BPS 34

Bar code positioning system - PROFIBUS DP

en 04-2016/10 50105437

We reserve the right to

make technical changes

Original operating instructions

Table of contents

1 General information ........................................................................................................... 3

1.1 Explanation of symbols ........................................................................................................ 3

1.2 Declaration of Conformity ....................................................................................................3

2 Safety .................................................................................................................................. 4

2.1 Intended use ........................................................................................................................ 4

2.2 Foreseeable misuse............................................................................................................. 5

2.3 Competent persons.............................................................................................................. 5

2.4 Exemption of liability ............................................................................................................ 6

2.5 Laser safety notices ............................................................................................................. 6

3 Fast commissioning steps at a glance ............................................................................ 8

4 Technical data of BPS 34 ................................................................................................ 14

4.1 General specifications BPS 34 .......................................................................................... 14

4.2 Dimensioned drawings....................................................................................................... 15

4.3 Electrical connection .......................................................................................................... 17

4.3.1 PWR IN - voltage supply and switching input/output................................................................... 19

4.3.2 DP IN - PROFIBUS DP incoming ................................................................................................20

4.3.3 DP OUT - PROFIBUS DP outgoing.............................................................................................20

4.3.4 SW IN/OUT – Switching input/switching output...........................................................................21

4.3.5 BPS 34 reading field curve..........................................................................................................22

5 MS 34 … / MSD 1 101 connection units ......................................................................... 23

5.1 MS 34 103 and MS 34 105 modular connector hoods....................................................... 23

5.1.1 General information .....................................................................................................................23

5.1.2 Technical data of the connection units ........................................................................................ 23

5.1.3 Dimensioned drawings ................................................................................................................ 24

5.1.4 Electrical connection....................................................................................................................25

5.1.5 Description of the LED states......................................................................................................25

5.2 MSD 1 101 modular service display .................................................................................. 26

5.2.1 General information .....................................................................................................................26

5.2.2 Dimensioned drawing ..................................................................................................................27

5.2.3 Electrical connection....................................................................................................................27

6 Bar code tape ................................................................................................................... 28

6.1 General information ........................................................................................................... 28

6.2 Technical data of the bar code tape................................................................................... 29

6.3 Mounting the bar code tape ............................................................................................... 30

6.4 Control bar codes............................................................................................................... 33

6.4.1 Controllable functions ..................................................................................................................34

6.5 Repair kit............................................................................................................................ 36

Leuze electronic BPS 34 1

Table of contents

7 Mounting........................................................................................................................... 38

7.1 Mounting the BPS 34 ......................................................................................................... 38

7.2 Device arrangement...........................................................................................................41

7.3 Mounting the bar code tape ............................................................................................... 42

8 Device parameters and interfaces.................................................................................. 43

8.1 PROFIBUS......................................................................................................................... 43

8.1.1 General information......................................................................................................................43

8.1.2 Electrical connection ....................................................................................................................43

8.1.3 PROFIBUS address .....................................................................................................................46

8.1.4 General information on the GSD file ............................................................................................46

8.1.5 Structure of the GSD modules .....................................................................................................47

8.1.6 Overview of the GSD modules.....................................................................................................48

8.1.7 Detailed description of the modules .............................................................................................51

9 Diagnostics and troubleshooting ................................................................................... 93

9.1 General causes of errors ................................................................................................... 93

9.2 Error on the PROFIBUS..................................................................................................... 93

10 Type overview and accessories ..................................................................................... 95

10.1 Type overview: BPS 34...................................................................................................... 95

10.2 Accessories - Modular connector hoods............................................................................ 95

10.3 Accessories - Modular service display ............................................................................... 95

10.4 Accessories - Termination ................................................................................................. 95

10.5 Accessories – Connectors ................................................................................................. 95

10.6 Accessories – Mounting device ......................................................................................... 95

10.7 Accessories - Ready-made cables for voltage supply ....................................................... 96

10.7.1 Contact assignment of PWR IN connection cable........................................................................96

10.7.2 Technical data of voltage supply cable ........................................................................................96

10.7.3 Order codes for voltage supply cables.........................................................................................96

10.8 Accessories - Ready-made cables for PROFIBUS connection ......................................... 97

10.8.1 General ........................................................................................................................................97

10.8.2 Contact assignment for PROFIBUS connection cable KB PB…..................................................97

10.8.3 Technical data of PROFIBUS connection cable...........................................................................98

10.8.4 Order codes for PROFIBUS connection cables...........................................................................98

10.9 Type overview: Bar code tape ........................................................................................... 98

11 Maintenance ................................................................................................................... 100

11.1 General maintenance information.................................................................................... 100

11.2 Repairs, servicing ............................................................................................................ 100

11.3 Disassembling, packing, disposing .................................................................................. 100

12 Appendix......................................................................................................................... 101

12.1 EC Declaration of Conformity .......................................................................................... 101

2 BPS 34 Leuze electronic

1 General information

U

L

US

C

LISTED

1.1 Explanation of symbols

The symbols used in this technical description are explained below.

Attention!

This symbol precedes text messages which must strictly be observed. Failure to observe the

provided instructions could lead to personal injury or damage to equipment.

Attention Laser!

This symbol warns of possible danger through hazardous laser radiation.

Note!

This symbol indicates text passages containing important information.

1.2 Declaration of Conformity

The bar code positioning system BPS 34, the modular connector hood MS 34 103/

MS 34 105, and the optional modular service display MSD 1 101 have been developed and

manufactured in accordance with the applicable European standards and directives.

The devices of the BPS 34 series also fulfill the cUL requirements (Underwriters Laboratory

Inc.) for the USA and Canada.

General information

Note!

A copy of all declarations of conformity available for the product can be found in the appendix of this handbook (see chapter 12.1 "EC Declaration of Conformity" on Page 101).

The manufacturer of the product, Leuze electronic GmbH + Co. KG in D-73277 Owen,

possesses a certified quality assurance system in accordance with ISO 9001.

Leuze electronic BPS 34 3

TNT 35/7-24V

Safety

2 Safety

The bar code positioning systems of the BPS 34 series and the MS 34 10x modular

connector hoods have been developed, produced and tested subject to the applicable safety

standards. They correspond to the state of the art.

2.1 Intended use

Bar code positioning systems of the BPS 34 series are optical measuring systems which use

visible red laser light to determine the position of the BPS relative to a permanently mounted

bar code tape.

The modular connector hoods MS 34 103/MS 34 105 are intended for the easy connection

of bar code positioning systems of type BPS 34 in a PROFIBUS system.

The modular service display MSD 1 101, which is optionally available, displays operational

data of the BPS 34 and is used as a simple means of access to the service interface of the

MS 34 105.

Areas of application

The BPS 34 bar code positioning systems are designed for the following areas of application:

• High-bay storage devices: Positioning in the travel and lifting axes

•Crane bridges and trolleys

• Side-tracking skates

•Telpher lines

•Elevators

CAUTION

Observe intended use!

Only operate the device in accordance with its intended use. The protection of per-

sonnel and the device cannot be guaranteed if the device is operated in a manner not

complying with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read the technical description before commissioning the device. Knowledge of this

technical description is an element of proper use.

NOTE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

Attention

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC

(National Electric Code).

4 BPS 34 Leuze electronic

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is

considered improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• as stand-alone safety component in accordance with the machinery directive

• for medical purposes

NOTE

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried

out by competent persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at

work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation

of the device.

Safety

1)

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with

relevant standards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

1) Use as safety-related component within the safety function is possible, if the component combination is designed

correspondingly by the machine manufacturer.

Leuze electronic BPS 34 5

TNT 35/7-24V

Safety

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser safety notices

ATTENTION, LASER RADIATION – LASER CLASS 2

Never look directly into the beam!

The device satisfies the requirements of IEC 60825-1:2007 (EN 60825-1:2007) safety

regulations for a product of laser class 2 as well as the U.S. 21 CFR 1040.10 regulations

with deviations corresponding to "Laser Notice No. 50" from June 24, 2007.

Never look directly into the laser beam or in the direction of reflected laser beams!

If you look into the beam path over a longer time period, there is a risk of injury to the

retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser

beam is accidentally directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflec-

tive surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here

or carrying out of differing procedures may lead to dangerous exposure to radiation.

Observe the applicable statutory and local laser protection regulations.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

6 BPS 34 Leuze electronic

NOTE

A Laser aperture

B Laser warning sign

C Laser information sign with laser parameters

B

B

C

A

Affix laser information and warning signs!

Laser information and warning signs are attached to the device (see Figure 2.1):

Safety

Figure 2.1:Laser apertures, laser warning and information signs

Leuze electronic BPS 34 7

TNT 35/7-24V

Fast commissioning steps at a glance

3 Fast commissioning steps at a glance

Note!

Below you will find a short description for the initial commissioning of the bar code posi-

tioning system BPS 34. Detailed explanations of all listed points can be found throughout

the handbook.

Description of the BPS 34 functions

The BPS 34 uses visible red laser light to determine its position relative to the bar code tape.

This essentially takes place in three steps:

1. Reading a code on the bar code tape

2. Determining the position of the read code in the scanning area of the scanning beam

3. Calculating the position to within a millimeter using the code information and the code

position relative to the device's center.

The position value is then output via the interface.

Mechanical design

Mounting the bar code tape

The bar code tape is to be affixed without tension to a dust- and grease-free mounting

surface.

Chapter 6.3 on Page 30

Mounting the BPS 34 device

There are 2 different types of mounting arrangements for the BPS 34:

1. Using 4 M4x6 screws on the rear of the device.

2. Using a mounting device (BT 56) on the dovetail fastening grooves.

8 BPS 34 Leuze electronic

Fast commissioning steps at a glance

000200

000216

000204

000208

000212

0

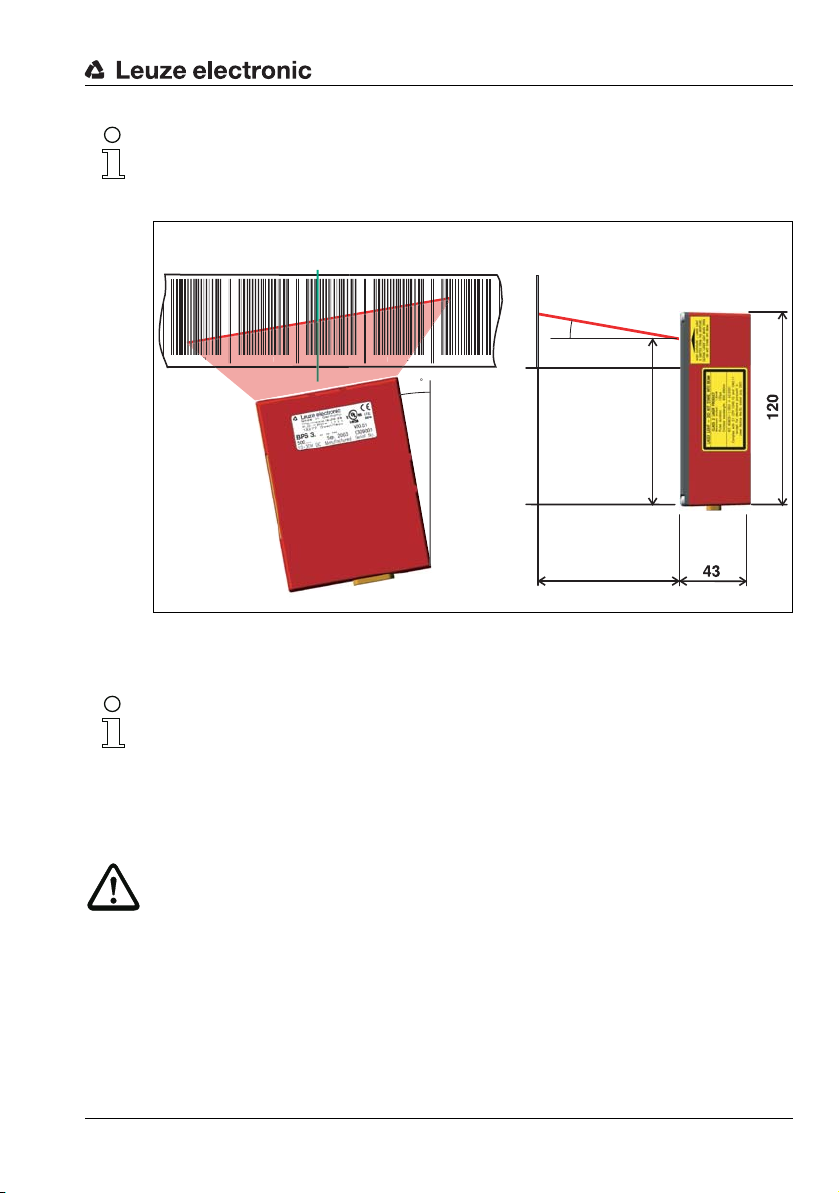

103 ± 2

10˚

Reading distance

Beam exit

all dimensions

in mm

Bar code tape

Center of the scanning beam

(device center, output position value)

Scanning beam

10° pitch

in the

vertical axis

(dependent on

the tape height,

see notes)

Note!

The installation dimensions listed in the following figure must absolutely be adhered to. Optically, it must be ensured that the scanner has an unobstructed view of the bar code tape at

all times.

