BCL 604i

Bar Code Reader

EN 2015/04 - 50129186

We reserve the right to

make technical changes

Original operating instructions

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Laser safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.1 Laser safety notices– laser class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Device overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Device construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.1 Structure of the control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.2 Status display and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5.3 LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 Operational controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.7 External parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 autoReflAct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 autoConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Reading techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Line scanner (single line). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Line scanner with oscillating mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Omnidirectional reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Device arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.1 Selecting a mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.2 Avoiding total reflection – Line scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.3 Avoiding total reflection – oscillating-mirror scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.4 Possible read angles between device and bar code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Installing the external parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 PWR – Voltage supply and switching inputs/outputs 3 and 4 . . . . . . . . . . . . . . . . . . . . . . 29

7.3 SERVICE – USB interface (type A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.4 SW IN/OUT – Switching input/switching output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.5 HOST / BUS IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6 BUS OUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.7 PROFIBUS termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.8 Cable lengths and shielding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Leuze electronic BCL 604i 3

8.1 The main menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Parameter menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.3 Language selection menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.4 Service menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.5 Actions menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 Commissioning – Leuze electronic webConfig tool . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Connecting the service USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2.2 Installing the USB driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Starting the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4 Short description of the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.5 Module overview in the Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Starting up the device - Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 General information on the PROFIBUS implementation . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.1Communication profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.2Bus-access protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.3Device types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.4Expanded DP functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.1.5Automatic baud rate detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.2 Measures to be performed prior to the initial commissioning . . . . . . . . . . . . . . . . . . . . . . 49

10.3 Setting the address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.3.1Setting the device address on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.4 Commissioning via the PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.4.1General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.4.2Preparing the control system for consistent data transmission . . . . . . . . . . . . . . . . . . . . . 51

10.4.3General information on the GSD file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.4.4Permanently defined parameters/device parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.5 Overview of the project modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.6 Decoder modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.6.1Modules 1-4 – Code table extensions 1 to 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.6.2Module 5 – Code type features (symbology) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.6.3Module 7 – Code reconstruction technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.7 Control modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.7.1Module 10 – Activations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.7.2Module 11 – Reading gate control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.7.3Module 12 – Multi-label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.7.4Module 13 – Fragmented read result. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.7.5Module 14 – Interlinked read result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.8 Result Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.8.1Module 20 – Decoder state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.8.2Modules 21-27 – Decoding result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.8.3Module 30 – Data formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.8.4Module 31 – Reading gate number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.8.5Module 32 – Reading gate time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.8.6Module 33 – Code position . . . . . . . . . . . . . . . .

10.8.7Module 34 – Reading reliability (equal scans) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.8.8Module 35 – Bar code length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.8.9Module 36 – Scans with information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.8.10Module 37 – Decoding quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.8.11Module 38 – Code direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.8.12Module 39 – Number of digits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.8.13Module 40 – Code type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68

Leuze electronic BCL 604i 4

10.8.14Module 41 – Code position in the swivel range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.9 Data Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.9.1Module 50 – Characteristics filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.9.2Module 51 – Data filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.10 Identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.10.1Module 52 – Segmentation according to the EAN process . . . . . . . . . . . . . . . . . . . . . . . 73

10.10.2Module 53 – Segmentation via fixed positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.10.3Module 54 – Segmentation according to identifier and separator . . . . . . . . . . . . . . . . . . 76

10.10.4Module 55 – String handling parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.11 Device Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.11.1Module 60 – Device status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.11.2Module 61 – Laser control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.11.3Module 62 – Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.11.4Module 63 – Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.11.5Module 64 – Oscillating mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.11.6Module 65 – Deflection mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.12 Switching inputs/ outputs SWIO 1 … 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.12.1Parameters for operating as an output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.12.2Parameters for operating as an input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.12.3Switch-on and switch-off functions for operation as an output. . . . . . . . . . . . . . . . . . . . . 85

10.12.4Input functions for operation as an input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.12.5Module 70 – Switching input/output SWIO1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.12.6Module 71 – Switching input/output SWIO2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.12.7Module 72 – Switching input/output SWIO3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.12.8Module 73 – Switching input/output SWIO4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.12.9Module 74 – SWIO status and control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.13 Data output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.13.1Module 80 – Sorting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.14 Reference code comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.14.1Module 81 – Reference code comparator 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.14.2Module 82 – Reference code comparator 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.14.3Module 83 – Reference code comparison pattern 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.14.4Module 84 – Reference code comparison pattern 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.15 Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.15.1Module 90

10.15.2Module 91 – AutoReflAct (automatic reflector activation) . . . . . . . . . . . . . . . . . . . . . . . . 98

10.15.3Module 92 – AutoControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.16 Example configuration: Indirect activation via the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.16.1Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.16.2Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.17 Sample configuration: Direct activation via the switching input . . . . . . . . . . . . . . . . . . . . 100

10.17.1Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.17.2Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

– Status and control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . 97

11 Care, maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11.3 Disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

12 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

12.1 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

12.2 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

13.1 What to do should servicing be required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Leuze electronic BCL 604i 5

14 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1.1 Line scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

14.1.2Oscillating-mirror scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

14.2 Dimensioned drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.3 Dimensioned drawings: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

14.4 Reading field curves / optical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

14.5 Reading field curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

14.5.1Medium Density (M) - optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

14.5.2Low Density (F) - optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

15 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

16 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

17 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

17.1 ASCII character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

17.2 Bar code samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

17.2.1Module 0.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

17.2.2Module 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Leuze electronic BCL 604i 6

1 About this document

1.1 Used symbols and signal words

Table 1.1: Warning symbols and signal words

Symbol indicating dangers to persons

NOTICE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger avoidance are not followed.

Table 1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

About this document

Table 1.3: Terms and abbreviations

BCL Bar code reader

CRT Code reconstruction technology

Symbols for action steps

Text passages with this symbol instruct you to perform actions.

Leuze electronic BCL 604i 7

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The device is designed as a stationary high-speed scanner with integrated decoder for all common bar

codes for automatic object detection.

Areas of application

The device is specially designed for the following areas of application:

• Object identification on fast-moving conveyor lines

• Omnidirectional reading

CAUTION

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability insurance asso-

ciation.

Safety

2.2 Foreseeable misuse

Any use other than that defined under “Intended use” or which goes beyond that use is considered

improper use.

In particular, use of the device is not permitted in the following cases:

• Rooms with explosive atmospheres

• Circuits relevant to safety

• For medicinal purposes

CAUTION

Do not modify or otherwise interfere with the device.

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant stan-

dards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

Leuze electronic BCL 604i 8

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

2.5 Laser safety notices

2.5.1 Laser safety notices– laser class 2

ATTENTION, LASER RADIATION – LASERCLASS2

Never look directly into the beam!

The device fulfills the IEC 60825-1:2007 (EN 60825-1:2007) requirements for a product in laser class 2

as well as the U.S. 21 CFR 1040.10 regulations with deviations corresponding to “Laser Notice No. 50”

from June 24th, 2007.

Never look directly into the laser beam or in the direction of reflecting laser beams.

If you look into the beam path over a longer time period, there is a risk of injury to the retina.

Do not point the laser beam of the device at persons!

Interrupt the laser beam using a non-transparent, non-reflective object if the laser beam is accidentally

directed towards a person.

When mounting and aligning the device, avoid reflections of the laser beam off reflective surfaces!

CAUTION! The use of operating or adjusting devices other than those specified here or carrying out

of differing procedures may lead to dangerous exposure to radiation.

Adhere to the applicable legal and local regulations regarding protection from laser beams.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Safety

CAUTION

Affix laser information and warning signs!

Laser information and warning signs attached to the device(see figure 2.1). Also included with the device

are self-adhesive laser warning and laser information signs (stick-on labels) in multiple languages (see

figure 2.3).

Affix the laser information sheet to the device in the language appropriate for the place of use.

When using the device in the US, use the stick-on label with the “Complies with 21 CFR 1040.10”

notice.

Affix the laser information and warning signs near the device if no signs are attached to the device (e.g.

because the device is too small) or if the attached laser information and warning signs are concealed

due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing the reader to the

laser radiation of the device or other optical radiation.

Leuze electronic BCL 604i 9

1 Laser aperture

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

2 mW

<150 µs

405 nm

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

2 3

1

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

2 mW

<150 μs

405 nm

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

2 3

1

2 Laser warning sign

3 Laser information sign with laser parameters

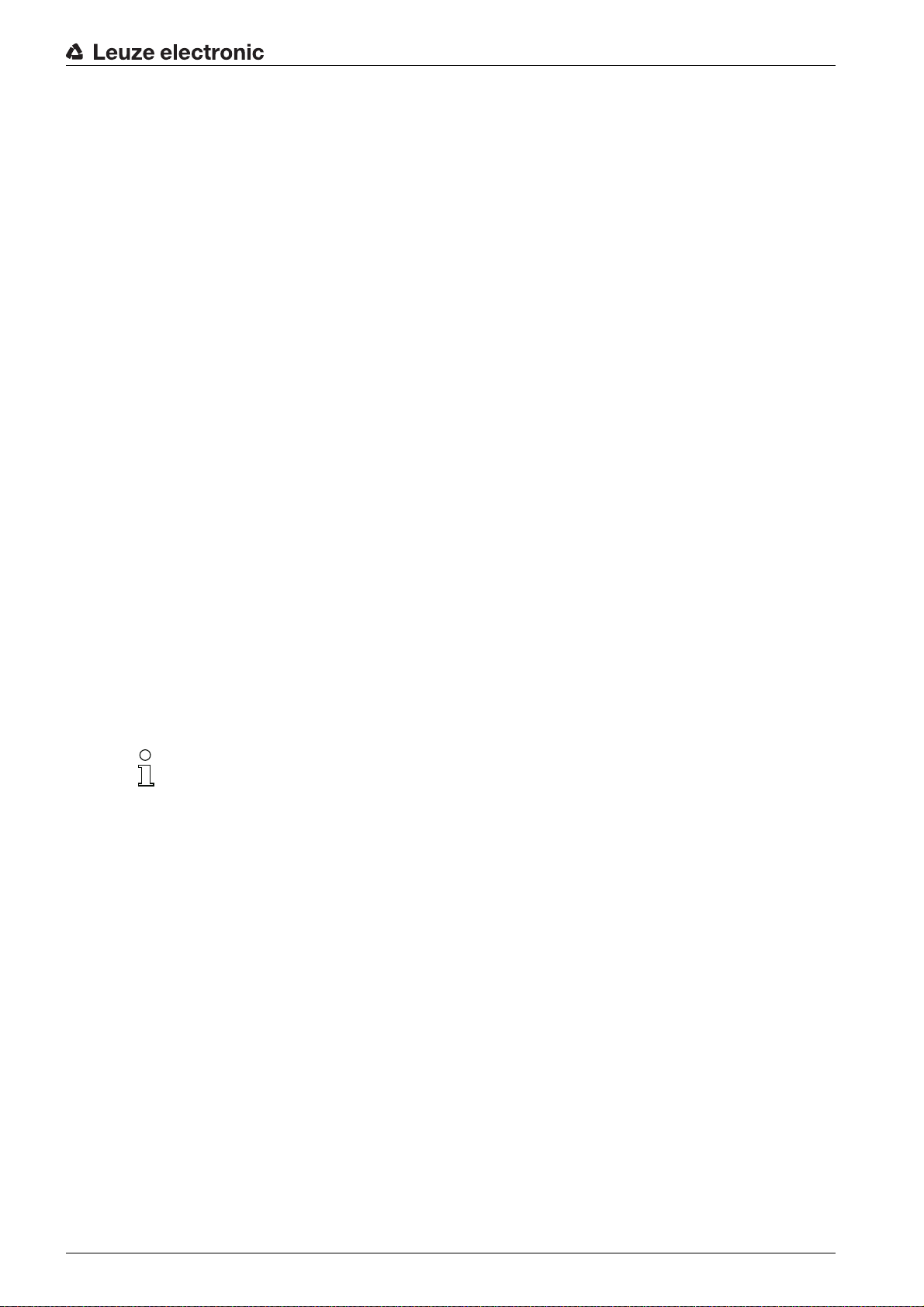

Figure 2.1: Laser aperture, laser warning and information signs - line scanner

Safety

1 Laser aperture

2 Laser warning sign

3 Laser information sign with laser parameters

Figure 2.2: Laser aperture, laser warning and information signs - oscillating-mirror scanner

