Page 1

12501 Telecom Drive, Tampa Florida 33637

Installation, Operating and

Maintenance Instructions

Supplement

30/1.5.1

Rev. 2

SMALL FLOW AIRMATE PRESSURE REDUCING

VALVES AND AIR LOADERS

CLASSES A-2, AG-2, AF-2, AFG-2, ETC.

INTRODUCTION........................................................................................................................................2

INSTALLATION.........................................................................................................................................3

OPERATION ...............................................................................................................................................3

MAINTENANCE.........................................................................................................................................3

DISMANTLING.......................................................................................................................................3

CLEANING OR REPLACING PARTS.................................................................................................4

DIAPHRAGM REPLACEMENT ..........................................................................................................4

Integral Filter Types – Class AF-2, etc.

REASSEMBLING ...................................................................................................................................4

Integral Filter Types – Class AF-2, etc.

TABLE OF CONTENTS

......................................................................................................4

......................................................................................................4

F

IGURE 1 - INSTALLATION DETAIL

F

IGURE 2 - CLASS

F

IGURE 3 - PARTIAL ASSEMBLY OF

F

IGURE 4 - CLASS

A-2 R

EGULATOR

P-2 P

ANEL LOADER

LIST OF ILLUSTRATION

..................................................................................................................3

................................................................................................................3

AF-2 T

YPE SHOWING ADDITIONAL PARTS IN FILTER ASSEMBLY

............................................................................................................4

............4

Page 2

INTRODUCTION

This Installation, Operation, and Maintenance Manual is

intended to be as complete and up to date as possible. It

covers installation, operation, and maintenance procedures

for Leslie Controls, Inc. Small Flow Airmate Pressure

Reducing Valves. Leslie reserves right to update this

manual and other product information concerning

installation, operation, and/or maintenance, at any time and

without obligation to notify product owners of such

changes.

Leslie is not responsible for injury to personnel or product

damage due to improper installation, operation, and/or

maintenance Leslie Controls, Inc. Small Flow Airmate

Pressure Reducing Valves. All installation, operation, and

maintenance procedures should only be performed by

trained/certified personnel. All personnel performing these

procedures should completely and carefully read and

understand all supplied materials before attempting

procedures. All personnel should pay strict attention to all

Notes, Cautions, and Warnings that appear within

procedures detailed in this manual.

Leslie welcomes user input as to suggestions for product or

manual improvement.

Contact Information

For information concerning warranties, or for questions

pertaining to installation,

Operation or maintenance of LESLIE products, contact:

LESLIE CONTROLS INC.

12501 Telecom Drive

Tampa, FL 33637

USA Phone: (813) 978-1000

USA Fax: (813) 978-0984

www.LESLIECONTROLS.com

To order replacement parts, contact LESLIE CONTROLS

at address listed above, or call toll free:

USA/Canada/Caribbean Phone: (800) 323-8366

Note: Please include model and serial number of unit for

which parts are being ordered. If ordering by phone, please

have this information readily available.

GENERAL NOTES AND WARNINGS

Notes:

• If questions are not answered by this manual, or if

specific installation, operation, and/or maintenance

procedures are not clearly understood, contact

Leslie Controls, Inc. for clarification before

proceeding.

• If unit is damaged during installation, operation, or

maintenance, complete following steps:

1. Turn off and lock out pneumatic supply to unit in

an approved manner.

2. Turn off all incoming valves.

3. Contact in-house maintenance personnel or Leslie

Controls, Inc. for instructions.

Note: Throughout this manual, warnings will be

denoted by BOXES

Piping system must be adequately designed and

supported to prevent extraordinary loads to pressure

It is strongly recommended that this document be reviewed

before attempting any installation, operation, or

maintenance procedures.

CAUTION!

equipment.

