Page 1

CFTIIP-015

Rev.0

__________________________________________________________________________________

INSTALLATION, OPERAT ING

AND MAINTENANCE INSTRUCTIONS

D SERIES

TABLE OF CONTENTS

GENERAL INFORMATION

TERMS CONCERNING SAFETY

UNPACKING

INSTALLATIONS

VALVE MAINTENANCE

VALVE DISASSEMBLY AND REASSEMBLY

PLUG STEM PINNING

ILLUSTRATION INDEX

Figure 1 – Typical bolting torque sequence

Figure 2 – Exploded dr awing

Figure 3 – Installat ion of ca rbon filled energized seal rin g

Figure 4 – Installation of Grafoil seal ring

Figure 4.1 – Grafoil seal rin g

Figure 5 – Plug stem pin n i n g

Figure 5.1 – Plug

Figure 6 – End to En d dimensions

Figure 7 – Trim types

Figure 7.1 – Single stage Balanced Trim

Figure 7.2 – Two stage Balanced Trim

Figure 7.3 – Standa rd Trim

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 1 of 15

Page 2

CFTIIP-015

Rev.0

__________________________________________________________________________________

1 General Information

The following instructions are designed to assist in

unpacking, installing and performing maintenance

as required on Circor D-series control valves.

Product user s and Maintenance personnel should

thoroughly review this bulletin prior to installing,

operating or performing any maintenance on the

valve.

To avoid possible injury to pers onnel or dama ge to

valve parts, WARNING and CAUTION notes must

be strictly followed. Modifying this product,

substituting non-factory parts or us i ng maintenance

procedures other than outlined coul d drastically

affect performance and be hazardo us to personnel

and equipment and may void existing warranties.

WARNING: Standard industry safety practices

must be adhered to when working on this o r any

other process control product. Specifically, personal

protective and lifting devices must be used as

warranted.

2 Terms Concerning Safety

The safety terms DANGER, WARNING,

CAUTION and NOTE are use in these instructions

to highlight particular dangers and/or to provide

additional information on aspects that may not be

readily apparent.

DANGER: indicates that death, severe

personal injury and/or substantial pr operty

damage will occur if proper precautions are

not taken.

WARNING: indicates that death, several

personal injury and/or substantial pr operty

damage can occur if proper precautions are not

taken.

CAUTION: indicates that minor personal

injury and/or property damage can occur if proper

precautions are not taken.

NOTE: indicates and provides additional technical

inform ation, which m ay not be very obv ious even

to qualified personnel

.

3 Unpacking

1. While unpacking the valve, check the packing

list against materials received. Lists describing

valve and accessories are in each

shipping container.

2. When lifting the valve from shipping container,

use the lifting lugs attached to the bonnet bolting.

Take care to position lifting straps to avoid damage

to the tubing and mounted accessories.

WARNING: When lifting a valve using the

lifting lugs, be aware that the center of gravity may

be above the lifting poi nt. Therefore, support must

be given t o prevent the a ctuator from rotating.

Failure to do so can cause serious injury to

personnel, damage to the valve or nearby

equipment.

3. Contact your shipper immediately if there is

shipping damage.

4. Should any problem aris e, contact your Circor

representative.

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 2 of 15

Page 3

CFTIIP-015

SIZE

(in)

150 ~ 600

0.75 6 152

900 ~ 1500

0.875 8 220

150 ~ 600

0.875 8 233

900 ~ 1500

1.25 8 583

150 ~ 600

0.875 8 307

900 ~ 1500

1.5 8 922

150 ~ 600

1

12

391

900

1.25

12

856

1500

1.75 8 1798

150 ~ 600

1

12

573

900

1.75 8 2631

1500

1.625

12

1629

150

1 8 879

300

1

12

586

600

1.25

16

550

150

1

12

873

300

1.25

12

1091

600

1.5

16

982

150

1.25

12

1605

300

1.5

12

1926

600

1.75

16

1685

Rev.0

__________________________________________________________________________________

4 Installations

1. Before installing the valve, clean the line of dirt,

welding chips, scale or other foreign material.

2. Whenev er possible, the valve should be installed

in an upright position. Vertical installation permits

easier valve maintenance.

