Page 1

12501 Telecom Drive, Tampa Florida 33637

Sizes ½” through 4” ANSI CLASS 125/250

Installation, Operating and

Maintenance Instructions

Supplement

DKLO D1 & D4 CONTROL VALVE

10/5.5.2

Rev. 1

TABLE OF CONTENTS

INTRODUCTION.......................................................................................................................................2

OPERATING PRINCIPLE.........................................................................................................................4

INSTALLATION.........................................................................................................................................4

START-UP....................................................................................................................................................4

TROUBLESHOOTING ..............................................................................................................................4

MAINTENANCE.........................................................................................................................................6

REMOVAL OF ACTUATOR FROM VALVE BODY ASSEMBLY.......................................................6

REVERSE ACTING PNEUMATIC ACTUATOR ...................................................................................6

DIRECT ACTING PNEUMATIC ACTUATOR.......................................................................................6

DISASSEMBLY OF VALVE BODY........................................................................................................6

DISASSEMBLY OF ACTUATOR ...........................................................................................................6

RE-ASSEMBLY OF ACTUATOR ...........................................................................................................7

LAPPING PLUG INTO SEAT ..................................................................................................................7

PACKING REPLACEMENT....................................................................................................................7

RE-ASSEMBLY OF VALVE BODY (D1) ...............................................................................................7

RE-ASSEMBLY OF VAVLE BODY (D4) ...............................................................................................7

REPLACING ACTUATOR ON VALVE BODY-PNEUMATIC.............................................................7

REVERSE ACTING..................................................................................................................................7

DIRECT ACTING .....................................................................................................................................7

ACTUATOR ADJUSTMENT – PNEUMATIC........................................................................................7

REVERSE ACTING..................................................................................................................................7

DIRECT ACTING .....................................................................................................................................7

PARTS LIST

.............................................................................................................................................................................

8

ILLUSTRATION INDEX

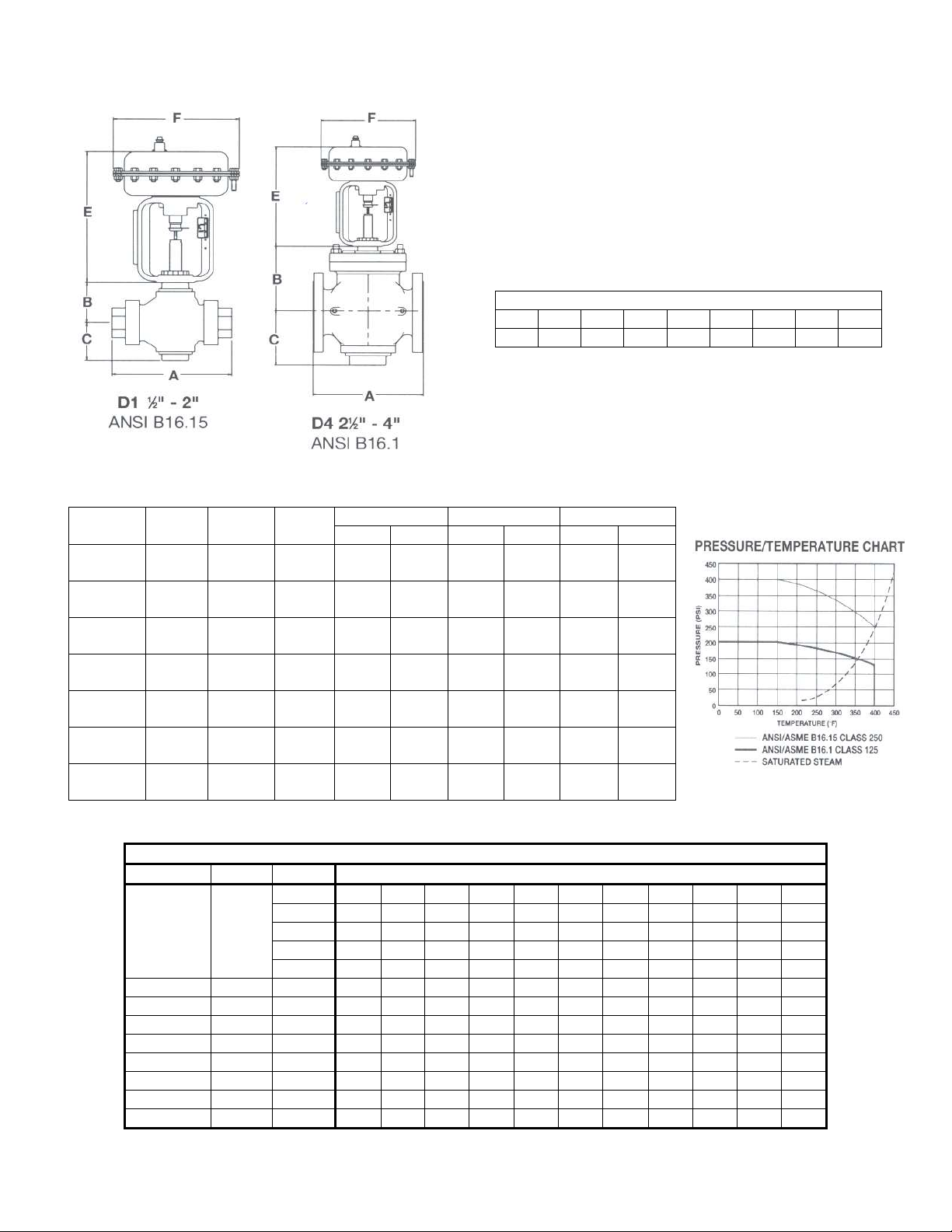

FIGURE 1 - TYPICAL STEAM INSTALLATION.......................................................................................................................4

