Page 1

12501 Telecom Drive, Tampa Florida 33637

Installation, Operating,

and Maintenance

Instructions Parts List

10/9.5.1.2

Rev. 2

CONTROL VALV

ES

Low Pressure, Single Ported, Cage Trim

Classes DLO-2, DDLO-2 125# & 250# Cast Iron

Classes DLOS-2 & DDLOS-2 150# & 300# Cast Steel

Classes DLOS-2 & DDLOS-2 150# & 300# Stainless Steel

TABLE OF CONTENTS

SECTION I – INSTALLATION .................................................................................................................... 2

SECTION II – OPERATION ......................................................................................................................... 2

SECTION III – MAINTENANCE ................................................................................................................. 3

SECTION IV – PARTS LIST....................................................................................................................... 10

ILLUSTRATION INDEX

DRAWINGS, DIMENSIONS, TYPICAL INSTALLATIONS AND

SCELLANEOUS DATA

MI

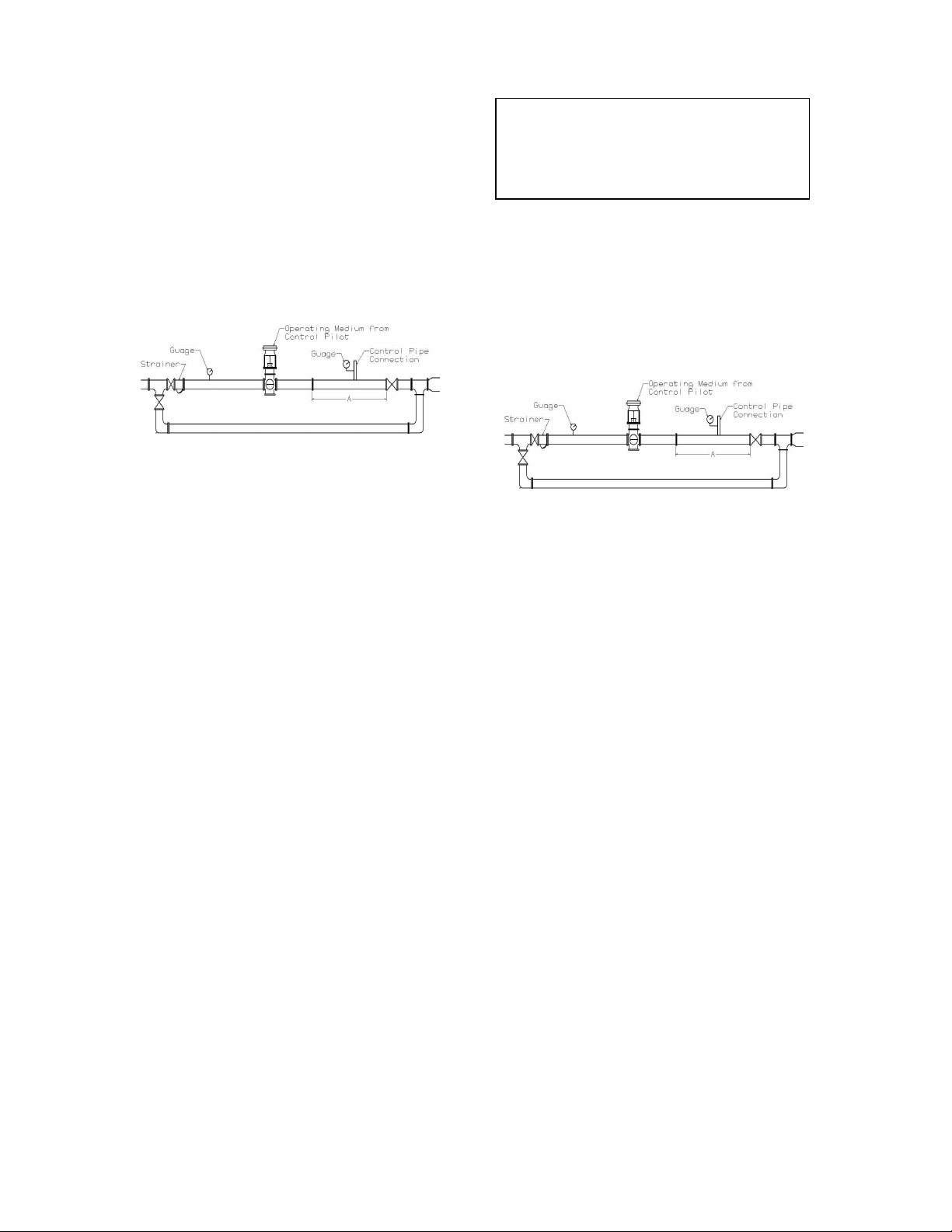

Figure 1 - Typical Installation Expand as required for fluid flow………………………………………………2

Figure 2 - Typical Control Valve Station for Control of Compressible Fluids at 25% or Less of Inlet Pressure.

Expand further as required for fluid flow………………………………………………………………….2

Figure 3 - Typical Valve Cutaway………………………………………………………………………………3

Figure 4 - Installation Sequence…………………………………………………………………………………4

Figure 5 - Installation Sequence…………………………………………………………………………………4

Figure 6 - Installation Sequence…………………………………………………………………………………5

Drawing - Diaphragm Control Valve…………………………………………………………………………..11

Drawing - Accessory Mount View……………………………………………………………………………..12

Drawing - Diaphragm Control Valve CLASS D(D)LOS-2, D(D)LOAS-2 and CLASS

D(D)LO-2, D(D)LOA-2……………………………………………………………………………14

Drawing - Direct Acting……………………………………………………………………………………….17

Drawing - Reverse Acting……………………………………………………………………………………..18

1

Page 2

ex

traordinary loads to the pressure

SECTION I – INSTALLATION

1. VALVE POSITION

Install control valve in the highest horizontal line

of piping in an accessible location and with

arrow on side of valve body in direction of fluid

flow. Control valve may be placed in any

position, but upright is preferable for ease of

maintenance.

Figure 1 - Typical Installation Expand as

required for fluid flow

2. PROBLEM PREVENTING

PROCEDURES

• Provide removal space above, below and

around control valve for easy removal of

parts during maintenance. See Dwg.

10/9.4.1 or 10/9.4.3 for dimensions.

• Blow or flush out pipelines thoroughly

before installing control valve.

• Protect control valve and following

equipment with a SELF-CLEANING

STRAINER.

• Install stop valves and gauges in inlet and

outlet lines to provide means for checking

adjustment and operation of equipment.

• Provide proper inlet and outlet drainage in

steam service to prevent water hammer or

possible erosion in equipment.

• Adhere to good piping practice. Install a

bypass around the control valve.

3. Connect operating medium tubing from

ontrol pilot, instrument or loading device to

c

diaphragm chamber connection of control

valve or to valve positioner, if one is in use.

Maximum allowable operating pressure for

diaphragm actuators is 60 psig.

4. Recommended Piping for Control of

ompressible Fluids at Values of 25% or

C

Less of Inlet Pressure.

The piping system must be adequately

designed and supported to prevent

Expand outlet pipe to twice control valve inlet

pipe size. Use tapered expander.

• Connect control pipe for control pilot ahead

of outlet stop valve and at least 2’ to 3’

downstream from end of expander.

• Make control pipe connection at least 18” to

2’ from outlet stop valve, any elbow or other

flow direction changing fitting.

Figure 2 - Typical Control Valve Station for

Control of Compressible Fluids at 25% or

Less of Inlet Pressure. Expand further as

required for fluid flow.

NOTE: Where sensing impulse is taken 2’ to 3’

downstream from control valve (expander),

dimension “A” minimum of 6’ to 10’ will

provide lowest noise and velocity factors,

accurate pressure sensing and reasonable

bypass length.

CAUTION!

SECTION II – OPERATION

1. Close inlet and outlet stop valves.

2. Check that control valve responds properly

rough rated travel in relation to changes in

th

operating pressure on the diaphragm. Rated

travel is shown by position of travel

indicator on valve stem relative to travel

indicator scale on yoke.

3. Manually operate control valves fitted with

manual operating devices through rated

travel to check freedom of movement.

Return manual operating device to its

standby position.

4. Place control valve in operation in

ccordance with instructions furnished with

a

control pilot or operating device.

2

Page 3

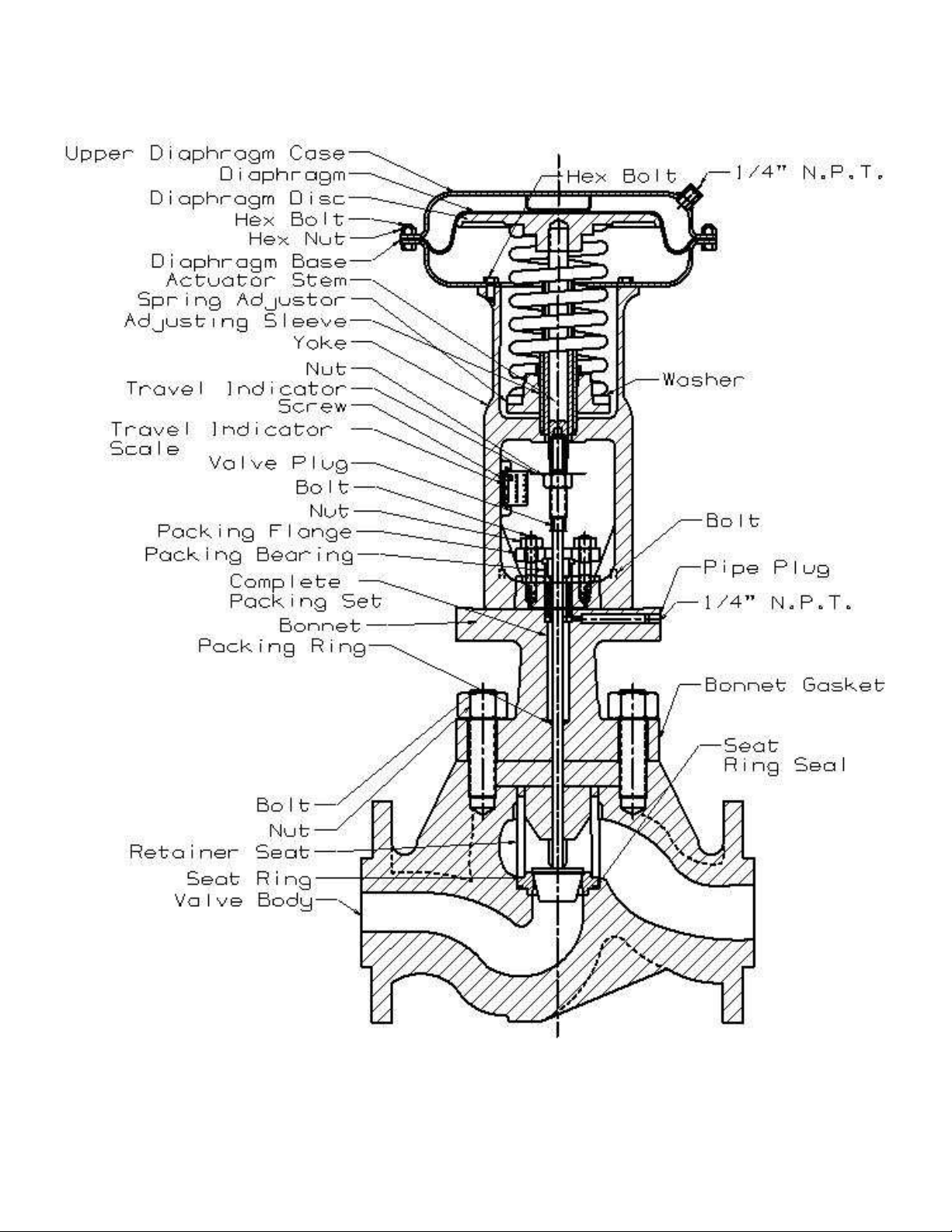

Figure 3 - Typical Valve Cutaway

3

Page 4

the valve.

