Lenze MGXQK User Manual

384 924 GB

Show/Hide Bookmarks

Operating instructions

DC shunt motors

Type MGXRK 090 ... 160

MGXQU 080 ... 160

MGXQK 063 ... 160

Titelbild K33.0002 / K33.0003

Show/Hide Bookmarks

Copyright Lenze GmbH & Co KG, Postfach 101352, D--31763 Hameln

First read operating instructions, then act !

Manufacturer:

Lenze GmbH & Co KG

Postfach 101352

D--31763 Hameln

Location:

Aerzen

Hans--Lenze--Straße 1

D--31855 Aerzen

Tel.: (05154) 82--0

Fax : (05154) 82--4040

Country of origin and year of construction:

See nameplate (chapter 4.4)

These Operating instructions are valid for DC shunt

motors of the series:

-- MGXRK 090 ... 160

-- MGXQU 080 ... 160

-- MGXQK 063 ... 160

BA 13.0005

Author: Motor Division

2nd edition 06/97

2

Contents Page

Show/Hide Bookmarks

1. Explanation of symbols 4

2. General safety notes 4

2.1 Users 4

2.2 Safety notes 4

3. Transport a nd storage 4

3.1 Unpacking 4

3.2 Transport within the site of installation 4

3.3 Conditions of storage 4

3.4 Waste disposal of the packing material 4

4. Product description 5

4.1 Function description 5

4.2 Area of application 5

4.2.1Other areas of application 5

4.3 Type code 6

4.4 Designation / Nameplate 7

4.5 Technical data 7

4.6 Emissions 8

5. Assembly / Installation 9

5.1 Preparations 9

5.2 Site of installation, nominal conditions, and influencing factors 9

5.3 Installation 9

5.4 Electrical connection 9

5.5 Parts for attachment 11

6. Commissioning and operation 12

6.1 Checking before commissioning 12

6.1.1 Measuring the insulation resistance 12

6.2 Function test 13

6.3 Inspection 13

6.4 Fault -- Cause -- Remedy 14

7. Maintenance / Repair 15

7.1 Maintenance periods 15

7.2 Wear check of carbon brushes 15

7.3 Wear check of the collector 17

7.4 Recognition of incorrect operating conditions 18

7.5 Waste disposal of the product 19

8. Spare parts 20

8.1 Spare parts lists 20

8.2 Ordering example for spare parts 22

Manufacturer’s Declaraction

Service addresses

3

1. Explanation of symbols

Show/Hide Bookmarks

3. Transport and storage

Danger !

General danger (Danger of persons and/or

material)

Use in hazardous areas is prohibited.

Dangerous electrical voltage.

High temperature.

Assembly or dismantling using hammers or

other striking tools is prohibited.

Note: Use raw material for recycling.

2. General safety notes

First read, then act !

3.1 Unpacking

¯ Take drive components out of the packing

and check for transport damages.

¯ Check if the shipment is complete.

3.2 Transport within the site of installation

¯ Tranport motors only with sufficiently strong

transportation tools or hoists. Ensure safe

fixing.

Some of the motors are equipped with

eyebolts for a safe fixing at the hoists (for

weights see chapter 4.5).

¯ Transport motors vibration--free

¯ Avoid strong shocks and impacts

3.3 Conditions of storage

¯ Location of storage:

-- v i b r a t i o n -- f r e e

If there is a risk of vibration, it is

recommended to rotate the rotor in its

bearings once a week.

-- dry without aggressive media

-- n o d u s t

-- no fast temperature changes

¯ Corrosion:

3.4

2.1 Users

Assembly, commissioning, operation, and

maintenance only by specialists or skilled

personnel.

2.2 Safety notes

n Read operating instructions before

asembly, commissioning, operation, and

maintenance.

n Observe safety notes and warning symbols

in the individual chapters.

n Observe regulations for safety and

prevention of accidents.

n Do not operate in hazardous areas !

n Only intended use is permissible.

n For non--intended use and non--authorized

modifications, the product liability and

warranty are invalid.

-- steel parts are protected against corrosion

by the factory. Do not remove this

protection, check in intervals of approx.

three months and renew, if necessary.