FIGURE 2 - VALVE BODY ASSEMBLY D1 1"-2".....................................................................................................................9

FIGURE 3 - VALVE BODY ASSEMBLY D1 - 1/2" - 3/4"...........................................................................................................9

FIGURE 4 - VALVE BODY ASSEMBLY D4.............................................................................................................................10

FIGURE 5 - ACTUATOR ASSEMBLY D1&D4.........................................................................................................................11

FIGURE 6 - PISTON DIAPHRAGM ASSEMBLY.....................................................................................................................12

Page 2

INTRODUCTION

This Installation, Operation, and Maintenance Manual is

intended to be as complete and up to date as possible. It

covers installation, operation, and maintenance procedures

for Leslie Controls, Inc. DKLO D1 & D4 Control Valve.

Leslie reserves right to update this manual and other

product information concerning installation, operation,

and/or maintenance, at any time and without obligation to

notify product owners of such changes.

Leslie is not responsible for injury to personnel or product

damage due to improper installation, operation, and/or

maintenance Leslie Controls, Inc Back Pressure

Regulators. All installation, operation, and maintenance

procedures should only be performed by trained/certified

personnel. All personnel performing these procedures

should completely and carefully read and understand all

supplied materials before attempting procedures. All

personnel should pay strict attention to all Notes, Cautions,

and Warnings that appear within procedures detailed in

this manual.

Leslie welcomes user input as to suggestions for product or

manual improvement.

Contact Information

For information concerning warranties, or for questions

pertaining to installation,

Operation or maintenance of LESLIE products, contact:

LESLIE CONTROLS INC.

12501 Telecom Drive

Tampa, FL 33637

USA Phone: (813) 978-1000

USA Fax: (813) 978-0984

www.LESLIECONTROLS.com

To order replacement parts, contact LESLIE CONTROLS

at address listed above, or call toll free:

USA/Canada/Caribbean Phone: (800) 323-8366

Note: Please include model and serial number of unit for

which parts are being ordered. If ordering by phone, please

have this information readily available.

GENERAL NOTES AND WARNINGS

Notes:

• If questions are not answered by this manual, or if

specific installation, operation, and/or maintenance procedures are not clearly

understood, contact Leslie Controls, Inc. for

clarification before proceeding.

• If unit is damaged during installation, operation, or

maintenance, complete following steps:

1. Turn off and lock out pneumatic supply to unit in

an approved manner.

2. Turn off all incoming valves.

3. Contact in-house maintenance personnel or Leslie

Controls, Inc. for instructions.

Note: Throughout this manual, warnings will be

denoted by BOXES

Piping system must be adequately designed and

supported to prevent extraordinary loads to pressure

It is strongly recommended that this document be reviewed

before attempting any installation, operation, or

maintenance procedures. Use Instruction 20/0.5.1 for

General Installation, Operation and Maintenance Data.

CAUTION!

equipment.

