Page 1

DCR 85

CMOS Imager Code Reader

EN 2017/03 - 50134018

We reserve the right to

make technical changes

O r i g i n a l o p e r a t i n g i n s t r u c t i o n s

Page 2

© 2017

Leuze electronic GmbH & Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic DCR 85 2

Page 3

Table of contents

Table of contents

1 About this document ............................................................................................5

1.1 Used symbols and signal words .............................................................................................5

2 Safety .....................................................................................................................6

2.1 Intended use ...........................................................................................................................6

2.2 Foreseeable misuse ............................................................................................................... 6

2.3 Competent persons ................................................................................................................ 6

2.4 Disclaimer ...............................................................................................................................7

3 Device description ................................................................................................8

3.1 Device overview...................................................................................................................... 8

3.1.1 About the DCR85 code reader ...........................................................................................8

3.1.2 Stand-alone operation .........................................................................................................8

3.2 Performance characteristics ...................................................................................................8

3.3 Device construction ................................................................................................................ 9

3.4 Connection technology ...........................................................................................................9

3.5 Display elements .................................................................................................................... 9

4 Mounting..............................................................................................................10

4.1 Selecting a mounting location............................................................................................... 10

5 Electrical connection..........................................................................................11

5.1 Voltage supply ......................................................................................................................11

5.2 Pin assignment .....................................................................................................................11

5.3 Switching input / switching output......................................................................................... 11

5.3.1 Switching input ..................................................................................................................12

5.3.2 Switching output ................................................................................................................12

5.4 PC or terminal connection .................................................................................................... 13

5.5 Cable lengths and shielding.................................................................................................. 13

6 Configuration and diagnostics software - SensorStudio...............................14

6.1 System requirements............................................................................................................ 14

6.2 Installing SensorStudio configuration software.................................................................... 15

6.2.1 Downloading configuration software .................................................................................15

6.2.2 Installing the SensorStudio FDT frame ............................................................................15

6.2.3 Install the communication DTM and device DTM..............................................................15

6.2.4 Connecting device to PC...................................................................................................15

6.3 Starting the SensorStudio configuration software................................................................ 16

6.4 Exiting SensorStudio ........................................................................................................... 17

6.5 Configuration parameters .....................................................................................................17

6.5.1 General tab........................................................................................................................ 18

6.5.2 Decode tab ........................................................................................................................19

6.5.3 Host interface tab ..............................................................................................................20

6.5.4 Diagnosis / Terminal.......................................................................................................... 20

6.5.5 Diagnosis / Image Viewer.................................................................................................. 21

7 Starting up the device - Configuration..............................................................22

7.1 Measures to be performed prior to the initial commissioning ............................................... 22

7.2 Starting the device ................................................................................................................22

7.2.1 Interface ............................................................................................................................22

7.2.2 Online commands .............................................................................................................22

7.2.3 Problems ...........................................................................................................................22

7.3 Setting the communication parameters ................................................................................22

Leuze electronic DCR 85 3

Page 4

Table of contents

8 Online commands...............................................................................................23

8.1 Overview of commands and parameters ..............................................................................23

8.2 General online commands.................................................................................................... 24

8.3 Text commands ....................................................................................................................25

9 Care, maintenance and disposal .......................................................................34

9.1 Cleaning................................................................................................................................ 34

9.2 Servicing ...............................................................................................................................34

9.3 Disposing ..............................................................................................................................34

10 Service and support ...........................................................................................35

10.1 What to do should servicing be required? ............................................................................ 35

11 Technical data .....................................................................................................36

11.1 General specifications .......................................................................................................... 36

11.2 Reading fields .......................................................................................................................37

11.3 Dimensioned drawings ......................................................................................................... 39

12 Order guide and accessories.............................................................................40

12.1 Type overview....................................................................................................................... 40

12.2 Accessories........................................................................................................................... 40

13 EC Declaration of Conformity ............................................................................41

14 Appendix..............................................................................................................42

14.1 Bar code samples .................................................................................................................42

14.2 Configuration via configuration codes................................................................................... 43

Leuze electronic DCR 85 4

Page 5

1 About this document

1.1 Used symbols and signal words

Tab.1.1: Warning symbols and signal words

Symbol indicating dangers to persons

NOTE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger avoidance are not followed.

Tab.1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

Symbols for action steps

Text passages with this symbol instruct you to perform actions.

About this document

Symbol for action results

Text passages with this symbol describe the result of the preceding action.

Tab.1.3: Terms and abbreviations

BCL Bar code reader

CMOS Semiconductor process for implementing integrated circuits

(Complementary Metal-Oxide-Semiconductor)

DCR Image-based code reader

(Dual Code Reader)

DTM Software device manager

(Device Type Manager)

EMC Electromagnetic compatibility

EN European standard

FDT Software frame for management of device managers (DTM)

(Field Device Tool)

FE Functional earth

GUI Graphical user interface

HID Device class for input devices with which users directly interact

(Human Interface Device)

IO or I/O Input/Output

LED LED

(Light Emitting Diode)

PLC Programmable Logic Control

(corresponds to Programmable Logic Controller (PLC))

Leuze electronic DCR 85 5

Page 6

2 Safety

This code reader was developed, manufactured and tested in accordance with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The DCR85 code reader is designed as a stationary scanner with integrated decoder for all common 1D

and 2D codes used for automatic object detection.

Areas of application

The DCR85 code reader is intended especially for the following areas of application:

• In automatic analyzers

• For space-critical code reading tasks

• For installation in a housing or beneath covers

Observe intended use!

The protection of personnel and the device cannot be guaranteed if the device is operated in a

manner not complying with its intended use.

Ä Only operate the device in accordance with its intended use.

Ä LeuzeelectronicGmbH+Co.KG is not liable for damages caused by improper use.

Ä Read these operating instructions before commissioning the device. Knowledge of the oper-

Safety

CAUTION

ating instructions is an element of proper use.

NOTICE

Comply with conditions and regulations!

Ä Observe the locally applicable legal regulations and the rules of the employer's liability insur-

ance association.

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is considered improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• in circuits which are relevant to safety

• for medical purposes

NOTICE

Do not modify or otherwise interfere with the device!

Ä Do not carry out modifications or otherwise interfere with the device. The device must not be

tampered with and must not be changed in any way.

Ä The device must not be opened. There are no user-serviceable parts inside.

Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Leuze electronic DCR 85 6

Page 7

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant standards

and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Disclaimer

LeuzeelectronicGmbH+Co.KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

Safety

Leuze electronic DCR 85 7

Page 8

3 Device description

3.1 Device overview

3.1.1 About the DCR85 code reader

The code reader is based on a CMOS imager with integrated decoder for all of the most popular 1D and 2D

codes such as DataMatrix, Aztec, QRCode, 2/5 Interleaved, Code39, Code128, UPC/EAN etc.

The many possible configurations of the device allow it to be adapted to a multitude of reading tasks. Due

to the small dimensions of the unit and the large reading field, the scan engine can also be used in highly

constrained spaces.

Information on technical data and characteristics: see chapter 11 "Technical data".

3.1.2 Stand-alone operation

The code reader is operated as a "stand-alone" single device. It is equipped with a 6-wire cable with open

ends for the electrical connection of the supply voltage, the interface, the trigger input and the switching

output.

