Page 1

12501 Telecom Drive, Tampa Florida 33637

INSTALLATION

V

ALVE POSITION

P

ROBLEM PREVENTING PROCEDURES

OPERATION

MAINTENANCE

R

EPLACING VALVE PLUG STEM PACKING

D

ISMANTLING

TO I

NSTALL A COMPLETE SET OF PACKING

R

EMOVING ACTUATOR FROM VALVE BODY ASSEMBLY

V

ALVES FITTED WITH CAGE TYPE TRIM (O IN CLASS

R

EPLACING SEAT RING(S

TO I

NSTALL SEAT RING(S

I

NSPECTION, CLEANING, REWORKING OR REPLACEMENT OF PARTS

O

RDERING PARTS

C

LEANING

L

APPING IN VALVE PLUG AND SEAT RING(S

C

ONTROL VALVES FITTED WITH CAGE TYPE TRIM

R

EASSEMBLY- SINGLE PORTED CONTROL VALVES

C

AGE TYPE TRIM

A

DJUSTING ACTUATOR SPRING PRELOAD (STARTING PRESSURE

S

INGLE PORTED UNBALANCED CONTROL VALVES

S

INGLE PORTED CONTROL VALVES

A

DJUSTED CONTROL VALVE FOR RATED TRAVEL

S

INGLE PORTED UNBALANCED

S

INGLE PORTED UNBALANCED CONTROL VALVES

ACTUATOR MAINTENANCE REPLACING DIAPHRAGMS, STEM

SEALS, ETC.

R

EASSEMBLY

A

LL ACTUATORS

TO C

NOTE 1: Where noise is a factor follows recommendations for piping and fittings per 5/0.3.1.

....................................................................................................................................................4

HANGE VALVE ACTION FROM NORMALLY OPEN TO NORMALLY CLOSED OR VICE-VERSA

Installation, Operation

and Maintenance

Rev. 0

CONTROL VALVES

SINGLE PORTED

CLASSES DL, DDL, DOS, DDOS

TABLE OF CONTENTS

..............................................................................................................................2

.........................................................................................................................................2

..........................................................................................................2

.......................................................................................................................................2

..............................................................................................................................3

...................................................................................................3

..............................................................................................................................................3

.................................................................................................3

..............................................................................3

)................................................................................4

)/I

10/1.5.1

NSERTS

)/I

........................................................................................................................................4

(DOS T

...............................................................................................................................................7

.........................................................................................................................................8

YPE CTRIM PARTS) (SEE FIG.

.......................................................................................................................................7

.............................................................................................................4

NSERTS

.............................................................................................................4

............................................................4

)/I

NSERT

..................................................................................5

.....................................................................................5

(DL T

YPE

) ...................................................................5

3)...........................................................................5

)...............................................................6

(DDL, DDOS T

(DL, DOS T

(DL, DOS T

YPES

.......................................................................................6

YPES

) ......................................................................................6

(DDL, DDOS T

YPES

)........................................................6

)..........................................................................6

YPES

) ..................................................7

................8

Page 2

Illustration Index

Figure 1 - Typical Installation .........................................................................................................................3

Figure 2 - Typical Control Valve Station for Control of Compressible Fluids at 25% or Less of Inlet Pressure

.................................................................................................................................................................3

Figure 3 - Cage Trim (DOS Type) ..................................................................................................................5

Figure 4 - Single Ported Control Valve Body Assmebly (Actuator Removed)...............................................5

Figure 5 - Use of Seat Ring Wrenches to Remove or Install Seat Rings.........................................................6

Figure 6 - Main Body Sub-Assembly..............................................................................................................6

Figure 7 - Alternate Method ............................................................................................................................7

Figure 8 - Direct Acting Diaphragm Actuator...............................................................................................10

Figure 9-Reverse Acting Diaphragm Actuator..............................................................................................10

2

Page 3

extraordinary loads to the pressure

INSTALLATION

Valve Position

(see Fig. 1)

