Page 1

DDLS 200

Bus-Capable Optical Data Transmission

en 03-2010/04 50036440

TECHNICAL DESCRIPTION

Page 2

Table of contents

1 General Information...........................................................................................4

1.1 Explanation of symbols ........................................................................................................ 4

1.2 Declaration of conformity ..................................................................................................... 4

1.3 Short description ..................................................................................................................4

1.4 Operating principle ............................................................................................................... 5

2 Safety Notices....................................................................................................6

2.1 Safety standards .................................................................................................................. 6

2.2 Intended use ........................................................................................................................ 6

2.3 Working safely ..................................................................................................................... 6

2.4 Organizational measures .....................................................................................................7

3 Technical Data ................................................................................................... 8

3.1 General technical data .........................................................................................................8

3.2 Dimensioned drawings.......................................................................................................10

4 Mounting / Installation (all device models).................................................... 11

4.1 Mounting and alignment..................................................................................................... 11

4.2 Arrangement of adjacent transmission systems ................................................................ 12

4.3 Cascading (series connection) of several DDLS 200 data paths....................................... 14

4.4 Electrical connection .......................................................................................................... 16

4.4.1 Electrical connection - devices with screwed cable glands and terminals................................... 16

4.4.2 Electrical connection - devices with M12 connectors ..................................................................19

5 PROFIBUS / RS 485 .........................................................................................21

5.1 PROFIBUS connection - devices with screwed cable glands and terminals ..................... 21

5.1.1 Converting the PROFIBUS model with terminals to M12 connectors ......................................... 22

5.2 PROFIBUS connection - devices with M12 connectors..................................................... 23

5.3 Device configuration PROFIBUS .......................................................................................24

5.4 LED Indicators PROFIBUS ................................................................................................25

6 INTERBUS 500kbit/s / RS 422......................................................................... 26

6.1 Electrical connection INTERBUS 500kbit/s ....................................................................... 26

6.2 Device configuration INTERBUS 500 kbit/s / RS 422......................................................... 27

6.3 LED indicators INTERBUS 500kbit/s / RS 422.................................................................. 28

7 INTERBUS 2Mbit/s Fiber-Optic Cable............................................................ 29

7.1 Fiber-optic-cable connection INTERBUS 2 Mbit/s.............................................................. 29

7.2 Device configuration INTERBUS 2 Mbit/s FOC.................................................................. 30

7.3 LED indicators INTERBUS 2Mbit/s fiber-optic cable ......................................................... 31

TNT 35/7-24V

Leuze electronic DDLS 200 1

Page 3

Table of contents

8 Data Highway + (DH+) / Remote I/O (RIO)......................................................32

8.1 Electrical connection DH+ / RIO ........................................................................................ 32

8.2 Device configuration DH+ / RIO......................................................................................... 33

8.3 LED indicators DH+ / RIO .................................................................................................. 34

9 DeviceNet / CANopen...................................................................................... 35

9.1 Electrical connection DeviceNet / CANopen - screwed cable glands/terminals ................ 35

9.1.1 Bus transceiver and device supplied via separate power connection..........................................36

9.1.2 Bus transceiver supplied via bus cable, device supplied via separate power line .......................36

9.1.3 Bus transceiver and device supplied via bus cable......................................................................37

9.1.4 Installation and connection of the optional M12 connectors ........................................................38

9.2 DeviceNet/CANopen electrical connection- M 12 connectors ........................................... 39

9.3 Device configuration DeviceNet / CANopen ...................................................................... 41

9.3.1 Baud rate conversion ...................................................................................................................41

9.3.2 Sorting (switch S4.1)....................................................................................................................41

9.3.3 Bus lengths as a function of the baud rate...................................................................................41

9.4 Wiring................................................................................................................................. 42

9.4.1 Termination ..................................................................................................................................43

9.5 DeviceNet/CANopen LED indicators ................................................................................. 44

9.6 Interruption of the data transmission path.......................................................................... 45

9.7 Important notices for system integrators............................................................................ 46

9.7.1 Schematic drawing of the inner construction................................................................................47

9.7.2 Timing ..........................................................................................................................................48

9.7.3 Synchronous messages...............................................................................................................49

9.7.4 Other implementation notes.........................................................................................................49

10 Ethernet............................................................................................................ 50

10.1 Ethernet connection - devices with screwed cable glands and terminals .......................... 50

10.2 Ethernet connection - devices with M12 connectors ......................................................... 51

10.3 Device configuration Ethernet............................................................................................ 52

10.3.1 Autonegotiation (Nway)................................................................................................................52

10.3.2 Transmission rate conversion ......................................................................................................52

10.3.3 Network expansion.......................................................................................................................52

10.4 Wiring................................................................................................................................. 53

10.4.1 Assignment of the RJ45 and M12 Ethernet cables......................................................................54

10.4.2 Installing cable with RJ45 connector............................................................................................55

10.5 LED Indicators Ethernet.....................................................................................................56

10.6 Important notices for system integrators............................................................................ 56

10.6.1 Typical bus configuration .............................................................................................................57

10.6.2 Timing ..........................................................................................................................................58

2 DDLS 200 Leuze electronic

Page 4

Table of contents

11 Commissioning / Operation (all device models)........................................... 60

11.1 Indicator and operating elements....................................................................................... 60

11.2 Operating modes ............................................................................................................... 61

11.3 Initial commissioning .......................................................................................................... 62

11.3.1 Switch on device / function check................................................................................................62

11.3.2 Fine adjustment ........................................................................................................................... 62

11.4 Operation ........................................................................................................................... 63

12 Maintenance.....................................................................................................64

12.1 Cleaning............................................................................................................................. 64

13 Diagnostics and Troubleshooting..................................................................65

13.1 Status display on the device .............................................................................................. 65

13.2 Diagnostic mode ................................................................................................................ 65

13.3 Troubleshooting ................................................................................................................. 66

14 Accessories...................................................................................................... 67

14.1 Accessory terminating resistors ......................................................................................... 67

14.2 Accessory connectors........................................................................................................67

14.3 Accessory ready-made cables for voltage supply.............................................................. 67

14.3.1 Contact assignment of PWR IN connection cable for voltage supply..........................................67

14.3.2 Technical data of PWR IN connection cable for voltage supply..................................................67

14.3.3 Order codes of PWR IN connection cable for voltage supply......................................................67

14.4 Accessory ready-made cables for interface connection..................................................... 68

14.4.1 General........................................................................................................................................68

14.4.2 Contact assignment for PROFIBUS connection cable KB PB… .................................................68

14.4.3 Technical data for PROFIBUS connection cable KB PB….......................................................... 69

14.4.4 Order codes for M12 PROFIBUS connection cables KB PB…...................................................69

14.4.5 Contact assignment for M12 Ethernet connection cable KB ET…..............................................70

14.4.6 Technical data for M12 Ethernet connection cable KB ET… ...................................................... 70

14.4.7 Order codes for M12 Ethernet connection cables KB ET…........................................................71

TNT 35/7-24V

Leuze electronic DDLS 200 3

Page 5

General Information

1 General Information

1.1 Explanation of symbols

The symbols used in this operating manual are explained below.

Attention!

Pay attention to passages marked with this symbol. Failure to heed this information can lead

to injuries to personnel or damage to the equipment.

Attention Laser!

This symbol warns of possible danger through hazardous laser radiation.

Note!

This symbol indicates text passages containing important information.

1.2 Declaration of conformity

The optical DDLS 200 data transmission system was designed and manufactured in accordance with

applicable European normatives and guidelines.

The manufacturer of the product, Leuze electronic GmbH + Co KG in D-73277 Owen/Teck, possesses

a certified quality assurance system in accordance with ISO 9001.

The declaration of conformity can be requested from the manufacturer.

U

L

C

US

LISTED

1.3 Short description

Where data have to be transmitted to and from moving objects, optical data transmission systems provide an ideal solution.

With the DDLS 200 Series, Leuze electronic offers optical, high-performance data transmission systems. The data transmission units are robust and are not subject to wear.

A DDLS 200 data transmission system consists of a set of two transmission and reception units: e.g.

DDLS 200/200.1-10 and DDLS 200/200.2-10.

4 DDLS 200 Leuze electronic

Page 6

General Information

Optical data transmission on

two frequencies

Features of the DDLS 200

The fact that bus systems are found in nearly all areas of industry places high demands on data transmission systems. The DDLS 200 fulfills these requirements, particularly with regard to:

• Transmission safety

• Minimum transmission times (real-time capable)

• Deterministic transmission

The DDLS 200 data transmission system, which is available in several model variations, makes possible the contact-free transmission of the following bus protocols:

• PROFIBUS FMS, DP, MPI, FMS - DP mixed-operation, up to max. 1.5Mbit/s, PROFISAFE

• INTERBUS 500kbit/s, RS 422 general, copper cable

• INTERBUS 2Mbit/s / 500kbit/s, fiber-optic cable

• Data Highway + (DH+) from Rockwell Automation (Allen Bradley)

• Remote I/O (RIO) from Rockwell Automation (Allen Bradley)

• DeviceNet

• CANopen

• Ethernet for all protocols based on TCP/IP or UDP

Other bus systems on request.

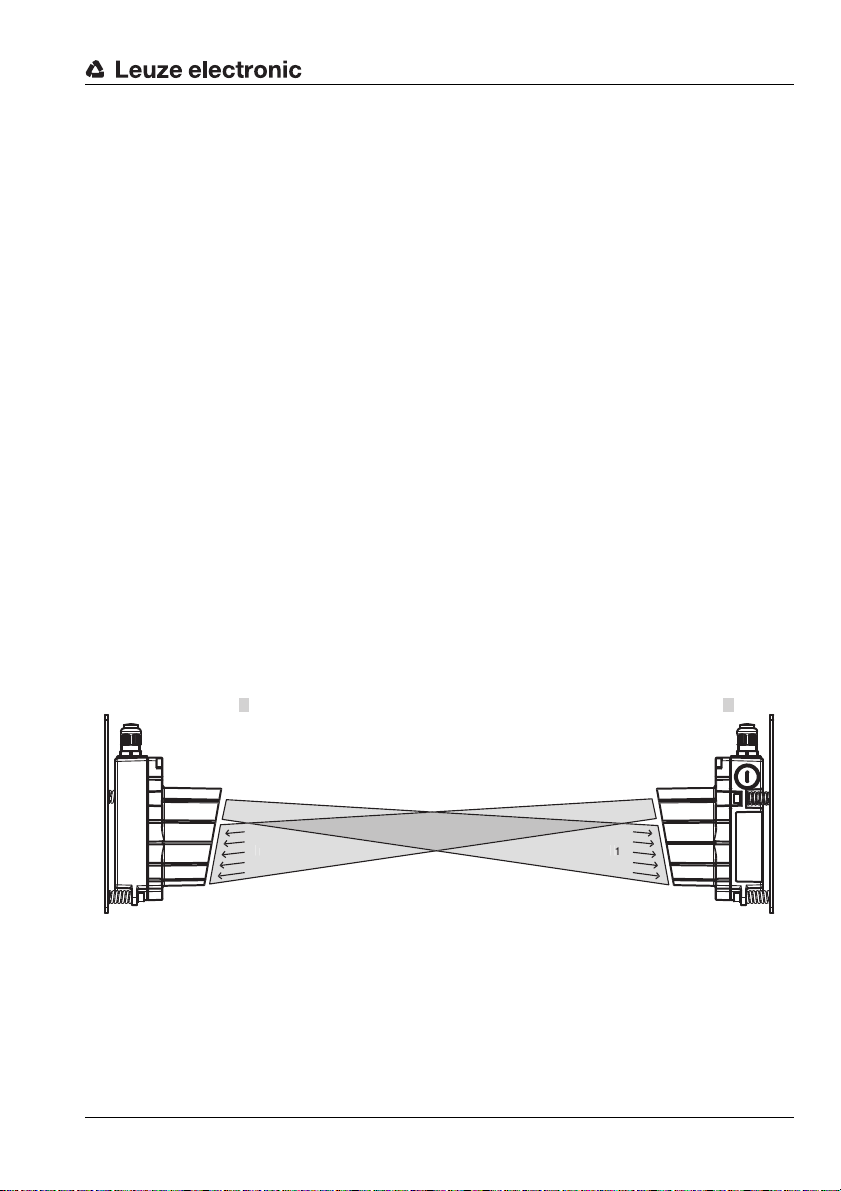

1.4 Operating principle

To prevent the devices from mutually interfering with one another during data transmission in duplex

operation, they use two different frequency pairs. These are indicated by the type designation ….1

and ….2 as well as the label frequency f

and frequency f

1

on the control panel.

2

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

Figure 1.1:Operating principle

The receiving level is checked at both devices and can be read on a bar graph LED indicator. If the

receiving level drops below a certain value, e.g. due to increased soiling of the optics, a warning output

is activated.

All work on the device (mounting, connecting, aligning, indicator/operating elements) is performed

comfortably on the front side.

Leuze electronic DDLS 200 5

TNT 35/7-24V

Page 7

Safety Notices

2 Safety Notices

2.1 Safety standards

The optical DDLS 200 data transmission system was developed, manufactured and tested in accordance with applicable safety standards. It corresponds to the state of the art. The device series

DDLS 200 is "UL LISTED" according to U.S. American and Canadian safety standards, and fulfills the

requirements of Underwriter Laboratories Inc. (UL).

2.2 Intended use

The DDLS 200 optical data transmission system has been designed and developed for the optical

transmission of data in the infrared range.

Attention!

The protection of personnel and the device cannot be guaranteed if the device is operated

in a manner not corresponding to its intended use.

Areas of application

The DDLS 200 is suitable for the following areas of application:

• Automated high-bay warehouses

• Stationary data transmission between buildings

• Anywhere, where data transmission to and from stationary or moving objects (visual contact) over

relatively long distances (up to 500m) is required.

• Rotary transmission

2.3 Working safely

Attention: Artificial optical radiation!

The DDLS 200 data transmission system uses an infrared diode and is a device of LED

Class 1 according to EN 60825-1.

When used under reasonable conditions, devices of LED Class 1 are safe. This even includes the use of optical instruments used for the direct observation of the laser beam.

For the operation of the data transmission system with artificial optical radiation, we refer to

directive 2006/25/EC or its implementation in the respective national legislation and to the

applicable parts of EN 60825.

Attention!

Interventions and changes to the device, except where expressly described in this operating

manual, are not authorized.

6 DDLS 200 Leuze electronic

Page 8

Safety Notices

2.4 Organizational measures

Documentation

All entries in this operating manual must be heeded, in particular those in the sections "Safety Notices"

and "Commissioning". Keep this technical description in a safe place. It should be accessible at all

times.

Safety regulations

Observe the locally applicable legal regulations and the rules of the employers' liability insurance association.

Qualified personnel

Mounting, commissioning and maintenance of the device may only be carried out by qualified personnel.

Work on electrical installations may only be carried out by qualified electricians.

Repair

Repairs must only be carried out by the manufacturer or an authorized representative.

