Page 1

DB 14B

Double Sheet Testing Unit

en 02-2015/09 50131012

We reserve the right to

make technical changes

Original operating instructions

Page 2

© 2015

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic DB 14B

Page 3

Table of contents

1 General information ........................................................................................................... 4

1.1 Explanation of symbols ........................................................................................................ 4

1.2 Declaration of conformity ..................................................................................................... 4

2 Safety notices..................................................................................................................... 5

2.1 Safety standards ..................................................................................................................5

2.2 Approved purpose................................................................................................................ 5

2.3 Areas of application ............................................................................................................. 5

2.4 Organisational measures .....................................................................................................5

3 Description of the device and system ............................................................................. 6

3.1 Set-up of the DB 14B ...........................................................................................................6

3.2 Performance features of the DB 14B ...................................................................................6

3.3 Function description DB 14B ............................................................................................... 7

3.4 Delivery contents / accessories / order codes ..................................................................... 8

4 Installation .......................................................................................................................... 9

4.1 Storage, transportation ........................................................................................................ 9

4.2 Mounting ............................................................................................................................ 10

4.3 Connection......................................................................................................................... 13

4.4 Disassembling, packing, disposing .................................................................................... 14

5 Commissioning ................................................................................................................15

5.1 Before switching on for the first time .................................................................................. 15

5.2 Display and control elements ............................................................................................. 15

5.2.1 VDB 14B evaluation unit.............................................................................................................. 15

5.2.2 Indicator functions........................................................................................................................ 16

5.2.3 Indicators VDB 14B/4 / VDB 14B/2..............................................................................................17

5.3 Switching on....................................................................................................................... 19

5.4 Adjustment ......................................................................................................................... 19

5.4.1 Starting adjustment...................................................................................................................... 19

5.4.2 Adjusting the ultrasonic sensors..................................................................................................19

5.4.3 Adjusting the capacitive sensor...................................................................................................21

5.4.4 Terminating adjustment ...............................................................................................................21

6 Sheet testing .................................................................................................................... 22

6.1 Conditions for readiness .................................................................................................... 22

6.2 Operating states................................................................................................................. 22

6.3 Calibration.......................................................................................................................... 23

6.3.1 Calibration error........................................................................................................................... 23

6.4 Testing for double sheets................................................................................................... 23

6.5 Testing for second sheets .................................................................................................. 24

6.6 Evaluation process............................................................................................................. 25

Leuze electronic DB 14B 1

Page 4

Table of contents

7 Interfaces .......................................................................................................................... 27

7.1 Serial interface ................................................................................................................... 27

7.2 Analogue interface ............................................................................................................. 28

8 Error messages (flashing)............................................................................................... 29

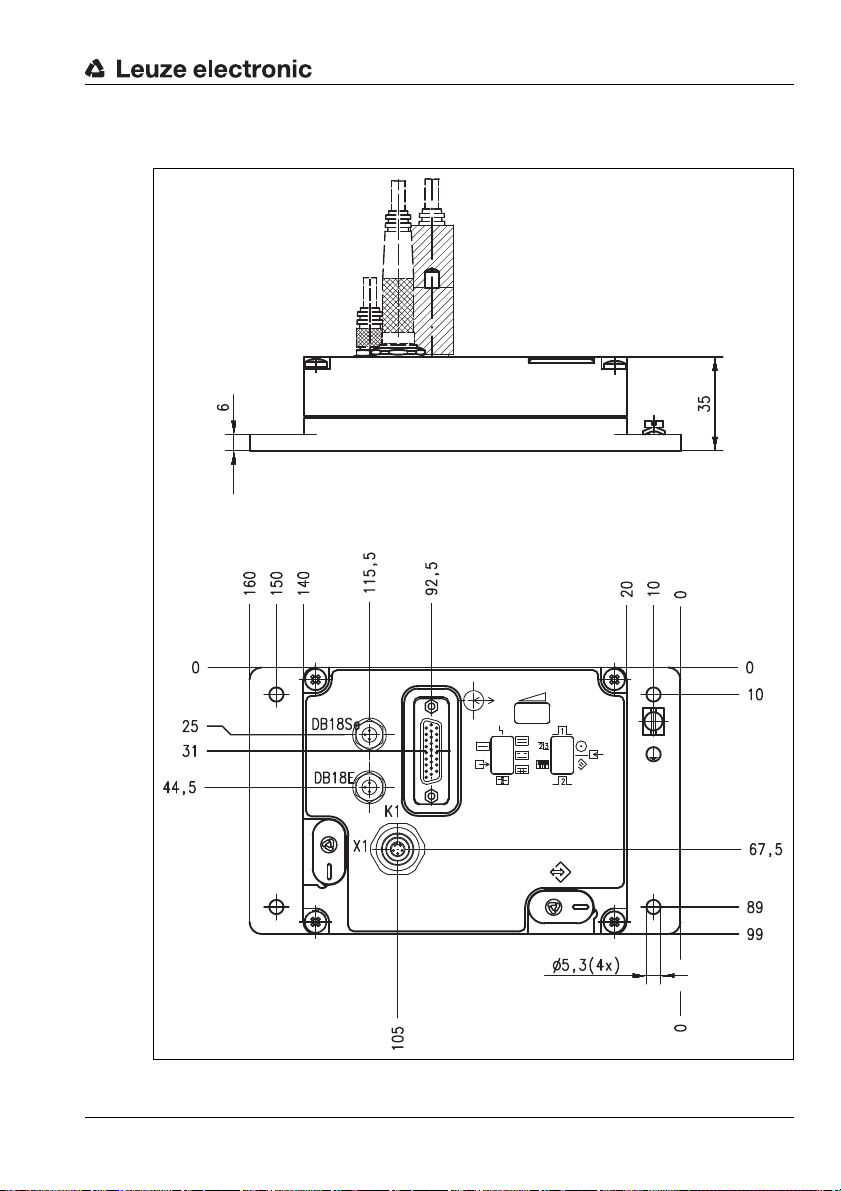

9 Dimensioned drawings.................................................................................................... 33

10 Specifications................................................................................................................... 35

11 Maintenance .....................................................................................................................37

11.1 General maintenance information...................................................................................... 37

11.2 Repairs and maintenance .................................................................................................. 37

12 Appendix: 2/3 sheet mode .............................................................................................. 38

12.1 Explanations of the calibration function ............................................................................. 39

12.2 Error case A: Multiple inquiries on the first sheet or

multiple single sheets before start of overlap43

12.3 Error case B: Double sheet on inquiry of the first sheet..................................................... 44

12.4 Error case C: Double sheet during calibration on the second sheet .................................. 44

12.5 Error case D: One or more single sheets with subsequent double sheet at start of overlap .

12.6 Symbol legend ................................................................................................................... 46

12.7 Critical cases in the overlap flow with 2/3 sheet scanning ................................................. 47

45

2 DB 14B Leuze electronic

Page 5

Figures and tables

Figure 3.1: DB 14B system set-up..................................................................................................6

Figure 4.1: Example for the sensor arrangement ......................................................................... 10

Figure 4.2: Mounting the ultrasonic sensors................................................................................. 11

Figure 4.3: Mounting the capacitive sensor.................................................................................. 12

Figure 4.4: Potential equalisation and connection........................................................................ 12

Table 4.1: Pin assignments of the 26-pin SUB-D connector ....................................................... 13

Figure 5.1: VDB 14B evaluation unit ............................................................................................ 15

Figure 5.2: Control inputs .............................................................................................................16

Figure 5.3: Control outputs ........................................................................................................... 17

Table 5.1: Indicators VDB 14B .................................................................................................... 17

Figure 5.4: Signal level of the DB 18 UP ...................................................................................... 20

Table 5.2: Signal level of the DB 18 UP ...................................................................................... 20

Figure 6.1: Evaluation process ..................................................................................................... 26

Figure 7.1: Interface symbol ......................................................................................................... 27

Table 7.1: Assignments of the serial interface ............................................................................ 27

Table 7.2: Assignments of the analogue interface X1................................................................. 28

Table 8.1: Error messages .......................................................................................................... 29

Figure 9.1: Dimensions of the VDB 14B evaluation unit............................................................... 33

Figure 9.2: Capacitive sensor DB 14 K ........................................................................................ 34

Figure 9.3: Ultrasonic transducer DB 18 UP ................................................................................ 34

Figure 12.1: Critical case 1............................................................................................................. 47

Figure 12.2: Critical case 2............................................................................................................. 47

Figure 12.3: Critical case 3............................................................................................................. 48

Figure 12.4: Critical case 4............................................................................................................. 48

