Page 1

Installation, Operating

and Maintenance

Instructions

90/6.5.0

Rev. 1

UNFIRED STEAM GENERATOR

LVSG SERIES

TABLE OF CONTENTS

INTRODUCTION ...................................................................................................................................................................................2

CONTACT INFORMATION.................................................................................................................................................................2

GENERAL NOTES AND WARNINGS ................................................................................................................................................2

C

ONNECTING ELECTRIC POWER SOURCE

CONTROLLER – OVERVIEW.............................................................................................................................................................3

CONTRACTOR WIRING......................................................................................................................................................................4

RATINGS.................................................................................................................................................................................................5

CONTROLLER SCREENS....................................................................................................................................................................5

SETTING CONTROLLER ....................................................................................................................................................................5

SCREEN LISTING..................................................................................................................................................................................5

INSTRUCTIONS FOR SETTING EACH SCREEN ...........................................................................................................................6

TERMINAL BOARD LAYOUT............................................................................................................................................................9

TROUBLE SHOOTING .......................................................................................................................................................................11

................................................................................................................................................3

Page 2

INTRODUCTION

This Installation, Operation, and Maintenance Manual is

intended to be as complete and up to date as possible. It covers

installation, operation, and maintenance procedures for Leslie

Controls, Inc. Unfired Steam Generator and 2001 SSCM

control module. Leslie reserves right to update this manual

and other product information concerning installation,

operation, and/or maintenance, at any time and without

obligation to notify product owners of such changes.

Leslie is not responsible for inaccuracies in specifications,

procedures and/or content of other product literature, supplied

by manufacturers of components used in Leslie Controls, Inc.

Unfired Steam Generator and 2001 SSCM control module

Leslie strives to use only highest quality components;

however, LESLIE has no direct control over their manufacture, or their consistent quality.

Leslie is not responsible for injury to personnel or product

damage due to improper installation, operation, and/or

maintenance Leslie Controls, Inc. Unfired Steam Generator

and 2001 SSCM control module. All installation, operation,

and maintenance procedures should only be performed by

trained/certified personnel. All personnel performing these

procedures should completely and carefully read and

understand all supplied materials before attempting

procedures. All personnel should pay strict attention to all

Notes, Cautions, and Warnings that appear within procedures

detailed in this manual.

Leslie welcomes user input as to suggestions for product or

manual improvement.

Contact Information

For information concerning warranties, or for questions

pertaining to installation,

operation or maintenance of LESLIE products, contact:

LESLIE CONTROLS INC.

12501 Telecom Drive

Tampa, FL 33637

USA Phone: (813) 978-1000

USA Fax: (813) 978-0984

www.LESLIECONTROLS.com

To order replacement parts, contact LESLIE CONTROLS at

address listed above, or call toll free:

USA/Canada/Caribbean Phone: (800) 323-8366

Note: Please include model and serial number of unit for

which parts are being ordered. If ordering by phone, please

have this information readily available.

General Notes and Warnings

Notes:

• This manual is intended to cover installation, operation,

and maintenance procedures for Leslie Controls, Inc.

Unfired Steam Generator and 2001 SSCM control

module.

• If questions are not answered by this manual, or if

specific installation, operation, and/or maintenance

procedures are not clearly understood, contact Leslie

Controls, Inc. for clarification before proceeding.

• All installation, operation, and maintenance procedures

should be performed only by experienced, trained and

certified personnel. Personnel should be trained in and

familiar with correct piping and electrical procedures

and methods, and should be experienced in working with

hot/boiler water systems and steam systems.

• Leslie Controls, Inc. Unfired Steam Generator and 2001

SSCM control module and other electronic controls are

designed for indoor use only, unless otherwise required

by design specifications.

• If unit is damaged during installation, operation, or

maintenance, complete following steps:

1. Turn off and lock out electric power supply to unit in

an approved manner.