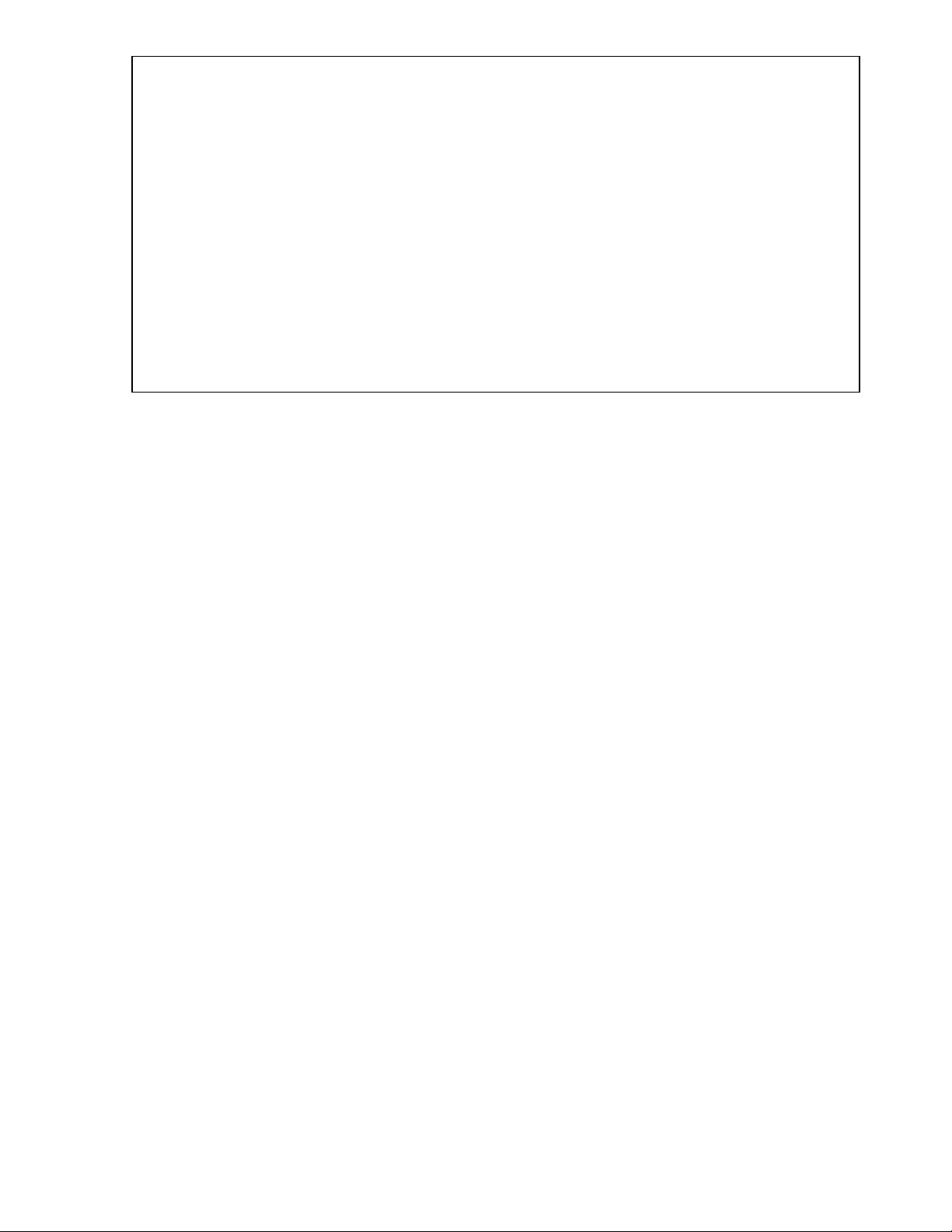

Install control valve in the highest horizontal line

of piping, in an accessible location and with

arrow on side of valve body in direction of fluid

flow. Control valve may be placed in any

position, but upright is preferable for ease of

maintenance.

Figure 1 - Typical Installation

Problem Preventing Procedures

1. Provide removal space above, below

and around control valve for easy

removal of parts during maintenance.

See proper drawing for dimensions.

2. Blow or flush out pipelines thoroughly

before installing control valve.

3. Protect control valve and the following

equipment with a self-cleaning strainer.

4. Install stop valves and gauges in inlet

and outlet lines to provide means for

checking adjustment and operation of

equipment.