Leuze electronic BCL 604i 10

Safety

AVOID EXPOSURE – LASER RADIATION

IS EMITTED FROM THIS APERTURE

EXPOSITION DANGEREUSE – UN RAYONNEMENT

LASER EST ÉMIS PAR CETTE OUVERTURE

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

DIN EN 60825-1:2008-05

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER

NON FISSARE IL FASCIO

APARRECCHIO LASER DI CLASSE 2

EN 60825-1:2007

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2007

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

EN 60825-1:2007

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

PRODUCTO LÁSER DE CLASE 2

EN 60825-1:2007

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

EQUIPAMENTO LASER CLASSE 2

EN 60825-1:2007

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

IEC 60825-1:2007

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

䉏⏘戟⺓

▎䦃展⏘㧮

伊䉏⏘ℶ❐

GB7247.1-2012

㦏⮶戢⒉᧤⽿⋋᧥

厘⑁㖐兼㢅梃

㽱栎

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150

µ

s

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

2 mW

<150 µs

405 nm

50127630

Figure 2.3: Laser warning and information signs – supplied stick-on labels

Leuze electronic BCL 604i 11

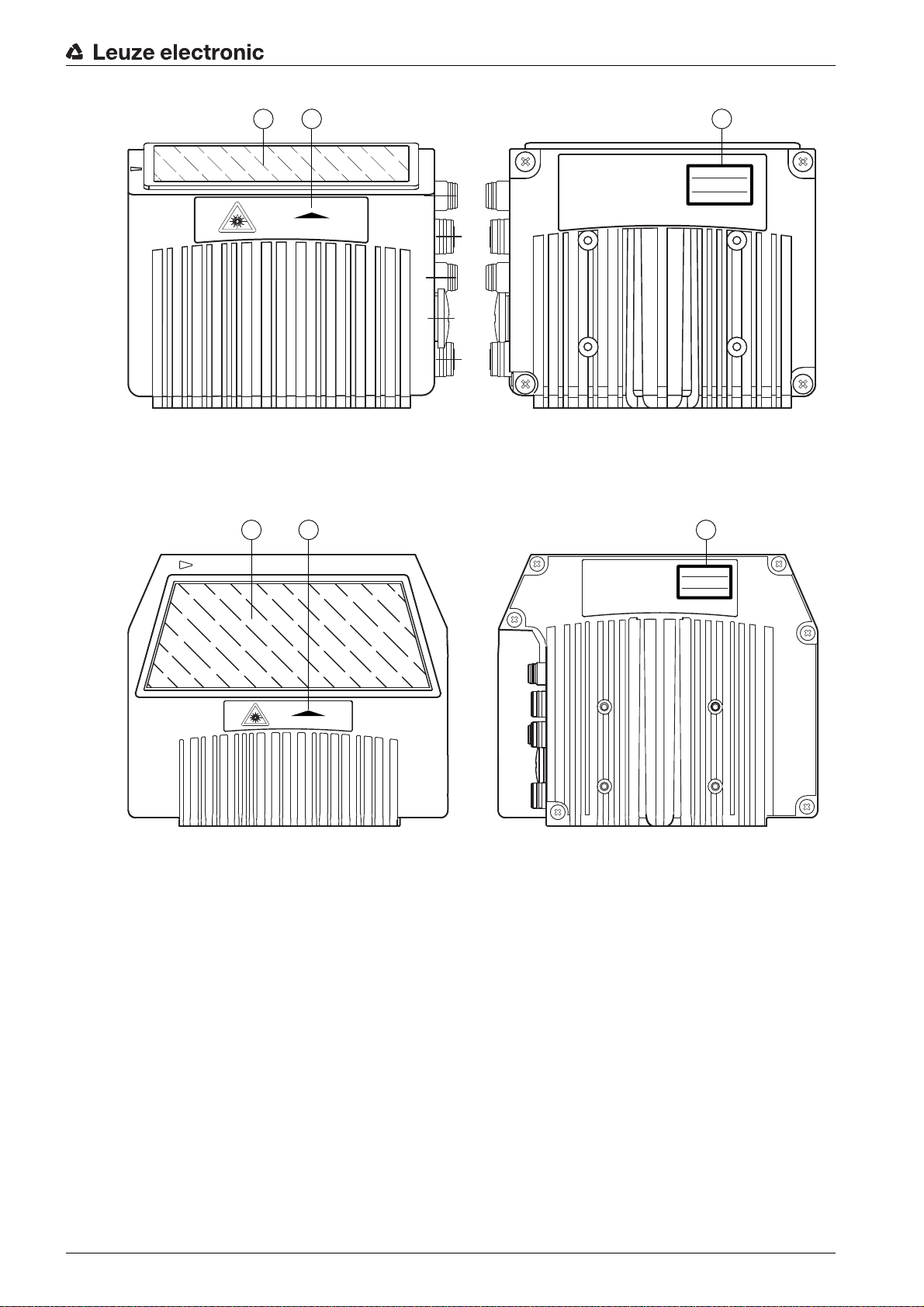

3 Device description

2

1

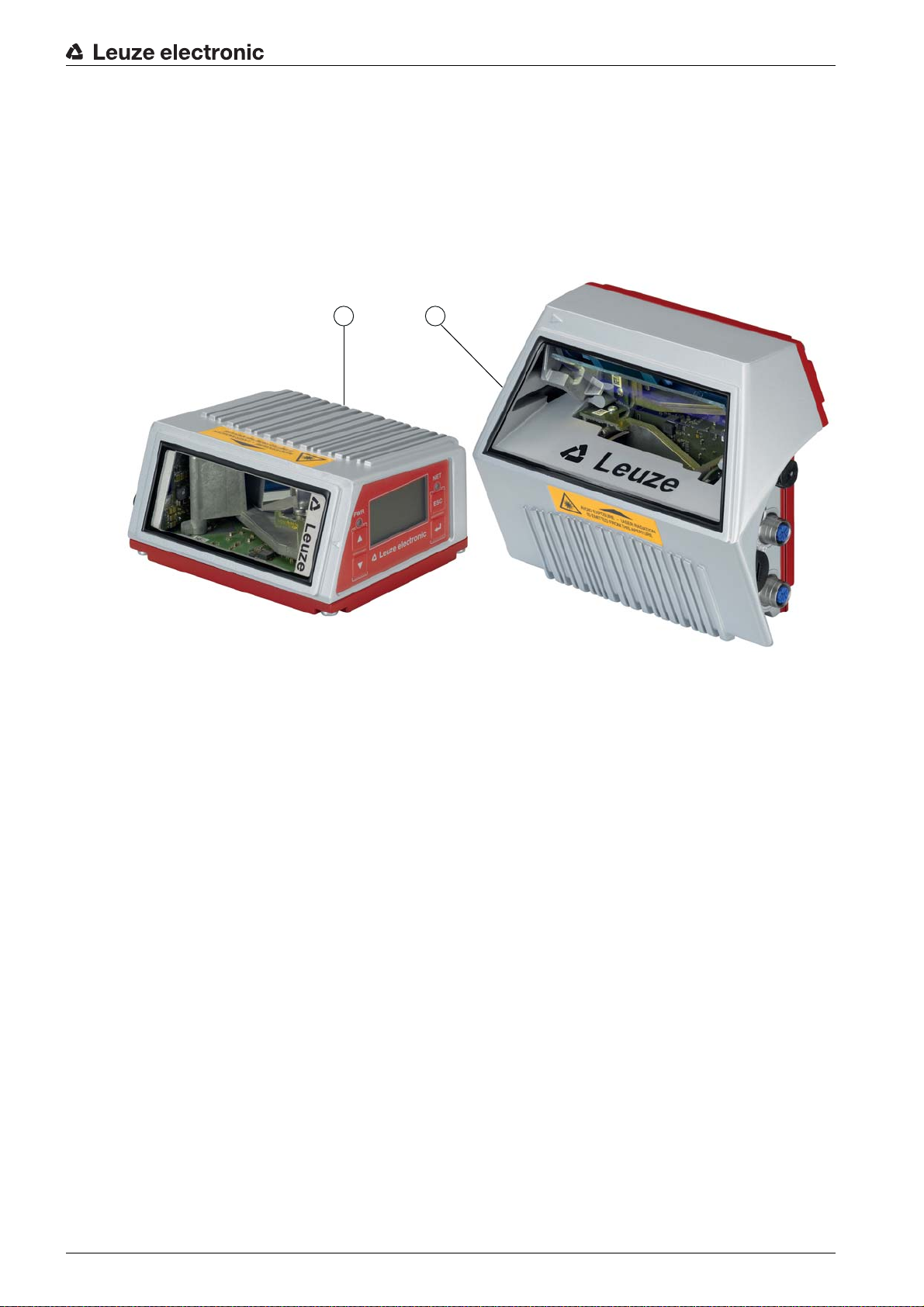

3.1 Device overview

Bar code readers of the BCL 600i series are high-speed scanners with integrated decoder for all

commonly used bar codes, e.g. 2/5 Interleaved, Code 39, Code 128, EAN 8/13 etc., as well as codes from

the GS1 DataBar family.

Bar code readers of the BCL 600i series are available in various optics models and as line scanners and

oscillating mirrors.

