LEROY SOMER LSA 43.2, LSA 44.2 Installation

3434 en - 11.2008 / h

|

|

|

|

is |

to |

be |

given |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|||

|

manual |

|

user |

|||||

|

|

|

||||||

This |

to |

the |

end |

|

|

|

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

124 |

198 |

|

|

|

|

|

|

|

|

207 |

|

|

|

|

|

|

|

|

|

120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28 |

1 |

|

|

|

|

|

|

|

|

37 |

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

33 |

|

|

|

|

|

|

|

|

|

320 |

|

|

|

|

|

|

|

|

|

325 |

|

|

|

|

|

|

|

|

|

322 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

323 |

324 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

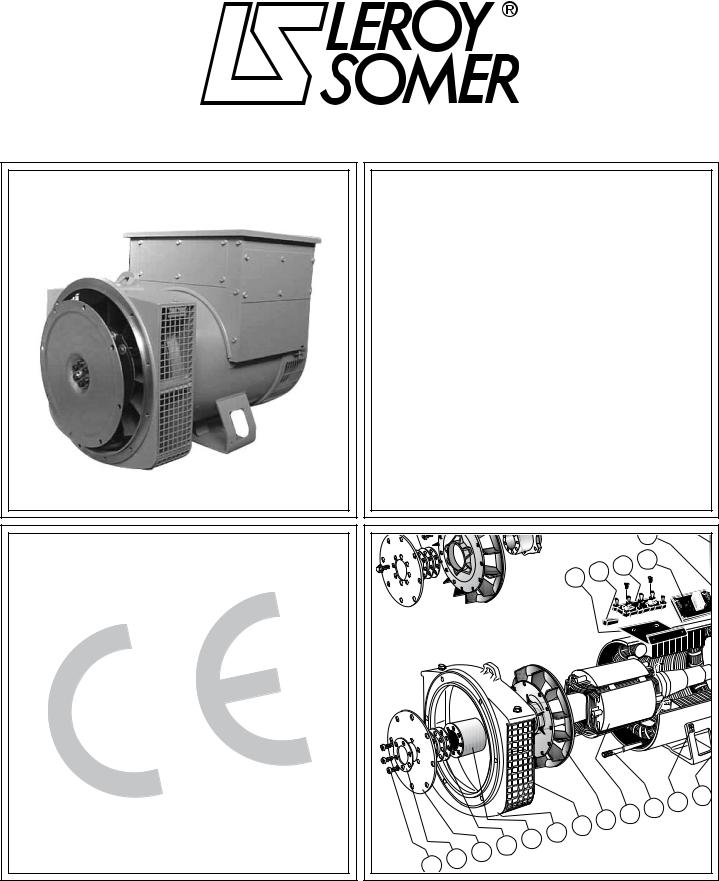

LSA 43.2/44.2 - 4 pole

ALTERNATORS

Installation and maintenance

LEROY-SOMER |

Installation AND maintenance |

3434 en - 11.2008/h |

LSA 43.2 / 44.2 - 4-pole

ALTERNATORS

This manual concerns the alternator which you have just purchased.

The latest addition to a whole new generation of alternators, this range benefits from the experience of the world’s leading manufacturer, using advanced technology and incorporating strict quality control.

SAFETY MEASURES

Before using your alternator for the first time, it is important to read the whole of this installation and maintenance manual.

All necessary operations and interventions on this alternator must be performed by a qualified technician.

Our technical support service will be pleased to provide any additional information you may require.

The various operations described in this manual are accompanied by recommendations or symbols to alert the user to potential risk of accident. It is vital that you understand and take notice of the different warning symbols used.

CAUTION

Warning symbol for an operation capable of damaging or destroying the alternator or surrounding equipment.

Warning symbol for general danger to personnel.

WARNING SYMBOLS

We would like to draw your attention to the following two safety measures that must be complied with:

a)During operation, do not allow anyone to stand in front of the air outlet guards, in case anything is ejected from them.

b)Do not allow children younger than 14 to go near the air outlet guards.

A set of self-adhesive stickers depicting the various warning symbols is included with this maintenance manual. They should be positioned as shown in the drawing below once the alternator has been fully installed.

WARNING

The alternators must not be put into service until the machines in which they are to be incorporated have been declared compliant with Directives 98/37/EC and 89/336 EC plus any other directives that may be applicable.

Warning symbol for electrical danger to personnel.