Leuze electronic DB 14B 3

Page 6

General information

1 General information

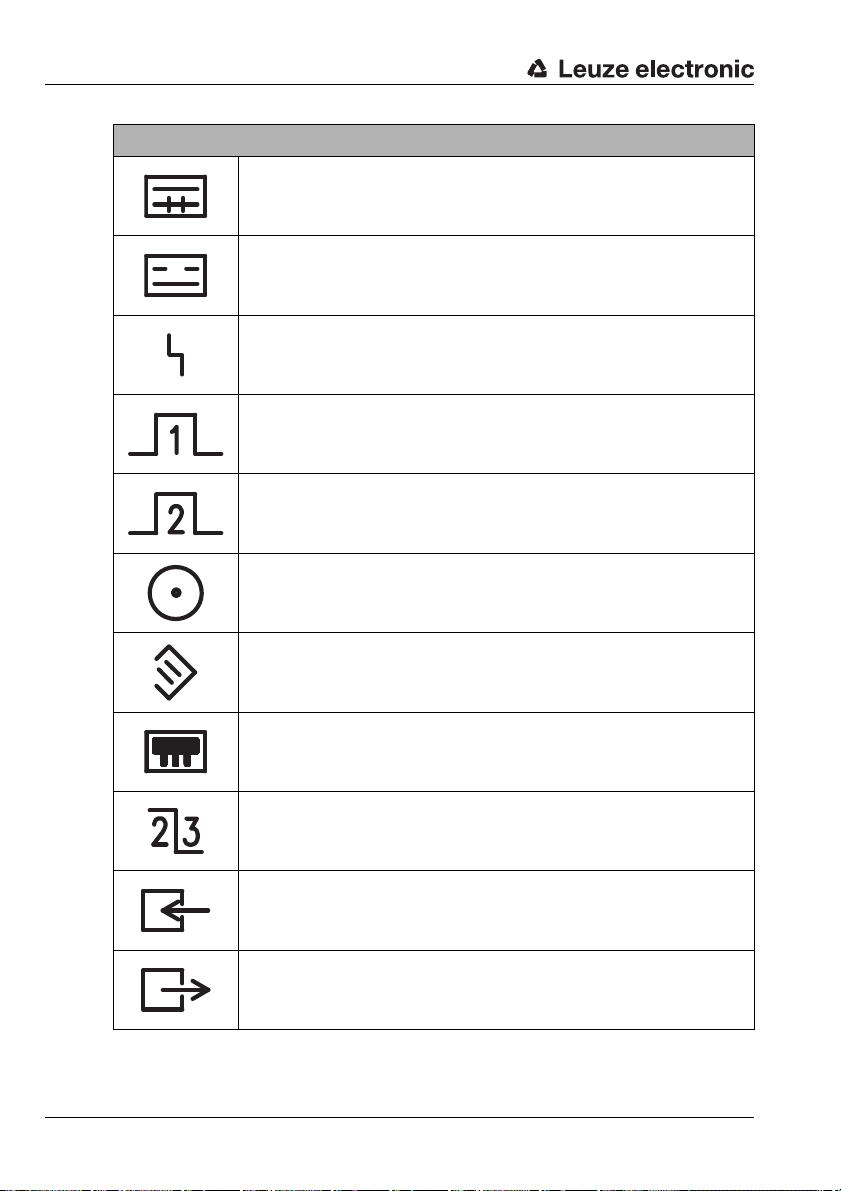

1.1 Explanation of symbols

The symbols used in this operating manual are explained below.

Attention!

Pay attention to passages marked with this symbol. Failure to heed this information can lead

to injuries to personnel or damage to the equipment.

Notice!

This symbol indicates text passages containing important information.

1.2 Declaration of conformity

The DB 14B double sheet testing unit sensor system has been developed and manufactured subject to the applicable European standards and directives.

Notice!

The corresponding declaration of conformity can be requested from the manufacturer.

The manufacturer of the product, Leuze electronic GmbH + Co. KG in D-73277 Owen/Teck,

possesses a certified quality assurance system in accordance with ISO 9001.

4 DB 14B Leuze electronic

Page 7

2 Safety notices

2.1 Safety standards

The DB 14B double sheet testing unit has been developed subject to the applicable safety

standard IEC 947-5-2.

2.2 Approved purpose

The DB 14B double sheet testing unit has been conceived as a monitoring device mainly for

paper working machines. It monitors incoming paper sheets and is used to detect and signal

double sheets in the sheet feeder during operation.

Attention!

The double sheet testing unit is not a safety module acc. to EU machinery directive!

The protection of machine and the device cannot be guaranteed if the device is operated in

a manner not corresponding to its intended use.

Access to or changes on the device, except where expressly described in this operating

manual, is not authorised.

2.3 Areas of application

Safety notices

Double sheets of the following materials with thicknesses from 20 g/m2 airmail paper to 2mm

thick cardboard can be recognised reliably by the DB 14B:

• Paper

• Paperboard

• Cardboard

• Plastic foil

2.4 Organisational measures

All entries in this operating manual must be heeded, in particular those in the sections

"Safety Notices" and "Commissioning".

Carefully store this operating manual where it is accessible at all times.

Safety regulations

Observe the locally applicable safety regulations.

Qualified personnel

Mounting, commissioning and maintenance of the device must only be carried out by qualified personnel.

Leuze electronic DB 14B 5

TNT 35/7-24V

Page 8

Description of the device and system

DB 14 K

DB 18 UP

VDB 14B/4 and

VDB 14B/2

to machine control system

3 Description of the device and system

3.1 Set-up of the DB 14B

The basic version of the DB 14B double sheet testing unit consists of the evaluation unit

VDB 14B/4 (PNP) or VDB 14B/4 (NPN), one transmitter DB 18 U, one receiver DB 18 U,

and a connection cable for the machine control system. It can be additionally equipped with

a capacitive sensor DB 14 K.

The capacitive sensor DB 14 K is required if double sheets of thick material, sheets with air

pockets or material with low transmission for ultrasonic signals should be recognised.

Figure 3.1: DB 14B system set-up

3.2 Performance features of the DB 14B

The DB 14B is a system which detects multiple sheets of paper. It is characterised by the

following features:

• A large measuring range from 20 g airmail paper to 2mm thick, homogeneous cardboard (capacitive >150g normal paper)

• Insensitive to printing and fluttering of paper

• Manual self-calibration

• Automatic readjustment during operation

• Extensive diagnostic options via 2-digit, 7 segment display

6 DB 14B Leuze electronic

Page 9

3.3 Function description DB 14B

The double sheet testing unit DB 14B is a computer-assisted system for the recognition of

multiple sheets of paper or cardboard and is applicable for use in clock-controlled machines.

After storing a material-specific reference value, the system can recognise multiple sheets

of paper and thus prevent damage to the machine.

The DB 18 UP ultrasonic sensors consists of a transmitter and a receiver and perform two

functions. They recognise the presence of a sheet of paper by the interruption of the sound

level and at the same time measure the signal level for the given type of paper. After calibration to the reference sheet, it can be determined whether zero, one or two sheets of paper

are in the ultrasonic beam. The double sheet testing unit can optionally be switched to

perform a capacitive measurement of the double sheet. In this operating mode, however,

the ultrasonic sensors remain necessary for sheet detection (start of measurement).

The reference value is always corrected to the current conditions by automatic readjustment

during operation. The testing of the sheet overlap is allowed by the possibility of an additional second inquiry at a time when two sheets should be at the measurement position and

to give a warning signal should the second sheet be missing.

The perfect operation of the double sheet testing unit is checked by an integrated self-test

after power-on of the DB 14B.

Description of the device and system

Leuze electronic DB 14B 7

TNT 35/7-24V

Page 10

Description of the device and system

3.4 Delivery contents / accessories / order codes

The minimum configuration requires:

Evaluation unit VDB 14B/4 (PNP) 501 06083

and VDB 14B/2 (NPN) 501 06807

Sensors DB 18 UP sensor pair 501 08998

Connection cable BK7 KB140-2000-20 500 37338

Transmitter/receiver,

M18 sensor housing,

25mm sensor length,

2.5m cable length

26-pin Sub-D socket,

20 strands assigned,

2m cable length

Available accessories:

Capacitive sensor DB 14 K - 7 500 34899

Sensors DB 18 UP,2500 501 08997

Connection cable BK7 KB140-5000-20 500 37339

Actuation distance 7mm

DB 14 K - 12 500 39790

Actuation distance 12mm

Transmitter/receiver,

M18 sensor housing,

40mm sensor length,

2.5m cable length

5m cable length

8 DB 14B Leuze electronic

Page 11

4 Installation

4.1 Storage, transportation

Attention!

When transporting, package the device so that it is protected against collision and humidity.

Optimal protection is achieved when using the original packaging. Heed the required environmental conditions specified in the technical data.

Check the packaging for any damage. If damage is found, notify the post office or ship-

ping agent as well as the supplier.

Check the delivery contents using your order and the delivery papers:

• delivered quantity

• device type and model as indicated on the nameplate

• accessories

• operating instructions

Keep the original packaging in case the device should be stored or transported at some

future time.

Please contact your supplier or your Leuze distributor to answer any questions (see inside

of the front cover of these operating instructions).

Notice!

Observe the local regulations regarding disposal of packaging material.

