Page 1

Installation, Operating and

Maintenance Instructions

12501 Telecom Drive, Tampa Florida 33637

Supplement

DIAPHRAGM ACTUATOR

35(R), 55(R), 85(R), 135(R)

TABLE OF CONTENTS

10/0.5.1

Rev. 1

SCOPE...............................................................................................................................................................................................2

INSTALLATION..............................................................................................................................................................................2

A

SSEMBLE DIRECT (SPRING TO RETRACT) ACTUATOR TO EQUIPMENT

A

SSEMBLE REVERSE (SPRING TO EXTEND) ACTUATOR TO EQUIPMENT

S

ETTING ACTUATOR STROKE

S

ETTING THE ACTUATOR SPRING LOAD

OPERATION....................................................................................................................................................................................3

MAINTENANCE..............................................................................................................................................................................3

G

ENERAL

D

IRECT ACTUATOR DISASSEMBLY

D

IRECT ACTUATOR REASSEMBLY

D

IRECT ACTUATOR

D

IRECT ACTUATOR

R

EVERSE ACTUATOR DISASSEMBLY

R

EVERSE ACTUATOR REASSEMBLY

R

EVERSE ACTUATOR

R

EVERSE ACTUATOR

TROUBLESHOOTING .................................................................................................................................................................16

.........................................................................................................................................................................................3

HOD D

HOD R

HOD D

HOD R

..........................................................................................................................................................2

..........................................................................................................................................2

..................................................................................................................................................3

...................................................................................................................................................3

ISASSEMBLY

EASSEMBLY

ISASSEMBLY

EASSEMBLY

.........................................................................................................................................4

..........................................................................................................................................4

.............................................................................................................................................10

...............................................................................................................................................10

....................................................................................................................................10

.....................................................................................................................................11

...........................................................................................2

...........................................................................................2

