Page 1

BA_MC−Card

RJSS-5381

RJSS-5381

.N*{

Ä.N*{ä

L−force Controls

Operating Instructions

Industrial PC

MC−xxx

MC card

MC-PNx

SYS

ST0

ST1

ST2

LINK

ACTIVE

l

Page 2

, Before you start working, read ...

ƒ these instructions

ƒ the operating instructions for the standard device

Follow the enclosed safety instructions!

The sets of documentation are part of the "PC−based Automation" and

"Controller−based Automation" manual collection which you can find on the DVDs of

the same name, or on the Internet at http://www.Lenze.com in the "Services &

Downloads" area.

Page 3

Contents i

1 About this documentation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Validity information 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Document history 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Conventions used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Notes used 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Scope of supply 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Variants 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Overview 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 MC−CAN2 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 MC−ETC, MC−ETH 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 MC−ISI 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 MC−PBM, MC−PBS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.6 MC−PNC, MC−PND 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Electrical installation 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important notes 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mounting 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Wiring and Configuration 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 MC−CAN2 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 MC−ETC, MC−ETH 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 MC−ISI 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 MC−PBM, MC−PBS 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 MC−PNC, MC−PND 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Appendix 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Use of the PCAN view/PCAN Explorer with MC−CAN2 43. . . . . . . . . . . . . . . . . . . . . .

5.2 Contact data of system partners 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BA_MC−Card EN 1.0

l 3

Page 4

1

About this documentation

Validity information

0Fig. 0Tab. 0

1 About this documentation

1.1 Validity information

These instructions are valid for

ƒ MC−CAN2 (dual CAN controller) from version 01

ƒ MC−ETH (Ethernet controller) as of version 01

ƒ MC−ETC (EtherCAT controller) as of version 01

ƒ MC−ISI (serial interfaces) from version 01

ƒ MC−PBM (PROFIBUS master) from version 01

ƒ MC−PBS (PROFIBUS slave) from version 01

ƒ MC−PNC (PROFINET controller ) as of version 01

ƒ MC−PND (PROFINET device) as of version 01

1.2 Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

I Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

1.3 Document history

Material number Version Description

.N*{ 1.0 11/2013 TD29 First edition

4

l

BA_MC−Card EN 1.0

Page 5

1.4 Conventions used

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Warnings

UL warnings

UR warnings

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

Documentation reference , Reference to another documentation with

About this documentation

Conventions used

Point In general, the decimal point is used.

For instance: 1234.56

J

O

Given in English and French

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

additional information

For example: , EDKxxx = see

documentation EDKxxx

1

BA_MC−Card EN 1.0

l

5

Page 6

1

About this documentation

Notes used

1.5 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Special safety instructions and application notes

Pictograph and signal word Meaning

J Warnings!

O Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety note or application note for the operation according to

UL or CSA requirements.

The measures are required to meet the requirements according

to UL or CSA.

6

l

BA_MC−Card EN 1.0

Page 7

2 Safety instructions

} Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

Safety instructions 2

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

BA_MC−Card EN 1.0

l

7

Page 8

3

Product description

Scope of supply

3 Product description

3.1 Scope of supply

NumberName

1 MC card

1 Mounting Instructions

) Note!

After receipt of the delivery, check immediately whether the items match the

accompanying papers. We do not accept any liability for deficiencies claimed

subsequently.

Claim

ƒ visible transport damage immediately to the forwarder

ƒ visible deficiencies/incompleteness immediately to your Lenze

representative.

