Page 1

12501 Telecom Drive, Tampa Florida 33637

Installation, Operating and

Maintenance Instructions

Supplement

20/5.5.1

Rev. 1

TEMPERATURE

Fixed and Adjustable Proportional Band Types

TABLE OF CONTENTS

INTRODUCTION........................................................................................................................................2

INSTALLATION.........................................................................................................................................3

OPERATION ...............................................................................................................................................3

WIDENING PROPORTIONAL BAND – RTP, DTP,

MAINTENANCE.........................................................................................................................................6

DISMANTLING.......................................................................................................................................6

CLEANING..............................................................................................................................................6

REASSEMBLY........................................................................................................................................6

HOW TO SET LEVER CLEARANCE..................................................................................................7

LEVER CLEARANCE ADJUSTMENT ...............................................................................................7

For Reverse Acting Types – R, RT, RTP, etc.

For Direct Acting Types – D, DT, DTP, etc.

ADJUSTING PROPORTIONAL BAND MECHANISM ....................................................................8

PARTS LIST ..............................................................................................................................................10

............................................................................................7

..............................................................................................7

ETC

...................................................................6

LIST OF ILLUSTRATIONS

F

IGURE 1 - TEMPERATURE PILOT INSTALLATION DETAILS

F

IGURE 2 - TYPICAL INSTALLATION ON STORAGE HEATER

F

IGURE 3 - TYPE

F

IGURE 4 - TEMPERATURE CONTROL SYSTEM UNSING TEMPERATURE PILOT AS AIR TEMPERATURE PILOT AS

AIR T

F

IGURE 5 - TEMPERATURE PILOT CONTROLLING ON INSTANTANEOUS HEATER IN CONJUNCTION WITH A

D

IFFERENTIAL PRESSURE PILOT

F

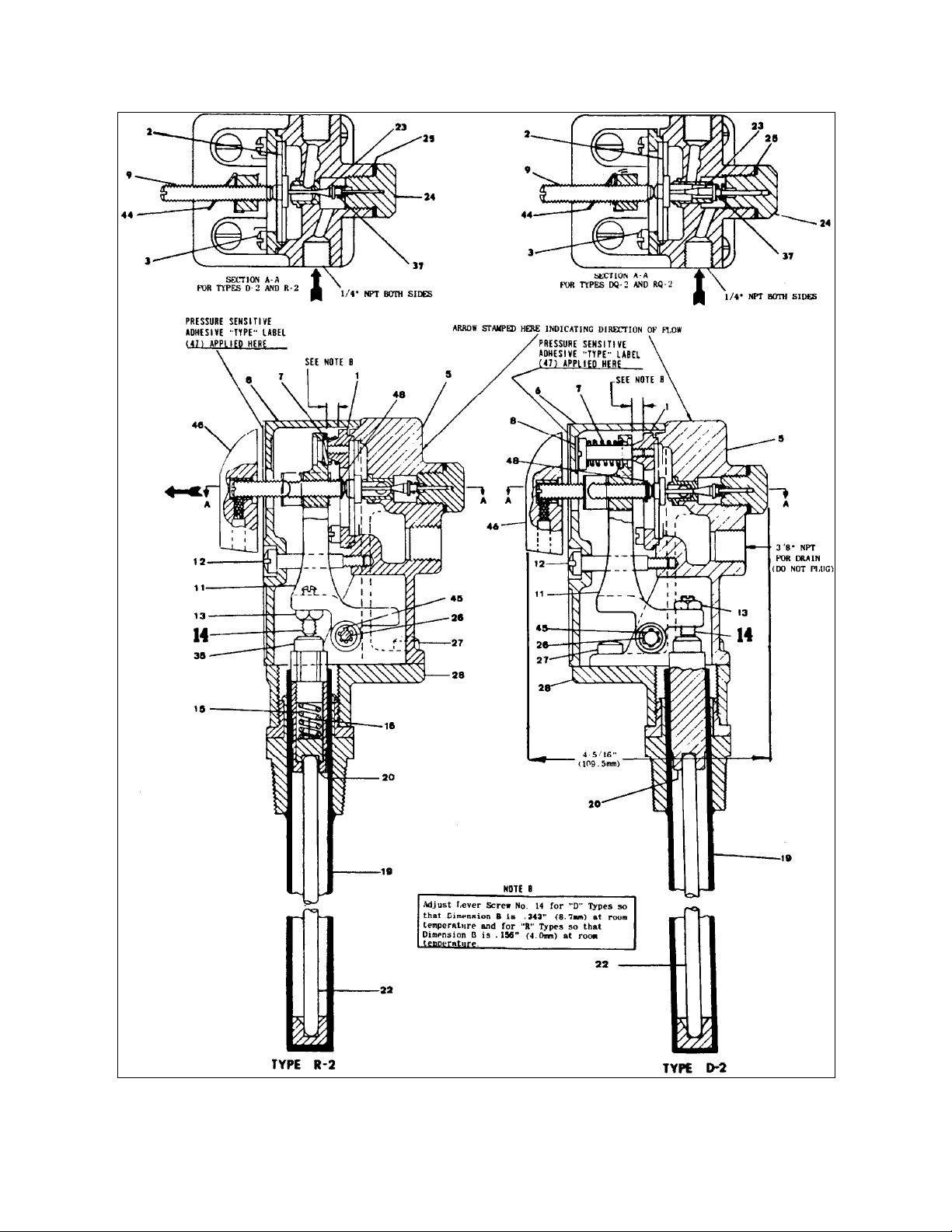

IGURE 6 - TYPE R AND D SECTIONALS

F

IGURE 7 - BODY ASSEMBLY

F

IGURE 8 - LOCATION OF MINIMUM BAND SETTING

F

IGURE 9 - LOCATION OF MAXIMUM BAND SETTING

F

IGURE 10 - ADJUSTABLE PROPORTIONAL BAND TYPE

F

IGURE 11 - ADJUSTABLE PROPORTIONAL BAND TYPE

RTP T

EMPERATURE TRANSMITTER

EMPERATURE PILOT WITH CLASS

..............................................................................................................4

