Page 1

Installation, Operating and

90/4.5.5

Maintenance Instructions

Rev. 0

Constantemp Double Wall Low pressure steam-water Heater

F-340LDW,F-640LDW, F-940LDW and F-1240LDW

Table of Contents

SECTION I...................................................................................................................................................................................2

INSTALLATION....................................................................................................................................................................... 2

OPERATION............................................................................................................................................................................. 2

SECTION II.................................................................................................................................................................................. 2

START-UP PROCEDURE ........................................................................................................................................................ 2

TO DRAIN UNIT FOR PROLONGED SHUT-DOWN ........................................................................................................... 3

SECTION III................................................................................................................................................................................ 7

MAINTENANCE OF SYSTEM COMPONENTS.................................................................................................................... 7

ACTUATOR ASSEMBLY........................................................................................................................................................2

VALVE PLUG ASSEMBLY.....................................................................................................................................................2

CONTROL VALVE ASSEMBLY ............................................................................................................................................ 2

MAINTENANCE OF SYSTEM COMPONENTS HEAT EXCHANGER............................................................................... 2

SECTION IV - TROUBLE SHOOTING GUIDE..................................................................................................................... 2

Recirculating Systems................................................................................................................................................................ 2

Heat Exchanger and Blending Valve ......................................................................................................................................... 3

Table of Figures

FIGURE 1..................................................................................................................................................................................... 4

FIGURE 2..................................................................................................................................................................................... 6

Figure 3 .........................................................................................................................................................................................2

Figure 5 .........................................................................................................................................................................................2

Figure 6 .........................................................................................................................................................................................2

F-340LDW ....................................................................................................................................................................................2

F-640LDW ....................................................................................................................................................................................3

F-940LDW ....................................................................................................................................................................................4

F-1240LDW ..................................................................................................................................................................................5

Page 2

Installation, Operating and

Maintenance Instructions

SECTION I

INSTALLATION

WARNING: When connecting heater to other than

copper pipe use dielectric unions,

(isolators) to prevent possible galvanic

action.

1. HEATER MAY BE WALL OF FLOOR STAND

MOUNTED - Allow recommended clearances over,

under and around heater shown on Piping Layout

Drawing for maintenance purposes; page 7-8.

2. CONNECTION OF STEAM TRAP DISCHARGE

PIPING – The Steam trap must discharge onto an

atmospheric or sub-atmospheric system. The

Condensate should be free flowing with no lift. If

steam supply pressure is greater than 5 psig, then the

MAXIMUM elevation of the trap discharge line above

the Heater is to be no more than 6 feet. If the steam

supply pressure can vary or if the maximum efficiency

is required, the best results under all operating

conditions will be obtained if the trap discharges to an

atmospheric or sub-atmospheric line located below the

level of the trap.

3. A safety valve must be installed in inlet steam piping

if steam pressure to Heater can exceed, 150 psig for

steel exchangers. See Piping Installation Drawing No.

35513C for details.

4. A pressure gauge must be installed in the inlet steam

piping close to Heater.

5. A spring loaded relief valve is incorporated in the

blending valve to relieve excess pressure that can be

caused by thermal expansion of water during a shutoff or no load condition.

6. Install a thermometer in hot water outlet piping close

to Heater.

NOTE: An adequate trap system must be provided to

insure that inlet steam piping to Heater is

properly drained.

OPERATION

1. Normally a heat exchanger having a constant

fixed steam supply pressure and a variable output

flow demand allows water temperature to

increase as flow demand decreased, and decrease

90/4.5.5

Rev. 0

as flow demand increases. This Heater has a

unique adjustable gain feature incorporated in the

Heater control system that automatically

compensates in most part for the wide

temperature variations normally encountered

when an uncontrolled steam supply pressure is

used. Compensation is accomplished by reproportioning the blend ratio of hot and cold

water on an automatic Feedforward basis. The

blending valve incorporated a third window

which is normally closed by a seal plate

assembly. In the event that some dirt or foreign

material enters the blending valve preventing its

movement, the yielding spring will allow the

diaphragm and stem to move upward, opening

the third window. As seal plate uncovers third

window, it allows cold water to flow into the

blended mix, thus preventing water from

becoming overheated.

NOTE: STEAM AND WATER OPERATING

PRESSURES FOR MODELS LOW PRESSURE

CONSTANTEMP HEATERS

• STEAM PRESSURE - 2 to 15 psig.

• WATER PRESSURE AT COLD WATER INLET

OF HEATER - Maximum water pressure MUST

be 5 psig ABOVE maximum steam pressure used

to operate heater.