3.2 Identification

Type code MC − xxx − xx

Module Card

CAN2 = dual CAN controller

ETC = EtherCAT controller

ETH = Ethernet controller

ISI = serial interfaces

PBM = PROFIBUS master

PBS = PROFIBUS slave

PNC = PROFINET controller

PND = PROFINET device

Version

8

l

BA_MC−Card EN 1.0

Page 9

Product description

Variants

Overview

3

3.3 Variants

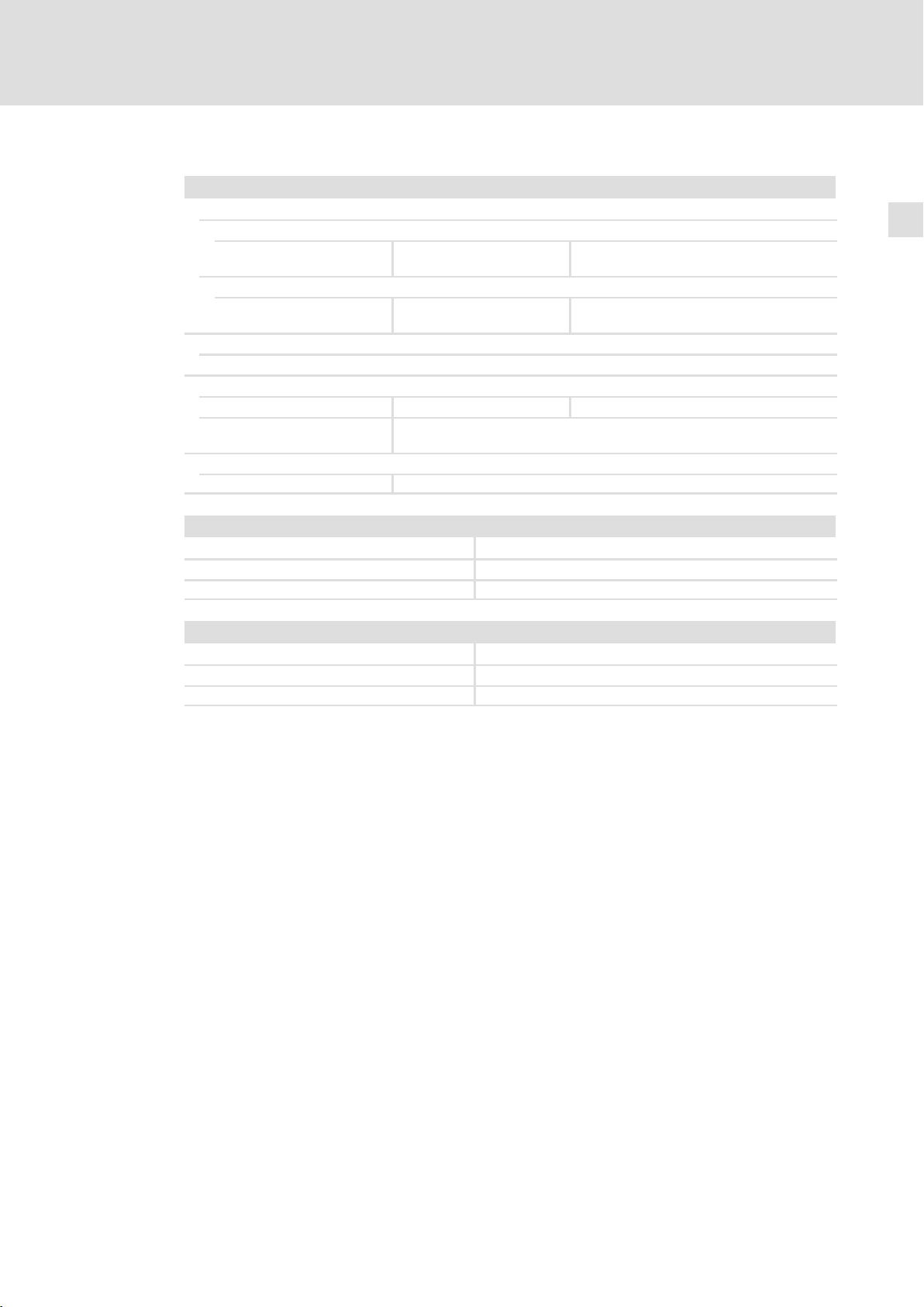

3.3.1 Overview

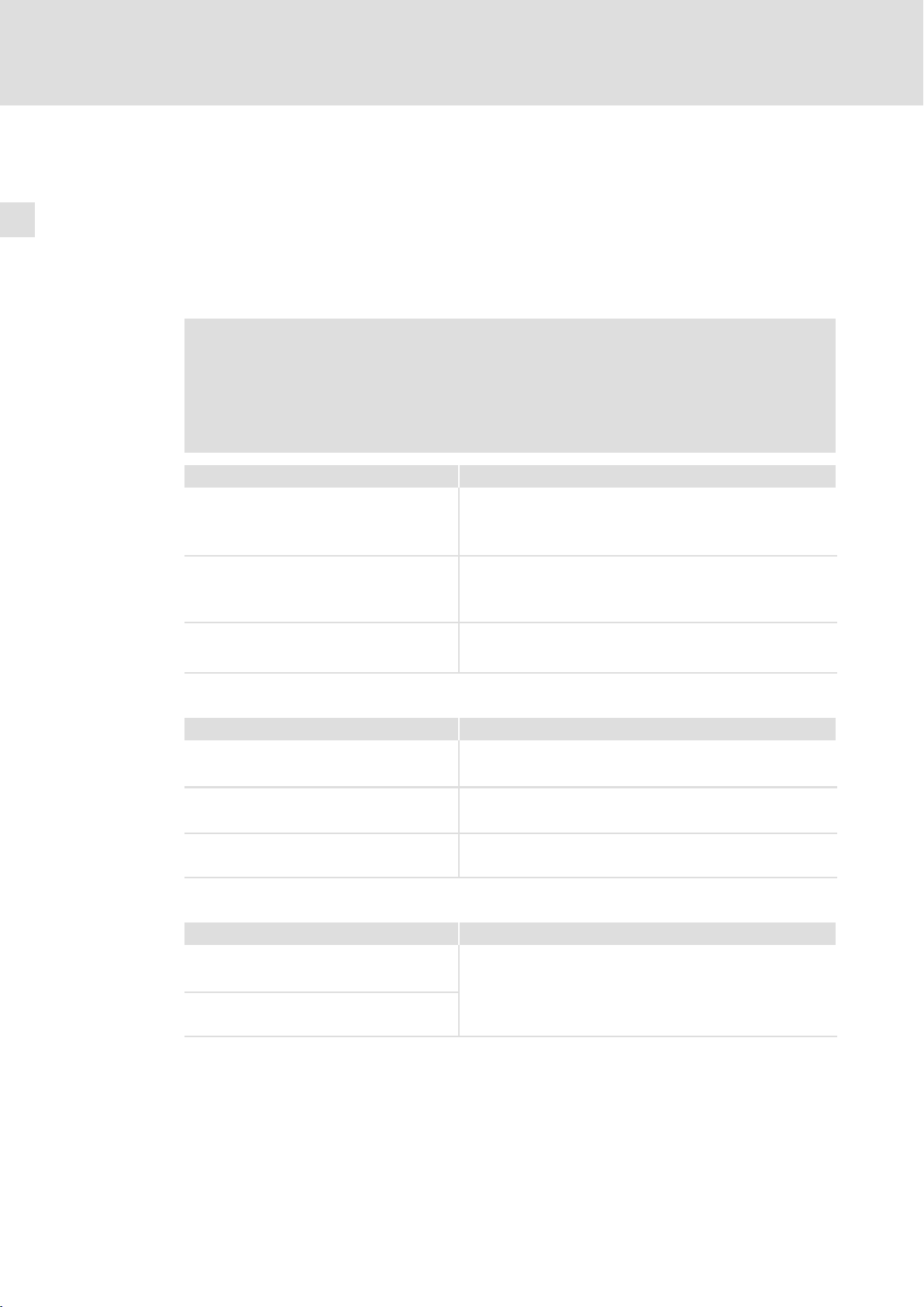

MC card Function For the use with

MC−CAN2 For connection to a CAN fieldbus;

MC−ETC For connection to a EtherCAT

MC−ETH For connection to a Ethernet

MC−ISI For the connection to RS 232,

MC−PBM For connection to a PROFIBUS

MC−PBS For connection to a PROFIBUS

MC−PNC For connection to a PROFINET

MC−PND For connection to a PROFINET

the card features 2 independent

CAN interfaces

network

network

RS 422, or RS 485; the card has 2

independent serial interfaces

system as master

system as slave

system as control system (controller

interface connection)

system as device (device interface

connection)

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Controller 3200 C

l Controller p500

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Controller 3200 C

l Controller p500

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Controller 3200 C

l Controller p500

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Controller 3200 C

l Controller p500

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Controller 3200 C

l Controller p500

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Controller 3200 C

l Controller p500

BA_MC−Card EN 1.0

l

9

Page 10

3

Product description

Variants

MC−CAN2

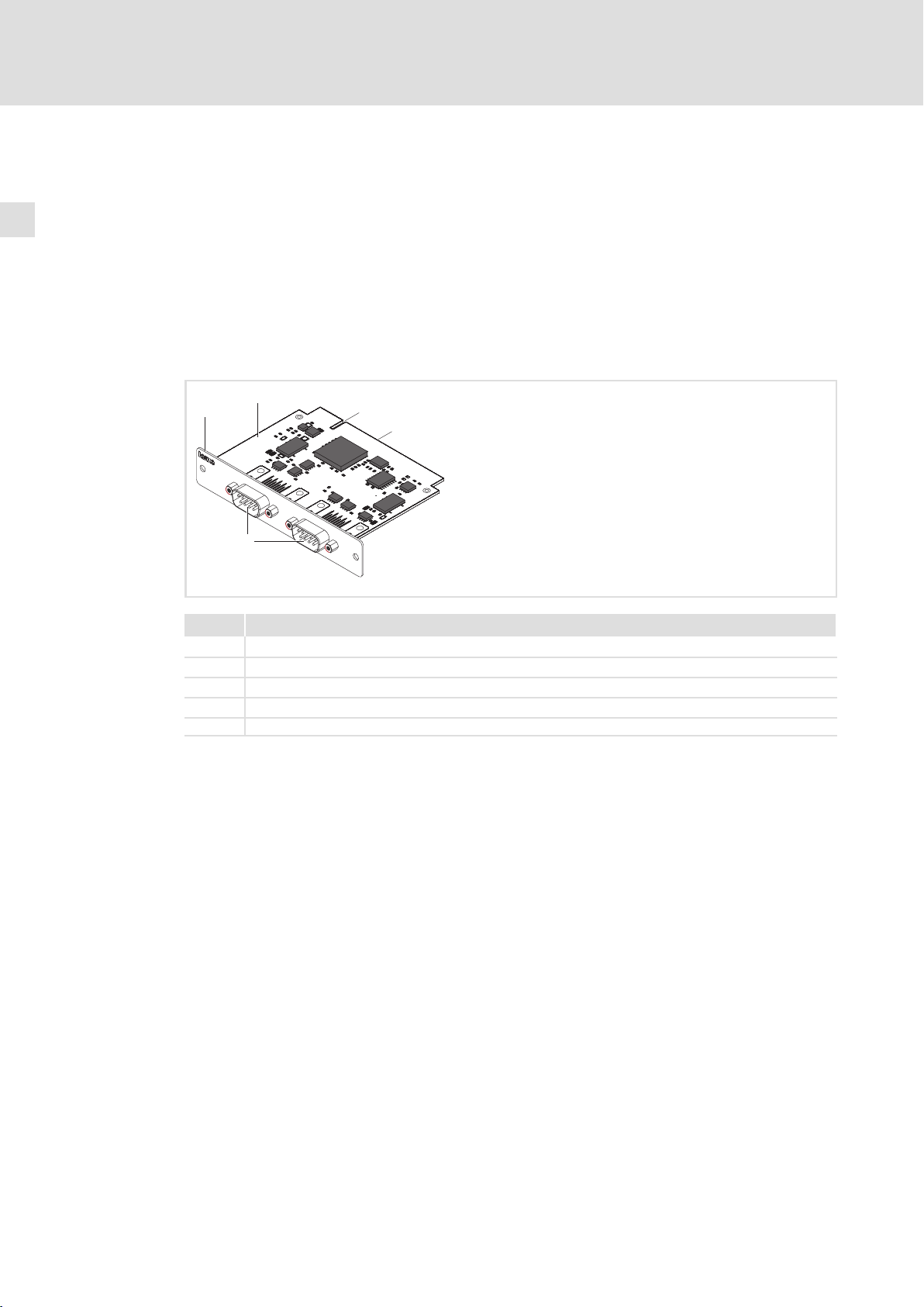

3.3.2 MC−CAN2

Application as directed

The MC−CAN2 is a plug−in card for the connection of a Lenze device to a CAN fieldbus. It

provides 2 independent CAN interfaces.

The MC card is used as directed if it is solely used in lenze device with MC card interface. A

different use, or one beyond these purposes, is not permissible.

Elements

0

MCCAN2

4

1

2

3

CAN2

CAN1

MC−CAN2−001

Pos. Description

0 Front panel

1 Printed circuit board

2 Coding

3 Standard device connection

4 Bus system connection

10

l

BA_MC−Card EN 1.0

Page 11

Product description

Variants

MC−CAN2

Technical data

MC−CAN2

Conformity, approval, directive

Conformity

CE EN 61000−6−4

EN 61000−6−2

Approval

UR UL 508

CSA C22.2

Directive

RoHS − Products lead−free in accordance with CE

General data and operating conditions

See standard device

Electrical data

Current < 0.2 A at standard device supply voltage of 24 V

Electrical isolation to the

fieldbus

Mechanical data

Mass < 0.1 kg

Communication

Type CAN, ISO011898

Protocol CAN

Topology Line, terminated on both sides with 120 W

Node Master or Slave

Number of nodes max. 63

Max. baud rate 1 MBaud

Bus length ^ CAN communication manual

yes

EMC Directive Class A,

industrial premises

Process Control Equipment

(File−No. E236341)

Directive 2011/65/EU

3

¸

O Warnings!

Use only together with appropriate cable connectors, provided with screws for

securement and secure connector to avoid loosening.

For use in controlled environment only.

¹

O Warnings!