Chapter 7.2 on Page 41

1

Figure 3.1:Beam exit and device arrangement of the BPS 34

Chapter 7.1 on Page 38

Note!

During mounting, the following angles of inclination must be taken into account in the vertical

axis:

10° for a tape height of 47mm,

7° for a tape height of 30mm and

5° for a tape height of 25mm;

the working range of the reading field curve must also be taken into account.

Attention!

For the position calculation, the scanning beam of the BPS 34 must be incident on the bar

code tape without interruption. Ensure that the scanning beam is always incident on the bar

code tape when the system is moving.

Leuze electronic BPS 34 9

TNT 35/7-24V

Fast commissioning steps at a glance

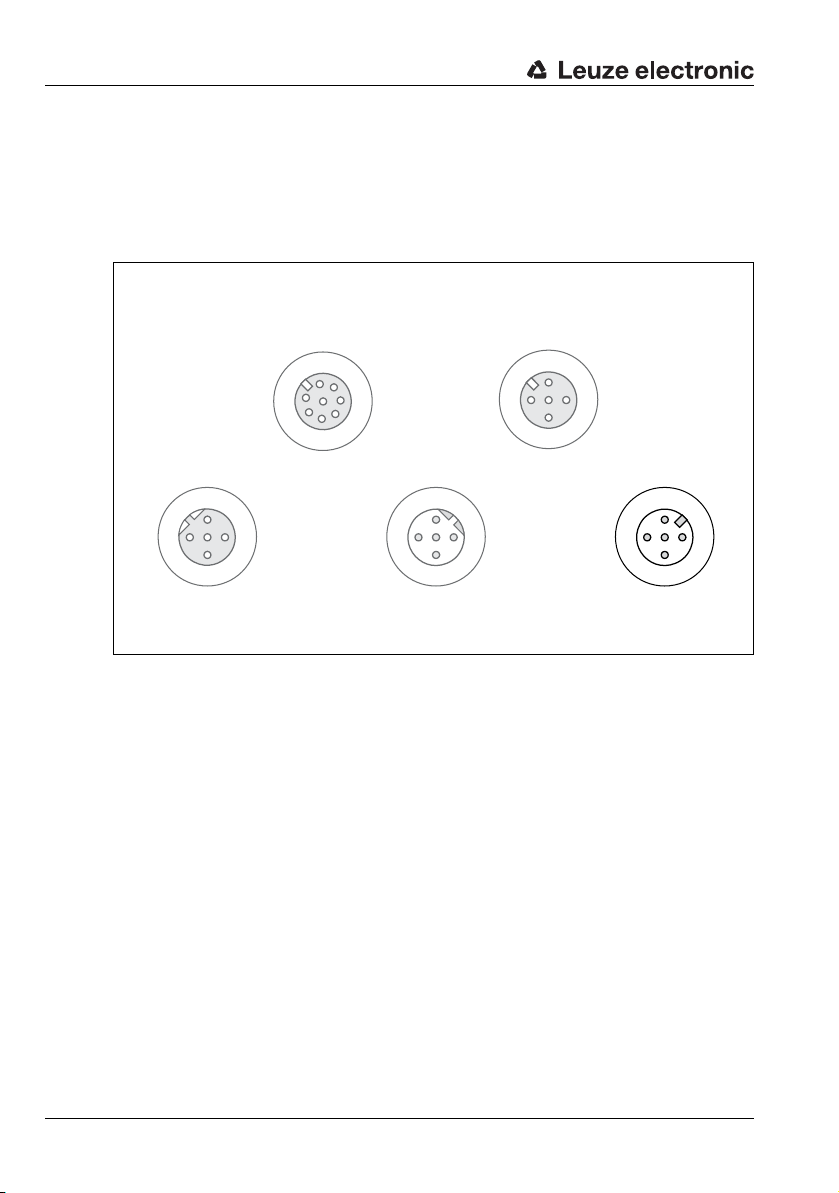

Socket

(A-coded)

Socket

(A-coded)

Socket

(B-coded)

Plug

(B-coded)

Plug

(A-coded)

Connecting the voltage supply and PROFIBUS

The BPS 34, in combination with an MS 34 103 or MS 34 105, is connected via M12

connectors.

Connecting the voltage supply

The voltage supply is connected via the PWR IN M12 connection.

MSD

VIN

TXD

2

/INT

/SERV

GND

DP OUT

A (N)

2

VCC

1

Figure 3.2:BPS 34 with MS 34 103/MS 34 105 – PWR IN connection

4

B (P)

GND

3

PE

3

1

7

SDA

RXD

4

5

SCL

6

GND

3

PE

DP IN

A (N)

2

4

B (P)

SW IN/OUT

VOUT

VCC

1

SWOUT

1

SWIN

2

3

4

GND VIN

GND

PE

PWR IN

SWOUT

3

PE

SWIN

2

1

4

10 BPS 34 Leuze electronic

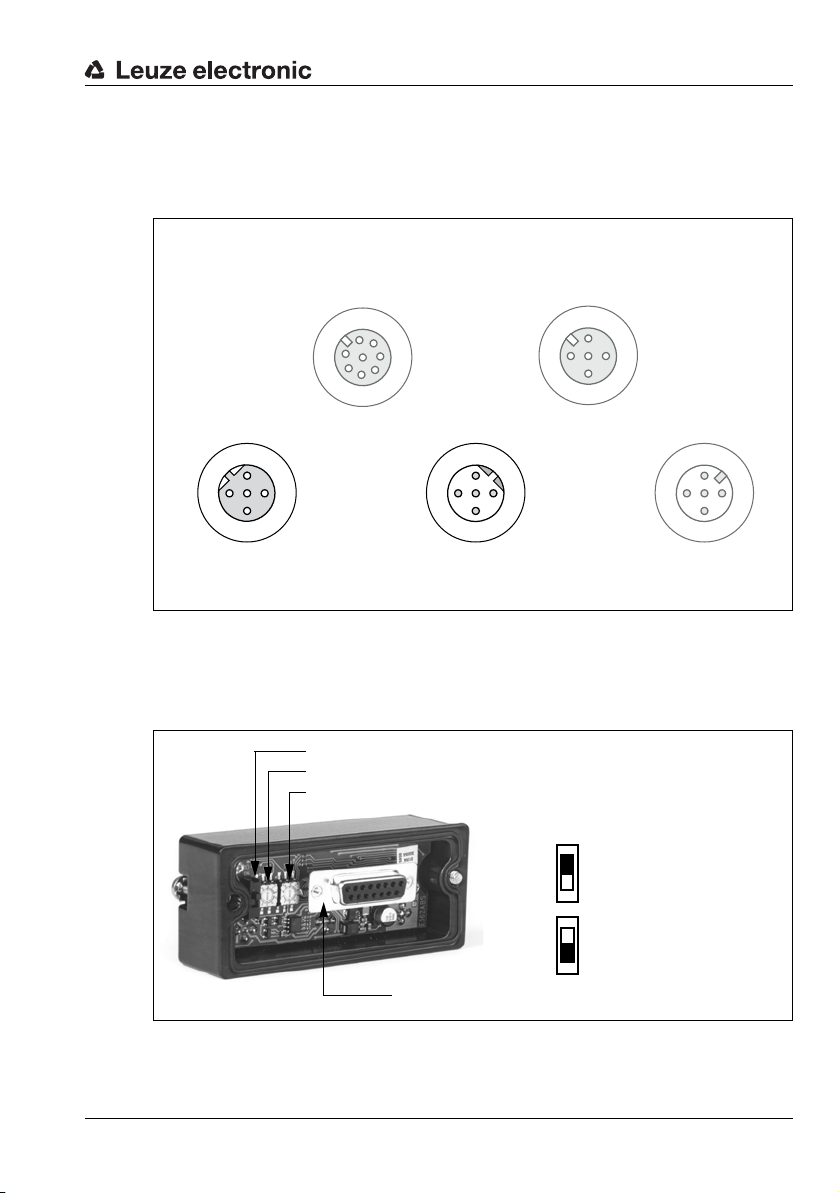

Fast commissioning steps at a glance

Socket

(A-coded)

Socket

(A-coded)

Socket

(B-coded)

Plug

(B-coded)

Plug

(A-coded)

DP IN

GND

3

2

1

4

PE

A (N)

B (P)

VCC

DP OUT

VCC

1

2

3

4

A (N)

B (P)

GND

PE

PWR IN

SWIN

SWOUT

3

2

1

4

GND VIN

PE

SW IN/OUT

1

2

3

4

VOUT

PE

SWIN

SWOUT

GND

1

2

3

4

MSD

5

6

7

/SERV

VIN

TXD

RXD

SCL

SDA

GND

/INT

Slide switch for the hundreds (marked with 102)

Rotary switch for the tens (marked with 10

1

)

Rotary switch for the single digits (marked with 10

0

)

Connection plug to the BPS 34

Position of the slide

switches:

Top address

100 - 126

Bottom address

1 - 99

Connecting the PROFIBUS

The PROFIBUS is connected via DP IN or, in the case of a continuing network, via DP OUT.

If DP OUT is not used, the PROFIBUS must be terminated at this point with an M 12 terminator plug (see chapter 10.4 "Accessories - Termination").

Figure 3.3:BPS 34 with MS 34 103/MS 34 105 – DP IN and DP OUT connections

Setting the PROFIBUS address

The PROFIBUS address must be set in the MS 34 10x connector plug hood. The correct

address setting on the PROFIBUS network is indicated by the green LED on the MS 34 10x.

Leuze electronic BPS 34 11

Figure 3.4:View of the inside of the MS 34

TNT 35/7-24V

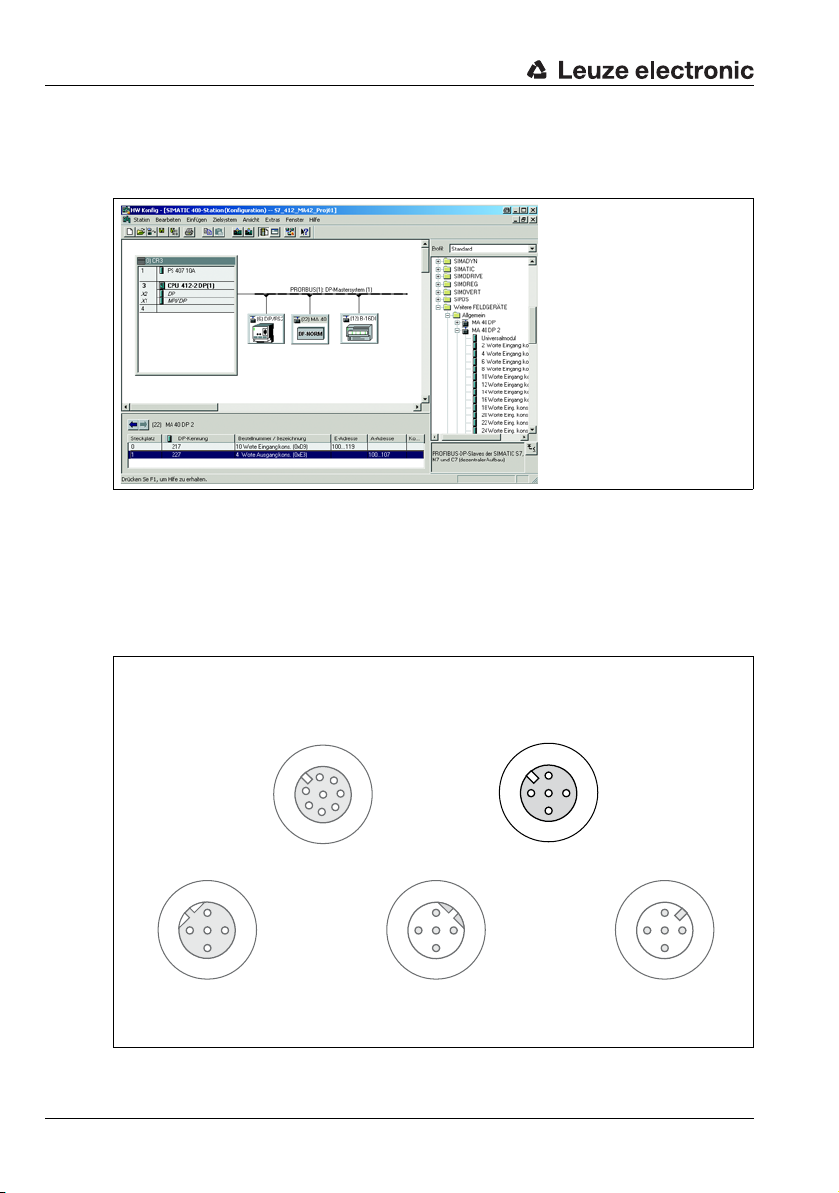

Fast commissioning steps at a glance

Socket

(A-coded)

Socket

(A-coded)

Socket

(B-coded)

Plug

(B-coded)

Plug

(A-coded)

PROFIBUS manager

Install the GSD file associated with the BPS 34… in the PROFIBUS manager of your control.

Activate the desired modules (at least module 1 - position value).

Figure 3.5:Example PROFIBUS manager

Store the slave address for the BPS 34 in the PROFIBUS manager. Ensure that the address

is the same as the address configured in the device.

Connecting the switching input/switching output to the BPS 34

The switching input/switching output is connected via SW IN/OUT.