Leuze electronic DDLS 200 7

TNT 35/7-24V

Page 9

Technical Data

3 Technical Data

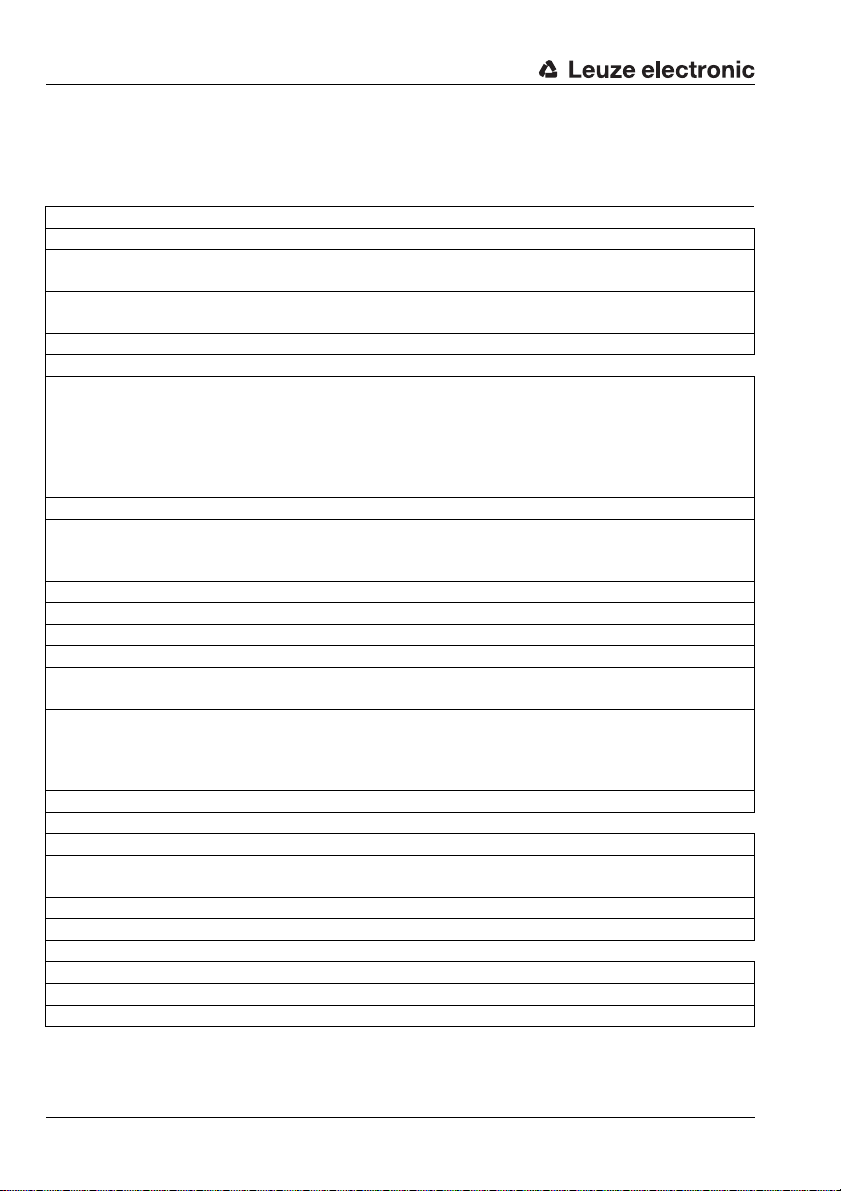

3.1 General technical data

Electrical data

Supply voltage Vin 18 … 30VDC

Current consumption

without optics heating

Current consumption

with optics heating

Optical data

Sensing distance 0.2 … 30m (DDLS 200/30…)

Transmission diode infrared light, wavelength 880nm

Opening angle ± 0.5° with respect to the optical axis for 120m … 500m models,

Ambient light > 10000 Lux according to EN 60947-5-2:2008

LED class 1 acc. to EN 60825-1

approx. 200mA with 24 VDC (no load at switching output)

approx. 800mA with 24 VDC (no load at switching output)

0.2 … 80m (DDLS 200/80…)

0.2 … 120m (DDLS 200/120…)

0.2 … 200m (DDLS 200/200…)

0.2 … 300m (DDLS 200/300…)

0.2 … 500m (DDLS 200/500…)

± 1.0° with respect to the optical axis for 80m models,

± 1.5° with respect to the optical axis for 30m models

Input/output

Input 0 … 2 VDC: transmitter/receiver deactivated

Output 0 … 2VDC: normal operation

Operating and display elements

Membrane buttons change the operating mode

Individual LEDs indicate voltage supply, operating mode, data traffic (depends on

LED strip bar graph display of the receiving level

Mechanical data

Housing aluminum diecast; light inlet/outlet, glass

Weight approx. 1200g

Protection class IP 65 acc. to EN 60529:2000

8 DDLS 200 Leuze electronic

18 … 30VDC: transmitter/receiver activated

Vin - 2VDC: limited performance reserve

output current max. 100mA, short-circuit proof, protected against

surge voltage, transients and overheating

the model)

Page 10

Technical Data

Environmental conditions

Operating temperature -5°C … +50 °C without optics heating

Storage temperature -30°C … +70°C

Air humidity max. 90% rel. humidity, non-condensing

Vibrations acc. to EN 60068-2-6:1996

Noise acc. to EN 60068-2-64:2009

Shock acc. to EN 60068-2-27:1995 and EN 60068-2-29:1995

*1

EMC

UL LISTED acc. to UL 60950 and CSA C22.2 No. 60950

*1 Warning: This is a Class A product. In a domestic environment this product may cause radio interfer-

ence, in which case the operator may be required to take adequate measures.

-30°C … +50°C with optics heating (non-condensing)

EN 61000-6-2:2006 and EN 61000-6-4:2007

Leuze electronic DDLS 200 9

TNT 35/7-24V

Page 11

Technical Data

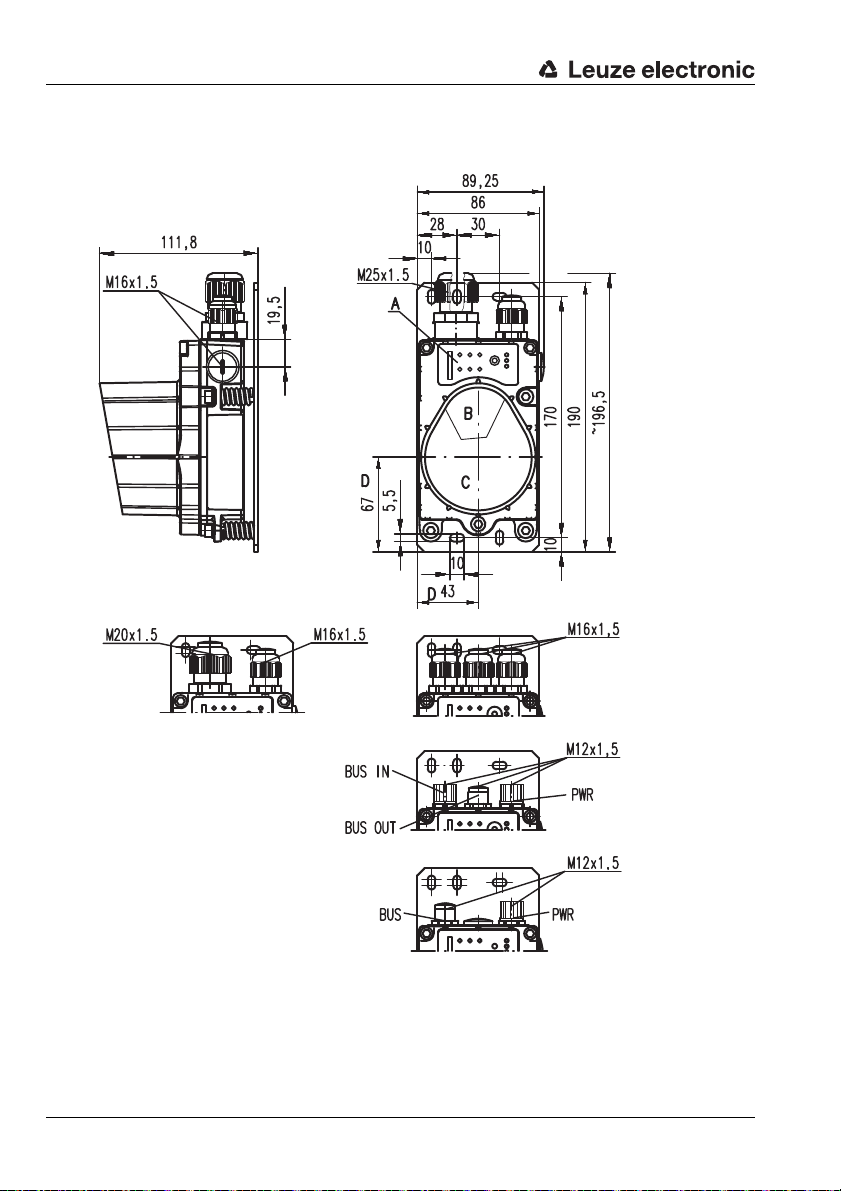

A Control panel

B Transmission optics

C Reception optics

D Optical axis

Permissible cables:

• M16 x 1.5:

round cable Ø 5 … 10 mm

• M20 x 1.5:

round cable Ø 7 … 12 mm

• M25 x 1.5:

round cable Ø 4.5 … 9 mm

DDLS 200 / … - 10 …

DDLS 200 / … - 20 …

DDLS 200 / … - 40 …

DDLS 200 / … - 50 …

DDLS 200 / … - 10 … - M12

DDLS 200 / … - 50 … - M12

DDLS 200 / … - 21 …

DDLS 200 / … - 60 … - M12

DDLS 200 / … - 60 …

3.2 Dimensioned drawings

Figure 3.1:Dimensioned drawing DDLS 200

10 DDLS 200 Leuze electronic

Page 12

Mounting / Installation (all device models)

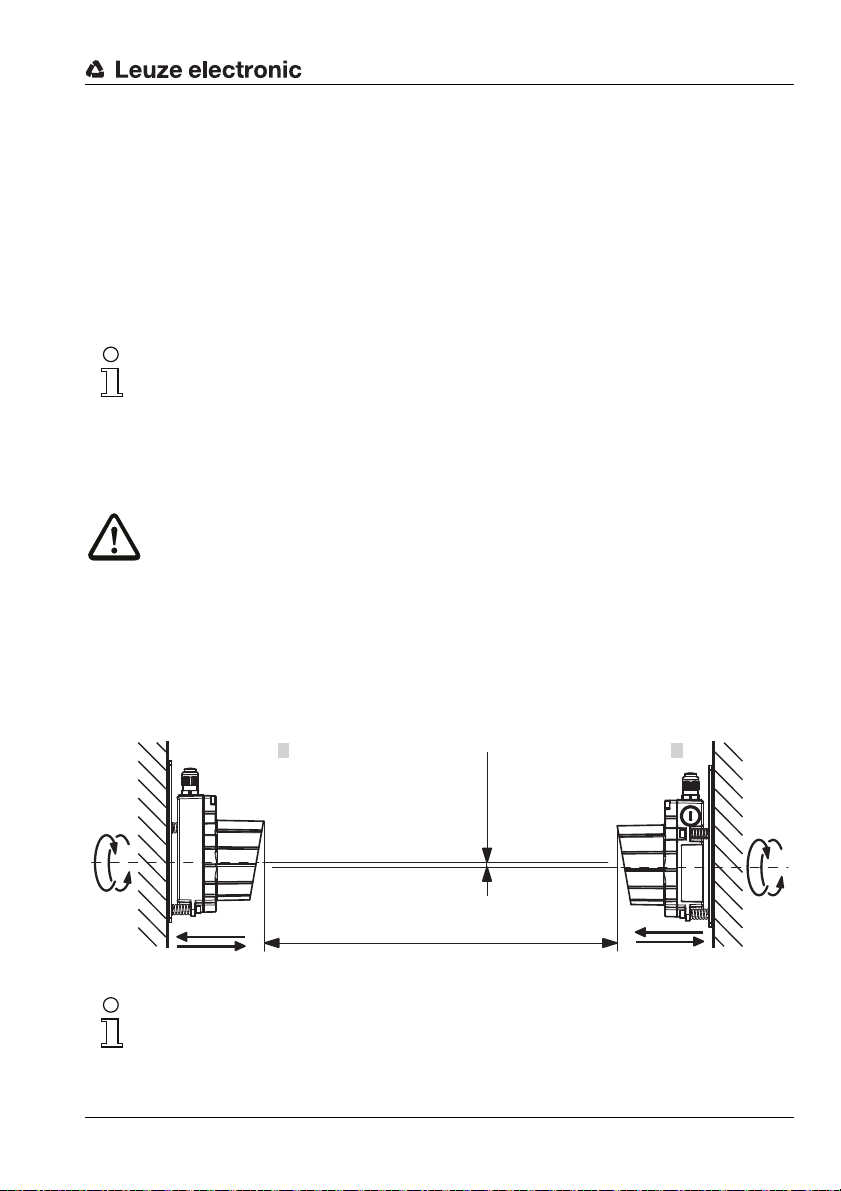

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

( frequency f1 ) ( frequency f2 )

Horizontal

and vertical

max. ± (A

min

• 0.01)

A

min

Optical axis

360°

rotation possible

360°

rotation possible

4 Mounting / Installation (all device models)

4.1 Mounting and alignment

An optical data transmission system, consisting of 2 DDLS 200 devices, involves mounting each of

the devices on mutually opposing, plane-parallel, flat and usually vertical walls with unobstructed view

of the opposing DDLS 200.

Make certain that, at the minimum operating distance A

with one another within ± A

• 0.01 to ensure that the transmission/reception beams of the two de-

min

vices lie within the opening angle. This also applies for rotary transmission.

Note

The opening angle (angle of radiation) of the optics is ± 0.5° (wide angle: ± 1.0° or ± 1.5°,

resp.) to the optical axis! For all device models, the horizontal and vertical adjustment angles

of the fine alignment with the adjustment screws is ±6° for each. The optical transmission

path between the DDLS 200s should not be interrupted. If interruptions cannot be avoided,

be sure to read the notice in chapter 11.4.

Therefore, pay close attention when selecting a suitable mounting location!

Attention!

When laying out a mobile arrangement for a DDLS 200, pay particular attention that the

alignment of the devices relative to one another remains unchanged over the transmission

path.The transmission can be interrupted by e.g. jolts, vibrations or inclination of the mobile

device due to irregularities in the floor or path.

Ensure adequate track stability! (see also "Diagnostic mode" on page 65)

Mount each device with 4 screws ∅ 5mm using 4 of the 5 fastening holes in the mounting plate of the

device (see chapter 3.2 "Dimensioned drawings").

the optical axes of the devices are aligned

min

Figure 4.1: Mounting the devices

Note

The fine alignment of the transmission system is performed during commissioning

(see chapter 11.3.2 "Fine adjustment"). The position of the optical axis of the DDLS 200 can

be found in chapter 3.2.

