Page 1

Installation, Operating and

Maintenance Instructions

10/2.5.1.B

Rev. 0

12501 Telecom Drive, Tampa Florida 33637

Supplement

AEROFLOW SUPPLEMENT

Special “Upseating Mini-P” Actuator Adjustment

TABLE OF CONTENTS

INSTALLATION.........................................................................................................................................1

MAINTENANCE.........................................................................................................................................2

ILLUSTRATION INDEX

F

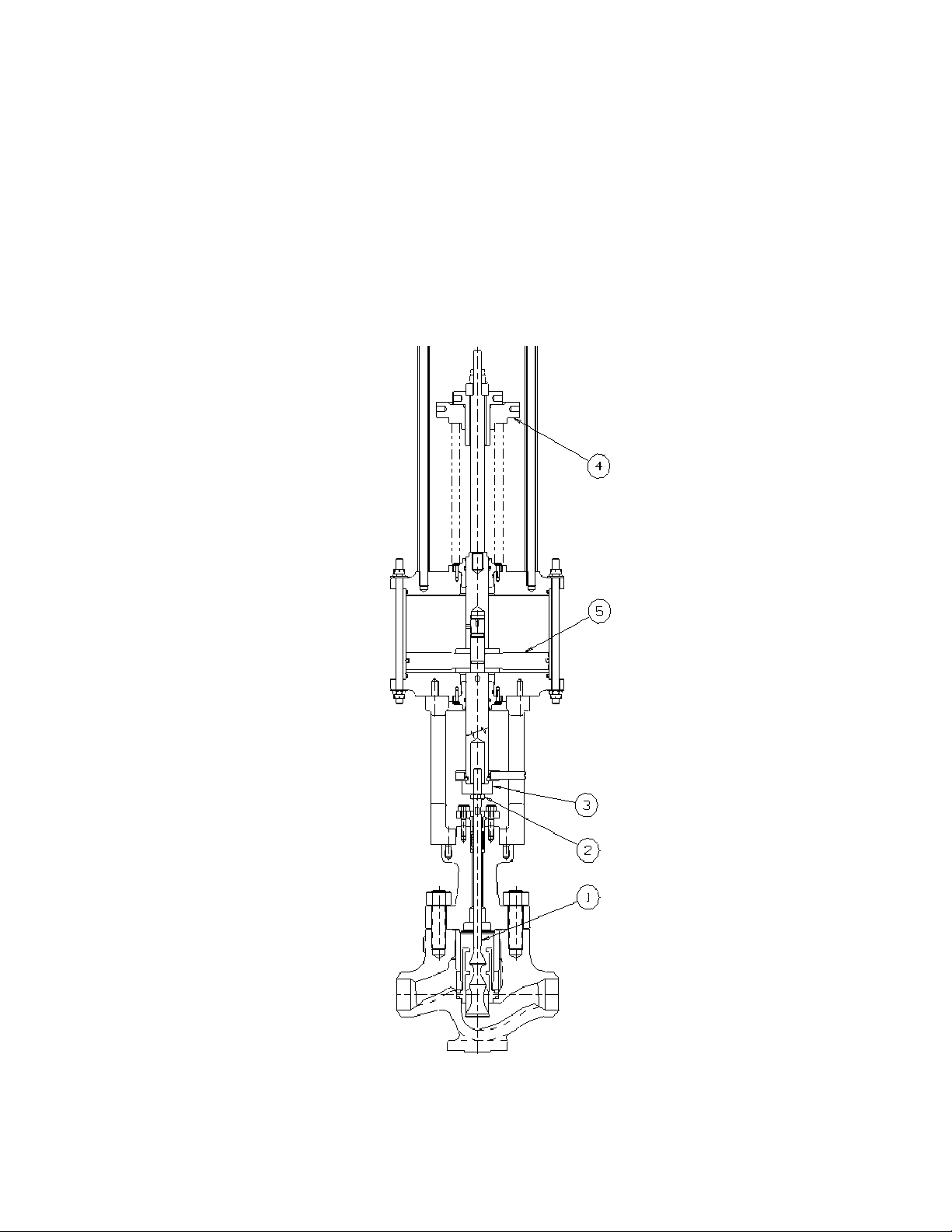

IGURE 1 – VALVE ASSEMBLY SHOWN IN OPEN POSITION

INSTALLATION

All warnings from valve IOM must be followed.

NOTE: Refer to Fig. 1 for installation.

1. Slide the seat-ring over the plug stem (1) and

lower the assembly down into the valve body with

the seat ring gasket (follow valve IOM for

assembly of valve). Note: Do not allow the valve

plug to slam into the bottom of the valve. Lower

the valve stem slowly until it comes to rest.

2. Disassemble the stem coupling (3) cap screws.

3. Mount the actuator to the top of the valve.

4. With the actuator mounted to the valve, the

actuator piston (5) will be in the “up” (retracted)

position (no air in actuator).

5. Thread the stem coupling (3) all the way down

onto the valve stem (1) . The packing in the

valve should be “loose” at this point to allow the

valve plug to retract into the valve body.

CAUTION!

......................................................................................................... 2

Keep all extremities away from moving parts on the

actuator. Failure to do so may cause injury or even

6. Ensure that the valve spring tensioner (4) is

completely unadjusted.

7. By placing air to the top of the actuator stroke the

actuator down 3.25” (air pressure not exceed 80

psi)

8. Pull up on the valve stem (1) and assemble the

stem coupling (3), by tightening the coupling cap

screws. The valve should now stroke about .75”.

(If this procedure is not followed, the valve

stem can be driven down into the valve lower

body and damage may occur to the valve

body, trim or both.)

9. The correct valve stroke for this trim set is 1”.

Put 80 psig air to the top of the actuator, unscrew

the valve stem (1) from the stem coupling (3) ¼ 1 full turn at a time. After each adjustment stroke

the valve until 1” stroke is obtained.

10. Tighten the valve locking nut (2). The spring

tensioning nut (4) should not need to be

CAUTION!

death.

Page 1 of 2

Page 2

adjusted. The bench set for the actuator should

be approximately starting at 21 psig to start

closing the valve (retracting stem) and ending at

26 psig when the valve is closed (actuator stem

fully retracted).

11. The valve is to have the limit switch mounted in

the valve closed position. The valve is an

upseating valve so the limit switch must be

adjusted to activate when the piston actuator

reaches the top of its stroke (fully retracts). (As a

point of reference Fig. 1 shows the valve in the

open position.)

MAINTENANCE

1. The valve IOM should be followed for all

operating and maintenance procedures.

Page 2 of 2

Figure 1 – Valve Assembly Shown in Open Position

Loading...

Loading...