Page 1

Asubsidiary of International, Inc.

12501 Telecom Drive, Tampa Florida

ADJUSTABLE PROPORTIONAL BAND PILOT CONTROLLERS (PDAP and PRAP Types)

SECTION I — INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SECTION II —OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

SECTION III — MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

SECTION IV — SETTING OF ADJUSTING PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

INSTALLATION, OPERATING,

AND MAINTENANCE INSTRUCTIONS

33637

PARTS LIST

LESLIE PILOT CONTROLLERS

TABLE OF CONTENTS

20/1.5.2

Rev.3

STEM LENGTH AND SENSITIVITY ADJUSTMENT (PRA-

CONSTANT PRESSURE PILOT CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CONSTANT, DIFFERENTIAL PRESSURE AND RATIO PILOT CONTROLLERS

Force Balance, Fixed Band Types

SECTION I — INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SECTION II — OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SECTION III — MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

PARTS LIST . . . . . . . .

ILLUSTRATION INDEX

DRAWING, DIMENSIONS, TYPICAL INSTALLATIONS AND MISCELLANEOUS DATA

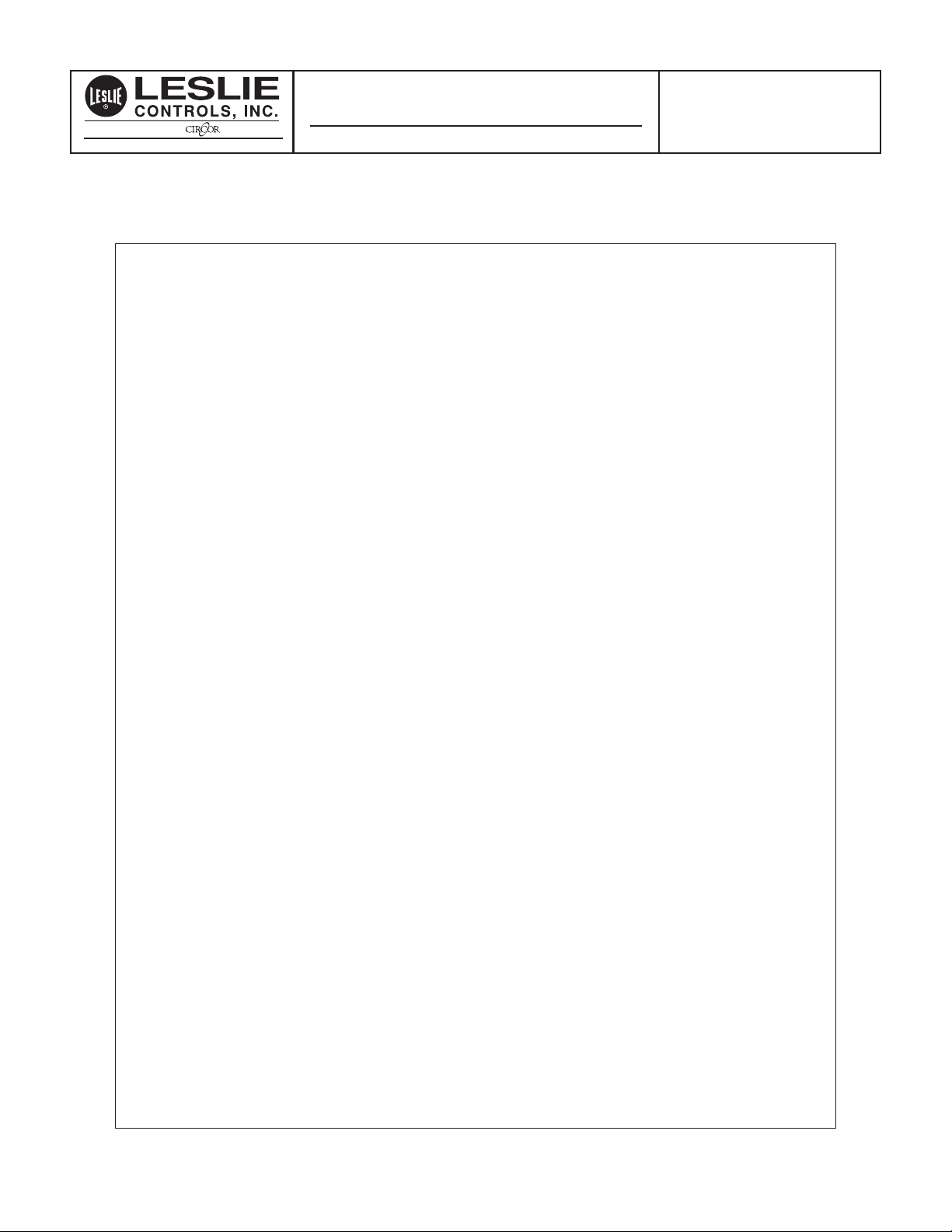

Figure 1 - Pilot Controller Piping Details - Pressure Reduction Station . . . . . . . . . . . . . . . . . .2

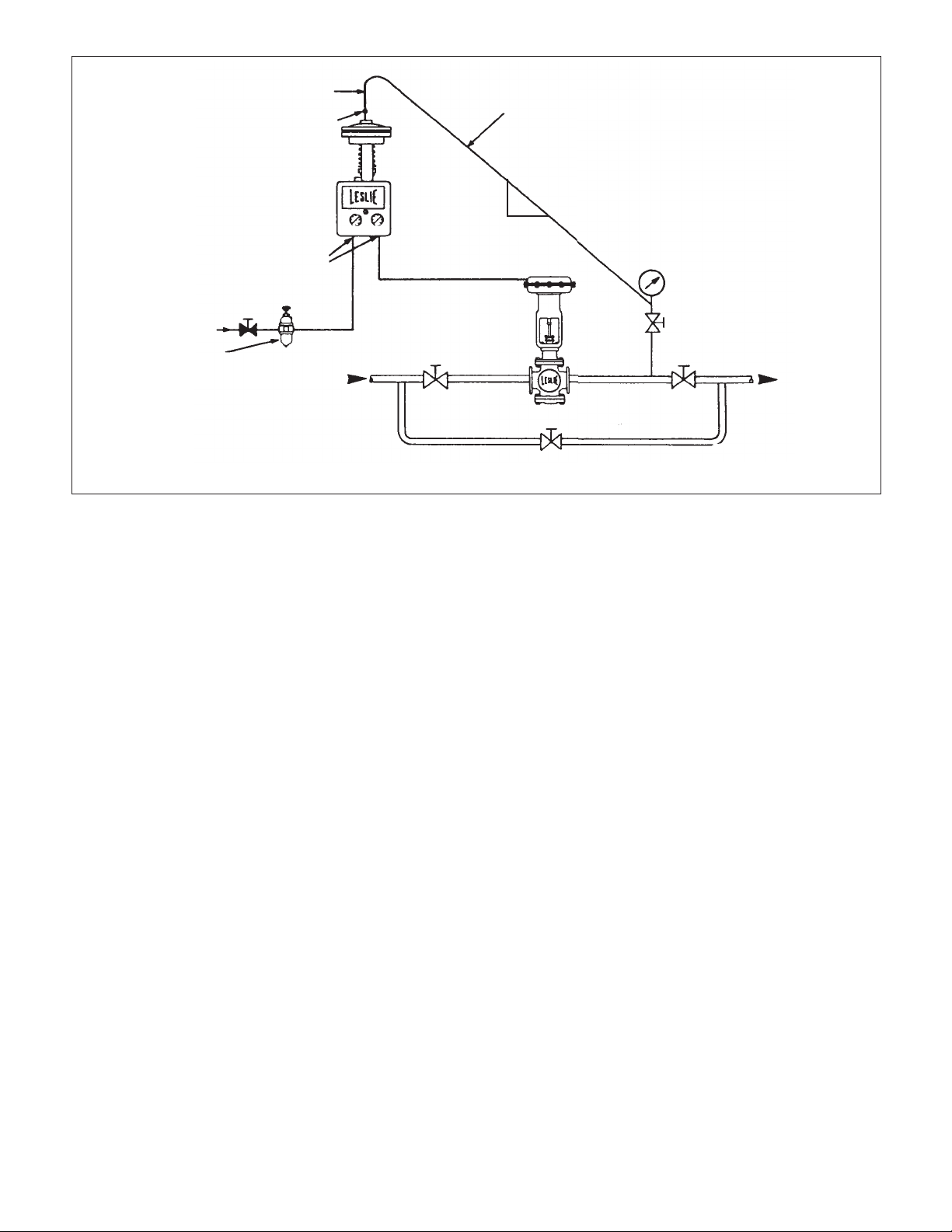

Figure 2 - Pilot Controller with 1:1 Volume Booster Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Figure 3 - Pilot Controller wit 1:1 Volume Booster and Reset Relay . . . . . . . . . . . . . . . . . . . . .3

Figure 4 - Pilot Controller with

Figure 5 - Pilot Controller with Inverse Derivative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

