Page 1

SHGPCBAUTO-001

13397576

Ä.Hlmä

L-force Controls

Software Manual

PC-based Automation

Industrial PC

Parameter setting & configuration

L

Page 2

Page 3

Industrial PC | Parameter setting & configuration

Contents

Contents

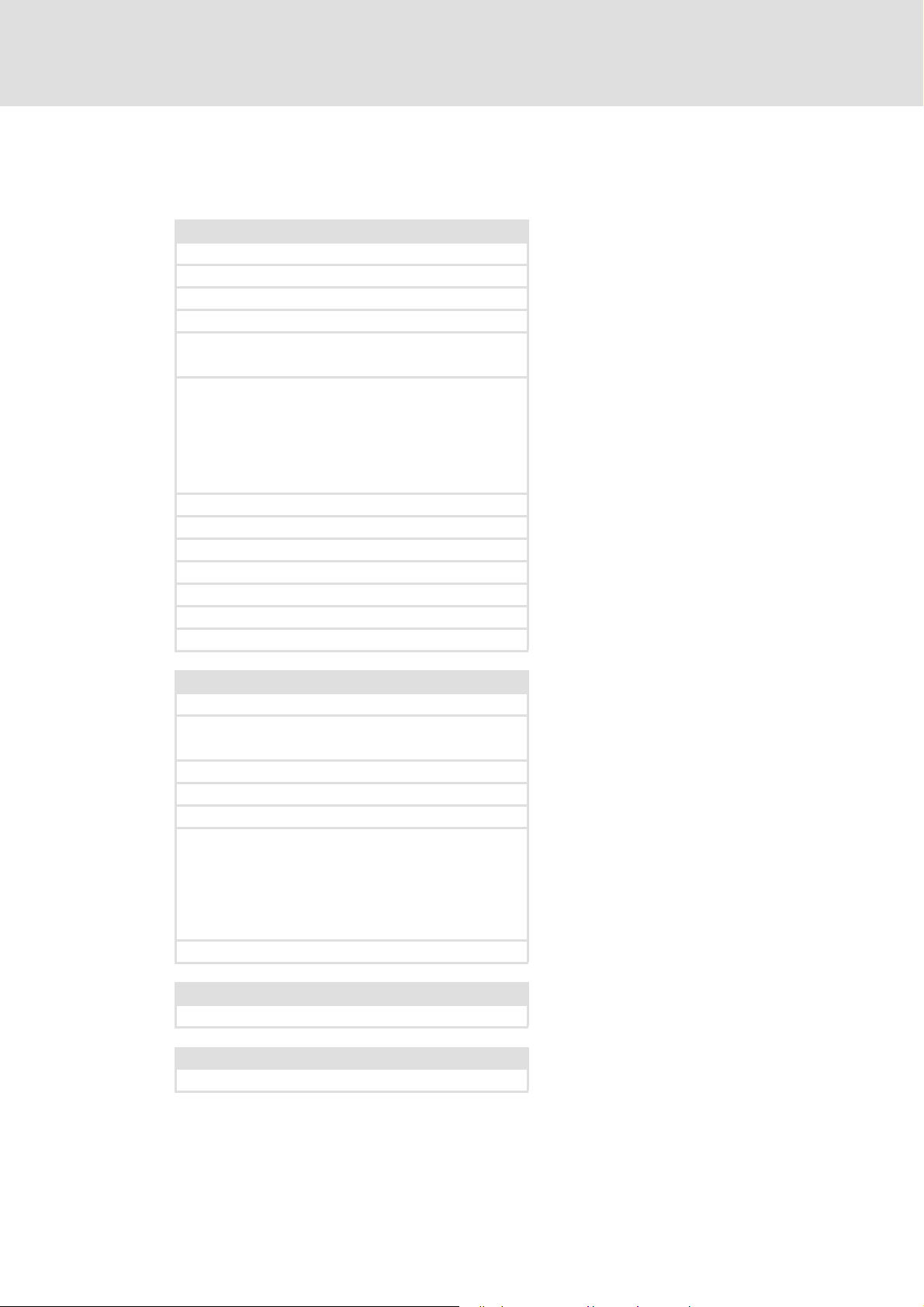

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Document history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3 Terminology used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Notes used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 The PC-based Automation system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.2 Module labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.3 Baseboard label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Control elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.1 LEDs at the front of the monitor panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.2 Function keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.3 Changing the function key assignment in the »WebConfig« . . . . . . . . . . . . . . . 26

4.2.4 Changing the function key assignment in the L-force »Engineer«. . . . . . . . . . 27

4.3 Technical background information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.1 Data management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3.2 Starting process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 Configuring the Industrial PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.1 Touch display calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.2 Establishing an automatic dial-up connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.3 Entering the IP address of the Industrial PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.3.1 Industrial PCs with a touch panel/with an external monitor. . . . . . 33

4.4.3.2 Industrial PC without touch panel/without external monitor. . . . . 33

4.4.4 Establishing Windows® CE access rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4.4.1 Setting up Windows® CE users in the »WebConfig« . . . . . . . . . . . . . 34

4.4.4.2 Setting up Windows® CE users in the »Engineer« . . . . . . . . . . . . . . . . 35

5 System structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.1 Engineering PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2 Industrial PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1 Centralised control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.2 IPC data manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.5 EN - 01/2012 L 3

Page 4

Industrial PC | Parameter setting & configuration

6 Parameterisation using the L-force »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.1 Parameterisation via codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2 Addressing structure in the »Engineer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.1 Volatile data of an »Engineer« project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.2 Saving data permanently . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3 Parameter reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4 Representation of the parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.1 Parameters with read access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.2 Parameters with write access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.2.1 Parameters with a setting range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.2.2 Parameters with a selection list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.2.3 Parameters with a bit-coded setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.2.4 Parameters with subcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Web-based parameterisation with »WebConfig« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 Parameterisation via codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Requirements for working with the web-based parameterisation. . . . . . . . . . . . . . . . . . 45

7.2.1 Online connection between the Engineering PC and Industrial PC . . . . . . . . . . 45

7.2.2 Setting IP addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Start of the web-based parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.3.1 Start at the Engineering PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.3.2 Start at the Industrial PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.4 User interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4.1 Parameters of the standard device of the Industrial PC. . . . . . . . . . . . . . . . . . . . . 51

7.4.2 Diagnostics/Command execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.3 Logbook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4.3.1 Explanations of the logbook entries, example . . . . . . . . . . . . . . . . . . . 53

7.4.3.2 Filter options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.4.3.3 Time filter for the display of logbook entries. . . . . . . . . . . . . . . . . . . . . 54

7.4.3.4 Export logbook entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4.4 Device commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4.5 User management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4.6 General parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4.7 Extension card parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4.7.1 CAN communication card (MC-CAN2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4.7.2 EtherCAT communication card (MC-ETC) . . . . . . . . . . . . . . . . . . . . . . . . 57

7.4.7.3 PROFIBUS master communication card (MC-PBM) . . . . . . . . . . . . . . . 58

7.4.7.4 Ethernet communication card (MC-ETH) . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4.8 Polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4.9 Language selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4.10 Parameter list buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4 L 2.5 EN - 01/2012

Page 5

Industrial PC | Parameter setting & configuration

Contents

8 Programming with the »PLC Designer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.2 Configuration and parameterisation via the control application . . . . . . . . . . . . . . . . . . . 60

8.3 Accessing IPC parameters from the PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.3.1 The LDM_ParameterAccess_FB function block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.3.2 The LLS_AddLog function block - Generate logbook entry . . . . . . . . . . . . . . . . . . 63

9 IPC backup & restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.1 Introduction to »IPC Backup & Restore« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.2 Differences between archive, backup and restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.3 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.4 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.5 Backup procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6 Restore procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.7 Software update procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10 Data integrity in the case of a voltage failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.1 Retain variables of the PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.2 Backup for systems with UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.3 Backup for systems without UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.1 Persisting the PLC's retain variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.2 Persisting the IPC parameterisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3.3 Persisting log files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11 Replacing the Industrial PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.1 Removing the connected Industrial PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.2 Connecting the new Industrial PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.3 Adapting the »Engineer« project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12 Remote maintenance and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

12.1 Remote Access Service (RAS) connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.1.1 RAS client configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

12.1.2 RAS settings with the web-based parameterisation. . . . . . . . . . . . . . . . . . . . . . . . 84

12.1.3 RAS settings in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12.2 telnet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.2.1 Settings of the web-based parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.2.2 Settings in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.5 EN - 01/2012 L 5

Page 6

Industrial PC | Parameter setting & configuration

12.3 FTP connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.3.1 FTP settings with the web-based parameterisation . . . . . . . . . . . . . . . . . . . . . . . . 88

12.3.2 FTP settings in the »Engineer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.3.3 FTP and web settings in the Internet Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

12.4 Windows® CE functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.4.1 Remote Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

12.5 logbook function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.5.1 logbook query via »WebConfig« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.5.1.1 logbook codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

12.5.2 Logbook query in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

12.5.2.1 Filtering logbook entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

12.5.2.2 Logbook codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13 Visualisation with »VisiWinNET®« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.1 Introduction to »VisiWinNET®« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.1.1 »VisiWinNET®« Compact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.1.2 Licensing of the visualisation (lic file) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.2 Basic functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.2.1 Start the »VisiWinNET®« development system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.2.1.1 »VisiWinNET®« Smart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.2.2 Creating a new project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

13.2.3 Open the Project Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

13.2.1.2 »VisiWinNET®« Professional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

13.2.2.1 Creating a new project in »VisiWinNET®« Smart . . . . . . . . . . . . . . . . . 105

13.2.2.2 Creating a new project in »VisiWinNET®« Professional . . . . . . . . . . . 105

6 L 2.5 EN - 01/2012

Page 7

Industrial PC | Parameter setting & configuration

Contents

13.3 Constellation and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

13.3.1 Use the CoDeSys direct driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

13.3.1.1 Use the direct driver for visualisations under Windows CE. . . . . . . . 108

13.3.1.2 Use the direct driver for visualisations under Windows XP . . . . . . . 109

13.3.2 Inserting the OPC tunnel in »VisiWinNET®« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

13.3.3 The Lenze Variables Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.3.3.1 Browsing for variable definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.3.3.2 Accept variable definitions to project . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.3.4 Entering variables manually. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.3.4.1 Using the SoftPLC OPC tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.3.4.2 Using the data manager OPC tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.3.4.3 Local use of CAN OPC tunnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.3.4.4 Using the Remote SoftPLC OPC tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.3.4.5 Using the Remote data manager OPC tunnel . . . . . . . . . . . . . . . . . . . . 115

13.3.4.6 Local use of Remote CAN OPC tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.3.5 Linking control elements and variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

13.3.6 Transferring an application to the target device . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

13.4 Configuration of the OPC tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

13.4.1 Local visualisation (integrated control system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

13.4.2 External visualisation (remote access) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

13.4.3 External visu on a Windows XP/XP Embedded IPC (remote access) . . . . . . . . . 122

13.5 Lenze specifications - exception handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13.5.1 Install additional fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13.5.2 No access to variables with AT declaration possible (CoDeSys direct driver) . 124

14 Parameter reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

14.1 Structure of the parameter description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

14.1.1 Data types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

14.1.2 Parameters with read access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

14.1.3 Parameters with write access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

14.1.3.1 Parameters with a setting range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14.1.3.2 Parameters with a selection list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14.1.3.3 Parameters with a bit-coded setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14.1.3.4 Parameters with subcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14.1.4 Parameter attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

14.2 Parameters of standard devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

14.3 Ethernet interface (on board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

14.4 Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

14.5 PLC (Logic/Motion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

2.5 EN - 01/2012 L 7

Page 8

Industrial PC | Parameter setting & configuration

14.6 Industrial PC extension modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

14.6.1 CAN communication card (MC-CAN2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

14.6.2 EtherCAT communication card (MC-ETC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

14.6.3 PROFIBUS master communication card (MC-PBM) . . . . . . . . . . . . . . . . . . . . . . . . . 207

14.6.4 Ethernet communication card (MC-ETH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

15 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

16 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Your opinion is important to us. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

8 L 2.5 EN - 01/2012

Page 9

Industrial PC | Parameter setting & configuration

1 About this documentation

This documentation provides general information on the parameterisation and

configuration of an Industrial PC. The Industrial PC is the central control system of the PCbased Automation system.