Device description

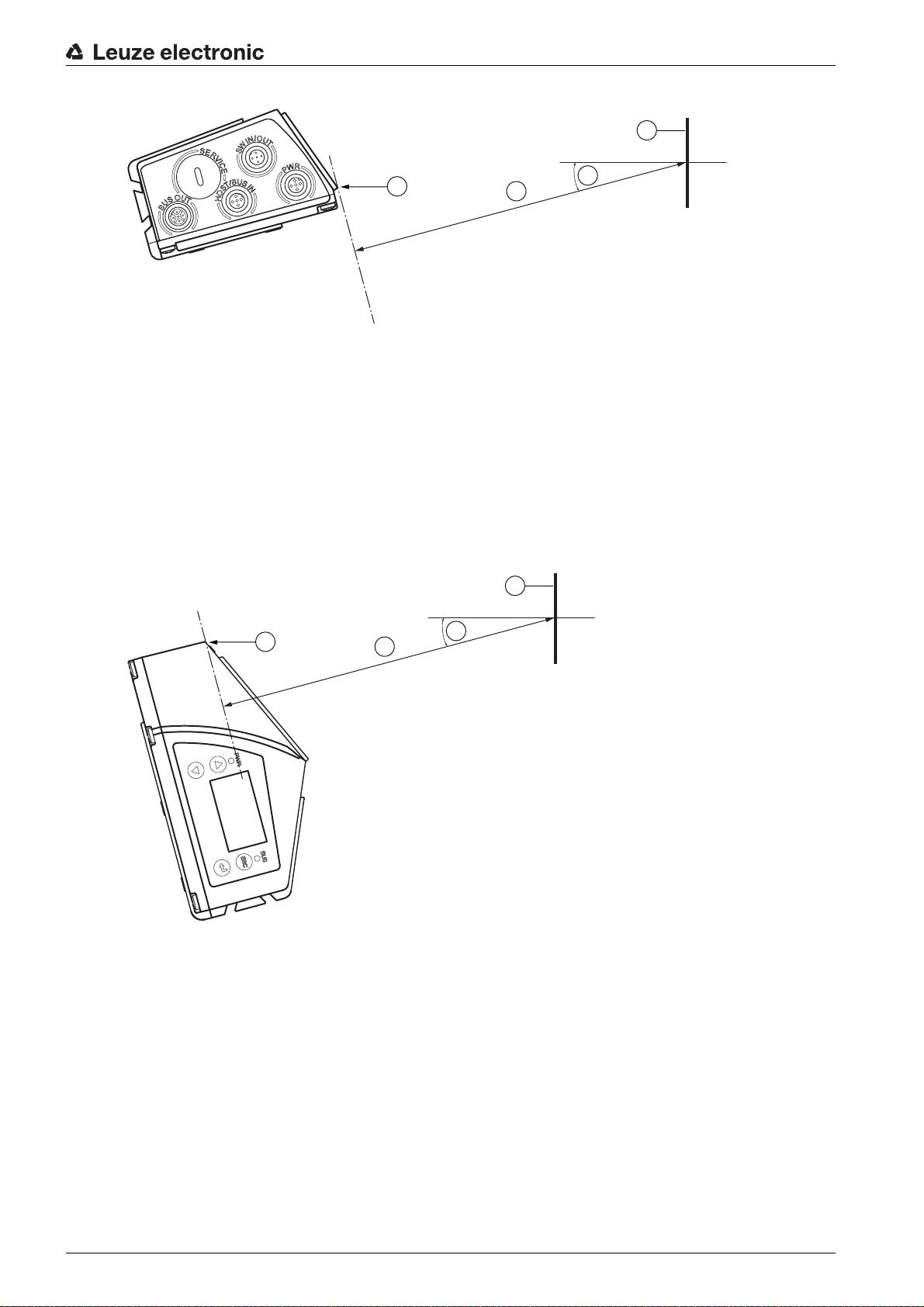

1 Line scanner

2 Oscillating-mirror scanner

Figure 3.1: Line scanner and oscillating-mirror scanner

The extensive options for device configuration via display or software enable adaptation to a multitude of

reading tasks. Due to the large reading distance combined with the great depth of field and a very compact

construction, the device is ideally suited for package and pallet transportation systems. In general, the bar

code readers of the BCL 600i series are designed for the conveyor and storage technology market.

The interfaces (RS 232, RS 485 and RS 422) integrated in the various device models and the fieldbus

systems (Profibus DP, PROFINET-IO, Ether net TCP/IP / UDP and Ethernet/IP) of the BCL 600i series bar

code readers offer optimum connection to the superior host system.

3.2 Performance characteristics

• Integrated fieldbus connectivity = i -> Plug-and-Play fieldbus coupling and easy networking

• Numerous interface variants facilitate connection to the superior systems

• RS 232, RS 422 as well as with integrated multiNet plus master

• RS 485 and multiNet plus slave

• alternatively, various fieldbus systems, such as

PROFINET-IO

Ethernet TCP/IP

Ethernet /IP

Ethernet

PROFIBUS DP

Leuze electronic BCL 604i 12

Device description

• Integrated code reconstruction technology (CRT) enables the identification of soiled or damaged bar

codes

• Maximum depth of field and reading distances from 400 mm to 1450 mm

• Large optical opening angle and, thus, large reading field width

• High scanning rate of 800 / 1000 scans/s for fast reading tasks

• Intuitive, backlit, multi-language display with user-friendly menu navigation

• Integrated USB 1.1 service interface

• Adjustment of all device parameters with a web browser

• Connection options for an external parameter memory

• Easy alignment- and diagnostics functions

• M12 connections with Ultra-Lock ™ technology

• Four freely programmable switching inputs/outputs for the activation or signaling of states