Installation

Leuze electronic DB 14B 9

TNT 35/7-24V

Page 12

Installation

4.2 Mounting

The components of the DB 14B should be mounted in the following order:

1. Ultrasonic and capacitive sensors

2. Evaluation unit

As long as the sensors are aligned according to the following instructions, the fitting position

of all components is arbitrary.

The following arrangement is, however, recommended:

First, the ultrasonic sensors should be covered in the direction of paper travel and

then the capacitive sensor should be covered.

The space requirements of the individual components can be found in the dimensioned

drawings in chapter 9.

Figure 4.1: Example for the sensor arrangement

Notice!

The transmitter and receiver of the ultrasonic sensors must be mounted on the feeder platform at a position where a single sheet is present for at least 2ms during normal operation.

10 DB 14B Leuze electronic

Page 13

Installation

20 … 40 mm

5 … 15 mm

C

A

Feeder platform

D

Notice!

When aligning the transmitter and receiver, take care

to ensure the most exact alignment possible. To ensure proper function, the sensors must be inclined by

the angle B towards the vertical.

Sheet material

Recomm. angle of inclination B

0° 15°… 25 ° 25°… 35 °

Standard paper up to 150g/m

2

XXX

Cardboard XX

Plastics X

A Receiver

B Angle of inclination

C Sheet material

D Transmitter

Machine direction

Mounting the DB 18 UP ultrasonic sensors

The transmitter and receiver (DB 18 UP) are identical in construction and are to be mounted

according to the table in figure 4.2 at an angle which is inclined relative to vertical. A larger

angle of inclination increases the flutter range; e.g. with a 35° pitch, flutter is permissible

within 50% of the measurement field.

The recommended distance is 20 … 40mm. The maximum distance is 60mm. The ultrasonic transmitter should be installed from below, approx. 5mm below the table top. The

receiver should be installed above the platform top.

Ensure that alignment is exact (±1°). If the alignment does not run along the axis, the

working range is reduced.

Figure 4.2: Mounting the ultrasonic sensors

Notice!

In order to measure, the capacitive sensor requires an electrically conductive grounding

plate for the opposite pole which is at least as large as itself. Usually the (metallic) feeder

platform serves this function.

Leuze electronic DB 14B 11

TNT 35/7-24V

Page 14

Installation

Paper sheet

Capacitive

sensor

Feeder platform

7mm ± 0.5mm

at DB 14 K - 7

12mm ± 0.5 mm

at DB 14 K - 12

Machine

foundation plate

VDB 14B/4

and VDB 14B/2

DB 14 K

Grounding plate

DB 18 UP

Potential equalisation cable

to machine control system

Mounting the capacitive sensor

The capacitive sensor should be mounted parallel to the feeder platform/grounding plate at

a distance of 7mm ± 0.5 mm (DB 14 K - 7) or 12mm ± 0.5 mm (DB 14 K - 12), respectively.

It is usually not necessary to readjust the sensor - grounding plate distance afterwards.

Fix a grounding plate in a non-metallic feeder platform, taking care that the sheet movement

is not disturbed.

Figure 4.3: Mounting the capacitive sensor

Connect the capacitive sensor and grounding plate with a potential equalisation cable. This

is absolutely necessary for a correct measurement. The potential equalisation cable must

also be connected to the machine foundation plate as well as to the VDB 14B.

Figure 4.4: Potential equalisation and connection

VDB 14B evaluation unit

Use four M4 screws to mount the evaluation unit close to the sensors.

12 DB 14B Leuze electronic

Page 15

4.3 Connection

Connect all individual components to the VDB 14B evaluation unit.

Attention!

The 26-pin Sub-D socket of the connection cable to the machine control as well as all

DB 18 U… and DB 14 K sensors must only be plugged in while in a voltage-free state.

If the DB 14 K capacitive sensor is plugged in or unplugged during operation, this is

not detected by the VDB 14B evaluation unit!

Ultrasonic transmitter DB 18 U...

Ultrasonic receiver DB 18 U...

Capacitive sensor DB 14 K K1

Machine control system 26-pin SUB-D connector with shielded cable

The following table describes the pin assignments of the 26-pin connector.

PIN Colour Function

1 red supply +18 … 30VDC (+UB)

2 blue supply 0V DC (GND)

3 violet 1st inquiry, single sheet check

4 white-green 2nd inquiry, second sheet check (last sheet recognition)

5 red-blue activation and error reset

6 white-yellow calibration

7 black switching capacitive – ultrasonic (high – low)

8 brown-green switching sheet mode 1/2 to 2/3 (option)

9 yellow-brown

Installation

Inputs

With "high" edge evaluation of the 1st inquiry

With "low" window evaluation during a neg. cam of the 1st inquiry

TNT 35/7-24V

Outputs

10 grey-pink sheet mode status 1/2 or 2/3 (option)

11 pink double sheet recognised

12 grey ready and calibrated

13 brown error

14 green 2nd sheet missing

15 yellow ultrasonic beam interrupted, first sheet recognition

16 white double sheet detected (sheet overlap signal)

Table 4.1: Pin assignments of the 26-pin SUB-D connector

Leuze electronic DB 14B 13

Page 16

Installation

17 white-pink reserved

18 pink-brown reserved

19 reserved

20 white-grey reserved

21 grey-brown reserved

22 reserved

23 reserved

24 reserved

25 reserved

26 reserved

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

Table 4.1: Pin assignments of the 26-pin SUB-D connector

1) Some reserved connections are connected to the 26-pin connector but are not, however,

assigned in the device.

4.4 Disassembling, packing, disposing

Repacking

For later reuse, the system is to be packed so that it is protected against shocks and dampness. Optimal protection is achieved when using the original packaging.

Notice!

Electrical scrap is a special waste product! Observe the locally applicable regulations regarding disposal of the product. The DB 14B double sheet testing unit does not contain any

internal batteries which would otherwise need to be removed before disposal.

14 DB 14B Leuze electronic

Page 17

5 Commissioning

5.1 Before switching on for the first time

Make yourself familiar with the operation and settings of the system before switching on

for the first time!

Before switching on, recheck all connections and ensure that they have been properly

made.

5.2 Display and control elements

5.2.1 VDB 14B evaluation unit

All plug connections for the system are located on the front side of the VDB 14B evaluation

unit. In addition, all indicator elements are also located here.

Commissioning

Figure 5.1: VDB 14B evaluation unit

The two 7 segment displays indicate the respective states of the inputs and outputs and, in

the case of an error, the appropriate error code. The error code flashes in the display. In

adjustment mode, the operating point of the capacitive sensor is indicated in the indicators.

Leuze electronic DB 14B 15

TNT 35/7-24V

Page 18

Commissioning

activation and error reset

changeover

sheet mode

1/2 or 2/3

2nd inquiry

changeover

capacitive / ultrasonics

1st inquiry

calibration

1st inquiry edge

edge/window

1 ON / 0 OFF

internal function

(capacitive amplification level)

5.2.2 Indicator functions

The indicator functions of the two 7 segment displays are described below.

Notice!

Error codes of the double sheet testing unit flash in the displays.

Control inputs

Figure 5.2 shows the right-hand indicator field, which describes the control inputs of the

DB 14B double sheet testing unit. The indicator elements are connected to the inputs and

thus reflect the outputs of the machine controller.

Figure 5.2: Control inputs

16 DB 14B Leuze electronic

Page 19

Commissioning

double sheet

first sheet recognition

ready and calibrated

sheet mode status

1/2 or 2/3 (option)

error

2nd sheet missing

sheet overlap signal

internal function

(capacitive empty-value creati on, flashes at

1Hz)

Control outputs

Figure 5.3 shows the left-hand indicator field, which describes the control outputs of the

DB 14B double sheet testing unit. The indicator elements are connected to the outputs and

thus reflect the signals sent to the machine controller.

Figure 5.3: Control outputs

5.2.3 Indicators VDB 14B/4 / VDB 14B/2

Indicators VDB 14B

Symbol Designation

ready and calibrated

first sheet recognition

double sheet

Leuze electronic DB 14B 17

Table 5.1: Indicators VDB 14B

TNT 35/7-24V

Page 20

Commissioning

Indicators VDB 14B

second sheet missing (last sheet recognition)

sheet overlap signal

error

1st inquiry

2nd inquiry

activation and error reset

calibration

switching capacitive - ultrasonic

switching sheet mode 1/2 and 2/3 (option)

1st inquiry edge/window mode (edge-high/window-low)

sheet mode status 1/2 or 2/3 (option)

(1/2 – low / 2/3 – high)

Table 5.1: Indicators VDB 14B

18 DB 14B Leuze electronic

Page 21

5.3 Switching on

The DB 14B double sheet testing unit does not have a particular switch for switching on and

off. The device is switched on and off through application of the supply voltage.

Notice!

After applying the supply voltage, it may take up to 3min. before the DB 14B is ready for operation. The non-ready state after power-on is indicated by the rotating bar in the 7 segment

display.

