Page 1

BPS 307i

Bar Code Positioning System

EN 2018/01 - 50127000

We reserve the right to

make technical changes

Original operating instructions

Page 2

© 2018

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic BPS 307i 2

Page 3

1 About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Laser warning notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

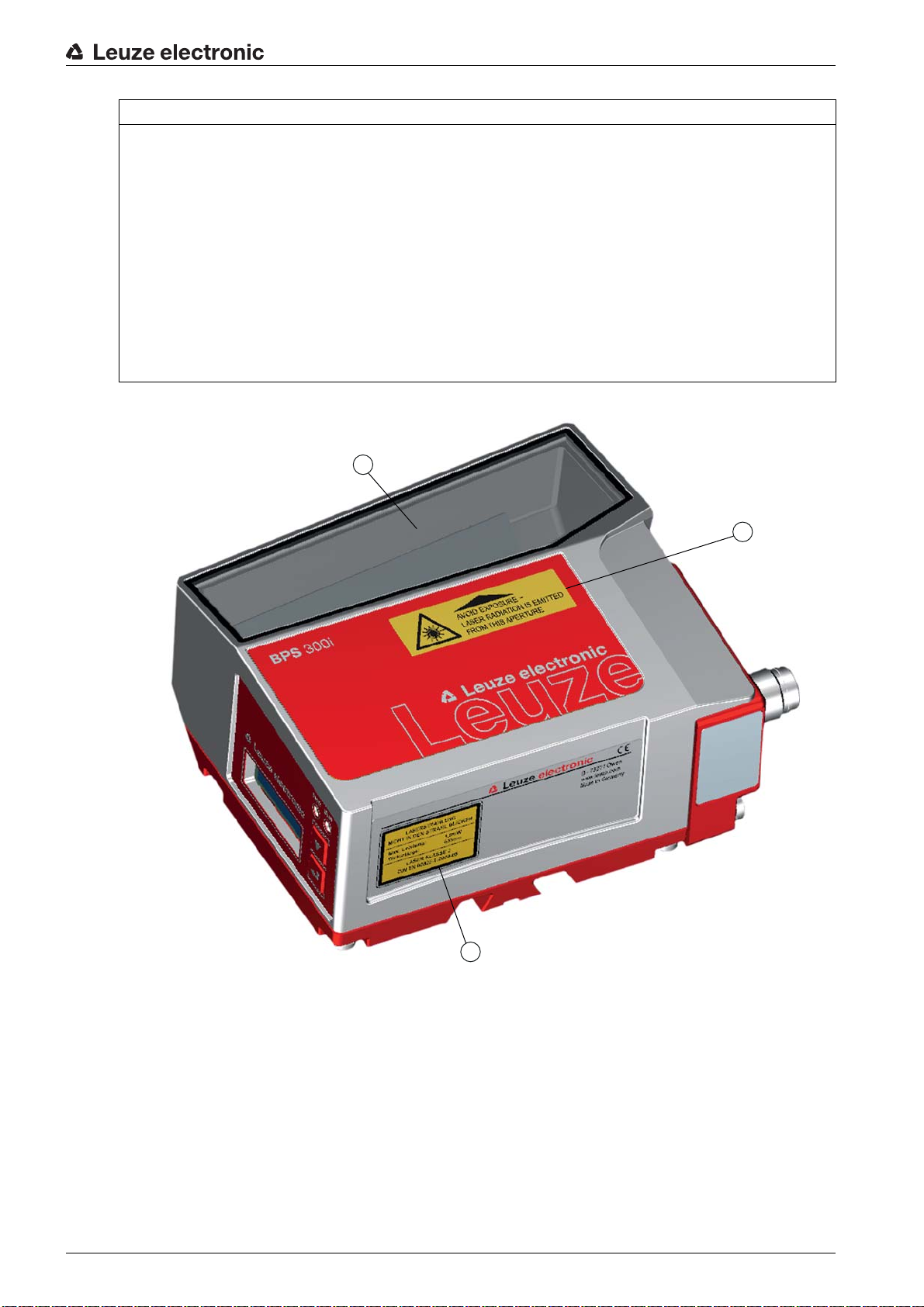

3.1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.4 Device model with heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 MS 307 connection hood with M12 connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 MK 307 connection hood with spring-cage terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3 KB 307 connection hood with cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Display indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Bar code tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4.2 Control bar codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4.3 Marker labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.4 Twin tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Position measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Speed measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4 Leuze webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5 Evaluation of the reading quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.6 Distance measurement to the bar code tape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 High-bay storage device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Telpher line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Gantry cranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 Mounting and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 Mounting bar code tape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1.1 Installation and application remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1.2 Cutting bar code tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.1.3 Mounting the BCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Bar code positioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.1 Mounting instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.2 Orientation of the BPS to the bar code tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.3 Mounting with the BTU 0300M-W mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.4 Mounting with the BT 300 W mounting bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.5 Mounting with BT 56 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.6 Mounting with BT 300-1 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Leuze electronic BPS 307i 3

Page 4

6.2.7 Mounting with M4 fastening screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 External parameter memory in the connection hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 MS 307 connection hood with connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 MK 307 connection hood with spring-cage terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.4 KB 307 connection hood with cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.5 Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.5.1 PWR / SW IN/OUT (Power and switching input/output) . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.5.2 SSI (HOST / BUS IN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.5.3 SSI connection cable KB 307 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.5.4 Service USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.6 Cable lengths and shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Basic configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1 Configuring the SSI interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1.1 Principal functionality of the SSI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1.2 Setting the configuration of the SSI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2 Configuring the switching inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.3 Configuring the resolution for the position value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.4 Configuring speed monitoring with switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5 Setting tape selection via the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.6 Configuration via the switches of the connection hood . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.7 Setting configuration parameters to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.8 Key factory settings of the BPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9 Leuze electronic webConfig tool – Extended configuration . . . . . . . . . . . . . . . . 58

9.1 Installing software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1.2 Install USB driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.2 Start webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.3 Short description of the webConfig tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3.2

CONFIGURATION

9.3.3

ALIGNMENT

PROCESS

9.3.4

9.3.5

DIAGNOSTICS

9.3.6

MAINTENANCE

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.1 What to do in case of failure? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.1.1Diagnostics with webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.2 Operating indicators of the LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.3 Error messages on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.4 Checklist for causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11 Care, maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.2.1Firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.2.2BCB repair with repair kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.3 Disposing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Leuze electronic BPS 307i 4

Page 5

12 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.1 What to do should servicing be required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.1 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.1.1BPS without heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.1.2BPS with heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.2 Bar code tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

13.3 Dimensioned drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.4 Dimensioned drawings: Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13.5 Dimensioned drawing bar code tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

14 Order guide and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.1 BPS 307i type overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.2 Connection hoods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.3 Cables accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.4 Other accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

14.5 Bar code tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

15 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

16 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

16.1 BCB bar code tape with 40 mm grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

16.2 Bar code tape BCB8 with 30 mm grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Leuze electronic BPS 307i 5

Page 6

1 About this document

1.1 Used symbols and signal words

Table 1.1: Warning symbols and signal words

Symbol indicating dangers to persons

Symbol indicating dangers from harmful laser radiation

NOTE Signal word for property damage

Indicates dangers that may result in property damage if the measures for

danger avoidance are not followed.

Table 1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

About this document

Table 1.3: Terms and abbreviations

BCB Bar code tape (general or specific BCB type with 40 mm grid)

BCB8 Bar code tape (BCB type with 30 mm grid)

BPS Bar code Positioning System

CFR Code of Federal Regulations

DAP Device Access Point

DCP Discovery and Configuration Protocol

EMC Electromagnetic compatibility

EN European standard

FE Functional earth

GSD General Station Description

GSDML Generic Station Description Markup Language

Symbol for action steps

Text passages with this symbol instruct you to perform actions.

GUI Graphical User Interface

IO or I/O Input/Output

I&M Information & Maintenance

IP Internet Protocol

LED Light Emitting Diode

MAC Media Access Control

MVS Type of control bar code

MV0 Type of control bar code

Leuze electronic BPS 307i 6

Page 7

NEC National Electric Code

OSI Open Systems Interconnection model

PELV Protective Extra-Low Voltage

RT Real Time

SNMP Simple Network Management Protocol

PLC Programmable Logic Control

Programmable Logic Control

SSI Synchronous Serial Interface

(Digital Synchronous Serial Interface)

TCP Transmission Control Protocol

UDP User Datagram Protocol

USB Universal Serial Bus

UL Underwriters Laboratories

About this document

UV Ultraviolet

XML Extensible Markup Language

Leuze electronic BPS 307i 7

Page 8

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The device is an optical measuring system which uses visible red laser light to determine its position relative to a permanently mounted bar code tape.

All accuracy details for the BPS 300 measurement system refer to the position relative to the permanently

mounted bar code tape.

Areas of application

The BPS is designed for positioning in the following areas of application:

• Telpher line

• Travel and lifting axes of high-bay storage devices

• Repositioning units

• Gantry crane bridges and their trolleys

•Elevators

CAUTION

Observe intended use!

Only operate the device in accordance with its intended use.

The protection of personnel and the device cannot be guaranteed if the device is operated in a manner

not complying with its intended use.

Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use.

Read the operating instructions before commissioning the device.

Knowledge of the operating instructions is an element of proper use.

Safety

NOTICE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability insurance asso-

ciation.

2.2 Foreseeable misuse

Any use other than that defined under “Intended use” or which goes beyond that use is considered

improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• for medical purposes

• as own safety component in accordance with the machinery directive

Use as safety-related component within the safety function is possible, if the component combi-

nation is designed correspondingly by the machine manufacturer.

NOTICE

Do not modify or otherwise interfere with the device!

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Leuze electronic BPS 307i 8

Page 9

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the original operating instructions of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant stan-

dards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations DGUV

(German Social Accident Insurance) provision 3 (e.g. electrician foreman). In other countries, there are

respective regulations that must be observed.

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

Safety

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser warning notices

ATTENTION, LASER RADIATION – LASERCLASS2

Never look directly into the beam!

The device satisfies the requirements of IEC 60825-1:2007 (EN 60825-1:2007) safety regulations for a

product of laser class 2 as well as the U.S. 21 CFR 1040.10 regulations with deviations corresponding

to “Laser Notice No. 50” from June 24, 2007.

Never look directly into the laser beam or in the direction of reflected laser beams!

If you look into the beam path over a longer time period, there is a risk of injury to the retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser beam is accidentally

directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflective surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here or carrying out

of differing procedures may lead to dangerous exposure to radiation.

Observe the applicable statutory and local laser protection regulations.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Leuze electronic BPS 307i 9

Page 10

Safety

2

1

3

NOTICE

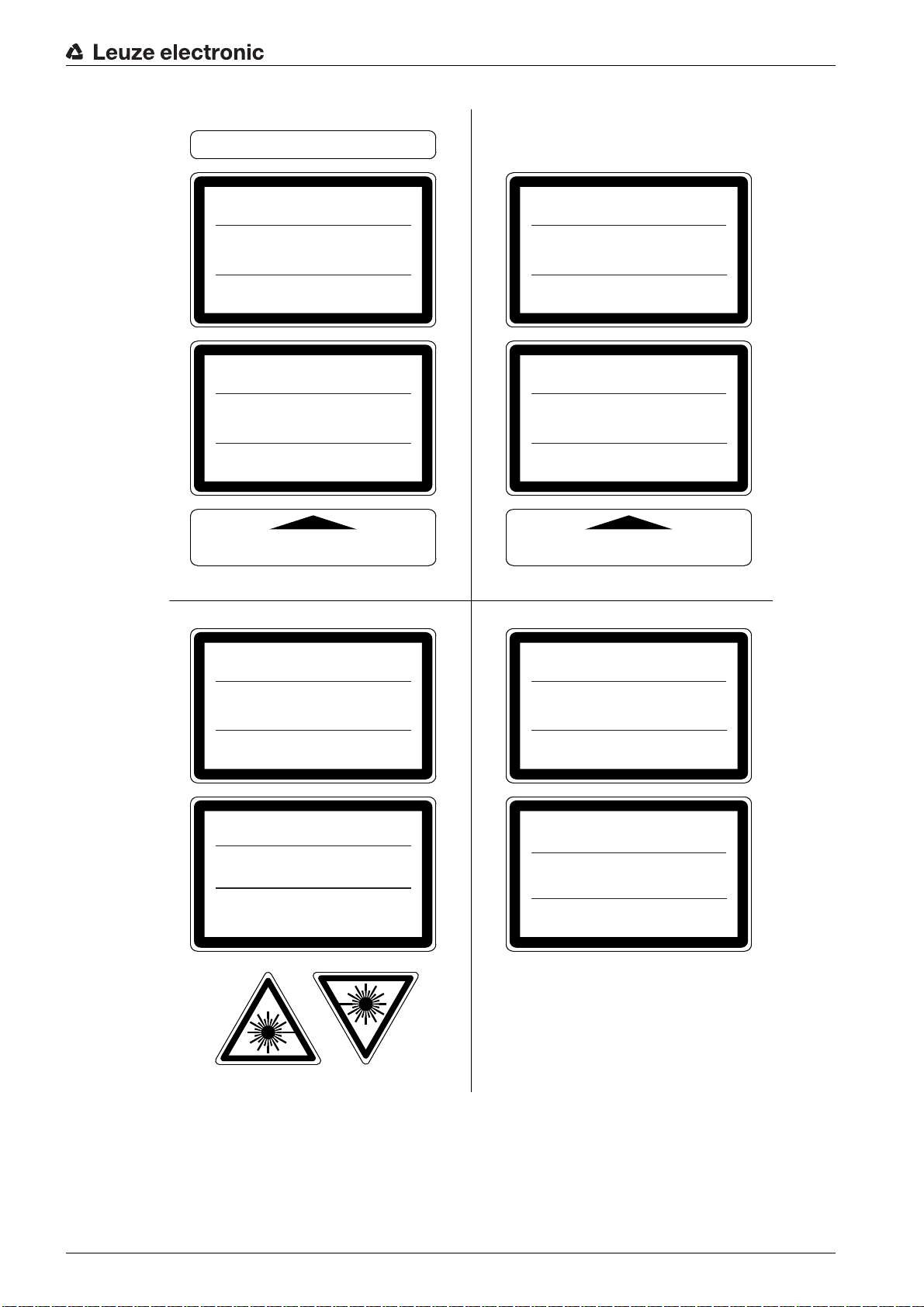

Affix laser information and warning signs!