RTP - DTP T

.........................................................................................................4

..........................................................................................................5

YPES

.............................................................................................7

..............................................................................3

.............................................................................3

GPK C

.......................................................................................8

......................................................................................8

DTP..........................................................................9

RTP ..........................................................................9

ONTROL VALVE

..........................................3

Page 2

INTRODUCTION

This Installation, Operation, and Maintenance Manual is

intended to be as complete and up to date as possible. It

covers installation, operation, and maintenance procedures

for Leslie Controls, Inc. Temperature Fixed and Adjustable

Proportional Band Types. Leslie reserves right to update

this manual and other product information concerning

installation, operation, and/or maintenance, at any time and

without obligation to notify product owners of such

changes.

Leslie is not responsible for injury to personnel or product

damage due to improper installation, operation, and/or

maintenance Leslie Controls, Inc. Temperature Fixed and

Adjustable Proportional Band Types. All installation,

operation, and maintenance procedures should only be

performed by trained/certified personnel. All personnel

performing these procedures should completely and

carefully read and understand all supplied materials before

attempting procedures. All personnel should pay strict

attention to all Notes, Cautions, and Warnings that appear

within procedures detailed in this manual.

Leslie welcomes user input as to suggestions for product or

manual improvement.

Contact Information

For information concerning warranties, or for questions

pertaining to installation,

Operation or maintenance of LESLIE products, contact:

LESLIE CONTROLS INC.

12501 Telecom Drive

Tampa, FL 33637

USA Phone: (813) 978-1000

USA Fax: (813) 978-0984

www.LESLIECONTROLS.com

To order replacement parts, contact LESLIE CONTROLS

at address listed above, or call toll free:

USA/Canada/Caribbean Phone: (800) 323-8366

Note: Please include model and serial number of unit for

which parts are being ordered. If ordering by phone, please

have this information readily available.

GENERAL NOTES AND WARNINGS

Notes:

• If questions are not answered by this manual, or if

specific installation, operation, and/or maintenance procedures are not clearly

understood, contact Leslie Controls, Inc. for

clarification before proceeding.

• If unit is damaged during installation, operation,

or maintenance, complete following steps:

1. Turn off and lock out pneumatic supply to unit in

an approved manner.

2. Turn off all incoming valves.

3. Contact in-house maintenance personnel or Leslie

Controls, Inc. for instructions.

Note: Throughout this manual, warnings will be

denoted by BOXES

Piping system must be adequately designed and

supported to prevent extraordinary loads to pressure

It is strongly recommended that this document be reviewed

before attempting any installation, operation, or

maintenance procedures.

CAUTION!

equipment.

2

Page 3

Classes and Types

(Letter “P” in Class Indicates

Adjustable Proportional Band Type)

REVERSE ACTING

R-2, RQ-2, RTP-2, RTHP-2 D-2, DQ-2, DTP-2, DTHP-2

DIRECT ACTING

INSTALLATION

Typical installations Figures 1 through 5. Follow sketch

applicable to equipment in use. Temperature Pilot may be

installed in any position. See note regarding liquid

operating mediums.

1. Control valve piping in figures are schematic. Consult

control valve instructions for proper piping details.

2. Location of Thermal Tube – Locate thermal bulb a

minimum of 6” from nearest heating or cooling coil.

DO NOT place in direct path of heating or cooling

fluids in injection systems. Full length of thermal tube

must be in contact with heated fluid at a point where

true changes in temperature will be felt immediately.

See Figure 5 for shell and tube heaters

(Instantaneous).

3. Thermometer – Position thermometer in immediate

area of thermal tube indication of signal temperature.

4. Location of Temperature Pilot – Temperature Pilot

may be installed as far as 50’ from the control valve.

However, in heat exchanger applications control valve

should be close enough to the heater to prevent

existence of an excessive reservoir of heating fluid

between valve and heater which will pass through

heater, after valve closure, causing override.

5. Liquid Operating Mediums – Elevation between

temperature pilot and control valve should not exceed

10’ when liquid is used as operating medium.

NOTE: New type covers have two directional arrows both

of which indicate “WARMER”. However, the LEFT side of

cover is marked “D-TYPES” and the right side is marked

“R-TYPES”. To INCREASE controlled temperature

setting, turn the knob to the left (counter-clockwise) for

“D-TYPES” and to the right (clockwise) for “R-TYPES).

OPERATION

NOTE: Start initially with all stop valves closed.

1. Open operating medium supply line. Adjust pressure

reducing valve to supply proper operating pressure to

temperature pilot. See Figure 6 for correct values.