SECTION III –

MAINTENANCE

To reduce maintenance time refer to proper

drawing and follow steps shown below for

applicable operation.

RENEWING VALVE PLUG STEM

PACKING

(See Fig. 3, Fig. 4 and 5)

Renew valve plug stem packing if control valve

has been in service beyond normal maintenance

and packing shows signs of wear. Wear will be

indicated by leakage at the packing gland. Minor

leakage of graphite packing can be corrected by

tightening the packing flange.

Over-tightening of the packing flange

adjustments can cause erratic operation of

Where LESLIE (BRAIDED TEFLON

GRAPHITE) packing is in use, additional

packing rings can be installed to overcome minor

leakage without dismantling the control valve or

breaking valve plug connection.

Shut down inlet and outlet stop valves and check

that valve body is not under pressure. Remove

nuts and lift packing flange and packing bearing

a sufficient height on valve plug stem to apply a

split packing ring around diameter of valve plug

stem. Lower packing bearing over the new ring,

lower packing flange and tighten sufficiently

with nuts to stop leakage.

To replace LESLIE “TEFLON” packing set or a

complete GRAPHITE 11 packing set, the control

valve must be dismantled.

Installation of Stem Packing

Stuffing box interior and valve plug stem must

be clean, smooth and free from imperfections

that may cause new packing to leak.

CAUTION!

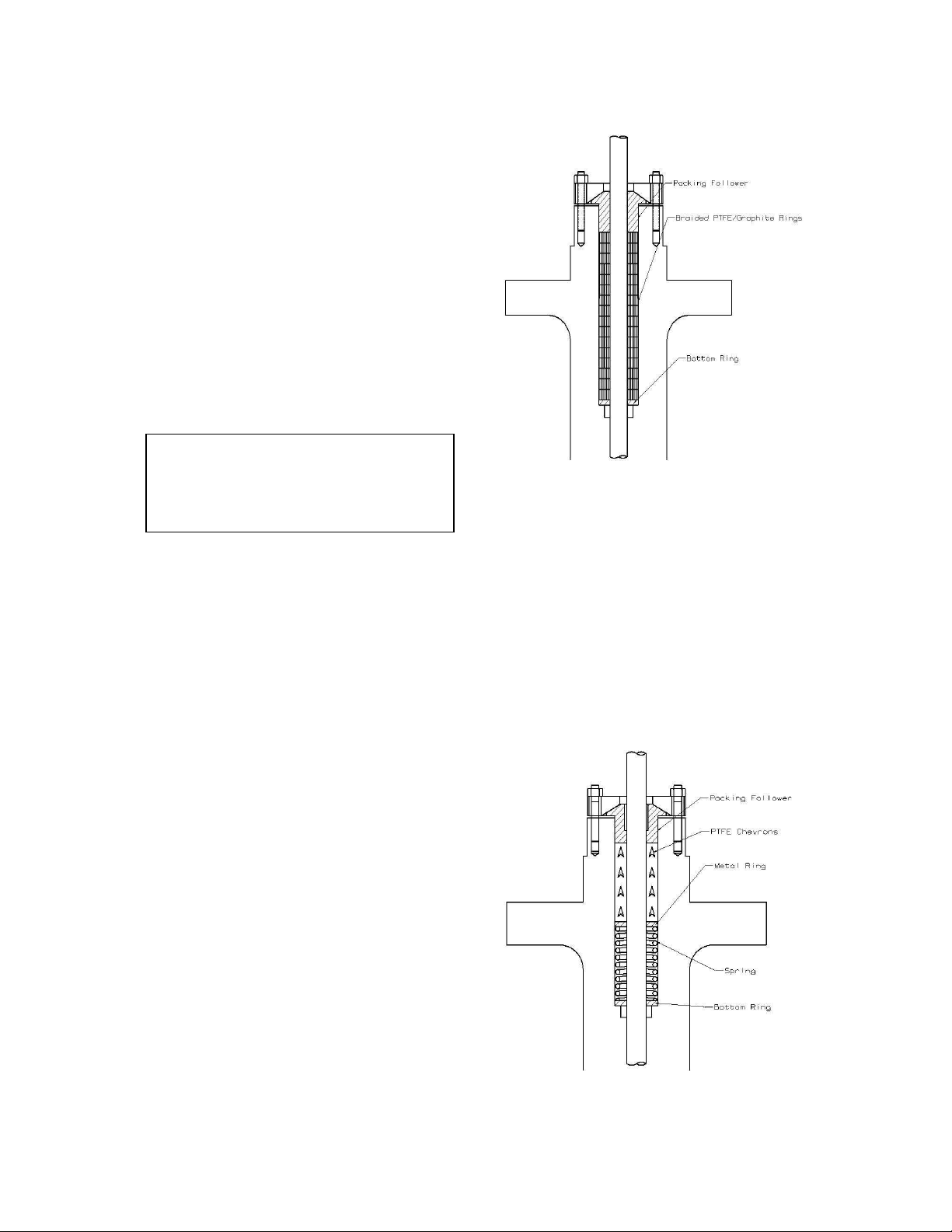

RAIDED PTFE/GRAPHITE TYPE

B

PACKING

Figure 4 - Installation Sequence

1. Place metal ring in stuffing box making sure

it bottoms in box followed by spring and

second metal ring. Install bottom Teflon

adaptor chevron, four Teflon packing

chevrons and top Teflon adaptor chevron in

accordance with Fig. 6.

2. Install packing follower, packing flange and

uts. Tighten stuffing box nuts until

n

follower bottoms on bonnet.

PTFE CHEVRON TYPE PACKING

Figure 5 - Installation Sequence

4

Page 5

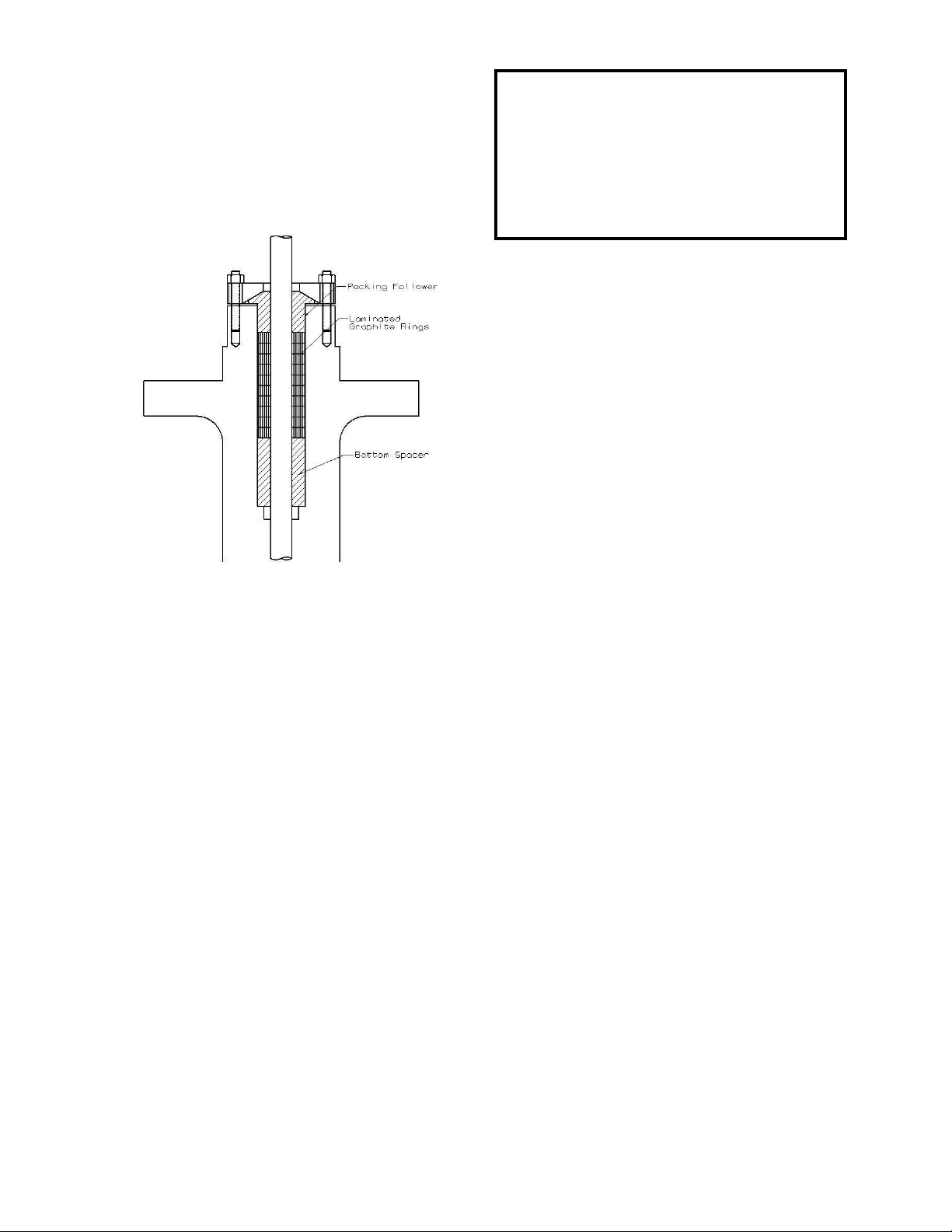

LAMINATED GRAPHITE PACKING

Packing tools are available from Leslie Controls

and should be used to insure proper installation

of packing. Packing tool reference numbers are

shown on Dwg. 10/0.5.9, which also shows how

to make the tools.

Figure 6 - Installation Sequence

INSTALLATION

Place spacers and packing rings over stem and

into packing box in order shown on drawing, one

at a time, seating each firmly and using care not

to tear rings on the stem threads. Adjust packing

gland nuts equally-finger tight plus 1/6 turn (one

flat of nut).

ADJUSTMENT

During start-up some leakage may be observed.

Do not readjust packing-allow at least 15

minutes for pressure/temperature stabilization to

occur. If leakage continues adjust a maximum of

1/6 turn at a time. If pressure is raised

considerably, the packing may leak slightly. Do

not readjust-leakage will stop when new

pressure/temperature stabilization is reached.

BREAK-IN

For best results it is recommended that after

packing installation and adjustment the valve be

fully stroked approximately 20 times to break-in

the packing and reduce stem friction.