Laser information and warning signs attached to the device (see figure 2.1). Also included with the device

are self-adhesive laser warning and laser information signs (stick-on labels) in multiple languages (see

figure 2.2).

Affix the laser information sheet to the device in the language appropriate for the place of use.

When using the device in the U.S.A., use the stick-on label with the “Complies with 21 CFR 1040.10”

notice.

Affix the laser information and warning signs near the device if no signs are attached to the device (e.g.

because the device is too small) or if the attached laser information and warning signs are concealed

due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing the reader to the

laser radiation of the device or other optical radiation.

1 Laser aperture

2 Laser warning sign

3 Laser information sign with laser parameters

Figure 2.1: Laser aperture, laser warning and information signs

Leuze electronic BPS 307i 10

Page 11

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER

NON FISSARE IL FASCIO

APARRECCHIO LASER DI CLASSE 2

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

PRODUCTO LÁSER DE CLASE 2

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

EQUIPAMENTO LASER CLASSE 2

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (avg):

Pulse duration:

Wavelength:

䉏⏘戟⺓

▎䦃展⏘㧮

伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

1,8 mW

<150 µs

655 nm

1,8 mW

<150 µs

655 nm

1.8 mW

<150 µs

655 nm

1,8 mW

<150

µ

s

655 nm

1,8 mW

<150 µs

655 nm

1,8 mW

<150 µs

655 nm

<1 mW

<150 µs

655 nm

1.8 mW

<150 µs

655 nm

50120562-02

Safety

Figure 2.2: Laser warning and information signs – supplied stick-on labels

Leuze electronic BPS 307i 11

Page 12

3 Device description

000040 000044 000048 000052 000056

000060 000064 000068

4

0000480000

0000556

1

2

4

3

3.1 Device overview

3.1.1 General information

The BPS bar code positioning system uses visible red laser light to determine its position and its speed

value relative to a bar code tape that is affixed along the travel path. This takes place in the following steps:

• Read a code on the bar code tape (see figure 3.1)

• Determine the position of the read code in the scanning beam

• Calculate the position to within less than a millimeter using the code information and the code position relative to the device's center.

The position and speed values are then output to the controller via the host interface.

The BPS consists of device housing and interface connection hood for the connection to the control. The

BPS can optionally be delivered with display and optics heating.

The following connection hoods are available for the connection of the SSI interface:

• MS 307 connection hood with M12 connectors

• MK 307 connection hood with spring-cage terminals

• KB 307 connection hood with cable

Device description

1 Bar code tape

2 Connection hood

3 Device housing

4 Middle of the scanning beam (device middle, output position value)

Figure 3.1: Device construction, device arrangement and beam exit

Leuze electronic BPS 307i 12

Page 13

3.1.2 Performance characteristics

The most important performance characteristics of the bar code positioning system:

• Positioning with submillimeter accuracy from 0 to 10,000 m

• For the control at high traverse rates of up to 10 m/s

• Simultaneous position and speed measurement

• Working range: 50 to 170 mm; enables flexible mounting positions

• Interfaces: PROFINET fieldbus, PROFIBUS fieldbus, SSI, RS 232/RS 422, RS 485

• Binary inputs and outputs for control and process monitoring

• Configuration via webConfig tool or fieldbus

• Diagnostics via webConfig tool or optional display

• Optional model with display

• Optional model with heating for use to -35 °C

3.1.3 Accessories

Special accessories are available for the bar code positioning system. The accessories are optimally

matched to the BPS:

• Highly flexible, scratch-, smudge- and UV-resistant bar code tape

• Mounting devices for precise mounting with one screw (easy-mount)

• Modular connection technology via connection hoods with M12 connectors, spring-cage terminals or

with cable.

Device description

3.1.4 Device model with heating

The bar code positioning system is optionally available as a model with integrated heating. In this case,

heating is permanently installed ex works.

NOTICE

No self-installation of the heating!

Self-installation of the heating on-site by the user is not possible.

The heating consists of two parts:

• Front cover heater

• Housing heater

Features of the integrated heating:

• Extends the application range of the BPS to -35 °C

• Supply voltage 18 … 30 VDC

• BPS release through an internal temperature switch (start-up delay of about 30 min for 24 V DC and

minimum ambient temperature of -35 °C)

• Required conductor cross-section for the power supply: At least 0.75 mm

NOTICE

Do not use ready-made cables!

It is not possible to use ready-made cables.

The current consumption of the BPS is too high for the ready-made cables.

2

Function

When the supply voltage is applied to the BPS, a temperature switch initially only supplies the heating with

current (front cover heater and housing heater). During the heating phase (around 30 min), when the

inside temperature rises above 15 °C, the temperature switch connects the BPS to the supply voltage. This

is followed by the self test and the changeover to read operation. The PWR LED lights up, showing overall

readiness for operation.

Leuze electronic BPS 307i 13

Page 14

When the inside temperature reaches approx. 18 °C, another temperature switch turns the housing heater

off and, if necessary, back on again (if the inside temperature drops below 15 °C). This does not interrupt

the read operation.

The front cover heater remains activated until an inside temperature of 25 °C is reached. At temperatures

above this, the front cover heater switches off and, with a switching hysteresis of 3 °C, back on again at

an inside temperature below 22 °C.

3.2 Connection technology

For the electrical connection of the BPS, the following connection variants are available:

• MS 307 connection hood with M12 connectors

• MK 307 connection hood with spring-cage terminals

• KB 307 connection hood with cable

The voltage supply (18 … 30 VDC) is connected acc. to the connection type selected.

Two freely programmable switching inputs/switching outputs for individual adaptation to the respective

application are also available here.

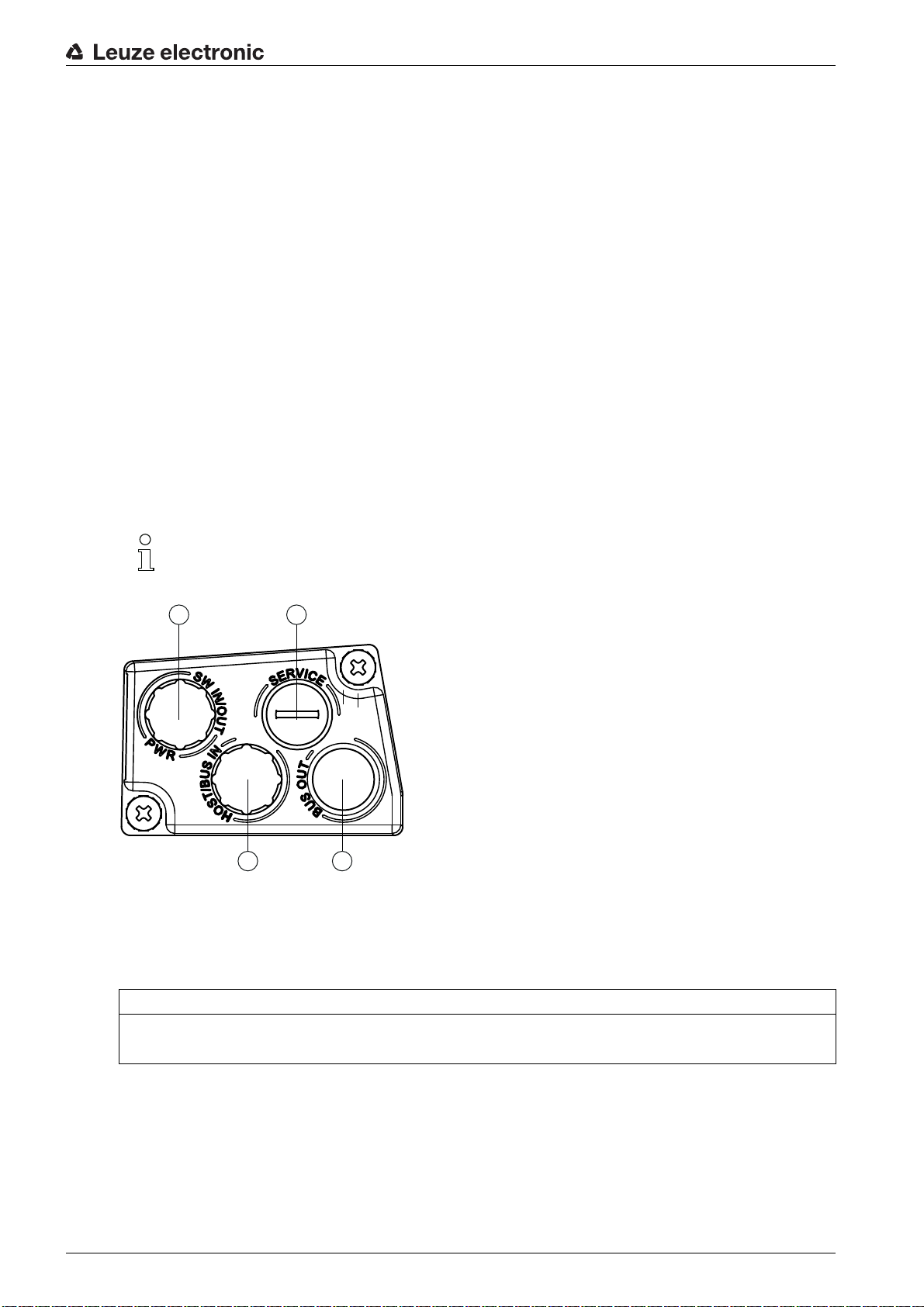

3.2.1 MS 307 connection hood with M12 connectors

The MS 307 connection hood features two M12 connector plugs and a Mini-B type USB socket as a

service interface for configuration and diagnostics of the BPS.

Device description

The configuration switches and the integrated parameter memory for the simple replacement of

the BPS are located in the MS 307.

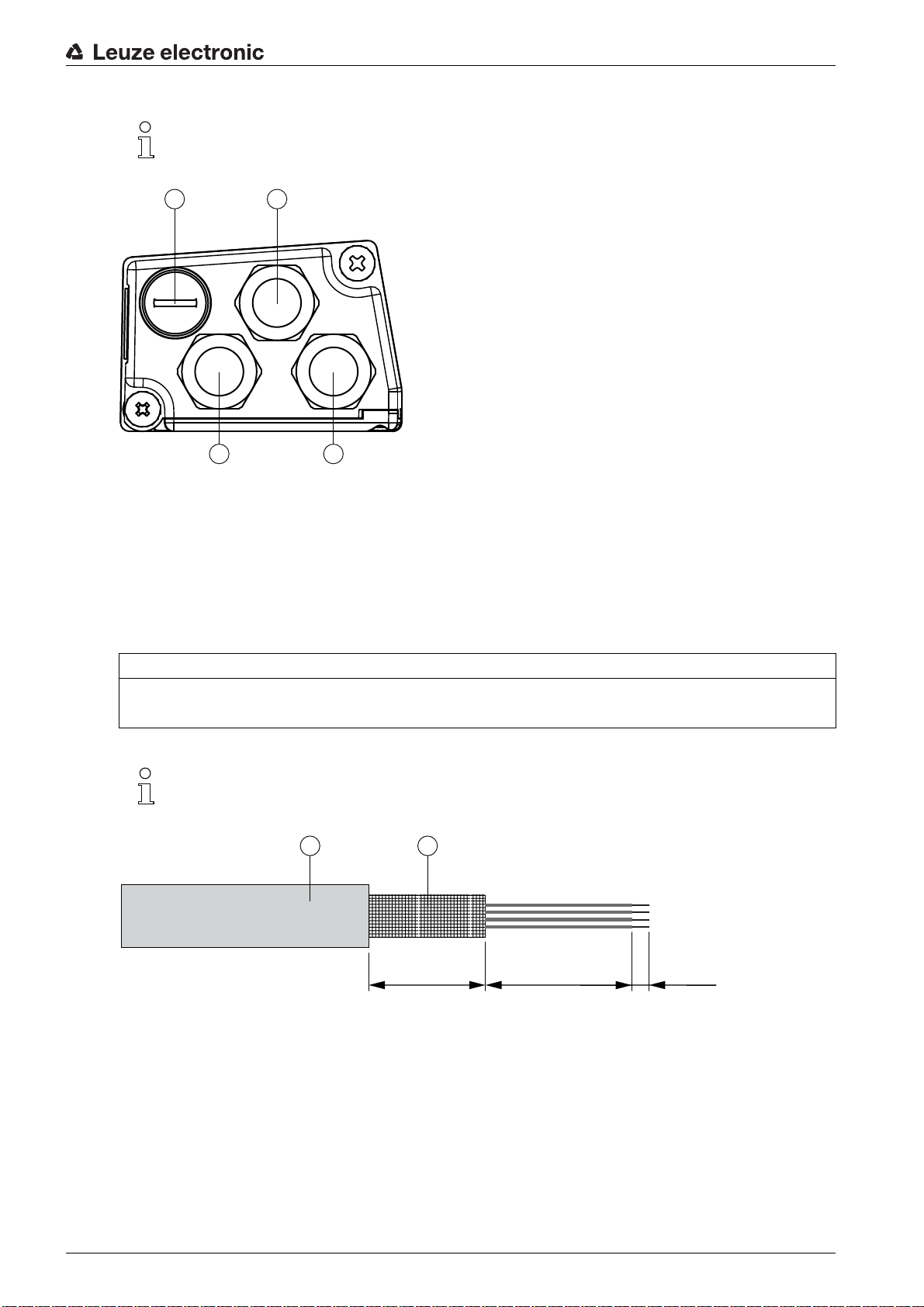

1

3

1 PWR / SW IN/OUT: M12 plug (A-coded)

2 SERVICE: Mini-B USB socket (behind protective cap)

3 HOST / BUS IN: M12 plug (B-coded), SSI

4 BUS OUT: not equipped

2

4

Figure 3.2: MS 307 connection hood, connections

NOTICE

Shielding connection

The shielding connection is done via the M12 connector housing.