2

Page 3

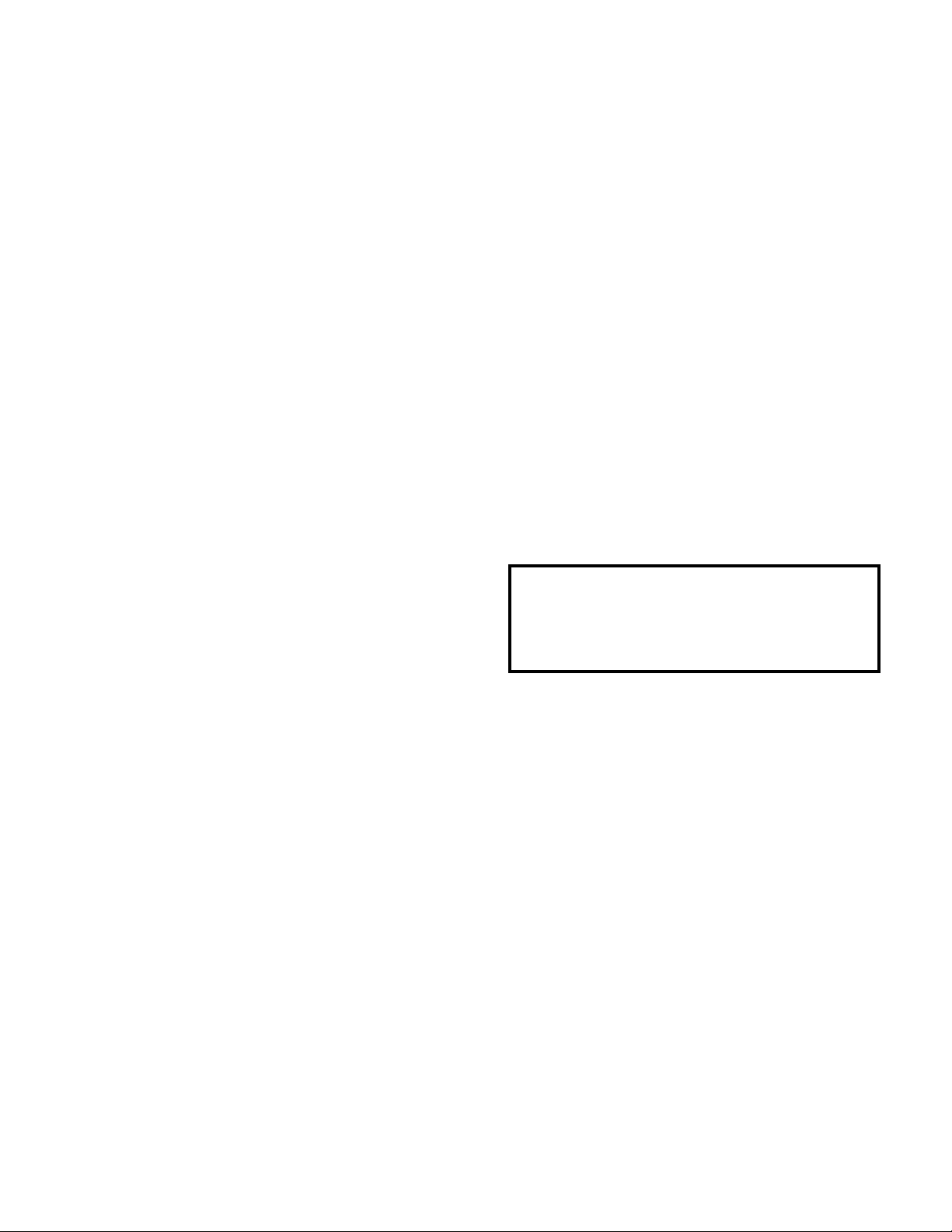

The DKLO Series Control Valve is designed for

Cv TABLE

DIMNESIONS

inches (mm)

AND WEIGHTS

pounds (kg)

economical control of steam, water, gas and process

applications in typical institutional, commercial and

industrial processes. The DKLO Series is available with

either a direct or reverse acting actuator that meets most

application requirements.

MAXIMUM RATED FLOW COEFFICIENTS* (Cv)

VALVE SIZE

½ ¾ 1 1 ¼ 1 ½ 2 2 ½ 3 4

5.2 7 11 20 25 30 71 94 146

Size

½ - ¾

(15)-(20)

1

(25)

1 ¼-1 ½

(32)-(40)

2

(50)

2 ½

(65)

3

(80)

4

(100)

A B C

5 ½

(140)

7 3/16

(183)

8 7/8

(226)

8 7/8

(226)

9 3/8

(238)

10

(254)

11 7/8

(302)

1 11/16

(43)

2 7/8

(74)

3 1/8

(79)

3 1/8

(79)

5 ¼

(133)

6 1/8

(155)

7 1/8

(181)

1 3/16

(30)

2 5/16

(58)

2 7/8

(74)

2 7/8

(74)

4 5/8

(118)

5 3/8

(136)

7 3/8

(187)

36 in2 60 in2 36 in2 60 in2 36 in2 60 in

9 7/8

(251)

9 7/8

(251)

9 7/8

(251)

9 7/8

(251)

--

--

--

--

--

--

E F Weight

--

--

11 ¾

(298)

11 ¾

(298)

11 ¾

(298)

11 7/8

(302)

11 7/8

(302)

11 7/8

(302)

9 ¼

(235)

9 ¼

(235)

9 ¼

(235)

9 ¼

(235)

--

--

--

--

--

--

--

--

11 ¼

(286)

11 ¼

(286)

11 ¼

(286)

11 ¼

(286)

11 ¼

(286)

11 ¼

(286)

21

(9.5)

25 ½

(11.6)

31 ½

(14.3)

33 ½

(15.2)

--

--

--

--

--

--

2

--

--

39

(17)

45

(20)

47

(21)

72

(33)

84

(39)

145

(66)

