Leslie Controls GP Pressure reducing valve User Manual

Page 2

SECTION I — INSTALLATION

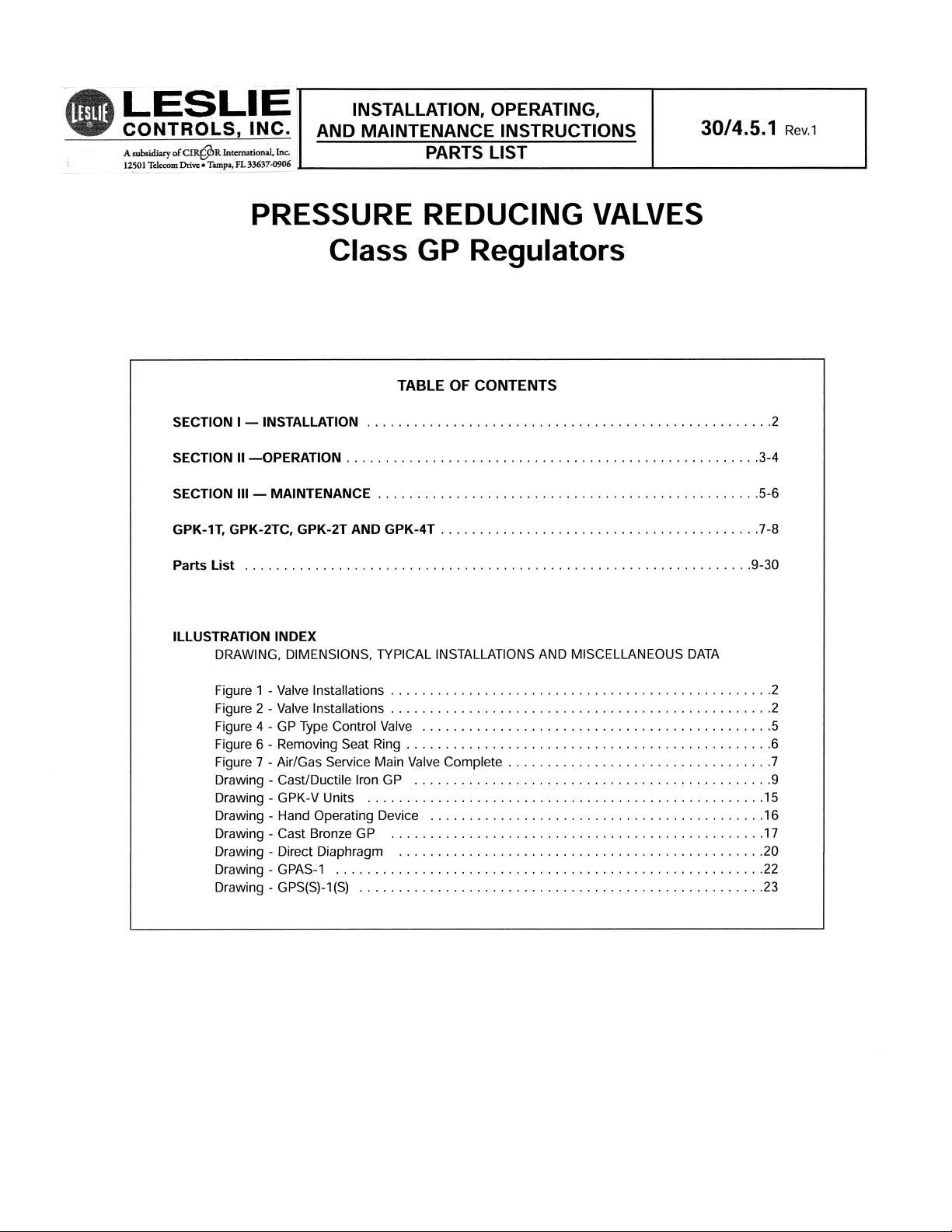

Piping Details

Recommended Straight Run Piping Dimensions inlet and

outlet — All Types and Pressures

Valve Position

Install valve upright in the highest horizontal line of piping, in

an accessible location and with the arrow on the side of the

body in the direction of fluid flow.

NOTE: STOP VALVE IS NECESSARY WHEN SENSING LINE IS

LOCATED DOWN STREAM OF OUTLET STOP VALVE.

Problem Preventing Procedure

1. Provide space above, below and around the valve for

removal of parts during maintenance.

2. Blow or flush out the pipe lines thoroughly before

installing the valve.

3. Remove raised faces of iron or steel line flanges to

which bronze valves are to be bolted. Make outside

diameter of gaskets the same as flanges; inside diam-

eter is 1/4” larger than the bore of the flanges.

4. Do not use red lead or cement in making up joints. In

threaded valves use pipe compound sparingly on male

threads only.

5. STRAINER — Protect the valve and following equip-

ment with a Self-Cleaning Strainer.

6. Install stop valves nd gages in inlet and outlet lines to

provide a means for checking adjustment and opera-

tion of the equipment.

7. In steam service, insulate all piping before and after the

valve to minimize condensation. Provide proper inlet

drainage to prevent water hammer or erosion in the

equipment.

8. Adhere to good piping practice. Install a bypass

around the valve.

Control Pipe — All Pressures

Connect 3/8” control pipe )having I.D. equivalent to 40 sched-

ule pipe) with stop valve, union and pressure gage (as shown

in Figures 1 and 2) from threaded connection in main body of

valve to section of outlet piping before outlet stop valve.

Slop control pipe downward to outlet piping to prevent

water pockets.

Important — Make control pipe connection in expanded out-

let piping at a point at least 24” downstream from the end of

the expander and not within 18” to 24” of the outlet stop

valve, any elbow or other flow direction changing fitting.