3.2.2 MK 307 connection hood with spring-cage terminals

The MK 307 connection hood makes it possible to connect the BPS directly and without additional connectors. The MK 307 features cable bushings in which the shielding connection for the interface cable is also

located. A Mini-B type USB socket is used for service purposes and for configuration and diagnostic of the

BPS.

Leuze electronic BPS 307i 14

Page 15

The configuration switches and the integrated parameter memory for simple replacement of the

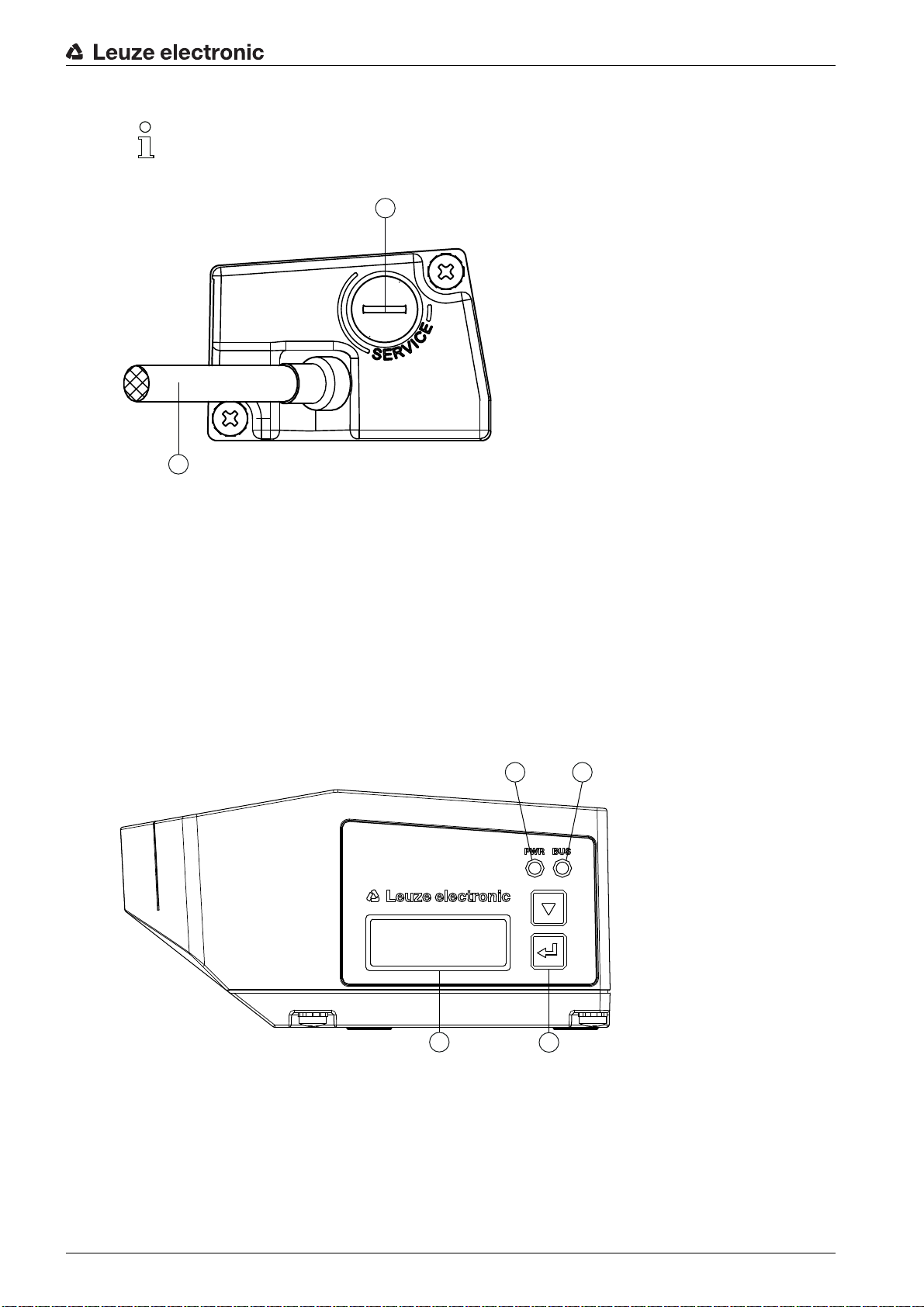

1

2

1 1

≈ 55 mm ≈ 8 mm ≈ 15 mm

1 2

BPS are located in the MK 307.

1 3x cable bushing, M16 x 1.5

2 SERVICE: Mini-B USB socket (behind protective cap)

Figure 3.3: Connection hood MK 307, connections

Device description

Cable fabrication and shielding connection

Remove approx. 78 mm of the connection cable sheathing.

15 mm of sheath of the shielded line must be freely accessible.

Lead the individual wires into the terminals according to the diagram.

NOTICE

Do not use wire-end sleeves!

When fabricating cables, we recommend against using wire-end sleeves.

The shield is automatically contacted when the cable is lead into the metal screw fitting and fas-

tened when the cord grip is closed.

1 Diameter of contact area, cable: 6 … 9.5 mm

Figure 3.4: Cable fabrication for connection hoods with spring-cage terminals

2 Diameter of contact area, shield: 5 … 9.5 mm

3.2.3 KB 307 connection hood with cable

With connection hood KB 307 , it is possible to directly connect the BPS. A Mini-B type USB socket is used

for service purposes and for configuration and diagnostic of the BPS.

The length of the connection cable is 3 m.

Leuze electronic BPS 307i 15

Page 16

To connect, the system plugs (JST) at the end of the cable must be removed.

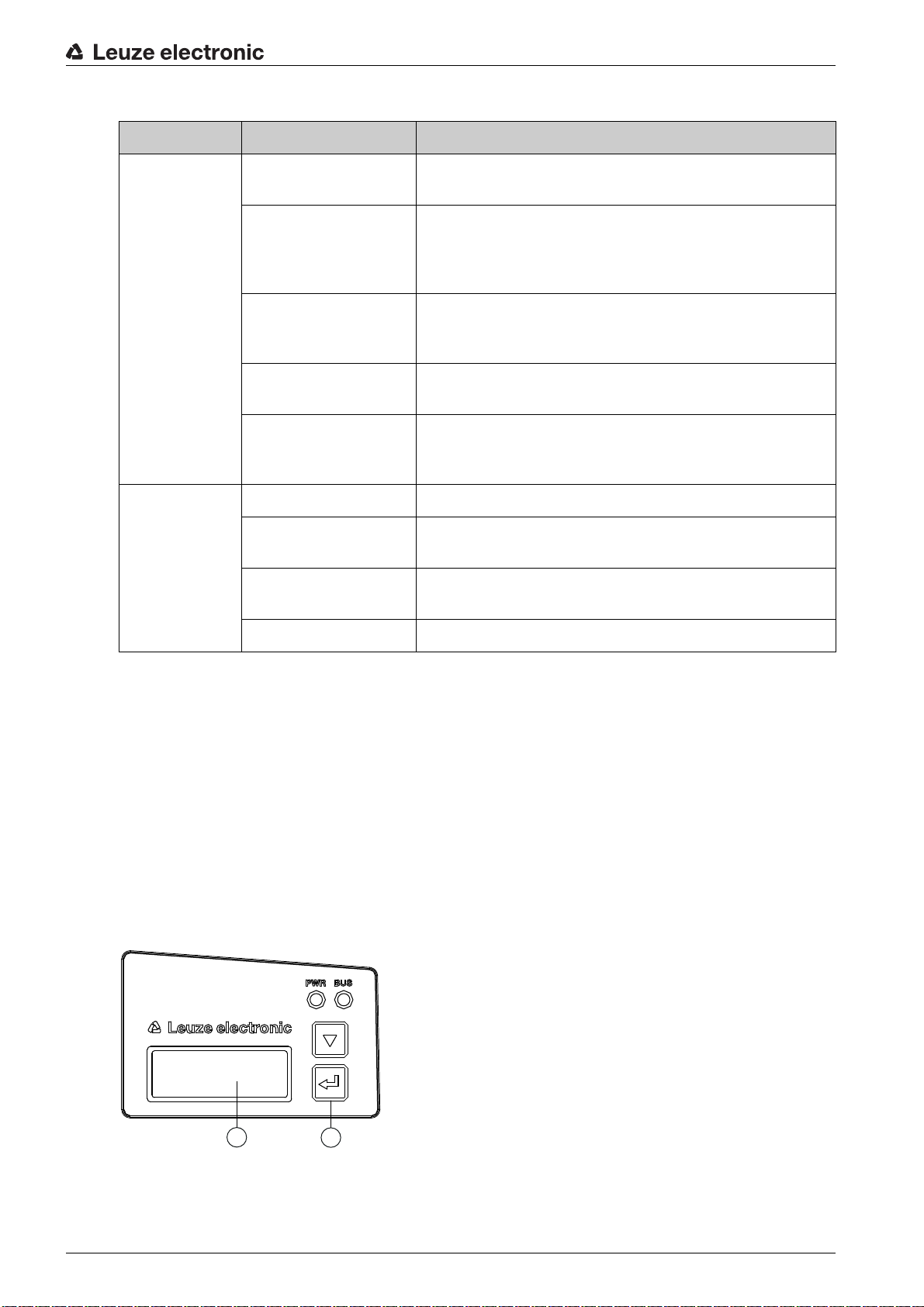

1

2

1

3 4

2

No parameter memory is integrated in connection hood KB 307.

1 SERVICE: Mini-B USB socket (behind protective cap)

2 Connection cable

Figure 3.5: Connection hood KB 307-3000

Device description

3.3 Display elements

The BPS is available optionally with display, two control buttons and LEDs or with only two LEDs as indicators on the device housing.