• Automatic monitoring of the read quality with autoControl

• Automatic recognition and setting of the bar code type using autoConfig

• Reference code comparison

• Heavy-duty housing of degree of protection IP 65

Leuze electronic BCL 604i 13

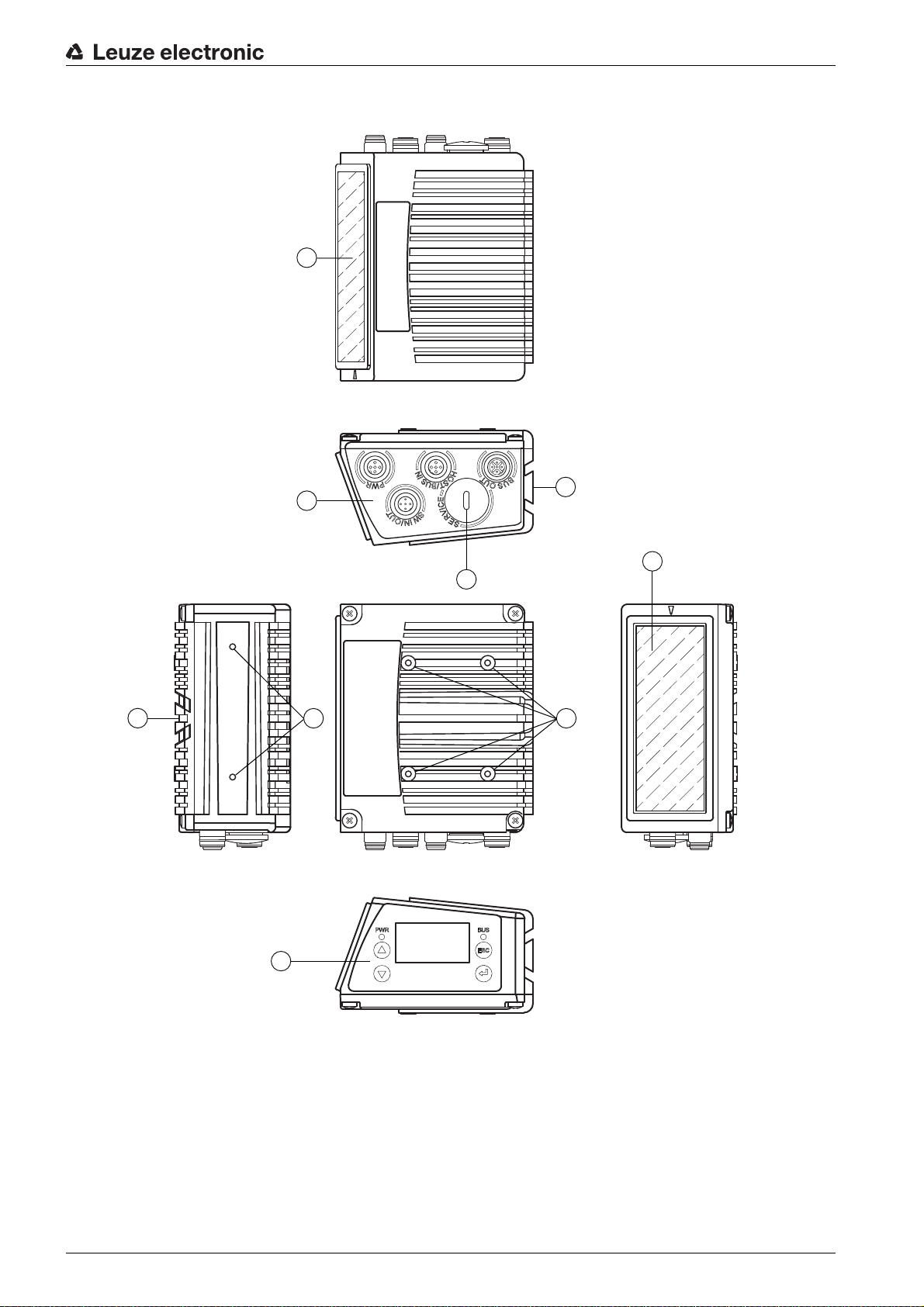

3.3 Device construction

1

1

2

3

5

6

4

66

Device description

1 Reading window

2 Control panel with display, LEDs and buttons

3 M12 connection technology

4 USB interface

5 Dovetail mounting

6 M4 mounting thread

Figure 3.2: Device construction

Leuze electronic BCL 604i 14

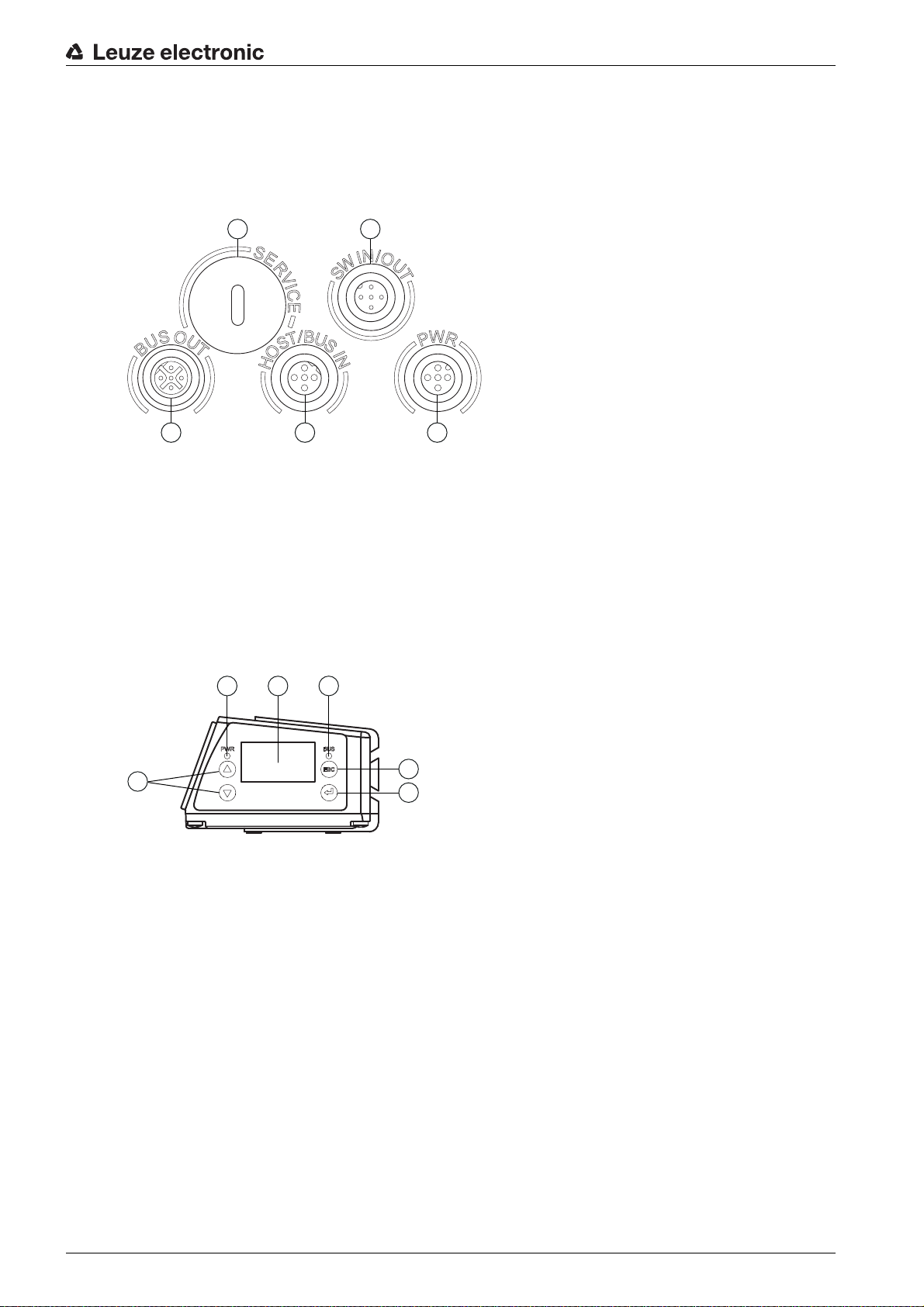

3.4 Connection technology

3 4 5

2

1

3

2

1

4

5

6

The bar code readers are connected using variously coded M12 connectors. This ensures unique connection assignments.

The additional USB interface is used for configuring the device.

For the locations of the individual device connections, please refer to the device detail shown below.

1 Service, USB socket, type A

2 SW In/Out, M12 socket (A-coded)

3 Bus Out, M12 socket (D-coded)

4 Host/Bus In, M12 socket (D-coded)

5 PWR, M12 plug (A-coded)

Figure 3.3: Location of the electrical connections

Device description

3.5 Display elements

3.5.1 Structure of the control panel

1LED PWR

2 LED NET

3 Navigation buttons

4 Escape button

5 Enter button

6 Display

Figure 3.4: Structure of the control panel

Leuze electronic BCL 604i 15

3.5.2 Status display and operation

Indicators in the display

le 3.1: Status displays of the switching inputs/outputs

Tab

Device description

IO1

Switching input or switching output 1 active (function dependent on set configuration).

Default: Switching input with the “Reading gate activation” function

IO2 Switching input or switching output 2 active (function dependent on set configuration).

Default: Input with the “Teach-in” function

IO3 Switching input or switching output 3 active (function dependent on set configuration).

Default: Switching input with the “Reading gate activation” function

IO4 Switching input or switching output 4 active (function dependent on set configuration).

Default: Switching output with the “No read” function

ATT Warning (Attention)

ERR Internal device error (Error) -> The device must be sent in for inspection

Bar graph

The read quality is described on a scale of 0 - 100 %. The quality is evaluated based on the “Equal Scans”

of the read result configured in the bar code reader.

Table 3.2: Status display of the USB interface

USB The device is connected to a PC via the USB interface.

MS An external parameter memory is properly connected to the USB interface of the device.

Read result

The read bar code information is displayed.

3.5.3 LED indicators

PWR LED

Off Device OFF

Flashes green Device ok, initialization phase

Green, continuous light

• No supply voltage

• No bar code reading possible

• Voltage connected

• Self test running

• Initialization running

Device OK

• Bar code reading possible

• Self test successfully finished

• Device monitoring active

Leuze electronic BCL 604i 16

Device description

Orange, continuous light

Service mode

• Bar code reading possible

• Configuration via the USB service interface

• Configuration via the display

• No data on the host interface

Flashes red Device ok, warning set

• Bar code reading possible

• Temporary operating fault

Red, continuous

light

Device error / parameter enable

• No bar code reading possible

NET LED

Off No supply voltage

• No communication possible

• Profibus DP communication not initialized or inactive

Flashes green Initialization

• of the device, establishing communication

Green, continuous light

Operation OK

• Network mode ok

• Connection and communication to IO controller (PLC) established (data

exchange)

Flashes red Communication error

Red, continuous

Network error

light

3.6 Operational controls

Navigating within the menus

Use the navigation buttons to move through the menu. Activate the desired selection with the enter

button .

Press the escape button to move up one menu level.

When one of the buttons is actuated, the display illumination is activated for 10 min.

Setting values

Set the desired value with the navigation buttons and the enter button .

An accidental incorrect entry can be corrected by selecting the left arrow button and then pressing the

enter button.

Then use the navigation buttons to select save and save the set value by pressing the enter button.

Selecting options

Set the desired option with the navigation buttons and the enter button .

• Parameterization or configuration failed (parameter failure)

•IO error

• No data exchange

• No communication (protocol) to IO controller established (no data exchange)

ESC

Leuze electronic BCL 604i 17

3.7 External parameter memory

The optionally available external parameter memory – based on a USB memory stick (compatible with

version 1.1) – is housed in an external hood with integrated connectors which cover the USB service interface when installed (IP 65).

The external parameter memory makes it easy and reduces the time needed to replace a device on site

by providing a copy of the current parameter set of the device. This eliminates the need to configure the

exchanged device manually.

The delivery contents of the external parameter memory include the hood with integrated connectors with

unscrewable cover and the USB memory stick.

To mount, the cover of the service interface must be unscrewed. Then take the USB memory

stick and plug it into the USB connection on the device. Then, take the connector hood of the

USB memory stick and screw this over the plugged-in USB memory stick to the service interface

to close the system and ensure degree of protection IP 65.

Device description

Leuze electronic BCL 604i 18

4 Functions

General information

The integrated fieldbus connectivity = i contained in the bar code readers of the BCL 600i series facilitates

the use of identification systems which function without connection unit or gateways. The integrated

fieldbus interface considerably simplifies handling. The Plug-and-Play concept enables easy networking

and very simple commissioning: Directly connect the respective fieldbus and all configuration is performed

with no additional software.

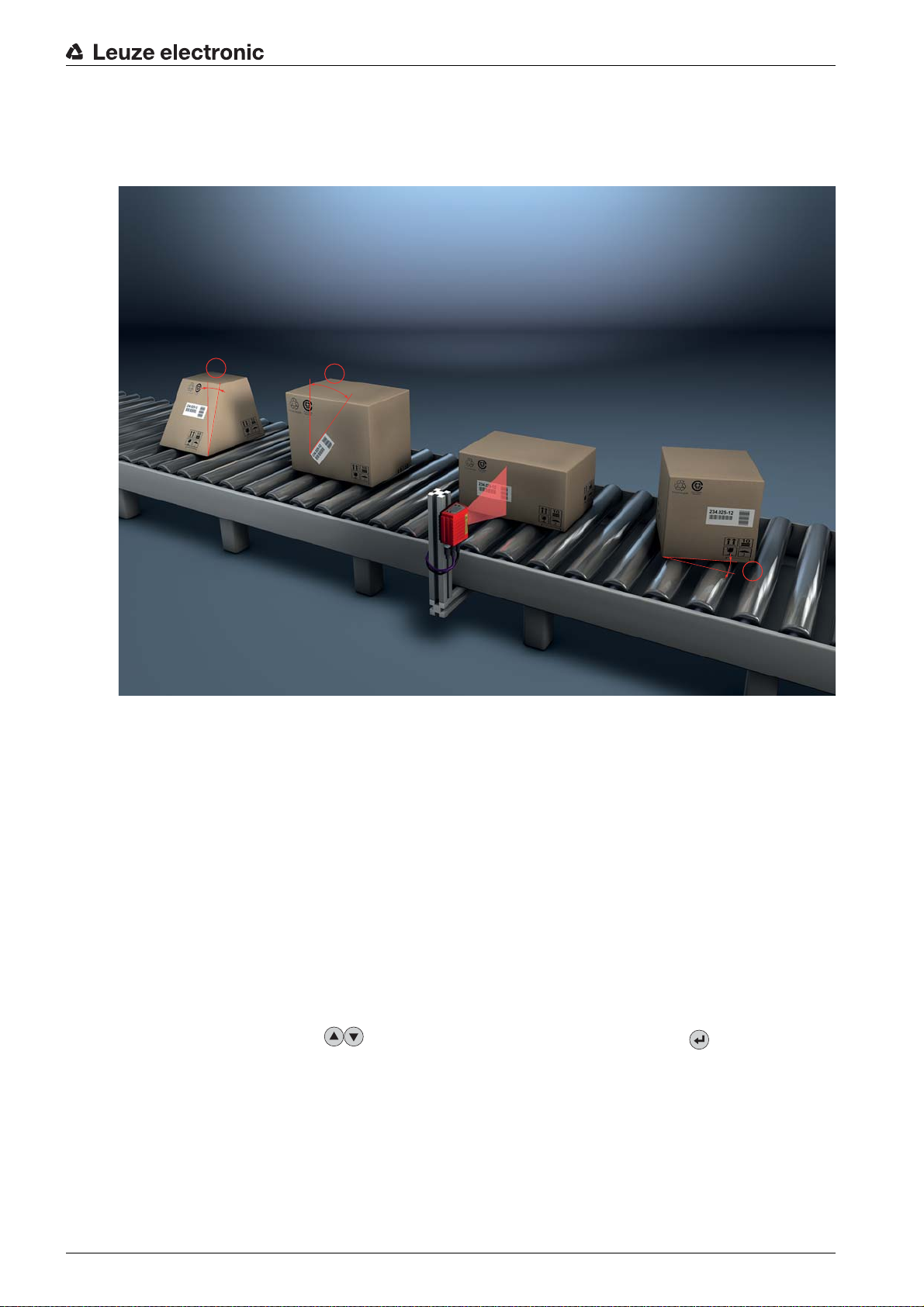

For decoding bar codes, the bar code readers of the BCL 600i series make available the proven CRT

decoder with code reconstruction technology:

The proven code reconstruction technology (CRT) enables bar code readers of the BCL 600i series to

read bar codes with a small bar height, as well as bar codes with a damaged or soiled print image.

With the aid of the CRT decoder, bar codes can also be read without problem in other demanding situations, such as with a large tilt angle (azimuth angle or even twist angle).