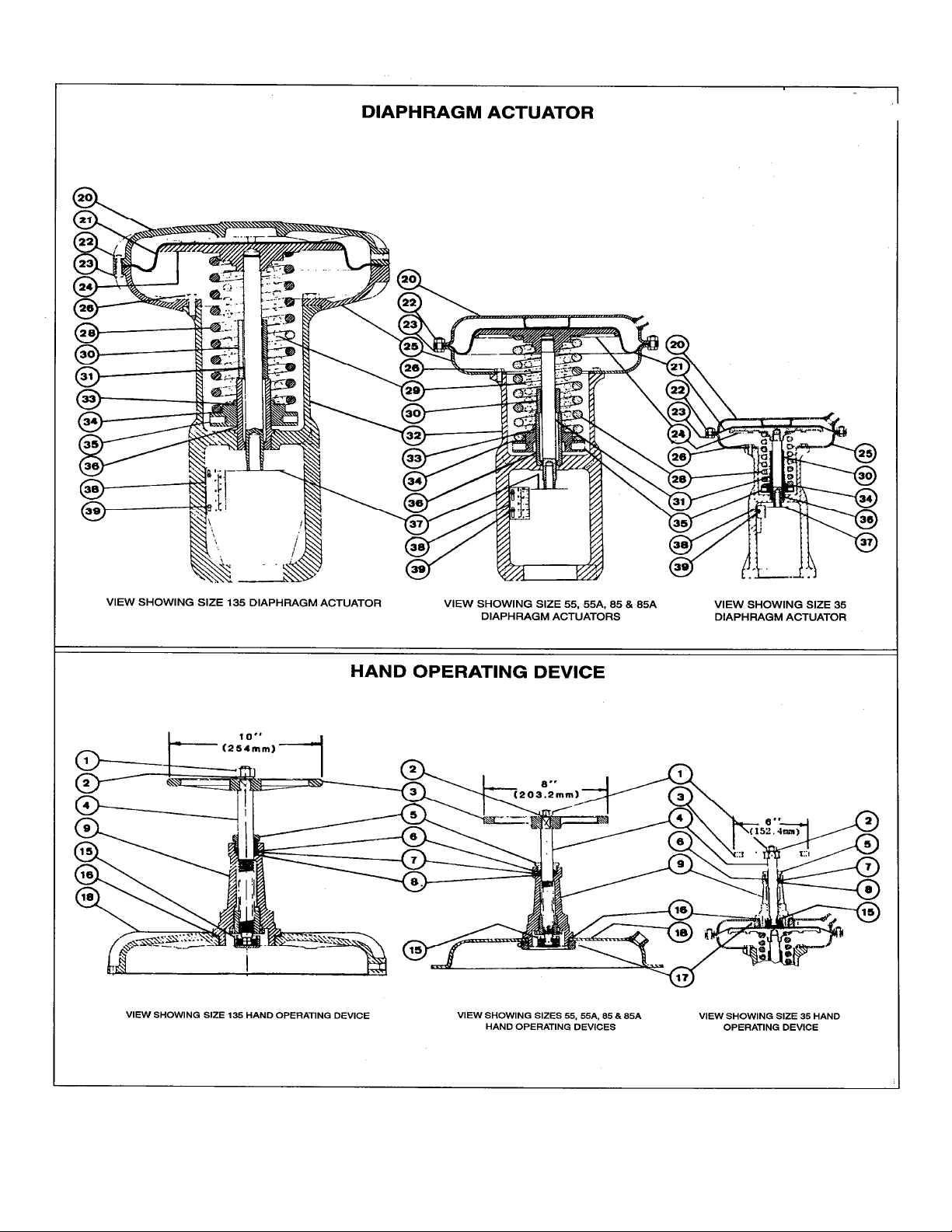

ILLUSTRATION INDEX

F

IGURE 1 - DIRECT DIAPHRAGM ACTUATOR/

F

IGURE 2 - EXTERNAL VIEW OF DIRECT ACTING DIAPHRAGM ACTUATOR

F

IGURE 3 - REVERSE DIAPHRAGM ACTUATOR/

F

IGURE 4 - DISENGAGING HANDSCREW DISC FROM NUT

F

IGURE 5 - EXTERNAL VIEW OF REVERSE ACTING DIAPHRAGM ACTUATOR

HOD.............................................................................................................................6

.........................................................................................8

HOD........................................................................................................................12

..................................................................................................................13

.....................................................................................13

1

Page 2

SCOPE

All warnings and instructions from equipment IOM

that Actuator is mounted to must be followed.

The following instructions cover installation, operation and

maintenance of Leslie's diaphragm actuators.

CAUTION!

INSTALLATION

Keep all body parts away from any moving parts of

actuator to prevent injury/death. Since air is being

used to move actuator proper safety equipment (i.e.

safety glasses) must be worn. Actuator contains a

very powerful spring, extreme caution must be used

when operating actuator. When supplying air to

Before starting installation of the actuator assembly, units

should be unpacked and checked against packing list and/or

the approved customer drawing.

1. Actuator is designed to be mounted in the vertical

position. For other than vertical installations piping

supports may be required. Consult factory.

Assemble Direct (Spring to

retract) Actuator to Equipment

1. Ensure that there is no spring tension on actuator by

"unscrewing" spring adjusting nut (35). (see Fig 1)

2. Connect air supply to the top of the actuator until the

stem is fully extended.

3. Ensuring that the thread size of the actuator and the

control valve stem (refer to Fig 2 dimension x) is the

same, and after lifting valve plug screw the actuator

onto the stem about 1 diameter of thread.

4. Remove air supply and secure actuator to equipment.

(NEED TO PUT BOLT TORQUE VALUES FOR

STUDS TO HOLD ACTUATOR DOWN)

CAUTION!

actuator do not exceed 60 psig.

5. See Stroke adjustments section for final setting of

actuator.