5. Provide proper inlet and outlet drainage

in steam service to prevent water

hammer or possible erosion of

equipment.

6. Adhere to good piping practice. Install

a bypass around the control valve.

Connect operating medium tubing from control

pilot instrument or loading device to diaphragm

chamber connection of control valve or to valve

positioner, if one is in use.

Important: If control valve is fitted with a

Thermo-Isolating bonnet, do not lag or insulate

bonnet or paint it other than dull black, otherwise

its heat emitting efficiency will be impaired and

packing will be submitted to excessive

temperature.

RECOMMENDED PIPING FOR CONTROL

OF COMPRESSIBLE FLUIDS AT VALUES

OF 25% OR LESS OF INLET PRESSURE.

1. Expand outlet pipe to twice control

2. Connect control pipe for control pilot

3. Make control pipe connection at least

NOTE: Where sensing impulse is taken 2’ to 3’

downstream from control valve (expander),

dimension “A” minimum of 6’ to 10’ will

provide lowest noise and velocity factors,

accurate pressure sensing and reasonable bypass

length.

The piping system must be adequately

designed and supported to prevent

valve inlet pipe size. Use tapered

expander.

ahead of outlet stop valve and at least 2’

to 3’ downstream from end of expander.

18” to 24’’ from outlet stop valve, any

elbow or other flow direction out

changing fitting. (see Fig. 2)

Figure 2 - Typical Control Valve Station for

Control of Compressible Fluids at 25% or

CAUTION!

Less of Inlet Pressure

OPERATION

1. Close inlet and outlet stop valves.

2. Check that control valve responds

properly through rated travel in relation

to changes in operating pressure on the

3

Page 4

diaphragm. Rated travel is shown by

position of travel indicator on valve

stem relative to travel indicator scale on

yoke.

3. Manually operate control valves fitted

with manual operating devices through

rated travel to check freedom of

movement.

4. Place control valve in operation in

accordance with instructions furnished

with control pilot or other operating

device.

MAINTENANCE

(DL, DDL, DOS, DDOS – 600 lbs. or

less)

NOTE: To reduce maintenance time refer to

proper drawing and follow steps shown below

for applicable maintenance operation.

To Renew Valve Plug

Stem Packing

To dismantle Control

Valve – Inspect Parts –

Replace or Regrind

Valve Plug/Seat

Ring(s)

To Reassemble

Control Valve

To Preload Adjusting

Spring Set Rated

Travel

To Replace Diaphragm

and/or Stem Seal

To change Valve

Action Normally Open

to Normally Closed or

Vice Versa

Injury or death can occur due to failure to

completely isolate valve from all sources of

pressure before beginning disassembly. Do not

proceed until valve has been completely isolated

from the process and vented to atmosphere.

WARNING

Maintenance

Maintenance Dismantling

Maintenance –

Reassembly

Maintenance –

Reassembly 3 thru 10

Actuator Maintenance

Actuator Maintenance

Replacing Valve plug Stem

Packing

Replace valve plug stem packing if control valve

has been in service beyond normal maintenance

and packing shows signs of wear. Wear will be

indicated by leakage, which cannot be corrected

by minor tightening of packing flange.

Where Leslie BRAIDED TEFLON GRAPHITE

packing is in use, additional packing rings can be

installed to overcome minor leakage without

dismantling the control valve or breaking valve

plug connection.

Dismantling

1. Close inlet and outlet stop valves. Operate

system on bypass, if necessary.

2. Shut off operating medium and relieve

pressure from diaphragm by disconnecting

tubing at diaphragm case.

To Install a Complete Set of

Packing

1. Disassemble control valve as far as

necessary for work required. Remove old

packing. Clean valve plug stem and packing

box thoroughly. Polish valve plug stem with

crocus cloth. Use approved, non-residue

forming solvent for cleaning. Wipe dry with

clean cloth.

2. Insert a new set of packing in packing box in

the order shown on the packing wrapper.

Packing wrapper contains complete

installation instructions on how to install a

set of packing. Each wrapper shows the

order in which the various pieces of packing

are to be inserted in the particular valve in

which they are to be used.

3. After packing is installed, reassemble

packing follower, packing box flange and

bolts/studs to bonnet. Tighten bolts/studs as

shown in instruction on wrapper.