3. Be sure to provide proper overhead clearance for

the actuator to allow for disassembly of the plug

from the valve body

4. Double-check flow direction to be sure the

valve is installed correctly. Flow direction is

indicated by the arrow attached to the body.

5. If welding the valve into the line, use extreme

care to avoid excess heat buildup in the valve.

6. Connect t he air supply and instrument s ignal

lines. Throttling control valves are equipped with a

valve positioner. Refer to the appropriate positioner

bulletin for connecti ons, maximum air supplies, and

maintenance instructions.

4.1 Quick-check

Prior to start-up, check the control valve by

following these steps:

1. Stroke the valve and obser ve the plug posit ion

indicator on the stem clamp compared to the stroke

indicator plate. The plug should change position in

a smooth, linear fashio n.

NOTE: Due to excessive friction, graphite packing

can cause the plug stem to move in a jerky fashion.

2. Check fo r full stroke by making appropriate

instrument s ignal change.

3. Check all air connections for leaks.

4. Check pack ing box bolting for the correc t

adjustment.

CAUTION: Do not over tighten

packing. This can cause excessive packing

wear and high stem friction that may impede

plug move ment.

5. Make sure the valve fails in the correct

direction in case of air failure. This is done

by turning off the air supply and observing

the failure direction.

6. After a temperature excursion has

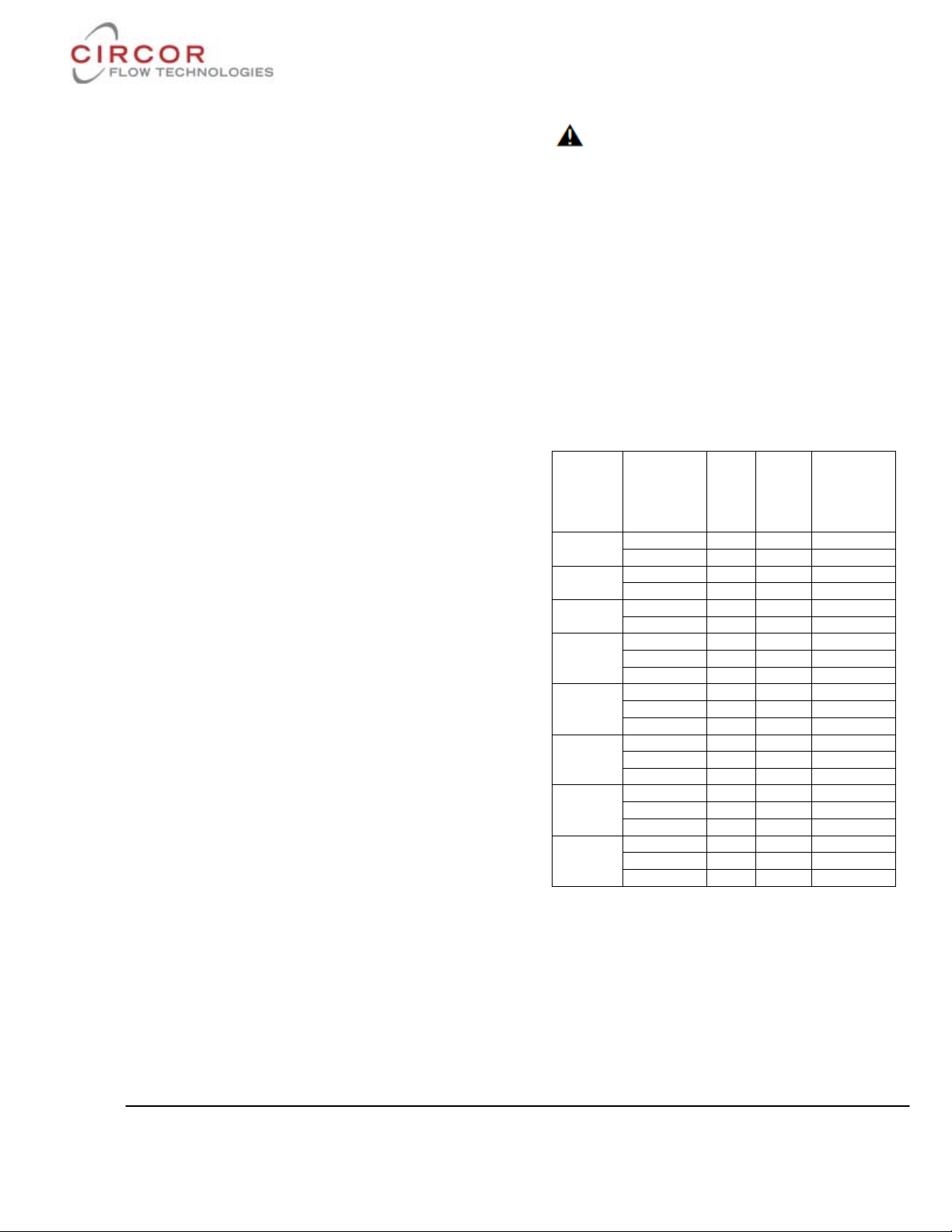

occurred, bonnet flange bolting s hould be retorqued to ensure bonnet gaskets do no t leak.

(Refer table 1)

Table 1

SIZE

OF THE

VALVE

2"

3"

4"

6"

8"

10"

12"

16"

CLASS

OF

THE

NUT

NO.

OF

NUTS

TORQUE

Nm

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 3 of 15

Page 4

CFTIIP-015

Rev.0

__________________________________________________________________________________

Typical Bolting torque sequence

Figure 1

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 4 of 15

Page 5

CFTIIP-015

Rev.0

__________________________________________________________________________________

5 Valve Maintenance

At least once every six months, check for

proper operation by following the

preventative maintenance steps outlined

below. These steps can be performed while

the valve is in-line and, in some cases

without interrupting service. If an internal

problem i s s us pected, refer to the “Valve

Disassembly and Reassembly” section.

1. Look for signs of gasket leakage through

the end flanges and bonnet. Re-torque flange

and bonnet bol ting (if r equired).

