Page 1

12501 Telecom Drive, Tampa Florida 33637

Installation, Operating and

Maintenance Instructions

Supplement

90/0.5.0

Rev. 5

DOUBLE SHELL & TUBE HEAT EXCHANGER

TABLE OF CONTENTS

INTRODUCTION .............................................................................................6

GENERAL NOTES AND WARNINGS ................................................................................................................................... 6

INSTALLATION AND OPERATION............................................................6

A. INSTALLATION ............................................................................................................................................................ 7

B. PIPE CONNECTIONS ......................................................................................................................................................... 7

C. ELECTRICAL CONNECTIONS .................................................................................................................................... 7

D. OPERATION OF NORMAL RECIRCULATION PUMP ...................................................................................................8

E. OPERATION OF SECOND RECIRCULATION PUMP..................................................................................................... 8

F. OPERATION OF SWITCH PANEL.....................................................................................................................................9

G. OPERATION DUE TO OVER TEMPERATURE CONDITIONS ...................................................................................... 9

H. GENERAL SETUP AND OPERATION OF BLEND VALVE.......................................................................................... 10

I. GENERAL OPERATION OF HEAT EXCHANGERS................................................................................................. 11

J. GENERAL OPERATING PRINCIPLE............................................................................................................................... 11

STORAGE AND TRANSPORTATION................................................................................................................................ 12

STARTUP ........................................................................................................................................................................... 13

CLEANING......................................................................................................................................................................... 13

CERTIFICATION ...............................................................................................................................................................14

1. GENERAL OPERATION OF RELIEF VALVE........................................................................................................... 14

REPLACEMENT PARTS ..............................................................................14

A. RECIRCULATION PUMP................................................................................................................................................. 14

D. BLEND VALVE............................................................................................................................................................14

MAINTENANCE.............................................................................................15

TROUBLESHOOTING..................................................................................17

UNIT SEPARATION FOR INSTALLATION.............................................18

UNIT STARTUP AFTER INSTALLATION...............................................20

Page 2

LIST OF ILLUSTRATION

F

IGURE 1 - TYPICAL HEATER ILLUSTRATION

F

IGURE 2 – CONTROL BOX

F

IGURE 3 - SWITCH BOX

F

IGURE 4 – LESLIE ELECTRICAL SCHEMATIC

F

IGURE 5 - MOTOR CONDUIT BOX WIRING DETAIL

F

IGURE 6 - PUMP SECTIONAL DRAWING

F

IGURE 7 - CROSS SECTION

F

IGURE 8 – FLOW DISTRIBUTION IN HEAT EXCHANGERS

F

IGURE 9 - FLOW DISTRIBUTION IN HEAT EXCHANGERS

F

IGURE 10 - THREADED AND FLANGED (COMPATIBLE WITH CL

F

IGURE 11 - COMPLETE INSTALLATION DIAGRAM

F

IGURE 12 - INSULATION TIED WITH STRAPS

F

IGURE 13 -

F

IGURE 14 -

MODEL B............................................................................................................................................................................15

MODEL C............................................................................................................................................................................15

.........................................................................................................................................................................4

.............................................................................................................................................................................5

......................................................................................................................................................................11

..............................................................................................................................................3

..............................................................................................................................................7

....................................................................................................................................8

.....................................................................................................................................................8

.........................................................................................................................11

..........................................................................................................................12

....................................................................................................................................13

.............................................................................................................................................13

Leslie Controls Inc

IOM Manual

(With the 130F Element)

For All Serial Numbers EXCEPT:

S#-0712-3

S#-0712-1

S#-0711-11

S#-0807-1

S#-0804-1

S#-0712-5

S#-0712-4

S#-0802-2

S#-0712-7

S#-0801-2

S#-0801-6

S#-0712-9

S#-0712-6

S#-0802-6

S#-0802-9

S#-0803-6

S#-0802-8

S#-0801-5

S#-0802-4

S#-0801-3

S#-0802-1

S#-0801-8

S#-0802-7

300)

CONNECTIONS

................................................................................12