PERCENT OF TRAVEL 5 10 20 30 40 50 60 70 80 90 100

Valve Size Travel Orifice

1/2 1/4

C 0.1 0.2 0.3 0.36 0.41 0.46 0.51 0.56 0.6 0.65 0.7

Cv

E 0.3 0.5 0.7 0.9 1.1 1.3 1.5 1.7 1.9 2 2.1

A 0.3 0.6 1.2 1.7 2.2 2.6 2.9 3.1 3.2 3.25 3.3

B 0.15 0.25 0.65 1.5 2.7 3.3 3.7 3.9 4.1 4.2 4.3

T 0.7 1.2 2.0 2.7 3.2 3.8 4.3 4.7 4.9 5.1 5.2

3/4 5/16 T 0.7 1.3 2.4 3.3 4.2 4.9 5.5 6.0 6.4 6.8 7.0

1 1/4 T 0.7 1.3 2.4 3.8 5.5 4.7 9.0 10.0 10.6 10.9 11.0

1-1/4 5/16 T 0.8 1.7 4.0 6.5 9.3 12.6 15.3 17.0 18.1 19.1 20.0

1-1/2 5/16 T 1.0 2.0 4.5 7.2 9.9 12.4 15.2 18.2 20.9 23.4 25.0

2 5/16 T 1.0 2.0 4.5 7.4 10.6 15.1 18.8 22.8 26.1 28.3 30.0

2-1/2 3/4 T 5 11 23 36 46 53 59 62.5 65.7 68 71

3 3/4 T 5 11 30 47 61 72 79 85 90 92 94

4 3/4 T 12 23 46 69 89 104 116 127 134 140 146

3

Page 4

OPERATING PRINCIPLE

The Dklo D1 & D4 Valves are flow to open, globe style,

pneumatic diaphragm control valves. The pneumatic

actuator can be arranged to operate with either air to open

control. A controller sensing the controlled variable

provides a signal to the actuator of the control valve to

obtain the desired control. See application guide for other

operating instructions.

service is recommended. To eliminate excessive noise with

steam and other compressible fluids, enlarge the delivery

pipe size to effect a reasonable flow velocity at the reduced

pressure. A concentric transition is recommended. If

possible, avoid sharp turns close to the valve bullheaded

tee connections to a low pressure main. Install initial and

delivery pressure gauges to indicate performance. If the

rating of the delivery system or connected equipment is

less than the initial pressure, provide a safety relief valve.

Figure 1 – Typical Steam Installation

START-UP

Flush piping system thoroughly to clear it of welding

beads, scale, sand, etc. Install valve with the arrow on the

side of the valve body pointing in the direction of fluid

flow. Install controller and accessories in accordance with

instructions furnished by the manufacturer of these items.

Connect necessary airlines and/or electrical connections

INSTALLATION

Locate the valve in a straight run of horizontal pipe as

shown in Figure 1. The valve should be mounted with the

actuator in the upright position. Allow room for removal of

the actuator. Prevent pipeline hammering in compressible

fluid service by providing proper drainage before and after

the valve. Avoid damaging effects of scale and dirt in

pipelines by using a strainer. A 3-valve by-pass to

facilitate inspection and maintenance without interrupting

to diaphragm chamber and valve mounted accessories. Use

1/4" O.D. tubing for all air lines. If length of the air line

exceeds 25 ft, use 3/8” O.D. tubing. Insulation, if desired,

may be applied to the valve body only. Do not insulate

bonnet. Caution: Hazardous fluids may be handled by this

valve. Only qualified personnel, who are familiar with

your installation, should be permitted to install, readjust,

inspect or maintain the valve.

TROUBLESHOOTING

For troubleshooting of the controlling device and

accessories, see instruction furnished by manufacturer of

these items. To troubleshoot valve and actuator, check for

the following: change in operating conditions; pneumatic

signal failure; diaphragm failure; foreign matter lodged

between seat ring and plug; actuator vent plug may be:

plugged, missing, replaced with a solid plug; packing

leakage.

4

Page 5

D1 & D4 ACTUATOR SHUTOFF TABLE

(Refer to Temperature Limits)

Size

(inches)

1/2

3/4 T

1 T

1-1/4 T

1-1/2 T

2 T

2-1/2 T 60

3 T 60

*Shutoff pressures are in conformance with ANSI/FCI 70-2 Class IV

CAUTION: D1 designed for 3-15 psi. Do not exceed 20 psi.

Reverse Acting – Fail Closed/Air to Open (FC/ATO)

Direct Acting – Fail Open/Air to Close (FO/ATC)

† Based on 20 psi air supply with positioner.

‡ Based on 30 psi air supply.

Orifice

A, C, E 36 6-15 0-400 -- -- 3-12 0-400 -- --

T 36 6-15 0-300 -- -- 3-9 0-400 -- --

Act.