In case of intermediate storage > 3 months

¯ Collector:

-- take off carbon brushes from the collector

surface

-- protect collector by a piece of paper

around the running surface.

3.4 Waste disposal of the packing material

n Packing material can be recycled.

4

4. Product description

Show/Hide Bookmarks

4.1 Function description

The motors of the MGXRK, MGXQU and

MGXQK series are separately excited DC

shunt motors.

The motors of the MGXRK series are

surface--cooled in IP54 enclosure and have a

round, ribbed housing. The motors of the

MGXQU and MGXQK series have a square

cross--section, are designed in IP23S

enclosure and internally ventilated.

The motors have fully--laminated stators and

are externally cooled by axially or radially

mounted blowers in their standard design

(type GF...). With reduced power, the motors

are also supplied with speed--dependent

self--ventilation (type GE...) and without

ventilation in self--cooled design (type GS...).

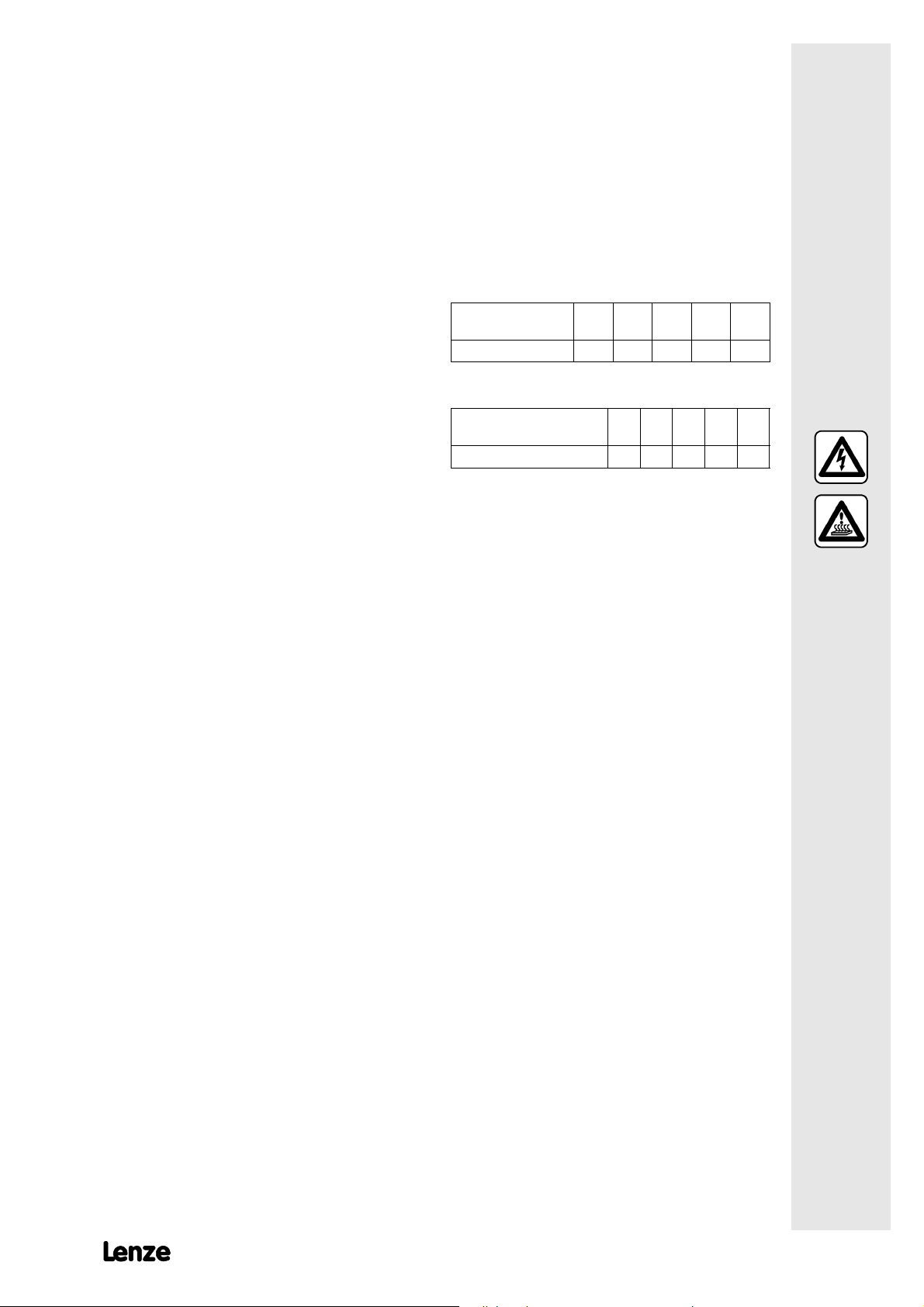

4.2.1 Other areas of application

¯ For other areas of application a power or

torque reduction is required using the

factors of the following table.

The permissible continuous power is

calculated from:

P’ = kJ¡ k

¡ P

h

d

with Pdbeing the permissible continuous

torque under normal conditions.

The torque can be calculated accordingly:

M’ = kJ¡ k

being the permissible continuous torque

M

d

¡ Md.

h

under normal conditions.

Cooling air temperature

5C

Power reduction

Power reduction with different ambient or cooling air

temperature

k

J

40 45 50 55 60

1.00 0.95 0.90 0.83 0.77

4.2 Area of application

n Do not use in hazardous areas !

n Fire risk !

Avoid contact with inflammable material !

¯ Ambient temperature must be up to

+40 5C, higher ambient temperature

require a power reduction.

¯ Installation height up to 1000 m above sea

level,

installation above 1000 m above sea level

requires a power reduction.