Page 2 of 25

Page 3

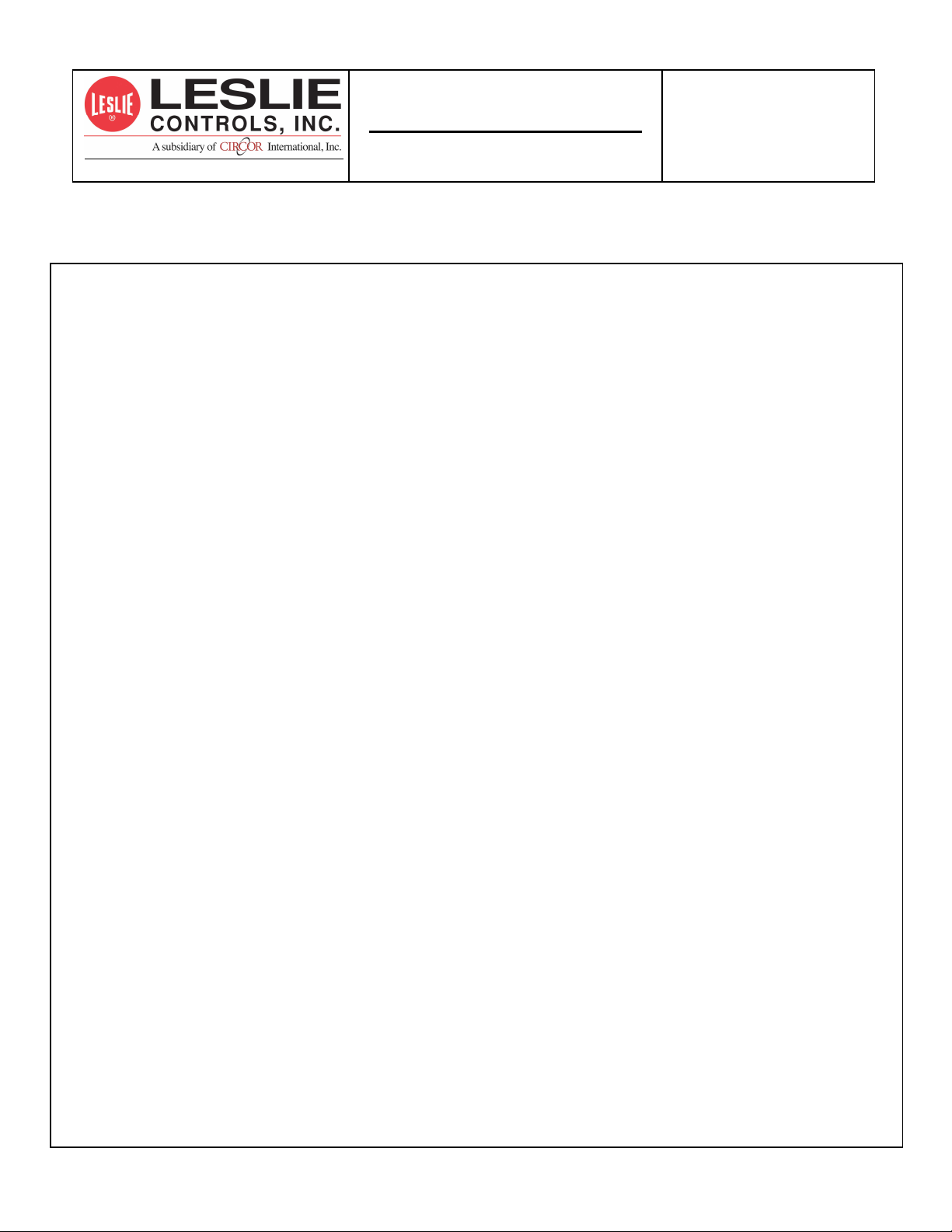

Figure 1 - Typical Heater Illustration

Page 3 of 25

Page 4

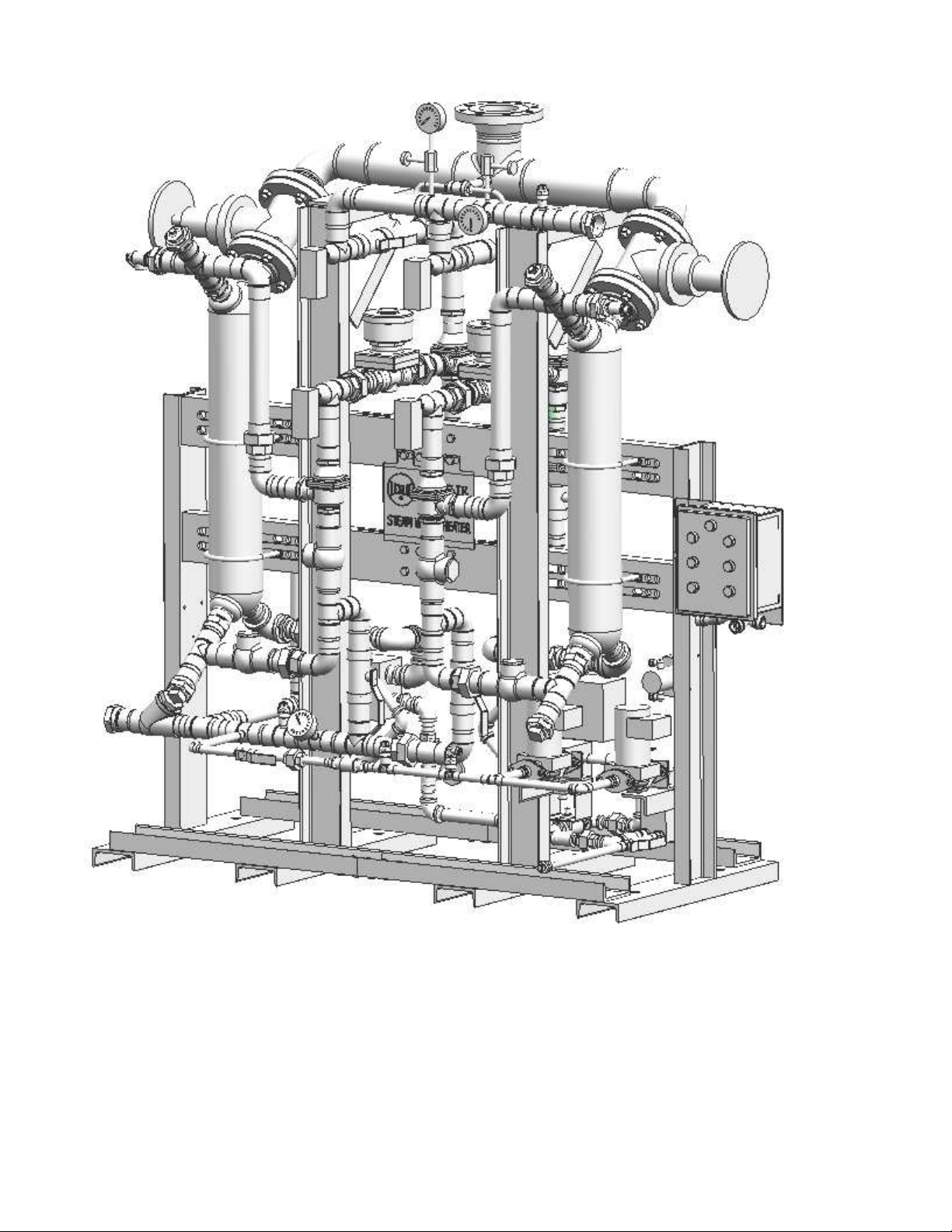

Figure 2 – Control Box

Page 4 of 25

Page 5

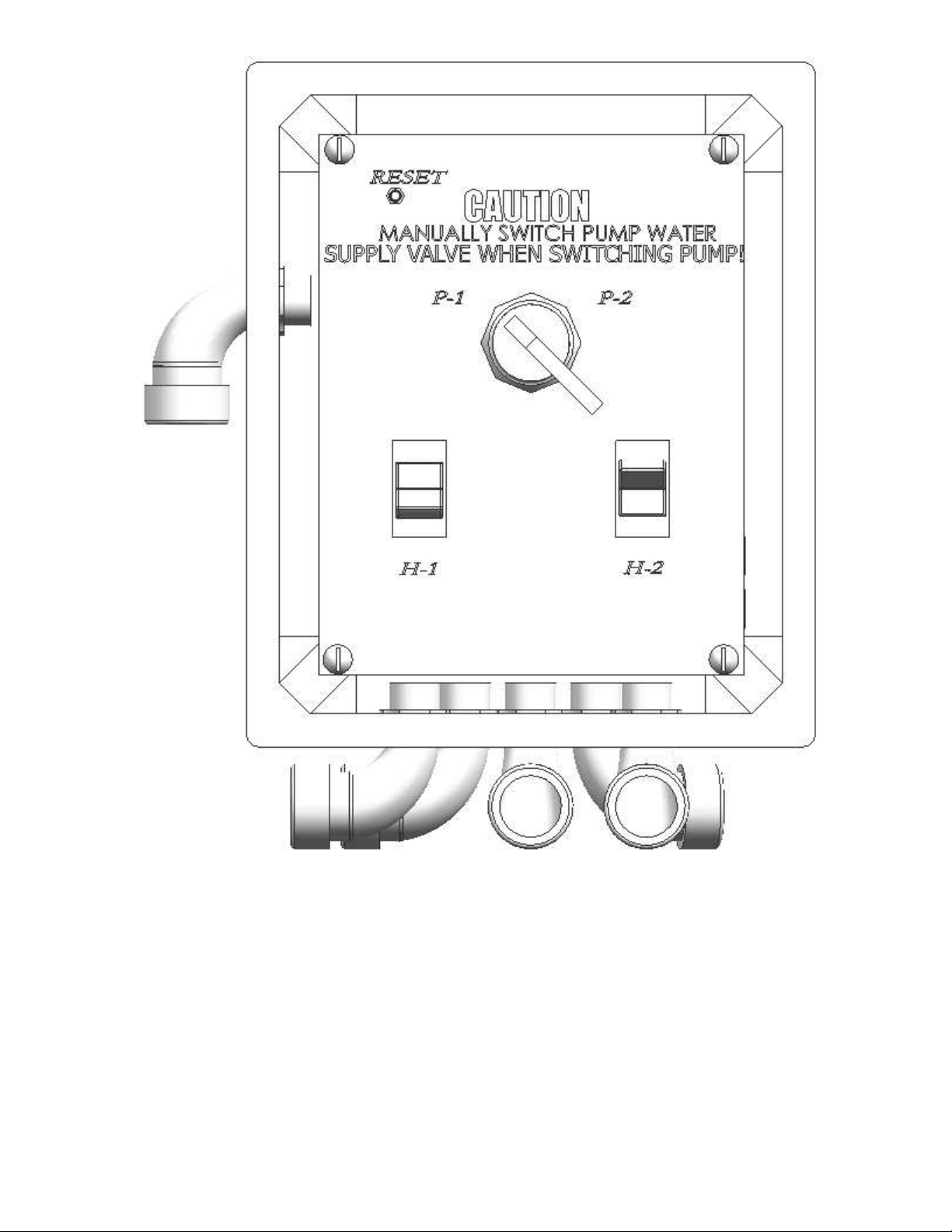

Figure 3 - Switch Box

Page 5 of 25

Page 6

Injury or death can occur due to failure to completely

isolate component from all sources of pressure before

beginning disassembly. Do not proceed until component

has been completely isolated from process stream and

WARNING!

vented to atmosphere.

Injury can occur due to adjusting secondary

temperature switches higher than 130 degrees F.

Check this setting before supplying steam to the unit.

WARNING!

INTRODUCTION

This Installation, Operation, and Maintenance Manual is

intended to be as complete and up to date as possible. It

covers installation, operation, and maintenance procedures

for Leslie Controls, Inc. Double Shell Tube. Leslie

reserves right to update this manual and/or product

information concerning installation, operation, and/or

maintenance, at any time and without obligation to notify

product owners of such changes.

Leslie is not responsible for inaccuracies in specifications,

procedures and/or content of product literature supplied by

manufacturers of components used in Leslie Controls, Inc.

Double Shell Tube, Leslie strives to use only highest

quality components; however, Leslie has no direct control

over manufacture or its consistent quality.

Leslie is not responsible for injury to personnel or product

damage due to improper installation, operation, and/or

maintenance of Leslie Controls, Inc. Double Shell Tube.

Trained/certified personnel should only perform all

installation, operation, and maintenance procedures.

Personnel should be trained in and familiar with correct

piping and electrical procedures and methods, and should

be experienced in working with hot/boiler water systems

and steam systems. All personnel performing procedures

should completely and carefully read and understand all

supplied materials before attempting procedures. All

personnel should pay strict attention to all Notes, Cautions,

and Warnings that appear within procedures detailed in

this manual.

Leslie welcomes user’s input as to suggestions for product

