Leonard Valve TM-2020B, TM-2020B-LF Installation Manual

INST ALLA TION ADJUSTMENT SERVICE

INSTALLATION

d

testedand

includ

ll

th

r

HIGH-LOW MANIFOLD

TM-2020B, TM-2020B-LF

IMPORTANT! Provide serial numbers for both valves when ordering parts!!

Small valve manufactured after July 2007 starting with serial # TM26272

Bulletin G-11E

April 2014

DOMESTIC OUTLET

8

0

0

6

1

20

30

0

0

0

10

4

LEONARD

40

0

50

-10

2

0

0

2

1

60

°C

°F

0

0

4

1

LEONARD

THERMOSTATIC

H

C

1017

HOT INLET

COLD INLET

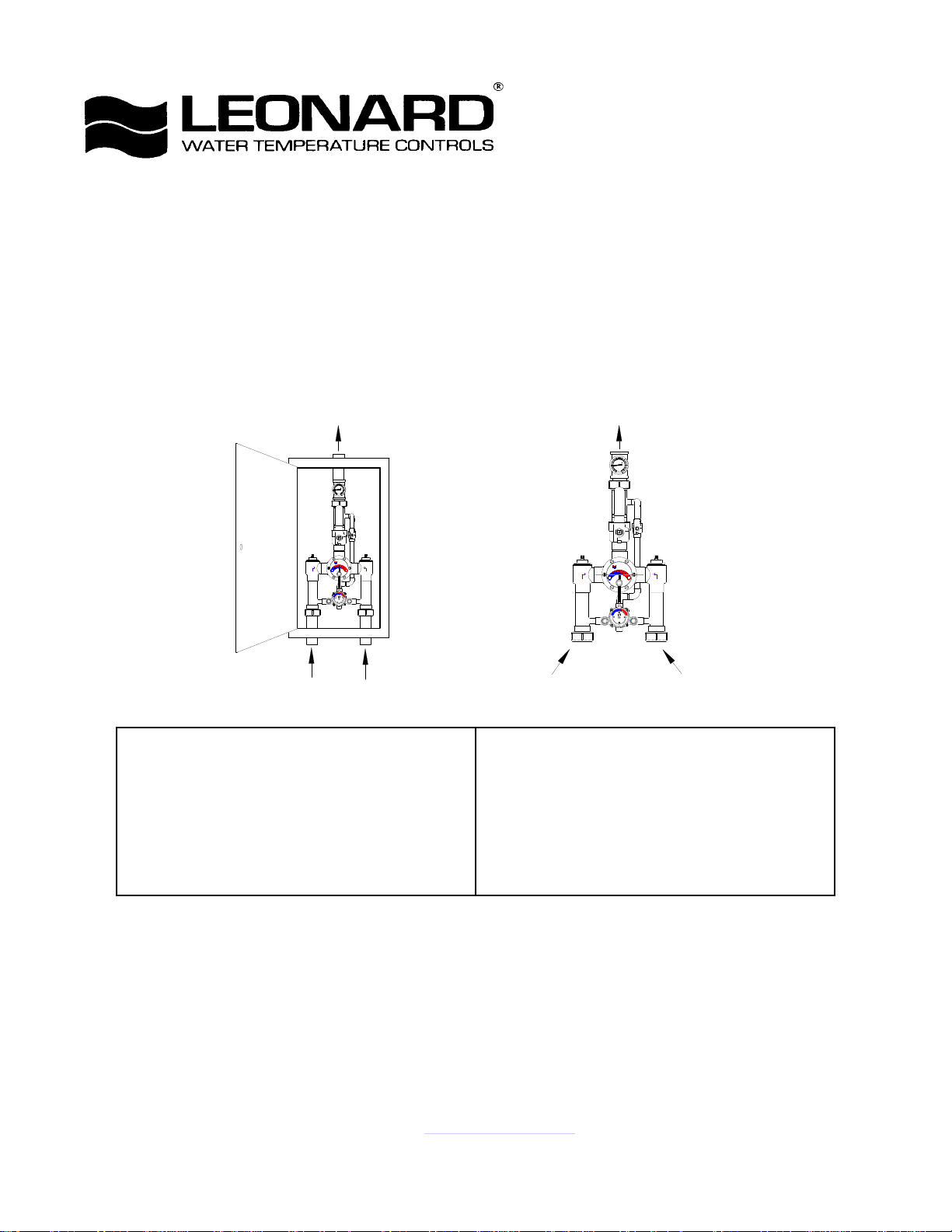

1. Type TM manifold systems are factory pre-assembled

an

elarge andsma

ermostaticwate

mixing valves which function as a system to meet both

high and low demand for tempered water.

2. System should be installed at a location where it can

easily be cleaned, adjusted or repaired.

3. System supplies must be connected as shown (Hot-left,

Cold-right). Exercise caution when soldering.

DOMESTIC OUTLET

8

0

0

6

20

1

30

0

0

0

10

4

LEONARD

40

0

50

-10

2

0

0

2

1

60

°C

°F

0

0

4

1

LEONARD

THERMOSTATIC

H

C

ASSE

1017

HOT INLET

COLD INLET

4. Flush pipes thoroughly after system has been

connected.