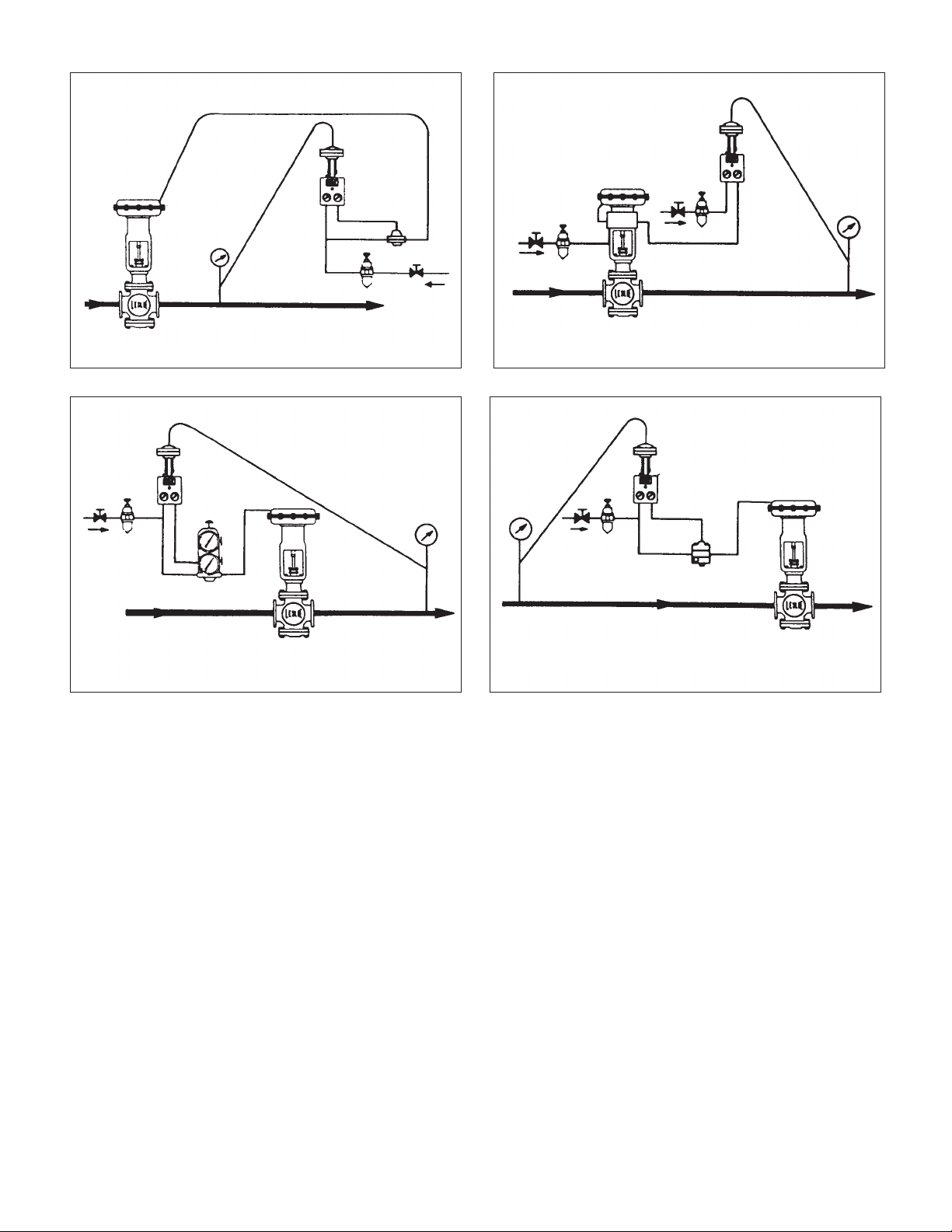

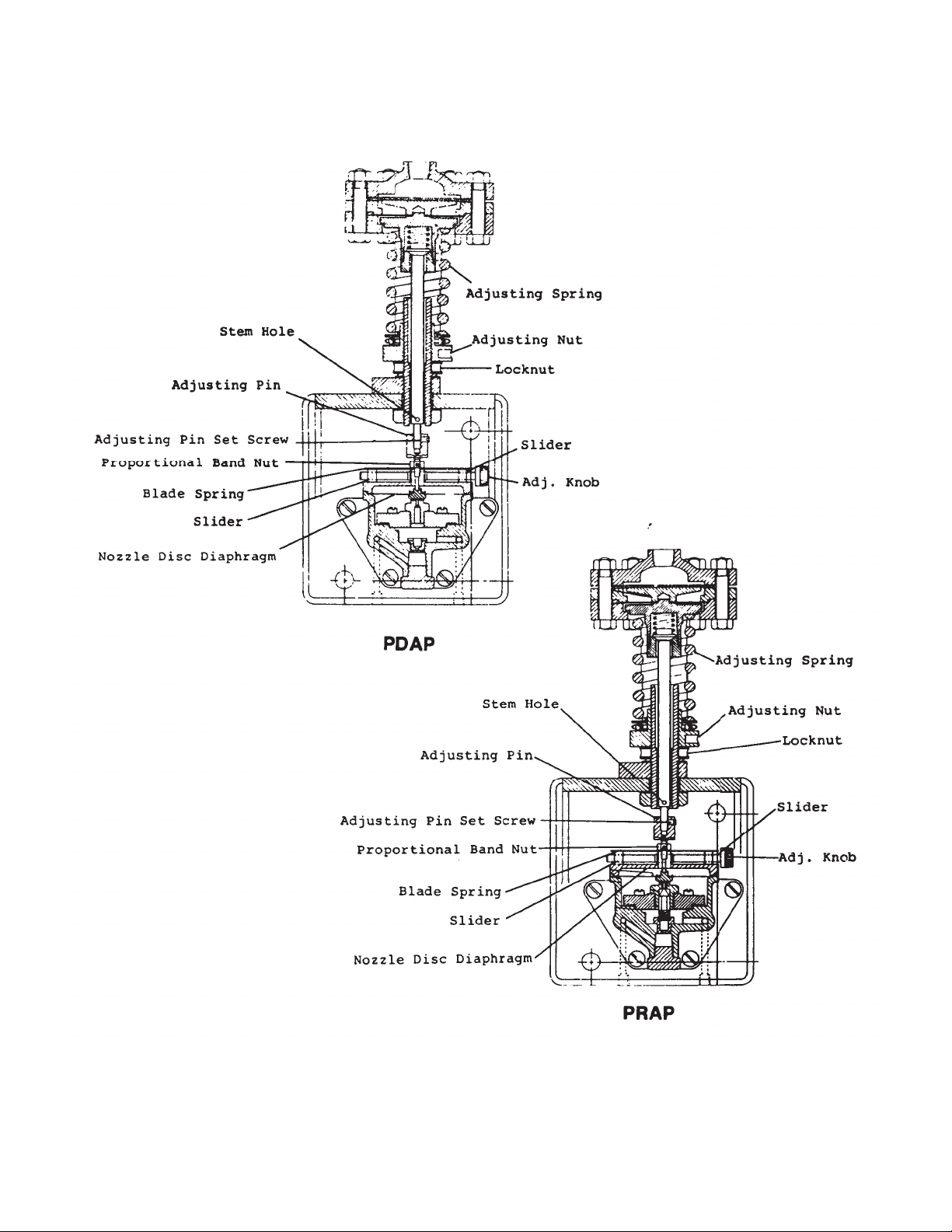

Figure 6 - Type PRAP Pilot Controller (5-80 psig range) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 7 - Type PDAP Pilot Body Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

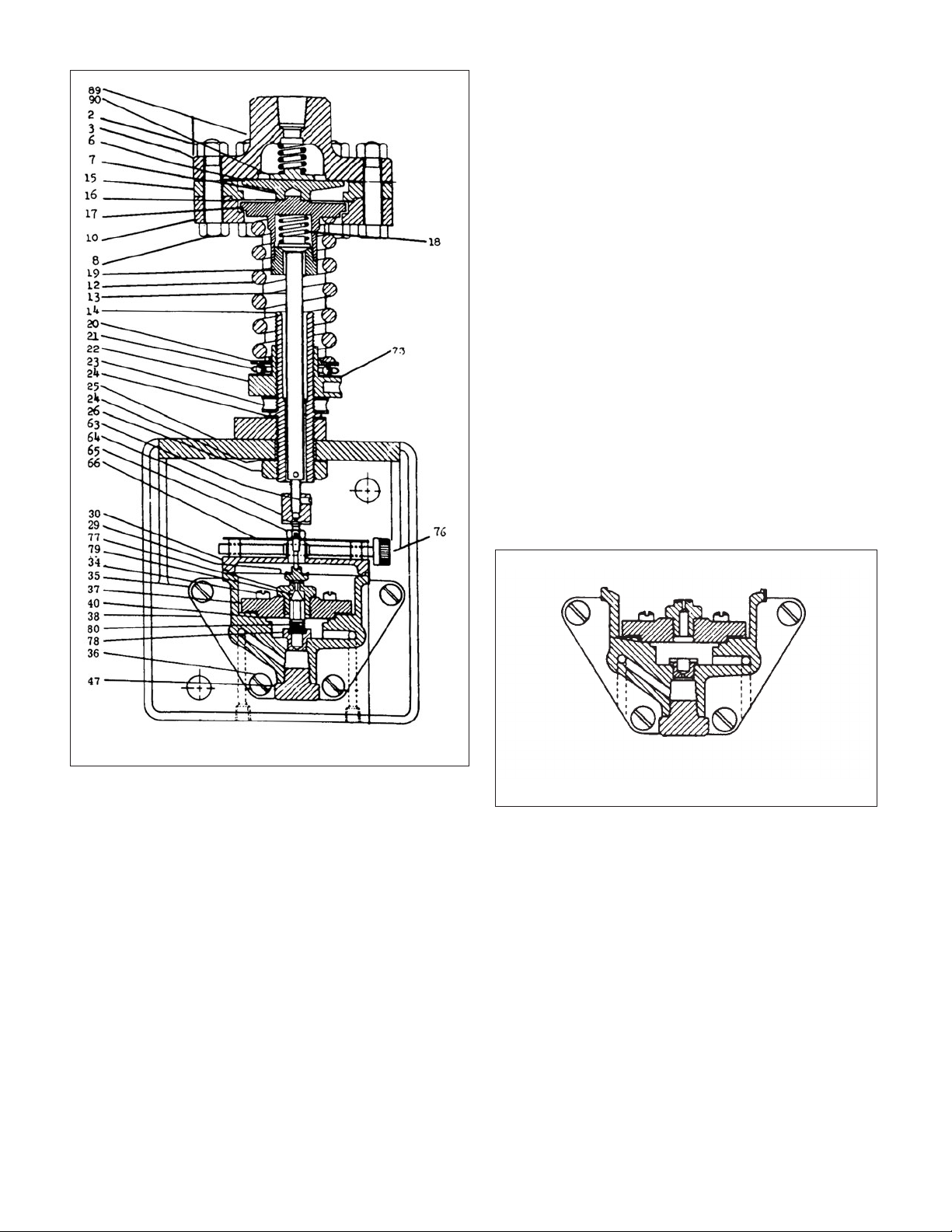

Figure 8 - Position of sliders for nut/blade spring adjustment . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 9 - Min./Max. Proportional Band Table .

Figure 10 - Adjustable Proportional Band Pilot Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 11 - PRA-1, PRW-1, PRQ, Pilot Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 12 - Pilot Controller piping details — Typical Installation . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 13 - Drawing showing Direct Acting Type Pilot Controller (PDA-1, etc.) . . . . . . . . . . . .9

Figure 14 - Partial Drawing showing lever and lever pin

Figure 15 - Diaphragm assembly for Pressure Ranges 13 PSIA - 20 PSIG to 50-125 . . . . . .11

Figure 16 - Back Pressure or Pressure Relief Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Drawing - Pilot Controllers Types PDA-1, PDQ-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Drawing - Pilot Controller Types PRA-1, PRA-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Drawing - Pilot Controller Type PDAP-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawing - Pilot Controller Types PRAP-1, Range 5-70 & 50-800 . . . . . . . . . . . . . . . . . . . . .20

Drawing - Differential Pilot Control Type UDDV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Drawing - Pilot Controller Type DDD, 15-75 Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1 and PRQ-1 Types)

14-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

tc. . . . . . . . . . . . . . . . . . . . . . . . . . .9

, e

. . . . . .

18

5

Page 2

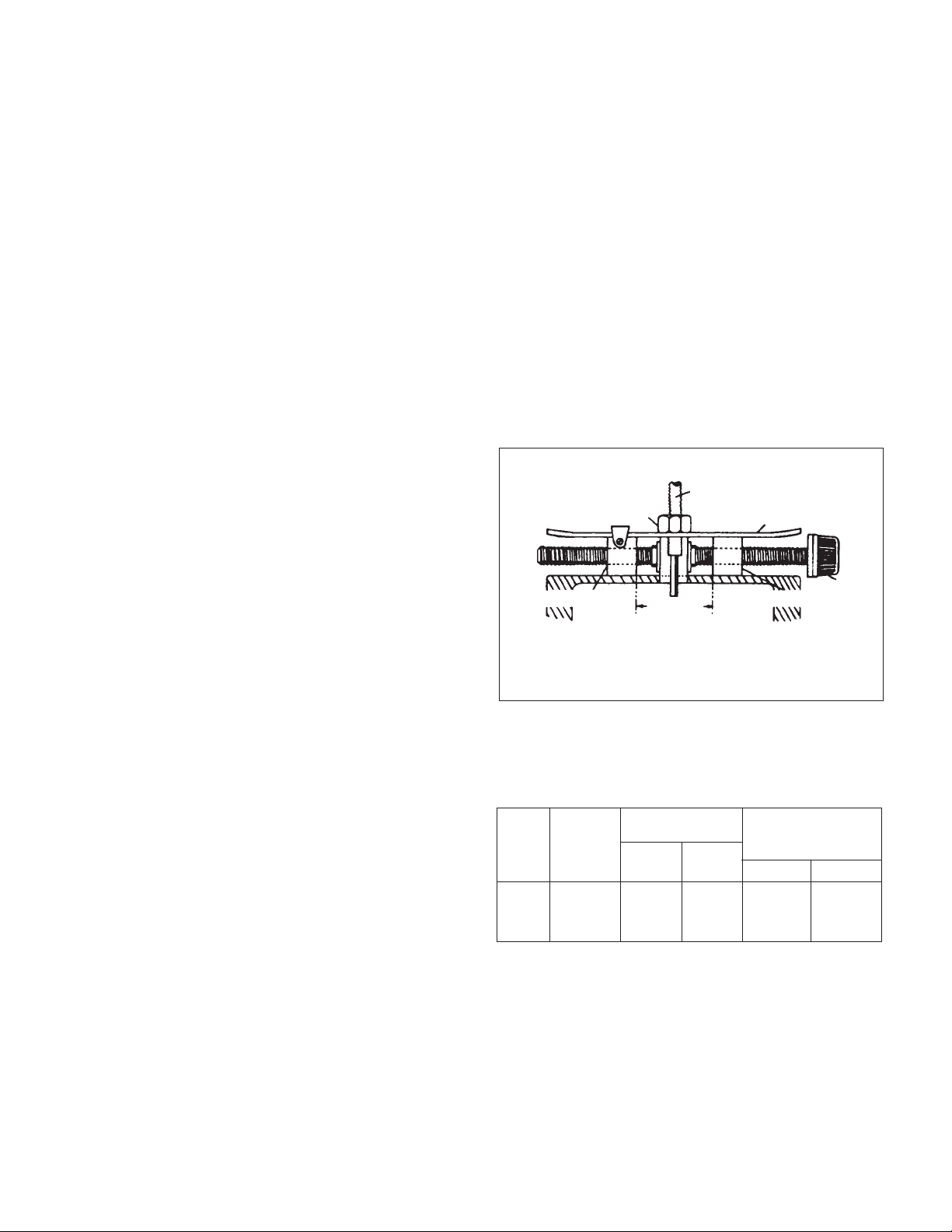

6" Vertical Section (Min.)

Air Lines-Use 1.4" I.D. pipe or tubing.

Use noncorrosive pipe and fittings.

Connect air supply to Pilot Controller

under gauge marked Operating Supply.

Connect outlet from P

under gauge marked Control Valves to

Diaphragm Control Valve.

LESLIE Class AF-2 Pressure Reducing

Valve. Set reducing valve to supply 2022 psig air to pilot.

ilot Controller

Figure 1. Pilot Controller Piping Details — Pressure Reduction Station

Union

Impulse LIne-Use 1/2" schedule 40 pipe or tubing

with equivalent I.D.

Avoid loops or pockets in impulse line to insure

true pressure signal to pilot diaphragm.

Slope as shown for condensible gas service 1" per

12"

foot minimum.

Slope toward pilot for steam and liquids.

Gage

Stop Valve

1"

SECTION I - INSTALLATION

Install pilot controller vertically, in an accessible location.

Allow removal space for ease of maintenance.

Pilot controller may be located above or below line controlled.

IMPULSE LINE CONNECTION AND LENGTH

Connect impulse line from top of diaphragm cover to controlled pressure line. Make connection at least 3 feet from the

valve body opening or the end of any expander. Best results

are obtained when the impulse line does not exceed 30 fe

Av

oid connections near turbulent areas such as those created by orifices, elbows, sharp bends, or other flow direction

changing components.

PITCH OR SLOPE OF IMPULSE LINE

Steam and liquid impulse lines should slope toward the sensing head. This ensures that the lines stay full of liquid or

condensate. Pre-fill the sensing line before startup.

For noncondensing gases such as air, slope the lines away

from the pilot, so that any liquid contaminants drain back to

the pr

ocess. M

inimum slope is 1" per foot.

Accessary Equipment

Volume booster relays, positioners, reset relays, derivative

units, etc. may be used with Leslie adjustable proportional

band pilot controllers where system characteristics require

their use.

et.

HYDROSTATIC HEAD PRESSURE

When the pilot controller is installed under the line controlled,

the total pressure resulting from hydrostatic head and controlled pressure must not exceed the maximum range of the

pilot co

ntroller

SECTION II - OPERATION

The pilot is factory set and requires no adjustments other than

those necessary to obtain the controlled pressure desired and

the width of proportional band required by the system.

1. Close inlet and outlet stop valves around the control

valve.

2. Open air supply line and impulse line stop valves. Set

proportional band adjustment at “Maximum Band.”

For Pressure Reducing Service Only (Refer to

Figures 6 & 7)

3. Turn adjusting nut (22) of pilot c

wise until control valve is wide open.