Note: LEROY-SOMER reserves the right to modify the characteristicsofitsproductsatanytimeinordertoincorporate the latest technological developments. The information contained in this document may therefore be changed without notice.

Copyright 2004: MOTEURS LEROY-SOMER This document is the property of: MOTEURS LEROY-SOMER

It may not be reproduced in any form without prior authorization.

All brands and models have been registered and patents applied for.

2

LEROY-SOMER |

|

Installation AND maintenance |

|

3434 en - 11.2008/h |

|

||||

|

|

LSA 43.2 / 44.2 - 4-pole |

|

|

|||||

|

|

|

|

ALTERNATORS |

|

|

|||

|

|

|

|

|

|

|

|||

1 - RECEIPT |

|

|

4 - SERVICING - MAINTENANCE |

|

|||||

1.1 |

- Standards and safety measures..................... |

4 |

4.1 |

- Safety measures.......................................... |

|

10 |

|||

1.2 |

- Inspection....................................................... |

|

4 |

4.2 |

- Regular maintenance................................... |

|

10 |

||

1.3 |

- Identification................................................... |

|

4 |

4.3 |

- Fault detection.............................................. |

|

10 |

||

1.4 |

- Storage........................................................... |

|

4 |

4.4 |

- Mechanical defects........................................ |

|

11 |

||

1.5 |

-Applications.................................................... |

|

4 |

4.5 |

- Electrical faults.............................................. |

|

11 |

||

1.6 |

- Contraindications to use ................................ |

|

4 |

4.6 |

- Dismantling, reassembly.............................. |

|

12 |

||

2 - TECHNICAL CHARACTERISTICS |

|

4.7 |

- Installation and maintenance of the PMG..... |

14 |

|||||

|

4.8 |

- Table of characteristics |

|

14 |

|||||

|

|

|

|

|

|

||||

2.1 |

- Electrical characteristics................................. |

|

5 |

4.9 |

- Table of weights |

|

15 |

||

|

|

|

|

|

|

||||

2.2 |

- Mechanical characteristics............................. |

|

5 |

|

|

|

|

|

|

3 - INSTALLATION - COMMISSIONING |

|

5 - SPARE PARTS |

|

|

|||||

|

5.1 |

- First maintenance parts |

|

16 |

|||||

|

|

|

|

|

|

||||

3.1 |

-Assembly........................................................ |

|

6 |

5.2 |

- Bearing designations |

|

16 |

||

|

|

|

|

|

|

||||

3.2 |

- Inspection prior to first use.............................. |

|

6 |

5.3 |

- Technical support service |

|

16 |

||

|

|

|

|

|

............................ |

||||

3.3 |

- Terminal connection diagrams........................ |

|

7 |

5.4 |

- Exploded view, parts list |

|

17 |

||

|

|

|

|

|

|

||||

3.4 |

- Commissioning............................................... |

|

9 |

|

|

|

|

|

|

3.5 |

- Settings.......................................................... |

|

9 |

EC DECLARATION OF INCORPORATION....... |

19 |

||||

3

LEROY-SOMER |

Installation AND maintenance |

3434 en - 11.2008/h |

LSA 43.2 / 44.2 - 4-pole

ALTERNATORS

1 - RECEIPT

1.1 - Standards and safety measures

Our alternators comply with most international standards and are compatible with:

- the recommendations of the

International Electrotechnical Commission

IEC 60034-1, (EN 60034)

- the recommendations of the

International Standards Organisation ISO 8528

-the European Community directive 89/336/EEC on Electromagnetic Compatibility (EMC)

-the European Community directives

73/23/EEC and 93/68/EEC (Low Voltage Directive)

They are CE marked with regard to the LVD (Low Voltage Directive) in their role as a machine component. Adeclaration of incorporation can be supplied on request.

1.2 - Inspection

On receipt of your alternator, check that it has not suffered any damageintransit.Ifthereareobvioussignsofknocks,contactthe transporter (you mayabletoclaimontheirinsurance) andaftera visual check, turn the machine by hand to detect any malfunction.

1.3 - Identification

The alternator is identified by means of a nameplate glued to the frame.

Make sure that the nameplate on the alternator conforms to your order.

The alternator name is defined according to various criteria (see below).