The present manual is part of the "PC-based automation" manual collection which consists

of the following components:

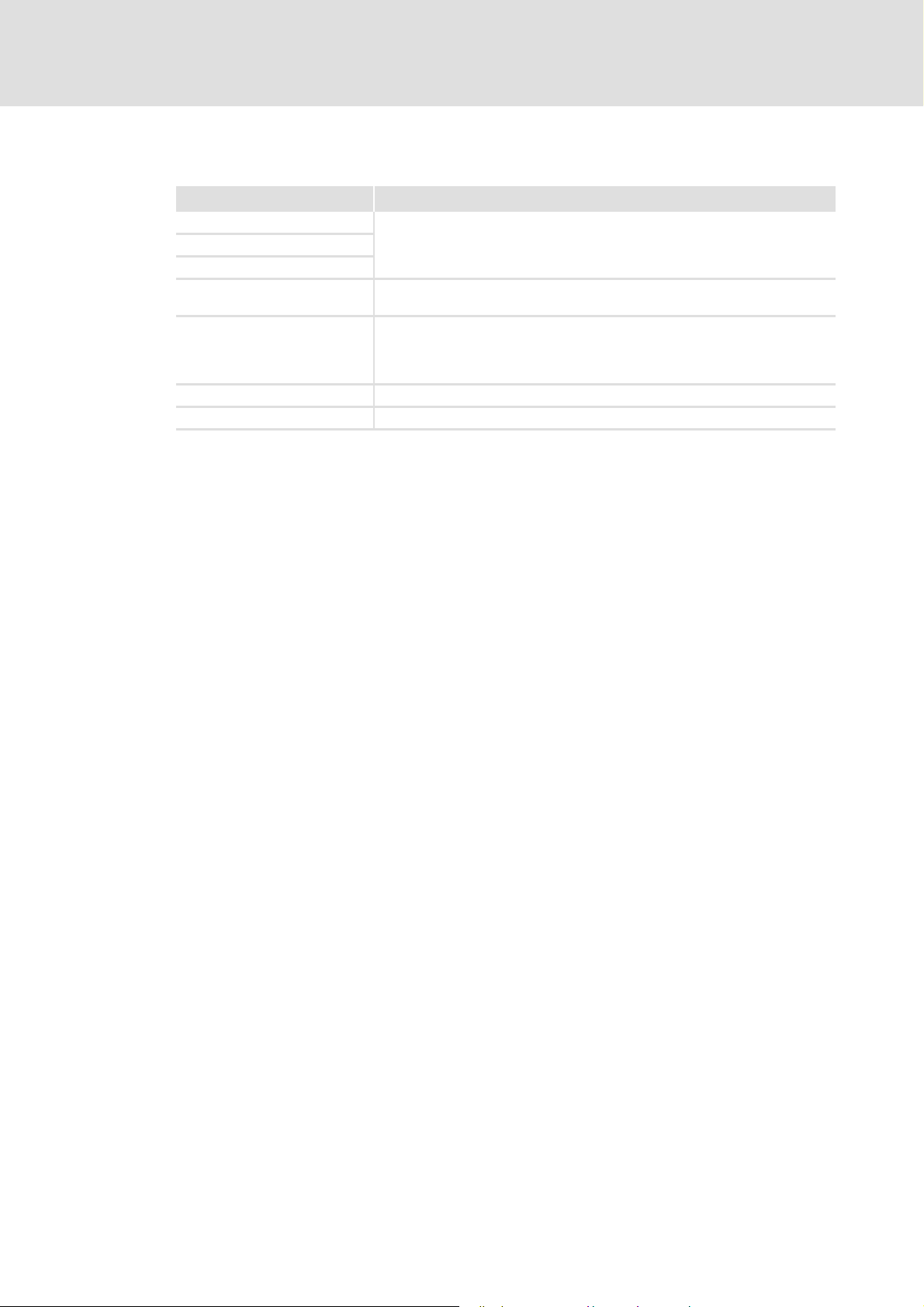

Documentation Subject

System manuals

PC-based Automation

Communication manuals

PC-based Automation

(Software) manual

PC-based Automation

Operating Instructions

Embedded Line Panel PC

Operating Instructions

Command Station

Operating Instructions

Control Cabinet PC

Operating Instructions

HMI EL 100

Further software manuals • Global Drive Control (GDC)

• Control technology - system structure & configuration

• Visualisation - system structure & components

• CANopen control technology

• EtherCAT control technology

• PROFIBUS control technology

• Industrial PC - Parameterisation & Configuration

• EL x800 - Panel PC with TFT display

• CS x800 - Stand-alone operator terminal

• CPC 2800 - Control cabinet PC

• EL 1xx - HMI with Windows

• IPC as gateway - Parameterisation & Configuration

• »Engineer«

• »PLC Designer« / »PLC Designer - SoftMotion« / »PLC Designer - CANopen

• »VisiWinNET® Smart«

About this documentation

® CE

for runtime systems«

Information on the use of the IPCs beyond control technology can be found in the

System manuals which are designed to meet the respective case of application.

2.5 EN - 01/2012 L 9

Page 10

Industrial PC | Parameter setting & configuration

About this documentation

Further technical documentation for Lenze components

Further information on Lenze components which can be used in connection with "PC based

Automation" can be found in the following documentation:

Mounting & wiring Legend:

MA 8400 StateLine/HighLine Printed documentation

MA 9400 StateLine/HighLine Online help/PDF

MA EPM-Txxx (I/O system IP20) Abbreviations used:

MA EPM-Sxxx (I/O system 1000) SHB System Manual

MA 8200 vector BA Operating Instructions

EMC-compliant wiring 8200 vector MA Mounting Instructions

MA ECSxS/P/M/A axis modules SW Software manual

MA ECSxE power supply modules KHB Communication manual

Accordingly for built-in variants:

• Built-in unit

• Push-through technique

•Cold plate technology

MA MC-CAN2 communication card

MA MC-ETC communication card

MA MC-ETH communication card

MA MC-PBM communication card

MA MC-PBS communication card

MA MC-MPI communication card

MAs for the communication modules

Parameterisation, configuration, commissioning

SW 8400 StateLine/HighLine frequency inverters

SW 9400 StateLine/HighLine/PLC controller

9400 HighLine commissioning guideline

SHB I/O system IP20 (EPM-Txxx)

SHB I/O system 1000 (EPM-Sxxx)

SHB 8200 vector

BA ECSxS "Speed and Torque" axis module

BA ECSxP "Posi & Shaft" axis module

BA ECSxM "Motion" axis module

BA ECSxA "Application" axis module

BA ECSxE power supply module

KHBs for the communication modules

Programming

SW 9400 function library

Establishing a network

KHBs for the communication modules

10 L 2.5 EN - 01/2012

Page 11

Industrial PC | Parameter setting & configuration

About this documentation

Target group

This documentation is directed at persons who wish to parameterise, configure, and

diagnose a PC-based control system using an Industrial PC in conjunction with the L-force

»Engineer« Engineering software.

2.5 EN - 01/2012 L 11

Page 12

Industrial PC | Parameter setting & configuration

About this documentation

Document history

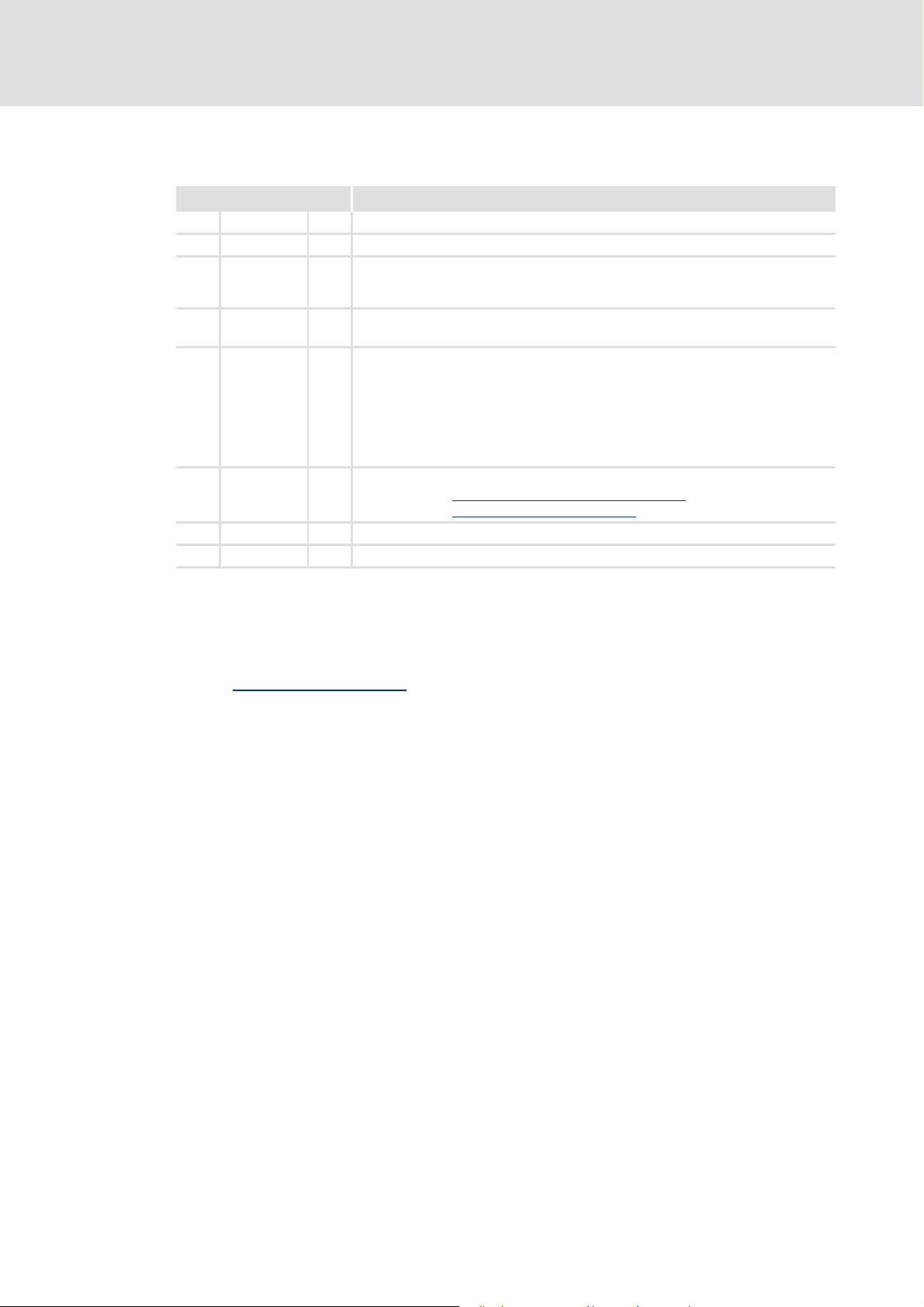

1.1 Document history

Version Description

1.0 07/2007 TD16 First edition control technology 1.0

1.5 11/2007 TD16 Updated parameter lists control technology 1.5, amended by the »WebConfig«