MSD

VIN

TXD

2

/INT

/SERV

GND

DP OUT

A (N)

2

VCC

1

Figure 3.6:BPS 34 with MS 34 103/MS 34 105 – SW IN/OUT connection

12 BPS 34 Leuze electronic

4

B (P)

GND

3

PE

1

7

6

SDA

3

4

5

GND

SCL

RXD

PE

DP IN

A (N)

3

4

B (P)

2

SW IN/OUT

VOUT

VCC

1

SWOUT

1

SWIN

2

GND

3

4

PE

PWR IN

SWOUT

3

GND VIN

PE

2

1

4

SWIN

Fast commissioning steps at a glance

Socket

(A-coded)

Socket

(A-coded)

Socket

(B-coded)

Plug

(B-coded)

Plug

(A-coded)

1

2

3

4

MSD

5

6

7

/SERV

VIN

TXD

RXD

SCL

SDA

GND

/INT

PWR IN

SWIN

SWOUT

3

2

1

4

GND VIN

PE

SW IN/OUT

1

2

3

4

VOUT

PE

SWIN

SWOUT

GND

DP IN

GND

3

2

1

4

PE

A (N)

B (P)

VCC

DP OUT

VCC

1

2

3

4

A (N)

B (P)

GND

PE

Connecting the MSD 1 101 modular service display

The MSD 1 101 is connected via cable KB 034-2000 (M12 connection on MSD and M12

connection on MSD 1 101, see chapter 10.3 "Accessories - Modular service display" on

Page 95).

Figure 3.7:BPS 34 with MS 34 103/MS 34 105 - MSD connection

The BPS 34 can be accessed via the MS 1 101 using the service interface.

Note!

Changes which were made via the service interface on the BPS 34 are lost following initialization on the PROFIBUS.

Leuze electronic BPS 34 13

TNT 35/7-24V

Technical data of BPS 34

4 Technical data of BPS 34

4.1 General specifications BPS 34

Optical data

Light source Laser diode

Beam deflection Via rotating polygon wheel

Reading distance See reading field (Figure 4.3.5)

Optical window Glass with scratch-resistant indium coating

Laser class 2 acc. to IEC 60825-1:2007

Wavelength 655nm

Max. output power (peak) 1.8mW

Impulse duration 120µs

Measurement data

Reproducibility (3 sigma) -1 mm

Response time 16 ms (configurable)

Output time 2ms

Basis for contouring error calculation

Working range 90 … 170 mm

Max. traverse rate 10m/s

Electrical data

Interface type PROFIBUS DP, up to 12MBd

Service interface RS 232 with default data format,

Switching input / switching output

Green LED Device ready (power on) and bus O.K.

Operating voltage Without optics heating: 10 … 30V DC

Power consumption Without optics heating: 5W

Mechanical data

Degree of protection IP 65

Weight Without optics heating: 400g

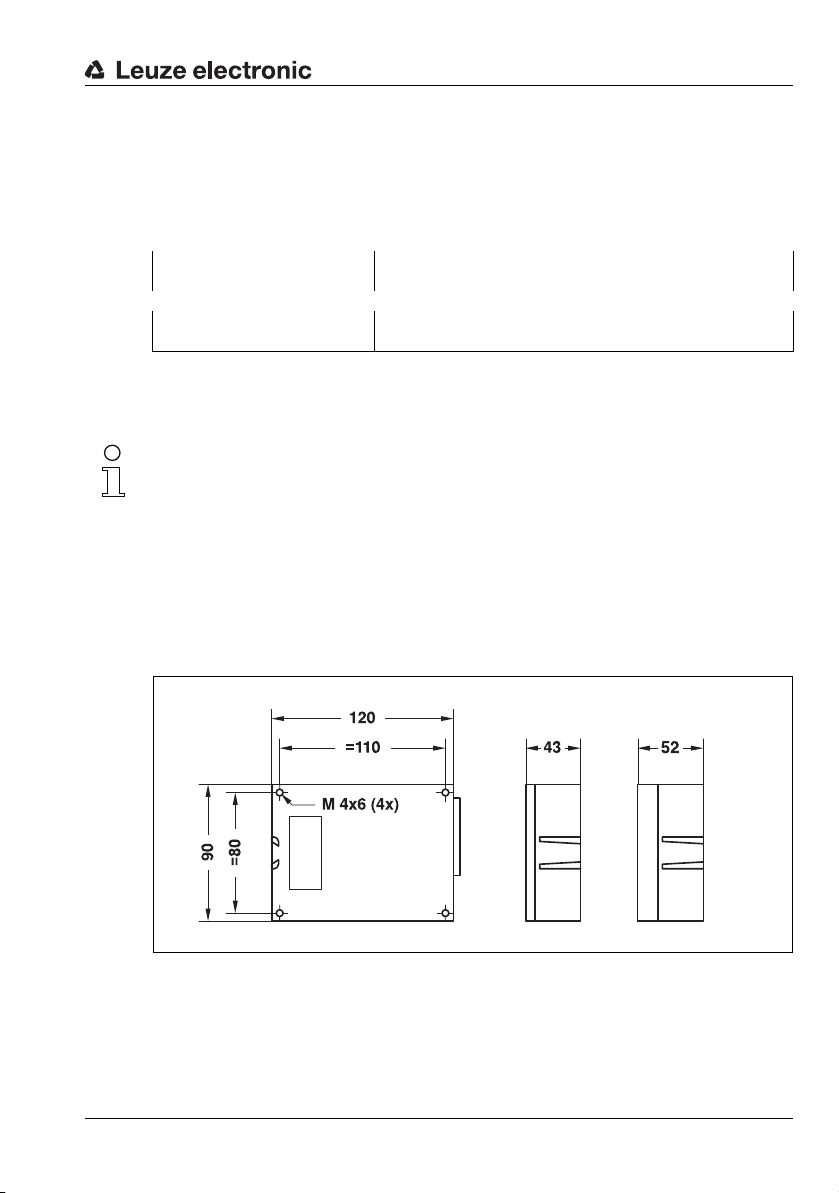

Dimensions (H x W x D) Without optics heating: 120 x 90 x 43mm

Housing Diecast aluminum

Environmental data

Operating temperature range Without optics heating: 0 °C … +40 °C

Storage temperature range -30°C … +60°C

Air humidity Max. 90 % rel. humidity, non-condensing

7ms

9600Bd, 8 data bits, no parity, 1 stop bit

1 switching input, 1 switching output, each is

programmable

With optics heating: 22 … 26V DC

With optics heating: max. 30W

2)

With optics heating: 480g

With optics heating: 120 x 90 x 52mm

With optics heating: -30°C … +40 °C

High temperature version: 0 °C … +50°C

1)

14 BPS 34 Leuze electronic

Vibration IEC 60068-2-6, test Fc

Top view

(without heat-

ing)

Rear view

all dimensions in mm

Top view

(with heating)

Shock IEC 60068-2-27, test Ea

Continuous shock IEC 60068-2-29, test Eb

Electromagnetic compatibility EN 55022, EN 55024, EN 61000-4-2, -3, -4 and -6,

Bar code tape

Max. length (measurement

length)

Ambient temperature -40 °C … -120 °C

Mech. properties Scratch and wipe resistant, UV resistant,

1) To ensure consistent heat emission

2) With MS 34 10x plugged in and M12 connectors/caps screwed into place

Table 4.1: General specifications

Note!

The warm-up time before devices with integrated heating are ready for operation is

approx. 30min. (depending on the environmental conditions).

For devices with integrated heating (…H models), window heating is in constant operation.

Regulation of device-internal heating is temperature dependent.