Example of description: LSA 43.2 M45 J6/4

• LSA: |

Name used in the PARTNER range |

• M: |

Marine |

• C: |

Cogeneration |

• T: |

Telecommunications |

• 43.2: |

Machine type |

• M45: |

Model |

• J: |

Excitation system (C: AREP/J: SHUNT or PMG/ |

• 6/4: |

E: COMPOUND) |

Winding number/number of poles |

1.3.1 - Nameplate

So that you can identify your alternator quickly and accurately, we suggest you fill in its specifications on the non-contractual nameplate below.

1.4 - Storage

Prior to commissioning, machines should not be stored in humid conditions: at relative humidity levels greater than 90%, themachineinsulationcandropveryrapidly,tojustabovezero at around 100%. The state of the anti-rust protection on unpainted parts should be monitored.

For storage over an extended period, the alternator can be placed in a sealed enclosure (heatshrunk plastic for example) with dehydrating sachets inside, away from significant and frequent variations in temperature to avoid the risk of condensation during storage.

If the area is affected by vibration, try to reduce the effect of these vibrations by placing the generator on a damper support (rubber disc or similar) and turn the rotor a fraction of a turn once a fortnight to avoid marking the bearing rings.

1.5 - Applications

These alternators are designed mainly to produce electricity in the context of applications involving the use of generators.

1.6 - Contraindications to use

Use of the alternator is restricted to operating conditions (environment, speed, voltage, power, etc.) compatible with the characteristics indicated on the nameplate.

ALTERNATEURS

ALTERNATORS

ALTERNATORS

LSA  Date

Date  N°

N°

Hz Min-1/R.P.M.

Hz Min-1/R.P.M.

Protection

Protection  Cos Ø /P.F.

Cos Ø /P.F.

Cl. ther. / Th. class

Cl. ther. / Th. class

Régulateur/A.V.R.

Régulateur/A.V.R.

Altit. |

m Masse / Weight |

Rlt AV/D.E |

bearing |

Rlt AR/N.D.E bearing  Graisse / Grease

Graisse / Grease

Valeurs excit / Excit. values

en charge |

/ |

full load |

|

à vide |

/ |

at no load |

|

|

PUISSANCE / RATING

Tension |

V |

|

Voltage |

||

Ph. |

||

|

||

Connex. |

|

Continue |

|

|

|

|

|

kVA |

||||

Continuous |

|

|

|

|

|

|

|

kW |

||

|

|

|

|

|

||||||

|

40C |

|

|

|

|

|

A |

|||

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

Secours |

|

|

|

|

|

|

|

|

kVA |

|

|

|

|

|

|

|

|

|

|||

|

Std by |

|

|

|

|

|

|

|

|

kW |

|

|

|

|

|

|

|||||

|

27C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|||||

4

LEROY-SOMER |

Installation AND maintenance |

3434 en - 11.2008/h |

LSA 43.2 / 44.2 - 4-pole

ALTERNATORS

2 - TECHNICAL CHARACTERISTICS

2.1 - Electrical characteristics

PARTNER LSA 43.2/44.2 alternators are generators without sliprings or revolving field brushes, wound as «2/3 pitch», 12wire; the insulation is class H and the field excitation system is available in either «SHUNT», «AREP» or «PMG» versions (seeAVR manual).

2.1.1 - Options

-Stator temperature detection probes.

-Space heaters.

Interference suppression conforms to standard EN 55011, group 1, class B. (Europe).

2.1.2 - SHUNT system with R 250 AVR

Other version R 251AVR for dedicated single-phase or R 448 for additional function.

|

MAIN FIELD |

|

Exiter |

|

Armature |

|

Varistor |

5 + |

Field |

6 – |

SERIES connection

2.1.3 - AREP system with R 438 AVR

2.2 - Mechanical characteristics

-Steel frame

-Cast iron end shields

-Protected ball bearings, greased for life

-Mounting arrangements:

IM 1201 (MD 35) foot and flange mounted, single-bearing with SAE coupling disc.

IM 1001 (B 34) double-bearing with SAE flange and standard cylindrical shaft extension.

