Lenze M Series, MCA21, MCA19 Supplement To Operating Instructions

M... MCA19, MCA21

Asynchronous servo motors with spring−applied

brake mounted on the B−bearing side

Supplement to Operating Instructions

EN

.Z!z

Ä.Z!zä

Please read these instructions before you start working!

Follow the safety instructions enclosed.

Important notes

This supplement is only valid together with the general motor operating instructions, see Internet!

Invalid chapters of the motor operating instructions: none

Additions to the "Maintenance and repair" section:

Stop!

When replacing the brake, complete rotor or the hub, the spare part from the

corresponding Lenze repair kit must always be used.

Characteristics and maintenance of the BFK457−16 R and BFK458−18 spring−applied brakes.

Encoder dismounting and mounting.

0Abb. 0Tab. 0

Contents i

1 Mechanical installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Important notes 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Spring−applied brake − holding brake 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Characteristics 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 BFK457−16R design − non−adjustable 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 BFK458−18 design − adjustable 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Maintenance/repair 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Spring−applied brake − holding brake 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Wear on spring−applied brakes 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Dismounting the MCA19 and 21 fan cover 9. . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 BFK457−16R air gap 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 Checking and re−adjusting the BFK458−18 air gap 11. . . . . . . . . . . . . . . . . .

2.2 Replacing the brake 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Dismounting the MCA 19 and 21 encoder 12. . . . . . . . . . . . . . . . . . . . . . . . .

2.3 BFK457−16R 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Dismounting and mounting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 BFK458−18 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Dismounting and mounting 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Encoder mounting 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lenze ¯ MA 33.0012 ¯ 1.0

3

1

1 Mechanical installation

1.1 Important notes

The brake that is mounted here is specially adapted to the use on the MCA 19 and 21.

Mechanical installation

Important notes

Stop!

If the wear air gap of a spring−applied brake is reached, the brake will no

longer be released. In this case, the complete rotor of the brake must be

replaced.

Note!

¯ BFK457−16R: It is not possible to re−adjust the brake. The complete

rotor must be replaced.

¯ BFK458−18: When the wear limit has been reached, the brake must be

re−adjusted, or the complete rotor must be replaced.

Safety system

Stop!

If a safety encoder is used, all maintenance and installation work must be

performed at the Lenze site.

Otherwise any warranty will expire and Lenze GmbH will not accept any

liability for consequential damage.

The IG2048−5V−V3

not be dismounted and mounted. This service work is performed by Lenze.

safety encoder can be mounted on the brakes described here and must

4

Lenze ¯ MA 33.0012 ¯ 1.0

1.2 Spring−applied brake − holding brake

1.2.1 Characteristics

Mechanical installation

Spring−applied brake − holding brake

Characteristics

1

Motor type Type of brake

MCA19 BFK457−16R 0.3 0.6 −−− −−− −−− 24.6 4

MCA21 BFK458−18 0.4 0.6 3.0 10.0 13.0 24.6 6

s

Lrated

+0.1 / −0.05

[mm] [mm] [mm] min. [mm] max. [mm] [Nm] No. of pieces

s

Lmax.

holding brake

Max.