SECTION II

START-UP PROCEDURE

1. Turn on cold water supply. With no water flow

through heater, slowly open steam stop valve to

heat exchanger making sure traps are functioning

properly to prevent water hammer.

2. Loosen pipe plug in top of heat exchanger casing

and vent all air from casing before re-tightening

pipe plug.

NOTE: BEFORE making any water temperature or

3. Loosen set screw in temperature adjuster (14)

gain control adjustments, please refer to

Capacity and Adjustment Table (Page 3) and

Gain Control Curves Diagram (Page 4) so that

maximum efficiency may be obtained from

Heater by proper use of the information provided

lock nut (13) and move lock nut away from cover

plate (16) (See Fig. 1). Check Capacity and

Page 3

Adjustment Table and after determining Heater

capacity shown under your operating conditions,

adjust flow through Heater for approximately

50% of calculated capacity. Move temperature

adjuster (14) to the right or left until the desired

water temperature is achieved.

4. NOTE: There must be a water flow through

Heater in order to adjust set-point gain. Operate

Heater from minimum to maximum flow and

observe temperature at both of these extremes.

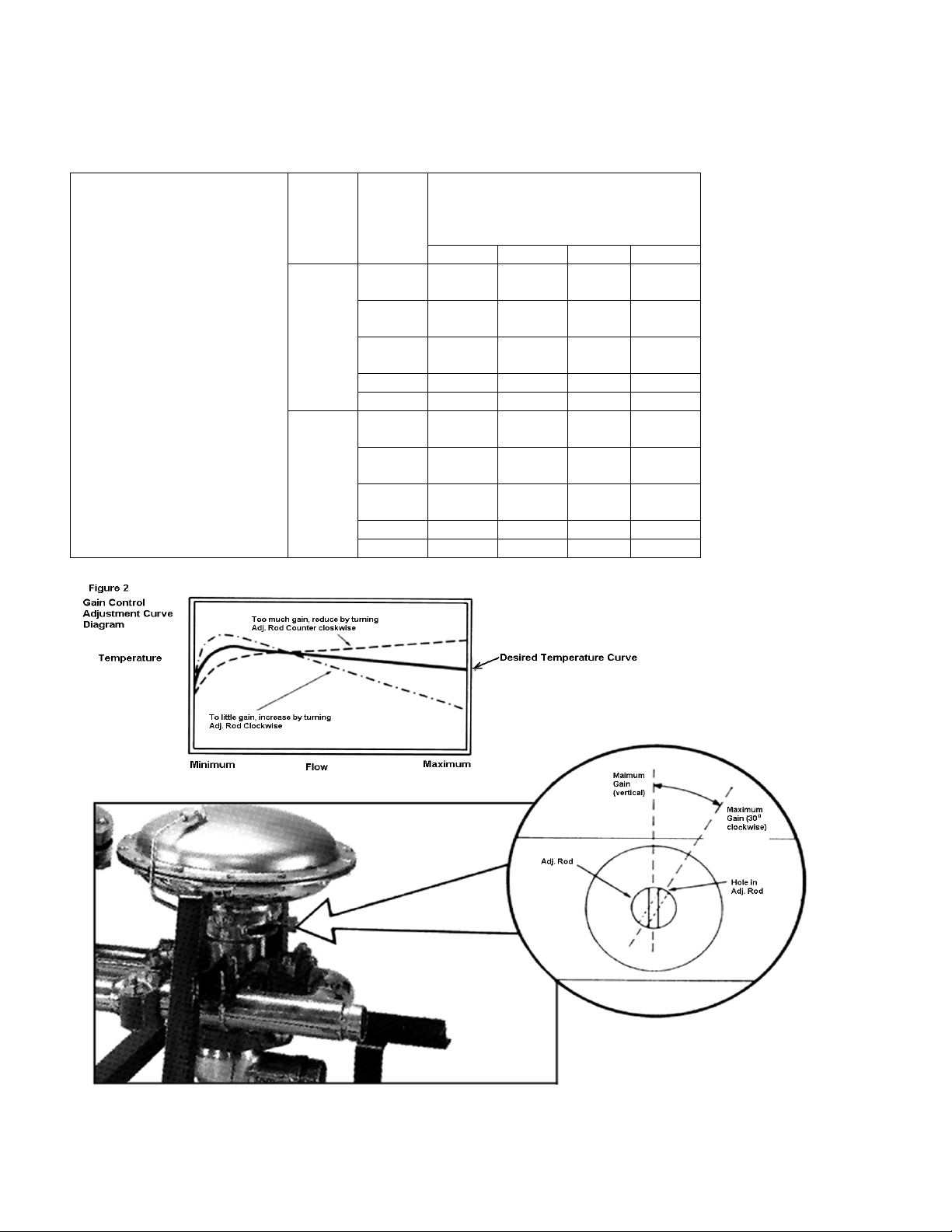

Rotate gain control as shown on Gain Adjustment

Curve Diagram until water temperature variations

are reduced to a minimum. Move gain adjuster in

small increments while adjusting, as total rotary

movement of adjuster is only 30 degrees. (See

Fig. 2)

5. After adjustments are completed, move lock nut

(13) until it is against plate (16) and lock in place

with lock nut set screw.