Leuze electronic DDLS 200 11

TNT 35/7-24V

Page 13

Mounting / Installation (all device models)

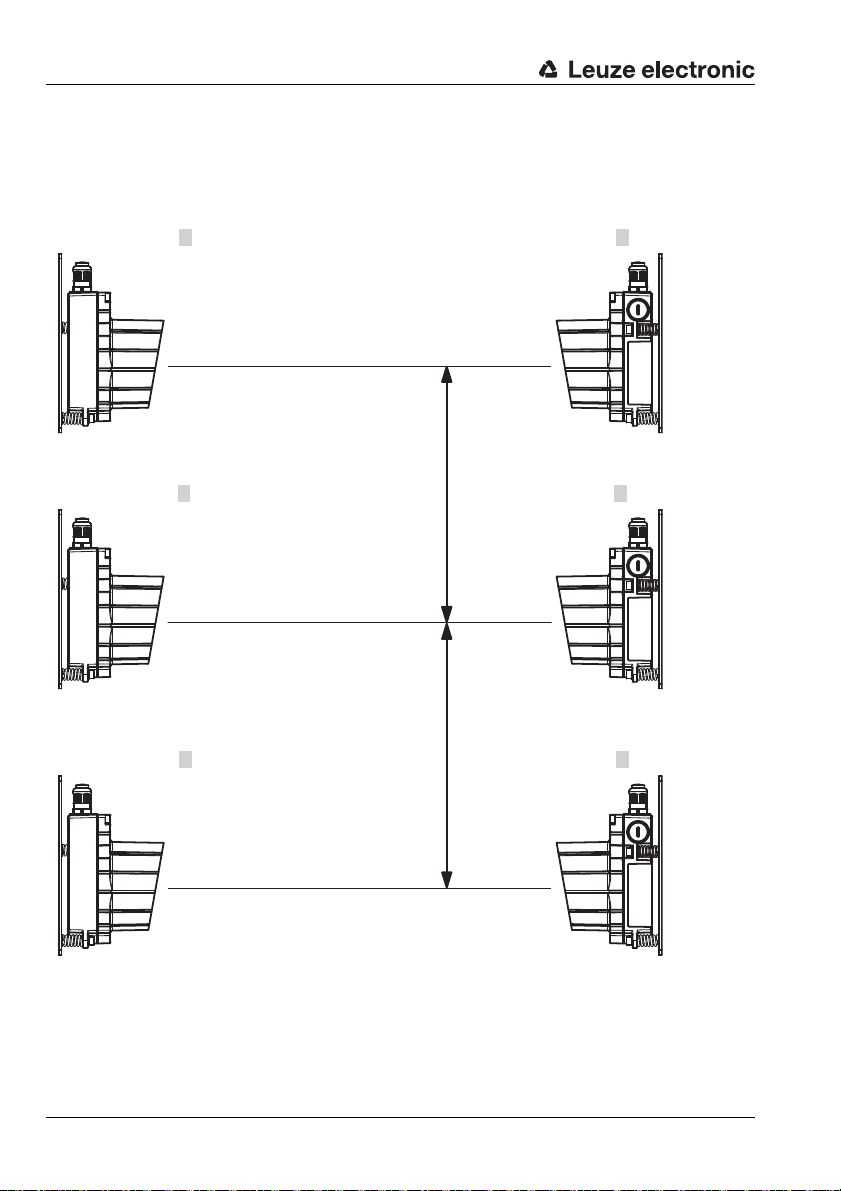

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

DDLS 200/XXX.1-YY DDLS 200/XXX.2-YY

( frequency f1 ) ( frequency f2 )

( frequency f

2

) ( frequency f1 )

( frequency f

1

) ( frequency f2 )

DDLS 200/XXX.1-YYDDLS 200/XXX.2-YY

min. 400mm (DDLS 200/30…)

min. 300mm (DDLS 200/80…)

min. 300mm (DDLS 200/120…)

min. 500mm (DDLS 200/200…)

min. 700mm (DDLS 200/300…)

min. 700mm (DDLS 200/500…)

Frequency-offset arrangement!

min. tan (0.5°) • operating range

(DDLS 200/120…500…)

min. tan (1.0°) • operating range

(DDLS 200/80…)

min. tan (1.5°) • operating range

(DDLS 200/30…)

Identical frequency

arrangement

4.2 Arrangement of adjacent transmission systems

To prevent mutual interference of adjacent transmission systems, the following measures should be

taken in addition to exact alignment:

Figure 4.2: Arrangement of adjacent transmission systems

12 DDLS 200 Leuze electronic

Page 14

Mounting / Installation (all device models)

• In the case of an offset frequency arrangement, the distance between two parallel data trans-

mission paths must not be less than

• 400mm (DDLS 200/30…)

• 300mm (DDLS 200/80…)

• 300mm (DDLS 200/120…)

• 500mm (DDLS 200/200…)

• 700mm (DDLS 200/300…)

• 700mm (DDLS 200/500…)

.

• In the case of identical frequency arrangement, the distance between two parallel data trans-

mission paths must be at least

• 400mm + tan (1.5°) • operating range (DDLS 200/30…)

• 300mm + tan (1.0°) • operating range (DDLS 200/80…)

• 300mm + tan (0.5°) • operating range (DDLS 200/120…)

• 500mm + tan (0.5°) • operating range (DDLS 200/200…)

• 700mm + tan (0.5°) • operating range (DDLS 200/300…)

• 700mm + tan (0.5°) • operating range (DDLS 200/500…)

.

Leuze electronic DDLS 200 13

TNT 35/7-24V

Page 15

Mounting / Installation (all device models)

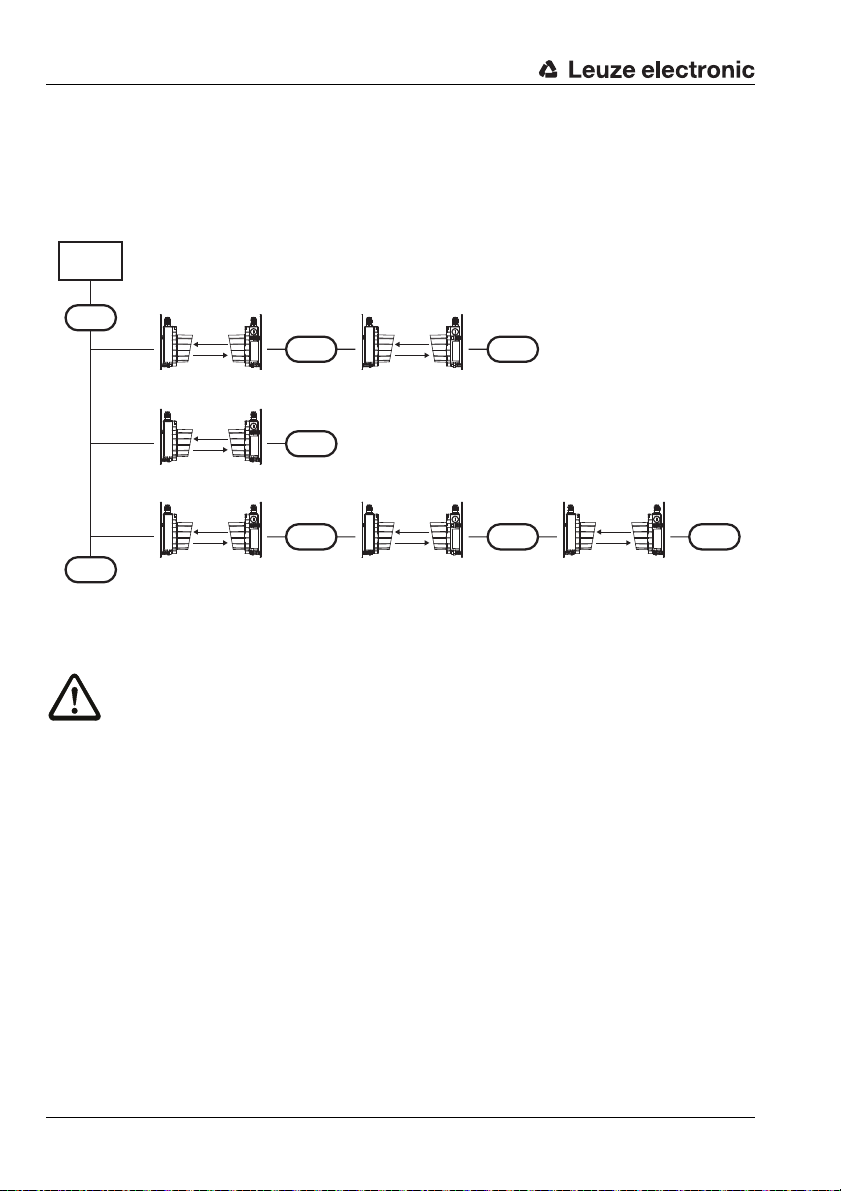

DDLS 200

DDLS 200

DDLS 200

DDLS 200

DDLS 200 DDLS 200

Master

TN1

TN8

TN2

TN4

TN5

TN3

TN6 TN7

Path 1

Path 3

Path 4

Path 2

Path 5 Path 6

4.3 Cascading (series connection) of several DDLS 200 data paths

If two communicating participants (TN) are separated by several optical transmission paths between

two participants, then this is called cascading. There are further participants between the individual

optical transmission paths in this case.

Figure 4.3: Cascading of several DDLS 200 systems

Attention!

If, for example, participant 3 (TN3) of a multi-master bus system wants to exchange data directly with participant 7 (TN7), then 5 optical transmission paths are cascaded.

This constellation can also occur if, e.g., a programming device that attempts to access participant 3 (TN3) is connected to participant 7 (TN7) for maintenance purposes or during commissioning of a master-slave-system.

14 DDLS 200 Leuze electronic

Page 16

Mounting / Installation (all device models)

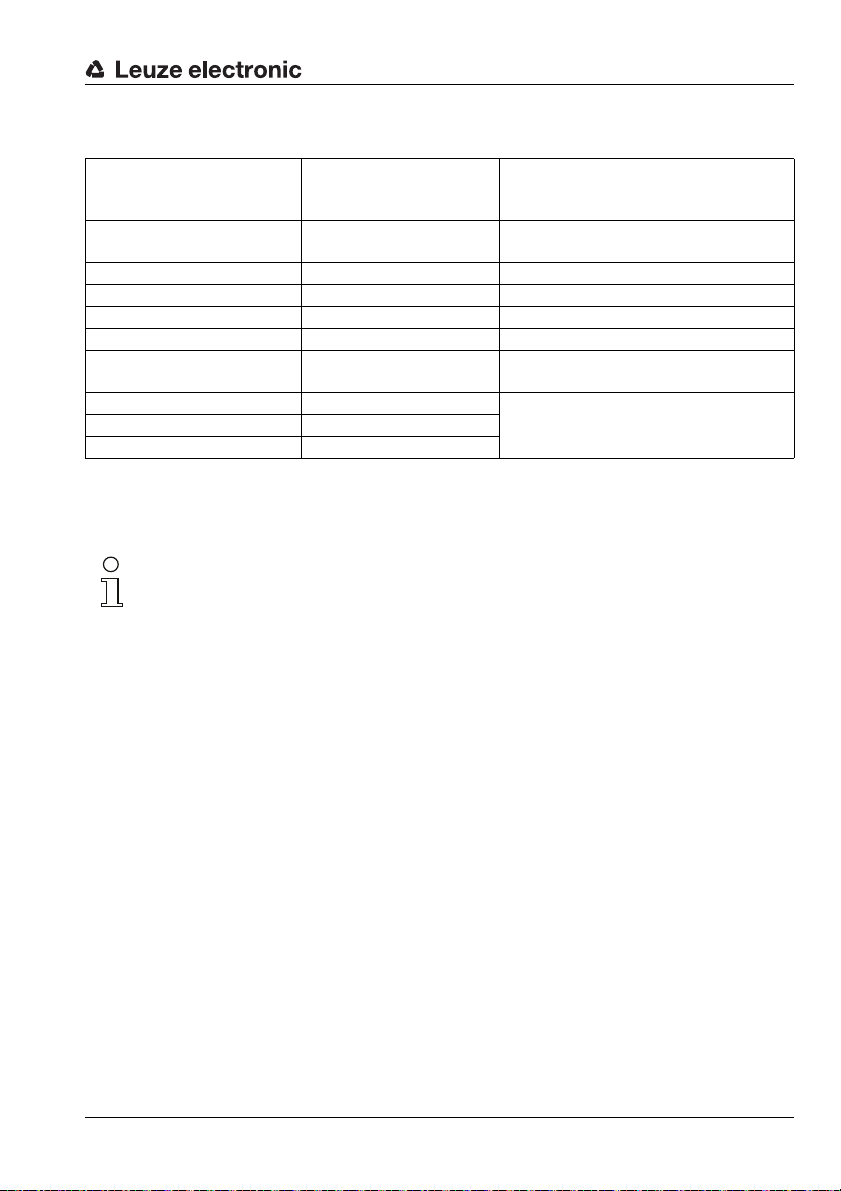

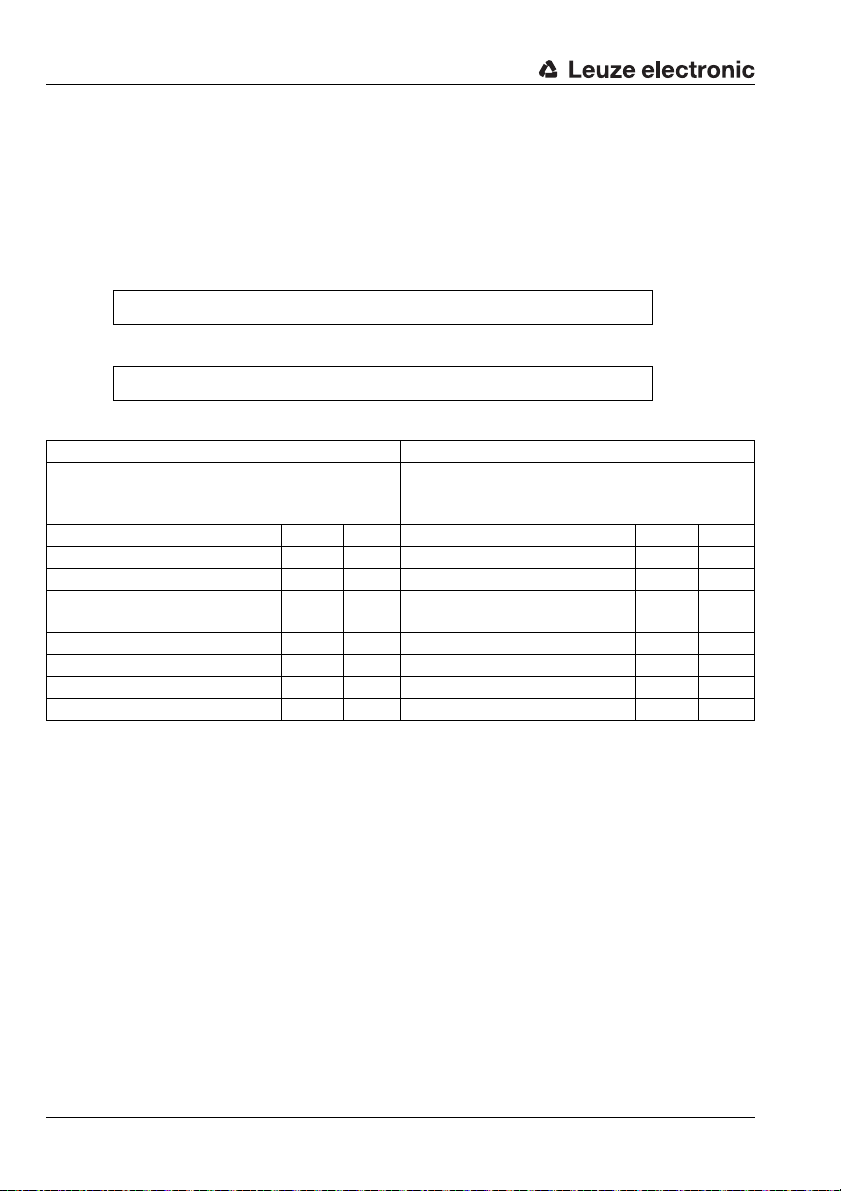

The following table shows the maximum number of optical transmission paths for cascading.