3.2 Performance characteristics

• High-performance, miniature CMOS Imager with front beam exit

• Compact design for simple integration, even in constrained spaces

• Reading of extremely small high-density codes and recording of standard codes in a large reading area

using a special optical system

• Reading of shiny surfaces using a gloss reduction process

• Excellent decoding characteristics

• Clearly visible alignment LED

• RS 232 interface, one triggering input, one switching output

Device description

Leuze electronic DCR 85 8

Page 9

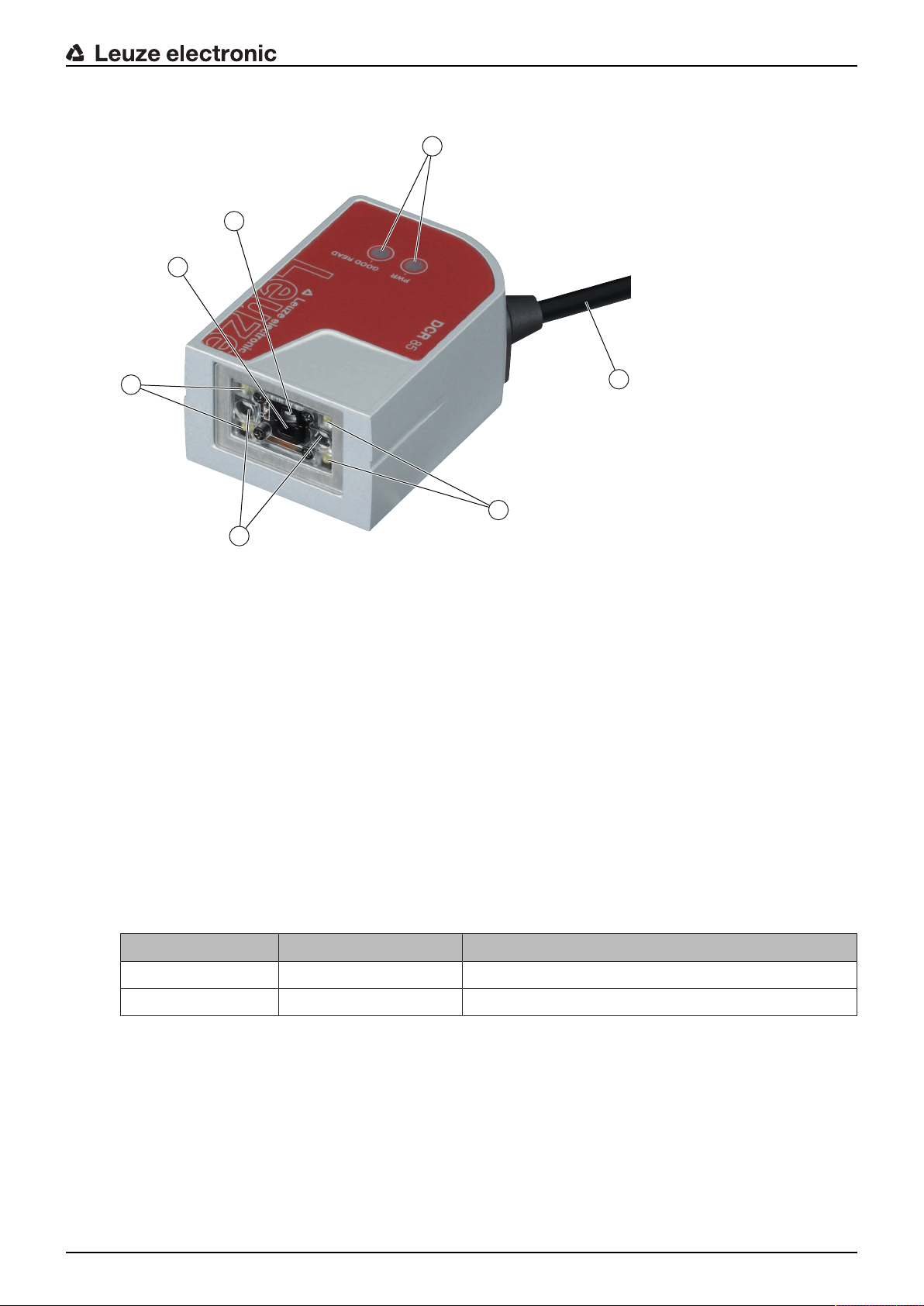

3.3 Device construction

3

5

5

1

2

4

6

Device description

1 High resolution reading field lens

2 Wide-range reading field lens

3 LED indicators

4 Connection cable

5 LEDs for illumination (red light)

6 Alignment LEDs (blue light)

Fig.3.1: Device construction of the DCR85

3.4 Connection technology

• Connection cable, 6-wire with open cable end

• Cable (approx. 0.15m) with M12 connector, 8-pin

3.5 Display elements

Located on device top are two LEDs that indicates the readiness for operation and the read status.

Tab.3.1: LED indicators

LED State Description

PWR ON (continuous light) Voltage supply OK

GOOD READ ON (continuous light) Reading successful

Leuze electronic DCR 85 9

Page 10

4 Mounting

α

β

γ

You can fasten the code reader at the M2.5 mounting threads.

4.1 Selecting a mounting location

NOTICE

The size of the code module influences the maximum reading distance and the width of the

reading field. Therefore, when selecting a mounting location and/or the code label, take into account the different reading characteristics of the scanner with various code modules.

NOTICE

Observe when choosing the mounting location!

Ä Maintaining the required environmental conditions (temperature, humidity).

Ä Possible soiling of the reading window due to liquids, abrasion by boxes, or packaging mate-

rial residues.

Ä Lowest possible chance of damage to the scanner by mechanical collision or jammed parts.

Ä Possible extraneous light influence (no direct sunlight).

In order to select the right mounting location, several factors must be considered:

• Size, orientation, and position tolerance of the bar codes or Data Matrix codes on the objects to be

scanned.

• The reading field of the code reader in relation to the code module width.

• The resulting minimum and maximum reading distance from the respective reading field (see chapter

11.2 "Reading fields").

• Alignment of the code reader for avoiding reflections.

• Distance between code reader and host system with respect to the interface.

The best read results are obtained when

• the reading distance lies in the middle area of the reading field.

• there is no direct sunlight and extraneous light is avoided.

• the bar code labels are of good print quality and have good contrast ratios.

• you do not use high-gloss labels.

• the bar code or the Data Matrix code is moved past the reading window with an angle of rotation of 10°

to 15°.

• the red light beam is narrowed down for its respective reading task in order to avoid reflections on shiny

components.

Mounting

NOTICE

The front beam exit of the scan engine is almost vertical to the optics. The code label must be

rotated by >10° to avoid a total reflection of the red light beam in the case of glossy labels.

α Azimuth angle

β Angle of inclination

γ Angle of rotation

Recommended angle of rotation: γ > 10°

Fig.4.1: Definition of the reading angles

Leuze electronic DCR 85 10

Page 11

5 Electrical connection

CAUTION

Safety notices

Ä Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

Ä Connection of the device and maintenance work while under voltage must only be carried

out by a qualified electrician.

Ä The power supply unit for the generation of the supply voltage for the code reader and the

corresponding connection units must have a secure electrical insulation according to

IEC60742 (PELV). For UL applications: only for use in class 2 circuits according to NEC.

Ä If faults cannot be cleared, the device should be switched off and protected against acciden-

tal use.

5.1 Voltage supply

The code reader is designed for connection to a 5V supply voltage.

• +5V DC (red)

• GND (violet)

An adapter circuit board with spring terminals, Molex plug connector and 9-pin SUB-D socket is available

as an accessory (see chapter 12.2 "Accessories").

• With the adapter circuit board, the conductors of the connection cable can be contacted via the spring

terminals and connected to the PC via the 9-pin SUB-D socket with an RS 232 interconnection cable.

• With the adapter circuit board, the voltage supply of 10…30V DC can be fed in via spring terminals

or, alternatively, 5V DC can be fed in via a micro USB connector.