2.0 05/2008 TD11 Control technology 2.0, amended by the parameter lists for the MC-CAN2, MC-ETH,

2.1 08/2008 TD11 Control technology 2.1, "(in preparation!)" removed for Release EtherCAT,

2.2 05/2009 TD11 Control technology 2.2, update for the new software version

2.3 11/2009 TD11 Control technology 2.2.2, update for the new software version

2.4 01/2011 TD11 Control technology 2.5, update for the new software version

2.5 01/2012 TD11 Control technology 2.6, update for the new software version

and

MC-ETC communication cards.

Update EtherCAT parameters.

• Update of the German »WebConfig« user interface,

• Added default settings of IP addresses,

• Amended by the IP port in the system overviews,

• Added contents from system verification,

• Added ID numbers to document,

• Amended by the parameter list of the MC-PBM communication card.

•new chapter: Lenze specifications - exception handling

•new chapter: Configuration of the OPC tunnel

Tip!

Current documentation and software updates on Lenze products can be found on

the Internet in the "Services & Downloads" area under:

http://www.Lenze.com

12 L 2.5 EN - 01/2012

Page 13

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types

of information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point Generally the decimal point is used.

Text

Version information Text colour blue All pieces of information that only apply to or from a

Program name » « The Lenze PC software »Engineer«...

Window Italics The Message window... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element Bold The OK button... / The Copy command... / The

Sequence of menu

commands

Keyboard command <Bold> Press <F1> to open the online help.

Program listings Courier

Keyword Courier bold

Industrial PC | Parameter setting & configuration

About this documentation

Conventions used

For example: 1234.56

specific software version are indicated accordingly in

this documentation.

Example: This function extension is available from

software version V3.0!

Properties tab... / The Name input field...

If several commands must be used in sequence to

carry out a function, then the individual commands

are separated by an arrow. Select File

If a command requires a combination of keys, a "+" is

placed between the key symbols:

With <Shift>+<ESC> you can...

IF var1 < var2 THEN

a = a + 1

END IF

Open to...

Hyperlink Underlined

Symbols

Page reference ( 13) Optically highlighted reference to another page. Is

Step-by-step instructions

Optically highlighted reference to another topic. Is

activated via mouse-click in this documentation.

activated via mouse-click in this documentation.

Step-by-step instructions are indicated by a

pictograph.

2.5 EN - 01/2012 L 13

Page 14

Industrial PC | Parameter setting & configuration

About this documentation

Terminology used

1.3 Terminology used

Term Meaning

»Engineer« Lenze engineering tools which support you throughout the whole life cycle of a

»Global Drive Control« / »GDC«

»PLC Designer«

Code "Container" for one or several parameters used for parameter setting or

Subcode If a code contains several parameters, the individual parameters are stored

IPC Industrial PC

PLC Programmable Logic Controller

machine with an Industrial PC - from planning to maintenance.

monitoring Lenze Servo Drives.

under "subcodes".

This manual uses a slash "/" as a separator between code and subcode

(e.g. "C00118/3").

14 L 2.5 EN - 01/2012

Page 15

1.4 Notes used

The following signal words and icons are used in this documentation to indicate dangers

and important information:

Safety instructions

Structure of safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Industrial PC | Parameter setting & configuration

About this documentation

Notes used

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to another documentation

2.5 EN - 01/2012 L 15

Page 16

Industrial PC | Parameter setting & configuration

Safety instructions

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller

or system using the Industrial PC.

Read the documentation supplied with the corresponding field device thoroughly

before starting to commission the devices with the Industrial PC!

The device documentation contains safety instructions which must be

observed!

Danger!

According to our present level of knowledge it is not possible to ensure the

absolute freedom from errors of a software.

If necessary, systems with built-in controllers must be provided with additional

monitoring and protective equipment according to relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents), so

that an impermissible operating status does not endanger persons or facilities.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by

the moving machine parts.

Stop!

If you change parameters in the »Engineer« or the »WebConfig« while a device

is connected online, the changes will be directly accepted by the device!

A wrong parameter setting can cause unpredictable motor movements. By

unintentional direction of rotation, too high speed or jerky operation, the driven

machine parts may be damaged!

16 L 2.5 EN - 01/2012

Page 17

Industrial PC | Parameter setting & configuration

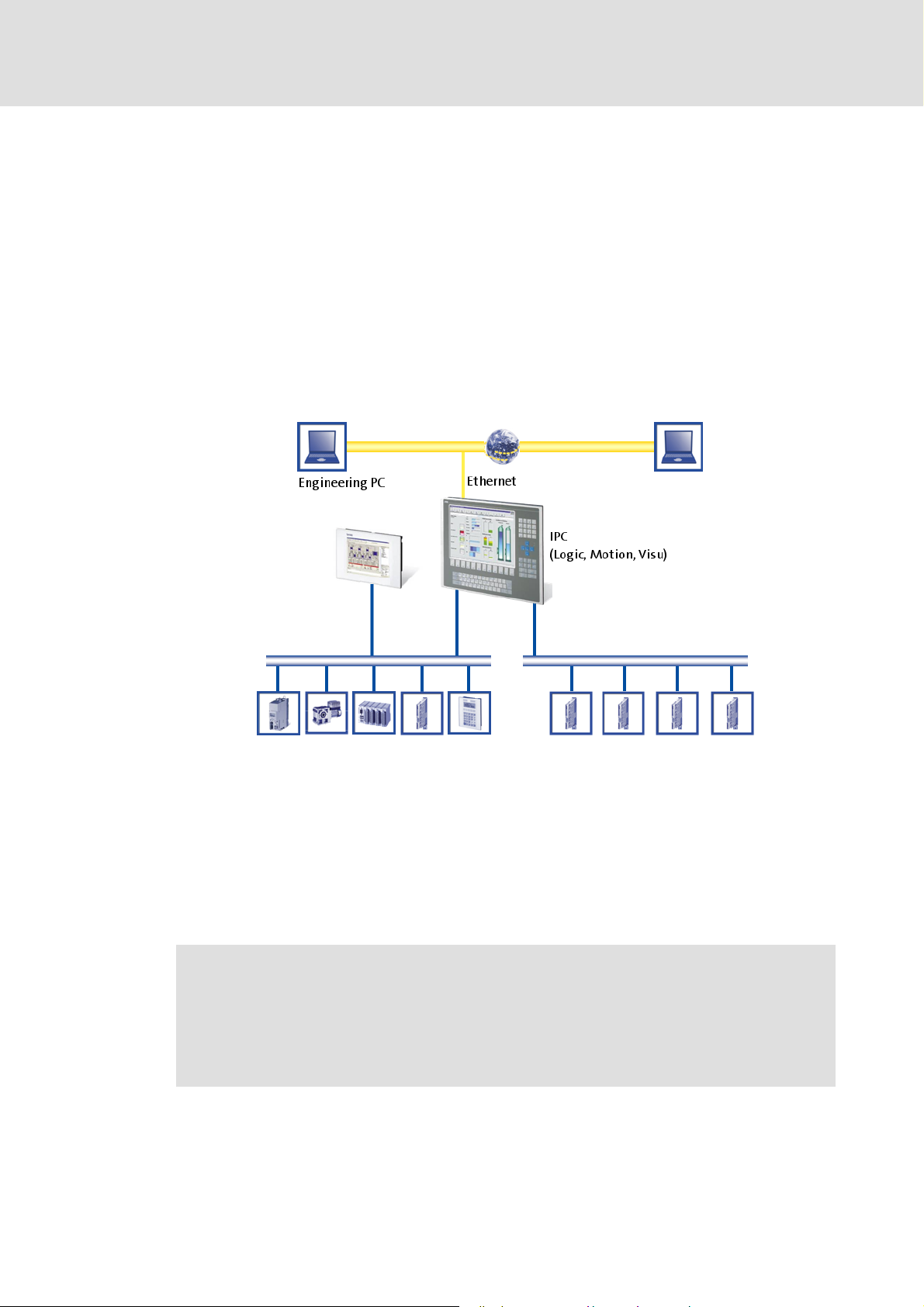

3 The PC-based Automation system

Industrial PCs (IPCs) keep finding their way into automation technology. Due to their

scaling options and various possibilities of combining visualisation and control in one

device, Industrial PCs offer great advantages for many applications.

Lenze Industrial PCs are available in the following software equipments:

Industrial PC as component, on request with operating system, without further

software

Industrial PC as visualisation system

Industrial PC as control and visualisation system

The PC-based Automation system enables central control of Logic and Motion systems.

The PC-based Automation system

For this pupose, Lenze provides well-matched system components:

Industrial PCs as control and visualisation system

– The IPC is the central component of the PC-based Automation system that uses the

Runtime Software to control the Logic and Motion functionalities.

– The IPC uses the fieldbus to communicate with the field devices.

– The IPC is available in various designs.

Note!

The PC-based Automation system also includes the EL 1xx PLC HMI series.

Regarding efficiency and other details, these devices differ considerably from

the Industrial PCs. However, the devices of the EL 1xx PLC HMI series are able to

perform smaller control tasks.

Engineering tools for the Engineering PC

– The Engineering PC uses the Ethernet to communicate with the IPC.

– Use the various Engineering tools to configure and parameterise the system.