6. Heater is now adjusted and operating. No other

adjustments should be necessary unless there is a

change in your initial operating conditions. To

SHUT DOWN HEATER close steam stop valve

first, followed by water stop valve.

TO DRAIN UNIT FOR PROLONGED

SHUT-DOWN

(Where drainage is necessary)

1. Turn off steam supply and water supply.

2. Open a vent line in high point of system piping.

3. Remove relief valve to drain water from control

valve.

4. Open drain connections in steam and condensate

lines.

5. Be sure all water is drained from hot water

control valve and system if there is any danger of

freezing.

6. When restarting system, tighten all connections

and close all vents. Follow instructions shown in

Section II - Start-up Procedure to put Heater back

in operation.

Page 4

Installation, Operating and

90/4.5.5

Maintenance Instructions

Rev. 0

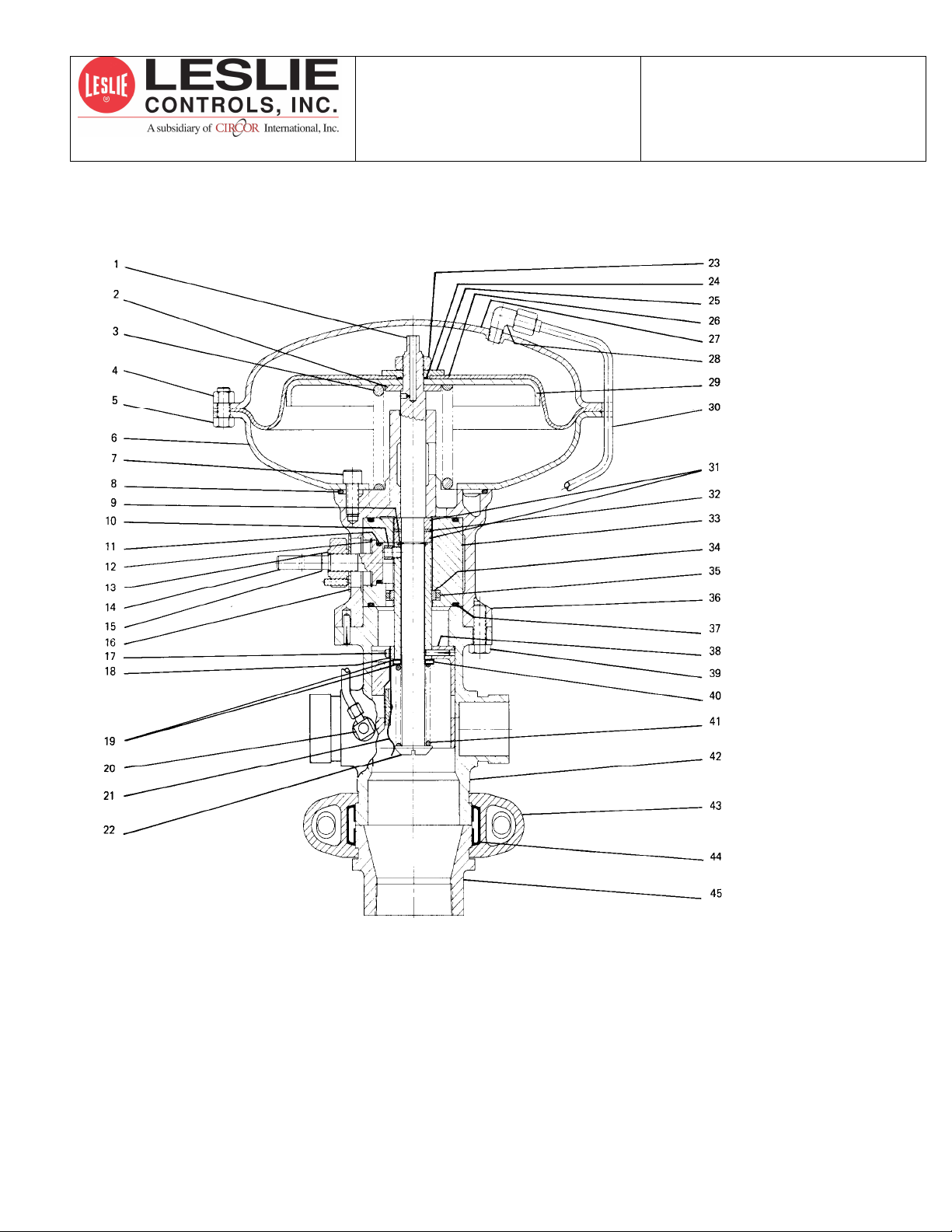

FIGURE 1

Page 5

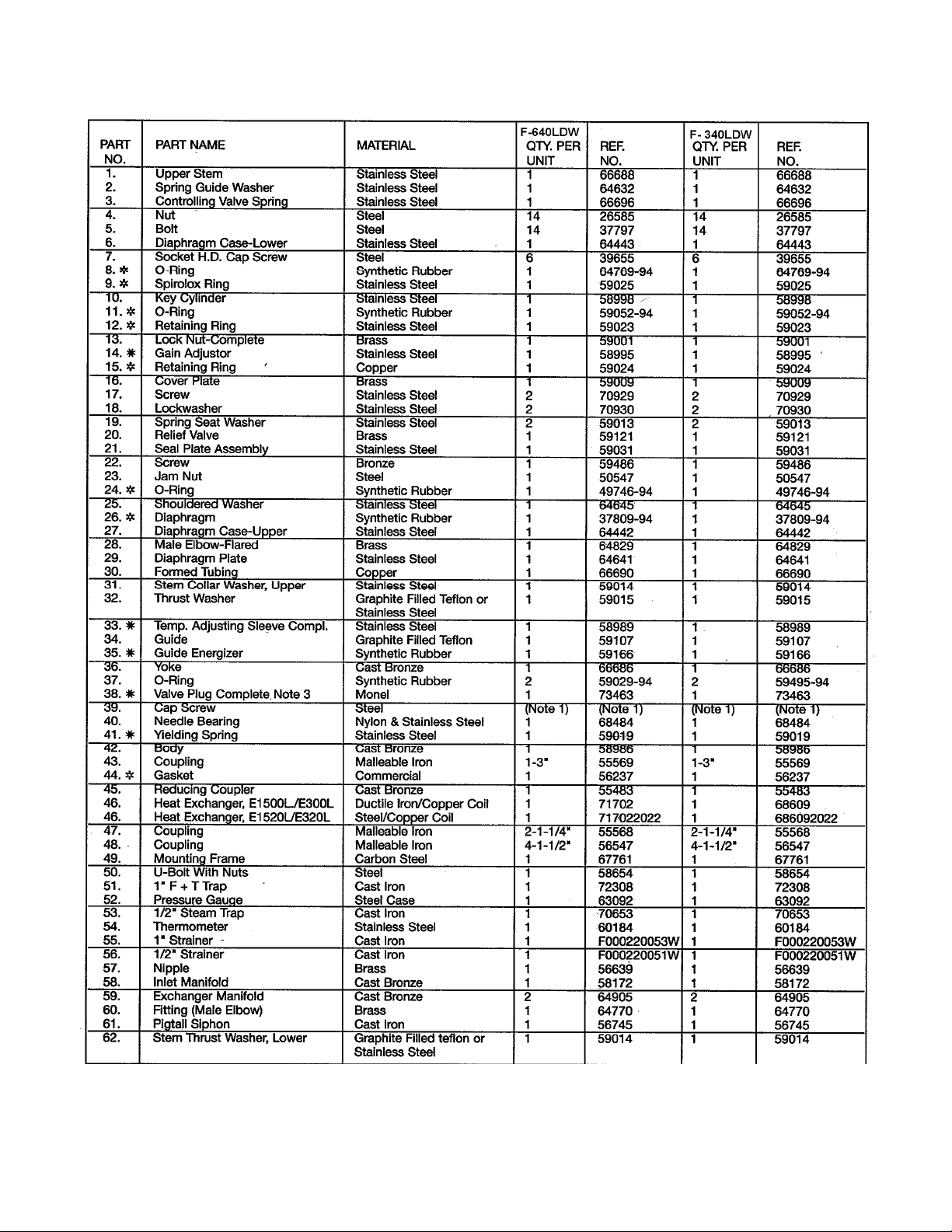

Note 1: Requires four (4) R/N 45840 and two (2) R/N 59478

Note 2: Furnished with Heater Coil but may be ordered separately.