Injury or death can occur due to failure to

completely isolate valve from all sources of

pressure before beginning disassembly. Do not

proceed until valve has been completely isolated

from the process and vented to atmosphere.

DISASSEMBLY OF ACTUATOR FROM

VALVE BODY ASSEMBLY

(See Fig. 6, 6A, 7 and 9 in Appendix)

WARNING

1. Close inlet and outlet stop valve and relieve

all pressure from piping involved. Remove

all compression from adjusting spring(s).

2. NORMALLY OPEN VALVES-DLO(S)-2.

Relieve air pressure from diaphragm of

actuator. Remove the tubing from upper

diaphragm case.

3. NORMALLY CLOSED VALVES-

DDLO(S)-2. Supply sufficient air to the

actuator diaphragm to keep valve plug from

touching seat while disengaging valve plug

stem from actuator stem.

4. Loosen valve stem nut. Use wrench on plug

stem flats and turn valve plug out of actuator

stem until stems separate. Remove the

tubing from lower diaphragm case.

5. Remove cap screws holding actuator to

onnet and lift off actuator.

b

DISASSEMBLY VALVE BODY

SUBASSEMBLY (VBSA)

(See Fig. 6 and 6A in Appendix)

1. Remove actuator from VBSA as previously

described in Disassembly of Actuator from

Valve Body Subassembly.

2. Remove bonnet nuts (10). Also bolts (11)

for DLOS only.

3. Lift bonnet assembly including valve plug

(2) from valve body (1).

4. Remove valve plug (2), packing bearing

12) and old packing set (17). Include

(

spring (15) for Teflon packing set.

5

Page 6

5. Remove bonnet gasket (8), seat retainer (5),

seat ring (4) and seal (3). If necessary,

remove seat ring by forcing a wooden dowel

into seat bore and lifting.

CLEANING

1. Clean all parts thoroughly. Polish valve

plug stem with crocus cloth. It should be

smooth and free of scratches in packing

area. Use approved, non-residue forming

solvent for cleaning. Wipe dry with clean

cloth.

2. Inspect all parts and replace any excessively

orn or damaged part.

w

3. Install a new packing set of braided Teflon

graphite or Teflon chevron rings as shown

on packing installation sketch Fig. 3, 4 or 5.

See previous section on renewing valve plug

stem packing.

4. The packing bearings have a long wearing

life material which under normal usage

should not require replacement, however, if

damaged or worn the packing bearing (12)

and/or the bonnet (6) must be replaced.

(Lower bearing in bonnet is not supplied

separately.)

5. The gasket (8) and seal (3) should be

eplaced each time the valve body

r

subassembly is disassembled for cleaning.

All LESLIE control valves are made of the finest

material obtainable, time-tested and backed by

over seventy-five years of know-how.

Machining is done by expert craftsmen and each

valve is inspected and service tested before

shipment to you.

REASSEMBLY VALVE BODY

SUBASSEMBLY LAPPING VALVE PLUG

AND SEAT

1. Insert raised face of seat ring (4) into seat

retainer cage (5) and place these into bore of

valve body bridge.

2. Place new bonnet gasket (8) into body

ecess.

r

3. With light pressure and turning motion

a

ssemble valve plug (2) to the bonnet (6)

being careful not to damage bearings or

packing set (17).

4. Apply very thin film of superfine lapping

compound to the valve plug seating surface.

5. Assemble bonnet (6) complete with valve

plug (2) to valve body (1) applying nuts (10)

only finger tight to studs or bolts (11). The

bonnet acts as a guide when grinding valve

plug.

6. Use wrench on flats of valve plug stem for

rning valve plug (2). Do not bear down on

tu

valve plug stem when lapping. Weight of

parts is sufficient to cause lapping action.

7. As lapping progresses lift valve plug off seat

occasionally and rotate 45˚ to keep

compound evenly distributed. Remove all

traces of compound after lapping. Excessive

lapping should be avoided.

8. Remove bonnet nuts (10), bonnet assembly,

and all body assembly parts. Then remove

all traces of lapping compound from both

valve plug (2) and seat ring (4). Check that

a fine continuous ring of contact has been

made on both seats. The contact ring should

be visible but without depth.

9. Apply silicone grease to seat ring seal (3)

nd insert seal into groove of seat ring (4).

a

10. Insert raised face of seat ring (4) into seat

retainer cage (5) and place these into bore of

valve body bridge. Seat ring (4) sealing face

must be firmly seated in place.

11. Place the bonnet gasket (8) in body recess

and add the bonnet assembly. Apply nuts

(10) to bolts or studs (11) and tighten evenly

for metal to metal joint.

12. Place actuator back on bonnet. CAUTION:

For reverse acting actuators only, air

pressure must be supplied to the diaphragm

chamber sufficient to cause actuator stem to

lift its full travel so valve plug threads may

later be engaged.

13. Place packing flange (13) with concaved

ide of hole facing down thru window of

s

6

Page 7

actuator over valve plug stem and bolts (9)

to top of packing bearing (12). Secure with

two nuts (7) finger tightened.

14. Secure Actuator flange to bonnet flange with

Cap Screws.

15. With wrench on flats of valve stem, lift

valve plug (2) and with counter-clockwise

motion engage threads in upper stem (31) of

actuator until valve plug can be turned no

more.

SETTING VALVE TRAVEL

CLASSES: DLO-2 AND DLOS DIRECT

ACTING ACTUATOR

(See Fig. 7 in Appendix)

1. Connect controlled air line to diaphragm

ase connector.

c

2. Supply 3 PSIG air pressure to actuator

diaphragm.

3. Compress actuator spring by turning spring

adjustor (35) until travel indicator (37) just

starts to move when air pressure is raised

above 3 PSIG.

NOTE: Alternately add compression and check

starting pressure slightly above 3 PSIG until

correct adjustment is attained. After each check

return air pressure to 3 PSIG.

4. Actuator spring preload adjustment can be

ade either with or without pressure in

m

valve body. Once correct compression is

made no further adjustment is necessary.

5. With valve plug and coupling threads

engaged supply 20 PSIG operating pressure

to actuator diaphragm. Valve will move to

closed position. Observe travel obtained as

shown by travel indicator and indicator

scale. Read- just as follows:

6. OVERTRAVEL – If travel is too great,

loosen stem locknut and turn valve plug

stem out of coupling the amount necessary

to obtain correct travel.

7. UNDERTRAVEL – (Travel is too short)

T

his is not possible if prior step 15 was done

and correct parts were used.

8. When correct travel has been obtained

reduce operating pressure sufficiently to

move valve plug away from seat ring. Then

turn valve stem one full turn out of upper

stem threads. Secure locknut.

9. The one full turn toward the seat ring, made

fter obtaining travel, provides the positive

a

closing force required to obtain tight valve

closure. In all cases be sure to make this

final adjustment.

10. Tighten locknut. Reconnect operating

medium tubing from the sensing element or

manual loading device to the diaphragm

case.

SETTING VALVE TRAVEL

CLASSES: DDLO & DDLOS REVERSE

ACTING ACTUATOR

(See Fig. 9 in Appendix)

1. Connect controlled air line to diaphragm

case connection.

2. Supply 3 PSIG air pressure to actuator

iaphragm.

d

3. Compress actuator spring until travel

indicator begins to move when air pressure

is raised above 3 PSIG.

NOTE: Alternately add compression and check

starting pressure slightly above 3 PSIG until

correct adjustment is attained. After each check

return air pressure to 3 PSIG.

4. The valve plug is closed against upward

fluid thrust by actuator spring force. Total

compression placed on actuator spring must

be sufficient to provide the 3 PSIG preload

plug force required to close the valve.

5. If preload adjustment is made with no

pressure in valve body, then, when the

control valve is placed in operation,

additional compression must be placed on

the actuator spring to provide valve closure

force. With proper adjustment valve will

7

Page 8

close tightly and will not begin to open until

the 3 PSIG operation pressure is exceeded.

NOTE A: A control valve which has been

adjusted to provide 3 PSIG starting pressure

plus valve closure force (with pressure in body)

will have a considerably higher start-pressure

than 3 PSIG, when tested at 0 body pressure.

NOTE B: Air pressures quoted are relative.

Actual pressures required in operation may vary

with pressure drop conditions existing and/or

actuator springs used.

6. Loosen lock nut. Apply air to diaphragm.

urn valve plug stem into upper stem

T

threads until valve plug is out of contact

with seat ring, when air is removed from

diaphragm. Then turn valve plug stem out

of coupling threads until valve plug just

contacts seat ring again.

7. Supply sufficient operating pressure to

actuator diaphragm to move valve plug

away from seat ring. Then turn valve plug

stem one full turn out of actuator upper stem

threads. Diaphragm disc determines travel.

With proper diaphragm disc correct travel

will result from adjustment.

8. OVERTRAVEL – If travel is too great,

loosen and turn valve plug stem out of upper

stem (35) and the amount necessary to

obtain correct travel.

9. UNDERTRAVEL – If travel is too short,

osen lock nut and turn valve plug stem

lo

further into upper stem (35) the amount

necessary to obtain correct travel.

10. When correct travel has been obtained

increase operating pressure sufficiently to

move valve plug away from seat ring. Then

turn valve plug stem one full turn out of

upper stem threads.

11. The one full turn toward the seat ring, made

after obtaining travel, provides the positive

closing force required to obtain tight valve

closure in single ported valves. In all cases

be sure to make this final adjustment.

12. Tighten locknut. Reconnect operating

edium tubing from the sensing element or

m

manual loading device to the diaphragm

case.

DISASSEMBLY

REPLACING DIAPHRAGM, STEM SEALS,

ETC.

(See Fig. 7 and 9 in Appendix)

1. Shut inlet and outlet stop valves for fluid

s

upply lines and air supply to actuator

connection.

2. Disconnect tubing at diaphragm case

onnection.

c

3. Remove compression on spring by turning

spring adjustor until spring is free. See label

on yoke for proper directions of rotation.

REPLACING DIAPHRAGM DIRECT

ACTING ACTUATOR ONLY

(See Fig. 7 in Appendix)

Follow steps 1 to 3

4. Remove diaphragm case nuts and bolts,

diaphragm case upper and diaphragm.

5. Replace diaphragm with a new one then

reposition diaphragm case upper bolts and

nuts. Tighten all nuts.

REPLACING DIAPHRAGM AND/OR

STEM SEALS REVERSE ACTING

ACTUATOR

(See Fig. 9 in Appendix)

6. Insert a lock rod through hole in the yoke

nd into hole in actuator stem. (Secure

a

actuator stem with wrench if stem has no

hole.)

7. Dismantle upper diaphragm case and Hand

Operating Device (if so fitted) from actuator

as described in instructions.

8. Remove the lock nut (16), diaphragm disc

(17), diaphragm (20) and collar (22).

9. 35R – Remove 8 cap screws from lower

diaphragm case, lift off case and remove

stem seal.

55R & 85R – Take out screws from seal

ring. Remove seal ring, stem seal, and stem

collar.

8

Page 9

10. Examine gasket. Replace seal if necessary

to obtain an air-tight seal.