4. Open outlet stop valve partially. Fully open inlet stop

valve slowly.

5. Make final adjustment for desired controlled pressure

value. To increase controlled pressure screw adjusting

nut (22) counter-clockwise. To decrease pressure screw

adjusting nut clockwise.

6. Open outlet stop valve fully.

ontro

ller counter-clock-

Page 2

Page 3

Pressure Reduction

Pressure Reduction

PDAP

N.O. Valve

Figure 2. Pilot Controller with 1:1 Volume Booster Relay

Pressure Reduction

PDAP

N.O. Valve

PRAP

N.C. Valve

Figure 4. Pilot Controller with Positioner. Split Ranging

may also be done.

Back Pressure

PRAP

N.O. Valve

Figure 3. Pilot Controller with 1:1 Volume Booster and

Reset Relay

For Back Pressure Service Only

3. Turn adjusting nut (22) of pilot controller counter-clockwise until control valve is fully closed.

4. Open inlet stop valve fully. Partially open outlet stop

valve. Turn adjusting nut (22) of pilot controller clockwise until control valve just begins to open. Open outlet

stop valve fully.

5. Make final adjustments for desired controlled pressure

value. To increase controlled pressure screw adjusting

nut (22) counter-clockwi

se. To d

sure screw adjusting nut clockwise.

ecrease controlled pres-

Figure 5. Pilot Controller with Inverse Derivative

ADJUSTMENT FOR REQUIRED

PROPORTIONAL BAND

Pilot controller is now ready for operation. Adjust for required

width of proportional band as follows:

Turn adjusting know (76) counter-clockwise, moving pointer

toward minimum band setting until the output air pressure

begins to cycle. Widen the proportional band until the cycling

stops.

Page 3

Page 4

SECTION III - MAINTENANCE

DISMANTLING

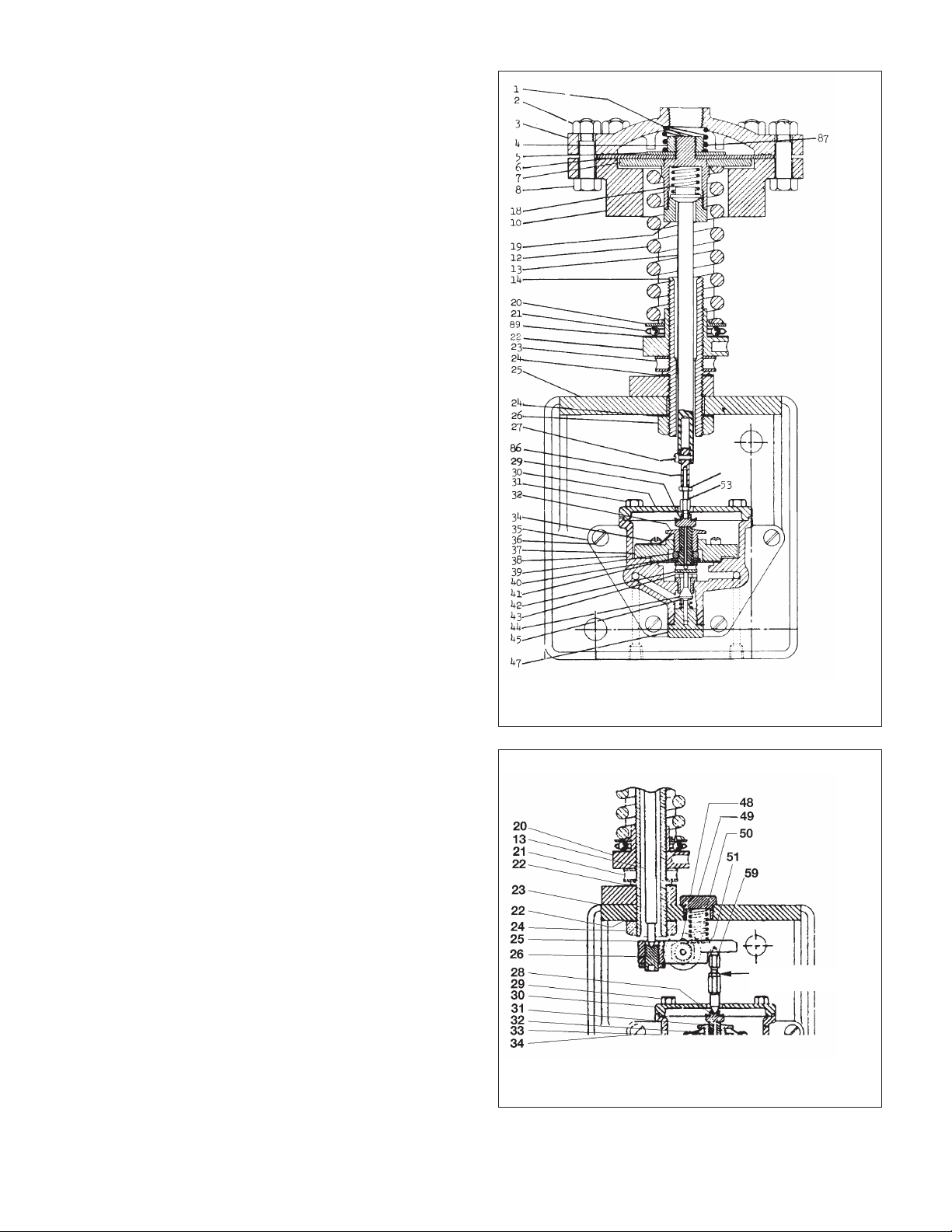

(Refer to Figures 6 and 7)

1. Bypass the control valve if system operation is necessary during maintenance work. Shut off air supply to

pilot controller.

2. Take out body screws (36). Slide pilot body assembly

off base in a downward direction away from adjusting

pin (64).

3. Remove bottom plug (47). Remove diaphragm plate (30)

from pilot body by removing capscrews.

NOTE: Do not disturb position of proportional band

parts on diaph

them.

Take out diaphragm nozzle disc (29) remove flange ring

(37) and gasket (40). In PRAP types remove nozzle valve

(79) and spring (80).

Cleaning and Reassembling Pilot Body Assembly

1. Wipe all parts clean. Check ports in pilot body, nozzle

and orifice to be sure they are clear. DO NOT use sharp

abrasives. Open air supply and blow out supply line.

ragm p

late, unless work is required on

Figure 6. Type PRAP Pilot Controller (5-80 psig range)

*NOTE: Spring (81) and spring seat (82) are not used in the 50800 psig range PRAP Pilot Controller.

Page 4

Figure 7. Type PDAP Pilot Body Assembly

2. Replace bottom plug (47) in pilot body. Place gasket

(40) in pilot body. In PRAP types rein

(79) and spring (80). Position flange ring (37) with nozzle

upward on gasket (40). Insert flange ring screws and

tighten.

3. Insert diaphragm nozzle disc (29) in pilot body with flat

disc end toward nozzle. Replace diaphragm plate (30)

on pilot body, with knob (76) on the right hand side. If

blade spring (66) was removed from the assembly, be

sure to reassemble it with the preformed end bends

pointing upward.

Cleaning or Replacing Parts in Superstructure

NOT

E: I

f maintenance work is necessary on superstructure

alone, remove pilot body assembly from base as described in

Step 2., Section III then proceed as shown below:

sert n

ozzle valve

Page 5

Dismantling Superstructure

1. Loosen setscrew (63) and disassemble adjusting pin

(64) from stem (13).

2. Remove diaphragm cover (3), diaphragm spring (81)

and diaphragm spring seat (82), diaphragm (6),

diaphragm disc (7), diaphragm spacer (15) and

diaphragm guide (16). Lift out top spring seat (17) with

stem (13), stem nut (19) and yielding spring (18).

Remove adjusting spring (12), bottom spring seat (20),

thrust bearing (21), adjusting nut (22) and locknut (23

3. Clean all parts. Replace any worn or damaged part. To

disassemble stem (13) from top spring seat (17) hold

top spring seat rigidly on hex, press down on stem and

remove stem nut from top spring seat.

REASSEMBLING SUPERSTRUCTURE

1. Reassemble locknut (23) (countersunk side downward),

adjusting nut (22), thrust bearing (21), bottom spring

seat (20) and adjusting spring (12) to adjusting sleeve

(14). Replace top spring seat (17) with assembled stem

in yoke (10). Place di

gm guide (16) in recess of

aphra

yoke (10).

2. Place diaphragm spacer (15) on yoke (10) with raised

face downward. Position diaphragm disc (7) on top

spring seat (17). Place diaphragm (6), diaphragm spring

seat (82), diaphragm spring (81) and diaphragm cover

(3) on diaphragm. Replace bolts (8) and nuts (2).

Tighten firmly. Reassemble adjusting pin (64) to stem

(13).

REASSEMBLING PILOT BODY ASSEMBLY TO BASE

proportional band nut down against blade spring until air output pressure decreases from 21 to 18 psig. With pin in stem

hole to keep stem from turning, loosen set screw and turn

adjusting pin upward away from pilot body approximately

1Z\v turns. Lock set screw.

For PRAP Adjustable Proportional Band Type

Adjust slider ZC\zn” apart as shown in sketch below. Move

proportional band nut upward on adjusting pi

hread suffi-

n t

ciently to keep nut from touching blade spring during stem

).

length adjustment. Loosen adjusting pin set screw and turn

adjusting pin either up or down until pilot air output is 21 psig.

Then turn adjusting pin downward toward pilot body until

pilot air output decreases from 21 to 0 psig. Lock set screw.

Turn proportional band nut down against blade spring until air

output pressure increases from 0 to 3 psig. With pin in stem

hole to keep stem from turning, loosen se

crew and turn

t s

adjusting pin upward away from pilot body approximately

1Z\v turns. Lock set screw.

Stem (13)

Nut (65)

Slider (70)

Figure 8. Position of sliders for nut/blade spring

adjustment

13/16"

Blade Spring (66)

Slider 975)

Knob

(76)

1. Slide pilot body assembly upward on base so that

adjusting pin (64

) p

asses smoothly through proportional

band blade spring. Replace pilot body screws (36) and

tighten firmly. Reconnect impulse line to diaphragm

cover. Open air supply line. Adjust pilot as described in

Section IV.

SECTION IV - SETTING OF ADJUSTING PIN

Supply 20-22 psig operating pressure to controller. Turn

adjusting nut to compress adjusting spring to set upper

diaphragm against its top limit stop. If possible, remove fluid

pressure from top of diaphragm, if not, comp

sufficiently to overcome fluid pressure and move diaphragm

to stop.

For PDAP Adjustable Proportional Band Type

Adjust sliders ZC\zn” apart as shown in sketch below. Move

proportional band nut upward on adjusting pin thread sufficiently to keep nut from touching blade spring during stem

length adjustment. Loosen adjusting pin set screw and turn

adjusting pin either up or down until pilot air output is 0 psig

then turn adjusting pin downward toward pilot body u

air output increases from 0 to 21 psig. Lock set screw. Turn

s spring

res

ntil p

ilot

NOTE: When the above adjustments have been properly

made, the proportional bands noted in Table - Figure 9 will be

obtained when the sliders are set the approximate distances

apart as shown.

SLIDER

PILOT TEST DISTANCE

RANGE PRESSURE BAND (PSIG)

(PSIG) (PSIG)

5-70 50 2

50-800 80 2

Figure 9. Min./Max. Proportional Band Table

MIN. MAX.

BAND BAND MIN. MAX.

3

⁄4"1

3

⁄4"1

1

⁄4" 2.0 - 4.5 7.0 - 11.0

1

⁄4" 5.5 - 8.5 15.0 - 21.

Page 5

Page 6

Figure 10. Adjustable Proportional Band Pilot

Controllers

Page 6

Page 7

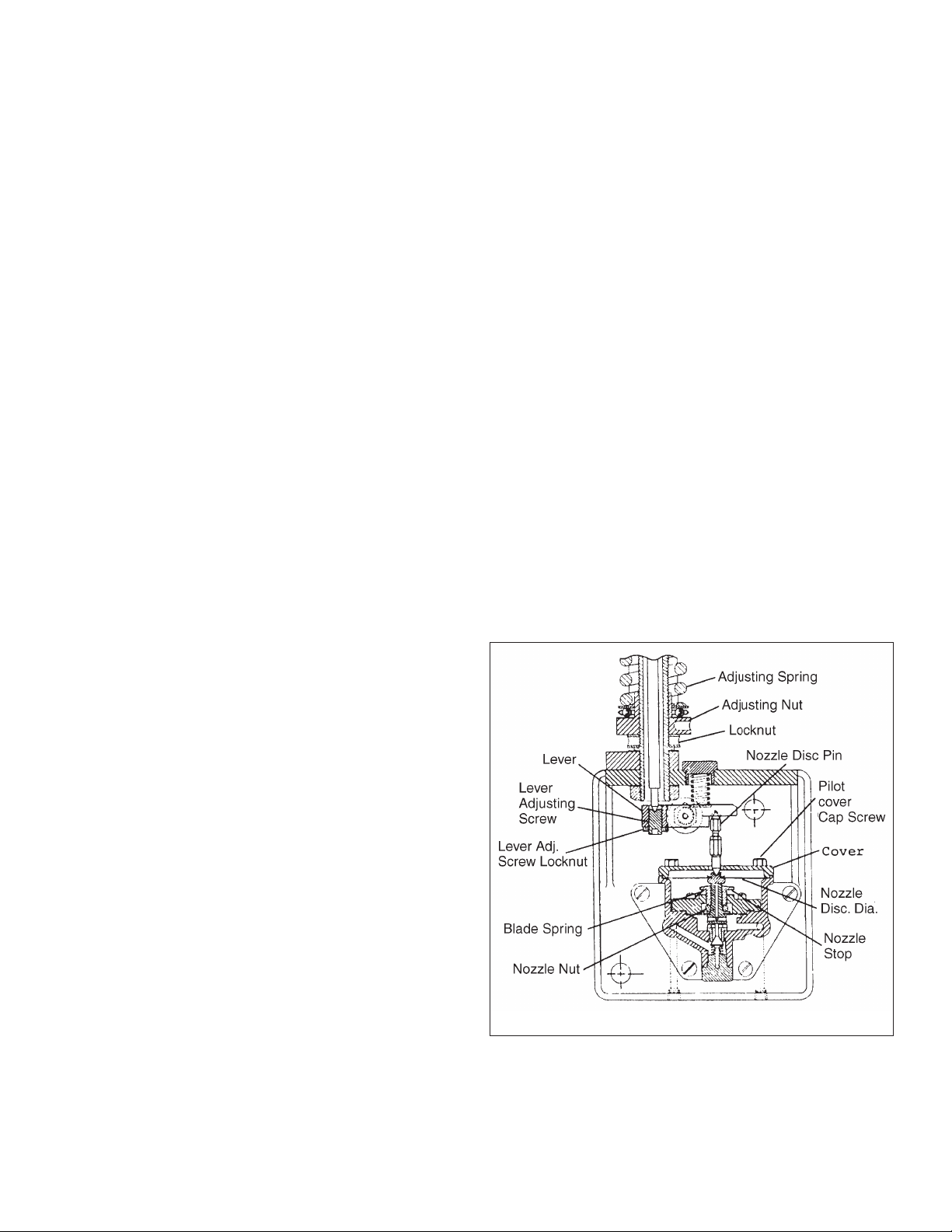

STEM LENGTH AND SENSITIVITY ADJUSTMENT

TYPES PRA-1 AND PRQ-1

CONSTANT PRESSURE PILOT CONTROLLERS

FORCE BALANCE, FIXED BAND TYPES

ADJUSTMENT PROCEDURE

Supply 20-22 psig operating pressure to the pilot controller.