A utiliser exclusivement avec des connecteurs de câble à vis adaptés. Fixer les

connecteurs pour éviter toute déconnexion.

Destiné uniquement à des zones à environnement contrôlé.

BA_MC−Card EN 1.0

l

11

Page 12

3

RJSS-5381

Product description

Variants

MC−ETC, MC−ETH

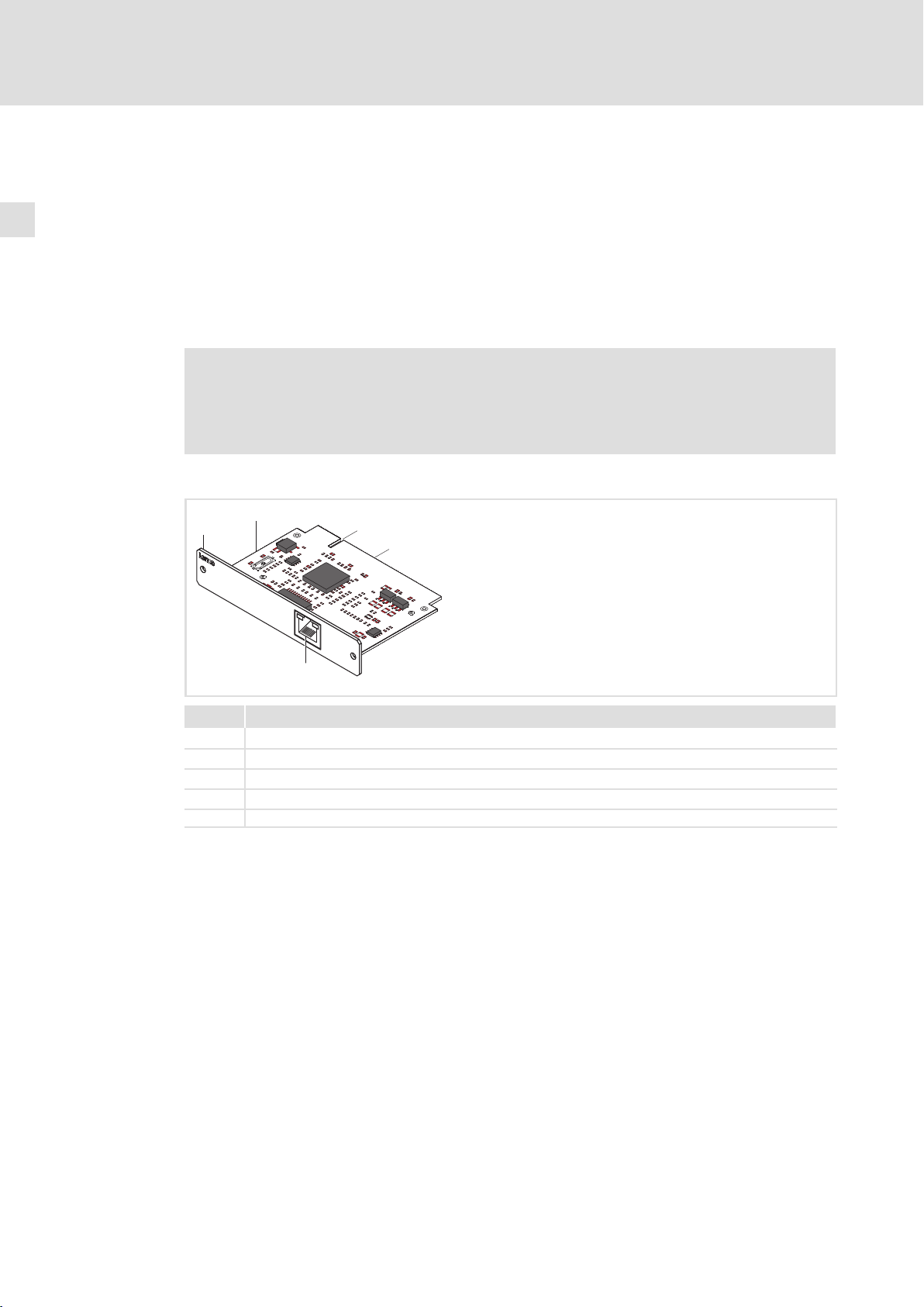

3.3.3 MC−ETC, MC−ETH

Application as directed

The MC−ETH is a plug−in card for connecting a Lenze device to a Ethernet network.

The MC−ETC is a plug−in card for connecting a Lenze device as master to a EtherCAT

network.

The MC card is used as directed if it is solely used in lenze device with MC card interface. A

different use, or one beyond these purposes, is not permissible.

) Note!

This is a device of class A. It can cause radio interference in residential areas. In

this case, the operator may have to take special measures. Any costs arising

from these measures must be paid by the operator.

Elements

1

0

MC-ETH

2

3

LINK

LA

SPEED

N

4

Pos. Description

0 Front panel

1 Printed circuit board

2 Coding

3 Standard device connection

4 Network connection

MC−ETH−001

12

l

BA_MC−Card EN 1.0

Page 13

Product description

Variants

MC−ETC, MC−ETH

Technical data

MC−ETH, MC−ETC

Conformity, directive

Conformity

CE EN 61000−6−4

EN 61000−6−2

Directive

RoHS − Products lead−free in accordance with CE

General data and operating conditions

See standard device

Electrical data

Current < 0.2 A at standard device supply voltage of 24 V

Electrical isolation to the

fieldbus

Mechanical data

Mass < 0.1 kg

yes

EMC Directive Class A,

industrial premises

Directive 2011/65/EU

3

MC−ETH

Protocol TCP/IP

Baud rate 10/100/1000 Mbits

Connection RJ45 socket to EN 50173

MC−ETC

Protocol EtherCAT

Baud rate 100 Mbits

Connection RJ45 socket to EN 50173

BA_MC−Card EN 1.0

l

13

Page 14

3

Product description

Variants

MC−ISI

3.3.4 MC−ISI

Application as directed

The MC−ISI is a plug−in card via which a Lenze device can exchange serial data with

peripheral devices.

It provides two independent, electrically isolated interfaces.

ƒ COM A: RS232

ƒ COM B: RS422 or RS485 (switchable)

The MC card is used as directed if it is solely used in lenze device with MC card interface. A

different use, or one beyond these purposes, is not permissible.

Elements

0

MC-ISI

6

1

2

3

12

ON

34

5

4

MC−ISI_001

Pos. Description

0 Front panel

1 Printed circuit board

2 Coding

3 Standard device connection

4 COM A connection (RS232)

5 COM B connection (RS422/RS485)

6 DIP switch

14

l

BA_MC−Card EN 1.0

Page 15

Product description

Variants

MC−ISI

Technical data

MC−ISI

Conformity, approval, directive

Conformity

CE EN 61000−6−4

EN 61000−6−2

Approval

UR UL 508

CSA C22.2

Directive

RoHS − Products lead−free in accordance with CE

General data and operating conditions

See standard device

Electrical data

Current < 0.2 A at standard device supply voltage of 24 V

Electrical isolation to the

fieldbus

Mechanical data

Mass < 0.1 kg

Communication

Type Serial interface

COM A

Type RS232, electrically isolated

Isolation 2.500 Vrms

ESD protection 15 kV

COM B

Type RS422/485 (switchable), electrically isolated

Isolation 2.500 Vrms

ESD protection 15 kV

Baud rate 600 Baud ... 115.2 kBaud

Data frame 5, 6, 7, 8 and 9 Bit

Parity Even, odd, none, space & mark

yes

EMC Directive Class A,

industrial premises

Process Control Equipment

(File−No. E236341)

Directive 2011/65/EU

3

BA_MC−Card EN 1.0

¸

O Warnings!

Use only together with appropriate cable connectors, provided with screws for

securement and secure connector to avoid loosening.

For use in controlled environment only.

¹

O Warnings!

A utiliser exclusivement avec des connecteurs de câble à vis adaptés. Fixer les

connecteurs pour éviter toute déconnexion.