Size

36

60 12-15 0-400 -- -- 3-7 0-400 -- -36

60 -- -- -- -- 3-7 0-400 -- -36

60

60

60

Bench

Range

6-15 0-400 -- -- 3-12 0-300 -- -- B 36

-- -- -- -- 3-9 301-400 -- --

6-15 0-100 -- -- 3-9 0-250 -- -9-15 101-225 -- -- -- -- -- --

12-15 226-300 -- -- -- -- -- --

9-15 0-150 -- -- 3-9 0-100 -- -12-15 151-250 -- -- -- -- -- -13-15 251-400 -- -- -- -- -- --

9-15 0-150 -- -- 3-9 0-150 -- -12-15 151-200 -- -- -- -- -- -13-15 201-250 -- -- -- -- -- -12-15 0-300 -- -- 3-7 0-300 -- -13-15 301-400 -- -- -- -- -- --

12-15 0-150 -- -- -- -- -- -- 36

13-15 151-200 -- -- -- -- -- -12-15 0-225 -- -- 3-7 0-200 -- -13-15 226-275 -- -- -- -- -- --

12-15 0-50 -- -- -- -- -- -- 36

13-15 51-75 -- -- -- -- -- -12-15 0-125 -- -- 3-7 0-100 -- -13-15 126-175 -- -- -- -- -- --

10-15 0-75 0-100 0-100 3-8 0-70 0-110 0-200

12-15 76-125 101-125 101-125 3-8 0-70 0-110 0-200

22-30 -- 125 125 3-8 0-70 0-110 0-200

10-15 0-40 0-60 0-60 3-8 0-40 0-60 0-100

12-15 41-60 0-80 0-80 3-8 0-40 0-60 0-100

22-30 -- 81-110 81-110 3-8 0-40 0-60 0-100

12-15 0-20 0-32 0-32 3-8 0-10 0-15 0-25 4 T 60

22-30 -- 33-50 33-50 3-8 0-10 0-15 0-25

3-15 psi 0-20 psi† 0-30 psi‡

Reverse Shutoff* Direct Shutoff*

Bench

Range

3-15 psi 0-20 psi† 0-30 psi‡

5

Page 6

DKLO SERIES CODE SELECTION CHART

CLASS ORIFICE

SIZE

D 1 T E 8 1 1 3 6 R B

1 2 3 4 5 6 7 8 9 10 11

Class –

Position 1&2

D1 = Bronze

D4 = Cast Iron

Orifice Size –

Position 3

A

B

C

E

T

Valve Size –

Position 4

C = 1/2

D = 3/4

E = 1

F = 1-1/4

G = 1-1/2

H = 2

J = 2-1/2

K = 3

M = 4

VALVE

SIZE

Connections –

Position 5

2 = 125 Flg

8 = Unions

Trim Material –

Position 6

1 = Metal

Packing –

Position 7

1 = V-ring

CONNEC-

TIONS

TRIM

MATERIAL

Actuator –

Position 8 & 9

01 = None

36 = 36 sq. in.

60 = 60 sq. in.

PACKING

ACTUATOR BENCH RANGE

Bench Range – Position 11 & 12

AA = None

DKLO only

DA = 3-12 Dir 36

DB = 3-9 Dir 36

RA = 6-15 Rev 36

RB = 9-15 Rev 36

RC = 12-15 Rev 36

RD = 13-15 Rev 36

DF = 3-10 Dir 60

DG = 3-7 Dir 60

RG = 12-15 Rev 60

RH = 13-15 Rev 60

DKLO-C only

DH = 3-8 Dir 60

RH = 10-15 Rev 60

RQ = 12-15 Rev 60

RT = 22-30 Rev 60

MAINTENANCE

REMOVAL OF ACTUATOR FROM VALVE

BODY ASSEMBLY

Close inlet and outlet stop valves. Be sure body is not

under pressure. Remove all accessories from control valve.

Refer to Figure 2.

REVERSE ACTING PNEUMATIC

ACTUATOR

Loosen stem nuts (24) and move to approximately 1/3

down valve stem. Re-tighten being careful not to move

valve stem. Energize actuator with air to lift the plug off

the seat. Disengage lock nut (26) from bonnet (25). Deenergize actuator. The actuator and yoke should move

away from bonnet. Lift actuator and yoke assembly along

with plug (39) off the seat. With an adjustable wrench,

unthread valve stem from actuator stem (Fig.6, #16) until

valve stem is disengaged from actuator stem. Remove stem

nuts, indicator, packing nut and lock nut.

DIRECT ACTING PNEUMATIC ACTUATOR

Energize actuator with air slightly (in case of back

seating). Loosen stem nuts (24) and re-tighten

approximately 1/8” away from actuator stem (Fig. 6, #16).

Disengage lock nut (26) from bonnet (25). With and

adjustable wrench, unscrew valve stem from actuator stem.

When valve stem reaches seat, lift actuator (to prevent

galling seat and plug). Remove stem nuts, indicator and

lock nut.

DISASSEMBLY OF VALVE BODY

Remove stem nuts (24), indicator (32) and lock nut (26).

Lift yoke off bonnet (25). To complete body disassembly,

unscrew bonnet for D1 and cap (42) for D4. For D4

remove bonnet nuts (34) and lift off blind flange (35),

bonnet, stem and plug assembly (37). Remove gasket (36).

A new gasket should be installed each time valve body is

disassembled. Turn stem and plug assembly out of bonnet

through packing. Replace packing if necessary. All parts

should be inspected for wear and cleaned thoroughly

before re-assembling valve body.