11. Clean all metal parts. Remove any rust, dirt

or sharp edges that might damage stem seal.

12. Lubricate spring washer(s) (33 & 34), spring

adjustor (35) and actuator stem threads with

anti-seize compound.

REASSEMBLY

1. 55R & 85R – Place the new stem seal in

osition and install the seal ring with the lip

p

upward. Tighten screws. Press stem seal

down until flush with spacer, install lower

diaphragm case and tighten nuts.

2. When reassembling, place a block under the

actuator stem to hold the stem high enough

so that clearance between the stem seal bead

and the groove is not greater than 1/8 inch.

Line up the actuator stem in the center of the

opening in the lower diaphragm case so that

the stem seal bead will enter the groove in

the stem collar when the lock nut is

tightened.

3. Place the stem collar over the actuator stem

with the groove upward followed by the

diaphragm and the diaphragm disc. Be sure

that the center hole in the diaphragm fits

properly over the raised lip of the collar.

4. Install the lock nut and tighten. REMOVE

HE LOCK ROD.

T

5. Install the upper diaphragm case and Hand

Operating Device (if fitted) to actuator and

tighten the nuts and bolts.

ALL ACTUATORS

Reset valve for proper travel and spring preload

as previously described, by compressing actuator

adjusting spring(s) sufficiently to move

diaphragm(s) up against actuator stop. Align

travel indicator plate and tighten screws. Plate

scale indicates rated valve travel.

9

Page 10

SECTION IV – PARTS LIST

DIAPHRAGM CONTROL VALVE

CLASS DLOS-2, DLOAS-2

CLASS DDLOS-2, DDLOAS-2

CAST STEEL

CAST IRON

CAST STAINLESS STEEL

1” – 2” THREADED & SWE

1” – 4” FLANGED ANSI 150 & 300

1” – 4” FLANGED DIN ND-16, & ND-40

(DIMENSIONS IN INCHES/MILLIMETERS)