Control pipe length should be held to approximately 3’.

Connect control pipe to side of outlet pipe if necessary to

obtain proper slope.

Recommended outlet piping for valves controlling compress-

ible fluids at values of 25% or less of inlet pressure;

Expand outlet pipe (E Dimension) to twice the valve size.

Use tapered expander — 15°/20° on included angle.

Note: Further expansion of low pressure outlet piping

beyond the outlet stop valve has no effect on operation of

this valve.

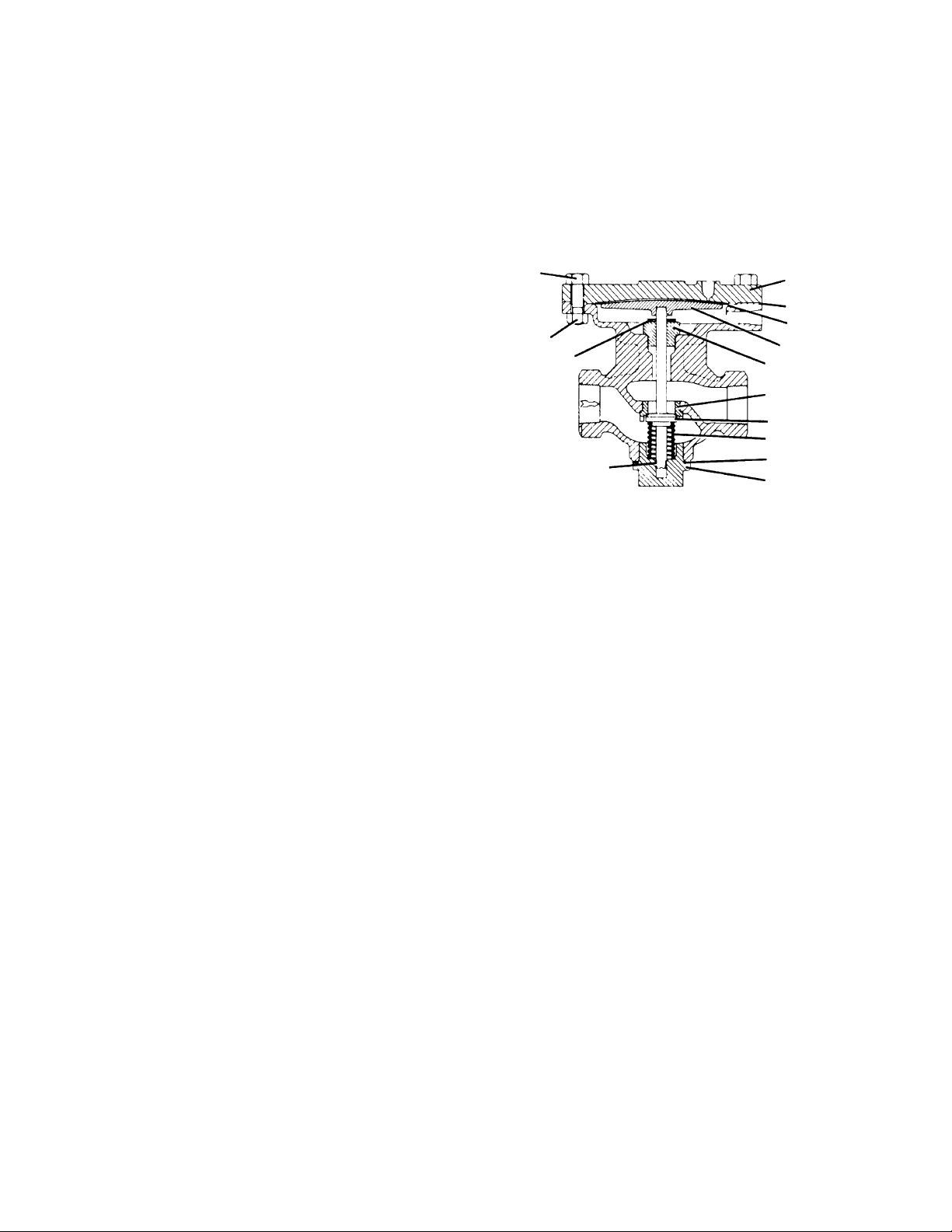

Figures 1 and 2

Recommended Valve Installations

DIMENSIONS

VALVE SIZE

DE

1/2” to 1-1/2” 1’6” to 5’ 4’ to 5’

2” to 4” 3’ to 5’ 4’ to 8’

Operating medium from air loader or sensing element

Operating medium from air loader or sensing element

Fig. 1 — For controlled pressures above 25%

of Inlet pressure (Compressible Fluid).

Fig. 2 — For controlled pressures of 25% or less

of Inlet pressure (Compressible Fluid).

Top view of Pressure Reducing Station showing

Bypass arrangement.

* Expand line after stop valve to cross sectional area

as required for steam flow.

Page 3

SECTION II — OPERATION

For installation, adjustment of loading device and operating

details, consult the proper instructions pertaining to the par-

ticular type of loading, sensing or other operating device.

Overall Valve Dimensions

For overall valve dimensions — face-to-face, height, etc., —

consult the drawing which applies to the valve in use.