Turn adjusting nut to compress adjusting spring to set upper

diaphragm against its top limit stop. If possible remove fluid

pressure from top of diaphragm, if not compress springs sufficiently to overcome fluid pressure and move diaphragm to

stop.

AD

JUSTING R

Remove nozzle disc pin, pilot cover and diaphragm nozzle

disc.

For Normal Response Sensitivity adjust pilot controller for

very minor or no leak off. To do this relieve pressure of blade

spring on nozzle stop by pressing lightly downward on it with

finger. Then screw nozzle stop downward until it is felt to barely seat on nozzle nut.

For Supersensitive Response adjust pilot controller for continuous leak off. To do this slowly screw nozzle st

downward until operating pressure flow is just detectable

through nozzle bleed port. To check amount of leak off place

finger lightly over nozzle bleed port to seal air (do not press

down on nozzle). Air pressure in output line to diaphragm control valve should not build up any faster than 3-5 psig in 20-30

seconds. Lock nozzle stop with blade spring.

ESPONSE SENSITIVITY

op f

urther

NOTE: THIS ADJUSTMENT IS FACTORY SET and should

not be disturbed unless it is obvious that the original setting

has been changed or major parts replacements were made

which may cause need for readjustment.

These adjustments can be made when the pilot controller is

set for either continuous or non-continuous leak off.

PRA-1 AND PRQ P

1. Loosen locknut on lever setscrew. With 20 psig air pressure on out put gauge turn setscrew upward into lever

until output air pressure just begins to fall away from 20

psig.

2. Then turn lever screw downward (out of lever) 3/4 turn

for all low pressure pilots (up to and including the 50-125

psig range) 1-1/4 turns for high pressure ranges (100-

200) psig and over). Tighten locknut.

NOTE: With pilot air output at 20/22 psig, lever should be

approximately in th

nozzle disc pin locknut and screw lower section of pin into or

out of upper section of pin until lever is parallel. Tighten locknut.

e p

arallel position. If not parallel loosen

ILOT C

ONTROLLERS

To Test Pilot Controller Body and Diaphragm Control Valve

for response press downward on center of nozzle until 20-

sig air pressure registers on output gauge. Control valve

p

should move through full travel. Release nozzle. Air output

pressure should drop to 0 psig and control valve should return

to its original position.

After completing sensitivity adjustment replace diaphragm

nozzle disc, nozzle disc pin and pilot cover.

LEVER SCREW ADJUSTMENT

Desired pilot controller performance will be obtained only if the

upper (sensing) diaphragm is operating at or near its mean

position

base and cover. Its position is determined by adjusting length

of lever adjusting screw.

.e. half way between its top and bottom limit stops in

, i

22

Figure 11. PRA-1, PRW-1, PRQ, Pilot Controllers

Page 7

Page 8

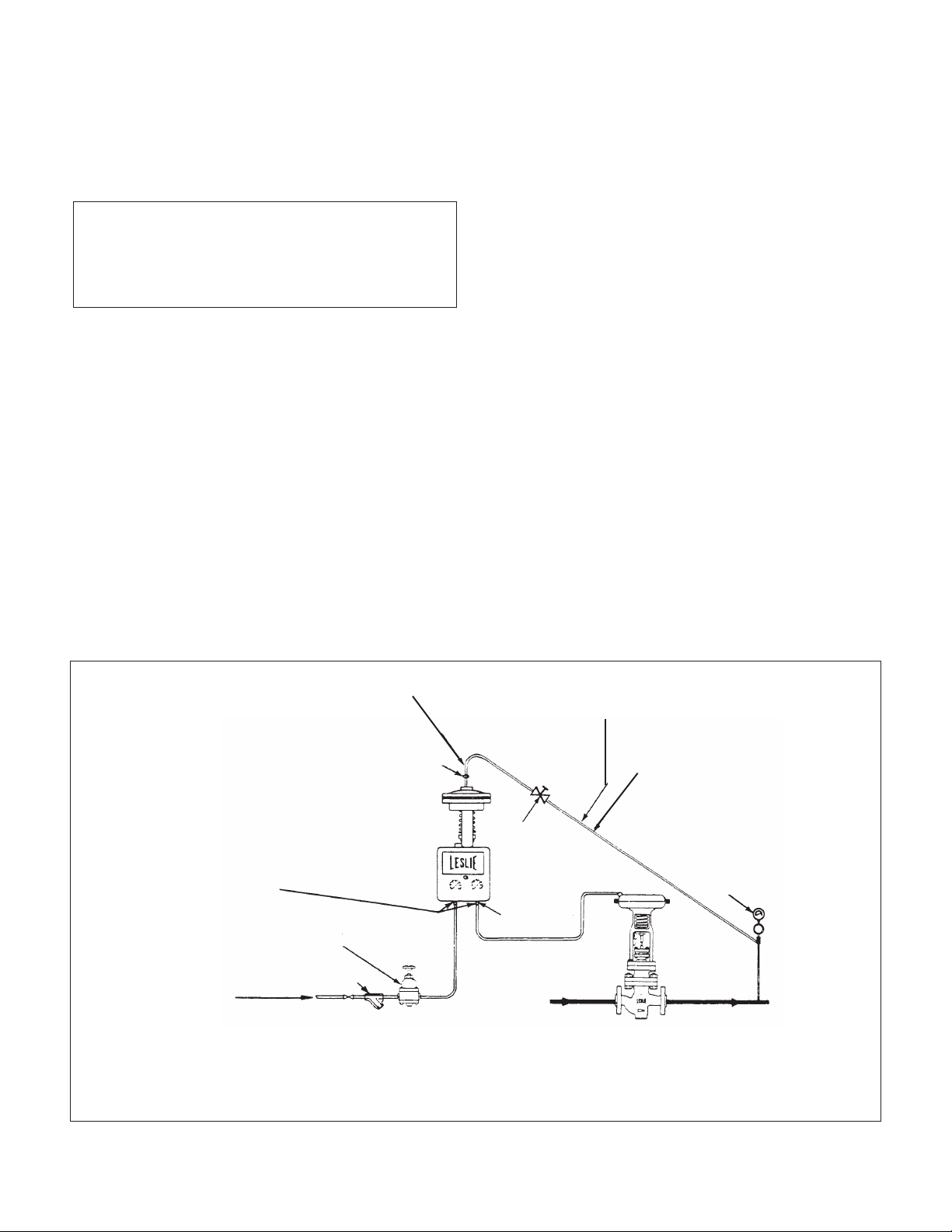

CONSTANT, DIFFERENTIAL PRESSURE AND RATIO

PILOT CONTROLLERS

Force Balance, Fixed Band Types

Types Covered:

PDA-1 PDW-1 PDQ-1 UDDV* DDD**

PRA-1 PRW-1 PRQ-1 UDRV* UDDD***

STOP — LOOK — READ OBSOLETE

ADHERENCE TO THESE INSTRUCTIONS

GUARANTEE OPTIMUM RESULTS

INSIST UPON THEIR BEING FOLLOWED.

SECTION I — INSTALLATION

Install Pilot Controller vertically in an accessible location.

Allow removal¬ space for ease of maintenance. Pilot

Controller may be located above or below line controlled.

NOTE: Whenever hydrostatic head exists on diaphragm effect

must be considered with

Piping Details

Figure 1 shows control pilot piping details. Control valve piping shown in figures is schematic only. Consult Control Valve

Instructions for piping details.

lation to obtainable pressures.

re

Control Pipe Connection and Length

Connect Control Pipe from top of diaphragm cover to controlled pressure line. Make connection in controlled pressure

line at least 3 feet from the valve body opening or the end of

the expander, if one is in use. Best results are obt

ained w

hen

length of control pipe does not exceed 30 feet. Avoid connections near turbulent areas such as those created by orifices, elbows, sharp bends, or other flow direction changing

components.

Pitch or Slope of Control Pipe

Pilot Above Line Controlled — Slope control pipe downward,

away from the Pilot Controller. Provide at least 6" of vertical

pipe at connection to pilot cover.

Pilot Below Line Controlled — Slope control pipe downward

toward Pilot Controller.

Hy

dro

static Head Pressure

Where the Pilot Controller is to be installed under the line controlled (and liquids or condensible gases are to be controlled)

total pressure resulting from hydrostatic head and controlled

pressure must not exceed the maximum range of the control

pilot.

AIR LINES — Use 5/16" (1/4"

I.D.) pipe or tubing. Use noncorrosive pipe and fittings.

Connect outlet of air reducing valve to

inlet of Pilot Controller (immediately

u

age marked “Operating

nder g

Supply”). Connect outlet of Pilot

Controller (immediately under gage

marked “Control Valve”) to diaphragm

connection of Control Valve.

Operating m

Reducing Valve to supply 20-22 psig

to pilot.

*NOTE: AIR CONNECTIONS — Pilot Controller is equipped

with stainless steel air supply and output fittings. DO NOT

remove. Connect air lines directly to these fittings.

edium clean air** Set

Figure 12. — Pilot Controller piping details — Typical installation

6" Vertical Section (Min.)

Union

Strainer

AVOID LOOPS OR POCKETS IN

CONTROL PIPES to insure true

pressure signal to pilot diaphragm.

Control pipe — use 1/2" 40 schedule pipe or tubing with equivalent

internal diameter

(For ranges up to and including

50-125 psig: for ranges 100-200

psig and over use 3/8" pipe).

Stop Valve

Gage

*See NOTE

**NOTE: Operating medium for Classes PRA-1, PDA-1,

UDRV, UDDV etc. (aluminum construction) must be

clean air. (Win Class designation) are suitable for oil or

water as operating medium.

cing u

*Use with Instruction 20/2.5.3 for repla

**Use instruction 20/3.5.1 for replacing upper diaphragms — DDD, UDDD Types.

pper diaphragms — UDDV, UDRV Types.

Page 8

Page 9

SECTION II — OPERATION

PROCEDURE: Follow Steps 1 and 2 then proceed with

Steps 3 through 5 whichever applies to the particular service.

1. Close inlet and outlet stop valves around the control

valve.

2. Open air supply line stop valve. Adjust 1/4" reducing

valve to supply 20-22 psig pressure to control pilot.

For Pressure Reduction Installation

3. Turn adjusting nut of Pilot Controller Until diaphragm

control valve is wide open.

4. Open outlet stop valve partially and

contro

l pipe stop

valve fully.

5. Open inlet stop valve slowly, until Pilot Controller takes

hold and starts to close the diaphragm control valve.

Screw adjusting nut upward to increase, downward to

decrease the controlled pressure. After desired controlled pressure is obtained, open inlet stop and outlet

valves fully.

For Overflow Relief Installation

3. Turn adjusting nut of Pilot Controller until diaphragm

control valve is closed.

4. Open inlet, outlet, and contro

l p

ipe stop valves fully.

5. Turn adjusting nut of Pilot Controller so that diaphragm

control valve starts to open when desired inlet pressure

is exceeded.

Differential Pressure Pilot Controllers

3. Turn adjusting nut of control pilot to adjust compression

on adjusting spring until control valve is wide open.

4. Open outlet stop valve partially and control pipe stop

valves fully.

Figure 13. — Drawing showing Direct Acting Type Pilot

Controller (PDA-1, etc.).

5. Open inlet stop valve slowly, until controller takes hold

and begins to close the control v

alve. R

eadjust the

adjusting nut of the control pilot to obtain desired differential. To increase differential, when highest pressure is

on top of diaphragm, screw adjusting nut upward; to

decrease differential, screw adjusting nut downward.

When highest pressure is on underside of diaphragm

screw adjusting nut upward to decrease differential;

downward to increase. After desired differential setting

is obtained, open inlet and outlet stop valves fully.

NOTE: Whe

ystems are in full operation, use caution in cut-

n s

ting a controller in so that system differential will not be disturbed.

Page 9

DO NOT DISTURB SETTING

OF THIS PIN

Figure 14. — Partial Drawing showing lever and lever pin,

etc., in lever action Types (PRA-1, etc.,).