10

Page 11

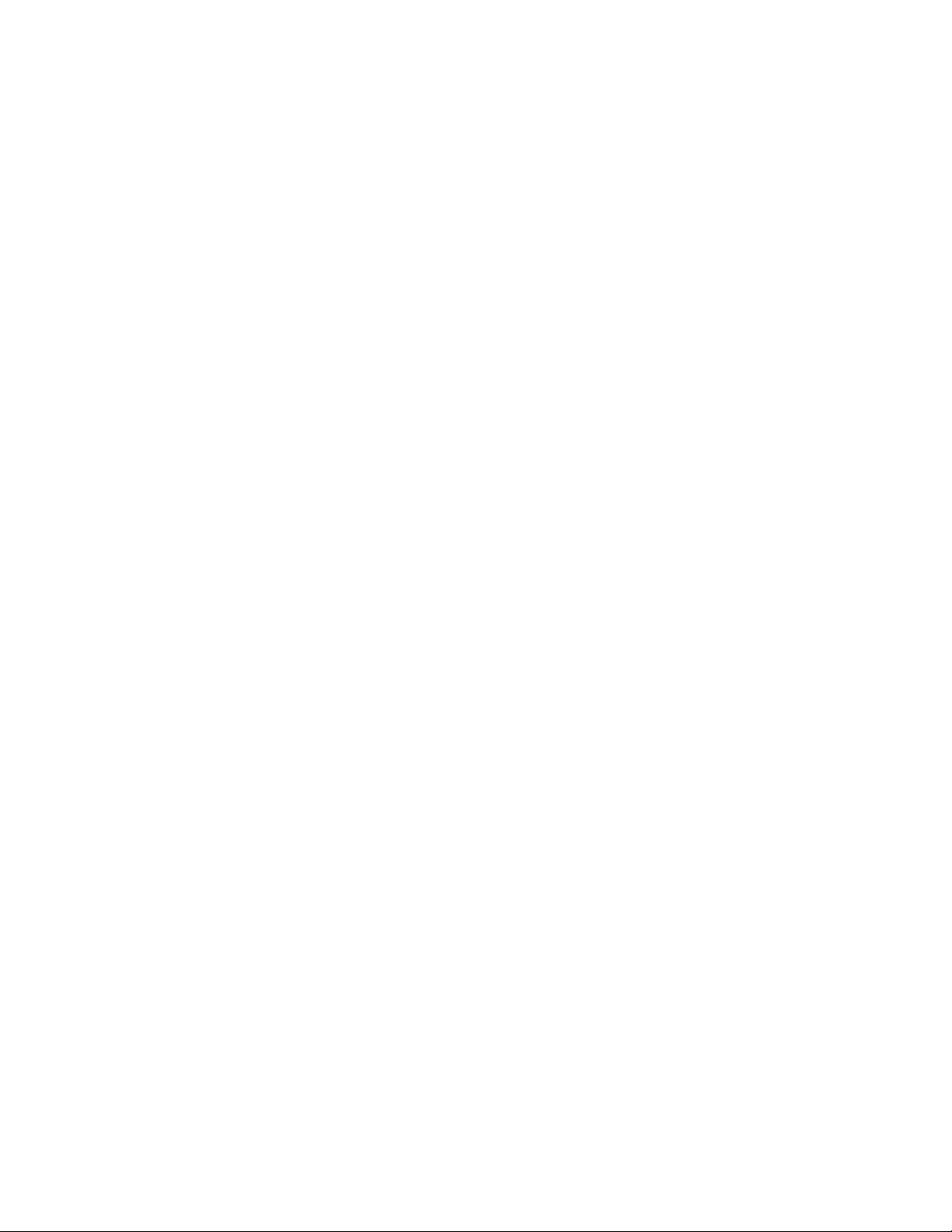

DIAPHRAGM CONTROL VALVE

CLASS DLOS-2 CAST STEEL, IRON AND

STAINLESS STEEL WITH DIAPHRAGM

ACTUATORS

DIRECT ACTING

LESLIE

CLASS DDLOS-2 CAST STEEL, IRON

AND STAINLESS STEEL

WITH DIAPHRAGM ACTUATORS

REVERSE ACTING

MAXIMUM ALLOWABLE AIR PRESSURE

FOR ALL DIAPHRAGM ACTUATORS IS

60 PSIG

11

Page 12

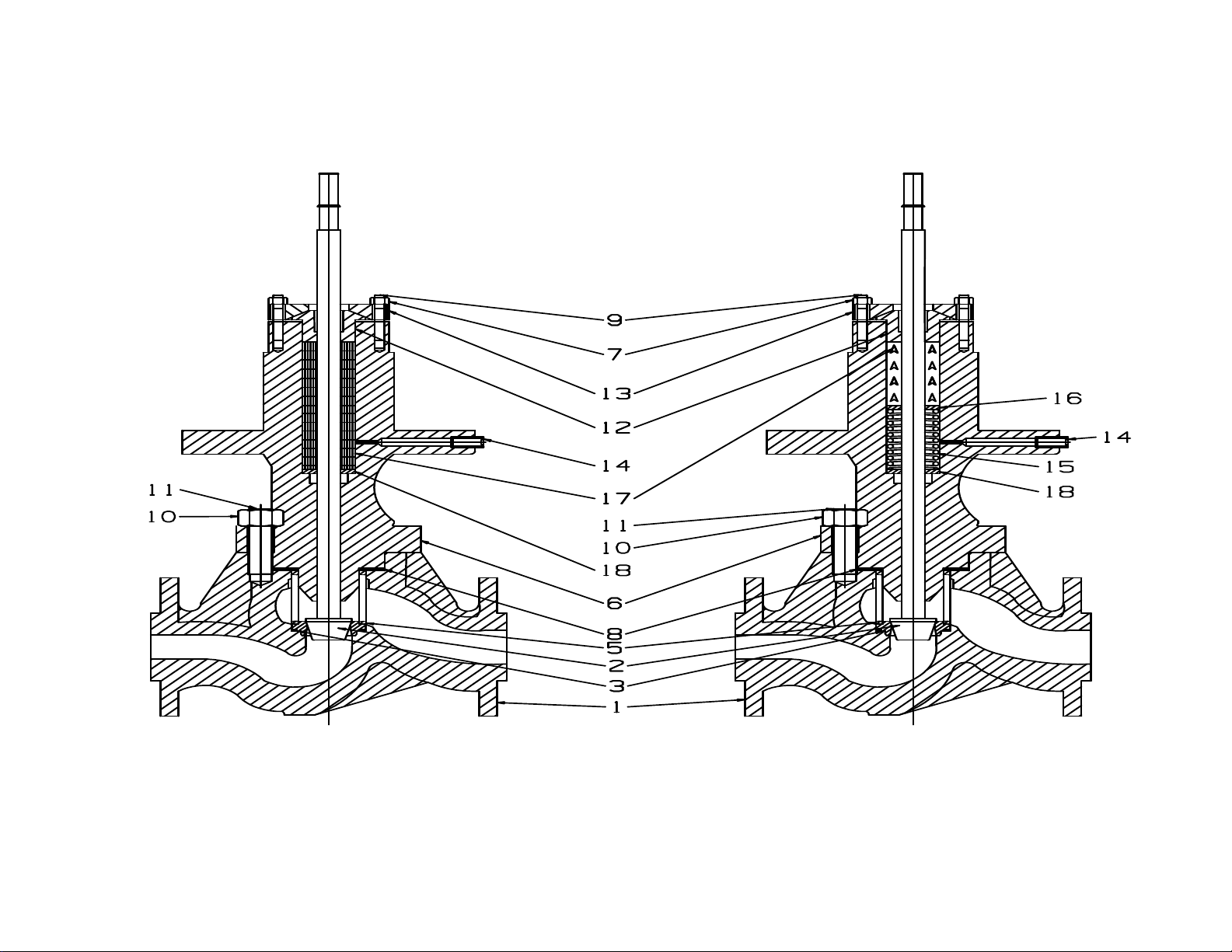

DIRECT ACTING DIAPHRAGM ACTUATORS AND HAND OPERATING DEVICE

DIMENSIONS IN INCHES AND MILLIMETERS

DIAPH

ACTUATO

R

35

55

55A

85

J J-J L M N-1 P R S T U V W X Z

in

9-1/4

mm

in

mm

in

mm

in

mm

235.0

12

304.8

12

304.8

14-3/4

374.7

3-15/16

100.0

5-1/16

128.6

5-1/16

128.6

6-1/4

158.8

12-3/8

314.3

15-1/4

387.4

15-1/4

387.4

19-5/8

498.5

12-3/8

6-1/4

314.3

158.8

15-1/4

387.4 7 177.8

15-1/4

387.4 7 177.8

19-5/8

8-1/2

498.5

215.9

5-1/2

139.7

5-1/2

139.7

5-1/2

139.7

6-7/16

163.5

1-3/8

34.9

1-3/8

34.9

1-3/8

34.9

1-3/4

44.5

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

9/16

14.3

9/16

14.3

9/16

14.3

9/16

14.3

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

2.687

68.2

2.687

68.2 1 25.4

2.687

68.2 1 25.4

2.687

68.2

11/16

17.5

1-1/4

31.8

*Approximate

REVERSE ACTING DIAPHRAGM ACTUATORS AND HAND OPERATING DEVICE

DIMENSIONS IN INCHES AND MILLIMETERS

ACTUATO

35R

55R

55AR

85R

SIZE

R

J J-J L M N-1 P R S T U V W X Z

in

9-1/4

mm

in

mm

in

mm

in

mm

235.0

12

304.8

12

304.8

14-3/4

374.7

3-15/16

100.0

5-1/16

128.6

5-1/16

128.6

6-1/4

158.8

12-3/8

314.3

18

457.2

18

457.2

23-1/4

590.6

9-7/8

250.8

14-1/4

362.0

14-1/4

362.0

18-3/4

476.3

6-1/4

158.8 4 101.6

6-7/8

174.6 4 101.6

6-7/8

174.6 4 101.6

8-9/16

4-5/16

217.5

109.5

1-3/4

44.5

1-3/4

44.5

1-3/4

44.5

2-1/4

57.2

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

9/16

14.3

9/16

14.3

9/16

14.3

9/16

14.3

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

2.687

68.2

2.687

68.2 1 25.4

2.687

68.2 1 25.4

2.687

68.2

11/16

17.5

1-1/4

31.8

*Approximat

DIAPHRAGM CONTROL VALVE – CAST STEEL & STAINLESS STEEL BODY

DIMENSIONS IN INCHES

SIZE A A-1 A-2 B C D E F G H

1

7-3/4

9-1/4

-

7-1/4

8-3/4

10

-

7-3/4

9-1/4

4-1/8

4-5/8

5-1/4

3-7/8

4-3/8

5-13/16

5-7/8

6-15/16

4-1/8

4-5/8

6-1/8

6-1/4

7-1/4

1-1/2

2

10-1/2

½

¾

1

1-1/2

2

2-1/2

10-7/8

3 4 11-3/4

13-7/8

½

¾

1

1-1/2

2

10-1/2

2-1/2

11-1/2

3 4 12-1/2

14-1/2

3-5/8

5-3/16

4-5/8

5-1/4

-

3-3/8

4-5/8

5

5-1/16

5-7/8

6-15/16

-

3-5/8

4-5/8

5

5-3/8

6-1/4

7-1/4

7-1/2

7-3/4

-

5-3/16

-

8-3/16

5

10-5/16

10-5/16

10-5/16

-

5-3/16

5

8-3/16

10-5/16

150 LB. ANSI FLANGE STANDARD

7-1/2

7-3/4

8-1/2

3-17/32

4-27/32

300 LB. ANSI FLANGE STANDARD

-

-

7-1/2

7-3/4

3-17/32

8-1/2

4-27/32

2-1/4

2-3/8

3-1/32

-

2-1/4

2-1/2

3-1/2

3-3/4

-

2-1/4

3-1/16

3-1/32

4-1/8

THREADED

-

-

-

-

-

-

-

-

-

4-1/4

7-1/2 9 1-1/16

4-7/8

6-1/8

6-1/2

7-1/2

8-1/4

-

3/8

5

5/8

6

9/16

7

5/8

7/8 5 6-3/16 6 7-1/2

-

-

-

-

5/8

¾

13/16

15/16

1-1/16

10

1-3/16 5 6-3/16

-

-

-

-

-

2

2-7/8

3-5/8

4-1/8

-

-

2

2-7/8

3-5/8

4-1/8

-

-

-

-

3-1/8

3-7/8

4-3/4

5-1/2

-

3-1/2

4-1/2

5

5-7/8

6-5/8

7-7/8

No. of

Hole

Holes

Size

-

-

-

-

-

-

-

-

1/16

1/16

1/16

1/16

1/16

1/16 4 8 ¾ ¾

1/16

1/16

1/16

1/16

1/16

1/16 8 8

4

4

4

4

-

-

-

4

4

8

8

7/8

7/8

7/8

7/8

-

-

-

-

¾

¾

¾

¾

-

¾

¾

DIAPHRAGM CONTROL VALVE – CAST STEEL & STAINLESS STEEL BODY

DIMENSIONS IN MILLIMETERS

SIZE A A-1 A-2 B C D E F G H

25

40

50

15

20

25

40

50

65

80

100

15

20

25

40

50

65

80

100

196.9

235.0

266.7

-

-

197.6

230

262.7

290

310

350

-

-

197.6

230

262.7

290

310

350

104.8

117.5

133.4

-

105

115

131.3

154.8

155

175

-

105

115

131.3

154.8

155

175

92.1

117.5

133.4

-

-

92.4

115

131.3

135.2

155

175

-

-

92.4

115

131.3

135.2

155

175

142.4

190.5

196.9

DIN 2543 FLANGE STANDARD ND-16

-

-

142.4

190.5

196.9

200.6

215.9

261.9

DIN 2545 FLANGE STANDARD ND-40

-

-

142.4

190.5

196.9

200.6

215.9

261.9

57.2

60.3

77.0

-

-

57.2

63.5

77.8

89.7

95.3

123

-

-

57.2

77.8

77

89.7

104.8

123

THREADED

-

-

-

-

-

115

16

150

15

165

17

185

15

200

17

220

17

-

-

115

16

150

15

165

17

185

19

200

21

235

21

-

-

68

88

102

122

138

158

68

88

102

122

138

162

-

-

-

-

-

-

-

-

-

-

-

85

110

125

145

160

180 3 3

-

-

85

110

125

145

160

190 3 3

-

-

-

-

-

-

No. of

Hole

Size

14

18

18

18

18

14

18

18

18

23

-

-

-

-

-

-

-

Approx. Net

Wt. kg.

7.3

12.3

15.5

-

-

8.6

15.9

18.6

25.9

35

55

-

-

9.5

16.8

20.5

30

40

63.6

Holes

-

-

-

-

-

-

-

-

-

-

2

4

3

4

3

4

3

4

8 8 18

-

-

-

-

2

4

3

4

3

4

3

8

8 8 18

12

3/8-24

3/8-24

½-20

½-20

3/8-24

3/8-24

½-20

½-20

ApproxNet

Wt. lb.

16

27

34

-

19

35

41

57

77

121

-

21

37

45

66

88

140

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

NET WT. lb/kg*

ALUM CAST

IRON

2 0 lb

9.1 kg

2 3 lb

10.4 k g

2 3 lb

10.4 k g

4 3 lb

19.5 k g

NET WT. lb/kg*

CAST

IRON

3 5 lb

15.9 k g

6 0 lb

27.2 k g

6 0 lb

27.2 k g

117 lb

53.1 k g

35( R )

55( R )

85( R )

35 lb

15.9 kg

50 lb

22.7 kg

50 lb

22.7 kg

96 lb

43.5 kg

ALUM

20 lb

9.1 kg

30 lb

13.6 kg

30 lb

13.6 kg

54 lb

24.5 kg

MAX.

in

mm ¾ 19.0

in

mm

in

mm

SIZE N-2 N-3

35( R )

55( R )

85( R )

in

mm

in

mm

in

mm

L-L

(MAX)

HAND

OPER

DEVIC

E

17-7/8

454.0

24-7/8

631.8

24-7/8

631.8

29-1/4

743.0

L-L

(MAX)

HAND

OPER

DEVIC

E

16-3/4

425.5

26-3/8

669.9

26-3/8

669.9

31-5/8

803.3

TRAVEL

1-1/2

38.1

2-1/8

54.0

2-1/2

63.5

2-1/2

63.5 3 76.2

2-1/2

63.5

NET WT. lb/kg*

WITH H.O.D. SIZE

ALUM.

23 lb

10.4 kg

28 lb

12.7 kg

28 lb

12.7 kg

48 lb

21.8 kg

NET WT. lb/kg*

WITH H.O.D.

CAST

IRON

38 lb

17.2 kg

65 lb

29.5 kg

65 lb

29.5 kg

122 lb

55.3 kg

2-1/2

63.5

4-1/8

104.8

CAST

IRON

38 lb

17.2 kg

55 lb

24.9 kg

55 lb

24.9 kg

101 lb

45.8 kg

ALUM

23 lb

10.4 kg

35 lb

15.9 kg

35 lb

15.9 kg

59 lb

26.8 kg

Page 13

CONTROL VALVE – CAST IRON BODY

DIMENSIONS IN INCHES

SIZE A A-1 A-2 B C D E F G H

½

7-3/4

¾

7-3/4

1

1-1/2 2 9-1/4

1-1/2

2-1/2

1-1/2

2-1/2

7-3/4

10-1/2

1

7-1/4

8-3/4

2

10-1/2

10-7/8

3

11-3/4

4

13-7/8

1

7-3/4

9-1/4

2

10-1/2

11-1/2

3

12-1/2

4

14-1/2

4-1/8

4-1/8

4-1/8

4-5/8

5-1/4

3-7/8

4-3/8

5

5-13/16

5-7/8

6-15/16

4-1/8

4-5/8

5-1/4

6-1/8

6-1/4

7-1/4

3-5/8

3-5/8

3-5/8

4-5/8

5-1/4

3-3/8

4-3/8

5

5-1/16

5-7/8

6-15/16

3-5/8

4-5/8

5-1/4

5-3/8

6-1/4

7-1/4

5-3/16

5-3/16

5-3/16

7-1/2

7-3/4

125 LB. ANSI FLANGE STANDARD (CAST IRON)

5-3/16

7-1/2

7-3/4

8-3/16

8-1/2

10-5/16

250 LB. ANSI FLANGE STANDARD (CAST IRON)

5-3/16

7-1/2

7-3/4

8-3/16

8-1/2

10-5/16

THREADED (CAST IRON)

2-3/8

2-3/8

2-3/8

2-3/8

3

2-1/8

2-1/2

3-1/2

3-3/4

4-1/2

2-1/8

3-1/16

3-1/4

3-3/4

4-1/8

4-1/4

3

7-1/2

4-7/8

6-1/8

6-1/2

7-1/2

8-1/4

5

10

-

-

-

-

-

5

6

7

9

-

-

-

-

-

7/16

9/16

5/8

11/16

¾

15/16

5/8

¾

13/16

15/16

1-1/16

1-3/16

-

-

-

-

-

-

-

-

-

-

-

2-11/16

3-9/16

4-3/16

4-15/16

5-11/16

6-15/16

-

-

-

-

-

3-1/8

3-7/8

4-3/4

5-1/2

6

7-1/2

3-1/2

4-1/2

5

5-7/8

6-5/8

7-7/8

CONTROL VALVE – CAST IRON BODY

DIMENSIONS IN MILLIMETERS

SIZE A A-1 A-2 B C D E F G H

15

20

25

40

50

15

20

25

40

50

65

80

100

15

20

25

40

50

65

80

100

196.9

196.9

196.9

235.0

266.7

-

-

194.5

230.2

262.7

290

310

385

-

-

197.6

234.2

266.7

290

310

393

104.8

104.8

104.8

117.5

133.4

-

-

103.6

115.1

131.4

154.8

155

175

-

-

105.2

117.1

133.4

154.8

155

175

92.1

142.4

92.1

142.4

92.1

117.5

133.4

131.4

135.2

133.4

135.2

142.4

190.5

196.9

DIN 2532/DIN 2533 FLANGE STANDARD (CAST IRON) ND-10/ND-16

90.9

155

175

92.5

155

175

-

-

-

-

-

-

-

-

142.4

190.5

196.9

200.6

215.9

261.9

DIN 2534/DIN 2535 FLANGE STANDARD (CAST IRON) ND-25/ND-40

-

-

142.4

190.5

196.9

200.6

215.9

261.9

THREADED (CAST IRON)

60.3

60.3

60.3

60.3

76.2

-

-

54

63.5

76.2

88.9

95.3

114.3

-

-

54

77.8

82.6

95.3

104.8

127

115

150

165

185

200

220

115

150

165

185

200

235

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

14

15

17

17

19

21

-

16

17

19

21

23

25

68

88

102

122

138

158

68

88

102

122

138

162

-

-

-

-

-

-

-

-

-

85

110

125

145

160

180

85

110

125

145

160

190

-

-

-

-

-

-

-

-

-

13

1/16

1/16

1/16

1/16

1/16

1/16

No. of

Holes

-

-

-

-

-

-

-

-

-

-

-

No. of

Holes

-

-

-

-

-

-

2

3

3

3

3

3

-

2

3

3

3

3

3

Hole

Size

-

-

-

-

-

4

4

4

4

4

8

4

4

8

8

8

8

Hole

Size

-

-

-

-

-

-

4

4

4

4

8

8

-

4

4

4

8

8

8

5/8

5/8

7/8

7/8

7/8

7/8

14

18

18

18

18

18

14

18

18

18

18

22

Approx.