Principle of Operation

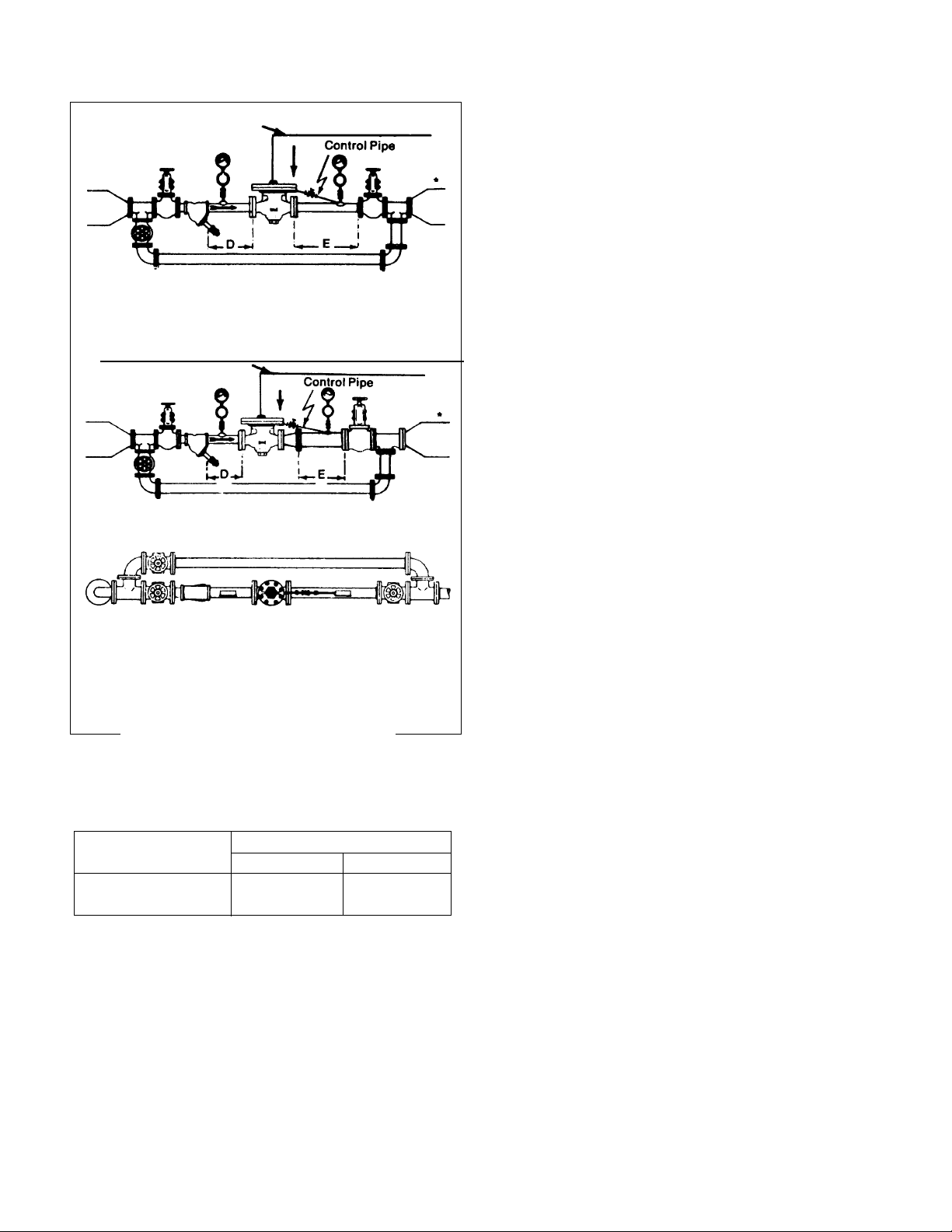

The control valves are operated by means of an airloading

force delivered by a loading valve, temperature pilot or similar

device which delivers an air signal to the diaphragm of the

regulator. Figure 3 shows the loading pressures required for

various valve sizes and pressure drops. Diaphragm pressure

quoted, for any particular size or pressure drop, is the pres-

sure required on the diaphragm to open the valve under the

existing conditions. Beyond this value an ratio of 1:1 delivered

steam pressure to additional air loading pressure will be

obtained. The valve will them maintain the controlled pres-

sure accurately and in direct relation to the loading pressure

value above that which is necessary to open the valve.

Operation of GP Type Control Valves

In conjunction With Air Loaders

Important: DO NOT apply air-loading force to diaphragm of

control valve until inlet stop valve is fully opened with full pres-

sure to inlet of the control valve.

Starting Up:

1. Open inlet stop valve.

2. Close outlet stop valve.

3. Dispose of condensation, dirt, etc., by opening the

strainer blow-off valve.

4. Crack outlet stop valve to permit slight flow when

adjusting the control valve.

5. Slowly supply loading pressure to control valve

diaphragm until the valve begins to open. Gradually

increase loading pressure until desired downsteam

controlled pressure is obtained.

6. Slowly open outlet stop valve.

7. To increase controlled pressure, increase loading pres-

sure. To decrease controlled pressure, decrease load-

ing pressure.

Shutting down:

To turn steam off, relieve loading pressure from diaphragm of

the control valve and close inlet and outlet stop valves.

Page 4

DIAPHRAGM PRESSURE ABOVE REDUCED PRESSURE

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

GPS-1T (S)

GPK-4T (S)

limit 25 psi

4” GPS-1

4” GPK only

100 200 300 400 500 600

PRESSURE DROP PSI (INLET PRESSURE MINUS OUTLET PRESSURE)

Classes GPHS & GPHS-1 only

4“ GPHS and

GPHS-1 only

1-1/2” and 2”

3”

1”

2-1/2””

3/4”

1/2”

MAX. INLET*

CLASS

& MAX. ∆P

GPK 250

GPB 300

GPS 300

GPS-1 300

GPHS 600

GPHS-1 600

GPAK 400

GPAS-1 400

*Subject to valve body limitations.