2. Turn off all incoming steam/hot water valves.

3. Contact in-house maintenance personnel or Leslie

Controls, Inc. for instructions.

Note: Throughout this manual, warnings will be denoted

by BOXES

- 2 -

Page 3

Warnings

As with any piece of equipment that utilizes hot/boiler

water or steam and electricity, potential exists for

severe personal injury if proper installation,

operation, and maintenance procedures are not

followed. Listed on following pages are specific

warnings pertaining to LESLIE Electronic Controls.

All warnings should be carefully read and

understood. All precautions contained in warnings

should be carefully followed to reduce chance of

injury.

All documentation for each major component has been

included with unit. It is strongly recommended that each

document be reviewed before attempting any installation,

operation, or maintenance procedures.

documentation for each major component may also contain

warnings and cautions identified by manufacturer of each

component. These warnings and cautions may be specific for

particular component, and therefore not covered in this general

Installation, Operation, and Maintenance Manual. They should

also be carefully reviewed before attempting installation,

operation, or maintenance procedures.

combination of electricity and water can pose a very

dangerous situation. Assure that all power has been

shut off/disconnected and locked out in an

appropriate manner, before attempting any installation

or maintenance procedures.

!

WARNING!

WARNING!

WARNING!

Areas of potential danger:

1. All electric power leads and connections;

Hot/boiler water and steam present a situation that can

be very dangerous due to fact it is under pressure and

at very high temperatures. To avoid possible injury or

death, use common sense and follow all accepted and

recommended procedures when performing

installation, operation, and maintenance procedures.

WARNING!

Connecting Electric Power Source

All installation procedures involving electric power

connection should only be performed by trained,

certified electricians.

WARNING!

WARNING!

Hot/boiler water and steam present a situation that can

be very dangerous because of high temperatures and

pressures. Use common sense and follow all accepted

and recommended procedures when performing

installation, operation, and maintenance procedures to

avoid possible injury or death.

combination of electricity and water can pose a very

dangerous situation. Assure that all power has been

shut off/disconnected and locked out in an approved

manner, before attempting any installation or

maintenance procedures.

WARNING!

2. All hot/boiler water lines, steam lines, joints,

valves, and relief valves; and

3. All joints at valve, gauges, etc.

WARNING!

Before attempting any installation, operation, or

maintenance procedures pertaining to unit.

1. Assure that electric power supply has been turned

off and locked out in an approved manner;

LESLIE Steam Generators have been wired during assembly.

Connecting electric power supply to unit consists of

connecting correct voltage, phase, and amperage power leads

to terminal strip or circuit breaker. Exact voltage, phase, and amperage requirements for unit can be determined from rating

plate affixed to jacket of unit, or from Submittal Sheet and

Wiring Diagrams supplied with unit

Controller – Overview

LESLIE SSCM 2001 control module is a solid state controller

designed to control limit, water feed, alarm, and timed

blowdown functions for LESLIE unfired steam generators.

- 3 -

Page 4

Solid State Control Module is supplied with a LED backlit

LCD display. LED pilot lights are supplied to indicate OnOff, high pressure, low pressure, low water, high water, water

feed, and blow down. Solid state control module allows

owner to set pressure limits on display screen. Solid state

control module has a flashing red alarm light and alarm horn

with built in alarm silence relay. Solid state control module is

supplied with dry contact closure outputs to indicate to

building automation control ( BAC) Power on, Low water,

High pressure, Water feed, High water, Low pressure and

Blow down occurring. Control module allows BAC to turn

Unfired Steam Generator on or off through a remote relay

suitable for 24 VAc, 1 amp. Control module allows BAC to

remotely monitor operating pressure. Control module is

supplied with an on-off switch and is mounted in a NEMA 4

enclosure.

Built in remote start stop: This feature allows Unfired Steam

Generator to be started or stopped from a remote location.

Typically this would be accomplished from Building

Automation Control (BAC) . Requires a dry contact suitable

for 24 VAc and 1 amp. Terminals P2 on panel are where BAC

on-off is wired.