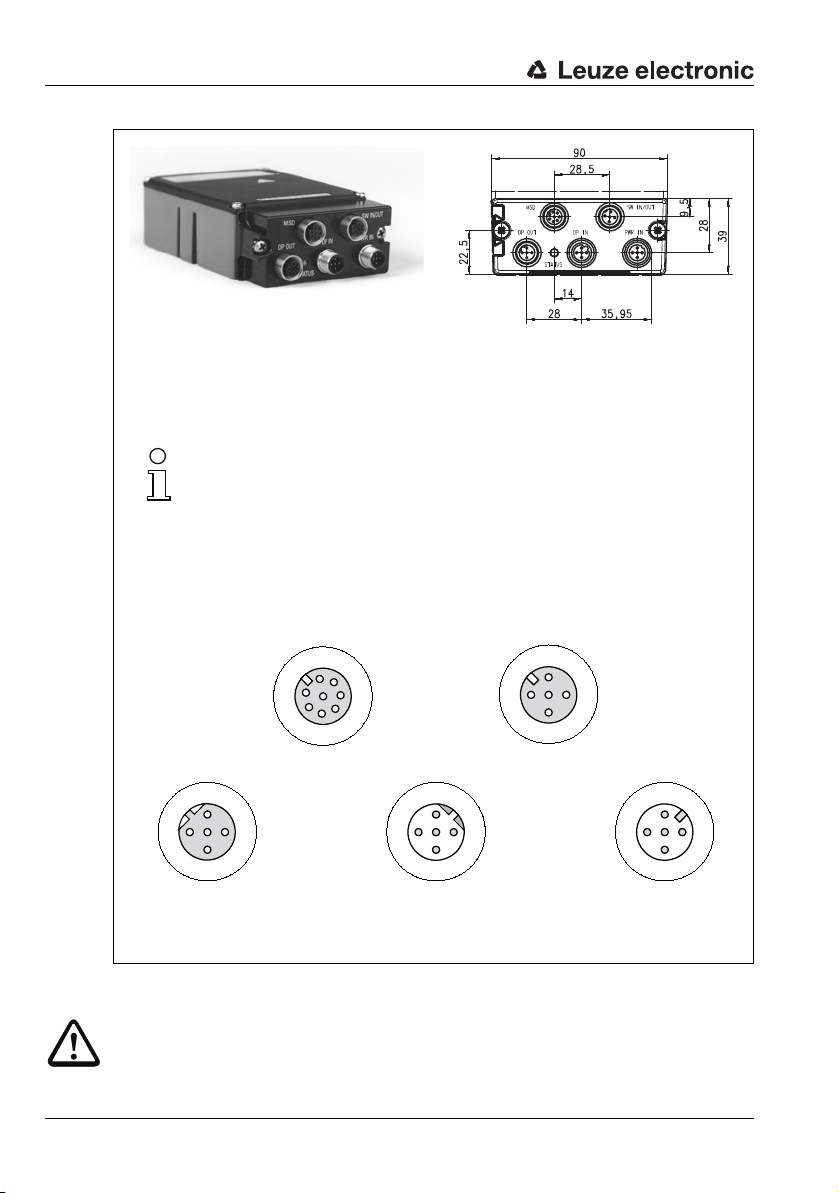

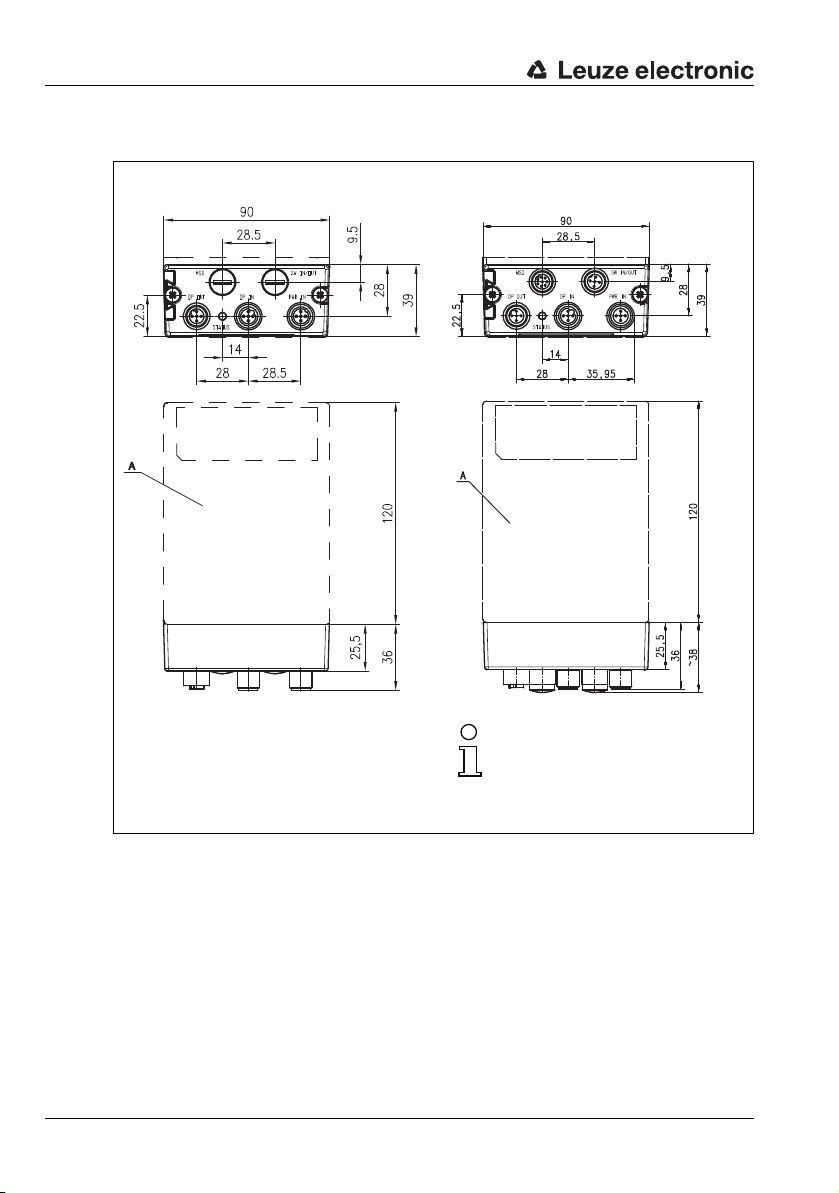

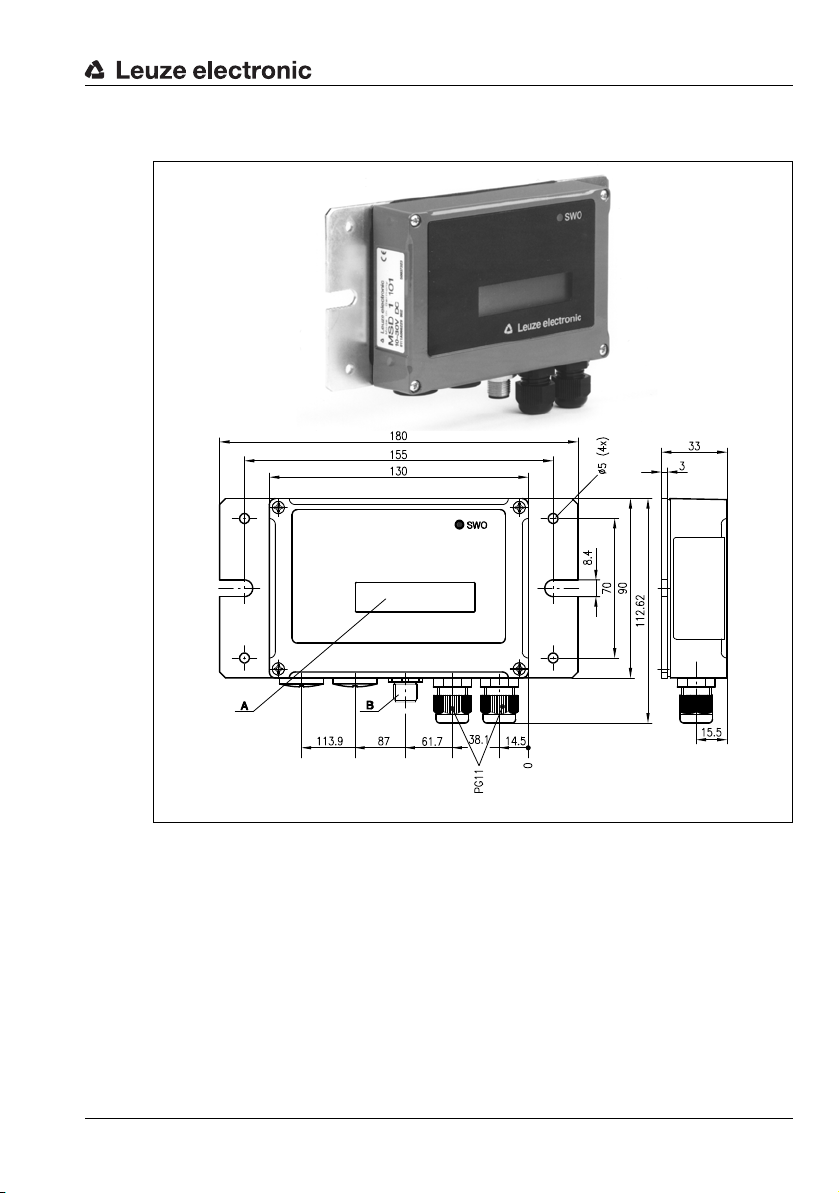

4.2 Dimensioned drawings

BPS 34 SM 100 / BPS 34 SM 100 H / BPS 34 SM 100 HT

Technical data of BPS 34

EN 61000-6-2 and -3

10000 m

moisture resistant, partly chemical resistant

1)

Figure 4.1:BPS 34 dimensioned drawing

Leuze electronic BPS 34 15

TNT 35/7-24V

Technical data of BPS 34

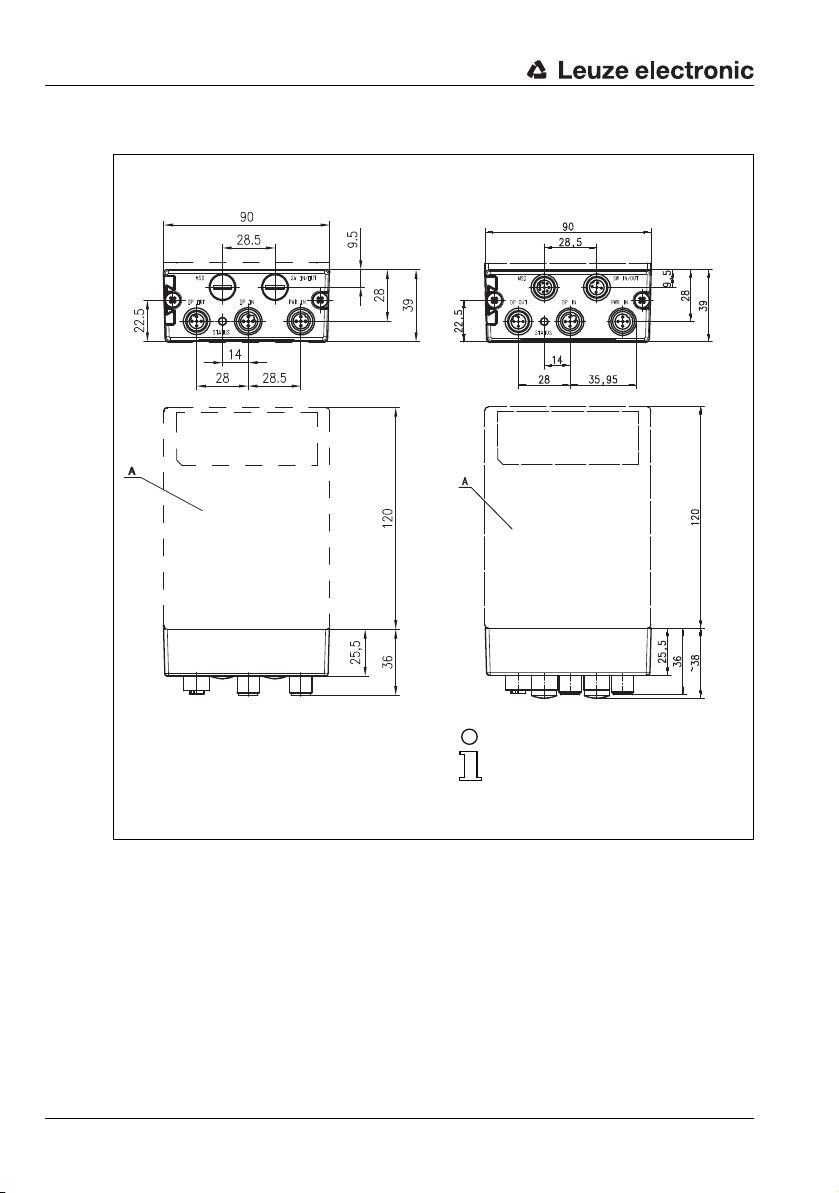

MS 34 105MS 34 103

A = BPS 34

all dimensions in mm

Note!

The MSD and SW IN/OUT

connections are sealed with caps

upon delivery.

MS 34 103 / MS 34 105

Figure 4.2:Dimensioned drawing MS 34 103 / MS 34 105

16 BPS 34 Leuze electronic

4.3 Electrical connection

The BPS 34 can be connected via the MS 34 103/MS 34 105 using M12 connectors. For the

locations of the individual device connections, please refer to the device detail shown in

Figure 4.3.

The corresponding mating connectors and ready-made cables are available as accessories

for all connections. For additional information, refer to Chapter 10 starting on Page 95.

Attention!

Connection of the device and cleaning must only be carried out by a qualified electrician.

If faults cannot be cleared, the device should be switched off and protected against accidental use.

Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

The power supply unit for the generation of the supply voltage for the BPS 34 and the

respective connection units must have a secure electrical insulation through double insulation and safety transformers according to EN 60742 (corresponds to IEC 60742).

Be sure that the protective conductor is connected correctly. Fault-free operation is only

guaranteed when the device is properly earthed.

Technical data of BPS 34

Leuze electronic BPS 34 17

TNT 35/7-24V

Technical data of BPS 34

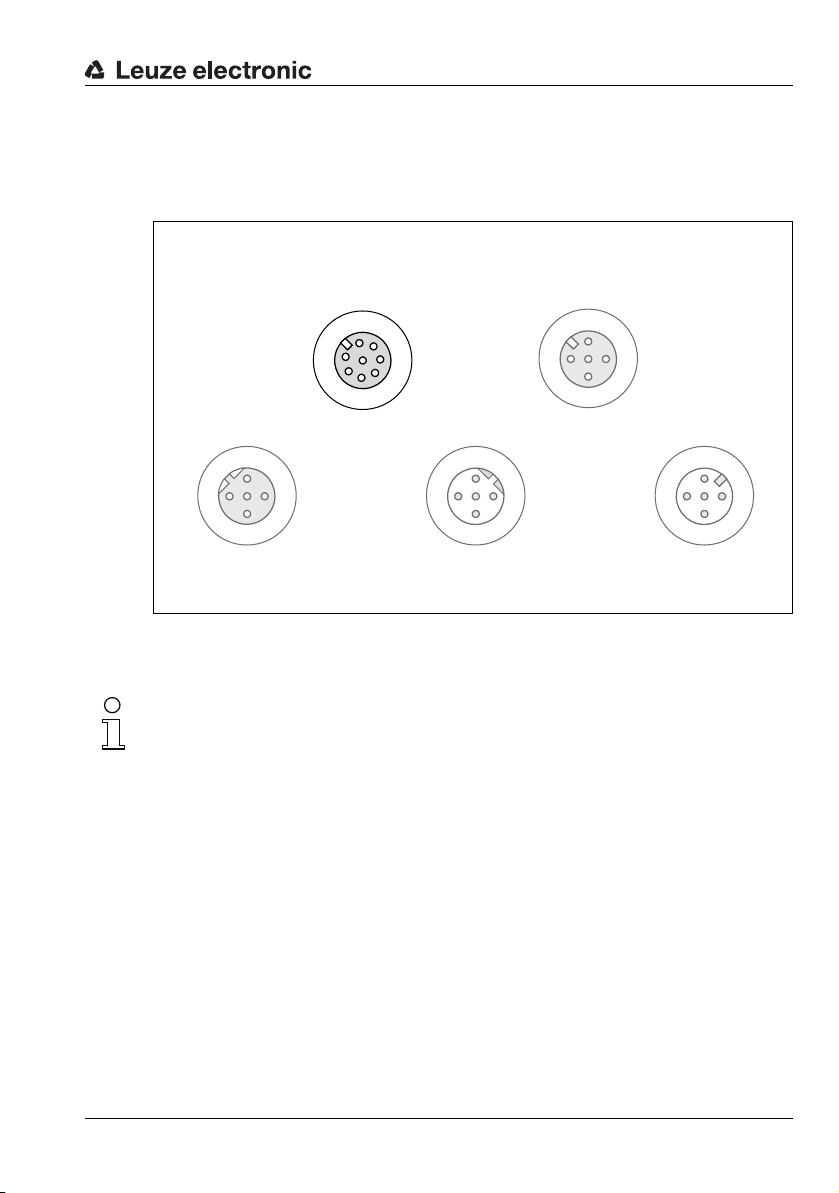

PWR IN = voltage supply

DP IN = PROFIBUS IN

DP OUT = PROFIBUS OUT

MSD = modular service display (MS 34 105 only)

SW IN/OUT = switching input/output (MS 34 105 only)

Note!

The MSD and SW IN/OUT

connections are sealed with caps upon delivery.

Socket

(A-coded)

Socket

(A-coded)

Socket

(B-coded)

Plug

(B-coded)

Plug

(A-coded)

all dimensions in mm

/SERV

DP OUT

A (N)

2

VCC

1

3

4

B (P)

GND

PE

/INT

VIN

1

7

MSD

2

6

SDA

TXD

3

5

GND

4

SCL

RXD

PE

DP IN

3

VOUT

A (N)

2

VCCGND

1

4

B (P)

SW IN/OUT

SWOUT

2

1

3

4

SWIN

GND VIN

GND

PE

PWR IN

SWOUT

3

PE

SWIN

2

4

Figure 4.3:Pin assignment of the BPS 34 with MS 34 103 / MS 34 105

Attention!

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into

place!