Page 10

SECTION III — MAINTENANCE

(CONSULT FIGURES OF APPLICABLE DRAWINGS)

IMPORTANT: ALWAYS MAKE SURE THAT CONTROL PIPES

AND AIR SUPPLY LINES ARE FREE AND CLEAR OF FOREIGN MATTER.

Dismantling Pilot Valve Bodies

1. By-pass diaphragm control valve if system operation is

necessary maintenance. Close air supply and control

pipe stop valves to pilot controller. Remove cover screw

and cover from base.

2. In lever action types (PRA-1, etc.), lift right hand end of

lever and re

setting of these parts as they are designed for initial

factory length adjustment only).

Loosen bottom plug (47.) Remove body screws (36)

and take body assembly off base (25). Disassemble

diaphragm plate capscrews (31), diaphragm plate (30)

and nozzle disc diaphragm assembly (29) from body.

3. Take out flange ring screws (34), flange ring complete

(37) and nozzle (42) with assembled parts. Disassemble

nozzle stop (32) from flange

(47), pilot valve spring (45) and seat (43) from body

unless it is damaged and must be replaced. (If removal

is necessary, use piece of flat stock or wide screwdriver

in lugs to loosen and unscrew).

Cleaning — Replacing Parts

1. Wipe all parts clean including pilot valve seat. Use an

approved, non-residue forming solvent, if necessary.

move l

ever pin assembly. (DO NOT disturb

emove bottom plug

ring. R

3. Replace body assembly on base (25). Insert body

screws (36) through body and into base threads. Start

carefully into threads. Tighten securely to make a good

gasket seal between body and base.

4. Note: Adjust nozzle stop setting for leak off or non-leak

off setting at this point. Proceed as described for the

particular setting desired.

Adjusting Response Sensiti

djust response sensitivity of a pilot controller supply 20-

To a

22 psig air to pilot controller then proceed as follows:

For Normal Response Sensitivity: Adjust pilot controller for

very minor or no leak off. To do this, relieve pressure of blade

spring on nozzle stop by pressing lightly downward o it with

finger. Then screw nozzle stop downward until it is felt to

barely seat on nozzle nut (39).

For Supersensitive Response: Adjust pilot controller for continuous leak

downward until operating pressure flow is just detectable

through nozzle bleed port. To check amount of leak off, place

finger lightly over nozzle bleed port to seal air (do not press

down on nozzle). Air pressure in output line to diaphragm

control valve should not build up any faster than 3-5 psig in

20-30 seconds. Lock nozzle stop with blade spring.

To Test Pilot Controller Body and Diaphragm Control Valve:

For response press

psig air pressure registers on output gauge. Control valve

should move through full travel. Release nozzle. Air output

pressure should drop to 0 psig and control valve should return

to its original position.

off. To do this slowly screw nozzle stop further

downward o

vity

n center of nozzle until 20-22

2. Inspect all parts. Replace any worn or damaged parts

including neoprene nozzle diaphragm (40) and “O” ring

body ga

3. To change nozzle diaphragm insert pin in bottom port in

nozzle for grip, loosen diaphragm nut (39). Disassemble

parts. Replace diaphragm. Reassemble parts. Tighten

diaphragm nut.

NOTE: Do not use abrasive cloth on parts or grind in pilot

valve as parts may be damaged or important dimensions

changed. If necessary, crocus cloth may be used. All working

parts must be clean and free moving. Open air supply line

valve and blow out ports.

Reassembling

1. Place pilot valve spring (45) and pilot valve (44) (with

seating face upward) on bottom plug. Position parts in

body. Screw bottom plug all the way in. Tighten.

2. Insert nozzle (42) with assembled parts in upper end of

body. Screw nozzle stop (32) part way into flange ring

(37). Position flange ring complete on nozzle diaphragm

(nozzle stop upward) with blade spring (33) on left hand

side facing gauges. Insert flange ring screws (34)

through flange ring a

ly into threads. Tighten evenly and sufficiently to make

a good air seal.

sket

s (35) in back of body.

Pilot Va

lve Bodies

nd i

nto body threads. Start careful-

NOTE: Maintenance work can be performed on superstructure, if necessary, as described under “Replacing Upper

Diaphragm.” If unnecessary, proceed with Reassembly Step 5.

5. Place nozzle disc assembly in body recess with dis

oward nozzle.

t

In PDA-1, etc. types, remove screw (27) from stem

complete (13). Lift extension pin (86) upward into stem

complete then replace diaphragm cover on body. Insert

capscrews (31) through cover into body. Tighten.

Position end of adjusting pin (53) properly in recess in

nozzle disc then insert screw (27) through stem complete and extension pin and tighten.

In PRA-1, etc. types, replace cover (30) on body. Insert

capscrews (29). Tighten. Then lift right hand en

lever and insert lever pin assembly in place between

lever and nozzle disc making sure that pointed ends

center in recesses in disc and lever. Check opposite

end of lever to make sure that point of stem complete

(13) has centered in recess in set-screw properly.

NOTE: If it was found necessary to disturb adjustment of

lever screw of adjusting pin readjust as described under

“STEM LENGTH ADJUSTMENT” shown on Page 4.

d o

c

f

Page 10

Page 11

Replacing Upper Diaphragms

Constant Pressure Pilot Controllers

(PDA-1, PRA-1, etc.)

For Type UDDV, UDRV Consult Instruction 20/2.5.3

For Type UDDD Consult Instruction 20/3.5.1

1. In all pilot controllers remove all adjusting spring compression by screwing locknut (23) downward as far as it

will go, then following with adjusting nut (22) until all

compression is removed from adjusting spring (12). In

the case of lever action types (PRA-1, etc.) relieve lever

s

pring c

ompression also by removing spring cap (49).

2. Disassemble bolts and nuts (2/8), diaphragm cover (3)

from diaphragm base (9). Remove spring (87) (13 psia 20 psig range only). Clean cover. In direct acting types

(PDA-1, etc.) take screw (27) out of stem (13).

3. For all ranges from 13 psia - 20 psig to 50-125 psig Lift

diaphragm assembly out of diaphragm base (9). Hold

diaphragm disc screw (1) rigidly on hex and loosen

diaphragm disc nut (4). Disassemble parts. Clean par

place diaphragm. Place diaphragm disc (7),

re

diaphragm (6), and diaphragm disc washer (5) on

diaphragm disc screw (1). Assemble diaphragm disc

nut (4) to diaphragm disc screw (1). Tighten snugly to

make a good pressure seal. Do not distort diaphragm.

For ranges 100-200 psig and over Diaphragm may be

changed by simply removing spring compression, disassembling bolts/nuts and cover, replacing diaphragm

and closing unit up again.

ts,

4. Replace diaphragm assembly in diaphragm base (9).

Reassemble diaphragm cover (3), and bolts and nuts

(2/8) to diaphragm base. Tighten bolts to make good

pressure seal.

Proceed with Step 5, “REASSEMBLY” insofar as it

applies t

o p

arts removed to permit rework of superstructure and stem length readjustment (if the latter is

necessary). Reassemble pilot cover and screw to base

(25). Do not overtighten screw.

5. Reconnect control pipe to diaphragm cover and operating medium lines to pilot controller and valve. Turn on

operating medium supply and adjust pilot controller for

desired controlled pressure as described under “OPERATION.”

Stem Length Adjustment (Pin/Lever)

Desired pilot contro

ller p

erformance will be obtained only if

the upper (sensing) diaphragm is operating at or near its mean

position, i.e. half way between its top and bottom limit stops

in base and cover. Its position is determined by adjusting

length of adjusting pin (53) in PDA-1, etc. types and lever

screw (26) in PRA-1, etc. types.

NOTE: THIS ADJUSTMENT IS FACTORY SET and should

not be disturbed unless it is obvious that the original setting

has been changed or major parts replacements were m

hich may cause need for readjustment.

w

ade

These adjustments can be made when the pilot controller is

set for either continuous or non-continuous leak off.

Figure 15. — FOR PRESSURE RANGES 13 PSIA - 20 PSIG TO

50-125 THIS TYPE OF DIAPHRAGM ASSEMBLY IS USED

NOTE: Balance of superstructure par

ts m

ay be cleaned,

examined, and replaced if necessary at this point. To examine

yielding spring (18)(PDA-1, etc.) hold disc screw (1), rigidly on

hex. Press down on stem (13). Remove stem nut (19).

Disassemble parts. Reassemble. Tighten stem nut.

Adjustment Procedure

In all cases: Supply 20-22 psig operating pressure to the pilot

controller. Turn adjusting nut (22) to compress adjusting

spring to set upper diaphragm against its top limit stop. If

possible, remove fluid pressure from top of diaphragm, if not,

compress spring sufficiently to overcome fluid pre

ssure a

nd

move diaphragm to stop. Blank off output connection to

D.C.V.

PDA-1, PDW-1, PDQ, UDDV, etc. Pilot Controllers

1. Loosen locknut (74) on adjusting pin (53). Turn adjusting

pin (53) downward toward pilot until 0-3 psig air pressure shows on output gauge.

2. Then turn adjusting pin (53) back upward into extension

pin (86) (away from pilot body) 1 turn for all low pressure pilots (up to and including the 50-125 psig range);

1-3/4 turns for high pressure pilots (ranges

p

sig and over). Tighten locknut (74).

100-200

3. Reconnect output to D.C.V.

PRA-1, PRW-1, PRQ, UDRV, Etc. Pilot Controllers

1. Loosen locknut (27) on lever setscrew (87). With 20 psig

air pressure on output gauge turn setscrew (87) upward

into lever until output air pressure just begins to fall

away from 20 psig.

Page 11

Page 12

2. Then turn lever screw (26) downward (out of lever) 3/4

turn for all low pressure pilots (up to and including the

50-125 psig range; 1-1/4 turns for high pressure

ranges (100-200 psig and over). Tighten locknut (27).

3. Reconnect output to D.C.V.

NOTE: Differential and Ratio pilot controller (UDDV, UDRV or

UDDD types) may require slight stem length readjustment to

obtain complete balancing of the sensing diaphragm, if

changes in static pressure on the diaphragm ca

use c

hanges

in pilot controller setpoint. To check this supply 20 psig operating pressure to pilot. Adjust pilot for a constant differential

within its range. Apply a change in static pressure across the

upper sensing diaphragms and observe output pressure on

right hand gauge. If output pressure changes, readjust stem

length in small increments (by turning adjusting pin or lever

screw upward or downward as required) until changes in static pressure do not affect the ai

utput pressure).

r o

To Decrease Sensitivity of Pilot Controllers

(Constant Pressure Types Only)

1. Readjust nozzle stop to non-leak off position (if leak off

is in use).

2. Move diaphragm slightly away from its mean position

by readjusting stem length in small increments of about

1/8 of a turn until desired operation is obtained.

Caution: DO NOT turn excessively.

PDA-1, PRW-1 PDQ Pilot Controllers — In reducing

service move diaphragm upward by increasing the stem

length.

ack pressure or relief service, move

In b

diaphragm downward by decreasing the stem length.

PRA-1, PRW-1, PRQ Pilot Controllers — In reducing

service move diaphragm downward by decreasing stem

length. In back pressure or relief service, move

diaphragm upward by increasing the stem length.

After making readjustment retest pilot controller to

make sure that it will change the operating output pressure from 0 psig to 20 psig or vice versa with a reasonable change in contro

ller p

ressure.

Operating

Medium

Pilot

Controller

Figure 16. — Back Pressure or Pressure Relief Service

For Differential Pilot Installation Sketches,

See Instructions 20/2.5.3

For Ratio Pilot Installation Sketch,

See Instructions 20/3.5.1

Control

Valve

Page 12

Page 13

PARTS LIST

8.6 kg

RANGE

ADJUSTABLE DIMENSIONS IN INCHES

NET WEIGHT WITH ACCESSORIES -

APPROX. 19 lb

50 409.5 114.3 89.6

PSI B C E F *

15 - 75 13-5/8 5-13/16 3-17/32 1/2

NOTE 1 13-5/8 6-5/16 3-17/32 1/2

50 - 125 13-5/8 5-13/16 3-17/32 1/2

100 - 200 16-1/8 4-1/2 3-17/32 3/8

175 - 300 16-1/8 4-1/2 3-17/32 3/8

275 - 450 16-1/8 4-1/2 3-17/32 3/8

400 - 600 16-1/8 4-1/2 3-17/32 3/8

550 - 800 16-1/8 4-1/2 3-17/32 3/8

ADJUSTABLE DIMENSIONS IN MM

PSI B C E

RANGE

NOTE 1 346. 160.3 89.6

15 - 75 346. 147.6 89.6

50 - 125 346. 147.6 89.6

100 - 200 409.5 114.3 89.6

175 - 300 409.5 114.3 89.6

- 4

275

400 - 600 409.5 114.3 89.6

550 - 800 409.5 114.3 89.6

NOTE 1 - 13 PSIA - 20 PSIG

* NPT

PSI - 900 lb.