Built in On-Off Switch: Allows for local on-off and is

convenient for service in unlikely event service is required.

This switch is mounted in side of panel.

Built in Alarm Horn: alarm horn will sound and fault LED

will light (blinking red) on low water or high pressure If

either high water or low pressure options are selected alarm

horn will also sound and alarm light will light (blinking red)

in event of high water or low pressure. 2001 Solid State

Control Module also features an alarm silence relay which

will silence alarm but not fault light when generator is being

serviced. When fault is cleared both alarm and fault light will

automatically reset.

Built in timer for timed blow down: If timed blowdown option

is selected time and duration of blow down can be easily

selected in Leslie 2001 Solid State Control Module.

Built in relay for water feed: Leslie 2001 Solid State Control

Module operates in conjunction with level control to signal

feed water solenoid or feed water pump to maintain correct

water level in unfired steam generator.

Built in operating pressure readout: Leslie 2001 Solid State

Control Module features an easy to read LED digital readout

of operating pressure.

Built in high pressure cut off and alarm: In event of high

pressure Leslie 2001 Solid State Control Module will close

source steam or HTHW supply valve and sound an alarm.

Power ON

Low water

High water

Water feed

High pressure

Low pressure

Blow down operating

Optional input / output

Alarm

Operating pressure (via a 0-10 Vdc

signal)

Built in low water cut off and alarm: In event of low water

Leslie 2001 Solid State Control Module will close source

steam or HTHW supply valve and sound an alarm.

Built in low pressure alarm: If activated, Leslie 2001 Solid

State Control Module will sound an alarm if a low pressure

condition occurs.

Built in optional input / output.

Built in LED display of functions and alarms: Leslie 2001

Solid State Control Module is designed for user to tell at a

glance how system is operating. Built in LED displays make

troubleshooting simple.

Function LED Indicator 1 LED Indicator 2

Power ON Green = Power

On

Low water Green = Water

level not low

High

pressure

Water feed Green = Water

High water Green = Water

Low

pressure

Blow down

operating

Optional

input/output

Built in contacts to notify BAC (Building Automation

Control) of functions and alarms: This control allows for

simple and reliable interface from a remote location. BAC can

also start and stop unfired steam generator.

Green = Normal

pressure

feeding

level normal

Green = Pressure

not low

Green=Blowdown

occurring

Blank = No power

Red = Low water

Red = High

pressure

Blank = Water not

called for

Red = High water

Red = Low

pressure

Blank = No

Blowdown

Contractor Wiring

All Power Connections should be performed by a trained,

certified electrician. Be sure factory supplied on-off

switch is in OFF position before connecting to building

power.

- 4 -

Page 5

Field wiring: Installer must run feed wires to terminals on

120V

AC

24V

AC

7

8

11

12

6

5

2

1

220V

AC

24V

AC

7

8

11

12

6

5

2

1

panel mounted on-off disconnect switch and green

ground wire to ground lug. Units are normally wired for 120

volt single phase input.

Next Select

WARNING!

Before drilling hole in panel for conduit connection

of power carefully open door and verify that nothing

in panel will be interfered with. BE CAREFUL not to

get any drill shavings or metal slug on board or

transformer or disconnect switch.

Panel is normally factory shipped for 120 Volt/ 1 phase/60/50

Hz. If so desired 220/1/50 or 60 Hz power can be used. To

convert to 220 volt input it is necessary to reconfigure 24 volt

output transformer. Below is wiring diagram for 120 volt and

220 volt input.

Before attempting to rewire transformer be sure power

coming to unit is turned off and locked out in an

approved manor

CAUTION!