2. Check for fluid leakage to the atmosphere

through the body drain pl ug, if applicable.

3. Examine the valve for damage caused by

corrosive fumes or process drippings.

4. Clean valve and repaint areas of severe

oxidation.

5. Check pack ing box bolting for proper

tightness.

6. If the valve is supplied with a lubricator

fitting, check l ubricant supply and add

lubricant if necessary.

7. If poss ible, stroke the valve and check for

smooth, ful l-stroke ope rat i on . Unsteady stem

movement could indicate an internal valve

problem.

NOTE: Due to excessive friction, graphite

packing can cause the plug stem to move in a

jerky fashion.

WARNING: Keep hands, hair and

clothing away from all moving parts when

operating the valve. Failure to do so can

cause serious injury.

8. Ensure all accessories, brackets and

bolting is securely fastened.

9. If possible, remove air s upply and observe

actuator for correct fail-safe action.

10. Clean any dirt and other foreign material

from the pl ug stem.

11. If an ai r filter is supplied, check and

replace cartridge if necessary.

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 5 of 15

Page 6

CFTIIP-015

Parts List

Part

Item

Body

1

Bonnet

2

Seat ring

17

Seat Gasket

5

Bonnet Gasket

4

Seal ring

16

Gland flange stud

13

Nut

14

Bonnet studs

6

Guide Bush

9

Lantern Ring

10

1/4 NPT Plug

3

Gland Bush

11

Gland Flange

12

Rev.0

__________________________________________________________________________________

Figure 2: Exploded Drawing

Table 2

Plug stem assy 15

Cage 18

Heavy Hex nut 7

Packing Ring 8

Plug stem assy has the following

Integral parts (Refer section 7)

15- Plug

19- Pin

20- Stem

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 6 of 15

Page 7

CFTIIP-015

Rev.0

__________________________________________________________________________________

6. Valve Disassembly and Reassembly

6.1 Disassembling the Body

To disassemble the valve body, refer to

Figure 2 then proceed as follows:

WARNING: Depressurize line to

atmosphe ric pressure and drain all fluids

before working on the valve. Failure to do so

can cause serious injury. Remove all

compression from adjusting springs

For Normally open valve, relieve air pressure

from the actuator. Remove the tubing from

upper diaphragm case.

For Normally closed val ve, apply suff icient

air to the actuator diaphragm to keep valve

plug from touching seat while disengaging

valve plug stem from actuator stem

1. Loosen valve stem nut. Use wrench on

plug stem flats and turn valve plug (15) put

of actuator stem until stems separate.