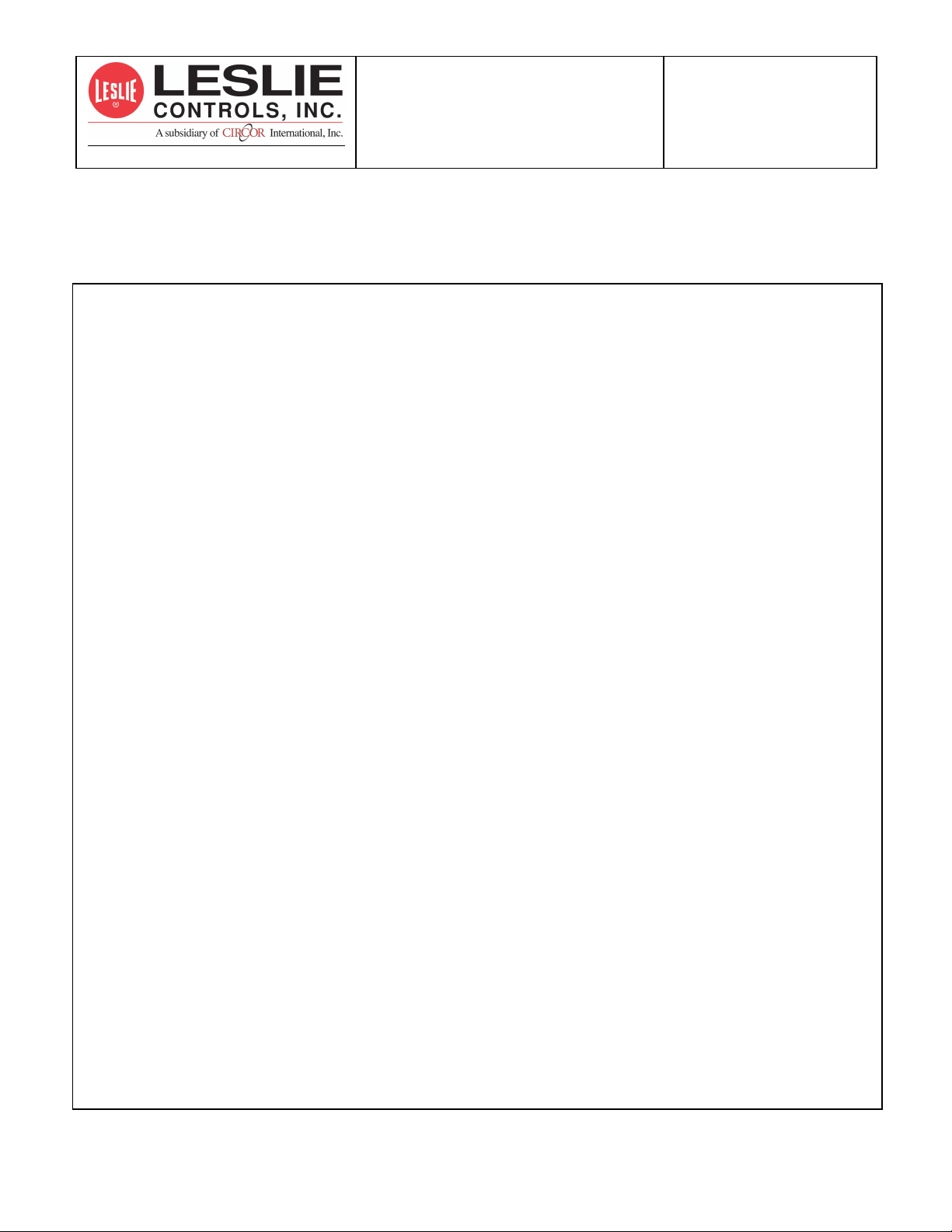

Figure 1 - Temperature Pilot Installation Details

Figure 2 - Typical Installation on Storage Heater

Figure 3 - Type RTP Temperature Pilot with Class

GPK Control Valve - Delivered heating or cooling

agent pressure limited by restricting loading pressure

value

3

Page 4