The above curves indicate the loading pressures above the

outlet pressure require for each size class GPK, GPAK,

GPB, GPS, GPHS, GPS-1, GPHS-1, and variants for all pres-

sure differentials across the valves.

EXAMPLE: If a 3” GPB reducing valve is required to reduce

steam from 300 psig to 20 psig, 44 psig air loading is

required. This is determined as follows: Enter the chart at

280 psi pressure drop and read up to the 3” size. Read

across to 24 psi, which must be added to the outlet pressure

to determine the required loading pressure.

NOTE: Maximum diaphragm joint pressure is 300 psig.

Loading pressure (reduced pressure plus diaphragm pres-

sure above reduced pressure must not exceed 300 psig.

SECTION II — OPERATION (CON’T)

Page 5

SECTION III — MAINTENANCE

Leslie control valves may be dismantled without removal from

pipeline when maintenance checks are desired.

Play Safe! Use Only Genuine

Leslie Replacement Parts

All Leslie control valves are made of high quality materials,

are time-tested and backed by more than a half century of

knowhow. Machining is done by expert craftsmen and each

valve is inspected and service-tested before shipment to

you.

Use of other than GENUINE LESLIE PARTS may impair their

ability to work properly. DO NOT change any dimensions

except as noted in these instructions. To assure long life,

preservation of parts interchangeability and low maintenance

costs, use only standard LESLIE PARTS.

CHECK NAMEPLATE FOR PROPER CLASS AND WRITE

FOR APPLICABLE DRAWINGS.

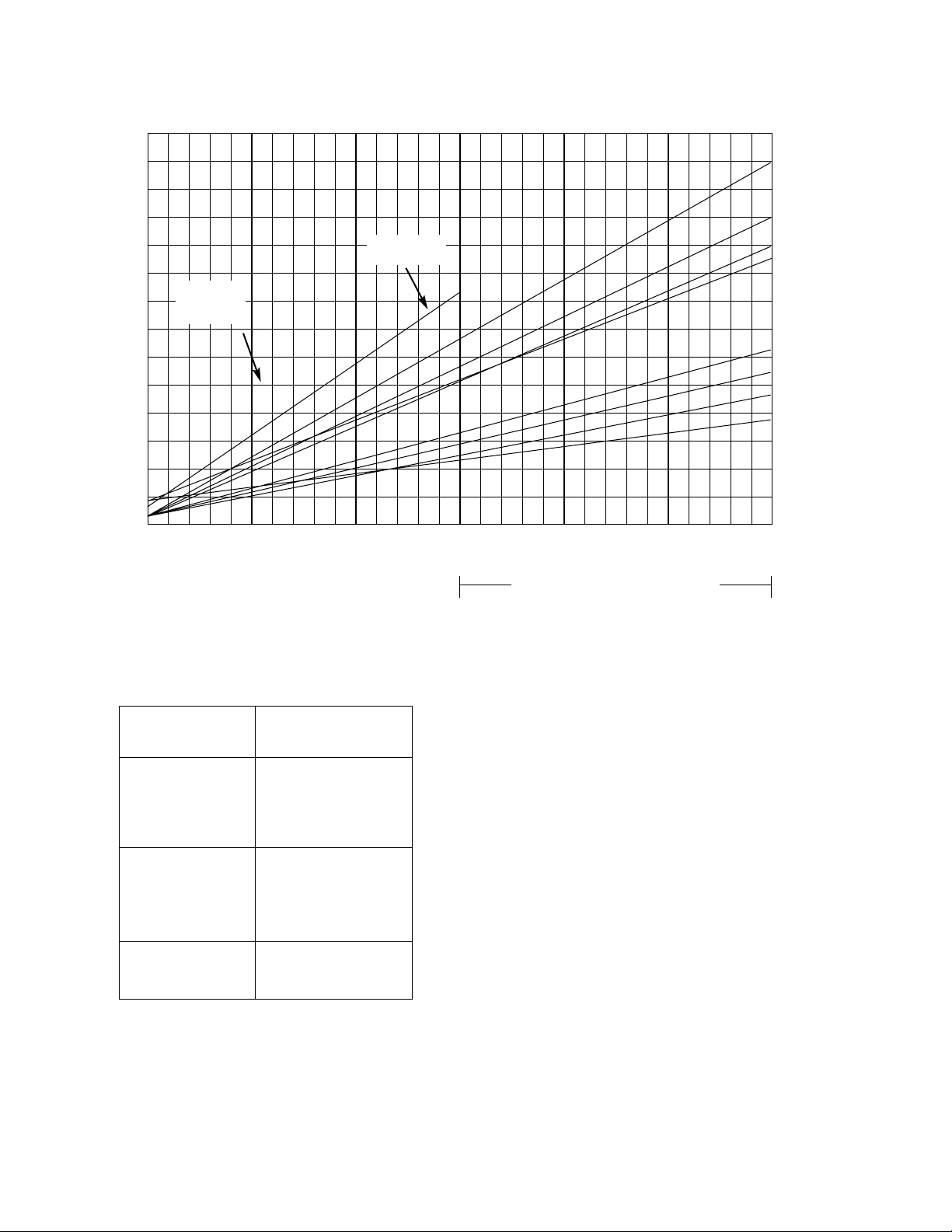

Dismantling

1. Shut off air supply. Disconnect loading line to release

air pressure from diaphragm area.

2. Close stop valves on inlet and outlet sides of control

valve and open strainer blowdown valve to vent

trapped fluid.

3. Loosen and remove bottom cap. Gasket, main valve

spring and main valve will follow.

4. Do not remove seat ring unless remachining or replace-

ment is necessary. If removal is necessary, see Figure

6 with accompanying instructions.