Destiné uniquement à des zones à environnement contrôlé.

l

15

Page 16

3

Product description

Variants

MC−PBM, MC−PBS

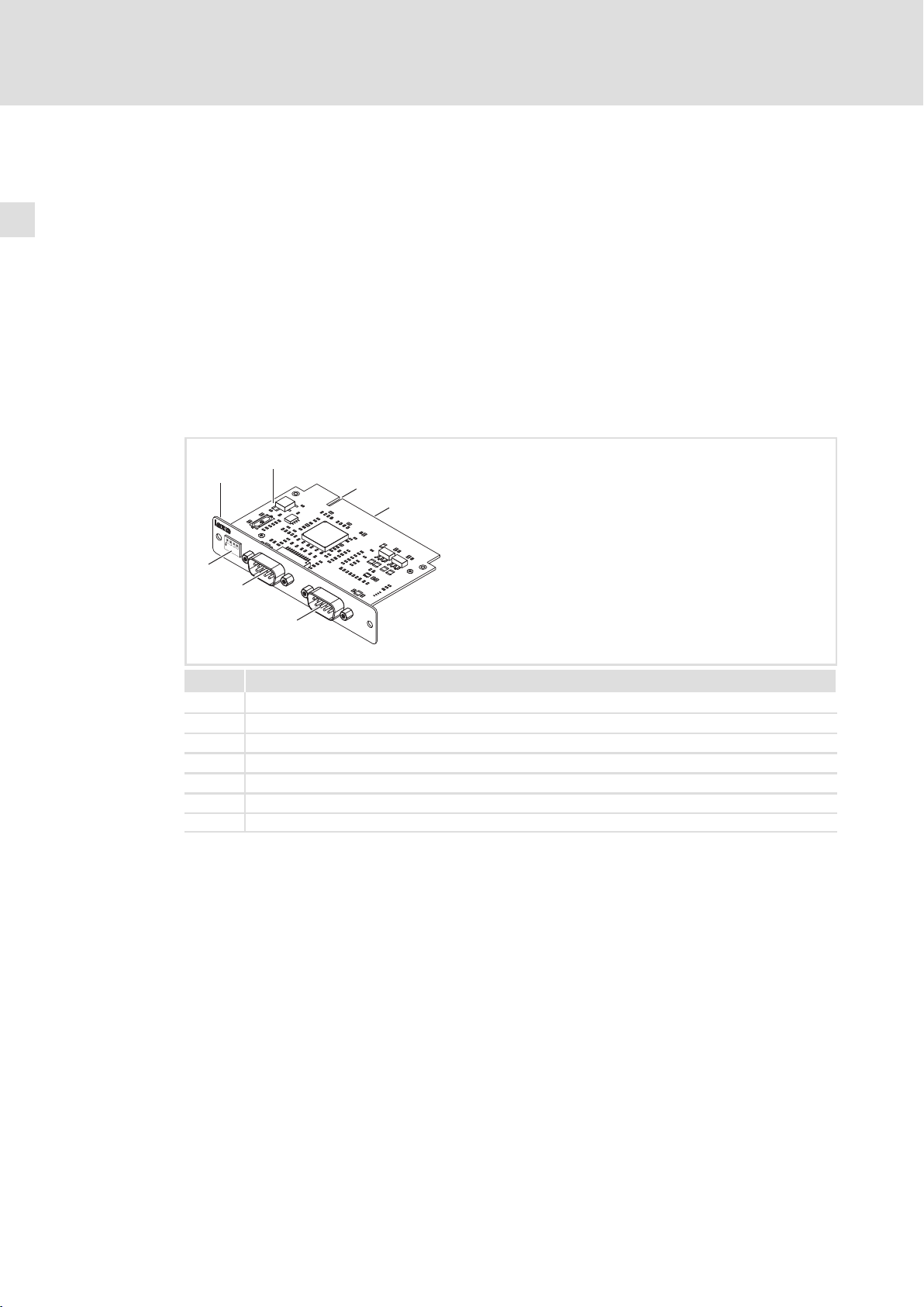

3.3.5 MC−PBM, MC−PBS

Application as directed

The MC−PBM and MC−PBS are plug−in cards for connecting a Lenze device to a PROFIBUS

system.

Whereas the slave interface connection (MC−PBS) serves to address the device as a node

under a PROFIBUS control, the master interface connection (MC−PBM) serves to enable the

user to establish a control on the basis of PROFIBUS.

The MC card is used as directed if it is solely used in lenze device with MC card interface. A

different use, or one beyond these purposes, is not permissible.

Elements

1

0

6

SYS

ST0

MC-PNx

ST1

ST2

5

6

PROFIBUS

2

3

4

MC−PBx−001

Pos. Description

0 Front panel

1 Printed circuit board

2 Coding

3 Standard device connection

4 Fieldbus connection

5 Status LEDs

16

l

BA_MC−Card EN 1.0

Page 17

Product description

Variants

MC−PBM, MC−PBS

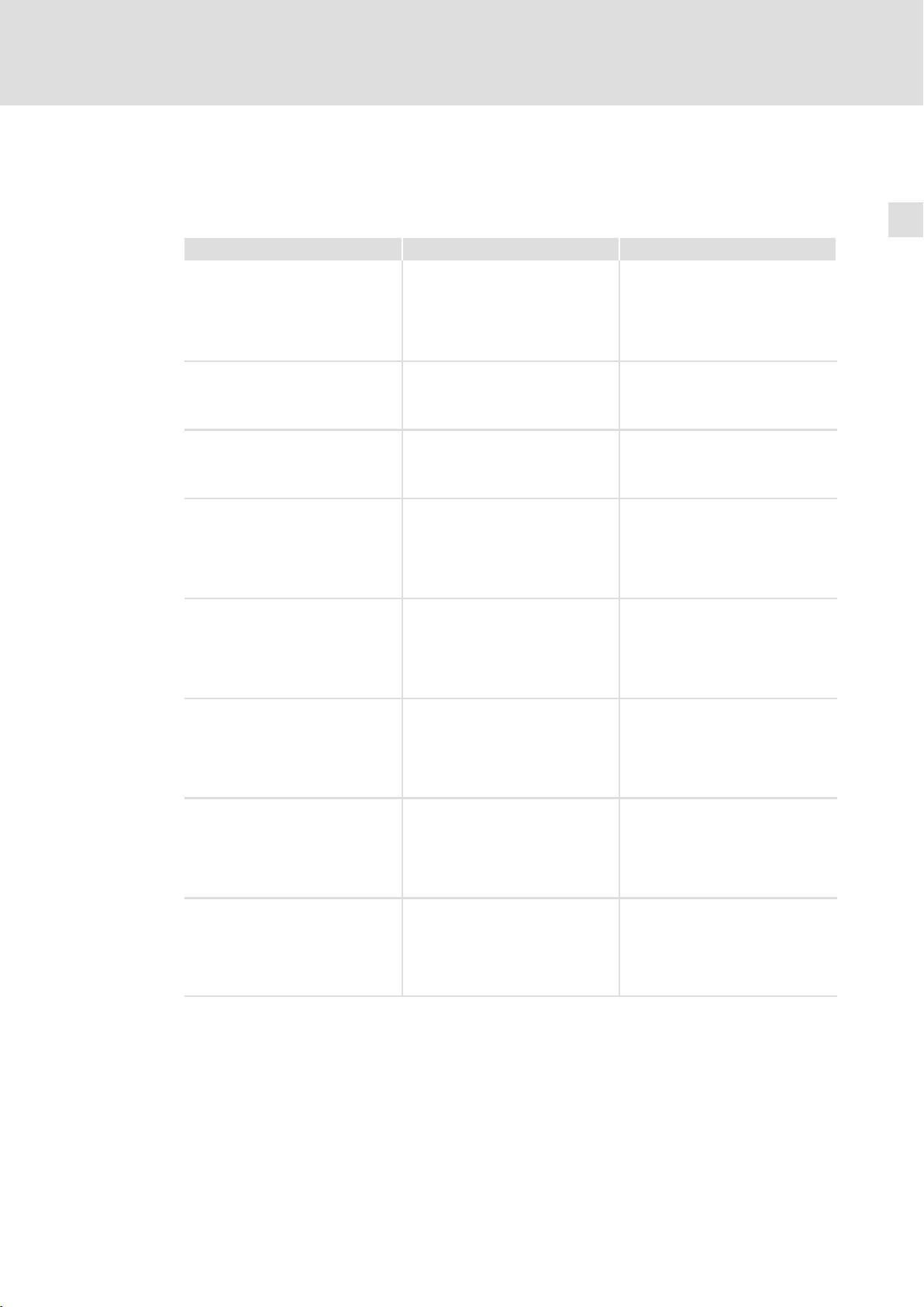

LED Colour Status Meaning at MC−PBM Meaning at MC−PBS

SYS Green

Yellow

− Off Supply voltage for the device is missing, or hardware is defective

ST0 − − No function

ST1 − − No function

ST2

Red On Device has a communication

Yellow

− Off Connection to Ethernet exists. Slave has not reached the

On Communication is running, the

Blinking with 5

Hz

Is blinking

irregularly

Blinking with 1Hz Device is in bootstraploader mode and is waiting for firmware download

Blinking with 5

Hz

Is blinking

irregularly

Is blinking

irregularly

On Device holds the PROFIBUS token

device has at least established a

connection to one configured node

No error within configuration,

communication has stopped, or

ready for communication, but no

connection to a slave

Start−up: No or incorrect configuration, commissioning required; runtime:

host−watchdog time error

Firmware download is carried out

Hardware or fatal system error detected

problem with at least one

PROFIBUS−DP slave or has detected a

short circuit

Device is within the PROFIBUS ring

and shares the token with other

PROFIBUS master devices

and can transmit telegrams

Slave is in cyclic data exchange with

DP master

Slave has no cyclic data exchange

with DP master

Application program

(communication mode: synchronous

to bus/device−controlled) is no

longer synchronous to the bus cycle

−

Slave has received

parameter/configuration data from

the DP master and has reached the

DataExchange state

DataExchange state

3

BA_MC−Card EN 1.0

l

17

Page 18

3

Product description

Variants

MC−PBM, MC−PBS

Technical data

MC−PBM, MC−PBS

Conformity, approval, directive

Conformity

CE EN 61000−6−4

EN 61000−6−2

Approval

UR UL 508

CSA C22.2

Directive

RoHS − Products lead−free in accordance with CE

General data and operating conditions

See standard device

Electrical data

Current < 0.2 A at standard device supply voltage of 24 V

Electrical isolation to the

fieldbus

Mechanical data

Mass < 0.1 kg

Communication

Type PROFIBUS−DP, ISO 7498

Protocol PROFIBUS−DP

Topology Line, system

Node MC−PBM (Master) / MC−PBS (Slave)

Max. number of nodes per

segment

Max. number of nodes per

system

Baud rate

Bus length

yes

max. 32

max. 128

^ 24

EMC Directive Class A,

industrial premises

Process Control Equipment

(File−No. E236341)

Directive 2011/65/EU

¸

O Warnings!