5.4 Adjustment

The sensors are adjusted to the installation conditions in the adjustment mode. The DB 14B

double sheet testing unit needs to be adjusted when

• first commissioned (even when working with only the ultrasonic sensors)

• a sensor or an evaluation unit is exchanged, added or removed

• height adjustment, distance change, change in the sensors' angle setting

Notice!

Adjustment can only take place when the sheet feeder is off. Ensure that the LED for "Activation" is off. Also make sure that there is no sheet in the measuring area.

Commissioning

5.4.1 Starting adjustment

Send a series of 12 pulses within 10 seconds to calibration input (PIN 6) from the machine

control system. The pulses as well as the pauses between the pulses should each be longer

than 100 ms!

Once the adjustment has started, a self-test is performed like when switching on. The

VDB 14B automatically recognises whether or not a capacitive sensor is connected and

registers or cancels it, respectively, with the system.

Notice!

During adjustment, the states of the outputs are undefined.

5.4.2 Adjusting the ultrasonic sensors

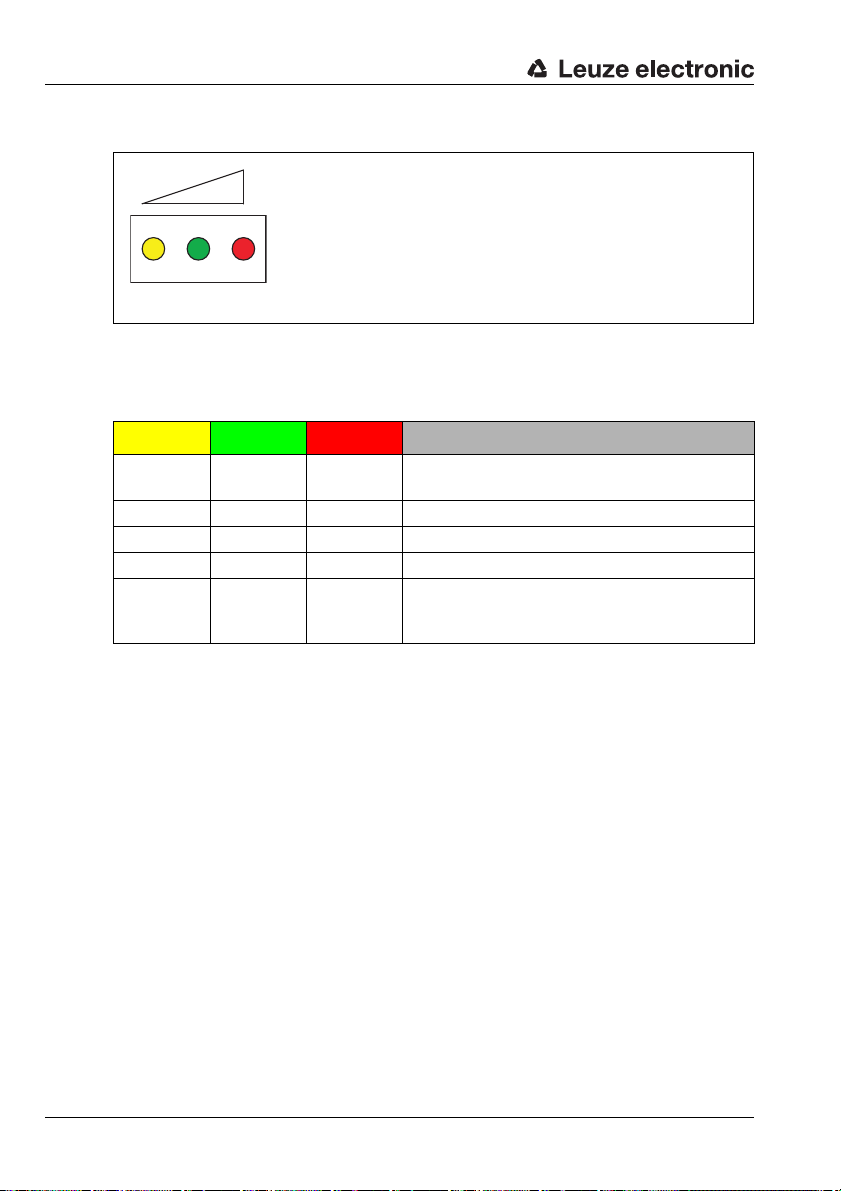

After adjustment has started, the VDB 14B checks the sensor signals when DB 18 UP ultrasonic sensors are connected. The signal status is indicated by means of the three differentcoloured LEDs, which are located between the two indicator segments.

Leuze electronic DB 14B 19

TNT 35/7-24V

Page 22

Commissioning

yellow green red

The figure 5.4 shows a depiction of the input signal with the aid of the three LEDs.

Figure 5.4: Signal level of the DB 18 UP

Shown in table 5.2 are the meanings of the various LEDs used to indicate the receiving level

of the ultrasonic sensor. Note that the red LED does not have any function at this time.

Yellow Green Red Function

ON ON

ON FLASHING level not sufficient, alignment not yet OK

ON OFF level weak

FLASHING OFF level very weak

OFF ON

Table 5.2: Signal level of the DB 18 UP

The double sheet testing unit functions properly only when alignment of the sensors has

been performed optimally. When the level is ideal, the yellow and green LEDs always illuminate during adjustment.

To change the receiving level, the transmitter of the ultrasonic sensors should be adjusted

or moved until the ideal level is achieved.

With ultrasonic sensors, the transmitter should ideally always be installed below. As a result

of the continuously emitted ultrasonic signal, a certain degree of self-cleaning is achieved.

If the ultrasonic sensors are not connected or are not adjusted, the double sheet testing unit

cannot function.

without function

level high, alignment OK

normal state after conclusion of the adjustment

process; if an error has occurred, note the error

message shown on the 7 segment displays

20 DB 14B Leuze electronic

Page 23

5.4.3 Adjusting the capacitive sensor

To achieve proper function of the capacitive sensor, the sensor must be adjusted during

commissioning of the double sheet testing unit. To do this, the sensor must be aligned with

respect to the counter electrode. This distance to the counter electrode should be

7 mm ±0.5mm.

The alignment of the capacitive sensor is displayed with two digits on the 7 segment display

of the VDB 14B amplifier during adjustment. The value range may be between 0 and 99.

The display value is dependent on several factors with different weighting. The factors

include e.g. distance to the counter electrode, air humidity, temperature and others.

For the capacitive sensors used up to now, the display range was from 30 … 90 in the

normal range and has led to good results.

Weighting:

01 distance to the counter electrode too small

99 distance to the counter electrode too large

or no capacitive sensor connected

If the capacitive sensor is not correctly adjusted, no calibration can be performed with the

sensor. In this case, the double sheet testing unit can only be operated with the ultrasonic

sensors.

5.4.4 Terminating adjustment

The adjustment procedure lasts at least 10 seconds.

To terminate the adjustment, an additional (13th) pulse must be applied at the calibration

input (PIN 6). The adjustment is concluded approx. 15 seconds after this last pulse is

applied.

The adjustment is now terminated and the VDB 14B evaluation unit recognises the parameters of the connected sensors. Before initiating sheet testing operation it is now neces-

sary to calibrate to the paper type so that the VDB 14B can reliably recognise double

sheets.

If the 7 segment display flashes after the adjustment has terminated, you can find the significance of the error message in chapter 8.

Notice!

The error message (flashing 7 segment display) disappears as soon as a pulse is applied at

the calibration input (PIN 6) or at the activation input (PIN 5).

Commissioning

TNT 35/7-24V

If the adjustment is interrupted by e.g. voltage interruption etc., a new adjustment start must

be performed as described in chapter 5.4.1.

Leuze electronic DB 14B 21

Page 24

Sheet testing

6 Sheet testing

6.1 Conditions for readiness

The following conditions must be met before the double sheet testing unit is ready for operation:

• the voltage supply must be applied to the VDB 14B

• the sensors (DB 18 UP) must be connected and correctly aligned.

• the VDB 14B must be correctly adjusted (see section section 5.4)

• the VDB 14B must be calibrated

• the activation should be applied at PIN 5

To restore operational readiness of the double sheet testing unit with detected double sheet

after an error message occurs, perform the following:

• remove the double sheet

• deactivate the VDB 14B and activate it again

6.2 Operating states

The DB 14 has two states of operation: "activated" and "deactivated", which can only be

controlled using the "activation" input.

During the "activated" state of operation

• +24VDC (high) must be applied at PIN 5 (applies for PNP-circuitry)

• the segment "Activation + error reset" illuminates on the 7 segment display of the

double sheet testing unit.

• the VDB 14B is ready for sheet testing if a calibration has been previously performed,

i.e. upon receiving the inquiry signal on input "1st inquiry" (PIN 3), the VDB 14B tests

whether a missing sheet, a single sheet or a double sheet is in the measurement area

and switches on the corresponding outputs.

During the "deactivated" state of operation

• 0VDC (low) must be applied at input PIN 5 or the input must not be connected

(applies for PNP wiring)

• the segment "Activation + reset error" on the 7 segment display of the double

sheet testing unit is off.