or manual improvement.

Contact Information

For information concerning warranties, or for

questions pertaining to installation, operation or

maintenance of Leslie products, contact:

Leslie Controls Inc.

12501 Telecom Drive

Tampa, FL 33637

USA Phone: (813) 978-1000

USA Fax: (813) 978-0984

www.LesleiControls.com

To order replacement parts, contact Leslie Controls at

address listed above, or call toll free:

USA/Canada/Caribbean Phone: (800) 323-8366

Note: Please include model and serial number of unit

for which parts are being ordered. If ordering by

phone, please have this information readily available.

GENERAL NOTES AND WARNINGS

Notes:

• If questions are not answered by this manual, or if

specific installation, operation, and/or maintenance

procedures are not clearly understood, contact Leslie

Controls, Inc. for clarification before proceeding.

• If unit is damaged during installation, operation, or

maintenance, complete following steps:

1. Turn off and lock out electric power supply

to unit in an approved manner.

2. Turn off all incoming valves.

3. Contact in-house maintenance personnel or

Leslie Controls, Inc. for instructions.

Note: Throughout this manual, BOXES will denote

warnings and cautions

Piping system must be adequately designed and

supported to prevent extraordinary loads to pressure

CAUTION!

equipment.

INSTALLATION AND

OPERATION

Page 6 of 25

Page 7

A. INSTALLATION

WARNING!

After connecting inlet cold water, outlet hot water, Steam

inlet, re-circulation inlet, safety relief valve drains and

condensate piping, lag unit to concrete floor.

Safety Relief valves and condensate drain must be

connected properly to drainage, to insure no hot water

1. Shut off cold water valves to secondary blend

valves.

2. Insure that cold water supply to primary blend

valves is turned on.

3. Slowly supply water pressure to primary blend

valves after full water pressure is reached then

open up cold water supply to secondary blend

valves slowly.

4. Slowly supply steam to unit, up to 8 psig.

Water pressure must be supplied slowly to the inlet of

the unit so that the solenoid valves are pressurized

correctly. If not, then correct temperature adjustment

CAUTION!

can contact people.

IMPORTANT!

CAUTION!

may not be possible.