2

Page 3

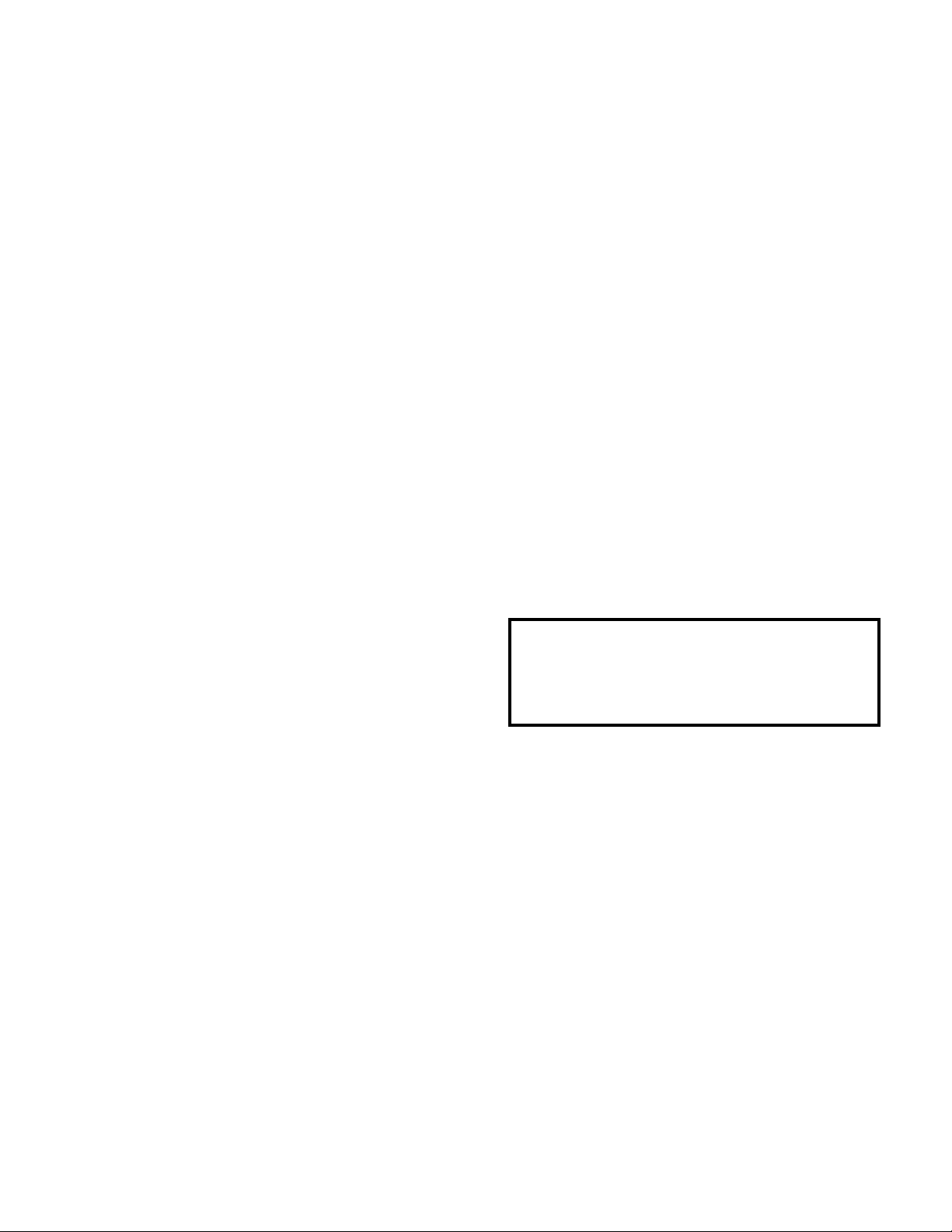

Figure 1 - Installation Detail

INSTALLATION

Install as shown in Fig. 1. Use non-corrosive fittings and

piping throughout. Use fine wire mesh or poromet filter

screen.

Note: Strainer, shown for Class A-2 Types, is not

necessary for Filter Type Classes, AF-2.

* When used with air motors or pulsating equipment,

line “A” should be of a sufficient length and diameter

to provide a reservoir. On close coupled installations

install small reservoir.

OPERATION

1. Open inlet supply valve to regulator.

Note: Supply pressure should be at least 5 PSIG above

maximum controlled pressure desired.