Assemble Reverse (Spring to

extend) Actuator to Equipment

1. Ensure that there is no spring tension on actuator by

"unscrewing" spring adjusting nut (40). (See Fig 3)

2. Ensuring that thread size of actuator and control valve

stem (refer to Fig 4 dimension x) is the same, and after

lifting valve plug screw actuator onto equipment about

1 diameter of thread.

3. Connect air supply to bottom of actuator and allow

actuator to come to rest on valve stem. Secure actuator

to stem.

4. See stroke adjustments section for final setting of

actuator.

Setting Actuator Stroke

1. Apply air to either bottom (Reverse) or top (Direct) of

actuator and note the total travel distance of actuator.

2. To adjust stroke of actuator, retract actuator stem by

removing air from actuator (Direct) or applying air to

actuator (Reverse). Screw equipment stem further into

actuator and then stroke actuator again.

3. Repeat step 2 until desired stroke is reached.

4. Secure Travel indicator (42) to actuator yoke (4) by

fastening screw (43) as shown. (See Fig 3)

Setting the Actuator Spring

Load

1. To adjust load given by failure mode

(Direct/Reverse) of actuator, first remove all air

pressure from actuator.

2. Hold actuator stem in place with a wrench.

3. Using a steel bar (see Table 1), turn spring

adjusting nut (40) one half turn. (See Fig 3)

4. Measure force output of spring to see if at desired

load. (This can be done by slowly applying air to

actuator and recording at what air pressure actuator

2

Page 3

starts to move. Take that air pressure and multiply

it by area of actuator (see Table 1) in order to

obtain the force output of spring.

5. Repeat steps 1-4 until desired load is reached.

Spring loads will vary if the actuator is mounted on

equipment that does not fully utilize the entire stroke

Actuator Size Stroke

35 3/4 34

35R 3/4 31

55 1 57

55R 1 54

85 2 90

85R 2 87

135 3 135

135R 3 131

Table 1- Actuator Load Parameters

NOTE

length of the actuator.

(in)

Area

(in2)

Spring Adjustor Rod

Dia. (in)

3/4

7/8

0.745

0.995

OPERATION

Once actuator stroke and spring load have been adjusted,

equipment can be placed into operation. Route air supply

from control system to actuator. Ensure that instrument air

is being used to operate actuator. See equipment instructions

for proper operation of assembly.

MAINTENANCE

General

1. Remove all air and accessories from actuator prior

to removal from equipment.

2. Support actuator prior to removing mounting bolts.

For reverse acting actuators apply air to top of

actuator before removing mounting bolts.

3. Remove actuator mounting bolts.

4. For direct acting actuators, air may need to be

applied to actuator before removing actuator from

equipment shaft. For reverse acting actuators, air

may need to be removed from actuator. Unscrew

actuator from equipment shaft by either spinning

actuator or unscrewing the shaft. (NOTE: If

actuator is mounted to a valve the valve shaft

must not be turned unless valve plug is lifted off

valve seat!)

5. Remove all air pressure from actuator and unload

spring tension by grasping actuator stem with a

wrench and unscrewing spring adjustment nut (40).

(see Fig 3)

6. Actuator is now ready for disassembly.

Direct Actuator Disassembly

(see Fig 1)

Spring load must be completely removed before

proceeding or injury/death can occur.

1. Remove nuts/bolts (22/23), upper diaphragm case

(20) and diaphragm (21).

2. To remove the other components, lift out

diaphragm disc (24) and entire diaphragm disc and

spring (28) assembly will lift out.

3. Unscrew diaphragm disc nut (16 only showing in

Fig 3) and remove springs (28,29) from the

assembly.

4. Remove spring adjustment nut (35).

5. Remove lower diaphragm case screws (26).

CAUTION!

Direct Actuator Reassembly

(see Fig 1)

Ensure that all the components being installed are free

from any nicks burrs or defects prior to assembly.