4

Page 5

Removing Actuator from Valve

Body Assembly

Direct Acting Actuator:

Loosen valve plug stem nut (29). Use wrench on

flats of valve plug stem and turn valve plug stem

out of actuator stem threads until it is

disengaged. (In large control valves, support

valve plug stem to prevent valve plug from

suddenly falling downward as valve plug stem

clears actuator stem). Take travel indicator off

valve plug stem.

Remove capscrews (39) holding actuator to

bonnet and lift actuator off bonnet.

Reverse Acting Actuator:

Insert lock rod (attached to yoke) through yoke

and stem, loosen valve plug stem nut, then

follow direct acting actuator procedure.

Single Ported Unbalanced Types

– DL, DOS Types

Remove nut (29) from valve plug stem.

Disassemble bonnet bolts/nuts (45/42). Lift

bonnet, valve plug assembly and bonnet gasket

(44) off valve body. Loosen and remove bottom

cap (flange) (48) and gasket (47) where

applicable. Disassemble packing flange

bolts/studs (37), packing flange (36) and packing

follower (38) from bonnet. Clean out packing

box.

(See Fig. 3 and 4)

Valves Fitted with Cage Type

Trim (O in Class)

(See Fig.3)

Trim components are: Seat retaining guide/cage

(48), seat ring/insert (51) and seat ring/insert

gasket (50). Body gasket (47), seat retaining

guide/cage (48), valve plug guide and throttling

sector will come out along with valve plug.

Disassemble parts when removing valve plug

from bonnet.

To remove seat ring/insert, place tapered wooden

dowel into seat ring/insert and lift out seat

ring/insert. Seat ring/insert gasket will follow.

(see Fig. 4)

Figure 4 - Single Ported Control Valve Body

Assmebly (Actuator Removed)

Replacing Seat Ring(s)/Inserts

Figure 3 - Cage Trim (DOS Type)

(Threaded Ring Only)

To remove threaded seat ring use seat ring

wrench see Fig. 5.

5

Page 6

Figure 5 - Use of Seat Ring Wrenches to

Remove or Install Seat Rings

All Leslie control valves are made of the finest

material obtainable, time-tested and backed by

over 100 years of know-how. Machining is done

by an expert craftsmen and each valve is

inspected and service tested before shipment to

you.

Use of other than genuine Leslie parts may

impair their ability to serve you. Leslie parts are

held to very close tolerance to eliminate field

machining and grinding on valve and seat

ring/inserts or reaming on (valve plug guide

bushings).

To Install Seat Ring(s)/Inserts

1. Carefully clean threads and joint contact

surfaces on seat ring(s) and in valve body.

2. Make sure joint surfaces are undamaged.

3. Screw seat ring into valve body threads and

pull up tight with wrench.

4. Tap end of seat ring wrench bar with

hammer to lock seat ring in place.

Inspection, Cleaning, Reworking

or Replacement of Parts

Inspect all parts, including valve plug and seat

ring/insert(s). Replace any excessively worn or

damaged part(s). Do not remove threaded type

seat ring(s) from valve body unless necessary to

replace.

Ordering Parts

Order parts from the proper drawing. Give valve

type, size, press class and part(s) reference

number(s) or part name, valve code number and

serial number.

Lapping in Valve Plug and Seat

Ring(s)/Insert

Apply superfine lapping compound to valve

seating surface and assemble valve plug and

bonnet to valve plug body as shown in figure 6.

Lap in until a fine continuous ring of contact has

been made on both surfaces. Do not lap until a

ridge is formed. (see Fig. 6)

Cleaning

Clean all parts thoroughly with an approved,

non-residue forming solvent. Remove encrusted

material with crocus cloth or very mild

aluminum oxide cloth. For parts repair

information, consult your local Leslie

Representative.

6

Figure 6 - Main Body Sub-Assembly

1. Bonnet acts as guide when grinding valve

plug.

2. Loosen packing flange studs/bolts slightly if

packing is installed.

3. Uses wrench on flats of valve plug stem for

turning valve plug. Do not bear down on

Page 7

valve plug stem when lapping. Weight of

parts is sufficient to cause lapping action.