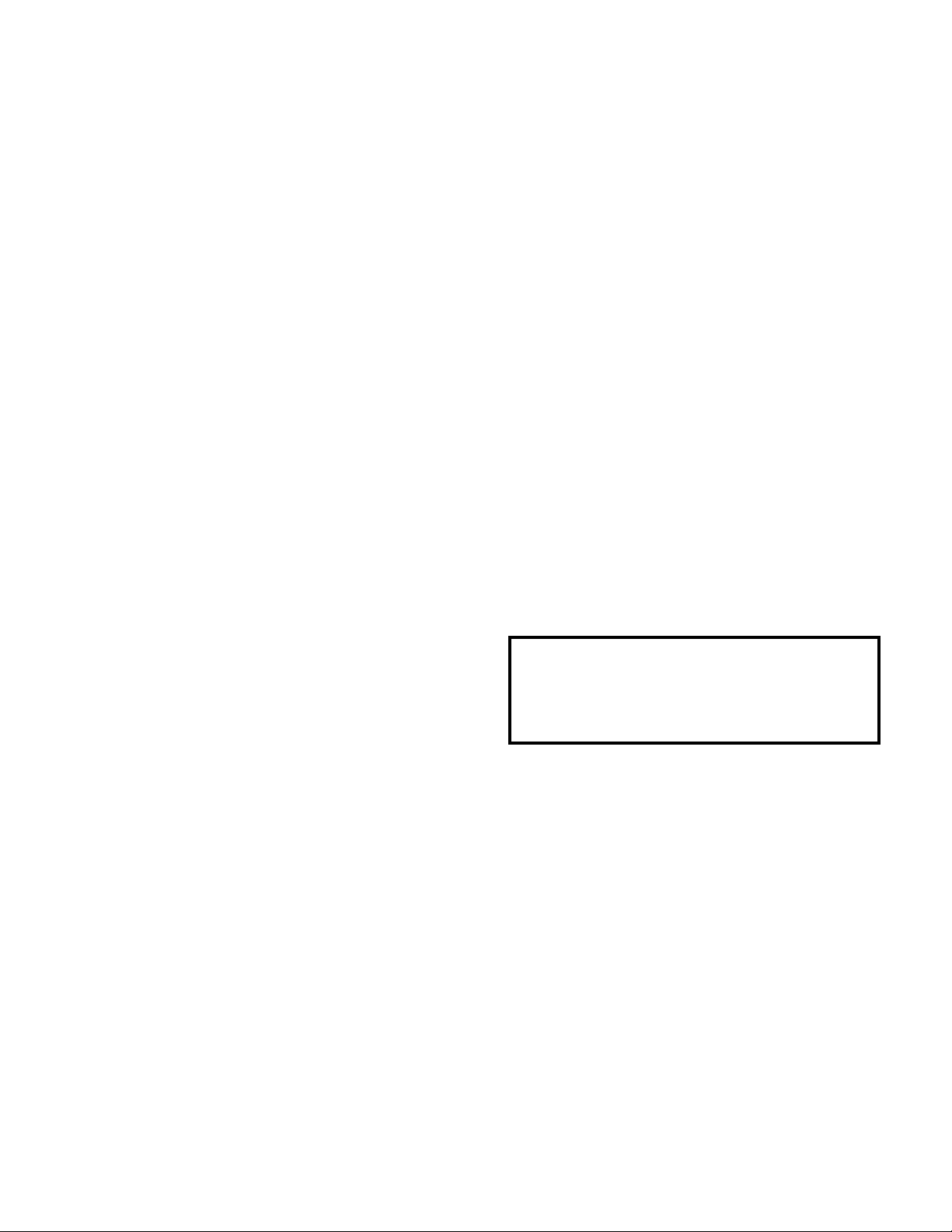

Figure 4 - Temperature Control

System using Temperature Pilot as

Air Temperature Transmitter.

NOTE: Satisfactory where pressure

limiting is not required.

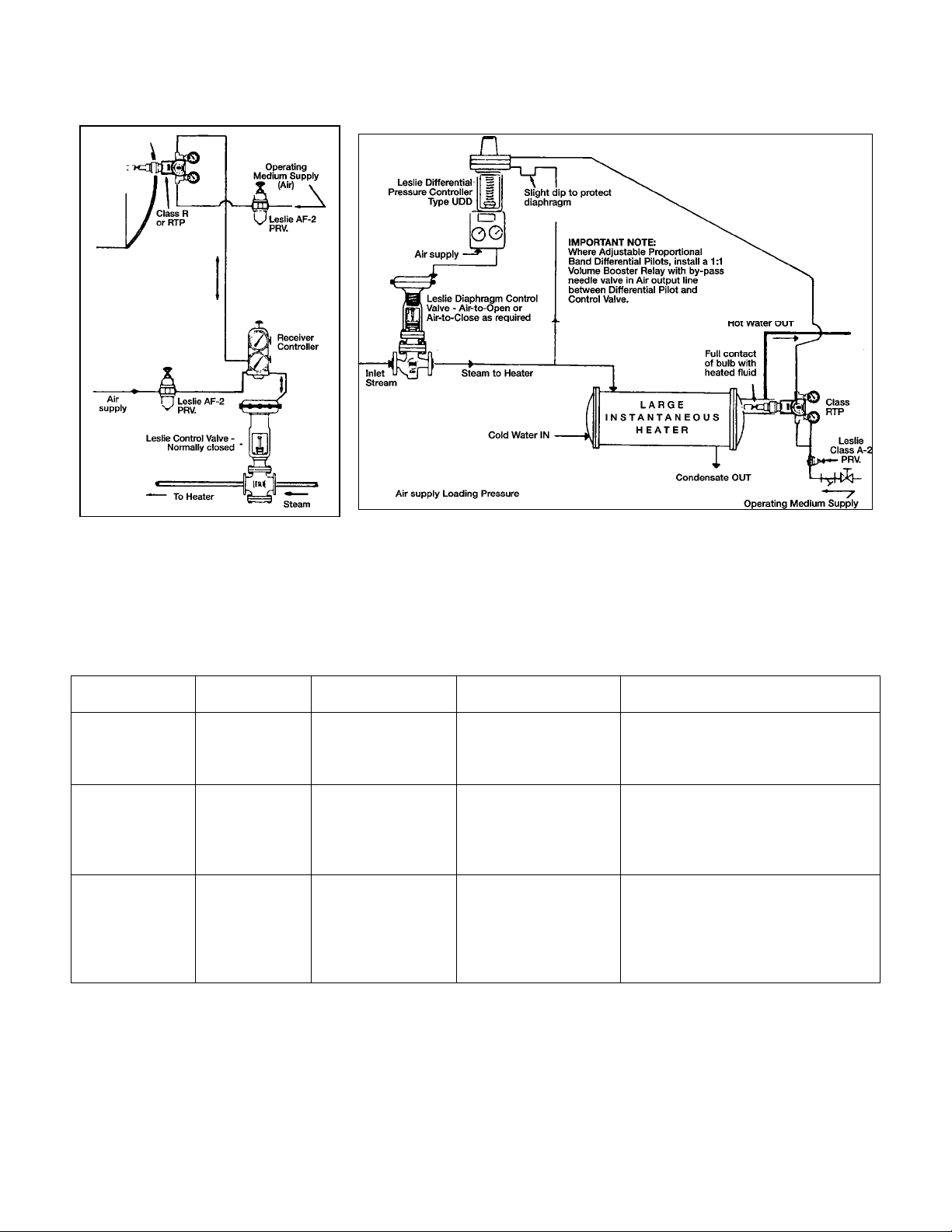

VALVE TYPE

Diaphragm

Control Valves

Internal Pilot

Piston Operated

Valves (Class

LTY, LTPY,

etc.)