Max. number of optical

Bus system

Profibus (with retiming) 3

RS 485 (without retiming) 2

Interbus 500kbit (RS 422) 3

Interbus FOC 3 Applies for 500kbit and 2 Mbit

RIO 3

DH+

DeviceNet 3

CANopen 3

Ethernet 3

1) See remarks in the respective chapters of the individual bus systems about the switch position filtered/not filtered depending on the transmission rate.

Note

The individual time delay of the optical transmission path is specified in the chapters of the

individual bus systems and depends on the type, switch position, and transmission rate.

transmission paths for

cascading

1)

1)

3

Remark

Attention:

Profibus FMS is a multi-master bus

Attention:

DH+ may be a multi-master bus

Depends significantly on the configuration of the master and on the requirements of the plant (timing).

Leuze electronic DDLS 200 15

TNT 35/7-24V

Page 17

Mounting / Installation (all device models)

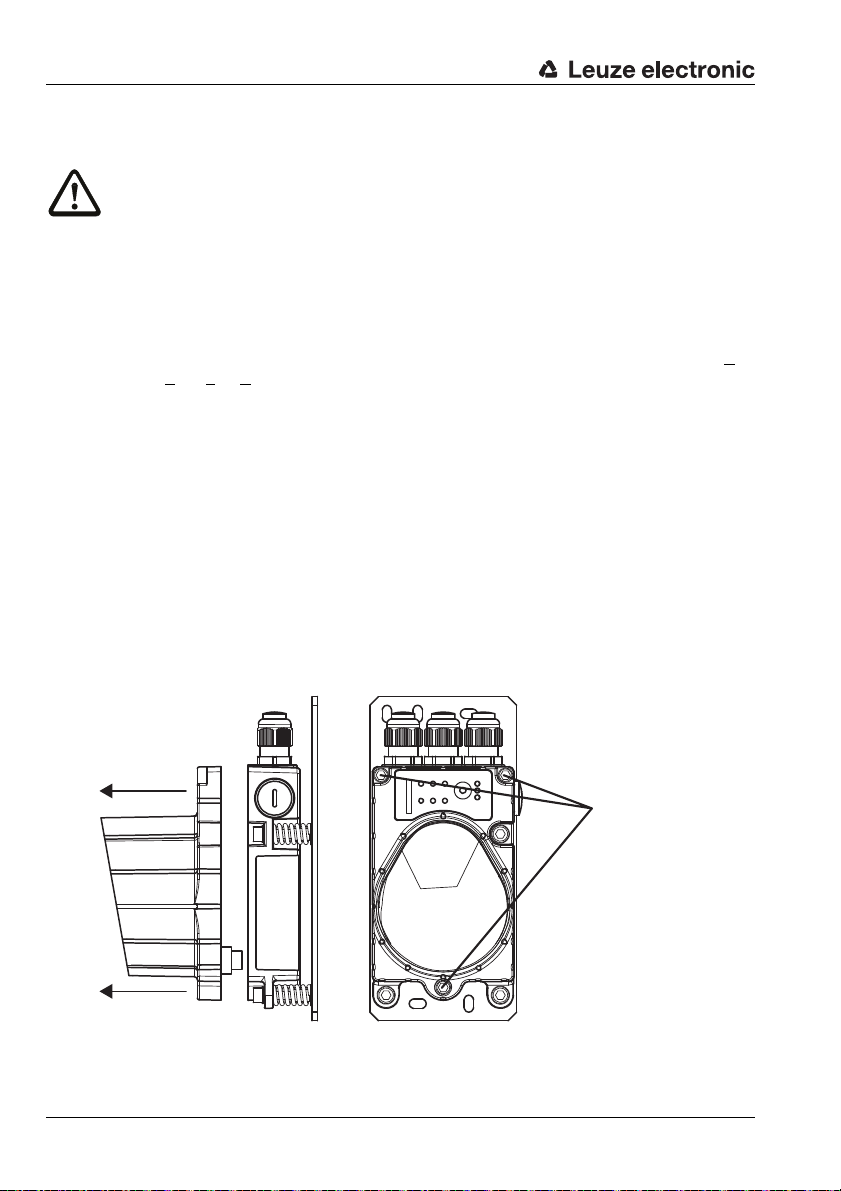

Loosen the 3

housing screws

Carefully pull off the

housing top

4.4 Electrical connection

Attention!

Connection of the device and maintenance work while under voltage must only be carried

out by a qualified electrician.

If faults cannot be corrected, the device should be removed from operation and protected

against possible use.

Before connecting the device, be sure that the supply voltage agrees with the value printed

on the nameplate.

The DDLS 200… is designed in accordance with safety class III for supply by PELV (P

tective E

For UL applications: only for use in class 2 circuits according to NEC.

Be sure that the functional earth is connected correctly. Error-free operation is only guaranteed if the device is connected to functional earth.

Described in the following two sub-chapters is the electrical connection of the supply voltage, the input

and the output.

The connection of the respective bus system is described in the following chapters.

xtra Low Voltage, with reliable disconnection).

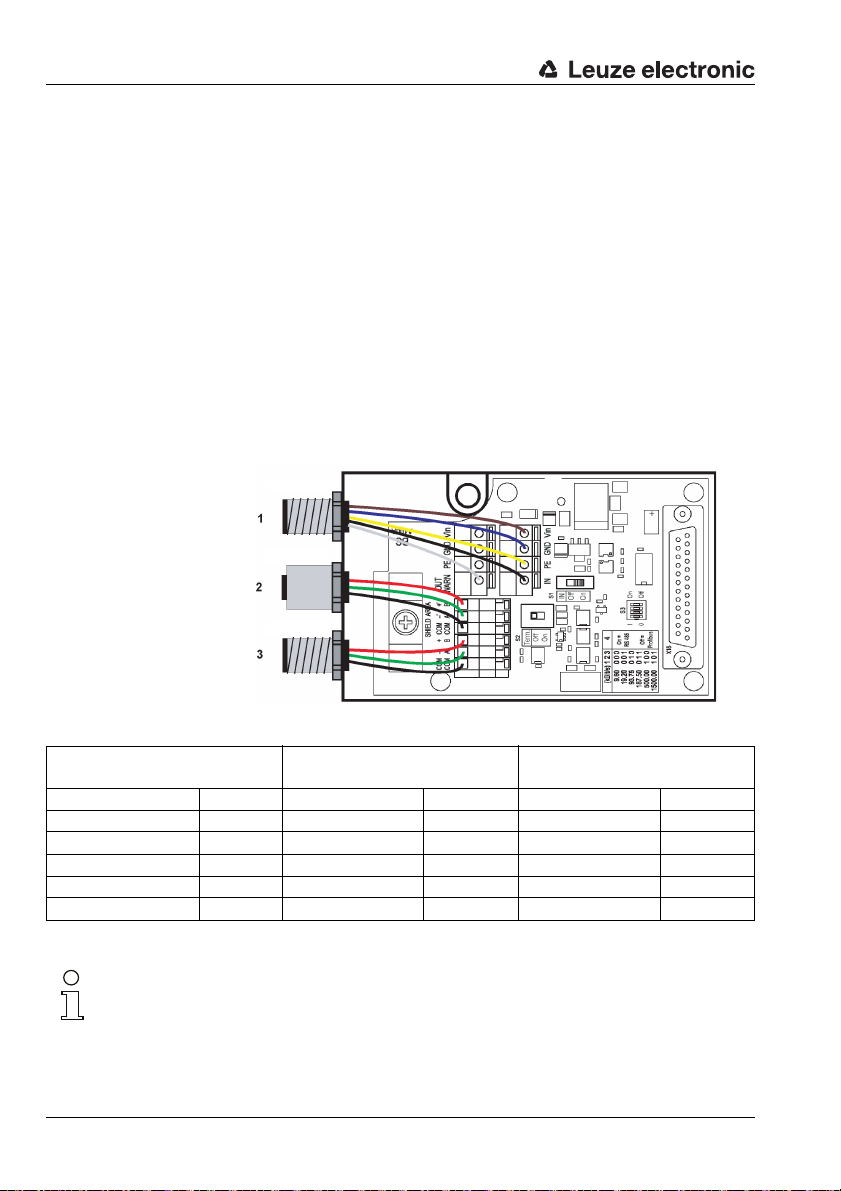

4.4.1 Electrical connection - devices with screwed cable glands and terminals

To establish the electrical connections, you must first remove the red housing top with the optics. To

do this, loosen the three housing hex screws. The housing top is now only electrically connected to

the base by means of a connector. Carefully pull the housing top straight forward without skewing.

ro-

Figure 4.4: Removing the housing top

16 DDLS 200 Leuze electronic

Page 18

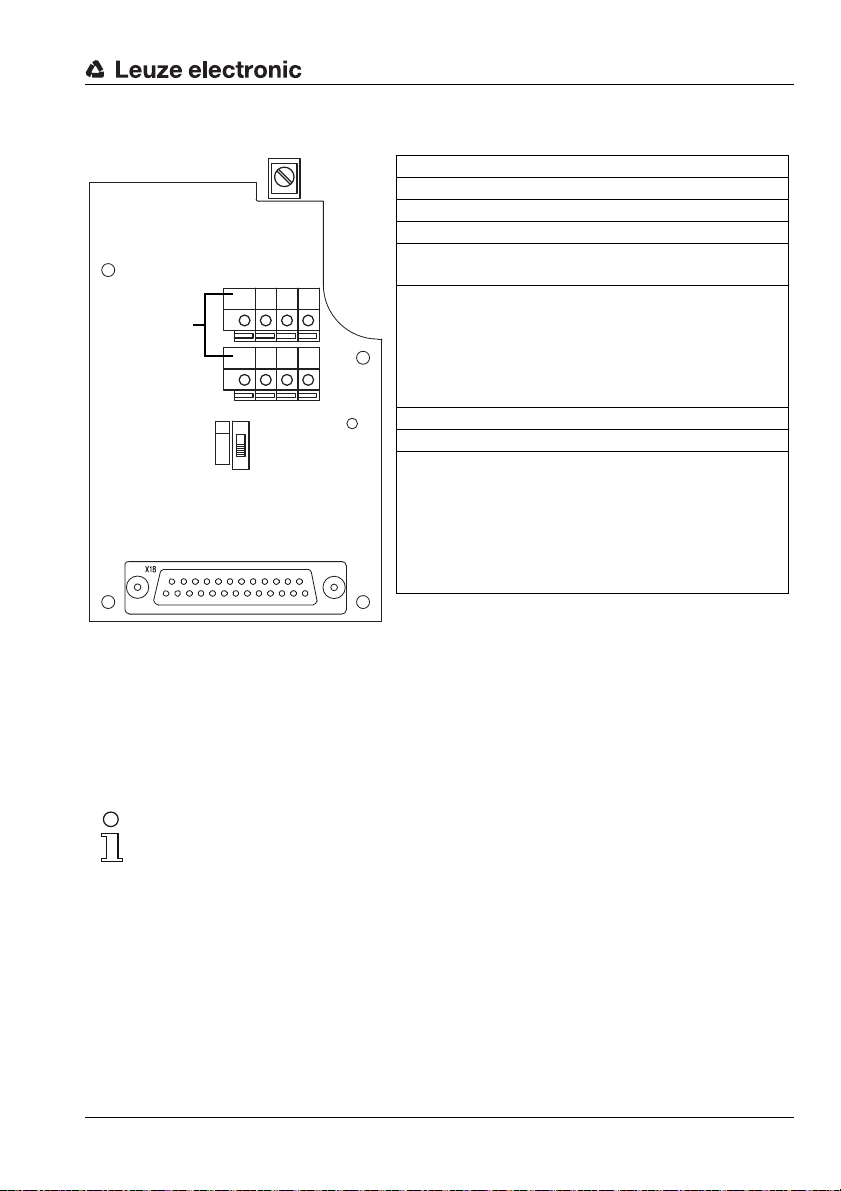

Mounting / Installation (all device models)

OUTOUT

WARNWARN PEPE

PEPE

GNDGND

VinVin

ININ

PEPE GNDGND

VinVin

S1

Off

On

IN

Terminal Function

Vin Positive supply voltage +18 … +30VDC

GND Negative supply voltage 0VDC

PE Functional earth

OUT

WARN

Switching output, activated if level

drops below the warning level

IN Switching input for transmitter/receiver

cut-off:

0…2VDC: transmitter/receiver

switched off, no transmission

18 … 30 V DC: transmitter/receiver

active, normal function

Switch Function

S1 On (default): the switching input is not

analyzed. The transmitter/receiver unit

is always in operation.

Off: the switching input is analyzed.

Depending on the input voltage, normal

function or transmitter/receiver unit

switched off.

Max.

core cross

section:

1.5 mm

2

The connection compartment in the housing base with the screwed cable glands is now freely accessible.

Figure 4.5: Positions of the general, non-bus-specific terminals and switches

Supply voltage

Connect the supply voltage, including the functional earth, to the spring terminals labeled Vin, GND

and PE (see figure 4.5).

Note

The connection terminals Vin, GND and PE are provided double to simplify wiring through

the supply voltage to other devices.

The functional earth can alternatively be connected at the screw terminal in the housing

base (max. core cross section 2.5mm

If you would like to wire through the supply voltage, you should replace the filler plugs on the

right side of the housing base with an M16 x 1.5 screwed cable gland and guide the continuing supply voltage cable through this gland. The housing seal is, in this way, ensured (Protection Class IP 65).

The housing top can be removed and replaced while under voltage.

2

)

Leuze electronic DDLS 200 17

TNT 35/7-24V

Page 19

Mounting / Installation (all device models)

Switching input

The DDLS 200 is equipped with a switching input IN, via which the transmitter/receiver unit can be

switched off, i.e. no infrared light is transmitted and at the bus terminals the corresponding bus bias

level is present / the bus driver is high resistance.

Input voltage: 0 … 2 V DC: transmitter/receiver switched off, no transmission

(relative to GND) 18 … 30 V DC: transmitter/receiver active, normal function

For easier operation, the switching input can be activated/deactivated via switch S1:

Position S1: On the switching input is not analyzed. The transmitter/receiver

Off the switching input is analyzed. Depending on the input volt-

Note!

When transmitter/receiver unit is switched off, the system behaves in the same way as in

the event of a light beam interruption (see chapter 11.4 "Operation").

The switching input can be used, for example, during a corridor change to completely avoid

interference effects from other sensors or the data transmission.

Switch S1 is also present on the device models with M12 connectors.

unit is always in operation (internal preselection of the switching input with Vin).

age, normal function or transmitter/receiver unit switched off.

Switching output

The DDLS 200 is equipped with a switching output OUT WARN which is activated if the receiving level

in the receiver drops.