Electrical connection

5.2 Pin assignment

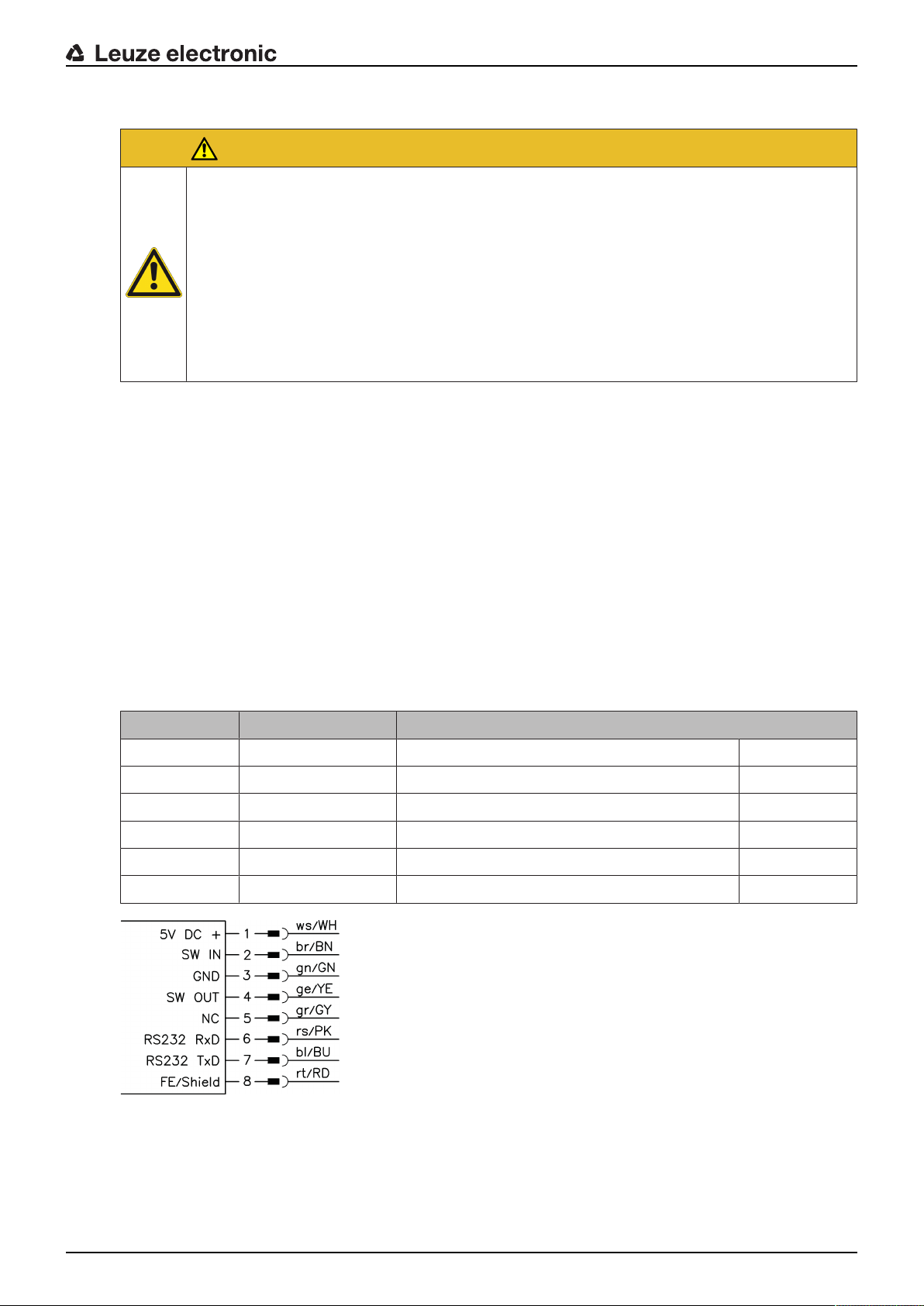

Tab.5.1: Cable with open wire ends

Wire Assignment Description

Red +5VDC Operating voltage 5VDC IN

Violet GND Operating voltage 0VDC / reference ground IN

Black SW OUT Switching output OUT

Orange SW IN Switching input IN

White RS232 RxD RxD signal line of the RS232 interface IN

Green RS232 TxD TxD signal line of the RS232 interface OUT

Fig.5.1: Cable with M12 connector, 8-pin, A-coded

5.3 Switching input / switching output

The code reader is provided with a switching input and a switching output.

• The switching input is used to trigger code reading.

• The switching output signals successful code reading.

Leuze electronic DCR 85 11

Page 12

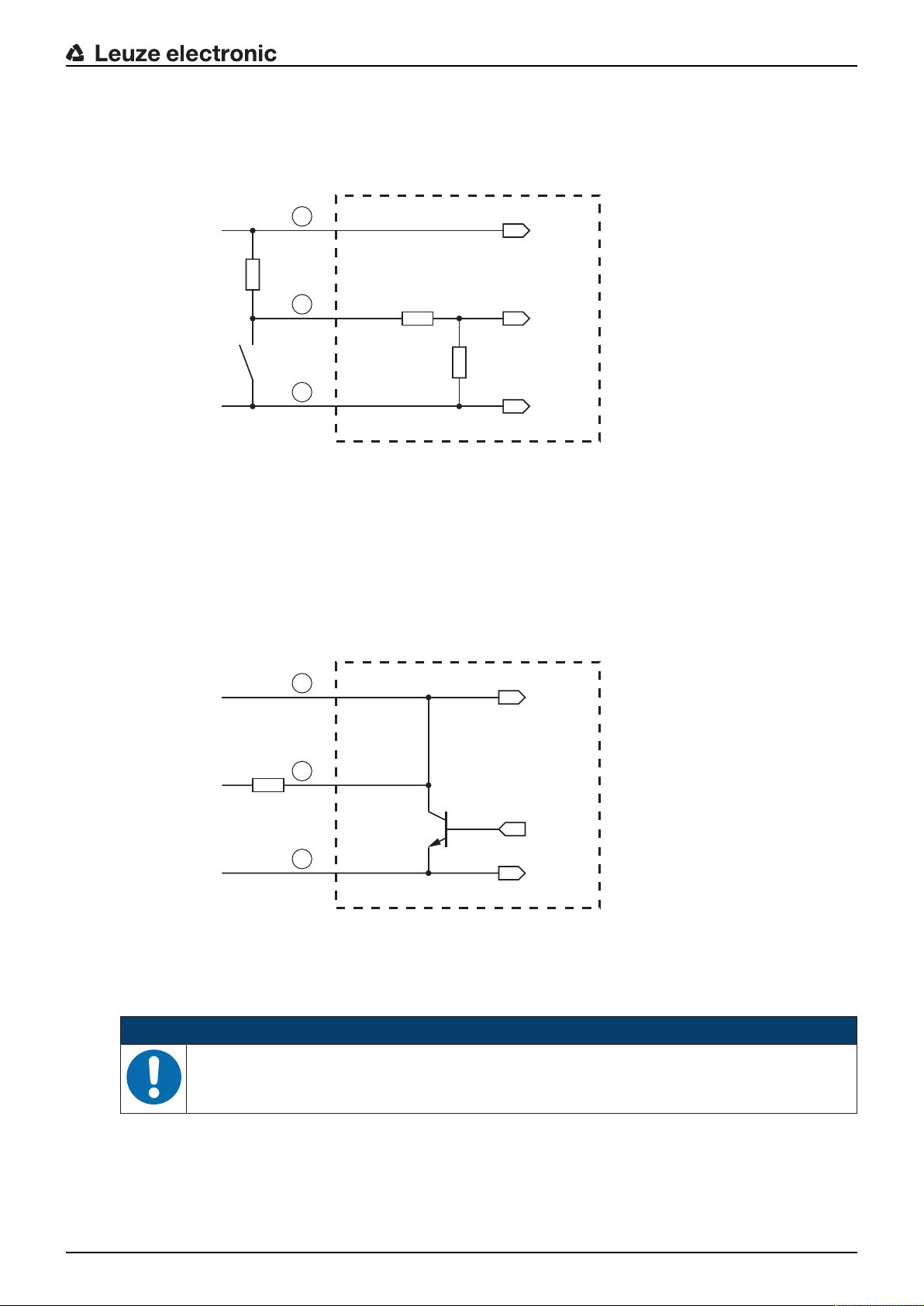

5.3.1 Switching input

+ 5 V DC

TRIGGER

GND

4.5 … 5.5 V DC

GND

2.2 k

1

2

3

+ 5 V DC

OUT

GND

GND

+ 5 … 30 V DC

max. 20 mA !

R

L

4.5 … 5.5 V DC

1

2

3

By means of the SW IN switching input connection, you can trigger a read process in the standard setting

(low = active) with the connection TRIGGER (orange) and GND (violet). We recommend wiring a 2.2kΩ

pull-up resistor as defined cable termination.

1 Red

2 Orange

3 Violet

Connection version NPN: standard setting (low = active)

Electrical connection

Fig.5.2: Switching input for connection variant NPN (standard setting)

5.3.2 Switching output

The NPN switching output connection between switching output (black) and GND (violet) switches if a code

is detected against GND.

1 Red

2 Black

3 Violet

Fig.5.3: Switching output

Leuze electronic DCR 85 12

NOTICE

Maximum loading of the switching output

Ä Do not load the switching output of the code reader with more than 20mA at +5…30 VDC!