3.3.1 LED indicators

The device housing features the following multicolor LED indicators as primary display element:

•PWR

•BUS

1PWR LED

2LED BUS

3 Display

4 Control buttons

Figure 3.6: Indicators on the device housing

Leuze electronic BPS 307i 16

Page 17

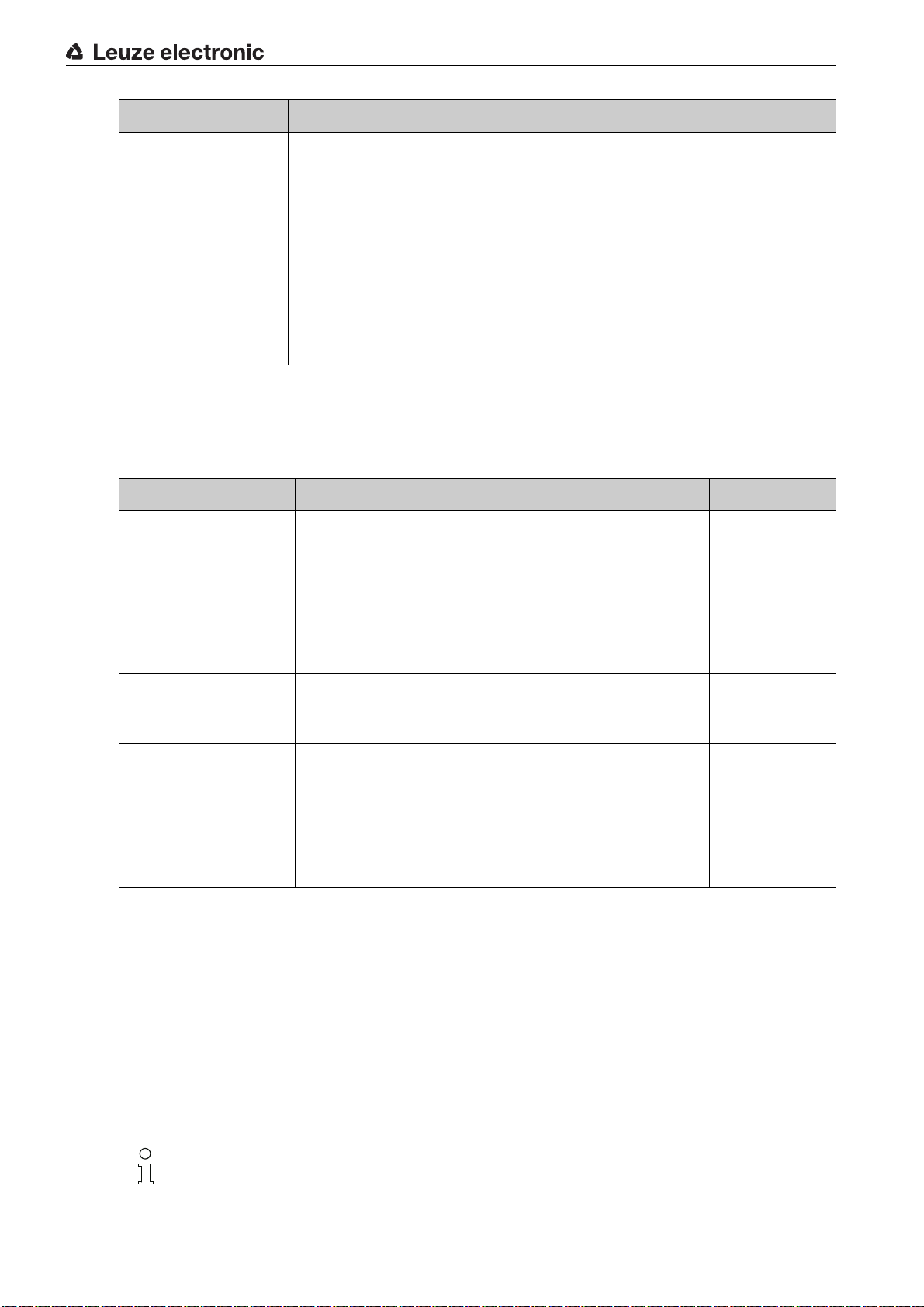

Table 3.1: Meaning of the LED indicators on the device housing

1 2

LED Color, state Description

Device description

LED 1

PWR

LED 2

BUS

Off Device is switched off

• No supply voltage

Green, flashing Device is being initialized

• Supply voltage connected

• Initialization running

• No measurement value output

Green, continuous light Device in operation

• Initialization finished

• Measurement value output

Red, flashing Warning set

• No measurement (e.g. no bar code tape)

Orange, continuous

light

Service active

• No data on the host interface

• Configuration via USB service interface

Off No supply voltage

Green, flashing Initialization of the host interface

• No communication

Green, continuous light Host interface active

• Communication possible

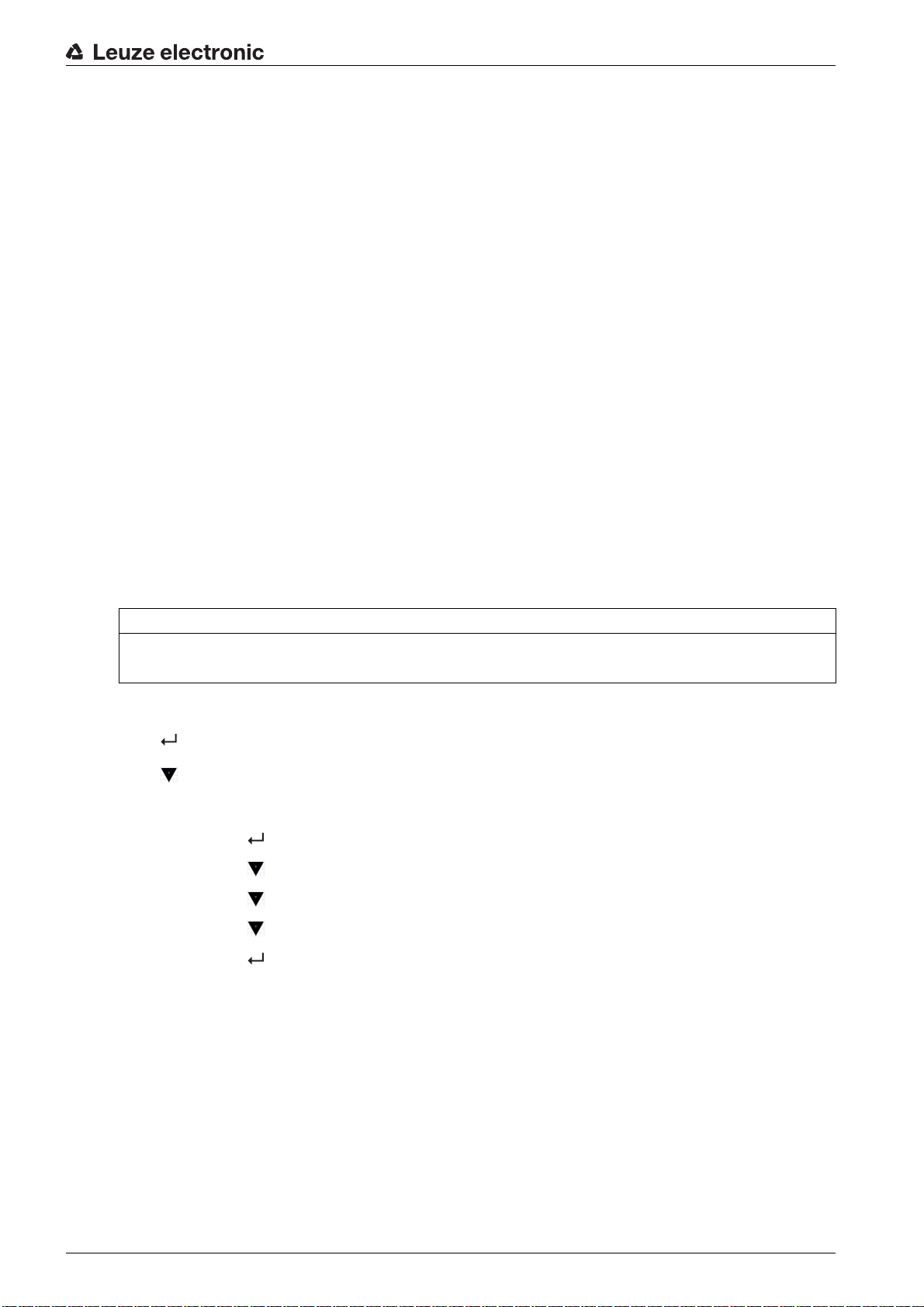

3.3.2 Display indicators

The optional display of the BPS is only used as a display element. The display has the following features:

• Monochromatic with white background lighting

• Double line, 128 x 32 pixels

• Display language: English

Two control buttons can be used to control which values appear in the display.

The background lighting is activated by pressing any control button and is automatically deactivated after

ten minutes have passed.

The display shows the content on two lines:

• The upper display line shows the selected function as an English term.

• The lower display line shows the data of the selected function.

Red, flashing Communication error detected

1 Display

2 Control buttons

Figure 3.7: Display on the device housing

Leuze electronic BPS 307i 17

Page 18

Display functions

The following functions can be displayed and activated in the display:

• Position value

•

Position Value

• Position value in mm

Display with “.” as decimal separator character (e.g.,

• Reading quality

•

Quality

• 0 … 100%

• Device status

•

BPS Info

•

System OK

• I/O status

Status of the inputs/outputs

•

I/O status

•

IO1 In:0

In/Out depending on configuration, 0/1 for state of the I/O

/

Warning

/

IO2 Out:0

/

Error

+ 34598.7 mm

Device description

)

• Version information

Software and hardware version of the device

•

Version

•

SW: V1.3.0 HW:1

NOTICE

Laser activation by selecting

If measurement is stopped, the laser is activated by selecting

The display is controlled via the control buttons:

• – Enter: activate or deactivate the display shift function

• – Down: scroll through functions (downwards)

Example: Representation of the I/O status on the display

1. Press button : Display flashes

2. Press button : Display changes from position value (

3. Press button : Display changes from reading quality (

4. Press button : Display changes from device status (

5. Press button : I/O status displayed, display stops flashing

Quality

!

Position Value

Quality

BPS Info

Quality

.

) to reading quality (

) to device status (

) to I/O status

BPS Info

Quality

)

)

Display during device start-up

During device start-up, a start-up display first appears which is briefly followed by the display with the

version information.

The standard display after starting up the BPS is

Leuze electronic BPS 307i 18

Position Value

.

Page 19

3.4 Bar code tape

3.4.1 General information

The bar code tape is available in different variants:

• BCB bar code tape with 40 mm grid

Code128 with character set C, increasing in increments of 4 (e.g., 000004, 000008, … )

• Bar code tape BCB8 with 30 mm grid

Code128 with character set C, increasing in increments of 3 (e.g. 000003, 000006, … )

A bar code tape consists of a sequence of individual position labels in one of the two grids. Defined cut

marks are provided for cutting the BCB.

The bar code tape is delivered on a roll. A roll contains up to 200 m of BCB, with the wrapping direction

from the outside to the inside (smallest number on the outside). If more than 200 m of BCB is ordered, the

total length is divided into rolls of 200 m.

Bar code tapes with special requirements with respect to height, length and value range can be ordered

from Leuze electronic (see chapter 14.5 "Bar code tapes").

NOTICE

Value range for BCB with special requirements!

When ordering bar code tapes with special requirements, make certain that the value range contains

only values that are divisible by three (BCB8 with 30 mm grid) or four (BCB with 40 mm grid).

It may otherwise not be possible to purchase and use repair tapes.

Device description

NOTICE

Only one BCB type per system!

In a given system, use either only BCB8 with 30 mm grid or only BCB with 40 mm grid.

If different BCB types are used in one system, the BPS cannot ensure an exact position determination.

NOTICE

Configure the BPS for the used BCB type!

The used BCB type must be set in the webConfig tool with the

chapter 9.3.2 "CONFIGURATION function".

On delivery, the BPS is set for BCB with a 40 mm grid.

If the BCB8 with a 30 mm grid is used, the

If the used BCB type does not correspond to the

determination cannot be performed by the BPS.

Tape selection

Tape selection

Tape selection

must be adjusted in the BPS configuration.

configured in the BPS, exact position

parameter; see

Leuze electronic BPS 307i 19

Page 20

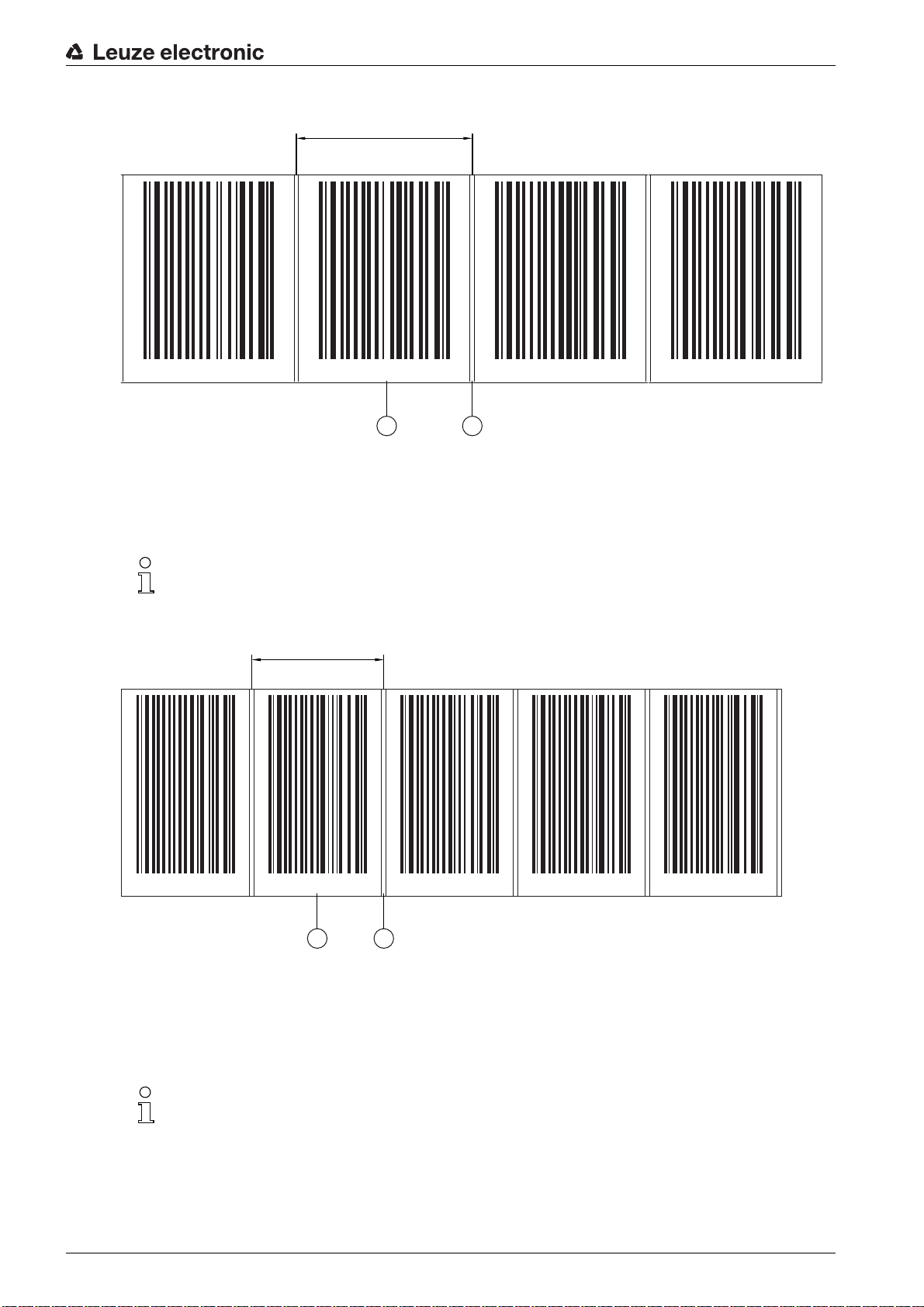

BCB bar code tape with 40 mm grid

1 2

000040 000044 000048 000052

40

BCB8

BCB8

BCB8 BCB8

BCB8

000018 000021 000024 000027 000030

1 2

30

1 Position label with position value

2 Cut mark

Figure 3.8: Bar code tape with 40 mm grid

Device description

The standard height of 47 mm can be adapted. Other BCB height (25 mm) and special heights on request.