Ratings

Input: selectable 120/220 VAC – 50/60 Hz @120 Vac min 90

volt max 130 volt

Output Contacts: 1 amp at 24 Vac

Building Automation outputs: Dry contacts, NO/NC .5 amp

maximum, non inductive

Display: LED display with resolution of

.3 % of scale

Available pressure ranges: 0-30 PSI, 30 – 150 PSI in 10 PSI

increments

Operating ambient temperature: Min 32 Deg F max 140 deg F

Operating Humidity: 5% to 95% relative humidity (RH) non

condensing

Alarm approximately 103 db.

NEMA 4 enclosure

LESLIE 2001 SCCM is a self contained board and can not be

field repaired. For a replacement board contact LESLIE

Corporation at address shown on page one of this manual.

Controller Screens

There are two tactile keys on front of panel. Left key, labeled

NEXT, is pushed to select desired function. Right key,

labeled SELECT, is pushed to access desired screen. Both

function and setting are read on LED backlit LCD display.

Pushing left key will display, in sequence, following screens

Screen 1 (Home)

MODE[NORMAL]

Screen 2

B-DOWN DURATION

PRESSURE PSI

[XXX]

Screen 3

Screen 4

B-DOWN INTERVAL HIGH PRESSURE

Screen 5

Screen 6

LOW PRESSURE DIFFERENTIAL

Screen 7

Screen 8

PRESSURE SENSOR LEVEL CONTROL

Screen 9

Screen 10

INITIAL SETTINGS DIAGNOSTICS

Screen 11

Screen 12

ABOUT QUIT

After 60 seconds in any screen ”Home” screen will be

displayed

Setting Controller

There are two tactile keys on front of panel. Left key, labeled

NEXT, is pushed to select desired function. Right key,

labeled SELECT, is pushed to access desired screen. Both

function and setting are read on LED backlit LCD display.

sequence to access and change any screen is as follows:

1. Press “NEXT” (left key) key until desired function

appears on screen.

2. Press “SELECT” (right key) and a setting will appear on

second line of screen.

3. Press “NEXT” key to change setting . Continue pressing

“NEXT” key, which will scroll though available settings

until desired setting is on screen.

4. Press “SELECT” key which will store last screen setting

into memory and return to controller screen to “HOME”

Screen Listing

This is screen which should be displayed during normal

operation:

Screen 1 (Home)

MODE[NORMAL]

PRESSURE PSI

[XXX]

Screen 3

B-DOWN INTERVAL HIGH PRESSURE

Screen 2

B-DOWN DURATION

Screen 4

- 5 -

Page 6

Screen 5

LOW PRESSURE DIFFERENTIAL

Screen 7

PRESSURE SENSOR LEVEL CONTROL

Screen 9

INITIAL SETTINGS DIAGNOSTICS

Screen 11

ABOUT QUIT

Conduit and piping system must be adequately

designed and supported to prevent extraordinary loads

to pressure/ electrical equipment.

There are two tactile keys on front of panel. Left key, labeled

NEXT, is pushed to select desired function. Right key,

labeled SELECT, is pushed to access desired screen. Both

function and setting are read on LED backlit LCD display.

sequence to access and change any screen is as follows:

1. Press “NEXT” (left key) key until desired function

appears on screen.

2. Press “SELECT” (right key) and a setting will appear on

second line of screen.

3. Press “NEXT” key to change setting . Continue pressing

“NEXT” key, which will scroll though available settings

until desired setting is on screen.

4. Press “SELECT” key which will store last screen setting

into memory and return to controller screen to “HOME”

Screen 6

Screen 8

Screen 10

Screen 12

CAUTION!

Instructions for Setting Each

Screen

Home Screen

This is screen which should be displayed during normal

operation:

Screen 1 (Home)

MODE

[NORMAL] PRESSURE PSI [XXX]

MODE can be either NORMAL or ALARM. Mode will read

normal in normal operation and alarm if any alarm condition

occurs. If an alarm condition is cleared mode will switch back

to normal reading.

Pressure psi: This is pressure of generated steam.

Timed Blow down

If timed blow down is a option which was purchased duration

and interval of blow down can be selected. Duration is length

of time blow down occurs (in seconds) and interval is number

of hours between blow downs.