18 BPS 34 Leuze electronic

1

Technical data of BPS 34

PWR IN

SWIN

SWOUT

3

2

1

4

GND VIN

PE

M12 plug

(A-coded)

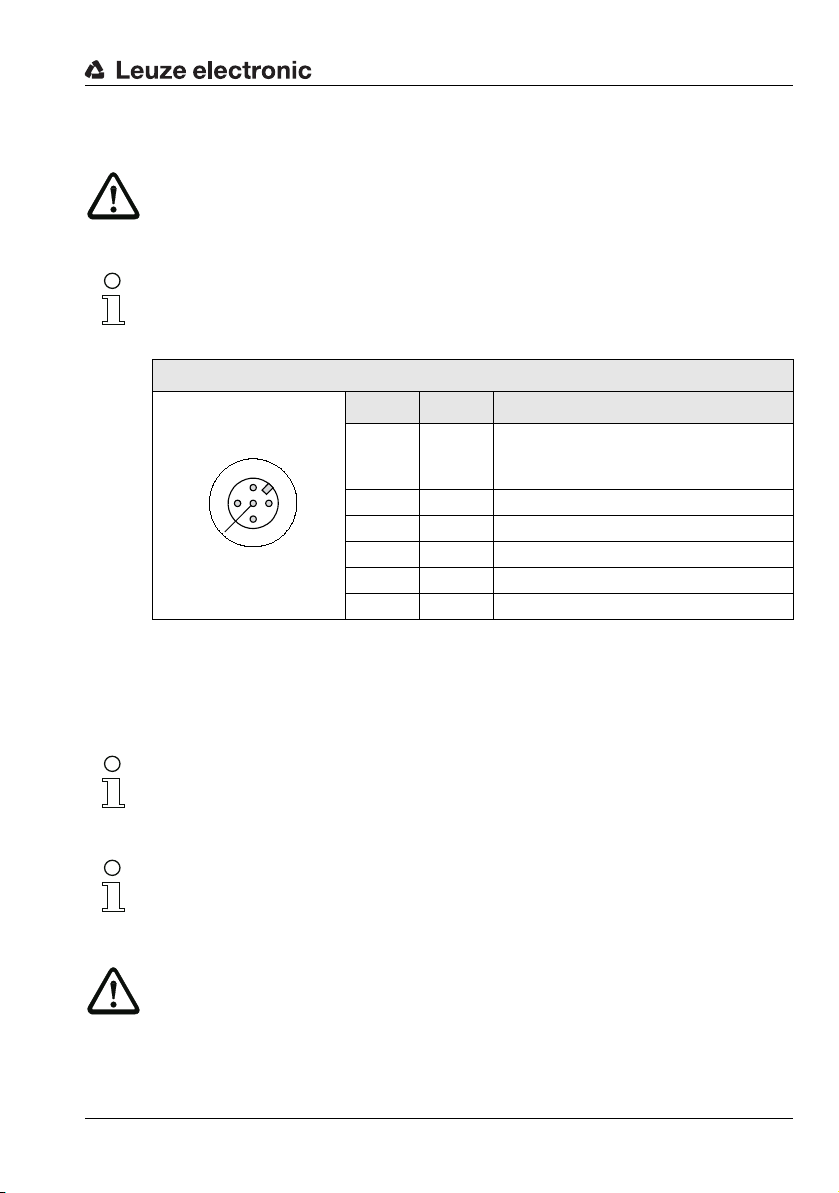

4.3.1 PWR IN - voltage supply and switching input/output

Attention!

For devices with integrated heating, the supply voltage must be wired with a minimum

2

(recommended 0.75mm2) core cross section. It is not possible to loop the

0.5mm

supply voltage through to other loads!

Note!

Cables with a wire cross section of 0.5mm² or 0.75mm² are not available as ready-made

cables from Leuze electronic.

PWR IN (5-pin plug, A-coded)

Pin Name Comment

Positive supply voltage

1VIN

2 SWOUT Switching output

3 GND Negative supply voltage 0V DC

4 SWIN Switching input

5 PE Functional earth

Thread PE Functional earth (housing)

Figure 4.4:Pin assignment - PWR IN

Without optics heating: +10 … +30VDC

With optics heating: +22 … +26VDC

Leuze electronic BPS 34 19

Connecting the functional earth PE

BPS 34 with MS 34 103/MS 34 105 connector hood:

Connect PE to PIN 5 of the M12 connector PWR IN for voltage supply!

Note!

Programming of the switching input/switching output is performed via module 7 (Switching

input) and module 8 (Switching output). For further information, see also Chapter 8.1.7.7,

Page 60 et seq.

Note!

The switching input/switching output of the PWR IN plug connection is identical to the SWIN

switching input and SWOUT switching output of the SW IN/OUT plug connection on the

MS 34 105.

Attention!

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into

place!

TNT 35/7-24V

Technical data of BPS 34

M12 plug

(B-coded)

M12 socket

(B-coded)

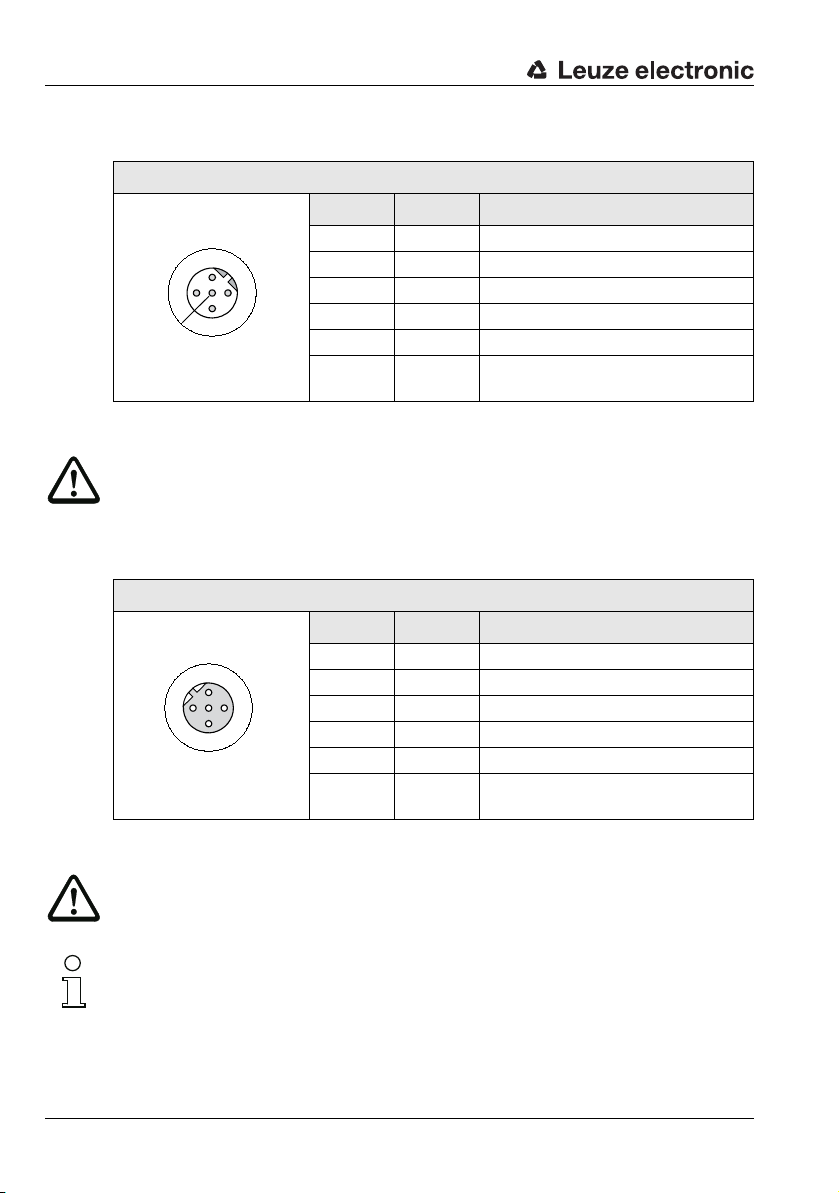

4.3.2 DP IN - PROFIBUS DP incoming

DP IN (5-pin plug, B-coded)

DP IN

A (N)

2

3

GND

PE

4

B (P)

VCC

1

Figure 4.5:Pin assignment - DP IN

Attention!

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into

place!

4.3.3 DP OUT - PROFIBUS DP outgoing

DP OUT

A (N)

2

4

B (P)

GND

3

PE

VCC

1

Pin Name Comment

1VCC5VDC for bus termination

2A (N)Receive/transmit data A-line (N)

3GNDFunctional earth for bus termination

4B (P)Receive/transmit data B-line (P)

5PEFunctional earth

Thread PE Functional earth (housing)

DPOUT (5-pin socket, B-coded)

Pin Name Comment

1VCC5VDC for bus termination

2A (N)Receive/transmit data A-line (N)

3GNDFunctional earth for bus termination

4B (P)Receive/transmit data B-line (P)

5PEFunctional earth

Thread PE Functional earth (housing)

Figure 4.6:Pin assignment - DP IN

Attention!

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into

place!

Note!

If the PROFIBUS is not connected to another participant via the MS 34 10x, the DP OUT

connection must be fitted with a TS 02-4-SA terminator plug for the purpose of bus termination. For further information, see also Chapter 10.4 on Page 95.

20 BPS 34 Leuze electronic

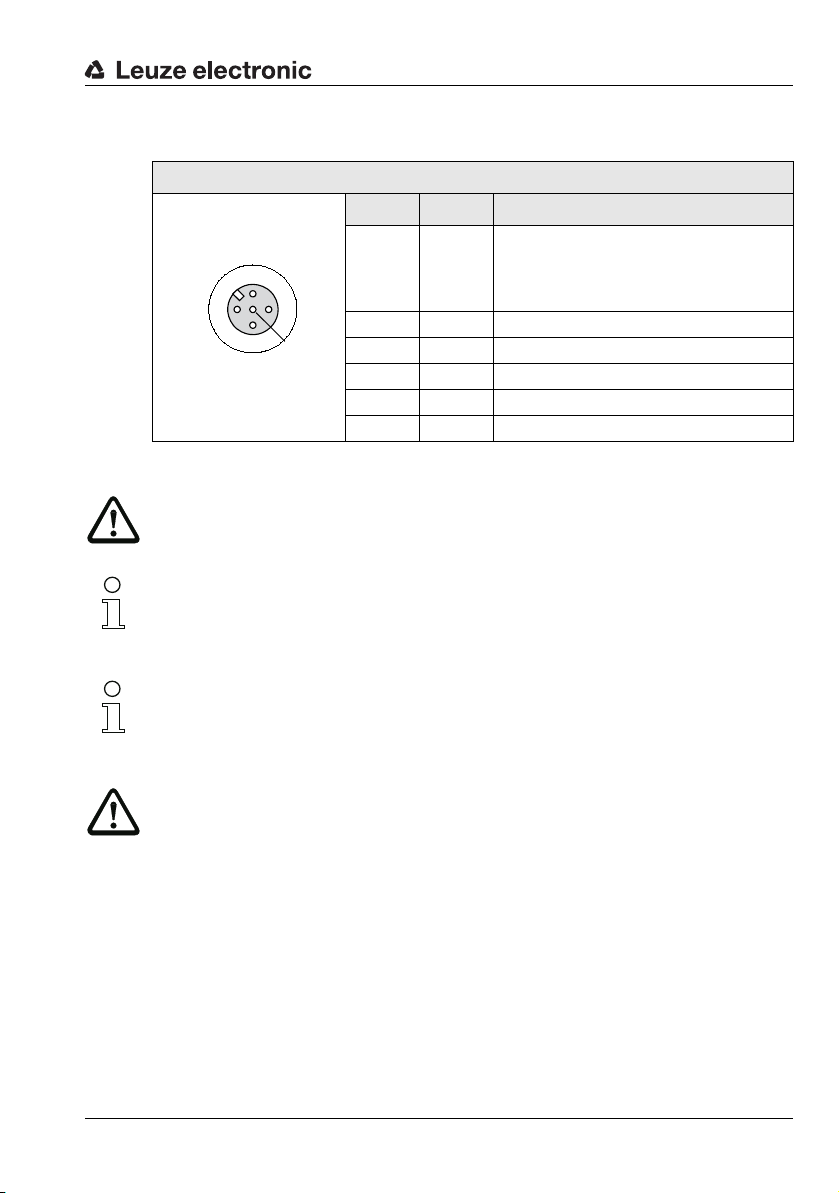

4.3.4 SW IN/OUT – Switching input/switching output

SW IN/OUT

1

2

3

4

VOUT

PE

SWIN

SWOUT

GND

M12 socket

(A-coded)

SW IN/OUT (5-pin socket, A-coded)

Pin Name Comment

Supply voltage for sensor system

1VOUT

2 SWOUT Switching output

3 GND Supply voltage for sensors 0VDC

4 SWIN Switching input

5 PE Functional earth

Thread PE Functional earth (housing)

Figure 4.7:Pin assignment - SW IN/OUT

Attention!

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into

place!

Note!

Programming of the switching input/switching output is performed via module 7 (Switching

input) and module 8 (Switching output). For further information, see also Chapter 8.1.7.7,

Page 60 et seq.

(VOUT identical to VIN at PWR IN)

Without optics heating: +10 … +30VDC

With optics heating: +22 … +26VDC

Technical data of BPS 34

Note!

The switching input/switching output of the PWR IN plug connection is identical to the SWIN

switching input and SWOUT switching output of the SW IN/OUT plug connection on the

MS 34 105.

Attention!

If you use a sensor with a standard M 12 connector, please note the following:

Only use sensors on which the switching output does not lie on pin 2, i.e. only sensor cables

on which pin 2 is not assigned. Otherwise, the switching output is not protected against feedback on the switching input. If the inverted sensor output lies on pin 2, for example,

erroneous behavior of the switching output will result!