22 DB 14B Leuze electronic

Page 25

6.3 Calibration

If the sheet material is changed, it is necessary to calibrate the DB 14B again.

The calibration is controlled by the machine and can only be performed when the activation

input (PIN 5) is switched off. Make certain here that the segment of the "Activation + reset

error" indicator has switched off before you begin the calibration.

For a functionally reliable calibration, the capacitive sensor must be connected to the

supply voltage for at least 10min.

Hold a reference sheet of the current print media in the measurement area. Make certain

that the ultrasonic sensors as well as the capacitive sensor are completely covered.

Apply +24V DC (high) at the "calibration" (PIN 6) input (applies for PNP circuitry). The

signal for the "calibration" function must always be at least 100 ms long. This signal initiates the calibration of the VDB 14B and the reference value is stored.

Following successful calibration, the "Ready and calibrated" segment illuminates and

+24V DC (high) is present at output PIN 12 (applies for PNP wiring).

The calibration value and the ultrasonic or capacitive operating mode are stored in the

VDB 14B in such a way that they are protected against power interruption. The system is

thus already calibrated and ready for operation after switching off and back on.

6.3.1 Calibration error

It can happen that a calibration of the VDB 14B is not possible because the reference material is too thin, too thick or not suitable. In this case the "ready" output (PIN 12) is switched

off and the "error" output (PIN 13) is switched on.

The 7 segment display then displays a corresponding, 2-digit error message (flashing

display). The error indicated by the plain text message can be found in chapter 8.

Sheet testing

6.4 Testing for double sheets

The normal operation of the double sheet testing unit is achieved only following calibration.

The system is not ready for monitoring until the "ready and calibrated" output is activated.

The double sheet testing unit always detects the current state between the sensors in the

measurement area. As soon as an inquiry pulse sent by the machine is present at input "1st

inquiry" of the VDB 14B, the double sheet testing unit outputs the status to the outputs. The

number of sheets in the measurement area must remain constant for the 2ms required for

the measurement.

During normal operation of the machine, only one sheet should be present between the

sensors or be pulled into the machine. In this case, the double sheet testing unit outputs a

"high" signal at the output "first sheet detection" (PIN 15).

Double sheet

As soon as two sheets are detected, the output "double sheet detected" (PIN 11) is set and

+24V DC (high) output at the output. A signal for the double sheet is output no later than

2 ms after the inquiry pulse.

Leuze electronic DB 14B 23

TNT 35/7-24V

Page 26

Sheet testing

After the double sheet is detected and the machine has been stopped, the following steps

can be performed in order to restart the machine:

The activation (PIN 5) must be switched off (low-signal) and both sheets must be

removed from the measurement path. Afterward, the two measurement paths between

the sensors must be completely free.

The error message "double sheet" remains until the double sheet has been manually

removed from the machine and the error message has been deleted from the machine by

means of the activation input (PIN 5).

Attention!

If the VDB 14B is in the "double sheet" state, nearly all other functions are disabled.

6.5 Testing for second sheets

By means of a second inquiry signal from the machine, it is possible to query at a defined

point in time for two sheets between the measurement area. To do this, a signal of +24 VDC

must be applied by the machine at input "2nd inquiry" (PIN 4).

By means of this function, it is possible to check for proper sheet overlap at the machine

intake. If only one sheet is present in the measurement area at the point in time the inquiry

is made, a "high" signal is output at the output "2nd sheet missing" (PIN 14).

The output signal is cleared following the next inquiry which shows a correct second sheet.

Alternatively, the input "activation" can be switched off briefly.

A missing second sheet will not block the VDB 14B. The sheet testing operation can be

continued without clearing the output "2nd sheet missing".

24 DB 14B Leuze electronic

Page 27

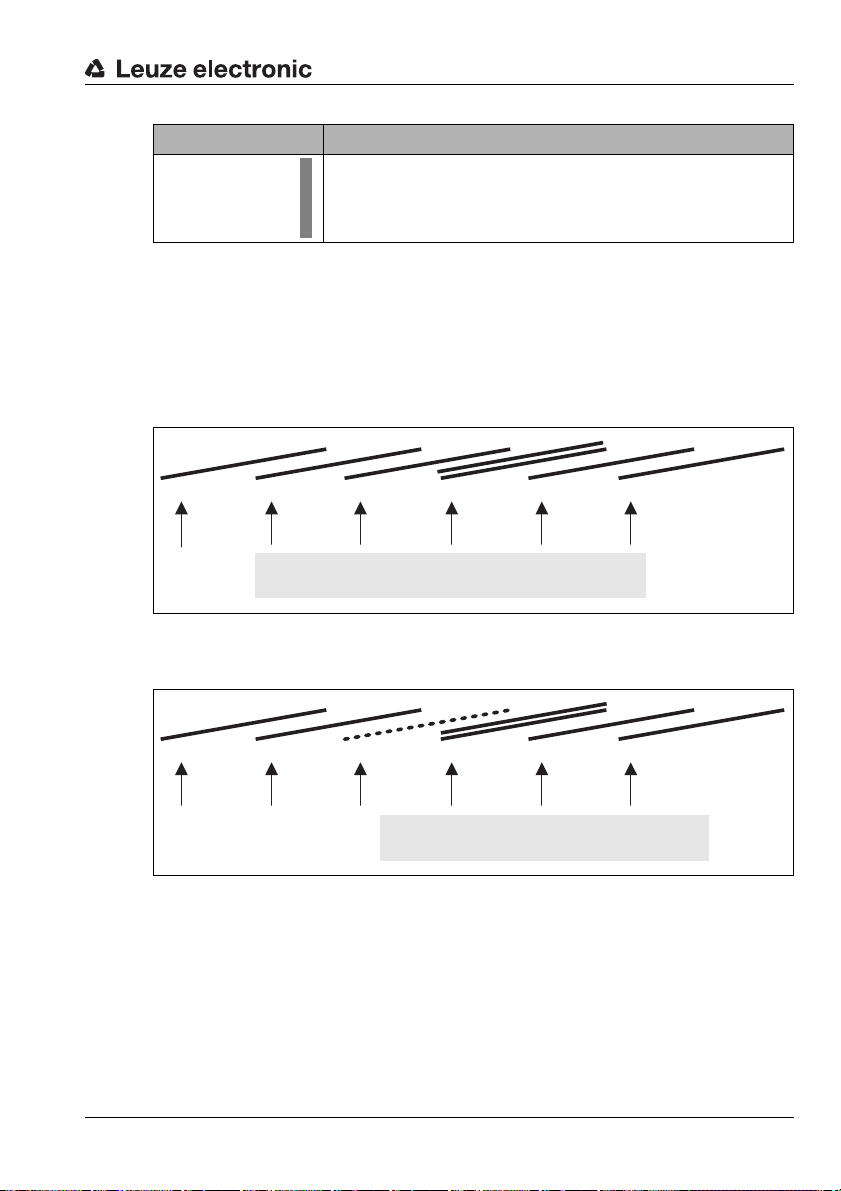

6.6 Evaluation process

The evaluation on double sheets can be performed with the VDB 14B using two different

processes.

The edge evaluation process can be thought of as the standard process.

The window evaluation process is an aid used to improve sheet movement for critical

papers or print media.

The window and edge evaluation processes are controlled by the state of the control input

PIN 9. The state of the input is detected upon activation of the VDB 14B. Later changes at

the input are not taken into consideration until the next activation.