¯ Observe temperature class F (155 5C)

according to DIN--IEC 34 / VDE 0530. If the

limit temperature is exceeded, the

insulation is weakened and damaged.

¯ Enclosure to DIN--IEC 34 is IP54 or IP23S.

The actual enclosure can be obtained from

the nameplate (see chapter 4.4.)

¯ No tropical insulation.

¯ Designs (to DIN--IEC 34 part 7)

MGXRK: IM B3, IM B5, IM B14

MGXQU, MGXQK: IM B35 and IM B34

Installation height above sea

level in m

Power reduction

Power reduction with different installation height

k

h

1000 2000 3000 4000 5000

1.00 0.92 0.83 0.77 0.67

¯ If the actual form factor FF* ≥1.05, a power

reduction or torque reduction is also

required.

The permissible continuous load is calculated

from:

P’= ( 1.05 / F

*)¡ P

F

d

The torque is calculated as follows:

M’ = ( 1.05 / F

*) ¡ M

F

d

The form factor can be improved, among

others, by using armature chokes. Armature

chokes which are suitable for Lenze

controllers can be obtained from the technical

descriptions of the controllers or from your

nearest Lenze representative.

The motors can be mounted in any

mounting position. Vertical arrangements

according to DIN--IEC 34 part 7 are

possible.

5

4.3 Type code

Show/Hide Bookmarks

Motor

Current type

MG = DC current

Cooling / Ventilation

F = forced--ventilated

E = self--ventilated (cooling effect depends on the speed)

S = natural cooling ( cooling by convection and radiation)

Design / Housing

Q = Smooth housing, square

R = Ribbed housing, round

Type of machine

K = compensated

U = not compensated

MGXXX XX XXX -- XX

Attachments

BI = Brake and pulse encoder

BR = Brake

BS = Brake and resolver

BT = Brake and tacho

BU = Brake + Tacho + pulse encode

IG = Pulse encoder

RS = Resolver

TA = Tacho, analog sensor

TI = Tacho + pulse encoder

XX = no attachments

Size

AxisheightinIMB3designinmm

Length

0 = VS very short

1 = S short

2 = M middle

3 = L long

4 = VL very long

Pole pair numbe

6

1 = p=1 (2--pole)

2 = p=2 (4--pole)