Page 13

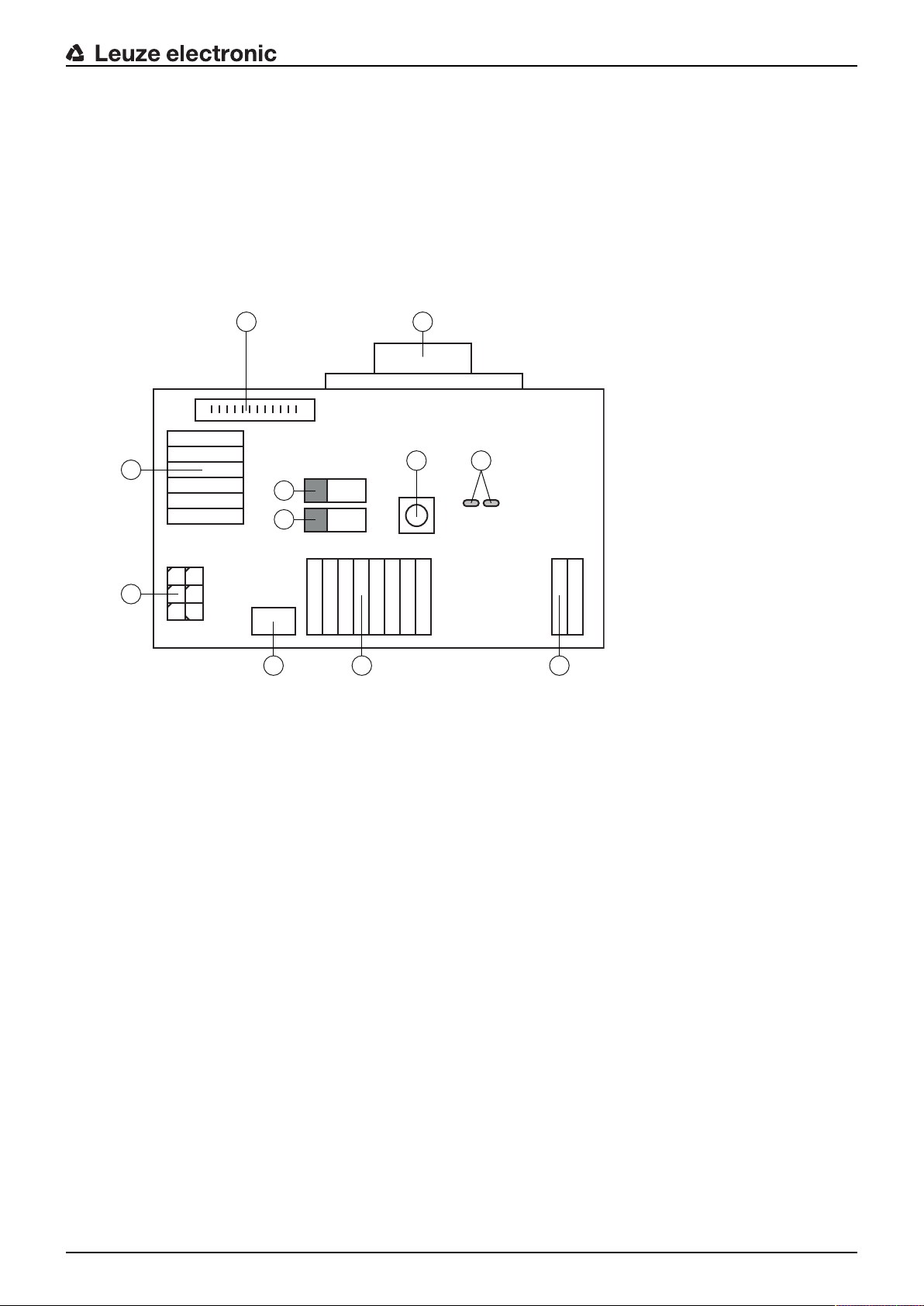

5.4 PC or terminal connection

1

2

10 11

3

4

8

9

5 6 7

Via the serial interface, you can configure the code reader by means of a PC or terminal. For this, you need

an RS232 connection that establishes the RxD, TxD and GND connections between PC and code reader.

The RS232 connection can be established in the following ways:

• Direct connection of the code reader connection wires to the PC or terminal via its own connector.

• Connection via an MA-CR adapter circuit board

To simplify the connection of the connection wires to the PC interface, an adapter circuit board (MACR) is available for implementing individual wire contacting to SUB-D, 9-pin (see chapter 12.2 "Accessories").

Electrical connection

1 RS232 connection

2 CR50 or DCR80 connection

3 CR100, CR55, DCR85 connection

4 Molex Micro-Fit, 6-pin

5 USB connection

6 Connection to machine control, PLC, external voltage supply 5VDC

7 External voltage supply 10…30VDC

8 SWIN DIP switch (level for trigger button; 5V if the scanner high switching input is active, GND if the low

input is active)

9 USB/PWR DIP switch (USB position if voltage is supplied via USB; PWR position if voltage is supplied

via(7))

10 Trigger button

11 Status LEDs

Fig.5.4: Connection options for MA-CR adapter circuit board

5.5 Cable lengths and shielding

The maximum cable length is 3m.

Should a cable extension be necessary, make certain that the cables of the RS232 interface are shielded.

Leuze electronic DCR 85 13

Page 14

Configuration and diagnostics software - SensorStudio

6 Configuration and diagnostics software - SensorStudio

The SensorStudio configuration software provides a graphical user interface for the operation, configuration and diagnosis of the device via the RS232 interface.

A device that is not connected to the PC can be configured offline.

Configurations can be saved and reopened as projects for transferring back to the device at a later time.

NOTICE

Only use the SensorStudio configuration software for products manufactured by Leuzeelectronic.

The SensorStudio configuration software is offered in the following languages: German, English, French, Italian and Spanish.

The FDT frame application of the SensorStudio supports all languages; all languages may not

be supported in the device DTM (Device Type Manager).

The SensorStudio configuration software is designed according to the FDT/DTM concept:

• You make the individual configuration settings for the bar code reader in the Device Type Manager

(DTM).

• The individual DTM configurations of a project can be called up via the frame application of the Field

Device Tool (FDT).

• Communication DTM for code readers: LeCommInterface

• Device DTM for the DCR 85 code reader

Procedure for the installation of the software and hardware:

Ä Install the SensorStudio configuration software on the PC.

Ä Install the communication and device DTM.

Communication and device DTM are included in the LeAnalysisCollectionSetup installation package.

Ä Create DCR85-DTM in the project tree of the Sensor Studio FDT frame.

Ä Connect code reader to PC (see chapter 5.4 "PC or terminal connection").

6.1 System requirements

To use the SensorStudio configuration software, you need a PC or laptop with the following specifications:

Tab.6.1: System requirements for SensorStudio installation

Operating system WindowsXP or higher (32bit, 64bit)

Computer Processor type: 1GHz or higher

Graphics card At least 1024x768 pixels

Required hard disk capacity for

SensorStudio and communication DTM

NOTICE

Administrator privileges on the PC are necessary for installing SensorStudio.

WindowsVista

Windows7

Windows8

Serial COM interface

CD-ROM drive

Main memory (RAM): at least 64MB

Keyboard and mouse or touchpad

35MB

Leuze electronic DCR 85 14

Page 15

Configuration and diagnostics software - SensorStudio

6.2 Installing SensorStudio configuration software

NOTICE

The installation files of the SensorStudio configuration software must be downloaded from the

Internet at www.leuze.com.

For subsequent updates, you can find the most recent version of the SensorStudio installation

software on the Internet at www.leuze.com.

6.2.1 Downloading configuration software

Ä Call up the Leuze home page: www.leuze.com

Ä Enter the type designation or part number of the device as the search term.

Ä The configuration software can be found on the product page for the device under the Downloads tab.

6.2.2 Installing the SensorStudio FDT frame

NOTICE

First install the software!

Ä Do not yet connect the device to the PC. First install the software.

NOTICE

If FDT frame software is already installed on your PC, you do not need the SensorStudio installation.

You can install the communication DTM and the device DTM in the existing FDT frame. Communication DTM and device DTM are included in the LeAnalysisCollectionSetup installation

package.

Ä Start the PC.

Ä Download the configuration software from the Internet to the PC (see chapter 6.2.1 "Downloading con-

figuration software").

Unpack the installation package.

Ä Start the SensorStudioSetup.exe file.

Ä Follow the instructions on the screen.

The Installation Wizard installs the software and places a shortcut on the desktop ( ).

6.2.3 Install the communication DTM and device DTM

Prerequisites:

ü An FDT frame is installed on the PC.

Ä Start the LeAnalysisCollection.exe file from the installation package and follow the instructions on the

screen.

The installation wizard installs communication DTM and device DTM for DCR85.

6.2.4 Connecting device to PC

The device is connected to the PC via the RS232 interface.

• You need an RS232 connection that establishes the RxD, TxD and GND connections between PC and

device (see chapter 5.4 "PC or terminal connection").

• The 5V DC voltage supply is to be fed in externally (see chapter 5.1 "Voltage supply").