To set duration of blow down:

1. Press NEXT key once and following screen will appear.

Screen 2

BLOW DOWN DURATION

2. Press SELECT key and screen will read.

Screen 3

BLOW DOWN DURATION

SECONDS [XXX]

3. Press NEXT key to scroll through various seconds

settings until desired number of seconds of blow down

appears on screen. seconds will read 0-250 seconds in 10

second increments.

4. Press SELECT key to place setting in memory and to

return to home screen.

NOTE: To disable timed blow down set duration to zero (0)

To set interval:

1. Press NEXT key twice and following screen will

appear:

Screen 3

B_DOWN INTERVAL

2. Press SELECT key and screen will read:

Screen 3

B- DOWN INTERVAL

HOURS [XXX]

3. Press NEXT key to scroll through various hour settings

until desired number of hours between blow downs

appears on screen. Hours will read 0-30 hours in one

hour increments and 40 through 160 hours in 10 hour

increments.

4. Press SELECT key to place setting in memory and

return to home screen.

NOTE: To disable timed blow down set interval to zero (0)

- 6 -

Page 7

High pressure cut out

This is pressure limit which is set 10-20% higher than desired

operating pressure. When high pressure cut out pressure is

reached controller will cause main control valve to close.

Operating pressure is set by control valve controller,

see USG I O & M manual for setting operating

pressure.

1. Press NEXT key three times and following screen will

appear:

Screen 4

HIGH PRESSURE

2. Press SELECT key and screen will read:

Screen 4

HIGH PRESSURE

CUT OFF PSI [XXX]

3. Press NEXT key to scroll through pressure settings until

desired pressure setting appears on screen.. Settings from

0-50 psi are in 1 psi increments and from 50 through 150

psi in 5 psi increments. NOTE: MAXIMUM SETTING

IS LIMITED BY RANGE OF PRESSURE SENSOR.

high pressure setting should be set lower than

relieving pressure ASME relief valve supplied with

generator. Pressure rating of relief valve is labeled on

relief valve body.

4. Press SELECT key to place setting in memory and return

to home screen.

Low pressure alarm

If desired a low pressure alarm can be set. This will alarm if

generated steam pressure falls below low pressure setting.

To set low pressure alarm:

1. Press NEXT key four times and following screen will

appear:

Screen 5

LOW PRESSURE

2. Press SELECT key and screen will read:

Screen 5

LOW PRESSURE

ALARM PSI [XXX]

3. Press NEXT key to scroll through pressure settings

until desired low pressure setting appears on screen..

Settings from 0-50 psi are in 1 psi increments.

Maximum low pressure setting is equal to high pressure

setting set on screen 4.

4. Press SELECT key to place setting in memory and

return to home screen.

NOTE: To disable low pressure alarm set pressure to zero (0).

CAUTION

High and low pressure reset differential

This is pressure differential from set point at which high or

low pressure will reset. Normally it is set at 2 psi but can be

set from 1 to 10 psi. NOTE: There is only one differential

setting and it will be same for both high and low pressure.

To set pressure differential:

1. Press NEXT key five times and following screen will

appear:

Screen 6

DIFFERENTIAL

2. Press SELECT key and screen will read:

Screen 6

DIFFERENTIAL

RESET PSI [XXX]

3. Press NEXT key to scroll through psi settings until

desired psi differential is displayed. Range is 1-10 psi.

4. Press SELECT key to place setting in memory and

return to home screen.

Setting Pressure Sensor Range

pressure sensor supplied with Unfired Steam Generator will

have a specific range, normally 0-30 psi or 0-60 psi or 0-150

psi. It is extremely important that range of pressure

sensor and range listed in solid state controller be same

range. Generator is factory shipped with matched ranges.