2. Open outlet stop valve partially.

3. Turn handwheel (1) clockwise to start flow through

regulator. Adjust for desired controlled pressure.**

Tighten locknut (2). Open outlet to stop valve fully.

** Turn handwheel clockwise to increase controlled

pressure; counterclockwise to decrease.

MAINTENANCE

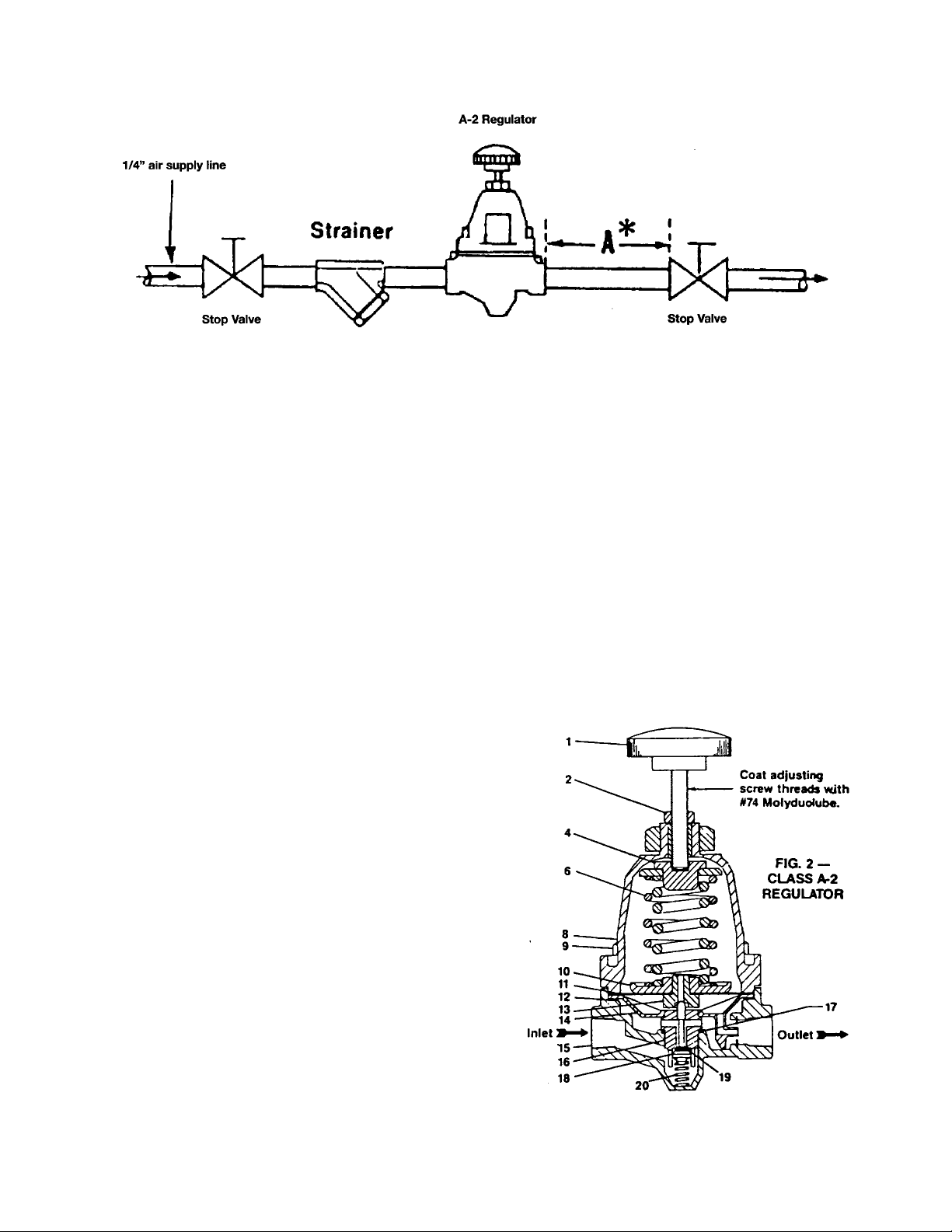

DISMANTLING

1. Shut-off air supply. Loosen locknut (2). Relieve all

adjusting spring compression.