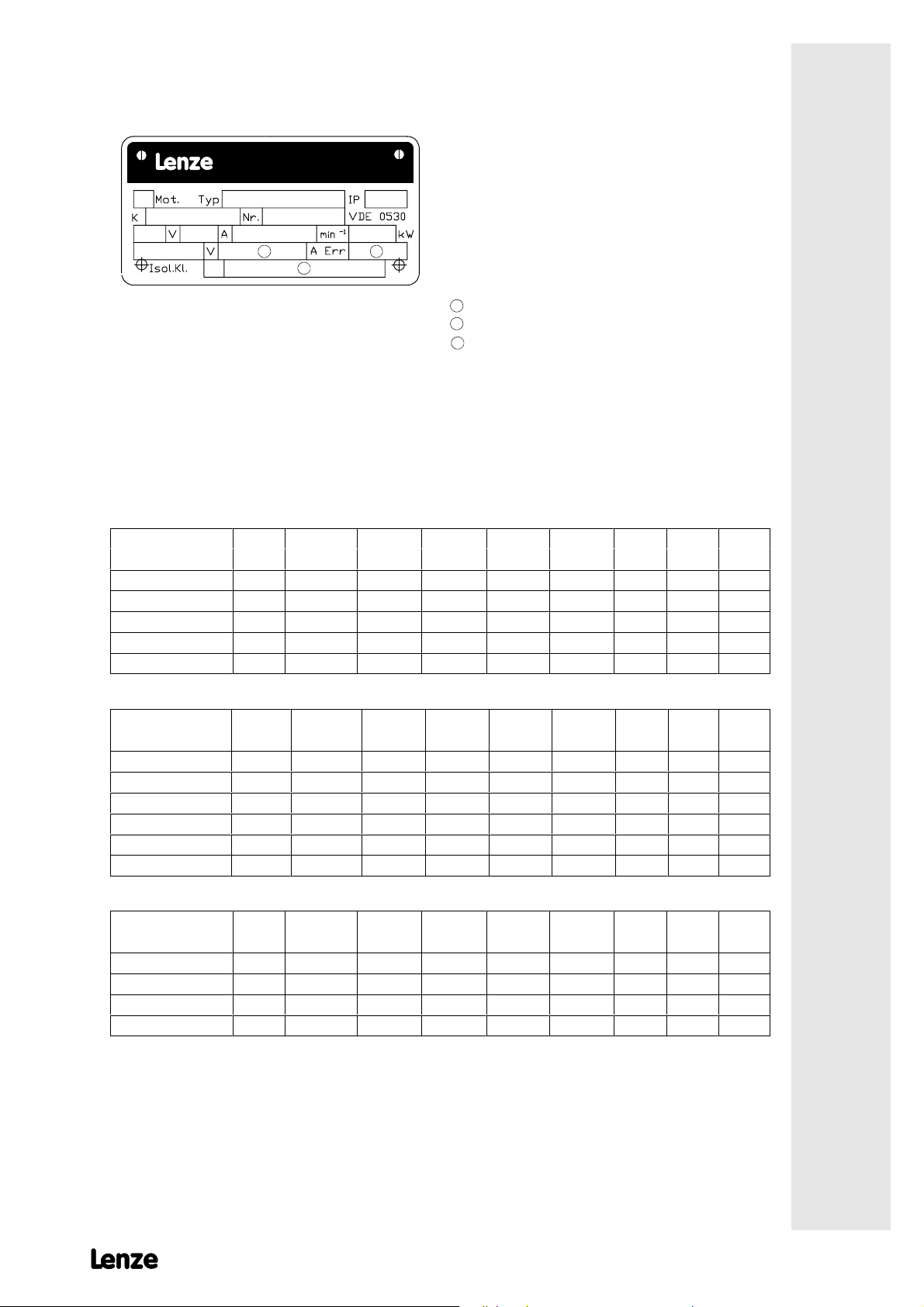

4.4 Designation / Nameplate

Show/Hide Bookmarks

The nameplate consists of the following data

(tolerances according to DIN--IEC 34):

Lenze GmbH & Co KG

Hans--Lenze--Straße 1, D--31855 Aerzen

➀

➃

➅➆

➉

➁

➂

➄

➇

11

13

➈

12

T374595

4.5 Technical data

The rated powers indicated on the nameplate

are based on a form factor of the armature

current of F

F=Ieff/Iarithm.