Net wt. lb.

-

-

-

-

-

¾

¾

¾

¾

¾

¾

-

-

-

-

-

-

-

-

-

17

17

17

28

35

19

35

41

58

80

135

21

37

45

64

91

152

Approx.

Net Wt. kg.

7.7

7.7

7.7

12.7

15.9

-

-

12.7

15.9

18.6

26.4

36.3

61.3

-

-

9.5

16.8

20.5

29

41.4

69

Page 14

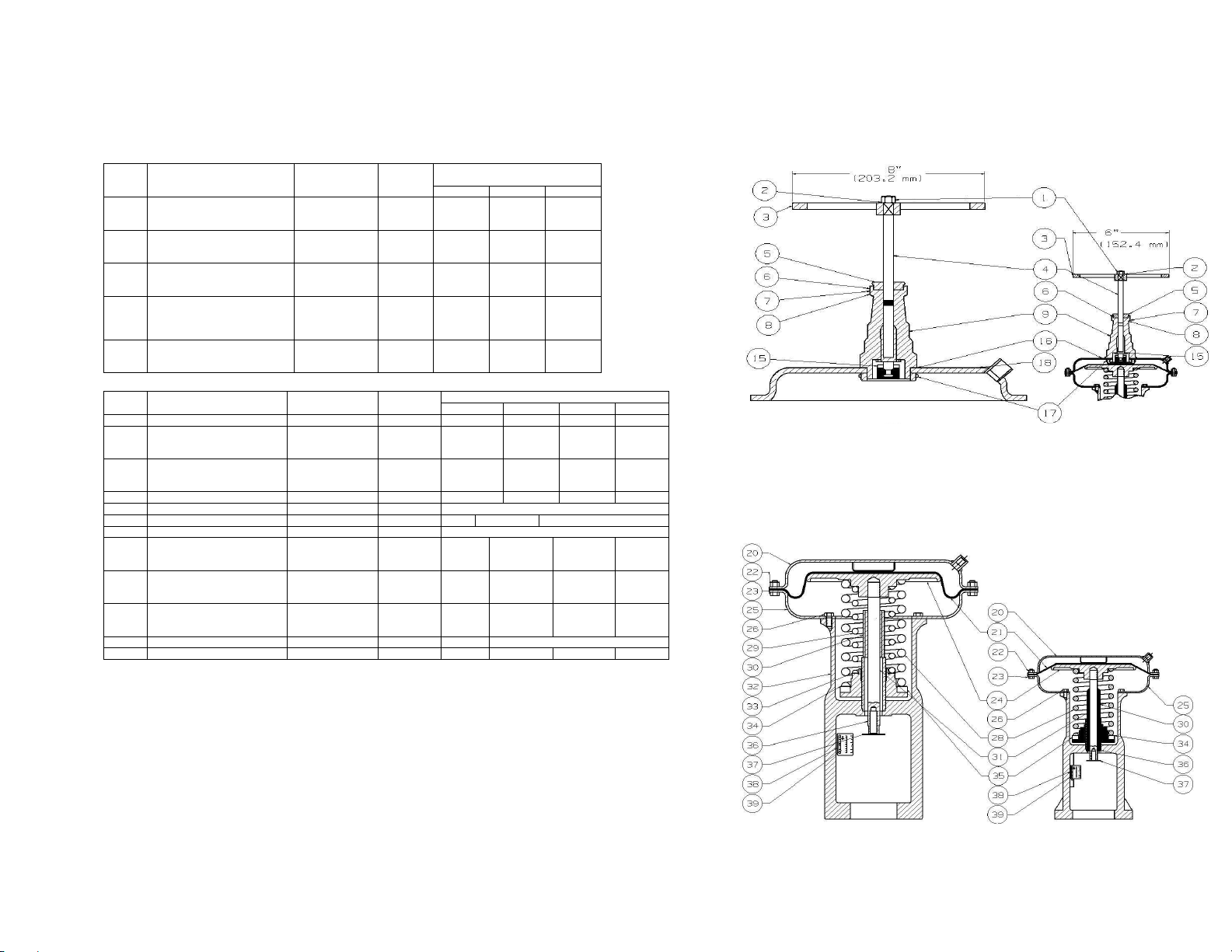

LESLIE DIAPHRAGM CONTROL VALVE

CLASS D(D)LOS-2, CLASS D(D)LOAS-2 AND CLASS D(D)LO-2, D(D)LOA-2

MAIN BODY SUBASSY (CAST IRON, CAST CARBON STEEL OR STAINLESS STEEL)

1 / 2” THRU 4” VALVE 1 / 2” THRU 4” VAVLE

(WITH BRAIDED TEFLON GRAPHITE PACKING) (WITH TEFLON CHEVRON PACKING)

14

Page 15

DIAPHRAGM CONTROL VALVE PARTS LIST

WHEN ORDERING PARTS, PLEASE GIVE PART NAME AND PART REF. NO. FROM TABLE BELOW. USE PART NUMBER ONLY TO LOCATE PART ON

PART NAME MATERIAL MATERIAL SPEC.

Valve Body, Threaded

Valve Body, 150 Flanged

Valve Body, 300 Flanged

Valve Body, DIN 2543 ND 16

Valve Body, DIN 2545 ND 40

Valve Body, Threaded

Valve Body, 150 Flanged

Valve Body, 300 Flanged

Valve Body, DIN 2543 ND16

Valve Body, DIN 2545 ND 40

Valve Body, Threaded

Valve Body, 125 Flanged

Valve Body, 250 Flanged

Valve Body, DIN 2533 ND 16

Valve Body, DIN 2535 ND 40

Valve Plug, Linear, Full Trim

Valve Plug, Linear, Res. Trim

Valve Plug, Linear, ¼” Trim

Valve Plug, Linear, ½” Trim

Valve Plug, Linear, ¾” Trim

Valve Plug, Linear, 1” Trim

Va lve P lug, Linea r, 1-1/ 2” Tr im

V a lv e Pl ug , Li ne ar , 2” T ri m

Valve Plug, Microtaper ¼” (NOTE 1)

Valve Plug, EQ% Full Trim

Valve Plug, Res. Trim

Valve Plug, EQ% ¼” Trim

Valve Plug., EQ% ½” Trim

Valve Plug, EQ% ¾” Trim

Valve Plug, EQ% 1” Trim

Valve Plug, EQ% 1-1/2” Trim

Valve Plug, EQ% 2” Trim

Valve Plug, Linear, Full Trim

Valve Plug, Linear, ¼” Trim

Valve Plug, Linear, ½” Trim

Valve Plug, Linear, ¾” Trim

Valve Plug, Linear, 1” Trim

Valve Plug, Linear, 1-1/2” Trim

Valve Plug, Linear, 2” Trim

Valve Plug, EQ% Full Trim

Valve Plug, EQ% ¼” Trim

Valve Plug, EQ% ½” Trim

Valve Plug, EQ% ¾” Trim

Valve Plug, EQ% 1” Trim

Valve Plug, EQ% 1-1/2” Trim

Valve Plug, EQ% 2” Trim

Seat Ring Gasket (To 450˚F)

Seat Ring Gasket (Above 450˚F) ํ

S.R. Gasket for Resilient Trim only

Seat Ring, Full Trim

Seat Ring, ¼” Trim

Seat Ring, ½” Trim

Seat Ring, ¾” Trim

Seat Ring, 1” Trim

Seat Ring, 1-1/2” Trim

Seat Ring, 2” Trim

Seat Ring, Full Trim

Seat Ring, ¼” Trim

Seat Ring, ½” Trim

Seat Ring, ¾” Trim

Seat Ring, 1” Trim

Seat Ring, 1-1/2” Trim

Seat Ring, 2” Trim

Seat Ring, Res. Trim

Seat Retainer Cage

Bonnet

Bonnet (For C.I. Body)

Bonnet (For SS Body)

Packing Nut

Bonnet Gasket

Packing Stud

Nut

Stud

Stud Bolt

Packing Bearing

Cast Steel

Cast Steel

Cast Steel

Cast Steel

Cast Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Cast Iron

Cast Iron

Cast Iron

Cast Iron

Cast Iron

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

RTFE

Inconel 600/Grap.

Fluorocarbon

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

St. Steel Stell.

Stainless Steel

Stainless Steel

Cast Steel

Note 2

316 SS

Stainless Steel

Inconel 600/Grap.

Steel

Steel Stell.

Steel Stell.

Steel

Stainless Steel

ASTM A-216

GRWCB

ASTM A-216

GRWCB

ASTM A-216

GRWCB

ASTM A-216

GRWCB

ASTM A-216

GRWCB

ASTM A-296

GRW316

ASTM A-296 GR 316

ASTM A-296 GR 316

ASTM A-296 GR 316

ASTM A-296 GR 316

ASTM A-126 CLB

ASTM A-126 CLB

ASTM A-126 CLB

ASTM A-126 CLB

ASTM A-126 CLB

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

COMMERCIAL

COMMERCIAL

COMMERCIAL

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

AISI TYPE 316

ASTM A351

GRCF8M

ASTM A216 GRWCB

ASTM A351CF8M

AISI TYPE 304

COMMERCIAL

AISI A-193GRB7

ASTM A194GB2H

ASTM A-193 GRB7

ASTM A-193 GRB7

AISI TYPE 316

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3†

3†

3†

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

5

6

6

6

7

8†

9

10

11

11

12

NO.

DRAWING.