Output voltage: 0 … 2 V DC: Operating range

(relative to GND) Vin - 2 V DC: Warning or shutoff range

The switching output is protected against:short-circuit, overcurrent, overvoltage,

Note!

The DDLS 200 is still completely functional when the level of the receiving signal drops to

the warning signal level. Checking the alignment, and, if applicable, a readjustment and/or

cleaning of the glass pane leads to a significant improvement of the received signal level.

18 DDLS 200 Leuze electronic

overheating and transients.

Page 20

Mounting / Installation (all device models)

BUS OUTBUS IN

All M12 device models:PWR IN

M12 plug, A-coded

M12 plug

(A-coded)

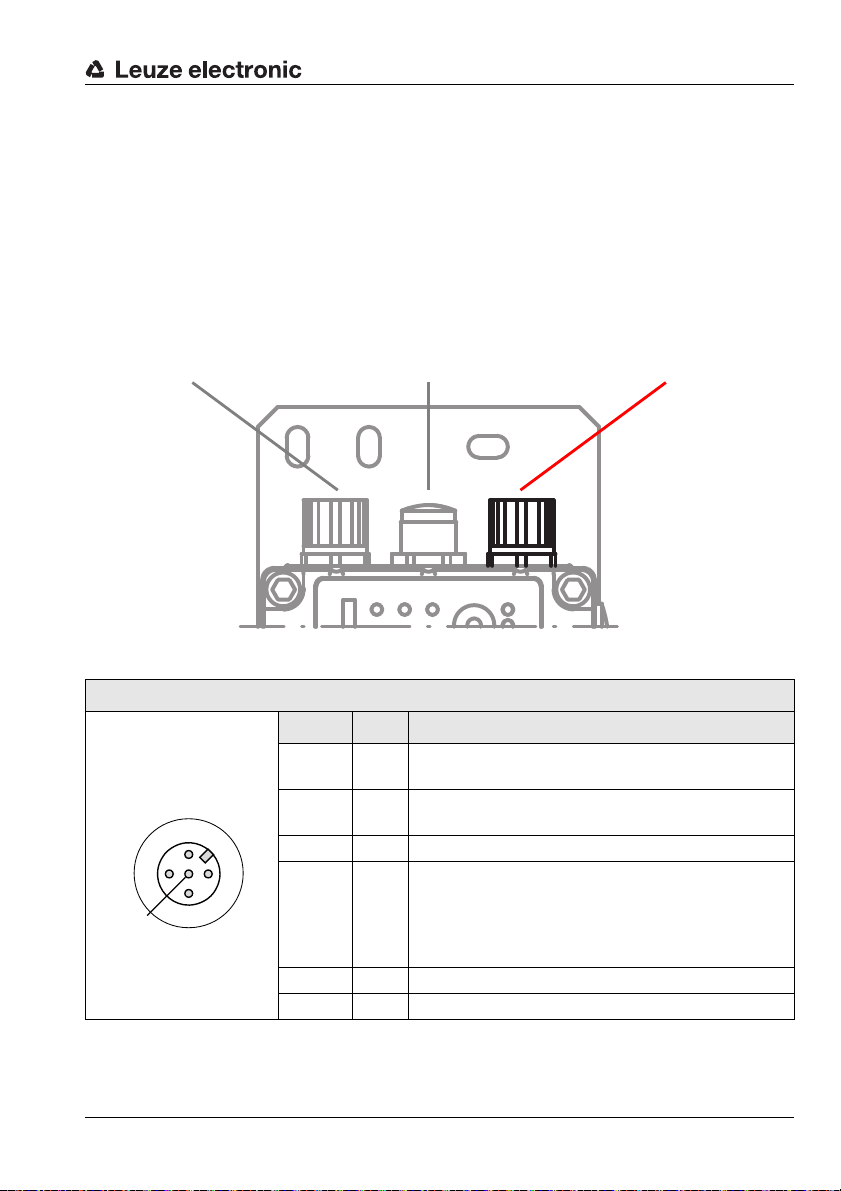

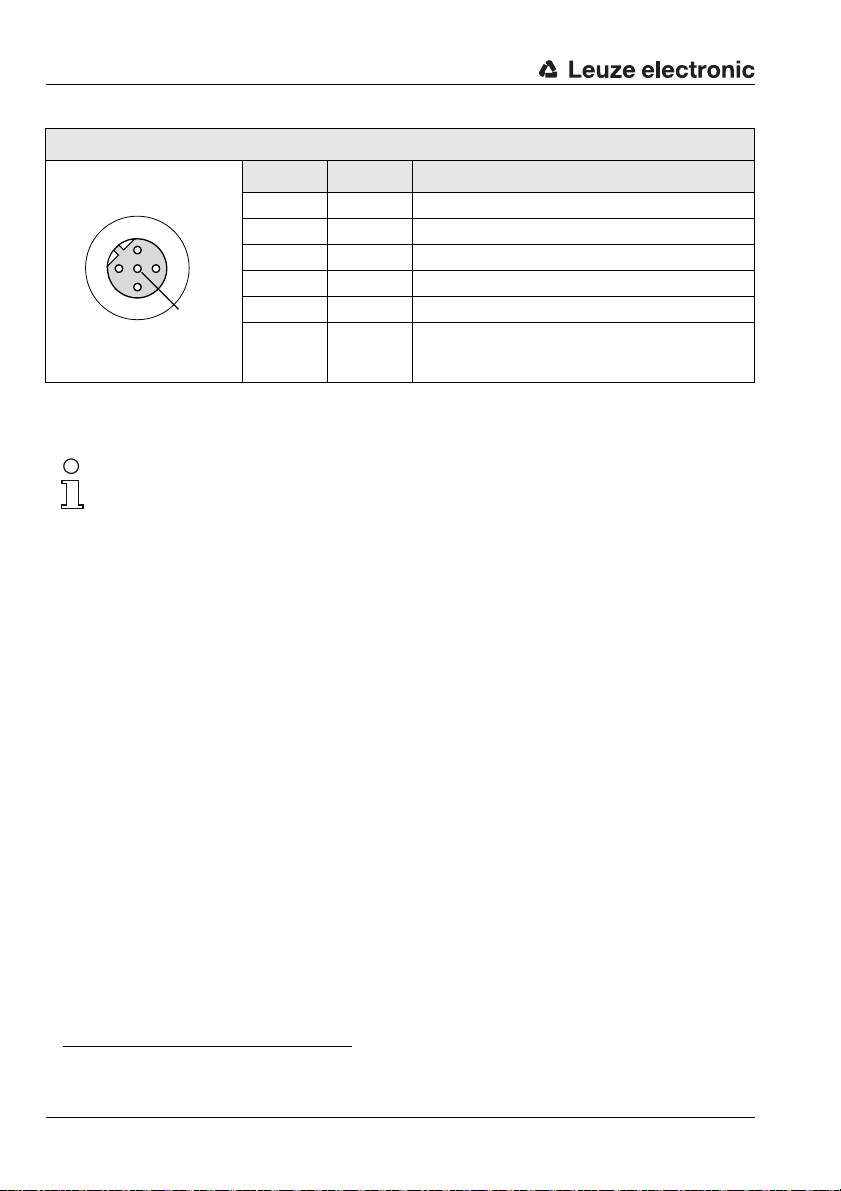

4.4.2 Electrical connection - devices with M12 connectors

The electrical connection is easily performed using M12 connectors. Ready-made connection cables

are available as accessories both for connecting supply voltage/switching input/switching output as

well as for connecting the respective bus system (see chapter 14 "Accessories").

For all M12 device models, the supply voltage, the switching input and the switching output are connected via the right, A-coded connector PWR IN (see figure 4.6).

Figure 4.6: Location and designation of the M12 connections

PWR IN (5-pin M12 plug, A-coded)

Pin Name Remark

PWR IN

1Vin

OUT

WARN

2

2

3 GND Negative supply voltage 0VDC

3

GND Vin

FE

Figure 4.7: Assignment M 12 connector PWR IN

Leuze electronic DDLS 200 19

IN

1

4

4IN

5 FE Functional ear th

Thread FE Functional earth (housing)

Positive supply voltage

+18 … +30VDC

OUT

Switching output, activated if level drops below the

WARN

warning level

Switching input for transmitter/receiver cut-off:

0…2VDC: transmitter/receiver switched off,

18 … 30 V DC: transmitter/receiver active,

no transmission

normal function

TNT 35/7-24V

Page 21

Mounting / Installation (all device models)

Supply voltage

Connect the supply voltage including functional earth according to the pin assignments (see

figure 4.7).

Switching input

The DDLS 200 is equipped with a switching input IN (pin 1), via which the transmitter/receiver unit can

be switched off, i.e. no infrared light is transmitted and at the bus terminals the corresponding bus bias

level is present / the bus driver is high resistance.

The upper part of the housing only needs to be removed if the switching input is to be activated/deactivated via switch S1 (for further information, see figure 4.4, figure 4.5 and "Switching input" on

page 18).

Input voltage: 0 … 2 V DC: transmitter/receiver switched off, no transmission

(relative to GND) 18 … 30 V DC: transmitter/receiver active, normal function

For easier operation, the switching input can be activated/deactivated via switch S1 (see chapter

4.4.1, figure 4.4 and figure 4.5):

Position S1: On the switching input is not analyzed. The transmitter/receiver

unit is always in operation (internal preselection of the switching input with Vin).

Off the switching input is analyzed. Depending on the input volt-

age, normal function or transmitter/receiver unit switched off.

Note!

When transmitter/receiver unit is switched off, the system behaves in the same way as in

the event of a light beam interruption (see chapter 11.4 "Operation").

The switching input can be used, for example, during a corridor change to completely avoid

interference effects from other sensors or the data transmission.

Switch S1 is also present on the device models with M12 connectors.

Switching output

The DDLS 200 is equipped with a switching output OUT WARN which is activated if the receiving level

in the receiver drops.

Output voltage: 0 … 2 V DC: Operating range

(relative to GND) Vin - 2 V DC: warning or shutoff range

The switching output is protected against:short-circuit, overcurrent, overvoltage,

Note!

The DDLS 200 is still completely functional when the level of the receiving signal drops to

the warning signal level. Checking the alignment, and, if applicable, a readjustment and/or

cleaning of the glass pane leads to a significant improvement of the received signal level.

20 DDLS 200 Leuze electronic

overheating and transients.

Page 22

PROFIBUS / RS 485

S2

S1

COMCOM COMCOMA B A'A' B'B'

OUTOUT

WARNWARN PEPE GNDGND

VinVin

ININ

PEPE GNDGND

VinVin

SHIELD AREASHIELD AREA

BSBS

A400AA400A

Term.

Off

On

COMCOM COMCOM– + –' +'+'

Off

On

IN

On =

RS 485

Off =

Profibus

S3

Off

On

0

1

PROFIBUS - terminals and switches

Terminal Function

A , – (N) PROFIBUS or (–) RS 485

B, + (P) PROFIBUS or (+) RS 485

COM Potential equalization

A’, –’ (N) PROFIBUS or (–) RS 485 of the

wired-through bus

B’, +’ (P) PROFIBUS or (+) RS 485 of the

wired through bus

Switch Function

S2 Termination On/Off

S3-1 … S3-3 Setting the baud rate of the PROFIBUS

segment

S3-4 Changeover PROFIBUS (Off) /

RS 485 (On)

5PROFIBUS / RS485

The PROFIBUS model of the DDLS 200 has the following features:

• Operating ranges 30m, 80 m, 120m, 200m, 300 m, 500m

• Electrically isolated interface

• The DDLS 200 does not occupy a PROFIBUS address

• Integrated repeater function (signal processing), can be switched off

• Protocol-independent data transmission, i.e. transmission of the FMS, DP, MPI,

FMS/DP mixed operation protocols, PROFISAFE

• 2 connection variants: terminal connection with screwed cable glands or M12 connectors

• Connectable bus terminator (termination), or ext. terminator plug on the M 12 model

• 6 baud rates configurable (see chapter 5.3)

• Optional M12 connector set for conversion available as accessory

• It is possible to cascade several DDLS 200 (see chapter 4.3)

5.1 PROFIBUS connection - devices with screwed cable glands and terminals

The electrical connection to the PROFIBUS is made at the terminals A, B, and COM. The terminals

A’, B’ and COM are provided for wiring through the bus.

Figure 5.1:Connection board for PROFIBUS model with terminals and screwed cable glands

Attention!

Please be sure to observe the installation requirements (bus cables, cable lengths, shielding, etc.) defined in the PROFIBUS standard EN 50170 (Vol. 2).

Leuze electronic DDLS 200 21

TNT 35/7-24V

Page 23

PROFIBUS / RS 485

M12 plug (power)

M12 socket (bus),

onward bus

M12 plug (bus),

incoming bus

5.1.1 Converting the PROFIBUS model with terminals to M12 connectors

Available as an optional accessory is an M12 connector set, consisting of M12 connector (A-coded,

power), M12 connector (B-coded, bus) and M12 socket (B-coded, bus), with ready-made wires (Part

No. 500 38937). This can be used to convert the PROFIBUS models with terminals/screwed cable

glands to M12 connectors.

Conversion to M12 connectors

1. Remove screwed cable gland 1, 2 and 3 (spanner size = 20mm)

2. Screw M12 plug (power) into the thread of the screwed cable gland 1 that you have just

removed and tighten it with spanner SW18.

3. Screw M12 socket (bus) into the thread of the screwed cable gland 2 that you have just

removed and tighten it with spanner SW18.

4. Screw M12 plug (bus) into the thread of the screwed cable gland 3 that you have just removed

and tighten it with spanner SW18.

5. Connect cables acc. to figure 5.2 and Table 5.1.

Figure 5.2:Installation and connection of the optional M12 connectors

(1) M12 plug (Power)

Pin 1 (brown) Vin Pin 1 (not used) – Pin 1 (not used) –

Pin 2 (white) OUT Pin 2 (green) A’ Pin 2 (green) A

Pin 3 (blue) GND Pin 3 (black) COM Pin 3 (black) COM

Pin 4 (black) IN Pin 4 (red) B’ Pin 4 (red) B

Pin 5 (yellow/green) PE Pin 5 (not used) – Pin 5 (not used) –

Table 5.1: Connection of M 12 connectors

(2) M 12 socket (bus),

onward bus

Screw fitting Shield Screw fitting Shield

(3) M12 plug (bus),

incoming bus

Note!

The orientation of the M12 connectors is not defined. The use of angular M12 connectors

as counterparts is therefore discouraged.

An external termination on the M12 socket is not possible. For terminating the device, the

termination switch S2 must be used always

22 DDLS 200 Leuze electronic

Page 24

PROFIBUS / RS 485

PROFIBUS: BUS OUT

M12 socket, B-coded

PROFIBUS: BUS IN

M12 connector, B-coded

All M12 device models:

PWR IN

M12 plug, A-coded

BUS IN

GNDP

3

2

1

4

NC

A (N)

B (P)

NC

M12 plug

(B-coded)

5.2 PROFIBUS connection - devices with M12 connectors

The electrical connection of the PROFIBUS is easily performed using M12 connectors. Ready-made

connection cables are available as accessories both for connecting the incoming bus as well as for

connecting the continuing bus (see chapter 14 "Accessories").

