Page 1

BA 12.0031

Show/Hide Bookmarks

.ð&Q

Ä."&Qä

Operating Instructions

G-motion

R

Integrated ATEX motors - 3D category

Page 2

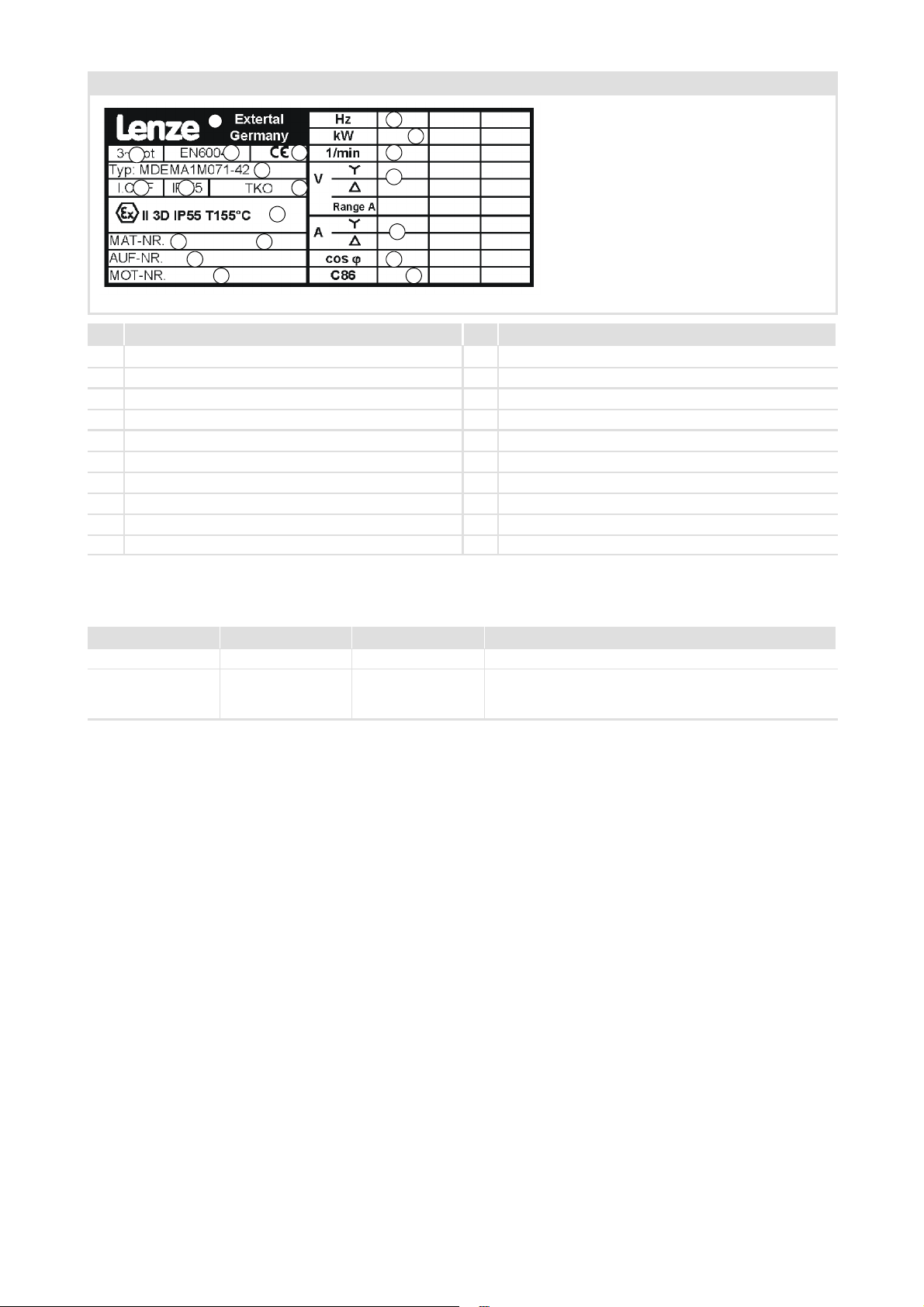

Motor nameplate

Show/Hide Bookmarks

Example / contents

1

2

6 7 8

10

3 4

5

9

11

12

13

14

15

16

17

18

19

20

No. Explanation No. Explanation

1 Manufacturer / assembly plant 11 Manufacturing date

2 Three-phase AC motor 12 Order no.

3 EN standard 13 Motor no.

4 CE designation 14 Rated frequency

5 Motor type 15 Rated power

6 Thermal class 16 Rated speed

7 Enclosure 17 Rated voltage

8 Thermal protection 18 Rated current

9 Explosion protection specification 19 Rated power factor cos ϕ

10 Material number 20 C86 code

What is new / what has changed in the Operating Instructions?

Material number Edition Important Contents

130 099 69 1.0 08/04 TD09 1st edition First edition

130 105 48 2.1 11/04 TD09 1st edition Added danger note for the characteristic for self-ventilation.

Changed table in Ch. 4.2 and added footnotes.

Declaration of Conformity: changed type designation.

© 2004

Lenze Drive Systems GmbH,Hans-Lenze-Straße 1,31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by

Systems GmbH

.

All information given in this documentation has been selected carefully and complies with the hardware and software described.

Nevertheless, deviations cannot be ruled out. We do not take any responsibility or liability for damages which might possibly occur.

Necessary corrections will be included in subsequent editions.

2

Lenze Drive

BA 12.0031 EN 2.1

Page 3

Contents i

Show/Hide Bookmarks

1 Safety instructions 4.........................................................

1.1 Application as directed 4................................................

1.2 Definition of notes used 5...............................................

2 Mechanical installation 6.....................................................

2.1 Preparation 6..................................................

2.2 Installation / mounting condition 6.......................................

3 Electrical installation 7.......................................................

4 Maintenance 12.............................................................

4.1 Maintenance intervals 12................................................

4.1.1 Periodic inspections 12...........................................

4.2 Maintenance and repair 13...............................................

5 Appendix 14................................................................

