so that they are protected against external damages.

Ä For further information: see EN ISO 13849-2, Table D.4.

Leuze electronic DDLS 548i 39

Page 40

5.2 POWER (supply voltage / switching input and switching output)

2

3

1

4

5

FE

5-pin, M12 plug (A-coded) for connecting to POWER.

Fig.5.2: Pin assignments for POWER connection

Tab.5.1: POWER pin assignments

Pin Designation Assignment

1 VIN Positive supply voltage +18…+30VDC

2 IO1 Switching output (intensity/SIGNALQUALITY)

Voltage:

• +18…+30VDC: received signal level/SIGNALQUALITY ok

• 0VDC: intensity warning: received signal level/SIGNALQUALITY not sufficient

Electrical connection

3 GND Negative supply voltage 0VDC

4 IO2 Switching input (transmitter shutdown)

Voltage:

• +18…+30VDC: transmitter not active

• 0VDC: transmitter active

5 FE Functional earth

(Thread for M12

connector plug)

FE Connection cable shield

The shield of the connection cable is on the thread of the M12 connector plug.

The thread of the M12 connector plug is part of the metallic housing. The housing is at the potential of the functional earth via pin5.

Connection cables: see chapter 13.2 "Cables accessories"

Switching input/output

The device is equipped with a switching output IO1 and a switching input IO2.

• Using the switching input, the transmitter (pin4) can be activated and deactivated. On deactivation, the

optical link is interrupted (OLK LED).

NOTICE

Deactivation of the transmitter can be used during a corridor change to avoid interference effects, e.g., with other optical sensors.

• If the received signal level drops (SIGNALQUALITY), the intensity warning is activated via the switching output.

The intensity warning is activated as soon as no green LED illuminates on the SIGNALQUALITY indicator.

NOTICE

Data transmission remains active until the last orange LED of the SIGNALQUALITY indicator

switches off. Data transmission is then deactivated.

The intensity warning remains active even after the last orange LED of the SIGNALQUALITY

Leuze electronic DDLS 548i 40

indicator switches off.

Page 41

NOTICE

1

32

4

Maximum input current!

The maximum input current of the switching input is 8mA.

NOTICE

Maximum loading of the switching output!

The switching output is protected against short-circuit, overcurrent, overvoltage, excess temperature and transients.

Ä Do not load the switching output with more than 60mA at +18…+30VDC.

5.3 BUS (bus input, Ethernet)

4-pin, M12 socket (D-coded) for connecting to BUS (Ethernet connection).

Electrical connection

Fig.5.3: Pin assignments for BUS connection

Tab.5.2: BUS pin assignments

Pin Designation Assignment

1 TD+ Transmit Data + (transmitter)

2 RD+ Receive Data + (receiver)

3 TD- Transmit Data - (transmitter)

4 RD- Receive Data - (receiver)

(M12-socket

thread)

FE Connection cable shield

The shield of the connection cable is on the thread of the M12 socket.

The thread of the M12 socket is part of the metallic housing. The housing is at the potential of the functional earth via pin5 of the POWER

connector plug.

Connection cables: see chapter 13.2 "Cables accessories"

NOTICE

The device supports a transmission rate of 100Mbit/s in full duplex mode as well as auto-crossover.

NOTICE

The entire interconnection cable must be shielded.

The shielding connection must be at the same potential at both ends of the data line. This

serves to prevent potential equalization currents over the shield and possible interference coupling through compensating currents.

Ä Use at least a CAT5 cable for the connection.

Leuze electronic DDLS 548i 41

Page 42

6 Starting up the device

4 5

1

2 63

6.1 Setting the operating mode

The active operating mode is displayed on the control panel to the left next to the operating mode selector

switch [MODE] via LEDs (see chapter 3.3.1 "Indicators and operational controls in the control panel").

Starting up the device

1 AUT – Automatic

2 MAN – Manual

3 ADJ – Adjust

4 LAS – Alignment laser for mounting support

5 LLC – LinkLossCounter

6 MODE – Operating mode selector switch

Fig.6.1: Operating mode selector switch and operating mode LEDs

The operating mode selector switch [MODE] is used to switch between the operating modes of the device:

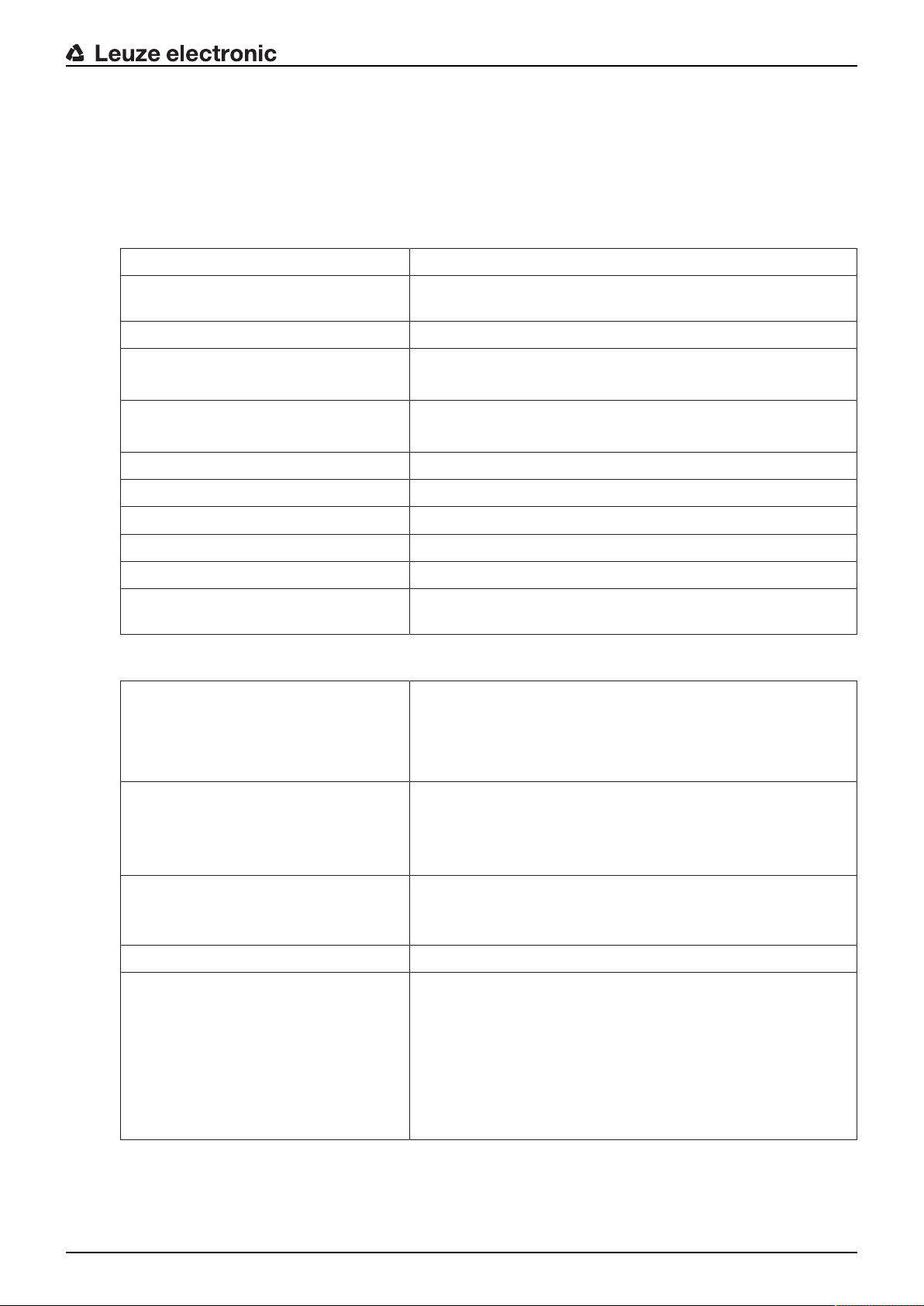

Tab.6.1: Operating modes

Operating mode Description

AUT

Automatic

Standard operating mode for data transmission. When the supply voltage is applied,

the device starts in the AUT operating mode.

Note:

Operating modes that were active before the device was switched off are no longer active after the device is switched back on.

MAN

Manual

Operating mode for fine adjustment of the devices via SHA (see chapter 6.2.2 "Fine

adjustment with the single-handed adjustment (SHA) process").

Data transmission switches off as soon as no green LEDs in the SIGNAL QUALITY indicator illuminate.

Note:

The AUT LED switches off if the MAN operating mode is activated.

ADJ

Aligning

(Adjust)

Operating mode for fine adjustment of the devices via SHA (see chapter 6.2.2 "Fine

adjustment with the single-handed adjustment (SHA) process").

• Data transmission to the connected participants is interrupted.

• The received signal level (SIGNAL QUALITY indicator) of the second device is

transmitted to the SIGNAL QUALITY indicator of the first device.

The quality of the fine adjustment is read directly on the device (SIGNAL QUALITY

indicator) on which the fine adjustment is performed via the alignment screws.

Notes:

• The AUT LED switches off if the ADJ operating mode is activated.

• The MAN LED switches off if the ADJ operating mode is activated.

Leuze electronic DDLS 548i 42

Page 43

Operating mode Description

Starting up the device

LAS

Laser Adjustment

System

(Alignment laser)

LLC

LinkLossCounte

r

(interruption diagnostics)

Operating mode for activation/deactivation of the alignment laser (see chapter 4.2

"Mounting with alignment laser and level").

Notes:

• The LAS operating mode can only be activated for devices with alignment laser.

• If the LAS operating mode is activated for an actively transmitting data transmission path, data transmission remains active.

• The AUT LED (green) illuminates simultaneously with the LAS LED (green).

• In the LAS operating mode, the MAN, ADJ and LLC operating modes are not to be

activated.

Operating mode for activation/deactivation of interruption diagnostics. If LLC is activated, an interruption of the optical link is displayed via the LLC LED (see chapter

3.3.1 "Indicators and operational controls in the control panel").

Notes:

• The LLC LED illuminates red even if the optical link is restored following an interruption.

• The AUT LED (green) illuminates simultaneously with the LLC LED (green or red).

• To reactivate LLC following an interruption of the optical link, the LLC operating

mode must be reset.

• In the LLC operating mode, the MAN, LAS and ADJ operating modes are deactivated.

Activating the operating mode

Ä Select the desired operating mode by briefly pressing the operating mode selector switch [MODE].

ð Repeatedly pressing the operating mode selector switch [MODE] selects the next operating mode,

rolling from top to bottom.

ð The LED of the selected operating mode flashes.

Ä Activate the selected operating mode.

ð Press the operating mode selector switch [MODE] for approx. two seconds until the LED of the se-

lected operating mode illuminates continuously.

ð Release the operating mode selector switch [MODE] to activate the selected operating mode.

ð The LED of the selected operating mode illuminates continuously.

NOTICE

Data transmission remains active while changing the operating mode.

Exception: operating mode ADJ. After activating the ADJ operating mode, data transmission of

process data is interrupted.

Deactivating the operating mode

Ä Select a new operating mode by repeatedly pressing the operating mode selector switch [MODE] for a

short time.

ð The LED of the newly selected operating mode flashes.

Ä Activate the newly selected operating mode.