Range of sensor will be printed on body of sensor. Range of

controller can be determined and if necessary changed as

follows:

1. Press NEXT key six times and following screen will

appear:

Screen 7

PRESSURE SENSOR

2. Press SELECT key and screen will read:

Screen 7

PRESSURE SENSOR

RANGE PSI [XXX]

3. Verify that psi range shown is equal to range of supplied

sensor. Range shown on screen is upper end of range. 030 will appear as 30 on screen, 0-60 will appear as 60 on

screen , etc. IF AND ONLY IF range of sensor is

different than screen setting should screen setting be

changed. To change screen setting press NEXT key to

scroll through various pressure settings. Available ranges

are 30-150 psi in 10 psi increments. When desired

pressure range appears on screen verify that this matches

pressure of sensor.

4. If both pressures match press SELECT key to place

setting in memory and return to home screen.

- 7 -

Page 8

Level control type

There are two types of level controllers, either one of which

may be supplied with Unfired Steam Generator. First type is a

4 ball float assembly type mounted in a stainless steel body

with a shape as shown below. This is TYPE [0]. second type

is a one ball float type with multiple switches in a cast iron

body with a shape as shown below. This is TYPE [1].

Type 0

Type 1

It is extremely important that type of level control supplied

and type listed in solid state controller be same. Generator

is factory shipped with matched types.

1. Press NEXT key 7 times and following screen will

appear:

Screen 8

LEVEL CONTROL

2. Press SELECT key and screen will read:

Screen 8

LEVEL CONTROL

TYPE [XXX]

3. Verify that type listed on screen and type supplied on

Unfired Steam Generator are same. IF AND ONLY IF

type of level control is different than screen setting should

screen setting be changed. To change screen setting press

NEXT key to scroll through two types

4. If both types match press SELECT key to place setting im

memory and return to home screen.

Initial Settings

Initial settings are for factory use only and can not be

accessed

Diagnostics

Are used for factory testing and are not field useable. To go to

“home” screen press Alarm Silence.

Screen 10

PRESSURE SENSOR

About

This screen lists version of controller. When contacting

factory about controller be sure to mention version.

1. Press NEXT key 10 times and following screen will

appear:

Screen 11

ABOUT

2. Press SELECT key and screen will read:

Screen 11

ABOUT

LESLIE VER [XXX]

3. Be sure to note version when contacting factory.

4. Press SELECT key to return to home screen.

Quit screen

This screen is only used to return to home screen.

1. Press NEXT key eleven times and following screen will

appear:

Screen 12

QUIT

2. Press select key and program will return to home screen.

Note: After 60 seconds in any screen “home” screen will be

displayed

- 8 -

Page 9

I

N

P

U

T

S

B

A

C

O

U

T

P

U

T

S

O

U

T

P

U

T

S

P

O

W

E

R

Conductivity probeI-1

BAC pressure reading (Output)I-2

Pressure sensorI-3

High water floatI-4

Stop water feedI-5

Start water feedI-6

Low level cut-offI-7

Optional inputI-8

UnusedI-9

B-1

B-2

B-3

B-4

B-5

B-6

B-7

B-8

B-9

B-10

Dry contact to BAC for "power on"

Dry contact to BAC for "blow down occuring"

Dry contact to BAC for "low water"

Dry contact to BAC for "water feed"

Dry contact to BAC for "high water"

Dry contact to BAC for "high pressure"

Dry contact to BAC for "low pressure"

Dry contact to BAC for "spare"

Dry contact to BAC for "alarm"

Dry contact to BAC for "optional

0-1

0-2

0-3

0-4

0-5

24V AC output to "feed water"

24V AC output to "high water cut-off"

24V AC output to "steam control valve"

24V AC output to "blow down valve"

24V AC output to "optional"

= Wire numbers

12

11

4

7

8

9

10

3

18

17

P1 P2

24V AC PWR

from transformer

24V AC 1 Amp

for

Remote Control

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

NC

NO

Com

To conductivity probe (yellow) (type 1 only)

Ground (green)

0-10V DC to BAC for pressure reading

Ground

+ output (white)