2.5 EN - 01/2012 L 17

Page 18

Industrial PC | Parameter setting & configuration

The PC-based Automation system

Fieldbuses

Field devices

18 L 2.5 EN - 01/2012

Page 19

4 Commissioning

This chapter provides general information on the first commissioning of an Industrial PC.

Depending on the actual hardware installed, different settings are required to integrate

the Industrial PC for machine control purposes into a network.

Note!

• Please observe the following predefined IP addresses when commissioning

your IPC for the first time:

– Engineering PC: 192.168.5.100

– Industrial PC: 192.168.5.99

Further information on the setting of the IP address of your Industrial PC can be found in

the following section: Entering the IP address of the Industrial PC

Industrial PC | Parameter setting & configuration

Commissioning

( 32)

Read the Mounting Instructions accompanying the controller first before you start

working!

The Mounting Instructions contain safety instructions which must be observed!

Further information on the device-specific properties can be found in the

Hardware Manual of the corresponding Industrial PC.

2.5 EN - 01/2012 L 19

Page 20

Industrial PC | Parameter setting & configuration

Commissioning

Identification

4.1 Identification

Note!

Here the documentation provides some general information on the

commissioning of an Industrial PC. Depending on the design and version of the

Industrial PC, the commissioning can vary.

Every Industrial PC is provided with a nameplate containing the device data. The device

data is required for being able to select the IPC in the »Engineer« corresponding to the

hardware components installed.

The Industrial PC can be identified by means of the nameplate. Nameplate

The nameplate contains information on the components installed which is required for

initial commissioning.

( 21)

20 L 2.5 EN - 01/2012

Page 21

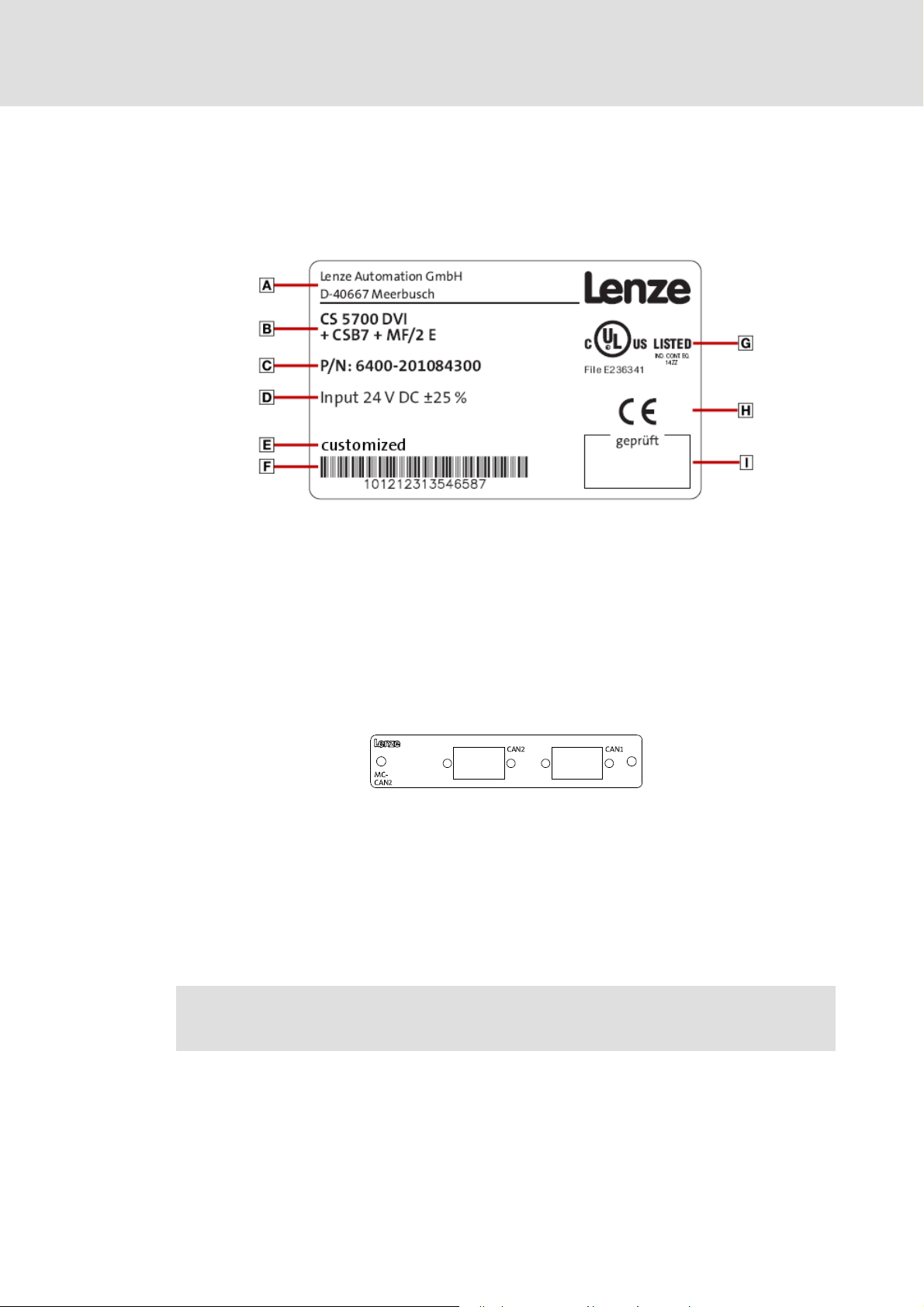

4.1.1 Nameplate

The nameplate is...

...on the back of the panel for Industrial PCs of the EL and CS series,

For cabinet PCs of the CPC series on the housing.

Industrial PC | Parameter setting & configuration

Commissioning

Identification

Manufacturer

address

Material number

(customised)

Inspector's signature

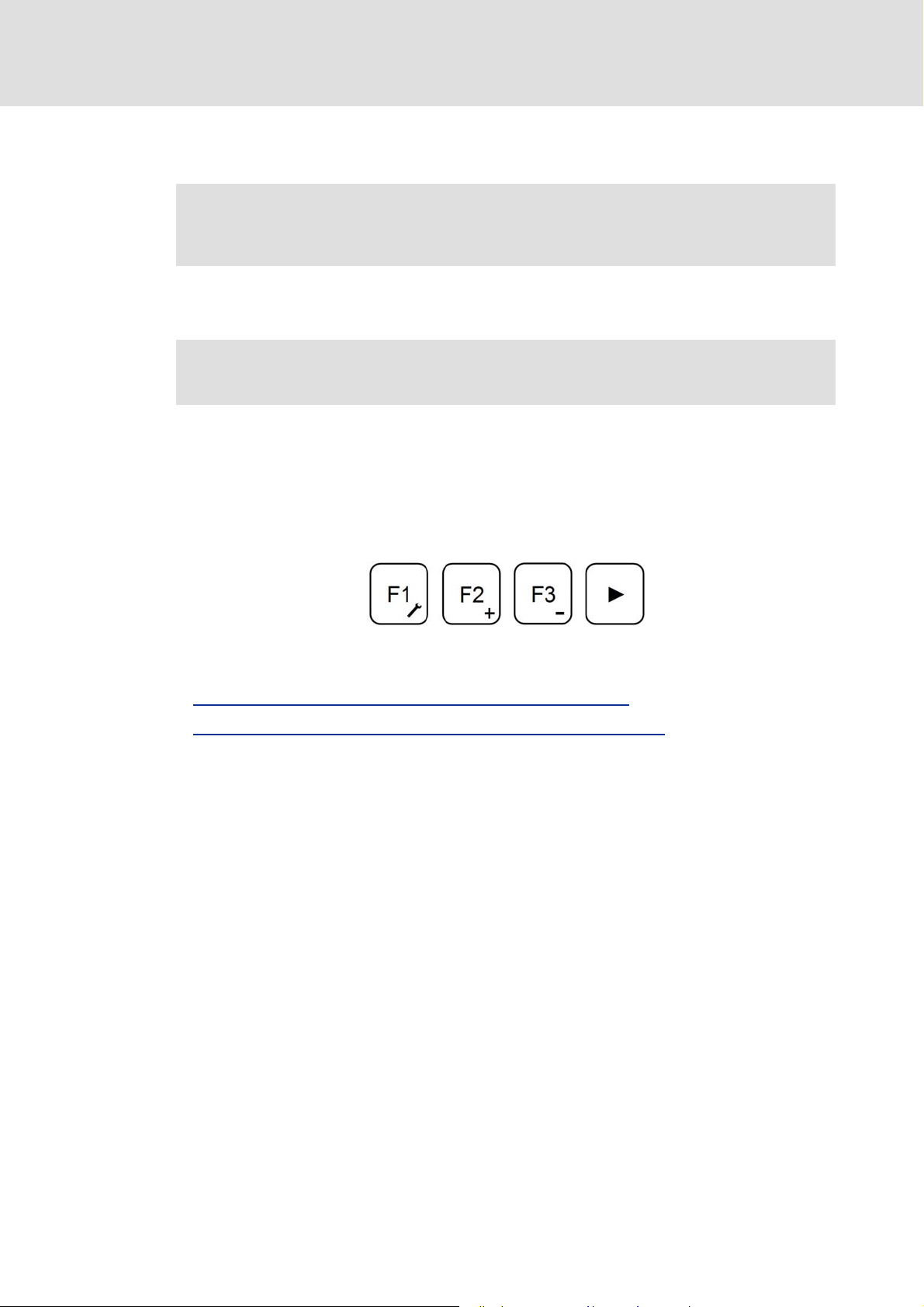

4.1.2 Module labelling

The extension module labelling indicates the connection options to the fieldbus.

Depending on the configuration, one or more fieldbus adapter are mounted.

[4-1] Module labelling, example: the CAN communication card (MC-CAN2)

Type designation Catalogue / order

Bar code

with serial number

number

Certification CE mark

Tip!

Data provided by module labelling facilitate the integration of IPC device modules

into the L-force »Engineer«.

Technical data

Further information on the L-force »Engineer« can be found in the online

documentation of the L-force »Engineer«.

2.5 EN - 01/2012 L 21

Page 22

Industrial PC | Parameter setting & configuration

Commissioning

Control elements

4.1.3 Baseboard label

The baseboard label illustrates possible connections to the main board of the IPC.

Therefore, quick wiring of the individual components is possible.

4.2 Control elements

Depending on the equipment level and the model series, the different series are provided

with different control elements. The monitor panels and embedded line front modules are

equipped with status LEDs, function keys and special keys.

The IPC can be operated

as standard via the function keys of the command stations and embedded line PCs next

to the panel,

or via the on-screen keyboard or touchscreen.

If extensive diagnostics and configurations are required, the Industrial PC can also be

operated via external input devices such as a keyboard or mouse.

4.2.1 LEDs at the front of the monitor panel

The LEDs are located at the front of the panel. Depending on the model design, the LEDs are

positioned in different places.

Power LED

The green power LED is lit when an input voltage is supplied.

If the LED is blinking, the Industrial PC is in service mode.

Fail LED

The red fail LED is lit if a fault has occurred in the current supply.