5. To examine diaphragm (two leaves) and main valve

guide or to clean diaphragm area, remove diaphragm

cover bolts/nuts, diaphragm and diaphragm disc. To

take out diaphragm disc, form two hooks of 1/16”

diameter wire and lift out disc.

Cleaning, Replacing or Repairing Parts

Clean all parts with kerosene or other approved solvent and

check as follows:

1. Examine main valve, seat ring and main valve guide.

Remove any encrusted material with crocus cloth.

2. FOR ALL-METAL SEATS ONLY: If main valve or seat

ring seating surfaces are cut or scored, regrind with

600 grit grinding compound. Remove all trace of

grinding compound before reassembling.

NOTE: If main valve, seat rings or both must be remachined

due to damage to seating surfaces, in order to maintain cor-

rect diaphragm disc to diaphragm seat dimension, it will be

necessary to shorten the main valve. To do this, remove

from the top of the main valve stem (diaphragm disc end) an

amount of metal equal to the amount (dimensional thickness)

removed from the main valve and or the seat ring.

Use 600 grit compound, lap the main valve into the seat.

When relapping main valves in sizes 2-1/2” larger, take off

diaphragm cover and remove diaphragms so that their spring

action will not interfere with the lapping operations.

Replacing Seat Rings

To remove seat rings, use the special wrench which is avail-

able on request. See Figure 6.

Position seat ring wrench and socket wrench as shown in

Figure 6. Hold tightly against seat ring. Tap handle of sock-

et with hammer to loosen seat ring. Then unscrew seat ring.

Figure 4 — GP Type Control Valve

Figure 5 — Soft Seat Ring

Figure 6 — Removing Seat Ring

Seat Ring Wrench -

Insert Bar Through Hole

Seat Ring

Diaphragm

Cover

Seat Ring

Diaphragm

(2 leaves)

Diaphragm

Disc

Main Valve

Guide

Main Valve

Main Valve

Spring

Gasket

Bottom Cap

Page 6

To Install Seat Ring

1. Carefully clean threads and joint contact surfaces on

seat ring and in the valve body.

2. Make sure joint surfaces are undamaged.

3. Use a light coating of Never-Seez or similar lubricant

on the first two threads only of seat ring. Screw seat

ring into valve body threads and pull up tight with

wrench.

4. Tap handle of socket wrench with hammer to lock seat

ring in place.

Hard Seats Only:

5. Lap in main valve and seat ring carefully. Use very fine

lapping compound.

Reassembly

1. Do not use graphite or compound on joints.

2. Place main valve, main valve spring and gasket on bot-

tom cap. Assemble bottom cap part way (enough to

hold in place) on main body.

3. Place diaphragm disc on main valve with guide end

over stem end of the main valve.

4. Put diaphragm leaves together, matching convolutions

as closely as possible, and position them carefully in

main body above diaphragm disc.

5. Assemble diaphragm cover and bolts/nuts to main

body. Snug up bolts alternately and evenly across

diaphragm cover. Then tighten firmly. Tighten bottom

cap. Reconnect air-loading line.