2. Disassemble adjusting spring case (8), top spring seat

(4), adjusting spring(s) (6) and nozzle-diaphragm

assembly from main body.

3. Grasp internal rib of aspirator plate (14) (marked “Lift

Here”) and lift out of main body. Remove gasket (12).

4. Unscrew valve seat (16) with “O” Ring (17) from

main body. Lift out main valve (18), with “O” Ring

(19), and main valve spring (20).

Figure 2 - Class A-2 Regulator

3

Page 4

CLEANING OR REPLACING PARTS

Examine and clean all parts. Use an approved detergent

(non-injurious to synthetic materials) for cleaning. Blow

out all ports and main body with air. Replace any badly

worn or damaged parts.

DIAPHRAGM REPLACEMENT

Disassemble nozzle disc assembly consisting of diaphragm

disc (10), diaphragm (11) and nozzle (13). Nozzle snaps

out of diaphragm disc by finger pressure on diaphragm

disc side. Reassemble parts (with curve of disc away from

diaphragm). Snap nozzle into place in diaphragm disc.

Integral Filter Types – Class AF-2, etc.

In integral filter types remove filter case (26) from main

body. Remove filter (23) and filter support disc (25).

2. Place gasket (12) in recess of main body (15). Insert

aspirator plate (14) with aspirator tube in outlet

orifice. Snap aspirator plate in place with finger

pressure. Place nozzle-diaphragm assembly in main

body with diaphragm disc (10) upward. Place

adjusting spring(s) (6) and top spring seat (4) on

diaphragm disc. Position spring case (8) with

handwheel (1) on main body. Insert screws (9) and

tighten.

Integral Filter Types – Class AF-2, etc.

In integral filter types, place spring (20) into valve spring

retainer (24), see figure 3, place filter support disc (25) and

filter (23) in filter case (26). Assemble gasket (12) and

filter case to main body. Insert screws (22) and tighten.

3. Readjust regulator as described under

“OPERATION”.

Figure 3 - Partial Assembly of AF-2 Type showing

Additional Parts in Filter Assembly. All other parts

(except main body) are the same as in A-2 Classes

NOTE: Removal of valve spring retainer (24) in integral

Filter Types is unnecessary unless it is to be replaced. To

remove, squeeze sidewalls together to clear groove in main

body, then pull. To insert new part, squeeze sidewalls

together sufficiently for shoulders to pass through body

opening and into groove.

REASSEMBLING

1. Place main valve spring (20) in main body (15). Place

“O” Ring (17) in recess of body. Assemble main valve

(18), with “O” Ring (19), in valve seat (16). Screw

valve seat into main body threads until seating face

contacts main body and tighten.

4

Figure 4 - Class P-2 Panel Loader

Page 5

5

Page 6

WHEN ORDERING PARTS PLEASE GIVE CLASS, PART NAME AND PART REFERENCE NUMBER FROM

TABLE BELOW. USE PART NUMBER ONLY TO LOCATE PART ON DRAWING. (SEE PG. 1 FOR DRAWING)

PART

NO.

1

Handwheel, Complete

2

Nut

3

Lock Nut

4

Top Spring Seat

5

Spring Seat Plate, Range 30-150 only

6

Adj. Spring Outer, Range 30-150 only

7

Adj. Spring, Range 2-30 only

7

Adj. Spring, Range 3-60 only

7

Adj. Spring, Range 3-150 only

8

Adj. Spring Case Compl.

9

Screw, Phillips Head

11

Diaph. Compl., Range 3-60 & 30-150 (NOTE 8)

11

Diaph. Compl., Range 2-30 (NOTE 8)

12

Gasket

14

Pilot Plate

15

Main Body Range 3-60 (NOTE 2)

15

Main Body Range 2-30 (NOTE 2)

15

Main Body Range 30-150

16

Valve Seat

17

O-ring, Valve Seat

18

Main Valve Complete (NOTE 3)

19

O-Ring

20

Main Valve Spring

21

Gage, 3-60 Range AG-2 & AFG-2 (NOTE 9)

21

Gage, 2-30 Range AG-2 & AFG-2 (NOTE 9)

21

21A

Please specify Range when ordering

NOTE 1 – Quantity one (1) for AP-2 and Quantity two (2) for AFP-2.