Use only together with appropriate cable connectors, provided with screws for

securement and secure connector to avoid loosening.

For use in controlled environment only.

¹

O Warnings!

A utiliser exclusivement avec des connecteurs de câble à vis adaptés. Fixer les

connecteurs pour éviter toute déconnexion.

Destiné uniquement à des zones à environnement contrôlé.

18

l

BA_MC−Card EN 1.0

Page 19

Product description

RJSS-5381

RJSS-5381

Variants

MC−PNC, MC−PND

3

3.3.6 MC−PNC, MC−PND

Application as directed

The MC−PNC and MC−PND are plug−in cards for connecting a Lenze device to a PROFINET

system.

Whereas the device interface connection (MC−PND) serves to activate the device as a node

under a PROFINET control, the controller interface connection (MC−PNC) serves to establish

an individual control system on the basis of PROFINET.

The MC card is used as directed if it is solely used in lenze device with MC card interface. A

different use, or one beyond these purposes, is not permissible.

1

0

MC-PNx

ST1

ST2

5

4

ACTIVE

PRO

6

FI

NET

6

LINK

SYS

ST0

4

2

3

MC−PNx−001

Elements

Pos. Description

0 Front panel

1 Printed circuit board

2 Coding

3 Standard device connection

4 Bus system connection

5 Status LEDs

6 Link /Active LED

BA_MC−Card EN 1.0

l

19

Page 20

3

Product description

Variants

MC−PNC, MC−PND

LED Colour Status Meaning at MC−PNC Meaning at MC−PND

SYS

Green

Yellow

− Off No supply voltage or defect hardware

ST0 Red

− Off No error

ST1 Red

− Off No error

ST2 − − No function

Link

Green On Connection to Ethernet exists

− Off No connection to Ethernet

Active Yellow Blinking Device transmits/receives Ethernet frames

On Operating system is running

Blinking with 1Hz Error during boot process

On Boot loader waits for boot process

On Together with ST1 "Red On": no valid

Blinking with 2

Hz

On No connection/no link. Or (together

with ST0 "Red On") no valid master

Blinking with 2

Hz

master licence

System error:

invalid configuration

licence

Configuration error: Not all

configured I/O devices are

connected.

Watchdog time−out; channel, generic

or extended diagnostics is available

DCP signal service is enabled via the

No configuration or slow physical

connection or no physical connection

System error:

bus

No data exchange

20

l

BA_MC−Card EN 1.0

Page 21

Product description

Variants

MC−PNC, MC−PND

Technical data

MC−PNC, MC−PND

Conformity, approval, directive

Conformity

CE EN 61000−6−4

EN 61000−6−2

Approval

UR UL 508

CSA C22.2

Directive

RoHS − Products lead−free in accordance with CE

General data and operating conditions

See standard device

Electrical data

Current < 0.2 A at standard device supply voltage of 24 V

Electrical isolation to the

fieldbus

Mechanical data

Mass < 0.1 kg

yes

EMC Directive Class A,

industrial premises

Process Control Equipment

(File−No. E236341)

Directive 2011/65/EU

3

MC−PNC (controller)

I/O data

Data transport l Ethernet frames

Communication l PROFINET IO−RT

Acyclic data l Read, write, record: max. 1 kbyte/request

Functions l Cyclic process data

Special features l No support for

l Configurable up to max. 5760 bytes input

l Configurable up to max. 5760 bytes output

– cyclic and acyclic

l Alarms

l Buffering host−controlled data exchange of cyclic data

l Minimum cycle time: 1 ms

l Different cycle times are configurable for different devices

l Max. 32 devices can be configured

l DCP

l Context management via CL−RPC

l One buffer is available per device for diagnostic data

– RT over UDP

– Multicast communication

– DHCP

l Only one IOCR1 per IO device is possible, IOCR data length:

1024 bytes

l Max. number of the connectable IO devices decreases to

25 when cycle times lower than 4 ms are used.

l NameOfStation of the IO controller cannot be set via the

DCP Set NameOfStation service but only by the

configuration during the start

BA_MC−Card EN 1.0

l

21

Page 22

3

Product description

Variants

MC−PNC, MC−PND

MC−PND (device)

I/O data

Communication l PROFINET IO−RT

Functions l Cyclic process data

Special features l Maximum number of modules: 244

l Configurable up to max. 1024 bytes input

l Configurable up to max. 1024 bytes output

– VLAN and priority tagging

– cyclic and acyclic

l Acyclic read and write requests

l Process and diagnostic alarm: 200 bytes

l DCP

l Context management via CLRPC

l Generic diagnostics, channel diagnostics, extended

channel diagnostics: 200 bytes

l Comparison of the setpoints / actual values of the

configuration

l Maximum number of submodules: 1

l No support for

– RT over UDP

– Multicast communication

l Only one device instance is supported

¸

O Warnings!

Use only together with appropriate cable connectors, provided with screws for

securement and secure connector to avoid loosening.

For use in controlled environment only.

¹

O Warnings!

A utiliser exclusivement avec des connecteurs de câble à vis adaptés. Fixer les

connecteurs pour éviter toute déconnexion.

Destiné uniquement à des zones à environnement contrôlé.

22

l

BA_MC−Card EN 1.0

Page 23

4 Electrical installation

RJSS-5381

RJSS-5381

RJSS-5381

RJSS-5381

RJSS-5381

RJSS-5381

4.1 Important notes

( Stop!

Short circuit and static discharges

The printed circuit board and the standard device contain components which

are endangered in the case of short circuit or static discharge.

Possible consequences:

ƒ The printed circuit board or devices connected are destroyed.

Protective measures:

ƒ For all operations on the printed circuit board, the latter as well as the

standard device have to be in a deenergised state. This in particular applies

to the connection/disconnection of the printed circuit board and the

connection/disconnection of connectors.

ƒ All persons handling printed circuit boards must regard ESD measures.

ƒ Connector contacts must not be touched.

ƒ Printed circuit boards must only be touched in contact−free places and must

only be placed on suitable bases (e. g. on ESD packaging or conductive

foamed material).

ƒ Printed circuit boards must only be transported and stored in ESD

packaging.

Electrical installation

Important notes

4

) Note!

4.2 Mounting

For mounting the unit, the housing of the industrial PC has to be opened

(^ documentation for the standard device).

LINK

SYS

ST0

MC-PNx

MC-ETH

ST1

ST2

R

J

S

S

-

5

3

8

1

ACTIVE

LINK

R

J

S

S

-

5

3

8

1

LA

SPEED

PROFINET

N

R

J

S

S

-5

3

8

1

LINK

SYS

ST0

MC-PNx

MC-ETH

ST1

ST2

R

J

S

S

-

5

3

8

1

ACTIVE

LINK

R

J

S

S

-

5

3

8

1

LA

SPEED

N

PROFINET

R

J

S

S

-5

3

8

1

MC−PNx−002

BA_MC−Card EN 1.0

l

23

Page 24

4

Electrical installation

Wiring and Configuration

MC−CAN2

4.3 Wiring and Configuration

4.3.1 MC−CAN2

Wiring

Pin assignment Description Connection type Cable type

1

6

MC−CAN−003

CAN bus connection

Pin 1: not assigned

Pin 2: CAN−LOW (LO)

Pin 3: CAN−GND (CG)

Pin 4: not assigned

Pin 5: not assigned

Pin 6: CAN−GND (CG)

Pin 7: CAN−HIGH (HI)

Pin 8: not assigned

Pin 9: not assigned

9−pole SUB−D plug See following table

A

1

CAN

CG

LO HI CG

RR

A1 Node 1

A2 Node 2

An Node n

CG CAN−GND

LO CAN−LOW

HI CAN−HIGH

R 120 W−bus terminating resistor

A

2

CAN

LO HI CG

A

CAN

LO HI

n

Specification of the transmission cable

We recommend the use of CAN cables in accordance with ISO 11898−2:

CAN cable in accordance with ISO 11898−2

Cable type Paired with shielding

Impedance 120 W (95 ... 140 W)

Cable resistance/cross−section

Cable length £ 300 m £ 70 mW/m / 0.25 0.34 mm2 (AWG22)

Cable length 301 1000 m £ 40 mW/m / 0.5 mm2 (AWG20)

Signal propagation delay £ 5 ns/m

EL100−009

24

l

BA_MC−Card EN 1.0

Page 25

Electrical installation

Wiring and Configuration

MC−CAN2

Use of the MC card in Windowsâ XP or Windowsâ Embedded Standard 2009

In order to use the communication card in Windowsâ XP, a device driver is required which

is part of the "communication software (CAN)". It is included on the "PC based

Automation" DVD and can also be found at www.Lenze.com in the download area. The

device driver assumes the entire management of the interface.