Fluid loaded

diaphragm

operated valves

(Class GPK,

etc.)

VALVE

ACTION

Air-to-Open

Air-to-Close

Air-to-Open Between 8 & 10 psi

Air-to-Open Opening pressure

Figure 5 - Temperature Pilot controlling on Instantaneous Heater in

conjunction with a Differential Pressure Pilot. Acts as Pressure Limiting

Device. Provides anticipating action - 1:1 ratio, air/steam.

NOTE: Place thermal bulb as close to heater outlet as possible but not in

heater unless it is designed for that purpose.

STARTS TO

TRAVEL AT

3 psig 15 psig or other

on diaphragm

depends on pressure

drop and valve size.

See chart Figure 7,

Instruction RVI

7a/12a.

FULL TRAVEL AT: REMARKS

Maximum air pressure

determined by pressure

drop.

At air loading pressure

required for controlled

pressure plus opening

pressure. Flow depends

on system demand.

Air at loading pressure

required for controlled

pressure plus opening

pressure.

In control Valves required air pressure

values may vary with pressure drop

variations.

Valve produces approximately 7 psig

delivered controlled pressure per 1

psig additional loading pressure

supplied after opening force is applied.

Max. loading pressure 35 psig.

Valve produces 1 psig delivered

controlled pressure per 1 psig loading

pressure supplied after opening force

is applied.

4

Page 5

Figure 4 - Type R and D Sectionals

5

Page 6

2. Turn adjusting screw knob (46) to supply sufficient

operating medium pressure to control valve to bring it

into opening position. See Figure 6 for values and

reference notes on the particular control valve in use.

3. Open inlet stop valve wide. Partially open outlet stop

valve to permit flow of heating or cooling fluid. Start

flow of fluid to be heated through heater.

4. Adjust temperature pilot to supply sufficient operating

pressure to move control valve to wide open position.

5. Observe temperature rise of fluid under control. When

desired temperature is reached, adjust operating

pressure to control valve by turning adjusting screw

knob (46) until valve just closes.

Increasing/Decreasing Temperature Setting - To

increase or decrease temperature setting turn adjusting

screw knob (46) carefully as indicated by direction of

arrow on cover for type pilot shown.

6. Check controlled temperature after a period of

operation. Readjust adjusting screw knob (46)

carefully if it is necessary to change temperature

setting.

NOTE: Final adjustment are made best when apparatus is

operating under normal load.

7. After adjustments are completed tighten lockscrew (3)

just enough to provide sufficient drag to prevent

adjusting screw knob (46) from moving due to

vibration.

WIDENING PROPORTIONAL BAND –

RTP, DTP, etc. See Figure 8

When making initial adjustments for temperature setting in

RTP, DTP, etc. types start with the knob fully clockwise

(narrowest band setting). If an unstable condition appears

in the system, indicating need for widening of proportional

band, turn knob (41) slowly in direction of arrow on knob

(41) to widen proportional band until system stabilizes. (11/4 turns produce widest band.)

NOTE: Readjust set point slightly as desired by turning

adjusting screw knob (46) as in Step 2.

To turn system off first close outlet stop valve then inlet

stop valve.

NOTE: With GP Class Control valves relieve operating

pressure from diaphragm before closing inlet stop valve.

To turn system on with temperature set open inlet stop

valve then slowly open outlet stop valve.

MAINTENANCE

(Refer to figures below or appropriate drawings available

on request.)

DISMANTLING

1. Remove cover screw (12) and cover (6). Take out

fulcrum pin (26), lever (11) and lever spring (7). In D

types remove lever spring screw (8) also.

2. Take out diaphragm plate screws (3), diaphragm plate

(1) and diaphragm complete (2) (In RTP, DTP, etc.

types take out spring (43) also). Lift out plunger (20)

and rod (22). To remove rod from tube in D types,

body (5) must be disassembled from base (28) first, by

removing screws (27). (This is only necessary when

rod, plunger or tube must be cleaned or replaced.)

3. Loosen and remove pilot valve plug (24), gasket (25)

and pilot valve spring (37) (in R and D Types)

In RTP, DTP, etc. types proportioning band screw

(39), pilot valve plug (24), “O” ring (40) and knob

(41) are a subassembly. When pilot valve plug is

removed from body the other parts will follow.

Disassemble proportional band screw from plug.

Clean all parts, replace “O” ring if necessary and

reassemble parts.

CLEANING

Clean all parts including body with an approved solvent.

Make sure body ports are clear. Use crocus cloth to

remove encrusted material. Replace any badly worn or

damaged part.

REASSEMBLY

1. Reassemble pilot valve (23), pilot valve spring (37),

gasket (25) and pilot valve plug (24) to body. In RTP,

DTP types these parts comprise a subassembly (pilot

valve being replaced by the proportional band screw).