Leuze electronic DCR 85 15

Page 16

Configuration and diagnostics software - SensorStudio

NOTICE

The MA-CR adapter circuit board with spring terminals and plug connector for connecting the

device, as well as 9-pin SUB-D socket for connecting an RS 232 interconnection cable, is available as an accessory. An RS232 interconnection cable to the PC is also available as an accessory (see chapter 12 "Order guide and accessories").

The adapter circuit board requires 10V…30VDC as external voltage supply, which can be fed

in via spring terminals.

6.3 Starting the SensorStudio configuration software

Prerequisites:

• The device has been mounted (see chapter 4 "Mounting") and connected (see chapter 5 "Electrical

connection") correctly.

• The device is connected to the PC via the RS232 interface (see chapter 6.2.4 "Connecting device to

PC").

• The SensorStudio configuration software is installed on the PC (see chapter 6.2 "Installing SensorStudio configuration software").

Ä Start the SensorStudio configuration software by double-clicking the SensorStudio icon ( ).

The mode selection of the Project Wizard is displayed.

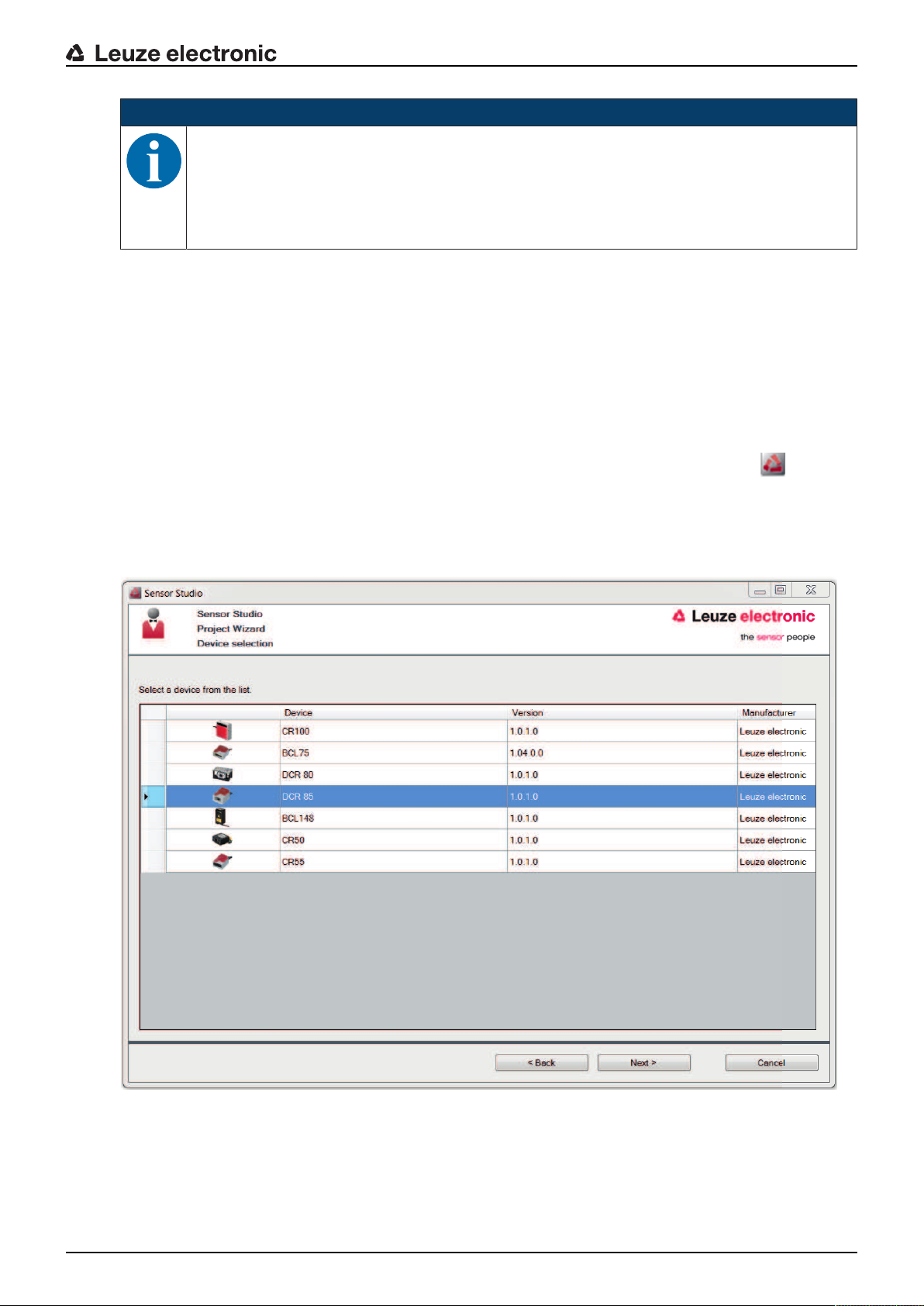

Ä Select the Device selection without communication connection (offline) configuration mode and

click on [Next].

The Project Wizard displays the device selection list of the configurable devices.

Fig.6.1: Device selection for code reader CR85

Ä Select DCR85 in the device selection and click on [Next].

The device manager (DTM) of the connected DCR85 starts with the offline view for the SensorStudio

configuration project.

Leuze electronic DCR 85 16

Page 17

Configuration and diagnostics software - SensorStudio

Ä Establish the online connection to the connected DCR85.

In the SensorStudio FDT frame, click on the [Establish connection with device] button ( ).

In the SensorStudio FDT frame, click on the [Upload parameters to device] button ( ).

The current configuration data is displayed in the device manager (DTM).

Fig.6.2: Configuration project: SensorStudio device manager (DTM) for DCR85

Ä The menus of the SensorStudio device manager (DTM) can be used to change or read out the config-

uration of the connected device.

The user interface of the SensorStudio device manager (DTM) is largely self-explanatory.

The online help system provides information on the menu items and adjustment parameters. Select the

Help menu item in the menu [?] ( ).

Ä Transfer the modified configuration parameters to the device.

If a connection exists, click on the [Download parameters to device] button ( ) on the task bar.

6.4 Exiting SensorStudio

After completing the configuration settings, close the SensorStudio configuration software.

Ä Exit the program via File > Exit.

Ä Save the configuration settings as a configuration project on the PC.

You can open the configuration project again at later time via File > Open or with the SensorStudio

Project Wizard ( ).

6.5 Configuration parameters

In this chapter, you will find information and explanations on the configuration parameters of the device

manager (DTM).

NOTICE

This chapter does not include a complete description of the SensorStudio configuration software.

Complete information on the FDT frame menu and on the functions in the device manager

(DTM) can be found in the online help system.

The device manager (DTM) of the SensorStudio configuration software offers the following configuration

functions:

• General (Control)

• Decode (see chapter 6.5.2 "Decode tab")

Leuze electronic DCR 85 17

Page 18

• Host Interface (see chapter 6.5.3 "Host interface tab")

• Diagnosis (see chapter 6.5.4 "Diagnosis / Terminal")

NOTICE

The online help system displays information on the menu items and configuration parameters

for each function. Select the Help menu item in the menu [?].

6.5.1 General tab

Configuration and diagnostics software - SensorStudio

Fig.6.3: General tab

Trigger duration

(Trigger Duration)

Reading fields

(Decode Area)

Scan mode

(Continuous Action)

LED illumination

(Illumination)

Target illumination

(Targeting)

Target illumination time setting

(Target Time before Decode)

Set the time, for which a read cycle remains active after a trigger

event.

Example: triggerduration=3000ms means that the scanner tries to

decode a code for a maximum of three seconds after a trigger event.

The read cycle ends after successful decoding or after the time that

has been preset here has relapsed.

Selection of the reading field. The scan engine has two reading fields:

• High resolution reading field

• Wide-range reading field

Selection of the reading behavior:

• Read when triggered

• Presentation mode

• Duration reading

Set the illumination time of the LEDs after successful reading.

Switch the blue alignment LEDs on and off.

Setting of the time until which reading takes place after a trigger event.

The blue alignment LEDs light up immediately when the trigger event

occurs.

Leuze electronic DCR 85 18

Page 19

6.5.2 Decode tab

Configuration and diagnostics software - SensorStudio

Fig.6.4: Decode tab

Code table

(DECODE)

Properties

(SYMBOLOGIES)

Here, the codes which are to be decoded are set. We recommend enabling only the code types which are to actually be read with the corresponding element numbers. Codes which are not enabled are not decoded!