Functions

Figure 4.1: Possible bar code orientation

With the BCL 604i, configuration is generally performed with the aid of the GSD file.

The device needs a suitable activation to start a read process as soon as an object is in the reading field.

This opens a time window (reading gate) in the device for the read process during which the bar code

reader has time to detect and decode a bar code.

In the basic setting, triggering takes place through an external reading cycle signal. Alternative activation

options include online commands via the host interface and the autoReflAct function. In the basic setting,

triggering takes place through an external reading cycle signal or via the PROFIBUS. An alternative option

for activation is the autoReflAct function.

In the basic setting, triggering takes place through an external reading cycle signal. Alternative activation

options include online commands via the host interface and the autoReflAct function. Through the read

operation, the device collects additional useful pieces of data for diagnosis which can also be transmitted

to the host. The quality of the read operation can be inspected using the alignment mode which is integrated in the webConfig tool.

A multi-language display with buttons is used to operate the device as well as for visualization purposes.

Two LEDs provide additional optical information on the current operating state of the device.

Leuze electronic BCL 604i 19

The four freely configurable switching inputs/outputs SWIO 1 … SWIO 4 can be assigned various functions and control e.g. activation of the device or external devices, such as a PLC.

System, warning and error messages provide assistance in setup/troubleshooting during commissioning

and read operation.

4.1 autoReflAct

autoReflAct st a nds for automatic Reflector Activation and permits an activation without additional sensors.

This is achieved by directing the scanner with reduced scanning beam towards a reflector mounted behind

the conveyor path. As long as the scanner is targeted at the reflector, the reading gate remains closed. If,

however, the reflector is blocked by an object such as a container with a bar code label, the scanner activates the read procedure, and the label on the container is read. When the path from the scanner to the

reflector has cleared, the read procedure has completed and the scanning beam is reduced and again

directed onto the reflector. The reading gate is closed.

You will find a matching reflector in Accessories, and more are available on request.

Functions

Figure 4.2: Reflector arrangement for autoReflAct

The autoReflAct function uses the scanning beam to simulate a photoelectric sensor and thus permits an

activation without additional sensors.

Leuze electronic BCL 604i 20

4.2 autoConfig

With the autoConfig function, the device offers an extremely simple and convenient configuration option

to users who only want to read one code type (symbology) with one number of digits at a time.

After starting the autoConfig function via the display, switching input or from a superior control, it is sufficient to position a bar code label with the desired code type and number of digits in the reading field of the

device.

Afterward, bar codes with the same code type and number of digits are recognized and decoded.

The settings made via display or webConfig configuration tool push the parameters set in the

Profibus only temporarily into the background. They are overwritten during integration into the

Profibus or when the parameter enable is deactivated!

Device settings for operating the device on the Profibus are managed and configured exclusively

by the Profibus controller (PLC). Permanent changes must be carried out here!

For further information, see chapter 10 "Starting up the device - Configuration".

Functions

Leuze electronic BCL 604i 21

5 Reading techniques

5.1 Line scanner (single line)

A line (scan line) scans the label. Due to the opt. opening angle, the reading field width is dependent on

the read distance. Through the movement of the object, the entire bar code is automatically transported

through the scan line.

The integrated code reconstruction technology permits twisting of the bar code (tilt angle) within certain

limits. These are dependent on the transport speed, the scanning rate of the scanner and the bar code

properties.

Areas of application of the line scanner

The line scanner is used:

• when the bars of the bar code are printed in the conveying direction ('ladder arrangement').

• with bar codes having very short bar lengths.

• when the ladder code is turned out of the vertical position (tilt angle).

• when the reading distance is large.

Reading techniques

Figure 5.1: Deflection principle for the line scanner

5.2 Line scanner with oscillating mirror

The oscillating mirror deflects the scan line additionally to both sides across the scan direction at a

randomly adjustable oscillation frequency. In this way, the device can also scan larger areas or spaces for

bar codes. The reading field height (and the scan line length useful for evaluation) depends on the reading

distance due to the optical opening angle of the oscillating mirror.

Leuze electronic BCL 604i 22

Reading techniques

Areas of application of the line scanner with oscillating mirror

For line scanners with oscillating mirror, oscillation frequency, start/stop position etc. are adjustable. It is

used:

• when the position of the label is not fixed, e.g. on pallets – various labels can, thus, be detected at

various positions.

• when the bars of the bar code are printed perpendicular to the conveying direction (“picket fence

arrangement”).

• when reading stationary objects.

• when the bar code is turned out of the horizontal position.

• when the reading distance is large.

• when a large reading field (reading window) has to be covered.

Figure 5.2: Deflection principle for the line scanner with oscillating mirror add-on

5.3 Omnidirectional reading

In order to read arbitrarily oriented bar codes on an object, at least 2 bar code readers are necessary. If

the bar code is not printed over-square, i.e. bar length > code length, bar code readers with integrated code

reconstruction technology are necessary.

Figure 5.3: Principle arrangement for omnidirectional reading

Leuze electronic BCL 604i 23

6 Mounting

The bar code readers can be mounted in different ways:

• Using two M4x6 screws on the rear of the device or using four M4x6 screws on the bottom of the

device (see figure 3.2).

• Using a BT 56 mounting device on the two fastening grooves (see figure 14.3).

• Using a BT 59 mounting device on the two fastening grooves (see figure 14.4).

6.1 Device arrangement

6.1.1 Selecting a mounting location

In order to select the right mount

• Size, orientation, and position tolerance of the bar codes on the objects to be scanned.

• The reading field of the device in relation to the bar code module width.

• The resulting minimum and maximum reading distance from the respective reading field (see

chapter 14.4 "Reading field curves / optical data").

• The permissible cable lengths between the device and the host system depending on which interface

is used.

• The correct time for data output. The device should be positioned in such a way that, taking into consideration the time required for data processing and the conveyor belt speed, there is sufficient time

to e.g. initiate sorting operations on the basis of the read data.

• The display and control panel should be very visible and accessible.

• For configuring and commissioning with the webConfig tool, the USB interface should be easily

accessible.

• Maintaining the required environmental conditions (temperature, humidity).

• Possible soiling of the reading window due to liquids, abrasion by boxes, or packaging material residues.

• Lowest possible chance of damage to the device by mechanical collision or jammed parts.

• Possible extraneous light (no direct sunlight or sunlight reflected by the bar code).

Mounting

ing location, several factors must be considered:

With the line scanner, the beam exits the device parallel to the housing base; with the oscillating

mirror, the beam exits perpendicular to the housing base. The housing base is the black surface.

The best read results are obtained when:

• The device is mounted in such a way that the scanning beam is incident on the bar code at an angle

of inclination greater than ±10° … 15° to vertical.

• The reading distance lies in the middle area of the reading field.

• The bar code labels are of good print quality and have good contrast ratios.

• You do not use high-gloss labels.

• There is no direct sunlight.

6.1.2 Avoiding total reflection – Line scann

The bar code label must be positioned at an angle of inclination greater than ±10° … 15° from vertical in

order to avoid total reflection of the laser beam (see figure 6.1)!

Total reflection occurs whenever the laser light of the bar code reader is directly incident on the surface of

the bar code at an angle of 90°. The light directly reflected by the bar code may overload the bar code

reader and thereby cause non-readings!

er

Leuze electronic BCL 604i 24

1 Zero position

x

1

2

x

1

2

2Bar code

x Distance acc. to reading field curves

a ±10 … 15°

Figure 6.1: Total reflection – line scanner

6.1.3 Avoiding total reflection – oscillating-mirror scanner

For the device with oscillating mirror, the laser beam exits at an angle of 90° to vertical.

In addition, the swivel range of ±20° is to be taken into account.

This means that in order to be on the safe side and to avoid total reflection, the device with oscillating mirror

must be inclined upward or downward 20° … 30°!

Mounting

1 Zero position

2Bar code

x Distance acc. to reading field curves

a±25°

Figure 6.2: Total reflection – oscillating-mirror scanner

Leuze electronic BCL 604i 25

6.1.4 Possible read angles between device and bar code

The optimum alignment of th

e device is accomplished when the scan line scans the code bars almost at

a right angle (90°). All read angles that are possible between the scan line and bar code must be taken

account (see figure 6.3).

Mounting

a Azimuth angle (tilt)

b Inclination angle (pitch)

g Rotation angle (skew)

In order to avoid total reflection, the skew g should be greater than 10 °

Figure 6.3: Reading angle for the line scanner

6.2 Installing the external parameter memory

Remove the cover of the USB connection on the device.

Insert the USB memory stick into the USB connection and then cover it with the connector hood to

ensure degree of protection IP 65.

The USB memory stick can be inserted regardless of whether or not the device is connected to supply

voltage.

• After the USB memory stick has been inserted and supply voltage applied, the following message

appears on the display.

Memory stick connected: Export internal configuration?

Use the navigation buttons to select OK and activate with the enter button .

The configuration is now transferred to the external parameter memory and is from now on updated immediately when the configuration is changed via display or online commands.

• The display of MS under the device address indicates that the USB memory stick is correctly connected and functional.

Replacing a defective device

Uninstall the defective device.

Remove the external parameter memory from the defective device by unscrewing the protection hood.

Leuze electronic BCL 604i 26

Mounting

Mount the external parameter memory on the new device.

Install and start up the new device.

The following message appears on the display again:

• Memory stick connected: Export internal configuration?

Use the navigation buttons to select Cancel and activate with the enter button .

Make sure you select Cancel. Otherwise, the configuration in the external parameter memory is

lost!

The configuration is now imported from the external parameter memory and the device is immediately

operational without any further configuration.

Leuze electronic BCL 604i 27

7 Electrical connection

3 4 5

2

1

CAUTION

Do not open the device yourself under any circumstances! There is otherwise a risk of uncontrolled

emission of laser radiation from the device. The housing of the device contains no parts that need to

be adjusted or maintained by the user.

Before connecting the device, be sure that the supply voltage agrees with the value printed on the

name plate.

Connection of the device and cleaning must only be carried out by a qualified electrician.

Ensure that the functional earth (FE) is connected correctly. Unimpaired operation is only guaranteed

when the functional earth is connected properly.

If faults cannot be corrected, the device should be removed from operation and protected against pos-

sible commissioning.

CAUTION

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National Electric Code). The bar code readers are designed in accordance with safety class III for supply by PELV

(protective extra-low voltage with reliable disconnection).

Electrical connection

CAUTION

Degree of protection IP 65 is achieved only if the connectors and caps are screwed into place!