= 1.05. With higher

form factors a power reduction according to

chapter 4.2.1 is required.

➀ Motor type (G for DC shunt motor)

➁ Motor type of the form MGXXXXX XXX -- XX

➅ Enclosure

➃ Commission number, including year of

construction

➄ Motor number

➅ Rated armature voltage

➆ Rated armature current

➇ Rated speed

➈ Rated power

➉ Rated excitation voltage

Rated excitation current

11

12

Temperature class

Attachments (B--side)

13

In the following, the technical ratings and

main dimensions (overall dimensions) of the

standard motors without B--side attachments

with separate blower and with filter element

are listed.

Table 1: Technical data of MGFRK standard motors (without B--side attachments) :

Moto r s ize M

MGFRK 090-22 5.8 0.0040 780 440 2100 21 492 253 200

MGFRK 100-22 8.9 0.0061 1000 500 2700 28 530 284 250

MGFRK 112-22 15.5 0.0142 1500 500 2800 40 538 298 280

MGFRK 132-22 32.5 0.0411 2200 1100 4500 84 709 354 325

MGFRK 160-32 73.7 0.1120 3000 1250 5100 172 941 406 376

N

Nm kgm

J F

2

r

N N N kg mm mm mm

F

a

F

r, v

Weight L W H

Table 2: Technical data MGFQU standard motors (without B--side attachments) :

Moto r s ize M

MGFQU080-22 18.3 0.0087 1200 400 1950 36 467 235 335

MGFQU100-22 36.1 0.0237 1600 580 3100 65 520 235 375

MGFQU112-22 73.8 0.0475 2300 1000 4900 115 660 259 451

MGFQU132-32 140.5 0.1120 2300 1350 4900 170 760 275 525

MGFQU160-22 279.0 0.2452 4950 3580 9700 250 864 508 606

MGFQU160-32 343.0 0.3200 5050 3580 9900 285 944 508 606

N

Nm kgm

J F

2

r

N N N kg mm mm mm

F

a

F

r, v

Weight L W H

Tab. 3: Technical data of MGFQK standard motors (without B--side attachments) :

Moto r s ize M

MGFQK 063-32 7.0 0.0032 750 400 1100 19 451 235 299

MGFQK 100-32 34.3 0.0170 1600 580 3100 65 520 247 427

MGFQK 160-22 289 0.2452 4950 3580 9700 250 864 508 606

MGFQK 160-32 356 0.3200 5050 3580 9900 285 944 508 606

N

Nm kgm

J F

2

r

N N N kg mm mm mm

F

a

F

r, v

Weight L W H

The torques and weights indicated in the

tables are only considered to be guidelines

for the dimensioning and bases.

The actual technical data must be obtained

from the nameplate of your motor

(see chapter 4.4).