5. If this assembly is installed on a recirculated hot water

system it MUST be piped according to LEONARD’S

REQUIRED PIPING METHODS (see pages 4 & 5).

6. Refer to page 3 of this bulletin for correct Setup

Instructions.

All thermostatic water-mixing valves have limitations. They will not provide the desired

accuracy outside of their flow capacity range. Consult the capacity chart on page 8. Minimum

flow must be no less than as shown.

Maximum Operating Pressure 125PSI (860 KPA) for Hot and Cold Water.

CAUTION

1360 Elmwood Avenue, Cranston, RI 02910 USA

Phone: 401.461.1200 Fax: 401.941.5310

Email: info@leonardvalve.com

Web Site: http://www.leonardvalve.com

ADJUSTMENT AND SERVICE

b

i

150°F(65.5°C),th

ll

HOTwill

deliver

r

i

CAP

1

t

S

REMOVED

.

Leonard Type TM Thermostatic Water Mixing

Valves are simple in design and may be easily

cleaned, adjusted and repaired. If the installation

is accessible, servicing may be completed without

NOTE: High Low Manifold Systems include

Thermostatic Water Mixing Valves, which must

be regularly maintained to provide best

performance. Frequency of cleaning depends on

disconnecting the valves. quality of local water conditions and usage. See

Maintenance Guide and Record MGR-1000

WARNING

These mixing valves are equipped with an adjustable high temperature limit stop factory set at approximately

120°F (49°C) with an incoming hot water supply temperature of 150°F (65.5°C). If the hot water supply

temperature ofthejo

sgreaterthan

evalves when turnedtofu

wate

excess of 120°F (49°C) and the limit stop MUST BE RESET BY THE INSTALLER!

TO RESET ADJUSTABLE HIGH TEMPERATURE LIMIT STOP:

TM-2020B LARGE MIXING VALVES TM-2020B SMALL MIXING VALVES

COLD HOT

ASSE

1017

WEB

STOP

LEONARD

THERMOSTATIC

C

POINTER

1. Loosen LTR screw

2. Remove SNAP CAP, SCREW & WASHER, Remove

POINTER.

3. Temporarily place POINTER on the spline rod, turn

RIGHT for warmer temperature, turn LEFT for cooler

temperature. When valve is delivering warmest temperature

desired, remove the pointer.

4. Replace POINTER on the spline rod so thatits RIGHT

edge is resting against the STOP SCREW located on the

RIGHT SIDE OF THE COVER.

5. The new maximum temperature has now been set. Test this

temperature by holding a thermometer under the flow of

water to be certain it is as desired.

* LIMIT STOP MUST BE RESET AND RECHECKED

EACH TIME HANDLE IS REMOVED.

SCREW

H

LTR

SET SC R EW

SNAP

FINE

POINTER SCREW

POINTER

STOP

. Loosen LTRSe

2. Adjust POINTER to maximum desired temperature.

3. Remove POINTER, replace POINTER on spline rod with

STOP (which is cast into the underside on the pointer),

resting against the BOTTOM side of the WEB on the

FINE ADJUSTMENT SCREW.

4. If fine adjustment is needed, adjust FINE ADJUSTMENT

SCREW on the cover, loosen for hotter or tighten for

cooler temperature.

5. Replace POINTER and check temperature, if set to

desired temperature replace POINTER SCREW, and

tighten LTR SET SCREW.

6. The new maximum temperature has now been set. Test

this temperature by holding a thermometer under the flow

of water to be certain it is as desired.

* LIMIT STOP MUST BE RESET AND

RECHECKED EACH TIME HANDLE IS

ADJUSTMENT

SCREW

(REST STOP AGAINST SCREW)

LTR

SET SCREW

crew, remove POINTERSCREW.

n

IMPORTANT! ALL MIXING VALVES MUST BE SET AT THE SAME

OPERATING TEMPERATURE.

SEE PAGES: 6 & 7 FOR COMPLETE PARTS BREAKDOWN

Check for significant variations in outlet flow. Thermostatic valves will NOT provide the desired accuracy

outside of their flow capacity range. Minimum flows must be no less than shown (see Flow Capacities, page 12).

If installed on a recirculated hot water system, make certain the valve is piped according to Leonard’s Required

Piping Methods (see page 4).

REMEMBER! THIS IS A CONTROL DEVICE WHICH MUST BE CLEANED AND MAINTAINED

ON A REGULAR BASIS. (SEE MAINTENANCE GUIDE AND RECORD, MGR-1000).

2

SETUP INSTRUCTIONS

LARGE

LEONARD

6.

Make

sure

Valve

V2at

the

large

TypeTMValve

isinthe

circulation

system

temperature,

see

page4.