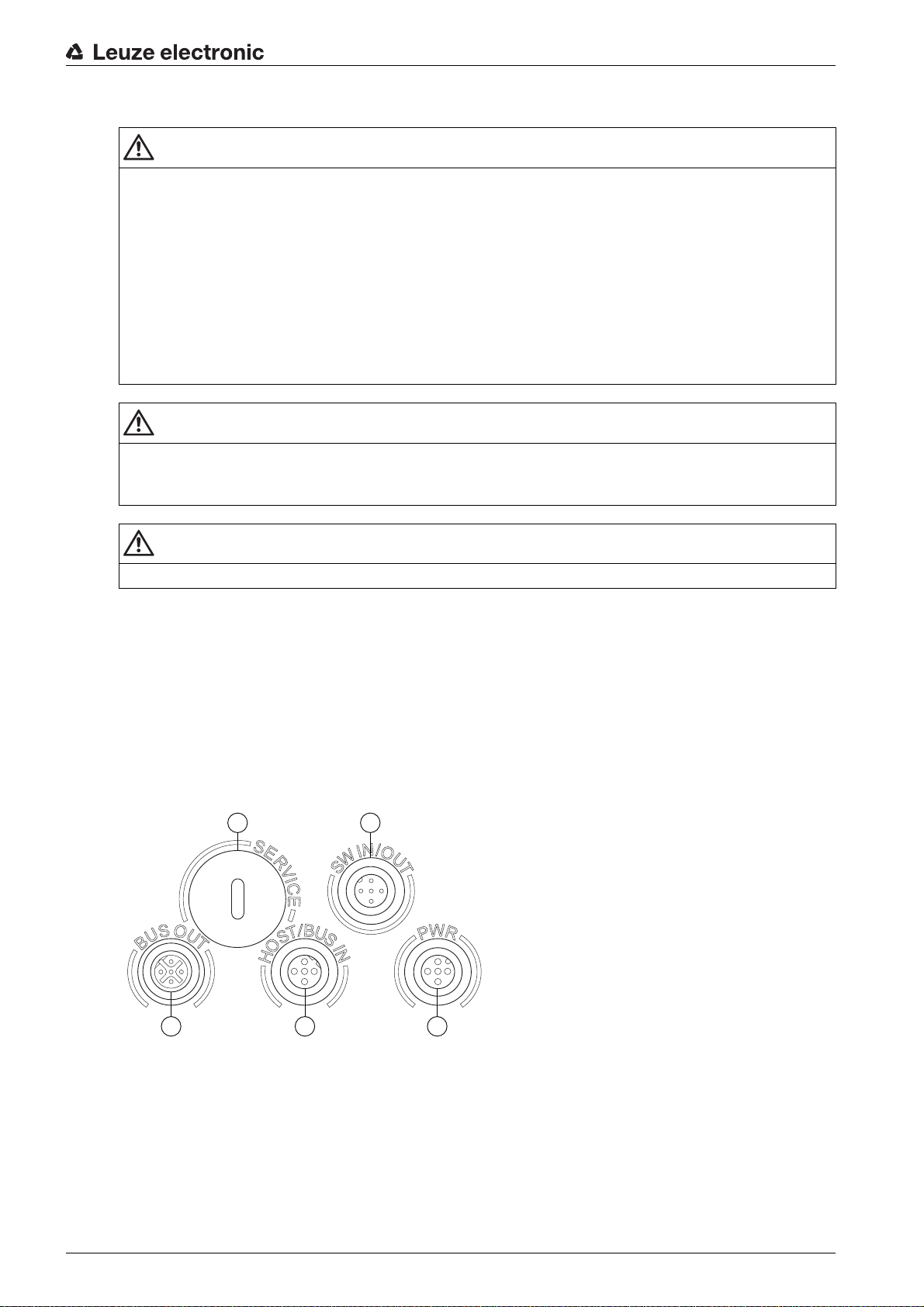

7.1 Overview

As a PROFIBUS participant, the device is equipped with four M12 plugs/sockets which are A- and Bcoded.

The voltage supply (PWR) as well as the four freely configurable switching inputs/outputs (SW IN/OUT and

PWR) are connected there.

The device is designed for use in PROFIBUS DP. An incoming DP IN - PROFIBUS DP is available as a

HOST / BUS IN interface for connecting to the PLC. An outgoing DP OUT - PROFIBUS DP is present as

another second physical BUS OUT interface for setting up the PROFIBUS DP network.

An USB connection is used as a SERVICE interface.

1 Service, USB socket, type A

2 SW In/Out, M12 socket (A-coded)

3 Bus Out, M12 socket (B-coded)

4 Host/Bus In, M12 socket (B-coded)

5 PWR, M12 plug (A-coded)

Figure 7.1: Connections of the device

Described in detail in the following are the individual connections and pin assignments.

Leuze electronic BCL 604i 28

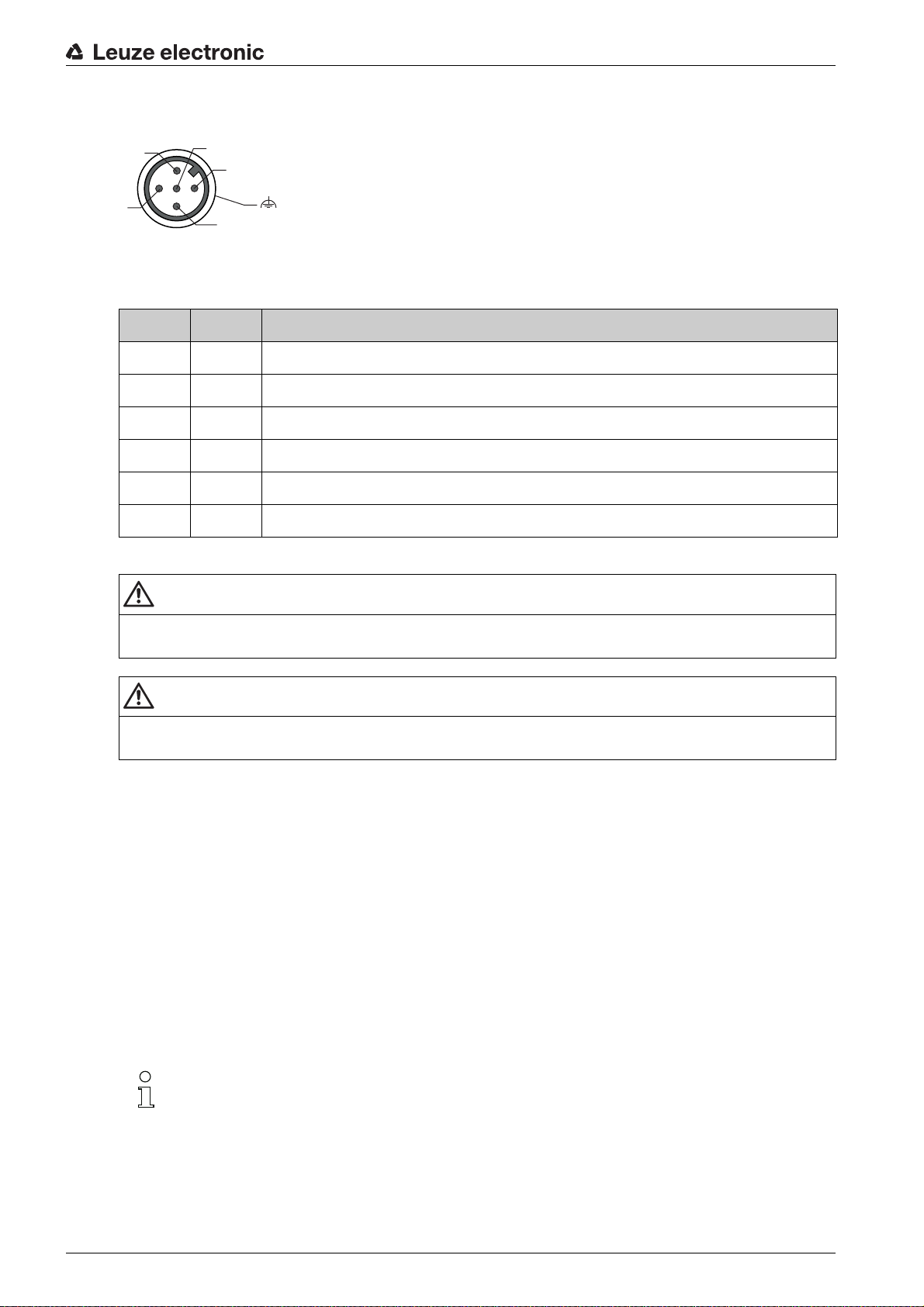

7.2 PWR – Voltage supply and switching inputs/outputs 3 and 4

2

3

1

4

5

FE

Figure 7.2: PWR, M12 plug (A-coded)

Table 7.1: Pin assignments - PWR

Pin Name Comment

1 VIN Positive supply voltage +10 ... +30 V DC

2 SWIO_3 Configurable switching input / output 3

3 GND Negative supply voltage 0 V DC

4 SWIO_4 Configurable switching input / output 4

5 FE Functional earth

Electrical connection

Thread FE Functional earth (housing)

Supply voltage

CAUTION

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National Electric Code).

CAUTION

The BCL 604i bar code readers are designed in accordance with safety class III for supply by PELV

(protective extra-low voltage with reliable disconnection).

Connecting functional earth FE

Ensure that the functional earth (FE) is connected correctly. Unimpaired operation is only guaranteed

when the functional earth is connected properly. All electrical disturbances (EMC couplings) are discharged via the functional earth connection.

Switching input/output

The device is equipped with four freely programmable, opto-decoupled switching inputs and outputs

SWIO_1 … SWIO_4.

The switching inputs can be used to activate various internal functions of the device (decoding,

autoConfig, …). The switching outputs can be used to signal the state of the device and to implement

external functions independent of the superior control.

The two switching inputs/outputs SWIO_1 and SWIO_2 are located on the SW IN/OUT M12 socket (see

chapter 7.4). The other two (SWIO_3 and SWIO_4) of the four freely configurable switching inputs/outputs

are located on the PWR M12 plug.

In general, configuration of the bar code reader takes place on the PROFIBUS via the corre-

sponding GSD file. Alternatively, you can temporarily set the respective function as input or out-

put via the display or with the aid of the webConfig configuration tool for the purpose of testing

the respective functionality. After reconnecting to the PROFIBUS or after deactivating parameter

enabling, the parameter settings set by the PROFIBUS are again active!

The external wiring as switching input and switching output is described in the following. For the respective

function assignment to the switching inputs/outputs see chapter 10.