For all M12 device models, the connection is made via the two left, B-coded connectors BUS IN and

BUS OUT (see figure 5.3).

Figure 5.3:Location and designation of the M12 PROFIBUS connections

Figure 5.4:Assignment M12 connector BUS IN

Leuze electronic DDLS 200 23

BUS IN (5-pin M12 plug, B-coded)

Pin Name Remark

1NCNot used

2A (N)Receive/transmit data A-line (N)

3 GNDP Data reference potential

4B (P)Receive/transmit data B-line (P)

5NCNot used

Thread FE Functional earth (housing)

TNT 35/7-24V

Page 25

PROFIBUS / RS 485

BUS OUT

VCC

1

2

3

4

A (N)

B (P)

GNDP

NC

M12 socket

(B-coded)

BUS OUT (5-pin M12 socket, B-coded)

Pin Name Remark

1VCC5VDC for bus terminator (termination)

2A (N)Receive/transmit data A-line (N)

3GNDPData reference potential

4B (P)Receive/transmit data B-line (P)

5NCNot used

Thread FE Functional ear th (housing)

Figure 5.5:Assignment M12 connector BUS OUT

Termination for devices with M12 connectors

Note!

If the PROFIBUS network begins or ends at the DDLS 200 (not a continuing bus), the

BUS OUT connection must be terminated with the TS 02-4-SA terminator plug, which is

available as an optional accessory (see chapter 14.1 on page 67).

In this case, please also order the TS 02-4-SA terminator plug.

5.3 Device configuration PROFIBUS

Termination for devices with screwed cable glands and terminals

The PROFIBUS can be terminated via the switch S2 in the DDLS 200. If the termination is active

(S2 = On), internal bus resistors are connected as per the PROFIBUS standard and the PROFIBUS

is not wired through at terminals A’ and B’.

Activate the termination when the PROFIBUS segment begins or ends at the DDLS 200. The default

setting is termination inactive (S2 = Off).

Adjustment of the transmission rate

You must set the transmission rate of your PROFIBUS segment using the three DIP switches S3-1

through S3-3. Possible transmission rates are:

• 9.6 kbit/s • 19.2 kbit/s

• 93.75 kbit/s • 187.5 kbit/s

• 500 kbit/s 1)• 1500 kbit/s

Set the transmission rate in accordance with the table printed on the connection circuit board (see

figure 5.1). The default setting is:

• 9.6kbit/s for DDLS 200 PROFIBUS device models with terminal connection

• 1500kbit/s for DDLS 200 PROFIBUS device models with M12 connection

1) Not for 500m operating range!

24 DDLS 200 Leuze electronic

1)

1)

Page 26

PROFIBUS / RS 485

PWR Tx Rx

AUT

MAN

ADJ

LED PWR: green = operating indicator

green flashing= transmitter /receiver unit switched off

via switching input IN or hardware error

off = no operating voltage

LED Tx: green = data are being transmitted to the bus

green flashing= with baud rates set to very low values,

the LEDs Tx and Rx flicker. At very

high baud rates (> 50kbit/s), flashing

LEDs Tx and Rx indicate faulty bus

communication.

off = no data on the transmission line

LED Rx: green = data are being received by the bus

green flashing= with baud rates set to very low values,

the LEDs Tx and Rx flicker. At very

high baud rates (> 50kbit/s), flashing

LEDs Tx and Rx indicate faulty bus

communication.

off = no data on the reception line

PROFIBUS / RS 485 changeover (default: ’Off’ = PROFIBUS)

The DDLS 200 has, as a standard function, a repeater function (signal processing) and is, with regard

to the PROFIBUS, to be viewed as a repeater.

Note!

Please observe the guidelines specified in EN 50170 (Vol. 2) regarding the use of repeaters.

The delay time of a data transmission path is maximum 1.5 µs + 1T

It is also possible to transmit other RS 485 protocols. For PROFIBUS applications, S3-4

should be set to 'Off' ('0'). DIP-switch S3-4 can be used to switch off the repeater function

for non-PROFIBUS applications (S3-4 = 'On'). In this case, no signal regeneration takes

place; the RS 485 protocol must, however, still provide certain features

Please contact the manufacturer if you would like to use the DDLS 200 for general

RS 485 protocols.

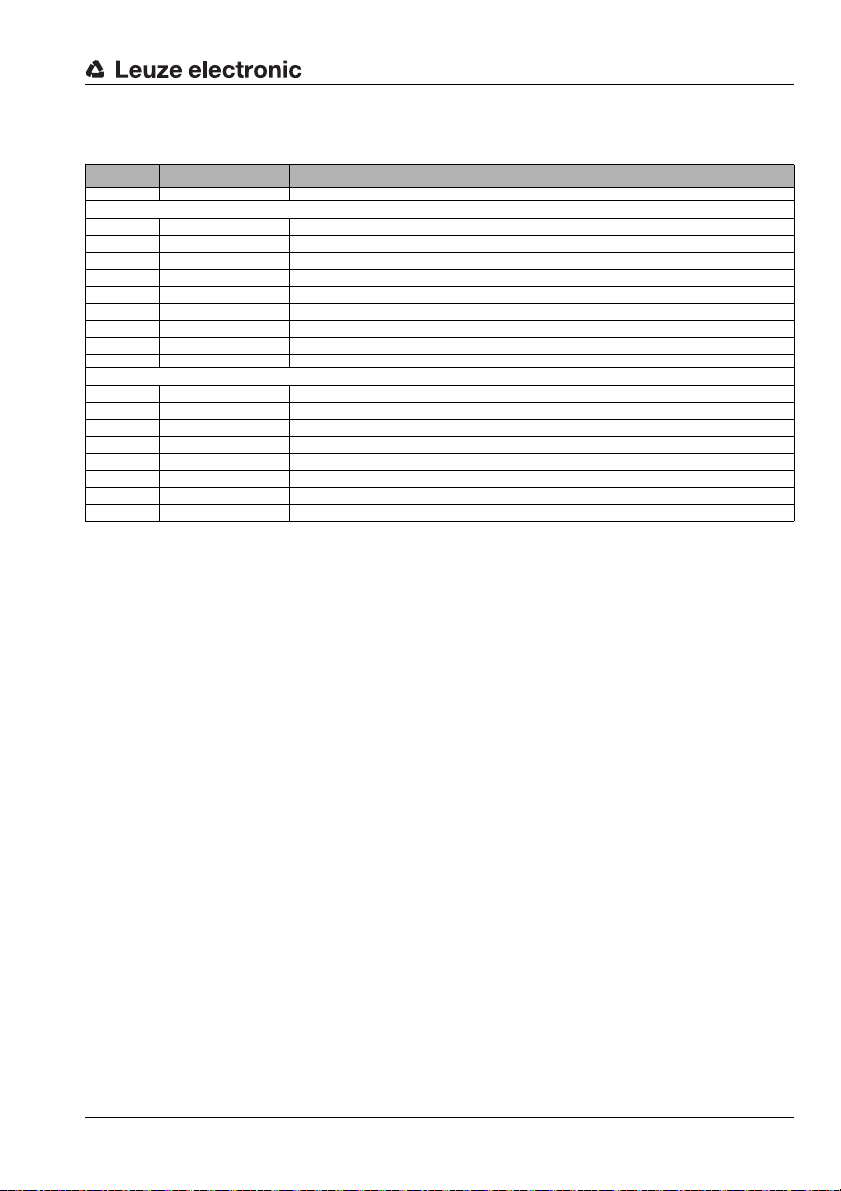

5.4 LED Indicators PROFIBUS

In addition to the indicator and operating elements present in all device models (bar graph, buttons,

LEDs AUT, MAN, ADJ; see chapter 11.1 "Indicator and operating elements"), the PROFIBUS model

includes the following additional indicators:

.

bit

Figure 5.6:Indicator/operating elements for the PROFIBUS model

Leuze electronic DDLS 200 25

TNT 35/7-24V

Page 27

INTERBUS 500kbit/s / RS 422

OUTOUT

WARNWARN

PEPE GNDGND

VinVin

ININ

PEPE GNDGND

VinVin

SHIELD AREASHIELD AREA

BSBS

A402AA402A

COM COM

TxTx– Tx+Tx+ RxRx–

Rx+

Rx+

COMCOM DI2DI2D02D02 OutOutD02D02 DI2DI2

COMCOM D01D01DI1DI1 InInDI1DI1 D01D01

BusBus

S4S4

S1

Off

On

IN

INTERBUS - terminals and switches

Terminal Function

DO1 / DI2, Rx+ Reception line +

DO1 / DI2, Rx– Reception line –

DI1 / DO2, Tx+ Transmission line +

DI1 / DO2, Tx– Transmission line –

COM Potential equalization

Switch Function

S4 Position In: incoming bus with

shielding connection

via RC circuit

Position Out (default):

outgoing bus with

direct shielding connection

6 INTERBUS 500kbit/s / RS 422

The INTERBUS model of the DDLS 200 has the following features:

• Operating ranges 30m, 120m, 200 m, 300m, for INTERBUS

• Electrically isolated interface

• The DDLS 200 is not an INTERBUS subscriber

• Protocol-independent data transmission, transparent compared to other RS 422 protocols

• 500kbit/s fixed transmission rate with INTERBUS,

with RS 422 generally lower transmission rates as well

• Operating range 500m for RS 422 up to 100 kbit/s

• Cascading of several DDLS 200 is possible (see chapter 4.3)

6.1 Electrical connection INTERBUS 500kbit/s

The electrical connection to the INTERBUS is made at terminals DO… / DI… and COM as shown in

figure 6.1.

Figure 6.1:Connection circuit board of the INTERBUS model

Attention!

Please be sure to observe the installation requirements (bus cables, cable lengths, shielding, etc.) defined in the INTERBUS standard EN 50254

26 DDLS 200 Leuze electronic

Page 28

INTERBUS 500kbit/s / RS 422

DO3

DO3

DI3

DI3

COM

COM

DI2

DI2

DO2

DO2

COM

DI1

DI1

DO1

DO1

COM

DI2

DI2

DO2

DO2

DO1

DO1

DI1

DI1

COM

DO2

DO2

DI2

DI2

COM

DO1

DO1

DI1

DI1

COM

INTERBUS Master

Switch S4

Position IN

Switch S4

Position OUT

Shielding connection of incoming bus

Shielding connec-

tion of outgoing bus

Bus

terminal

Sub-

scriber

PLC

1 MΩ 15 nF

PE PE

Incoming bus

set S4 to In

Outgoing bus

set S4 to Out

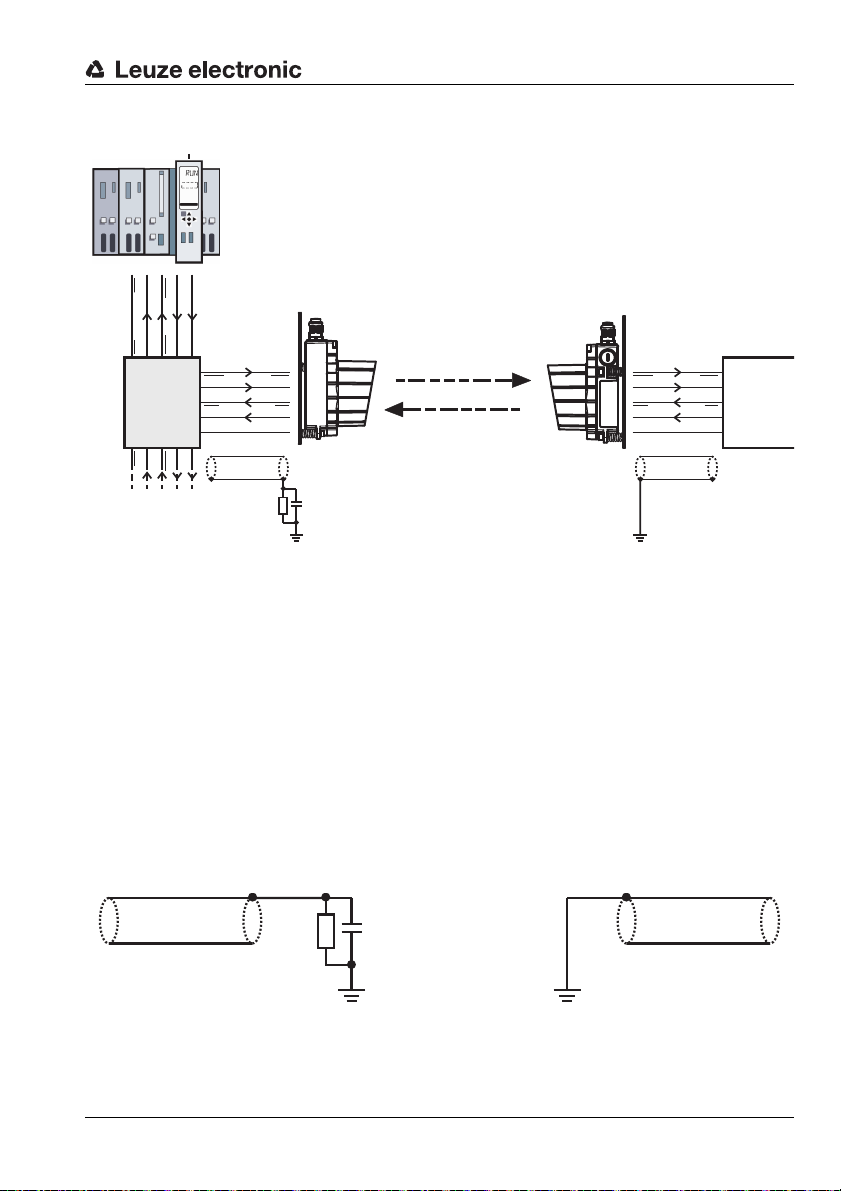

Figure 6.2:Connection of the DDLS 200 to the INTERBUS (copper line)

6.2 Device configuration INTERBUS 500kbit/s / RS 422

Device configuration INTERBUS

Changeover incoming/outgoing bus and shielding connection (default: ’Out’)

Switch S4 must be used to specify in the DDLS 200 whether the connected bus cable is for the incoming bus (In) or outgoing bus (Out):

Switch S4 Position In: incoming bus, the shielding connection (clamp) is connected via an RC

Figure 6.3:Shielding connection for incoming/outgoing bus

Leuze electronic DDLS 200 27

Position Out: outgoing bus, the shielding connection (clamp) is connected directly to

PE.

circuit to PE.

TNT 35/7-24V

Page 29

INTERBUS 500kbit/s / RS 422

PWR Tx Rx

AUT

MAN

ADJ

LED PWR: green = operating indicator

green flashing= transmitter /receiver unit switched off

via switching input IN or hardware error

off = no operating voltage

LED Tx: green = data are being transmitted to the bus

green flashing= with baud rates set to very low values,

the LEDs Tx and Rx flicker. At very

high baud rates (> 50kbit/s), flashing

LEDs Tx and Rx indicate faulty bus

communication.

off = no data on the transmission line

LED Rx: green = data are being received by the bus

green flashing= with baud rates set to very low values,

the LEDs Tx and Rx flicker. At very

high baud rates (> 50kbit/s), flashing

LEDs Tx and Rx indicate faulty bus

communication.

off = no data on the reception line

Device configuration RS 422

General RS 422 protocols can be transmitted with the DDLS 200. No baud rate setting is necessary

(max. 500kbit/s). The shielding connection can be set via switch S4 as with the Interbus.