NOTE 2 – Main Body is furnished complete with variable Pilot.

NOTE 3 – Main Valve is furnished complete with O-Ring Part No. 19.

NOTE 4 – Material is Spring Steel, Cadmium Plated.

NOTE 5 – Not shown on drawing, used on Reverse side of Body when Gage is specified for Class AG-2 & AFG-2 only.

NOTE 6 – Quantity one (1) for AG-2 & AFG-2 Classes and Quantity two (2) for AP-2 & AFP-2 Classes.

NOTE 7 – Quantity four (4) for AP-2 & AG-2 Classes and Quantity eight (8) for AFP-2 & AFG-2 Classes.

NOTE 8 – Diaphragm Complete includes Diaphragm, Diaphragm Disc and Nozzle.

NOTE 9 – Gages are dual calibrated for Metric & Std.

Gage, 30-150 Range AG2 & AFG-2 (NOTE 9)

Pipe Plug (NOTE 5)

23

Filter, 5 Micron

24

Valve Spring Retainer

25

Filet Support Disc

26

Filter Case

27

Drain Cock

PART NAME MATERIAL

Phenolic & Steel

Steel, Cad. Plated

Steel, Cad. Plated

Steel, Cad. Plated

Aluminum

.219 Wire Diam. (NOTE 4)

.135 Wire Diam. (NOTE 4)

.117 Wire Diam. (NOTE 4)

.148 Wire Diam. (NOTE 4)

Aluminum

Steel, Cad. Plated

Synthetic Rubber & Celcon

Synthetic Rubber & Celcon

Synthetic Rubber

Celcon

Aluminum

Aluminum

Aluminum

Aluminum

Synthetic Rubber

Celcon

Buna N

Music Wire, Cad. Plated

Steel Case, Clearlok Crystal

Steel Case, Clearlok Crystal

Steel Case, Clearlok Crystal

Nylon

Resin Imperg. Cellulose

Celcon

Stainless Steel

Aluminum

Brass

QTY.

PER

UNIT

1

1

1

1

1

1

1

1

1

1

NOTE 7

1

1

NOTE 1

1

1

1

1

1

1

1

1

1

1

1

1

NOTE 6

1

1

1

1

1

52680

24772

11689

20571

59514

53362

57791

33974

54484

52665

58661

56507

58659

52992

52899

54494

54496

52664

52676

51162-94

54488

54458-94

52706

-------

-------

-------

-------

-------

-------

-------

-------

-------

REFERENCE NUMBERS

AP-2

AG-2 &

AP-2

52680

24772

11689

20571

59514

53362

57791

33974

54484

52665

58661

56507

58659

52992

52899

54495

54497

52694

52676

51162-94

54488

54458-94

52706

54457

58087

54558

53030

-------

-------

-------

-------

-------

AF-2

52690

24772

11689

20571

59514

53362

57791

33974

54484

52665

58661

56507

58659

52992

52899

54498

54500

52671

52676

51162-94

54488

54458-94

52706

-------

-------

-------

------52936

52922

52990

52921

58269

AFG-2

& AFP-2

52680

24772

11689

20571

59514

53362

57791

33974

54484

52665

58661

56507

58659

52992

52899

54499

54501

52696

52676

51162-94

54488

54458-94

52706

54557

58087

54558

53030

52936

52922

52990

52921

58269

6

Page 7

NET WEIGHT - 2.5 lbs. (1.1 kg)

PATENTED

AIR LOADER

TYPE

P-2

RANGE

2-30 0-30 AP-2(2-30)

PF-2

P-2

3-60 0-60 AP-2(3-60)

PF-2

P-2

30-150 0-160 AP-2(30-150)

PR-2

30 PP-1 & PPF-1 2-300-30 AP-2(-30)

60 PP-1 & PPF-1 3-60 0-60 AP-2(3-60)

150 PP-1 & PPF-1 30-150 0-160 AP-2(30-150)

SPARE PARTS ARE FURNISHED IN KITS IN QUANTITIES SHOWN IN TABLE BELOW

NO. PART NAME

11

Diaphragm Compl.