Use the … button to the right of the given code to select the code-specific settings.

Alternatively, the property settings can be selected directly via the

navigation tree under the Decode button.

The properties can be individually set for each code type.

Fig.6.5: Standard settings for the Properties window (SYMBOLOGY SETTINGS) – Decode tab

Leuze electronic DCR 85 19

Page 20

6.5.3 Host interface tab

Configuration and diagnostics software - SensorStudio

Fig.6.6: Host interface tab

Select the desired baud rate, the stop bits, the data bits, the parity and various transmission modes here.

The desired acknowledgment settings are also to be set in this selection window.

6.5.4 Diagnosis / Terminal

Fig.6.7: Terminal

The Terminal tab provides the following functions:

• Send online commands to the code reader for diagnostic purposes.

• Visualize the code reader output.

The contents of the terminal display can be printed out or saved in a file for subsequent offline evaluation.

Leuze electronic DCR 85 20

Page 21

6.5.5 Diagnosis / Image Viewer

Configuration and diagnostics software - SensorStudio

Fig.6.8: Diagnosis / Image Viewer

You can use the Image Viewer to display the image captured in the reading field on the screen. This helps

you find the optimum position for reliable reading.

If both reading fields are activated (Decode Area Both Fields), the high-resolution reading field and the

far-range reading field are displayed in the GUI.

Leuze electronic DCR 85 21

Page 22

Starting up the device - Configuration

7 Starting up the device - Configuration

7.1 Measures to be performed prior to the initial commissioning

NOTICE

Ä Please observe the notices for device arrangement, see chapter 4.1 "Selecting a mounting

location".

Ä If possible, always trigger the scanner with the aid of commands or an external signal trans-

mitter (photoelectric sensor).

Ä Before commissioning, familiarize yourself with the operation and configuration of the de-

vice(s).

Ä Before connecting the supply voltage, recheck all connections and ensure that they have

been properly made.

7.2 Starting the device

7.2.1 Interface

Proper function of the interface can be most easily tested in service operation using the serial interface with

the SensorStudio configuration software and a notebook computer.

7.2.2 Online commands

Using the online commands, important device functions can be checked, e.g. reading activation.

7.2.3 Problems

If a problem occurs that cannot be rectified even after checking all electrical connections and settings on

the devices and on the host, contact your responsible Leuzeelectronic subsidiary or Leuzeelectronic customer service, see chapter 10 "Service and support".

7.3 Setting the communication parameters

You have now commissioned the device. Usually, you will have to configure it before you can use it. Using

the configuration options offered in the SensorStudio or by means of the device DTM, the device can be

individually configured according to your application. For information on the various configuration options,

see chapter 6 "Configuration and diagnostics software - SensorStudio" or refer to the online help.

It is normally sufficient to set the code type and code length in accordance with the 1D or 2D codes that are

to be read in order to be able to operate the device.

The setting of code type and code length is usually accomplished by using the SensorStudio configuration

software (see chapter 6 "Configuration and diagnostics software - SensorStudio").

Leuze electronic DCR 85 22

Page 23

8 Online commands

8.1 Overview of commands and parameters

Online commands can be used to send commands directly to the device for control and configuration. For

this, the device has to be connected to a computer (host) via the serial interface.

Using the online commands you can:

• query the device version.

• activate and deactivate code reading.

• perform a software reset.

Command syntax

<cmd-prefix><cmd-type><data-size>[<data>]<reserved><crc>

<cmd-prefix> <0xEE><0xEE><0xEE><0xEE>

<cmd-type> One ASCII character

<data-size> Byte value 0…240

Number of bytes in <data>

[<data>] Optional: command data (byte values) in range of 0…255

Online commands

<reserved> One byte, always <0x00>

<crc> Two bytes crc16 check sum

Answer syntax

<start-tag><packet-type>[<packet-data>]<EOT>

<start-tag> <0x01>X<0x1E>ap/

<packet-type> One ASCII character

[<packet-data>] Optional: answer data

<EOT> One byte <EOT> (<0x04> hex.)

Leuze electronic DCR 85 23

Page 24

8.2 General online commands

Software version number

Command <cmd-prefix>I<0x00><0x00><0x03><0x3C>

Description Requests device version information

Parameter None

Answer <start-tag>iVVVVWWWWXXXXSSSSSSSSSSAOODYYYYHHIIIIJJJJKKKKL-

LLL <TAB>Z…Z<EOT>

• i: "I" string output

• VVVV: application firmware version number

• WWWW:core application firmware version number

• XXXX: reserved

• A: current execution state:

• OO: OEM identifier

• D: display type

• YYYY: reserved

• HH: hardware version

• IIII: hardware type identifier (value in register 21B)

• JJJJ: boot application version

• KKKK: operating system kernel version

• LLLL: root file-system version

• <TAB>: ASCII TAB character

• Z…Z: OEM decoder version:

Example:

i10261026none0020366861A0600000080006001600660002 -> cd(14.2.0)

Online commands

"A": core is running

"0": no display device

null-terminated string of printable ASCII characters

Software reset

Command <cmd-prefix>Z<0x01>1<0x00><0x1C><0x04>

Description Carries out a software reset. The device is restarted and reinitialized, leaving it

in the same state as when the supply voltage is switched on.

Parameter None

Acknowledgment <start-tag>d<EOT>

"d": done response

Start decoding

Command <cmd-prefix>P<0x0C>(35)7FFFFFFF<0x00><0x57><0x5F>

<cmd-prefix>$<0x01><0x03><0x00><0x1F><0x5C>

Description The command consists of two individual commands.

• The first command sets the decoder duration to infinity.

• The second command activates decoding.

Parameter None

Acknowledgment <start-tag>d<EOT>

"d": done response (twice)

Leuze electronic DCR 85 24

Page 25

Online commands

Stop decoding

Command <cmd-prefix>P<0x05>(35)0<0x00><0x65><0x5B>

Description The command sets the decoder duration to zero and stops decoding.

Parameter None

Acknowledgment <start-tag>d<EOT>

"d": done response

Start continuous decoding

Command <cmd-prefix>P<0x06>(C4)03<0x00><0x01><0x75>

Description The command activates duration decoding.

The read result is continuously output until it is terminated by a command.

Parameter None

Acknowledgment <start-tag>d<EOT>

"d": done response

End continuous decoding

Command <cmd-prefix>P<0x06>(C4)FF<0x00><0x1C><0x71>

Description The command ends duration decoding.

Parameter None

Acknowledgment <start-tag>d<EOT>

8.3 Text commands

Text commands are activated via the following start sequence: ;>PA1<CR>

With PA8<CR>, the input of text commands is ended.

Example:

Tab.8.1: Activate decoding of Interleaved 2 of 5 codes with 10 (0x0A) characters

Command Description

;>PA1<CR> Activate text commands

P(6E)1<CR> Activate decoding of Interleaved 2 of 5 codes

P(C9)0A<CR> Code length: 10 (0x0A) characters

PA8<CR> Deactivate text commands

Command syntax

"d": done response

<Command-Type><Command-Data><CR>

<CommandType>

P The settings are stored in a register. The settings are lost when the device is

restarted.

C The settings are stored in a register. The settings remain stored when the device is

restarted.

<Command

See tables

Data>

<CR> Carriage return

ASCII control character 0x0D

Leuze electronic DCR 85 25

Page 26

Command data

Format: (XXX)YYY

• XXX: register number in ASCII hex

• YYY: setting value in ASCII hex

Tab.8.2: Decoding – Common properties

Parameter settings Command data

Online commands

Common properties

Tab.8.3: Decoding – 1D codes

Maximum labels to decode (34)1…10

Ignore duplicate codes (ms) (159)0…7FFFFFF

Code Parameter settings Command data

Code properties 1D barcode aggressiveness

Most aggressive (13)0

Less aggressive (13)1

Less aggressive (13)2

Interleaved 2 of 5 Settings of register C9 are bitwise OR-connected.

• The length (number of digits) is always even and can be represented by an integer value without using bit 0.