Leuze electronic BCL 604i 29

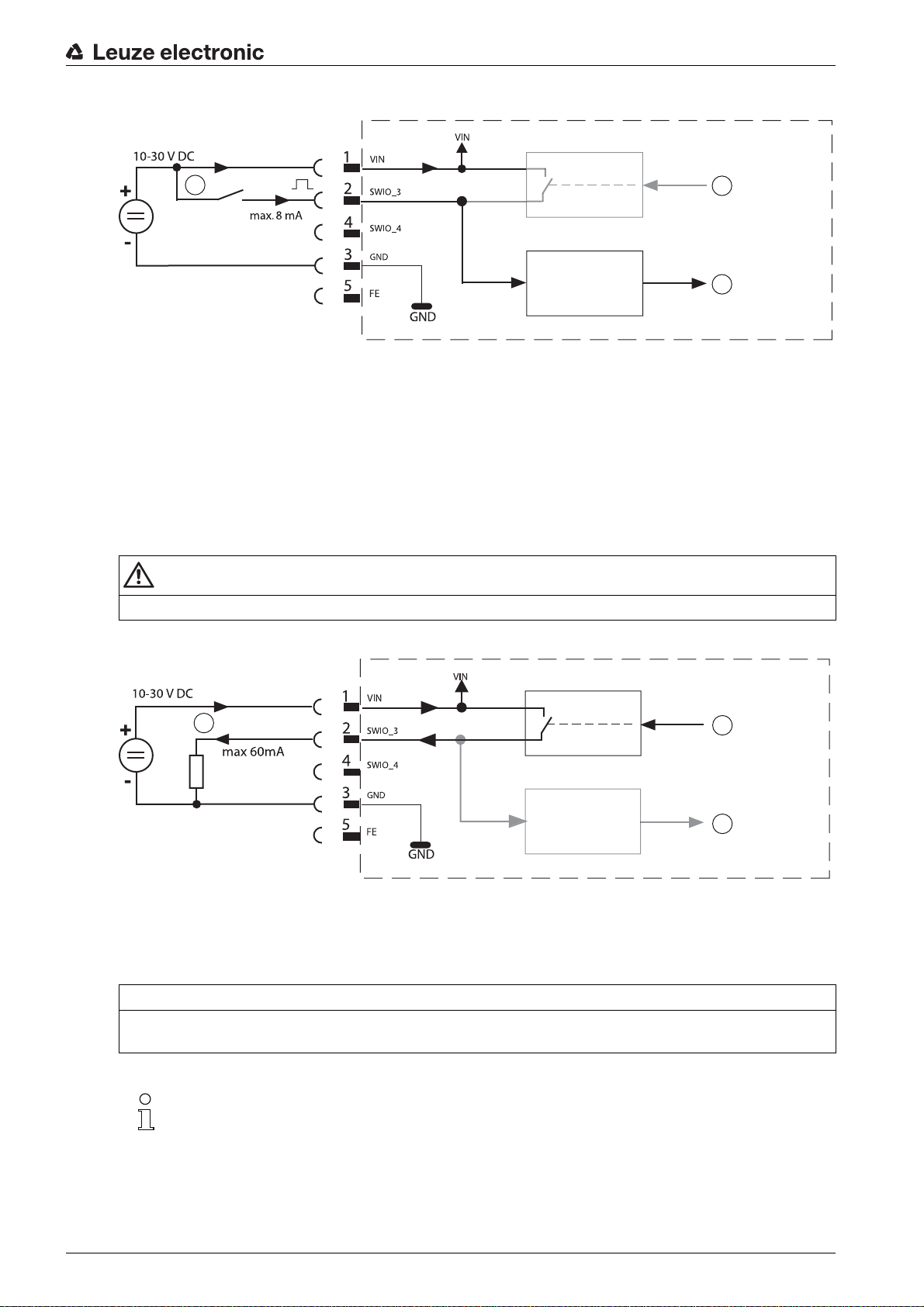

Function as switching input

1

2

3

Electrical connection

1

2

3

1 Switching input

2 Switching output from controller (deactivated)

3 Switching input to controller

Figure 7.3: Switching input connection diagram SWIO_3 and SWIO_4

If you use a sensor with a standard M12 connector, please note the following:

Pins 2 and 4 must not be operated as switching outputs if sensors which function as inputs are also

connected to these pins.

If, for example, the inverted sensor output is connected to pin 2, and pin 2 of the bar code reader is, at

the same time, configured as an output (and not as an input), the switching output malfunctions.

CAUTION

The maximum input current must not exceed 8 mA!

Function as switching output

1 Switching output

2 Switching input from controller

3 Switching output to controller (deactivated)

Figure 7.4: Switching output connection diagram SWIO_3 / SWIO_4

NOTICE

Each configured switching output is short-circuit proof! Do not load the respective switching output of the

device with more than 60 mA at +10 … +30 V DC in normal operation!

By default, the two switching inputs/outputs SWIO_3 and SWIO_4 are configured so that switch-

ing input SWIO_3 activates the reading gate and switching output SWIO_4 switches on “No

Read”.

Leuze electronic BCL 604i 30

7.3 SERVICE – USB interface (type A)

4

3

1

2

1

3

2

4

5

FE

Figure 7.5: Service, USB, type A

Table 7.2: Pin assignments of SERVICE – USB interface

Pin Name Comment

1 VB Positive supply voltage +5 V DC

2 D- Data -

3 D+ Data -

4 GND Ground

NOTICE

Maximum load of the +5 V DC supply voltage of the USB interface is 200 mA!

Ensure adequate shielding.

The entire interconnection cable must absolutely be shielded acc. to the USB specifications. Cable

length must not exceed 3 m.

Use the Leuze-specific USB service cable (see chapter 15 "Ordering information and accessories") for

the connection and use a service PC to configure.

Electrical connection

NOTICE

IP 65 is achieved only if the connectors and caps are screwed into place.

7.4 SW IN/OUT – Switching input/switching output

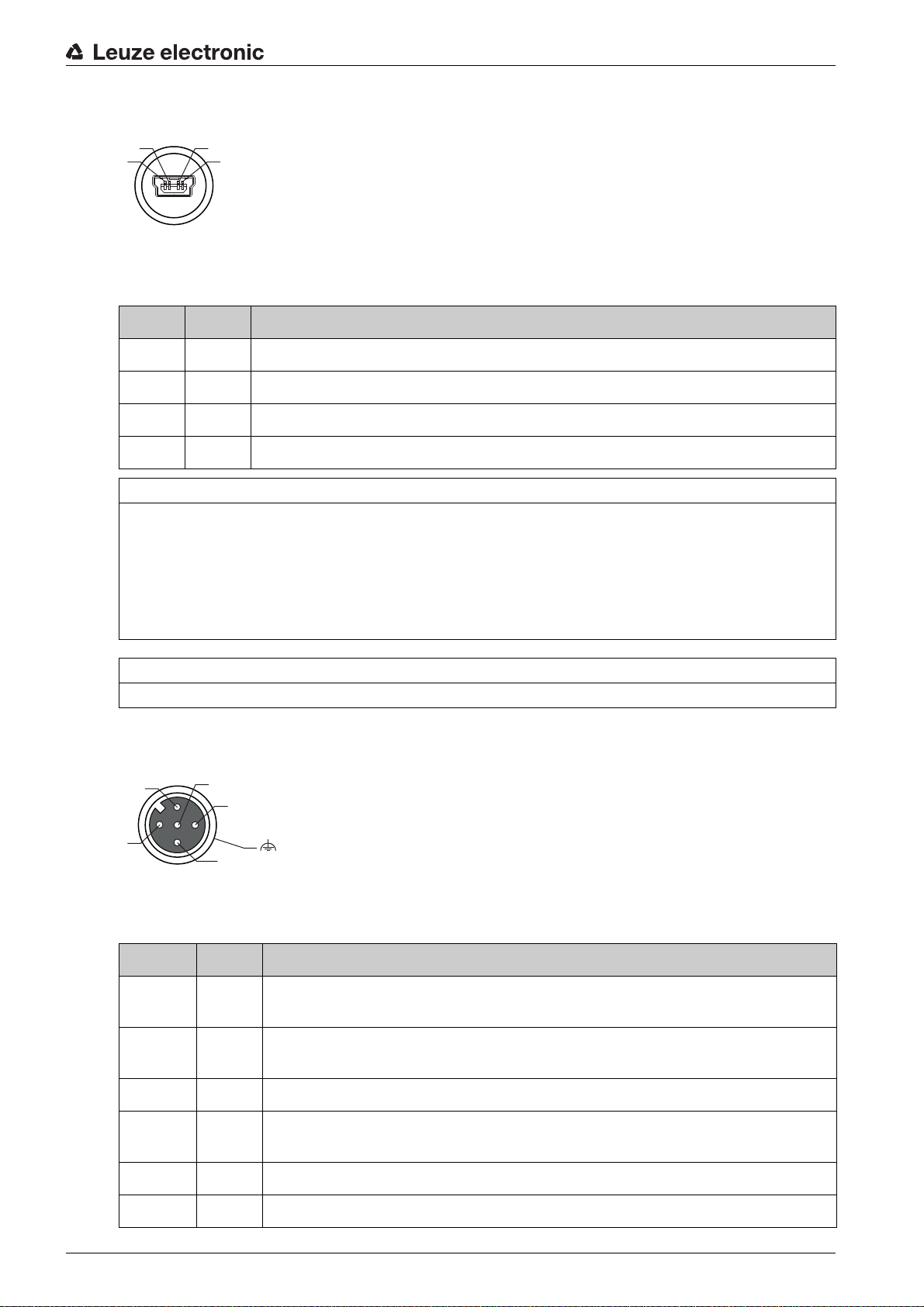

Figure 7.6: SW IN/OUT, M12 socket (A-coded)

Table 7.3: Pin assignment SW IN/OUT

Pin Name Comment

1 VOUT Voltage supply for sensors

(VOUT identical to VIN at PWR IN)

2SWIO_

1

3 GND GND for the sensors

Configurable switching input / output 1

4SWIO_

Configurable switching input / output 2

2

5 FE Functional earth

Leuze electronic BCL 604i 31

Thread FE Functional earth (housing)

Electrical connection

1

2

3

4

The device is equipped with four freely programmable, opto-decoupled switching inputs and outputs

SWIO_1 … SWIO_4.

The two switching inputs/outputs SWIO_1 and SWIO_2 are located on the SW IN/OUT M12 socket. The

other two (SWIO_3 and SWIO_4) of the four freely configurable switching inputs/outputs are located on

the PWR M12 plug (see chapter 7.4).

The external wiring as switching input and switching output is described in the following. For the respective

function assignment to the switching inputs/outputs see chapter 10.

Function as switching input

1 Output

2 Switching output from controller (deactivated)

3 Switching input to controller

4 Reflection light scanner

Figure 7.7: Switching input connection diagram SWIO_1 and SWIO_2

NOTICE

If you use a sensor with a standard M12 connector, please note the following: Pins 2 and 4 must not be

operated as switching outputs if sensors which function as inputs are also connected to these pins. If, for

example, the inverted sensor output is connected to pin 2, and pin 2 of the bar code reader is, at the same

time, configured as an output (and not as an input), the switching output malfunctions.

NOTICE

The maximum input current must not exceed 8 mA!

Function as switching output

1

2

3

1 Switching output

2 Switching output from controller

3 Switching input to controller (deactivated)

Figure 7.8: Switching output connection diagram SWIO_1 / SWIO_2

NOTICE

Each configured switching output is short-circuit proof! Do not load the respective switching output of the

device with more than 60 mA at +10 … +30 V DC in normal operation!

Leuze electronic BCL 604i 32

By default, the two switching inputs/outputs SWIO_1 and SWIO_2 are configured so that they

3

1

2

4

FE

5

1

3

2

4

5

function as switching inputs. Switching input SWIO_1 activates the start reading gate function

and switching input SWIO_2 activates the reference code teach-in function.

The functions of the individual switching inputs/outputs are programmed via the display or via configuration

in the webConfig tool under the Switching input or Switching output heading (see chapter 10 "Starting up

the device - Configuration").