If the LED is blinking, there is no screen signal.

22 L 2.5 EN - 01/2012

Page 23

Status LED (optional)

Note!

In the case of some IPC variants the status LED has no function!

Depending on the IPC design, the status LED can signalise the access to the respective

storage medium.

Further information on the device-dependent function of the light-emitting diodes

can be found in the Hardware Manual of the corresponding Industrial PC.

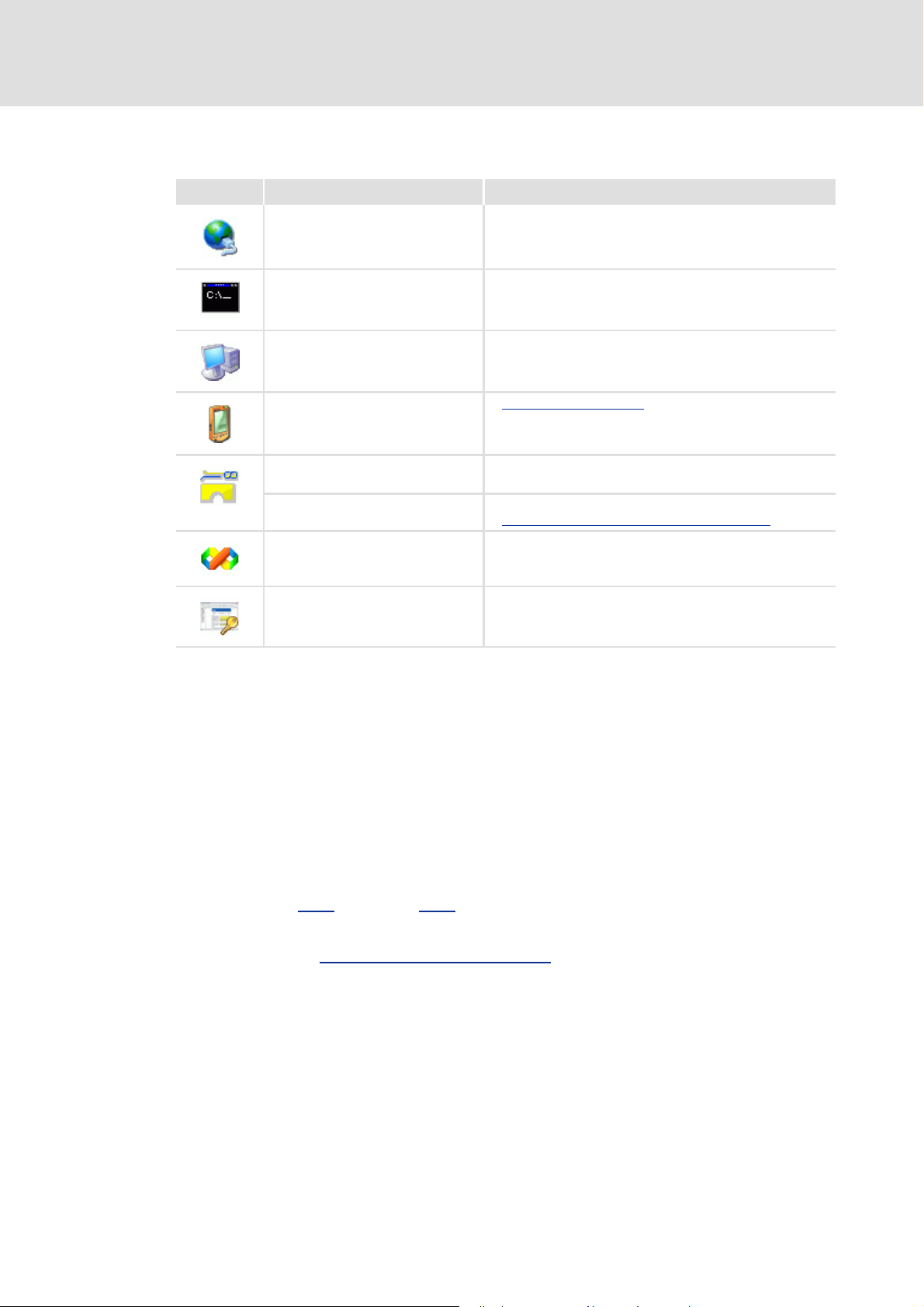

4.2.2 Function keys

At the least the panel is equipped with function keys F1, F2, F3 and a shift key at the front

module. The following description applies to the IPC series ELxx00, MPxx00 and CSxx00.

Here the function keys are located on the right of the display. Depending on the IPC design,

the position and assignment of the keys may vary.

Industrial PC | Parameter setting & configuration

Commissioning

Control elements

The key assignment of function keys F1-F3 can be parameterised via the »Engineer«or the

»WebConfig«.

Changing the function key assignment in the »WebConfig«

Changing the function key assignment in the L-force »Engineer« ( 27)

Every function key has two functions. The additional functions can be activated via a

service mode.

( 26)

How to activate the service mode:

1. Keep the key

• While the LED is blinking, the service mode is active.

2. In the service mode the screen brightness can be changed via F2 and F3.

• F1 starts the control panel.

3. To return to standard mode, wait until the green LED is lit permanently or press

again.

pressed until the green LED is blinking.

2.5 EN - 01/2012 L 23

Page 24

Industrial PC | Parameter setting & configuration

Commissioning

Control elements

Function key "F1"

Standard mode: The key sends the key code for <SHIFT>+<F1>.

• In the standard assignment, <F1> starts the input panel.

In the service mode, <F1> sends the key code for <SHIFT>+<F4> and starts the Windows®

CE control panel: Control panel

( 25)

The View menu provides further options for representation.

24 L 2.5 EN - 01/2012

Page 25

Industrial PC | Parameter setting & configuration

Control panel

Icon Designation Information

Network Connections Open configuration of the network connections

Service Command Open command line box

System Show system properties

Commissioning

Control elements

Touch Calibration Touch display calibration

»VisiWinNET®« Project Manager Start »VisiWinNET®« Project Manager

• Manage »VisiWinNET®« projects

»VisiWinNET®« Remote Access Start »VisiWinNET®« Remote Access

Transferring an application to the target device

VisualStudio Connect VisualStudio2005 ConManClient

»WebConfig« Start »WebConfig«

( 31)

Function key "F2"

Standard mode: The key sends the key code for <SHIFT>+<F2>

The standard assignment of the function key is the right mouse-click.

Service mode: The screen brightness is increased.

Function key "F3"

Standard mode: The key sends the key code for <SHIFT>+<F3>

( 116)

Service mode: The screen brightness is reduced.

The codes C422

(C0422) and C423 (C0423) contain the parameters for screen brightness.

Further information on the codes containing the values of the screen brightness can be

found in chapter Parameters of standard devices

( 129)

Shift key ""

Standard mode: The key sends the key code for <SHIFT>+<F4>.

The shift key activates the Service mode. When the system is started, the shift key

interrupts batch processing and executes the

Windows® CE control panel.