Note!

The latency of a light path is about 1.5 µs (depending on the distance).

6.3 LED indicators INTERBUS 500kbit/s / RS 422

In addition to the indicator and operating elements present in all device models (bar graph, buttons,

LEDs AUT, MAN, ADJ; see chapter 11.1 "Indicator and operating elements"), the INTERBUS model

includes the following additional indicators:

Figure 6.4:Indicator/operating elements for the INTERBUS model

28 DDLS 200 Leuze electronic

Page 30

INTERBUS 2Mbit/s Fiber-Optic Cable

OUTOUT

WARNWARN

PEPE GNDGND

VinVin

ININ

H1H1H2H2

PEPE GNDGND

VinVin

BSBS

A402AA402A

S1

S3

Off

On

IN

In

Bus

Out

Bus

500K

2M

S2

Out IN

INTERBUS - terminals and switches

Fiber-opticcable socket

Function

H1 Receiver fiber-optic cable

H2 Transmitter fiber-optic cable

Switch Function

S2 Position 500k: INTERBUS fiber-optic-

cable transmission rate

500 kbit/s

Position 2M (default):

INTERBUS fiber-opticcable transmission rate

2 Mbit/s

S3 Position In Bus (default):

incoming bus fiberoptic cable

Position Out Bus: outgoing bus fiber-

optic cable

7 INTERBUS 2Mbit/s Fiber-Optic Cable

The INTERBUS fiber-optic-cable model of the DDLS 200 has the following features:

• Operating ranges 200m, 300 m

• Transmission protected against interference through the use of fiber-optic cables

• Bus connection by means of polymer-fiber-cable with FSMA connector

• The DDLS 200 is an INTERBUS subscriber (Ident-Code: 0x0C = 12

but does not occupy data in the bus

• Adjustable transmission rate 500kbit/s or 2 Mbit/s

• Cascading of several DDLS 200 is possible (see chapter 4.3)

7.1 Fiber-optic-cable connection INTERBUS 2Mbit/s

The connection to the INTERBUS is by means of the FSMA connectors H1 and H2 as shown in

figure 7.1.

Recommended fiber-optic cable:

• PSM-LWL-KDHEAVY… (Phoenix Contact)

• PSM-LWL-RUGGED… (Phoenix Contact)

Note!

The maximum length of the fiber-optic cables is 50m.

dec.

),

Figure 7.1:Connection circuit board of the INTERBUS model

Leuze electronic DDLS 200 29

TNT 35/7-24V

Page 31

INTERBUS 2Mbit/s Fiber-Optic Cable

Switch S3

Position In Bus

Switch S3

Position Out Bus

Incoming bus Outgoing bus

Subscriber

Connection group

Fiber-opticcable bus

terminal

FOC

Subscriber

FOC

H1

H2

H2

H1

Attention!

Please be sure to observe the installation requirements defined in the INTERBUS standard

EN 50254 and follow the handling and installation specifications for fiber-optic cables as

specified by the manufacturer.

For the infeed of the fiber-optic cable, use only the large screwed cable gland M20 x 1.5.

Make certain that bending radii are not tighter than specified for the used fiber-opticcable type! Observe the maximum fiber-optic cable length!

Figure 7.2:Connection of the DDLS 200 to the INTERBUS (fiber-optic cable)

7.2 Device configuration INTERBUS 2Mbit/s FOC

Transmission rate changeover (default:’2M’)

In the DDLS 200, switch S2 must be used to specify in the transmission rate of the fiber-optic-cable

INTERBUS:

Switch S2 Position 500k: transmission rate 500 kbit/s.

Position 2M (default): transmission rate 2 Mbit/s.

Changeover incoming/outgoing bus (default: ’In Bus’)

Switch S3 must be used to specify in the DDLS 200 whether the connected fiber-optic cable is for the

incoming bus (In Bus) or outgoing bus (Out Bus):

Switch S3 Position In Bus (default): incoming bus - fiber-optic cable; outgoing bus - optical data

Position Out Bus: incoming bus - optical data transmission; outgoing bus -

30 DDLS 200 Leuze electronic

transmission.

fiber-optic cable.

Page 32

INTERBUS 2Mbit/s Fiber-Optic Cable

UL RC BA

AUT

MAN

ADJ

RD FO1 FO2

LED UL: green = operating indicator (Power on)

green flashing= transmitter /receiver unit switched off via

switching input IN or hardware error

off = no operating voltage

LED RC: green = INTERBUS connection OK

off = INTERBUS in reset mode or connection

not OK

LED BA: green = display of bus activity

off = no bus activity

LED RD: yellow = continuing bus switched off

off = continuing bus detected

LED FO1: yellow = initialization faulty or MAU warning (Mas-

ter in RUN state)

off = initialization OK, no MAU warning (Master

in READY state)

LED FO2: yellow = initialization faulty or MAU warning (Mas-

ter in RUN state)

off = initialization OK, no MAU warning (Master

in READY state)

UL = logic voltage U

L

RC = Remote Bus Check

BA = Bus Activity

RD = Remote Bus Disable

FO1 = Fiber Optics 1

FO2 = Fiber Optics 2

Note!

The delay time of a light path is approx. 2.5 µs.

7.3 LED indicators INTERBUS 2Mbit/s fiber-optic cable

In addition to the indicator and operating elements present in all device models (bar graph, buttons,

LEDs AUT, MAN, ADJ; see chapter 11.1 "Indicator and operating elements"), the INTERBUS model

includes the following additional indicators:

Figure 7.3:Indicator/operating elements for the INTERBUS model

Note!

The DDLS 200 is an INTERBUS subscriber (Ident-Code: 0x0C = 12

scriber description can be downloaded from http://www.leuze.com.

If the value falls below the warning level (bar graph), a peripheral error message is transmitted via the INTERBUS. When this error message is transmitted, the usual cause is soiling

of the glass optics (see chapter 12.1 "Cleaning"), an incorrectly adjusted data transmission

path, or an interrupted light path.

You can also use the diagnostic options available via the INTERBUS.

Leuze electronic DDLS 200 31

). A current CMD sub-

dec

TNT 35/7-24V

Page 33

Data Highway + (DH+) / Remote I/O (RIO)

OUTOUT

WARNWARN

PEPE

1

82 82 Ω

2 3 1 2 3 GNDGND

VinVin

ININ

PEPE GNDGND

VinVin

A401A-BSA401A-BS

S2 S3

1

0

DH+DH+ RIORIO

SHIELDSHIELD

CLEARCLEAR

BLUEBLUE

2

1

3

SHIELDSHIELD

BLUEBLUE

CLEARCLEAR

kBit/s

115.2

57.6

230.4

1

0

1

0

2

S2

S2

1

Filter On=1

Filter Off=0

S3S3

1

0

0

S1

Off

On

IN

DH+/RIO - terminals and switches

Terminal Assignment DH+ Assignment RIO

1 CLEAR BLUE

2 SHIELD SHIELD

3 BLUE CLEAR

Switch Function

S2-1, S2-2 Setting the transmission rate (see table

on the connection circuit board),

default: 230.4kbit/s

S3-1 Filter for interference-peak rejection.

Positi on On (1): Filter switched-on

(default)

Positi on Off (0): Filter switched off

S3-2 Not used

8 Data Highway + (DH+) / Remote I/O (RIO)

The DH+/RIO model of the DDLS 200 has the following features:

• Operating ranges 120m, 200m, 300 m

• Electrically isolated interface

• Direct connection to the Data Highway + and Remote I/O bus from Rockwell Automation

(Allen Bradley)

• Adjustable transmission rate 57.6 / 115.2 or 230.4kbit/s

• Cascading of several DDLS 200 is possible (see chapter 4.3)

8.1 Electrical connection DH+ / RIO

The electrical connection to the DH+ / RIO bus is made acc. to the table on the connection board at

terminals 1, 2 and 3. Each of these terminals is provided twice for wiring through the bus.

Cable to be used: Bluehouse Twinax (Belden 9463 or Allen Bradley 1770-CD)

Figure 8.1:Connection circuit board of the DH+ / RIO model

Attention!

The right DH+ / RIO connections 1 and 3 are equipped standard with an 82

terminating the bus. Remove this terminating resistor when the bus cable in the DDLS 200

is to be wired through to another bus subscriber, i.e. the DDLS 200 is not the last device on

the bus cable. The use of the DDLS 200 is limited to bus systems with 82

32 DDLS 200 Leuze electronic

Ω

resistor for

Ω

termination.

Page 34

Data Highway + (DH+) / Remote I/O (RIO)

Path 1

Path 1

Path 1

Path 2

Path 2 Path 3

1 DDLS 200 transmission path

2 DDLS 200 transmission paths

3 DDLS 200 transmission paths

PLC

PLC

PLC

8.2 Device configurati on DH+ / RIO

Cascading of multiple DDLS 200 transmission paths (filter, default: ’On’ = on)

If multiple DDLS 200 transmission paths are to be cascaded within a bus segment (see figure 8.2),

the filter for interference-peak suppression (switch S3-1) must be adjusted appropriately for the selected transmission rate. Observe also the notices in chapter 4.3.

Figure 8.2:Cascading multiple optical transmission paths with DH+ / RIO

In accordance with the following table, set the filter for each DDLS 200 transmission path at both devices for the given path using switch S3-1.

Baud rate

57.6kbit/s Path 1: On (1)

115.2kbit/s

and

230.4kbit/s

Table 8.1: Filter settings when cascading multiple DDLS 200 transmission paths

Leuze electronic DDLS 200 33

Path 1: On (1)

1 path 2 paths 3 paths

Position of S3-1 for

Path 1: On (1)

Path 2: Off (0)

Path 1: On (1)

Path 2: On (1)

Path 1: On (1)

Path 2: Off (0)

Path 3: Off (0)

Path 1: On (1)

Path 2: On (1)

Path 3: On (1)

TNT 35/7-24V

Page 35

Data Highway + (DH+) / Remote I/O (RIO)

PWR Tx Rx

AUT

MAN

ADJ

LED PWR: green = operating indicator

green flashing= transmitter/receiver unit switched off

via switching input IN or hardware error

off = no operating voltage

LED Tx: green = data are being transmitted to the bus

green flashing= with baud rates set to very low values,

the LEDs Tx and Rx flicker. At very

high baud rates (> 50kbit/s), flashing

LEDs Tx and Rx indicate faulty bus

communication.

off = no data on the transmission line

LED Rx: green = data are being received by the bus

green flashing= with baud rates set to very low values,

the LEDs Tx and Rx flicker. At very

high baud rates (> 50kbit/s), flashing

LEDs Tx and Rx indicate faulty bus

communication.

off = no data on the reception line

Note!

The delay time of a light path is approx.: S3-1 On (1) = approx. 1.5 µs + 1.5 T

S3-1 Off (0) = approx. 1.5 µs

8.3 LED indicators DH+ / RIO

In addition to the indicator and operating elements present in all device models (bar graph, buttons,

LEDs AUT, MAN, ADJ; see chapter 11.1 "Indicator and operating elements"), the DH+/RIO model includes the following additional indicators:

bit

Figure 8.3:Indicator/operating elements of the DH+/RIO model

Note!

You can also use the diagnostic options available via the bus system.

34 DDLS 200 Leuze electronic

Page 36

DeviceNet / CANopen

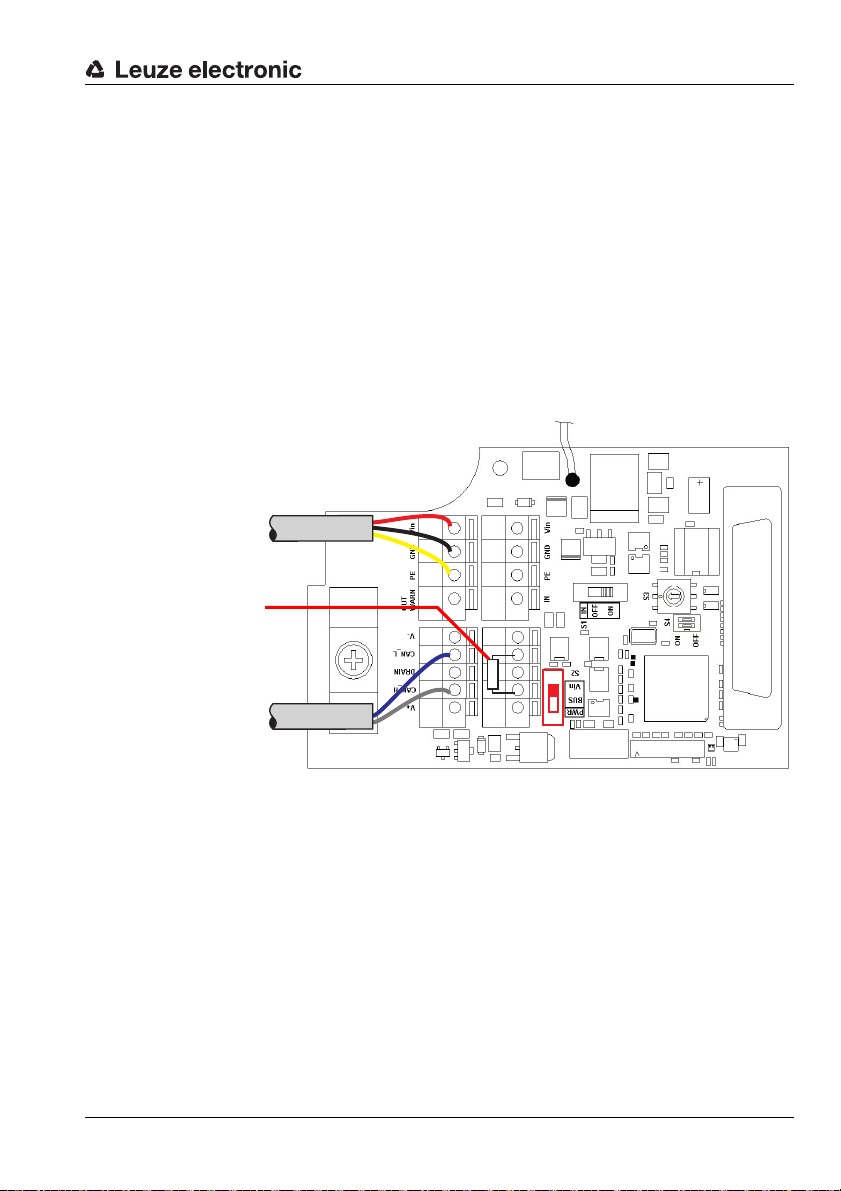

No. Ter mi nal Cable color Function

1 V- black neg. supply (CAN ground reference)

2 CAN_L blue bus signal (LOW)

3 DRAIN transparent shield

4 CAN_H white bus signal (HIGH)

5 V+ red pos. supply

Switch Position Function

S2

BUS bus transceivers are supplied via the bus

cable (V- and V+ lines)

Vin default bus transceivers are supplied via internal

DC/DC converters

S3

0 default 125 kbit baud rate CANopen / Devi-

ceNet

1 250 kbit baud rate CANopen / Devi-

ceNet

2 500 kbit baud rate CANopen / Devi-

ceNet

3 10 kbit baud rate CANopen

4 20 kbit baud rate CANopen

5 50 kbit baud rate CANopen

6 800 kbit baud rate CANopen

7 1000 kbit baud rate CANopen

8 Reserved

9 Reserved

ON sorting memory is active

9 DeviceNet / CANopen

The DeviceNet/CANopen model of the DDLS 200 has the following features:

• Operating ranges 120m, 200 m, 300m

• The DDLS 200/___.-50 can transmit both DeviceNet as well as CANopen protocols

• Electrically isolated interface

• The DDLS 200 does not occupy an address

• CAN controller acc. to 2.0B standard

• Can simultaneously process 11-bit and 29-bit identifiers

• 8 baud rates can be set (10, 20, 50, 125, 250, 500, 800kbit/s, 1Mbit/s)

• Baud rate conversion possible

• With DDLS 200 it is possible to extend the overall size of a CAN network

• M12 connector set available as accessory

• Various supply options are possible for the device

• Cascading of several DDLS 200 is possible (see chapter 4.3)

9.1 Electrical connection DeviceNet / CANopen - screwed cable glands/terminals

The electrical connection to DeviceNet / CANopen is made at terminals V-, CAN_L, DRAIN, CAN_H,

V+. The terminals are available as double connectors for wiring through the bus.