Remove the tubing from lower diaphragm

case. Do NOT grasp the stem with pliers.

2. Remove cap screws holding actuator to

bonnet (2) and lift off actuator. Use caution

not damage the valve stem with yoke.

3. Remove the stem nut, travel indicator,

packing flange Studs & nuts (13, 14),

packing flange (12), and packing follower

(11).

4. Remove bonnet nuts and lift bonnet (2)

straight up until it clears valve plug stem (15)

being careful not to damage threads. Take

out bonnet gasket (4).

5. Lift out valve plug (15) assembly and cage

(18).

6. Remove seat ring (17) and seat ring gasket

(5)

7. Hold plug assy (15) with a wrench on stem

flats and r emove the pin holding the plug

head. Loosen the plug st em from the plug

head.

6.2 Cleaning

Remove the old packing from the bonnet and

clean and polish the stuffi ng box. Cle an all

parts with solvent.

Polish the parts with a fine aluminium oxide

cloth to remove any foreign matter. Replace

any worn or damaged parts. Be sure all

gasket seating surfaces are clean and smooth.

If any of the gasket faces are steam cut and

remachining is needed, it is recommended

that the valve be sent to Leslie controls

rebuilding department fro repair. ALL

CRITI CAL dimensions must be mainta ined

during ma chining process.

6.3 Lapp ing-in of valve plug and seat

ring

1. Place seat ring (17) in body recess with

seating surface upward. Lower cage (18) into

body with w indow opening downward. Ma ke

sure cage fits into body with window

openings downward. Make sure cage fits

over raised face of seat ring (17).

2. Use a sm all amount of Ca rborundum gra de

“CF” lapping compound (or equal) evenly

spread around valve plug seating surface.

Carefully insert valve plug (15) into body

until plug contacts seat ring (17). Lower

bonnet (2) over valve stem making sure stem

threads are not damaged. Place one metal

packing ring (8) over valve stem and into

bottom of stuffing box to act as a guide while

lapping plug . Lightly lap plug to seat ring

(15) using weight of plug only and by

rotating the plug in ¼ turn increments. Lift

and rotat e plug 90 deg., three or four times

during lapping procedure. This will ensure

even distribution of compound. DO N OT lap

excessively- 10 to 12 turns should be

sufficient. Remove the parts and clean them

thoroughly after lapping. Plug (15) and seat

ring (17) contact may be checked by the

bluing met hod before assembly.

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 7 of 15

Page 8

CFTIIP-015

Rev.0

__________________________________________________________________________________

6.4 Reassembling the Body

To reassemble the valve body, refer to Figure

2 then proceed as follows:

1. Install new bonnet (2) and seat gaskets (5)

with the bevelled edge up

NOTE: All gaskets should be replaced

whenever the valve is disassembled.

2. Relocate the seat ring (17). Carefully

install the cage (18), taking care to ensure

they installed with the correct ends up.

3. Replace the plug seals (16) on the plug,

referring to Figure 3 and observing the

following directions:

WARNING: Gloves shoul d be worn to

protect the hands from being bur ned.

PTFE Seals: Heat the seal to 300°F (150 °C)

and slip it over the plug into the seal groove.

Thermal expansion causes the ring to stretch,

thereby making it relatively easy to slide

over the plug head. Care must be taken to

prevent the seal from rolling, rather than

sliding over the plug.

Figure 3: Installation of Carbon filled

Teflon energ ised seal ring

FTC

FTO

By hand, evenly exert a sufficient thrust to

constrain seal ring to slide until its groove.

Take care not to damage seal ring dur ing this

step. Ensure seal ring is completely and

correctly inserted before perform next

assembly step.

NOTE: To easy introducing plug with its

seal ring into the cage, it is recommended to

apply a sm all amount of grease such as

Bardhal® (or equivale nt) around the seal ring

(17).

Figure 4: Installation of Grafoil seal

ring

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 8 of 15

Page 9

CFTIIP-015

Rev.0

__________________________________________________________________________________

Figure 4.1 Gra foil seal ring

CAUTION: Graphite seal rings are brittle

parts, so care must be taken to avoid

damage during following steps.

• Using a sharp knife, score the

graphite ring in one location.