See Torque Values in Table 2

1. Install lower diaphragm case bolts (26) and torque

to the values given in Table 2.

NOTE

3

Page 4

2. Install spring adjusting nut (35) and thread it all the

way down as shown.

3. Install springs (28,29).

4. Install diaphragm disc nut (16 only showing in Fig

3) and diaphragm disc (24). (See table 2)

5. Slide diaphragm plate/assembly into yoke (32) as

shown.

6. Install diaphragm (21) and align holes with those in

diaphragm case (For sizes 35, 55 and 85). For 135

actuators place the bead of diaphragm (21) in the

recess of lower diaphragm case (25).

7. For 35 actuators and where flat stock diaphragm

material is used as an emergency measure see

special "performing" instructions in step 8. Install

upper diaphragm case (20) and install (4) nuts and

bolts (22/23) (90o apart) and finger tighten. Install

remaining bolts and nuts and torque to the values

given in Table 2.

8. Special "Performing" Instructions - Flat stock

material is used for 35 diaphragms and emergency

measure diaphragms. First finger tightens all

diaphragm case bolts. Then compress actuator

spring sufficiently to move diaphragm through its

full travel. This performs diaphragm and permits

full movement through rated travel without

resistance from a taut diaphragm.

Act.

Size

(see

Fig 1)

35 15-20 15-20

55 30-36 15-20

85 30-36 15-20

135 45-50 15-20

Table 2 - Torque Values (ft-lbs)

Size 1 5 17

35 15-20 2-5 50-80

55, 55A,

85, 85A

135 30-36 2-5 50-80

Table 3 – Torque Values Hand Operating Device (ft-lbs)

Lower

Dia.

Casing

Bolts

(26)

15-20 2-5 50-80

Upper

Dia.

Casing

Bolts

(22,23)

Direct Actuator HOD

Disassembly

(see Fig 1)

Spring load must be completely removed

before proceeding or injury/death can occur.

1. Remove nut (1), lock washer (2), and handwheel

(3).

2. Remove packing gland (5), packing ring(s) (6),

washer (7), and O-Ring (8) from bonnet (9).

3. Screw handscrew (4) down into bonnet (9) until

stem bottoms on bonnet threads.

4. Remove handscrew disc (15) after removing

retaining ring and half rings above it.

5. Remove handscrew (4) through upper end of

bonnet (9).

CAUTION!

Direct Actuator HOD

Reassembly

(see Fig 1)

Ensure that all components being installed are free

from any nicks burrs or defects prior to assembly.

1. Insert handscrew (4) in top of bonnet (9) and screw

down through bonnet threads.

2. Place retaining ring over handscrew thread. Insert

half rings in the handscrew groove with wide face

of rings upward toward bonnet (9). Install

handscrew disc (15) over half rings and fit retainer

ring into groove of disc making sure it enters

groove.

3. Screw handscrew (4) up through bonnet (9). Place

O-Ring (8) over handscrew (4) stem and into

bonnet (9) followed by washer (7) and packing

ring(s) (6). Screw packing gland (5) into bonnet (9)

and tighten sufficiently to prevent handwheel (3)

NOTE

4

Page 5

from turning due to vibration, etc. install bonnet (9)

on upper diaphragm case.

4. Place handwheel (3) over stem. Install lock washer

(2) and tighten nut (1).