MAXIMUM ALLOWABLE STATIC PRESSURE

PILOT CONTROLLER TYPES PDA-1, PDQ-1 AIR ACTUATED

Page 13

Page 14

TYPES PDA-1, PDQ-1 PILOT CONTROLLERS

WHEN ORDERING PARTS, PLEASE GIVE PAT NAME AND PART REFERENCE NUMBER FROM TABLE BELOW

PART QTY. PER 15-75 50-125 100-200 175-300 275-450 400-600 550-800

NO. PART NAME MATERIAL UNIT (NOTE 4) PSI PSI PSI PSI PSI PSI PSI

1 Disc Screw Aluminum 1 33930 33930 33930 - - - - - - - - - 3 Diaphragm Cast Aluminum 1 33949 33950 33951 33924 33925 33926 33927 33928

4 Diaphragm Disc Nut Aluminum 1 33932 33932 33932 - - - - - - - - - -

5 Diaphragm Disc Washer Aluminum 1 33931 33931 33931 - - - - - - - - - 6 Diaphragm, Upper Synthetic Rubber 1 12476 13

7 Diaphragm,Disc Cast Aluminum 1 33915 33916 33917 33939 33940 33941 33942 33943

8 Bolt Steel, Cadmium Plated (NOTE 3) 12291 12291 12291 45749 45749 45749 45749 45749

10 Yoke Cast Aluminum 1 58408 58409 58410 33971 33971 33971 33971 33971

12 Adjusting Spring Spring Steel, Plated 1 12475 12474 12474 13218 13218 13218 13218 13218

13 Stem, Complete Aluminum 1 47133 47133 47133 47134 47134 47134 47134 47134

14 Adjusting Sleeve Stainless Ste

15 Diaphragm Spacer Cast Aluminum 1 - - - - - - 33934 33935 33936 33937 33938

16 Diaphragm Guide Stainless Steel 1 - - - - - - 33933 33933 33933 33933 33933

17 Top Spring Seat Cast Aluminum 1 - - - - - - 33944 33944 33944 33944 33944

87 Upper Diaphragm Spring Stainless Steel 1 53566 - - - - - - - - - - - - - -

PART QTY. PER

NO. UNIT

2 Nut Steel, Cadmium Plated (NOTE 3) 42843

18 Yielding Spring Steel, Nickel Plated 1 12471

19 Stem Nut Aluminum 1 31839

20 Bottom Spring Seat Stainless Steel 1 11683

21 Thrust Bearing Stainless Steel & Brass 1 11684

22 Adjusting Nut Cast Bronze 1 12395

23 Lock Nut Brass 1 12833

24 Washer Stainless Steel 2 30673

25 Base Aluminum 1 43320

26 Nut Steel, Cadm

27 Screw Stainless Steel 1 48063

29 Diaph. Nozzle Disc, Comp. (NOTE 2) Stainless Steel 1 15086

30 Diaphragm Plate Cast Aluminum 1 38030

31 Cap Screw Aluminum 2 33679

32 Nozzle Stop Aluminum 1 33673

PART NAME MATERIAL REFERENCE NUMBERS - ALL RANGES

el 1 3

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

REFERENCE NUMBERS - EACH PRESSURE RANGE

257 1

3985 33985 33985 33986 33986 33986 33986 33986

ALL PARTS BELOW ARE INTERCHANGEABLE IN ALL PRESSURE RANGES

lated 1 13744

ium P

3257 13226 13226 13226 13226 13226

34 Screw Aluminum 4 33678

35 O-Ring Synthetic Rubber 2 42213

36 Screw Steel, Cadmium Plated 4 33959

37 Flange Ring, Complete Aluminum 1 33672

38 Body Aluminum 1 40445

39 Diaphragm Nut Stainless Steel 1 33316

40 Diaphragm Synthetic Rubber 1 12368

41 Diaphragm Washer

42 Nozzle Aluminum 1 38347

43 Pilot Valve Seat Celcon 1 12353

44 Pilot Valve, Complete Stainless Steel 1 33675

45 Pilot Valve Spring Stainless Steel 1 33666

47 Bottom Plug Aluminum 1 33667

49 Cover Aluminum 1 40447

50 Cover Screw Steel, Plated 1 33960

51 Pressure Gage. Steel Case, Clearlok Crystal 2 52354

53 Adjusting Pin Brass 1 12401

54 Connector Piece Cold Rolled Steel 2 41637

74 Lock Nut Stainless Steel 1 47138

86 Extension Pin Stainless Steel 1 4

9 Washer Stainless Steel 1 11685

8

88 Cover Screw Washer Rubber 2 57685

Adjusting Rod Steel, Plated 1 11808

RECOMMENDED SPARE PARTS

THESE PARTS SHOULD BE ON HAND, PLUS RECOMMENDED SPARE PARTS WHEN OVERHAULING THIS EQUIPMENT.

ALL PARTS ARE SAME AS PDA-1 SHOWN IN TABLE ABOVE, EXCEPT FOR PARTS SHOWN BELOW

PART NO. PART NAME MATERIAL QTY. PER REFERNCE NO.

42 Nozzle Aluminum 1 38981

43 Pilot Valve Seat Stainless Steel 1 12358

44 Pilot Valve Complete Stainless Steel 1 12350

NOTE 1 - Consists of Stem and Stem Head.

NOTE 2 - Consist of Nozzle Disc; Retaining Ring, and Diaphragm

NOTE 3 - Quantities are: Eight (8) for 13 psia - 20 psig to 50 - 125 Pressure Ranges and Size (6) for 100 - 200 to 550 - 800 Pressure R

OTE 4 - Range 13 psia to 20 psig (3.5 Hg. Vacuum).

N

FOR ALL TYPES NOT LISTED, PLEASE ORDER PARTS BY NAME AND INCLUDE RANGE, TYPE AND SERIAL NUMBER

teel 1 33676

Stainless S

PDQ-1

UNIT

anges.

7097

Page 14

Page 15

mm. 346.1 147.6 120.7 89.7

15-75 in. 13-5/8 5-13/16 4-3/4 3-17/32 1/2

NOTE 1 in. 13-5/8 6-5/16 5 3-17/32 1/2

PRESSURE DIMENSIONS IN INCHES AND MILLIMETERS

RANGE-PSI B C D E F*

mm. 346.1 147.6 120.7 89.7

50-125 in. 13-5/8 5-13/16 4-3/4 3-17/32 1/2

mm. 346.1 147.6 120.7 89.7

100-200 in. 16-1/8 4-1/2 4 3-17/32 3/8

mm. 409.6 114.3 101.6 89.7

175-300 in. 16-1/8 4-1/2 4 3-17/32 3/8

mm. 409.6 114.3 101.6 89.7

275-450 in. 16-1/8 4-1/2 4 3-17/32 3/8

mm. 409.6 114.3 101.6 89.7

mm. 409.6 114.3 101.6 89.7

400-600 in. 16-1/8 4-1/2 4 3-17/32 3/8

For pressure ranges 100-200

550-800 in. 16-1/8 4-1/2 4 3-17/32 3/8

to 550-800 this type of

mm. 409.6 114.3 101.6 89.7

Diaphragm Assembly is used.

* NPT

NOTE 1 - Range 13 psia to 20 psig (3.5 Hg Vacuum).

MAXIMUM ALLOWABLE STATIC PRESSURE 900 PSI

APPROX. NET WT. WITH ACCESSORIES 19 LB. (8.6KG)

SUPERSEDES DRAWING NO. CP 12750 F, ALT.

PILOT CONTROLLER TYPES PRA-1, PRQ-1 AIR ACTUATED

Page 15

Page 16

PILOT CONTROLLER TYPES PRA-1, PRQ-1 AIR ACTUATED

WHEN ORDERING PARTS, PLEASE GIVE RANGE TYPE, PART NAME AND PART REFERENCE NUMBER FROM TABLE BELOW

PART QTY. PER REFERENCE NUMBERS - EACH RANGE

NO. PART NAME MATERIAL UNIT NOTE 5 15-75 50-125 100-200 175-300 275-450 400-600 550-800

1 Disc Screw Aluminum 1 33929 33929 33929 - - - - - - - - - 2 Nut Steel, Cad. Plated (NOTE 6) 42843 42843 42843 42843 42843 42843 42843 42843

3 Diaphragm Cover Cast Aluminum 1 33949 33950 33951 33924 33925 33926 33927 33928

4 Diaphragm Disc Nut Aluminum 1 33932 33932 33932 - - - - - - - - - 5 Diaphragm Disc Washer Aluminum 1 33931 33931 33931 - - - - - - - - - -

6 Diaphragm, Upper Synthetic Rubber 1 12476 N1325794 13257 13226 13226 13226 13226 13226

7 Diaphragm Disc Cast Aluminum 1 33915 33916 33917 33939 33940 33941 33942 33943

8 Bolt Steel, Cad. Plated (NOTE 6) 12291 12291 12291 45749 45749 45749 45749 45749

10 Yoke Cast Aluminum 1 58408 58409 58410 33971

12 Adjusting Spring Spring Steel, Plated 1 12475 12474 12474 13218 13218 13218 13218 13218

13 Stem, Complete (NOTE 1) Stainless Steel 1 12382 12382 12382 13218 13218 13218 13218 13218

14 Adjusting Sleeve Stainless Steel 1 33985 33985 33985 33986 33986 33986 33986 33986

15 Diaphragm Spacer Cast Aluminum 1 - - - - - - 33934 33935 33936 33937 33938

16 Diaphragm Guide Stainless Steel 1 - - - - - - 33933 33933 33933 33933 33933

17 Top Spring Seat Cast Aluminum 1 - - - - - - 33968 33968 33968 33968 33968

87 Upper Diaphragm Spring Stainless Steel 1 53566 - - - - - - - - - - - - - -

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

LL PARTS LISTED BELOW ARE INTERCHANGEABLE

A

13 PSIA - 20 PSIG TO 550 - 800

18 Bottom Spring Seat Stainless Steel 1 11683

19 Thrust Bearing Stainless Steel & Brass 1 11684

20 Adjusting Nut Cast Bronze 1 12395

21 Lock Nut Brass 1 12833

22 Washer Stainless Steel 2 30673

23 Base Die Cast Aluminum 1 43321

24 Nut Steel, Cad. Plated 1 13744

25 Lever, Complete (NOTE 2) Brass 1 20159

27 Set Screw Stainless Steel 1 56775

28 Diaphragm Nozzle Disc, Stainless Steel 1 15831

Comp. (NOTE 3)

29 Cap Screw Aluminum 2 33679

30 Diaphragm Plate Die Cast Aluminum 1 38030

31 Nozzle Stop Aluminum 1 33673

32 Washer Stainless Steel 1 11685

33 Screw Aluminum 4 33678

34 O-Ring Synthetic Rubber 2 42213

35 Screw Steel, Cad. Plated 4 33959

36 Flange Ring, Complete Die Cast Aluminum 1 33672

37 Body Die Cast Aluminum 1 40445

38 Diaphragm Nut Stainless Steel 1 33316

39 Diaphragm Synthetic Rubber 1 12368

40 Diaphragm Washer Stainless Steel 1 33676

41 Nozzle Aluminum 1 38347

42 Pilot Valve Seat Celcon 1 12353

43 Pilot Valve, Complete Stainless Steel 1 33675

44 Pilot Valve Spring Stainless Steel 1 33666

46 Bottom Plug Aluminum 1 33667

48 Nut Brass 1 12827

49 Lever Spring Cap Aluminum 1 33923

50 Lever Spring Spring Steel, Plated 1 15960

51 Lever Stud Stainless Steel 1 12373

53 Cover Die Cast Aluminum 1 40447

54 Cover Screw Steel, Plated 1 33960

55 Gauge Steel Case, Clearlok 2 52354

57 Connector Piece Cold Rolled Steel 2 41637

59 Adjusting Pin, Male Brass 1 47265

(NOTE 4)

60 Adjusting Pin, Female Brass 1 47266

(NOTE 4)

61 Lock Nut Stainless Steel 1 47138

63 Jam Nut Stainless Steel 1 56776

64 Cover Screw Washer Rubber 2 57685

Adjusting Rod Cold Rolled Steel 1 11808

IN ALL RANGES

Crystal

REFERENCE NUMBERS

13 PSIA - 20 PSIG TO 550 - 800

Page 16

Page 17

PILOT CONTROLLER TYPES PRA-1, PRQ-1 AIR ACTUATED

ALL PARTS ARE SAME AS PRA-1 SHOWN IN TABLE ON PAGE 3, EXCEPT FOR PARTS SHOWN BELOW.

PRQ-1

PART QTY. PER REF.

NO. PART NAME MATERIAL UNIT NO.

41 Nozzle Aluminum 1 38981

42 Pilot Valve Seat Stainless Steel 1 12358

43 Pilot Valve Complete Stainless Steel 1 12350

RECOMMENDED SPARE PARTS.

THESE PARTS SHOULD BE ON HAND. PLUS RECOMMENDED SPARE PARTS, WHEN OVERHAULING THIS EQUIPMENT.

NOTE 1 - Consists of Stem and Retainer.

NOTE 2 - Consists of Lever; Set Screw, Part No. 27 and Jam Nut, Part No. 63.

NOTE 3 - Consists of Nozzle Disc, Retaining Ring and Diaphragm.

NOTE 4 - May be furnished as individual parts or as Nozzle Disc Pin Complete, Ref. No. 12377.

NOTE 5 - Range: 13 PSIA - 20 PSIG (3.5 Hg Vacuum).

NOTE 6 - Quantities are: Eight (8) for R

FOR ALL TYPES NOT LISTED, PLEASE ORDER PARTS BY NAME AND INCLUDE RANGE, TYPE AND SERIAL NUMBER.

anges 13 PSIA - 20 PSIA - 20 PSIG to 50 -125 and Six (6) for 100 - 200 to 500 - 800 Ranges.

Page 17

Page 18

823

6157

181912

PRESSURE

CONTROLLED

(89.7mm)

3-17/32 in

49

88

40

51

OPER. CONTROL

54

76

51

75

CONTROL

AIR

OPERATING MEDIUM

VALVE

1/4 in. (6mm) LESLIE SELF CLEANING STRAINGER

PRESSURE REDUCING VALVE

1/4 in. (6mm) APPLICABLE LESLIE

TYPES PDAP-1, RANGE 5-70 & 50-800

PILOT CONTROLLERS, AIR ACTUATED

WITH ADJUSTABLE PROPORTIONAL BAND

WITH ADJUSTABLE PROPORTIONAL BAND

PILOT CONTROLLERS, AIR ACTUATED, TYPES PDAP-1, RANGE 5-70 & 50-800

3/8 in. NPT

CONNECTION

CONTROL PIPE

4-1/2 in.