With a standard bar code tape and a repair tape with 40 mm grid, the printed numerical values

are divisible by four without a remainder.

Bar code tape BCB8 with 30 mm grid

1 Position label with position value

2 Cut mark

Figure 3.9: Bar code tape with 30 mm grid

The standard height of 47 mm can be adapted. Other BCB heights (25 mm and 30 mm) and special

heights on request.

With a standard bar code tape and repair tape with 30 mm grid, the printed numerical values are

divisible by three without a remainder.

For bar code tapes with 30 mm grid, the designation

BCB8

the position value.

Leuze electronic BPS 307i 20

is printed in plain text in addition to

Page 21

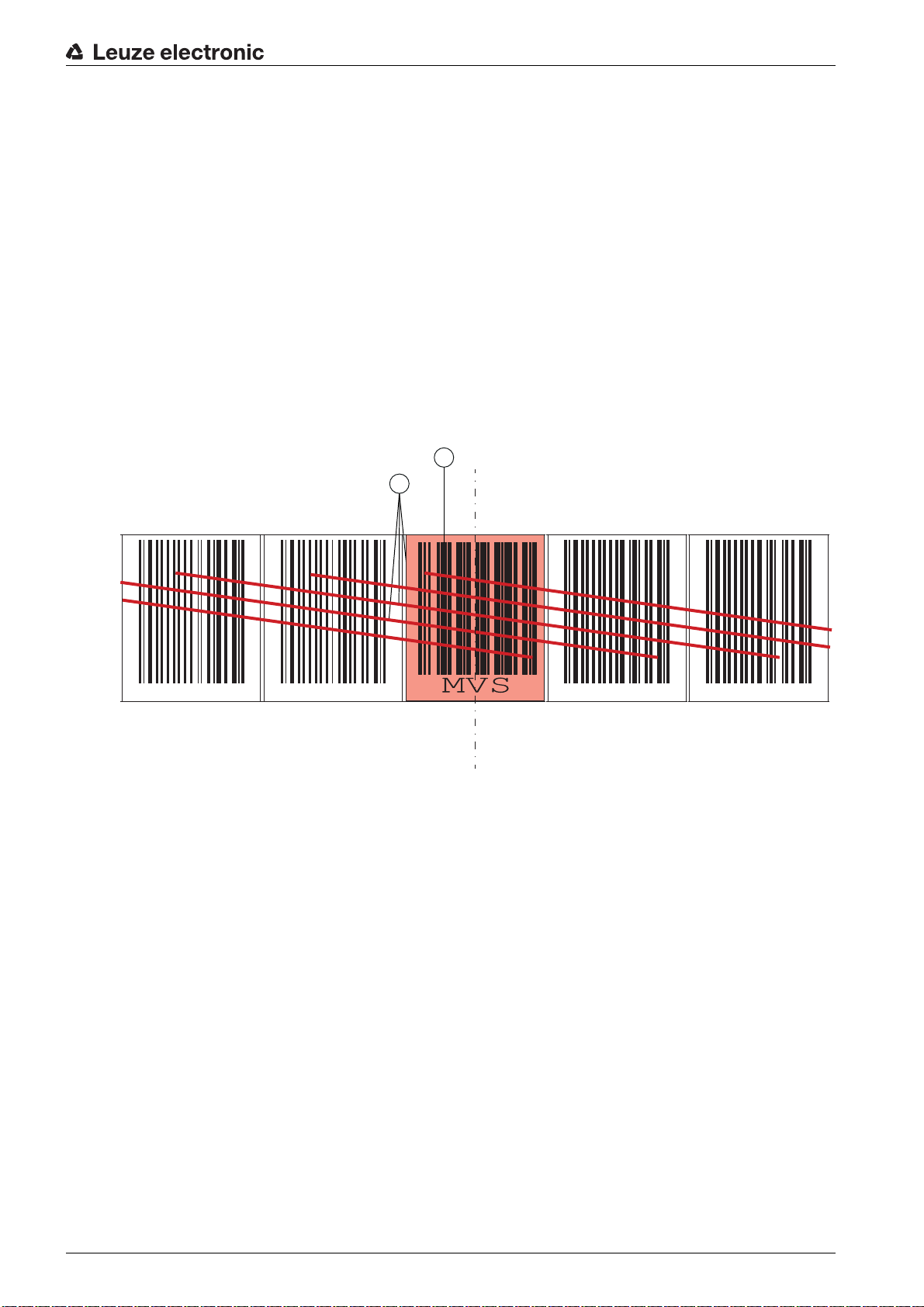

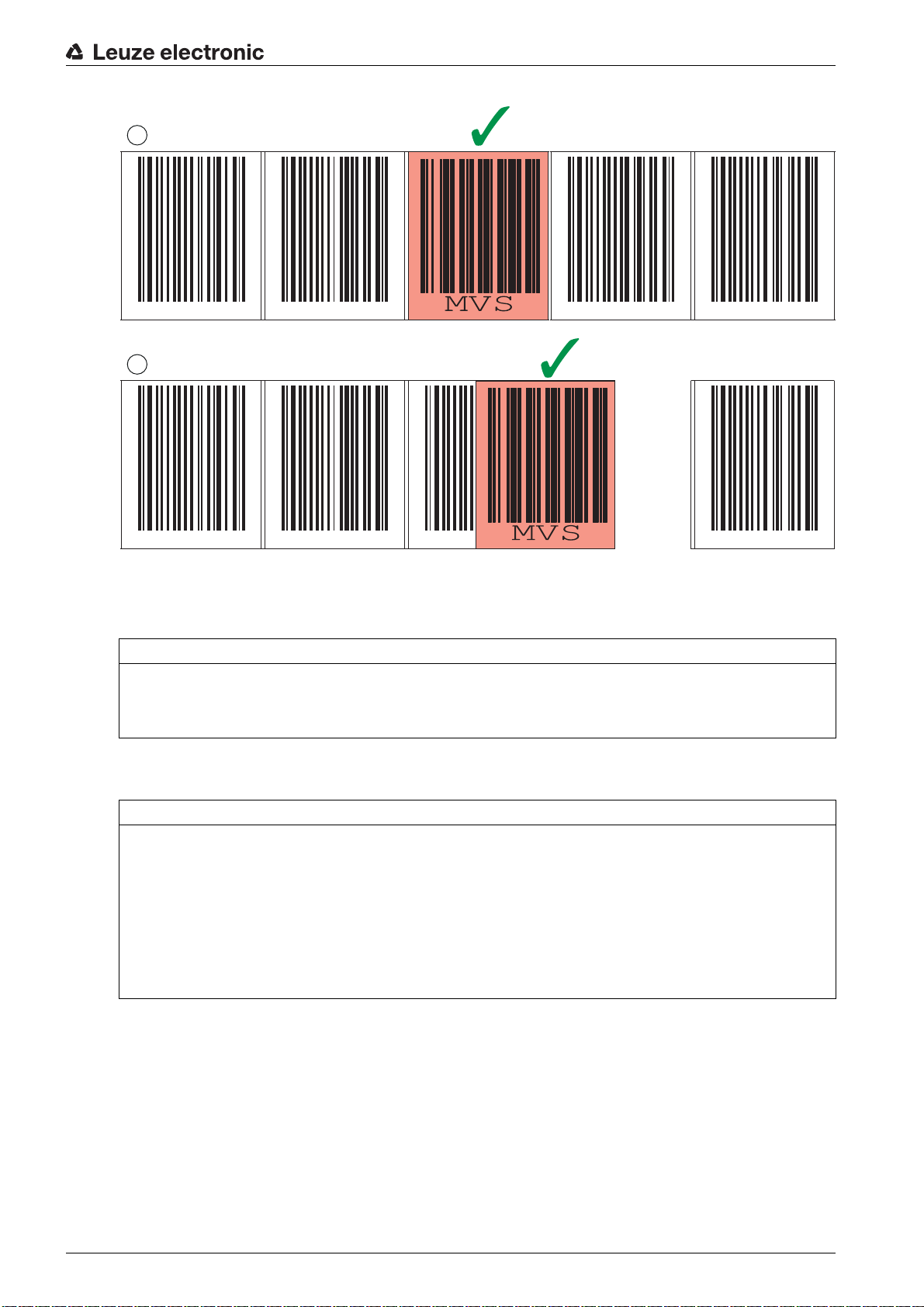

3.4.2 Control bar codes

2

000040 000044 000048 0150000 015004

1

With the help of control bar codes that are affixed on top of the bar code tape at appropriate positions, functions in the BPS can be activated or deactivated, e.g., for changing various position values at switches.

Code type Code128 with character set B is used for the control bar code.

The

MVS

label is a control bar code for the direction-independent switching of the position values from one

bar code tape to another in the middle of the control bar code label.

• If, upon reaching the changeover position in the middle of the

the new BCB section in the scanning beam, the position value of the first BCB section is still output

after the middle of the

The

MV0

label is a control bar code for the deactivation of the position output.

• If the BPS detects the middle of the

MV0

label.

Arrangement of the control bar codes

The control bar code is attached in such a way that it replaces one position bar code or seamlessly

connects two bar code tapes with different value ranges to one another (see figure 3.10).

MVS

label for half of the label width.

MV0

label, no position values are output after the middle of the

Device description

MVS

label, the BPS does not detect

1 Control bar code

2 The control bar code is decoded in the marked scans

Figure 3.10: Arrangement of the MVS control bar code

Leuze electronic BPS 307i 21

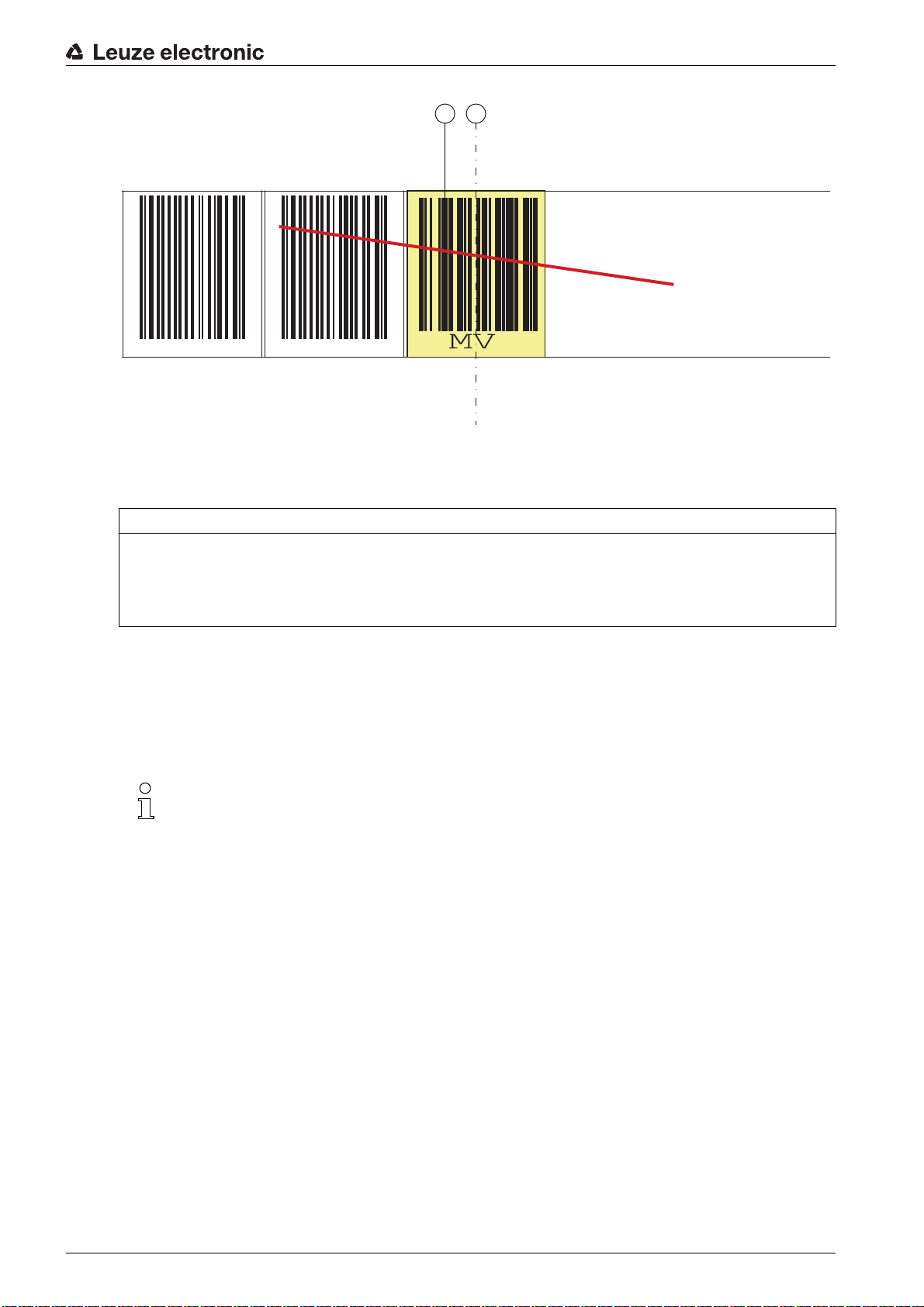

Page 22

1 Control bar code

000040 000044

0

1

2

2 End of position determination from the middle of the control bar code

Figure 3.11: Arrangement of the MV0 control bar code

Device description

NOTICE

Distance between two control bar codes!