QTY/

UNIT

1

A654170

1

1

1

1

1

A654170

1

1

1

1

1

A65429

1

1

1

1

1

A69327

1

A69331

1

A69323

1

1

1

1

1

1

A69322

1

A69329

1

A69332

1

A69325

1

1

1

1

1

1

A69328

1

A69324

1

1

1

1

1

1

A69330

1

A69326

1

1

1

1

1

1

A79477

1

A72654

1

A65361

1

A72565

1

A72567

1

1

1

1

1

1

A72571

1

A72568

1

1

1

1

1

1

A65717

1

A652640

1

A72597

1

A72597

1

A691160

2

A23194

1

A72659

2

A57572

8

A13243

4

A44867

4

A69471

1

A65370

15

½” ¾ ” 1” 1-1/2” 2” 2-1/2” 3” 4”

A654180

3

--

--

--

-A654180

5

--

--

--

--

A65430

--

--

--

--

A69339

A69344

A69323

--

A69327

--

--

--

--

A69322

A69333

A69343

A69325

--

A69329

--

--

--

--

A69338

A69324

--

A69328

--

--

--

--

A69334

A69326

--

A69330

--

--

--

--

A79477

A72654

A65361

A72569

A72567

--

A72565

--

--

--

--

A72564

A72568

--

A72571

--

--

--

--

A65718

A652640

5

A72597

A72597

A691160

5

A23194

A72659

A57572

A13243

A44867

A69471

A65370

A651860

3

--

A651870

-A651880

--

A658040

-A658040

5

A651860

--

A651870

--

--

A651880

A658040

--

A658040

--

A65268

A65269

--

A65270

--

A65903

--

A65904

A69345

A69353

A69323

A69327

--

A69339

--

--

--

A69322

A69349

A69354

A69325

A69329

--

A69333

--

--

--

A69346

A69324

A69328

--

A69338

--

--

--

A69350

A69326

A69330

--

A69334

--

--

--

A79477

A72654

A65361

A72566

A72567

A72565

--

A72569

--

--

--

A72570

A72568

A72571

--

A72564

--

--

--

A65719

A652640

5

A72597

A72597

A691160

5

A23194

A72659

A57572

A13243

A44867

A69471

A65370

REFERENCE NUMBERS PART

A652960

3

A652940

3

A652950

3

A658050

3

A658050

3

A652960

5

A652940

5

A652950

5

A658050

5

A658050

5

A65293

A65291

A65292

A65905

A65906

A69367

A69371

A69341

--

--

--

A69369

A69372

A69336

--

--

-A69368

A69342

--

--

-A69370

A69337

--

--

-A79478

A72655

A65362

A72573

A72572

--

--

-A72574

A72575

--

--

-A65720

A652990

5

A72594

A72594

A691180

5

A23194

A72660

A57572

A03676

A23209

A69472

A65370

A653320

3

3

3

3

3

5

5

5

5

5

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

5

5

3

A653330

3

A653340

3

A658060

3

A658060

3

A653320

5

A653330

5

A653340

5

A658060

5

A658060

5

A65337

A65335

A65336

A65907

A65908

A69373

A69377

--

--

--

A69348

--

--

-A69375

A69378

--

--

-A69351

--

-A69374

--

--

-A69347

--

-A69376

--

--

-A69352

--

-A79479

A72516

A65363

A72493

--

--

-A72494

--

-A72495

--

--

-A72492

--

-A65721

A653030

5

A72514

A72514

A75879

A23194

A72661

A57572

A03676

A23207

A69472

A65371

--

A654040

3

A654050

3

A658070

3

A658080

3

--

A654040

5

A654050

5

A658070

5

A658080

5

-A65402

A65403

A65909

A65910

A69379

A69383

--

--

--

-A69385

--

-A69381

A69384

--

--

--

-A69387

-A69380

--

--

--

-A69386

-A69382

--

--

--

-A69388

-A79480

A72656

A66218

A72563

--

--

--

-A72560

-A72561

--

--

--

-A72562

-A65722

A654120

5

A72599

A72599

A691220

5

A23194

A72662

A57572

A03677

A11083

A69473

A65371

--

A654360

3

A654370

3

A658090

3

A658100

3

--

A654360

5

A654370

5

A658090

5

A658100

5

-A65438

A65439

A65911

A65912

A69389

A69393

--

--

--

-A69385

--

-A69391

A69394

--

--

--

-A69387

-A69390

--

--

--

-A69386

-A69392

--

--

--

-A69388

-A79481

A72657

A65479

A72554

--

--

--

-A72555

-A72557

--

--

--

-A72556

-A65723

A653740

5

A72601

A72601

A72430

A23194

A72663

A57572

A03677

A09393

A69474

A65371

A654850

A654860

A658110

A658120

A654850

A654860

A658110

A658120

A65487

A65448

A65929

A65930

A69395

A69399

A69401

A69397

A69400

A69403

A69396

A69402

A69398

A69404

A79482

A72658

A65480

A72558

A74410

A72559

A74409

A65724

A653750

A72603

A72603

A72925

A23194

A72664

A57572

A03678

A42747

A69475

A65371

--

3

3

3

3

--

5

5

5

5

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

5

Page 16

13

Packing Flange

14

Pipe Plug

Packing Spring Teflon Packing

15†

16

Washer, Teflon Packing

Packing Set, Teflon Chevron

17†

Packing Set Braided Teflon Grpht

17†

Packing Set, Hi-Temp

17†

Packing Set, Hi-Temp

17†

Packing Ring, Teflon

18

18

Packing Spacer, Graphite Packing

18

Packing Spacer

Steel

Steel

Monel 400

Monel 400

Teflon

Teflon/Graphite

Graphite Type II

Graphite Type II

Stainless Steel

Stainless Steel

* Resilient Seat Only

† Recommended Spare Parts

These parts should be on hand, plus recommended spare parts when overhauling this equipment

For use with Bleedport option only

Not used with Iron Body

Stainless Steel

AISI 1144

COMMERCIAL

COMMERCIAL

COMMERCIAL

COMMERCIAL

COMMERCIAL

COMMERCIAL

COMMERCIAL

AISI TYPE 302

AISI TYPE 302

AISI TYPE 302

1

A69405

1

A66166

1

A65353

1

A63926

1

A28015

1

A69423

1

A72363

1

A70380

1

A23192

1 1 A72626

A72646

A69405

A66166

A65363

A63926

A28015

A69423

A72363

A70380

A23192

A72626

A72646

A69405

A66166

A65353

A63926

A28015

A69423

A72363

A70380

A23192

A72626

A72646

A69405

A66166

A65353

A63926

A28015

A69423

A72363

A70380

A23192

A72626

A72646

A69405

A66166

A65355

A65368

A69460

A69424

A72647

A72653

A66909

A72627

A66909

NOTE 1: Microtaper valve plug furnished only as valve

NOTE 2: Bonnet material is cast steel ASTM A215WCB

A69405

A66166

A65355

A65368

A69460

A69424

A72647

A72653

A66909

A72627

A66909

plug and seat set. Not available separately.

for ½” – 3’ valves. Material is C.I. A126CLB

for 4” valves.

A69405

A66166

A65355

A65368

A69460

A69424

A72647

A72653

A66909

A72627

A66909

A69405

A66166

A65355

A65368

A69460

A69424

A72647

A72653

A66909

A72627

A66909

16

Page 17

NO.

HAND OPERATING DEVICE

DIAPHRAGM ACTUATOR

DIRECT ACTING

WHEN ORDERING PARTS, PLEASE GIVE PART NAME AND PART REFERENCE

NUMBER FROM TABLE BELOW. USE PART NUMBER ONLY

TO LOCATE PART ON DRAWING.

PART

1

Nut

2

Lock Washer

3

Handwheel

4

Handscrew

5

Packing Gland

6*

Packing Ring

7

Washer

8*

O-Ring

9

Bonnet, Compl., Iron Actuator

9

Bonnet, Compl., Alum. Actuator

15

Handscrew Disc, Compl. (NOTE

16*

6)

Gasket

17

Lock Nut, Iron Actuator

17

Lock Nut, Aluminum Actuator

18

Diaphragm Case, Upper

PART NAME MATERIAL

Steel

Steel

Cast Aluminum

Stainless Steel

(NOTE 1)

Molded Rings

(NOTE 1)

Synthetic Rubber

(NOTE 2)

(NOTE 3)

Stainless Steel

Sheet Packing

(NOTE 2)

(NOTE 3)

Pressed Steel

QTY PER

UNIT

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

REFERENCE NUMBER – EACH

35 55 & 55A 85

13243

10392

43064

43016

38644

69609

38658

38664-94

38635

39069

43008

38657-95

38655

39070

38661

SIZE

13243

10392

23649

49228

34859

33551

35760

27293-94

42228

42228

42077

37845-95

37710

37710

37764

27293-94

37845-95

13243

10392

23649

49228

34859

33551

35760

42228

42228

42077

37710

37710

37770

NO.

20* Diaphragm Case, Upper Pressed Steel 1 38369 37795 37795 37791

21

22

23

24

24

25

26 Cap Screw Steel (NOTE 8) 38420 37796 37796 23400

28 Adjusting Spring Steel, Plated 1 (SEE TABLE)

29 Inner Adjusting Spring Steel, Plated 1 -- -- (SEE TABLE)

30 Limit Stop Steel 1 (SEE TABLE)

31

32

32

33

34

35

35

36

37

38 Travel Indicator Scale Aluminum 1 38404 (SEE TABLE)

39 Screw Steel, Cad. Plated (NOTE 11) 34728 34728 34728 34728

* RECOMMENDED SPARE PARTS

NOTE 1 – Material is Brass for size 35 Actuator and Aluminum for 55, 55A and 85 Actuators

NOTE 2 - Material is Cast Iron for 35 Actuator and Cast Aluminum for 55, 55A and 85 Actuators.

NOTE 3 – Material is Cast Bronze for 35 Actuator and Cast Aluminum for 55, 55A and 85 Actuators.

NOTE 4 – Used on Cast Iron Actuators only.

NOTE 5 – Used on Cast Aluminum Actuators only.

NOTE 6 – Includes one each, Handscrew Disc, Retainer Insert and two each Split ring.

NOTE 7 – Quantities are: Twelve (12) for the 35 size, Fourteen (14) for the 55 and 55A sizes, Sixteen (16) for the 85 sizes.

NOTE 8 – Quantities are: Eight (8) for the 35, 55 & 55A sizes and Six (6) for the 85 size Actuators.

NOTE 9 – Used only when Inner Adjusting Spring, Part No. 29 is used.

NOTE 10 – Yoke, Part No. 32, is furnished complete with Adjusting Sleeve, Part No. 36.

NOTE 11 – Quantities are: One (1) for 35 Actuator and Two (2) for all other sizes.

NOTE: Part Numbers 10, 11, 12, 13, 14, 19 and 27 have been deleted. For Part Numbers 28, 29, 30 and 38 see back page.