(114.3mm)

80

90

FOR PRESSURE RANGE 5-70 PSIG. THIS

TYPE OF DIAPHRAGM ASSEMBLY IS USED.

18

16-7/8 in.

(428.6mm)

19

FOR PRESSURE RANGE 50-80 PSIG. THIS

TYPE OF DIAPHRAGM ASSEMBLY IS USED.

67686970717274

73

9/16 in. hole

(14.3mm)

22

1/4 in.

(31.8mm)

ADJUSTABLE PROPORTIONAL BAND.

PLAN VIEW SHOWING ARRANGEMENT OF

6-1/2 in.

(165.1mm)

4-1/4 in.

(108.0mm)

1 in.

(31.8mm)

MAXIMUM ALLOWABLE STATIC PRESSURE 900 PSI

1/4 in. (6mm)

PIPE THREAD

(36.5mm)

1-7/16 in.

3-3/4 in.

(95.3mm)

APPROX. NET WT. WITH ACCESSORIES 14 LB. (6.4 kg)

6-1/8 in.

(155.6mm)

236

7

151617

8

121314202122232425242663646566

10

Page 18

302977343537403878

36

47

15/16 in.

(23.8mm)

Page 19

PILOT CONTROLLERS, AIR ACTUATED, TYPES PDAP-1, RANGE 5-70 & 50-800

WITH ADJUSTABLE PROPORTIONAL BAND

WHEN ORDERING PARTS, PLEASE GIVE TYPE, PART NAME AND PART REFERENCE NUMBER FROM TABLE BELOW.

PART PART NAME MATERIAL MATERIAL SPEC. PER

NO. UNIT 5-70 50-800

2 Nut Steel, Cadmium Plated ASTM A-194 Gr. 2H 6 42843 42843

3 Diaphragm Cover Cast Aluminum ASME B-26 Alloy 356. OT6 1 33927 33928

6 Diaphragm Synthetic Rubber Neoprene 1 13226 13226

7 Diaphragm Disc Aluminum ASTM B-211 2017/2024 1 33942 33943

8 Bolt Steel, Cadmium Plated ASTM A-193 Gr. B7 6 45749 45749

10 Yoke Cast Aluminum` ASTM B-26 Alloy B443.0 1 33971 33971

12 Adjusting Spring Spring Steel, Plated Commercial 1 51483 13218

13 Stem, Compl. (Note 2) Aluminum ASTM B-211 2017/2024 1 45085 45085

14 Adjusting Sleeve Stainless Steel AISI Type 410 1 33986 33986

15 Diaphragm Spacer Aluminum ASTM B-211 2017/2024 1 33937 33938

16 Diaphragm Guide Stainless Steel AISI Type 302 1 33933 33933

17 Tope Spring Seat Cast Aluminum ASTM B-26 Alloy B443.0 1 33944 33944

18 Yielding Spring Steel, Nickel Plated Commercial 1 12471 12471

19 Stem Nut Aluminum ASTM B-211 2017/2024 1 31839 31839

20 Bottom Spring Seat Stainless Steel AISI Type 410 1 11683 11683

21 Thrust Bearing Stainless Steel & Brass AISI Type 320 & ASTM B16 1 11684 11684

22 Adjusting Nut Cast Bronze ASTM B-61 1 12395 12395

23 Lock Nut Brass ASTM B-16 1 12833 12833

24 Washer Stainless Steel AISI Type 410 1 30673 30673

25 Base Die Cast Aluminum ASTM B-85 Alloy A360 1 43320 43320

26 Nut For Frame Steel, Cadmium Plated Commercial 1 13744 13744

29 Diaph. Nozz. Disc, Compl. (Note 1) Stainless Steel AISI Type 302 1 15086 15086

30 Diaph. Plate Die Cast Aluminum ASTM B-85 Alloy A360.0 1 38030 38030

34 Screw Aluminum ASTM B-211 2017/2024 4 33678 33678

35 O-Ring Synthetic Rubber Neoprene 2 42213 42213

36 Screw Aluminum ASTM B-211 2017/2024 4 33959 33959

37 Flange Ring Die Cast Aluminum ASTM B-85 Alloy A360.0 1 47910 47910

38 Body Die Cast Aluminum ASTM B-85 Alloy A360.0 1 40445 40445

40 Gasket Synthetic Rubber Neoprene 1 47916 47916

47 Bottom Plug Aluminum ASTM B-211 2017/2024 1 33991 33991

49 Cover Die Cast Aluminum ASTM B-85 Alloy A360.0 1 40447 40447

50 Cover Screw Steel, Cadmium Plated Commercial 1 33960 33960

51 Gage Steel Case, Clearlok Crystal Commercial 2 52354 52354

54 Connector Piece Cold Roll;ed Steel AISI 1117 2 41637 41637

63 Allen Set Screw Steel, Cadmium Plated Commercial 1 12390 12390

64 Adjusting Pin Aluminum ASTM B-211 2017/2024 1 38032 38032

65 Nut Steel, Cadmium Plated ASTM A-194 Gr. 2H 1 38060 38060

66 Blade Spring Stainless Steel AISI Type 301-2B 1 38036 38036

67 Screw Stainless Steel Commercial 2 38123 38123

68 Bearing Stainless Steel AISI Type 302 1 38034 38034

69 Adjusting Screw Stainless Steel AISI Type 302 1 38033 38033

70 Proportioning Slider, Rt. Hand Stainless Steel AISI Type 302 1 38028 38028

71 Drive Screw Steel, Cadmium Plated ASTM A-228 1 58376 58376

72 Indicator Stainless Steel AISI Type 302 1 38027 38027

73 Washer Stainless Steel AISI Type 302 1 11685 11685

74 Cap Screw Aluminum Commercial 2 33679 33679

75 Proportioning Slider, Left Hand Stainless Steel AISI Type 302 1 38029 38029

76 Knob Plastic Commercial 1 38126 38126

77 Nozzle Aluminum AISI Type 316 1 22339 22339

78 Orifice Plug Aluminum ASTM B-211 2017/2024 1 33990 33990

88 Cover Screw Washer Rubber Commercial 2 57685 57685

89 Diaphragm Spring Inconel Commercial 1 10980 - 90 Diaphragm Spring Seat Aluminum ASTM B-211 2017/2024 1 58128 - -

Adjusting Rod Cold Rolled Steel Commercial 1 11808 11808

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

QTY REF. NO. - EACH RANGE

RECOMMENDED SPARE PARTS.

THESE PARTS SHOULD BE ON HAD, PLUS RECOMMENDED SPARE PARTS, WHEN OVERHAULING THIS EQUIPMENT.

NOTE 1 - CONSISTS OF NOZZLE DISC, RETAINING RING AND DIAPHRAGM

NOTE 2 - CONSISTS OF STEM AND STEM HEAD

FOR ALL TYPES NOT LISTED, PLEASE ORDER PATS BY NAME AND INCLUDE RANGE, TYPE AND SERIAL NUMBER

Page 19

Page 20

PRESSURE

CONTROLLED

49

88

40

51

OPER. CONTROL

51

VALVE

CONTROL

WITH ADJUSTABLE PROPORTIONAL BAND

823

3/8 in. NPT

CONNECTION

CONTROL PIPE

6157

FOR PRESSURE RANGE 5-70 PSIG.

THIS TYPE OF DIAPHRAGM

ASSEMBLY IS USED.

181912

16-7/8 in.

(428.6mm)

18

(89.7mm)

3-17/32 in

FOR PRESSURE RANGE 50-80 PSIG. THIS

TYPE OF DIAPHRAGM ASSEMBLY IS USED.

67686970717274

73

(14.3mm)

9/16 in. hole

54

76

75

AIR

OPERATING MEDIUM

PLAN VIEW SHOWING ARRANGEMENT OF

1/4 in. (6mm) LESLIE SELF CLEANING STRAINGER

ADJUSTABLE PROPORTIONAL BAND.

6-1/2 in.

(165.1mm)

4-1/4 in.

(108.0mm)

PRESSURE REDUCING VALVE

1/4 in. (6mm) APPLICABLE LESLIE

MAXIMUM ALLOWABLE STATIC PRESSURE 900 PSI

APPROX. NET WT. WITH ACCESSORIES 14 LB. (6.4 kg)

1 in.

(25.4mm)

TYPES PRAP-1, RANGE 5-70 & 50-800

PILOT CONTROLLERS, AIR ACTUATED

(36.5mm)

1-7/16 in.

WITH ADJUSTABLE PROPORTIONAL BAND

PILOT CONTROLLERS, AIR ACTUATED, TYPES PRAP-1, RANGE 5-70 & 50-800

4-1/2

89

(114.3)

236

90

7

151617

8

191213142021222324252426636465

10

Page 20

66

30297779343537403880783647

1/4 in. NPT

15/16 in.

(23.8mm)

3-3/4 in.

(95.3mm)

6-1/8 in.

(155.6mm)

Page 21

PILOT CONTROLLERS, AIR ACTUATED, TYPES PRAP-1, RANGE 5-70 & 50-800

WITH ADJUSTABLE PROPORTIONAL BAND

WHEN ORDERING PARTS, PLEASE GIVE TYPE, PART NAME AND PART REFERENCE NUMBER FROM TABLE BELOW.

PART PART NAME MATERIAL MATERIAL SPEC. PER

NO. UNIT 5-70 50-800

2 Nut Steel, Cadmium Plated ASTM A-194 Gr. 2H 6 42843 42843

3 Diaphragm Cover Aluminum Alloy ASME SB-211 Alloy 6061-T6 1 33927 33928

6 Diaphragm Synthetic Rubber Neoprene 1 13226-94 13226-94

7 Diaphragm Disc Aluminum

8 Bolt Steel, Cadmium Plated ASTM A-193 Gr. B7 6 45749 45749

10 Yoke Cast Aluminum` ASTM B-26 Alloy B443.0 1 33971 33971

12 Adjusting Spring Spring Steel, Plated Commercial 1 51483 13218

13 Stem, Compl. (Note 2) Aluminum ASTM B-211 2017/2024 1 45085 45085

14 Adjusting Sleeve Stainless Steel AISI Type 410 1 33986 33986

15 Diaphragm Spacer Aluminum ASTM B-211 2017/2024 1 33937 33938

16 Diaphragm Guide Stainless Steel AISI Type 302 1 33933 33933

7 To

1

18 Yielding Spring Steel, Nickel Plated Commercial 1 12471 12471

19 Stem Nut Aluminum ASTM B-211 2017/2024 1 31839 31839

20 Bottom Spring Seat Stainless Steel AISI Type 410 1 11683 11683

21 Thrust Bearing Stainless Steel & Brass AISI Type 320 & ASTM B16 1 11684 11684

22 Adjusting Nut Cast Bronze ASTM B-61 1 12395 12395

23 Lock Nut Brass ASTM B-16 1 12833 12833

24 Washer Stainless Steel AISI Type 410 1 30673 30673

25

26 Nut For Frame Steel, Cadmium Plated Commercial 1 13744 13744

29 Diaph. Nozz. Disc, Compl. (Note 1) Stainless Steel AISI Type 302 1 15086 15086

30 Diaph. Plate Die Cast Aluminum ASTM B-85 Alloy A360.0 1 38030 38030

34 Screw Aluminum ASTM B-211 2017/2024 4 33678 33678

35 O-Ring Synthetic Rubber Neoprene 2 42213-94 42213-94

36 Screw Aluminum ASTM B-211 2017/2024 4 33959 33959

37 Flange Ring Die Cast Aluminum ASTM B-85 Al

38 Body Die Cast Aluminum ASTM B-85 Alloy A360.0 1 40445 40445

40 Gasket Synthetic Rubber Neoprene 1 47916-95 47916-95

47 Bottom Plug Aluminum ASTM B-211 2017/2024 1 33992 33992

49 Cover Die Cast Aluminum ASTM B-85 Alloy A360.0 1 40447 40447

50 Cover Screw Steel, Cadmium Plated Commercial 1 33960 33960

51 Gage Steel Case, Clearlok Crystal Commercial 2 52354 52354

54 Connector Piece Cold Roll;ed Steel AISI 1117 2 41637 41637

63 Allen Set Screw Steel, Ca

64 Adjusting Pin Aluminum ASTM B-211 2017/2024 1 38032 38032

65 Nut Steel, Cadmium Plated ASTM A-194 Gr. 2H 1 38060 38060

66 Blade Spring Stainless Steel AISI Type 301-2B 1 38036 38036

67 Screw Stainless Steel Commercial 2 38123 38123

68 Bearing Stainless Steel AISI Type 302 1 38034 38034

69 Adjusting Screw Stainless Steel AISI Type 302 1 38033 38033

70 Proportioning Slider, Rt. Hand Stainless Steel AISI Type 302 1 38028 38028

71 Drive Scr

72 Indicator Stainless Steel AISI Type 302 1 38027 38027

73 Washer Stainless Steel AISI Type 302 1 11685 11685

74 Cap Screw Aluminum Commercial 2 33679 33679

75 Proportioning Slider, Left Hand Stainless Steel AISI Type 302 1 38029 38029

76 Knob Plastic Commercial 1 38126 38126

77 Nozzle Stainless Steel AISI Type 316 1 47909 47909

78 Orifice Plug Aluminum ASTM B-211 2017/2024 1 33990 33990

79 Nozzle Valve Stainless Steel AISI Ty

80 Spring Stainless Steel AISI Type 302 1 23922 23822

88 Cover Screw Washer Rubber Commercial 2 57685 57685

89 Diaphragm Spring Inconel Commercial 1 10980 - -

90 Diaphragm Spring Seat Aluminum ASTM B-211 2017/2024 1 58128 - -

pe Spring Seat Cast Aluminum ASTM B-26 Alloy B443.0 1 33944 33944

Base Die Cast Aluminum ASTM B-85 Alloy A360 1 43320 43320

ew S

Adjusting Rod Cold Rolled Steel Commercial 1 11808 11808

TYPE PRAP-1, RANGE 5-70 AND 50-800

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

QTY REF. NO. - EACH RANGE

ASTM B

-211 2017/2024 1 33942 33943

loy A

360.0 1 47910 47910

dmium P

lated Commercial 1 12390 12390

teel, Cadmium Plated ASTM A-228 1 58376 58376

pe 3

02/304 1 47903 47903

RECOMMENDED SPARE PARTS.