Tighten pilot valve plug.

2. Reassemble rod (22) and plunger (20) in tube with

recessed end over end of rod. Install diaphragm

complete (2) in body recess with disc end toward

nozzle. In RTP, DTP, etc. types make sure that small

valved portion of disc enters orifice of nozzle. In D

types reassemble body to base.

6

Page 7

Figure 5 - Body assembly RTP - DTP Types, showing

adjustable proportional band mechanism

3. Place diaphragm plate (1) on diaphragm complete

(raised face downward). Insert screws (3) and turn

down into body threads just enough to hold diaphragm

plate snug. DO NOT overtighten as this will cause

snap in diaphragm with possible erratic response

resulting.

4. In R and RTP, etc. types assemble lever spring (7) and

lever (11) to body, then insert fulcrum pin (26) in

holes in body and lever. Test action of lever. It should

be smooth and free. Check lever clearance as

described under “Setting Lever Clearance”*.

In D, DPT, etc. types assemble lever (11) to body and

insert fulcrum pin (26). Test action of lever. It should

be free and smooth. Check lever clearance as

described under “Setting Lever Clearance”*. Then

assemble lever spring (7) on lever, insert screw (8)

through spring and into diaphragm plate (1). Tighten

screw.

* If lever clearance is correct DO NOT DISTURB

adjustment.

5. Reassemble cover (6) to body. Insert screw (12).

Tighten. Reconnect operating medium tubing (if

disconnected). Readjust as described under

“OPERATION”.

HOW TO SET LEVER CLEARANCE

NOTE: Lever setting is factory set. Do not disturb if

dimension corresponds to that shown below for the

particular temperature pilot.

* To adjust when necessary, subject tube of temperature

pilot to a temperature of approximately 70°F then turn

adjusting screw (9) outward until it is clear of diaphragm

complete (2) and proceed as follows (See Figure 7).

LEVER CLEARANCE ADJUSTMENT

NOTE: Thermo tube must be at room temperature while

making lever clearance adjustments.

For Reverse Acting Types – R, RT, RTP, etc.

1. Loosen temperature adjusting knob lock screw and

remove knob.

2. Remove cover screw and lift off cover.

3. Move temperature adjusting screw upward until

bottom of screw is no longer in contact with

diaphragm.

4. Check dimension “A” with a scale. Distance from

bottom of lever to top of diaphragm plate should be

5/32”.

5. If dimension is incorrect, loosen adjusting screw lock

nut and screw adjusting screw into lever toward

plunger plug if dimension is greater than 5/32” or

away from plunger plug if dimension is less than

5/32”. Check clearance. Repeat procedure until 5/32”

clearance is obtained. Hold adjusting screw in place

with a screwdriver and tighten lock nut. Replace cover

and cover screw.

6. Adjust pilot for required control temperature. Replace

temperature adjusting knob with pointer in center

position of cover and tighten adjusting knob lock

screw.

For Direct Acting Types – D, DT, DTP, etc.

1. Loosen temperature adjusting knob lock screw and

remove knob.

2. Remove cover screw and lift off cover.

3. Move temperature adjusting screw upward until

bottom of screw is no longer in contact with

diaphragm.

4. Check “A” dimension with a scale. Distance from

bottom of lever to top of diaphragm plate should be

11/32”.

5. If dimension is incorrect, remove lever spring screw

and lever spring.

6. Remove one fulcrum pin retaining washer and push

out fulcrum pin.

7

Page 8

7. Loosen lever adjusting screw lock nut and screw

adjusting screw into lever toward plunger plug if

dimension is less than 11/32”. Replace lever and

fulcrum pin. Hold lever tip down so that adjusting

screw rests firmly against end of plunger plug. Check

clearance. Repeat procedure until a clearance of

11/32” is obtained. Hold adjusting screw in place with

a screwdriver and tighten lock nut.

8. Replace lever, fulcrum pin and retaining washer, lever

spring and lever spring screw. Tighten lever spring

screw. Replace cover and cover screw.

9. Adjust pilot for required control temperature. Replace

temperature adjusting knob with pointer in center

position of cover and tighten adjusting knob lock

screw.

ADJUSTING PROPORTIONAL BAND

MECHANISM

NOTE: This adjustment is factory set with and air supply

pressure of 20 psig. Adjustment should not be disturbed

unless replacement of a part is necessary in the

proportional band mechanism or if the inlet supply

pressure is changed to a higher value. If it is necessary to

disturb adjustment, readjust in the following manner.

1. Loosen set screw in knob (39). Remove knob from

proportional band screw (23).

2. Supply desired operating pressure to temperature

pilot. Then turn proportional band screw (23) inward

toward seat until all air flow ceases through pilot. (Do

Not squeeze screw against seat.)

3. Back proportional band screw (23) away from its seat

the number of degrees shown in curve Figure 9 for the

particular supply pressure in use.

4. Replace knob (39) on proportional band screw (23)

with pointer against ping in plug (24) in a fully

clockwise position.

5. This setting will produce minimum proportional band.

Turning knob (39) counter-clockwise, widens

proportional band. Maximum width of band is reached

when pointer is turned counter-clockwise the percent

of full rotation shown in curve Figure 10 for the

particular air supply pressure in use.

6. Adjust for desired temperature and width of band as

described under “Operation”.