5.1 EC Declaration of Conformity 14..........................................

BA 12.0031 EN 2.1

3

Page 4

1

Show/Hide Bookmarks

Safety instructions

Application as directed

1 Safety instructions

ƒ These Operating Instructions are valid only in conjunction with the general

Operating Instructions for MDXM three-phase AC motors! It represents an

addendum and is amended with aspects concerning explosion protection. In

addition, please observe the safety instructions for gearboxes in the ATEX gearboxes

Operating Instructions.

ƒ If the data are inconsistent, these Operating Instructions have priority.

ƒ Pay attention to an installation according to EMC, especially for frequency inverter

operation!

If these Operating Instructions are disregarded, especially the inspection and

maintenance intervals, the EC declaration of conformity will become void.

1.1 Application as directed

The motors described in these operating instru ctions are designed specifically for direct

mounting on Lenze gearboxes of the G-motion series. In this design, the interface

between motor and gearbox can no longer be separated since components of the motor

become components of the g earbox and vice versa. Among other things, these

components also handle functions that ensure safe operation with respect to explosion

protection. For example, the shaft sealing ring of the motor handles the sealing of the

gearbox.For this reason, the subsequent text also refers to the geared motor since the

safety aspects listed here do not apply only to the motor and a separate operation of the

(without gearbox) would not make any sense.

The geared motors are intended for use in machinery and systems and may only be

used in accordance with these operating instructions, the nameplate and the text of the

order confirmation. They correspond to existing standards and regulations and meet

the requirements of EU directive 94/9/EG.

Explosive gas, fog, vapour, or dust atmospheres can cause severe injuries or death when

getting in contact with hot and / or sparking parts of the geared motor.

All operations concerning mounting, connection, commissioning as well as

maintenance and repairs on the geared motor and the electrical supplementary

equipment must only be carried out by qualified personnel!

ƒ During installation, EN 50281-1-2 in potentially explosive (dust) atmospheres must

be observed!

4

The machines can be used as follows:

A In zone 22 (dust Ex, category 3D) with non-conductive dusts with a minimum

ignition power > 3mJ.