B. PIPE CONNECTIONS

Connection Drawing symbol

Inlet water M

Outlet Hot water N

Inlet Steam L

Re-circulation Inlet P

Condensate Outlet R

Model Connection Conn. Size

NYCHA60

NYCHA90

Inlet water 2” F NPT

Outlet Hot water 2” F NPT

Inlet Steam 4” RF

Outlet Condensate ¾”F NPT

Inlet water 2” F NPT

Outlet Hot water 2” F NPT

Inlet Steam 4” RF

Outlet Condensate ¾”F NPT

Inlet water 2” F NPT NYCHA120

Outlet Hot water 2” F NPT

Inlet Steam 4” RF

Outlet Condensate ¾”F NPT

NYCHA150

Inlet water 2” F NPT

Outlet Hot water 2” F NPT

Inlet Steam 4” RF

Outlet Condensate ¾”F NPT

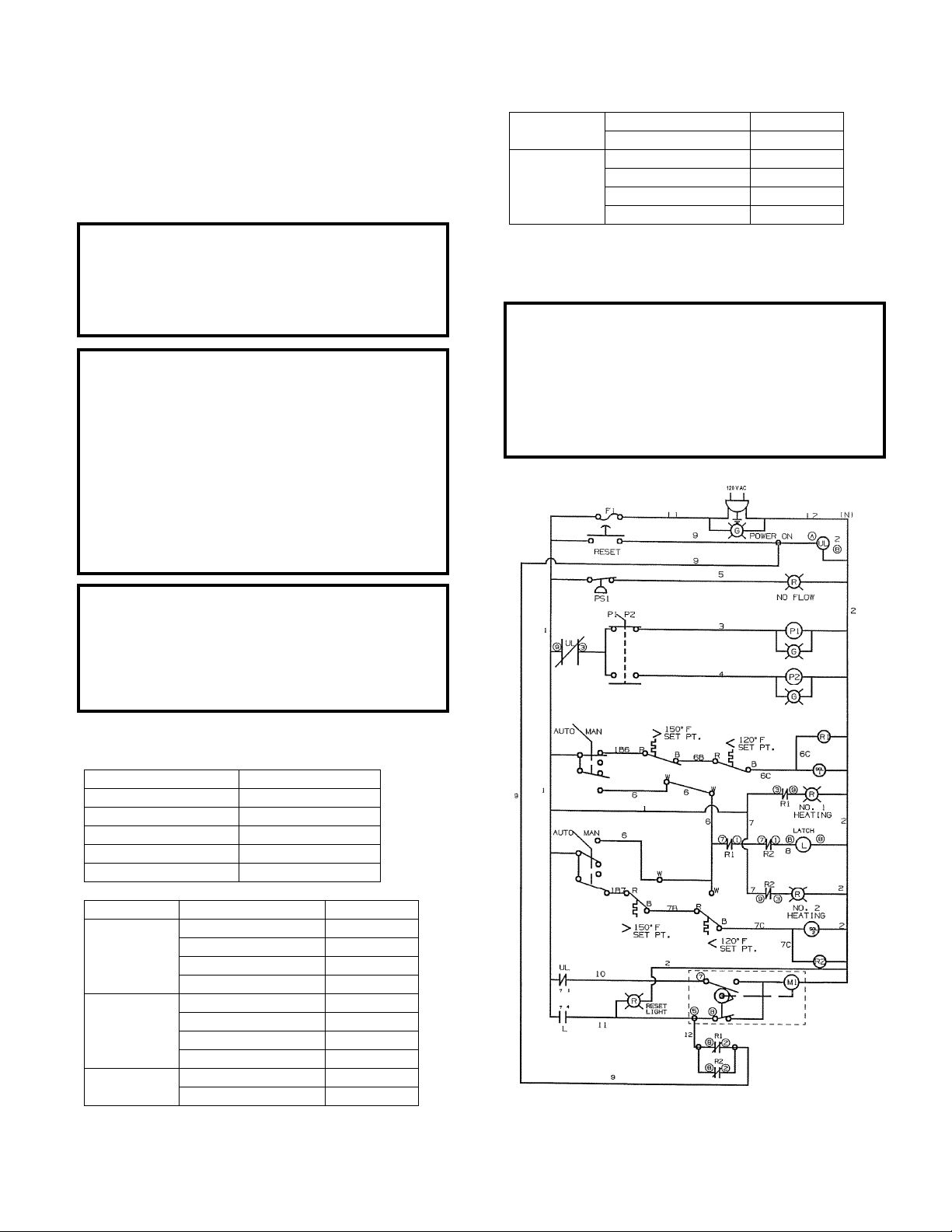

C. ELECTRICAL CONNECTIONS

Be certain that all connections are secure and the

conduit box cover is closed before electrical power is

connected. Failure to follow these instructions could

result in serious personal injury, death and/or property

damage.

See drawing for latest revision of wiring.

ELECTRICAL SHOCK HAZARD

Figure 4 – Leslie Electrical Schematic

Page 7 of 25

Page 8

Schematic Component Descriptions

1. Power on Light:

• Indicates that power is being supplied to

system.

• Fuse F1 blown, burnt out light or

disconnection of power will cause light to go

out.

2. No flow light:

• Will light red when pressure switch

(PS1) senses no pressure across pumps.

3. Reset Switch:

• This switch is only used if unit was set up so

that it will not automatically reset. It is a

manual switch that will unlatch latched relay

and set all switches back to start position

after an over temperature condition was seen

by unit .

• Note, this switch is not required if unit is

setup for automatic restart.

4. P1/P2 Switch:

• Turns first pump on and second pump off or

vice versa.

• Front panel light will identify active pump.

5. Primary and secondary over temperature

switches:

• If either primary or secondary switch sees an

over temperature condition, then:

1. Solenoid supplying hot water is de-

energized to the shut position.

2. Latching relay and over temperature

light are energized.

3. Power to re-circulation pump is cut off.

4. Latching relay supplies power to three

way condensate diverting valve and

Three way condensate diverting valve

diverts hot condensate water away from

cooler and sends it directly to condensate

return line.

• Latching relay:

1. Upon an over temperature condition,

latch will hold three way condensate

diverting valve in diverting position until

over temperature switch has reset and

over temperature condition no longer

exists. It will then allow diverting valve

to go back to sending condensate water

to cooler.

6. Auto/Manual Switches:

• Perform same function as primary and

secondary temperature over temperature

switches.

Manufacture’s IOM must be referred to. This IOM is

CAUTION!

FOR GENERAL USE ONLY .