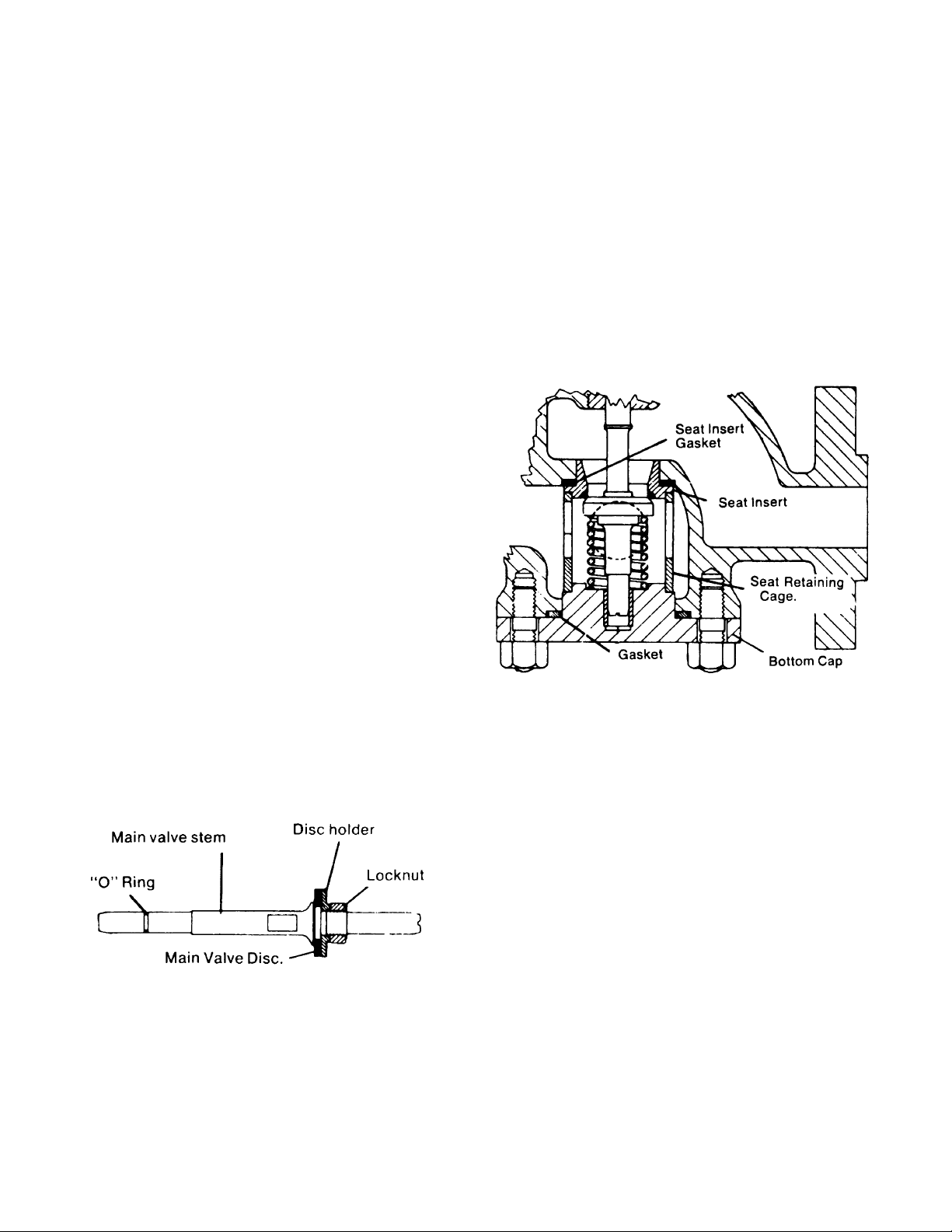

Replacing Main Valve Disc

Air or Gas Service Valves

Figure 7 — Air/Gas Service

Main Valve Complete

Hold locknut rigidly. Use wrench on flats of stem to

loosen stem. Disassemble parts. Install new valve

disc and reassemble. Replace “O” ring if worn.

Lubricate "O" ring (use grease suitable to fluid under

control). If valve is controlling oxygen, use suitable

lubricate. Note: Do not grind in main valve.

Steel Valves Fitted with Cage Type Trim

When dismantling steel valves fitted with cage trim, the seat

insert, seat-insert cage and the seat-insert gasket may be

easily removed for inspection, cleaning or rework after the

bottom cap and other parts have been removed. When

reassembling, always use new seat insert and bottom cap

gaskets. Tighten bottom cap down evenly until the faces of

the bottom cap and main body meet.

For steel valves without cage trim, use the procedures.

Figure 7 — Cage Type Trim

Page 7

GPK-1T, GPK-2TC, GPK-2T AND GPK-4T

PRESSURE REDUCING VALVES SIZES

1

⁄2

" THROUGH 4"

HOW TO IDENTIFY YOUR VALVE TYPE

GPK-1 T— Fitted with three (3) stainless steel diaphragms.

GPK-2T—This is a converted GPK-1T fitted with a SUPER-

FLEX diaphragm and a metal spacer ring to control diaphragm

crush.

GPK-4T— As” - 1As” sizes only with Super G body design and

resilient seat.

NOTE: If you wish to take advantage of the long-life

expectancy of the new SUPERFLEX diaphragm, your

GPK-1T can be easily converted to either a GPK-2TC or

GPK-2T during your valve maintenance period.

DISASSEMBLY

1. Remove bolts and nuts from diaphragm cover and lift off

cover. Take out diaphragm(s) and diaphragm disc.

Remove spacer ring if used.

2. Remove bottom cap and bottom cap gasket, main valve

and spring.

3. To remove seat ring, place seat ring wrench over lugs of

ring and strike end of wrench with a hammer several

times while holding wrench in place to loosen seat ring

for removal.

4. Clean diaphragm disc, diaphragm cover and main body

diaphragm seating surface including the rounded portion

below diaphragm face. Cleaning is important as a

diaphragm life can be decreased if diaphragm is allowed

to flex over any rough or scaled areas. A rotary wire

brush is excellent for cleaning these surfaces. Check

diaphragm cover air connection making sure it is not

plugged.

5. Clean and polish seat ring threads and flat face, bottom

cap gasket face and threads, main valve guide in main

body and main valve guide bushing in bottom cap

(Bottom cap bushings are removable in 1/2” through 2”

sizes). To polish main valve and guides, place them in a

lathe and spin rapidly. Use 320 Aluminum Oxide cloth

as polishing agent.

6. After cleaning check all parts for erosion or damage.

Replace if necessary.

7. Use a rotary wire brush and clean main body seat ring

face and threads. Check for any erosion or damage to

threads or flat face. All deposits must be removed from

flat face as a metal to metal steam seal must be

obtained between ring face and main body. Check bot-

tom cap gasket face of main body. Gasket face must be

flat and square; minor nicks should be removed with fine

emery.

8. Blow out all loose scale etc. from body with air.

ASSEMBLY

1 Use a light coating of Never-Seez or similar lubricant on

the first two threads only of seat ring. Blue in seat ring

before final tightening making sure there is full, all-

around contact between seat ring and main body flat

faces. Tighten seat ring to 150 foot pounds torque.

Install main valve guide and tighten.

2. FOR ALL-METAL SEATS ONLY: Place a small amount

of extra fine lapping compound (Carborundum Grade

CF) evenly spaced on main valve seating surface and

lightly lap valve to seat ring. Remove all traces of com-

pound from parts before reassembly.

For TROUBLE FREE OPERATION and TIGHT SHUT-OFF

carefully follow the MAINTENANCE PROCEDURES outlined in this INSTRUCTION.

Diaphragm Cover

Crush Limit Ring

Diaphragm(s)

Diaphragm Disc

Main Valve Guide

Seat Ring

Main Valve

Main Valve Spring

Bottom Cap Gasket

Bottom Cap

Bolt

Nut

*Travel Stop

Bottom Cap Guide

*1/2” through 2” GPK-2TC and GPK-2T do not have a travel stop.

Page 8

3. Install main valve, main valve spring, bottom cap with

guide bushing and bottom cap gasket. Tighten bottom

cap.