BA 12.0031 EN 2.1

Page 5

1.2 Definition of notes used

Show/Hide Bookmarks

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Safety instructions

Definition of notes used

1

Pictograph and signal word Meaning

Application notes

Pictograph and signal word Meaning

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical

voltage.

Danger!

Danger!

Stop!

Note!

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Important note to ensure trouble-free operation

X

H

BA 12.0031 EN 2.1

Tip!

Useful tip for simple handling

Reference to another documentation

5

Page 6

2

Show/Hide Bookmarks

Mechanical installation

Installation / mounting condition

Preparation

2 Mechanical installation

2.1 Preparation

ƒ It must be checked that the data given on the nameplate of the motor and in the

order confirmation text comply with the permissible explosion-proof application

conditions on site:

–Exgroup

–Excategory

–Zone

– Maximum surface temperature

ƒ The use of the geared motor is only permissible at an ambient temperature of -20 °C

to +40 °C unless the nameplate bears another temperature.

2.2 Installation / mounting condition

Danger!

ƒ

Parts of the geared motor consist of aluminium and must be protected

against external shocks in order to prevent shock sparks.

ƒ

The geared motors must

ƒ

The geared motors must be included in the equipotential bonding of the

system.

ƒ

The installation of the geared motors must be carried out in such a way that

a sufficient dissipation of heat loss is ensured and the fan of the motor can

supply the cooling air required for safe operation.

not

be used in systems with cathodic protection!

6

BA 12.0031 EN 2.1

Page 7

3 Electrical installation

Show/Hide Bookmarks

Electrical installation 3

Power supply connection

The motor is connected to the motor terminal board in the following structure accor ding

to theterminal connection diagram affixed insidethe terminal box. Ensurethat the screw

connections are secure.

7

6

5

4

3

2

1

Fig. 1 Terminal stud of motor terminal board

Danger!

The safety instructions in Chapter 1 must be observed!

1 Windingconnection

2 Hexagon nut

3Washer

4 Motor connection cable lug / power supply

5Washer

6 Hexagon nut

7 Terminal board stud

BA 12.0031 EN 2.1

7

Page 8

Electrical installation3

Show/Hide Bookmarks

PE conductor connection

At the PE conductor connection in the terminal box and on the housing of the motor, the

PE conductormust be connected byplacing a plainwasher between cablelug and housing

of the motor. A serrated lock washer between cable lug and screw head / hexagon nut

ensures an electrically well-conductive connection. The following illustrations show the

correct connection for the different designs of the PE conductor connections:

4

3

2

1

Fig. 2 Earth connection at housing and in terminal box

1Washer

2 Earth connection cable lug

3 Serrated lock washer

4Screw

56

4

3

2

1

Fig. 3 Earth connection via terminal stud in terminal box

1Terminalstud

2Earthsymbol

3Washer

4 Earth connection cable lug

5 Serrated lock washer

6 Hexagon nut

Selection of cable gland

8

Thethreaded holes ofthe terminalbox areclosed usinghigh-quality screwplugs withseal.

To insert the supply conductor in the terminal box, the corresponding screw plug is

replaced bya cable glandwith strain relief.For this purpose,it is necessary toselect a cable

gland that is certified for explosion protection and features at least enclosure IP54.

BA 12.0031 EN 2.1

Page 9

Electrical installation 3

q

y

Show/Hide Bookmarks

Protection against impermissible high temperatures

Under normal operating conditions, the motors ensure safe operation within the

explosion protection specification listed on the nameplate. To protect the motor against

impermissible high temperatures in case of an overload, the thermal contact embedded

in the motor winding must be analysed by a device that is suitable for this purpose. If the

thermal contact is tripped, all phases of the motor must be disconnected from mains.

Danger!

Before commissioning, the effectiveness of the protective device must be

checked.

Frequency inverter operation

Motors of category 3D in the combination listed below can be operated with the Lenze

frequency inverter.