Leuze electronic BPS 34 21

TNT 35/7-24V

Technical data of BPS 34

Sensor

SW IN/OUT connector

PWR plug

-80

-60

-40

-20

0

20

40

60

80

0

25 75 125 17550 100 17090 150 200

250

225

Reading distance [mm]

Reading field width [mm]

Working range

BPS 34

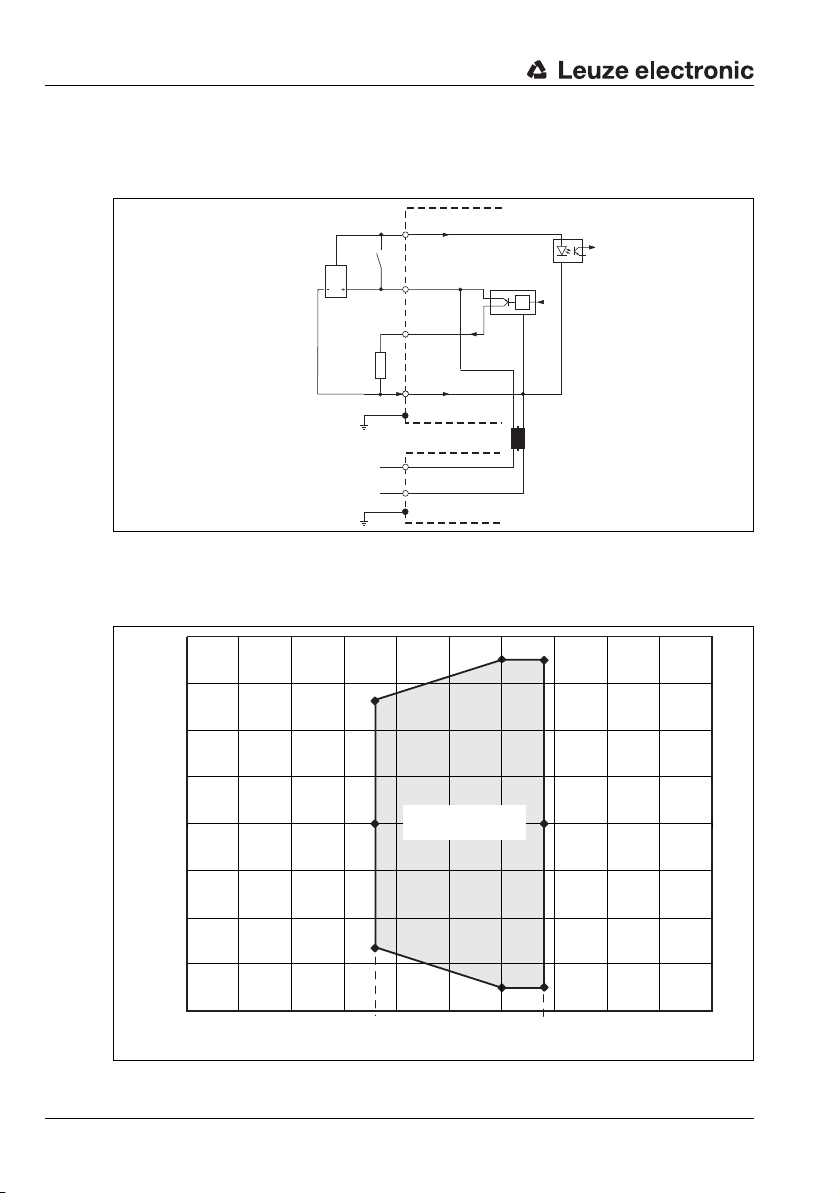

Connecting the switching input / switching output

The BPS 34 is provided with a switching input and a switching output. The connection is

performed as shown in Figure 4.8:

SWIN4

Figure 4.8:Connecting the switching input / switching output of the BPS 34

4.3.5 BPS 34 reading field curve

A

max.

100 mA

V OUT1

SW OUT2

GND3

PE5

V IN1

GND IN3

22 BPS 34 Leuze electronic

Figure 4.9:BPS 34 reading field curve

MS 34 … / MSD 1 101 connection units

5 MS 34 … / MSD 1 101 connection units

5.1 MS 34 103 and MS 34 105 modular connector hoods

A modular connector hood of type MS 34 103 or MS 34 105 is part of every BPS 34. The

two connector hoods are used to connect the BPS 34 to the PROFIBUS. For this, they

feature one DP IN and one DP OUT connection each, as well as switches for address

setting.

If only the connection to the PROFIBUS is intended, type MS 34 103 is sufficient.

If, in addition, a switching input/output or modular service display are to be connected, an

MS 34 105 is required. Although switching input and output are available on the PWR IN

voltage supply connector, the switching input of the MS 34 105 has the advantage that a

standard sensor connector can be used.

5.1.1 General information

The modular connector hoods with integrated connectors are necessary accessories for

connecting a BPS 34 in a PROFIBUS system. On the MS 34 10x, the PROFIBUS is

connected, the PROFIBUS address set and the BPS 34 supplied with voltage.

MS 34 103

The MS 34 103 offers the following interfaces:

•PROFIBUS incoming DP IN

• PROFIBUS outgoing DP OUT

• Voltage supply PWR IN with switching input and switching output

MS 34 105

In addition to the MS 34 103, the MS 34 105 offers the following interfaces:

• For the MSD modular service display

• M 12 connection for switching input and switching output SW IN/OUT

5.1.2 Technical data of the connection units

Mechanical data

Degree of protection IP 65

Weight 160g

Dimensions (H x W x D) 38 x 90 x 39 mm

Housing Diecast zinc

1) With M12 connectors/caps screwed into place

Leuze electronic BPS 34 23

1)

TNT 35/7-24V

MS 34 … / MSD 1 101 connection units

MS 34 105MS 34 103

A = BPS 34

all dimensions in mm

Note!

The MSD and SW IN/OUT

connections are sealed with caps

upon delivery.

5.1.3 Dimensioned drawings

Figure 5.1:Dimensioned drawing MS 34 103 / MS 34 105

24 BPS 34 Leuze electronic

5.1.4 Electrical connection

Electrical data

Interface type PROFIBUS DP, up to 12MBd

Service interface

1)

RS232 with default data format,

9600Bd, 8 data bits, no parity, 1 stop bit

Switching input / switching

output

1 switching input, 1 switching output, each is programma-

ble

Operating voltage Without optics heating: 10 … 30VDC

With optics heating: 22 … 26 VDC

Power consumption Without optics heating: 5W

With optics heating: max. 30 W

1) Only in combination with the MS 34 105 and MSD 1 101 devices

5.1.5 Description of the LED states

MS 34 103 / MS 34 105

A status LED is located between the M12 connectors DP IN and DP OUT on the modular

connector hood. It indicates the state of the PROFIBUS connection.

State Meaning

Off Voltage off or device not yet recognized by the PROFIBUS

Green, flashing Initialization of the device, establishing the PROFIBUS communication

Green, continuous light Data operation

Red, flashing Error on the PROFIBUS, error can be resolved by a reset of the control

Red, continuous light Error on the PROFIBUS, error cannot be resolved by a reset of the control

Orange, continuous light Service operation active

2) Note: The LED remains off until the BPS 34 is recognized by the PROFIBUS. Only after

the PROFIBUS has addressed the BPS 34 for the first time, the following state descriptions apply.

MS 34 … / MSD 1 101 connection units

2)

TNT 35/7-24V

Leuze electronic BPS 34 25

MS 34 … / MSD 1 101 connection units

5.2 MSD 1 101 modular service display

5.2.1 General information

The modular service display is used to display the calculated positions and operational data

on the one hand, and as simple access to the service interface on the other. The RS 232

service interface of the BPS 34 is located on the 9-pin sub-D connector of the MSD.

To connect the MSD 1 101 to the MS 34 105, an 8-pin cable (M12) with a length of 2m is

used (see chapter 10.3 "Accessories - Modular service display").

Using the service display, new settings for the BPS 34 can be tried quickly and easily,

without having to configure these settings via the PROFIBUS. The settings can be made via

a PC using the BPS Configuration Tool.

Once optimal settings for standard operation have been found, these must be configured in

the PROFIBUS project in order for them to become permanently active.

Note!

The BPS 34, in combination with the MS 34 10x, is equipped with an internal parameter

memory in which all configured settings are stored. When switching back from service operation to PROFIBUS operation, the settings specified in service operation are overwritten by

the settings stored in the control.

Attention!

If parameters are changed that can also be set via the PROFIBUS, they are overwritten with

the parameter setting defined in the PROFIBUS project after PROFIBUS start-up. If device

or module parameters are to be changed permanently, they must be set in the PROFIBUS

project.

26 BPS 34 Leuze electronic

5.2.2 Dimensioned drawing

A LED indicator

B M12 device plug, 8-pin, for connecting to the MS 34 105

MS 34 … / MSD 1 101 connection units

Figure 5.2:MSD 1 101 modular service display

5.2.3 Electrical connection

MSD 1 101

The connection between the MSD 1 101 and the MS 34 105 is established via the readymade cable KB 034 2000. The service interface for connecting a PC is located inside the

MSD 1 101 and is designed as a 9-pin sub-D connector. The pin configuration of the 9-pin

sub-D connector corresponds to a standard RS 232 interface:

• PIN 2 = RxD

• PIN 3 = TxD

• PIN 5 = GND

Leuze electronic BPS 34 27

TNT 35/7-24V

Bar code tape

6 Bar code tape

6.1 General information

The bar code tape (BCB) is delivered on a roll. A roll contains up to 200m of BCB, with the

wrapping direction from the outside to the inside (smallest number on the outside). If a BCB

is ordered which is considerably longer than 200m, the total length is divided into rolls of

200m each (see chapter 10.9 "Type overview: Bar code tape" on Page 98).

Figure 6.1:Roll with bar code tape

Features:

• Robust and durable polyester adhesive tape

• High dimensional stability

• Max. length 10,000 m

• Self-adhesive, high adhesive strength

28 BPS 34 Leuze electronic

6.2 Technical data of the bar code tape

Dimensions

Standard height 47 mm (other heights on request)

Length 0 … 5m, 0 … 10 m, 0 … 20 m, …, 0 … 150 m, 0 … 200m,

special lengths and special codings for lengths from

150m, for details see order guide in Chapter 10.9,

Page 98

Structure

Manufacturing process Filmsetting

Surface protection Polyester, matt

Base material Polyester film, affixed without silicone

Adhesive Acrylate adhesive

Strength of adhesive 0.1mm

Adhesive strength

(average values)

Environmental data

Processing temperature

received

Temperature resistance -40 °C … -120 °C

Dimensional stability No shrinkage, tested according to DIN 30646

Curing Final curing after 72 h, the position can be detected

Heat expansion Due to the high elasticity of the BCB, heat expansion of

Tear resistance 150 N

Elongation at tear Min. 80%, tested in accordance with DIN 50014,

Weathering resistance UV light, humidity,

Chemical resistance

(checked at 23 °C over 24 h)

Behavior in fire Self-extinguishing after 15 s, does not drip

Surface Grease-free, dry, clean, smooth

Table 6.1: Technical data of the bar code tape

On aluminum: 25N/25 mm

On steel: 25N/25mm

On polycarbonate: 22N/25 mm

On polypropylene: 20 N/25mm

0 °C … -45 °C

immediately by the BPS 34 after the BCB is affixed

the base material on which the BCB is affixed is not

known to have an effect

DIN 51220

salt spray fog (150 h/5 %)

Transformer oil, diesel oil, white spirit, heptane,

ethylene glycol (1:1)

Bar code tape

TNT 35/7-24V

Leuze electronic BPS 34 29

Bar code tape

000028 000032 00

Cut mark

Cut mark

Gap

6.3 Mounting the bar code tape

To prevent deposits of dirt from forming, it is recommended that the BCB be affixed vertically, possibly with a roof-like cover. If the application does not permit this, permanent

cleaning of the BCB by on-board cleaning devices such as brushes or sponges is not

permitted in any case. Permanent on-board cleaning devices polish the BCB and give it a

glossy finish. The reading quality deteriorates as a result.

Note!

When mounting the BCB, it must be ensured that neither strong sources of ambient light nor

reflections of the base on which the BCB is affixed occur in the area of the scanning beam.

The recommended interruption points on the BCB are at the provided cut marks.

Figure 6.2:Cut mark on the bar code tape

Note!

Cutting the BCB and affixing the tape so that a gap forms which is so large that a label can

no longer be reliably detected in the scanning beam results in double positions during the

position calculation of the BPS. The gap must not be greater than the distance from one cut

mark to the next (max. one label).

max. 40 mm

000020 000024 000028 000032 000036

Figure 6.3:Gap in the cut bar code tape

30 BPS 34 Leuze electronic

Bar code tape

Procedure:

• Check the surface. It must be flat, without warping, free of grease and dust, and dry.

• Define a reference edge (e.g. metal edge of the busbar)

• Remove the backing and affix the BCB along the reference edge tension free.

Secure the bar code tape to the mounting surface by pressing down with the palm of

your hand. When affixing, make certain that the BCB is free of folds and creases and

that no air pockets form.