DISASSEMBLY OF ACTUATOR

Remove actuator from valve. Remove regular casing bolts

(4) and casing nuts (5). Gradually loosen nuts on

remaining long casing bolts (14) to allow pre-compression

of actuator springs. Remove upper casing (2). Pull actuator

stem (16), along with diaphragm (15), springs (3) and

piston (13), out through bushing (7). Place a wrench on the

6

Page 7

machined flats of actuator stem, and remove stem nut (10),

seal washer (12) and stem washer (11). Remove o-ring (8)

from bushing and replace if necessary. Lubricate o-ring

after installing.

RE-ASSEMBLY OF ACTUATOR

Refer to Figure 6 for correct orientation of casings,

diaphragm (15), piston (13), stem (16) and springs (3) for

direct or reverse action. Be sure piston spring recesses line

up between casing ribs as shown in Figure 8C. Lubricate

bushing O-ring (8) and insert actuator stem through

bushing. Re-attach upper casing (2) with long bolts (14) &

nuts (5), tightening alternately. Install remaining casing

nuts and bolts. Apply air to diaphragm case and check for

leakage, full travel and dead band less than .2 psi.

LAPPING PLUG INTO SEAT

Seats and plugs should never require more than the lightest

touch up with very fine (400 grit) grinding compound.

Heavy lapping will produce galling, a wider seating

surface and a groove in the plug, all of which tend to cause

leakage. Reface a damaged surface before attempting to

grind it in. Lap sparingly. Replace stem and plug (39) in

bonnet (25) through packing. Apply lapping compound to

plug. Place bonnet and bonnet flange (35 for D4 only) on

body. After lapping, disassemble and clean and parts

thoroughly.

PACKING REPLACEMENT

Check stem for marks and scratches if packing leaks.

Replacement packing cartridges can be installed.

RE-ASSEMBLY OF VALVE BODY (D1)

Tighten bonnet (25) to body. Replace yoke (9), lock nut

(26), stem nuts (24) and travel indicator (32) over stem

(34).

RE-ASSEMBLY OF VAVLE BODY (D4)

Install a new gasket (36). Attach bonnet (26) and bonnet

flange (35) to body with bonnet studs and nuts (33, 34). Be

sure to tighten bolts alternately and evenly to ensure proper

seating of the plug. Replace yoke (9), lock nut (27), stem

nuts (31) and travel indicator (23) over stem (30).

REPLACING ACTUATOR ON VALVE

BODY-PNEUMATIC

Put actuator assembly over valve stem. Place lock nut (Fig.

2, #26), and stem nuts (24) with travel indicator (32) on

valve stem. Rest actuator stem (16) on valve stem. Tighten

stem nuts approximately 2/3 down valve stem. Lift

actuator assembly and engage valve stem with actuator

stem (be careful not to gall plug & seat).

REVERSE ACTING

When sufficient engagement is met, the actuator can be

energized with air to place the yoke on the bonnet (25) and

lift the plug off the seat. Tighten lock nut and packing nut.

DIRECT ACTING

Engage valve stem with actuator stem so no contact is

made between plug and seat when bottom of yoke is rested

on bonnet. Tighten lock nut.

ACTUATOR ADJUSTMENT – PNEUMATIC

Close inlet and outlet stop valves. Be sure valve body is

not under pressure. Place a wrench on the machined flats

of actuator stem (16). Counter two stem nuts (24)

approximately halfway down the threads of the stem (34).

REVERSE ACTING

Apply sufficient air pressure to diaphragm case to start

moving valve through its rated travel. This is shown by

travel indicator (32). Engage lower stem nut (24) and turn

body stem (34) into actuator stem (16) until precompression of actuator springs (3) is relieved (plug

should not be seating on seat ring when air pressure is

removed from actuator case). Apply prescribed setting

pressure to actuator. This is determined by specific

operating conditions. Turn body stem out of actuator stem

until plug seats on seat ring (28). To prevent galling, do

not turn body stem after plug has contacted seat ring. Turn

stem nuts up plug & stem assembly and tighten to lock

them in position. Reduce air signal to 0 psi and calibrate

indicator scale (20). Check that full travel is achieved with

a 15 psi signal.

DIRECT ACTING

Engage lower stem nut (24) and turn body stem (34) into

actuator stem (16) until plug & stem assembly stops at

upper limit of travel and/or a slight downward movement

of actuator stem is detected. Turn stem nuts up body stem

and tighten them to lock in position. Calibrate indicator

scale (20). Check that full travel is achieved at a 3 psi

signal.

7

Page 8

D1 VALVE BODY ASSEMBLY PART NUMBERS

PART NAME MATERIAL

NO.