Note 3: Includes seal plate (#21), screws (#17) and lock washers (#18)

Page 6

✡ Recommended spare parts

* These parts should be on hand, plus recommended spare parts, when overhauling equipment.

F-340LDW

Capacity and

Adjustment Table

(Capacity in GPM)

Numbers in brackets are

approximate Gain Adjustor

settings in degrees.

*Maximum water temperature

setting for F-340LDW

is 150 0F

** Steam pressure is measured

at the Heat Exchanger inlet.

Inlet

Water

Temp

0

40

F

Set

Point

0

F

2 5 10 15

120 27

(250)

140 20

(300)

150 17

(300)

160 * * * *

F-340LDW

Steam

Pressure

psig

20 (240) 30

(230)

22

(300)

19

(300)

24

(300)

21

(300)

30

(220)

27

(300)

23

(300)

180 * * * *

60

120 30

(220)

140 23

(250)

150 20

(280)

30

(210)

25

(240)

22

(270)

30

(200)

27

(230)

24

(270)

30

(190)

30

(220)

27

(260)

160 * * * *

180 * * * *

FIGURE 2

Page 7

F-640LDW

Capacity and

Adjustment Table

(Capacity in GPM)

Numbers in brackets are

approximate Gain Adjustor

settings in degrees.

*Maximum water temperature

Inlet

Water

Temp

0

40

F

Set

Point

0

F

120 54

140 46

setting for F-340LDW

is 150 0F

150 40

** Steam pressure is measured

at the Heat Exchanger inlet.

160 34

180 21

120 60

60

140 57

150 49

160 42

180 29

SECTION III

MAINTENANCE OF SYSTEM

COMPONENTS

Hot Water Control Valves Dismantling

1. Close all steam and water inlet and outlet stop

valves. Disconnect tubing from valve body and

upper diaphragm case.

2. Disconnect Victaulic coupling (43) and remove

gasket (44). Remove reducing coupling (45) and

remove tubing (30).

3. Loosen and remove casing bolts (5) and nuts (4).

Lift off upper diaphragm case (27).

4. Remove retaining ring (15) from temperature

adjuster (14) followed by lock nut (13) and cover

plate (16).

5. Take out retaining ring (12) from adjusting sleeve

(33) and take out temperature adjuster (14) and

key cylinder (10).

6. Hold upper stem (1) fast by placing an open end

wrench on the upper stem flats and remove the

jam nut (23) with another wrench.

7. Take out the shouldered washer (25), O-ring (24),

diaphragm (26), diaphragm plate (29), control

valve spring (3), and the spring guide washer (2)

from the lower diaphragm case (6).

CAUTION: Do not allow valve plug assembly to fall

from lower end of the valve body.

F-640LDW

Steam

Pressure

psig

2 5 10 15

60 (140) 60

(150)

(360)

(300)

(300)

(300)

(120)

(150)

(230)

(300)

(300)

54

(250)

49

(300)

41

(300)

23

(300)

60

(110)

59

(140)

54

(210)

49

(280)

33

(300)

(130)

58

(250)

53

(270)

44

(300)

25

(300)

60

(100)

60

(130)

57

(180)

51

(250)

39

(300)

8. Take valve plug assembly from lower opening of

valve body (42).

9. Remove socket head cap screws (7) and take off

lower diaphragm case (6). Take out O-ring (8)

from top of yoke (36).

10. Disconnect Victaulic couplings from valve body

(42) and remove gaskets.

11. Take out cap screws (39) and remove valve body

(42).

12. Push temperature adjusting sleeve (33) out of

yoke (36).

13. Valve plug assembly should not be disassembled

unless parts replacement is necessary due to wear

or damage. For disassembly, see instructions

covering assembly of valve plug and reverse

instruction procedure.

14. All parts should be cleaned with an approved

solvent. Wipe off with a clean cloth. Do Not Use

Abrasives of any kind. Care should be taken in

60

(120)

60

(200)

54

(250)

46

(300)

28

(300)

60

(90)

60

(120)

60

(160)

56

(200)

44

(300)

Page 8

a work bench.

.

handling parts so as not to damage critical

surfaces. Replace any badly worn or damaged

surfaces.

NOTE: If a complete dismantling of control valve is

necessary, it is recommended that valve be

removed from Heater and work performed on

ACTUATOR ASSEMBLY

IMPORTANT: Lubricate all O-rings with Silicon

Grease.

1. Place O-ring (8) in the top of yoke (36). Position

and attach lower diaphragm case (6) to the yoke.

(See Fig. 3) Fasten case to the yoke with cap

screws (7) sequentially from each other until tight

(21 ft-lb).