2.5 EN - 01/2012 L 25

Page 26

Industrial PC | Parameter setting & configuration

Commissioning

Control elements

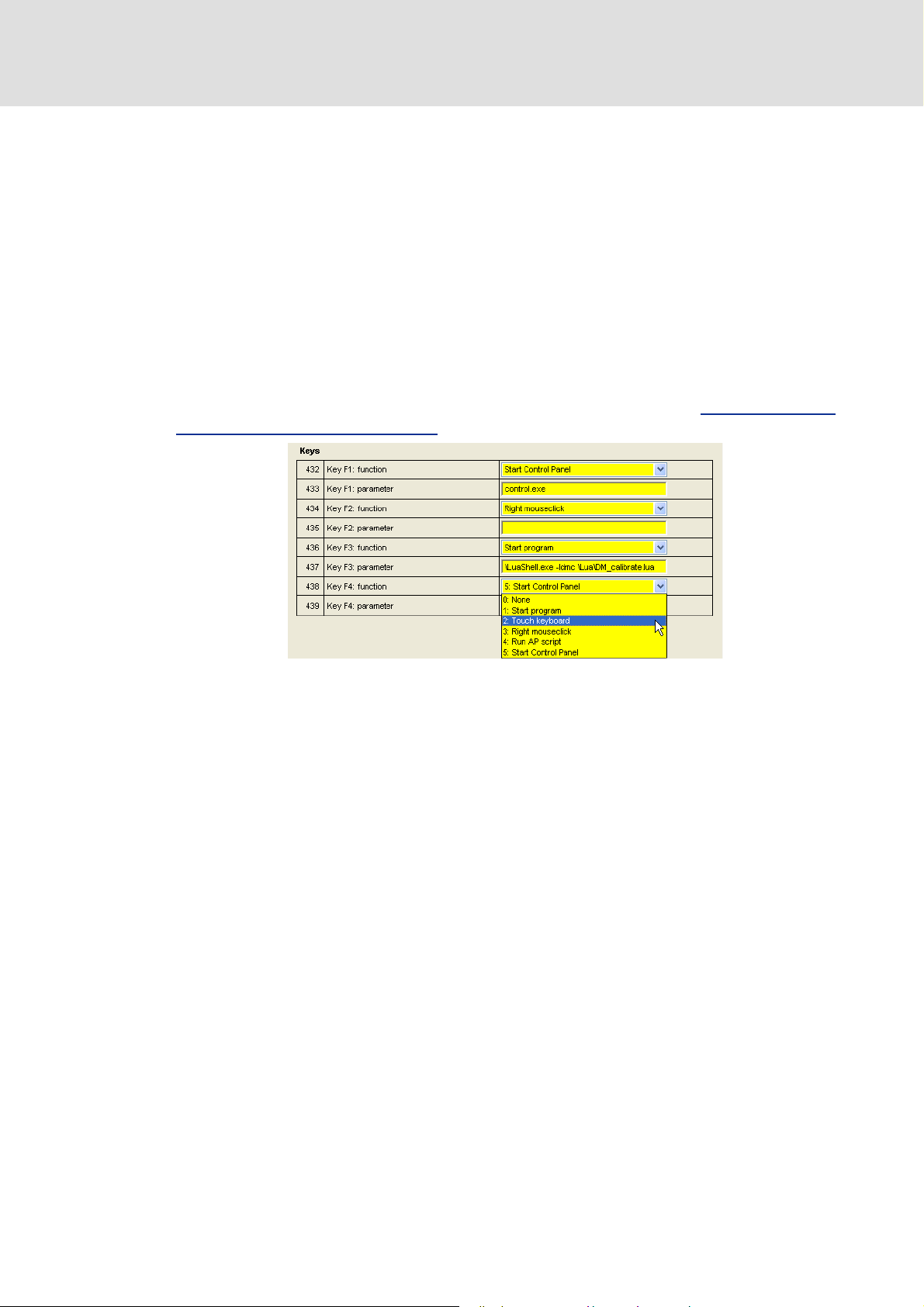

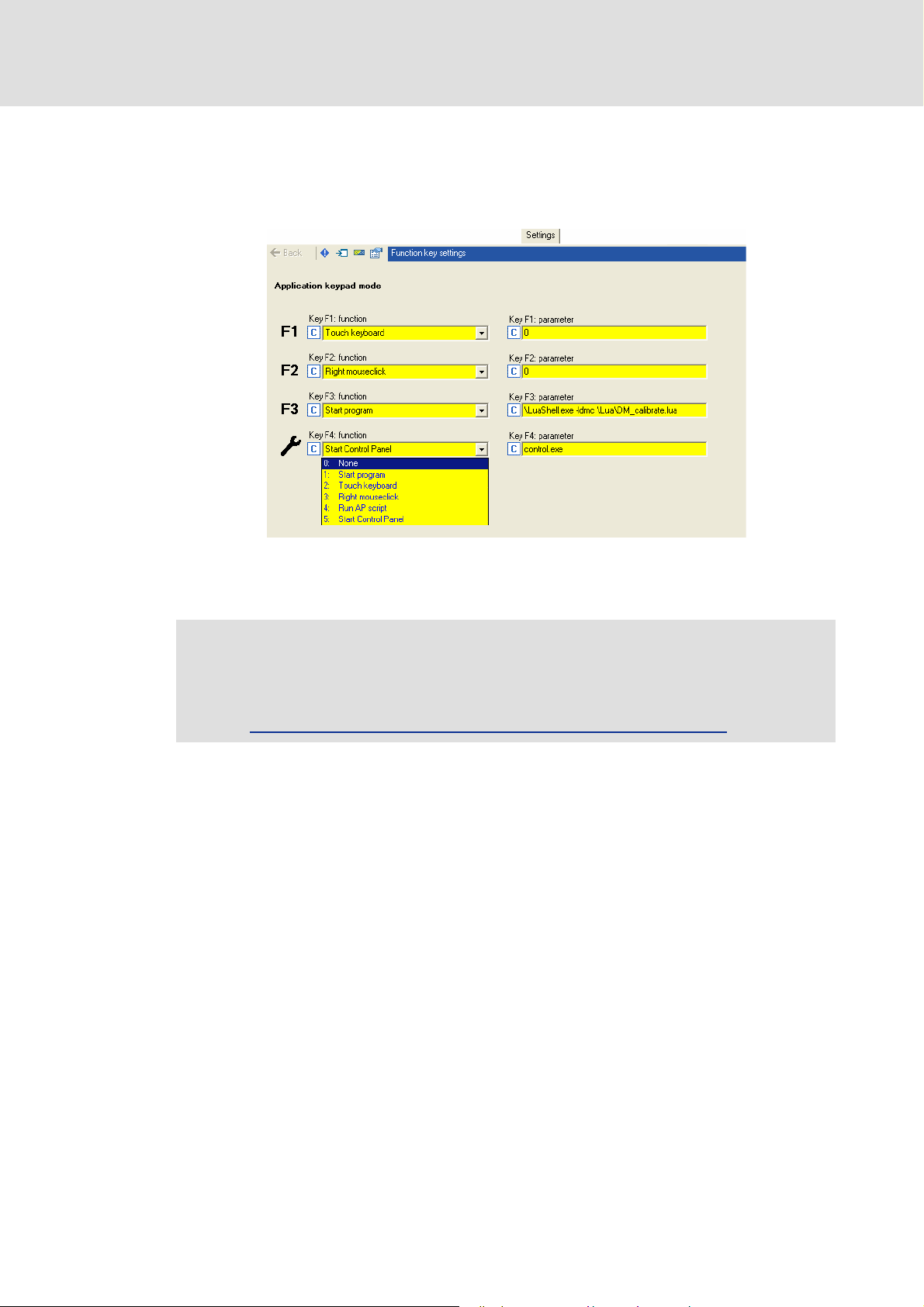

4.2.3 Changing the function key assignment in the »WebConfig«

The assignment of the function keys of the panel can be configured via the

»WebConfig«.

Each function key can be assigned with different functions via a selection list:

–The Start program option enables linking a function key to the start of an

application,

– Touch keyboard assigns the function key to the on-screen keyboard,

– Right mouse-click assigns the function key with the right mouse-click,

– Run AP script starts an automation panel script,

– Start control panel starts the Windows® CE control panel.

The function key assignment can be changed via the Panel button. Parameters of the

standard device of the Industrial PC ( 51)

[4-2] Representation of the function key assignment as a list field (example: the F4 key)

26 L 2.5 EN - 01/2012

Page 27

Industrial PC | Parameter setting & configuration

4.2.4 Changing the function key assignment in the L-force »Engineer«

The panel function key assignment can be configured in the »Engineer«.

Every function key has a selection list including different function assignments.

Commissioning

Control elements

[4-3] Function key assignment in the L-force »Engineer« with an online connection to the Industrial PC

Note!

The function key assignment can only be changed if an online connection to the

Industrial PC has been established.

Online connection between the Engineering PC and Industrial PC

( 45)

2.5 EN - 01/2012 L 27

Page 28

Industrial PC | Parameter setting & configuration

Commissioning

Control elements

How to start the function key assignment in the »Engineer«:

1. Highlight the corresponding Industrial PC in the project view.

2. Establish the online connection to the Industrial PC selected.

• Observe the chapter "Establishing the online connection to an Industrial PC" in

the »Engineer« documentation.

3. Click the Settings tab.

For every function key a selection list with different functions is available:

–The Start program option enables linking a function key to the start of an

application,

– Touch keyboard assigns the function key to the on-screen keyboard,

– Right mouse-click assigns the function key with the right mouse-click,

– Run AP script starts an automation panel script,

– Start control panel starts the Windows® CE control panel.

Alternatively the function key assignments can also be configured via codes C432 to

C439.

28 L 2.5 EN - 01/2012

Page 29

4.3 System boot-up

Note!

Removing the CF card causes a failure of the system! The CF card is required for

the system start, as the operating system and all the system files required for the

boot process are stored on the CF card.

The CF card is the storage medium of the Industrial PC.

During the system start-up, the Industrial PC generates the required data in the main

memory from the data bases of the CF card. Thus the Industrial PC can only be operated

in connection with the CF card.

Configurations which have been saved previously, e.g. the entry of the IP address and

the touch calibration, are taken into account for the system start.

Industrial PC | Parameter setting & configuration

Commissioning

Technical background information

4.4 Technical background information

4.4.1 Data management

During a system start the data management generates the required

registry entries from the reference data saved. As the registry is not saved with mains

failure protection, the Industrial PC regenerates the registry at every system start.

The reference data base is composed of the IPC data and parameters which are saved

to the files of the data manager. The remaining data are stored within the databases

by the Industrial PC. The CF card serves as a storage medium for saved data.

4.4.2 Starting process

The operating system is stored in a binary file on the CF card. During system start-up the

Industrial PC loads the system data and starts the operating system. The Industrial PC

executes the following steps during a start-up:

1. Loading the system data from the binary file into the main memory and starting the

operating system:

2. Unpacking the system programs and installing the device drivers:

– Unpacking of the basic settings from the database,

– Installation of the "backup and restore“ components,

– Installation of the device scanner,

– Installation of the data manager.

After unpacking the system files, the Industrial PC starts the system programs. The device

scanner identifies the IPC configuration and establishes the topological addressing.

2.5 EN - 01/2012 L 29

Page 30

Industrial PC | Parameter setting & configuration

Commissioning

Configuring the Industrial PC

Note!

• The Industrial PCs are preconfiured, i.e. during initial commissioning the

touch display is already calibrated and a default IP address (192.168.5.99) is

defined.

• After 15 seconds the network configuration and the touch calibration are

closed automatically, and the Industrial PC continues to boot.

The preset IP configurations can be configured using the »Engineer« and »WebConfig«.

Entering the IP address of the Industrial PC

4.5 Configuring the Industrial PC

This chapter will inform you on how to configure the Industrial PC during initial

commissioning. The configuration of the IP address and the touch calibration are

maintained when the system is restarted.

( 32)

30 L 2.5 EN - 01/2012

Page 31

4.5.1 Touch display calibration

Tip!

Use a ballpoint pen with retracted cartridge for the touch calibration or a special

PDA/touch pen. In this way the calibration can be carried out more precisely.

Note!

• The touch calibration can be viewed for 15 seconds. Then the touch display

remains in an uncalibrated state so that the touch function does not properly

work. When the system is started again, the Industrial PC carries out another

touch calibration.

• The touch calibration can be started manually:

– Via one of the function keys, standard setting <F3>,

–In the Windows® CE control panel on the IPC Control panel

Industrial PC | Parameter setting & configuration

Commissioning

Configuring the Industrial PC

( 25)

Touch calibration is required if...

...you replace the CF card,

...you have updated the IPC software,

...a USB data carrier with backup / restore configuration has been connected,

...the Industrial PC remains in the service mode due to start-up problems,

...the Industrial PC detects a change in the hardware configuration when the system is

started.

How to calibrate the touch display:

1. If the touch calibration cannot be viewed, press function key <F3>.

• The icon appears on the screen surface.

2. Press the red-white icon displayed on the screen with your finger, PDA/touchpen,

or similar.

• The icon skips from its initial position to the upper left-hand corner.

2.5 EN - 01/2012 L 31

Page 32

Industrial PC | Parameter setting & configuration

Commissioning

Configuring the Industrial PC

3. Keep the icon pressed.

• The icon gets smaller and after letting go skips to the right upper corner.

4. Repeat step 3 times.

• Until the Accept button appears.

5. Press Accept.

4.5.2 Establishing an automatic dial-up connection

Further information on how to establish an automatic dial-up connection, remote

maintenance and diagnostics options can be found under: Remote maintenance and

diagnostics ( 82)

In order to carry out a remote maintenance on the Industrial PC different mechanisms are

provided:

Remote Access Service (RAS) connection

telnet connection ( 86)

FTP connection ( 88)

4.5.3 Entering the IP address of the Industrial PC

The Industrial PC has the following network settings by default:

Setting Value

IP address 192.168.5.99

Subnetwork 255.255.255.0

Default gateway 192.168.5.1

When the Industrial PC is commissioned for the first time, the desired

IP address must be entered.

( 82)

32 L 2.5 EN - 01/2012

Page 33

Industrial PC | Parameter setting & configuration

4.5.3.1 Industrial PCs with a touch panel/with an external monitor

Tip!

Connect a keyboard to the Industrial PC for entering the IP address. Alternatively

you can start the input panel with the F1 function key on the Industrial PC. Make

your entries afterwards:

[4-1] IP settings of the Industrial PC by default

Start the control panel with <Shift+F4>.

Commissioning

Configuring the Industrial PC

Start the network connections by double-click and enter the IP address, subnet mask,

and the default gateway.

After clicking the button the IP address is saved and need not be entered again

when the system is restarted.

4.5.3.2 Industrial PC without touch panel/without external monitor

If no external monitor is provided, a laptop with a suitable IP address as well as a

subnetwork template and a default gateway are required to carry out the settings. The

preset IP address of the Engineering PC is 192.168.5.100.