23 A* STEM BOLT- SHORT BRASS 04-17277-00 04-17277-00 04-17277-00 04-17277-00 04-17277-00 04-17277-00

23B** STEM BOLT-LONG BRASS 04-17281-00 04-17281-00 04-17281-00 04-17281-00 04-17281-00 04-17281-00

24 STEM NUT BRASS 05-17342-00 05-17342-00 05-17342-00 05-17342-00 05-17342-00 05-17342-00

25 BONNET ASSY BRASS 557B109-01 557B109-01 557B107-02 557B107-02 557B110-02 557B110-02

26 LOCK NUT ST STL 05-17330-00 05-17330-00 05-17330-00 05-17330-00 05-17330-00 05-17330-00

27 WAVE WASHER ST STL -- -- 122A155-01 122A155-02 122A155-02 122A155-02

28A SEAT RING, 1/2A D1

SEAT RING, 1/2B D1

SEAT RING, 1/2C D1

SEAT RING, 1/2E D1

SEAT RING, T D1

28B SEAT RING, 1/2A D5

SEAT RING, 1/2B D5

SEAT RING, 1/2C D5

SEAT RING, 1/2E D5

SEAT RING, T D5

29 TAILPIECE GALV IRON SX227 SMP462 SMP463 SBB227 SMP465 SMP593

30 BODY BRONZE 292B110-01 292B110-01 SAM1167B SAN1167B SAN1167B 564B116-01

31 CAP BRASS -- -- 557B101-01 SB312E

32 TRAVEL INDICATOR ALUM 05-12962-00 05-12962-00 05-12962-00 05-12962-00 05-12962-00 05-12962-00

33 V RING PACKING SET TFE/SS/VITON 204A104-01 204A104-01 204A104-01 204A104-01 204A104-01 204A104-01

34 STEM ST STL 552A117-01 552A117-01 552A115-01 552A115-02 552A115-02 552A115-02

35* YOKE BUSHING BRASS 04-17278-00 04-17278-00 04-17278-00 04-17278-00 04-17278-00 04-17278-00

36** SPACER BRASS 04-17280-00 04-17280-00 04-17280-00 04-17280-00 04-17280-00 04-17280-00

37 NUT ST STL 05-17342-00 05-17342-00 -- -- -- -38 GUIDE ST STL -- -- 556A111-01 556A111-02 556A111-02 556A111-02

39 PLUG, 1/2A

PLUG, 1/2B

PLUG, 1/2C

PLUG, 1/2D

PLUG, 1/2E

PLUG, T

40 UNION NUT GALV IRON SMP487 SMP467 SMP468 SMP470 SMP470 SMP592

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

ST STL

1/2 3/4 1 1-1/4 1-1/2 2

SN217

SUU217

SN217

SN217

SX217

562A110-01

562A110-01

562A110-01

562A110-01

562A112-01

554A154

554A158

554A153

554A156

554A159

554A157

--

--

--

--

SM217

--

--

--

--

562A113-01

--

--

--

--

--

554A155

* Not included in body assembly; order K-KIT separately.

** Not included in body assembly; order separately.

VALVE SIZE ITEM

--

--

--

--

562A114-02

--

--

--

--

562A114-02

--

--

--

--

--

554A146-02

--

--

--

--

562A114-03

--

--

--

--

562A114-03

--

--

--

--

--

554A146-03

--

--

--

--

562A114-04

--

--

--

--

562A114-04

--

--

--

--

--

554A146-04

--

--

--

--

562A114-05

--

--

--

--

562A114-05

--

--

--

--

--

554A146-05

Page 9

Figure 2 – Valve Body Assembly – D1 1” – 2” Figure 3 – Valve Body Assembly – D1 – 1/2" – 3/4"

When ordering parts,

its essential that the

valve type, size,

service and serial

number be stated.

Select part by item

number, but order by

part number.

Specify complete part

number when

ordering.

NO. PART NAME MATERIAL

23 Pointer Aluminum 5-12962-0 5-12962-0 5-12962-0

24 Stem bolt Brass 4-17277-0 4-17277-0 4-17277-0

25 Packing box Brass 204A104-01 204A104-01 204A104-01

26 Bonnet Ductile iron 558B113-02 558B113-02 558B113-02

27 Nut Stl/zinc pltd 5-17330-0 5-17330-0 5-17330-0

28 Yoke bushing Brass 4-17278-0 4-17278-0 4-17278-0

29 Stem bearing 303 ss SU260 SU260 SU260

30 Valve stem 303 ss 552A117-02 552A117-02 552A117-02

31 Nut 316 ss 5-17342-0 5-17342-0 5-17342-0

32 Disc 420 ss 4-08242-0 4-01918-0 4-01931-0

33 Tap stud Steel 4-10119-0 4-05443-0 4-10119-0

34 Nut Steel 5-02860-0 5-02856-0 5-02860-0

35 Blind flange Cast iron 4-17334-0 4-17337-0 4-17334-0

36 Gasket Graphite 5-02367-1 5-02369-1 5-02371-1

37 Disc stem 304 ss 4-17333-0 4-17340-0 4-17344-0

38 Nut C1018 5-02973-0 5-02973-0 5-02974-0

39 Seat Ring 420 ss 4-11539-0 4-11484-0 4-11565-0

40 Body Cast iron 4-00653-0 4-00655-0 4-00659-0

41 Cap Cast iron 4-01325-0 4-17339-0 4-17346-0

42 Pipe plug 12L14 4-03769-0 4-03769-0 4-03769-0

2-1/2 3 4

VALVE SIZE ITEM

9

Page 10

D1 and D4 are designed and manufactured in

accordance with Article 3, Section 3 of the Pressure

NOTE

Equipment Directive.