Make certain that there is only one control bar code (or marker label) in the scanning beam at a time.

The minimum distance between two control bar codes is determined by the distance between the BPS

and bar code tape and the resulting length of the scanning beam.

The control bar codes are simply affixed over the existing bar code tape.

A control bar code should cover an entire position bar code and must have the correct grid dimension (see

figure 3.12):

• 30 mm with BCB8 bar code tapes

• 40 mm with BCB bar code tapes

Keep the gap between the BCBs that are switched between as small as possible.

Leuze electronic BPS 307i 22

Page 23

Device description

1

2

000040 000044 000048 015000 015004

000040 000044 000048 015004

1 Control bar code perfectly affixed on the bar code tape

2 Control bar code at small gap between two bar code tapes

Figure 3.12: Correct positioning of the control bar code

NOTICE

Gaps in bar code tape

Avoid polished and high-gloss surfaces.

Keep the gaps between the two bar code tapes and the control bar code as small as possible.

Measurement value switching between two bar code tapes with different value ranges

MVS

or

MV0

The

control bar code is used to switch between two bar code tapes.

NOTICE

1 m minimum distance of the bar code values for measurement value switching!

For different BCB value ranges, make certain that the minimum distance of 1 m between the preceding

position bar code (before the control bar code) and the subsequent position bar code (after the control

bar code) is maintained.

Example (BCB with 40 mm grid): If the last position bar code on the BCB before the control bar code

is

75120

, the following position bar code on the BCB after the control bar code must be at least

If the minimum distance between the bar code values is not maintained, position determination may

be faulty.

• The end of the preceding bar code tape and the start of the subsequent bar code tape can end and

begin, respectively, with completely different position bar codes.

• BCB changeover by means of a control bar code always occurs at the same position, i.e., it serves to

change from the preceding tape to the subsequent tape and vice versa.

• If the center of the BPS reaches the transition point of the control bar code, the device switches to

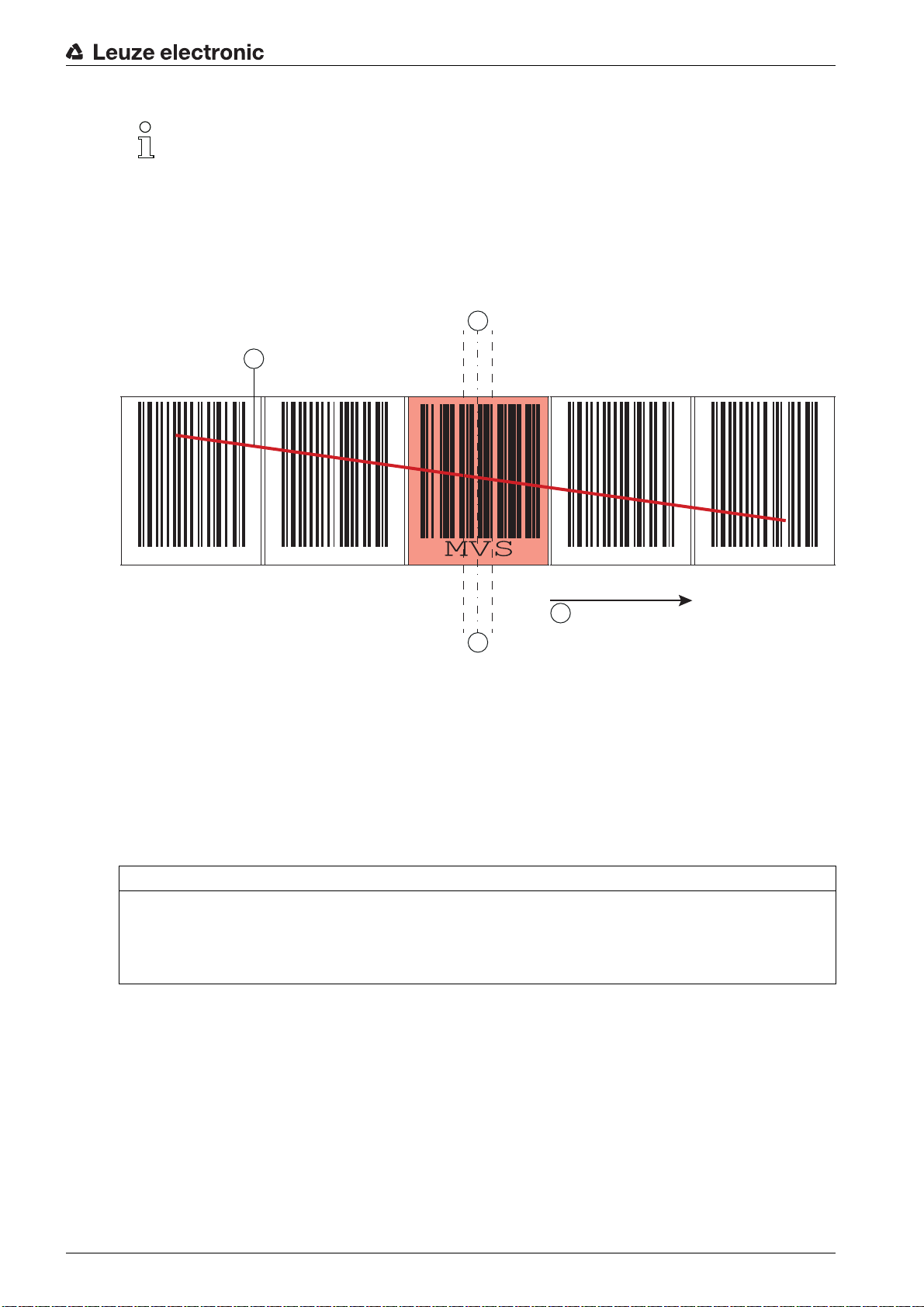

the second BCB, provided the next position label is in the BPS's scanning beam (see figure 3.13).

The output position value is thereby always uniquely assigned to one BCB.

75220

.

Leuze electronic BPS 307i 23

Page 24

Device description

000040 000044 000048 0150000 015004

1

2

3

4

If the BPS does not detect the new BCB section upon reaching the changeover position, the posi-

tion-value output is dependent on the used control bar code.

MVS

control bar code: The position value of the first BCB is output beyond the middle of the

MVS

label for half of the label width.

MV0

control bar code: No position values are output after the middle of the

MV0

label.

• When the control label is passed, the new BCB value is output relative to the middle of the device or

label.

1 Scanning beam

2 Middle of the control bar code

3 Middle of the BPS

4 Direction of movement

Figure 3.13: Changeover position with

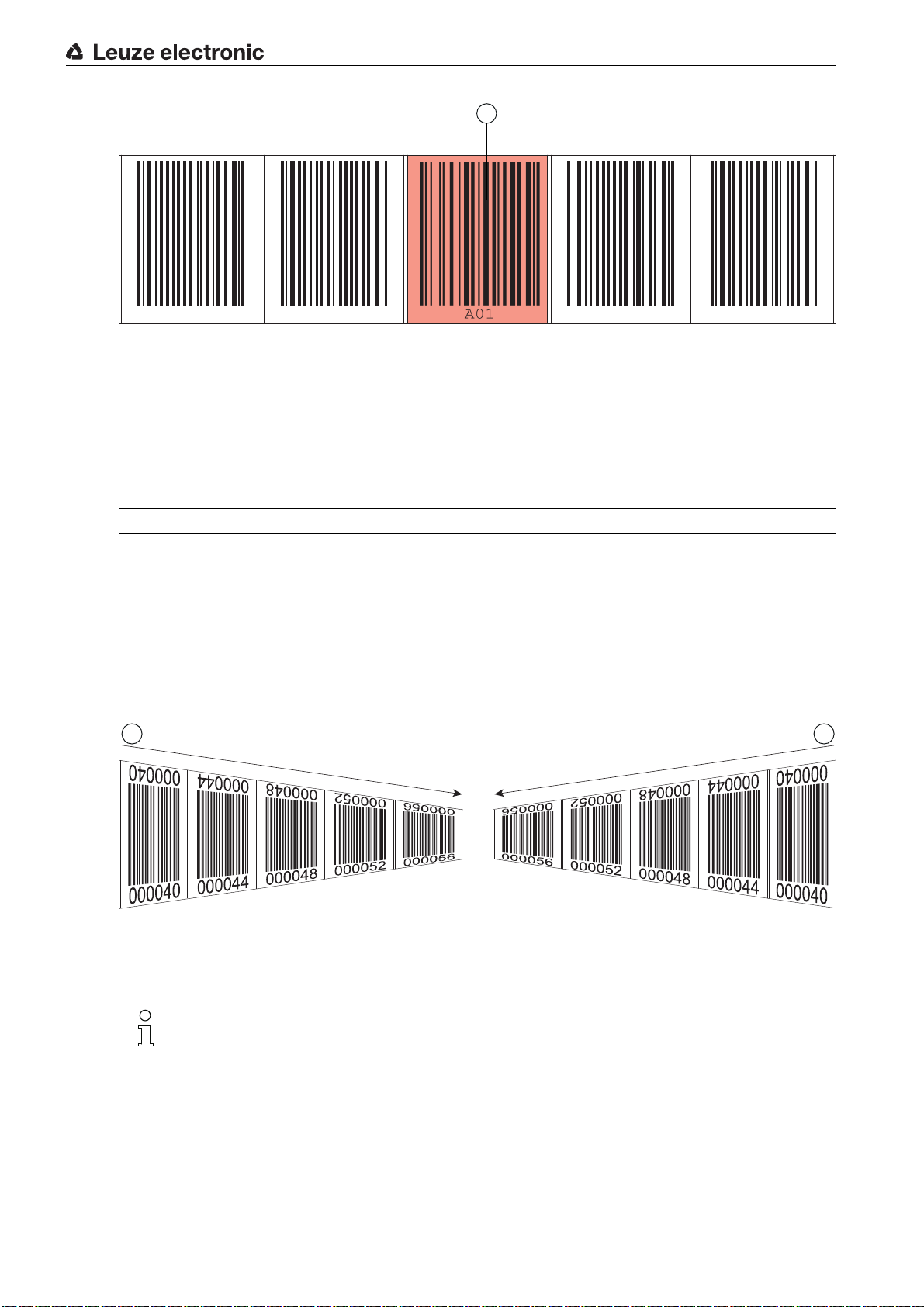

3.4.3 Marker labels

Marker labels, which are affixed at the appropriate locations on top of the bar code tape, can be used to

trigger various functions in the superior control. The BPS detects the defined marker labels in the scanning

beam, decodes them, and makes them available to the control.

NOTICE

Distance between two marker labels!

Make certain that there is only one marker label (or control bar code) in the scanning beam at a time.

The minimum distance between two marker labels is determined by the distance between the BPS and

bar code tape and the resulting length of the scanning beam.

Definition of the marker label

The following combinations of letters and numbers may be used as marker labels:

First character: A … Z, a … z

Second character: Digit from 0 … 9

Third character: Digit from 0 … 9

MVS

control bar code for BCB changeover

Structure of the marker labels

Code type Code128 with character set B is used for the marker labels.

Arrangement when using the marker label with positioning

The marker label must be attached to the bar code tape aligned with the grid of the actual coding. A posi-

Leuze electronic BPS 307i 24

tion code should be visible before and after the marker label.

Page 25

Figure 3.14: System arrangement of marker labels

000040 000044 000048 0000052 000056

1

1

2

Arrangement when using the marker label without positioning

The marker label must be positioned within the BPS's detection range.