5. Reinstall HOD assembly on actuator.

5

Page 6

Figure 1 - Direct Diaphragm Actuator/ HOD

6

Page 7

DIRECT ACTING PARTS LIST

7

Page 8

Figure 2 - External View of Direct Acting Diaphragm Actuator

8

Page 9

DIAPHRAGM ACTUATORS – DIRECT ACTING

DIMENSIONS IN INCHES AND MILLIMETERS

2-1/2

63.5

2-1/2

63.5 3 76.2

2-1/2

63.5 3 76.2

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

4-1/8

104.8

4-1/8

104.8

4-1/8

104.8

5-5/8

142.9

5-5/8

142.9

DIAPHRAGM

ACTUATOR

35 in

55

55A

85

85A

85*

135

135(1-1/4)

Dia. Stem

MAX

TRAV

EL

mm ¾ 19.0

in

1-1/2

mm

38.1

in

1-1/2

mm

38.1

in

2-1/8

mm

54.0

in

2-1/8

mm

54.0

in

2-1/8

mm

54.0

in

mm 3 76.2

in

mm 3 76.2

J J-J L M N-1 N-2 N-3 P R S T U V W X Z

9-1/4

3-15/16

235.0

100.0

12

5-1/16

304.8

128.6

12

5-1/16

304.8

14-3/4

14-3/4

14-3/4

128.6

6-1/4

374.7

158.8

6-1/4

374.7

158.8

6-1/4

374.7

158.8

18

457.2 9 228.6

18

457.2 9 228.6

12-3/8

314.3

15-1/4

387.4

15-1/4

387.4

19-5/8

498.5

22-1/4

565.2

20-1/4

514.4

27-3/8

695.3

27-3/8

695.3

12-3/8

314.3

15-1/4

387.4 7 177.8

15-1/4

387.4 7 177.8

19-5/8

498.5

22-1/4

565.2

20-1/4

514.4

24-5/8

625.5

24-5/8

625.5

6-1/4

158.8

8-1/2

215.9

11-1/8

282.6

9-1/8

231.8

11-1/8

282.6

11-1/8

282.6

ACTUATOR

SIZE

270 (in)

270 (mm)

*Mounting Flange Dimensions same as 135 ( R) Yoke.

** Approximate

MAX

TRAVEL

3

76.2

N-1 N-2 N-3 P R S T U V W X NET

11-1/16

281.0

2-1/2

63.5

5-5/8

142.9

Table 4 - Direct Acting Actuators Dimensions

DIMENSIONS IN INCHES AND MILLIMETERS

8-9/16

217.5

2-1/2

63.5

5-1/2

139.7

5-1/2

139.7

5-1/2

139.7

6-7/16

163.5

8-9/16

217.5

7-1/16

179.4

8-9/16

217.5

8-9/16

217.5

4-3/4

120.7

NET WT. Lb/kg** SIZE

ALUM.

1-3/8

3-13/16

34.9

1-3/8

34.9

1-3/8

34.9

1-3/4

44.5

2-1/2

63.5

1-3/4

44.5

2-1/2

63.5

2-1/2

63.5

11/16

17.5

96.8

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

4-3/4

120.7

4-3/4

120.7

4-3/4

120.7

5-3/4

146.1

9/16

14.3

9/16

14.3

9/16

14.3

9/16

14.3

11/16

17.5 6 152.4

11/16

17.5 6 152.4

11/16

17.5 6 152.4

11/16

17.5 7 177.8

6

152.4

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

3.500

88.9

2.687

2.687

2.687

2.687

3.500

3.500

3.500

4.500

114.3

11/16

68.2

68.2 1 25.4

68.2 1 25.4

68.2

88.9

88.9

88.9

1-5/16

33.3

17.5

1-1/4

31.8

1-5/16

33.3

1-5/16

33.3

1-15/16

33.3

1-5/16

33.3

3/8-24

3/8-24

½-20

½-20

¾-16

½-20

¾-16

¾-16

¾-16

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

3/8

NPT

3/8

NPT

95.3 kg

WT**

Lb/kg

210 lb

9.1 kg

10.4 kg

10.4 kg

19.5 kg

21.8 kg

20.4 kg

104 lb

47.2 kg

104 lb

47.2 kg

20 lb

23 lb

23 lb

43 lb

48 lb

45 lb

CAST

IRON

35 lb

15.9 kg

50 lb

22.7 kg

50 lb

22.7 kg

96 lb

43.5 kg

116 lb

52.6 kg

113 lb

51.3 kg

187 lb

84.8 kg

187 lb

84.8 kg

NET WT**

W/H.O.D.

lb/kg

225 lb

102.1 kg

9

Page 10

Reverse Actuator Disassembly

(see Fig 3)

Spring load must be completely removed before

proceeding or injury/death can occur.