4. Place lapping compound on valve plug face.

5. As lapping progresses lift valve plug off seat

occasionally and rotate 45° to keep

compound evenly distributed.

6. Remove all traces of compound after

lapping.

Control Valves Fitted with Cage

Type Trim

(see Fig. 7)

Assemble component parts as shown in figure 7.

Follow lapping procedure described or use

alternate method described below and shown in

figure 7.

Place seat ring/insert in a suitable holding device

(that will not distort seat ring/insert). Position

seat-retaining guide/cage on seat ring/insert. (In

the case of “O” trim – Classes DOS, etc. – be

sure to assemble the valve plug guide/cage in

their respective positions before lapping,

regardless of procedure followed). Very little

lapping is required with cage type trim. A few

turns should be sufficient.

Reassembly- Single Ported

Control Valves (DL Type)

(See Fig. 4)

1. After all parts have been cleaned and

prepared for reassembly, place gasket (47)

on bottom cap (flange) (48).

2. Assemble bottom cap (flange) (48) to valve

body and tighten.

3. Place bonnet gasket (44) on valve body.

4. Insert valve plug stem through bonnet (43).

5. Position on valve body making sure that

valve plug engages seat ring/insert properly.

6. In the case of heavy units, first insert valve

plug in seat carefully down over valve plug

stem.

7. Tighten evenly and firmly.

8. Install packing in packing box.

9. Replace actuator on bonnet. Insert

capscrews (39) and tighten.

10. Reassemble nut (34) and travel indicator

(31) to valve plug stem.

11. Lift valve plug stem and engage its threads

with those in actuator stem (25).

12. Screw valve plug stem at least one diameter

into actuator stem.

13. Adjust actuator spring preload and rated

travel of valve. (See Adjusting Actuator

Spring Preload).

Cage Type Trim (DOS Type Ctrim

Parts)

1. Install internal components in valve body

2. Place rod in valve body and down through

Figure 7 - Alternate Method

7

(see Fig. 3)

before assembling bonnet to body.

body bridge to prevent seat ring/insert or

gasket from falling into body throat when

assembling.

Page 8

3. Place new gasket (50) in recess in valve

body.

4. Follow with seat ring/insert (51), with valve

plug seating face toward bonnet end of

body.

5. Position seat retaining guide (48) on seat

ring/insert.

Adjusting Actuator Spring

Preload (Starting Pressure)

1. Connect controlled air line to diaphragm

case connection at “A”.

2. Supply 3 psig air pressure to actuator

diaphragm.

3. Compress actuator spring until travel

indicator begins to move when air pressure

is raised above 3 psig.

TO COMPRESS ACTUATOR SPRING

SCREW SPRING ADJUSTOR UPWARD

NOTE: Alternately add compression and check

starting pressure slightly above 3 psig until

correct adjustment is attained. After each check,

return air pressure to 3 psig.

Single Ported Unbalanced

Control Valves (DL, DOS Types)

Control Valves with Direct Acting Actuators

Actuator spring preload adjustment can be made

either with or without pressure in valve body.

Once correct compression is made no further

adjustment is necessary.

Single Ported Control Valves

(DDL, DDOS Types)

With Reverse Acting Actuators

Spring Closing Types

In a single ported unbalanced control valve

(reverse acting actuator), the valve plug is closed

against upward fluid thrust by actuator spring

force. Total compression placed on actuator

spring must be sufficient to provide the 3 psig

preload plug force required to close the valve.

If preload adjustment is made with no pressure in

valve body, when the control valve is placed in

operation, additional compression must be

placed on the actuator spring to provide valve

closure force. With proper adjustment valve will

close tightly and will not begin to open until the

3 psig operation pressure is exceeded.

NOTE A: A control valve which has been

adjusted to provide 3 psig starting pressure plug

valve closure force (with pressure in body) will

have a considerably higher start-pressure than 3

psig, when tested at 0 body pressure.

NOTE B: Air pressure quoted are relative.

Actual pressures required in operation may vary

with pressure drop conditions existing and/or

actuator springs used.