PART NAME MATERIAL

Diaphragm

Nut

Bolt

Diaphragm Disc (NOTE 4)

Diaphragm Disc (NOTE 5)

Diaphragm Case, Lower

Upper Stem

Yoke (NOTE 10) (NOTE 4)

Yoke (NOTE 10) (NOTE 5)

Washer, Inner Spring (NOTE 9)

Washer

Adjusting Nut (NOTE 4)

Adjusting Nut (NOTE 5)

Adjusting Sleeve

Travel Indicator

Synthetic Rubber

Steel

Steel

Cast Iron

Cast Aluminum

Pressed Steel

Stainless Steel

Cast Iron

Cast Aluminum

Stainless Steel

Stainless Steel

Cast Iron

Cast Bronze

Stainless Steel

Stainless Steel

QTY PER

UNIT

1

(NOTE 7)

(NOTE 7)

1

1

1

1

1

1

1

1

1

1

1

1

REFERENCE NUMBER – EACH SIZE PART

35 55 55A 85

38399-94

13901

38420

38393

38877

38345

38398

38335

38876

-38401

38394

58349

38397

38405

37810-94

26585

37797

37838

37839

37672

23263

37693

37692

-23260

23262

27978

37694

38920

37810-94

26585

37797

37838

37839

37672

61386

37693

37692

-23260

23262

27978

37694

15672

37819-94

26585

37797

37843

37844

37678

24273

37995

37994

-24271

24274

30081

37766

38921

VIEW SHOWING SIZES 55, 55A, &85

HAND OPERATING

17

VIEW SHOWING SIZES 55, 55A, & 85

DIAPHRAGM ACTUATORS

DEIVICES

VIEW SHOWING SIZE 35

HAND OPERATING

DEVICE

VEIW SHOWING SIZE 35

DIAPHRAGM ACTUATOR

Page 18

HAND OPERATING DEVICE

DIAPHRAGM ACTUATOR

REVERSE ACTING

WHEN ORDERING PARTS, PLEASE GIVE PART NAME AND PART REFERENCE

NUMBER FROM TABLE BELOW. USE PART NUMBER ONLY

TO LOCATE PART ON DRAWING.

NO.

1

2

3

4

5

6

7

7

8

14 Diaphragm Case, Upper Pressed Steel 1 38748 41788 41787

NO.

15 Diaphragm Case, Upper Pressed Steel 1 38392 37832 37832 37833

16

17

18

19

20*

21

22 Collar, Comp. (NOTE 4) (NOTE 11) 1 38412 37760 37760 38113

22

23

26*

27

28

29*

30

31

34

34

35

36

37

38

39

40

40

41

42

43

45 Washer St eel 1 39784 -- -- --

* RECOMMENDED SPARE PARTS

NOTE 1 – Material is Cast Iron for size 35R Actuator and Case Aluminum for 55R, 55AR and 85R Iron Actuators.

NOTE 2 – Material is Cast Bronze for 35R Actuator and Cast Aluminum for 55R, 55AR and 85R Actuators.

NOTE 3 – Quantities are: Four (4) for 35R Actuator and Six (6) for 55R, 55AR and 85R Actuator.

NOTE 4 – Used on Cast Iron Actuators only.

NOTE 5 – Used on Cast Aluminum Actuators only.

NOTE 6 – Material is Steel for the 35R, 55R and 85R Iron Actuator.

NOTE 7 – Quantities are: Twelve (12) for the 35R size, Fourteen (14) for the 55R & 55AR sizes, Sixteen (16) for the 85R sizes.

NOTE 8 – Quantities are: Eight (8) for the 35R, 55R & 55AR sizes and Six (6) for the 85R size Actuators.

NOTE 9 – Material is Steel for the 55R & 55AR, Ref. No. 37802; Cast Iron for the 85R Iron Actuator, Ref. No. 38116 and Cast Aluminum for the 85R

NOTE 10 – Used only when Inner Adjusting Spring, Part No. 37 is used.

NOTE 11 – Material is Steel for 35R Iron Actuators, Aluminum Alloy for 55R, 55AR and 85R Aluminum and Iron Actuators.

NOTE 12 – Quantity is One (1) for 35R size and Two (2) for all other size Actuators.

NOTE: - Part Numbers 24, 32 and 33 have been deleted. For Part Numbers 17, 36, 37 and 42 see back page.

PART NAME MATERIAL

Nut

Lockwasher

Handwheel, Complete

Handscrew Bearing

Assembly

Lockwasher

Screw

Bonnet, Complete (NOTE 4)

Bonnet, Complete (NOTE 5)

Diaphragm Nut

PART NAME MATERIAL

Nut

Diaphragm Disc

Nut

Bolt

Diaphragm

Diaphragm Case, Lower

Collar, Comp. (NOTE 5)

Cap Screw

Diaphragm Base Gasket

Stem Seal Ring

Screw

Stem Seal

Top Spring Seat

Stem Seat Collar

Yoke (NOTE 4)

Yoke (NOTE 5)

Upper Stem

Adjusting Spring

Inner Adjusting Spring

Washer, Inner Adj Spg (NOTE

10)

Washer

Adjusting Nut (NOTE 4)

Adjusting Nut (NOTE 5)

Indicator Disc

Indicator Scale

Screw

Aluminum Actuator, Ref. No. 38117.

Steel

Steel

Cast Aluminum

Stainless Steel

Steel

Stainless Steel

(NOTE 1)

(NOTE 2)

Steel

Steel

(NOTE 6)

Steel

Steel

Synthetic Rubber

Pressed Steel

(NOTE 11)

Steel

Synthetic Rubber

Steel

Stainless Steel

Synthetic Rubber

(NOTE 9)

Cold Rolled Steel

Cast Iron

Cast Aluminum

Stainless Steel

Steel, Blk. Japanned

Steel, Blk. Japanned

Stainless Steel

Stainless Steel

Case Iron

Cast Bronze

Stainless Steel

Aluminum

Steel, Plated

QTY PER

UNIT

1

1

1

1

(NOTE 3)

(NOTE 3)

1

1

1

QTY PER

(NOTE 7)

(NOTE 7)

(NOTE 8)

(NOTE 12)

REFERENCE NUMBER – EACH SIZE PART

35 55R & 55AR 85R

UNIT

1

1

1

1

1

1

1

6

1

1

1

1

1

1

1

1

1

1

1

1

1

1

13243

10392

43064

43043

11467

17186

38720

39077

38696

38400-94

38417-94

13243

10392

42226

51456

13077

41933

42224

42224

42220

REFERENCE NUMBERS – EACH SIZE PART

35R 55R 55AR 85R

24005

13901

38420

38391

38412

38420

--

--

--

-38416

38343

38940

38408

--

38401

38395

58350

38406

38404

34728

36229

(SEE

TABLE)

26585

37797

37809-94

37774

37760

37796

37761-95

37731

30501

37740-95

(NOTE 9)

28177

37728

37727

37758

(SEE

TABLE)

(SEE

TABLE)

-23260

31641

30623

38920

34728

13243

10392

42226

51456

13077

41933

42224

42224

41793

36229

26585

37797

37809-94

37774

37760

37796

37761-95

37731

30501

37740-95

(NOTE 9)

28177

37728

37727

61387

--

23260

31641

30623

1 5 6 7 2

(SEE T ABLE)

3 4 7 2 8

18

36229

26585

37797

37818-94

38081

38113

23400

38107-95

37731

30501

37740-95

(NOTE 9)

28177

37973

37972

38085

25393

24271

28174

31592

38921

34728

VIEW SHOWING SIZES 55R, 55AR, &85R

HAND OPERATING

DEIVICES

VIEW SHOWING SIZES 55R, 55AR, & 85R

DIAPHRAGM ACTUATORS

VIEW SHOWING SIZE 35R

HAND OPERATING

DEVICE

VEIW SHOWING SIZE 35R

DIAPHRAGM ACTUATOR

Page 19

FOR REVERSE ACTING ACTUATOR

PART NO. 17 DIAPHRAGM DISC

5/8 in

¾ in

7/8 in

1 in

1-1/4 in

1-1/2 in

2 in -- -- 37685

35 55R & 55AR 85R

38351

38351

--

--

--

--

ACTUATOR SIZE

37683

37683

37683

37683

49950

37684

1-1/8 in

1-1/4 in

1-1/2 in

FOR DIRECT ACTING ACTUATOR

PART NO. 30 LIIT STOP

VALVE TRAVEL

5/8 in

¾ in

7/8 in

1 in

2 in

15.9 mm

19.1 mm

22.2 mm

25.4 mm

28.6 mm

31.8 mm

38.1 mm

50.8 mm

35 55 & 55A 85

38403

--

--

--

--

--

--

--

ACTUATOR SIZE

44077

23393

23393

23394

23395

23395

23997

--

24482

46890

24482

24483

23366

23366

23367

23368

VALVE TRAVEL

ADJUSTING SPRING, INNER ADJUSTING SPRINGS AND TRAVEL INDICATOR SCALES ARE THE SAME FOR

EITHER DIRECT OR REVERSE ACTING ACTUATORS

PART NO. 28

PART NO. 36

ADJUSTING SPRING **

VALVE TRAVEL

5/8 in

15.9 mm

¾ in

19.1 mm

7/8 in

22.2 mm

1 in

1-1/8 in

1-1/4 in

1-1/2 in

** Springs listed are based on Standard Spring that will give the

25.4 mm

28.6 mm

31.8 mm

38.1 mm

2 in

50.8 mm

nearest range to 3-15 psi for the travel indicated. This is

based on zero pressure drop through valve. For various

pressure drops or ranges, these Springs can be interchanged

any way in each particular size. Consult Leslie Controls

when special range is required.

ACTUATOR SIZE

35® 55® & 55A® 85®

38422

38422

--

--

--

--

--

--

41969

41968

23239

24296

43078

24297

24298

--

35014

37719

24299

35014

41970

24299

24300

24301

PART NO. 29

PART NO. 37

INNER ADJUSTING SPRING

5/8 in

7/8 in

1 in

1-1/4 in

1-1/2 in

15.9 mm

22.2 mm

25.4 mm

31.8 mm

38.1 mm

ACTUATOR

SIZE VALVE TRAVEL

85®

37718

24481

--

--

--

PART NO. 38

PART NO. 42

TRAVEL INDICATOR SCALE

INDICATOR SCALES

SUBJECT TO ACTUATOR

MAXIMUM TRAVEL LIMIT

VALVE TRAVEL REF. NO.

¼ in

3/8 in

½ in

5/8 in

¾ in

7/8 in

1 in

1-1/8 in

1-1/4 in

1-1/2 in

1-3/4 in

2 in

6.4 mm

9.5 mm

12.7 mm

15.9 mm

19.1 mm

22.2 mm

25.4 mm

28.6 mm

31.8 mm

38.1 mm

44.5 mm

50.8 mm

37686

37686

37686

37686

38699

38699

48224

48048

48047

38904

38905

38906

38907

38908

38909

38910

49641

38911

19

Page 20

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance

shall be afforded with selection of materials based on technical information supplied to Leslie Controls Inc.; however,

system designer and user retain final responsibility. Designer should consider applicable Codes, material

compatibility, product ratings and application details in selection and application. Improper selection, application or

use of products described herein can cause personal injury or property damage. If designer or user intends to use

product for an application or use other than originally specified, he must reconfirm tat selection is suitable for new

operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

20

Loading...

Loading...