THERMOMETER

80

0

6

20

1

30

0

0

0

10

4

R

LEONARD

40

0

50

-10

2

0

0

2

1

60

°C

°F

0

0

4

1

V2

SMALL

VALVE

HOT

INLET

V1

THERMOSTATIC

H

C

VALVE

COLD

INLET

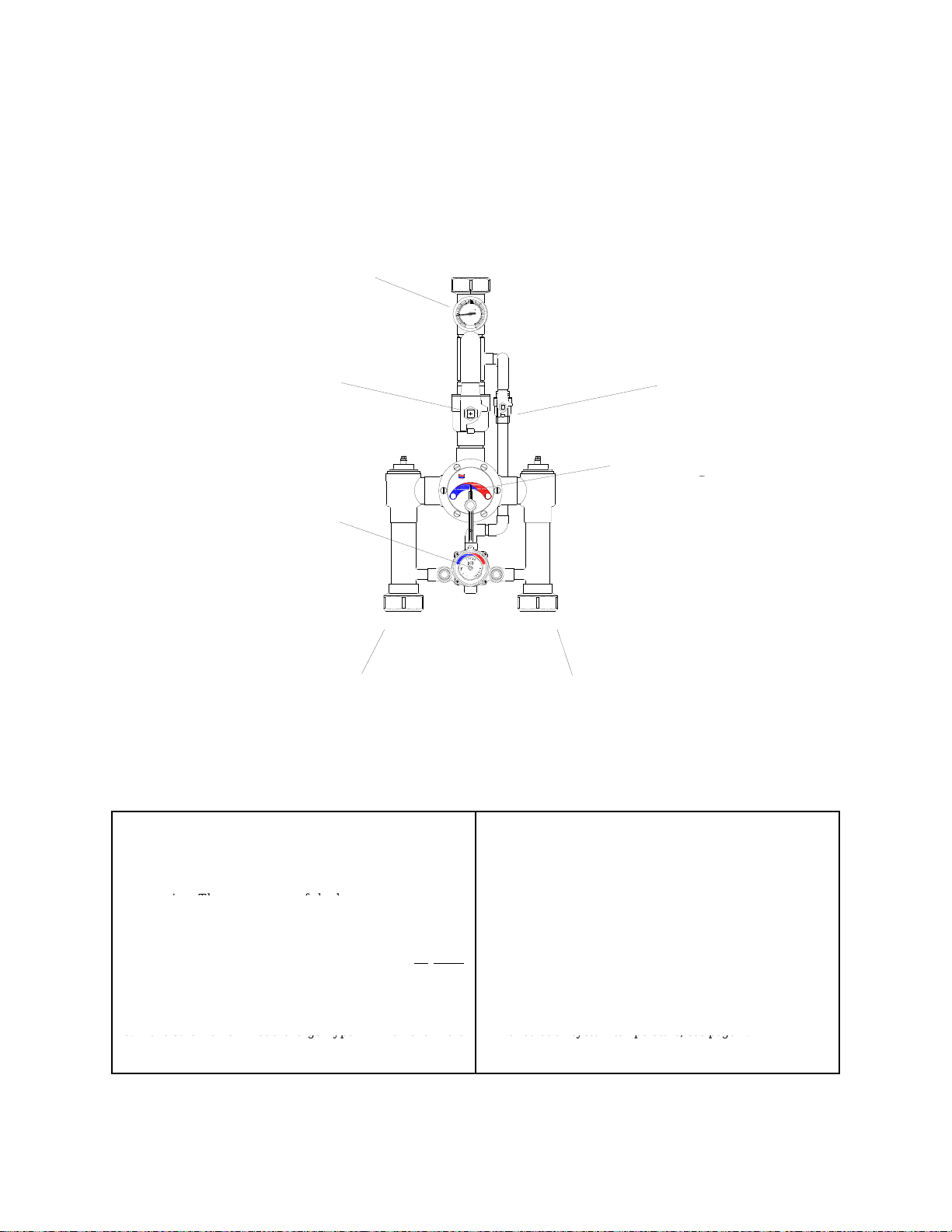

1. The High-Low Unit MUST be piped according to a

Leonard Required Piping Method (see page 4).

2. Make sure full hot and cold supplies to this assembly are

operating.The temperature ofthehot watersource must

be properly set and maintained.

3. The circulator (if used) must be turned OFF before setup.

4. Turn on enough fixtures for a flow of at least 30 GPM

(114 l/min.) downstream from this system. Make sure

each fixture is set to deliver full "HOT" water.

5. Close outlet Valve V1 at the smaller Type TM Valve

7. Set outlet temperature of the large Type TM Valve to the

required level.

8. Open outlet Valve V1 at the small TM Valve.

9. Shut outlet Valve V2 at the large TM valve.

10. Turn on enough fixtures for a flow of at least 2 GPM

(7.6 l/min) downstream from this system. Make sure

each fixture is set to deliver full "HOT" water.

11. Set outlet temperature of the small TM valve to the same

temperature as Step 7.

12. Open outlet Valve V2. System is operational. To balance

full open position.

•NOTE! FOR OPTIONAL OUTLET SETUP PIPING ARRANGEMENT, SEE PAGE 8

3

Loading...

Loading...