• Never pull the BCB. Because this is a plastic tape, forceful pulling may stretch it. This

results in a distortion of the measurement units on the tape. While the BPS 34 can

still perform the position calculation, the accuracy in this case is no longer ensured. If

the values are taught using a teach-in process, distortions are irrelevant.

• Expansion joints with widths up to several millimeters can simply be covered with the

bar code tape. The tape must not be interrupted at this spot.

• Protruding screw heads can simply be taped over. Cut out the bar code which covers

the screw head at the cut marks.

• If the application dictates the necessity of a gap, the tape is to be affixed over this gap

and the affected cut marks cut out. If the gap is small enough that the scanning beam

can detect the label to the left or to the right of the gap, measurement values are

delivered without interruption. If the scanning beam cannot completely scan any label,

the BPS 34 returns the value 0. As soon as the BPS 34 can again scan a complete

label, it calculates the next position value.

• The maximum gap between two bar code positions without affecting the measurement value is 40mm.

Note!

If the bar code tape was damaged, e.g. by falling parts, a repair kit can be downloaded from

the Internet (www.leuze.com).

Attention!

Bar code tapes with different value ranges may not directly follow one another. If the value

ranges are different, the gap between the two BCBs must be greater than the detection

range of the scanning beam or control bar codes must be used (for further information, see

also Chapter 6.4 on Page 33).

Note!

When working with the BCB in cold warehouses, it should be ensured that the BCB be

affixed before the warehouse is cooled. However, if it should be necessary to work with the

BCB at temperatures outside of the specified processing temperature, please make sure

that the bonding surface as well as the BCB are at processing temperature.

Note!

When working with BCB in curves, the BCB should only be partially cut at the cut mark and

affixed along the curve like a fan; it must also be ensured that the BCB is affixed without tension (see Figure 6.4).

Leuze electronic BPS 34 31

TNT 35/7-24V

Bar code tape

007000

0

0

7

0

0

4

0

0

7

0

0

8

0

0

7

0

1

2

Figure 6.4:Partial cutting of the bar code tape in curves

32 BPS 34 Leuze electronic

6.4 Control bar codes

The control bar code is decoded in

the marked scans

Control bar code

With the aid of control bar codes, which are simply affixed over the bar code tape at the

necessary positions, functions can be activated and deactivated in the BPS 34.

Structure of the control bar codes

The control bar codes utilize code type Code128 with character set B; the position bar

codes, on the other hand, utilize Code128 with character set C. Code 128 with character set

B enables the display of all letters and numbers in the ASCII character set.

System arrangement

Bar code tape

Figure 6.5:System arrangement of control bar codes

The control bar code is affixed either within one or between two bar code tapes in such a

way that one position bar code is replaced or two bar code tapes are seamlessly connected

to one another.

Attention!

It must be ensured that only one control bar code is located in the scanning beam at any one

time. Thus, the minimum distance between two control bar codes is determined by the distance between the BPS and bar code tape and the resulting length of the scanning beam.

Leuze electronic BPS 34 33

TNT 35/7-24V

Bar code tape

Control bar code

correctly affixed on the

bar code tape

Control bar code

incorrectly affixed on

the bar code tape

For error-free function, when using control bar codes it must absolutely be ensured that the

distance between the BPS and bar code tape is selected large enough. The scanning beam

of the BPS should cover three or more bar codes; this is ensured at a distance which lies in

the working range of the reading field curve.

The control bar codes are simply affixed over the existing tape. When affixing the control bar

codes, make certain to cover entire bar codes to ensure that a bar code spacing of 4cm is

maintained.

Figure 6.6:Correct positioning of the control bar code

6.4.1 Controllable functions

Measurement value switching between 2 bar code tapes with different value

ranges

The "MVS" control bar code is used to switch between two bar code tapes. The end of one

tape and the start of the next can end and begin, respectively, with completely different position bar codes. If the center of the BPS 34 reaches the transition point of the control bar

code, the device switches to the second tape, provided the next position label is in its scanning beam. As a result, the output position can always be uniquely associated with one tape.

34 BPS 34 Leuze electronic

Bar code tape

SM1

MVS

8500

1808

BPS center

+ hysteresis

±5mm

Center of

control label

Scanning

beam

Direction of movement

Measurements

Position values

Figure 6.7:"MVS" control bar code for switching between tapes

Use of the "MVS" control bar code for switching between tapes is not dependent on direction. This means that it functions for switching from tape 1 to tape 2 and vice versa.

Figure 6.8:Switching position with the "MVS" control bar code

If the "MVS" label is passed over, the new tape value is always output relative to the center

of the device or label (see Figure 6.8). In this situation, the hysteresis of ±5mm is irrelevant.

If, however, the device is stopped within the hysteresis on the "MVS" label and the direction

changed, the starting position values have an inaccuracy ±5mm.

Leuze electronic BPS 34 35

TNT 35/7-24V

Bar code tape

Note!

When affixing the BCB in a system in which the end of one BCB meets the start of another

BCB (position value X with position value 0), ensure that position labels 0 - 20 are not used.

This means that position label 24 must be the first label used on the continuing bar code

tape.

Note!

If only the "MVS" label is read within the scanning beam, the scanning beam must not be

interrupted during the read operation until the scanner can again read a complete position

label.

If only the "MVS" label is located in the scanning beam, the voltage on the BPS 34 must not

be switched off. Otherwise the BPS 34 will return a position value of zero when the voltage

is switched back on.

Moreover, the scanner must not be configured while in this position. Otherwise, a value of

zero is output as long as no position label is present in the scanning beam due to the fact

that the scanning beam is switched off during configuration.

6.5 Repair kit

Note!

If the bar code tape was damaged, e.g. by falling parts, a repair kit can be downloaded from

the Internet (www.leuze.com).

In these files you will find all code information for a tape with the length of 500 m within the

range of 0 … 9999.96m. 1 m of bar code tape is provided on each A4 sheet. Each meter is

divided into 5 lines of 20 cm, each with 5 code segments of information covering lengths

of 4cm each.

Procedure when replacing the defective area:

1. Determine the coding of the defective area.

2. Print out the area determined to be defective

3. Affix the printed area over the defective location

36 BPS 34 Leuze electronic

Bar code tape

000020 000024 000028 000032 000036

40 mm

Important note for printing:

1. Select only those pages that are required.

2. Change the printer settings so that the code is not distorted.

Suggestion for printer settings, see Figure 6.9.

3. Verify the printing result by measuring the distance between two codes (see

Figure 6.10).

4. Cut the code strips and concatenate them. It is important that the code content

always increases or decreases in blocks of 4 cm.

Figure 6.9:Printer settings for BCB repair kit

Figure 6.10:Checking the print results of the BCB repair kit

Leuze electronic BPS 34 37

TNT 35/7-24V

Mounting

Laser-beam exit

window

4x M4 mounting threads on the

rear of the device

15-pin sub-D

connector on the

bottom of the device

Dovetail

fastening grooves

7 Mounting

7.1 Mounting the BPS 34

There are 2 different types of mounting arrangements for the BPS 34:

• Using 4 M4x6 screws on the rear of the device.

• Using the BT 56 mounting device on the fastening grooves.

Figure 7.1:BPS 34 mounting options

BT 56 mounting device

The BT 56 mounting device is available for mounting the BPS 34 using the fastening

grooves. It is designed for rod mounting (Ø 16mm to 20 mm). For order guide, please refer

to Chapter 10.6 on Page 95.

38 BPS 34 Leuze electronic

Clamping jaws for

mounting on the BPS

Clamp profile for

mounting to round or

oval pipes

Ø16…20mm

A Rod holder, turnable 360°

B Rods Ø 16 … 20mm

all dimensions in mm

Mounting

Figure 7.2:BT 56 mounting device

Leuze electronic BPS 34 39

TNT 35/7-24V

Mounting

BPS 34

BT 56

mounting device

Modular connector hood

MS 34 103 or

MS 34 105

Modular service display

MSD 1 101

Mounting example BPS 34

Figure 7.3:Mounting example BPS 34

Note!

During mounting, the following angles of inclination must be taken into account in the vertical

axis:

10° for a tape height of 47mm,

7° for a tape height of 30mm and

5° for a tape height of 25mm;

the working range of the reading field curve must also be taken into account.

Attention!

For the position calculation, the scanning beam of the BPS 34 must be incident on the bar

code tape without interruption. Ensure that the scanning beam is always incident on the bar

code tape when the system is moving.

40 BPS 34 Leuze electronic

7.2 Device arrangement

000200

000216

000204

000208

000212

0

103 ± 2

X

10˚

Reading distance

Beam exit

all dimensions in mm

Bar code tape

Center of the scanning beam

(device center, output position value)

Scanning beam

10° pitch

in the

vertical axis

(dependent on

the tape height,

see notes)

Selecting a mounting location

In order to select the right mounting location, several factors must be considered:

• The scanning range determined from the scanning curve must be adhered to at all

areas at which a position determination is to be made

• The BPS should be mounted at an angle of 10° (depending on the tape height, see

note Page 40) in the vertical axis towards the bar code tape to ensure continued reliable positioning results even the bar code tape is soiled.

• On the BPS 34, the beam is not emitted perpendicular to the cover of the housing, but

with an angle of 10° towards the top. This angle is intended to prevent total reflection

on the bar code tape. This beam exit is already integrated in the device. As a result,

the BPS can be at the minimum reading distance and mounted parallel to the bar

code tape.

Mounting

1

Figure 7.4:Beam exit and device arrangement of the BPS 34

Dimension X in Figure 7.4 shows the mounting height of the BCB center relative to the

housing of the BPS 34. Dimension X is dependent on the reading distance. Please refer to

the following table for the value:

Reading distance

[mm]

90 16 120 21 150 26

100 18 130 23 160 28

110 19 140 25 170 30

Dim. X [mm]

Reading distance

[mm]

Dim. X [mm]

Reading distance

[mm]

Dim. X [mm]

Leuze electronic BPS 34 41

TNT 35/7-24V

Mounting

Note!

The best functionality is obtained when:

Mounting location

When choosing the mounting location, observe the following:

Mounting outdoors/devices with integrated heating

When mounting outdoors or for devices with integrated heating, also observe the following

points:

Note!

When installing the BPS 34 in a protective housing, it must be ensured that the scanning

beam can exit the protective housing without obstruction.

• the BPS is guided parallel to the tape.

• the permitted working range is not exited.

• maintaining the required environmental conditions (humidity, temperature),

• possible soiling of the reading window due to liquids, abrasion by boxes, or packaging

material residues.

• mount the BPS 34 in a way which provides maximum thermal isolation, e.g. using

rubber-bonded metal.

• mount in such a way that the device is protected from relative wind; mount additional

shields if necessary.

7.3 Mounting the bar code tape

The BPS 34 and bar code tape combination is mounted in such a way that the scanning

beam is uninterrupted and is incident on the bar code tape as described in Figure 7.4 on

Page 41.

Note!

For further information on mounting the bar code tape, please refer to Chapter 6.3 on

Page 30.

42 BPS 34 Leuze electronic

Device parameters and interfaces

Socket

(A-coded)

Socket

(A-coded)

Socket

(B-coded)

Plug

(B-coded)

Plug

(A-coded)

8 Device parameters and interfaces

8.1 PROFIBUS

8.1.1 General information

The BPS 34 with MS 34 103/MS 34 105 is designed as a PROFIBUS device (PROFIBUS

DP-V0 acc. to IEC 61784-1) with a baud rate of 12MBd. The functionality of the device is

defined via parameter sets which are clustered in modules. These modules are contained in

a GSD file. The GSD file can be downloaded from the Leuze homepage at www.leuze.com.

By using an application-specific configuration tool, such as, e.g. Simatic Manager for the

Siemens PLC, the required modules are integrated into a project during commissioning and

its settings and parameters are configured accordingly. These modules are provided by the

GSD file.

All input and output modules described in this documentation are described from the viewpoint of the control:

• Input data arrives at the control

• Output data is sent out by the control.

8.1.2 Electrical connection

SW IN/OUT

VOUT

VCC

1

SWOUT

1

SWIN

2

GND

3

4

PE

PWR IN

SWOUT

3

GND VIN

PE

SWIN

2

4

VCC

DP OUT

A (N)

2

1

4

B (P)

/INT

/SERV

GND

3

PE

GND

VIN

1

7

MSD

2

6

SDA

TXD

3

4

5

GND

RXD

SCL

3

PE

DP IN

A (N)

2

4

B (P)

Figure 8.1:Electrical connection of PROFIBUS connections DP IN and DP OUT

Leuze electronic BPS 34 43

TNT 35/7-24V

1

Device parameters and interfaces

M12 plug

(B-coded)

M12 socket

(B-coded)

DP IN - PROFIBUS DP incoming

DP IN (5-pin plug, B-coded)

DP IN

A (N)

2

GND

3

PE

4

B (P)

VCC

1

Figure 8.2:Pin assignment - DP IN

DP OUT - PROFIBUS DP outgoing

DP OUT

A (N)

2

4

B (P)

GND

3

PE

VCC

1

Pin Name Comment

1VCC5VDC for bus termination

2A (N)Receive/transmit data A-line (N)

3GNDFunctional earth for bus termination

4B (P)Receive/transmit data B-line (P)

5PEFunctional earth

Thread PE Functional earth (housing)

DPOUT (5-pin socket, B-coded)

Pin Name Comment

1VCC5VDC for bus termination

2A (N)Receive/transmit data A-line (N)

3GNDFunctional earth for bus termination

4B (P)Receive/transmit data B-line (P)

5PEFunctional earth

Thread PE Functional earth (housing)

Figure 8.3:Pin assignment - DP IN

Attention!