1. Remove nuts/bolts (18,19), upper diaphragm case

(15) and diaphragm (20).

2. Insert (3/4, 7/8, 0.745, 0.995) in diameter rod

through the hole in Yoke (34) and actuator stem

(35) to prevent stem from rotating. NOTE: If this

step is not done then permanent damage will

occur to lower stem boot. For 35 actuator use a

wrench on wrench flats to prevent stem from

rotating.

3. Remove actuator stem nut (16), diaphragm disc

(17), diaphragm (20), and collar (22). Remove

actuator stem (35), springs (36,37), spring seat

(30), washers (38,39), spacer (33) for 135R, and

stem seal collar (31). Remove spring adjustment

nut (40).

4. Remove stem seal (29) as follows: In 35R, remove

capscrews (23) and disassemble lower diaphragm

disc (21) from yoke (34) and lift out stem seal (29).

In 55R and 85R, remove screws (28), seal ring (27)

and stem seal (29), then remove lower diaphragm

bolts, lower diaphragm case (21) and gasket (26).

For 135R, remove capscrews (23) and disassemble

lower diaphragm case (21) from yoke (34) and lift

out stem seal (29).

CAUTION!

Reverse Actuator Reassembly

(see Fig 3)

Ensure that all components being installed are free

from any nicks burrs or defects prior to assembly.

1. Assemble spring adjusting nut (40) washer(s)

(38,39), spacer (33) for 135R, stem seal collar (31),

springs (36,37), and spring seat (30).

NOTE

2. Position stem seal (29) on stem seal collar (31), in

sizes 55R, 85R, and 135R place bead of stem seal

in recess of stem seal collar.

3. In 35R actuators, install stem seal (29) and collar

(31) over actuator stem (35) in yoke (34). Install

lower diaphragm base (21) to yoke (34). Insert cap

screws (23) through holes in diaphragm lower case

(21) and stem seal (29) and tighten as described

below.

4. In 55R and 85R actuators, install stem seal (29)

and seal ring (27) and torque per Table 2. What

about the base plate?

5. In 135R actuator, install stem seal (29) and collar

(31) over actuator stem (35) in yoke (34). Install

lower diaphragm base (21) to yoke (34). Insert

studs and nuts (24) through holes in diaphragm

case (21) and stem seal (29) and tighten as

described below.

6. Pre-setting stem seal (55R, 85R & 135R) - Place

collar (22) on stem seal (29) making sure the bead

on stem seal enters recess in collar. Reassemble

diaphragm (20) over actuator stem (35). Fit center

hole in diaphragm around raised face of collar (22).

Replace diaphragm disc (17) and nut (16). Hold

actuator stem steady with rod through yoke and

stem or on wrench flats. Failure to do so may

result in stem seal failure. Then tighten nut.

Replace upper diaphragm case (15) and nuts/bolts

(18/19) and torque to requirements in Table 2.

7. Presetting stem seal 35R - Place collar (22) on stem

seal (29), assemble nut (16) to actuator stem (35)

and tighten. Then press actuator stem downward to

make stem seal move to taut position. Tighten

capscrews to the requirements of Table 2 and

remove nut (16).

Reverse Actuator HOD

Disassembly

(see Fig 3)

Spring load must be completely removed

before proceeding or injury/death can occur.

1. Remove nut (1), lockwasher (2), and handwheel

(3).

CAUTION!

10

Page 11

2. Screw handscrew (4) into the bonnet as far as it

will go.

3. Remove nuts and bolts (18,19 see Fig 3) from

upper diaphragm case (14).