The following files are installed with the device driver:

ƒ can2bdrv.sys (visible in the Windows device manager as "CAN2 Bus Driver")

ƒ can2fdrv.sys (visible in the Windows device manager as "CAN Device")

ƒ mccan2services.exe (visible in the Windows task manager as "McCAN2 Wrapper

Service")

The communication card is configured via the Lenze system bus configurator. The settings

entered there are valid for all applications which communicate via this card.

4

Parameter Value range Comment

Baud rate 5, 10, 20, 50, 100,

125, 250, 500,

1000

Time limit for the node search 0.5 ... 10 s Total time the bus scan is waiting for the feedback of

Communication time−out 0.1 ... 10 s Time up to which a CAN node must have responded;

Parameter channel 0, 1, 2 0: CANopen

Repeat tests 1 ... 10 Repetition of the CAN telegrams in case of an error

Expansion slot (MC1 / MC2) 1, 2 Number of the module card slot at the IPC (see

Channel (CAN1 / CAN2) 1, 2 Number of the CAN terminal on the corresponding card

in kbps

all nodes

after that an error is reported.

1: Lenze system bus parameter channel 1

2: Lenze system bus parameter channel 2

labelling of the slots at the IPC)

(see labelling at the front panel of the card)

BA_MC−Card EN 1.0

l

25

Page 26

4

Electrical installation

Wiring and Configuration

MC−CAN2

For diagnostic purposes, the following tools are provided on the "PC based Automation"

DVD:

ƒ PCAN view: Simple CAN monitor

ƒ PCAN stat: Status monitor of the device driver

Further information on how to apply these diagnostic programs can be found in the

appendix.

The device driver contains a user interface which can be addressed with the following

tools:

ƒ PCAN Light

A simple DLL interface for accessing max. one communication card MC−CAN2. The API

"PCAN Light" comprises all functions for initialising, parameter setting, exchanging

data, and reading out status information.

The API comes in two DLLs on the "PC based Automation" DVD: PCAN_MC_CAN.DLL

for accessing CAN1 and PCAN_MC_CAN2.DLL for accessing CAN2, hence the CAN

terminals of the first plugged MC−CAN2 card. The access to a second MC−CAN2 card is

not possible with PCAN Light but only by means of the integrated development

environments PCAN Evaluation or PCAN Developer (see below).

Further information on "PCAN Light" can be obtained from the online help for "PCAN

Light" on the "PC based Automation" DVD. There you will also find the source code of

example programs for a quick training.

CAUTION: In order to use "PCAN Light" together with the MC−CAN2 card, you must get

an additional licence. This is coupled with the communication card and made visible by

a licence sticker. Before using "PCAN Light", please check if you have got the required

licence since otherwise you would violate the copyright.

ƒ PCAN Evaluation / PCAN Developer

These complex integrated development environments provide more comprehensive

functions than PCAN Light; e.g.:

– Event operation

– Error frame handling

– Operation of several clients with one hardware

The integrated development environments can be obtained from the Peak company

(¶ 44).

) Note!

Addressing the communication card from your own applications requires

special programming skills. Lenze does not offer any support regarding this

matter.

The communication card is compatible with the technology of Peak (¶ 44).

There you will get the required support.

26

l

BA_MC−Card EN 1.0

Page 27

Electrical installation

Wiring and Configuration

MC−CAN2

Use of the MC card in Windowsâ CE

In Windowsâ CE the card interact via control system. All required drivers are installed

) Note!

No special support is provided currently if you use the communication card in

your own applications. For special projects, please contact your sales office.

4

BA_MC−Card EN 1.0

l

27

Page 28

4

Electrical installation

Wiring and Configuration

MC−ETC, MC−ETH

4.3.2 MC−ETC, MC−ETH

Wiring

LINK

LAN

) Note!

Description Connection type Cable type

SPEED

MC−ETH port

"Link" LED:

On: Connection OK

Blinking: Data transfer

"Speed" LED:

MC−ETH−003

Off: 10 Mbps

Green: 100 Mbps

Yellow: 1000 Mbps

MC−ETC port

"Link" LED:

On: Connection OK

Blinking: Data transfer

"Speed" LED:

Green: 100 Mbps

RJ45 socket

CAT5 S/UTP or CAT5e S/FTP

(recommended) network

cable, max. cable length

100 m

If the RJ45 plug connection is exposed to oscillating or vibrating stress:

ƒ Use a strain relief in the immediate vicinity of the RJ45 socket.

ƒ Select the contact surface on which the device is mounted as fixing point of

the strain relief.

ƒ Comply with the related minimum bending radius of the cable used.

Use of the MC card in Windowsâ XP or Windowsâ Embedded Standard 2009

In order to use the communication card in Windowsâ XP, a device driver is required. It is

already pre−installed and also included on the "PC based Automation" DVD. For the

implementation of the communication card in your own applications, use "WinSockets",

which are provided by corresponding programming systems. A special library is not

required.

) Note!

Addressing the communication card from your own applications requires

special programming skills. Lenze does not offer any support regarding this

matter. However, we can refer you to service providers who execute

customised programming and are familiar with Lenze Industrial PCs.

28

l

BA_MC−Card EN 1.0

Page 29

Electrical installation

Wiring and Configuration

MC−ETC, MC−ETH

Use of the MC card in Windowsâ CE

You can use the card in Windowsâ CE only with IPCs, not with controllers.

â

In order to be able to use the communication card in Windows

required. It is already pre−installed. For integrating the communication card into individual

applications, use so−called "WinSockets" which are provided by the corresponding

programming systems. A special library is not required.

CE, a device driver is

4

BA_MC−Card EN 1.0

l

29

Page 30

4

Electrical installation

Wiring and Configuration

MC−ISI

4.3.3 MC−ISI

Configuration

DIP switch for setting the mode:

DIP switch Description

1234

ON

Set the mode:

Mode DIP switch setting

RS485 mode, two−wire conductor, deactivated echo function (default)

RS485 mode, two−wire conductor, activated echo function

RS485 mode, four−wire conductor

RS422

) Note!

Pos. 1 = ON: RS485 mode

Pos. 2 = ON: RS422 mode

Pos. 3 = ON/OFF: four−wire conductor/two−wire conductor (only relevant for RS485 mode)

Pos. 4 = ON/OFF: echo function activated/deactivated (only relevant for RS485 mode +

two−wire conductor)

MC−ISI_004

Pos. 1 = ON

Pos. 1+4 = ON

Pos. 1+3 = ON

Pos. 2 = ON

ƒ If switch 1 = ON (RS485), switch 2 must be set to OFF;

if switch 2 = ON (RS422), switch 1 must be set to OFF.

ƒ The echo function monitors the RS485 bus for collisions.

Further settings:

Jumper Function

JP1 plugged−on to ENA: default setting

JP3 plugged−on to HW: default setting

plugged−on: terminating resistor for RS422−/485 mode activated

JP5

open: terminating resistor for RS422−/485 mode deactivated

Do not assign JP2! Lenze service personnel only.

MC−ISI_003

30

l

BA_MC−Card EN 1.0

Page 31

Electrical installation

Wiring and Configuration

MC−ISI

Wiring

COM A (RS232):

Pin assignment Description Connection type Cable type

COM A

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 NC

1

6

MC−CAN−003

RS232

Pin 1: DCD

Pin 2: RXD

Pin 3: TXD

Pin 4: DTR

Pin 5: GND

Pin 6: DSR

Pin 7: RTS

Pin 8: CTS

Pin 9: RI

xxx

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 NC

9−pole Sub−D plug Control cable

4

MC−ISI_005

COM B (RS422/485):

Pin assignment Description Connection type Cable type

1

Pin 1: NC

Pin 2: TXD+

Pin 3: RXD+ (Data+)

6

Pin 4: NC

Pin 5: GND

9−pole Sub−D plug Control cable

Pin 6: NC

Pin 7: TXD−

Pin 8: RXD− (Data −)

Pin 9: NC

MC−CAN−003

COM B COM B

1 NC

2 TXD+

3 RXD+

4 NC

5 GND

6 NC

7 TXD8 RXD9 NC

RS422

(4-wire)

xxx xxx

1 NC

2 TXD+

3 RXD+

4 NC

5 GND

6 VCC

7 TXD8 RXD9 NC

1 NC

2 TXD+

3 RXD+

4 NC

5 GND

6 NC

7 TXD8 RXD9 NC

RS485

(2-wire)

1 NC

2 TXD+

3 RXD+

4 NC

5 GND

6 VCC

7 TXD8 RXD9 NC

) Note!