Figure 9.1: DeviceNet / CANopen, connection-board variant

Attention!

The maximum permissible current which may pass over terminals V+ / V- is 3A; the maximum permissible voltage is 25V (11 … 25V)!

Leuze electronic DDLS 200 35

TNT 35/7-24V

Page 37

DeviceNet / CANopen

Power

DeviceNet/CANopen

outgoing bus

DeviceNet/CANopen

incoming bus

Power

DeviceNet/CANopen

outgoing bus

DeviceNet/CANopen

incoming bus

9.1.1 Bus transceiver and device supplied via separate power connection

• Switch S2 = Vin.

• Bus electrically insulated (isolated node)

• CAN_GND must be connected to V-

Figure 9.2: Bus transceiver and device supplied via separate power connection

9.1.2 Bus transceiver supplied via bus cable, device supplied via separate power line

• Switch S2 = BUS.

• Bus electrically insulated (isolated node)

Figure 9.3: Bus transceiver supplied via bus cable, device supplied via separate power line

36 DDLS 200 Leuze electronic

Page 38

DeviceNet / CANopen

DeviceNet/CANopen

outgoing bus

DeviceNet/CANopen

incoming bus

Row 1 Row 2

9.1.3 Bus transceiver and device supplied via bus cable

• Switch S2 = BUS.

•Bus not electrically insulated (non-isolated node)

• Current consumption see chapter 3 "Technical Data".

Figure 9.4: Bus transceiver and device supplied via bus cable

Incoming bus cable Outgoing bus cable

Cable Terminal Cable Terminal

V- (bla ck ) V- ( row 1) V- (black) GND

CAN_L (blue) CAN_L (row 1) CAN_L (blue) CAN_L (row 2)

DRAIN (transparent) DRAIN (row 1) DRAIN (transparent) DRAIN (row 2)

CAN_H (white) CAN_H (row 1) CAN_H (white) CAN_H (row 2)

V+ (red) V+ (row 1) V+ (red) Vin

Bridge between Vin and V+ (row 2)

Bridge between GND and V- (row 2)

Table 9.1: Connection table

TNT 35/7-24V

Note!

In order for this interface connection to be conformant with the DeviceNet Ground concept,

the load on the switching output and/or the source at the switching input must be potential

free.

If the complete device is operated using the supply in the bus cable, it must be ensured that

the voltage is at least 18V.

The total current of the device is the device current plus the current drawn at the switching

output.

Leuze electronic DDLS 200 37

Page 39

DeviceNet / CANopen

M12 plug (Power)

M12 socket (bus),

onward bus

M12 plug (bus),

incoming bus

9.1.4 Installation and connection of the optional M12 connectors

An M12 connector set is available as an accessory. It consists of an M12 plug (power), an M12 plug

(bus), and an M12 socket (bus) with ready-made cables (Part No. 500 39348). If the M12 connector set

is used, a possible termination should be carried out with the optionally available terminal connector.

Conversion to M12 connectors

1. Remove screwed cable gland 1, 2 and 3 (spanner size = 20mm)

2. Screw M12 plug (power) into the thread of the screwed cable gland 1 that you have just

removed and tighten it with spanner SW18.

3. Screw M12 socket (bus) into the thread of the screwed cable gland 2 that you have just

removed and tighten it with spanner SW18.

4. Screw M12 plug (bus) into the thread of the screwed cable gland 3 that you have just removed

and tighten it with spanner SW18.

5. Connect cables acc. to figure 9.5 and Table 9.2.

Figure 9.5: Installation and connection of the optional M 12 connectors

(1) M12 plug (Power)

Pin 1 (brown) Vin Pin 1 (transparent) DRAIN Pin 1 (transparent) DRAIN

Pin 2 (white) OUT Pin 2 (red) V+ Pin 2 (red) V+

Pin 3 (blue) GND Pin 3 (black) V- Pin 3 (black) VPin 4 (black) IN Pin 4 (white) CAN_H Pin 4 (white) CAN_H

Pin 5 (yellow/green) FE Pin 5 (blue) CAN_L Pin 5 (blue) CAN_L

Table 9.2: Connection of M 12 connectors

Note!

(2) M 12 socket (bus),

onward bus

(3) M12 plug (bus),

incoming bus

The orientation of the M12 connectors is not defined. The use of angular M12 connectors

as counterparts is therefore discouraged.

38 DDLS 200 Leuze electronic

Page 40

9.2

BUS OUT

DeviceNet/CANopen:

M12 socket, A-coded

BUS IN

DeviceNet/CANopen:

M12 plug, A-coded

All M12 device models:

PWR IN

M12 plug, A-coded

BUS IN

CAN_H

V+

3

2

1

4

V- Drain

CAN_L

M12 plug

(A-coded)

DeviceNet/CANopen electrical connection-

The electrical connection of DeviceNet/CANopen is performed using M12 connectors.

Figure 9.6:Location and designation of the M12 DeviceNet/CANopen connections

BUS IN (5-pin M12 plug, A-coded)

Pin Name Remark

1Drainshield

2V+

3V4 CAN_H Bus signal High

5 CAN_L Bus signal Low

Thread FE Functional earth (housing)

Figure 9.7:Assignment M12 connector BUS IN

M 12 connectors

Positive supply bus transceiver

(switch S2 = bus)

Negative supply bus transceiver

(switch S2 = bus)

DeviceNet / CANopen

TNT 35/7-24V

Leuze electronic DDLS 200 39

Page 41

DeviceNet / CANopen

BUS OUT

CAN_H

V+

3

2

1

4

V-Drain

CAN_L

M12 socket

(A-coded)

BUS OUT (5-pin M12 socket, A-coded)

Pin Name Remark

1DrainShield

2V+

3V4 CAN_H Bus signal High

5 CAN_L Bus signal Low

Thread FE Functional ear th (housing)

Figure 9.8:Assignment M12 connector BUS OUT

Via the selector switch S2, the bus transceiver can optionally be supplied via Power or V+ / V-.

S2 = Vin (default) bus transceivers are supplied internally

S2 = BUS, bus transceivers are supplied via V+/V-.

Attention!

The supply voltage

V+

/ V- is 11 … 25V DC.

Termination

Positive supply bus transceiver

(switch S2 = bus)

Negative supply bus transceiver

(switch S2 = bus)

Note!

If the CANopen or DeviceNet network begins or terminates at the DDLS 200 (not a continuing bus), the

BUS OUT

connection must be terminated with the TS01-5-SA terminator plug

(Part No. 50040099), which is available as an option.

In this case, please also order the TS 01-5-SA terminator plug.

40 DDLS 200 Leuze electronic

Page 42

DeviceNet / CANopen

9.3 Device configuration DeviceNet / CANopen

9.3.1 Baud rate conversion

Through the use of an optical transmission system, the bus is divided into two segments. Different

baud rates can be used in the physically separated segments. The DDLS 200s then function as baud

rate converters. During baud rate conversion, it must be ensured that the bandwidth of the segment

with the lower baud rate is adequate for processing the incoming data.

9.3.2 Sorting (switch S4.1)

With the aid of switch S4.1, sorting of the internal memory can be activated and deactivated. If sorting

is deactivated (switch S4.1 = OFF, default), CAN frames are handled according to the FIFO principle

(First-In-First-Out).

If sorting is active (switch S4.1 = ON), CAN frames are sorted according to their priority. The message

with the highest priority in memory is the next one to be put onto the connected network for arbitration.

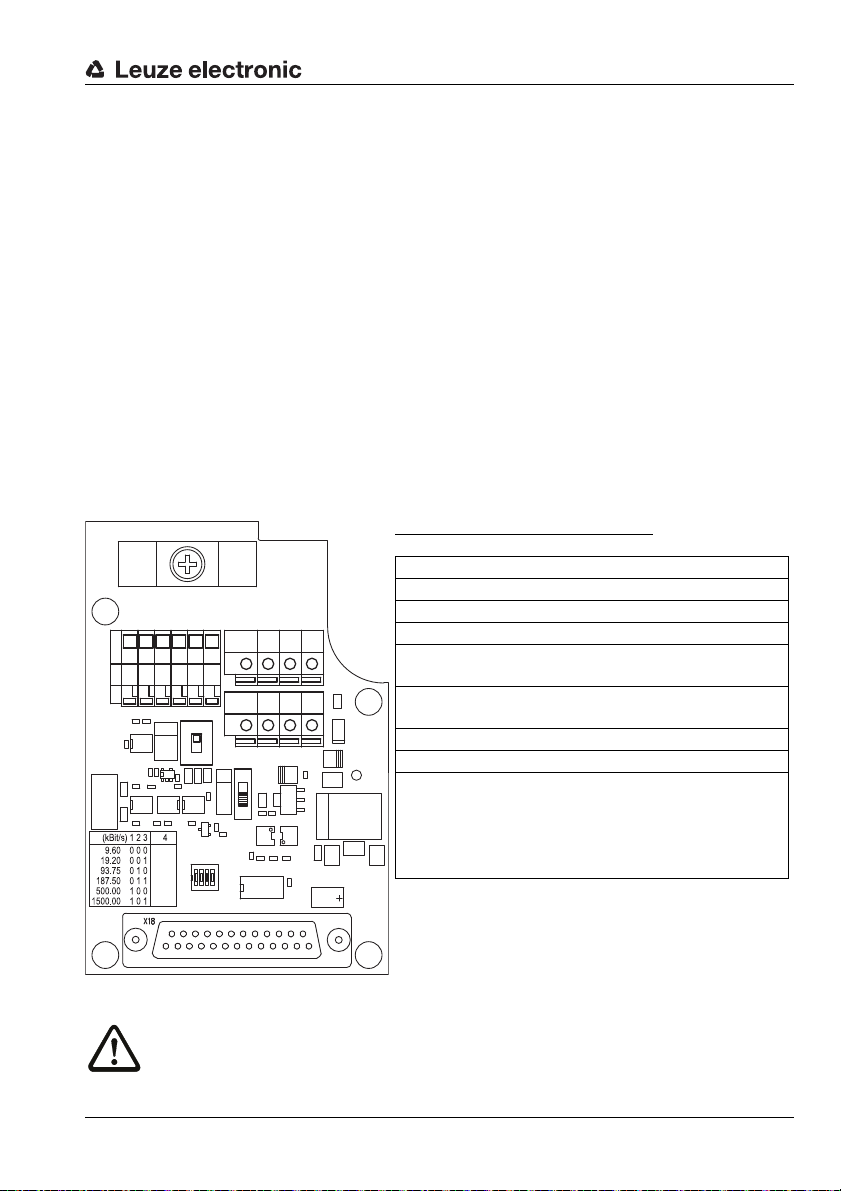

9.3.3 Bus lengths as a function of the baud rate

Switch position

S3

0 (default) 125kbit 500m CANopen / DeviceNet

1 250 kbit 250 m CANopen / DeviceNet

2 500 kbit 100 m CANopen / DeviceNet

3 10kbit 5000m CANopen

4 20kbit 2500m CANopen

5 50kbit 1000m CANopen

6 800 kbit 50m CANopen

7 1000kbit 30m CANopen

Note!

The mechanical expansion of the bus system can be increased through the use of the

DDLS 200.

Leuze electronic DDLS 200 41

Baud rate

max. cable length

per bus segment

Interface

TNT 35/7-24V

Page 43

DeviceNet / CANopen

R

TN = bus subscriber

Physical bus segment 1 Physical bus segment 2

Physical bus segment 3

TN

DT DT

DT DT

TN

TN

TN

TN

TN

TN

R

R

RR

RR

PE

PE

PE

1)

1)

1) Part of the communication device

1)

9.4 Wiring

• The ends of the bus lines must be terminated between CAN_L and CAN_H for each physical bus

segment (see figure 9.9 ).

• Typical CAN cables consist of a twisted-pair cable with a shield that is usually used as CAN_GND.

Only use cables recommended for DeviceNet or CANopen.

• The ground reference CAN_GND must only be connected to earth potential (PE) at one place on a

physical bus segment (see figure 9.9).

Figure 9.9: DeviceNet / CANopen wiring

42 DDLS 200 Leuze electronic

Page 44

DeviceNet / CANopen

120 Ohm

Power

DeviceNet/CANopen

incoming bus

Termination with 120Ω

9.4.1 Termination

DeviceNet

• External termination for M 12 connector version is available as an option (see chapter 9.2)

• Resistance and other features are described in the DeviceNet specifications of the ODVA (Open

DeviceNet Vendor Association).

CANopen

• Value: typically 120Ω (included with the device, mounted between CAN_L and CAN_H)

• External termination for M 12 connector version is available as an option

• Resistance and other features are described in the CANopen specification ISO 11898.

Figure 9.10: Termination in the unit.

A 120Ω resistor is connected standard between terminals CAN_L and CAN_H. If the device is not the

last subscriber of the bus segment, the resistor must be removed and the outgoing bus cable connected to the terminal strip.

Leuze electronic DDLS 200 43

TNT 35/7-24V

Page 45

DeviceNet / CANopen

PWR Tx Rx

AUT

MAN

ADJ

BUF ERPA BOFF

LED PWR: green = operating indicator

green flashing = transmitter/receiver unit switched off via switching

input IN or hardware error

off = no operating voltage

LED Tx: green = data are being transmitted to the bus

green flashing = with baud rates set to very low values, or with low

bus traffic, the LEDs Tx and Rx flicker.

off = no data are being transmitted to the bus

LED Rx: green = data are being received by the bus

green flashing = with baud rates set to very low values, or with low

bus traffic, the LEDs Tx and Rx flicker.

off = no data on the reception line

LED BUF:yellow =buffer load: > 70%

yellow flashing= buffer load: 30% … 70 %

off = buffer load: < 30%

LED ERPA: yellow = DDLS 200 is in "Error Passive" state, full communi-

cation functionality, however in the event of an error,

a passive error flag is sent (see also "BOSCH CAN

Specification 2.0").

Measures:

- check termination, wiring, baud rate

off = DDLS 200 is in "Error Active" state, full communica-