4. Place travel stop washer over upper end of main valve

stem followed by diaphragm disc (GPK-2T and GPK-

2TC, sizes 1” through 2” do not have a travel stop).

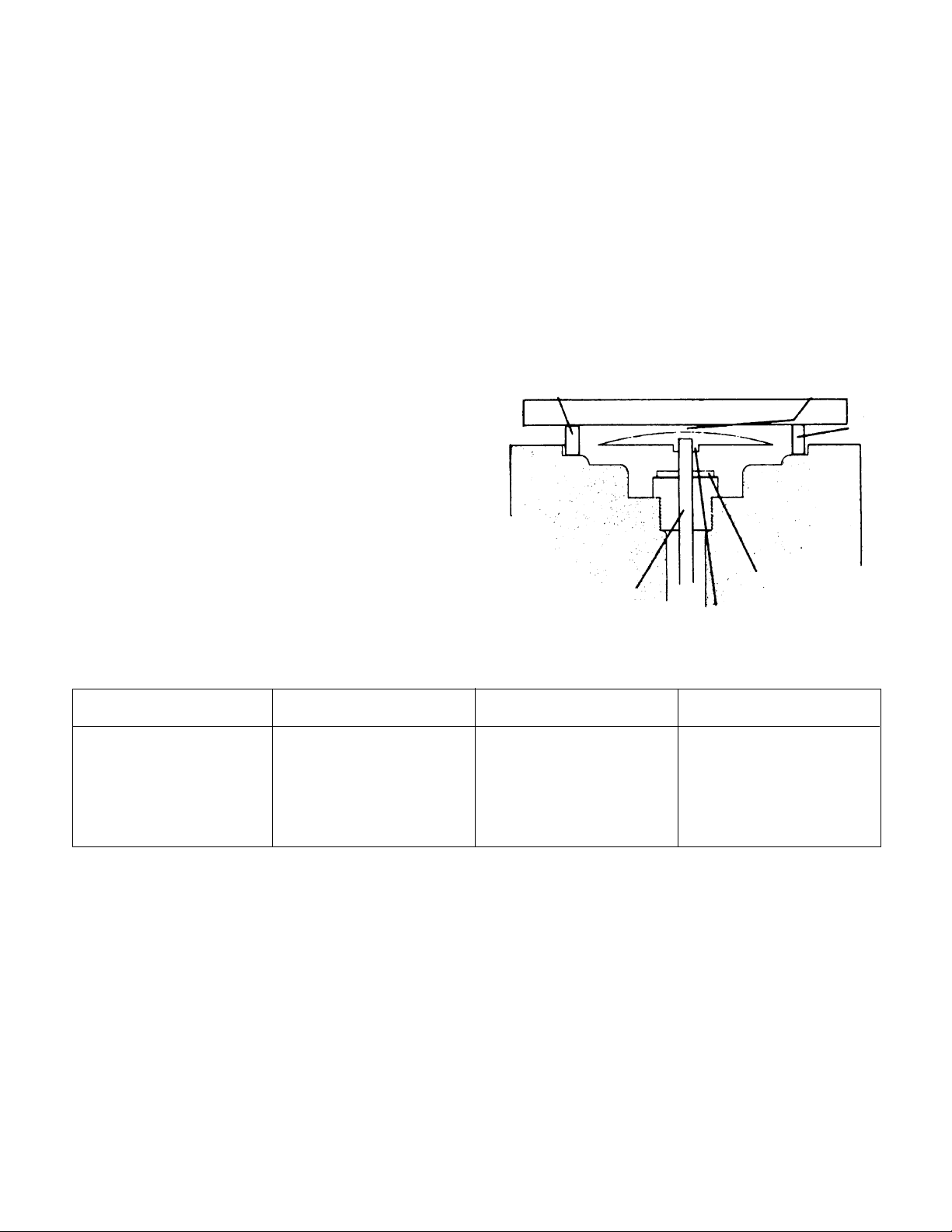

5. Check height of disc. IMPORTANT: Height of diaphragm

disc MUST be correct to obtain TIGHT SHUT-OFF of

main valve. See Clearance Table and sketch for details.

If MINIMUM clearance is LESS than that shown in

Clearance Table, remove main valve and grind just

enough metal from end of main valve stem to obtain

proper clearance* (see view) If MAXIMUM clearance is

MORE than that shown in Clearance Table, the rated

travel of main valve will be reduced causing a reduction

in the rated steam capacity of valve. If reduced capacity

is great enough to affect system operation, a new seat

ring and main valve should be installed.

6. GPK-1T Type—Replace the three diaphragms mak- ing

sure the lower two leaves are those having a small bleed

hole. The upper or top diaphragm is solid and does not

have a bleed hole. GPK-2TC and GPK-2T Types —

Replace SUPERFLEX DIAPHRAGM.

7. Loosen bottom cap sufficiently until diaphragm disc

rests against main valve guide or travel stop if one is

used. Place SUPERFLEX diaphragm on top of disc and

center into recess of valve body. Replace diaphragm

cover spacer ring on GPK-2TC only. In-stall diaphragm

cover and tighten nuts evenly and securely. Retighten

bottom cap.

8. If possible check valve for tight seating, using steam

pressure equal to actual operating pressure before

installing valve in line.

9. BEFORE INSTALLING VALVE: Clean strainer at in-let of

valve and blow out piping including impulse pipe.

Check traps for proper operation. Check pressure

gages to make sure they read pressure correctly.