Adjusted Control Valve for Rated

Travel

(Indicator scale shows rated travel of a valve)

Single Ported Unbalanced (DL,

DOS Types)

With Direct Acting Actuators

With valve plug and actuator stem threads

engaged as described in “REASSEMBLY”,

supply 20 psig operating pressure to actuator

diaphragm. Observe travel obtained as shown by

travel indicator and indicator scale. Readjust as

follows:

Overtravel - If travel is too great, loosen stem

locknut and turn valve plug stem out of actuator

stem the amount necessary to obtain correct

travel.

Undertravel - If travel is too short, loosen stem

locknut and turn valve plug stem further into

actuator stem the amount necessary to obtain

correct travel.

Positive Compression Force

When correct travel has been obtained reduce

operating pressure sufficiently to move valve

8

Page 9

plug away from seat ring/insert(s). Then turn

valve plug stem one full turn out of actuator stem

threads until valve plug just contacts seat

ring/insert again.

Single Ported Unbalanced

Control Valves (DDL, DDOS

Types)

(With Reverse Acting Actuators)

Loosen stem locknut, apply air to diaphragm.

Turn valve plug stem into actuator stem threads

until valve plug is out of contact with seat ring,

with air removed from diaphragm. Then turn

valve plug stem out of actuator stem threads until

valve plug just contacts seat ring again.

Supply sufficient operating pressure to actuator

diaphragm to move valve plug away from seat

ring/insert. Then turn valve plug stem one full

turn out of actuator stem threads. Diaphragm

plate determines travel. With proper diaphragm

plate correct travel will result from adjustment.

For under or overtravel, proceed as described

above.

Positive Closing Force

The one full turn toward the seat ring/insert

made after obtaining travel, provides the positive

closing force required to obtain tight valve

closure in single ported valves. In all cases be

sure to make this final adjustment.

All Actuators

Tighten stem locknut and travel indicator against

actuator stem. Reconnect operating medium

tubing from the sensing element or manual

loading device to the diaphragm case.

ACTUATOR MAINTENANCE

REPLACING DIAPHRAGMS,

STEM SEALS, ETC.

Remove compression on actuator spring by

screwing adjuster counterclockwise until

actuator spring is free.

Dismantling

(See Fig. 8)

Direct Acting

(See Page 9, Valve Action)

Remove bolts/nuts (23/22), upper diaphragm

case (20) and old diaphragm (21).

To examine, clean or replace other internal

components lift off diaphragm plate (24)

assembled with actuator stem (31), actuator

spring (28), washer (34) and unscrew spring

adjuster from adjuster sleeve (36).

– SIZES 35, 55, 85, 135

Reassembly

Replace internal parts. Install new diaphragm.

For sizes 35, 55 and 85 line up holes with those

in lower diaphragm case. For size 135 place

bead on diaphragm in recess in lower diaphragm

case. Place upper diaphragm case on diaphragm.

Assemble four bolts and nuts through parts (90°

apart). Finger tighten. Assemble balance of

bolts/nuts to actuator. Tighten evenly and

alternately across diaphragm case. (Before

tightening bolts in 35R actuator or where flat

diaphragm material is being used as an

emergency measure) consult note relating to

preforming diaphragms.

Reverse Acting

(See Page 9, Valve Action)

Remove bolts/nuts (19/18) and upper diaphragm

case (15). Insert rod through holes in yoke (34)

and actuator stem (35) to prevent twisting of

stem seal (29) when removing self-locking nut

(16). (For size 35R use wrench flats on actuator

stem). Remove self-locking nut (16), diaphragm

plate (17), diaphragm (20), collar (22) and stem

seal (29). Remove stem seal as follows: (Before

tightening bolts in 35R Actuator or where flat

diaphragm material is being used as an

emergency measure). In 135R remove capscrews

(23) in 35R and disassemble lower diaphragm

base (21) from yoke (34). Lift out stem seal. In

55R and 85R DO NOT remove lower diaphragm

base unless gasket (26) needs to be replaced.

Stem seal (29) is held in place by seal ring (27)

and screws (28). Remove these parts and lift out

stem seal.

9

Page 10

Figure 8 - Direct Acting Diaphragm Actuator

Figure 9-Reverse Acting Diaphragm Actuator

Reassemble spring adjuster (40), washer (39),

actuator spring (36), top spring seat (30) to

actuator stem (35) (If they have been removed).