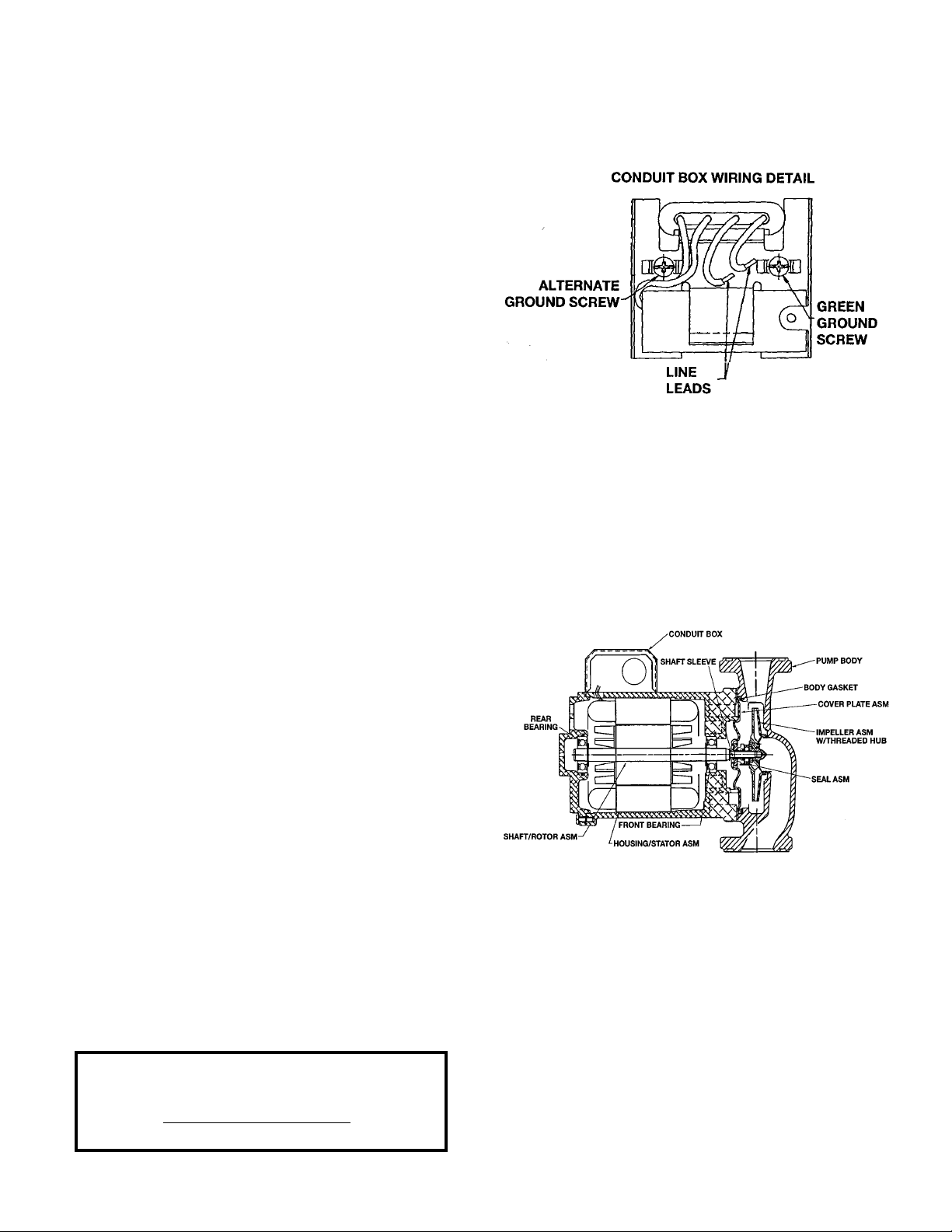

Pump Connections

Figure 5 - Motor Conduit Box Wiring Detail

D. OPERATION OF NORMAL

RECIRCULATION PUMP

PERIODIC INSPECTION

It is recommended that periodic inspections be made to

check for potential problems with pump. If any leakage or

evidence of leakage is present, repair or replace unit.

Figure 6 - Pump Sectional Drawing

“P-1” pump is used under normal situations. Green light

for “P-1” is lit and red light for “NO-FLOW” is not lit. If

this pump should fail then Red light for “NO_FLOW” will

light. Follow instructions for isolating this pump and

starting secondary pump.

E. OPERATION OF SECOND

RECIRCULATION PUMP

This pump is used under maintenance situations. Light for

“P-2 is lit and red light for “NO-FLOW” is not lit. If this

Page 8 of 25

Page 9

pump should fail then Red light for “NO_FLOW” will

light. Follow instructions for isolating this pump and

starting primary pump or shutting down system.

Pressure may be present in the pump body. Loosening

flange bolts and shifting pump assembly slightly to

allow pressurized water to escape can relieve this

pressure. Failure to follow these instructions could

When disassembling a gasketed joint, always use a new

result in serious personal injury or death

gasket upon reassembly. NEVER RE-USE OLD

GASKETS. Failure to follow these instructions could

result in serious personal injury or death

Pressurize the body slowly while checking for leaks at

all joint with gaskets. NEVER RE-USE OLD

GASKETS. Failure to follow these instructions could

result in serious personal injury or death

Do not run pumps dry, seal damage may occur. Failure

to follow these instructions could result in serious

WARNING!

WARNING!

WARNING!

CAUTION!

personal injury or death

F. OPERATION OF SWITCH

PANEL

(Ref Figure 2)

Light/Switch Indication Notes

Power On Green Electrical

power is

being

supplied to

unit.

Pump 1 On Primary pump P1 is

on. Green

Pump 2 On Secondary Pump

P2 is on. Green

No Pump

Flow

Re-circulation

system flow has

stopped. Red

Pump can

have power

but not pump

fluid

Pump can

have power

but not pump

fluid

Water

pressure

before pumps

is same as

after pumps

No. 1 Heater

Over Temp

No. 2 Heater

Over Temp

H-1 Turn hot water to

H-2 Turn hot water to

P-1 Select primary

P-2 Select secondary

Reset Momentary switch

IF AN OVER TEMPERATURE CONDITION WAS

DETECTED:

1. The hot water supply is shut off and only cold

2. Re-circulation pump power is turned off.

3. Condensate bypasses cooler.

RESET WILL OCCUR AUTOMATICALY AFTER

WATER TEMPERATURE REDUCES AND

RECIRCULATION CONTINUES

Hot water is off.

Red

Hot water is off.

Red

side one on

side two on

pump on, secondary

off

pump on, primary

off

to reset from a fail

condition

CAUTION!

water is supplied to building.

One or more

temp

controllers on

side one

detected an

over temp

condition.

One or more

temp

controllers on

side two

detected an

over temp

condition.

Turns system

on (Both

switches need

to be on)

Turns system

on (Both

switches need

to be on)

Power to

primary

pump. Off to

secondary

Power to

secondary

pump. Off to

primary

Fail condition

latches unit to

supply only

cold water

G. OPERATION DUE TO OVER

TEMPERATURE CONDITIONS

Temperature switch settings:

First switch = 180 degrees F

Page 9 of 25

Page 10

Second switch = 130 degrees F

Should an over temperature condition occur a temperature

switch in first or second stage of one or both sides of the

unit will recognize this and switch the relay in the control

box. Relay will:

1. Cause solenoid supplying hot water to shut off

supply of hot water to output of system.

2. Cause three way valve (101) to rotate and divert

condensate water away from condensate cooler

and send it directly to drain.

3. Cause “RESET”, “NO. 1 HEATER OVER

TEMPERATURE “NO. 2 HEATER OVER

TEMPERATURE” light or all three lights to light

up.

4. When temperature switch senses the water

temperature has cooled down and the three way

valve has reached its full rotation, relay in the

control box will switch three way valve to rotate

back to its original position. Only then will the

solenoid valves open up again and normal

operation begin.

H. GENERAL SETUP AND

OPERATION OF BLEND VALVE

Gain adjuster valves, item 39 are used to adjust cold

water to final blend valve to insure holding set

temperature over flow range of unit. Valves are

generally set at 4.5 turns from full open position,

however they should be adjusted for each installation

since each building has it’s own characteristics.

Valves should be re-adjusted when season

INITIAL SETTING OF GAIN ADJUSTER VALVES

PROCEDURE

changes from winter to summer.

1. Ensure all connections are made and unit is

running at specified maximum flow.

2. Turn off supply of water to one side. Half of

specified maximum flow is now being delivered.

3. Check outlet water temperature and insure it is

120 degrees F.

4. If warmer then turn gain valve handle

counterclockwise for ¼ turn.

5. Recheck water temperature and repeat until

reaching desired temperature.

6. Note: Temperature will not change quickly and

must be left to seek it’s normal setting.

7. If the water was colder then turn the gain valve

handle clockwise for ¼ turn.

8. Recheck water temperature and repeat until

reaching desired temperature.

NOTE

9. Re-open the supply of water to side turned off.

Wait for the system to stabilize.

10. Repeat step 2 through 9 for the second side.

BLEND VALVE OPERATION

Motive force of operation comes from expansion of a

special wax material which remains in a semi-solid form

and which is highly sensitive to temperature changes.