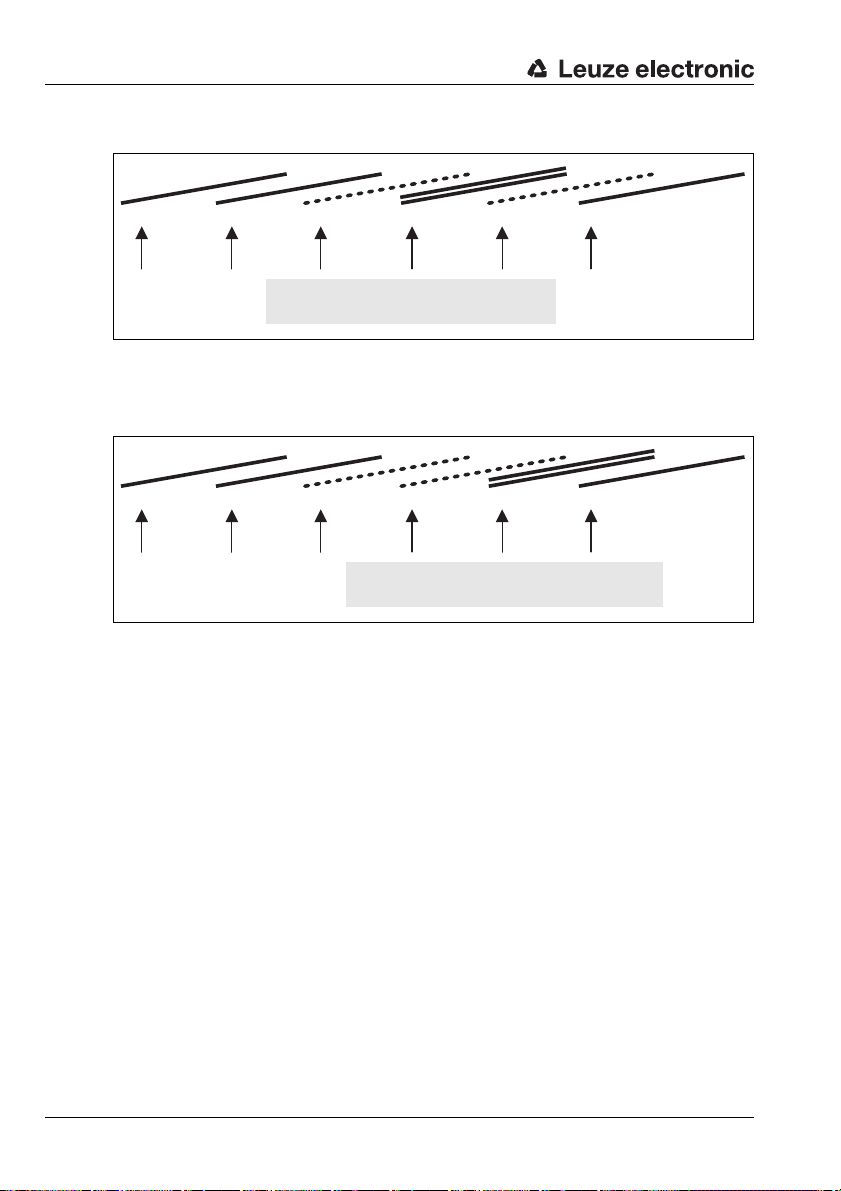

Edge evaluation

When input PIN 9 is activated ("high" signal), edge evaluation is used as the evaluation

process.

As soon as a positive edge is present at input "1st inquiry" (PIN 3), the VDB 14B checks for

a double sheet. The result of this inquiry is passed on immediately to the double sheet output

(PIN 11).

Window evaluation

Window evaluation improves sheet movement, particularly for inhomogeneous materials. To

activate window evaluation, a "low" signal must be present at PIN 9.

Edge evaluation, which is used in most cases, may lead to switching errors caused by

double sheet detection when inhomogeneous materials are used. If a positive edge is

queried at a inhomogeneous position in the material, a double sheet may be output. Window

evaluation typically results in improved sheet movement.

During a window (negative cam at input PIN 3), the VDB 14B continuously measures the

status of the sheets by means of the ultrasonic sensors. If a single sheet is detected within

this window, this means that two sheets do not lie within the control area. At the end of the

negative cam or of the window area, no double sheet signal is output.

Sheet testing

Leuze electronic DB 14B 25

TNT 35/7-24V

Page 28

Sheet testing

Inquiry timing during

edge evaluation

Shaft with cam

Inquiry time

Inquiry window

Edge evaluation

positive edge (cam)

Window evaluation

negative cam

Paper sheet

Air pockets or wood

particles

Edge evaluation

Window evaluation

Possible double sheet detection

caused by material inclusions

within the area A

No double sheet detection caused

by homogenous material within

the area B of the window inquiry

BA

Figure 6.1: Evaluation process

26 DB 14B Leuze electronic

Page 29

7 Interfaces

1

The VDB 14B evaluation unit of the double sheet testing unit has two sockets at which

various interface signals can be picked up. All GNDs of the various interfaces are connected

to one another.

7.1 Serial interface

The serial interface is located on the lower right-hand side of the amplifier and is labelled

with the following symbol:

Figure 7.1: Interface symbol

This interface can be used to load a new firmware version into the double sheet testing unit.

This process must only be performed by authorised personnel.

Assignments of the serial interface

Function Signal Pin No. Pin layout

+5V DC 1

+U

B

ground GND 2

transmit data TXD 3

receive data RXD 4

download MOSI MOSI 5

download MISO MISO 6

download SCK SCK 7

download RESET RESET 8

Table 7.1: Assignments of the serial interface

Interfaces

TNT 35/7-24V

Leuze electronic DB 14B 27

Page 30

Interfaces

1

7.2 Analogue interface

In order to perform measurements with the system during machine operation, the values for

the sensor amplifiers were moved to socket X1. All signals are available as analogue values

in the range from 0 … 12V at this socket.

Assignments of the analogue interface

Function Signal Pin No. Pin layout

capacitive sensor no. 3 Out Cap 3 1

ground GND 2

ultrasonic sensor double sheet 1 US DB 1 3

ultrasonic sensor single sheet 1 US EB 1 4

ultrasonic sensor double sheet 2 US DB 2 5

ultrasonic sensor single sheet 2 US EB 2 6

capacitive sensor no. 1 Out Cap 1 7

capacitive sensor no. 2 Out Cap 2 8

Table 7.2: Assignments of the analogue interface X1

Attention!

No electrical isolation exists between the analogue interface and the VDB 14B

Damage to the measurement device or to the VDB 14B caused by improper handling during

measurements cannot be excluded.

28 DB 14B Leuze electronic

Page 31

8 Error messages (flashing)

Critical errors in the VDB 14B evaluation unit are indicated on the two 7 segment displays

with two flashing digits.

The error numbers and the corresponding errors are listed in the following table:

Error messages (flashing)

Error no.

(flashing)

00 Device internal error.

Calibration is not possible.

01

The material is too thick (applies only to capacitive sensor in the 1/2 sheet

mode).

Calibration is not possible.

02

The measurement value of the ultrasonic sensors was too low (too strongly

dampened).

03 Device internal error.

Calibration is not possible.

04

The material is too thick (applies only to capacitive sensors in the 2/3 sheet

mode).

05 Device internal error.

During the self test, an interference caused by extraneous sound was

30

detected.

During the self test, a sheet was detected between the ultrasonic sensors.

31

Possible causes: Ultrasonic sensors not connected or defective.

During the self test, a sheet was detected between the ultrasonic sensors.

32

Possible causes: Ultrasonic sensors not connected or defective.

During the self test, an insufficient signal was detected at the ultrasonic

receiver. Possible causes:

33

Ultrasonic sensors not aligned correctly, sheet between the sensors, poor

connector contact or defective ultrasonic sensors.

34 Device internal error.

Calibration is not possible.

35

The material is too thick for ultrasonic sensing.

Calibration is not possible.

36

The material is too thin for ultrasonic sensing.

40 … 59 Internal device error.

Measurement value of the capacitive sensor during calibration too low

60

(high amplification).

Measurement value of the capacitive sensor during calibration too low

61

(low amplification).

Table 8.1: Error messages

Description

TNT 35/7-24V

Leuze electronic DB 14B 29

Page 32

Error messages (flashing)

Error no.

(flashing)

Measurement value of the capacitive sensor during calibration too high

62

(high amplification).

Measurement value of the capacitive sensor during calibration too high

63

(low amplification).

64 Material during 1st inquiry too thick (applies only to capacitive sensor).

69 Device internal error.

With the 1st inquiry in 2/3 sheet mode with 2 sheets, two are expected, how-

70

ever only one was detected. Cause could be e.g. an irregular overlap flow.

With the 1st inquiry in 2/3 sheet mode with 2 sheets, two are expected, how-

71

ever no sheet was detected.

72 Device internal error (3/4 mode).

73 Device internal error (3/4 mode).

74 Device internal error (3/4 mode).

75 Device internal error (3/4 mode).

Combined preselection of 2/3 sheet mode and ultrasonics. This is not permit-

76

ted. The capacitive sensor must be selected (PIN 7).

No adjustment performed prior to the calibration.

Possible causes:

The capacitive sensor was not adjusted following replacement or height

adjustment of a VDB 14B or sensor. The warm-up phase of approx. 15min.

77

for the DB 14 K during initial adjustment was not adhered to. The pulse

sequence (12 pulses) for adjustment did not arrive at the VDB 14B. During

the basic adjustment, paper was underneath the DB 14 K.

80 No adjustment performed prior to the calibration.

The control voltage from the capacitive sensor is too low.

81

The sensor is too close to the opposing plate.

The control voltage from the capacitive sensor is too high. The sensor is not

82

connected or is too far from the opposing plate.

Capacitive sensor not adjustable (low amplification level).

83

Check distance of the capacitive sensor to the grounding plate.

Capacitive sensor not adjustable (high amplification level).

84

Cause could be e.g. long distance to the counter electrode.

Reception signal of the ultrasonic sensors too weak. Sensors defective or not

85

aligned or sheet between the sensors.

Adjustment of the capacitive sensor was not successful.

86

No calibration is possible.

After applying the operating voltage, the measurement path of the capacitive

87

sensor was not clear. Remove printed material between the sensors!

Table 8.1: Error messages

Description

30 DB 14B Leuze electronic

Page 33

Error messages (flashing)

Error no.

(flashing)

88 With activation ON, the measurement path was not clear.

With activation ON, the preselected values do not match the current state.

89

Clear measurement path.