Replace assembled parts in yoke (34). Place

stem seal collar (31) on actuator stem (35).

Reassemble spacer (33) to yoke in 135R.

Position stem seal collar (31) on actuator stem

(35). In sizes 55R, 85R and 135R place bead of

stem seal in recess of stem seal collar.

In 35R and 135R actuators reassemble lower

diaphragm base (21) to yoke (34). Assemble

nuts (24) to spacer studs (32) in 135R. Tighten.

In 35R insert capscrews (23) through holes in

lower diaphragm case and diaphragm and into

threads in yoke. Tighten after presetting stem

seal as described below.

In 55R and 85R actuators replace sealing ring

(27) and screws (28). Tighten.

Presetting Stem Seal

(55R, 85R & 135R)

Place collar (22) on stem seal (29) making sure

that bead on stem seal enters recess in collar.

Reassemble diaphragm (20) over actuator stem

(35). Fit center hole in diaphragm around raised

face of collar (22). Replace diaphragm plate (17)

and self-locking nut (16). Hold actuator stem

steady with rod through yoke and stem (55R,

85R, 135R) or with wrench on flats on actuator

stem (35R) then tighten self-locking nut.

Replace upper diaphragm case (15) and

bolts/nuts. Tighten as described previously. See

Instruction Sheet 10/0.5.8 for precautions to

observe when replacing seals.

Presetting Stem Seal – (135R)

Place collar (22) on stem seal (29), assemble

self-locking nut (16) to actuator stem (35) and

tighten down against parts. Then press actuator

stem downward to make stem seal move to taut

position. Tighten capscrews and remove selflocking nut (16).

NOTE: To check actuator spring and other

components in size 135R disassemble spacer

(33) and lift out parts. In 35R, 55R and 85R

parts are taken out from the underside.

All Actuators

Set preload on actuator spring, reassemble

actuator to valve body assembly, if it has been

removed, adjust valve for rated travel and

reconnect operating medium tubing.

10

Page 11

SOME IMPORTANT NOTES

FLAT SHEET RUBBER MATERIAL

Flat sheet rubber material may be used in 55R,

85R and 135R actuators as emergency

replacement material but for guaranteed results it

should be replaced at the earliest opportunity

with the LESLIE ROLLING ACTION

DIAPHRAGM designed specifically for these

actuators. When flat material is used in

emergency preform as described below.

PREFORMING 35R ACTUATOR

DIAPHRAGMS

Flat stock material is used for diaphragms in 35R

actuators. When assembling, first finger tighten

all diaphragm case bolts. Then compress

actuator spring sufficiently to move diaphragm

through full travel to the upper or lower

diaphragm case (depending on whether actuator

is direct or reverse acting). This preforms

diaphragm and permits full movement through

rated travel without resistance from a taut

diaphragm.

To Change Valve Action from

Normally Open to Normally

Closed or Vice-Versa

To reverse the action of a single ported

diaphragm control valve it is only necessary to

replace the actuator in use with one having the

opposite action. A single “D” in the control

valve class indicates actuator is “DIRECT

ACTING” - Air moves diaphragm downward.

A double D (“DD”) indicates actuator is

“REVERSE ACTING” - Air moves diaphragm

upward. NOTE: Final valve action in response

to air signal on diaphragm depends on whether

valve plug is positioned above or below the seat

ring.

To change actuator, loosen valve plug stem

locknut under travel indicator and turn valve

plug stem all the way out of the actuator stem.

Remove capscrews securing actuator to bonnet.

Replace actuator with one having desired action.

Re-insert and tighten capscrews. Reconnect

valve plug stem to actuator stem. Adjust

actuator spring preload and set valve for rated

travel. For more detailed instruction consult

general instruction pertaining to the particular

type of control valve.

11

Page 12

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance

shall be afforded with selection of materials based on technical information supplied to Leslie Controls Inc.; however,

system designer and user retain final responsibility. Designer should consider applicable Codes, material

compatibility, product ratings and application details in selection and application. Improper selection, application or

use of products described herein can cause personal injury or property damage. If designer or user intends to use

product for an application or use other than originally specified, he must reconfirm tat selection is suitable for new

operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

12

Loading...

Loading...