Connect the laptop to the Industrial PC by means of a "crossed" network cable.

Change the settings on an HTML compliant browser:

Setting IP addresses

Establish the connection from the laptop to the Industrial PC. For this purpose enter the

IP address of the Industrial PC on the browser: 192.168.5.99 (default setting).

Select the Ethernet button and enter the desired IP address, subnet mask, and the

default gateway of the Industrial PC.

Click Accept & Save all

Set Apply IP configuration to the value "Activate device"

( 45)

Re-click Accept & Save all to save the network settings.

2.5 EN - 01/2012 L 33

Page 34

Industrial PC | Parameter setting & configuration

Commissioning

Configuring the Industrial PC

4.5.4 Establishing Windows® CE access rights

In order to be able to establish a connection to the Industrial PC, each user must be

allocated access rights. For this the respective user has to be set up as a Windows® CE user

with a user name and a password. Windows® CE users can be set up via the »WebConfig«

and the »Engineer«:

Setting up Windows® CE users in the »WebConfig«

Setting up Windows® CE users in the »Engineer« ( 35)

4.5.4.1 Setting up Windows® CE users in the »WebConfig«

Note!

You have to be set up as Windows® CE user to have authorisations for further

services like FTP, telnet, or web server access.

Up to ten Windows® CE users can be set up in the »WebConfig« in the User

management area.

In codes 101 to 169 the user name, password, and various authorisations are set up for

a maximum of ten users.

( 34)

The representation for user 1 is displayed. Users 2 to 10 are represented analogously.

Detailed information on the parameters can be found in the following section:

Parameters of standard devices

34 L 2.5 EN - 01/2012

( 129)

Page 35

Industrial PC | Parameter setting & configuration

4.5.4.2 Setting up Windows® CE users in the »Engineer«

Note!

You have to be set up as a Windows® CE user to be authorised for other services

such as FTP, telnet or web server access. For the actual access you additionally

have to be registered. The assigned user passwords are unencrypted!

In the »Engineer« you can set up to ten Windows® CE users.

The value for code C100 shows the number of users set up.

In codes C101 to C170 you set up the user name, password, and different

authorisations for the users.

Commissioning

Configuring the Industrial PC

2.5 EN - 01/2012 L 35

Page 36

Industrial PC | Parameter setting & configuration

System structure

Engineering PC

5 System structure

This chapter gives you an overview of the general system structure in control technology.

Further information can be found in the respective documentation of the

corresponding Engineering software.

5.1 Engineering PC

The Engineering PC serves to:

– parameterise, configure and maintain the IPC: »WebConfig«, »Engineer«),

– parameterise, configure, and maintain the field devices connected

(»Engineer«, »Global Drive Control«),

– program the IPC (»PLC Designer«),

– creating a visualisation project (»VisiWinNET®«)

– the backup/restore preparation with »IPC Backup & Restore«.

5.2 Industrial PC

The following programs run on the Industrial PC:

– the control software (L-force Logic, L-force Motion),

– the fieldbus drivers,

– the optional visualisation software, and

– additional services (data manager, web server, logbook).

36 L 2.5 EN - 01/2012

Page 37

5.2.1 Centralised control system

The PLC of the Industrial PC (Logic/Motion) is the central control component, consisting

of the PLC runtime program with the running PLC application.

– Via the data manager and the fieldbus driver the PLC (Logic/Motion) has access to

the system components and field devices.

Industrial PC | Parameter setting & configuration

System structure

Industrial PC

[5-1] * The PROFIBUS fieldbus driver can only be accessed via PLC (Logic/Motion). Access via Engineer, GDC or VisiWinNET®

Runtime is not provided.

Field devices and the Industrial PC compose the machine to be commissioned by the

Engineering PC.

The Industrial PC can read parameters from and write parameters to the connected

field devices via the fieldbus (Logic/Motion).

5.2.2 IPC data manager

With the Data manager, Lenze Industrial PCs contain a central tool for the configuration

and data management of a system.

A system in this connection is the combination of an Industrial PC and the field devices

connected to it and registered via the fieldbus.

2.5 EN - 01/2012 L 37

Page 38

Industrial PC | Parameter setting & configuration

Parameterisation using the L-force »Engineer«

Parameterisation via codes

6 Parameterisation using the L-force »Engineer«

This chapter provides information on how to configure the Industrial PC using the

L-force »Engineer«. Further information on the settings in the »Engineer« is provided in the

corresponding topics of the online help.

6.1 Parameterisation via codes

All settings by means of which you parameterise the Industrial PC are summarised in a

parameter list that is numbered serially. The individual entries of this list are called

"codes". Each code can be addressed via a number.

Codes can also contain subparameters. They are also numbered and can be addressed

via a subindex. With the code number and the subindex you can address each

parameter unambiguously.

Tip!

In addition to the parameterisation via the »Engineer«,

you can also parameterise the Industrial PC by means of the »WebConfig«.

The web-based parameterisation can be found in the chapter

Web-based parameterisation with »WebConfig«

( 44)

The parameter lists can be found in the chapters entitled

Parameter reference

38 L 2.5 EN - 01/2012

( 125)

Page 39

Industrial PC | Parameter setting & configuration

6.2 Addressing structure in the »Engineer«

In order to be able to address the individual components, the »Engineer« maps the

complete Industrial PC in a linear code range. Each parameter is listed in a code which can

either be changed or can only be read. The length of the code list depends on the

corresponding hardware assembly.

The basic IPC device uses the code range from 0 to 200;

The Ethernet on board interface uses the code range

from 220 to 260;

The optional panel uses the code range from 400 to 600;

The PLC (Motion/Logic) uses the code range from 600 to 800;

If optional extension modules are used, the code range is extended accordingly. Every

extension module is provided with the card and the interface parameters;

A card plugged into a slot is equipped with one or more interfaces. If a card is plugged

into a slot, the code range is extended accordingly:

Parameterisation using the L-force »Engineer«

Addressing structure in the »Engineer«

The parameters of the extension modules use a maximum of 500 parameters each. The

code number range depends on the slot:

– Slot 1 uses codes 1000 to 1499,

– Slot 2 uses codes 1500 to 1999.

2.5 EN - 01/2012 L 39

Page 40

Industrial PC | Parameter setting & configuration

Parameterisation using the L-force »Engineer«

Addressing structure in the »Engineer«

6.2.1 Volatile data of an »Engineer« project

During operation, the Industrial PC manages the data in the main memory. Since the main

memory is a volatile memory, all information which has not been saved permanently on

the CF card will be lost in the case of a restart.

Changes on individual codes, which are carried out online with the »Engineer« for instance

are volatile data.

Tip!

An existing online connection is indicated in the »Engineer« by an animated icon

below the project view bar:

Note!

Detailed information on the use of the »Engineer« software can be found in the

corresponding »Engineer« documentation.

The settings that you carry out in an

»Engineer« project during an online connection is established remain volatile at first.

– If changes carried out with regard to individual parameters during the online

connection was established are incorrect, the last stable status can be retrieved by

restarting the Industrial PC and the changes can be carried out again.

Manual data backup is possible for saving the current settings permanently.

40 L 2.5 EN - 01/2012

Page 41

6.2.2 Saving data permanently

Code 18 enables you to transmit commands. A command overview can be found in the

description of code 18 of the parameter lists.

Via the Persist all command you can permanently save the changes carried out with an

online connection.

– The complete changes since the last restart of the Industrial PC are persistent.

The Industrial PC stores the data saved manually by the user on the CF card. For the project

management within the Industrial PC, different device commands are available, which can

be activated via code 18.

Industrial PC | Parameter setting & configuration

Parameterisation using the L-force »Engineer«

Parameter reference

When an online connection has been established, you can use the »Engineer« to

activate a device command by selecting it from the Device commands tab in C00018.

6.3 Parameter reference

The codes are numbered and marked in the documentation by a "C" in front of the code,

e.g. "C00002".

For the sake of clarity, some codes contain "subcodes" for storing parameters. This

documentation uses a slash "/" as a separator between code and subcode, e.g.

"C00118/3".

The All parameters tab shows all available codes for parameterising the Industrial PC.

2.5 EN - 01/2012 L 41

Page 42

Industrial PC | Parameter setting & configuration

Parameterisation using the L-force »Engineer«

Representation of the parameters

6.4 Representation of the parameters

6.4.1 Parameters with read access

The »Engineer« displays the parameters with read access with a grey background or,

when an online connection has been established, with a pale yellow background:

6.4.2 Parameters with write access

Input values outside the valid setting range are represented in red font by the

»Engineer«.

6.4.2.1 Parameters with a setting range

In the »Engineer« parameters are set by entering the desired value into the input field

or by means of the two arrow buttons:

The two arrow buttons can be used to increase/decrease the displayed value stepwise.

6.4.2.2 Parameters with a selection list

In the »Engineer« the parameters can be changed via a selection list:

42 L 2.5 EN - 01/2012

Page 43

Industrial PC | Parameter setting & configuration

6.4.2.3 Parameters with a bit-coded setting

The »Engineer« uses a dialog box for the parameter setting in which the individual bits

can be set or reset. Alternatively, the value can be entered as a decimal or hexadecimal

value:

Parameterisation using the L-force »Engineer«

Representation of the parameters

6.4.2.4 Parameters with subcodes

In the »Engineer« parameter list each subcode is itemised individually.

2.5 EN - 01/2012 L 43

Page 44

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

Parameterisation via codes

7 Web-based parameterisation with »WebConfig«

This chapter provides information on the parameterisation of the Industrial PC using webbased parameterisation.

7.1 Parameterisation via codes

All settings by means of which you parameterise the Industrial PC are summarised in a

parameter list that is numbered serially. The individual entries of this list are called "codes".

Each code can be addressed via a number.

Codes can also contain subparameters. They are also numbered and can be addressed via

a subindex. With the code number and the subindex you can address each parameter

unambiguously.

The web-based parameterisation can be carried out LOCALLY on the Industrial PC or

REMOTELY via http by each Engineering PC transmitted which can be reached via the

network. The Engineering PC is a workplace PC including the Windows® XP operating

system.

Tip!

The web server and the »WebConfig« for the web-based parameterisation are

preinstalled on the Industrial PC.