4. Lift diaphragm case (14) while moving the case to

one side so that handscrew disc assembly can be

disengaged from diaphragm nut (8) by passing it

through the slot in the diaphragm nut. (see Fig 4)

5. Remove handscrew (4) from bonnet (7).

NOTE: Clean all parts and replace any that are worn or

damaged.

Reverse Actuator HOD

Reassembly

(see Fig 3)

Ensure that all components being installed are free

from any nicks burrs or defects prior to assembly.

1. Insert handscrew (4) into bonnet (7) and screw

down through bonnet threads.

2. Insert diaphragm case (14) making sure that

handscrew disc assembly is engaged to diaphragm

nut (8). (see Fig 4)

NOTE

3. Tighten nuts and bolts (18,19 see Fig 3) into upper

diaphragm case (14).

4. Screw handscrew (4) up through bonnet (7).

5. Place handwheel (3) over stem. Install lockwahser

(2) and tighten nut (1).

Act. Size (see

Fig 1)

35R 15-20 15-20

55R/55AR 30-36 15-20

85R/85AR 30-36 15-20

135R 45-50 15-20

Table 5 – Torque Values Hand Operating Device (ft-lbs)

Lower Dia.

Casing Bolts (23,24)

Table 4 - Torque Values (ft-lbs)

Size 1 6

35R 15-20 3-5

55R/55AR 15-20 15-20

85R/85AR 15-20 15-20

135R 30-36 15-20

Upper Dia. Casing

Bolts (18,19)

11

Page 12

Figure 3 - Reverse Diaphragm Actuator/ HOD

12

Page 13

Figure 4 - Disengaging Handscrew Disc from Nut

Figure 5 - External View of Reverse Acting Diaphragm Actuator

13

Page 14

DIAPHRAGM ACTUATORS – REVERSE ACTING

DIMENSIONS IN INCHES AND MILLIMETERS

2-1/2

63.5

2-1/2

63.5 3 76.2 4 101.6

2-1/2

63.5 3 76.2 4 101.6

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5

2-1/2

63.5 4 101.6

4-1/8

4-5/16

104.8

4-1/8

104.8

4-1/8

104.8

5-5/8

142.9

5-5/8

142.9

109.5

4-15/16

125.4

5-9/16

141.3

5-9/16

141.3

5-9/16

141.3

SIZE

35R

55R

55AR

85R

85R*

85AR in

135R

135R

(1-1/4)

MAX

TRAVEL

in

mm ¾ 19.0

in

1-1/2

mm

38.1

in

1-1/2

mm

38.1

in

2-1/8

mm

54.0

in

2-1/8

mm

54.3

2-1/8

mm

54.0

in

mm 3 76.2

in

mm 3 76.2

J L M J-J N N-2 N-3 P R S T U V W X Z

9-1/4

235.0

12

304.8

12

304.8

14-3/4

374.7

14-3/4

374.7

14-3/4

374.7

18

457.2

18

457.2

12-3/8

314.3

457.2

457.2

23-1/4

590.6

23-7/8

606.4

25-7/8

657.2

32-1/4

819.2

32-1/4

819.2

18

18

9-7/8

3-15/16

250.8

14-1/4

362.0

14-1/4

362.0

18-3/4

476.3

19-3/8

492.1

21-3/8

542.9

28-3/8

720.7 9 228.6

28-3/8

720.7 9 228.6

100.0

5-1/16

128.6

5-1/16

128.6

6-1/4

158.8

6-1/4

158.8

6-1/4

158.8

6-1/4

158.8

6-7/8

174.6

6-7/8

174.6

8-9/16

217.5

9-3/16

233.4

11-1/8

282.6

11-1/8

282.6

11-1/8

282.6

ACTUATOR

SIZE

270R (in)

270R (mm)

*Mounting Flange Dimensions same as 135 ( R) Yoke.