-Drip-proof machine, self-cooled

-Degree of protection: IP 23

2.2.1 - Mechanical options

-Air inlet filter

-Regreasable bearings (only for LSA44.2 and SHUNT or AREP version)

-IP 44 protection

STATOR : 12 wires (marked T1 to T12)

T1 |

T7 |

T2 |

T8 |

T3 |

T9 |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T4 |

T10 |

T5 |

T11 |

T6 |

T12 |

R 250 |

Power supply and voltage reference |

|

MAIN FIELD

Exiter |

Auxiliary windings |

Armature

Varistor

5 + |

Field |

6 – |

|

|

|

|

Yellow |

Green |

Black |

||

|

PARALLEL |

Red |

|||

|

|

|

|

|

|

|

connection |

R 438 |

|||

|

|

||||

STATOR : 12 wires (marked T1 to T12)

T1 |

T7 |

|

T2 |

T8 |

T3 |

T9 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T4 T10 T5 T11 T6 T12

Voltage reference

Voltage reference

2.1.4 - PMG system with R 438 AVR

|

|

MAIN FIELD |

|

Exiter |

|

|

Armature |

|

|

|

Varistor |

5 + |

Field |

6 – |

|

||

|

PARALLEL |

|

|

connection |

|

STATOR : 12 wires (marked T1 to T12)

T1 |

T7 |

|

T2 |

T8 |

T3 |

T9 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PMG

T4 T10 T5 T11 T6 T12

R 438 |

Voltage reference |

|

5

LEROY-SOMER |

Installation AND maintenance |

3434 en - 11.2008/h |

LSA 43.2 / 44.2 - 4-pole

ALTERNATORS

3 - INSTALLATION

Personnel undertaking the various operations discussed in this section must wear the appropriate personal protective equipment for mechanical and electrical hazards.

3.1.2.2 - Two-bearing alternator

- Semi-flexible coupling

Careful alignment of the alternator and the heat engine is recommended, checking that the differences in concentricity and parallelism of the two parts of the coupling do not exceed 0.1 mm.

3.1 - Assembly

All mechanical handling operations must be undertaken using approved equipment and the machine must be horizontal. Check how much the alternator weighs (see 4.9) before choosing the lifting tool. During this operation, do not allow anyone to stand under the load.

CAUTION

This alternator has been balanced with a half-key.

3.1.3 - Location

Ensure that the ambient temperature in the room where the alternator is placed cannot exceed 40 °C for standard power ratings (for temperatures > 40 °C, apply a derating coefficient). Fresh air, free from damp and dust, must be able to circulate freelyaroundtheairintakegrillesontheoppositesidefromthe coupling.

3.1.1 - Handling

The generously-sized lifting rings are for handling the alternator alone. They must not be used to lift the genset. The choice of lifting hooks or handles should be determined by the shape of these rings. Choose a lifting system that has regard for the integrity and environment of the alternator.

3.1.2 - Coupling

3.1.2.1 - Single-bearing alternator

Before coupling the alternator and the heat engine, check they are compatible by:

-undertaking a torsional analysis of the transmission on both units

-checking the dimensions of the flywheel and its housing, the flange, coupling discs and offset.

CAUTION

When coupling the alternator to the prime mover, the holes of the coupling discs should be aligned with the flywheel holes by cranking the engine.

Do not use the alternator fan to turn the rotor.

Make sure the alternator is securely bedded in position during coupling.

Tighten the coupling disc screws to the recommended torque and check that there is lateral play on the crankshaft.

3.2 - Inspection prior to first use

3.2.1 - Electrical checks

Under no circumstances should an alternator, new or otherwise, be operated if the insulation is less than 1 megohm for the stator and 100,000 ohms for the other windings.

There are three possible methods for restoring the above minimum values.

a)Dry out the machine for 24 hours in a drying oven at a temperature of approximately 110 °C (without theAVR).

b)Blow hot air into the air inlet, having made sure that the machine is rotating with the exciter field disconnected.

c)Run in short-circuit mode (disconnect theAVR):

-Short-circuit the three output terminals (power) using connections capable of supporting the rated current (try not to exceed 6A/ mm2)

-Insertaclampammetertomonitorthecurrentpassingthrough the short-circuit connections

-Connect a 48 Volt battery in series with a rheostat of approximately 10 ohms (50 W) to the exciter field terminals, respecting the polarity

-Open all the alternator openings fully

-Run the alternator at its rated speed, and adjust the exciter fieldcurrentusingtherheostattoobtaintheratedoutputcurrent in the short-circuit connections

Note: Prolonged standstill: In order to avoid these problems, we recommend the use of space heaters, as well as turning over the machine from time to time. Space heaters are only really effective if they are working continuously while the machine is stopped.

CAUTION

Ensure that the alternator has the degree of protection matching the defined environmental conditions.

6

Loading...

Loading...