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into

place!

44 BPS 34 Leuze electronic

Device parameters and interfaces

Note!

For connecting DP IN and DP OUT, we recommend our ready-made PROFIBUS cables.

For further information on this topic, refer to Chapter 10.8 on Page 97.

The BPS 34 can be used in combination with an MS 34 103/MS 34 105 to branch out the

PROFIBUS network. The continuing network is connected via DP OUT.

If the PROFIBUS is not connected to another participant via the MS 34 10x, the DP OUT

connection must be fitted with a TS 02-4-SA terminator plug for the purpose of bus termination. For further information, see also Chapter 10.4 on Page 95.

Attention!

Never open the device yourself, as this may compromise degree of protection IP 65.

Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

Connection of the device and cleaning must only be carried out by a qualified electrician.

The power supply unit for the generation of the supply voltage for the BPS 34 and the

respective connection units must have a secure electrical insulation through double insulation and safety transformers according to EN 60742 (corresponds to IEC 60742).

Be sure that the protective conductor is connected correctly. Fault-free operation is only

guaranteed when the device is properly earthed.

If faults cannot be cleared, the device should be switched off and protected against accidental use.

To then further isolate the error, proceed as described in Chapter 9 on Page 93.

Leuze electronic BPS 34 45

TNT 35/7-24V

Device parameters and interfaces

Slide switch for the hundreds (marked with 102)

Rotary switch for the tens (marked with 10

1

)

Rotary switch for the single digits (marked with 10

0

)

Connection plug to the BPS 34

Position of the slide

switches:

Top address

100 - 126

Bottom address

1 - 99

8.1.3 PROFIBUS address

In the MS 34 103 and MS 34 105 modular connector hoods, the PROFIBUS address can be

set via two rotary switches and one slide switch.

The configuration and function of the address switches is shown in Figure 8.4.

Figure 8.4:Setting the PROFIBUS address in the MS 34 103/MS 34 105

8.1.4 General information on the GSD file

You can find the GSD file at www.leuze.com.

This file stores all the data required for the operation of the BPS 34. This data consists of

device parameters required for the operation of the BPS 34 and the definition of the control

and status bits. If parameters are changed in the project tool, for example, these changes

are stored in the project, not in the GSD file.

The GSD file is part of the device and must not be changed manually. The file is not changed

by the system either.

If the BPS 34 is operated in a PROFIBUS network, configuration must be performed exclusively via the PROFIBUS. The functionality of the BPS 34 is defined via parameter sets. The

parameters and their functions are structured in the GSD file using modules. A user-specific

configuration tool is used during PLC program creation to integrate the required modules

and configure them appropriately for their respective use.

During operation of the BPS 34 on the PROFIBUS, all parameters are set to default values.

If these parameters are not changed by the user, the device functions with the default

settings delivered by Leuze electronic. For the default settings of the BPS 34, please refer

to the following module descriptions.

Note!

A least one module in the GSD file must be activated in the configuration tool for the control,

usually the "Position value" module 1.

46 BPS 34 Leuze electronic

Note!

Some controls make available a so-called "universal module". This module must not be activated for the laser.

Attention!

The BPS 34 does not permanently store parameters changed via the PROFIBUS. Following

Power off/on, the currently configured parameters are downloaded from the PROFIBUS

manager. If no PROFIBUS manager is available following Power off/on, the BPS 34 activates its stored default settings.

8.1.5 Structure of the GSD modules

In the current version, a total of 27 modules are available for use. The modules may be

included into the project according to requirements and application.

The modules fall into the following categories:

• Parameter module for the configuration of the BPS 34.

• Status or control modules that influence the input/output data.

• Modules that may include both parameters and control or status information.

Note!

All input and output modules described in this documentation are described from the

viewpoint of the control:

Inputs (I) described are inputs of the control.

Outputs (O) described are outputs of the control.

Parameters (P) described are parameters of the GSD file in the control.

Device parameters and interfaces

Note!

At least one module must be activated to permit operation of the device at the PROFIBUS

DP.

Note!

Under some circumstances, not all 27 modules can be activated simultaneously in the configuration tool. Otherwise, the available memory for a participant may be exceeded. The

maximum available memory for a device is control dependent.

Leuze electronic BPS 34 47

TNT 35/7-24V

Device parameters and interfaces

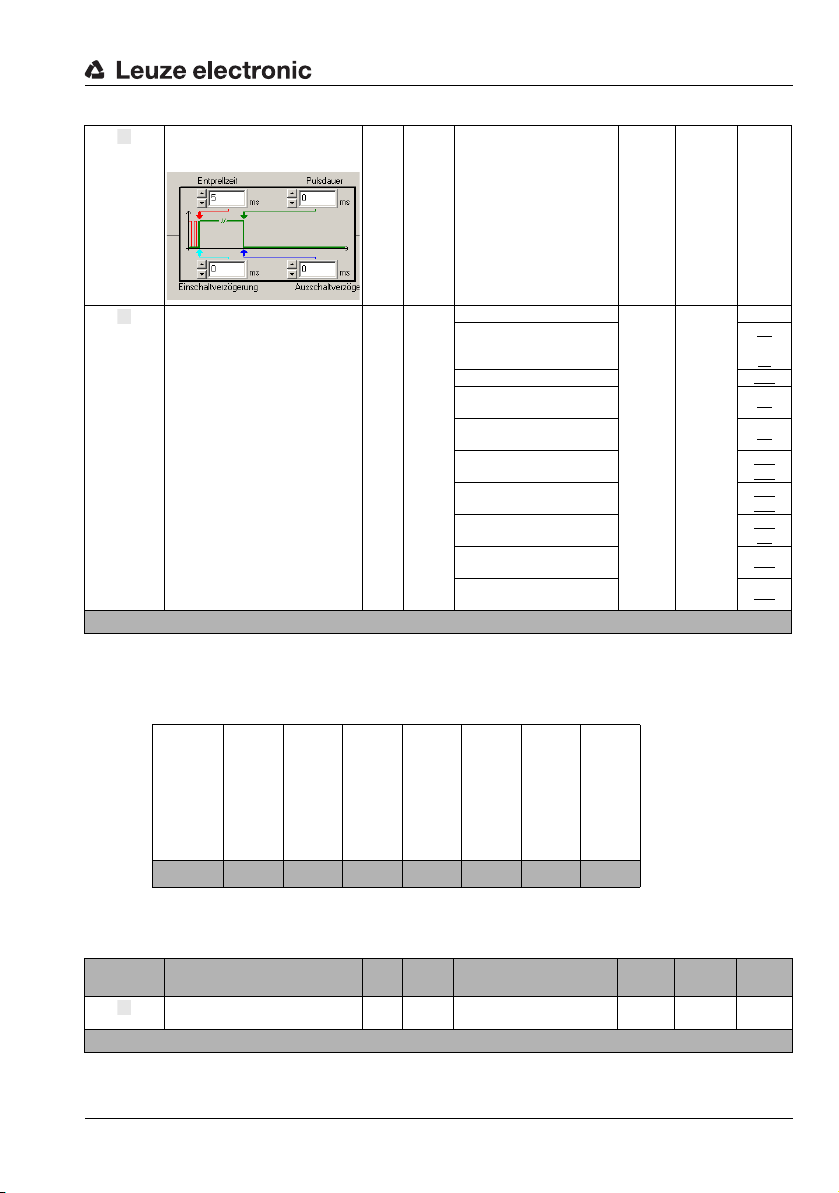

8.1.6 Overview of the GSD modules

Note!

Inputs and outputs are described from the viewpoint of the PROFIBUS master.

Module

Page

M1

Page 5 2

M2

Page 5 3

M3

Page 5 4

M4

Page 5 6

M5

Page 5 7

M6

Page 5 8

M7

Page 6 0

M8

Page 6 2

M9

Page 6 4

M10

Page 6 6

M11

Page 6 7

Module name Module contents

(P) = Parameter, (O) = Output, (I) = Input

Position value

(P) Sign

(I) Position value

Resolution (P) Resolution for the position value

(P) Preset value added to tape value

Static preset

(O) Preset teach

(O) Preset reset

(O) Preset teach

Dynamic preset

(O) Preset reset

(O) Preset value

Offset value (P) Offset value

Scaling (P) Scaling factor

(P) Inversion

(P) Mode

(P) Debounce time

Switching input

(P) start-up delay

(P) Pulse duration

(P) Switch-off delay

(P) Function

(I) State

(P) Bias level

(P) Selection of the speed limit value

Switching output

(P) Pulse duration

(P) Switch-on function

(P) Switch-off function

(O) Switching output "PROFIBUS edge"

(P) Measurement start mode

(P) Measurement stop mode

(P) Stop timeout

Control

(I) Position control state

(O) Start event

(O) Stop event

(O) BPS standby

Measurement value

acquisition

Measurement value

preparation

(P) Maximum permitted measurement length

(P) Minimum permitted measurement length

(P) Integration depth

(O) Counting direction for position calculation

48 BPS 34 Leuze electronic

Device parameters and interfaces

Module

Page

M12

Page 7 0

M13

Page 7 1

M14

Page 7 3

M15

Page 7 4

M16

Page 7 5

M17

Page 7 6

M18

Page 7 7

M19

Page 7 8

M20

Page 7 9

M21

Page 8 0

Module name Module contents

(P) = Parameter, (O) = Output, (I) = Input

(I) Measurement error

(I) Range state (outside of measurement range)

(I) Preset active

Status

(I) Dynamic preset teach

(I) State

(I) Position limit value status 1

(I) Position limit value status 2

(I) Standby status

(P) Min./max. mode

(P) Min./max. duration

Min./max. position

(I) Min. position

(I) Max. position

(O) Min./max. reset

(P) Limit value check on/off

Static position limit

value 1

(P) Switching type (value is above or below the

defined limits)

(P) Hysteresis

(P) Limit value

(P) Limit value check on/off

Static position limit

value 2

(P) Switching type (value is above or below the

defined limits)

(P) Hysteresis

(P) Limit value

(P) Limit value check on/off

Dynamic position limit

value 1

(P) Switching type (value is above or below the

defined limits)

(P) Hysteresis

(O) Limit value

(P) Limit value check on/off

Dynamic position limit

value 2

(P) Switching type (value is above or below the

defined limits)

(P) Hysteresis

(O) Limit value

Measurement error tol-

erance

Service

(P) Position tolerance time

(P) Error output delay

(I) Status

(O) Reset to factory settings

Speed (I) Current speed

(P) Resolution

(P) Scaling factor

Speed parameters

(P) Integration depth

(P) Tolerance time (on error message)

(P) Error output delay

TNT 35/7-24V

Leuze electronic BPS 34 49

Device parameters and interfaces

Module

Page

Module name Module contents

(P) Speed measurement start mode

(P) Speed measurement stop mode

M22

Page 8 2

Speed

measurement

control

(I) Speed measurement state

(O) Start event

(O) Stop event

(O) Min./max. speed mode

(O) Min./max. speed reset

(I) Measurement error

(I) Limit value status 1 exceeded

(I) Limit value status 2 exceeded

(I) Limit value status 3 exceeded

(I) Limit value status 4 exceeded

M23

Page 8 4

Speed

measurement

status

(I) Dynamic limit value status exceeded

(I) Movement status

(I) Direction of movement

(I) Compare limit value state 1

(I) Compare limit value state 2

(I) Compare limit value state 3

(I) Compare limit value state 4

(I) Compare dynamic limit value state

M24

Page 8 6

Min./max.

speed

(I) Minimum speed

(I) Maximum speed

(P) Speed limit value mode (active/not active)

(P) Direction selection (both directions or only one)

(P) Switching type (value is above or below the

Static speed limit values

M25

Page 8 7

(for limit value 1 … 4)

defined limits)

(P) Speed limit value

(P) Hysteresis

(P) Range start

(P) Range end

(O) Limit value control

(O) Switching type (value is above or below the

defined limits)

(O) Direction selection

(O) Limit value

(O) Hysteresis

M26

Page 8 9

Dynamic

speed

limit values

(O) Range start

(O) Range end

M27

Page 9 1

Tape value correction

(P) Real length

(P) Range start

(P) Range end

Table 8.1: Overview of the GSD modules

(P) = Parameter, (O) = Output, (I) = Input

50 BPS 34 Leuze electronic

8.1.7 Detailed description of the modules

a

zacgb

Note!

In the following detailed descriptions of the modules, you will find in the last column of the

tables cross references (CR) to parameters and input/output data of other modules

which are directly related to the described parameter. These cross references must be

observed during configuration.

The individual modules are numbered from 1…27.

The parameters and input/output data within a module are alphanumerically labeled

from … .

Example:

The Static preset value in [mm] parameter in module 3 only becomes active when the

preset teach occurs via module 12 , 7 or 3

Device parameters and interfaces

.

TNT 35/7-24V

Leuze electronic BPS 34 51

Device parameters and interfaces

a

b

8.1.7.1 Module 1: Position value

Description:

With this module, the current position value is output.

Note!

The position value is the position value calculated from the tape value and the settings for

resolution, preset and offset.

Parameters