12

Gasket

14

Pilot Plate

16

Valve Seat

17

O-Ring, Valve Seat

18

Main Valve Complete

20

Main Valve Spring

23

Filter

NOTE 3 – Main Valve is furnished complete with o-Ring, Part No. 19.

NOTE 8 – Diaphragm complete includes Diaphragm, Diaphragm Disc and Nozzle.

SEE PG. 4 & 5 FIR AIRMATE LOADERS

GAGE

CALIBRATION

KIT REF.

NO.

QTY. REF. NO. QTY. REF. NO. QTY. REF. NO.

(8)

2

1

2

52992

52899

52676

(3)

011911301 011911303 011911302 PART

2

2

2

2

--

AIR

LOADER

56507

2

1

2

51162-94

54488

52706

SPARE PARTS KITS

NO. 011 9113 03

FOR AP-2, AG-2, P-2 2-30 RANGE

AND 30 PP-1 AND 30 PPF-1 PANELS

NO. 011 9113 01

FOR AP-2, AG-2, P-2, PF-2 3-60 & 30-150

RANGES AND 60 & 150 PP-1 AND 60-150

PPF-1 PANELS

NO. 011 9113 02

FOR FILTER ONLY

2

52992

52899

52676

2 51162-94

2

2

--

56459

10

54488

52706

10

52992

--

--

--

52936

--

--

--

7

Page 8

WHEN ORDERING PARTS PLEASE GIVE PART NAME AND PART REFERENCE NUMBER FROM TABLE

BELOW. USE PART NUMBER ONLY TO LOCATE PART ON DRAWING

NO.

12

21

21

21

22

23

25

26

27

28

29

30

31

32

33

Please Specify Range When Ordering

NOTE 9 – Quantity one (1) for P-2 and PF-2. Quantity two (2) for PP-1 and PPF-1.

NOTE 10 – For Types PF-2 & PPF-1 only. MAX. INLET PRESSURE - 200 PSI

PART NAME MATERIAL

GASKET (Note 10)

Gage, 0-30

Gage, 0-60

Gage, 0-160

Screw (Note 10)

Filter (Note 10)

Filter Support Disc (Note 10)

Filter Case (Note 10)

Drain Cock (Note 10)

Panel

Female Coupling

Male Elbow

Tubing

Cover (Note 10)

Nipple (Note 10)

Steel, Plastic Crystal

Steel, Plastic Crystal

Steel, Plastic Crystal

Resin Imperg. Cellulose

Synthetic Rubber

Steel, Cad. Plated

Stainless Steel

Aluminum

Aluminum

Cast Aluminum

Brass

Brass

Brass

Copper

Brass

QTY.

PER

UNIT P-2 PF-2 PP-1 PPF-1

1

Note 9

Note 9

1

4

1

1

1

1

1

1

2

1

1

1

REFERENCE NUMBERS PART

--

52992

38546

35647

53583

35634

35646

34911

54833

38546

35647

53583

--

52993

--

52936

--

52990

--

52921

--

58269

35634

35646

34911

53367

--

54751

--

49474

MAX. TEMPERATURE - 150° F

-54070

54071

54072

--

--

--

--

-54068

35646

34911

53368

--

--

52992

54070

54071

54072

52990

52936

52990

52921

58269

54068

35646

34911

53368

54751

49474

8

Page 9

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance

shall be afforded with selection of materials based on technical information supplied to Leslie Controls Inc.; however,

system designer and user retain final responsibility. Designer should consider applicable Codes, material

compatibility, product ratings and application details in selection and application. Improper selection, application or

use of products described herein can cause personal injury or property damage. If designer or user intends to use

product for an application or use other than originally specified, he must reconfirm tat selection is suitable for new

operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

9

Loading...

Loading...