After applying the operating voltage, the measurement path of the ultrasonic

sensors was not clear. Possible cause:

90

Printed material between the sensors or sensors not connected. Stored reference value will be lost!

During the self test, it was determined that the signal of the ultrasonic sensors

91

is too low when the measurement path is clear.

During the self test, it was determined that the signal of the capacitive sensor

92

is not in the valid range (without paper).

During the self test, it was determined that the switching of the amplifier of the

93

capacitive sensor does not function.

During the self test, it was determined that the signal of the capacitive sensor

is not in the expected range (without paper, high amplification).

The cause could be that adjustment was not performed following mounting or

the position of the capacitive sensor was changed. This error message also

appears if the ultrasonic sensors were not adjusted following delivery.

If this error no. occurs relatively frequently, there is no defect; rather, the sen-

94

sor is signalling that the environmental conditions for the capacitive sensor

have changed (humidity, temperature etc.).

Recommendation: During work with the capacitive sensor, calibration

on the printed material should be performed each time the supply voltage is switched on.

After conclusion of the self test (3min. warm-up phase), the signal of the

95

capacitive sensor was not in the expected range.

For measures, see error no. 94.

99 Device internal error.

Table 8.1: Error messages

Description

TNT 35/7-24V

Notice!

The error message (flashing 7 segment display) disappears as soon as a pulse is applied at

the calibration input (PIN 6) or at the activation input (PIN 5).

Leuze electronic DB 14B 31

Page 34

Error messages (flashing)

Troubleshooting when switching on

When voltage is applied to the VDB 14B evaluation unit, the controller performs a self test.

This lasts approx. 10 seconds. Immediately after applying the voltage, all segments of the 7

segment display illuminate, i.e. including the two dots as well as all three yellow/green/red

LEDs.

After this self test has been performed without error, only the green LED and the respective

element of the 7 segment display remain illuminated (depending on the state of activation of

one of the inputs).

Other

The decimal point of the right-hand 7 segment display (control inputs) indicates the amplifier

stage currently selected by the VDB 14B for the capacitive sensor. If the point is illuminated,

the amplification is high.

The decimal point of the left-hand 7 segment display (control outputs) indicates deviceinternal information about the 2/3 sheet mode of the VDB 14B.

If the VDB 14B is adjusted for operation with a DB 14 K capacitive sensor, it may take up

to 3min. after applying the supply voltage before the VDB 14B is ready for operation.

The non-ready state after power-on is indicated by the rotating bar in the 7 segment display.

32 DB 14B Leuze electronic

Page 35

9 Dimensioned drawings

Device top (cover)

Device bottom

Dimensioned drawings

Figure 9.1: Dimensions of the VDB 14B evaluation unit

Leuze electronic DB 14B 33

TNT 35/7-24V

Page 36

Dimensioned drawings

Coupling plug

5-pin

Full-surface metallic paper support, grounded

Diagnostics plug

depth

(active width)

Model Part No. Distance A

DB 14 K - 7 50034899 7mm

DB 14 K - 12 50039790 12mm

A

A 40mm housing length for DB 18 UP.1-40, 2500

Figure 9.2: Capacitive sensor DB 14 K

Figure 9.3: Ultrasonic transducer DB 18 UP

34 DB 14B Leuze electronic

Page 37

10 Specifications

Specifications for the system of the DB 14B double sheet testing unit

Manufacturer Leuze electronic GmbH + Co. KG

Model DB 14B, double sheet testing unit

Evaluation unit VDB 14B/4 (PNP) and VDB 14B/2 (NPN)

Electrical data

Operating voltage U

Residual ripple ≤ 15% of U

Power consumption max. 8.5W at 24V DC, idle operation

Inputs 24V DC opto-decoupled, R

Pulse length min. 100ms

Outputs PNP (NPN) transistor outputs

Output current max. 100 mA

Signal voltage high/low ≥ (U

Timing

Measurement duration, double

sheet

Reaction time to 1st inquiry ≤ 2 ms (time until output "Double sheet detected" switches)

Delay before start-up ≤ 2min. for DB 18 UP,

Specifications

In der Braike 1, D-73277 Owen/Teck

B

18 … 30VDC (incl. residual ripple)

B

approx. 5kΩ

in

–2V) / ≤ 2V

B

approx. 2ms

≤ 15min. for DB 14 K

Interfaces

RS 232 for downloading new firmware and for visualising the meas-

urement values on a separate PC with special software

Analogue interface X1 analogue signals 0 … 12VDC of the ultrasonic sensors and

the capacitive sensor

Indicators

Yellow LED signal level DB 18 UP

Green LED signal level DB 18 UP

Red LED without function

Two 7 segment displays states of the control inputs and of the control outputs

Mechanical data

Housing aluminium

Weight 450g

Colour black

Connection type machine interface: 26-pin SUB-D connector

sensors: 3-pin and 5-pin connectors

Leuze electronic DB 14B 35

TNT 35/7-24V

Page 38

Specifications

Environmental data

Ambient temp. operation/storage0 … +40°C / -20 … +70°C

Air humidity max. 50% rel. humidity, non-condensing

Protective circuit

VDE safety class III

Protection class IP 40, IP 54 is possible using a special hood with

Standards applied IEC 947-5-2

Sensors

Ultrasonic sensors DB 18 UP

Operating range 20 … 40 mm

Ultrasonic frequency 200kHz ±2%

Ultrasonic lobe 12° opening angle

Housing brass, nickel-faced

Weight 30g

Protection class IP 65

Connection type M 8 connector, 3-pin, with 2.5m cable

Capacitive sensor DB 14 K - 7

Nominal distance 7mm

Measurement range

Reaction time 25 ms (settling time before a sheet change is detected)

Housing aluminium

Weight 80g

Protection class IP 65

Connection type 5-pin connector, with 2.5m cable

1)

2,3

integrated SUB-D connector

150 … 800g/m

150 … 560g/m

²

in 1/2 sheet mode,

²

in 2/3 sheet mode

Capacitive sensor DB 14 K - 12

Nominal distance 12mm

Measurement range

400 … 2400g/m

400 … 1600g/m

²

in 1/2 sheet mode,

²

in 2/3 sheet mode

Reaction time 25 ms (settling time before a sheet change is detected)

Housing aluminium

Weight 80g

Protection class IP 65

Connection type 5-pin connector, with 2.5m cable

1) 2=polarity reversal protection, 3=short-circuit protection for all outputs

36 DB 14B Leuze electronic

Page 39

11 Maintenance

11.1 General maintenance information

The DB 14B double sheet testing unit does not normally require any maintenance from the

operator. It is, however, recommended that the adjustment described in chapter 5.4 be

performed once per year. The maximum performance reserve is thereby achieved.

Cleaning

Clean the soiled transmitter and receiver of the ultrasonic sensors with a soft cloth.

Attention!

Do not use aggressive cleaning agents such as thinner or acetone for cleaning the device.

11.2 Repairs and maintenance

Repairs to the device must only be carried out by the manufacturer.

Contact your Leuze distributor or service organisation should repairs be required.

The addresses can be found on the inside of the front cover of these operating instructions.

Maintenance

Leuze electronic DB 14B 37

TNT 35/7-24V

Page 40

Appendix: 2/3 sheet mode

12 Appendix: 2/3 sheet mode

The DB 14B double sheet testing unit can, under certain conditions, also be operated in the

2/3 sheet mode. To do this, the following conditions must be met:

1. The capacitive sensor must be connected and the double sheet testing unit must be

adjusted. The capacitive sensor must be preselected.

2. The control input "sheet mode changeover" (PIN 8) on 1/2 sheet or 2/3 sheet scan-

ning must be set to "high". 2/3 mode is then preselected. The sheet mode must be

preselected before the calibration is performed.

3. The calibration of the DB 14B double sheet testing unit in 2/3 sheet mode is per-

formed on the first sheet and is only performed manually. The 2nd sheet is calibrated

automatically as the first overlap is fed in.

4. The control input "2nd inquiry" (PIN 4) should be activated. Only then can drift and

environmental influences be compensated for. Sensing without the 2nd inquiry is also

possible, however, compensation of drift and environmental influences is omitted. In

this case, the system functions with reduced performance reserve.

5. Appropriate values are present at the control output "sheet mode changeover status"

(PIN 10):

"low" signal 1/2 sheet mode

"high" signal 2/3 sheet mode

6. The values of the overlap (number of sheets) are automatically adjusted during this

calibration to the 2/3 sheet mode.

7. The evaluation "2nd sheet missing" is automatically adjusted in the 2/3 sheet mode.

38 DB 14B Leuze electronic

Page 41

12.1 Explanations of the calibration function

23

Appendix: 2/3 sheet mode

Activa-

Adjustment of the sensors

Blank calibration

Good sheet calibration in the 2/3

sheet mode

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

tion

12x <10s

and pulse

length

0

0

0

100ms

pulse/pause

>100ms

1x

pulse length

>100ms

1x

pulse length

>100ms

0

play + LEDs

Start basic calibration

(adjustment of the sensors)

Attention: do not confuse

with good sheet calibration on

a sheet.