2. Install O-ring (37) in temperature adjusting sleeve

(33) grooves. Insert guide energizer (35) (rubber)

and valve plug guide (34) (Teflon) into groove in

bore of adjusting sleeve (33). Chamfer on guide

to face out, ends should butt against the two

Groove-pins. (See Fig. 4 and Fig. 6)

3. Insert temperature adjusting sleeve assembly (33)

into yoke (36) with Teflon guide (34) facing out

and hole in side of sleeve lining up with yoke

window.

TOP VIEW SHOWING POSITION OF NOTCHES TO

VALVE BODY, ALSO TUBING AND FITTING TO

COLD WATER INLET

30

28

20

Top View Showing Position of Notches To Valve

Body, Also Tubing and Fitting to Cold Water

Inlet

Figure 3

VALVE PLUG ASSEMBLY

1. Fasten seal plate assembly (21) to valve plug (38)

with screws (17) and lock washers(18)(7 ft-lb).

2. Place a stem collar washer (31), Teflon thrust

washer (32), and a second stem collar washer (31)

in this order over upper stem (1) making sure

parts shoulder on step of upper stem. Insert

Spirolox retaining ring (9) into upper stem (1)

groove.

3. Insert upper stem (1) through small hole in valve

plug (38) so that stem collar (31) will rest on the

smaller end of valve plug.

4. Place bearing assembly, which consists of

washing (19), thrust washer (40) and washer (19)

over upper stem (1) into large bore of valve plug

(38) so that it rests on bottom of bore, and follow

with spring seat washer (19) and yield spring

(41). Hold upper stem (1) at extreme upper end of

stem with a wrench.

5. Tighten screw (22)(10 ft-lb) making sure that

screw shoulders on lower section of upper stem.

Apply a light coating of Silicon Grease to the

surface of the valve plug.

Page 9

Groove

-

pin

Key

Cylinder

CONTROL VALVE ASSEMBLY

9. Install pressure relief valve (20) in boss on side of

body. Make sure correct valve body (42) is used.

Body is identified by a drilled hole on side of

flange on center line above hot water inlet for E300L body. E-600L has no identification hole

drilled in flange.

10. Assemble valve body (42) to yoke (36) with cold

water inlet facing in the same direction as

window in yoke. Secure with cap screws (39).

11. Install O-ring (11) in groove of temperature

adjuster (14), and, temporarily for alignment

purposes, insert adjuster through yoke window.

Keyway must be vertical and notch on outer

diameter of adjuster, and line up with pin in

temperature adjusting sleeve (33) (See Fig. 5) DO

NOT INSTALL RETAINING RING (12).

12. With valve plug key and temperature adjuster

(14) lined up on approximately the same center

Figure 5

Figure 6

line, insert valve plug assembly into valve body

(42) bore. Plug assembly will move freely into

body bore until stem collar hits Teflon guide in

temperature adjusting sleeve (33). Push plug stem

up through guide until plug hits stop in valve

body. If plug does not bottom against valve body

stop, turn temperature adjuster (14) back and forth

while pushing plug upwards until key enters into

keyway in temperature adjuster (14). With plug

against stop in body, the lower end of plug will be

approximately 2-3/16 inches inside the lower face

of body.

IMPORTANT: Plug assembly must be held in place

during step 13.

13. Holding valve plug assembly in place, install the

control valve spring (3). Make sure spring seats

properly on yoke (36) spring seat area. Place

spring guide washer (2) over upper stem and seat.

Install diaphragm plate (29), diaphragm (26), O-

Page 10

ring (24), shouldered washer (25), and jam nut

(23) over upper stem. Tighten jam nut after

positioning diaphragm holes over lower

diaphragm case (6) holes.

14. Install upper case (27) and position over

diaphragm holes. Make sure diaphragm lays flat

on flange and is not pinched or twisted. Fasten

bolts (5) and nuts (4) sequentially across from

each other until tight.

MAINTENANCE OF SYSTEM

COMPONENTS HEAT EXCHANGER

Check tightness of all casing bolts and nuts (80 to 90 ft-lb)

after unit has been in operation for a few hours and again

in twenty-four hours.

DISASSEMBLY

1. Disconnect water piping.

2. Remove all nuts around casing.

3. Remove casing from base plate.

4. Remove manifold nuts and lock rings. Coil

manifold and manifold gaskets.

ASSEMBLY

Clean all parts and replace any damaged parts. Use new

gaskets.

5. Install manifold gaskets between manifold collar

and base plate. Insert coil manifolds into base

plate.