Figure 6 - Location of Minimum Band Setting

Figure 7 - Location of Maximum Band Setting

8

Page 9

Figure 8 - Adjustable Proportional Band Type DTP

Figure 9 - Adjustable Proportional Band Type RTP

9

Page 10

PARTS LIST

TYPES D-2, DQ-2, DTP-2, DTHP-2, R-2, RQ-2, RTP-2 AND RTHP-2

WHEN ORDERING PARTS, PLEASE GIVE PART NAME AND PART REFERENCE NUMBER FROM TABLE BELOW

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

10

Page 11

TYPES D-2, DQ-2, DTP-2, DTHP-2, R-2, RQ-2, RTP-2 AND RTHP-2

11

Page 12

Type

Casing

SHORT

1/8

LONG

1/8

SHORT

LONG

Maximum

Working

Pressure

1,000

P.S.I

2,000

P.S.I

1,000

P.S.I

2,000

P.S.I

1,000

P.S.I

1,000

P.S.I

Ref.

Material

Monel 56330

Stainl. Steel, Carpenter 20 45862

Stainless Steel, 316

Stainless Steel, 304 23954

Stainless Steel, 316

Stainless Steel, 304 32200

Stainless Steel, 316

Stainless Steel, 304 22632

Monel 22000

Stainless Steel, 316

Stainless Steel, 304

SPECIAL ONE PIECE CONSTRUCTION

Stainless Steel, 316

Stainless Steel, 316

No.

48552 7-1/4 6-7/8 1

50022 14-3/4 14-3/8 1`

Dimensions

A B C

7-1/4 6-7/8 1

7-1/4 6-7/8 1-

14-3/4 14-3/8 1

14-3/4 14-3/8 1-

TYPES D-2, DQ-2, DTP-2, DTHP-2, R-2, RQ-2, RTP-2 AND RTHP-2

WHEN ORDERING PARTS, PLEASE GIVE PART NAME AND PART REFERENCE

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING ON PAGE 11

TYPE DESCRIPTION

D-2 Direct Acting - Fixed Proportional Band. Air, non-corrosive gas or water as

R-2 Reverse Acting - Fixed Proportional Band. Air, non-corrosive gas or water as

DQ-2 Similar to D-2 except larger pilot valve porting permitting the use of water or

RQ-2 Similar to R-2 except larger pilot valve porting permitting the use of water or

DTP-2 Direct Acting - Adjustable Proportional Band. Air or non-corrosive gas as

RTP-2 Reverse Acting - Adjustable Proportional Band. Air or non-corrosive gas as

DTHP-2 Similar to DTP-2 except constructed for higher adjustable temperature range.

RTHP-2 Similar to RTP-2 except constructed for higher adjustable temperature range.

On all “D” (Direct Acting) types, an increase in the temperature of the control agent causes an

increase in output pressure of the operating medium from the pilot controller. On all “R”

(Reverse Acting) types, an increase in the temperature of the control agent causes a decrease

in output pressure of the operating medium from the Pilot controller.

TYPE PILOT D-2 & R-2 DQ-2 & RQ-2

ADJ. RANGE °F 32-400

TUBE LENGTH 7°(177.8mm) 14°(355.6mm) 7°(177.8mm) 14°(355.6mm) 7°(177.8mm) 14°(355.6mm) 7° (177.8mm)

PROP. BAND 20 PSI

SUPPLY 3-15 PSI

OUTPUT IN °F

AVER. LOADING

CAP. 20 PSI SUPPLY

3-15 PSI OUPUT

(1) DTHP-2 & RTHP-2 available with 7*(177.8mm) tube only.

operating medium.

operating medium.

other non-corrosive liquids of low viscosity as operating medium or higher

volume output for air or non-corrosive gas as operating medium.

other non-corrosive liquids of low viscosity as operating medium or higher

output for air or non-corrosive gas as operating medium.

operating medium.

operating medium.

NUMBER FROM TABLE BELOW

DTP-2 & RTP-2

MIN.

BAND

4.8 3.0 13.3 8.0 15 50 8 30 15 50

.45 cfm AIR

.120 gpm WATER

1.26 cfm AIR

.336 gpm WATER

.06 cfm

AIR

MAX.

BAND

.72 cfm

AIR

MIN.

BAND

.06 cfm

AIR

MAX.

BAND

.72 cfm

AIR

DTHP-2 &

RTHP-2 (1)

MIN.

BAND

.06 cfm

AIR

MAX.

BAND

.72 cfm

AIR

12

Page 13

For Classes D

-

2, DQ-2, DTP

-

2 and DTHP

-

2. Material is Music Wire, Cad. Pl. For Classes R

-

2, RQ-2, RTP

-

2 and RTHP

-

2 Material is Stainless Steel.

PART

NO.

11

12

13

14

15

16

19

19

19

19

20

22

22

23

24

25

26

27

28

33

34

35

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FOR ALL TYPES NOT LISTED. PLEASE ORDER PARTS BY NAME AND INCLUDE RANGE, TYPE, AND SERIAL NUMBER.

☼ Recommended spare parts.

* These parts should be on hand, plus recommended spare parts, when overhauling equipment.

NOTE 1: Diaphragm; Complete, Reference Number 10895 consists of: Diaphragm, Ref. No. 9967, Material Phosphor. Bonze; two (2) Retaining Rings, Ref. No. 48065, Material Brass, and Disc, Ref. No. 11201, Material

Monel; Diaphragm Complete, Ref. No. 21996 consists of: Diaphragm, Ref. No. 9967, Material Phosphor Bonze; two (2) Retaining Rings, Ref. No. 48065, Material Brass; and Disc, Ref. No. 20183, Material Monel.