adjustment,

permissible

wear path

Rotor thickness Tightening

torque of the

fixing screws

Fixing screws

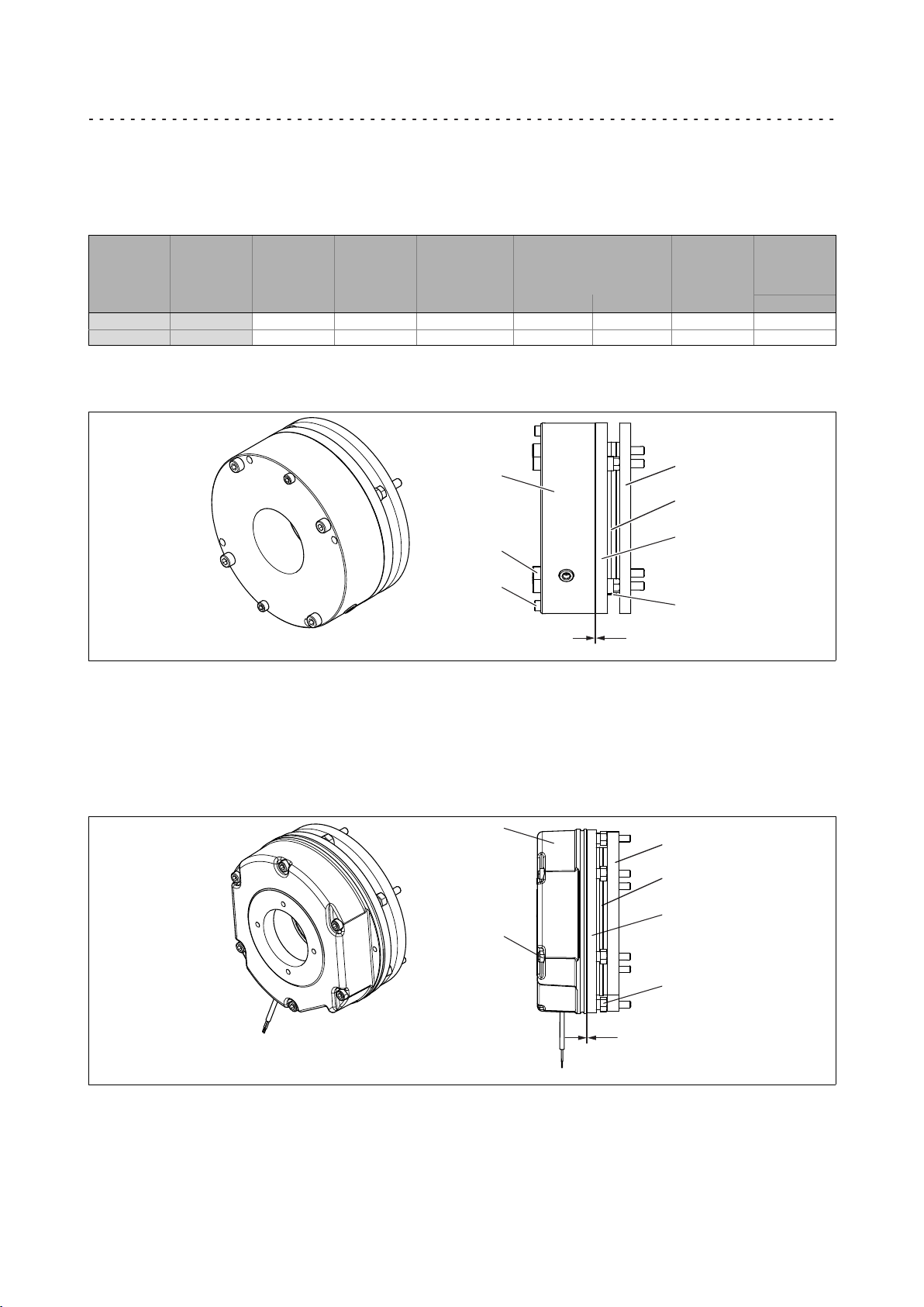

1.2.2 BFK457−16R design − non−adjustable

1

5

3

2

6

7

4

s

L

Fig. 1 Design of an INTORQ BFK457−16 Compact spring−applied brake, fully mounted rotor and flange