• Hold each s ide of the ring around the

score mark between thumbs and

forefingers and bend the ring to

break at the scribe mark.

• By means of a very fine file, adjust

each broken end so that the external

ring circumference equal the proper

internal circumference of the cage

(18).

• Remove seal ring from the cage.

Open the seal ring sufficiently to

place it around the top of the plug.

Slide the ring along the plug and

insert into groove.

Graphite seal ring:

The seal ring cut location shall be placed at

180° apart when both the seal rings are

inserted int o plug groove.

4. Lower t he plug (15) into the body and

cage (18). Care should be tak en with the plug

(16) seals to avoid scoring or galling the

sealing surface while fitting them into the

cage bore.

5. Lower t he bonnet (2) onto the plug (15)

and body, taking great care to avoid scoring

the plug stem.

6. Once the bonnet is resti ng squarely in the

valve body, finger tighten the bonnet flange

bolting.

7. Reinstall the packing (8), guide bush (9)

and Lantern ring (10) referring to the

appropriate packing installation manual and

reinstalling new packing exactly as shown.

Make sure at least 1⁄8" is left at the top of

packing box for the top gui de to enter

8. Replace and tighten the packing gland

(12) and bolting (13, 14).

9. Turn actuator back onto the body

assembly, without turning the plug i ns ide the

bonnet. Leave a 3⁄32" to 1⁄8" (2 mm to 3

mm) gap between the mating surfaces of the

bonnet and yoke. Tighten

Yoke bolting to close this gap. Firmly tighten

the yoke bolting.

10. Using the actuator, seat the plug two or

three times to centre the seat ring (17) using

pressure on the top of the actuator.

11. Tighte n the body bolting, following the

bolting sequence outline d in Figure 1. Use a

minimum of four steps to reach the

suggested bolt torque values shown in Table

1. Never exceed more than 30% of the

suggested bolt torque value in a single step.

12. Slowly stroke the plug up and down to

check the alignment of the plug with the

cage.

13. Perform a Quick Check as described in

section 4. 1.

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 9 of 15

Page 10

CFTIIP-015

in mm in mm in mm in mm in mm in mm in mm Ft.Lbs daN.M in mm

2" 50 0.79 20 1/2 12.7 0.248 6.3 0.75 19.05 0.63 16 0.24 6 44 6 11/16 17

7/8 22

1 1/16 27

4" 100 1.06 27 5/ 8 15.87 0.248 6.3 1 25.4 0.87 22 1 1/16 27

6" 150 1.5 38 3/ 4 19.05 0.248 6.3 1.5 38.1 1.38 35 0.59 15 1 1/16 27

1 1/4 30

1 7/16 36

12" & 16" 300 & 400 2.76 70 1 1/4 1.25 0.394 10 2.56 65 1.97 50 1 7/16 36

Plug Shank

Dia. ''A"

Plug Ste m

Dia . ''B''

Pin Hole

Dia . ''C''

Pin Le ngth

''F''

"D''

"X''

Torque on

Plug Ste m

Wrench

Size ''E''

0.9825 5/8

15.87

0.248

6.3125.4

0.87

22

0.31

8

118

16

35

0.79

20

1.97501

25.4

0.248

6.3

Valve size

184

25

80

200 & 250

3"

8" & 10"

2

50.8

1.38

Rev.0

__________________________________________________________________________________

7. Plug Stem Pinning

Shouldered Plug stem

Standard Plug stem

Plug pin

Figure 5- Plug ste m pinning

Table 3

Plug Head Plug head Assy.

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 10 of 15

Page 11

CFTIIP-015

Non-guiding

Surface

Rev.0

__________________________________________________________________________________

Plug stem pinni ng during field as sembly

may be divided into two parts:

— Replacing old plug and old stem,

— Replacin g only old stem.

Replacing Plug and Stem

The plug (15) and stem (20) assembly

consists of a shaft threaded into the plug and

pinned in place. To re pl ace the stem (20) it is

necessary to drill or drive out the pin (19)

and unscrew the stem (20) from the plug

(15).

If it is necessary to replace the plug, it is

necessary to replace the plug stem at the

same time. Indeed, the original pin hole in an

old stem prevents satisfactory results and

might seriously impair strength of the

assembly.