Upon warming sliding valve moves up to extended

position. By-pass closes off as sliding valve seats and

water is diverted to outlet (Port C on valve). In actual

operation, sliding valve is normally in about mid-position.

When wax material expands with rising temperature,

rubber plug is forced into a reduced diameter in piston

guide, which multiplies movement of piston by and

extruding action.

Operating range is determined by chemical composition

of wax material. Expanding wax develops a pressure that

easily overcomes return spring force of over 100 lb.

Construction is simple and rugged, yet unit is very

sensitive to changes in temperature. Changes in pressure

do not affect element and, due to valve construction,

surges in pressure do not tend to upset stability of

Thermostatic valve.

Thermostatic valves have Tamper-Proof Temperature

Setting, and are Completely Self-Contained.

3-way action of thermostatic valve allows a constant

volume of water through system at all times with no

restriction to flow when system is cold.

MATERIALS OF CONSTRUCTION

Temperature Element Assemblies are made of brass and

bronze. Seals are Buna N. Certain fluids may be damaging

to standard valve body and seal materials.

TEMPERATURE SETTINGS

Thermostatic Valves are set to a predetermined

temperature at factory, errors due to mistakes of operating

personnel are eliminated. After a Thermostatic Valve had

been installed, it is impossible for operator to arbitrarily

change operating temperature unless element assemblies

themselves are changed.

For long life, Thermostatic Valves should not be operated

continuously at temperatures more than about 25ºF (14ºC)

above their nominal ratings. If higher continuous over

temperatures are expected, contact factory for

recommendations.

Page 10 of 25

Page 11

I. GENERAL OPERATION OF

HEAT EXCHANGERS

Heat exchangers are designed to transfer heat between

steam and water at various temperatures, fluid flows, and

pressures.

WITH FRESH CLEAN WATER EVERY SIX

MONTHS. An inspection and maintenance log must

CONSTRUCTION FEATURES

WARNING!

FLUSH HEAT EXCHANGERS

be maintained.

exchangers are most common type of heat exchangers.

These heat exchangers are counter flow units, which from

a thermodynamic point of view extract more heat from a

given fluid stream than order common types of heat

exchangers.

Heating medium flows through tubes. Thermal energy is

transferred through tube walls. Total heat load is

dependent on flow parameters of fluid.

Figure 7 - Cross Section

Heat exchangers are designed and fabricated as a single

unit with non-removable parts. Cylindrical shell encloses

a tube bundle which consists of circular layers of helically,

corrugated tubes. Each layer flows in opposite direction to

layers surrounding it in a criss-cross manner. Tube bundle

has perforated bottom, which are welded near

connections. Both ends of cylindrical shell are enclosed

within hemispherical heads.

Each heat exchanger has a total of four (4) symmetrically

located connections, two on each hemispherical head. One

pair of opposing connections is connected to tube side

while other pair is connected to shell side.

J. GENERAL OPERATING

PRINCIPLE

A heat exchanger is a device in which heat is transferred

from one flowing fluid to another. Shell and Tube heat

Figure 8 – Flow Distribution in Heat Exchangers

Page 11 of 25

Page 12

Figure 9 - Flow Distribution in Heat Exchangers

N 1 Heating Fluid In

N 2 Heating Fluid Out

N 3 Cold Fluid In

N 4 Cold Fluid Out

MATERIALS

Heat exchangers are manufactured according to following

table.

Standard Materials

Shell ASTM 316L

Tubes ASTM 316L

Nozzle ASTM 316L

Connection flanges Stainless Steel/ Carbon Steel

with Stainless Steel Lining

OPERATING PARAMETERS OF HEAT

EXCHANGERS

Standard maximum working parameters of heat

exchangers are as follows:

Design Pressure

Shell 300 psig (2.0 Mpa)

Tube 300 psig (2.0 Mpa)

Design temperature

Shell 422°F (217°C)

Tube 422°F (217°C)

OPERATING PRECAUTIONS

In order to achieve maximum performance from heat

exchanger, following must be strictly followed:

Heat exchangers should be used according to

specification given.

Pressures and temperatures should not exceed limits set

forth in Operating Parameters and Selection of Heat

Exchangers Section.

Initial start up should be done according to Start up

Section.

Heat exchangers should be free of any debris existing in

fluid.

In central heating applications, hot water should not

exceed 140 °F (60 °C). Over this limit, lime will form on

tube walls.

Prevent evaporation of fluid on shell side. Steam or vapor

should only flow through tubes.

Clean heat exchangers according to Cleaning Section.

System should be designed to prevent heat exchanger

from encountering pressure shocks.

Prevent rapid temperature increases in heat exchangers.

This would include installation of expansion tanks and

safety valves into system.

Prevent any fluids from dropping below freezing point.

Figure 10 - Threaded and Flanged (compatible with CL

300) connections

A name plate is placed on shell and includes following

data:

Type of heat exchanger

Serial number

Production year

Maximum working pressure and temperature

ASME stamp of approval

CRN registration number

Manufacturer logo

STORAGE AND TRANSPORTATION

Heat exchangers should be stored in a clean place away

from corrosive environments or weather elements (e.g.

Page 12 of 25

Page 13

rain). During transportation, ensure that they are not

exposed to mechanical damages.

STARTUP

To prepare heat exchanger for operation, it should initially

be:

Mounted properly

Filled with working fluids

Deaerated

All connections checked for leaks

During startup, first open valves, then start pump of

heated medium followed by opening cycle of heating

medium. Valves should be opened gradually in order to

achieve a steady increase in flow and pressure. Pressure

increase/decrease should not exceed 72 psi/min (0.5

Mpa/min).

Figure 11 - Complete Installation Diagram

Figure 12 - Insulation tied with straps

Insulation is mainly used to reduce heat loss, and also

offers operator some degree of personal protection from

hot surface of unit. Insulation should be designed for

temperatures up to 130°C.

CLEANING

Heat exchangers are cleansed by flushing units with

fluids which do not react with stainless steel.

Dirt deposit in heat exchanger will result in an increase in

pressure drop, lower temperature difference in heated

medium or a higher exit temperature on heating medium

side. Flushing can be done without removal of heat

exchanger from system.

Following fluids are prohibited for use as a flushing agent:

Hydrochloric acid up to 0.1% concentration

Solutions which contain MCI

Chlorides (MgCl2 NaCl between 0.01 – 1%, CuCl up to

1%, CaCl

Any fluid which should deposit alkaline residue or

phosphorous

Cleaning solutions are easily accessible at businesses

carrying chemical cleaning agents for heat exchangers or

tubing and piping applications. As a guideline to

purchasing cleaning solutions, check for following

products data:

- Compatibility with stainless steel

from 5% to saturation, KCL, MgCl2)

2

Page 13 of 25

Page 14

- Accepted for use in food processing industries (if

applicable)

- Removes scale, slag, tarnishes, and hard water

deposits

- Easily rinsed out of system

- No objectionable or corrosive fumes

CERTIFICATION

Heat exchangers are designed and fabricated in accordance

with ASME Code Sec. VIII, Div.1 for symbols “U” and

“UM”. Heat exchangers are CSA approved and have

obtained CRN in Canadian provinces.