** Approximate

MAX

TRAVEL

3

76.2

N-1 N-2 N-3 P R S T U V W X NET

11-1/8

282.6

2-1/2

63.5

5-5/8

142.9

Table 5 - Reverse Acting Actuators Dimensions

DIMENSIONS IN INCHES AND MILLIMETERS

5-9/16

141.3

3-1/8

79.4

4-3/4

120.7

1-3/4

44.5

1-3/4

44.5

1-3/4

44.5

2-1/4

57.2

2-1/4

57.2

3-1/8

79.4

3-1/8

79.4

3-1/8

79.4

11/16

17.5

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

3-13/16

96.8

4-3/4

120.7

4-3/4

120.7

4-3/4

120.7

5-3/4

146.1

9/16

4-13/16

14.3

9/16

14.3

9/16

14.3

9/16

14.3

11/16

17.5 6 152.4

11/16

17.5 6 152.4

11/16

17.5 6 153.4

11/16

17.5 7 177.8

152.4

122.2

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

6

3.500

88.9

2.687

2.687

2.687

2.687

3.500

3.500

3.500

4.500

114.3

11/16

68.2

68.2 1 25.4

68.2 1 25.4

68.2

88.9

88.9

88.9

1-5/16

1-5/16

1-5/16

1-5/16

1-5/16

33.3

17.5

1-1/4

31.8

33.3

33.3

33.3

33.3

3/8-24

3/8-24

½-20

½-20

½-20

¾-16

¾-16

¾-16

¾-16

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

¼

NPT

3/8

NPT

3/8

NPT

WT**

Lb/kg

288 lb

130.6 kg

NET WT** ACTUATOR

IRON ALUM.

30 lb

15.9 kg

60 lb

27.2 kg

60 lb

27.2 kg

117 lb

53.1 kg

120 lb

54.4 kg

123 lb

55.8 kg

197 lb

89.4 kg

197 lb

89.4 kg

20 lb

9.1 kg

30 lb

13.6 kg

30 lb

13.6 kg

54 lb

24.5 kg

56 lb

25.4 kg

59 lb

26.8 kg

155 lb

70.3 kg

155 lb

70.3 kg

NET WT**

W/H.O.D.

lb/kg

300 lb

136.1 kg

14

Page 15

REVERSE ACTING PARTS LIST

15

Page 16

TROUBLESHOOTING

Problem Possible Cause

Equipment not shutting off or it does not appear

to be enough force when air is removed from the

actuator.

When air is supplied to the actuator the actuator

is not fully stroking or giving enough load.

When air is removed from the actuator the

actuator does not return to either the open or

closed position.

An air control signal is being sent to the actuator

but the actuator does not fully stroke?

Actuator does not move smoothly Check that valve packing is not over tightened. Check that spring is not

Not enough spring load. Check the spring load by following section

on "Setting the Actuator Spring Load".

Check air supply pressure to the requirements of the initial actuator

sizing. Check for seal leakage by using a "leak detect solution". Make

sure you also check the stem boot seal for reverse acting actuators.

Replace seals as necessary.

Check for blockage in equipment. Check for a broken spring.

Check the bench range of the actuator by reviewing the original

specifications for the actuator.

rubbing on sides of spring case.

16

Page 17

It is solely responsibility of system designer and user to select products and materials suitable for their specific

application requirements and to ensure proper installation, operation and maintenance of these products. Assistance

shall be afforded with selection of materials based on technical information supplied to Leslie Controls Inc.; however,

system designer and user retain final responsibility. Designer should consider applicable Codes, material

compatibility, product ratings and application details in selection and application. Improper selection, application or

use of products described herein can cause personal injury or property damage. If designer or user intends to use

product for an application or use other than originally specified, he must reconfirm tat selection is suitable for new

operating conditions. Life expectancy for this product defaults to warranty period of sales contract.

17

Loading...

Loading...