Motor frame size

063 - 12 0.12 ---

063 - 32 0.18 ---

063 - 42 0.25 E82EV251

071 - 32 0.37 E82EV371

071 - 42 0.55 E82EV551

080 - 32 0.75 E82EV751

080 - 42 1.1

090 - 32 1.5

100 - 12 2.2 E82EV222

100 - 32 3.0 E82EV302

112 - 22 4.0 E82EV402

112 - 32 5.5 E82EV552

132 - 22 7.5 E82EV752

132 - 32 9.2 E82EV113

Tab. 1 Motor - frequency inverter assignment 50 Hz

P

N

[kW] [Hz]

f

50

N

Frequency inverter

E82EV152

E82EV152

BA 12.0031 EN 2.1

9

Page 10

Electrical installation3

q

y

Show/Hide Bookmarks

Motor frame size

063 - 12 0.21 E82EV251

063 - 32 0.33 E82EV371

063 - 42 0.45 E82EV551

071 - 32 0.66 E82EV751

071 - 42 1.00 E82EV152

080 - 32 1.35 E82EV152

080 - 42 2.0

090 - 32 2.7

100 - 12 3.9 E82EV402

100 - 32 5.4 E82EV552

112 - 22 7.1 E82EV752

112 - 32 9.7 E82EV113

132 - 22 13.2 E82EV153

132 - 32 16.2 E82EV223

Tab. 2 Motor - frequency inverter assignment 87 Hz

Danger!

P

N

[kW] [Hz]

During operation, special attention should be paid that the maximum

permissible speeds for the gearbox are not exceeded.

f

87

N

Frequency inverter

E82EV222

E82EV302

Analogous to mainsoper ation, operating the motor with frequency inverter mayresult in

impermissible high surface temperatures in case of overload or at low operating

frequencies. Forthis reason, thefrequency inverteroperation is onlypermissible usingthe

analysis of the thermal contact via a suitable instrument.

Danger!

Before commissioning, the effectiveness of the protective device must be

checked.

10

BA 12.0031 EN 2.1

Page 11

Electrical installation 3

Show/Hide Bookmarks

Motor frame size-dependent torque reduction with self-ventilation and operation with

frequency inverter

Danger!

If the characteristics indicated in the following diagram are used with

self-ventilation, only S2 - 10-min - operation is permissible below 20 Hz.

Motor frame size

Output frequency of frequency inverter

Fig. 4 Torque reduction with frequency inverter operation

The use of a separate fan allowsfor operation without restrictions concerning torque and

duty cycle.

BA 12.0031 EN 2.1

11

Page 12

4

Show/Hide Bookmarks

Maintenance

Maintenance intervals

Periodic inspections

4 Maintenance

4.1 Maintenance intervals

Based on EN 60079-17, the following terms are used in this chapter:

Visual inspection

Inspection which identifies, without the use of access equipment or tools, those defects,

such as missing bolts, which will be apparent to the eye.

Close inspection

Inspection which encompasses those aspects covered by a visual inspection and, in

addition, identifies those defects, such as loose bolts, which will be apparent only by the

use of access equipment, for example steps, and tools.

Danger!

If there are unusual operating noises, vibrations, or increased temperatures in

the geared motor during or between the prescribed checks, the geared motor

must be immediately put out of operation and maintenance must be

performed!

On principle, the requirements from the applicable regulations and standards,

such regulations from professional trade ass ociations (BGV A2), operating

regulations (EN 50110) and installation regulations (EN 60079-17) must be

observed!

Plastic parts must be damp-cleaned only to prevent electrostatic charge.

Maintenance and repair

Combination of any actions carried out to retain an item (here: the motor) in, or restore it

to conditions in whichit is able to meet therequirements of therelevant specificationand

perform its required functions.

4.1.1 Periodic inspections

Gearedmotors withdirect motormounting(without standard cup)are also equippedwith

oil-sight glass or oil-level check plug in category 3. This is to provide a means of checking

for oil loss in the gearbox if oil enters the motor unnoticed through leakage at the shaft

sealing ring of the motor.

For the mounting positions A, B, C, E and F, the time intervals listed below can be doubled.