Copies of above certificates are available upon request.

1. GENERAL OPERATION OF

RELIEF VALVE

PRESSURE RELIEF VALVE IS NATIONAL

BOARD CERTIFIED. TEMPERATURE

STEAM RATED

ANS Z21.22 RELIEF VALVES CONFORMS

TO H.U.D./F.H.A. REQUIREMENTS.

Discharge from relief valve shall be conducted to a

suitable place for disposal when relief occurs by

installation of a drain line to any open drain. Make sure

water in drain cannot freeze and cause a stop-up. Relief

line must be such that relief valve outlet and drain line will

drain dry.

Do not use reduced couplings or restrictions to install drain

line to valve discharge.

This valve protects a water system from over-pressure. It

will automatically shut off after providing such protection.

If valve fails to shut off, check for excessive pressure

and/or heat input control operation.

This product contains a chemical known to the State

of California to cause cancer, birth defects or other

WARNING!

reproductive harm.

REPLACEMENT PARTS

A. RECIRCULATION PUMP

(ref Figure 6)

Pump replacement parts are :

• Impeller

• Impeller seal

• Body Gasket

Do not attempt to replace motor bearings, replace the

motor as a whole unit. Refer to manufactures specific IOM

for further details.

D. BLEND VALVE

Service Parts For Model BO

Ref

No

3 9585L001 Seat, Bolted-In

4 1182 Sleeve

5 11132L050 Capscrews

6 11133 Lockwasher

7 1183 Element O-Ring, Buna-N

8 1096X(TEMP) Element Assembly

9 761 O-Ring

Blend Valve temperature ranges are:

150 degrees F for the first valve

130S degrees F (S = Special 120 degree F unit)

Service Kit No. 9167X(Temp.) Standard Element

Ref

No

3 1 Element 1125X(Temp.)

4 1 O-Ring 1205

5 1 O-Ring 277L145

6 1 O-Ring 11080L001

7 1 O-Ring 11079L001

No adjustments are ever required on thermostatic valves.

Once installed a thermostatic valve will provide years of

trouble-free service. It is entirely self-contained, and there

are no external bulbs or lines to become damaged or

broken. There are no packing glands to tighten and no

parts to oil. Temperature is permanently set at factory and

requires no further adjustment.

Operating temperature can be changed only by changing

temperature element assemblies which is easily

accomplished by unbolting housing. Element assemblies

are all interchangeable within each lettered valve series.

Larger valves in “B” and “H” series contain multiple

element assemblies in one housing. This means that a

temperature element assembly will fit any size

thermostatic valve housing in that series.

Part No Description

Qty Description Part No.

Page 14 of 25

Page 15

are to be sent to sales@lesliecontrols.com

MAINTENANCE

Warranty will be void if heat exchanger tubes are not

flushed every six months. Reports on this

maintenance by Heater Serial number must be

provided to Leslie after each flushing. These reports

HEAT EXCHANGERS

(Refer to manufactures specific IOM)

(ref. Valve listing)

Shut down steam and supply water to heat exchanger by

turning off valves on the side to be flushed (59), and two

(41).

Open plugs (19) on the ends of the water pipes to the heat

exchanger.

Flush the heat exchanger per manufactures instructions.

Replace the plugs (19) after Teflon taping the threads to

insure no leakage.

Re-turn all valves to there run position.

Do not torque the U-bolts nuts more than 10 ft-lbs.

Over tightening of the nuts can cause the U-bolts to

collapse the shell of the heat exchanger.

BLEND VALVES

(Refer to manufactures specific IOM)

WARNING!

CAUTION!

Figure 13 - MODEL B

Service Parts For Model BO

Ref

No

3 9585L001 Seat, Bolted-In

4 1182 Sleeve

5 11132L050 Capscrew

6 11133 Lockwasher

7 1183 Element O-Ring, Buna-N

8 1096X(TEMP) Element Assembly

9 761 O-Ring

Service Kit No. 9167X(Temp.) Standard Element

Ref

No

3 1 Element 1125X(A83723)

4 1 O-Ring 1205

5 1 O-Ring 277L145

6 1 O-Ring 11080L001

7 1 O-Ring 11079L001

An element may be quickly checked by immersing it in an

agitated bath of water. Never use oil for checking the

element. Element number and nominal temperature setting

(last three numbers of part number) are stamped on flange

of element. At 10o F to 13

bypass port B should be closed.

Order new element by Part No. and Nominal Temperature

Setting, which is found on element flange. If these are not

known, send complete Model No. and Serial No. on Valve

Nameplate.

Part No Description

Figure 14 - MODEL C

Qty Description Part No.

o

F above nominal setting ,

Page 15 of 25

Page 16

SOLENOID VALVES

(Ref ASCO Form number V6297R2)

See ASCO solenoid instruction set for Installation,

Operation and Maintenance Instructions.

RECIRCULATION PUMPS

(Ref Bell and Gossett manual P81884 Rev C)

Be certain electrical power is not present at motor leads

before continuing. Failure to follow these instructions

could result in serious personal injury or death

Pressure may be present in the pump body. Loosening

flange bolts and shifting pump assembly slightly to

allow pressurized water to escape can relieve this

pressure. Failure to follow these instructions could

result in serious personal injury or death

1. Reference instructions for repairing mechanical

seal.

2. Close valves on the suction and discharge sides of

pump.

3. Loosen conduit box cover screw and remove

cover.

4. Disconnect electrical supply lines.

5. Remove flange bolts and nuts and then remove

pump from piping.

6. Loosen four cap screws that hold motor housing

to pump body. Remove these screws and remove

the housing from pump body.

7. Place pump on a flat work surface and insert a

screwdriver into one of endplate ventilation slots

until it engages a rotor cooling fin. While holding

rotor with screwdriver, turn impeller clockwise.

Note that impeller is molded around a metal hub

with a left hand thread. Remove impeller from

shaft.

8. Remove seal assembly from shaft by sliding it off

shaft sleeve.

9. Clean seal seat with a clean rag and inspect for

grooving or cracks. If it shows no grooving or

cracks, it may be cleaned and reused.

10. If seal seat is to be replaced, face plate must be

removed from motor housing. Remove it by

gently prying it away from housing.

11. Remove seal seat and cup. Lubricate cup with

soapy water and install new parts in face plate

WARNING!

WARNING!

recess. Reposition face plate on motor housing.

Gently tap face plate evenly around its diameter

to drive it into recess provided in motor housing.

12. Clean shaft and sleeve before installing new seal.

13. Slide new carbon seal head onto shaft sleeve until

it contacts seal seat. Slide new “O-Ring” and

back-up ring along shaft sleeve until they fit

inside counter bore in seal head. Place seal spring

between back-up ring and seal cage while

positioning seal cage flush with end of sleeve.

Place small end of spring against back-up ring.