7.5 HOST / BUS IN

The device makes an PROFIBUS DP IN interface available as host interface.

Figure 7.9: HOST/BUS IN – DP IN, M12 socket (B-coded)

Table 7.4: Pin assignment HOST / BUS IN

Electrical connection

Pin Name Comment

1 N.C. Not used

2 A (N) Receive/transmit data A-line (N)

3 N.C. Not used

4 B (P) Receive/transmit data B-line (P)

5 FE Functional earth

Thread FE Functional earth (housing)

NOTICE

Ensure adequate shielding. The entire interconnection cable must be shielded and earthed.

7.6 BUS OUT

To set up the PROFIBUS with additional participants, the device makes available another interface of type

PROFIBUS DP OUT.

Figure 7.10: M12 socket (B-coded)

Leuze electronic BCL 604i 33

Table 7.5: Pin assignment BUS OUT

Pin Name Comment

1 VP +5VDC for bus termination

2 A (N) Receive/transmit data A-line (N)

Electrical connection

3GND 48

5

4 B (P) Receive/transmit data B-line (P)

5 FE Functional earth / shield

Thread FE Functional earth (housing)

NOTICE

Ensure adequate shielding. The entire interconnection cable must be shielded and earthed.

RS 485 ground reference for bus termination

7.7 PROFIBUS termination

The last physical PROFIBUS participant must be terminated with a terminating resistor (see chapter 15

"Ordering information and accessories") on the BUS OUT socket.

7.8 Cable lengths and shielding

Observe the following maximum cable lengths and shielding types:

Table 7.6: Cable lengths and shielding

Connection Interface Max. cable length Shielding

BCL – service USB 3 m Shielding absolutely

necessary acc. to USB

specifications

BCL – host PROFIBUS DP Acc. to PNO specifications Acc. to PNO specifica-

tions

BCL – power supply

unit

Switching input 10 m Not necessary

Switching output 10 m Not necessary

30 m Not necessary

Leuze electronic BCL 604i 34

8 Menu description

After voltage is applied to the bar code reader, a startup screen is displayed for several seconds. The

display then shows the bar code reading window with all status information.

8.1 The main menus

Use the navigation buttons to move through the menu. Activate the desired selection with the enter

button .

Device information This menu item contains detailed information on

Menu description

• Device type

• Software version

• Hardware version

• Serial number

Network settings

Bar code reading window

Parameter

Language selection

Service

Actions

A detailed description of the individual parameters can be found in the description of the Profibus

GSD modules (see chapter 10.5 "Overview of the project modules").

Changes made via the display are overwritten!

Device settings for operating the device on the PROFIBUS are managed and configured exclu-

sively by the PLC. If parameters are changed via the display during bus operation, the device is

separated from the PROFIBUS at the moment parameter enabling is activated via the display.

Parameters set by the PROFIBUS are moved to the background, and changes to parameters

can be made via the display. When parameter enabling is exited, the device is automatically re-

connected to the PROFIBUS. Upon connection to the PROFIBUS, the device receives all param-

eters from the PLC.

• Display of the network settings

• Visualization of the read bar code information

• Status overview of the switching inputs/outputs

• Bar graphs for read quality of the current bar code

Further information see chapter "Indicators in the display".

• Configuration of the bar code reader

Further information see chapter 8.2 "Parameter menu".

• Selection of the display language

Further information see chapter 8.3 "Language selection menu".

• Scanner diagnosis and status messages

Further information see chapter 8.4 "Service menu".

• Various functions for scanner configuration and manual operation

Further information see chapter 8.5 "Actions menu".

8.2 Parameter menu

Parameter handling

The Parameter handling submenu is used to lock and release the parameter input via the display and for

resetting to default values.

Leuze electronic BCL 604i 35

Table 8.1: Parameter handling submenu

Menu description

Level 3 Level 4 Level 5 Selection/configuration option

Parameter enable OFF/ON

Default parameters By pressing the enter button after selecting

Description

The standard setting (OFF) prevents unintended parameter

changes.

If parameter enabling is activated (ON), parameters can be

changed manually.

As long as parameter enabling is activated, the device is disconnected from the PROFIBUS.

Parameters to default, all parameters are reset to their standard settings without any further security prompts.

In this case, English is selected as the display language.

Standard

OFF

Decoder table

In the Decoder table submenu, 4 different code type definitions can be stored. Bar codes that have been

read can only be decoded if they correspond to one of the definitions stored here.

Table 8.2: Decoder table submenu

Level 3 Level 4 Level 5 Selection/configuration option

Max. no. of

labels

Decoder 1 Symbology

(Code type)

Description

Value between 0 and 64

The value set here specifies the maximum number of labels that

should be detected for each reading gate.

No code

Code 2/5 Interleaved

Code 39

Code 32

Code UPC

Code EAN

Code 128

EAN Addendum

Codabar

Code 93

GS1 DataBar Omnidirectional

GS1 DataBar Limited

GS1 DataBar Expanded

If No code is configured, the current and all subsequent decoders

are deactivated.

Standard

1

Code 2/5i

Number of digits Interval mode OFF/ON

Digits 1 0 to 64 characters

Digits 2 0 to 64 characters

Digits 3 0 to 64 characters

Digits 4 0 to 64 characters

Digits 5 0 to 64 characters

Reading reliability Value from 2 to 100

Check digit method Standard

Check digit transmission

With the ON setting, the values in digits 1 and 2 define a range of

character numbers that are to be read.

First decodable number of characters or lower range limit.

Second decodable number of characters or upper range limit.

Third decodable number of characters.

Fourth decodable number of characters.

Fifth decodable number of characters.

Number or scans required to reliably detect a label.

No check

Depending on the symbology (code type) selected for the decoder,

further calculation algorithms can be selected here.

Check digit method used for the decoding of the bar code that has

been read.

If Standard is set, the check digit method intended for the respective code type is used.

Standard

Not standard

Specifies whether the check digit is transmitted. Standard means

that the transmission matches the standard intended for the

respective code type.

OFF

10

0

0

0

0

4

Standard

Standard

Leuze electronic BCL 604i 36

Menu description

Level 3 Level 4 Level 5 Selection/configuration option

Decoder 2 Symbology As decoder 1 Code 39

Number of digits Interval mode OFF/ON ON

Digits 1 0 to 64 characters 4

Digits 2 0 to 64 characters 30

Digits 3 0 to 64 characters 0

Digits 4 0 to 64 characters 0

Digits 5 0 to 64 characters 0

Reading reliability Value from 2 to 100 4

Check digit method As decoder 1 Standard

Check digit transmission

Decoder 3 Symbology As decoder 1 Code 128

Number of digits Interval mode OFF/ON ON

Digits 1 0 to 64 characters 4

Digits 2 0 to 64 characters 63

Digits 3 0 to 64 characters 0

Description

As decoder 1 Standard

Standard

Digits 4 0 to 64 characters 0

Digits 5 0 to 64 characters 0

Reading reliability Value from 2 to 100 4

Check digit method As decoder 1 Standard

Check digit transmission

Decoder 4 Symbology As decoder 1 Code UPC

Number of digits Interval mode OFF/ON OFF

Digits 1 0 to 64 characters 8

Digits 2 0 to 64 characters 0

Digits 3 0 to 64 characters 0

Digits 4 0 to 64 characters 0

Digits 5 0 to 64 characters 0

Reading reliability Value from 2 to 100 4

Check digit method As decoder 1 Standard

Check digit transmission

As decoder 1 Standard

As decoder 1 Standard

Digital SWIO

The Digital SWIO submenu is used to configure the 4 switching inputs/outputs of the device.

Leuze electronic BCL 604i 37

Table 8.3: Digital SWIO submenu

Menu description

Level 3 Level 4 Level 5 Selection/configuration option

Sw. input/output 1 I/O mode Input / Output / Passive

Switching input Invert OFF / ON

Debounce time Value from 0 to 1000

Start-up delay Value from 0 to 65535

Pulse duration Value from 0 to 65535

Delay off time Value from 0 to 65535

Function No BCL600i function

Description

Determines the function of switching input/output 1.

In the case of passive, the connection is on 0 V if the

Inverted parameter is set to OFF, and on +UB if the

Inverted parameter is set to ON.

OFF = activation of the switching input function upon high

level at the switching input

ON = activation of the switching input function upon low

level at the switching input

Time in milliseconds for which the input signal must be

present and stable.

Time in milliseconds between the end of the debounce

time and activation of the function configured below.

Minimum activation time in milliseconds for the function

configured below.

Time in milliseconds for which the function configured

below remains activated after the switching input signal is

deactivated and the pulse duration has expired.

Reading gate start/stop

Reading gate stop

-Reading gate start

Teach reference code

Autoconfig start/stop

The function set here is carried out after the switching input

is activated.

Standard

Input

OFF

5

0

0

0

Reading gate

start/stop

Leuze electronic BCL 604i 38

Menu description

Level 3 Level 4 Level 5 Selection/configuration option

Switching output Invert OFF / ON

Signal delay Value from 0 to 65535

Pulse duration Value from 0 to 65535

Activation function 1 No function

Description

OFF = activated switching output upon high level

ON = activated switching output upon low level

Time in milliseconds between activation function and

switching of the switching output.

Switch-on time of the switching output in milliseconds. If

the Pulse duration is set to 0, the switching output is

switched on via the Activation function and switched off via

the Deactivation function.

If the Pulse duration is greater than 0, the Deactivation

function has no effect.

Reading gate start

Reading gate end

Positive reference code comparison 1

Negative reference code comparison 1

Valid read result

Invalid read result

Device ready

Device not ready

Data transmission active

Data transmission not active

AutoCont. good quality

AutoCont. bad quality

Reflector detected

Reflector not detected

External event, pos. edge

External event, neg. edge

Device active

Device standby

No device error

Device error

Positive reference code comparison 2

Negative reference code comparison 2

The function set here specifies which event activates the

switching output.

Standard

OFF

0

400

No function

Deactivation function 1 See Activation function 1 for selection options

Sw. input/output 2 I/O mode Input / Output / Passive Output

Switching input Invert OFF / ON OFF

Debounce time Value from 0 to 1000 5

Start-up delay Value from 0 to 65535 0

Pulse duration Value from 0 to 65535 0

Delay off time Value from 0 to 65535 0

Function see switching input/output 1 No function

Switching output Invert OFF / ON OFF

Signal delay Value from 0 to 65535 0

Pulse duration Value from 0 to 65535 400

Activation function 2 see switching input/output 1 Valid read result

Deactivation function 2 see switching input/output 1 Reading gate

The function set here specifies the event that deactivates

the switching output.

No function

start

Leuze electronic BCL 604i 39

Menu description

Level 3 Level 4 Level 5 Selection/configuration option

Sw. input/output 3 I/O mode Input / Output / Passive Input

Switching input Invert OFF / ON OFF

Debounce time Value from 0 to 1000 5

Start-up delay Value from 0 to 65535 0

Pulse duration Value from 0 to 65535 0

Delay off time Value from 0 to 65535 0

Function see switching input/output 1 Reading gate

Switching output Invert OFF / ON OFF

Signal delay Value from 0 to 65535 0