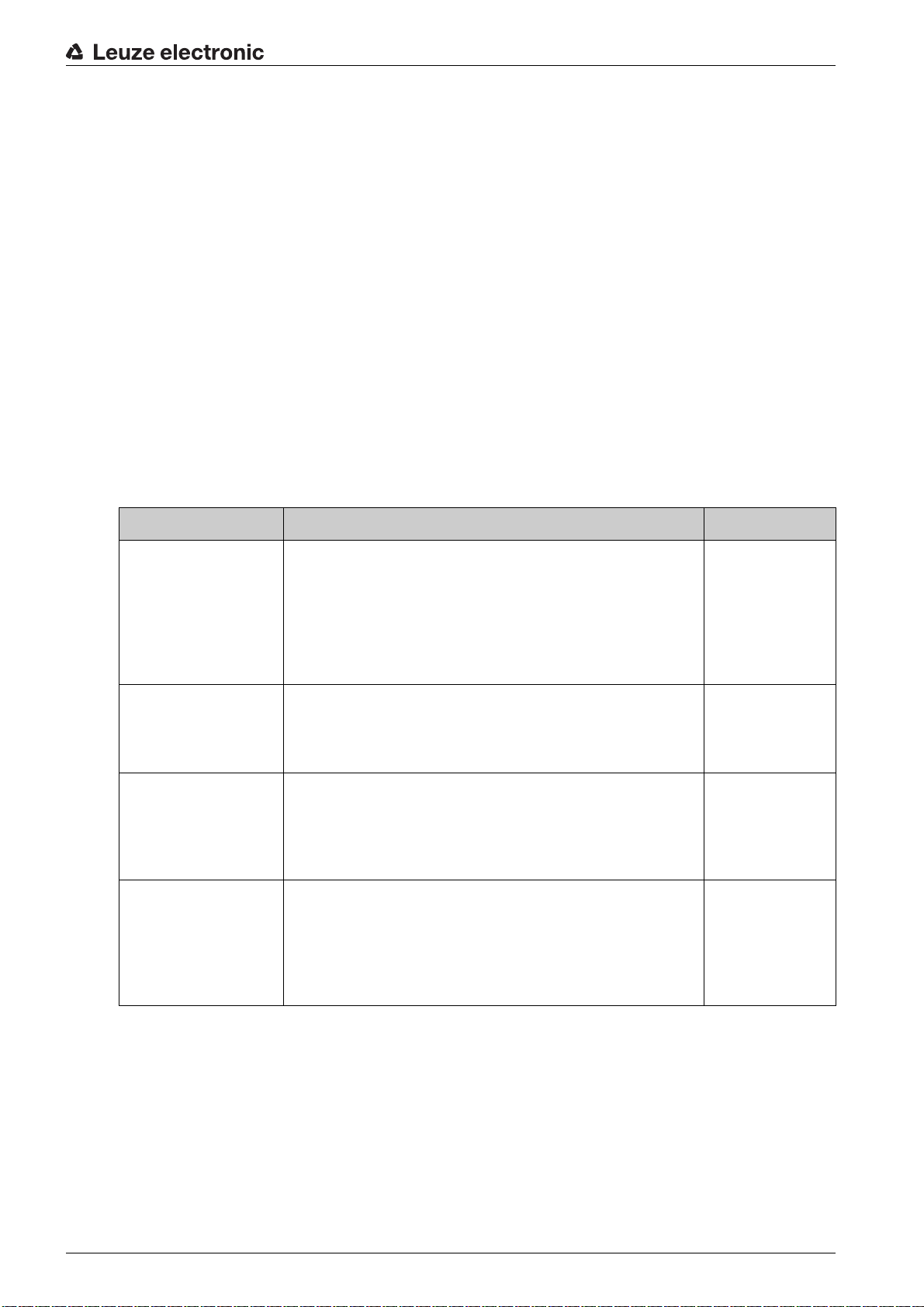

3.4.4 Twin tapes

Twin tapes are jointly manufactured bar code tapes with the same value range.

Device description

1 Marker label

NOTICE

A twin tape always consists of two bar code tapes!

When ordering a twin tape, two bar code tapes are always included with an order.

Twin tapes are used if positioning with two bar code tapes is necessary, e.g., with crane systems or elevators.

Because they are manufactured jointly, both tapes have the same length tolerance. As a result, differences

in length and code position are minimal. By having the same code position on both tapes, improved

synchronization can be achieved during positioning compared to bar code tapes that are manufactured

separately.

1 Twin bar code tape 1

2 Twin bar code tape 2

Figure 3.15: Twin tape with double numbering

Twin tapes are always delivered in pairs on two rolls.

If twin tapes are replaced, both tapes are to be replaced.

Twin tapes can be ordered from Leuze electronic (see chapter 14.5 "Bar code tapes").

Leuze electronic BPS 307i 25

Page 26

4 Functions

This chapter describes the functions of the BPS and the parameters for adaptation to the respective application conditions and requirements.

The parameters are set via the webConfig tool; see chapter 9 "Leuze electronic webConfig tool –

Extended configuration".

Main functions:

• Position measurement

• Speed measurement

The following parameters are relevant for the timing of the position and speed measurement:

• Measurement value preparation

Configurable response time

• Measurement error tolerance

Configurable time-based error suppression

4.1 Position measurement

The output value of the position measurement is calculated from the measurement and the settings for

resolution, preset, offset, etc.

The most important individual parameters for the position measurement are:

Functions

Parameter Description Range/Values

Position resolution The parameter specifies the resolution of the position value.

It acts only on the host interface.

The resolution has no effect on the set parameter values

such as offset or preset.

Unit The parameter specifies the measurement unit of the mea-

sured position and speed.

The selection of the measurement unit affects all parameters with measurement units.

Offset The offset is used to correct the position value by a fixed

amount.

If the offset is activated, the offset is added to the position

value. This yields a new output value:

Output value = position value + offset

Preset Like the offset, the preset is used to correct the position

value.

With preset, a preset value is specified. The value is

accepted during a corresponding event (switching input or

fieldbus).

If the preset is activated, this has priority over the offset.

0.001 mm

0.01 mm

0.1 mm

1 mm

10 mm

or

Free resolution

Metric (mm)

or

inch (1/100 in)

1 mm

or

inch/100

1 mm

or

inch/100

4.2 Speed measurement

The current speed is ascertained and output on the basis of the respective position values.

The most important individual parameters for the speed measurement are:

Leuze electronic BPS 307i 26

Page 27

Functions

Parameter Description Range/Values

Speed resolution The parameter defines the resolution of the speed value. It

Averaging The parameter specifies the averaging time of the calcu-

4.3 Timing

The BPS of the 300i series operate with a scanning rate of 1000 scans per second. A measurement value

is ascertained every 1 ms.

The following parameters are relevant for the timing of the position and speed measurement:

Parameter Description Range/Values

Integration depth The integration depth affects the measurement of position

affects only the fieldbus output.

lated speed values in steps.

and speed. The

number of sequential measurements that the BPS uses for

position determination.

The integration results in smoothing of the output measurement value.

An

integration depth

measurement values) results in a response time of 8 ms.

integration depth

of 8 (position determination with 8

parameter specifies the

1 mm/s

10 mm/s

100 mm/s

1000 mm/s

or

Free resolution

Steps:

2 ms, 4 ms,

8 ms,

16 ms, 32 ms,

64 ms, 128 ms

Factory setting:

8

Update rate The update rate (50 µs to 2 ms) of the measurement values

at the SSI interface can be configured via the webConfig

tool; see chapter 9.3.2 "CONFIGURATION function".

Error delay time Errors that occur are suppressed for the configured time.

If no valid position or speed value can be ascertained in the

configured

output.

If the error persists after the

value of the

ter is then output (standard).

4.4 Leuze webConfig tool

The webConfig configuration tool offers a graphical user interface for the display of process data, configuration and diagnostics of the BPS via a PC; see chapter 9 "Leuze electronic webConfig tool – Extended

configuration".

4.5 Evaluation of the reading quality

The BPS can signal the reading quality of the BPS. The reading quality is displayed in % values.

The parameters for the evaluation of the reading quality are set via the webConfig tool:

CONFIGURATION > DATA PROCESSING > Reading quality; see chapter 9.3.2 "CONFIGURATION

function".

error delay time

, the last valid value is always

error delay time

elapses, the

Position/Speed value in case of error

Factory setting:

2 ms

Factory setting:

50 ms

parame-

The values of the reading quality are displayed via the optional display (

munication protocol and via the webConfig tool; see chapter 9.3.3 "ALIGNMENT function".

Leuze electronic BPS 307i 27

Quality

), the serial com-

Page 28

The evaluation of the reading quality provides the following information, e.g.:

• The reading quality is constantly bad: Soiling of the BPS optics

• The reading quality is always bad at certain position values: Soiling of the BCB

4.6 Distance measurement to the bar code tape

Within the reading field, the BPS can output the current distance from the read head to the BCB. The

distance from the position label closest to the reference point is output.

The distance measurement value is output via:

•The

ALIGNMENT

only available in the

function (

Service

Quality

menu) in the webConfig tool (see chapter 9.3.3); this function is

operating mode.

Functions

Leuze electronic BPS 307i 28

Page 29

5 Applications

Wherever systems are moved automatically, it is necessary to uniquely determine their respective positions. In addition to mechanical measuring sensors, optical methods are particularly well suited for position

determination as they can be used to determine position without mechanical wear and slippage.

Compared to common optical measurement techniques, the Leuze electronic Bar code Positioning

System (BPS) is able to measure a position with absolute sub-millimeter accuracy, i.e. independent of

reference points. As a result, it is able to provide a unique position value at any time. With the highly flexible

and hard-wearing Bar Code Tape (BCB), the system can even be used without problem in systems with

curves or guide tolerances. And this at lengths of up to 10,000 meters.

The product family of Leuze electronic bar code positioning systems convinces with a variety of advantages:

• The laser simultaneously scans three bar codes and, as a result, is able to determine the position

with sub-millimeter accuracy. The wide reading field makes accurate position determination possible

even in the event of minor damage to the tape.

• With the systems' flexible depth of field, it is also possible to bridge over mechanical deviations.

• Due to the large reading distance combined with the great depth of field, a large opening angle and a

very compact construction, the device is ideally suited for the conveyor and storage technology market.

• The BPS devices are capable of simultaneously measuring position and speed and are thus also

suitable for control tasks in your automation applications.

• Using a mounting device, the BPS can be mounted with millimeter accuracy with just one screw. If

mounted using a mounting device, a new device is automatically aligned correctly should it be necessary to exchange a device (easy-mount).

• The unique labeling of the bar code tape allows the system to be put back into operation without

problem even after a brief voltage drop without, e.g., needing to utilize a reference point.

• The Leuze electronic bar code tape is very robust, highly flexible and, thanks to the self-adhesive

back, can be easily integrated into your overall mechanical system. It can be fit optimally to both vertical as well as horizontal curved paths and thereby reliably facilitates trouble-free and reproducible

measurement at any point in your system with sub-millimeter accuracy.

Applications

Typical applications for the BPS include:

• High-bay storage device (see chapter 5.1)

• Telpher line (see chapter 5.2)

• Gantry cranes (see chapter 5.3)

Leuze electronic BPS 307i 29

Page 30

5.1 High-bay storage device

Applications

Figure 5.1: High-bay storage device

Simultaneous position and speed measurement for regulation tasks

Precise positioning with a reproducibility of

0.15 mm

Control at high traverse rates of up to 10 m/s

Leuze electronic BPS 307i 30

Page 31

5.2 Telpher line

Applications

Figure 5.2: Telpher line

The working range from 50 - 170 mm allows for flexible mounting positions and reliable position detec-

tion at varying distances

Control codes for changing to different position values at switches

Leuze electronic BPS 307i 31

Page 32

5.3 Gantry cranes

Applications

Figure 5.3: Gantry cranes

Positioning from 0 to 10,000 meters

Scratch- and smudge-proof, UV-resistant bar code tapes

Synchronous positioning with twin tapes on both rails

Mounting device for fast, precise mounting with one screw

Leuze electronic BPS 307i 32

Page 33

6 Mounting and installation

6.1 Mounting bar code tape

6.1.1 Installation and application remarks

NOTICE

BCB mounting

When processing BCBs, observe the specified processing temperatures.

When processing BCBs in cold storage facilities, the BCB must be affixed before cooling the storage

facility.

However, if it should be necessary to affix the BCB at temperatures outside of the specified processing

temperature, assure that the bonding surface as well as the BCB are at the processing temperature.

Avoid dirt deposits on the BCB.

If possible, affix the BCB vertically.

If possible, affix the BCB below an overhead covering.

The BCB must never be continuously cleaned by on-board cleaning devices such as brushes or

sponges. Permanent on-board cleaning devices polish the BCB and give it a glossy finish. The reading

quality deteriorates as a result.

After affixing the BCBs, make certain that there are no polished, high-gloss surfaces in the scanning

beam (e.g., glossy metal at gaps between the individual BCBs), as the measurement quality of the

BPS may be impaired.

Affix the BCBs to a diffusely reflective support, e.g., a painted surface.

Avoid sources of extraneous light and reflections on the BCB.

Ensure that neither strong sources of extraneous light nor reflections of the support on which the BCB

is affixed occur in the vicinity of the BPS scanning beam.

Affix the BCB over expansion joints up to a width of several millimeters.

The BCB must not be interrupted at this location.

Cover protruding screw heads with the BCB.

Ensure that the BCB is affixed without tension.

The BCB is a plastic tape that can be stretched by strong mechanical tension. Excessive mechanical

stretching results in lengthening of the tape and distortion of the position values.

Mounting and installation

NOTICE

BCB application

Make certain that the BCB is located in the scanning beam of the BPS over the entire traversing path.

The BPS can determine the position on BCBs with arbitrary orientation.

Bar code tapes with different value ranges may not directly follow one another.

In the case of different value ranges, a gap of at least 1 m must be maintained between the last position

bar code of the preceding BCB and the first position bar code of the subsequent BCB (see

chapter 3.4.2).