GAGE BLOCK MINIMUM MAXIMUM

VALVE SIZE HEIGHT CLEARANCE CLEARANCE

1

⁄2" - 1

1

⁄2" .187 + .000 .073 to .071 .100

- .022

1

1

⁄2" - 2" .218 + .000 .076 to .074 .103

- .002

2

1

⁄

2" - 4" .312 + .000 .024 to .022 .066

- .002

To check disc height, place two gage blocks on flat of diaphragm face opposite each other. Place a straight edge across blocks

and measure clearance between bottom edge of straight edge and top of diaphragm disc as shown in sketch.

CLEARANCE TABLE

Gage Block

Clearance

(See Table)

Straight Edge

Gage

Block

Travel Stop

Dia. Disc

*Grind Off

Main Valve

Stem At

This End

Page 9

CAST /DUCTILE IRON GP, TYPE DIRECT,

DIAPHRAGM OPERATED REDUCING VALVES

DIMENSIONS IN INCHES AND MILLIMETERS

NOMINAL

BOLT NO. OF BOLT

PIPE A B C C-D D E F G H J K NET WT.

HOLE HOLES SIZE

SIZE

THREADED

1/2” 6-1/8 5-1/2 3-3/8 6-3/8 — — — — — 8-5/8 3-5/8 — — — 33 lb.

15 mm 155.6 139.7 85.7 161.9 — — — — — 219.1 92.1 — — — 15 kg.

3/4” 6-1/2 5-1/16 3-5/16 6-3/8 — — — — — 8-5/8 3-5/8 — — — 36 lb.

20 mm 165.1 128.6 84.1 161.9 — — — — — 219.1 92.1 — — — 16.3 kg.

1” 7-1/4 5-1/4 3-3/8 6-3/8 — — — — — 8-5/8 4 — — — 42 lb.

25 mm 184.2 133.3 85.7 161.9 — — — — — 219.1 101.6 — — — 19.1 kg.

1-1/4” 7-5/8 5-9/16 3-15/16 6-7/8 — — — — — 10-1/4 4-1/8 — — — 55 lb.

32 mm 193.7 141.3 100.0 174.6 — — — — — 260.4 104.4 — — — 24.9 kg.

1-1/2” 8-1/2 5-3/4 4-1/2 7-7/8 — — — — — 10-1/4 4-5/16 — — — 56 lb.

40 mm 215.9 146.0 114.3 200.0 — — — — — 260.4 109.5 — — — 25.4 kg.

2” 8-1/2 5-3/4 4-1/2 7-7/8 — — — — — 10-1/4 4-5/16 — — — 56 lb.

50 mm 215.9 146.0 114.3 200.0 — — — — — 260.4 109.5 — — — 25.4 kg.

125# ANSI FLANGED

2" 10 6-1/2 4-7/16 10 6 11/16 — 4-3/4 — 10-1/4 4-5/16 3/4 4 5/8 70 LB

50MM 254.0 165.1 112.1 254.0 152.4 17.5 — 121.6 — 260.4 109.5 19.1 4 15.9 31.8 KG

2-1/2" 10-7/8 7-3/16 5-1/2 7-1/8 7 11/16 — 5-1/2 — 16 4 3/4 4 5/8 192 LB

65MM 276.2 182.6 139.7 181.0 177.8 17.5 — 139.7 — 406.4 101.6 19.1 4 15.9 89.4 KG

3" 11-3/4 8-11/16 6-1/2 8 7-1/2 3/4 — 6 — 16 4-13/16 3/4 4 5/8 220 LB

80MM 298.5 220.6 165.1 203.2 190.5 19.1 — 152.4 — 406.4 122.2 19.1 4 15.9 99.7 KG

4" 13-7/8 9-15/16 7-5/16 9-1/4 9 15/16 — 7-1/2 — 16 6-1/8 3/4 8 5/8 247 KG

100MM 352.4 252.4 184.2 235.0 228.6 23.8 — 190.5 — 406.4 155.5 19.1 8 15.9 112.3 KG

250# ANSI FLANGED

1-1/2" 10-1/2 5-13/16 4-7/16 7-7/8 6-1/8 13/16 3-9/16 4-1/2 1/16 10-1/4 4-3/8 7/8 4 3/4 74 LB

44MM 266.7 147.6 112.7 200.0 155.6 20.6 90.5 114.3 1.6 260.4 111.1 22.2 4 19.1 33.6 KG

2" 10-1/2 5-13/16 4-7/16 7-7/8 6-1/2 1 4-3/16 5 1/16 10-1/4 4-3/8 3/4 8 5/8 74 LB

50MM 266.7 147.6 112.7 200.0 165.1 25.4 160.3 127.0 1.6 260.4 111.1 19.1 8 15.9 22.6 LB

2-1/2" 11-1/2 7-3/8 5-1/2 7-1/8 7-1/2 1 4-15/16 5-7/8 1/16 16 4 7/8 8 3/4 197 LB

65MM 292.1 187.3 139.7 180.9 190.5 25.4 125.4 149.2 1.6 406.4 101.6 22.2 8 19.1 89. KG

3" 12-1/2 8-5/8 6-3/8 8 8-1/4 1-1/8 5-11/16 6-5/8 1/16 16 5-1/4 7/8 8 3/4 230 LB

80MM 317.5 219.0 161.9 203.2 209.6 28.6 144.5 168.3 1.6 406.4 133.3 22.2 8 19.1 104.3 KG

4" 14-1/2 9-15/16 7-5/16 9-1/4 10 1-1/4 6-15/16 7-7/8 1/16 16 6-5/16 7/8 8 3/4 280 LB

100MM 368.3 252.4 185.7 235.0 254.0 31.7 176.2 200.0 1.6 406.4 160.3 22.2 8 19.1 127.3 kg

Loading...

Loading...