6. Place lock rings over manifold ends with locks

fitted into slots. Install manifold nuts and tighten

securely. (A light coating of thread lubricant

should be used on manifold threads before

assembly of nuts.)

7. Place casing gasket on base plate and follow with

casing. Make sure recesses inside casing line up

with top of manifolds.

8. Install nuts and bolts and tighten evenly to assure

a tight leakproof seal.

9. Reinstall water piping.

10. Vent steam side of heater as described under

Section II - Start-up Procedure.

SECTION IV - TROUBLE SHOOTING

GUIDE

IMPORTANT! Study installation drawings and

CAREFULLY read the details concerning

installation of your Heater and Trapping System.

Following these recommendations will insure that

you obtain the maximum efficiency from your

CONSTANTEMP HEATER.

Recirculating Systems

PROBLEM: EXCESSIVE RISE IN WATER

TEMPERATURE OCCURRING DURING OR AFTER

PROLONGED PERIODS WHEN NO WATER IS BEING

USED FROM HEATER AND A RECIRCULATING

SYSTEM IS PROVIDED.

Too much water being re-circulated through

heater. Reduce water flow through heater by

throttling re-circulation stop valve to allow

enough time for water in piping system to

cool and assume new temperature setting. If

piping system is extensive and contains a

large volume of water, then the readjustment

of temperature can be speeded up by closing

steam supply stop valve to heat exchanger

and by then opening faucets etc. Preferably,

at end of loop until water temperature drops a

few degrees below the heaters adjusted water

temperature. Close off the re-circulation stop

valve and open the steam stop valve to

heater. With re-circulating pump in

operation, open re-circulation stop valve in

small increments while allowing adequate

time for water to be re-circulated throughout

piping before proceeding to next increment

of adjustment. Continue until desired recirculation water temperature is achieved.

1. IF A THREE-WAY THERMOSTATIC VALVE

IS USED, the port connected to the heaters cold

water supply MUST CLOSE to prevent excessive

flow of water back to heater. An excessive flow

will cause water temperature in piping to rise

above adjusted temperature setting of heater. If

port does not close, check for dirt or obstruction

between seating surfaces, or for damaged element

or seals.

2. CHECKING FOR FAULTY ELEMENT,

immerse unit in an agitated bath of hot water.

With a rise in water temperature of from 10 to

12¼F above rated operating range of element, the

port connected to heaters cold water supply pipe

should be replaced.

CHECK OPERATING RANGE OF ELEMENT

MAKING SURE RANGE IS THAT NEEDED

FOR YOUR SYSTEM.

1. NOTE: Operating range of Thermostatic Valve

should normally be from 10 to 150 F lower than

that of Heaters adjusted water operating

temperature. If heater is adjusted for 1400 F hot

water and a 1100 F 3-way valve is used, the re-

Page 11

circulated water will assume a temperature of

1100 F during prolonged periods when no water is

being used from heater. If a 1800 F range unit is

used under the same conditions as above, the recirculated water temperature will rise to 1800 F.

PROBLEM: EXCESSIVE DROP IN WATER

TEMPERATURE OCCURRING DURING OR AFTER

PROLONGED PERIODS WHEN NO WATER IS BEING

USED FROM HEATER AND RE-CIRCULATING

SYSTEM IS PROVIDED.

1. Check for correct inlet steam pressure to heat

exchanger.

2. No water being re-circulated back to heater.

Check re-circulating system for proper operation

of pump, re-circulation valves and controls.

Heat Exchanger and Blending Valve

PROBLEM: DROP IN CONTROLLED WATER

TEMPERATURE OCCURRING BEFORE RATED

CAPACITY (GPM) OF YOUR HEATER IS OBTAINED.

1. Check for correct inlet water operating pressure

and steam pressure to heater before and during

any operational test. LOW PRESSURE Heaters water pressure MUST be at least 5 psig ABOVE

maximum steam pressure used to operate Heater.

The MAXIMUM water pressure for all

Heaters is 150 psig.

NOTE: Seal plate (Part 45) must be tight seating to

prevent cold water from leaking into blended

water. This can cause an uncontrolled drop in

blended water adjusted temperature.

2. Check to make sure all steam strainers are clean

and that all traps are functioning efficiently. A

flooded or partly flooded heat exchanger will

cause little or no heat transfer. Excessive back

pressure in trap discharge piping system, or partly

clogged piping can restrict flow of condensate

from Heater and cause flooding. Dirty or partly

plugged strainer screens can also cause this

problem.

The above system must be operating efficiently

before any check for fouled coils can be made.