The terminating resistor at the physically first and last node must be activated

(¶ 30).

MC−ISI_006

BA_MC−Card EN 1.0

l

31

Page 32

4

Electrical installation

Wiring and Configuration

MC−ISI

Use of the MC card in Windowsâ XP or Windowsâ Embedded Standard 2009

In order to use the communication card in Windowsâ XP, a device driver is required.

Usually, the communication card in the IPC is already mounted and the driver is installed

and configured. Thus, an installation is only required if the communication card has been

ordered separately or the system is to be set up anew.

The device driver can be found on the "PC based Automation" DVD or on the Internet at

www.Lenze.com in the download area.

) Note!

The communication card is configured via jumper and DIP switch. The driver

cannot be used for this purpose.

) Note!

Addressing the communication card from your own applications requires

special programming skills. Lenze does not offer any support regarding this

matter. However, we can refer you to service providers who execute

customised programming and are familiar with Lenze Industrial PCs.

Use of the MC card in Windowsâ CE

In Windowsâ CE the card interact via control system. All required drivers are installed

) Note!

No special support is provided currently if you use the communication card in

your own applications. For special projects, please contact your sales office.

32

l

BA_MC−Card EN 1.0

Page 33

Electrical installation

Wiring and Configuration

MC−PBM, MC−PBS

4

4.3.4 MC−PBM, MC−PBS

Wiring

Pin assignment Description Connection type Cable type

PROFIBUS connection

5

9

4

8

3

7

2

6

1

Master

RxD/TxD-P(B)

RxD/TxD-N(A)

Schirm

Pin 1: not assigned

Pin 2: not assigned

Pin 3: RxD/TxD−P(B)

Pin 4: RTS

Pin 5: M5V

Pin 6: P5V

Pin 7: not assigned

Pin 8: RxD/TxD−N(A)

Pin 9: not assigned

epm−t223

6

P5V

3

8

5

M5VM5V

9−pole Sub−D socket See following table

Slave

330W 330W

3

RxD/TxD-P(B)

220W 220W

330W 330W

RxD/TxD-N(A)

8

Schirm

3

8

Slave

6

P5V

RxD/TxD-P(B)

3

RxD/TxD-N(A)

8

5

Schirm

) Note!

The PROFIBUS cable must be terminated with its surge impedance.

Specification of the transmission cable

) Note!

Only use cables complying with the listed specifications of the PROFIBUS user

organisation.

Field Values

Specific resistance 135 ... 165 W/km, (f = 3 ... 20 MHz)

Capacitance per unit length £ 30 nF/km

Loop resistance < 110 W/km

Core diameter > 0.64 mm

Core cross−section > 0.34 mm

Cores Twisted double, insulated and shielded

2

SLIO090

BA_MC−Card EN 1.0

l

33

Page 34

4

Electrical installation

Wiring and Configuration

MC−PBM, MC−PBS

Baud rate / length of bus cable

Baud rate [kBit/s] Length [m]

9.6 − 93.75 1200

187.5 1000

500 400

1500 200

3000 − 12000 100

Use of the MC card in Windowsâ XP or Windowsâ Embedded Standard 2009

In order to use the communication card in Windowsâ XP, a device driver is required.

The device driver assumes the entire management of the interface and contains a simple

C interface which is addressed via a DLL. The user is only responsible for the transfer of the

correct parameters to the device driver. All dependencies on the operating system like

interrupt management and time monitoring are executed by the driver.

The driver comprises all functions for initialising, parameter setting, exchanging data, and

reading out status information. It operates in the polling or interrupt mode and controls

maximally two cards in an IPC.

Together with the device drivers, example programs are supplied in the source code for a

quick training. Other components are an installation program for registration at the

operating system and the SyCon.net bus configurator of the master.

) Note!

The communication card is based on the netX technology of the Hilscher

company (¶ 44). Further information on the programming interface and

programming examples for the CIF Device Driver can be obtained from the

Hilscher company.

Only drivers approved by Lenze may be used.

Addressing the communication card from your own applications requires

special programming skills. Lenze can only assist you in the basic

commissioning of the card. If you have special questions about programming,

the Hilscher company will help you after contacting Lenze. There, also

chargeable services can be ordered.

Usually, the communication card in the IPC is already mounted and the driver is installed

and configured. Thus, the following steps are only required if the communication card has

been ordered separately or the system is to be set up anew.

The "cifX Device Driver" and the corresponding documentation can be found on the "PC

based Automation" DVD or on the Internet at www.Lenze.com in the download area.

34

l

BA_MC−Card EN 1.0

Page 35

Electrical installation

Wiring and Configuration

MC−PBM, MC−PBS

X How to install the device driver:

1. Switch on the IPC after installing the communication card.

The operating system recognises the new hardware and the "Found New Hardware

Wizard" starts.

2. Select Install from a list or specific location.

3. Insert the "PC based Automation" DVD into the DVD drive and click Next.

4. Select the Search the best driver in these locations option field and the Search

exchangeable disk storage (floppy disk, CD,..) control field in the following dialog.

5. Click Next.

The CifX driver is installed. The installation progress is displayed. At the end, the wizard

reports that the software for the "cifX PCI/PCIe Device" has been installed.

6. Click Complete.

7. Check if the communication card has been installed correctly:

– Start the Windows

– If you have set the "classic view", double−click the System entry. If you have set the

"category view", select Performance and Maintenance W System.

– Select the Hardware register from the "System properties" dialog.

The device manager is opened. If no error is reported under "CIFx Communication

Interface" W "CifX PCI/PCIe Device", the communication card has been installed

correctly.

â

system control.

4

BA_MC−Card EN 1.0

l

35

Page 36

4

Electrical installation

Wiring and Configuration

MC−PBM, MC−PBS

X How to configure the device driver:

1. Start the "cifX Driver Setup Utility":

– Open the Windows

– If you have set the "classic view", double−click the cifx Setup entry. If you have set

the "category view", first select Other Control Panel Options in the left window

area and then double−click the cifx Setup entry.

â

system control.

I Tip!

If, in an exceptional case, the device driver is to be installed before the

communication card has been installed, start the "cifX Driver Setup Utility" via

the Windows Explorer. For this purpose, go to the x:\Programs\cifX Device

Driver folder and double−click cifX Setup.exe.

After the application has started, its user interface is displayed. Use the object tree in

the left window area to open the corresponding dialog pages in which you assign a

firmware file to the communication card.

) Note!

The navigation pane can be shown and hidden via the Hide navigation pane /

Show navigation pane icon.

2. Assign the bus−specific firmware file to the communication channel 0 (CH#0):

– Go to the object tree and open the Active Devices folder and the (sub) folder of the

communication card (e.g. cifX0 ( )) you want to configure.

– Click the communication channel you want to assign to a firmware file. The

respective dialog page is displayed.

– Go to the Downloads (Modules) area, click the Add button and select the firmware

file (*.nxf) in the following menu.

– Confirm the selection with OK. The file path and the name of the firmware file are

displayed in the "File" list.

– Click the Apply button.

36

l

BA_MC−Card EN 1.0

Page 37

Electrical installation

Wiring and Configuration

MC−PBM, MC−PBS

3. Exit the "cifX Driver Setup Utility" application via the File W Quit menu.

) Note!

Only for MC−PBM (Master):

ƒ Configure the bus via the host application or the bus configurator

"SyCon.net".

Only for MC−PBS (Slave):

ƒ Configure the bus via the warm start parameters in the "cifX Driver Setup

Utility". Further information can be obtained from the online help of the

"cifX Driver Setup Utility" and the documentation of Hilscher.

Use of the MC card in Windowsâ CE

A) IPCs

The following conditions must be met for operating the card:

4

1. There must be a "Config" folder on the CF card in the storage drive.

2. This folder must contain a firmware file named "Firmware.nxt".

3. The card must be configured:

– MC−PBS (MPI): Configuration via an end application.

– MC−PBM: There must be a "Config.dbm" file in the "Config" folder. Further

information on this can be found in the documentation for your FDT frame

application.

At the next system start, the driver loads the firmware and the configuration from the

"Config" folder to the communication card.

) Note!

No special support is provided currently if you use the communication card in

your own applications. For special projects, please contact your sales office.

B) Controller

â

In Windows

CE the card interact via control system. All required drivers are installed

) Note!

No special support is provided currently if you use the communication card in

your own applications. For special projects, please contact your sales office.

BA_MC−Card EN 1.0

l

37

Page 38

4

Electrical installation

Wiring and Configuration

MC−PNC, MC−PND

4.3.5 MC−PNC, MC−PND

Wiring

Description Connection type Cable type

Ethernet connection

18

MC−PNx−003

* Bridged and terminated by RC circuit against PE

** Bridged and terminated by RC circuit against PE

Pin 1: TX+

Pin 2: TX−

Pin 3: RX+

Pin 4: Term1*

Pin 5: Term1*

Pin 6: RX−

Pin 7: Term2**

Pin 8: Term2**

) Note!