For

MVS/MV0

position bar code before the control bar code and the first position bar code after the control bar code

must be maintained.

For bar code tapes with different value ranges, both BCBs must correspond to the BCB type config-

ured in the BPS (see chapter 3.4.1).

Avoid position bar code labels with the value

Measurements to the left of the center of a

be displayed correctly.

Leuze electronic BPS 307i 33

control bar codes (see chapter 3.4.2), the minimum distance of 1 m between the last

00000

.

00000

label produce negative position values that may not

Page 34

6.1.2 Cutting bar code tapes

1

000040 000044 000048 000052 000056

1

000040 000044 000148 000152 000156

2

3

NOTICE

Avoid cutting BCB!

If possible, avoid cutting bar code tapes.

Optimum position value determination by the BPS is achieved with continuously affixed BCB.

If there are mechanical gaps, first affix the BCB continuously. Then cut the BCB.

The BCB is cut at the indicated cut marks; see figure 6.1.

Mounting and installation

1 Cut mark

Figure 6.1: Cut mark on the bar code tape

If another BCB is to be affixed directly after the preceding BCB, the subsequent bar code value must differ

from the preceding BCB by at least 1 m; see figure 6.2.

1 Preceding bar code tape

2 Cut mark

3 Subsequent bar code tape, value range + 1 m

Figure 6.2: Cut bar code tape

If there is a gap without tape after the preceding BCB, it must be at least 300 mm wide before the subsequent BCB is affixed; see figure 6.3. The first bar code value of the subsequent BCB must differ by at least

20 (200 mm) from the last bar code value of the preceding BCB.

Leuze electronic BPS 307i 34

Page 35

1 Preceding bar code tape

000040 000044 000064 000068

2

2

1

3

4

2 Cut mark

3 Gap, at least 300 mm

4 Subsequent bar code tape

Figure 6.3: Gap in cut bar code tape to avoid double positions

Mounting and installation

NOTICE

No glossy gaps in the cut bar code tape!

Ensure that there are matt, bright surfaces behind the gaps in the BCB.

Polished, reflective, and high-gloss surfaces in the scanning beam may impair the measurement quality of the BPS.

6.1.3 Mounting the BCB

Mount the BCB as follows:

Check the surface.

It must be flat, free of grease and dust, and be dry.

Define a reference edge (e.g., metal edge of the busbar).

Remove the backing and affix the BCB along the reference edge tension free.

Secure the bar code tape to the mounting surface by pressing down with the palm of your hand.

When affixing, make certain that the BCB is free of folds and creases and that no air pockets form.

NOTICE

When mounting, do not pull on the BCB!

The BCB is a plastic tape that can be stretched by strong mechanical tension. The stretching results

in lengthening of the tape and distortion of the position values on the BCB.

While the BPS can still perform the position calculation in the event of distortions, the absolute measurement accuracy is no longer ensured in this case. If the values are taught using a teach-in process,

stretching of the BCB is irrelevant.

If a bar code tape was damaged, e.g., by falling parts, you can download a repair kit for the BCB

from the Internet (see chapter 11.2.2 "BCB repair with repair kit").

Use the bar code tape created with the repair kit only temporarily as an emergency solution.

Leuze electronic BPS 307i 35

Page 36

Mounting and installation

1

2

3

BCB mounting in horizontal curves

NOTICE

Limited absolute measurement accuracy and reproducibility!

BCB mounting in curves decreases the absolute measurement accuracy of the BPS, since the dis-

tance between two bar codes is no longer exactly 40 mm or 30 mm.

For horizontal curves, maintain a minimum bending radius of 300 mm (see figure 6.4).

1BPS

2 Reading distance

3 Radius of the bar code tape, R

= 300 mm

min

Figure 6.4: Mounting the bar code tape for use in horizontal curves

BCB mounting in vertical curves

NOTICE

Limited absolute measurement accuracy and reproducibility!

BCB mounting in curves decreases the absolute measurement accuracy of the BPS, since the dis-

tance between two bar codes is no longer exactly 40 mm or 30 mm.

In areas where the BCB is fanned out around curves, limitations of the reproducibility must be

expected.

Leuze electronic BPS 307i 36

Page 37

Mounting and installation

1

2

Only partially cut the BCB at the cut mark.

Affix the BCB along the curve like a fan (see figure 6.5).

Ensure that the BCB is affixed without mechanical tension.

NOTICE

No glossy gaps in the bar code tape!

Ensure that there are matt, bright surfaces behind the fanning in the BCB curves.

Polished, reflective, and high-gloss surfaces in the scanning beam may impair the measurement quality of the BPS.

000040

000044

000048

000052

000056

Figure 6.5: Preparing the bar code tape for use in vertical curves

Mounting twin tapes

If two bar code tapes with the same value range are used for positioning, e.g., for crane systems or eleva-

tors, the use of twin tapes is recommended (see chapter 3.4.4 "Twin tapes").

“Upside down” in order to have the same values at the same position (see figure 6.6).

1 Twin bar code tape 1

2 Twin bar code tape 2

Leuze electronic BPS 307i 37

Figure 6.6: Mounting twin tapes

Page 38

Mounting and installation

1

2

NOTICE

A twin tape always consists of two bar code tapes.

When ordering twin tapes, two bar code tapes are always included with an order.

Ensure that the BCB is affixed without tension.

The BCB is a plastic tape that can be stretched by strong mechanical tension. Excessive mechanical

stretching results in lengthening of the tape and distortion of the position values.

Mounting two bar code tapes with the same value range

For crane systems or elevators, two bar code tapes with the same value range are used for positioning.

If two bar code tapes with the same value range are needed, the use of twin tapes is recom-

mended (see chapter 3.4.4 "Twin tapes").

If a twin tape is not used: To have the same values at the same position, one bar code tape must be affixed

with numbers upside down while the other is affixed normally (see figure 6.7).

1 BCB affixed upside down

2 BCB affixed normally

Figure 6.7: Affixing two bar code tapes with the same value range

6.2 Bar code positioning system

The BPS can be mounted in the following ways:

• Mounting using a mounting device on the fastening grooves

• BTU 0300M-W: Wall mounting

• BT 56: Mounting on a rod

• Mounting using a mounting device on the M4 mounting threads on the rear of the device

• BT 300 W: Mounting on a mounting bracket

• BT 300-1: Mounting on a rod

• Mounting using four M4 mounting threads on the rear of the device

If the BTU 0300M-W mounting device is used to mount the device, the new device is automati-

cally aligned correctly should it be necessary to exchange a device.

Leuze electronic BPS 307i 38

Page 39

6.2.1 Mounting instructions

300 mm

NOTICE

Select the mounting location.

Make certain that the required environmental conditions (humidity, temperature) are maintained.

Make certain that the distance between BPS and bar code tape is sufficiently large.

The scanning beam of the BPS should cover three or more bar codes.

The distance between BPS and bar code tape must be in the working range of the reading field curve.

Make certain that the exit window does not become soiled, e.g., by leaking liquids, abrasion from card-

board packaging or residues from packaging material.

Mounting the BPS outdoors or with BPS with integrated heating:

Mount the BPS in a way which provides maximum thermal isolation, e.g., using rubber-bonded metal.

Mount the BPS so that it is protected from airflow, e.g., in a protective housing.

Mounting the BPS in a protective housing:

When installing the BPS in a protective housing, ensure that the scanning beam can exit the protective

housing without obstruction.

Make certain that the scanning range determined from the scanning curve is adhered to at all locations

where a position determination is to be made.

Ensure that the scanning beam is always incident on the BCB when the system is moving.

For the position calculation, the scanning beam of the BPS must be incident on the BCB without interruption.

For the best functionality, the BPS must be guided parallel to the BCB. It is not permitted to move outside of the approved working range of the BPS (50 … 170 mm) while the system is in motion.

Make certain that there is only one control bar code (or marker label) in the scanning beam at a time.

The minimum distance between two control bar codes is determined by the distance between the BPS

and bar code tape and the resulting length of the scanning beam.

Mounting and installation

NOTICE

For parallel mounting, maintain the minimum distance!

Maintain the minimum distance of 300 mm if you mount two BPS next to or above one another.

Figure 6.8: Minimum distance for parallel mounting

NOTICE

Install the connection hood before mounting the BPS!

Screw connection hood MS 307, MK 307 or KB 307 to the device housing with two M4 screws.

Tighten the screws on the connection hood with a tightening torque of 1.4 Nm.

Leuze electronic BPS 307i 39

Page 40

6.2.2 Orientation of the BPS to the bar code tape

1

3

2

2

50

The beam of the BPS must be oriented at an incline of 7° to the bar code tape (see figure 6.9). When positioning, make certain that the angle of radiation to the rear side of the housing is 90 ° and the reading

distance to the bar code tape is maintained.

Mounting and installation

4

4

4

1 Reading distance

2 Reference point for the bar code position

3 Scanning beam

Figure 6.9: Beam exit

6.2.3 Mounting with the BTU 0300M-W mounting device

Mounting the BPS with a BTU 0300M-W mounting device is intended for wall mounting. For ordering information see chapter 14; for dimensioned drawing see figure 13.9.

Leuze electronic BPS 307i 40

Page 41

Mounting and installation

1

2

3

1 Clamp profile

2 Clamping jaws

3 Screw terminal

Figure 6.10: Mounting the BPS with the BTU 0300M-W mounting device

Mount the BTU 0300M-W on the system side with M6 fastening screws (not included in delivery con-

tents).

Mount the BPS with the dovetail fastening grooves on the clamping jaws of the BTU 0300M-W with limit

stop at end.

Secure the BPS with the M6 screw terminal.

Maximum tightening torque for the M6 screw terminal: 8 Nm

6.2.4 Mounting with the BT 300 W mounting bracket

Mounting of the BPS with a BT 300 W mounting bracket is intended for wall mounting. For ordering information see chapter 14; for dimensioned drawing see figure 13.10.

Mount the BT 0300 W mounting bracket on the system side with M6 fastening screws (included in deliv-

ery contents).

Mount the BPS on the mounting bracket with M4 fastening screws (included in delivery contents).

Maximum tightening torque of the M4 fastening screws: 2 Nm

6.2.5 Mounting with BT 56 mounting device

Mounting of the BPS with a BT 56 mounting device is intended for rod mounting. For ordering information

see chapter 14; for dimensioned drawing see figure 13.11.

Mount the BT 56 on the rod with the clamp profile (system-side).

Mount the BPS with its fastening grooves on the clamping jaws of the BT 56 with limit stop at end.

Secure the BPS with the M6 screw terminal.

Maximum tightening torque for the M6 screw terminal: 8 Nm

Leuze electronic BPS 307i 41

Page 42

6.2.6 Mounting with BT 300-1 mounting device

Mounting of the BPS with a BT 300-1 mounting device is intended for rod mounting. For ordering information see chapter 14; for dimensioned drawing see figure 13.12.

Mount the BT 300-1 mounting device with the clamp profile on the rod (system-side).

Mount the BPS on the mounting bracket of the BT 300-1 with M4 fastening screws (included in delivery

contents).

Maximum tightening torque of the M4 fastening screws: 2 Nm

6.2.7 Mounting with M4 fastening screws

Mounting and installation

all dimensions in mm

Figure 6.11: Dimensioned drawing of rear of BPS

Mount the BPS on the system with M4 fastening screws (not included in delivery contents).

Maximum tightening torque of the fastening screws: 2 Nm

Leuze electronic BPS 307i 42

Page 43

7 Electrical connection

CAUTION

Safety notices!

Before connecting the device, be sure that the supply voltage agrees with the value printed on the

name plate.

Only allow competent persons to perform the electrical connection.

Ensure that the functional earth (FE) is connected correctly.

Fault-free operation is only guaranteed if the functional earth is connected properly.

If faults cannot be rectified, take the device out of operation. Protect the device from accidentally being

started.

CAUTION

UL applications!

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National

Electric Code).

Electrical connection

NOTICE

Protective Extra Low Voltage (PELV)

The BPS is designed in accordance with protection class III for supply with PELV (protective extra-low

voltage).

NOTICE

Connection hood and degree of protection IP 65

Before connecting, mount the connection hood on the BPS device housing.

To ensure degree of protection IP 65 is fulfilled, the screws of the connection hood are tightened with

a tightening torque of 1.4 Nm for connecting to the BPS.

Degree of protection IP 65 is not fulfilled until connectors or cable bushings are screwed on and caps

are installed.

For all connections (connection cable, interconnection cable, etc.), use only the cables listed in

the accessories (see chapter 14).

7.1 External parameter memory in the connection hood

To enable simple exchange of the BPS, the integrated parameter memory of the MS 307 and MK 307

connection hoods store a copy of the current parameter set.

Also located in the MS 307 and MK 307 are switches S1 and S2.

• Slide switch S1 is used to toggle the encoding of the output measurement value between

binary

.

• Rotary switch S2 is used to set the resolution of the position value (in mm) or a speed monitoring

function.

NOTICE

No parameter memory and no configuration switches in connection hood KB 307!

No parameter memory is integrated in connection hood KB 307.

Connection hood KB 307 does not include any switches for configuring the BPS.

Leuze electronic BPS 307i 43

Gray

and

Page 44

7.2 MS 307 connection hood with connectors

The MS 307 connection hood features two M12 connector plugs and a Mini-B type USB socket as a

service interface.