Common (black)

+ input (red)

14

13

High water float (brown)

Common

Stop water feed float (blue)

Common

Start water float (yellow) or 1 from #157 NC

Common or 2 from #157 NC

Low level cut-off float (red) or 5 from #157 NO

Float common (black) or 6 from #157 NO

Optional input NO

Optional input NO

Unused

16

15

2

1

6

5

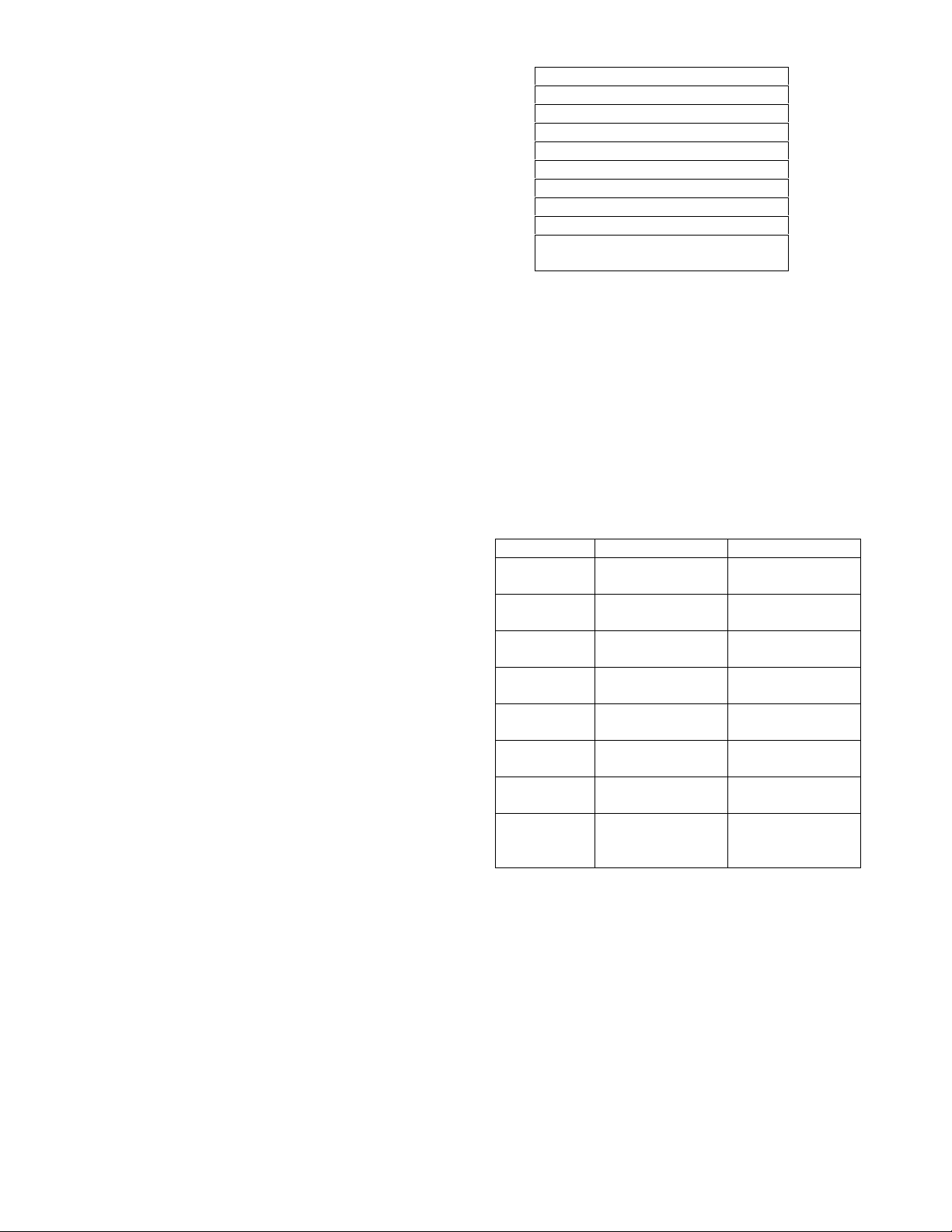

Terminal Board Layout

- 9 -

Page 10

Building Automation Control (BAC)

Interface

LESLIE 2001 SSCM has built in contacts to interface with

building automation control (BAC).