Three driving legs of seal cage should engage

three slots on seal head. While holding rotor

assembly with screwdriver, thread impeller onto

shaft in a counter clockwise direction. Tighten

impeller with light hand pressure. Take care to

avoid bending a rotor cooling fin or damaging

shaft sleeve.

14. Clean recess in pump body and install a new body

gasket.

15. Install pump in body and secure with four

capscrews. Apply torque evenly in a criss cross

pattern in 40 in-lb to a torque of 80 in-lb.

Page 16 of 25

Page 17

Valve Listing and Functions (refer to assembly drawing for particular size heater)

Item No. ON OFF

15 Flow diverter, primary flow to Pump 1, no flow to

pump 2

16 Emergency pressure relief, flow to drain No flow to drain

37 Hand Op Ball, re-circulation water to Cold inlet

water

39 Gain Adjuster Valves Adjust cold water flow to insure constant

41 Hand Op. Ball, Supply cold water to blend valve Shut off cold water to blend valve

42 Blend Valve, 150 F, Blending Water No blending of water

43 Blend Valve, 130 F, Blending Water No blending of water

46 Check Valve, no back flow of hot water from heat

exchanger

47 Solenoid Valve, Hot water to second blend valve No hot water to second blend valve

59 Gate valve, Supply steam Shut off steam supply

68 Hand Op Ball, Bypass condensate cooler Flow through condensate cooler

76 Gate valve, flow of condensate to drain No flow of condensate to drain

78 Needle valve, Steam to gauge and pressure sensor Shut of steam for maintenance of gauge

101 Condensate Diverter, Condensate through Cooler Condensate to drain and bypass

No flow to pump 1, flow to pump 2

No re-circulation water to Cold inlet

water

temperature over the range of flow.

N/A

Condensate Cooler in fail mode.

TROUBLESHOOTING

Condition Possible Cause Fix

No Hot water

System

Tripped

No Steam/Low Steam Adjust steam regulator.

Blocked tubes in heat exchanger Flush Heat exchanger.

Drain valves from steam traps are shut Open drain valves.

Condensate drain line is blocked or valves are turned off Clear line and turn on valves.

Solenoid is tripped Turn on Manual switches “H-1” and

Blend valve element defective Test blend valve element and replace if

Over temperature condition was reached and Thermo Switches

are still engaged.

Shut of the Gain adjusters Cold water main from street is shut off.

Steam pressure above 15 psi Steam adjust steam pressure or fix

Steam Traps broken and steam is being sent to the condensate

cooler

Blend valve element defective. Test blend valve element and replace if

H-2”

necessary.

Find out why over temperature

happened and let Thermo Switches

reset.

Reset Gain Valves (39)

steam regulator.

Fix Steam traps.

necessary.

Page 17 of 25

Page 18

Water

temperature

fluctuates or is

colder than

required

Water

temperature

can not be

maintained at

120 F

Pump 1 or

Pump 2 Light

is lit and No

Flow light is

on. Can see

Pump is

turning and

water is recirculating.

Blockage in condensate line causing condensate to back up into

heat exchangers.

Gain adjusters not adjusted correctly

Solenoid valves were back pressured and solenoid plug is

blocking flow.

Water was drained from system and tubing to differential

pressure switch was not bled of air.

New differential pressure switch installed. Run pump and then loosen inlet

UNIT SEPARATION FOR

INSTALLATION

To get unit into building may require separating the unit

into two parts. The following instructions are to be used as

a guide to separating the unit.

1. Remove steam header from the unit and place aside

protecting the flange face from damage.

Check the temperature of heat

exchanger outside casing. If top is hot

and bottom is warm or cold, shut unit

off and check draining of condensate.

Shut down unit, disassemble and

inspect solenoid units.

Run pump and then loosen inlet

compression fitting and bleed line until

all air is out of line. Do same with

outlet compression fitting.

compression fitting and bleed line until

all air is out of line. Do same with

outlet compression fitting. If light is

still on then adjust pressure switch

according to manufactures instructions.

2. Remove Aquastats by removing cover and loosening

clamp screw that holds thermostat to well.

Note: Thermostat can be hung off of unit but be

careful to not disturb heat conductive compound on

thermostat bulb.

Page 18 of 25

3. Undo copper water supply unions.

Page 19

5. Undo steam side unions and remove condensate drain

line between steam traps and condensate cooler.

4. Remove output water copper tubing section and put it

aside.

6. Remove bottom rail bolts from frame.

Page 19 of 25

Page 20

7. Remove center rail bolts from frame. Frame is ready to

be split in two sections.

Never lift or push in any place but frame of unit.

Damage to piping and or components can occur if

CAUTION!

pressure is applied to them.

3. Ensure output hot water connection is tight.

4. Connect emergency relief valve to drain.

UNIT STARTUP AFTER

INSTALLATION

1. Lag the frame to the floor.

2. Insure input cold water connection is tight.

5. Connect steam supply to flange. Check steam pressure

gage and sensor connections.

Page 20 of 25

Page 21

6. Set condensate drain valves such that the condensate

flow passes through cooler.

7. Open up both steam gate valves to full open.

Page 21 of 25

Page 22

8. Open all other valves. Open cold water supply valves

to heat exchangers before opening valves to second

blend valves.

(THESE VAVLES FIRST)

(THESE VAVLES LAST)

Page 22 of 25

Page 23

9. Set three way diverting valve for pump to be used.

10. Plug in the electronic control box and make sure the

correct re-circulation pump is on.

11. Loosen connection to differential pressure switch and

make sure the lines are free of air and filled with

water.

Page 23 of 25

Page 24

12. Set the front and back aquastat thermal switches for

proper temperature setting.

13. Supply proper steam pressure to the unit.

14. Wait until the system stabilizes and then run procedure

to set

GAIN VALVE SETTING PROCEDURE

1. Ensure all connections are made and unit is

running at specified maximum flow.

2. Turn off supply of water to one side. Half of

specified maximum flow is now being

delivered.

3. Check outlet water temperature and ensure it is

120 degrees F.

4. If warmer then turn gain valve handle

counterclockwise for ¼ turn.

5. Recheck water temperature and repeat until

reaching desired temperature.

6. Note: Temperature will not change quickly and

must be left to seek its normal setting.

7. If the water was colder then turn the gain valve

handle clockwise for ¼ turn.

8. Recheck water temperature and repeat until

reaching desired temperature.

9. Turn on the supply of water to side turned off.

Wait for the system to stabilize.

10. Repeat step 2 through 9 for the second side.

Page 24 of 25

Page 25

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products.

Assistance shall be afforded with selection of materials based on technical information supplied to Leslie Controls

Inc.; however, system designer and user retain final responsibility. Designer should consider applicable Codes,

material compatibility, product ratings and application details in selection and application. Improper selection,

application or use of products described herein can cause personal injury or property damage. If designer or user

intends to use product for an application or use other than originally specified, he must reconfirm tat selection is

suitable for new operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

Page 25 of 25

Loading...

Loading...