1 Stator 3 Rotor with friction lining 6 Fixing screws

2 Armature plate 4 Spacer bush 7 Screws of the emergency manual

5 Flange s

release

Air gap

L

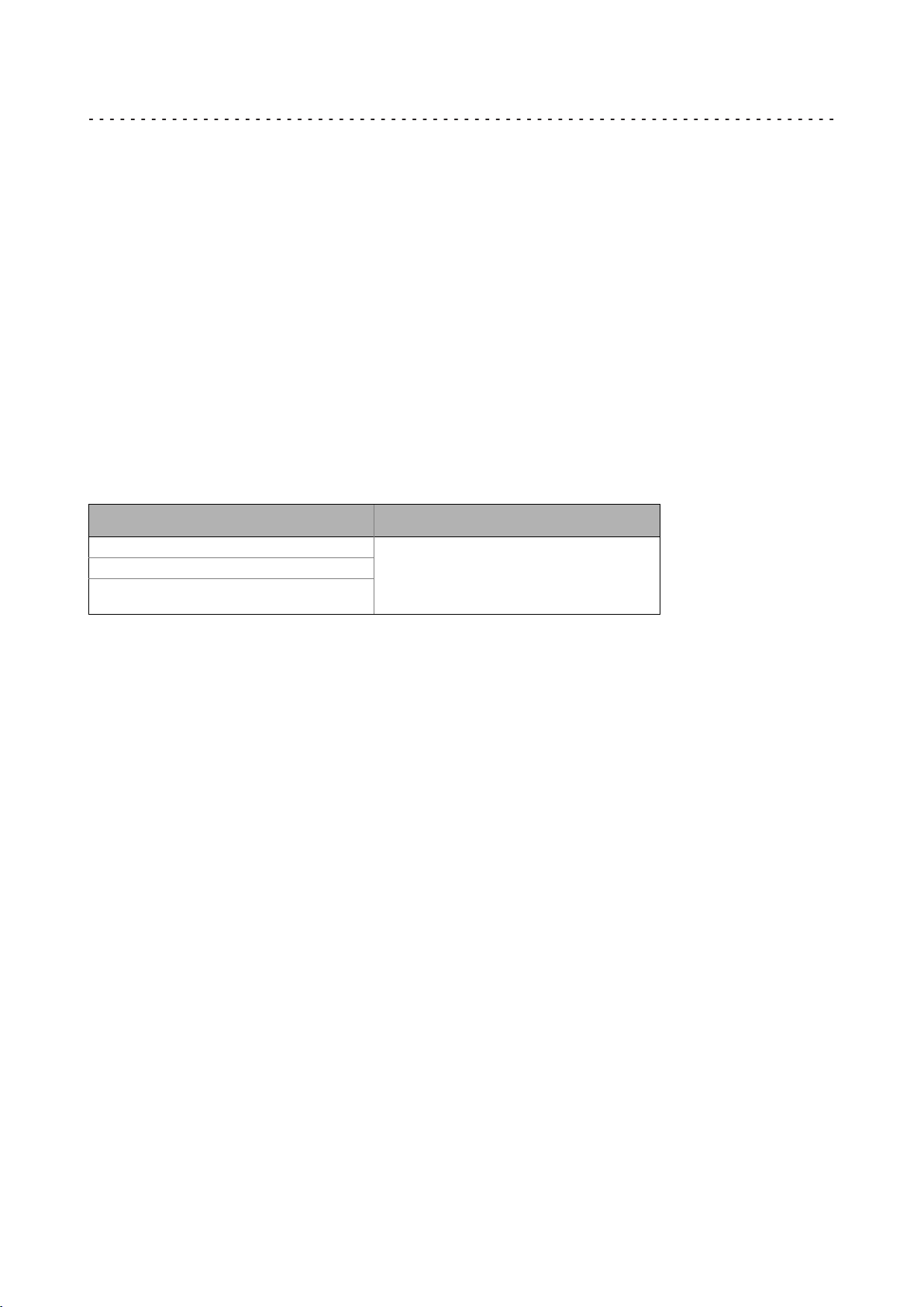

1.2.3 BFK458−18 design − adjustable

1

5

3

2

6

8

s

L

Fig. 2 Design of an INTORQ BFK458 spring−applied brake: basic module E (complete stator) + rotor + hub + flange

1 Stator 3 Rotor with friction lining 6 Fixing screws

2 Armature plate 5 Flange 8 Sleeve bolts

s

Air gap

L

Lenze ¯ MA 33.0012 ¯ 1.0

5

2

Maintenance/repair

Spring−applied brake − holding brake

2 Maintenance/repair

2.1 Spring−applied brake − holding brake

The brakes need to be checked on a regular basis to ensure safe and trouble−free

operation.

The necessary maintenance intervals primarily depend on the stress to which the brake

is subjected in an application. When a maintenance interval is being calculated, all

causes of wear must be taken into account (see notes "Wear on spring−applied brakes").

In the case of brakes which are subjected to low levels of stress, e.g. holding brakes with

emergency stop function, regular inspections at a fixed time interval are recommended.

In order to reduce the amount of work involved in maintenance, perform the inspection

at the same time as other maintenance work carried out cyclically on the machine if

possible.

If the brakes are not properly serviced, operating faults, production outages or damage

to machinery can occur. A maintenance concept adapted to the operating conditions

and the stresses to which the brakes are subjected must therefore be drawn up for every

application. For brakes, the maintenance intervals and servicing work listed in the

following table are necessary.

Maintenance interval for holding brake with

emergency stop

At least every 2 years

After 1 million cycles at the latest

Shorter intervals in the case of frequent emergency

stops!

Maintenance work

Inspection of the brake integrated in the motor:

¯ Check ventilation function and

activation/deactivation

¯ Measure air gap (re−adjust air gap, if necessary),

2.1.4

6

Lenze ¯ MA 33.0012 ¯ 1.0

Loading...

Loading...