NOTE 2:

PART NAME MATERIAL

1

Diaphragm Plate

2

Diaphragm, Complete (NOTE 1)

3

Screw

5

Body

6

Cover

7

Lever Spring

8

Lever Spring Screw

9

Adjusting Screw

Lever

Cover Screw

Nut

Lever Screw

Plunger Spring

Spring Seat

Thermo Tube, Complete, 14” Length

Thermo Tube, Complete, 14” Length

Thermo Tube, Complete, 7” Length

Thermo Tube, Complete, 7” Length

Plunger

Rod, 14” Length

Rod, 7” Length

Pilot Valve

Pilot Valve Plug

Pilot Valve Plug Gasket

Fulcrum Pin

Screw

Base

Control Pressure Gauge

Supply Pressure Gauge

Plunger Plug

Pilot Valve Spring

Proportional Band Cap

Proportional Band Screw

O-ring

Control Knob

Indicator Label

Diaphragm Spring

Adjusting Screw Clamp

Fulcrum Pin Retaining Washer

Adjusting Screw Knob, Complete

Label

Adjusting Screw Retaining Washer

Street Tee (1/4)

Spring Washer

TYPES D-2, DQ-2, DTP-2, DTHP-2, R-2, RQ-2, RTP-2 AND RTHP-2

QTY.

PER

UNIT

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

DTP-2 DTHP-2 R-2 RQ-2 RTP-2 RTHP-2

58563

21996

9981

20676

58048

58085

9986

58089

58060

58090

9734

9984

--

-10127

12991

10608

21536

9985

9976

16222

--

-10137

9972

9982

10132

58092

58093

--

-52619

52618

52625

53348

52626

52620

58063

58088

58091

58094

58257

28188

58561

Cast Aluminum

Phosphor Bronze

Brass

Cast Bronze

Cast Aluminum

(NOTE 2)

Brass

Brass

Brass

Brass

Brass

Brass

Monel

Brass

Brass

Stainless Steel

Brass

Stainless Steel

Brass

Steel

Steel

Stainless Steel

Brass

Copper

Monel

Brass

Cast Bronze

Steel Case

Steel Case

Brass

Stainless Steel

Brass

Stainless Steel

Synthetic Rubber

Plastic

Mylar

Spring Steel

Aluminum

Copper

Plastic

Aluminum

Copper

Brass

Cad. Plated Spring Steel

MATERIAL

SPEC

ASTM B-108

ASTM B-103

Commercial

ASTM B-61

ASTM B-26 Alloy B443.0

(NOTE 2)

ASTM B-16

ASTM B-16

ASTM B-146

Commercial

ASTM B-16

ASTM B-16

ASTM B-164 Cl. B

ASTM B-16

Commercial

AISI Type 316

ASTM B-16

AISI Type 316

ASTM B-16

Carpenter Invar #36

Carpenter Invar #36

AISI Type 302/304

ASTM B-16

Commercial

ASTM B-164 Cl. B

Commercial

ASTM B-61

Black En. Finish

Black En. Finish

ASTM B-16

AISI Type 302

ASTM B-16

AISI Type 302

Commercial

Commercial

Commercial

ASTM A-228

ASTM B-103

Commercial

Commercial

ASTM B-209

Commercial

ASTM B-16

Commercial

REFERENCE NUMBERS - EACH TYPE

58563

21996

9981

20676

58048

58085

9986

58089

58060

58090

9734

9984

--

--

--

--

--

21536

9985

--

20207

--

--

10137

9972

9982

10132

58092

58093

--

-52619

52618

52625

53348

52626

52620

58063

58088

58091

58094

58257

28188

58561

58059

10895

9981

11764

58048

58086

-58089

58060

58090

9734

9984

1030

9979

10127

12991

10608

21536

9977

9976

16222

11312

9966

10137

9972

9982

10132

58092

58093

9978

33666

--

--

--

--

--

-58063

58088

58091

58094

58257

28188

--

58059

10895

9981

38258

58048

58086

-58089

58060

58090

9734

9984

10130

9979

10127

12991

10608

21536

9977

9976

16222

11312

9966

10137

9972

9982

10132

58092

58093

9978

33666

--

--

--

--

--

-58063

58088

58091

58094

58257

28188

--

58563

21996

9981

20676

58048

58086

-58089

58060

58090

9734

9984

10130

9979

10127

12991

10608

21536

9977

9976

16222

--

--

10137

9972

9982

10132

58092

58093

9978

-52619

52618

52625

53348

52626

52620

58063

58088

58091

58094

58257

28188

58561

58563

21996

9981

20676

58048

58086

-58089

58060

58090

9734

9984

10130

9979

--

--

-21536

9977

-20207

--

-10137

9972

9982

10132

58092

58093

9978

-52619

52618

52625

53348

52626

52620

58063

58088

58091

58094

58257

28188

58561

13

Page 14

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance

shall be afforded with selection of materials based on technical information supplied to Leslie Controls Inc.; however,

system designer and user retain final responsibility. Designer should consider applicable Codes, material

compatibility, product ratings and application details in selection and application. Improper selection, application or

use of products described herein can cause personal injury or property damage. If designer or user intends to use

product for an application or use other than originally specified, he must reconfirm tat selection is suitable for new

operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

14

Loading...

Loading...