3. To check for fouled coils, remove pipe plugs from

blending valve base and cover, and install a gauge

in each connection. Temperature of water from

heat exchanger outlet piping should be

approximately 200 to 2150F when heater is being

operated within its rated capacity. (Temperature

may be checked by using a contact Pyrometer

held against a smooth filed section of exchanger

outlet piping.)

Steam pressures of from 2 to 15 psig

may be checked by using the

CAPACITY AND ADJUSTMENT

TABLE found in your Heater Manual to

determine GPM and water temperature

per your operating conditions.

TEST PROCEDURE: With traps functioning

efficiently, and with flow adjusted for 60% of heater rated

capacity (approx. 5 psig differential across blending valve

diaphragm), the heat exchanger outlet water temperature

drops below 200¼F and continues to drop as flow is

increased to heaters rated capacity in GPM, it indicates

that coils are fouled and should be cleaned or replaced. A

coil cleaning Adaptor Kit is available through your Leslie

Representative, along with instructions for its use. If

quality of water being used for Heater is poor, coils may

foul rapidly indicating that corrective water treatment may

be necessary.

PROBLEM: INSUFFICIENT STEAM TO HEAT

EXCHANGER.

1. See Paragraphs 1 and 2 above of trouble shooting

guide.

2. Check steam reducing valve operation, if one is

used with Heater.

3. PROBLEM: EXCESSIVE STEAM PRESSURE

TO HEAT EXCHANGER.

3. Check steam reducing valve if one is used or

steam source supplying heater.

PROBLEM: EXCESSIVE RISE IN WATER

TEMPERATURE ABOVE HEATERS

SETPOINT OCCURRING AT LOW FLOWS.

1. The above problem may occur if Heater

Controlled Temperature is overset due to:

a. fouled coils

b. drop in inlet water supply pressure

c. adjustment of controlled water

temperature while exceeding Heaters

rated capacity in GPM.

See Paragraphs 1 and 2 of the second problem for

further information.

PROBLEM: EXCESSIVE DROP IN WATER

TEMPERATURE BELOW HEATERS

ADJUSTED SETPOINT OCCURRING

DURING LOW FLOW.

1. See Paragraph 1 of Problem 2 above.

2. Inefficient trap operation or increase in trap

discharge drain piping back-pressure. See

Paragraph 2 of Problem 3.

3. Too little gain. Readjust gain setting as shown in

Paragraph 2 of Problem 3.

Page 12

NOTE: A 30F change in inlet water temperature to Heater

will produce a change in the Heaters adjusted

water temperature of 10F.

Page 13

F-340LDW

Page 14

F-640LDW

Page 15

F-940LDW

Page 16

Re-Circulation System

F-1240LDW

Page 17

Page 18

INSTALLATION CHECK LIST

NOTE 1: PROVIDE ADEQUATE DRIP LEG AND TRAP TO KEP STEAM SUPPLY LINE FREE OF

CONDENSATE.

NOTE 2: INSTALL SAFETY VALVE AT THIS CONNECTION WHEN STEAM SUPPLY PRESSURE MAY

EXCEED 75 PSIG FOR DUCTILE IRON EXCHANGERS AND 150 PSIG FOR CAST STEEL

EXCHANGERS.

NOTE 3: INSTALL SMALL TRAP AND STRAINER TO DRAIN CONDENSATION DURING NO LOAD OR

STANDBY CONDITION.

NOTE 4: INSTALL THERMONETER SUPPLIED ON OUTLET HOT WATER LINE.

NOTE 5: INSTALL STOP VALVES ON STEAM CONDENSATE AND WATER INLET AND OUTLET

LINES.

NOTE 6: SEE TABLE BELOW FOR MAXIMUM ELEVATION OF CONDENSATE DISCHARGE.

MAXIMUM ELEVATION TABLE

INLET PRESSURE (PSIG) MAXIMUM ELEVATION OF CONDENSATE DISCHARGE

2-4 0 ft 0 cm

5-6 2 ft 61.0 cm

7-8 4 ft 121.9 cm

9-10 6 ft 182.9 cm

Page 19

10-12 8 ft 243.8 cm

12-15 10 ft 304.0 cm

It is solely the responsibility of the system designer and the user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance shall be

afforded with the selection of the materials based on the technical information supplied to Leslie Controls Inc.; however, the

system designer and user retain final responsibility. The designer should consider applicable Codes, material compatibility,

product ratings and application details in the selection and application. Improper selection, application or use of the products

described herein can cause personal injury or property damage. If the designer or user intends to use the product for an

application or use other than originally specified, he must reconfirm tat the selection is suitable for the new operating

conditions. Life expectancy for this product defaults to the warranty period of the sales contract.

Loading...

Loading...