7

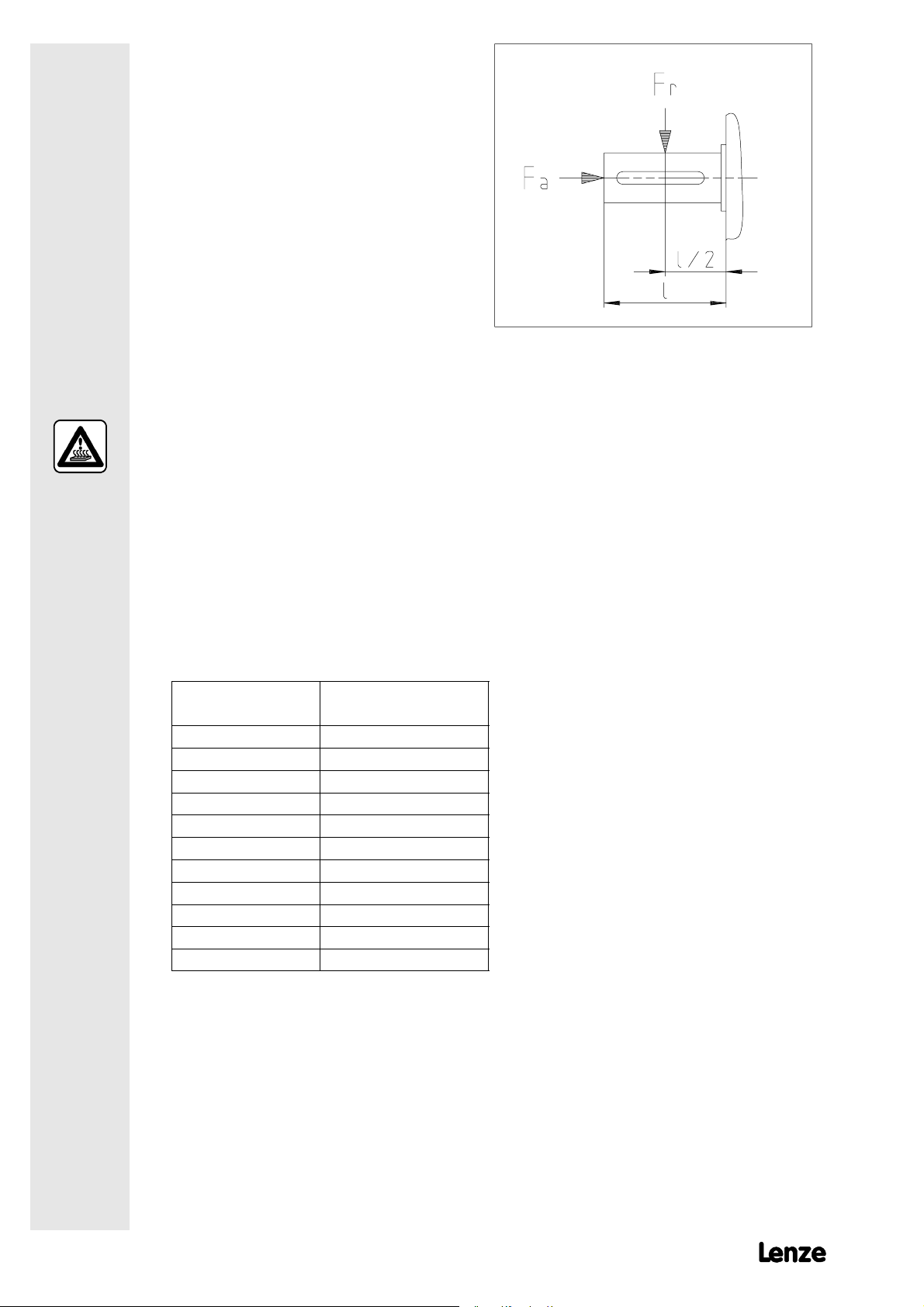

Signs:

Show/Hide Bookmarks

M

= Rated torque

N

J = Inertia

F

F

F

= Permissible radial load

r

= Permissible axial load

a

= Permissible radial load with

r,v

reinforced bearing

Gew. = Motor weight (incl. blower)

L = Motor length

H = Motor height

W = Motor width

-- The permissible loads mentioned in table

1 to 3 are understood to be either radial

loads or axial loads.

4.6 Emissions

n Risk of burning !

The surface temperature of the motors can

be up to 905C depending on the operating

state.

K12.311--08

Fig.1: Point of application of radial and axial

loads

¯ Noises:

The noise level of 70 dB(A) is not

exceeded by the following motors:

MGFRK 090--22

MGFRK 100--22

MGFQU 080--22

MGFQK 063--32

Noise level of the other motors:

Moto r t ype Noise level

MGFRK 112-22 75

MGFRK 132-22 76

MGFRK 160-32 78

MGFQU100-22 76

MGFQU112-22 81

MGFQU132-32 83

MGFQU160-22 86

MGFQU160-32 86

MGFQK 100-32 76

MGFQK 160-22 86

MGFQK 160-32 86

dB(A)

¯ Dusts :

8

Scuff of carbon brushes inside the motor

with enclosed motors,

in the outlet air of enclosed--ventilated

motors.

Composites:

-- different metals

-- graphite

-- possibly epoxy resin or other bonding

agents

Loading...

Loading...