12

BA 12.0031 EN 2.1

Page 13

Maintenance

Show/Hide Bookmarks

Maintenance intervals

Maintenance and repair

Types of inspection

Visual Close

Inspection to be made in the time interval of operating hours: --- 500 h

Not later than after: 1month 3months

Actions

Visual inspection of the geared motor.

Dust accumulation should be cleaned depending on the amount of dust collected. It is

recommended to remove dust accumulations of 1 mm thickness and more on the

housing and in the cooling ribs.

Check for oil entering the motor by checking the oil level in the gearbox acc. to Ch. 4.3

of the ATEX gearboxes operating instructions.

4.2 Maintenance and repair

Maintenance/repair to be made in the time interval of operating hours: 1) 2)

Not later than after: 5years ---

Actions

Replace shaft sealing rings of motor.

Check condition of sealing lip contact area, repair if necessary.

Replace roller bearing grease

Replace roller bearings of the motors.

1) Conforming with the gearbox: Determining the time frame for measuring the oil temperature according to Chapter

4.5 and oil change diagram according to Chapter 5.2 of the ATEX gearbox operating instructions.

2) Conforming with the gearbox: Determining the time frame according to roller bearing main tenance diagram

according to Chapter 5.2.2 of the ATEX gearbox operating instructions.

•

•

Types of inspection

Maintenance/repair

•

•

4

Danger!

The repair work of explosion-protected electrical machines must only be

performed by the manufacturer or skilled personnel qualified for these tasks in

a workshop equipped for these tasks. Use only the respective original spare

parts from Lenze. The operating steps must be performed in accordance with

the instructions from the manufacturer.

Equipment which has been changed or repaired at parts that guarantee the explosion

protection, must only be started again if an expert has confirmed the conformance with

the valid technical regulations.

BA 12.0031 EN 2.1

13

Page 14

5

Show/Hide Bookmarks

Appendix

EC Declaration of Conformity

5 Appendix

5.1 EC Declaration of Conformity

EC Declaration of Conformity

For the purpose of t he EC Directive ”Equipment and protective systems

intended for use in potentiallyexplosive atmospheres”, appendix VIII and

appendix X

Thefollowingproductsweredeveloped, designed andmanufactured inaccordance

with the aforementioned EC Directive on the exclusive responsibility o f

Lenze Drive Systems GmbH, Postfach 10 13 52, D-31763 Hameln

l

l

ll

Lenze Drive Systems GmbH

P.O.box101352

D-31763 Hameln

Site: Bösingfeld

Breslauer Straße 3

D-32699 Extertal

Phone (05154) 82-0

Fax (05154) 82-15 75

Product: Type designation: Specification acc. to

nameplate

Motors MDXMA 3D

This is to confirm that the aforementioned motors for direct mounting on the gearboxes of series

GFL, GST, GKS, GKR and GSS from Lenze Drive Systems GmbH meet the requirements stipulated by

the Council for aligning the legal regulations of the member states for devices and protective

systems for application as directed in potentially explosive atmospheres (94/9/EG) in its current

version. The declaration applies to all units manufactured according to the manufacturing

documentation on file at the manufacturer, which are a part of this declaration.

The motors are components of the drive technology and must only be installed by qualified

personnel in

Zone 22 (category 3 D).

The relevant safety regulations must be observed!

Applied standards that have been valid at the time of the signature date:

EN1127-1

EN50281-1-1

Potentially explosive atmospheres, explosion protection, part 1: Fundamentals and

methodology

Electrical equipment for the use in areas with combustible dust,

Part 1-1: Electrical equipment with protection through housing - Design and inspection

Hameln, August 01, 2004

14

(Dr.-Ing. Etienne Nitidem)

Head of Research and Dev elopment

Department for Electromechanics

BA 12.0031 EN 2.1

Page 15

N

Show/Hide Bookmarks

Lenze Drive Systems GmbH

Hans-Lenze-Straße 1

31855 Aerzen

Germany

Service 0080002446877(24hhelpline)

¬

Service +49 (0) 51 54 82-1112

E-Mail lenze@lenze.de

Internet www.lenze.com

BA 12.0031 2.1 11/2004 TD09

2004

+49(0)515482-0

10987654321

Loading...

Loading...