THESE PARTS SHOULD BE ON HAD, PLUS RECOMMENDED SPARE PARTS, WHEN OVERHAULING THIS EQUIPMENT.

IAPHRAGM

NOTE 1 - CONSISTS OF NOZZLE DISC, RETAINING RING A

NOTE 2 - CONSISTS OF STEM AND STEM HEAD

FOR ALL TYPES NOT LISTED, PLEASE ORDER PATS BY NAME AND INCLUDE RANGE, TYPE AND SERIAL NUMBER

ND D

Page 21

Page 22

TYPE UDDV, DIFFERENTIAL PILOT CONTROL

HIGH PRESSURE AT CONN. “A” ADJ. DIFF. 0 - 100 P.S.I.

HIGH PRESSURE AT CONN. “B” ADJ. DIFF. 0 - 35 P.S.I.

MAXIMUM STATIC PRESSURE ON EITHER CONN. “A” OR “B” 600 P.S.I.

(BI-DIRECTIONAL - DIFFERENTIAL)

RATIO 1:1

APPROX. NET WT. 25 lb. (11.3 kg)

Page 22

Page 23

TYPE UDDV CONTROL PILOT

WHEN ORDERING PARTS, PLEASE GIVE PART NAME AND PART REFERENCE NUMBER FROM TABLE BELOW

PART MATERIAL QTY. PER REF.

NO. PART NAME MATERIAL SPEC UNIT NO.

1 Diaphragm Cover Cast Aluminum ASTM B-26 Alloy 319.0 1 49058

2 Connector Bolt Stainless Steel AISI Type 416 1 49030

3 Lock Nut Steel, Cadmium Plated Commercial 1 40348

4 Bolt Steel, Cadmium Plated Commercial 6 49087

5 Nut Steel, Cadmium Plated ASTM A-194 GR. 2H 8 42842

6 Diaphragm Disc, Upper Aluminum ASTM B211, 2011/2024 1 49029

7 Diaphragm Synthetic Rubber Fairprene 2 13257

10 Vent Chamber Cast Aluminum ASTM B-26 Allow 139.0 1 49028

11 Diaphragm Disc Aluminum ASTM B211 2017/2024 1 49002

13 Diaphragm Seal Spacer Aluminum ASTM B211 2017/2024 1 41187

14 Diaphragm Base Cast Aluminum ASTM B-26 Alloy 319.0 1 41184

15 Diaphragm, Small Synthetic Rubber Fairprene 1 19446

16 Diaphragm Washer, Complete Aluminum Commercial 1 33089

17 Diaphragm Ring Aluminum ASTM B211 2017/2024 1 41188

18 Set Screw Steel, Cadmium Plated Commercial 1 41197

19 Connector Bolt Nut Aluminum ASTM B211 2017/2024 1 31836

20 Screw Stainless Steel Commercial 6 30638

21 Spring Seat Stainless Steel AISI Type 301/302 2 11683

22 Yielding Spring Steel, Nickel Plated Commercial 1 12471

23 Stem Nut Aluminum ASTM B211 2017/2024 1 31839

24 Stem, Complete (Note 4) Aluminum ASTM B211 2017/2024 1 47135

25 Adjusting Spring Steel, Cadmium Plated Commercial 1 12474

26 Adjusting Sleeve Stainless Steel AISI Type 416 1 47259

27 Yoke Cast Aluminum ASTM B26 Alloy B443.0 1 34006

28 Thrust Bearing Stainless Steel & Brass AISI 316 & B-16 1 11684

29 Adjusting Nut Cast Bronze ASTM B-61 1 12395

30 Lock Nut Brass ASTM B-16 1 12833

31 Washer Stainless Steel AISI Type 302 2 30673

32 Base Die Cast Aluminum ASTM B-85 Alloy A360.0 1 43320

33 Nut Steel, Cadium Plated Commercial 1 13744

36 Adjusting Pin Brass ASTM B-16 1 12401

37 Diaphragm Nozzle Disc, Compl. (Note 1) Stainless Steel AISI Type 303 1 15086

38 Diaphragm Plate Die Cast Aluminum ASTM B-85 Alloy A360.0 1 38030

39 Cap Screw Aluminum Commercial 2 33679

42 Screw Aluminum Commercial 4 33678

43 O-Ring Synthetic Rubber Commercial 2 42213

44 Screw Steel, Cadium Plated Commercial 4 33959

45 Flange Ring, Complete (Note 2) Die Cast Aluminum ASTM B-85 Alloy A360.0 1 33672

46 Body Die Cast Aluminum ASTM B-85 Alloy A360.0 1 40445

50 Nozzle Aluminum Commercial 1 38347

53 Pilot Valve Spring Stainless Steel Commercial 1 33666

55 Bottom Plug Aluminum Commercial 1 33667

63 Cover Die Cast Aluminum ASTM B-85 Alloy A360.0 4 40447

64 Cover Screw Steel, Plated Commercial 1 33960

65 Pressure Gage Steel Case, Clearlok Crystal Commercial 2 52354

67 Diaphragm Disc, Lower Aluminum ASTM B211 2017/2024 1 49003

68 Connector Piece Cold Rolled Steel Commercial 2 41637

69 Spring Cap, Complete Stainless Steel AISI Type 302 1 46427

70 Gasket Aluminum Annealed Commercial 1 46420

71 Upper Spring Steel AISI 1095 1 46387

72 O-Ring Synthetic Rubber Commercial 1 23656

73 Screw Stainless Steel AISI Type 302/304 1 48063

74 Lock Nut Stainless Steel Commercial 1 47138

86 Extension Pin Stainless Steel Commercial 1 47097

87 Pilot Valve Seat Celcon Commercial 1 12353

88 Nozzle Stop Aluminum ASTM 211 2017/2024 1 33673

89 Pilot Valve, Complete Stainless Steel AISI Type 302/304 1 33675

90 Diaphragm Nut Stainless Steel Commercial 1 33316

91 Diaphragm Washer Stainless Steel AISI Type 302/304 1 33676

92 Diaphragm Synthetic Rubber Neoprene 1 12368

93 Blade Spring (Note 3) Stainless Steel AISI Type 302 1 33677

103 Bolt Steel, Cadium Plated Commercial 2 49422

104 Cover Screw Washer Rubber Commercial 2 57685

Adjusting Rod Cold Rolled Steel Commercial 1 11808

NOTE 1: Requires four (4) R/N 45840 and two (2) R/N 59478.

NOTE 2: Furnished with Heater Coil but may be ordered separately.

NOTE 3: Includes seal plate (#21), screws (#17) and lock washers (#18)

NOTE 4: Consists of Stem and Stem Head.

FOR ALL TYPES NOT LISTED. PLEASE ORDER PARTS BY NAME AND INCLUDE RANGE. TYPE AND SERIAL NUMBER.

Recommended spare parts.

These parts should be on hand, plus recommended spare parts, when overhauling equipment.

USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

Page 23

Page 24

R

P

I

P

1/4RE

P

IPE

3/8

1/4LESLIESELFCLEANI

N

G

S

TRAINER

/

CSSSUUC

G

PILOT CONTROLLER — TYPE DDD, 15-75 RANGE

REF PRESSURE

PIPE CONNECTION

1/4” PIPE THREAD

REF PRESSURE

PIPE CONNECTION

3/8” PIPE THREAD

1/4” LESLIE SELF-CLEANING STRAINER

1/4” APPLICABLE LESLIE

PRESSURE REDUCING VALVE

MAXIMUM STATIC PRESSURE 300 PSIG.

RATIOS

SPECIFY WHEN ORDERING

1.1:1

1.2:1

1.3:1

1.4:1

1.5:1

1.6:1

2:1

3:1

SUPERSEDES DRAWING NO. CP-14620 F, ALT. 3

Page 24

Page 25

PILOT CONTROLLER — TYPE DDD, 15-75 RANGE

WHEN ORDERING PARTS, PLEASE GIVE RANGE, TYPE, PART NAME AND PART REFERENCE NUMBER FROM

PART QTY PER

NO. PART NAME MATERIAL UNIT REF. NO.

1

2

3

4

5

6

7

8

9

10

11

11

11

11

11

11

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

36

37

38

39

40

42

43

44

45

46

47

48

49

50

51

52

53

55

57

58

59

60

61

62

63

64

65

66

67

68

74

86

88

NOTE 1 - Consists of Nozzle Disc, Retaining Ring and Diaphragm.

NOTE 2 - Ref. No. 41183 for Ratios 1.3:1, 1.4:1. 1.5:1, 1.6:1. and 2:1. Ref. No. 46396 for Ratios 1.2:1 & 1.1:1 and Ref. No. 55835 for Ratio 3:1.

NOTE 3 - Ref. No. 49002 for 3:1 Ratio and Ref. No. 41189 for all other Ratios.

Diaphragm Cover

Connector Bolt

Lock Nut

Bolt

Nut

Diaphragm Disc, Upper

Diaphragm

Diaphra

Signal Chamber

Vent Chamber

Diaphragm Disc, Ratio 2:1 & 3:1

Diaphragm Disc, Ratio 1.1:1

Diaphragm Disc, Ratio 1.2:1 & 1.4:1

Diaphragm Disc, Ratio 1.3:1

Diaphragm Disc, Ratio 1.5:1

Diaphragm Disc, Ratio 1.6:1

Diaphragm, Seal Spacer

Diaphragm Base

Diaphragm, Small

Diaphragm Washer, Complete

Diaphragm Ring

Set Screw

Connector Bolt Nut

Screw

Spring Seat

Yielding Spring

Stem Nut

Stem

Adjusting Spring

Adjusting Sleeve

Yoke

Thrust Bearing

Adjusting Nut

Lock Nut

W

B

Nut, Frame

Screw

Adjusting Pin

Dia. Nozzle Disc, Compl. (NOTE 1)

Diaphragm Plate

Cap Screw

Nozzle Stop

Screw

O-ring

Screw

Flange Ring, Complete

Body

Diaphragm Nut

Diaphragm

Diaphragm Washer

Nozzle

Pilot Valve Seat

Pilot Valve, Complete

Pilot Valve Spring

Bottom Plug

Knob

Needle Valve Stem

O-ring

Needle Valve Bonnet

O-ring

O-ring

Cover

Cover Screw

Pressure Gage, Control Valve

Pressure Gage, Operating Supply

Diaphragm Disc, Lower

Connector Piece

Lock Nut

Ext

Cover Screw Washer

Adjusting Rod

asher

ase

ension P

gm S

pacer

in

BELOW. USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

Cast Aluminum

Stainless Steel

Steel, Cadmium Plated

Steel, Cadmium Plated

Steel, Cadmium Plated

Aluminum

Synthetic Rubber

Cast Aluminum

Cast Aluminum

Cast Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Aluminum

Cast Aluminum

Cast Aluminum

Synthetic Rubber

Aluminum

Aluminum

Steel, Cadmium Plated

Aluminum

Stainless Steel

Stainless Steel

Steel, Nickel Plated

Aluminum

Aluminum

Steel, Cadmium Plated

teel

Stainless S

C

ast Aluminum

Stainless Steel & Brass

Cast Bronze

Brass

Stainless Steel

Aluminum

Steel,Cadmium Plated

Stainless Steel

Brass

Stainless Steel

Aluminum

Aluminum

Aluminum

Aluminum

Synthetic Rubber

Steel, Cadmium Plated

Aluminum

Aluminum

Stainless Steel

Synthetic Rubber

Stainless Steel

Aluminum

Celcon

Stainless Steel

Stainless Steel

Aluminum

Phenolic

Stainless Steel

Synthetic Rubber

Stainless Steel

Synthetic Rubber

Synthetic Rubber

Aluminum

Steel, Cadmi

Plastic

Plastic

Aluminum

Cold Rolled Steel

Stainless Steel

Stainless Steel

Red Rubber

Steel, Plated

FOR ALL TYPES NOT LISTED, PLEASE ORDER PARTS B

lated

um P

Y N

AME AND INCLUDE RANGE, TYPE AND SERIAL NUMBER

1

1

1

8

8

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

6

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

1

4

2

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

2

1

41181

41185

40348

41194

42842

46405

13257

41186

41182

(NOTE 2)

41190

49438

46439

46440

46441

41189

41187

41184

19446

33089

41188

41197

31836

30638

11683

12471

31839

47135

12474

47259

34006

11684

12395

12833

30673

43320

13744

48063

12401

15086

38030

33679

33673

33678

42213

33959

33

0445

4

33316

12368

33676

38347

12353

33675

33666

33667

38126

43072

23869

43070

28421

23656

40447

33960

12393

19815

(NOTE 3)

41637

47138

47097

57685

11808

672

Page 25

Page 26

NOTES:

Page 26

Page 27

NOTES:

Page 27

Page 28

Asubsidiary of International, Inc.

20/1.5.2Rev.3/0012

12501 Telecom Drive, Tampa, Florida

33637

Ph: (813) 978-1000 • Fax: (813) 978-0984

w w w . l e s l i e c o n t r o l s . c o m

PRINTED IN USA

Loading...

Loading...