The device supports the auto−crossover function where RX and TX can be

exchanged, if required.

RJ45 socket

Network cable CAT5 S/UTP or

CAT5e S/FTP (recommended),

cable length max. 100 m

) Note!

If the RJ45 plug connection is exposed to oscillating or vibrating stress:

ƒ Use a strain relief in the immediate vicinity of the RJ45 socket.

ƒ Select the contact surface on which the device is mounted as fixing point of

the strain relief.

ƒ Comply with the related minimum bending radius of the cable used.

38

l

BA_MC−Card EN 1.0

Page 39

Electrical installation

Wiring and Configuration

MC−PNC, MC−PND

Use of the MC card in Windowsâ XP or Windowsâ Embedded Standard 2009

In order to use the communication card in Windowsâ XP, a device driver is required.

The device driver assumes the entire management of the interface and contains a simple

C interface which is addressed via a DLL. The user is only responsible for the transfer of the

correct parameters to the device driver. All dependencies on the operating system like

interrupt management and time monitoring are executed by the driver.

The driver comprises all functions for initialising, parameter setting, exchanging data, and

reading out status information. It operates in the polling or interrupt mode and controls

maximally two cards in an IPC.

Together with the device drivers, example programs are supplied in the source code for a

quick training. Other components are an installation program for registration at the

operating system and the SyCon.net bus configurator of the master.

) Note!

The communication card is based on the netX technology of the Hilscher

company (¶ 44). Further information on the programming interface and

programming examples for the CIF Device Driver can be obtained from the

Hilscher company.

Only drivers approved by Lenze may be used.

Addressing the communication card from your own applications requires

special programming skills. Lenze can only assist you in the basic

commissioning of the card. If you have special questions about programming,

the Hilscher company will help you after contacting Lenze. There, also

chargeable services can be ordered.

4

Usually, the communication card in the IPC is already mounted and the driver is installed

and configured. Thus, the following steps are only required if the communication card has

been ordered separately or the system is to be set up anew.

The "cifX Device Driver" and the corresponding documentation can be found on the "PC

based Automation" DVD or on the Internet at www.Lenze.com in the download area.

BA_MC−Card EN 1.0

l

39

Page 40

4

Electrical installation

Wiring and Configuration

MC−PNC, MC−PND

X How to install the device driver:

1. Switch on the IPC after installing the communication card.

The operating system recognises the new hardware and the "Found New Hardware

Wizard" starts.

2. Select Install from a list or specific location.

3. Insert the "PC based Automation" DVD into the DVD drive and click Next.

4. Select the Search the best driver in these locations option field and the Search

exchangeable disk storage (floppy disk, CD,..) control field in the following dialog.

5. Click Next.

The CifX driver is installed. The installation progress is displayed. At the end, the wizard

reports that the software for the "cifX PCI/PCIe Device" has been installed.

6. Click Complete.

7. Check if the communication card has been installed correctly:

– Start the Windows

– If you have set the "classic view", double−click the System entry. If you have set the

"category view", select Performance and Maintenance W System.

– Select the Hardware register from the "System properties" dialog.

The device manager is opened. If no error is reported under "CIFx Communication

Interface" W "CifX PCI/PCIe Device", the communication card has been installed

correctly.

â

system control.

40

l

BA_MC−Card EN 1.0

Page 41

Electrical installation

Wiring and Configuration

MC−PNC, MC−PND

X How to configure the device driver:

1. Start the "cifX Driver Setup Utility":

– Open the Windows

– If you have set the "classic view", double−click the cifx Setup entry. If you have set

the "category view", first select Other Control Panel Options in the left window

area and then double−click the cifx Setup entry.

â

system control.

I Tip!

If, in an exceptional case, the device driver is to be installed before the

communication card has been installed, start the "cifX Driver Setup Utility" via

the Windows Explorer. For this purpose, go to the x:\Programs\cifX Device

Driver folder and double−click cifX Setup.exe.

After the application has started, its user interface is displayed. Use the object tree in

the left window area to open the corresponding dialog pages in which you assign a

firmware file to the communication card.

4

) Note!

The navigation pane can be shown and hidden via the Hide navigation pane /

Show navigation pane icon.

2. Assign the bus−specific firmware file to the communication channel 0 (CH#0):

– Go to the object tree and open the Active Devices folder and the (sub) folder of the

communication card (e.g. cifX0 ( )) you want to configure.

– Click the communication channel you want to assign to a firmware file. The

respective dialog page is displayed.

– Go to the Downloads (Modules) area, click the Add button and select the firmware

file (*.nxf) in the following menu.

– Confirm the selection with OK. The file path and the name of the firmware file are

displayed in the "File" list.

– Click the Apply button.

BA_MC−Card EN 1.0

l

41

Page 42

4

Electrical installation

Wiring and Configuration

MC−PNC, MC−PND

3. Exit the "cifX Driver Setup Utility" application via the File W Quit menu.

) Note!

Only for MC−PNC (Controller):

ƒ Configure the bus via the host application or the bus configurator

"SyCon.net".

Only for MC−PND (Device):

ƒ Configure the bus via the warm start parameters in the "cifX Driver Setup

Utility". Further information can be obtained from the online help of the

"cifX Driver Setup Utility" and the documentation of Hilscher.

Use of the MC card in Windowsâ CE

A) IPCs

The following conditions must be met for operating the card:

1. There must be a "Config" folder on the CF card in the storage drive.

2. This folder must contain a firmware file named "Firmware.nxt".

3. The card must be configured:

– MC−PBS (MPI): Configuration via an end application.

– MC−PBM: There must be a "Config.dbm" file in the "Config" folder. Further

information on this can be found in the documentation for your FDT frame

application.

At the next system start, the driver loads the firmware and the configuration from the

"Config" folder to the communication card.

) Note!

No special support is provided currently if you use the communication card in

your own applications. For special projects, please contact your sales office.

B) Controller

At the time the Lenze controllers can only communicate with the MC−PND via control

system, not with the MC−PNC.

In Windows

â

CE the card interact via control system. All required drivers are installed

42

) Note!

No special support is provided currently if you use the communication card in

your own applications. For special projects, please contact your sales office.

l

BA_MC−Card EN 1.0

Page 43

Use of the PCAN view/PCAN Explorer with MC−CAN2

5 Appendix

5.1 Use of the PCAN view/PCAN Explorer with MC−CAN2

Peak System Technik GmbH provides the PCAN Explorer software for the diagnostics of a

CAN network. The PCAN view program is the basic free−of−charge version of this program.

When using these programs with the MC−CAN2 card, please observe the following:

ƒ In the PCAN software, the MC−CAN2 card is not represented as hardware but as

client of a network. For this reason, the networks in the PCAN software are

represented as "internal networks" as if these networks would have no connection

to a hardware.

ƒ The status bar of the PCAN Explorer indicates a symbol with a crossed out hardware

even with a correct connection. Information such as "Busheavy" is not displayed in

the status bar.

ƒ The PCAN view shows information such as "Busheavy" only for one second, then it

disappears again.

Appendix

5

The network names are defined as follows:

Expansion slot Connection Network name

MC 1 CAN 1 LSysbusNet1

MC 1 CAN 2 LSysbusNet2

MC 2 CAN 1 LSysbusNet3

MC 2 CAN 2 LSysbusNet4

The following illustration shows how the MC−CAN2 and the connected networks are

represented in the PCAN stat diagnostic program.

BA_MC−Card EN 1.0

The baud rate is exclusively selected via the system bus configurator, not via network

names.

The windows "Receive" and Transmit" now continuously show the telegrams.

Details of the PCAN view, PCAN stat and PCAN Explorer programs can be found in the

corresponding online helps.

l

43

Page 44

5

5.2 Contact data of system partners

Appendix

Contact data of system partners

Hilscher

Hilscher Gesellschaft für Systemautomation mbH

Rheinstraße 15

D−65795 Hattersheim

+49 6190 / 9907−0

www.hilscher.com

Peak

Peak System Technik GmbH

Otto−Röhm−Str. 69

D−64293 Darmstadt

+49 6151 / 8173−0

www.peak−system.com

44

l

BA_MC−Card EN 1.0

Page 45

Appendix

Contact data of system partners

5

BA_MC−Card EN 1.0

l

45

Page 46

F

(

Ê

ü

© 11/2013

Lenze Automation GmbH

Hans−Lenze−Str. 1

D−31855 Aerzen

Germany

+49(0)51 54 /82−0

+49(0)51 54 /82 − 28 00

Lenze@Lenze.de

www.Lenze.com

Service Lenze Service GmbH

Breslauer Straße 3

D−32699 Extertal

Germany

(

Ê

008000/ 2446877 (24 h helpline)

+49(0)5154/ 82−11 12

Service@Lenze.de

BA_MC−Card § .N*{ § EN § 1.0 § TD29

10987654321

Q

Loading...

Loading...