Figure 4 – Valve Body Assembly – D4

10

Page 11

D1 & D4 ACTUATOR PART NUMBERS

ITEM # PART NAME MATERIAL PART # QTY

1 Vent plug H.D. poly -- 1

2

3 Springs Steel See Below See Below

4 Casing bolt standard 304 ss -- 10./14

5 Casing nut 316 ss -- 12./16

6

7 Bushing Bronze -- 1

*8 “””O””Ring” Buna-n 5-04017-0 1

9 Yoke Cl/powder coat -- 1

*10 Stem nut Steel 5-13374-0 1

*11 Stem washer 316 ss 5-12963-0 1

*12 Seal washer Steel 5-13203-0 1

13 Piston 316 ss -- 1

*14 Casing bolt long 304 ss 5-04889-0 2

*15 Diaphragm – 36 sq. in.

16 Actuator stem 303 ss -- 1

17 Machine screw Steel -- 3

18 Casing gasket Buna-n -- 1

19 Machine screw Steel -- 2

*20 Indicator scale Aluminum 5-13190-0 1

*21 Specification plate Aluminum 5-13199-0 1

**22

Upper casing Stl/powder

coat

Lower casing Stl/powder

coat

Nitrile 0-12869-0

Diaphragm – 60 sq. in.

Stop 12-15 psi

Stop 10-15 & 22-30 psi

Zinc alloy 5-17360-0

-- 1

-- 1

@-12986-0

5-17362-0

1

1

1

1

* These parts furnished in Actuator Repair Kit.

** Used in D4 only

Figure 5 – Actuator Assembly – D1 & D4

11

Page 12

D1 & D4 ACTUATOR SPRING KITS

†

D1 & D4 ACTUATOR CONNECTOR KITS

Part # Notes Code Range Code Range Code Range Code Range QTY Color Part#

36KIT100 (1) 36RA 6-15 - - 36DA 3-12 - - 6 YELLOW 05-12991-00 36KIT102 (3) 36RB 9-15 - - - - - - 6 YELLOW 05-12992-00 36KIT104 (2) (4) 36RC 12-15 - - - - - - 6 RED 05-13090-01 -

36KIT106 (2) (4) 36RD 13-15 - - - - - - 4 RED 05-13090-01

36KIT110 (1) - - - - 36DB 3-9 - - 6 METAL 05-05121-00 -

60KIT100 (1) (4) 60RG 12-15 - - 60DG 3-7 - - 6 BROWN 05-13093-01 60KIT102 (1) (4) 60RH 13-15 60RH 10-15 - - DH 3-8 4 BROWN 05-13093-01 60KIT104 (1)

60KIT110 (1)

For Direct Shutoff – Invert Springs, Piston and Diaphragm from Reverse Shutoff Actuator.

††

To convert a D1 actuator to a D4 actuator you must add travel stop (05-17362-00) into the actuator and vice versa.

Reverse Shutoff

(Air-to-Open) Bench Range

D1 D4

- - 60RQ 12-15 - - - - 6 BLACK 05-13097-00

- - 60RT 22-30 - - - -

††

Direct Shutoff

(Air-to-Close) Bench Range

D1 D4 Spring Other

(1) For D1 & D4 ONLY – Mounts using KKIT-1 (3) For D1 & D4 ONLY – Mounts using KKIT-3

(2) For D1 & D4 ONLY – Mounts using KKIT-2 (4) Includes VLG travel scale

†

6 6 BROWN

Spring Kit Includes: Part #

GRAY

05-13093-00

05-13094-00

05-12963-00

(1) Washer

05-04889-00

(2) Bolts

requires

special

assembly

PART # SIZE ORIFICE

SEAT

STYLE

FOR USE WITH KKIT Includes:

D1 D4 Steam Bolt Bushing Spacer

KKIT-1 1/2 – 4 All All X X 04-17277-00 04-17278-00 KKIT-2 1/2 – 2 All All X 04-17281-00 07-17278-00 KKIT-3 1/2 – 2 All All X 04-07281-00 04-17278-00 04-17280-00

Figure 6 – Piston Diaphragm Assembly

ACUTATOR REPAIR KIT PART NUMBERS

36 SQ. IN. 60 SQ. IN.

51447 51448

12

Page 13

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance

shall be afforded with selection of materials based on technical information supplied to Leslie Controls Inc.; however,

system designer and user retain final responsibility. Designer should consider applicable Codes, material

compatibility, product ratings and application details in selection and application. Improper selection, application or

use of products described herein can cause personal injury or property damage. If designer or user intends to use

product for an application or use other than originally specified, he must reconfirm tat selection is suitable for new

operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

13

Loading...

Loading...