• Bit 0 is used to enable/disable Small Quiet Zone (SMZ)

Interleaved 2 of 5 Decoding

enable (6E)1

disable (6E)0

Interleaved 2 of 5 Length (C9)0…64

Interleaved 2 of 5 Small Quiet Zone (SMZ)

enable (C9)1

disable (C9)0

Interleaved 2 of 5 Checksum checking

disable (71)0

enable (71)1

Enable and strip from output (71)2

Code 32

Code 39

Decoding

disable (6B)0

enable Code39 but not Code32 (6B)1

enable Code32 but not Code39 (6B)2

enable Code39 and Code32 (6B)3

Code 39 Checksum checking

disable (70)0

enable (70)1

Enable and strip from output (70)3

Code 39 Full ASCII symbology

disable (49)0

enable (49)1

Leuze electronic DCR 85 26

Page 27

Code Parameter settings Command data

Code93 Decoding

disable (6C)0

enable (6C)1

Online commands

Code UPC

Code EAN

UPC and EAN codes enabled

disable (6A)0

enable (6A)1

Code UPC Supplemental data output

disable (4E)0

enable (4E)1

Code 128 Decoding

enable (6D)1

disable (6D)0

Codabar Decoding

enable (6F)1

disable (6F)0

Codabar Checksum checking

disable (48)0

enable (48)1

Enable and strip from output (48)3

GS1 DataBar The settings of register 4C are bitwise OR-connected

• Example: Command (4C)06 enables GS1 DataBar Limited decoding and GS1

DataBar Expanded Stacked decoding

• Command (4C)00 disables all GS1 DataBar symbologies

GS1 DataBar Omnidirectional Decoding, Truncated Decoding

enable (4C)08

disable (4C)00

GS1 DataBar Limited decoding

enable (4C)04

disable (4C)00

GS1 DataBar Expanded decoding

enable (4C)01

disable (4C)00

GS1 DataBar Omnidirectional Stacked Decoding, Stacked Decoding

enable (4C)10

disable (4C)00

GS1 DataBar Expanded tacked decoding

enable (4C)02

disable (4C)00

Leuze electronic DCR 85 27

Page 28

Code Parameter settings Command data

MSI Plessey The settings of register 4F are bitwise OR-connected

• Example: Command (4F)25 enables MSI Plessey decoding with Two Bytes Modulo 11/10 checksum and UK Plessey decoding

• Command (4F)00 disables all MSI Plessey decoding and the checksum settings

MSI Plessey Decoding

enable (4F)01

disable (4F)00

MSI Plessey Checksum method

Checksum checking disabled (4F)00

One Byte Modulo 10 (4F)02

Two Bytes Modulo 11/10 (4F)04

Two Bytes Modulo 10 (4F)06

One Byte Modulo 10 and strip from output (4F)09

Online commands

Two Bytes Modulo 11/10 and strip from

(4F)0A

output

Two Bytes Modulo 10 and strip from out-

(4F)0C

put

MSI Plessey UK Plessey (original) decoding

enable (4F)20

disable (4F)00

Tab.8.4: Decoding extras – 1D codes

Parameter settings Command data

Settings of register 24F are bitwise OR-connected.

Example: Command (24F)8435 enables the following options

• Send Code39 start and stop delimiter

• Force output of all decoding data to upper case

• Remove UPC-A check digit

• Remove UPC-A number system digit

• Convert EAN-8 to EAN-13

• Remove GS1 DataBar “()” characters

Send Code39 start and stop delimiters

enable (24F)0001

disable (24F)0000

Remove Codabar start and stop delimiters

enable (24F)0002

disable (24F)0000

Force all decoding data to upper case

enable (24F)0004

disable (24F)0000

Force all decoding data to lower case

enable (24F)0008

disable (24F)0000

Leuze electronic DCR 85 28

Page 29

Parameter settings Command data

Remove UPC-A check digit

enable (24F)0010

disable (24F)0000

Remove UPC-A number system digit

enable (24F)0020

disable (24F)0000

Remove UPC-E check digit

enable (24F)0040

disable (24F)0000

Remove UPC-E number system digit

enable (24F)0080

disable (24F)0000

Remove EAN-13 check digit

enable (24F)0100

Online commands

disable (24F)0000

Remove EAN-8 check digit

enable (24F)0200

disable (24F)0000

Convert EAN-8 to EAN-13

enable (24F)0400

disable (24F)0000

Convert UPC-A to EAN-13

enable (24F)0800

disable (24F)0000

Convert Bookland EAN-13 to ISBN

enable (24F)1000

disable (24F)0000

Convert Bookland EAN-13 to ISSN

enable (24F)2000

disable (24F)0000

Remove GS1 DataBar “()” characters

enable (24F)8000

disable (24F)0000

Leuze electronic DCR 85 29

Page 30

Tab.8.5: Decoding – Stacked codes

Code Parameter settings Command data

PDF417 Decoding

enable (29)1

disable (29)0

Micro PDF417 decoding

enable (2A)1

disable (2A)0

Tab.8.6: Decoding – 2D codes

Code Parameter settings Command data

Code properties Image transform

No transform (14)0

Mirror (14)1

DataMatrix Settings of register 19 are bitwise OR-connected. Example:

• Command (19)5 enables standard and mirror DataMatrix decoding and disables

inverse DataMatrix decoding.

Online commands

DataMatrix Standard decoding

enable (19)1

disable (19)0

DataMatrix Inverse decoding

enable (19)2

disable (19)0

DataMatrix Mirror decoding

enable (19)4

disable (19)0

DataMatrix Rectangular symbology

enable (16)1

disable (16)0

Aztec Settings of register 50 are bitwise OR-connected. Example:

• Command (50)5 enables standard and mirror Aztec decoding and disables inverse Aztec decoding.

Aztec Standard decoding

enable (50)1

disable (50)0

Aztec Inverse decoding

enable (50)2

disable (50)0

Aztec Mirror decoding

enable (50)4

disable (50)0

Leuze electronic DCR 85 30

Page 31

Code Parameter settings Command data

QRcode Settings of register 2B are bitwise OR-connected. Example:

• Command (2B)11 enables standard and mirror QRCode decoding and disables

inverse, micro, and Model1 QRCode decoding.

QRcode Standard decoding

enable (2B)01

disable (50)00

QRcode Inverse decoding

enable (2B)02

disable (2B)00

QRcode Micro decoding

enable (2B)04

disable (2B)00

QRcode Mirror decoding

enable (2B)10

Online commands

disable (2B)00

QRcode Model1 decoding

enable (2B)20

disable (2B)00

Tab.8.7: Output

Parameter settings Command data

Notification of read failure

enable (55)1

disable (55)0

Output result with AIM ID

AIM ID in prefix (ED)1

No AIM ID in prefix (ED)0

Leuze electronic DCR 85 31

Page 32

Tab.8.8: Control options

Option Parameter settings Command data

Trigger duration

Trigger duration [ms] (35)0…7FFFFFFF

Decode area

Read in both fields (39)3

Read in high-density field (39)5

Read in wide-angle field (39)6

Continuous action

idle (C4)FF

Read continuously in both fields (C4)03

Read continuously in high-density field (C4)05

Read continuously in wide-angle field (C4)06

Motion control (C4)F0

Illumination

Online commands

Targeting

Beep volume

Minimum illumination (04)0

Leave illumination during read (04)1

enable (0F)1

disable (0F)0

Target time before decoding [ms] (33)0…7FFFFFFF

silent (26)00

low (26)21

medium (26)32

high (26)42

full (26)64

Leuze electronic DCR 85 32

Page 33

Tab.8.9: Host interface settings

Setting Parameter settings Command data

RS232 Baud rate [BAUD]

9600 (1C)02580

19200 (1C)04B00

38400 (1C)09600

57600 (1C)0E100

115200 (1C)1C200

RS232 Data length

7 bits (1E)7

8 bits (1E)8

RS232 Parity

none (22)0

odd (22)1

even (22)2

Online commands

RS232 Stop bits

1 bit (1D)1

2 bits (1D)2

RS232 Flow control

Disabled (1F)0

Hardware (1F)1

Handshake Acknowledgment expected

enable (42)1

disable (42)0

Acknowledgment time limit [ms] (37)0…7FFFFFFF

Leuze electronic DCR 85 33

Page 34

9 Care, maintenance and disposal

Usually, the device does not require any maintenance by the operator.

9.1 Cleaning

Clean the glass window of the device with a soft cloth before mounting.

NOTICE

Do not use aggressive cleaning agents!

Ä Do not use aggressive cleaning agents such as thinner or acetone for cleaning the device.

9.2 Servicing

Repairs to the device must only be carried out by the manufacturer.

Ä For repairs, contact your responsible Leuzeelectronic subsidiary or Leuzeelectronic customer service

(see chapter 10 "Service and support").