A. Reference Marking on the Plug Stem

Measure the depth of the pilot recess in the

plug (X in Figure 5) and make a reference

mark to the plug stem at the same distance,

from the t hread.

B. Screwing Stem into Plug

1. Hold the plug in a vise.

2. Apply a small amount of grease such as

Gripcott® (or an equivalent compatible with

the fluid process) on t he threaded part of the

plug stem.

3. Lock one nut against another one to the

end of the ne w plug stem a nd, using a

wrench on the upper nut, screw the stem

solidly into the plug. When properly

assembled, the reference mark should be

flush with the end of the plug s hank.

C. Drilling the New Parts

1. Measure the “D” dimension,

(See Table 3).

2. Place the plug shank on a V-bloc k and, by

means of a centre punch, make a centre mark

on the plug shank area.

3. Using a suitable size drill bit, drill the

plug-stem assembly. After drilling, remove

any burrs from the plug s hank by making a

slight chamfer.

D. Pinning the Plug-Stem Assembly

1. Select the correct size pin according to

plug shank diameter and stem diameter, (see

Table 3). Apply a sma l l amount of grease

it, and hand place the pin to the hole inle t.

2. By means of an hammer, introduce the pin

into the hole. Use a flat-ended punch to

ensure the pin is recessed by the same

amount at both sides, (see Figure 5).

3. After the plug has been pi nned, it shoul d

be placed in a lathe to insur e it is running

“true.” The stem should be placed in a collet

with the plug s hank against it and the plug

should be struck on the no n guiding surface

of the plug using a mallet / nylon hammer

without causing mechanical damage to the

surface. Alignment of plug stem can be

perform ed using appropriate means.

Note: While pinning is being performed, care

must be taken not to damage the seating

surface or plug guide. In holding plug in

order to tightening the plug stem, always

tighten the jaws of the vise on a non-guiding

surface of the parts. Always use a soft metal

vise jaw with a special machining to hold the

shank of the plug (see F igure 5.1).

on

Figure 5.1 – Plug

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 11 of 15

Page 12

CFTIIP-015

Rev.0

__________________________________________________________________________________

Replacing Only Old Stem

A. Removing Old Pin and Stem from the

Plug

1. Place the plug shank on a V-block, and

using a drift punch, driv e out the old pi n.

Note: If it is necessary to drill out the pin, a

drill bit somewhat smaller than the pin

should be used and the remainder of t he pin

driven o ut .

2. Hold the plug shank in a vise, (see

bordered note in the paragraph A on previous

page).

3. Lock one nut against another one to the

end of the plug stem and, using a wrench on

the lower nut, unscrew the stem from the

plug. The stem is removed by turning it anticlockwise.

Note: In case of great sizes and/or high

temperature service and some other cases,

the plug stem has a shoulder which allows to

unscrew plug stem without using of the two

nuts, (see Table 3 for the required

Wrench sizes).

B. Screwing Stem to Plug

Refer to paragraph B of the above section

“REPLACING PLUG AND STEM”.

C. Drilling the New Stem

Place the plug shank on a V-block and, using

a suitable size drill bit, drill the stem using

the hole in t he plug as a guide.

Note: If the hole in the plug shank has bee n

slightly damaged while removing of t he old

pin, choose a drill bit and a pin with a

diameter somewhat larger than the normal

Pin.

D. Pinning

Select the correct size pin according to plug

shank diameter and pi n hole diamet er, (see

Figure 5). Proceed as described in the above

paragraph D2, taking care not to damage the

plug shank area.

Ensure plug s t em alignment as indicated in

the above paragraph D3.

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 12 of 15

Page 13

CFTIIP-015

Rev.0

__________________________________________________________________________________

Assembly Dimensional Details

Figure 6

Table 4

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 13 of 15

Page 14

CFTIIP-015

Rev.0

__________________________________________________________________________________

Table 5

Table 6

Dimensions ar e in Inches (mm).

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 14 of 15

Page 15

CFTIIP-015

Rev.0

__________________________________________________________________________________

Trim Types

Single stage Balanced Trim

Figure 7.1

Two stage Balanced Trim

Figure 7.2

This document is the property of Circor Flow Technologies India Pvt Limited should not copied or

reproduced in one form or another.

Page 15 of 15

Standard Trim

Figure 7.3

Loading...

Loading...