Parameterisation with the »Engineer« can be found in the chapter

Parameterisation using the L-force »Engineer«

44 L 2.5 EN - 01/2012

( 38)

Page 45

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

Requirements for working with the web-based parameterisation

The parameter lists can be found in the chapter entitled: Parameter reference ( 125)

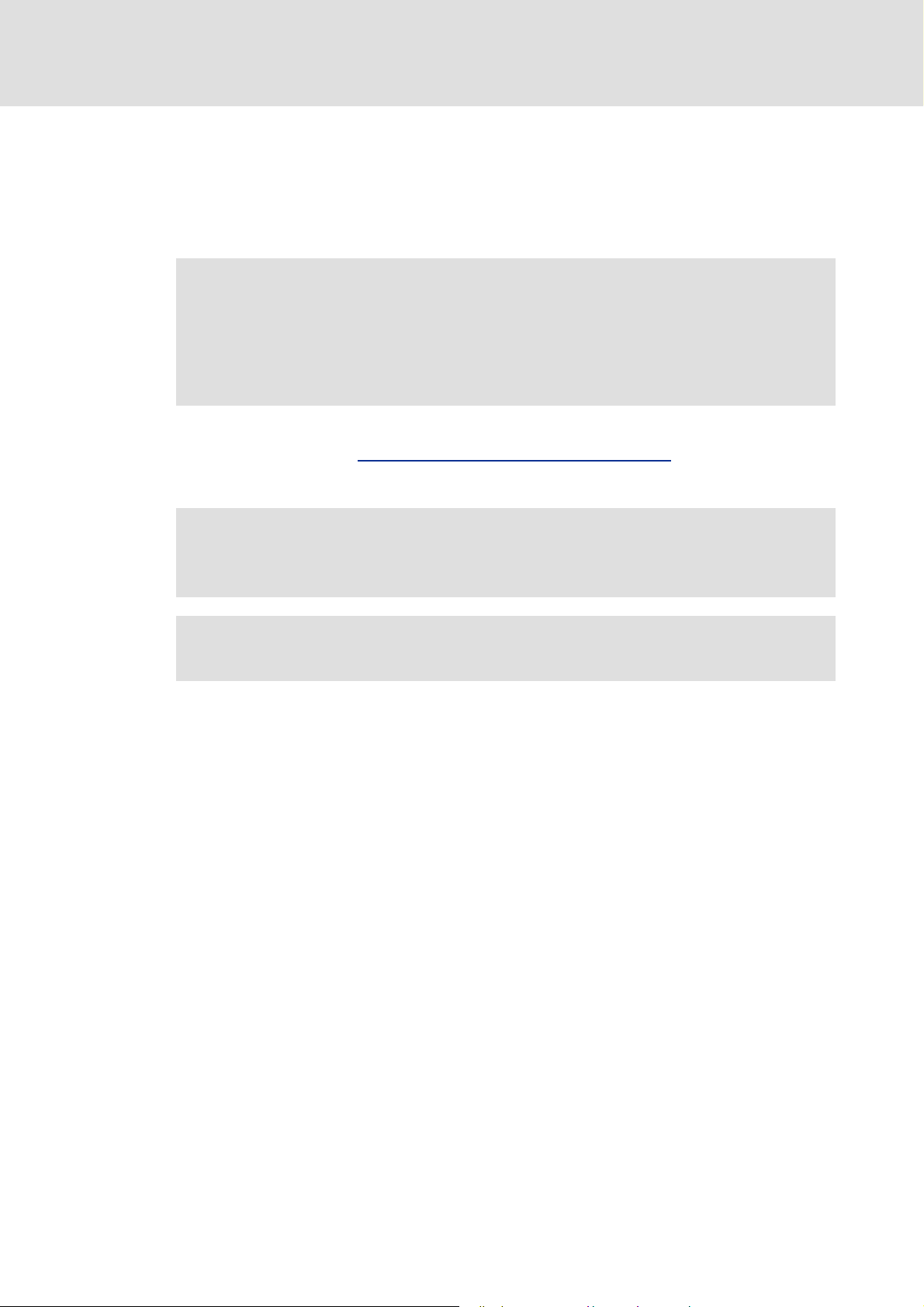

7.2 Requirements for working with the web-based parameterisation

This chapter provides you with information on how to prepare a remote connection for the

web-based parameterisation.

7.2.1 Online connection between the Engineering PC and Industrial PC

Connect the Engineering PC directly to the Industrial PC using a network cable.

or

Connect the Industrial PC to the network to which the Engineering PC has access.

Note!

In the case of a direct connection between the Engineering PC and the Industrial

PC, a crossed network cable is required.

The settings of the static IP address of the Engineering PC are only to be carried

out for the direct connection between the Engineering PC and Industrial PC.

7.2.2 Setting IP addresses

Note!

Recommended setting for the Engineering PC:

IP address: <192.168.5.100>

Default setting of the Industrial PC:

IP address: <192.168.5.99>, subnetwork <255.255.255.0>.

Setting for the direct connection between the Engineering PC and Industrial PC:

How to set the static IP address of the Engineering PC:

1. Open the Network connections dialog box Network connections.

(StartSettingsNetwork connections)

2. Select the network interface the Industrial PC is connected to.

Right-click Properties.

3. Select Internet protocol (TCP/IP).

4. Click the Properties button.

5. Select the Alternative configuration tab.

2.5 EN - 01/2012 L 45

Page 46

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

Requirements for working with the web-based parameterisation

6. Select the User configured option.

• Enter the IP address of the Industrial PC (default address: <192.168.5.99>).

• Enter the subnet mask of the Engineering PC

(standard setting: <255.255.255.0>)

7. Close the individual dialog windows with OK or Close

The Properties of internet protocol (TCP/IP) dialog window

How to set the browser:

1. Open the browser at the Engineering PC

(This setting refers to the Microsoft Internet Explorer).

2. Select the Proxy settings dialog window

(ToolsInternet options ConnectionsSettingsAdvanced)

3. Position the cursor in the Exceptions field at the end of the entries available.

4. Enter the IP address of the Industrial PC:

<;172.31.217*> (example of the IP address of an Industrial PC, default address:

<192.168.5.99>)

5. Close the individual dialog windows with OK.

46 L 2.5 EN - 01/2012

Page 47

Industrial PC | Parameter setting & configuration

7.3 Start of the web-based parameterisation

7.3.1 Start at the Engineering PC

Start a browser at the Engineering PC and enter the IP address of the Industrial PC.

– The dialog box for entering the connection data appears:

Web-based parameterisation with »WebConfig«

Start of the web-based parameterisation

.

1. Enter<User name:password>. As default setting, admin:admin is preselected. Any user

set up on the Industrial PC can log in. User management

2. Confirm with OK .

3. Afterwards the user interface of the web-based parameterisation appears.

User interface

7.3.2 Start at the Industrial PC

After connection to the current supply, the Industrial PC starts automatically. If no external

keyboard has been connected, the on-screen keyboard can be shown via the function key

<F1>.

Change to <Shift+F4> in the Control Panel.

( 49)

( 55)

2.5 EN - 01/2012 L 47

Page 48

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

Start of the web-based parameterisation

Double-click the WebConfig icon:

1. Enter <User name:password> in the Enter Network Password dialog box . As standard

setting admin:admin is preselected. Every registered user can log in.

2. Confirm with OK .

3. Afterwards the user interface of the web-based parameterisation appears.

User interface

( 49)

.

48 L 2.5 EN - 01/2012

Page 49

7.4 User interface

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

User interface

The user interface of the »WebConfig« is divided into the following areas

- :

Note!

The representation of the user interface in area depends on the respective

system configuration! The example shows an Industrial PC including the

following extension cards: MC-ETC in slot 1 and MC-CAN2 in slot 2.

2.5 EN - 01/2012 L 49

Page 50

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

User interface

Area Information

Menu buttons Parameters of the standard device of the Industrial PC

• Parameter list 1: All parameters of the standard device

• Parameter list 2: All parameters of the installed extension cards

• PLC parameters

• Ethernet (on board) parameters

•Panel parameters

Diagnostics/Command execution

• Logbook parameters

• Logbook of the Industrial PC

• Device commands

•Remote control

User management

• Setting users 1-10

General parameters

•Time

•UPS settings

• Monitoring functions

•Memory

• Identification

Extension card parameters

( 55)

( 56)

( 52)

( 56)

( 51)

Note:

• The represented parameters of slots 1 and 2 depend on the corresponding extension

modules that are installed!

• The additional buttons for the actually installed extension cards are automatically

added to the menu buttons.

• The top-down order of the buttons corresponds to the order in which the extension

Buttons Parameter list buttons

Display area Parameter display

cards have been installed (slot 1, slot 2).

• In the following section, the parameters of the communication cards are listed in

numerically ascending order: Industrial PC extension modules

Polling

Language selection

( 58)

( 58)

( 58)

Depending on the selected menu button, the parameters can be viewed in this area.

• Code numbers

• Name of the code

• Representation of the display, entry, selection, control and list fields.

( 161)

According to the equipment of the Industrial PC, deviating components are shown by use

of the menu control fields.

Detailed information on the parameters can be found in the section entitledParameter

reference ( 125)

50 L 2.5 EN - 01/2012

Page 51

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

User interface

Representation of parameter values

In the display area of the web-based parameterisation, settings of device parameters are

represented with different background colours which have the following meaning:

Colour Example Meaning

Pale yellow Parameter (read only)

• Display of status information and actual values.

Yellow Parameter (read and write)

• The current parameter value of the device is displayed. Changes with regard to a

parameter have to be transmitted to the device with Submit or Submit & Persist

all.

Red Entry of a value beyond the valid range.

•Via Refresh the original value is shown again.

• A correct value can be entered in the red input field and transmitted to the device

with Submit or Submit & Persist All.

In the following the individual menus of the web-based parameterisation »WebConfig«

are described.

7.4.1 Parameters of the standard device of the Industrial PC

Button Function

Displays all parameters of the standard device of the Industrial PC in

numerically ascending order.

• This user interface helps you to e.g.

–Find system properties and version numbers (read-only parameters),

–Set the system time,

–Activate the USB connection at the front of the monitor panel.

Parameters of standard devices

The other menu buttons of areas , and are a filtered view of parameter

list 1.

Displays all parameters of the installed extension cards in numerically

ascending order.

• The parameters of the extension cards are listed according to the order in

which they have been installed.

Extension card parameters

The other menu buttons of area are a filtered view of parameter list 2.

Displays the PLC parameters in numerically ascending order.

• This user interface shows you e.g.

–The PLC status,

–Information on a PLC project.

PLC (Logic/Motion)

Displays the Ethernet (on board) parameters in numerically ascending order.

• On this user interface the network settings of the on board

network connection are displayed/set.

Ethernet interface (on board)

Displays the panel parameters in numerically ascending order.

• This user interface helps you setting the settings for the monitor panel

and the function keys. Here you can e.g.

–Change the brightness of the monitor panel,

–Edit the parameters of the F1 to F4 function keys.

Panel

( 155)

Further information on the parameterisation of the function keys:

Commissioning

( 51)

( 19)

( 129)

( 56)

( 153)

2.5 EN - 01/2012 L 51

Page 52

Industrial PC | Parameter setting & configuration

Web-based parameterisation with »WebConfig«

User interface

7.4.2 Diagnostics/Command execution

Button Function

Displays parameters of the following areas:

•Diagnostics

•Logbook

In the Logbook area you can configure settings regarding the Logbook.

Further information on remote maintenance options

of the Industrial PC:

Remote maintenance and diagnostics

Displays logbook contents.

• Different filter settings display, for instance, only the oldest or only the