9.3 Disposing

Ä For disposal observe the applicable national regulations regarding electronic components.

Care, maintenance and disposal

Leuze electronic DCR 85 34

Page 35

10 Service and support

24-hour on-call service at:

+49 (0) 7021 573-0

Service hotline:

+49 (0) 7021 573-123

Monday to Friday 8.00a.m. to 5.00p.m. (UTC+1)

E-mail:

service.identify@leuze.de

Return address for repairs:

Service center

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Service and support

10.1 What to do should servicing be required?

NOTICE

Please use this chapter as a master copy should servicing be required!

Ä Enter the contact information and fax the form together with your service order to the fax

number given below.

Customer data (please complete)

Device type:

Serial number:

Firmware:

Display messages:

Status of LEDs:

Error description:

Company:

Contact person/department:

Phone (direct dial):

Fax:

Street/No:

ZIP code/City:

Country:

Leuze Service fax number:

+49 (0) 7021 573-199

Leuze electronic DCR 85 35

Page 36

11 Technical data

11.1 General specifications

Tab.11.1: Optics

Optical system CMOS Imager, Rolling Shutter (1280x960)

Optical resolution High-resolution reading field 960x640

Reading area 20mm…300mm

Contrast 1D code: 25%

Resolution 1D code: m=0.076mm (3mil), distance dependent

Technical data

Wide-range reading field 960x640

2D code: 35%

2D code: m=0.127mm (5mil), distance dependent

Light sources

• Illumination

• Alignment LEDs (Aimer)

Tab.11.2: Code specifications

integrated LEDs

• visible red light

• visible blue light

Code type: 1D Codabar, Code11, Code32 , Code39, Code93, Code128, Inter-

leaved2of5, GS1DataBar (RSS), MSIPlessey, Pharmacode, UPC/EAN,

2of5 (IATA, Matrix, Hong Kong, Straight, NEC), Telepen

Code type: Stacked 1D PDF417, MicroPDF, GS1Composite, CodablockF

Code type: 2D DataMatrix, AztecCode, QRCode, MicroQR, MaxiCode

Postal Codes AustralianPost, IntelligentMail, JapanPost, KIXCode, KoreaPost, Planet,

Postnet, UKRoyalMail, UPUIDTags

Tab.11.3: Interfaces

Interface type RS232

Baud rate 9600…115200baud, configurable

Data formats configurable

Trigger • Switching input

• active: 0V

• inactive: +5V or not connected

• Presentation Mode (Motion Control)

Switching output NPN transistor output, max. 20mA, Good Read

Tab.11.4: Electrical equipment

Operating voltage 4.5…5.5VDC

Current consumption Duration reading: typ. 350mA

Inactive illumination: typ. 75mA

LEDs 1 device status

1 read status

Leuze electronic DCR 85 36

Page 37

Tab.11.5: Mechanical data

Degree of protection IP54

Connection type fixed cable, 2m long, 6x0.081mm² (AWG28)

Weight 70g (without cable)

Dimensions (H x W x D) 25x39x55.5mm

Fastening 3x M2.5 bore holes, 5mm deep

Housing Metal, die-cast aluminum

Tab.11.6: Environmental data

Ambient temp. (operation/storage) 0°C…+50°C/-20°C…+60°C

Air humidity 10%…90% rel. humidity, non-condensing

Electromagnetic compatibility EN55022:2006 ClassB

IEC62471:2006

Conformity CE, FCC

Ambient light max. 100000Lux

Technical data

11.2 Reading fields

NOTICE

Please note that the actual reading fields are also influenced by factors such as labeling material, printing quality, scanning angle, printing contrast etc., and may thus deviate from the reading fields specified here. The origin of the read distance always refers to the front edge of the

housing of the beam exit.

Leuze electronic DCR 85 37

Page 38

Technical data

1

2

3

4

3

4

80 102

33 182

20 220

28 280

43 115

33 150

20 180

28 343

1 Reading fields – side view

2 Reading fields – top view

3 High resolution reading field

4 Wide-range reading field

Fig.11.1: Reading fields

Tab.11.7: Reading fields

Code type Resolution Typical reading distance [mm]

Code 39 0.076mm (3mil)

Code 39 0.190mm (7.5mil)

GS1Data bar 0.267mm (10.5mil)

UPCData bar 0.330mm (13mil)

Data Matrix 0.127mm (5mil)

Data Matrix 0.160mm (6.3mil)

Data Matrix 0.254mm (10mil)

Data Matrix 0.528mm (20.8mil)

Leuze electronic DCR 85 38

Page 39

11.3 Dimensioned drawings

Technical data

all dimensions in mm

A 4 integrated LEDs for illumination (red light)

B1 High resolution reading field lens

B2 Wide-range reading field lens

C 2 integrated target LEDs (blue light)

D Status LEDs

Fig.11.2: DCR85 dimensioned drawing

Leuze electronic DCR 85 39

Page 40

12 Order guide and accessories

12.1 Type overview

Tab.12.1: Part numbers

Part no. Part designation Description

50131458 DCR85M2/R2 CMOS Imager code reader for 1D- and 2D-codes,

50131581 DCR85M2/R2-150-M12.8 CMOS Imager code reader for 1D- and 2D-codes,

12.2 Accessories

Tab.12.2: Accessories

Part no. Part designation Description

Order guide and accessories

RS232 interface, permanently attached connection cable,

2m long

RS232 interface, approx. 0.15m cable with M12 connector (8-pin)

50128204 MA-CR Adapter circuit board for contacting the 12-pin plug

connector and conversion to SUB-D, 9-pin

50113396 KB DSub-9P-3000 RS232 interconnection cable, cable length 3m

50104591 K-D M12A-8P-2m-PUR M12 connection cable, axial 8-pin socket, cable

length 2m, shielded

SensorStudio configuration software

Download at www.leuze.com

see chapter 6.2.1 "Downloading configuration software"

SensorStudio designed according to the FDT/DTM

concept. Contains: communication DTM and device

DTM

Leuze electronic DCR 85 40

Page 41

13 EC Declaration of Conformity

The scan engines of the DCR85 series have been developed and manufactured in accordance with the

applicable European standards and directives.

EC Declaration of Conformity

Leuze electronic DCR 85 41

Page 42

14 Appendix

14.1 Bar code samples

Module 0.3

Fig.14.1: Code type 01: Interleaved 2 of 5

Module 0.3

Fig.14.2: Code type 02: Code 39

Appendix

Module 0.3

Fig.14.3: Code type 11: Codabar

Module 0.3

Fig.14.4: Code 128

Module 0.3

Fig.14.5: Code type 08: EAN 128

SC 2

Fig.14.6: Code type 06: UPC-A

Leuze electronic DCR 85 42

Page 43

SC 3

Fig.14.7: Code type 07: EAN 8

Appendix

Fig.14.8: Example codes

14.2 Configuration via configuration codes

The device can also be configured using configuration codes. The device parameters in the device are set

and permanently saved after reading this code.

Leuze electronic DCR 85 43

Page 44

DCR 80 Configuration Guide

Appendix

Fig.14.9: DCR80 Configuration Guide

Leuze electronic DCR 85 44

Page 45

DCR 80 Configuration Guide

Appendix

Fig.14.10: DCR80 Configuration Guide

Leuze electronic DCR 85 45

Page 46

DCR 80 Configuration Guide

Appendix

Fig.14.11: DCR80 Configuration Guide

Leuze electronic DCR 85 46

Page 47

DCR 80 Configuration Guide

Appendix

Fig.14.12: DCR80 Configuration Guide

Leuze electronic DCR 85 47

Page 48

DCR 80 Configuration Guide

Appendix

Fig.14.13: DCR80 Configuration Guide

Leuze electronic DCR 85 48

Page 49

DCR 80 Configuration Guide

Appendix

Fig.14.14: DCR80 Configuration Guide

Leuze electronic DCR 85 49

Page 50

DCR 80 Configuration Guide

Appendix

Fig.14.15: DCR80 Configuration Guide

Leuze electronic DCR 85 50

Page 51

DCR 80 Configuration Guide

Appendix

Fig.14.16: DCR80 Configuration Guide

Leuze electronic DCR 85 51

Page 52

DCR 80 Configuration Guide

Appendix

Fig.14.17: DCR80 Configuration Guide

Leuze electronic DCR 85 52

Page 53

DCR 80 Configuration Guide

Fig.14.18: DCR80 Configuration Guide

Appendix

Leuze electronic DCR 85 53

Loading...

Loading...