Leaving

adjustment mode

After setting the calibration

pulse, wait at least 10s

The blank calibration can be

used to quickly set an empty

value. In this way, the automatic calculation can be performed explicitly (duration: at

least 20s).

The outputs are set as follows:

"ready+calibrated" = OFF

as long as input

"calibration" = ON,

"Error" = ON.

2/3 sheet mode preselected

via control input "sheet mode"

= ON.

Only "capacitive calibration"

preselection is permitted.

Capacitive and ultrasonic sensors must have been free at

least 30s prior to calibration.

7 segment display shows

capacitive alignment value.

LEDs show level

of ultrasonics.

7 segment display is switched

to standard operation

TNT 35/7-24V

Leuze electronic DB 14B 39

Page 42

Appendix: 2/3 sheet mode

23

I

2I1

1

Activa-

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

tion

1x

0

pulse length

>100ms

0

Semi-automatic calibration

in 2/3 sheet mode

0

play + LEDs

If the calibration was successful, then the output

"ready+calibrated" = ON.

Error:

Adjustment not possible.

In this case, as long as input

"Calibration" = ON, the out-

puts are then set as follows:

"Error" = ON,

"Ready+calibrated" = OFF

Attention: the condition for

adjustment can be fulfilled

through excessive calibration

in too short a period of time!

Clear ultrasonic sensors.

Good sheet calibration performed in the 2/3 sheet mode

(see above).

2/3 sheet mode preselected

via control input "sheet mode"

= ON.

VDB 14B capacitively calibrated, i.e. control output

"ready+calibrated" = ON.

Ultrasonic sensors must be

clear.

In the event of an

error, the error

codes flash in the

display

Pick-up on and still no sheet

under the sensors.

Pick-up on and still no sheet

under the sensors.

Capacitive and ultrasonic sensors completely covered with

only one sheet at the time the

I

40 DB 14B Leuze electronic

inquiry is made.

Inquiry only on 1st sheet.

With 2 sheets, output "double

sheet detected" set.

Page 43

Appendix: 2/3 sheet mode

2

1

Activa-

tion

I

I

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

At time the second inquiry

made, 2 sheets are expected.

With only one measured

sheet, the output "2nd sheet

missing" is set, otherwise it is

reset.

The 2nd sheet is automatically calibrated here.

A second sheet is expected

(the calibration value must be

greater than the measurement

value for 1.5 sheets and less

than the measurement value

for 2.5 sheets).

If the capacitive calibration

was successful, the output

"double sheet detected (overlap)" is reset.

Error:

Ultrasonic sensors covered

and capacitive measurement

value > 2.5 sheets:

Output "double sheet

detected" = ON.

Ultrasonic sensors covered

and capacitive measurement

value < 1.5 sheets:

No reaction, but renewed

waiting for start of overlap

(1 sheet). As a result, the single sheet being withdrawn

may partially cover the capacitive and/or ultrasonic sensor.

Ultrasonic sensors not covered or ultrasonic sensors not

covered in the previous

1st inquiry and now in the next

1st inquiry two sheets are

under the sensors, i.e. the status which is evaluated as an

inquiry on the 1st sheet is:

output "Double sheet

detected" = ON.

Note: When restarting in the

case of an error, set input

"Activation" = OFF and back

to = ON and repeat the semiautomatic calibration with the

1st inquiry on one sheet to

restart.

play + LEDs

TNT 35/7-24V

Leuze electronic DB 14B 41

Page 44

Appendix: 2/3 sheet mode

I

2

1

Activa-

tion

I

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

Printing on (inquiry missing for

2nd sheet).

Output "double sheet

detected (overlap)" set.

If the third sheet is missing,

the output "2nd sheet missing" is set.

Printing on (inquiry on double

sheets).

The output "double sheet

detected (overlap)" is reset.

With 3 sheets, the output

"double sheet detected" is set.

play + LEDs

42 DB 14B Leuze electronic

Page 45

Appendix: 2/3 sheet mode

23

1

I

1

1

I

1

1

1

12.2 Error case A: Multiple inquiries on the first sheet or multiple single sheets before start of overlap

Activa-

Semi-automatic calibration

in 2/3 sheet mode

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

tion

I

I

I

play + LEDs

Good sheet calibration performed in the 2/3 sheet mode

(see above).

2/3 sheet mode preselected

via control input "sheet mode"

= ON.

VDB 14B capacitively calibrated, i.e. control output

"ready+calibrated" = ON.

First inquiry on the 1st sheet.

Output "double sheet

detected (overlap)" is not set.

First inquiry on the 1st sheet.

Output "double sheet

detected (overlap)" is not set.

No reaction, but renewed

waiting for start of overlap

(1 sheet). As a result, single

sheets are also possible on

the feeder platform.

First inquiry on the 2nd sheet.

Output "double sheet

detected (overlap)" is set

prior to the first inquiry and

reset after the inquiry.

First inquiry on the 2nd sheet.

Output "double sheet

detected (overlap)" is not set.

As before.

TNT 35/7-24V

First inquiry on the 2nd sheet.

Output "double sheet

I

Leuze electronic DB 14B 43

detected (overlap)" is set.

Output "double sheet

detected" is set.

Page 46

Appendix: 2/3 sheet mode

1

1

23

1

12.3 Error case B: Double sheet on inquiry of the first sheet

Activa-

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

tion

23

I

First inquiry on the 1st sheet.

Output "double sheet

detected (overlap)" is set.

Output "double sheet

detected" is set.

play + LEDs

12.4 Error case C: Double sheet during calibration on the second sheet

Activa-

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

tion

I

I

First inquiry on the 1st sheet.

Output "double sheet

detected (overlap)" is not set.

First inquiry on the 2nd sheet.

Output "double sheet

detected (overlap)" is set.

Output "double sheet

detected" is set.

play + LEDs

44 DB 14B Leuze electronic

Page 47

Appendix: 2/3 sheet mode

23

1

I

1

1

I

1

12.5 Error case D: One or more single sheets with subsequent double sheet at start of overlap

Activa-

Semi-automatic calibration

in 2/3 sheet mode

Inquiry Calibration Sheet movement Effects / prerequisites 7 segment dis-

tion

I

I

play + LEDs

Good sheet calibration performed in the 2/3 sheet mode

(see above).

2/3 sheet mode preselected

via control input "sheet mode"

= ON.

VDB 14B capacitively calibrated, i.e. control output

"ready+calibrated" = ON.

First inquiry on the 1st sheet.

Output "double sheet

detected (overlap)" is not set.

First inquiry on the 1st sheet.

Output "double sheet

detected (overlap)" is not set.

No reaction, but renewed

waiting for start of overlap

(1st sheet); thus single sheets

are possible on the feeder

platform.

First inquiry on the 2nd sheet.

The output "double sheet

detected (overlap)" is set

before the query.

The output "double sheet

detected" is set, the calibration (manually on a good

sheet) is retained.

Output "double sheet

detected" remains set.

TNT 35/7-24V

Leuze electronic DB 14B 45

Page 48

Appendix: 2/3 sheet mode

0

I

1

2

12

23

12.6 Symbol legend

Symbol Description

Activation = OFF.

Activation = ON.

Multiple passes.

1st inquiry,

may be capacitive or ultrasonic sensing.

2nd inquiry,

may be capacitive or ultrasonic sensing.

Preselection 1/2 sheet mode,

capacitive sensing for 2 sheets (double sheet).

Preselection 2/3 sheet mode,

capacitive sensing for 3 sheets (double sheet).

Preselection capacitive sensing. The ultrasonic sensors are only

used for first sheet recognition.

Ultrasonic sensors

Ultrasonic sensors with capacitive sensor.

Inquiry on one sheet.

Inquiry on two sheets.

Inquiry on three sheets.

46 DB 14B Leuze electronic

Page 49

Appendix: 2/3 sheet mode

Output

"double sheet detected" is set (ON).

Cycle

Output

"double sheet detected" is set (ON).

Cycle

Symbol Description

Symbolises a single sheet at multiple inquiries, which is the case

in 2/3 sheet scanning. A single sheet undergoes two 1st inquiries

in this case.

12.7 Critical cases in the overlap flow with 2/3 sheet scanning

Requirement for the following cases: in the event of a missing sheet, the input "Pickup ON"

or "Sheet feeder" does not switch off.

Case 1:double sheet detected

Figure 12.1: Critical case 1

Case 2:double sheet is detected 1 cycle later

Figure 12.2: Critical case 2

Leuze electronic DB 14B 47

TNT 35/7-24V

Page 50

Appendix: 2/3 sheet mode

Attention!

Double sheet is not detected

Cycle

Output

"double sheet detected" is set (ON).

Cycle

Case 3:double sheet in overlap not detected

Figure 12.3: Critical case 3

Case 4:after the overlap has passed, double sheet is detected only by at least

one blank 1st inquiry

Figure 12.4: Critical case 4

48 DB 14B Leuze electronic

Loading...

Loading...