Remote On-Off:

Terminal block P-2 is a three pole block with two outside

poles connected in series with 24 VAC incoming power from

supply transformer. Unfired Steam Generator is shipped with

a jumper installed between terminals 1- 3 of terminal block P-

2. To wire for remote on-off remove this jumper and install a

switch or relay contacts connecting terminals 1 and 3. Do not

connect anything to terminal 2 of P-2.

TERMINALS 1 -3 ARE 24 VAC AND WILL HAVE

A LOAD OF 1 AMP. BE SURE SWITCH OR

RELAY CONNECTED TO THESE TERMINALS IS

RATED FOR A MINIMUM OF 24 VAC 1 AMP.

Built in contacts to notify BAC of functions and alarms:

This control allows for simple and reliable interface with BAC

via dry contact to enable BAC to monitor following functions

from a remote location:

Refer to “Terminal Board Layout” page of this manual for key

to and location of terminal connections to BAC. Note that all

of function relays give either a COM-NO or COM-NC dry

contact output. Rating of dry contacts are 1 amp at 24 VAC or

.5 amp at 120 VAC.

Do not connect any voltage above 120 volts across

BAC contacts on terminal block..

CAUTION

Power ON

Low water

High water

Water feed

High pressure

Low pressure

Blow down operating

Optional input / output

Alarm

CAUTION

Contact closure as follows:

Operating pressure (via a 0-10 VDC signal);

Terminal block I-2 will output a 0-10 VDC signal. This

signal will be scaled to pressure range of supplied pressure

sensor. To scale BAC : Determine pressure range printed on

body of supplied sensor and scale 0-10 VDC output signal to

this range. This range should

also be listed in submittal supplied for generator.

- 10 -

Power ON

Low water

High water

Water feed

High pressure

Low pressure

Blow down

operating

Optional input

Alarm

bottom terminal of 1-2 is connected to an isolated

chassis ground. This may interfere with BAC

system. BAC engineering should determine if BAC

needs isolation for this signal.

No current should be applied to terminals I-2.

COM - NO contact made when

power is on

COM - NO contact made when in

low water condition

COM - NO contact made when

high water occurs

COM - NO contact made when

water is feeding

COM - NO contact made when

high pressure occurs

COM - NO contact made when

low pressure occurs

COM - NO contact made when

blow down occurs

COM - NO contact made when

optional contact close

COM - NO contact made when any

alarm occurs

CAUTION

CAUTION

Page 11

TROUBLE SHOOTING

CONDITION CHECK

Any

Cold water

No water

Low water

High pressure

Low pressure

• Check all alarms and lights on controller

• Electrical power source and all electrical connections.

• Steam source stopped.

• Clogged piping

• No water supply

• Clogged water supply line

• Closed shut off supply valve

• Steam supply pressure

• Leak in steam supply

• Low steam pressure supplied

It is solely responsibility of system designer and user to select products and materials suitable for their specific application

requirements and to ensure proper installation, operation and maintenance of these products. Assistance shall be afforded

with selection of materials based on technical information supplied to Leslie Controls Inc.; however, system designer and user

retain final responsibility. designer should consider applicable Codes, material compatibility, product ratings and application

details in selection and application. Improper selection, application or use of products described herein can cause personal

injury or property damage. If designer or user intends to use product for an application or use other than originally specified,

he must reconfirm tat selection is suitable for new operating conditions. Life expectancy for this product defaults to the

warranty period of the sales contract.

- 11 -

Loading...

Loading...